Endress+Hauser Topcal S CPC310 Operating Instructions Manual

Operating Instructions

Topcal S CPC310

Automation of pH/Redox Measurements

Field communication via HART® protocol

BA409C/07/en/11.06

71028144

As of software version:

2.60

Brief overview

MEASCAL

DIAGPARAM

15.75

400

320 12.60

227 8.94

16.54

12.87

420

327

250 9.84

300 11.81

max.5/10 m

max.16.4/32.8 ft

max.5 m 16.4ft

max.200 m 656ft

max.2.5 m 8.20ft

C

140107-1000-3A

CPG310

100-110 - 230 VAC

Zusatzventile/

auxiliaryvalves

Jumper

100-230V

/

/

/

/

1

2

1

2

1

2

1

2

r

r

r

r

e

e

til

til

fe

fe

fe

fe

f

f

n

n

f

f

lv

lv

u

u

u

u

a

a

Ve

Ve

P

v

b

v

P

b

100V/

230V

110V

45

46

48 56515752 58

47

200 7.87

24

0.94

13.78

350

B

4142

V1 V2 V3 V4 V9

Power

InterneEingänge/

internalinputs

/

Sicherung/Fuse:

/

/

r

2

M3,15A

r

1

2

e

1

e

r

r

r

r

ig

n

fe

fe

fe

fe

.

.

in

a

f

100-230V

f

f

f

e

u

u

u

.c

.c

u

le

AC

P

b

P

n

n

R

b

c

PE

PEL+PEN- PE

P6

D1P3D2P4P1P5P2

geradeZahlen:minus; ungeradeZahlen:plus;even-numbers: minus; odd-numbers:plus

71027539

Mycom

SPSEingänge/

PCSinputs

/

Programmwahl/

/

ly

r

r

r

b

e

e

tu

m

ig

n

a

e

in

a

s

e

rm

s

le

R

A

a

c

55

V6

/

/

tik

tic

re

n

a

programchoice

a

e

e

5

u

e

/

m

ic

m

8

s

ic

s

1

0

2

v

p

4

v

s

a

p

.

to

r

to

V

r

e

e

S

u

e

u

in

in

.c

in

to

2

e

A

Sto

a

s

R

S

s

b

b

n

b

M

m

1

85 93

B

A

82 9086 9483 918784 9288

81 89

L+ L-

Steuer-Ausgänge/

InterneEingänge/

RückmeldungArmatur/

SPSAusgänge/

driveoutputs

internalinputs

feedbackassembly

PCSoutputs

re

D

/

/

/

u

/

/

/

t-

E

e

f

s

r

/

re

r

n

r

n

e

e

s

e

e

e

r

r

-L

lu

e

u

e

e

u

e

e

lte

h

r

ic

ic

o

k

o

e

s

ic

s

ic

s

s

/

ic

s

r

ic

a

s

c

s

s

v

s

a

s

a

t

p

v

te

rv

rv

rv

itc

h

f

r

liv

rv

n

n

r

e

e

e

e

a

e

ru

e

e

c

u

ir

e

ir

e

e

e

e

w

A

S

s

M

m

D

s

a

s

S

S

s

s

L

a

Wa

w

S

s

M

m

V1V2Ass.

71

12

62 72657566 76

D4 1311 14

61

D3

K1K2

Meas.

V7 V8

S0 S1 S2 S3

3

4

M2

M1

2

1

5

7

6

M3

M4

D

Ausfall

8

HOLD

9

10

11

12

136

1

Messen

2

3

7.54

pH

[¯ ]Wahl

4

5

MEAS CAL

DIAG

PARAM

A

1

2

3

4

7

E

5

F

A

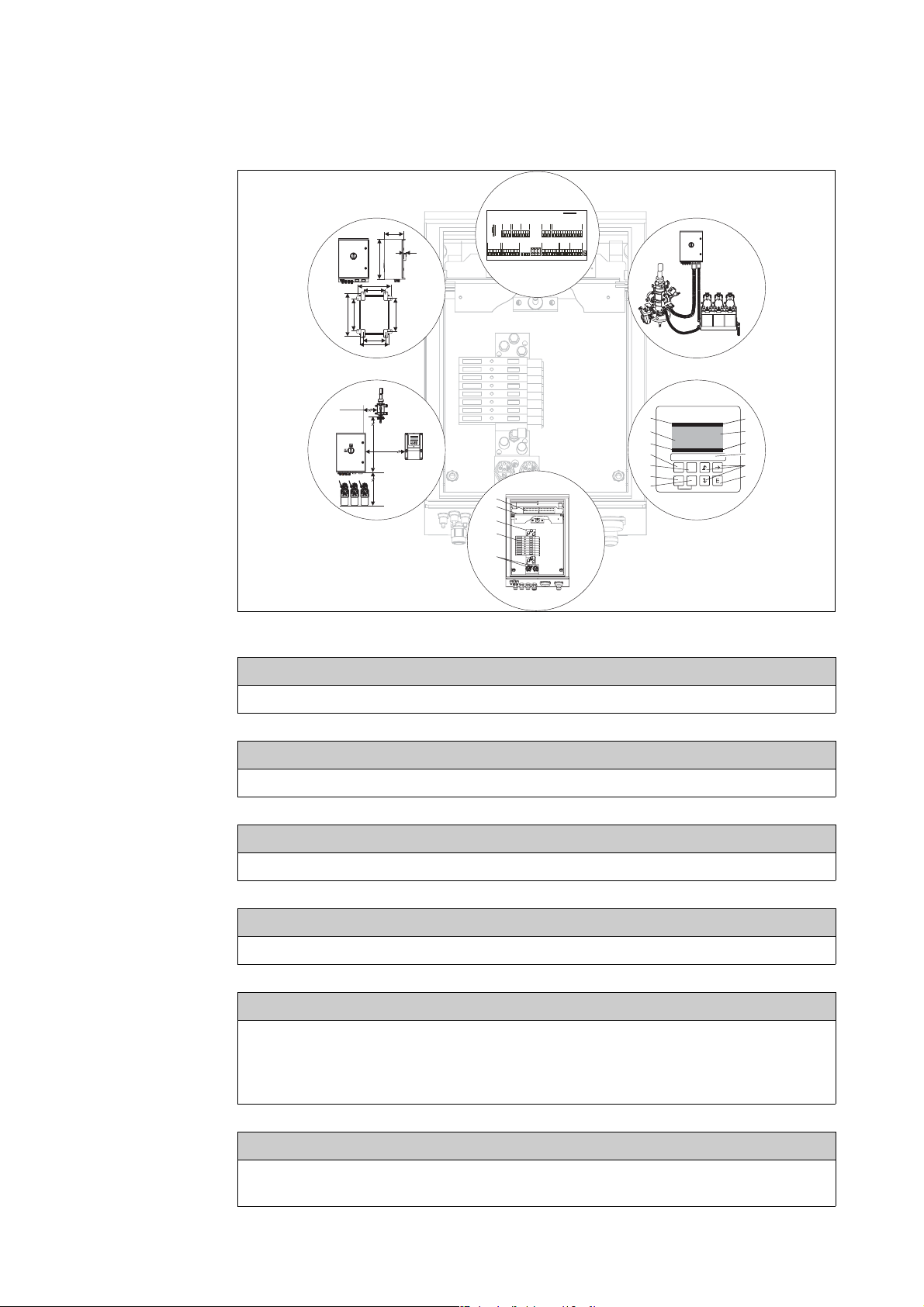

→ ä 11 Installation instructions: Types of mounting, maximum spacing, assembly installation

Æ

B

→ ä 14 Dimensions and installation

Æ

C

→ ä 19 Electrical connection of mandatory and optional system components

Æ

D

→ ä 41 Pneumatic system connection

Æ

E

→ ä 52

→ ä 57

→ ä 106

→ ä 115

Operation

Commissioning

HART commands

Calibration

a0005033

→ ä 135

→ ä 145

Æ

F

Troubleshooting

Spare parts

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 7

2.1.3 Product structure . . . . . . . . . . . . . . . . . . . . 8

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . 10

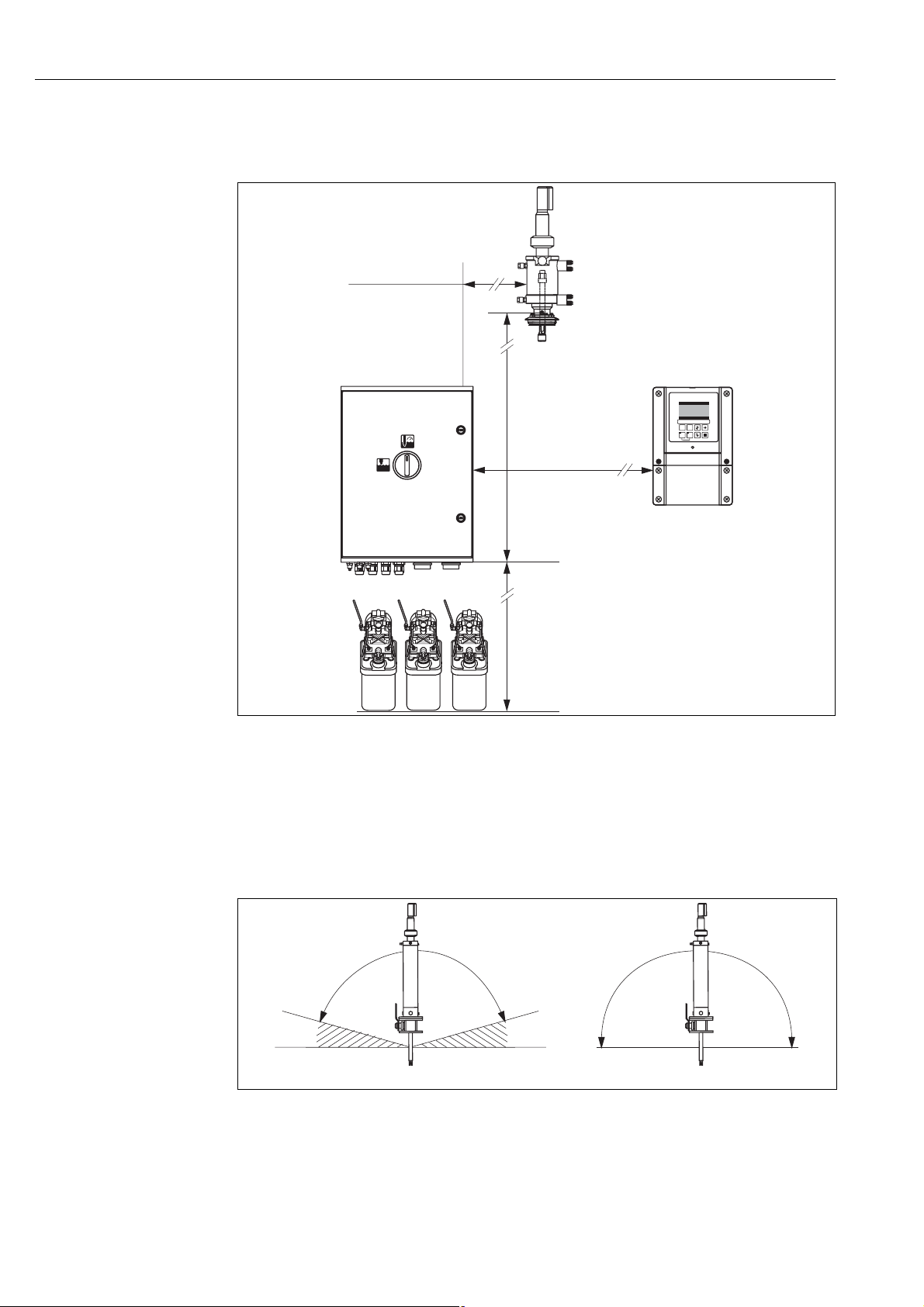

3.1 System setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Incoming acceptance, transport, storage . . . . . . . . . 11

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 Types of mounting . . . . . . . . . . . . . . . . . . . 11

3.3.2 Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.3 Assembly installation . . . . . . . . . . . . . . . . . 12

3.3.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Installation instructions . . . . . . . . . . . . . . . . . . . . . 14

