Page 1

BA01471T/09/EN/03.18

71425988

2018-12-24

Products Solutions Services

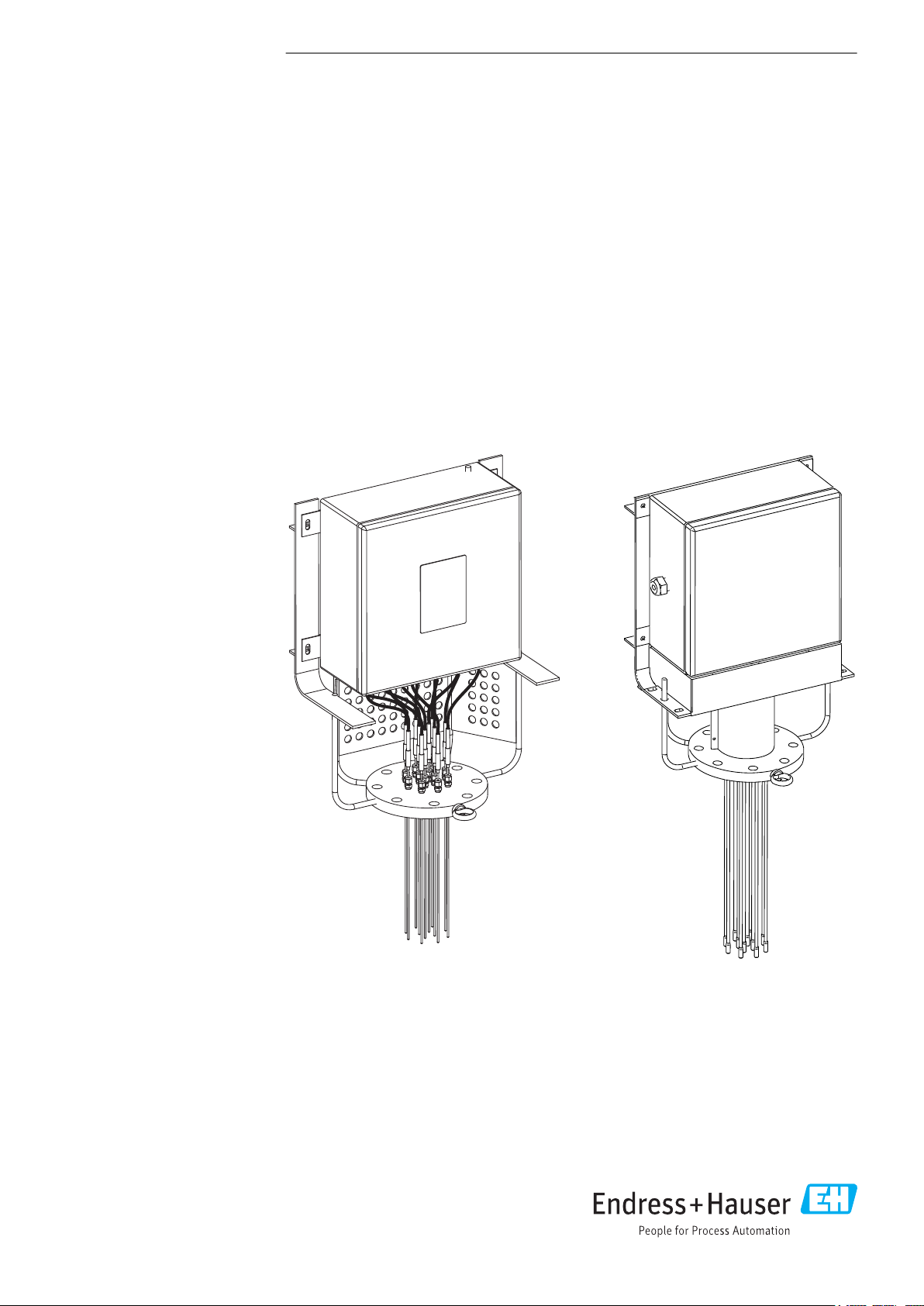

Operating Instructions

iTHERM

MultiSens Flex TMS01

Modular direct contact TC and RTD multipoint

thermometer for Oil & Gas and Petrochemical

applications

Page 2

Page 3

iTHERM MultiSens Flex TMS01 Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Symbols .............................. 4

2 Basic safety instructions ............ 6

2.1 Requirements for the personnel ............ 6

2.2 Designated use ........................ 6

2.3 Workplace safety ....................... 7

2.4 Operational safety ...................... 7

2.5 Product safety ......................... 7

3 Product description ................. 8

3.1 Product design ......................... 8

4 Incoming acceptance and product

identification ..................... 11

4.1 Incoming acceptance ................... 11

4.2 Product identification ................... 11

4.3 Storage and transport .................. 12

5 Mounting ......................... 13

5.1 Mounting requirements ................. 13

5.2 Mounting the assembly ................. 14

5.3 Post-mounting check ................... 16

10 Accessories ....................... 29

10.1 Device-specific accessories ............... 29

10.2 Communication-specific accessories ........ 30

10.3 Service-specific accessories ............... 31

11 Technical data .................... 32

11.1 Input ............................... 32

11.2 Output ............................. 32

11.3 Environment ......................... 33

11.4 Mechanical construction ................ 34

11.5 Certificates and approvals ............... 40

11.6 Documentation ....................... 41

6 Wiring ............................ 18

6.1 Quick wiring guide ..................... 18

6.2 Connecting the sensor cables ............. 20

6.3 Connecting the power supply and signal

cables .............................. 21

6.4 Shielding and grounding ................ 22

6.5 Degree of protection ................... 22

6.6 Post-connection check .................. 22

7 Commissioning .................... 24

7.1 Preliminaries ......................... 24

7.2 Function check ....................... 24

7.3 Switching on the device ................. 26

8 Diagnostics and troubleshooting ... 26

8.1 General troubleshooting ................. 26

9 Repair ............................ 27

9.1 General notes ........................ 27

9.2 Spare parts .......................... 27

9.3 Endress+Hauser services ................ 27

9.4 Return .............................. 27

9.5 Disposal ............................ 28

Endress+Hauser 3

Page 4

About this document iTHERM MultiSens Flex TMS01

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

4 Endress+Hauser

Page 5

iTHERM MultiSens Flex TMS01 About this document

,…,

Symbol Meaning

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.4 Documentation

Document Purpose and content of the document

iTHERM TMS01 MultiSens Flex

(TI01256T/09/)

Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com →

Downloads

1.2.5 Registered trademarks

• FOUNDATION™ Fieldbus

Registered trademark of the Fieldbus Foundation, Austin, Texas, USA

• HART®

Registered trademark of the HART® FieldComm Group

• PROFIBUS®

Registered trademark of the PROFIBUS Nutzerorganisation e.V. (Profibus User

Organization), Karlsruhe - Germany

Endress+Hauser 5

Page 6

Basic safety instructions iTHERM MultiSens Flex TMS01

2 Basic safety instructions

Instructions and procedures in the operating instructions may require special precautions

to ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by safety pictograms and symbols. Please refer

to the safety messages before performing an operation preceded by pictograms and

symbols. Although the information provided herein is believed to be accurate, be advised

that the information contained herein is NOT a guarantee of satisfactory results.

Specifically, this information is neither a warranty nor guarantee, expressed or implied,

regarding performance. Please note that the manufacturer reserves the right to change

and / or improve the product design and specifications without notice.

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

The product is intended to measure the temperature profile inside a reactor, vessel or pipe

through RTD or thermocouple technologies.

The manufacturer is not liable for damage caused by improper or non-designated use.

The product has been designed according to the following conditions:

Condition Description

Internal pressure The design of joints, threaded connections and sealing elements has been

executed as a function of the maximum allowable pressure inside the reactor.

Operating temperature The materials used were chosen according to the operating and design

minimum and maximum temperatures. Thermal displacement has been taken

into account to avoid intrinsic stresses and to ensure proper integration

between the instrument and the plant. Specific care has to be taken when the

instrument’s sensing elements are fixed to the plant internals.

Process fluids Dimensions and choice of materials minimize:

• distributed and localized corrosion,

• erosion and abrasion,

• corrosion phenomena due to uncontrolled and unpredictable chemical

reactions.

Specific process fluids analysis is necessary to properly ensure the maximum

operating life of the device, through proper material selection.

Fatigue Cyclic loads during operations are not foreseen.

6 Endress+Hauser

Page 7

iTHERM MultiSens Flex TMS01 Basic safety instructions

Condition Description

Vibrations The sensing elements can be subjected to vibrations, due to high immersion

lengths from the constraint located in the process connections. This vibrations

can be minimized by properly selecting the route of the sensing element into

the plant, by fixing it on internals by means of accessories like clips and end

tips. The extension neck has been designed for withstanding vibratory loads to

preserve the junction box from cyclic loading, and to avoid the unscrewing of

the threaded components.

Mechanical stress The maximum stress on the measuring device multiplied by a safety factor is

guaranteed to stay below the yielding stress of the material, for every working

condition of the plant.

External environment The junction box (with and without head transmitters), wires, cable glands and

other fittings have been selected to work within the allowed ranges in terms of

external temperature.

