Endress+Hauser TMT122 Operating Instructions Manual

BA155R/24/ae/10.04

51006562

Operating Instructions

TMT122 DIN rail

iTEMP

®

HART

®

Temperature Transmitter

Temperature DIN rail transmitter

2 Endress+Hauser

Temperature DIN rail transmitter Table of Contents

Endress+Hauser 3

Table of Contents

Safety Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Short form instructions

. . . . . . . . . . . . . . . . . . . . . . 5

1 Safety notes

. . . . . . . . . . . . . . . . . . . . . . . . . . .

6

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Installation, commissioning and operation . . . . . . . . 6

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Safety pictograms and symbols . . . . . . . . . . . . . . . . . 7

2 Identification . . . . . . . . . . . . . . . . . . . . 8

2.1 Unit identification . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Delivery contents . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . 9

3.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Typical North American installation . . . . . . 10

3.2.2 Typical European installation . . . . . . . . . . . 11

4Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Measurement unit connection . . . . . . . . . . . . . . . . 12

4.2.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Output signal and power supply . . . . . . . . . 12

4.2.3 HART

®

connection . . . . . . . . . . . . . . . . . . 12

4.3 Potential grounding . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Ground the Transmitter . . . . . . . . . . . . . . . . . . . . . 14

5 Operation . . . . . . . . . . . . . . . . . . . . . 14

5.1 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.1 HART® Communicator DXR 275/375 . . . 14

5.1.2 COMMUWIN II-operating program . . . . . . 15

6Commissioning . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Installation and function check . . . . . . . . . . . . . . . . 16

6.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2.1 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2.2 Configuration with HART® protocol and DXR

275/375 hand operated module . . . . . . . . 17

6.2.3 Configuration with HART® protocol and

COMMUWIN II . . . . . . . . . . . . . . . . . . . . 18

6.2.4 Configuration using HART® protocol and PC

configuration software ReadWin® 2000 . . 20

6.2.5 Description of unit functions . . . . . . . . . . . 21

6.2.6 Supported HART® commands . . . . . . . . . 25

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 Accessories . . . . . . . . . . . . . . . . . . . . . 26

9 Trouble-shooting . . . . . . . . . . . . . . . . 26

9.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . . 26

9.2 Application fault messages . . . . . . . . . . . . . . . . . . . 26

9.3 Application faults without messages . . . . . . . . . . . . 27

9.4 Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.6 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 Technical Data . . . . . . . . . . . . . . . . . . 29

10.1 Function and system design . . . . . . . . . . . . . . . . . . 29

10.2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.3 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.4 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.5 Performance characteristics . . . . . . . . . . . . . . . . . . 31

10.6 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 32

10.7 Environmental conditions . . . . . . . . . . . . . . . . . . . 33

10.8 Mechanical construction . . . . . . . . . . . . . . . . . . . . 33

10.9 Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.10 Certificates and approvals . . . . . . . . . . . . . . . . . . . 34

Safety Message Temperature DIN rail transmitter

4 Endress+Hauser

Safety Message

Instructions and procedures in the operating instructions may require special precautions to ensure

the safety of the personnel performing the operations. Information that potentially raises safety

issues is indicated by safety pictograms and symbols. Please refer to the safety messages before performing an operation preceded by pictograms and symbols, see chapter 1.5.

Though the information provided herein is believed to be accurate, be advised that the information

contained herein is NOT a guarantee of satisfactory results. Specifically, this information is neither

a warranty nor guarantee, expressed or implied, regarding performance; merchantability, fitness, or

other matter with respect to the products; and recommendation for the use of the product / process

information in conflict with any patent. Please note that Endress+Hauser reserves the right to

change and / or improve the product design and specifications without notice.

#

Warning!

Failure to follow these installation guidelines could result in death or serious injury.

– Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

– Do not remove the connection head cover in explosive atmospheres when the circuit is live.

– Before connecting a Model 275/375 HART

®

Communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with instrinsically safe or nonincendive field wiring practices.

– Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazar-

dous locations certifications.

– All connection head covers must be fully engaged to meet explosion-proof requirements.

Process leaks could result in death or serious injury.

– Do not remove the thermowell while in operation.

– Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury.

– Use extreme caution when making contact with the leads and terminals.