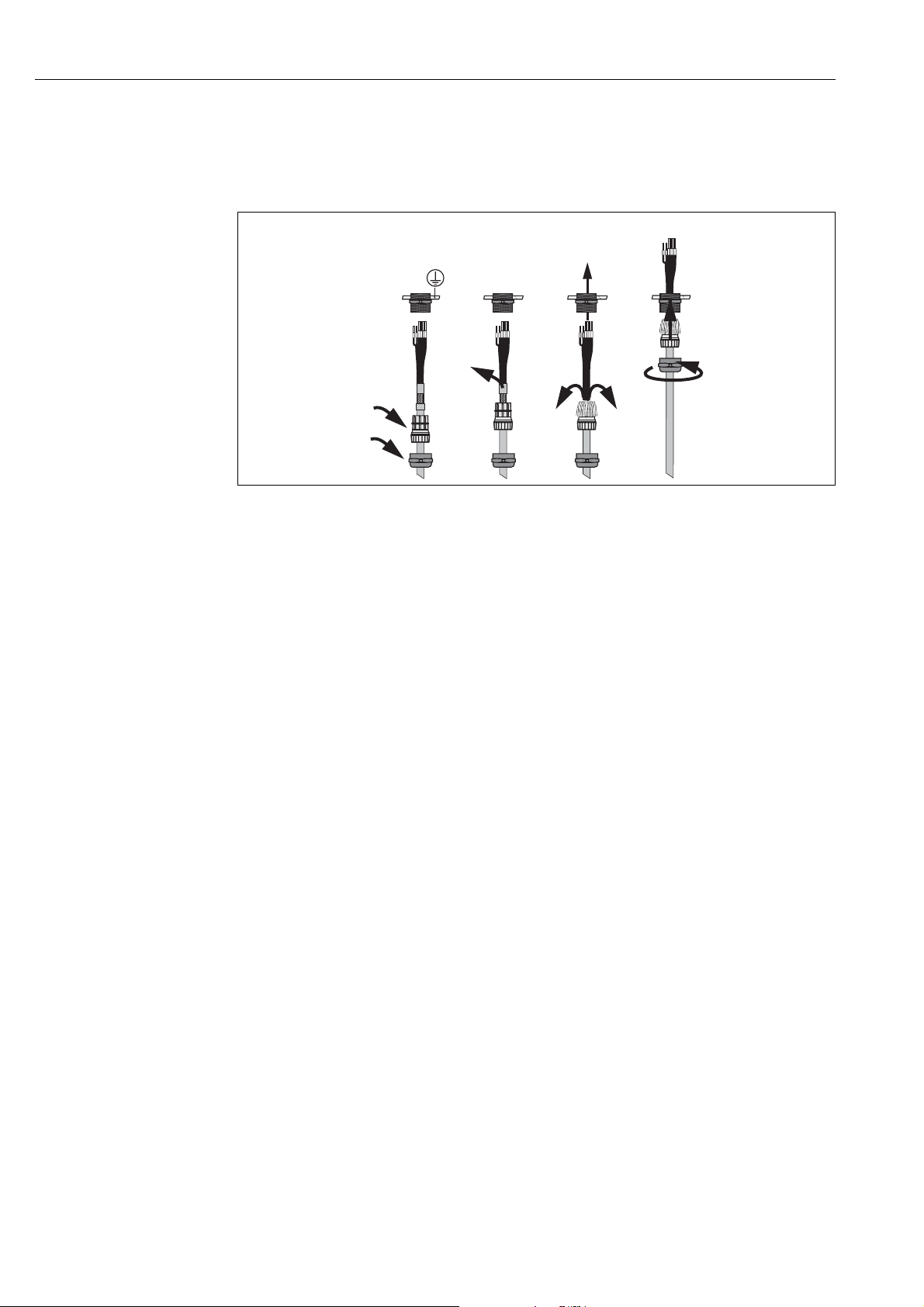

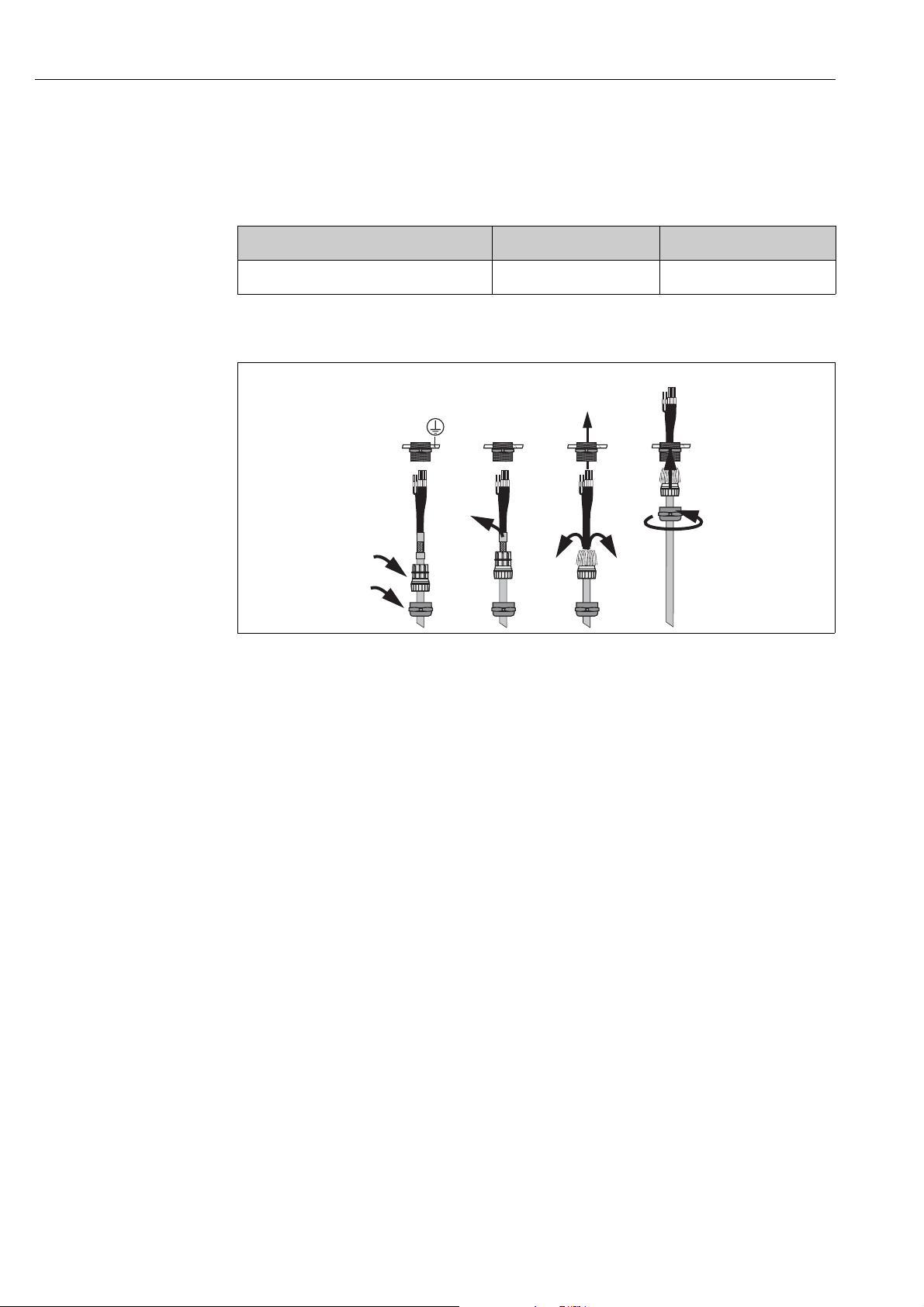

3.4.1 Securing rinsing block to assembly . . . . . . . 14

3.4.2 Installation instructions . . . . . . . . . . . . . . . 14

3.4.3 Wall mounting . . . . . . . . . . . . . . . . . . . . . 15

3.4.4 Post mounting and panel mounting . . . . . . 16

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 18

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . 19

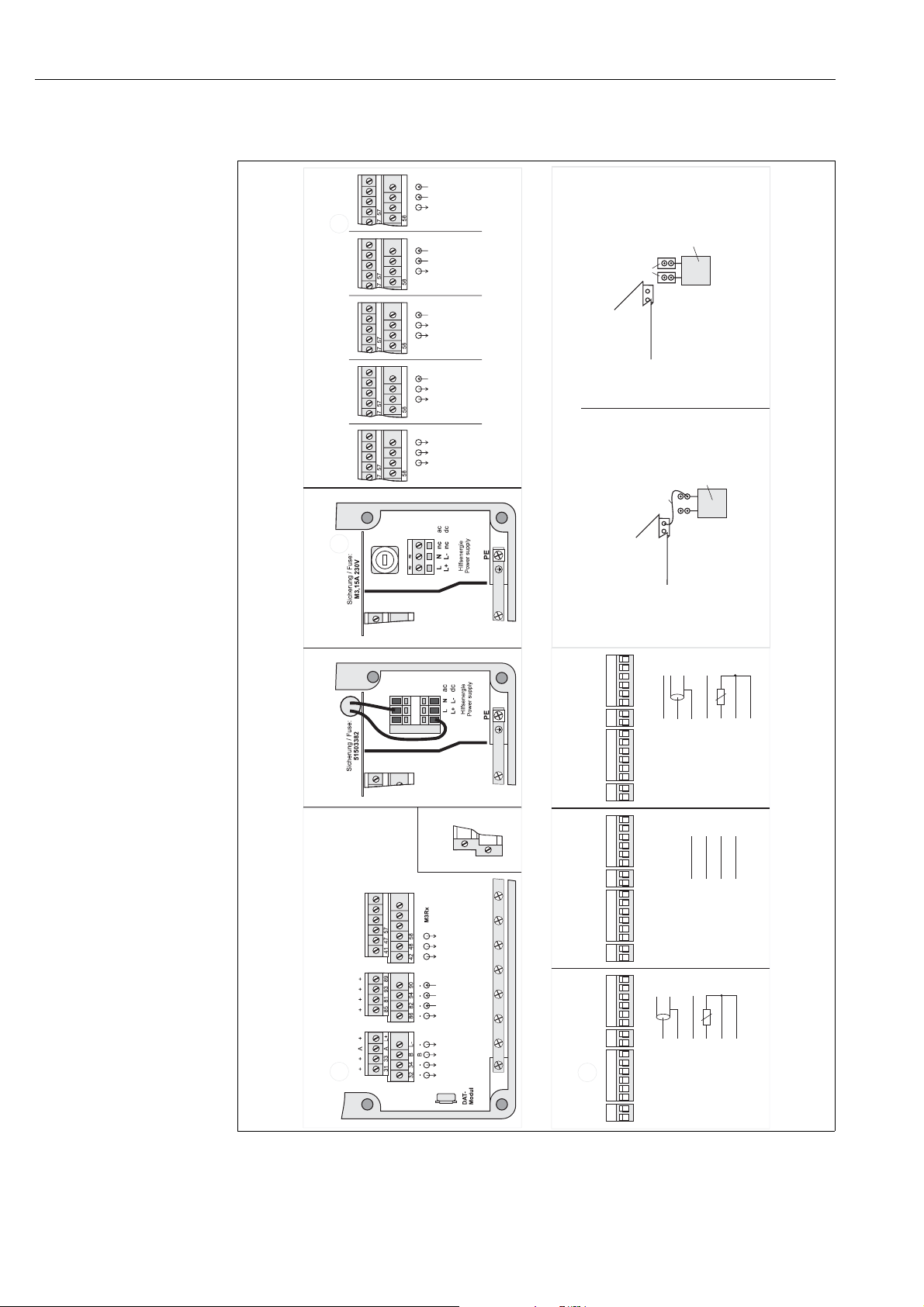

4.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.2 Connection compartment sticker for

CPG310 control unit . . . . . . . . . . . . . . . . . 21

4.1.3 Connection compartment sticker,

Mycom S CPM153 . . . . . . . . . . . . . . . . . . 22

4.1.4 Power supply and communication connection

between transmitter and control unit . . . . . 23

4.1.5 Level probes for buffer and cleaner . . . . . . 24

4.1.6 Analog sensors . . . . . . . . . . . . . . . . . . . . . 25

4.1.7 Digital sensors with

Memosens technology . . . . . . . . . . . . . . . . 30

4.1.8 Current outputs . . . . . . . . . . . . . . . . . . . . . 32

4.1.9 Mycom relays . . . . . . . . . . . . . . . . . . . . . . 35

4.1.10 External inputs (PLC to CPG310 ) and

outputs (CPG310 to PLC) . . . . . . . . . . . . . 36

4.1.11 External inputs (PLC to Mycom) . . . . . . . . 37

4.1.12 Inductive limit position switch . . . . . . . . . . 38

4.2 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 40

5 Medium connection. . . . . . . . . . . . . . . 41

5.1 Compressed air pipe and additional valves . . . . . . . 41

5.2 Water pipe and rinse chamber . . . . . . . . . . . . . . . . 42

5.3 Multihoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3.1 Connecting multihoses . . . . . . . . . . . . . . . 44

5.4 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4.1 Cleanfit CPA471/472/475 . . . . . . . . . . . . 45

5.4.2 Cleanfit CPA473/474 . . . . . . . . . . . . . . . . 47

5.5 Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5.1 Compressed air control . . . . . . . . . . . . . . . 49

5.5.2 Buffer and cleaner . . . . . . . . . . . . . . . . . . . 50

5.5.3 Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 51

6 Operation . . . . . . . . . . . . . . . . . . . . . . 52

6.1 Display and operating elements . . . . . . . . . . . . . . . 52

6.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.1.2 Function of keys . . . . . . . . . . . . . . . . . . . . 52

6.1.3 Service switch . . . . . . . . . . . . . . . . . . . . . . 53

6.1.4 Measured value display . . . . . . . . . . . . . . . 54

6.1.5 Operation access authorization . . . . . . . . . . 54

6.1.6 Menu editor types . . . . . . . . . . . . . . . . . . . 55

6.2 Operation via FieldCare . . . . . . . . . . . . . . . . . . . . . 56

7 Commissioning . . . . . . . . . . . . . . . . . . 57

7.1 Points to note when commissioning

digital sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2 Points to note when commissioning

ISFET sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5.1 Configuring Clean program . . . . . . . . . . . . 61

7.6 Device configuration . . . . . . . . . . . . . . . . . . . . . . . 63

7.6.1 Set up 1 - Sensor input . . . . . . . . . . . . . . . . 63

7.6.2 Set up 1 - Display . . . . . . . . . . . . . . . . . . . 64

7.6.3 Set up 1 - Access codes . . . . . . . . . . . . . . . 64

7.6.4 Set up 1 - Current outputs . . . . . . . . . . . . . 65

7.6.5 Set up 1 - Relays . . . . . . . . . . . . . . . . . . . . 67

7.6.6 Set up 1 - Temperature . . . . . . . . . . . . . . . 68

7.6.7 Set up 1 - Alarm . . . . . . . . . . . . . . . . . . . . 70

7.6.8 Set up 1 - Hold . . . . . . . . . . . . . . . . . . . . . 71

7.6.9 Set up 1 - Calibration . . . . . . . . . . . . . . . . . 73

7.6.10 Set up 1 - Topcal validation function . . . . . 78

7.6.11 Set up 2 - Data log . . . . . . . . . . . . . . . . . . . 79

7.6.12 Set up 2 - Check . . . . . . . . . . . . . . . . . . . . 80

7.6.13 Set up 2 - Controller configuration . . . . . . . 82

7.6.14 Set up 2 - Limit switch . . . . . . . . . . . . . . . . 88

7.6.15 Set up 2 - Controller quick adjustment . . . . 90

7.6.16 Set up 2 - Topcal . . . . . . . . . . . . . . . . . . . 90

7.6.17 Set up 2 - Chemoclean . . . . . . . . . . . . . . 100

7.6.18 Manual operation . . . . . . . . . . . . . . . . . . 104

3

7.7 HART commands . . . . . . . . . . . . . . . . . . . . . . . . 106

7.7.1 Universal commands . . . . . . . . . . . . . . . . 106

7.7.2 Common practice commands . . . . . . . . . . 107

7.7.3 Device-specific commands . . . . . . . . . . . . 108

7.8 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.9 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.9.1 Calibration pH . . . . . . . . . . . . . . . . . . . . . 116

7.9.2 Calibration redox . . . . . . . . . . . . . . . . . . . 118

11 Technical data . . . . . . . . . . . . . . . . . . 154

11.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11.4 Performance characteristics . . . . . . . . . . . . . . . . . 155

11.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.6 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.7 Mechanical construction . . . . . . . . . . . . . . . . . . . 156

8 Maintenance . . . . . . . . . . . . . . . . . . . 122

8.1 Maintenance of the overall measuring point . . . . . 122

8.1.1 Cleaning the transmitter . . . . . . . . . . . . . 122

8.1.2 Cleaning the sensors . . . . . . . . . . . . . . . . 122

8.1.3 Maintenance of digital sensors . . . . . . . . . 124

8.1.4 Liquid KCl supply . . . . . . . . . . . . . . . . . . 124

8.1.5 Manual calibration . . . . . . . . . . . . . . . . . . 124

8.1.6 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.1.7 Cables, connections and

power supply lines . . . . . . . . . . . . . . . . . . 125

8.1.8 Control unit . . . . . . . . . . . . . . . . . . . . . . 126

9 Accessories . . . . . . . . . . . . . . . . . . . . 127

9.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.2 Connection accessories . . . . . . . . . . . . . . . . . . . . 127

9.3 Mounting accessories . . . . . . . . . . . . . . . . . . . . . . 128

9.4 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9.5 Offline configuration . . . . . . . . . . . . . . . . . . . . . . 130

9.6 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 130

9.7 Housing CYC310 . . . . . . . . . . . . . . . . . . . . . . . . 131

9.7.1 Product structure . . . . . . . . . . . . . . . . . . . 132

9.8 Operating panel for CPC310 . . . . . . . . . . . . . . . . 133

12 Appendix . . . . . . . . . . . . . . . . . . . . . . 157

12.1 Operating matrix . . . . . . . . . . . . . . . . . . . . . . . . 157

12.2 Wiring example for external program start . . . . . . 170

12.3 Buffer tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Index . . . . . . . . . . . . . . . . . . . . . . . . .172

10 Troubleshooting . . . . . . . . . . . . . . . . 135

10.1 Troubleshooting instructions . . . . . . . . . . . . . . . . 135

10.2 System error messages . . . . . . . . . . . . . . . . . . . . . 136

10.3 Process-specific errors . . . . . . . . . . . . . . . . . . . . . 140

10.4 Device-specific errors . . . . . . . . . . . . . . . . . . . . . . 143

10.5 Response of outputs to errors . . . . . . . . . . . . . . . . 144

10.5.1 Current output behavior . . . . . . . . . . . . . 144

10.5.2 Response of contacts to errors . . . . . . . . . 144

10.5.3 Response of contacts to power failure . . . . 145

10.5.4 Assembly behavior . . . . . . . . . . . . . . . . . . 145

10.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.6.1 Device view Mycom S . . . . . . . . . . . . . . . 146

10.6.2 Spare parts list Mycom S . . . . . . . . . . . . . 146

10.6.3 Control unit device view . . . . . . . . . . . . . 147

10.6.4 Control unit spare parts list . . . . . . . . . . . 147

10.6.5 View of canister with membrane pump

and level sensor . . . . . . . . . . . . . . . . . . . . 148

10.6.6 Spare parts list for canister with membrane

pump and level sensor . . . . . . . . . . . . . . . 149

10.6.7 Pneumatic and hydraulic control unit . . . . 150

10.6.8 Rinsing block . . . . . . . . . . . . . . . . . . . . . . 151

10.7 Replacing the device fuse . . . . . . . . . . . . . . . . . . . 152

10.8 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

10.9 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4

Safety instructions

1 Safety instructions

1.1 Designated use

Topcal S CPC310 is a fully automated measuring, cleaning and calibration system for pH and redox

measurement.