2.3 Workplace safety

The external installation area must be free of interferences to avoid any injury during

installation, and to avoid any damage to the measuring device.

2.4 Operational safety

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection or safety equipment):

Based on the technical data on the nameplate, check whether the ordered device is

‣

permitted for the intended use in the hazardous area. The nameplate can be found on

the side of the junction box.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

Electromagnetic compatibility

The measuring system complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326 and NAMUR Recommendation NE

21 and NE 89.

NOTICE

The unit must only be powered by a power supply that operates using an energy-

‣

limited electric circuit that is compliant with IEC 61010-1, "SELV or Class 2 circuit".

2.5 Product safety

The unit is constructed using the most up-to-date production equipment and complies

with the safety requirements of the local guidelines. The temperature measuring system is

fully factory tested according to the specifications indicated on the order and/or any

additional test which is considered as safety-relevant. However, if it is installed incorrectly

or is misused, certain application dangers can occur. Installation, wiring and maintenance

of the unit must only be done by trained, skilled personnel who are authorized to do so by

the plant operator. This skilled staff must have read and understood these instructions and

must follow them. The plant operator must make sure that the measurement system has

been installed by tightening the threaded components (e.g bolts and nuts) with the

predefined torques and tools → 13, and correctly wired according to the wiring

diagrams. → 18

Endress+Hauser 7

Page 8

Product description iTHERM MultiSens Flex TMS01

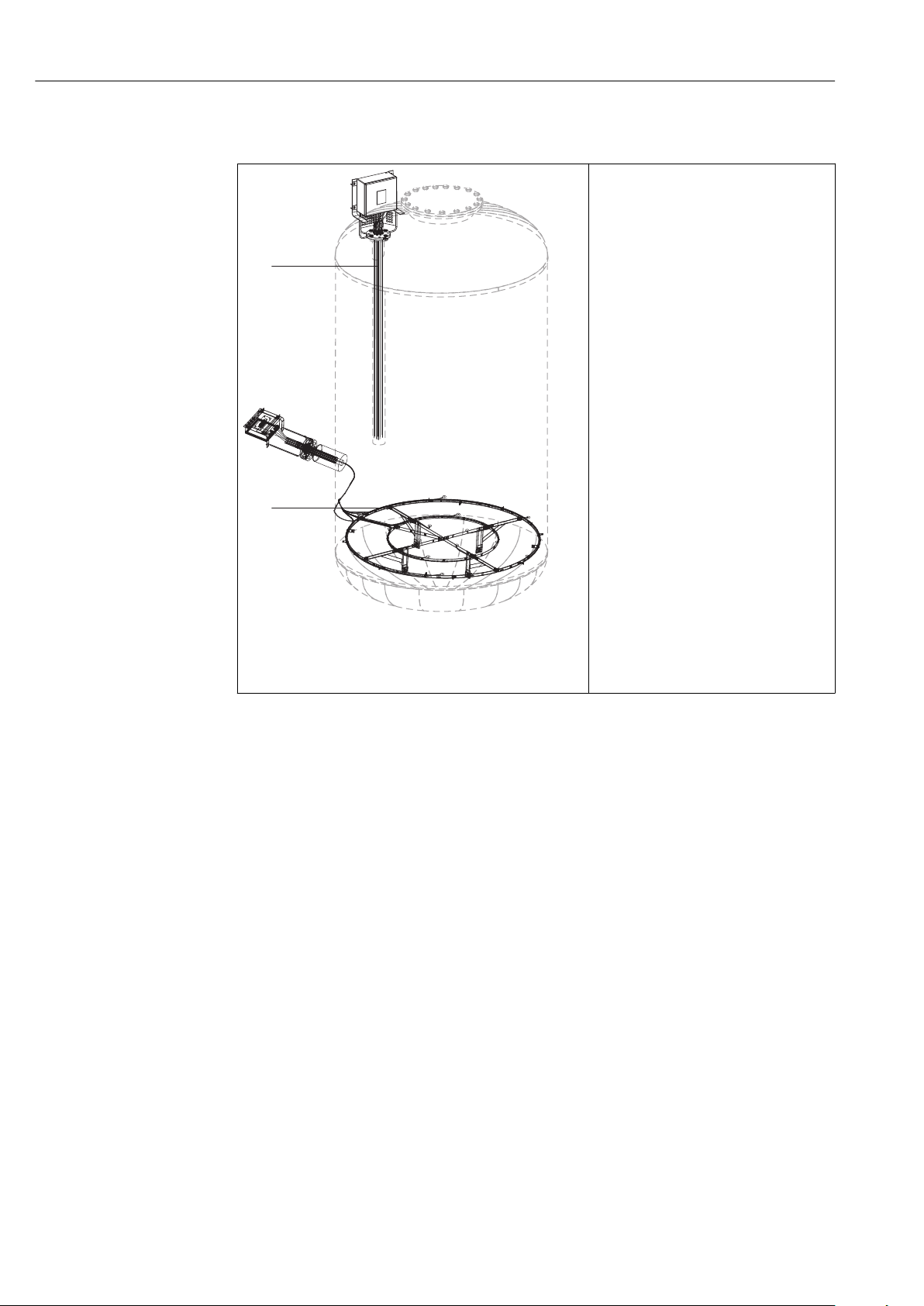

1

2a

3

4

6a

5

7

2b

6b

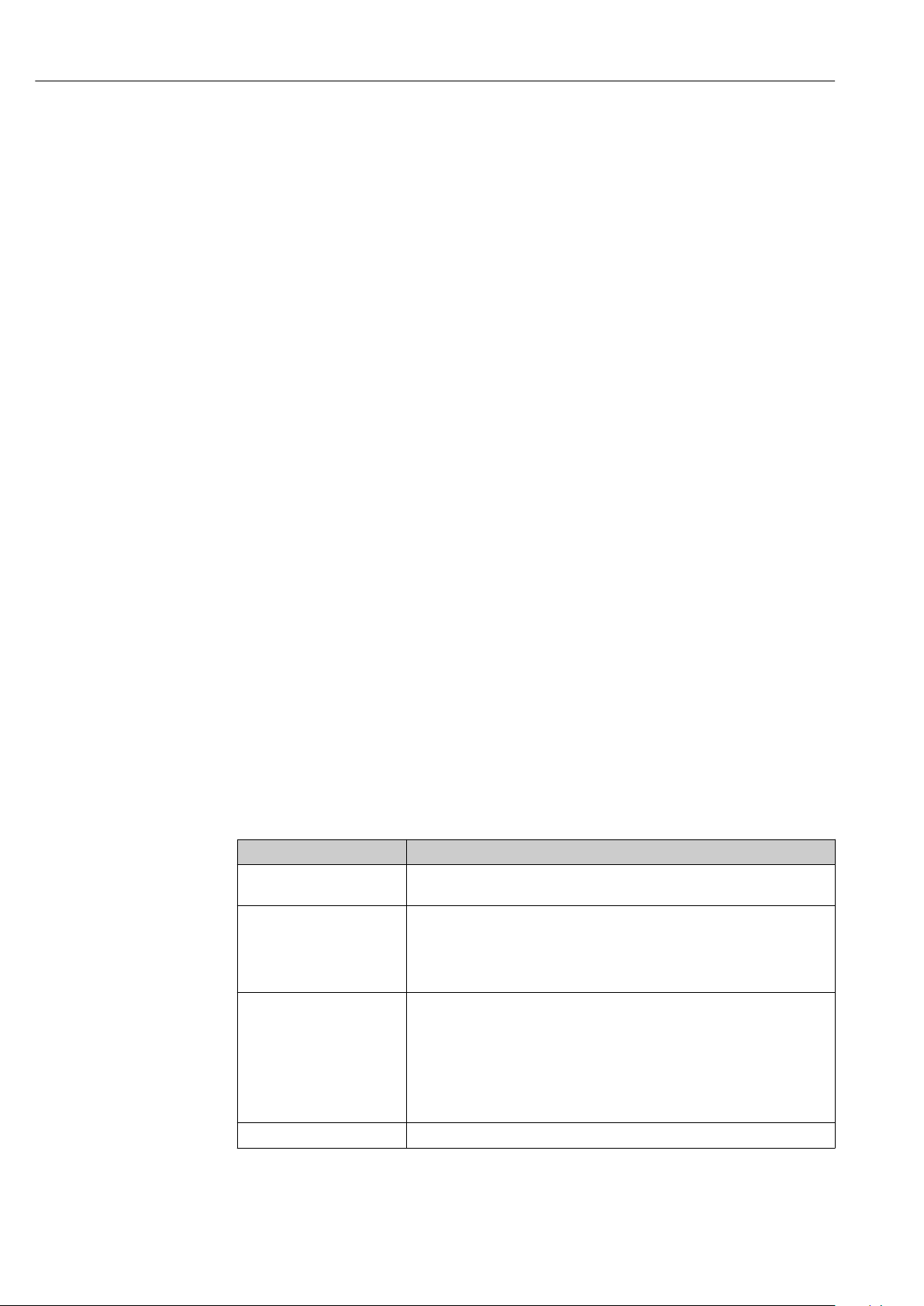

3 Product description

3.1 Product design

The multipoint thermometer belongs to a range of modular product configuration for

multipoint temperature detection with a design where subassemblies and components can

be managed individually for easy maintenance and spare part ordering.

