Page 1

TI01399T/09/EN/02.19

71456860

2019-10-21

Products

Solutions Services

Technical Information

iTHERM TMS12

MultiSens Linear

Modular TC and RTD multipoint with primary

thermowell (with diagnostic chamber)

Application

• Easy-to-use device with modular design, provided of its own primary thermowell

and ready to be installed

• Specifically designed for Oil & Gas and Petrochemical processing industries

• Measuring range:

• Resistance insert (RTD): –200 to 600 °C (–328 to 1 112 °F)

• Thermocouple (TC): –270 to 1 100 °C (–454 to 2 012 °F)

• Static pressure range: Up to 240 bar (3 481 psi). Specific maximum process

pressure achievable depending on process type and temperature

• Degree of protection: IP66/67

Head transmitter

All Endress+Hauser transmitters are available with enhanced accuracy and reliability

compared to directly wired sensors. Easy customizing by choosing one of the

following outputs and communication protocols:

• Analog output 4 to 20 mA

• HART

• PROFIBUS® PA

• FOUNDATION Fieldbus™

Your benefits

• High degree of customization thanks to a modular product design

• Easy integration due to IEC 60584, ASTM E230 and IEC 60751 inserts

• Electrical and Pressure Directive compliance for an easy process integration

• Compliance to different types of protection for use in hazardous locations for a

• Possibility to individually replace inserts, even in operating conditions

• Superior mechanical strength thanks to a primary thermowell for temperature

• Advanced diagnosis to monitor the performances of the complete thermometric

®

wide and easy process integration

sensors protection

device during its operating time and to plan in advanced any maintenance action

Page 2

Table of contents

iTHERM TMS12 MultiSens Linear

Function and system design ................... 3

Measuring principle ............................ 3

Measuring system ............................. 3

Equipment architecture ......................... 4

Input ..................................... 7

Measured variable ............................. 7

Measuring range .............................. 7

Output ................................... 7

Output signal ................................ 7

Family of temperature transmitters ................. 7

Power supply .............................. 8

Wiring diagrams .............................. 8

Performance characteristics ................... 9

Accuracy ................................... 9

Response time .............................. 10

Shock and vibration resistance .................... 10

Calibration ................................. 10

Installation ............................... 11

Mounting location ............................ 11

Orientation ................................ 11

Installation instructions ........................ 11

Other standards and guidelines ................... 25

Material certification .......................... 25

Test report and calibration ...................... 25

Ordering information ....................... 26

Accessories ............................... 29

Device-specific accessories ...................... 29

Communication-specific accessories ................ 30

Service-specific accessories ...................... 30

Documentation ............................ 31

Environment .............................. 13

Ambient temperature range ..................... 13

Storage temperature .......................... 13

Humidity .................................. 13

Climate class ............................... 13

Electromagnetic compatibility (EMC) ............... 13

Process .................................. 13

Process temperature range ...................... 13

Process pressure range ......................... 14

Mechanical construction .................... 14

Design, dimensions ........................... 14

Weight ................................... 20

Materials .................................. 21

Process connection ........................... 22

Compression fittings .......................... 22

Thermal contacts components .................... 23

Operability ............................... 24

Certificates and approvals ................... 25

CE Mark .................................. 25

Hazardous area approvals ....................... 25

PED approval ............................... 25

Certification HART ........................... 25

Certification FOUNDATION Fieldbus ................ 25

Certification PROFIBUS® PA ..................... 25

2 Endress+Hauser

Page 3

iTHERM TMS12 MultiSens Linear

Function and system design

Measuring principle Thermocouples (TC)

Thermocouples are comparatively simple, robust temperature sensors which use the Seebeck effect

for temperature measurement: if two electrical conductors made of different materials are connected

at a point, a weak electrical voltage can be measured between the two open conductor ends if the

conductors are subjected to a thermal gradient. This voltage is called thermoelectric voltage or

electromotive force (emf.). Its magnitude depends on the type of conducting materials and the

temperature difference between the "measuring point" (the junction of the two conductors) and the

"cold junction" (the open conductor ends). Accordingly, thermocouples primarily only measure

differences in temperature. The absolute temperature at the measuring point can be determined

from these if the associated temperature at the cold junction is known or is measured separately and

compensated for. The material combinations and associated thermoelectric voltage/temperature

characteristics of the most common types of thermocouple are standardized in the IEC 60584 and

ASTM E230/ANSI MC96.1 standards.

Resistance thermometer (RTD)

These resistance thermometers use a Pt100 temperature sensor according to IEC 60751. The

temperature sensor is a temperature-sensitive platinum resistor with a resistance of 100 Ω at

0 °C (32 °F) and a temperature coefficient α = 0.003851 °C-1.

There are generally two different kinds of platinum resistance thermometers:

• Wire wound (WW): Here, a double coil of fine, high-purity platinum wire is located in a ceramic

support. This is then sealed top and bottom with a ceramic protective layer. Such resistance

thermometers not only facilitate very reproducible measurements but also offer good long-term

stability of the resistance/temperature characteristic within temperature ranges up to

600 °C (1 112 °F). This type of sensor is relatively large in size and it is comparatively sensitive to

vibrations.

• Thin film platinum resistance thermometers (TF): A very thin, ultrapure platinum layer,

approx. 1 μm thick, is vaporized in a vacuum on a ceramic substrate and then structured

photolithographically. The platinum conductor paths formed in this way create the measuring

resistance. Additional covering and passivation layers are applied and reliably protect the thin

platinum layer from contamination and oxidation, even at high temperatures. The primary

advantages of thin film temperature sensors over wire wound versions are their smaller sizes and

better vibration resistance. A relatively low principle-based deviation of the resistance/

temperature characteristic from the standard characteristic of IEC 60751 can frequently be

observed among TF sensors at high temperatures. As a result, the tight limit values of tolerance

category A as per IEC 60751 can only be observed with TF sensors at temperatures up to approx.

300 °C (572 °F). For this reason, thin-film sensors are generally only used for temperature

measurements in ranges below 400 °C (752 °F).

Measuring system

Endress+Hauser offers a complete portfolio of optimized components for the temperature measuring

point – everything you need for the seamless integration of the measuring point into the overall

facility.

This includes:

• Power supply unit/active barrier

• Configuration units

• Overvoltage protection

For more information, see the brochure 'System Components - Solutions for a Complete

Measuring Point' (FA00016K/09)