The system is fully equipped with power supply cables and hose systems.

Topcal S CPC310 can be operated using the handheld terminal DXR375 or at a PC by means of the

FieldCare program via a HART

The system is particularly suitable for use in the following areas:

• Chemical process systems

• Pharmaceuticals

• Foodstuff industry

• Water treatment and monitoring

• Wastewater treatment

• Sewage treatment plants

• Chemical pulp and paper industry

Topcal S CPC310 is suitable for use in hazardous atmospheres.

Any use other than that described here compromises the safety of persons and the entire measuring

system and is, therefore, not permitted.

The manufacturer accepts no liability for damage resulting from incorrect use or use other than that

designated.

®

modem, e.g. Commubox FXA191.

1.2 Installation, commissioning and operation

Note the following points:

• Installation, commissioning, operation and maintenance of the measuring system must be carried

out exclusively by specially trained technical personnel.

The personnel must be authorized to perform such work by the system operator.

• The electrical connection may only be established by an electrical technician.

• Technical personnel must have read and understood these Operating Instructions and must

adhere to them.

• Before commissioning the entire measuring point, check all the connections for correctness.

Ensure that electrical cables and hose connections are not damaged.

• Do not commission damaged products. Protect them against inadvertent commissioning. Mark

the damaged product as defective.

• Faults at the measuring point may only be rectified by authorized and specially trained personnel.

• If faults cannot be rectified, you must take the products out of operation and protect them against

inadvertent commissioning.

• Repairs not described in these Operating Instructions may only be carried out directly at the

manufacturer's or by the service organization.

1.3 Operational safety

The system is designed to meet state-of-the-art safety requirements, has been tested and left the

factory in a condition in which it is safe to operate. The applicable regulations and European

standards have been taken into consideration.

As the user, you are responsible for ensuring the following safety regulations are observed:

• Installation regulations

• Local standards and regulations

5

Safety instructions

#

Electromagnetic compatibility

With regard to electromagnetic compatibility, this device has been tested in accordance with the

applicable European standards for industry.

The electromagnetic compatibility indicated only applies to a device that is connected in accordance

with the instructions in these Operating Instructions.

1.4 Return

If the device has to be repaired, please return it cleaned to your sales center.

For returns please use the original packaging.

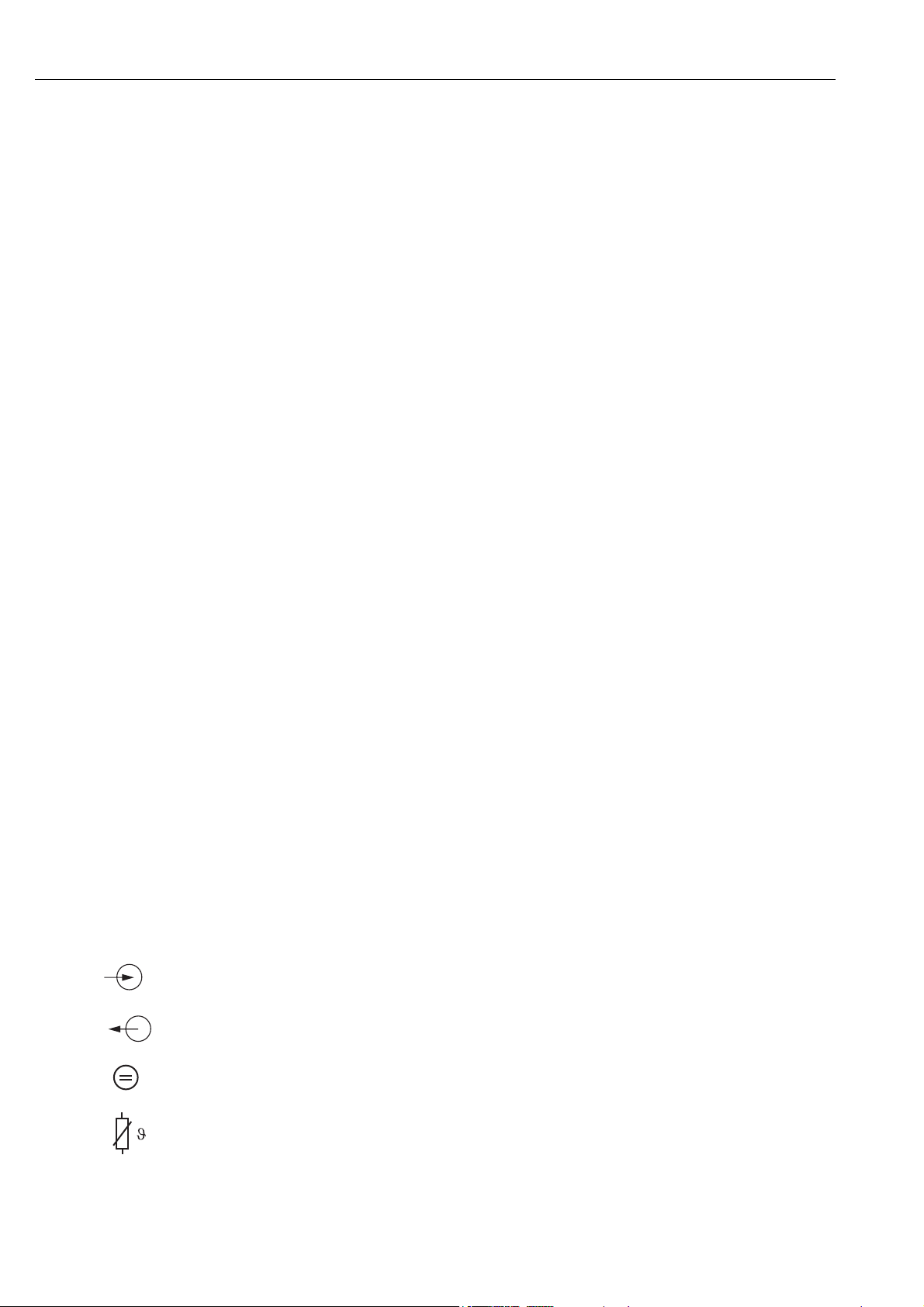

1.5 Notes on safety conventions and icons

Warnings

Warning!

This symbol alerts you to hazards which could cause serious injuries, as well as damage to the

instrument, if ignored.

"

!

%

&

(

)

*

b

Caution!

This symbol alerts you to possible faults which could arise from incorrect operation. They could

cause damage to the instrument if ignored.

Note!

This symbol indicates important items of information.

Electrical symbols

Direct current

A terminal at which DC voltage is applied or through which DC flows.

Alternating current

A terminal at which (sine-form) alternating voltage is applied or through which AC flows.

Direct or alternating current

A terminal at which direct or alternating voltage is applied or through which AC flows.

Ground connection

A terminal which, from the user's point of view, is already grounded using a grounding system.

Protective earth terminal

A terminal which must be grounded before other connections may be established.

Alarm relay

Input

Output

DC voltage source

Temperature sensor

6

2 Identification

2.1 Device designation

2.1.1 Nameplate

The transmitter and the control unit each has its own nameplate.

Made in Germany, D-70839 Gerlingen

MYCOM S

Order code

Serial no

Meas. range:

Temperature:

Channels:

Output 1:

Output 2:

Mains:

Fig. 1: CPM153 nameplate (example)

pH / Redox

CPM153-A2C10A010

.

55000505G08

-2 ... +16 pH

-50 … +150 °C

1

4 … 20 mA

0/4…20mA

100-230 VAC 50/60 Hz

-1500 mV ... +1500 mV

10 VA

Identification

IP65

-10 < Ta < +55 °C

a0003930

Made in Germany, D-70839 Gerlingen

CPG310

Order code

Serial no

Mains:

CPG310

.

3C000505G09

230 VAC 50/60 Hz

0158

12 VA

IP54

0 < Ta < +55 °C

Fig. 2: CPC310 nameplate (example)

2.1.2 Scope of delivery

The scope of delivery of the system comprises:

• 1 Mycom S CPM153 transmitter

• 1 CPG310 control unit

• 1 rinsing block with securing clamps for assembly

• 4 multihoses

• 2 technical buffer solutions pH 4.00 and 7.00

• 3 double-membrane pumps for conveying cleaner and buffer with canisters

• 1 communication/power supply cable CPG310 / Mycom S CPM153

• 3 level probes, complete with CPG310 cable to canisters

• 1 pressure reduction valve with pressure gauge

•1 water filter

• 1 device identification card

• 1 set of Operating Instructions in English

• Accessories where applicable

If you have any questions, please contact your supplier or sales center.

a0004843

7

Identification

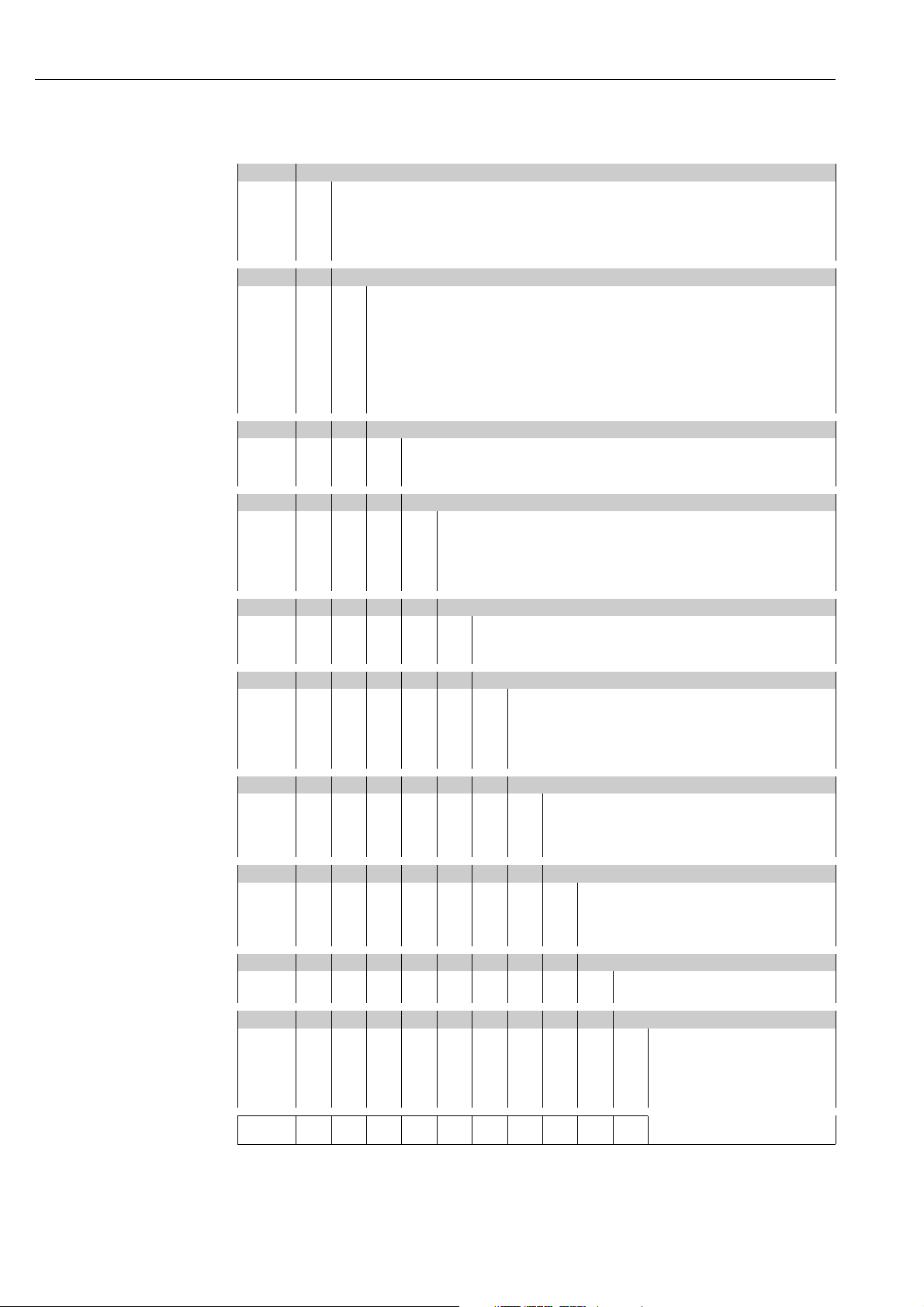

2.1.3 Product structure

Approval

A Basic features: Non-Ex

G With ATEX approval, ATEX II (1) 2G EEx, em ib[ia] IIC T4

O With FM approval Cl. I, Div. 2, with NI input and output circuits, sensor IS Cl. I, Div. 1

P With FM approval Cl. I, Div. 2, with NI input and output circuits

S With CSA approval, Cl. I, Div. 2, sensor IS Cl. 1, Div. 1

Material of rinsing block, O-ring, connection

00 PVDF, Viton, G ¼ male

01 PVDF, Viton, NPT ¼" male

02 PVDF, Kalrez, G ¼ male

03 PVDF, Kalrez, NPT ¼" male

10 Stainless steel 1.4404 (AISI 316L), Viton, G ¼ male

11 Stainless steel 1.4404 (AISI 316L), Viton, NPT ¼" male

12 Stainless steel 1.4404 (AISI 316L), Kalrez, G ¼ male

13 Stainless steel 1.4404 (AISI 316L), Kalrez, NPT ¼" male

Sensor input Mycom S

1 1 measuring circuit for glass electrodes, pH/redox and temperature

2 1 measuring circuit for glass electrodes/ISFET sensors, pH/redox and temperature

5 1 measuring circuit for digital Memosens sensors, pH/redox and temperature

Measurement output Mycom S

A 2 current outputs 0/4 ... 20 mA, passive (Ex and non-Ex)

B 2 current outputs 0/4 ... 20 mA, active (non-Ex)

C HART with 2 current outputs 0/4 ... 20 mA, passive

D HART with 2 current outputs 0/4 ... 20 mA, active

E PROFIBUS PA, without current outputs

Power supply

0 ... 230 V AC

1 110 ... 115 V AC

8 24 V AC / DC

Language

A English / German

B English / French

C English / Italian

D English / Spanish

E English / Dutch

Cable entry

0 Cable glands M20 x 1.5

1 Adapter for cable glands NPT ½"

3 Cable gland M20 x 1.5, PROFIBUS-PA-M12 connector

4 Cable gland NPT ½", PROFIBUS-PA-M12 connector

Length of multihose

05 m

1 5 m with electric heating

210 m

3 10 m with electric heating

Additional equipment

0 Basic version

1 Preparation for CYC310 housing

Setting

A Factory setting

B IQ/OQ template German

C IQ/OQ template English

D Standard FAT German

E Standard FAT English

CPC310- Complete order code

8

Identification

2.2 Certificates and approvals

Declaration of conformity

The product meets the statutory requirements of the harmonized European standards. The

manufacturer certifies compliance with the standards by using the 4 mark.