It consists of the following main sub-assemblies:

• Insert: Done by a metal sheathed sensing measuring element (thermocouple or

resistance), extension cables and transition bushing. Each insert can be handled as an

individual spare part that is replaceable by untightening its compression fitting installed

onto the process connection. They can be ordered via specific standard product order

codes (e.g. TSC310, TST310) or special codes. For the specific order code please contact

the Endress+Hauser service department.

• Process connection: Represented by an ASME or EN flange, it might be provided with

eyebolts for lifting the device.

• Head: It is composed of a junction box provided with its components such as cable

glands, draining valves, earth screws, terminals, head transmitters, etc.

• Neck: It is designed to support the junction box by components such as supporting rods

and plates or tube extension.

• Additional accessories: Components that can be ordered independently from the

selected product configuration, such as clips, pads, tips, spacers and plates for tag

sensors.

• Thermowells: They are directly welded on the process connection, designed to

guarantee higher degree of mechanical protection and corrosion resistance for each

sensor.

In general, the system measures the temperature profile inside the process environment

by means of many sensors, jointed to a suitable process connection which ensures the

right tightness levels. Externally, the extension cables are wired into the junction box,

which can be directly mounted or remote as option.

Design Description, available options and

materials

1: Head Hinged cover junction box for

electrical connections. It includes

components such as electrical

terminals, transmitters and cable

glandes.

• 316/316L

• Other materials on request

2a: Frame neck and

2b: Tube neck

3: Compression fitting High performance compression

A0028078

Modular frame support that is

adjustable for all available junction

boxes.

316/316L

Modular tube support that is

adjustable for all available junction

boxes and ensures extension cable

inspection.

316/316L

fitting for a proper tightness

between process and external

environment, for a wide range of

process fluids concentration and

severe combination between

temperature and pressure.

• 316L

• 316H

8 Endress+Hauser

Page 9

iTHERM MultiSens Flex TMS01 Product description

Design Description, available options and

materials

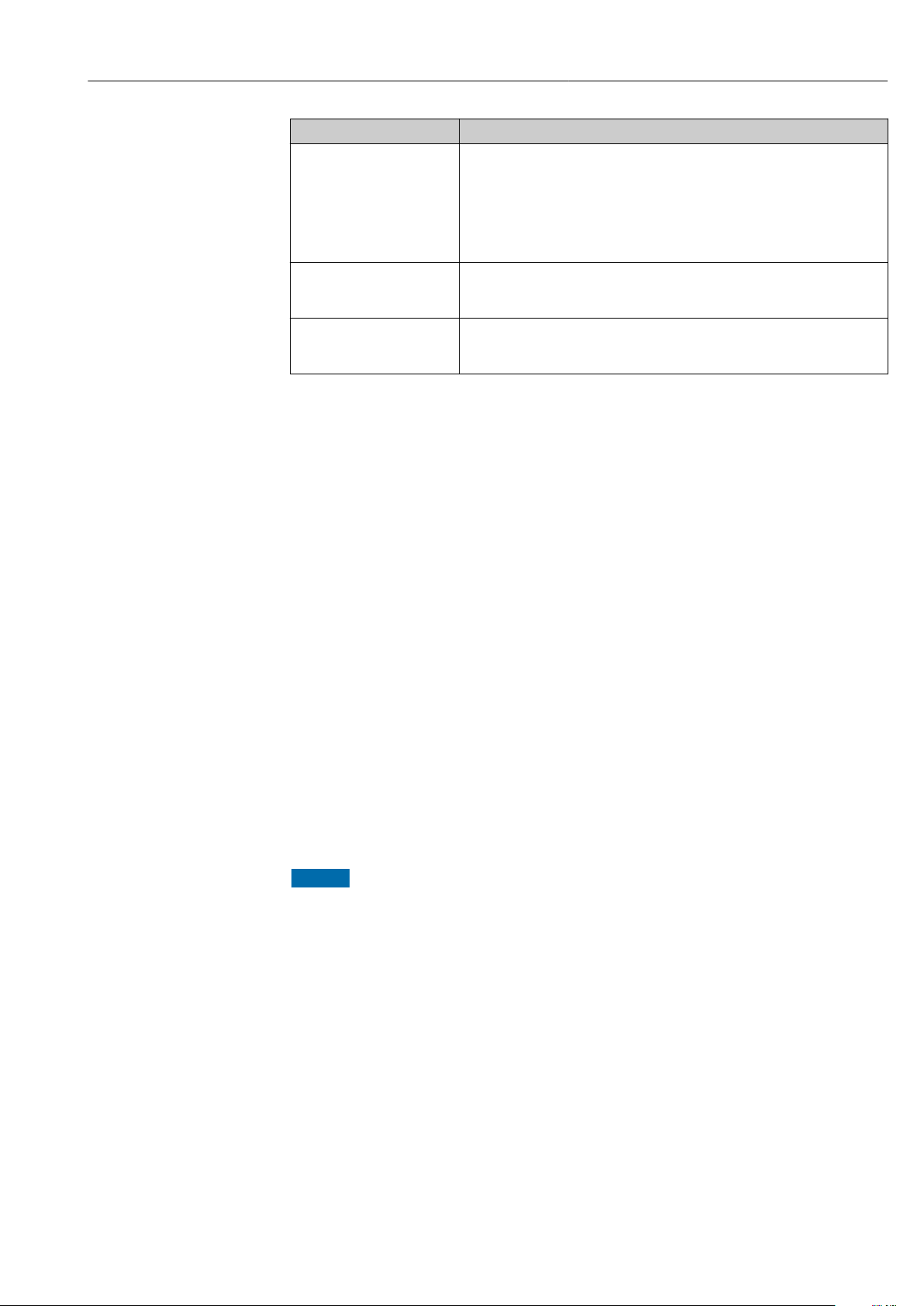

4: Process connection Represented by a flange according to

international standards, or

engineered to satisfy specific process

requirements. → 39

• 304 + 304L

• 316 + 316L

• 316Ti

• 321

• 347

• Other materials on request

5: Insert • Thermocouple (type J, K)

grounded and ungrounded

execution or RTD (Pt100 wire

wound).

• Insert sheath material: Alloy600,

316, 316L, Pyrosil

• Available in several diameters,

please refer to the ordering

information table.

6a: Protecting

thermowells

6b: Guiding open tubes

7: Eyebolt Lifting device for easy handling

The thermometer can be equipped:

• either with protecting

thermowells for increased

mechanical strength and

corrosion resistance

• or open guiding tubes for

installation in an existing

thermowell.

• 316/316L

• 321

• 347

• Alloy 600

• Other materials on request

during installation phase.