Endress+Hauser 3

Page 4

iTHERM TMS12 MultiSens Linear

1 2

3 4

6

HAW56x

1 IN 2

3 OUT 4

HAW56x

3 OUT 4

1 IN 2

HAW56x

3 OUT 4

1 IN 2

HAW56x

3 OUT 4

1 IN 2

5

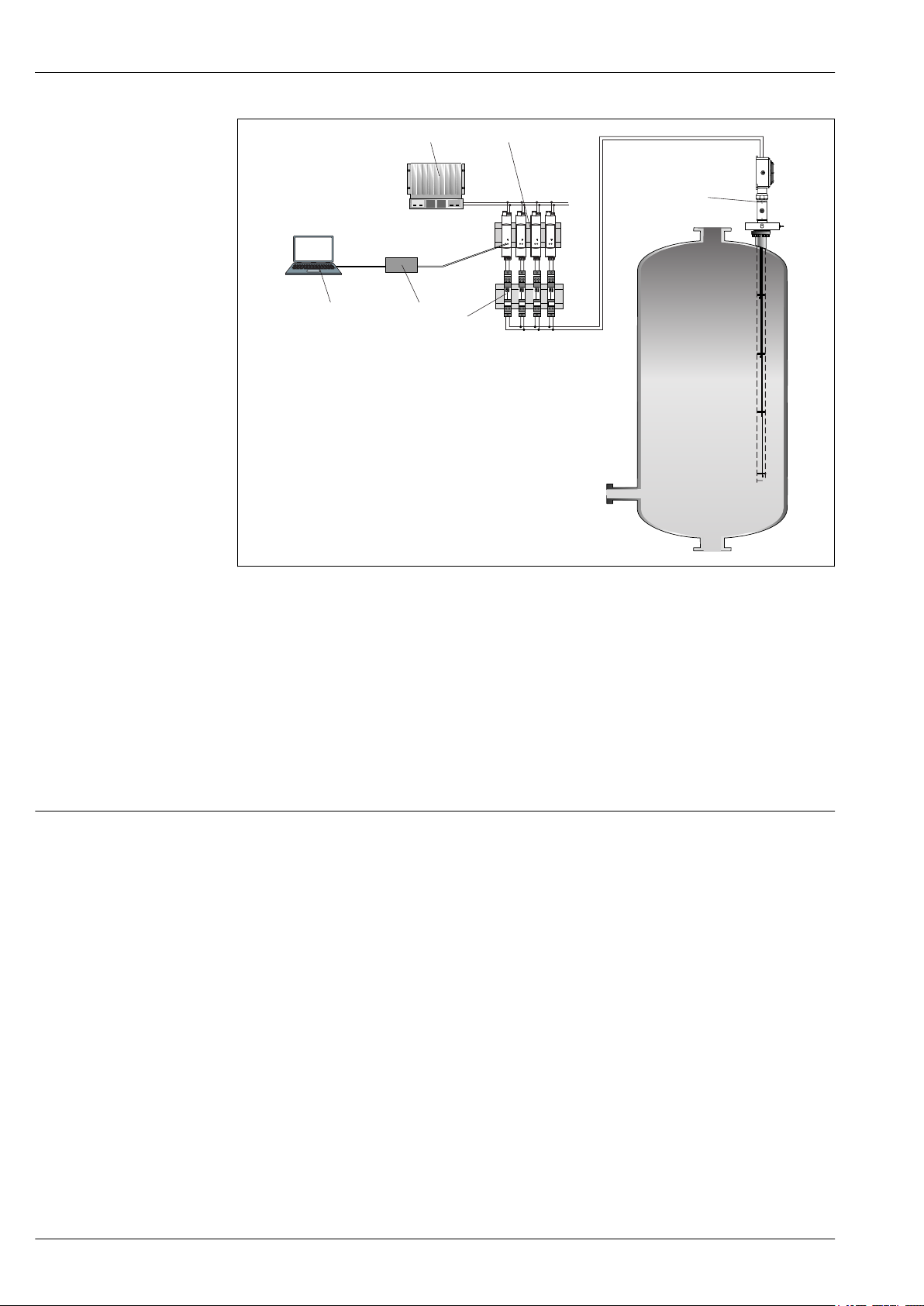

Equipment architecture

A0036464

1 Application example in a reactor.

1 Device configuration with application software FieldCare

2 Commubox

3 PLC

4 Active barrier RN221N (24 VDC, 30 mA) that has a galvanically isolated output for supplying voltage to loop-

powered transmitters. The universal power supply works with an input supply voltage of 20 to 250 V DC/AC;

50/60 Hz, which means that it can be used in all international power grids.

5 Surge arrester modules HAW562 for protection of signal lines and components in hazardous areas, e.g.

4 to 20 mA- , PROFIBUS® PA, FOUNDATION Fieldbus™ signal lines. More information on this can be found

in the Technical Information → 31

6 Mounted multipoint thermometer with its own primary thermowell, optionally with built-in transmitters in

the junction box for 4 to 20 mA-, HART-, PROFIBUS® PA-, FOUNDATION Fieldbus™ communication or

terminal blocks for remote wiring.

The multipoint thermometer belongs to a range of modular product configuration for multipoint

temperature detection with a design where subassemblies and components can be managed

individually for easy maintenance and spare part ordering.

It consists of the following main sub-assemblies:

• Insert: Composed by individual metal sheathed sensing elements (thermocouples or thermosresistance) protected by the primary thermowell welded to the process connection. In addition,

individual guiding tubes or protecting themowells allow inserts replacement during operating

conditions. When applicable, each insert can be handled as an individual spare part and ordered

via specific standard product order codes (e.g. TSC310, TST310) or special codes. For the specific

order code please contact your Endress+Hauser specialist.

• Process Connection: Represented by an ASME or EN flange. It is provided with pressure port and

it might be provided with eyebolts for lifting the device.

• Head: It is composed of a junction box provided with its components such as cable glands, draining

valves, earth screws, terminals, head transmitters, etc.

• Head Support System: It is designed to support the junction box by swivelling joint.

4 Endress+Hauser

Page 5

iTHERM TMS12 MultiSens Linear

1a

2

4

6b

11

7

8

9

3

12

6b

5

1b

2

4

6a

10b

7

10a

9

3

8

11

12

6a

5

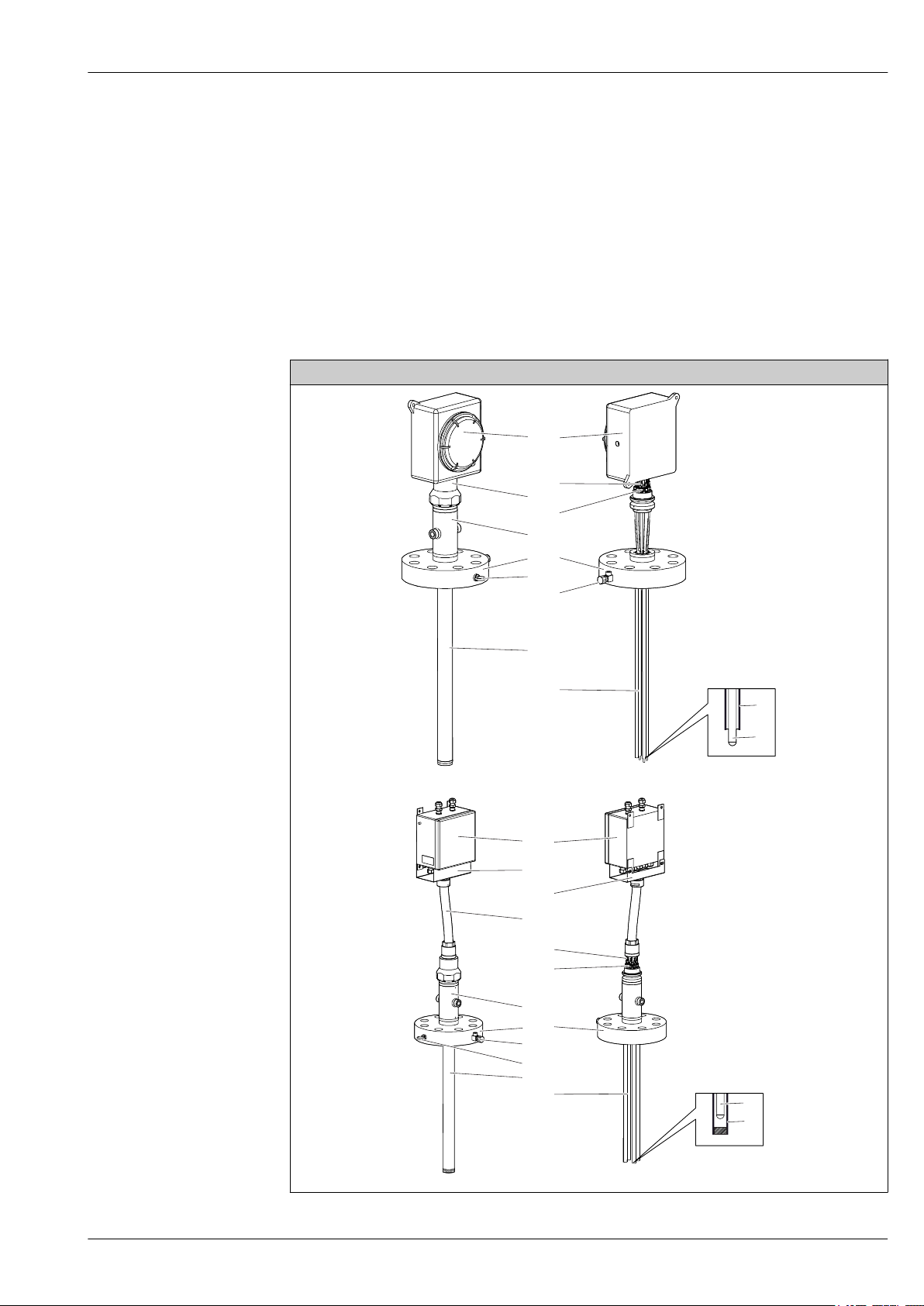

• Additional Accessories: They can be ordered for any configuration, and they are recommended in

• Primary Thermowell: It is directly welded to the process connection, designed to guarantee high

• Diagnostic Chamber: This subassembly consists in a closed volume that ensures the continuous

In general, the system measures a linear temperature profile inside the process environment. It is

also possible to obtain a three-dimensional temperature profile by installing more than one

Multisens Linear (either horizontally, vertically or obliquely).

case of replaceable sensors configuration (such as pressure transducers, manifolds, valves and

fitting).

degree of mechanical protection and corrosion resistance.

monitoring of the device conditions during its operating life and safe leakage containment. The

chamber has integrated connections for accessories (such as valves, manifolds). A wide range of

accessories is available to get the highest level of system information (pressure, temperature,

fluids composition and next maintenance step).

Design

A0036465

A0036466

Endress+Hauser 5

Page 6

iTHERM TMS12 MultiSens Linear

Description, available options and materials

1: Head

1a: Directly mounted

1b: Remote

2: Support System Swivelling support joint for junction box orientation.

3: Primary thermowell The primary thermowell is made by a tube with calculated and

4: Process connection, flanged

according to ASME, or EN standards

5: Insert Mineral insulated grounded and ungrounded thermocouples or RTD

6 Tip design of sensor thermal contacts

6a: for protecting thermowells

6b: for guiding tubes The sensors inside the primary thermowell can be kept in the right

7: Eyebolt Lifting device for easy handling during installation phase.