9

Installation

3 Installation

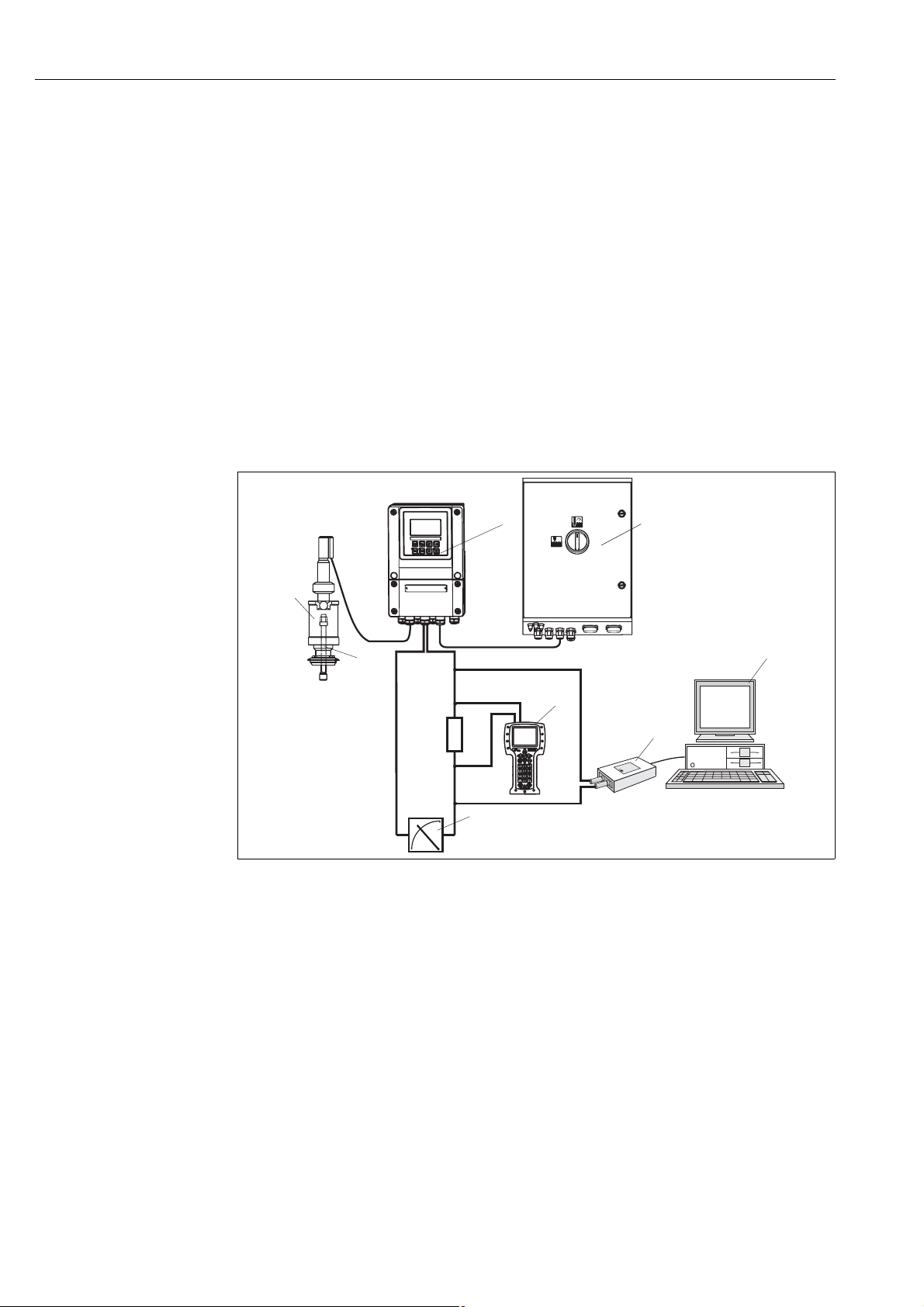

3.1 System setup

A complete system unit comprises:

• Mycom S CPM153 transmitter

• CPG310 control unit

• A rectractable assembly, e.g. CPA475; with or without a potential matching pin (PML)

• A pH/redox sensor: e.g. CPS71 (pH glass), CPS471 (ISFET) or CPS71D (Memosens)

• A measuring cable: CPK9 (pH), CPK12 (ISFET) or CYK10 (Memosens)

•HART

•HART

• PC with FieldCare software (see Accessories) and Mycom DTM

•Recorder

®

handheld terminal DXR375

®

modem Commubox FXA191

Optional:

Fieldgate FXA320 instead of HART

1

2

min.

250 W

Fig. 3: Example of a measuring system

1

Retractable assembly CPA475

2

pH/Redox sensor

3

Mycom S CPM153

4

Topcal S CPC310

®

modem

8

3

7

5

PC with FieldCare

6

HART

HART

7

Recorder

8

4

6

®

modem Commubox FXA191

®

handheld terminal DXR375

5

a0006963

10

Installation

3.2 Incoming acceptance, transport, storage

• Make sure the packaging is undamaged!

Inform the supplier about damage to the packaging.

Keep the damaged packaging until the matter has been settled.

• Make sure the contents are undamaged!

Inform the supplier about damage to the delivery contents.

Keep the damaged goods until the matter has been settled.

• Check that the scope of delivery is complete and matches your order and the shipping documents.

• For storage and transport purposes, pack the instrument so that it is protected against impacts and

humidity. The original packaging offers the best protection. Furthermore, the permitted ambient

conditions must be observed (see "Technical data").

• If you have any questions, please contact your supplier or sales center.

3.3 Installation conditions

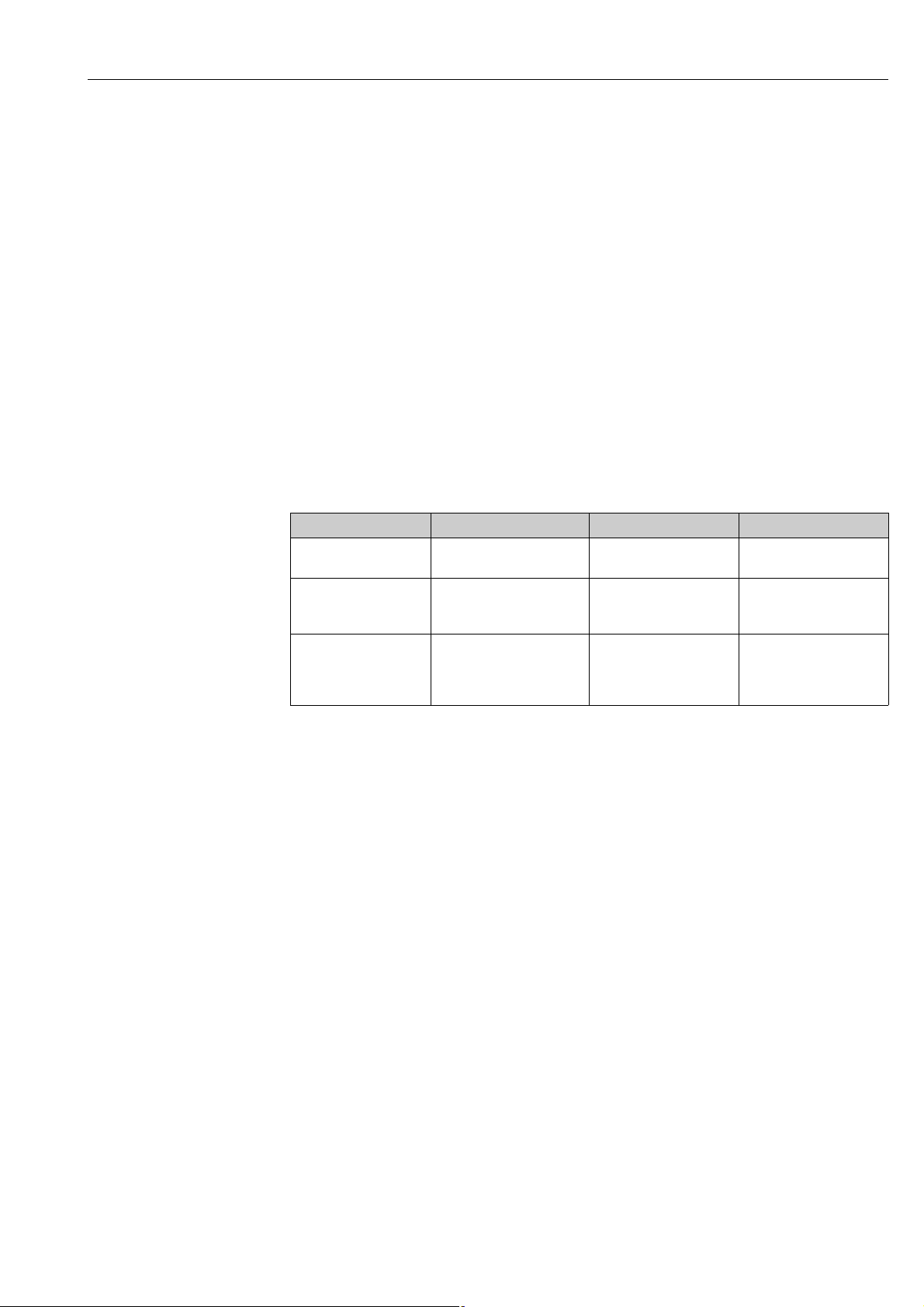

3.3.1 Types of mounting

You can choose from the following types of mounting for the individual components:

Device Wall mounting Post/pipe mounting Panel mounting

CPG310 control unit Mounting set included in the

Mycom S CPM153,

protected

Mycom S CPM153,

outdoors

scope of delivery.

Required:

2 screws Ø 6 mm (0.24")

2 wall plugs Ø 8 mm (0.31")

Weather protection cover

CYY102-A required if directly

exposed to weather conditions

(see Accessories).

not applicable not applicable

Mounting set included in

the scope of delivery.

Weather protection cover

CYY102-A and 2x round

post fixtures required (see

Accessories).

Mounting set included in

the scope of delivery.

not usual

11

Installation

MEAS CAL

DIAG

PARAM

?

3.3.2 Spacing

The graphic below illustrates the maximum distances between the system components.

max. 5/10 m

(max. 16.4/32.8 ft)**

max. 5 m (16.4 ft)

PARAM

max. 200 m (656 ft)

max. 2.5 m (8.20 ft)*

Fig. 4: Maximum spacing for Topcal S CPC310 system components

* When using the multihoses supplied as standard

** Depending on the multihose version ordered

3.3.3 Assembly installation

A Glass electrode: Installation angle of at least 15 ° to the horizontal.

B ISFET sensor Tophit: No restrictions, 0 ... 180

° recommended

a0006069

12

15°

15°

A

Fig. 5: Permitted orientation depending on the sensor used

B

a0002720

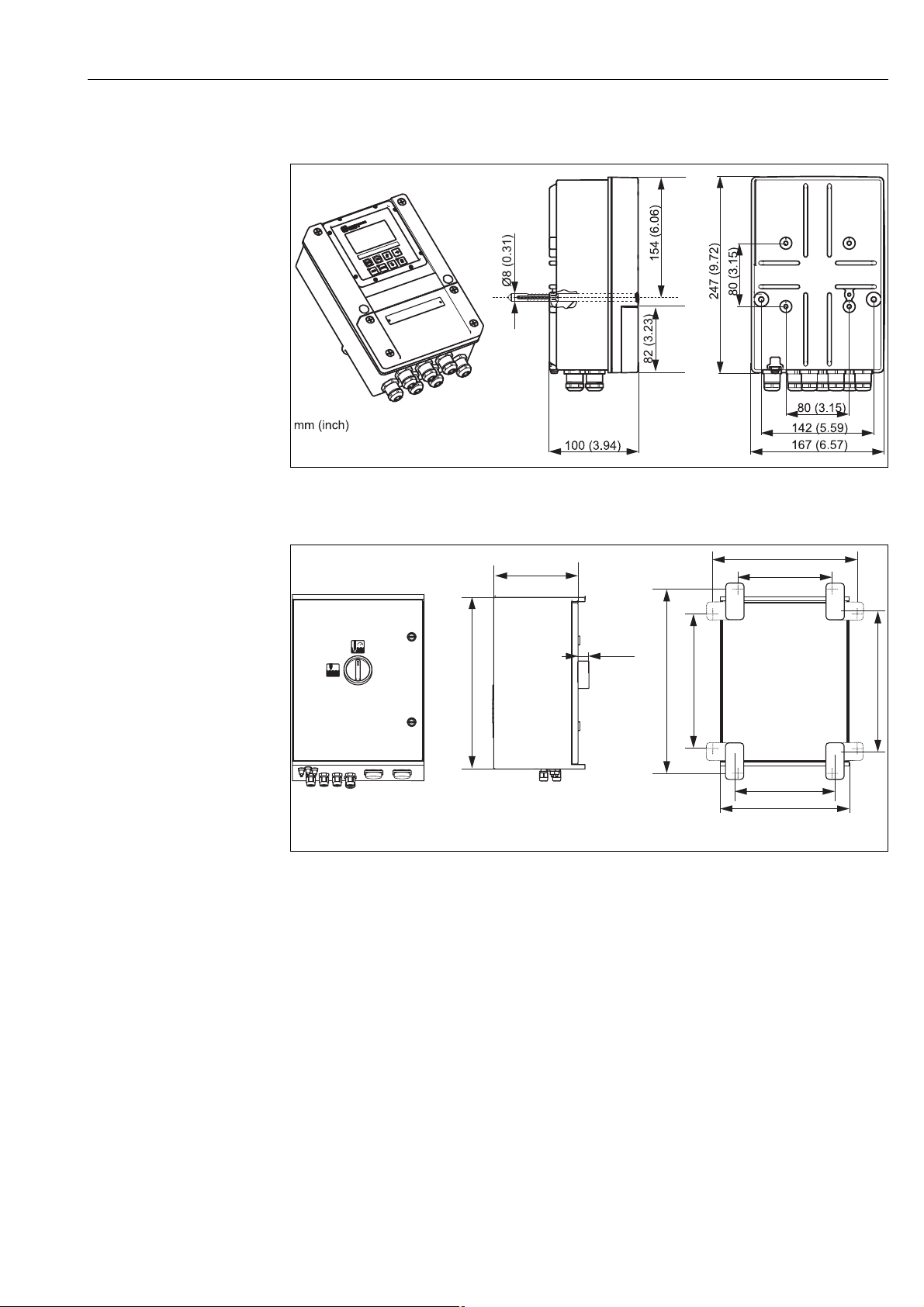

3.3.4 Dimensions

Fig. 6: Dimensions of Mycom S

Installation

cxm153-dim.cdr

200 (7.87)

400 (15.75)