316

Endress+Hauser 9

Page 10

Product description iTHERM MultiSens Flex TMS01

1

2

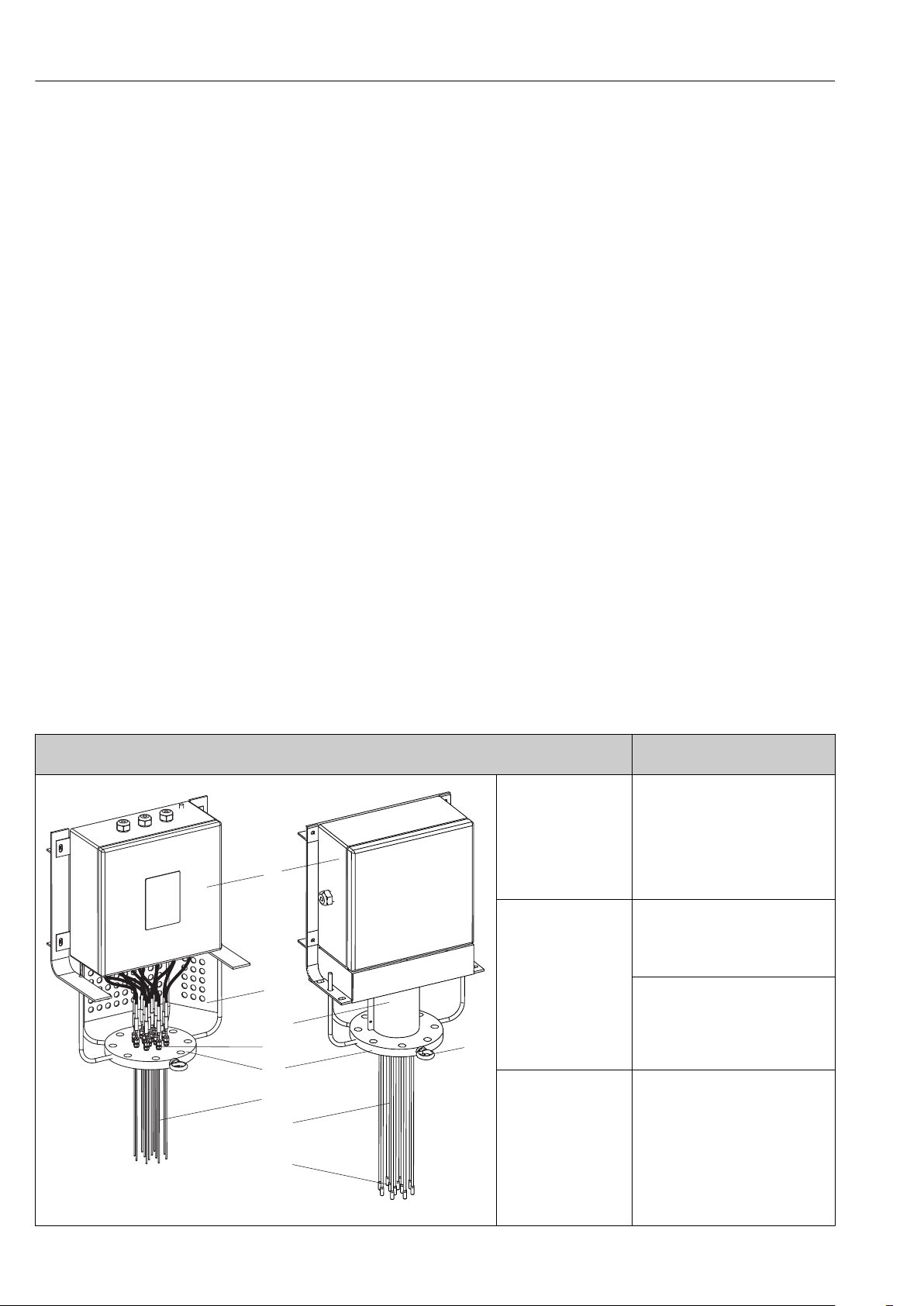

The modular multipoint thermometer is characterized by the following possible main

configurations:

• Linear configuration

The different sensors are aligned along

the straight direction coinciding with the

longitudinal axis of the multipoint

assembly itself (linear multipoint

measurement). This configuration can be

used to install the multipoint either in an

existing thermowell as part of the reactor

or in direct contact with the process.

• 3D distribution configuration

All the inserts, regardless of using the

single insert thermowell protection or not,

can be bent and arranged in a three

dimensional configuration by fixing them

through clips or other equivalent

accessories. This configuration is

commonly used to reach several

measurement points distributed at

different cross sections and levels. Specific

support frames can be provided and

installed on request if they are not already

available on site.

A0028362

1 Main configuration possibilities

1 Linear configuration

2 3D configuration

10 Endress+Hauser

Page 11

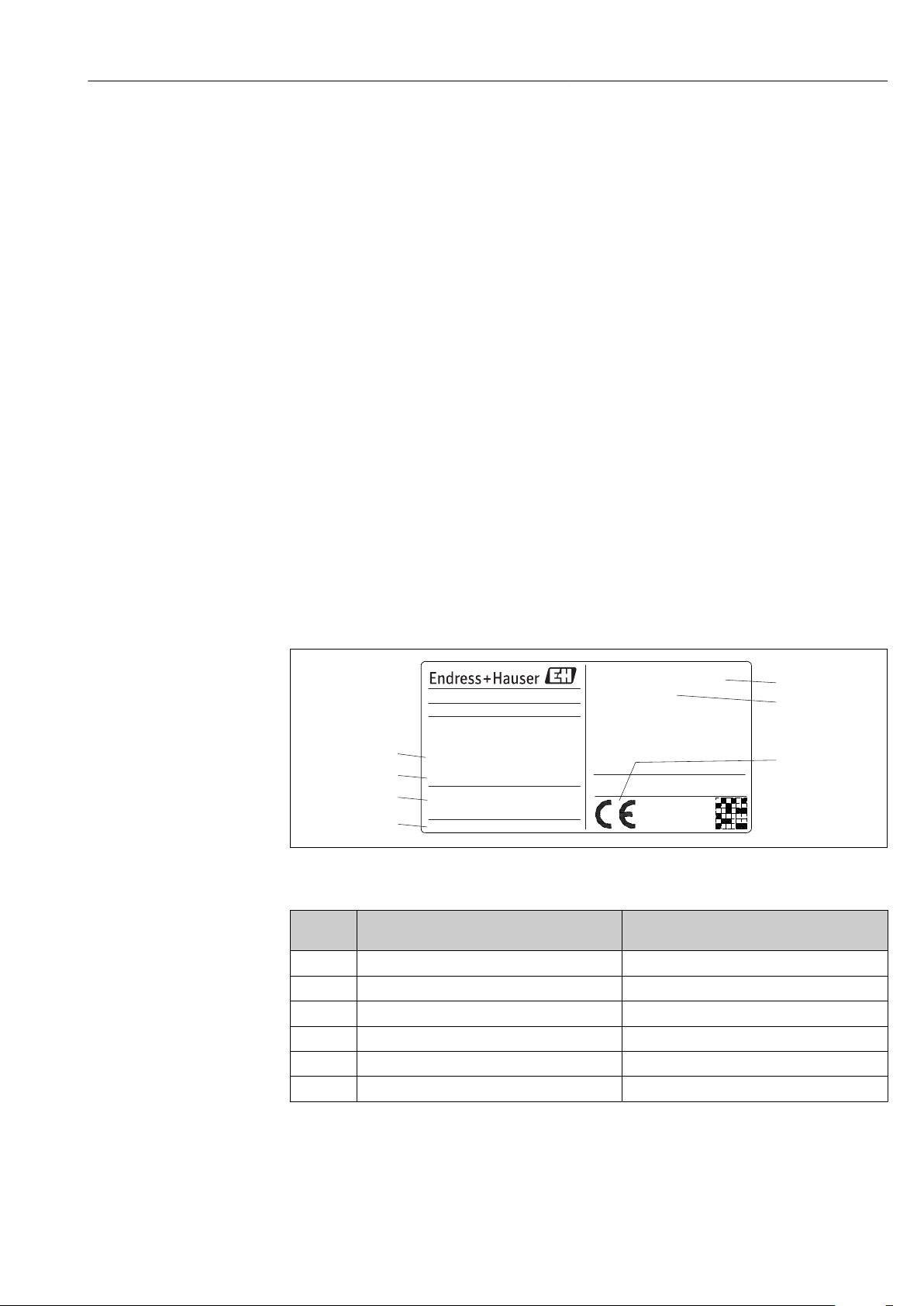

iTHERM MultiSens Flex TMS01 Incoming acceptance and product identification

Made in Italy 2018

20060 Pessano con Bornago-MI

iTHERM MultiSens Flex

Ser.no.: XXXXXXXXXXX

Ord.cd.: T -XXXX/XXMS01

2xPt100/TF/4Cl.A

no. of inserts: 8

TMT182-B

No of transmitter:12

Ref to BA01471T/09/en

Measuring range: 0...250 °C

0044

PED information

5

6

7

TSV00XXXX-XXXXX

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Before proceeding with the installation the following incoming acceptance procedures are

suggested:

• Once the device is received it is always suggested to verify the integrity of the packaging

and possible damages. Non-compliances should be immediately reported to the

manufacturer. Damaged material shall not be installed: in these conditions, in fact, the

manufacturer cannot guarantee the original safety requirements and cannot be

considered responsible for any consequential effect.

• Compare the scope of delivery with the order content.

• Carefully remove all packaging/protection related to the freight.

4.2 Product identification

The following options are available for identification of the device:

• Nameplate specifications

• Enter the serial number from the nameplate in the W@M Device Viewer https://

www.endress.com/deviceviewer. All data relating to the device and an overview of the

Technical Documentation supplied with the device are displayed.

The following nameplate layout serves to identify the specific product information from

the serial number, design conditions, sizes, configuration to approvals:

2 Nameplate of the multipoint thermometer (example as landscape format)

Field

number

1 Order code and serial number -

2 TSV drawing number TSV301237-XXXXX

3 Sensor and product configuration e.g. number of measuring points

4 Assembled transmitter -

5 Sensor measuring temperature range -

6 PED information (if applicable) e.g. volume, pressure, temperature

Description Examples

A0029056

Endress+Hauser 11

Page 12

Incoming acceptance and product identification iTHERM MultiSens Flex TMS01

Field

number

7 CE marking -

- Approval number, hazardous area classification

Description Examples

and Ex logo (if applicable)

Safety instructions number (if applicable)

Ambient temperature (if hazardous area

classification is applicable)

-

e.g. –50 to 60 °C (–58 to 140 °F) for hazardous

area application

Compare and check the data on the nameplate of the device against the requirements

of the measurement point.

4.3 Storage and transport

Carefully remove each package and protection relative to the transportation packaging.

NOTICE

Transportation of the device to the installation area

Handle the device by always using the provided eyebolt as the main lifting part.

‣

Handle with care. During mounting phases avoid each load to welded or threaded parts,

‣

under the action of the weight of the device.

When the device has to pass from the horizontal to the vertical position or vice versa,

‣

particular attention must be taken.

It is strictly requested to avoid bumping against obstacles nearby the place where the

‣

device is to be installed.

Avoid any friction between the device and the other surrounding bodies.

‣

Avoid twisting of the sensing element twisting.