Temperature DIN rail transmitter Short form instructions

Endress+Hauser 5

Short form instructions

Using the following short form instructions you can commission your system easily and quickly:

Safety notes page 6

↓

Installation page 9

↓

Wiring page 12

↓

Commissioning (including a description of the unit functions)

A complete description of all the functions as well as a detailed overview of the function

matrix can be found in this chapter.

Quick Setup - Fast entry into the unit configuration for standard

measuring.

page 16

↓

Trouble-shooting / fault-finding

If problems occur after commissioning or during operation always start fault

finding using the check list. Special questions will act as a guide to the cause of the fault

and the necessary cure.

page 26

1 Safety notes Temperature DIN rail transmitter

6 Endress+Hauser

1 Safety notes

Safe and secure operation of the DIN rail transmitter can only be guaranteed if the

operating instructions and all safety notes are read, understood and followed.

1.1 Designated use

Designated use • The unit is a universal, presettable temperature transmitter for resistance thermometer (RTD),

thermocouple (TC) as well as resistance and voltage sensors. The unit is constructed for mounting

on a DIN rail.

• The manufacturer cannot be held responsible for damage caused by misuse of the unit.

• Separate Ex documentation is part of this operating manual, for measurement systems in hazardous areas. The installation conditions and connection values

indicated in these instructions must be followed!

1.2 Installation, commissioning and operation

Installation, commissioning and operation

The unit is constructed using the most up-to-date production equipment and complies to the safety

requirements of the local guidelines. The TMT122 temperature transmitter is fully factory tested

according to the specifications indicated on the order. However, if it is installed incorrectly or is

misused, certain application dangers can occur. Installation and wiring of the unit must only be done

by trained, skilled personnel who are authorized to do so by the plant operator. This skilled staff

must have read and understood these instructions and must follow them to the letter. The plant

operator must make sure that the measurement system has been correctly wired to the connection

schematics. Due to its construction, the transmitter cannot be repaired. When disposing of the DIN

rail transmitter, please take note of the local disposal regulations.

Electrical temperature sensors such as RTD's and thermocouples produce low-level signals proportional to their sensed temperature. The TMT122 temperature transmitter converts the low-level

sensor signal to a standard 4 to 20 mA DC signal that is relatively insensitive to lead length and electrical noise. This current signal is then transmitted to the control room via two wires.

The transmitter can be commissioned before or after installation. It may be useful to commission it

on the bench, before installation, to ensure proper operation and to become familiar with its functionality. Make sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices before connecting a HART

®

communicator in an explosive

atmosphere.

The printed circuit board of the transmitter is protected by the DIN rail housing, resisting moisture

and corrosive damage. Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

#

Warning!

Electrical shock could cause death or serious injury. If the sensor is installed in a high voltage environment and a fault or installation error occurs, high voltage may be present on the transmitter leads

and terminals.

SAFETY INSTRUMENTED SYSTEMS (SIS)

Third party validated metrics are available for the TMT122 temperature transmitter. Testing is done

per IEC 61508 for Safety Instrumented Systems. The safety manual can be ordered separately under

order code:

SD007R09EN.

More details and download see:

www.us.endress.com

Temperature DIN rail transmitter 1 Safety notes

Endress+Hauser 7

1.3 Operational safety

Operational safety Hazardous areas

When installing the unit in a hazardous area, the national safety requirements must be met. Make

sure that all personnel are trained in these areas. Strict compliance with installation instructions and

ratings as stated in this documentation is mandatory.

The measuring device complies with the general safety requirements in accordance with IEC61010,

the EMC requirements of IEC61326 and NAMUR recommendation NE21 and NE43.

Technical advancement

The manufacturer reserves the right to modify technical data without prior notice. Your E+H distributor can supply you with current information and updates to these Operating Instructions.

1.4 Returns

Returns Please follow the Return Authorization Policy at the end of these instructions.

1.5 Safety pictograms and symbols

Safety pictograms and symbols

Safe and reliable operation of this unit can only be guaranteed if the safety notes and warnings in

these operating instructions are followed. The safety notes in these

instructions are highlighted using the following symbols.

!

Note!

This icon indicates activities and actions that, if not followed correctly, could have an indirect influence on the unit operation or could lead to an unforeseen unit reaction.

"

Caution!

This icon indicates activities and actions that, if not followed correctly, could lead to faulty unit operation or even damage to the unit.