8: Extension cables Cables for electrical connections between the inserts and junction

9: Pressure port (threaded hole) Auxiliary connections and fittings for pressure detection.

10: Protections

10a: Cable conduit system (in case of

remote head)

10b: Extension cables cover

Hinged or screwed cover junction box for electrical connections. It

includes components such as electrical terminals, transmitters and

cable glandes.

• 316/316L

• Aluminium alloys

• Other materials on request

316/316L

selected thickness according to reference international standards. It is

designed to protect the sensors against harsh process conditions such

as dynamic and static loads and corrosion.

• 316/316L

• 321

• 304/304L

• 310L

Represented by a flange according to international standards, or

engineered to satisfy specific process requirements → 14.

• 316 + 316L

• 304

• 310

• 321

• Other materials on request

(Pt100 wire wound).

For details, refer to the Ordering information table.

The sensors inside the primary thermowell can be kept in the right

measuring location by means of closed-end protecting thermowells

which end with:

• welded thermal block discs to ensure the optimal heat transfer

thorough the primary thermowell wall and the temperature

sensors. Sensors are replaceable.

• individual thermal blocks pressed against the internal wall to

ensure the optimal heat transfer between the primary thermowell

and the replaceable temperature sensor.

• straight tip.

For details, refer to the Ordering information table

measuring location by means of open-end guiding tubes which end

with:

• bimetallic stripes to push the sensor in contact with the internal

wall of the main thermowell and allow faster response time.

Sensors are not replaceable.

• bent tip.

SS 316

box.

• Shielded PVC

• Shielded Hyflon MFA

• Unshielded PVC flying leads

Cable conduit: made by flexible polyamide to connect the top of the

diagnostic chamber and the remote junction box.

Extension cable cover: made by a shaped stainless stell plate fixed to

the junction box frame in order to protect the cable connections.

6 Endress+Hauser

Page 7

iTHERM TMS12 MultiSens Linear

Description, available options and materials

11: Compression fitting High performing fittings for the tightness between the diagnostic

12: Diagnostic chamber

12a: Basic Chamber

12b: Advanced Chamber

Input

chamber-head and the external environment, suitable for a wide

range of process fluids and severe combination between temperature

and pressure.

Diagnostic chamber for leakage detection and safe containment.

System behavior monitoring thanks to a continuous pressure

detection of the contained fluids.

Basic configuration: not replaceable inserts. Extension cables

replaceable in case of accidental damages (through the replacement

of the external insert stump).

Advanced configuration: complete inserts replacement allowed.

Measured variable

Measuring range

Output signal

Temperature (temperature linear transmission behavior)

RTD:

Input Designation Measuring range limits

RTD as per IEC 60751 Pt100 –200 to +600 °C (–328 to +1 112 °F)

Thermocouple:

Input Designation Measuring range limits

Thermocouples (TC) as per IEC

60584, part 1 - using an

Endress+Hauser - iTEMP

temperature head transmitter

Type J (Fe-CuNi)

Type K (NiCr-Ni)

Type N (NiCrSi-NiSi)

Internal cold junction (Pt100)

Cold junction accuracy: ± 1 K

Max. sensor resistance: 10 kΩ

–210 to +720 °C (–346 to +1 328 °F)

–270 to +1 150 °C (–454 to +2 102 °F)

–270 to +1 100 °C (–454 to +2 012 °F)

Output

Generally, the measured value can be transmitted in one of two ways:

• Directly-wired sensors - sensor measured values forwarded without a transmitter.

• Via all common protocols by selecting an appropriate Endress+Hauser iTEMP temperature

transmitter. All the transmitters listed below are mounted directly in the junction box and wired

with the sensory mechanism.

Family of temperature transmitters

Thermometers fitted with iTEMP transmitters are an installation-ready complete solution to

improve temperature measurement by significantly increasing accuracy and reliability, when

compared to direct wired sensors, as well as reducing both wiring and maintenance costs.

PC programmable head transmitters

They offer a high degree of flexibility, thereby supporting universal application with low inventory

storage. The iTEMP transmitters can be configured quickly and easily at a PC. Endress+Hauser offers

free configuration software which can be downloaded from the Endress+Hauser Website. More

information can be found in the Technical Information.

HART® programmable head transmitters

The transmitter is a 2-wire device with one or two measuring inputs and one analog output. The

device not only transfers converted signals from resistance thermometers and thermocouples, it also

transfers resistance and voltage signals using HART® communication. It can be installed as an

intrinsically safe apparatus in Zone 1 hazardous areas and is used for instrumentation in the

terminal head (flat face) as per DIN EN 50446. Swift and easy operation, visualization and

Endress+Hauser 7

Page 8

iTHERM TMS12 MultiSens Linear

3

5

6

RTD

3

4

5

6

RTD

1

2

TC

6

4

3-wire

4-wire

Power supply

head transmitter and

analog output 4 to 20 mA,

or bus connection

(red) (red)

(red) (red)

(white) (white)

(white)

maintenance by PC using operating software, Simatic PDM or AMS. For more information, see the

Technical Information.

PROFIBUS® PA head transmitters

Universally programmable head transmitter with PROFIBUS® PA communication. Conversion of

various input signals into digital output signals. High accuracy over the complete ambient

temperature range. Swift and easy operation, visualization and maintenance using a PC directly from

the control panel, e. g. using operating software, Simatic PDM or AMS. For more information, see

the Technical Information.

FOUNDATION Fieldbus™ head transmitters

Universally programmable head transmitter with FOUNDATION Fieldbus™ communication.

Conversion of various input signals into digital output signals. High accuracy over the complete

ambient temperature range. Swift and easy operation, visualization and maintenance using a PC

directly from the control panel, e.g. using operating software such as ControlCare from Endress

+Hauser or NI Configurator from National Instruments. For more information, see the Technical

Information.

Advantages of the iTEMP transmitters:

• Dual or single sensor input (optionally for certain transmitters)

• Unsurpassed reliability, accuracy and long-term stability in critical processes

• Mathematical functions

• Monitoring of the thermometer drift, sensor backup functionality, sensor diagnostic functions

• Sensor-transmitter matching for dual sensor input transmitter, based on Callendar/Van Dusen

coefficients

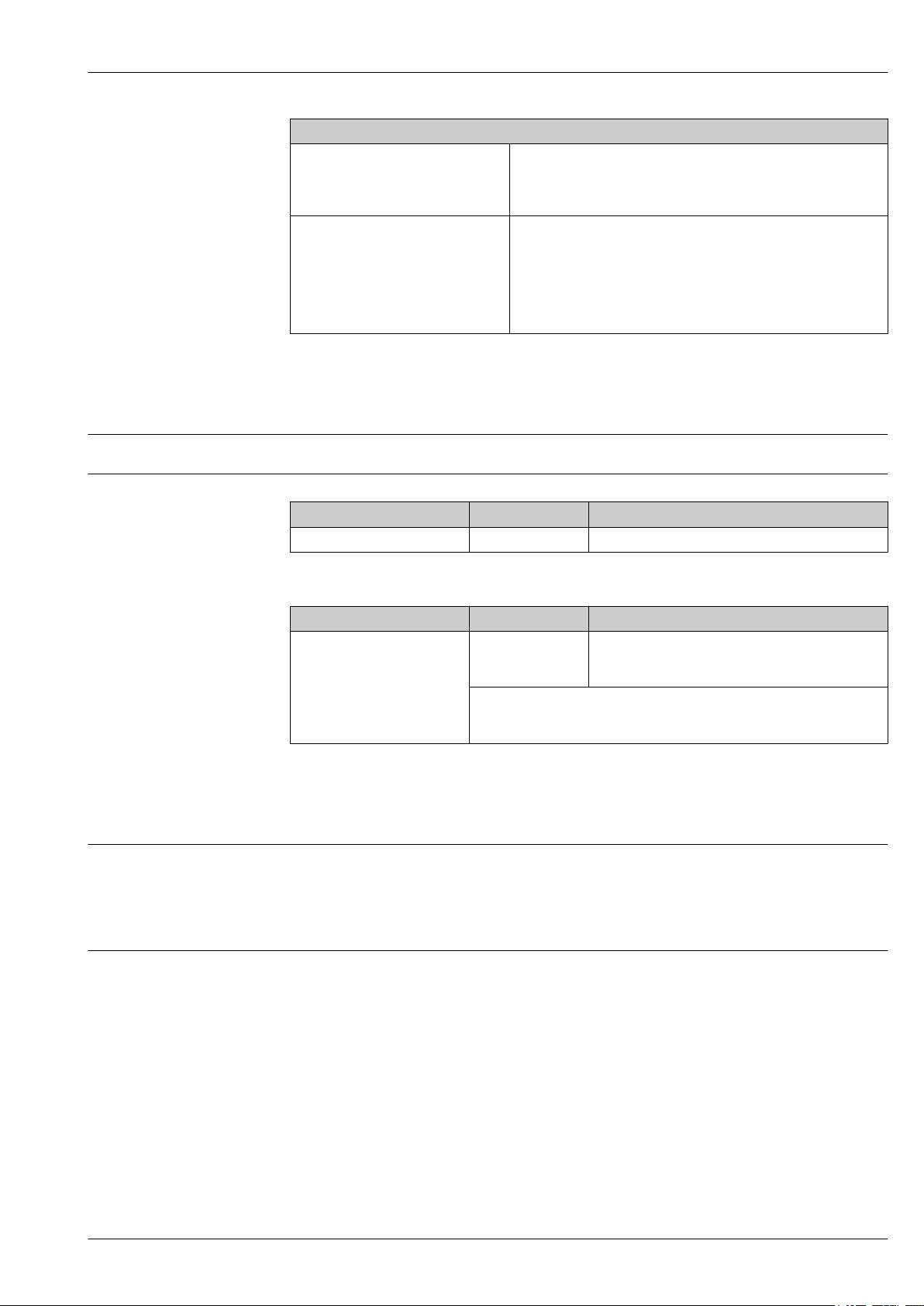

Wiring diagrams

Power supply

• Electrical connecting cables must be smooth, corrosion resistant, easy to be cleaned and

inspected, robust against mechanical stresses, no-humidity sensitivity.