‣

Pack the device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

For permitted storage temperature → 33

12 Endress+Hauser

Page 13

iTHERM MultiSens Flex TMS01 Mounting

5 Mounting

5.1 Mounting requirements

WARNING

L

Failure to follow these installation guidelines could result in death or serious injury

Make sure only qualified personnel perform the installation.

‣

WARNING

L

Explosions could result in death or serious injury

Do not remove the junction box cover in explosive atmospheres when the circuit is live.

‣

Before connecting any additional electric and electronic device in an explosive

‣

atmosphere, make sure the instruments in the loop are installed in accordance with

intrinsically safe or non incendive field wiring practices.

Verify that the operating atmosphere of the transmitters is consistent with the

‣

appropriate hazardous locations certifications.

All covers and threaded components must be fully engaged to meet explosion-proof

‣

requirements.

WARNING

L

Process leaks could result in death or serious injury

Do not release screwed parts while in operation. Install and tighten the fittings before

‣

applying pressure.

NOTICE

Additional loads and vibrations from other plant components can affect the operation

of the sensor elements.

Is it not allowed to apply additional loads or external moments to the system coming

‣

from the connection with another system not foreseen from installation plan.

The system is not suitable for being installed in locations where vibrations are present.

‣

The deriving loads can undermine the sealing of the junctions and damage the

operation of the sensing elements.

It will be care of the final user to verify the installation of suitable devices in order to

‣

avoid the overcoming of the admitted limits.

For the environment conditions please refer to the technical data → 33

‣

When installing in an existing thermowell, an internal inspection of the thermowell is

‣

recommended to check if any internal load is present before starting with the insertion

activities of the whole device. While installing the measurement system, avoid any

friction during installation, specifically avoid sparks generation. Ensure the thermal

contact between the inserts and the bottom/wall of the existing thermowell. When

accessories like spacers are provided, make sure that no distortions are occurred and

the original geometry and position is maintained.

When the installation is performed by direct contact with the process, ensure that any

‣

applied external loads (i.e. due to the tip fixing of the probe to any reactor internals)

don't generate deformations and strains on the probe and on welds.

Endress+Hauser 13

Page 14

Mounting iTHERM MultiSens Flex TMS01

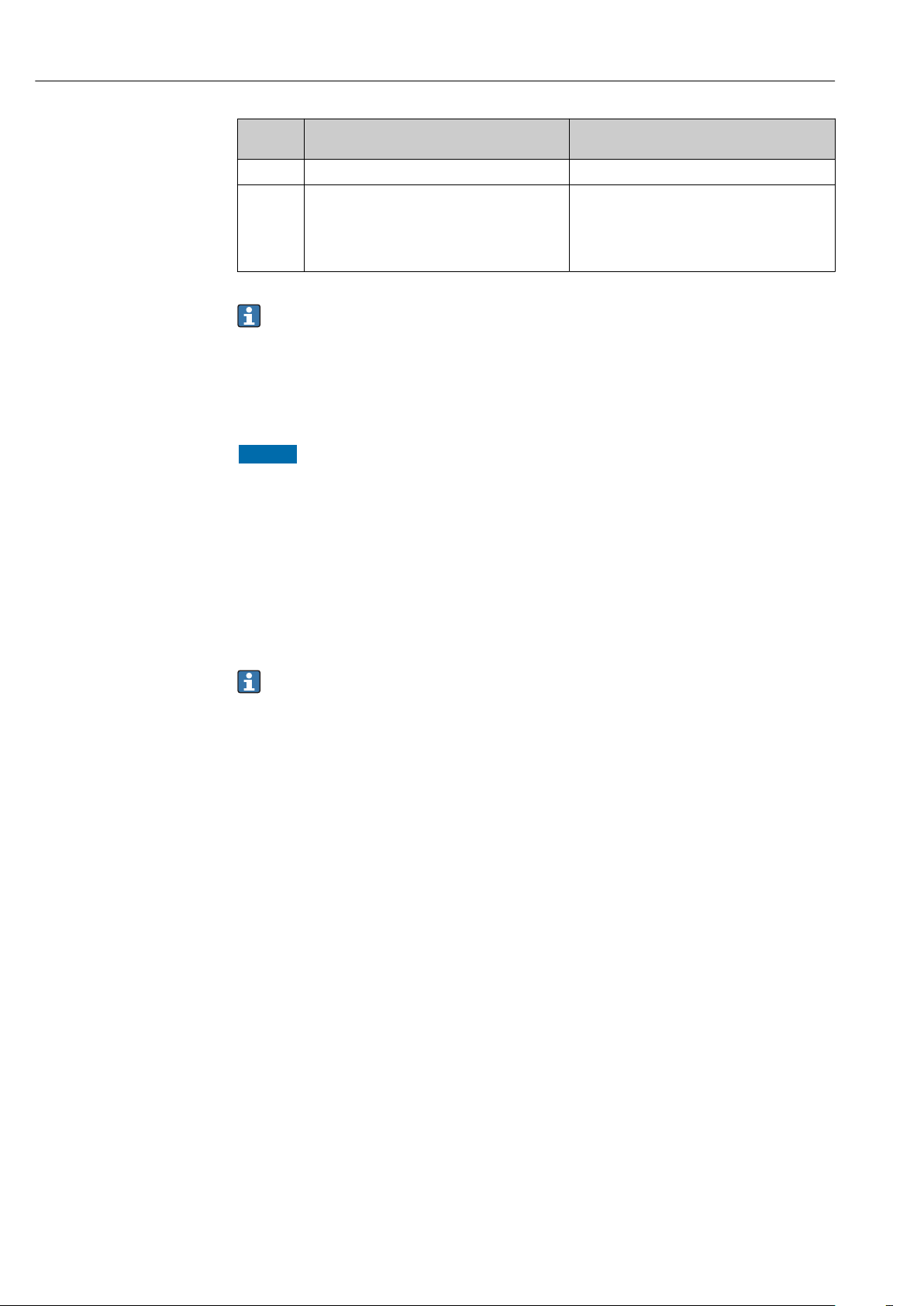

1.

2.

3.

4.

5.2 Mounting the assembly

The following instructions have to be followed for the proper installation of the device:

1.

A0028369

Place the gasket between the flanged nozzle and the flange of the device (after

checking the cleanliness of gasket seats on the flanges).

2. Bring the device to the nozzle, inserting the thermoelements or the thermoelements

bundle through the nozzle, avoiding interlacing and deformation of the same.

3.

A0028370

Start the bolts insertion through the flanges’ holes and tighten them with the nuts by

using a suitable wrench tool - but do not tighten them completely.

4.

A0028374

Complete the bolts insertion through the flanges’ holes and tight them with the

crossed method by means of an appropriate equipment (i.e. controlled tensioning

according to the applicable standards).