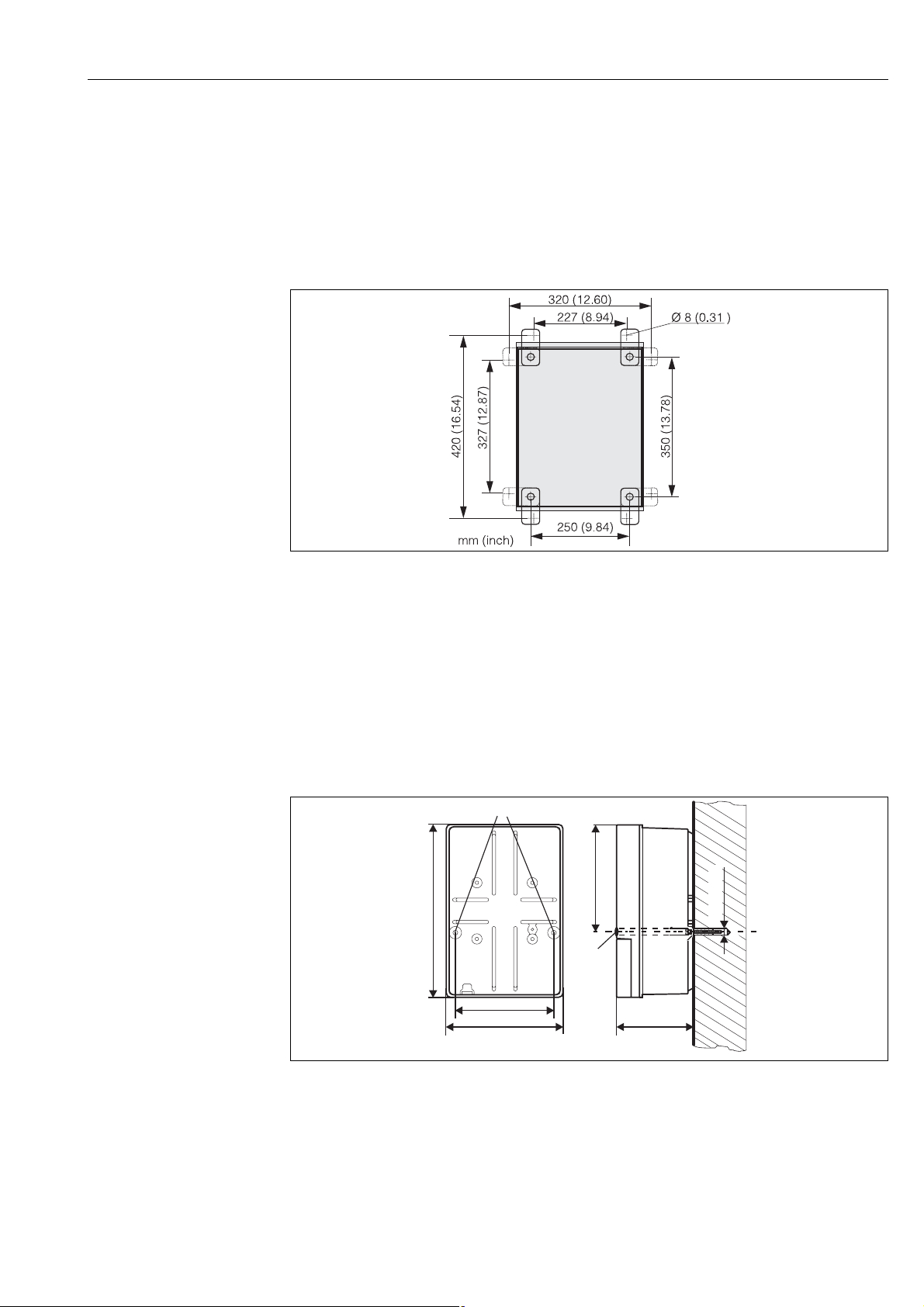

Fig. 7: Dimensions of CPG310 control unit

24

(0.94)

420 (16.54)

327 (12.87)

320 (12.60)

227 (8.94)

350 (13.78)

250 (9.84)

300 (11.81)

mm (inch)

a0005790

13

Installation

3.4 Installation instructions

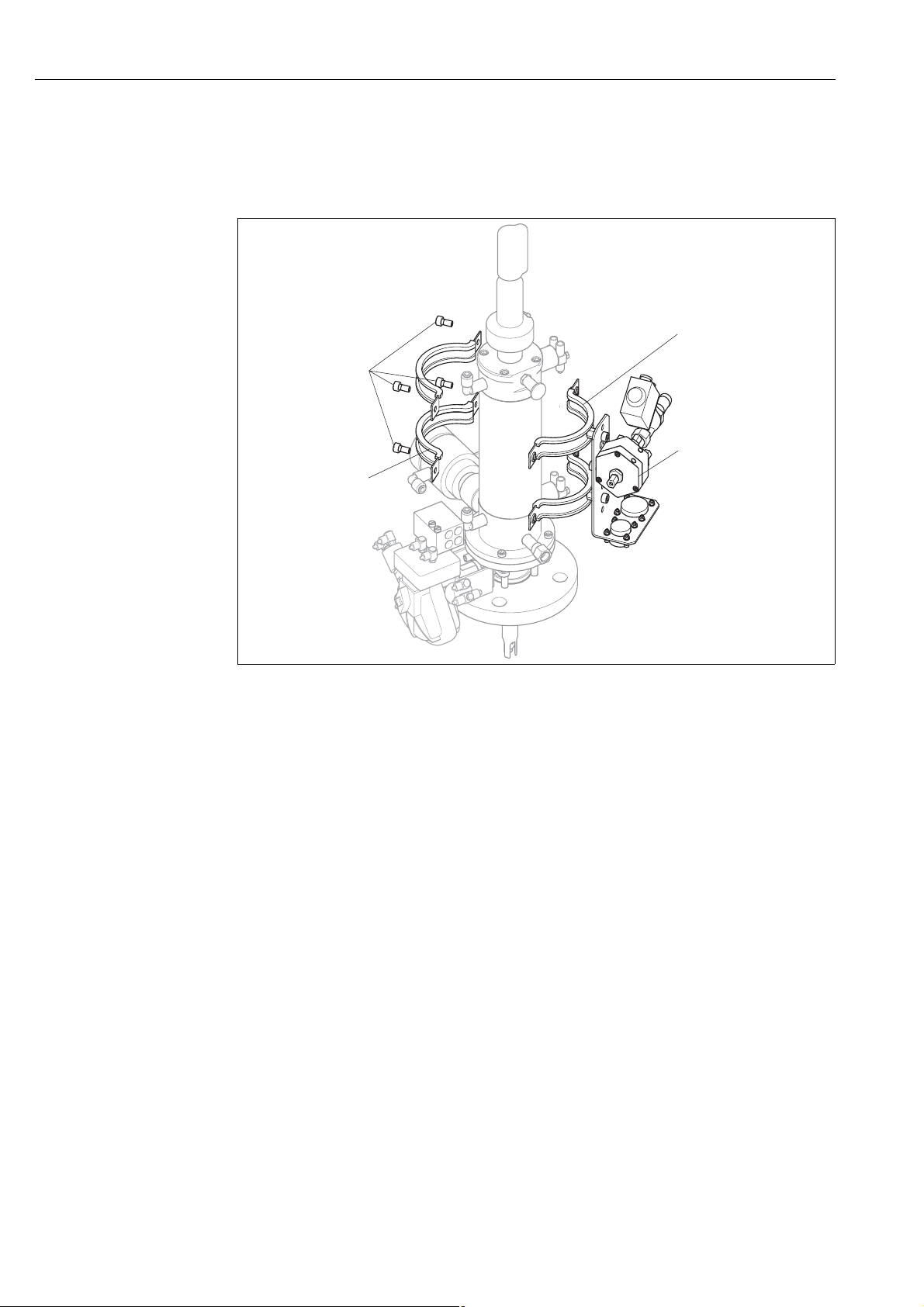

3.4.1 Securing rinsing block to assembly

3

1

4

2

a0006202

Fig. 8: Mounting the rinsing block on the assembly (example CPA473)

Proceed as follows to mount the rinsing block:

1. Fit the securing clamps with the rinsing block (3 and 4) on the assembly cylinder.

2. Fit the counterclamps (2) on the assembly cylinder from the other side.

3. Connect the clamps with the screws (1) supplied.

3.4.2 Installation instructions

• The Mycom S transmitter is used as a field device as standard. It can also be installed as a

panel-mounted instrument.

• Mycom S is suitable for wall mounting with securing screws and for post mounting to cylindrical

pipes.

• Always install the transmitter horizontally in such a way that the cable entries are always pointing

downwards.

14

3.4.3 Wall mounting

Caution!

"

• Make sure the maximum permitted ambient temperature range of -20 ... +60

is observed. Avoid direct sunlight.

• Always mount the wall-mount housing in such a way that the cable entries point downwards.

Control unit

°C (-4 ... 140 °F)

Installation

a0004861

Fig. 9: Dimensions for wall mounting with wall securing kit (part of scope of delivery)

Proceed as follows to wall-mount the unit:

1. Please note that the maximum suction height for buffer and cleaner is 2.5 m (8.2 ft.) when

using the standard multihoses supplied. Bore the holes as per the graphic above.

2. Screw the elements of the wall securing set supplied to the rear wall of the housing.

3. Secure the housing to the wall without any inclination.

Transmitter

1

154 (6.06)

247 (9.72)

2

Ø 8 (0.31)

142 (5.59)

167 (5.57)

mm (inch)

Fig. 10: Dimensions for wall mounting, securing screw: Ø 6 mm (0.24"), wall plug: Ø 8 mm (0.31")

1 Securing bores

2 Plastic caps

100 (3.94)

a0003953

15

Installation

Proceed as follows to wall-mount the unit:

1. Bore the holes as per Fig. 10.

2. Push the two securing screws from the front through the securing bores (item 1).

3. Mount the transmitter housing to the wall as illustrated.

4. Cover the bores with the plastic caps (item 2).

3.4.4 Post mounting and panel mounting

!

Note!

You need a special mounting kit to secure the transmitter to horizontal and vertical posts or pipes

(max. Ø 70 mm (2.76")) and for panel mounting.

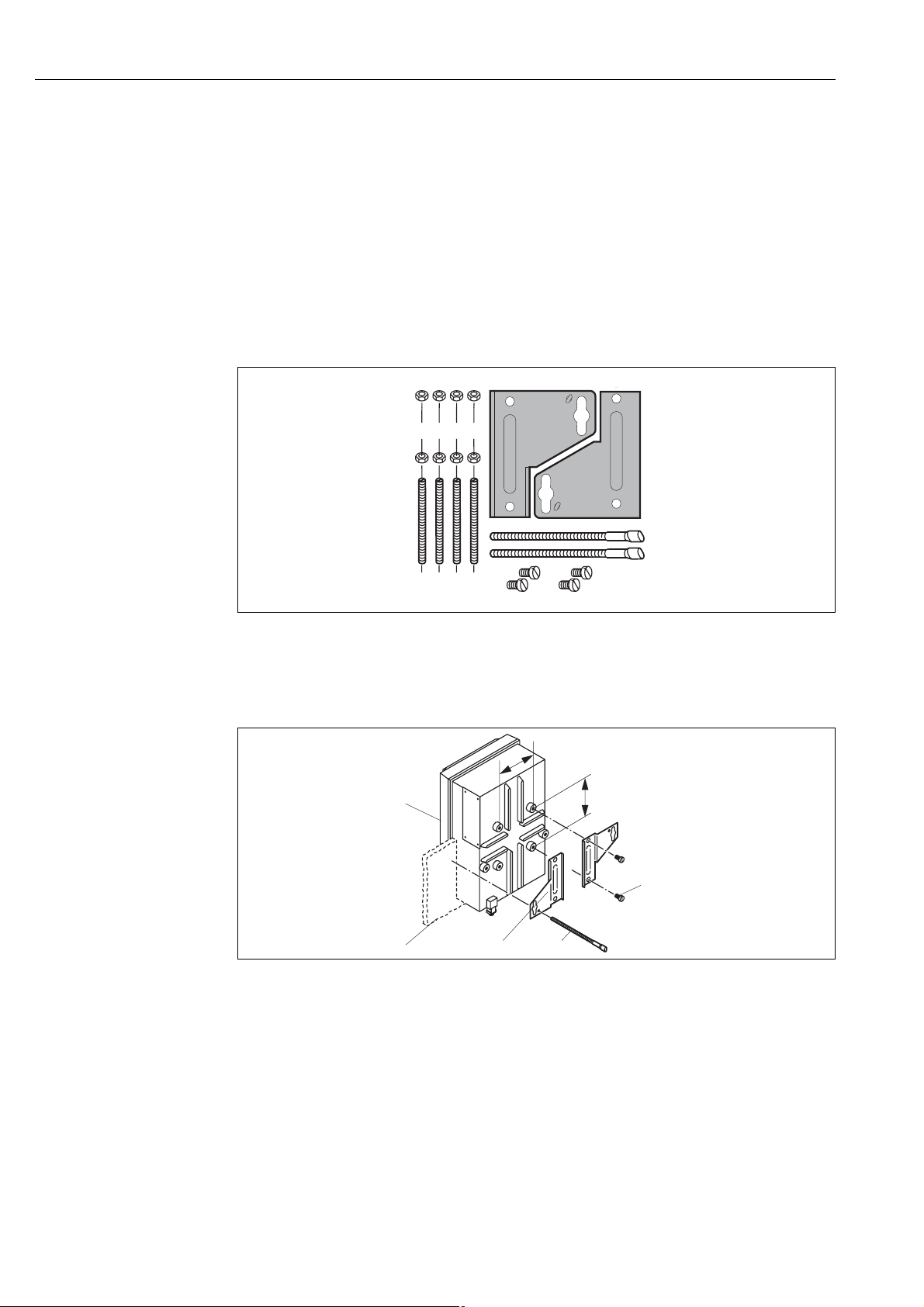

a0003955

Fig. 11: Mounting kit

Panel mounting

Proceed as follows to panel-mount the transmitter:

80

80

5

4

a0003956

Fig. 12: Panel mounting

1

2

3

1. Make the necessary mounting cutout, measuring 161 x 241 mm (6.34" x 9.49").

The installation depth is 134 mm (5.28").

2. Unscrew the top housing section (item 1).

3. Secure the securing plates (item 3) to the transmitter housing base using the securing screws

(item 5) in accordance with Fig. 12.