• Grounding or shielding connections are possible via ground terminals on the junction box.

Wiring diagrams for TC and RTD connection

A0016712-EN

2 Wiring diagram of the single sensor input head transmitters (TMT18x)

8 Endress+Hauser

Page 9

iTHERM TMS12 MultiSens Linear

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor input 2

Sensor input 1

RTD 4- and 3-wire:

RTD 3-wire:

Bus connection

and supply voltage

Display connection

red

white

red red

red

whitewhite

TC

TC

A

AA

-200 -100 0 100 200 300 400 500 600°C

0.5

1.0

1.5

2.0

B

2.5

3.0

- 0.5

- 1.0

- 1.5

- 2.0

- 2.5

- 3.0

B

A

AA

Max. deviation (°C)

Max. deviation (°C)

3 Wiring diagram of the dual sensor input head transmitters (TMT8x)

A0016711-EN

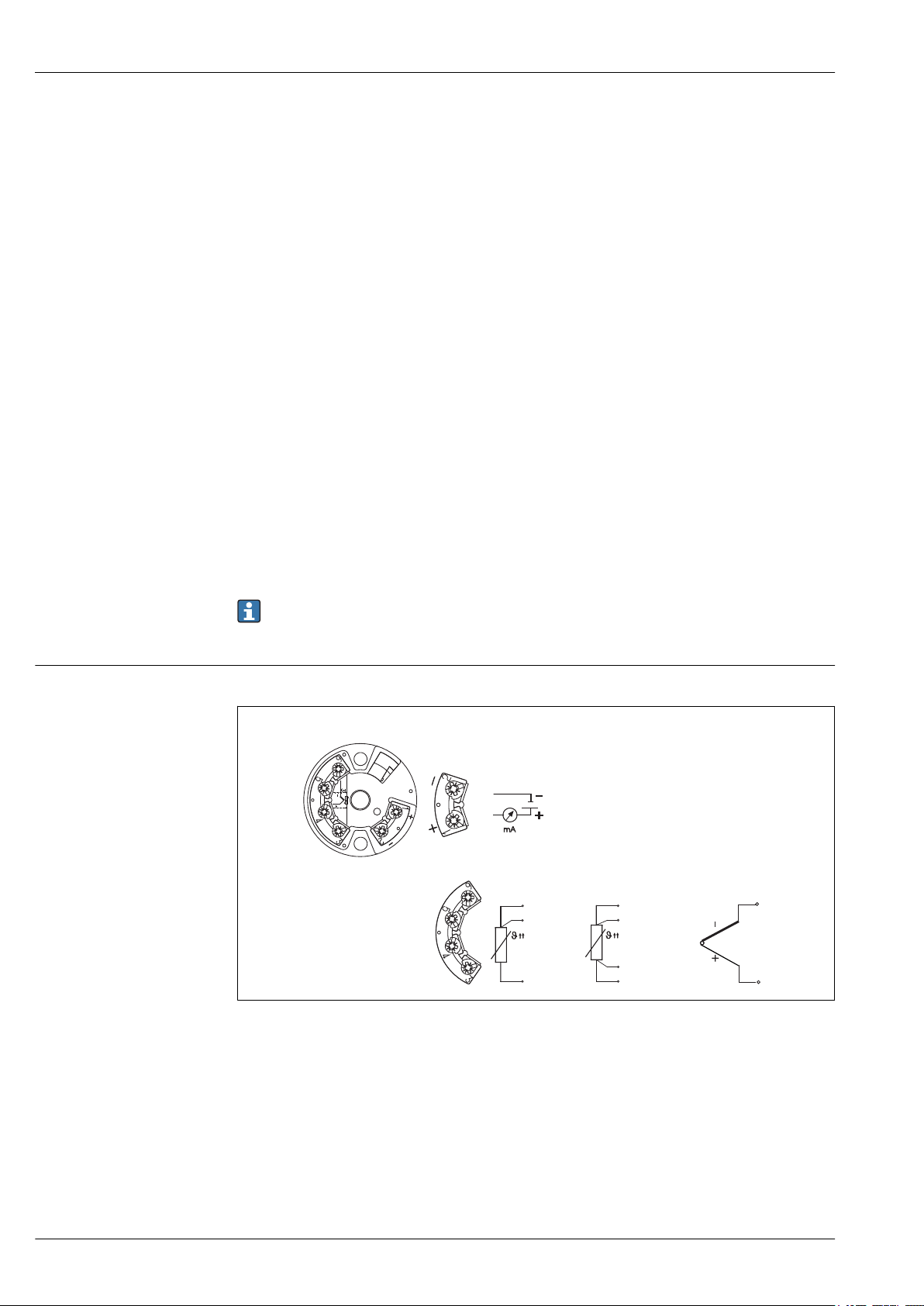

Performance characteristics

Accuracy

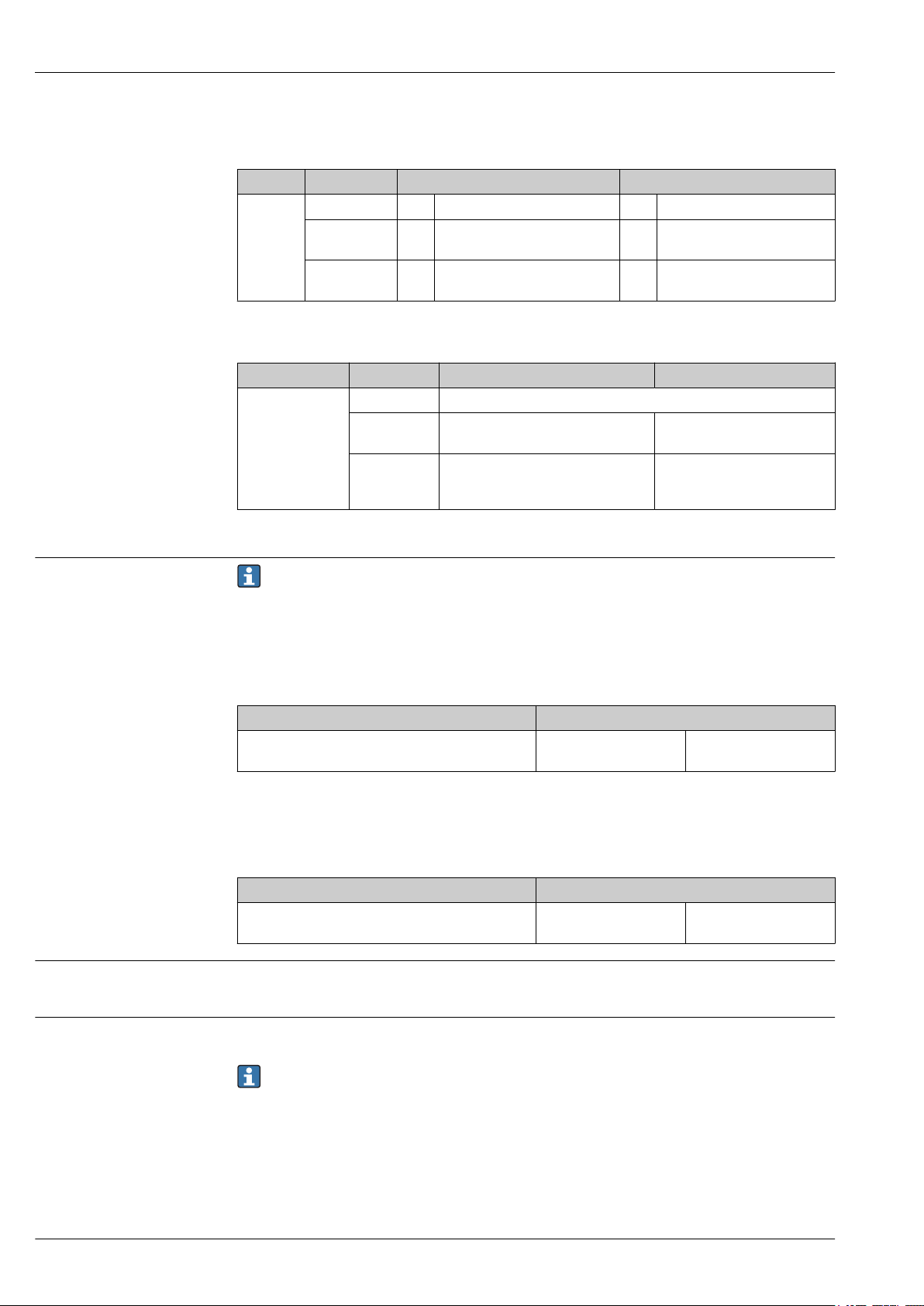

Class Max. tolerances (°C) Characteristics

Cl. AA, former 1/3

Cl. B

Cl. A ± (0.15 + 0.002 · |t|

Cl. B ± (0.3 + 0.005 · |t|

Temperature ranges for compliance with the

tolerance classes

Wire wound

sensor (WW):