14 Endress+Hauser

Page 15

iTHERM MultiSens Flex TMS01 Mounting

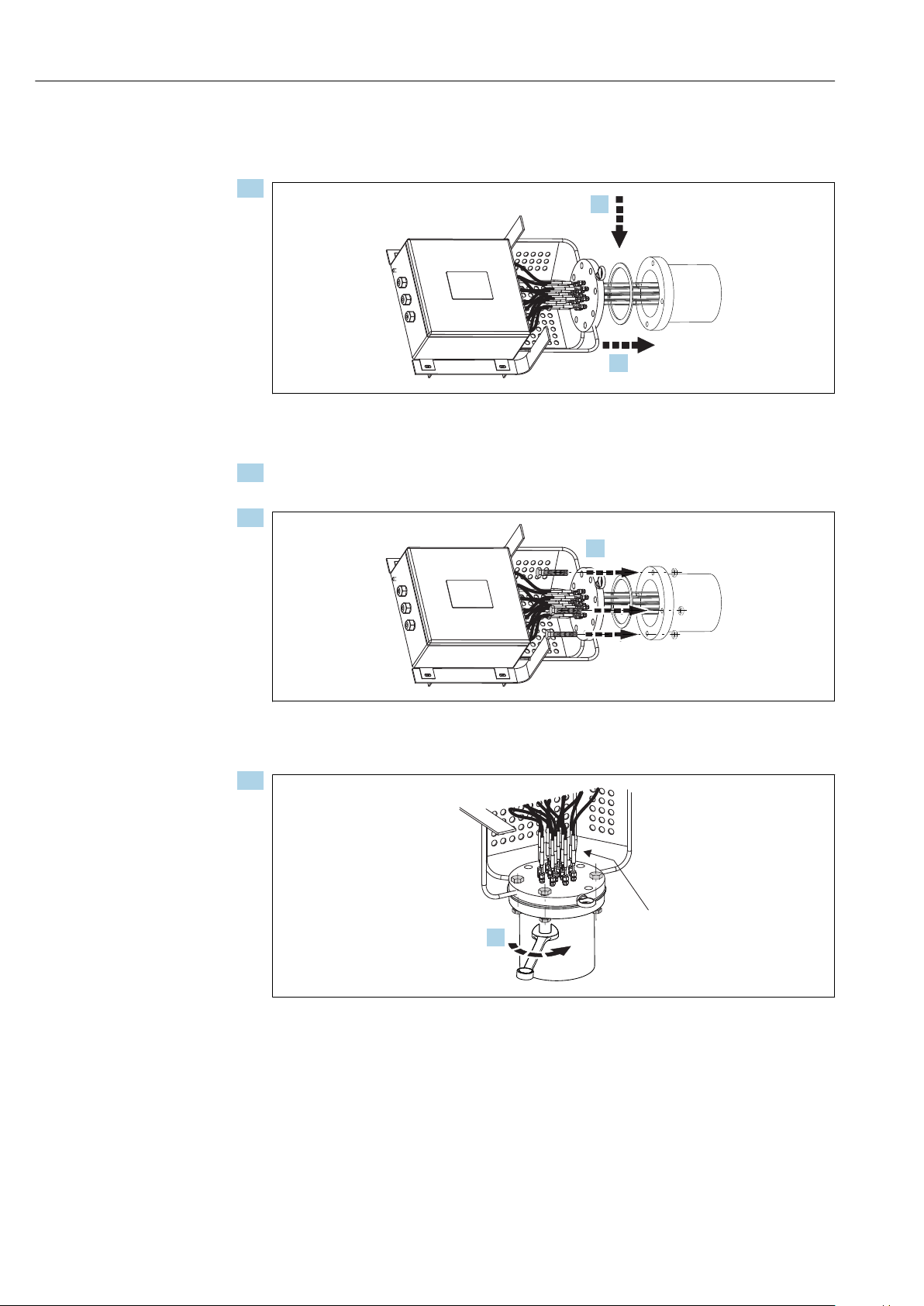

1 2 3 4

2

5.

1 Support frame

2 Fixing bar

3 Fixing clip

4 Inserts or protecting thermowells tip

A) For 3D installation fix all the inserts or thermowells to the support structures

(frame, bars, clips and all the accessories foreseen) according to drawings starting

from the tip fixing and bending the rest along its length. When the complete path is

defined, permanently fix the inserts or thermowells from the nozzle to the tip

having the chance to leave the extra-length close to the measuring point by means of

U or Ω curves (when necessary). Remark: Bend each probe with a minimum radius of

5 times its external diameter and fix it to the pre-mounted structures inside the

reactor by means of clips, tie wraps or welding it.

6. B) When installing in an existing thermowell, it is recommended to perform an

internal inspection of the thermowell. Check if there is any obstacle, with the aim of

making an easy insertion. While installing the measurement system, avoid any

friction during installation, specifically avoid sparks generation. Ensure that the

thermal contact between the tip end of the inserts or thermowells and the existing

thermowell wall is guaranteed. When accessories such as spacers and/or centered

rods are provided, make sure that no distortions can occur and that the original

geometry is maintained.

A0029266

Endress+Hauser 15

Page 16

Mounting iTHERM MultiSens Flex TMS01

+

+

-

-

+

+

-

-

+

+

-

-

7. 8.

7.

A0028375

In case of direct wiring completely introduce the extension or compensating cables

through the respective cable glands in the junction box.

8. Tighten the cable glands on the junction box.

9. After having opened the cover of the junction box, connect the compensating cables

to the terminals of the junction box following the wiring instruction provided,

ensuring the right matching between the cable tag numbers and the terminals tag

numbers.

10. Close the cover ensuring the right gasket position to avoid any impact on the IP

degree of protection.

11. In case of using the tube neck, check if all its components are still coupled properly

one each other.

The mounting of the assembly is completed.

NOTICE

After the mounting, perform few simple checks on the thermometric system

installed.

Check the tightness of the threaded connections. If any part is loosened, tight it

‣

applying the proper torque.

Check for correct wiring, test the electrical continuity of the thermocouples (warming

‣

up the thermocouple hot junction, when feasible) and then verify the absence of short

circuits.

5.3 Post-mounting check

Before commissioning the measuring system make sure that all final checks have been

carried out:

Device conditions and specifications

Is the device undamaged (visual inspection)?

Do the ambient conditions match the device specification?

For example:

• Ambient temperature

• Proper conditions

Are the threaded components undeformed?

Are the gaskets not permanently deformed?

Installation

16 Endress+Hauser

Is the equipment aligned with the nozzle axis?

Are the gasket seats of flanges clean?

Is the coupling between the flange and its counter flange reached?

Page 17

iTHERM MultiSens Flex TMS01 Mounting

Are the thermoelements not interlaced and undeformed?

Are the bolts completely inserted in the flange? Make sure the flange is completely attached to

the nozzle.

Are the thermoelements fixed to the support structures? → 15

Are the cable glands tightened on the extension cables?

Are the extension cables connected to the junction box terminals?

Endress+Hauser 17

Page 18

Wiring iTHERM MultiSens Flex TMS01

6 Wiring

CAUTION

L

Failure to observe this may result in destruction of parts of the electronics.

Switch off power supply before installing or connecting the device.

‣

When installing Ex-approved devices in a hazardous area please take special note of

‣

the instructions and connection schematics in the respective Ex documentation added

to these Operating Instructions. The local Endress+Hauser representative is available

for assistance if required.

When wiring to a transmitter also observe the wiring instructions in the enclosed

Brief Operating manuals of the relevant transmitter.

For wiring the device proceed as follows:

1. Open the housing cover on the junction box.

2. Open the cable glands on the sides of the junction box. → 16

3. Feed the cables through the opening in the cable glands.

4. Connect the cables as shown on → 18

5. On completion of the wiring, screw the screw terminals tight. Tighten the cable

glands again. In doing so, also pay particular attention to → 22. Close the

housing cover again.

6. In order to avoid connection errors always take note of the hints given in the post

connection check! → 22

6.1 Quick wiring guide

Terminal assignment

NOTICE

Destruction or malfunction of parts of the electronics through ESD - electrostatic

discharge.

Take measures to protect the terminals from electrostatic discharge.

‣

To avoid incorrect measuring values an extension or compensation cable for direct

wiring of thermocouple and RTD sensors for the signal transmission has to be used.

The polarity indication on the respective terminal block and the wiring scheme has to

be observed.

The planning and the installation of the bus connection cables of the plant is not to be

concerned of the manufacturer of the device. Therefore the manufacturer cannot be

considered to be responsible for possible damages due to the choice of materials that

are not suitable for that application or to a faulty installation.

18 Endress+Hauser

Page 19

iTHERM MultiSens Flex TMS01 Wiring

1

CHANNEL ERROR

COM/

ERR

1:

2:

3-8: Not Used

Write Lock

Simulate Enable

PWR

2 3 5 6 7 84

Do not open !

CH1

RTD

Ω

TC

mV

CH1...CH8

H

H

H

H

H

S

L

L

L

L

L

L

L

FOUNDATION

Fieldbus

TM

0032

0123456789101

1019876543210

TMT125-XXXXXXXX

Ser.No.:

TAG No.:

Order Code:

TMT125

PTB 05ATEX xxxxX

II 3G EEx nAII T4

II 3G EEx nLIIC T4

II (3)G [EEx nL] IICT4

PTB 05ATEX xxxx

II2 (1G/D)G EEx ia IICT4

II(1) GD [EEx ia ] IIC

-40°C<Ta < 70°C

FISCO according to IECTS 60079-27

DEVICE ID 452B4810CD-...

Avoid electrostatic charge!

inst. per XA056R/09/a3/XX.XX

-

LH

+

#

4-wire

2-wire

3-wire

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor input 2

Sensor input 1

RTD 4- and 3-wire:

RTD 3-wire:

Bus connection

and supply voltage

Display connection

red

white

red red

red

whitewhite

TC

TC

3 Wiring diagram of multi channel transmitter

4 Wiring diagram of the dual sensor input head transmitters (TMT8x)

A0006330-EN

A0016711-EN

Endress+Hauser 19

Page 20

Wiring iTHERM MultiSens Flex TMS01

3

5

6

RTD

3

4

5

6

RTD

1

2

TC

6

4

3-wire

4-wire

Power supply

head transmitter and

analog output 4 to 20 mA,

or bus connection

(red) (red)

(red) (red)

(white) (white)

(white)

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

1B

1B

1A

1A

A0016712-EN

5 Wiring diagram of the single sensor input head transmitters (TMT18x)

Thermocouple cable colors

According to IEC 60584 According to ASTM E230

• Type J: Black (+), white (-)

• Type K: Green (+), white (-)

• Type N: Pink (+), white (-)

• Type T: Brown (+), white (-)

• Type J: White (+), red (-)

• Type K: Yellow (+), red (-)

• Type N: Orange (+), red (-)

• Type T: Blue (+), red (-)

6.2 Connecting the sensor cables

Each sensor is marked with an individual TAG number. As default configuration, all

wires are always connected to the installed transmitters or terminals and generally

checked in house before final shipment.

The wiring is done in consecutive order, which means that the input channel(s) of

transmitter no. 1 are connected to the insert wires starting from insert no. 1. Transmitter

no. 2 is not used until all channels of transmitter no. 1 are fully connected. The wires of

each insert are marked with consecutive numbers starting from 1. If double sensors are

used the internal marking has a suffix to distinguish the two sensors, e.g. 1A and 1B for

double sensors in the same insert or measuring point no. 1.

20 Endress+Hauser

6 Direct wiring on the mounted terminal block. Example for the internal sensor wires marking with 2 x TC

sensors in insert no. 1.