4. Secure the transmitter to the panel (item 2) using the clamping screws (item 4).

5. Place the flat seal (see "Accessories" section) on the housing base.

6. Screw the top housing section back on.

16

Post mounting

Proceed as follows to mount the transmitter to a post:

Installation

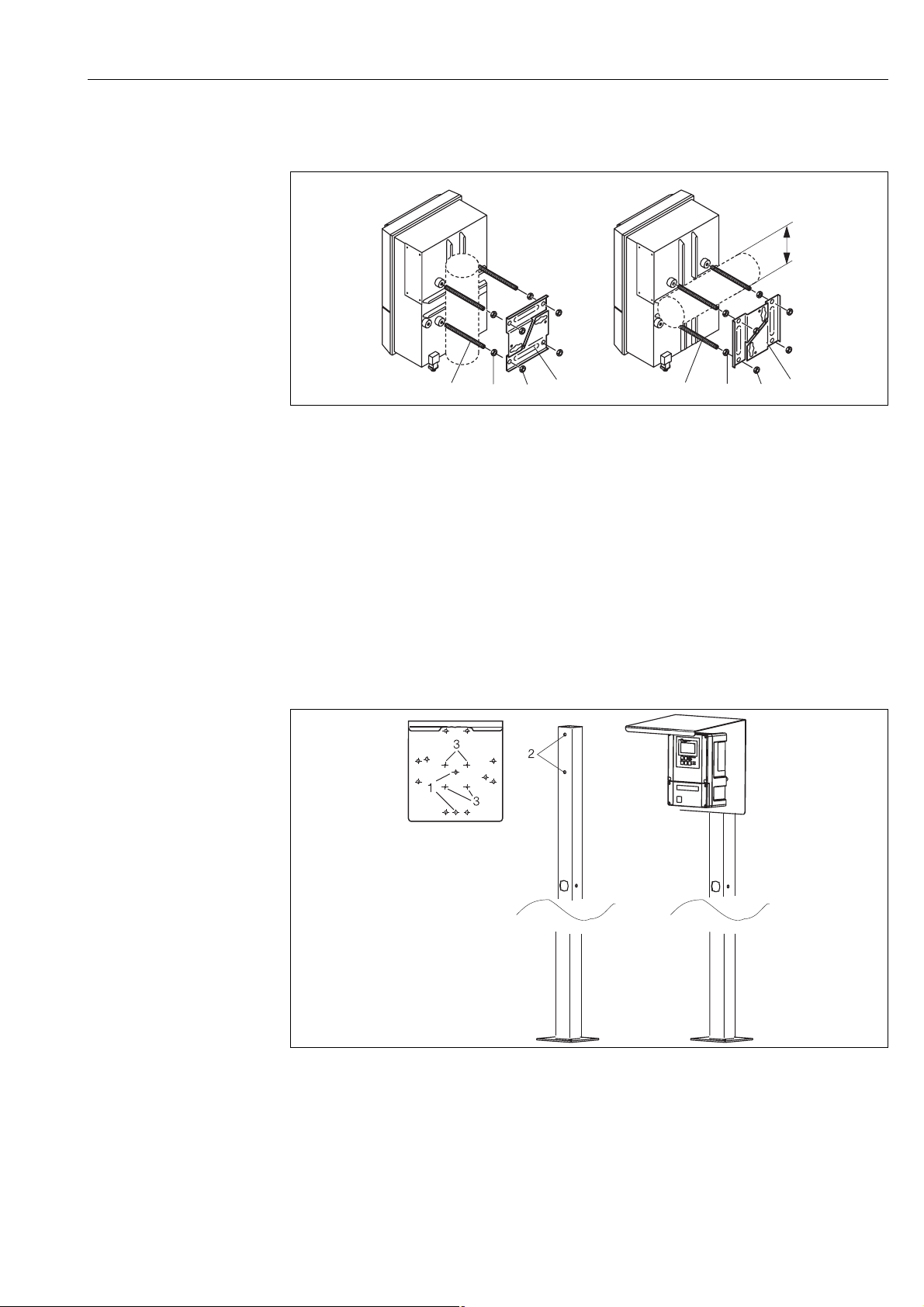

Fig. 13: Post mounting

AVertical mounting

B Horizontal mounting

A

2 3

1

4

B

Ø70

2 3

1

4

a0003954

1. Screw the four securing screws (item 1) into the threaded openings on the transmitter.

2. Counter every securing screw with a nut (item 2).

3. Set the transmitter to the desired position on the post or pipe.

4. Push the securing plates (item 4) onto the securing screws in accordance with Fig. 13.

5. Screw a nut (item 3) onto each securing screw and tighten it so that the transmitter is securely

fastened to the post or pipe.

You can also secure the field device to a square universal post in conjunction with the weather

protection cover. These are available as accessories, see the "Accessories" section.

Fig. 14: Mounting the field device with a universal post and weather protection cover

a0003957

Proceed as follows to mount the weather protection cover:

1. Screw the weather protection cover onto the upright post (bores 2) with 2 screws (bores 1).

2. Secure the field device to the weather protection cover. To do so, use the bores (3).

17

Installation

3.5 Post-installation check

• After installation, check the transmitter and the control unit for damage.

• Check whether the transmitter and control unit are protected against rain and direct sunshine.

18

4 Wiring

Wiring

#

!

Warning!

• The electrical connection must only be carried out by an electrical technician.

• The electrical technician must have read and understood these Operating Instructions and must

adhere to them.

• Before beginning the connection work, ensure no voltage is applied to any cable.

4.1 Electrical connection

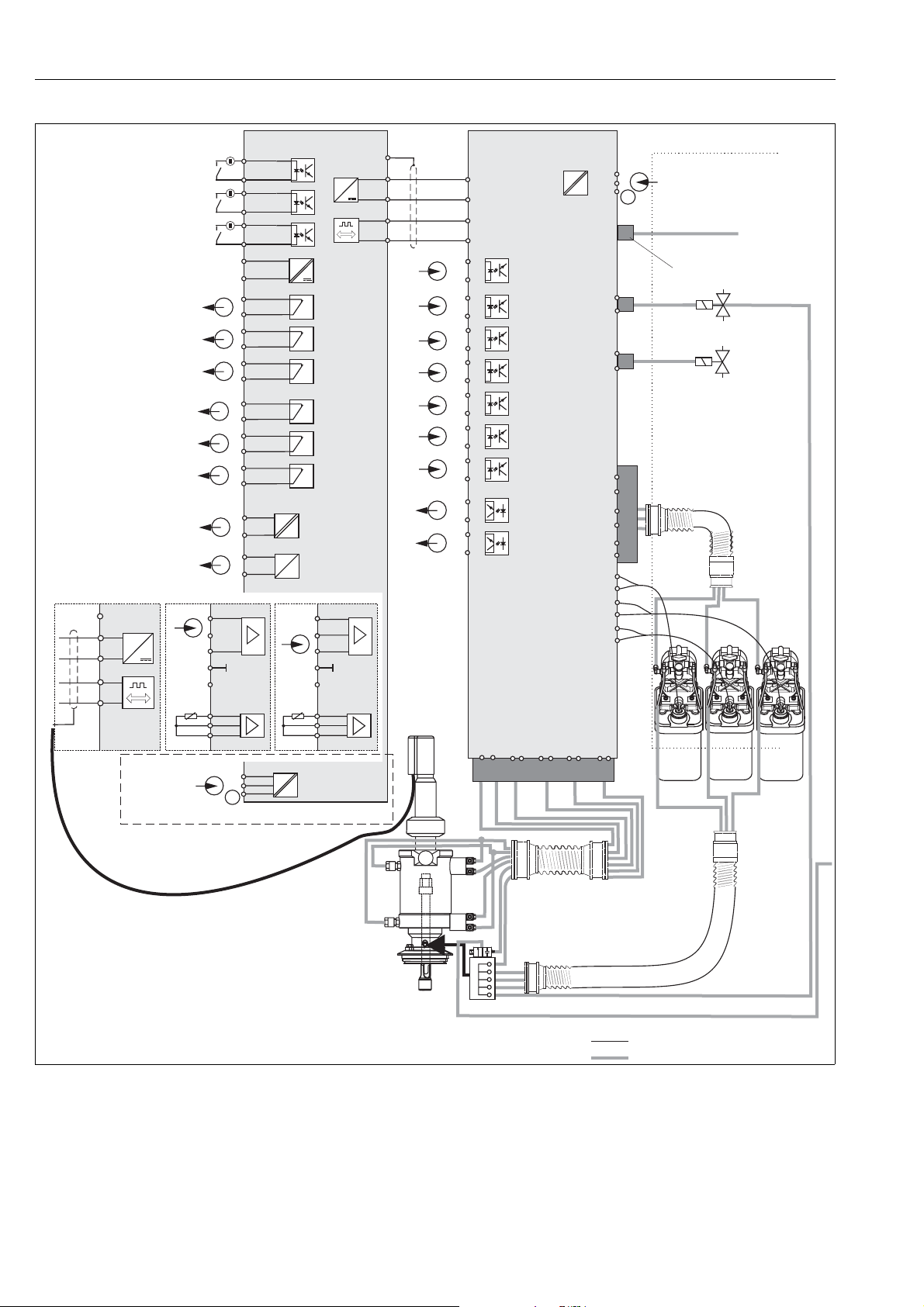

4.1.1 Overview

You have the following connection options at your disposal:

• Direct connection to the transmitter via current output 1 (terminals 31 /32)

• Connection via the 4 ... 20 mA circuit

Hinweis!

• Connect unused signal cores of input and output cables to the internal PE rail of the transmitter.

• The current/resistance input may only be connected with a shielded cable, whereby the shield

must be connected to the PE rail of the transmitter.

• Make sure that the grounding in the connection compartment cover is connected to the PE rail

in the housing by means of the PE line.

• The measuring circuit must have a minimum load of 250

• Current output 1 is permanently set to "4 ... 20 mA".

• Without an external power supply, communication via current output 1 is only possible if the

jumper setting is "active".

Ω in current output 1.

19

Wiring

Digital sensor

PE

E1: ext. Hold*

E2: Chemoclean

"Clean"*

E3: Chemoclean

"User"*

Power supply

output*

Alarm relay

(NAMUR: Failure

Relay 1

(NAMUR: Mainten. requ.)

Relay 2

(NAMUR: Function control)

Relay 3

Relay 4

Relay 5

Current

output 1

Current

output 2

S

87

BN

88

WH

GN

96

YE

97

Power supply

(operator supply)

Mycom CPM153

+

81

82

+

93

94

+

89

90

85

+

–

+

+

-

+

-

15 V

86

41

42

47

48

57

58

51

52

54

55

44

45

31

mA

32

33

mA

34

pH electrode or ISFET pH sensor

pH

n.c.

Ref.

PA/

PM

Temp. 1

SS

JJ

11 11

J

12

13

L/L+

N/L–

PE

)

Temp. 1

DRN

SRC

Ref.

12

13

PA/

PM

CPG310

PE

BN

L+

WH

L–

12V DC

GN

A

CPG

YE

B

comm.

10 ... 40 V

+

–

A

B

94

93

+

92

+

91

90

+

89

88

+

87

86

+

85

84

+

83

82

+

81

66

+

65

62

+

61

Assembly

service*

Assembly

measure

n.c.

Automatic stop

bin. 2

bin. 1

bin. 0

Assembly

service

Assembly

measuring

Start programme 1-8

(binary)

L/L+

N/L–

PE

Pneumatic

connection

42

41

46

45

51

52

47

48

pumps

58

57

Control of membrane

P6

P5

P4

P3

Level check

P2

P1

Installation and connection

by operator

Power supply

)

AD6/ID4

Multihose coupling

1

2

Compressed

air supply

4...6bar,

filtered 50 µm,

free of oil and

condensate

Pressurized steam,

water, cleaner

Val ve 1

(optional)

Val ve 2

3

J

Assembly

55

56

1112 13

Feedback measure

Feedback service

71

14

Multihose coupling

2/2-way valve

72

Rinse air

76

75

A

Cleaner

B

Buffer 1

C

Buffer 2

20

n.c.: do not connect!

2

3

5

6

CPA475

Rinse block

Fig. 15: Connecting in the non-hazardous area

electric line

compressed air/medium

Water

a0005788-en

CPG310

Wiring

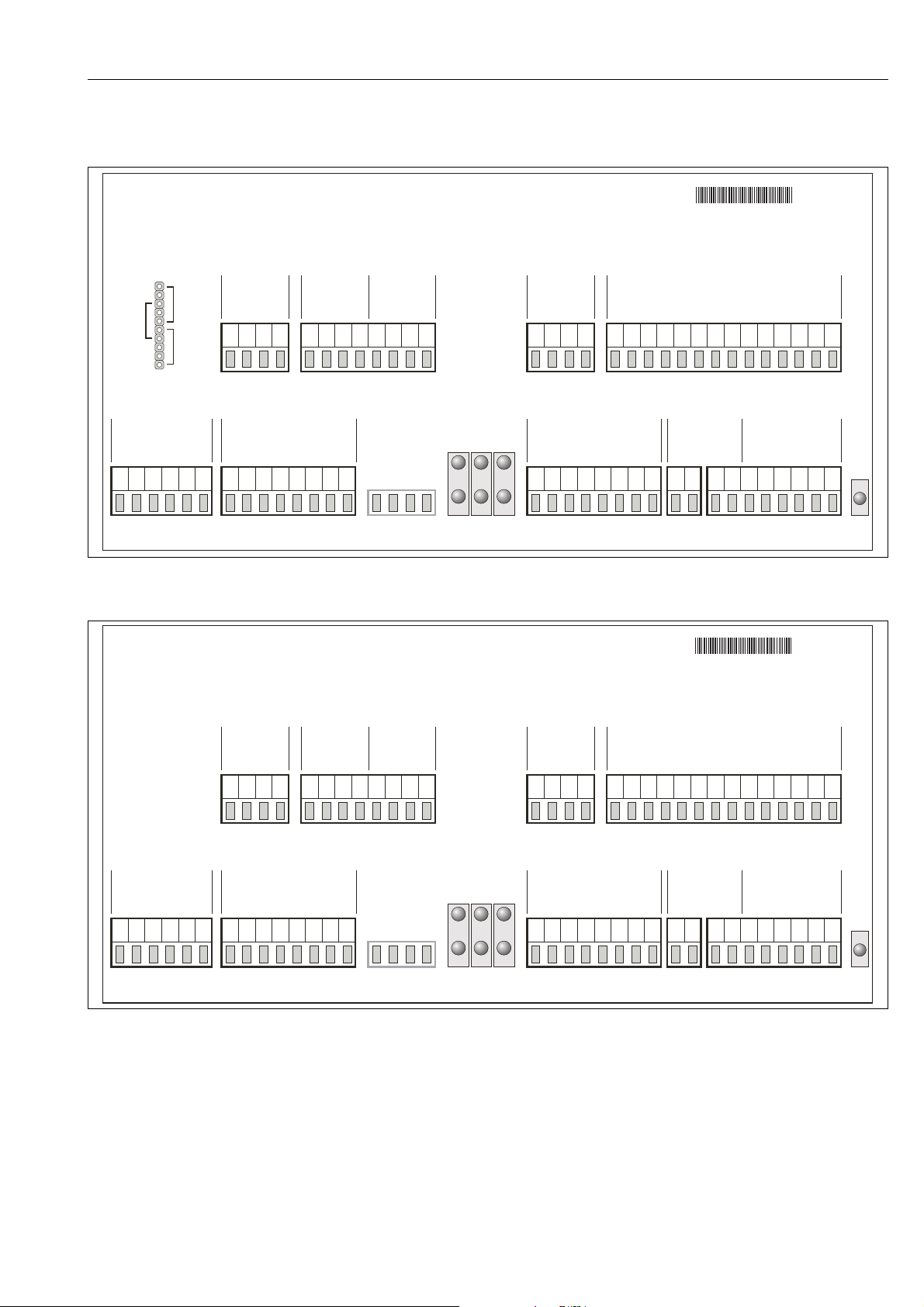

4.1.2 Connection compartment sticker for CPG310 control unit

140107-1000-3A

71027539

100 - 110 - 230 VAC

Zusatzventile /

Jumper

230V

100V/

110V

Power

Sicherung / Fuse:

M3,15A

100-230V

AC

PE

PEL+PEN- PE

gerade Zahlen: minus; ungerade Zahlen: plus; even-numbers: minus; odd-numbers: plus

auxiliary valves

100-230V

Ventil 1 /

valve 1

Ventil 2 /

Puffer 1 /

valve 2

buffer 1

Puffer 2 /

buffer 2

45

46

48 56515752 58

41 42

V1 V2 V3 V4 V9

Interne Eingänge /

n.c.

n.c.

D1

D2P4P1P5P2

47

internal inputs

Puffer 2 /

Puffer 1 /

buffer 1

P3

buffer 2

Reiniger /

cleaner

P6

55

Armatur /

assembly

Reiniger /

V6

cleaner

Fig. 16: Connection compartment sticker for CPG310, 100 /110/ 230 V AC

CPG310

24VAC/DC

Steuer-Ausgänge /

drive outputs

V1

Ass.

Meas.

V2

Mycom

RS485

12V

B

L+ L-

SPS Ausgänge /

61

A

PCS outputs

Service /

service

Messen /

measure

62 72657566 76

Wasser /

71

V7 V8

SPS Eingänge /

PCS inputs

Programmwahl /

program choice

Automatik

Stop /

automatic

bin 1

bin 0

82 9086 9483 91

81 89

Luft /

water

bin 2

85 93

84 9288

Interne Eingänge /

internal inputs

Service-

Schalter /

service

air

K1 K2

S0 S1 S2 S3

stop

87

Druckluft-

sensor /

air pressure

sensor

switch

D4 1311 14

D3

71027540

n.c.