Thin-film version

(TF):

Standard –30 to +300 °C 0 to +150 °C

± (0.1 + 0.0017 · |t|

Cl. A Cl. AA

–100 to +450 °C –50 to +250 °C

Cl. A Cl. AA

RTD resistance thermometer as per IEC 60751

1)

)

1)

)

1)

)

1) |t| = absolute value °C

Endress+Hauser 9

In order to obtain the maximum tolerances in °F, the results in °C must be multiplied by a factor

of 1.8.

A0008588-EN

Page 10

iTHERM TMS12 MultiSens Linear

Permissible deviation limits of thermoelectric voltages from the standard characteristic for

thermocouples as per IEC 60584 or ASTM E230/ANSI MC96.1:

Standard Type Standard tolerance Special tolerance

IEC 60584 Class Deviation Class Deviation

J (Fe-CuNi) 2 ±2.5 °C (–40 to 333 °C)

±0.0075 |t|

K (NiCr-NiAl)

N (NiCrSi-NiSi)

1) |t| = absolute value °C

Standard Type Standard tolerance Special tolerance

ASTM E230/ANSI

MC96.1

J (Fe-CuNi) ±2.2 K or ±0.0075 |t|

K (NiCr-NiAl)

N (NiCrSi-NiSi)

2 ±2.5 °C (–40 to 333 °C)

±0.0075 |t|

Deviation, the larger respective value applies

±2.2 K or ±0.02 |t|

±2.2 K or ±0.0075 |t|

(0 to 1 260 °C)

1)

(333 to 750 °C)

1)

(333 to 1 200 °C)

1)

(0 to 760 °C) ±1.1 K or ±0.004 |t|

1)

(–200 to 0 °C)

1)

1 ±1.5 °C (–40 to 375 °C)

±0.004 |t|

1 ±1.5 °C (–40 to 375 °C)

±0.004 |t|

(0 to 760 °C)

±1.1 K or ±0.004 |t|

(0 to 1 260 °C)

1)

(375 to 750 °C)

1)

(375 to 1 000 °C)

1)

1)

Response time

Shock and vibration resistance

1) |t| = absolute value °C

Response time for the sensor assembly without transmitter. When response time of the

complete assembly is requested (including primary thermowell), a dedicated calculation

depending on the sensor layout will be preformed.

RTD

Calculated at an ambient temperature of approx. 23 °C by immersing the insert in running water (0.4

m/s flow rate, 10 K excess temperature):

Insert diameter Response time

As an example, in case of thermowell thickness,

3.6 mm (0.14 in), bent guiding tubes design

t

90

108 s

Thermocouple (TC)

Calculated at an ambient temperature of approx. 23 °C by immersing the insert in running water (0.4

m/s flow rate, 10 K excess temperature):

Insert diameter Response time

As an example, in case of thermowell thickness,

3.6 mm (0.14 in), bent guiding tubes design

t

90

52 s

• RTD: 3G / 10 to 500 Hz according to IEC 60751

• TC: 4G / 2 to 150 Hz according to IEC 60068-2-6

Calibration

Calibration is a service that can be performed on each individual insert, either in order phase, or after

multipoint installation (only in case of replaceable sensors).

When calibration shall be performed once the multipoint is installed, please contact the

Endress+Hauser service to get full support. Together with the Endress +Hauser service any

further activity can be organised to achieve the calibration of the target sensor. In any case it is

forbidden to unscrew any threaded component on the process connection under operating

conditions (running process), without knowing the pressure inside the primary thermowell.

Calibration involves comparing the measured values of the sensing elements of the multipoint

inserts (DUT device under test) with those of a more precise calibration standard using a defined and

reproducible measurement method. The aim is to determine the deviation of the DUT measured

values from the true value of the measured variable.

10 Endress+Hauser

Page 11

iTHERM TMS12 MultiSens Linear

1

2

Two different methods are used for the inserts:

• Calibration at fixed-point temperatures, e.g. at the freezing point of water at 0 °C (32 °F).

• Calibration compared against a precise reference thermometer.

Installation

Evaluation of inserts

If a calibration with an acceptable uncertainty of measurement and transferable measurement

results is not possible, Endress+Hauser offers an insert evaluation measurement service, if

technically feasible.

Mounting location

Orientation

The installation location must meet the requirements listed in this documentation, such as ambient

temperature, protection classification, climatic class, etc.. Care should be taken when checking the

sizes of possible existing support frames or brackets welded on the reactor’s wall (usually not

included in the scope of delivery) or of any other existing frame in the installation area.

No restrictions. The multipoint thermometer can be installed either in horizontal, oblique or in

vertical configuration, related to the reactor or vessel vertical axis. The measurement of a

threedimensional temperature profile can be achieved in different ways:

• by installing several vertical multipoint thermometers in the longitudinal direction (1) of the

reactor.

• by installing the multipoint thermometer systems in horizontal (2) or inclined direction.

Vertical configuration (1):

The different sensors are aligned along the straight direction

coinciding with the longitudinal axis of the vessel (linear

multipoint measurement).

Radial configuration (2):

The different sensors are aligned along the straight direction

coinciding with an horizontal diameter of the vessel (in

combination with a nozzle entry). Adequate support systems

have to be foreseen.

Inclined configuration:

The different sensors are mounted obliquely along a straight

direction coinciding with an inclined vessel entry. Adequate

support have to be foreseen.

A0036472

Installation instructions

The modular multipoint thermometer is designed to be installed with a flanged process connection

into a vessel, reactor, tank or similar environment. All parts and components have to be handled

with care. During the installation phase, lifting and introduction of the equipment through the

preset nozzle, the following must be avoided:

• Misalignment with the nozzle axis.

• Any load on the welded or threaded parts due to the action of the weight of the device.

• Deformation or crushing of the threaded components, bolts, nuts, cable glands and compression

fittings.

• Friction between the primary thermowell and the internals of the reactor.

• Fixing the primary thermowell to the reactor's infrastructures without allowing axial

displacements or movements.

Endress+Hauser 11

Page 12

iTHERM TMS12 MultiSens Linear

1

1

When internals are not usable as interface, Endress + Hauser provides dedicated support

components with minimum process invasiveness to achieve the desired measuring points.

A0036473

A0036474

During installation the whole thermometer must only be lifted and moved by using ropes

properly mounted on the eyebolt of the flange (1) or careful on the thermowell.

12 Endress+Hauser

Page 13

iTHERM TMS12 MultiSens Linear

Environment

Ambient temperature range

Storage temperature

Humidity

Climate class

Junction box Non-hazardous area Hazardous area

Without mounted transmitter –50 to +85 °C (–58 to +185 °F) –50 to +60 °C (–58 to +140 °F)

With mounted head

transmitter

With mounted multi-channel

transmitter

Junction box

With head transmitter –50 to +100 °C (–58 to +212 °F)

With multi-channel transmitter –40 to +80 °C (–40 to +176 °F)

With DIN rail transmitter –40 to +100 °C (–40 to +212 °F)

Condensation according to IEC 60068-2-33:

• Head transmitter: Permitted

• DIN rail transmitter: Not permitted

Maximum relative humidity: 95% according to IEC 60068-2-30

Determined when the following components are installed into the junction box:

• Head transmitter: Class C1 according to EN 60654-1

• Multi-channel transmitter: Tested as per IEC 60068-2-30, meets the requirements regarding class

C1-C3 in accordance with IEC 60721-4-3

• Terminal blocks: Class B2 according to EN 60654-1

–40 to +85 °C (–40 to +185 °F) Depends on the respective hazardous area

approval. Details see Ex documentation.