A0033288

Page 21

iTHERM MultiSens Flex TMS01 Wiring

+

1

-

2

7

6

5

4

3

+

1

-

2

7

6

5

4

3

+

1

-

2

7

6

5

4

3

+

1

-

2

7

6

5

4

3

1B

1A

1A

1B

+

1

-

2

7

6

5

4

3

+

1

-

2

7

6

5

4

3

2

3

4

A0033289

7 Mounted and wired head transmitter. Example for the internal sensor wires marking with 2 x TC

Sensor type Transmitter type Wiring rule

1 x RTD or TC • Single input (one channel)

• Double input (two channel)

• Multi-channel input (8 channel)

2 x RTD or TC • Single input (one channel)

• Double input (two channel)

• Multi-channel input (8 channel)

• 1 Head transmitter per insert

• 1 Head transmitter for 2 inserts

• 1 Multi-channel transmitter for 8 inserts

• Not available, wiring excluded

• 1 Head transmitter per insert

• 1 Multi-channel transmitter for 4 inserts

6.3 Connecting the power supply and signal cables

Cable specification

• A shielded cable is recommended for fieldbus communication. Take the plant grounding

concept into consideration.

• The terminals for connecting the signal cable (1+ and 2-) are protected against reverse

polarity.

• Conductor cross-section:

– Max 2.5 mm2 (14 AWG) for screw terminals

– Max 1.5 mm2 (16 AWG) for spring terminals

Always observe the general procedure on → 18.

A0033290

8 Connecting the signal cable and power supply to the installed transmitter

1 External ground terminal

2 Terminals for signal cable and power supply

3 Internal ground terminal

4 Shielded signal cable, recommended for fieldbus connection

Endress+Hauser 21

Page 22

Wiring iTHERM MultiSens Flex TMS01

6.4 Shielding and grounding

For any specific electrical shielding and grounding regarding the transmitter wiring

please refer to the appropriate operating manual of the installed transmitter.

Where applicable, national installation regulations and guidelines must be observed

during the installation! Where there are large differences in potential between the

individual grounding points, only one point of the shielding is connected directly with the

reference ground. In systems without potential equalization, therefore, cable shielding of

fieldbus systems should only be grounded on one side, for example at the supply unit or at

safety barriers.

NOTICE

If the shielding of the cable is grounded at more than one point in systems without

potential matching, power supply frequency equalizing currents can occur that

damage the signal cable or have a serious effect on signal transmission.

In such cases the shielding of the signal cable is to be grounded on only one side, i.e. it

‣

must not be connected to the ground terminal of the housing (terminal head, field

housing). The shield that is not connected should be insulated!

6.5 Degree of protection

In order to fulfil the degree of protection after installation or service, the following points

must be taken into consideration: → 9, 22

• The housing seals must be clean and undamaged before they are replaced in the sealing

rebate. If they are found to be too dry, they should be cleaned or even replaced.

• All housing screws and covers must be tightened.

• The cables used for connection must be of the correct specified outside diameter (e.g.

M20 x 1.5, cable diameter from 0.315 to 0.47 in; 8 to 12 mm).

• Tighten cable gland or NPT fitting.

• Loop the cable or conduit before placing into the entry ("Water sack"). This means that

any moisture that may form cannot enter the gland. Install the device so that the cable

or conduit entries are not facing upwards.

• Entries not used are to be blanked off using the blanking plates provided.

• The protective grommet must not be removed from the NPT fitting.

A0011260

9 Connection hints to maintain IP protection

6.6 Post-connection check

Is the device undamaged (internal equipment inspection)?

Electrical connection

Does the supply voltage match the specifications on the nameplate? This depends on the

applicated transmitter.

Do the cables have adequate strain relief?

22 Endress+Hauser

Page 23

iTHERM MultiSens Flex TMS01 Wiring

Are the power supply and signal cables correctly connected? → 18

Are all the screw terminals well tightened and have the connections of the spring terminals been

checked?

Are all the cable glands installed, tightened and sealed?

Are all the housing covers installed and tightened?

Does the marking of the terminals and cables match?

Is the electrical continuity of the thermocouple verified?

Endress+Hauser 23

Page 24

Commissioning iTHERM MultiSens Flex TMS01

7 Commissioning

7.1 Preliminaries

Set-up guidelines of Standard, Extended and Advanced Commissioning for Endress

+Hauser instruments in order to guarantee the function of the instrument according to:

• Endress+Hauser operating manual

• Customer set up specification, and/or

• Application conditions, when applicable under process conditions

Both the operator and the person responsible for the process should be informed that a

commissioning job will be carried out, observing the following actions:

• If applicable, before disconnecting any sensor that is attached to the process, determine

what chemical or fluid is being measured (observe safety data sheet).

• Be aware of the temperature and pressure conditions.

• Never open a process fitting or loosen flange bolts before you have confirmed it is safe to

do so.

• Be sure not to disturb the process when disconnecting inputs/outputs or when

simulating signals.

• Ensure our tools, equipment and the customer process are protected from cross

contamination. Consider and plan necessary cleaning steps.

• When commissioning requires chemicals (e.g. as reagents for standard operation or for

cleaning purposes), always follow and observe the safety regulations.

7.1.1 Reference documents

• Endress+Hauser Standard Operating Procedure for Health and Safety (see

documentation code: BP01039H)

• Operating Manual of relevant tools and equipment to perform the commissioning job.

• Relevant Endress+Hauser Service Documentation (operating manual, work instructions,

service info, service manual, etc.).

• Calibration certificates of the quality relevant equipment if available.

• If applicable, safety data sheet.

• Customer specific documents (safety instructions, setup points, etc.).

7.1.2 Tools and equipment

Multimeter and instrument related configuration tools as necessary from the above

mentioned action list.

7.2 Function check

Before commissioning the device make sure that all final checks have been carried out

• "Post-mounting check” checklist → 16

• “Post-connection check” checklist → 22

The commissioning should be performed according to our commissioning segmentation

(Standard, Extended and Advanced).

7.2.1 Standard commissioning

Visual inspection of device

1. Check the instrument(s) for damage which may have been caused during transport/

shipping or mounting/wiring

2. Check that the installation is done according to the operating manual

24 Endress+Hauser

Page 25

iTHERM MultiSens Flex TMS01 Commissioning

3. Check that the wiring is done according to the operating manual and the local

regulations (e.g. grounding)

4. Check the dust/water tightness of the instrument(s)

5. Check safety precautions (e.g.. radiometric measurements)

6. Power up the instrument(s)

7. Check the alarm list if applicable

Environmental conditions

1. Check that the environmental conditions are appropriate for the instrument(s):

Ambient temperature, humidity (ingress protection IPxx), vibrations, hazardous

areas (Ex, Dust-Ex), RFI/EMC, sun protection, etc.

2. Check access to the instrument(s) for utilization and maintenance

Configuration parameters

Configure the instrument(s) according to the Operating Manual with the parameters

‣

specified by the customer or mentioned on the design specification

Output signal value check

Check and confirm that the local display and the output signals of the instrument(s)

‣

conform with the customer’s display

7.2.2 Extended commissioning

In addition to the steps of Standard Commissioning, the following should be additionally

completed:

Instrument Conformity

1. Check the received instrument(s) with the purchase order or design specification

including accessories, documentation and certificates

2. Check Software Version (e.g. application software such as “Batching”) when provided

3. Check that the documentation has the correct issue and version

Functional test

1. Test of the instrument outputs, including switching points, auxiliary inputs/outputs

with the internal or an external simulator (e.g. FieldCheck)

2. Compare the measuring data/results with a reference from the customer. (e.g.

laboratory result in case of an analyzer, weight scale in the case of a batching

application, etc.)

3. Adjust the instrument(s) if necessary and as described in the operating manual

7.2.3 Advanced commissioning

The Advanced Commissioning provides a loop test in addition to the steps covered in the

Standard and Extended Commissioning.

Loop test

1. Simulate a minimum of 3 output signals from the instrument(s) to the control room

2. Read out/note the simulated and indicated values and check for linearity

Endress+Hauser 25

Page 26

Diagnostics and troubleshooting iTHERM MultiSens Flex TMS01

7.3 Switching on the device

Once the final checks have been successfully completed, it is time to switch on the supply

voltage. Afterwards the multipoint thermometer is operational. If there are Endress

+Hauser temperature transmitter in use, please refer to the enclosed Brief Operating

Instructions for commissioning.

8 Diagnostics and troubleshooting

8.1 General troubleshooting

NOTICE

Repair of parts of the device

In the event of a serious fault, a measuring device might have to be replaced. In the

‣

case of replacement see section 'Return' → 27.

It is always important to check the connection between the cables and terminals, in

‣

order to guarantee the proper strain relief to the cables, and the tightening and the

sealing of the screw terminals.

Before commissioning the measuring system make sure that all final checks have been

carried out:

• Follow the checklist in section 'Post-mounting check' → 16

• Follow the checklist in section 'Post-connection check' → 22

If transmitters are used, please refer to the documentation of the transmitter installed for

diagnostic and troubleshooting procedures → 41.