#

Warning!

This icon indicates activities and actions that, if not followed correctly, could lead to personal injury,

a safety risk or even total damage to the unit.

-

Hazardous area

This symbol identifies the hazardous area in the diagrams in these Operating Instructions.

– Devices that are used in hazardous areas or cables for such devices must have the corresponding

type of protection.

.

Safe area (non-hazardous areas)

This symbol identifies the non-hazardous area in the diagrams in these Operating Instructions.

– Devices in non-hazardous areas must also be certified if connection cables run through a hazar-

dous area.

120

Explosion protected, type examined operating equipment

If one of these icons is on the device’s nameplate, the device can be used in hazardous areas.

2 Identification Temperature DIN rail transmitter

8 Endress+Hauser

2 Identification

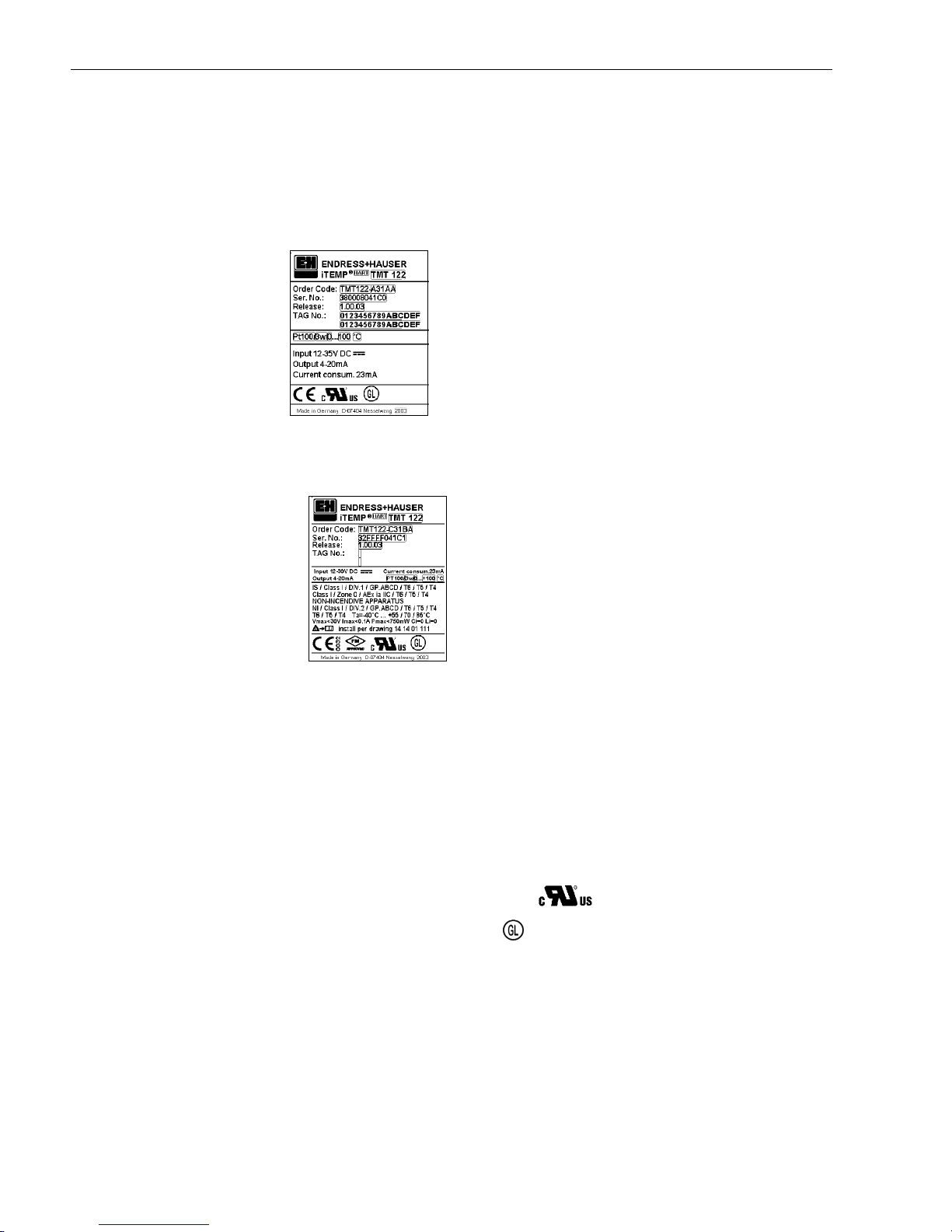

2.1 Unit identification

Unit identification Compare the legend plates on the DIN rail transmitter with the following figures:

fig. 1: DIN rail transmitter legend plate (examples)

fig. 2: Identification for hazardous area use (example, only on FM certified units)