–40 to +85 °C (–40 to +185 °F) –40 to +70 °C (–40 to +158 °F)

Electromagnetic compatibility (EMC)

Process temperature range

Depending on the head transmitter used. For detailed information see the related Technical

Information, listed at the end of this document.

Process

The process temperature and process pressure are the minimum input parameters for the selection

of the right product configuration. If special product features are requested, additional data such as

process fluid type, phases, concentration, viscosity, stream and turbulences, corrosion rate have to be

considered as mandatory for the whole product definition.

Up to +816 °C (+1 501 °F) (Based on standard process connection materials).

Process connection flanges with their specific ratings, selected according to the plant

requirements, define the maximum process conditions, which the device has to operate.

Endress+Hauser 13

Page 14

iTHERM TMS12 MultiSens Linear

Process pressure range

Design, dimensions

0 to 240 bar (0 to 3 481 psi)

Anyhow, the maximum required process pressure has to be combined with the maximum

design process temperature. Process connections like compression fittings, flanges with their

specific ratings, thermowells, selected according to the plant requirements, define the

maximum process conditions at which the device has to operate. Endress+Hauser experts can

support the customer on any related questions.

Process applications:

• Atmospheric/Vacuum Distillation

• Catalytic Cracking/Hydrocracking

• Catalytic reforming

• Hydrodesulphurization

• N-based inorganics

• Ammonia

• Urea

• NGTL

• Distillation units and hydrogenation

• Hydrotreating

• Visbreaker

• Delayed cocking

Mechanical construction

The overall multipoint assembly is composed of different sub-assemblies. Different inserts are

available, based upon specific process conditions, in order to have the highest accuracy and an

extended lifetime. The primary thermowell should be selected to increase mechanical performances

and corrosion resistance, and to allow insert replacement. Associated shielded extension cables are

available with high resistance sheath materials to withstand different environmental conditions and

to ensure steady and noiseless signals. The transition between the inserts and the extension cable is

obtained by the usage of specially sealed bushings, ensuring the declared IP degree protection.

14 Endress+Hauser

Page 15

iTHERM TMS12 MultiSens Linear

B

A

L

L

MPx

MPx

C

I

H

E

D

T

U

A0036476

Endress+Hauser 15

Page 16

iTHERM TMS12 MultiSens Linear

B

A

L

L

MPx

MPx

C

I

H

E

D

T

U

F

4 Design of the modular multipoint thermometer with swivelling joint. Directly mounted head in the first

picture or with remote head in the second picture. All dimensions in mm (in)

A, B,CDimensions of the junction box, see following figure

A0036475

D Diagnostic chamber = 390 mm (15.35 in)

E Extension length

F Flexible hose length

I, H Encumbrance of the junction box and support system

L

Immersion length of sensing elements or protecting thermowells

MPx

L Device length

MPx Numbers and distribution of measuring points: MP1, MP2, MP3 etc.

T Lagging length

U Immersion length

16 Endress+Hauser

Page 17

iTHERM TMS12 MultiSens Linear

1

2

3

A

B

C

Junction box

1 Cable glands

2 Junction box

3 Frame

A0028118

The junction box is suited for chemical agents environments. Sea water corrosion resistance and

extreme temperature variation stability is guaranteed. Ex-e Ex-i terminals can be installed.

Possible junction box dimensions (A x B x C) in mm (in):

A B C

150 (5.9) 150 (5.9) 100 (3.93)

200 (7.87) 200 (7.87) 160 (6.29)

270 (10.6) 270 (10.6) 160 (6.29)

270 (10.6) 350 (13.78) 160 (6.29)

350 (13.78) 350 (13.78) 160 (6.3)

350 (13.78) 500 (19.68) 160 (6.3)

500 (19.68) 500 (19.68) 160 (6.3)

280 (11.02) 305 (12) 228 (8.98)

420 (16.53) 420 (16.53) 285 (11.22)

332 (13.07) 332 (13.07) 178 (7)

330 (12.99) 495 (19.49) 171 (6.73)

Type of specification Junction box Cable glands

Material AISI 316 / Aluminium NiCr Plated brass

AISI 316 / 316L

Ingress protection (IP) IP66/67 IP66

Ambient temperature range –50 to +60 °C

(–58 to +140 °F)

Approvals ATEX, IEC, UL, CSA, FM

approvals for use in hazardous

area

–52 to +110 °C (–61.1 to +140 °F)

ATEX approval for use in hazardous area

Endress+Hauser 17

Page 18

iTHERM TMS12 MultiSens Linear

Type of specification Junction box Cable glands

Marking • ATEX II 2GD Ex e IIC/ Ex ia

Ga

• ATEX IIC Ex tb IIIC Db

T6/T5/T4

• IECEX II 2GD Ex e IIC/ Ex ia

Ga IIC Ex tb IIIC Db

T6/T5/T4

• IECEX II 2GD Ex e IIC/ Ex ia

Ga IIC Ex tb IIIC Db

T6/T5/T4

• ATEX II 2GD Ex d IIC T6T3/Ex tDA21 IP66 T85oCT200oC

• IECEX II 2GD Ex d IIC T6T3/ Ex tDA21 IP66 T85oCT200oC

• UL913 Class I, Division 1

Groups B, C, D T6/T5/T4

• FM3610 Class I, Division 1

Groups B, C, D T6/T5/T4

• CSA C22.2 No. 157 Class I,

Division 1 Groups B, C, D

T6/T5/T4

Cover Hinged and threaded -

Maximum sealing diameter - 6 to 12 mm (0.24 to 0.47 in)

→ 19-

Support system

A swiveling joint is foreseen in case of direct mounted junction box for different angular positions

respect the system body.

It ensures the connection between the head of the diagnostic chamber and the junction box. The

mounting design ensures easy access for monitoring and maintaining inserts and extension cables. It

guarantees a high stiffness connection for the juncetion box and vibration loads.

Inserts, guiding tubes and protecting thermowells

Thermocouple

Diameter in mm (in) Type Standard Hot junction type Sheath material

1x type K

2x type K

3 (0.12)

1x type J

2x type J

1x type N

2x type N

IEC 60584 /ASTM

E230

Grounded/Ungrounded

Alloy600 / AISI 316L /

Pyrosil

Conductor thickness

Sensor Type Diameter in mm

(in)

Single Thermocouple 3 mm (0.11 in) Standard 0.3 mm (0.01 in) 0,45 mm = 25 AWG

Double Thermocouple 3 mm (0.11 in) Standard 0.27 mm (0.01 in) 0,33 mm = 28 AWG

Wall Min. Sheath

Thickness (S)

Min. Conductors Diameter

(C)

18 Endress+Hauser

Page 19

iTHERM TMS12 MultiSens Linear

RTD

Diameter in mm (in) Type Standard Sheath material

3 (0.12) 1x Pt100 WW/TF IEC 60751 AISI 316L

3 (0.12) 1x Pt100 WW IEC 60751 AISI 316L

Protecting thermowells or guiding tubes

A0035318

External diameter in mm (in) Sheath material Type Thickness in mm (in)

6 (0.24) AISI 316L

8 (0.32) AISI 316L closed or open 1 (0.04)

closed or open 0.5 (0.02) or

1 (0.04)

Sealing components

The sealing components (compression fittings) are welded on the diagnostic chamber head to

guarantee proper tightness under all the foreseen operating conditions and to allow the

maintenance/replacement of the stump-insert (basic solution) or inserts (advanced solution).

Material: AISI 316/AISI 316H

Cable Glands

Installed cable glands provide the proper level of reliability under the mentioned ambient and

operating conditions.

Material Marking IP Rating Ambient T range Max. sealing

diameter

NiCr Plated

brass

Atex II 2/3 GD Ex d IIC, Ex e II,

Ex nR II, Ex tD A21 IP66

IP66 –52 to +110 °C

(–61.6 to +230 °F)

6 to 12 mm

(0.23 to 0.47 in)

Endress+Hauser 19

Page 20

Diagnostic function

1

2

3

4

2

5

4

6

2

2

5

iTHERM TMS12 MultiSens Linear

A0036477

5 Left side: Basic version, right side: Advanced version

1 Extension free wires (Interruption)

2 Sensor

3 Transition bushing

4 Opened guiding tube

5 Primary thermowell

6 Protecting thermowell

First level of diagnostic

The reactors where the multipoint assembly operates are usually characterized by severe conditions

in terms of pressure, temperature, corrosion and dynamics of the process fluids. Thanks to the

pressure port, it is possible to detect and monitor possible leakages (or gases permeation) occurring

through the primary thermowell, and plan the maintenance.

Second level of diagnostic

The diagnostic chamber is a module designed to allow the multipoint behavior monitoring and the

safe containment of possible leakage or permeation coming from process after having crossed the

primary thermowell barrier and one of the following elements:

• insert sheath

• welding seams between inserts and process connection

• protecting thermowells.

Through the elaboration of all the acquired information, it allows to evaluate measurement accuracy

trends, residual lifetime and maintenance plan.