Rückmeldung Armatur /

feedback assembly

Messen /

measure

Service /

Messen /

measure

Service /

service

12

140107-2000-3A

service

Alive-LED

a0006256

Zusatzventile /

auxiliary valves

24V

Reiniger /

cleaner

Armatur /

Ventil 1 /

valve 1

Ventil 2 /

Puffer 1 /

valve 2

buffer 1

45

46

48 56515752 58

41 42

V1 V2 V3 V4 V9

Power

Sicherung / Fuse:

M3,15A

24V

AC/DC

PE

PEL+PEN- PE

gerade Zahlen: minus; ungerade Zahlen: plus; even-numbers: minus; odd-numbers: plus

Interne Eingänge /

n.c.

n.c.

D1

D2P4P1P5P2

47

internal inputs

Puffer 2 /

Puffer 1 /

buffer 1

P3

buffer 2

Reiniger /

P6

Puffer 2 /

buffer 2

cleaner

assembly

55

V6

Fig. 17: Connection compartment sticker for CPG310, 24 V AC/DC

Steuer-Ausgänge /

drive outputs

V1

Ass.

Meas.

V2

Mycom

RS485

12V

B

L+ L-

SPS Ausgänge /

61

A

PCS outputs

Service /

service

Messen /

measure

62 72657566 76

Wasser /

71

V7 V8

SPS Eingänge /

PCS inputs

Programmwahl /

program choice

Automatik

Stop /

automatic

bin 0

bin 1

bin 2

82 9086 9483 91

81 89

water

85 93

84 9288

Interne Eingänge /

internal inputs

Service-

Schalter /

Luft /

service

air

K1 K2

S0 S1 S2 S3

stop

87

Druckluft-

sensor /

air pressure

sensor

switch

D4 1311 14

D3

n.c.

Rückmeldung Armatur /

feedback assembly

Messen /

measure

Service /

Messen /

measure

Service /

service

12

service

Alive-LED

a0006257

21

Wiring

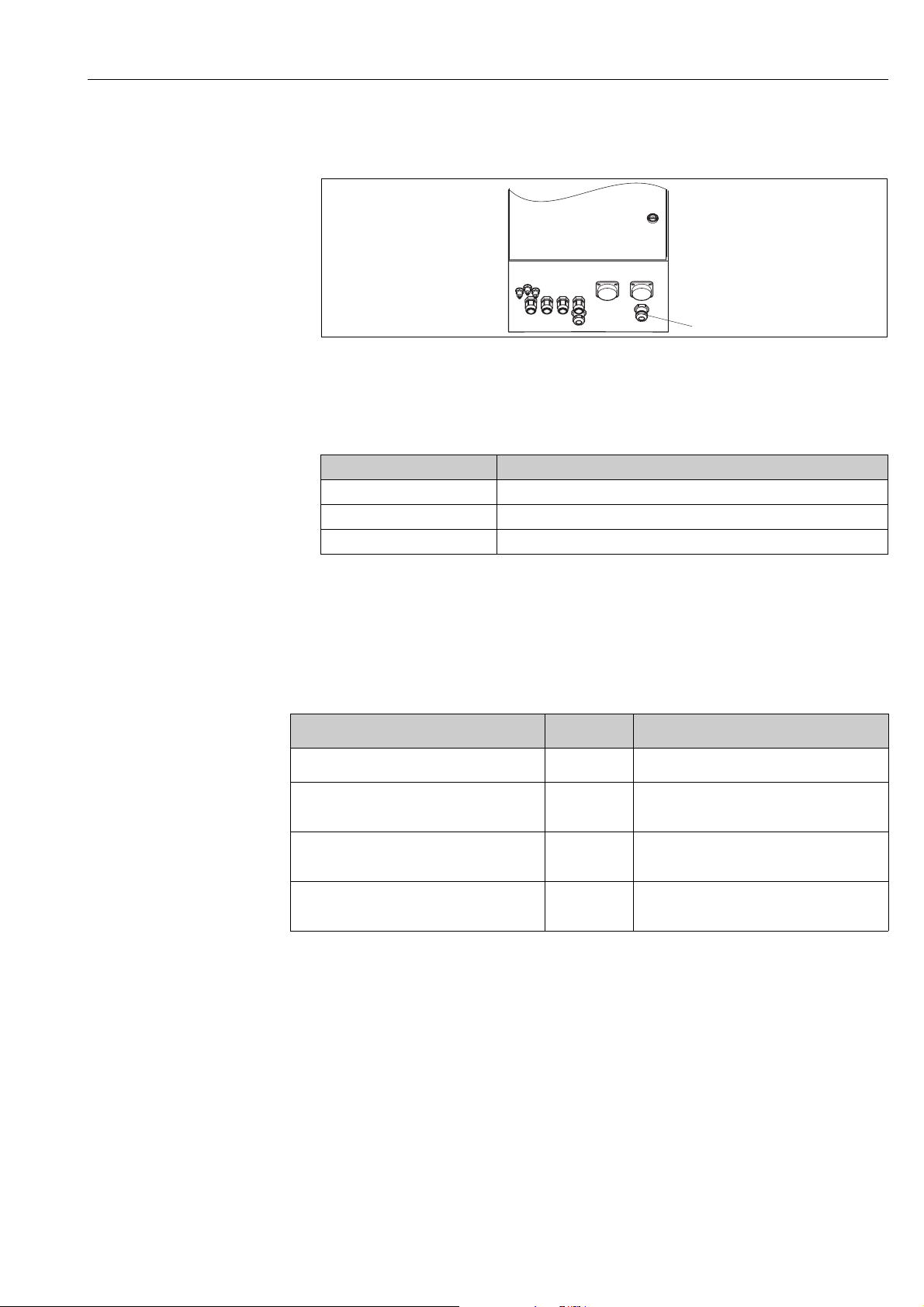

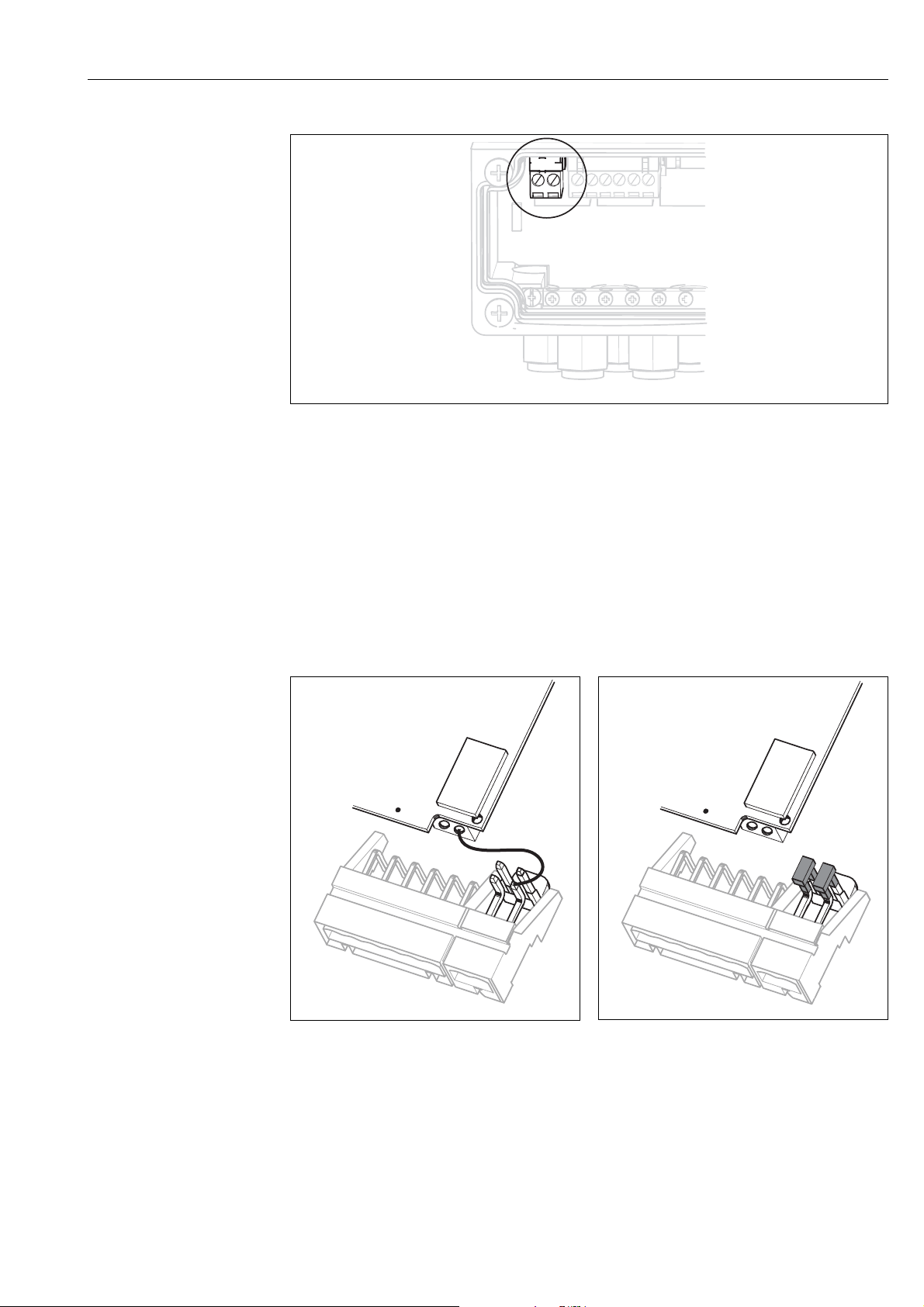

4.1.3 Connection compartment sticker, Mycom S CPM153

Kontakte, contacts, order code*Best.-Variante /

non EX

-..5..

-..4..

-..3..

-..2..

-..1..

+

+

+

+

+

+

-

22

-

51 23 21

52 24

-

22

-

51 23 21

52 24

-

22

51 54 21

52 55

-

22

51 54 21

52 55

45

51 54 44

52 55

0-1k /10k

WW

4-20mA

4-20mA

4-20mA

WW

0-1k /10k

4-20mA

Relay contact 3

Klemmen (Rückseite) /

terminals (back side)

Relay contact 3

Relay contact 4

Relay contact 3

Steckbrücken entsprechend der Zeichnung hinten an den Klemmen

Relay contact 4

Relay contact 3

Relay contact 5

Relay contact 4

Relay contact 3

4.

Steckbrücken /

jumpers

Transmittermodul /

transmitter module

aufstecken. /

Plug the jumpers onto the back side of the terminals as shown below.

Verbindungsleitung /

connecting line

Sensorkabel entsprechend ISFET-Belegung anschließen. /

Connect sensor cable according to ISFET assignment.

Gehäuse-Oberteil des CPM 153 wieder schließen. /

Close the housing cover of the CPM 153.

6.

5.

Klemmen (Rückseite) /

terminals (back side)

Wechsel Glas auf ISFET / Changing from glass to ISFET

Transmittermodul /

transmitter module

Gehäuse-Oberteil des CPM 153 öffnen. /

Gehäuse-Unterteil des CPM153 öffnen und Leitungen des

Open the housing cover of the CPM 153.

Sensorkabels von Klemmen am Gehäusedeckel abziehen. /

Open the lower housing section of the CPM153 and remove the

wires of the sensor cable from the terminals in the housing cover.

2.

1.

Verbindungsleitung zwischen Rückseite Klemme und

Transmittermodul entfernen. /

Remove the line connecting the terminal back side and

the transmitter module.

3.

N

F

L

F

EX

zusammengehörige

Klemmen /

combined clamps

Relay contact 2

Relay contact 1

Alarm contact

CPM153

Stromausgang / current out / Hart

E3: CC "User"

E2: CC "Clean"