CE Mark, declaration of conformity 4

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the

factory in a condition in which they are safe to operate. The devices comply with the applicable standards and regulations in accordance with IEC61010 "Protection Measures for Electrical Equipment

for Measurement, Control, Regulation and Laboratory Procedures" and with the EMC requirements

of IEC61326.

The measuring system described in these Operating Instructions thus complies with the statutory

requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

UL recognized component to UL 3111-1

GL German Lloyd marine approval

GL Type Approval for temperature measurements in hazardous locations on GL Classed Vessels,

Marine and Offshore Installations.

Temperature DIN rail transmitter 3Installation

Endress+Hauser 9

2.2 Registered trademarks

•HART

®

Registered trademark of HART® Communication Foundation, Austin, Tx, USA

• PROFIBUS

®

Registered trademark of PROFIBUS Nutzerorganisation e. V., Karlsruhe, Germany

• Microsoft

®

Windows NT® and Windows® 2000

Registered trademarks of Microsoft Corporation, Redmond, USA

• iTEMP

®

and ReadWin® 2000

are registered trademarks of Endress+Hauser Wetzer GmbH + Co. KG, Nesselwang, Germany

2.3 Delivery contents

Delivery contents The delivery contents of a DIN rail temperature transmitter are as follows:

• Transmitter TMT 122

• Operating instructions

• Control drawing for use in hazardous areas

3Installation

3.1 Installation conditions

Installation conditions Caution!

The unit must only be powered by a power supply that operates using an IEC 61010-1 compliant

energy limited circuit: ’SELV or Class 2 circuit’.

• When installing and operating the unit, please take note of the allowable ambient

temperature (see chapter 10 "Technical Data").

• When using the unit in a hazardous area, the limits indicated in the certification must be adhered

to (see control drawing).

Dimensions

The DIN rail transmitter dimensions can be found in chapter 10 "Technical Data".

Installation point

Installation on DIN rail according to EN 50 022-35, e.g. in control panel.

Installation angle

There are no limits as to the angle of installation.