Weight

The weight can vary based upon the configuration, depending on the junction box and the frame

design. The approximate weight of a typically configured multipoint thermometer (number of inserts

= 12, main body = 3", medium size junction box) = 40 kg (88 lb).

The eyebolt, which is part of the process connection, must be used as the only lifting component to

move the entire device.

20 Endress+Hauser

Page 21

iTHERM TMS12 MultiSens Linear

Materials

The listed material properties have to be taken into account when selected for wetted parts:

Material

name

AISI

316/1.4401

AISI 316L/

1.4404

1.4435

INCONEL®

600 / 2.4816

AISI

304/1.4301

AISI 316Ti/

1.4571

AISI

321/1.4541

AISI

347/1.4550

Short form Recommended

max.

temperature for

continuous use

in air

X2CrNiMo17-12-2 650 °C (1 202 °F) • Austenitic, stainless steel

X2CrNiMo17-12-2

X2CrNiMo18-14-3

NiCr15Fe 1 100 °C

X5CrNi18-10 850 °C (1 562 °F) • Austenitic, stainless steel

X6CrNiMoTi17-12-2 700 °C (1 292 °F) • Properties comparable to AISI316L.

X6CrNiTi18-10 815 °C (1 499 °F) • Austenitic stainless steel

X6CrNiNb10-10 800 °C (1 472 °F) • Austenitic stainless steel

650 °C (1 202 °F) • Austenitic, stainless steel

(2 012 °F)

Properties

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

• Increased resistance to intergranular corrosion

and pitting

• Compared to 1.4404, 1.4435 has even higher

corrosion resistance and a lower delta ferrite

content

• A nickel/chromium alloy with very good

resistance to aggressive, oxidizing and reducing

atmospheres, even at high temperatures.

• Resistant to corrosion caused by chlorine gas and

chlorinated media as well as many oxidizing

mineral and organic acids, sea water etc.

• Corrosion from ultrapure water.

• Not to be used in a sulfur-containing atmosphere.

• Well usable in water and lowly pollute waste

water

• Only at relatively low temperatures resistant to

organic acids, saline solutions, sulphates, alkaline

solutions, etc.

• Addition of titanium means increased resistance

to intergranular corrosion even after welding

• Broad range of uses in the chemical,

petrochemical and oil industries as well as in coal

chemistry

• Can only be polished to a limited extent, titanium

streaks can form

• High resistance to intergranular corrosion even

after welding

• Good welding characteristics, suitable to all

standard welding methods

• It is used in many sectors of the chemical

industry, petrochemical, and pressurized vessels

• Good resistance to a wide variety of

environments in the chemical, textile, oilrefining, dairy and food industries

• Added niobium makes this steel impervious to

intergranular corrosion

• Good weldability

• Main applications are furnace fire walls, pressure

vessels, welded structures, turbine blades

Endress+Hauser 21

Page 22

Process connection

4

1

2

3

iTHERM TMS12 MultiSens Linear

A0036478

6 Flange as process connection

1 Flange

2 Eyebolt

3 Pressure port

4 Compression fitting

Standard process connection flanges are designed according to the following standards:

Compression fittings

Standard

ASME 1 1/2”, 2", 3” 150#, 300#, 400#, 600#, 900# AISI 316/L, 304/L, 310, 321

EN DN40, DN50, DN80 PN10, PN16, PN25, PN 40, PN

1) Flanges according to GOST standard are available on request.

1)

Size Rating Material

63, PN100, PN150

316/1.4401, 316L/1.4404, 321/1.4541,

310L/1.4845, 304/1.4301, 304L/

1.4307

The compression fittings are welded onto the diagnostic chamber head to ensure the sensors

replacement(when applicable). Dimensions are coherent with the insert dimensions. Compression

fittings comply with the highest standards of reliability in terms of materials and performances

required

Material AISI 316/316H

22 Endress+Hauser

Page 23

iTHERM TMS12 MultiSens Linear

1

3

2

5

4

1

2

3

1

3

2

2

4

Thermal contacts components

A: Thermal contact block

1 Guiding tube

2 Spacer

3 Insert

4 Thermal block

5 Primary thermowell wall

B: Bent guiding tubes and spacers

Pressed against the internal wall to ensure the

optimal heat transfer between the primary

thermowell and the replaceable temperature

sensor

A0036153

• Used on straight configurations and existing

thermowells for axial centering of the insert

bundle

• Give flexural stiffness to the sensor bundle

• Allow sensor replacement

• Guarantee thermal contact between the

sensor tip and the existing thermowell

• Modular design

1)

1 Spacer

2 Guiding tube

3 Insert

C: Protecting tubes and spacers

1 Protection thermowell

2 Spacer

3 Insert

4 Primary thermowell wall

A0028783

Each sensor is protected by its protecting

thermowell with straight tip

A0036632

Endress+Hauser 23

Page 24

iTHERM TMS12 MultiSens Linear

3

2

6

5

4

7

1

8

1

2

3

D: Thermal block (welded to the primary thermowell)

1 Primary thermowell wall

2 Spacer

3 Guiding tube

4 Insert

5 Welded contact

6 Thermal block disc

7 Welding seam

8 Supporting rod

E: Bimetallic stripes

• Ensure the optimal heat transfer through

the primary thermowell wall and the

temperature sensors.

• Sensors are replaceable.

A0036155

• Doesn't allow sensor replacement

• Guarantee thermal contact between the

sensor tip and the thermowell due to

bimetallic stripes activated by temperature

difference

• No friction during installation even with

already installed sensors

A0028435

7 Bimetal strips with or without guiding tubes

1 Guiding tube

2 Insert

3 Bimetallic stripe

1) Can be mounted in-house or on-site

Operability

For details of operability, see the Technical Information of the Endress+Hauser temperature

transmitters or the manuals of the related operating software.

24 Endress+Hauser

Page 25

iTHERM TMS12 MultiSens Linear

Certificates and approvals

CE Mark

Hazardous area approvals

PED approval

Certification HART

Certification FOUNDATION Fieldbus

The complete assembly is provided with individual components CE marked, to ensure safe use in

hazardous areas and pressurized environments.

The Ex approval applies to individual components like junction box, cable glands, terminals. For

further details on the available Ex versions (ATEX, UL, FM, CSA, IEC-EX, NEPSI, EAC-EX), please

contact your nearest Endress+Hauser sales organization. All relevant data for hazardous areas can

be found in separate Ex documentation.

ATEX Ex ia inserts are available only for diameters ≥ 1.5 mm (0.6 in). For further details contact an

Endress+Hauser technician.

The thermometer assembly can be provided with PED approval if required as the European Directive

2014/68/UE says. Calculation reports, testing procedures, certificates , are provided according the

required calculation code and as foreseen in the product technical dossier.

The HART® temperature transmitter is registered by the FieldComm Group. The device meets the

requirements of the HART® Communication Protocol Specifications.

The FOUNDATION Fieldbus™ temperature transmitter has successfully passed all test procedures

and is certified and registered by the Fieldbus Foundation. The device thus meets all the

requirements of the following specification:

• Certified according to FOUNDATION Fieldbus™ specification

• FOUNDATION Fieldbus™ H1

• Interoperability Test Kit (ITK), up to date revision status (device certification no. available on

request): the device can also be operated with certified devices of other manufacturers

• Physical layer conformance test of the FOUNDATION Fieldbus™

Certification PROFIBUS® PA

Other standards and guidelines

Material certification

Test report and calibration

The PROFIBUS® PA temperature transmitter is certified and registered by the PNO (PROFIBUS®

Nutzerorganisation e. V.), PROFIBUS user organization. The device meets all the requirements of the

following specifications:

• Certified according to FOUNDATION Fieldbus™ specification

• Certified in accordance with PROFIBUS® PA Profile (the up to date profile version is available on

request)

• The device can also be operated with certified devices of other manufacturers (interoperability)

• IEC 61326-1:2007: Electromagnetic compatibility (EMC requirements)

• IEC 60529: Degree of protection of housing (IP code)

• IEC 60584 and ASTM E230/ANSI MC96.1: Thermocouples

• ASME B16.5, B16.36, EN 1092-1, GOST 12820-20: Flange

The material certificate 3.1 (according to standard EN 10204) can be requested separately. The

certificate includes a declaration related to the materials used in the construction of the single sensor

and guarantees the traceability of the materials through the identification number of the multipoint.

The data related to the origin of the materials can subsequently be requested by the client if

necessary.

The "Factory calibration" is carried out according to an internal procedure in a laboratory of Endress

+Hauser accredited by the European Accreditation Organization (EA) to ISO/IEC 17025. A

calibration which is performed according to EA guidelines (SIT/Accredia) or (DKD/DAkkS) may be

requested separately. The calibration is performed on the inserts of the multipoint.

Endress+Hauser 25

Page 26

iTHERM TMS12 MultiSens Linear

Ordering information

Overview of the scope of delivery see the configuration table below.