E1: ext.Hold

15V 9mA

CPC Supply

CPC RS485

I2: 0-20mA

I1: 0-20mA / Hart

135042-0001-4C

Fig. 18: Connection compartment sticker, Mycom S CPM153

DRN Drain

SRC Source

REF Reference

* Only order version -..1.. is applicable

ISFET

digital sensor

Digitaler Sensor /

Glaselektrode / glass electrode

S

11

12 13

PA

REF

Kanal / channel 2

DRN SRC

S

11

13

12

PA

REF

Kanal / channel 1

DRN SRC

97 96 88 87 S

NC

Kanal / channel 2

NC NC

97 96 88 87 S

NC

Kanal / channel 1

NC NC

S

11

12 13

PA

REF

Kanal / channel 2

PH

S

11

13

12

PA

REF

Kanal / channel 1

PH

rot / red

DRN

pH / mV

braun / brown

Koax / coax

SRC

PA

REF

gelb / yellow

grün / green

97

96

braun / brown

grün / green

Koax / coax

PA

11

REF

grün / green

11

weiß / white

88

gelb / yellow

12

()gelb / yellow

12

braun / brown

87

weiß / white

13

Pt1000

weiß / white

13

Schirm auf PE / screen to PE

Pt100 / Pt1000

a0006259

22

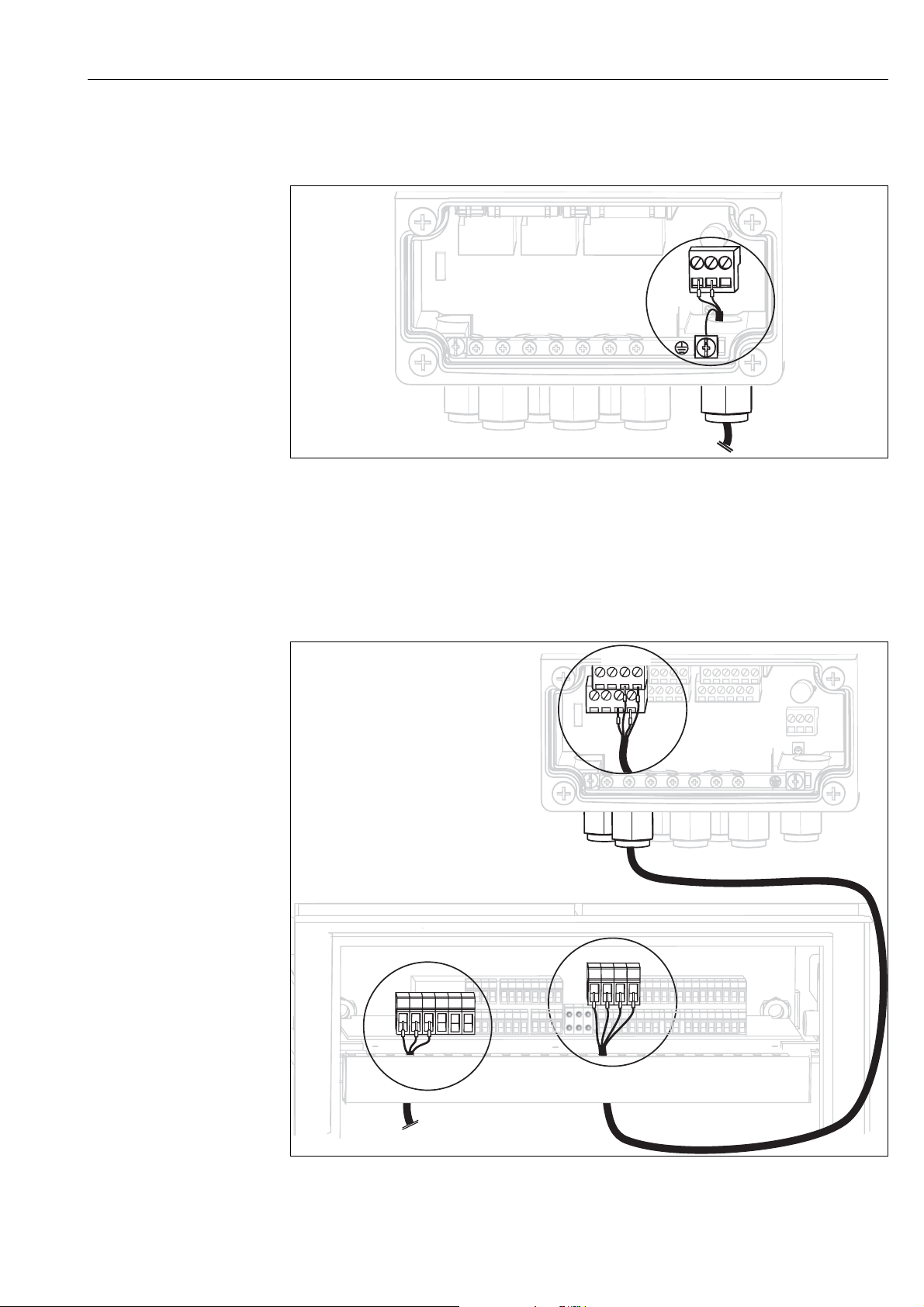

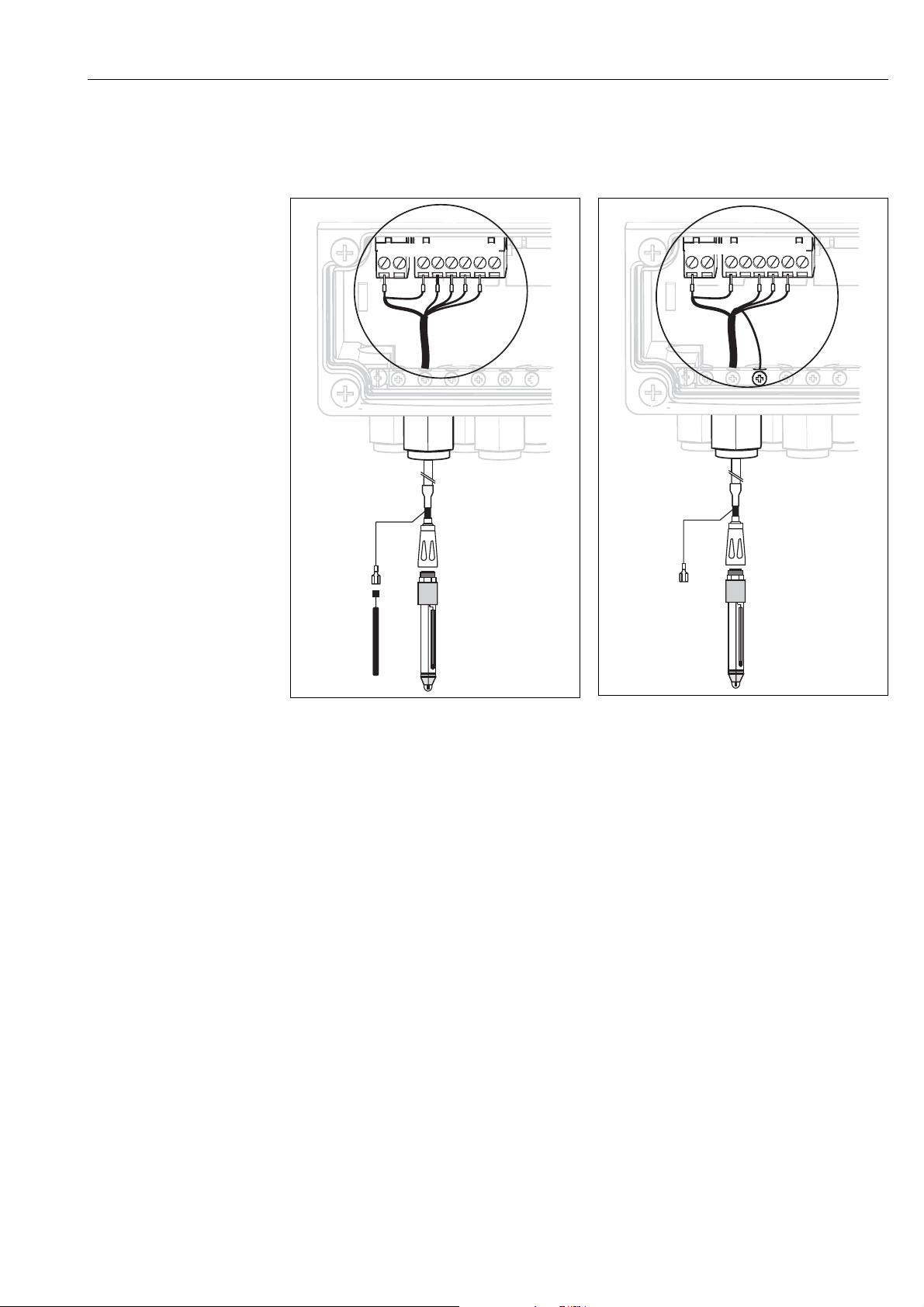

4.1.4 Power supply and communication connection between

transmitter and control unit

N

L

L-

L+

-

+

Fig. 19: Connecting power supply Mycom S

Wiring

a0003960

Mycom S power supply:

1. Guide the power cable through the right Pg cable gland and into the Mycom housing.

2. Connect the green/yellow core to the PE terminal.

3. Connect the two other cable cores to terminals "L" and "N".

BN

GN

YE WH

3133AL+

34 B

32

L-

WH

GN

BN

YE

L+L- B A

PE

PE PE

N-

PE

L+

Fig. 20: Connecting power supply for control unit and communication connection

a0004875

23

Wiring

Control unit power supply

1. Guide the voltage cable through a suitable Pg gland and into the control unit housing.

2. Connect the green/yellow core to the PE terminal.

3. Connect the two other cable cores to terminals "L+" and "N-" (bottom terminal block, left).

Communication connection between Mycom and control unit

1. Guide the end of the communication cable with the black shield wire through a suitable Pg

gland on Mycom.

2. Guide the other end of the communication cable through a Pg gland on the control unit.

3. Connect the cable cores as follows:

Cable core Mycom connection Control unit connection

Yellow (YE) Terminal B Terminal B

Green (GN) Terminal A Terminal A

White (WH) Terminal L- Terminal L-

Brown (BN) Terminal L+ Terminal L+

Black (BK) PE grounding bar n.c.

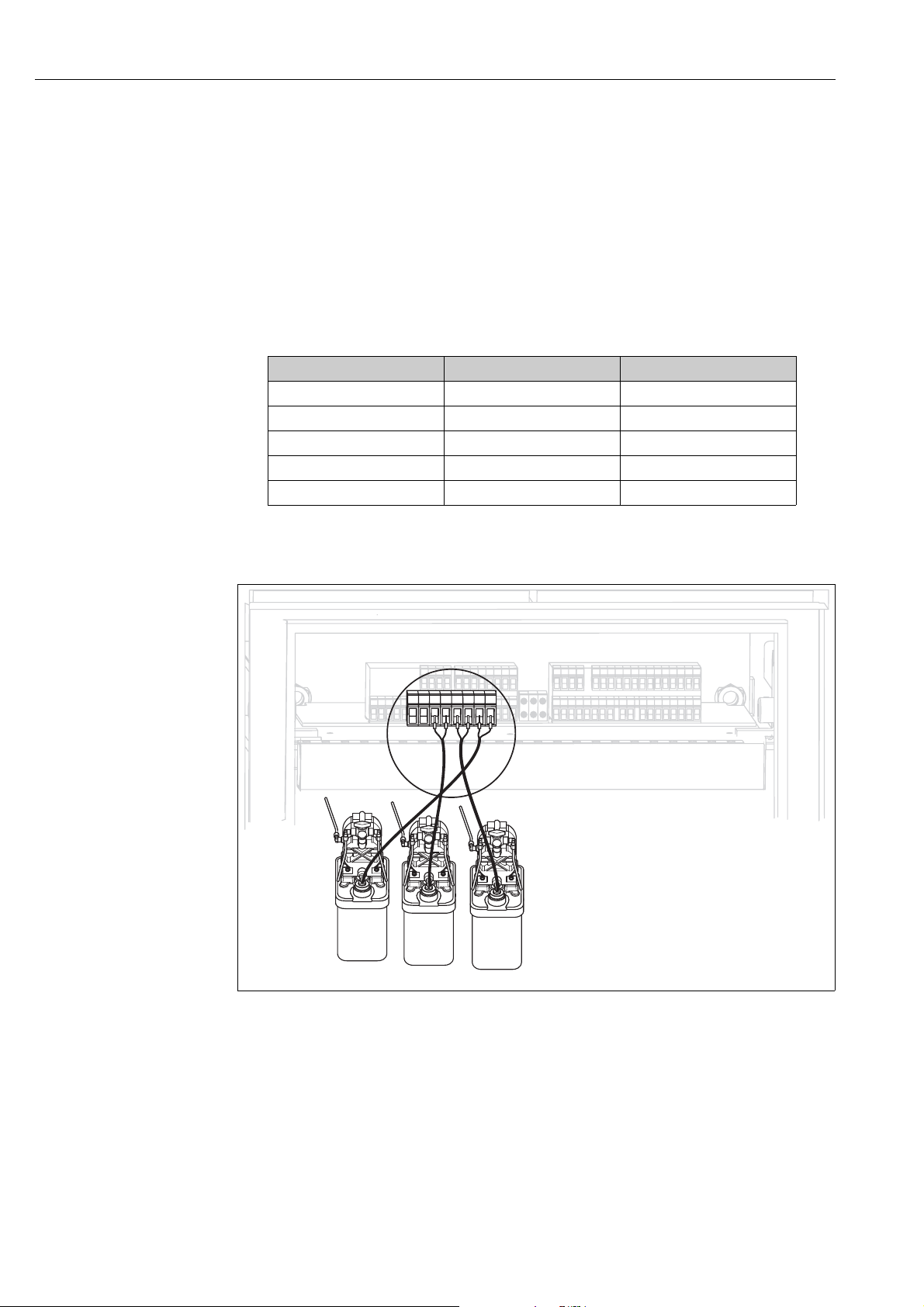

4.1.5 Level probes for buffer and cleaner

D1 D2 P1 P2 P3 P4 P5 P6

A

Fig. 21: Connecting level probes for buffer and cleaner

ACleaner

B Buffer 1

C Buffer 2

B

C

a0005835

24

Wiring

1. Guide the cables of the level probes for the buffer and cleaner through the threefold Pg gland

behind the multihose connection (see Fig. 22).

1

Fig. 22: Guiding the level probe cable

1 Threefold Pg gland

a0006021

2. Connect the cable cores as follows. Polarity does not matter here:

Cable core Control unit connection

Level probe, buffer 1 Terminal P1 and P2

Level probe, buffer 2 Terminal P3 and P4

Level probe, cleaner Terminal P5 and P6

4.1.6 Analog sensors

Measuring cables

You require shielded special measuring cables to connect pH and redox sensors to the transmitter.

You can use the following multicore and preterminated cable types:

Sensor type Cable Extension

Electrode without temperature sensor CPK1 VBA / VBM box + CYK71 cable

!

Electrode with Pt 100 temperature sensor and

TOP68 plug-in head

ISFET sensor with Pt 100 / Pt 1000 temperature

sensor and TOP68 plug-in head

pH individual electrode with separate reference

electrode and separate temperature sensor

CPK9 VBA / VBM box + CYK71 cable

CPK12 VBA / VBM box + CYK12 cable

CPK2 VBA / VBM box + PMK cable

Note!

Further information on the cables and junction boxes can be found in the "Accessories" section.

25

Wiring

Preparing cables

Caution!

"

Danger of inaccuracy.

Make sure to protect connectors, terminals and cables against moisture.

1

Fig. 23: Outer screen connection with metal cable gland

2

3

4

a0003976

1. Slide the cable gland and the clamping ring over the cable.

2. Remove the inner insulation.

3. Remove the outer shield from the cable and fold it back over the clamping ring.

4. Guide the sensor cable through the cable opening of the device and screw the gland closed.

Shield contacting takes place automatically here.

26

pH/redox glass electrodes

Connect the cable cores in the device as follows:

Connection with PML (symmetrical) Connection without PML (unsymmetrical)

Wiring

BN

PA/PM

pH

WH

Coax

Ref

BK

PA

BN

pH

WH

Ref

BK

Coax

11

12

13

S

WH

GN

YE

BN

d.n.c

PA

BN

11

12

13

S

WH

GN

YE

!

a0003961

Fig. 24: Connecting pH glass electrode with PML

Fig. 25: Connecting pH glass electrode without PML

d.n.c (do not connect)

Note!

• The yellow (YE), white (WH) and green (GN) cable cores do not apply when using CPK1.

• The outer shield of the cable is grounded by means of the metal gland.

• More information on pH measurement with PML and without PML is provided on the

"Additional information" CD-ROM supplied.

a0003962

27

Wiring

ISFET sensors

Connect the cable cores in the device as follows:

Connection with PML (symmetrical) Connection without PML (unsymmetrical)

11

12

Ref

DRN

SRC

Ref

DRN

11

12

13

PA

S

SRC

13

PA

S

!

BK

BN

YE

WH

GN

WH

Coax

BN

PA/PM

Fig. 26: Connecting ISFET sensors with PML

WH

RD

Coax

BN

d.n.c

a0003963

Fig. 27: Connecting ISFET sensors without PML

BK

BN

YE

WH

GN

a0003964

d.n.c (do not connect)

Note!

• The outer shield is grounded by means of the metal gland.

• More information on pH measurement with PML or without PML is provided on the "Additional

information" CD-ROM supplied.

28

Changing the pH input from glass electrode to ISFET sensor

In the glass/ISFET version (CPC310-xx2xxxxxxx), Topcal S is supplied for measuring with glass

electrodes as standard.

Proceed as follows to switch the connection:

1. Open the bottom housing section of the device.

2. If a glass electrode is connected, disconnect the cores of the sensor cable.

3. Remove the "pH" terminal on the housing cover (see Fig. 28) from the device and replace it

with the "DRN/SRC" terminal supplied.

Wiring

pH

pH

Ref

11

12

13

PA

S

a0003977

Fig. 28: pH terminal on housing cover

4. Open the top housing section of the device.

5. On the right-hand side of the housing cover, disconnect the red cable to the pH input at both

ends (see Fig. 29).

!

6. Attach the jumpers supplied as illustrated in Fig. 30.

7. Connect the sensor cable in accordance with the ISFET assignment.

8. In the Quick Setup, change the electrode type to "ISFET".

Note!

Proceed accordingly for changing from ISFET sensors to glass electrodes.

Fig. 29: pH input module in the housing cover with

cable (red) for connecting glass electrodes

a0003978

Fig. 30: pH input module in the housing cover with

jumper for connecting ISFET sensors

a0003979

29

Wiring

4.1.7 Digital sensors with Memosens technology

Measuring cables

You require the Memosens CYK10 data cable to connect digital sensors:

Sensor type Cable Extension

Digital sensors with temperature sensor CYK10 RM junction box + CYK81 cable

Preparing cables

1

Fig. 31: Outer screen connection with metal cable gland

2

3

4

a0003976

1. Slide the cable gland and the clamping ring over the cable.

2. Remove the inner insulation.

3. Remove the outer shield from the cable and fold it back over the clamping ring.

4. Guide the sensor cable through the cable opening of the device and screw the gland closed.

Shield contacting takes place automatically here.

30

Loading...

Loading...