3 Installation Temperature DIN rail transmitter

10 Endress+Hauser

3.2 Installation

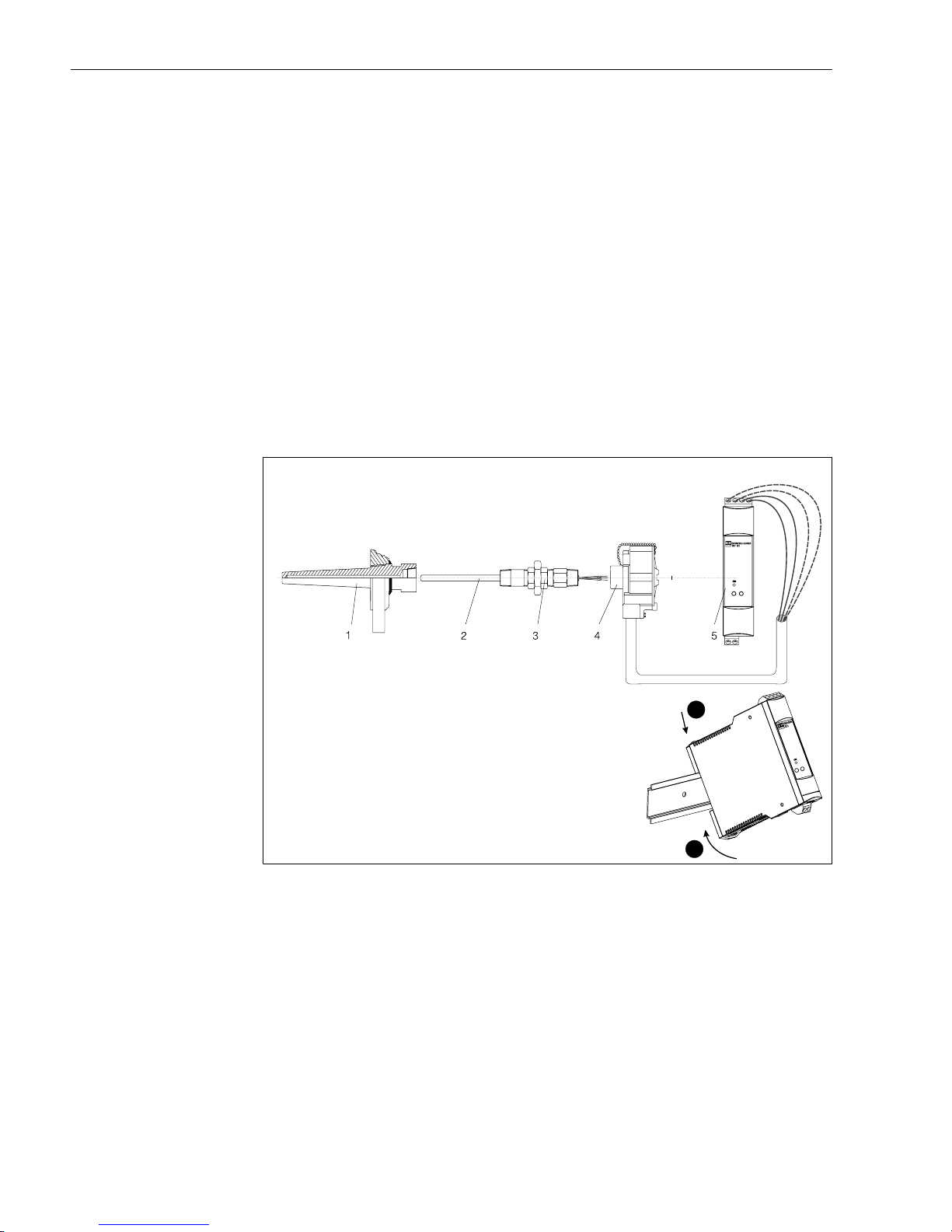

3.2.1 Typical North American installation

Installation For installation, proceed as follows:

• Attach the TMT 122 transmitter to a suitable rail or panel.

• Attach thermowell (1) to pipe or process container wall. Install and tighten the thermowell before

applying process pressure.

• Attach necessary extension nipples and adapters (3) to the thermowell (1). Seal the nipple and

adapter threads with silicone tape.

• Screw the sensor (2) into the thermowell (1). Install drain seals if required for harsh environments

or to satisfy code requirements.

• Screw the connection head (4) to the sensor assembly.

• Attach the sensor lead wires to the connection head terminals.

• Connect sensor wires from the terminals inside the head to the TMT 122 transmitter (5).

• Install and tighten the connection head cover. Enclosure covers must be completely engaged to

meet explosion-proof area requirements.

fig. 3: Installation of DIN rail TMT 122 transmitter.