Detailed ordering information is available from your Endress+Hauser Sales Center:

www.addresses.endress.com

Insert design

Replaceable

Not replaceable

Process connection: Flange

Standard • Asme B16.5

• En1092-1

Material • 316/1.4401

• 316L/1.4404

• 321/1.4541

• 310L/1.4845

• 304/1.4301

• 304L/1.4307

Face • RF

• RTJ

• Type A

• Type B1

Size • 1 1/2", 2", 3"

• DN40, DN50, DN80

________

________

Other process connections, have to be specified in terms of dimensions and overall characteristics.

Max n. points depending on insert layout

Thermal contact design: A=B=C=D E

Thermowell size 1 1/2 7 7

2 10 8

2 1/2 12 10

3 12 12

1) In case of order , the maximum number of points are subjected to a feasibility check.

Primary Thermowell

Thermowell dimension • 1 1/2"

• 2"

• 2 1/2"

• 3"

Thermowell material • 316/1.4401

• 316L/1.4435

• 321/1.4541

• 310L/1.4845

• 304/1.4301

• 304L/1.4307

1)

26 Endress+Hauser

Page 27

iTHERM TMS12 MultiSens Linear

Insert, sensor

Measuring principle • Thermocouple (TC)

Type TC: J, K, N

Design • TC: Single, duplex

Execution • TC: Grounded, Ungrounded

Sheath material 316L, Alloy 600, Pyrosil ________

Approvals Intrinsic Safety

Standard/Class • IEC/Class 1

Measurement point distribution

Positioning • Equi spaced

Number 2, 4, 6, 8, 10, 12

• Resistance Temperature Detection (RTD)

RTD: Pt100

• RTD: 3-wire, 4-wire, 2x3-wire

• RTD: Wire wound (WW), Thin Film (TF)

Non hazardous

• ASTM/Class special

• IEC/Class A

• IEC/Class AA

• Customized

1)

________

________

Insertion length TAG (description) (L

MP

MP

.....

MP

1

2

3

x

_________________________________________ __________

_________________________________________ __________

_________________________________________ __________

_________________________________________ __________

) in mm (in)

MPx

1) Different numbers/configurations are available on request

Junction box (Head)

Material Stainless steel (standard)

Aluminum (to be specified)

Others on request

Electrical connection Terminal block wiring:

• Terminal block - standard/number

• Terminal block - compensated/number

• Terminal block - spare/number

Transmitter wiring:

• HART protocol, e. g.: TMT182, TMT82

• PROFIBUS PA protocol, e. g.: TMT84

• FOUNDATION Fieldbus protocol, e. g.: TMT85

• Quantity

/ _____

/ _____

/ _____

_______

Approvals Ex e / Ex ia / Ex d _______

Cable entries (process side) Single or multiple, type: M20

Quantity

_______ / _______

_______ / _______

Other on request (In case of remote junction box with

flexible hose, M32, polyamide)

Cable entries (wiring side) Single or multiple, type: M20, M25, NPT ½", NPT 1"

Quantity

_______ / _______

_______ / _______

Other on request

Endress+Hauser 27

Page 28

Junction box supporting frame

• Remote

• Swivelling joint

• Other on request

TAG

Device information Refer to customer specification /

As specified

Measuring point

information

Refer to customer specification

Location, as specified:

• Tagging (TAG), on device (black foil)

• Tagging (TAG), by customer

• Tagging (TAG), on Transmitter

• Tagging (TAG), on device (metal tag)

• Tagging (TAG), on extension cable

• Tagging (TAG), RFID

• To be specified

iTHERM TMS12 MultiSens Linear

__________

(table)

Additional requests

Extension wire lengths,

only for remote head

Extension wires material • PVC, -20…105°C

Specification in mm:

• Hyflon MFA, -200…250°C

• Others on request

________

________

28 Endress+Hauser

Page 29

iTHERM TMS12 MultiSens Linear

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress + Hauser,

are available for the device. Detailed information on the order code is available from your local

Endress+Hauser sales center.

Device-specific accessories

Accessories Description

Tags Nameplate can be applied to identify each measuring

points and the whole assembly. Tags can be placed on

the extension cables in the extension area and/or in to

the junction box on individual wires or on other device.

Pressure transducer Digital or analogical pressure transmitter with welded

metal sensor for measurement in gases, steam or liquids.

Ref to Endress+Hauser PMP sensors family

Fitting, manifolds and valves are available for the

installation of the pressure transmitter on the pressure

port connection, and so allows the continuous

monitoring of the device under the operating conditions.

A0034865

Fitting / manifolds / valves

Purging system A purging system for the depressurization of the

diagnostic chamber. The system is composed by:

• 2 and 3 ways trunnion valves

• Pressure transmitter

• Two ways relief valves

The system eventually allows the connection of multiple

number of diagnostic chambers installed in the same

reactor.

Portable sampling system A portable field system that allows to sample the fluid

present inside the diagnostic chamber, so that can be

chemically analyzed in an external laboratory. The

system is composed by:

• Three cylinders

• Pressure regulator

• Rigid abd flexible tubes

• Vent lines

• Quick connectors and valves

Composed by a polyamide cable conduit to connect the

top of the top of the thermowell and the remote junction

box, already provided of a shaped stainless steel cover

fixed to the junction box frame to protect the cable

connections.

A0036534

Remote cable conduit system

Endress+Hauser 29

Page 30

iTHERM TMS12 MultiSens Linear

Communication-specific accessories

Configuration kit TXU10 Configuration kit for PC-programmable transmitter with setup software and

interface cable for PC with USB port

Order code: TXU10-xx

Commubox FXA195

HART

Commubox FXA291 Connects Endress+Hauser field devices with a CDI interface (= Endress+Hauser

HART Loop Converter

HMX50

Wireless HART adapter

SWA70

Fieldgate FXA320 Gateway for the remote monitoring of connected 4-20 mA measuring devices via a

For intrinsically safe HART communication with FieldCare via the USB interface.

For details, see "Technical Information" TI00404F

Common Data Interface) and the USB port of a computer or laptop.

For details, see "Technical Information" TI00405C

Is used to evaluate and convert dynamic HART process variables to analog current

signals or limit values.

For details, see "Technical Information" TI00429F and Operating Instructions

BA00371F

Is used for the wireless connection of field devices.

The WirelessHART adapter can be easily integrated into field devices and existing

infrastructures, offers data protection and transmission safety and can be operated

in parallel with other wireless networks with minimum cabling complexity.

For details, see Operating Instructions BA061S

Web browser.

For details, see "Technical Information" TI00025S and Operating Instructions

BA00053S

Service-specific accessories

Fieldgate FXA520 Gateway for the remote diagnostics and remote configuration of connected HART

measuring devices via a Web browser.

For details, see "Technical Information" TI00025S and Operating Instructions

BA00051S

Field Xpert SFX100 Compact, flexible and robust industry handheld terminal for remote configuration

and for obtaining measured values via the HART current output (4-20 mA).

For details, see Operating Instructions BA00060S

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

• Graphic illustration of the calculation results

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

• Via the Internet: https://portal.endress.com/webapp/applicator

• On CD-ROM for local PC installation.

W@M Life cycle management for your plant

W@M supports you with a wide range of software applications over the entire

process: from planning and procurement, to the installation, commissioning and

operation of the measuring devices. All the relevant device information, such as

the device status, spare parts and device-specific documentation, is available for

every device over the entire life cycle.

The application already contains the data of your Endress+Hauser device. Endress

+Hauser also takes care of maintaining and updating the data records.

W@M is available:

• Via the Internet: www.endress.com/lifecyclemanagement

• On CD-ROM for local PC installation.

30 Endress+Hauser

Page 31

iTHERM TMS12 MultiSens Linear

FieldCare FDT-based plant asset management tool from Endress+Hauser.

Documentation

This guide is referred to the complete assembly. To have a complete overview of the technical and

operative instructions of the parts refer to the other documents of the individual components

manufactured by Endress+Hauser:

• Technical Information iTEMP temperature transmitters:

• Technical Information of inserts:

• Technical Information of pressure transmitter:

It can configure all smart field units in your system and helps you manage them. By

using the status information, it is also a simple but effective way of checking their

status and condition.

For details, see Operating Instructions BA00027S and BA00059S

• HART® TMT82, two-channel, RTD, TC, Ω, mV (TI01010TEN_1715)

• HART® TMT182, two-channel, RTD, TC, Ω, mV (TI078ren_1310)

• TMT181, PC-programmable, single-channel, RTD, TC, Ω, mV (ti070ren)

• PROFIBUS® PA TMT84, two-channel, RTD, TC, Ω, mV (TI00138ren_0412)

• FOUNDATION FieldbusTM TMT85, two-channel, RTD, TC, Ω, mV (TI00134REN_0313)

Thermocouple thermometer iTHERM TSC310 (TI00255ten_0111)

CERABAR S PMP71 (TI00451PEN_0111)

Endress+Hauser 31

Page 32

www.addresses.endress.com

Loading...

Loading...