1 thermowell

2 sensor

3 extension nipples and adapters

4 connection head

5 TMT 122 transmitter

2

1

35mm

IEC 60715

Temperature DIN rail transmitter 3Installation

Endress+Hauser 11

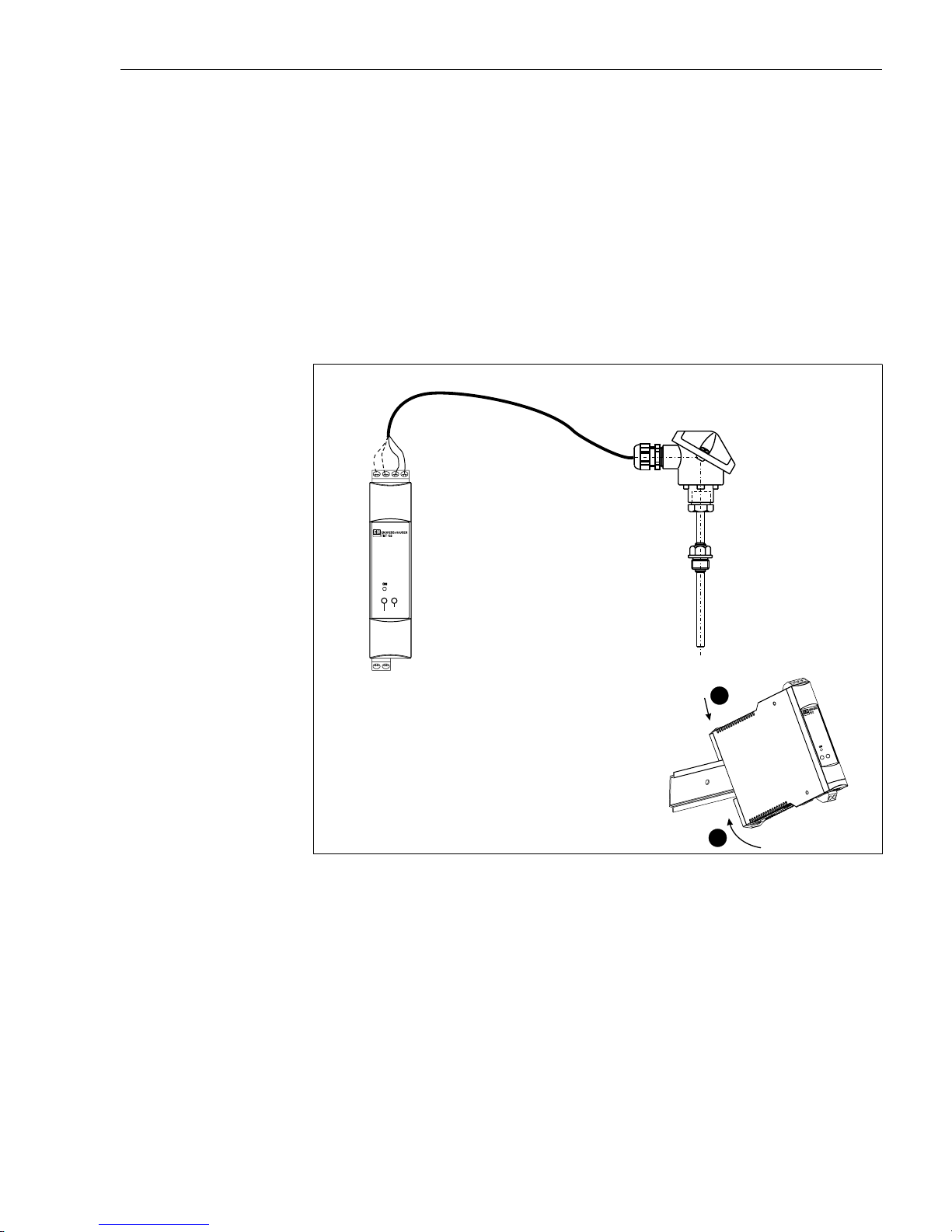

3.2.2 Typical European installation

For installation, proceed as follows:

• Attach the TMT 122 transmitter to a suitable rail or panel.

• Attach thermowell to pipe or process container wall. Install and tighten the thermowell before

applying any pressure.

• Attach and connect appropriate lengths of sensor lead wire from the connection head to the sensor terminal block.

• Tighten the connection head cover. Enclosure covers must be completely engaged in order to

meet explosion-proof area requirements.

• Run the sensor lead wires from the sensor assembly to the TMT 122 transmitter.

• Attach the sensor wires to the TMT 122 transmitter.

fig. 4: Installing the TMT 122 DIN rail transmitter

2

1

35mm

IEC 60715

4 Wiring Temperature DIN rail transmitter

12 Endress+Hauser

4Wiring

4.1 Overview

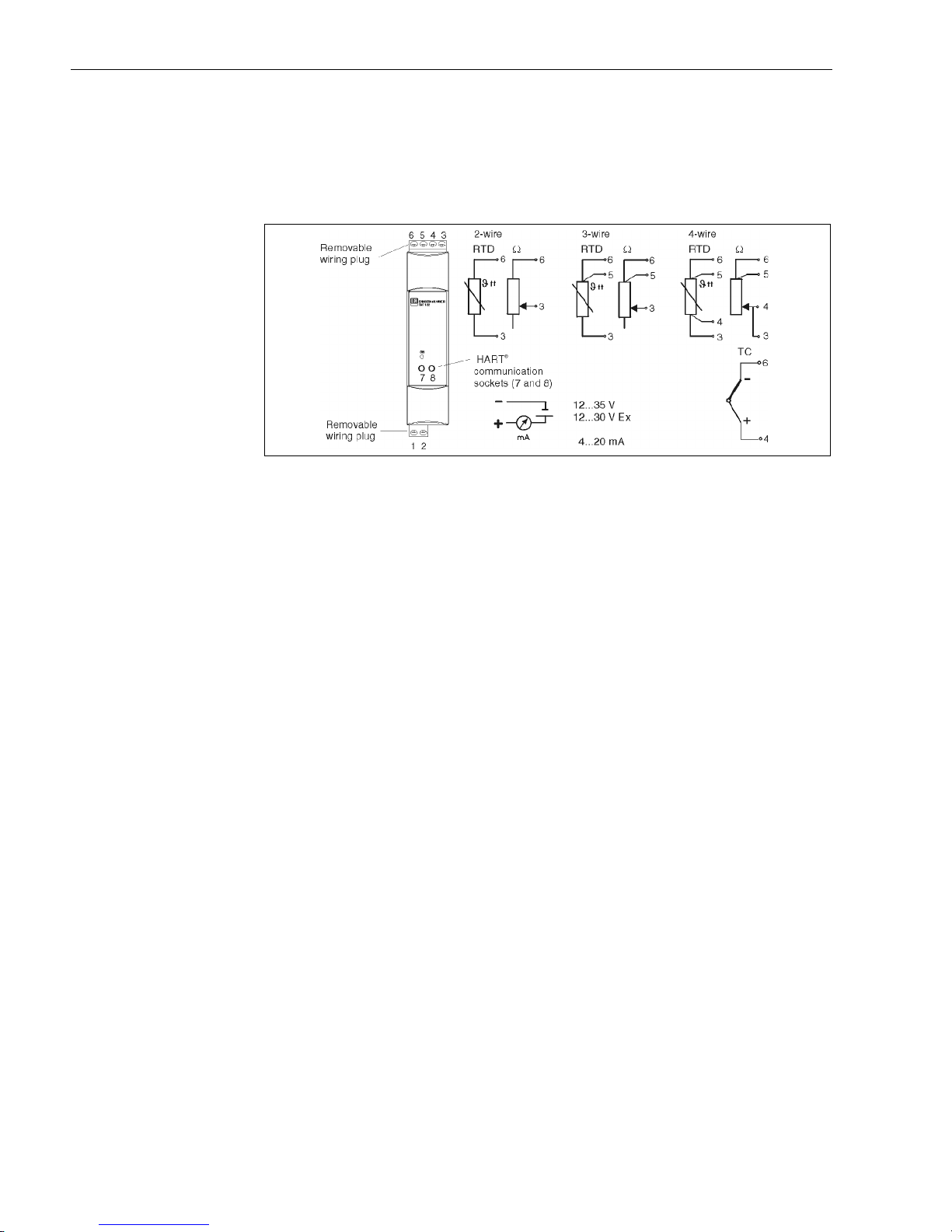

Wiring overview Terminal layout

fig. 5: DIN rail transmitter wiring

4.2 Measurement unit connection

Measurement unit

connection

"

Caution!

Switch off power supply before opening housing cover of the temperature sensor. Do not install or

connect the unit to power supply before the sensor is connected to the transmitter. If this is not followed, parts of the electronic circuit will be damaged.

4.2.1 Sensors

Connect the sensor cables to the respective DIN rail transmitter terminals (Terminals

3 to 6) by following the wiring diagram (see fig. 5). Wiring plugs are removable for easy access.

4.2.2 Output signal and power supply

Connect the cable wires from the power supply to terminal 1 and 2 according to the wiring diagram

(see fig. 5). For convenient installation, the connection is designed as a removable plug, so the connection can be made on the terminals, then plug in the connection socket to the transmitter housing.

!

Note!

The screws on the terminals must be screwed in tightly.

4.2.3 HART® connection

Connection is made directly at the communication socket 7 and 8 at the front wall of the transmitter. The sockets are inside the loop to a power supply or barrier. In order to connect the transmitter

in a hazardous area, please read the separate Ex documentation.

!

Note!

The measurement circuit must have a load of at least 250 Ω. If using the E+H power

supplies RNS 221 and RN 221N, this resistance is already installed in the unit and is therefore not

required externally (see fig. 6, and see fig. 7)!

Loading...

Loading...