26 Endress+Hauser

Page 27

iTHERM MultiSens Flex TMS01 Repair

9 Repair

9.1 General notes

The accessibility around the device for maintenance has to be guaranteed. Each

component that is part of the device must be – in the case of replacement – replaced by an

original spare part of Endress+Hauser which guarantees the same characteristics and

performance. To ensure continued operational safety and reliability it is suggested to carry

out repairs on the device only if they are expressly permitted by Endress+Hauser,

observing federal/national regulations pertaining to repair of an electrical device.

9.2 Spare parts

When ordering spare parts, please specify the serial number of the unit!

Spare parts of the Multipoint thermometer assembly are:

• Inserts

• Cable glands

• Transmitters or electrical terminals

• Junction box and related accessories

• Ferrule sets of the compression fittings

9.3 Endress+Hauser services

Service Description

Certifications Endress+Hauser is able to fulfill requirements belonging to the design, product

manufacturing, tests and commissioning according to specific approvals by

handling or suppling individual certified components and by checking the

integration on the whole system.

Maintenance All Endress+Hauser systems are designed for an easy maintenance due to a

modular design, allowing the replacement of old or wear out parts. Standardized

parts ensure fast reaction for maintenance.

Calibration Endress+Hauser’s range of calibration services covers on-site verification tests,

accredited laboratory calibrations, certificates and traceability to ensure

compliance.

Installation Endress+Hauser helps you commission plants while minimizing costs. Fault free

installation is decisive for the quality and longevity of the measurement system

and plant running. We provide the right expertise at the right time to meet

project deliverables.

Tests In order to ensure product quality and to guarantee efficiency during the entire

lifetime the following tests are available:

• Dye penetration test according to ASME V art. 6, UNI EN 571-1 and ASME VIII

Div. 1 App 8 standards

• PMI test accoding to ASTM E 572

• HE test according to EN 13185 / EN 1779

• X-ray test according to ASME V art. 2, art. 22 and ISO 17363-1 (requirements

and methods) and ASME VIII div. 1 and to ISO 5817 (acceptance criteria).

Thickness up to 30 mm

• Hydrostatic test according to PED Directive, EN 13445-5 and harmonized

• Ultrasonic test available by qualified external partners, according to ASME V

Art. 4

9.4 Return

The measuring device must be returned if it is need of repair or a factory calibration, or if

the wrong measuring device has been delivered or ordered. Legal specifications require

Endress+Hauser 27

Page 28

Repair iTHERM MultiSens Flex TMS01

Endress+Hauser, as an ISO-certified company, to follow certain procedures when handling

products that are in contact with the medium.

To ensure safe, swift and professional device returns, please refer to the procedure and

conditions for returning devices provided on the Endress+Hauser website at

http://www.endress.com/support/return-material

9.5 Disposal

9.5.1 Removing the measuring device

1. Switch off the device.

2.

WARNING

L

Danger to persons from process conditions.

Beware of hazardous process conditions such as pressure in the measuring device,

‣

high temperatures or aggressive fluids.

Carry out the mounting and connection steps from the chapters "Mounting the

measuring device" and "Connecting the measuring device" in the logically reverse

sequence. Observe the safety instructions.

9.5.2 Disposing of the measuring device

WARNING

L

Danger to personnel and environment from fluids that are hazardous to health.

Ensure that the measuring device and all cavities are free of fluid residues that are

‣

hazardous to health or the environment, e.g. substances that have permeated into

crevices or diffused through plastic.

Observe the following notes during disposal:

• Observe valid federal/national regulations.

• Ensure proper separation and reuse of the device components.

28 Endress+Hauser

Page 29

iTHERM MultiSens Flex TMS01 Accessories

1

2

1

2

3

10 Accessories

Various accessories, which can be ordered with the device or subsequently from Endress

+Hauser, are available for the device. Detailed information on the order code is available

from your local Endress+Hauser sales center.

10.1 Device-specific accessories

Accessories Description

Tip end

Terminal closure welded at the tip end of the probe in

order to protect the insert (or the thermowell) from

aggressive process conditions and to facilitate its fixing

by means of metallic tie wraps.

A0028427

Thermal contact system

Insert and spacers

1 Insert

2 Spacer

Guiding tubes and spacers

• Used on straight configurations and in case of an

existing thermowell for axial centering of the insert

bundle

• Prevent the twisting of the inserts

• Give flexural stiffness to the sensor bundle

A0033485

• Used on straight configurations and in case of an

existing thermowell for axial centering of the insert

bundle

• Give flexural stiffness to the sensor bundle

• Allow sensor replacement

• Guarantee thermal contact between the sensor tip and

the existing thermowell

• Modular design

1)

A0028783

1 Spacer

2 Guiding tube

3 Insert

Endress+Hauser 29

Page 30

Accessories iTHERM MultiSens Flex TMS01

1

2

1

2

3

Accessories Description

Thermowells and spacers

A0028434

1 Thermowell

2 Spacer

Bimetallic stripes

• Used on straight configurations and inside existing

thermowells

• Allow sensor replacement

• Guarantee thermal contact between the sensor tip and

the thermowell due to bimetallic stripes activated by

temperature difference

• No friction during installation even with already

installed sensors

A0028435

10 Bimetal strips with or without guiding tubes

1 Guiding tube

2 Insert

3 Bimetallic stripe

1) Can be mounted in-house or on-site

10.2 Communication-specific accessories

Configuration kit TXU10 Configuration kit for PC-programmable transmitter with setup software and

interface cable for PC with USB port

Order code: TXU10-xx

Commubox FXA195

HART

Commubox FXA291 Connects Endress+Hauser field devices with a CDI interface (= Endress+Hauser

HART Loop Converter

HMX50

For intrinsically safe HART communication with FieldCare via the USB interface.

For details, see "Technical Information" TI00404F

Common Data Interface) and the USB port of a computer or laptop.

For details, see "Technical Information" TI00405C

Is used to evaluate and convert dynamic HART process variables to analog current

signals or limit values.

For details, see "Technical Information" TI00429F and Operating Instructions

BA00371F

Wireless HART adapter

SWA70

Is used for the wireless connection of field devices.

The WirelessHART adapter can be easily integrated into field devices and existing

infrastructures, offers data protection and transmission safety and can be operated

in parallel with other wireless networks with minimum cabling complexity.

For details, see Operating Instructions BA061S

30 Endress+Hauser

Page 31

iTHERM MultiSens Flex TMS01 Accessories

Fieldgate FXA320 Gateway for the remote monitoring of connected 4-20 mA measuring devices via a

Web browser.

For details, see "Technical Information" TI00025S and Operating Instructions

BA00053S

Fieldgate FXA520 Gateway for the remote diagnostics and remote configuration of connected HART

measuring devices via a Web browser.

For details, see "Technical Information" TI00025S and Operating Instructions

BA00051S

Field Xpert SFX100 Compact, flexible and robust industry handheld terminal for remote configuration

and for obtaining measured values via the HART current output (4-20 mA).

For details, see Operating Instructions BA00060S

10.3 Service-specific accessories

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

• Graphic illustration of the calculation results

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

• Via the Internet: https://wapps.endress.com/applicator

• On CD-ROM for local PC installation.

W@M Life cycle management for your plant

W@M supports you with a wide range of software applications over the entire

process: from planning and procurement, to the installation, commissioning and

operation of the measuring devices. All the relevant device information, such as

the device status, spare parts and device-specific documentation, is available for

every device over the entire life cycle.

The application already contains the data of your Endress+Hauser device. Endress

+Hauser also takes care of maintaining and updating the data records.

W@M is available:

• Via the Internet: www.endress.com/lifecyclemanagement

• On CD-ROM for local PC installation.

FieldCare FDT-based plant asset management tool from Endress+Hauser.

It can configure all smart field units in your system and helps you manage them. By

using the status information, it is also a simple but effective way of checking their

status and condition.

For details, see Operating Instructions BA00027S and BA00059S

Endress+Hauser 31

Page 32

Technical data iTHERM MultiSens Flex TMS01

11 Technical data

11.1 Input

11.1.1 Measured variable

Temperature (temperature linear transmission behavior)

11.1.2 Measuring range

RTD:

Input Designation Measuring range limits

RTD as per IEC 60751 Pt100 –200 to +600 °C (–328 to +1 112 °F)

Thermocouple:

Input Designation Measuring range limits

Thermocouples (TC) as per IEC

60584, part 1 - using an

Endress+Hauser - iTEMP

temperature head transmitter

Type J (Fe-CuNi)

Type K (NiCr-Ni)

Type N (NiCrSi-NiSi)

Type T (Cu-CuNi)

Internal cold junction (Pt100)

Cold junction accuracy: ± 1 K

Max. sensor resistance: 10 kΩ

–210 to +720 °C (–346 to +1 328 °F)

–270 to +1 150 °C (–454 to +2 102 °F)

–270 to +1 100 °C (–454 to +2 012 °F)

–270 to +370 °C (–454 to +698 °F)

Thermocouples (TC) - flying

leads - as per IEC 60584 and

ASTM E230

1) Limited by jacket material of insert

Type J (Fe-CuNi)

Type K (NiCr-Ni)

Type N (NiCrSi-NiSi)

Type T (Cu-CuNi)

–270 to +720 °C (–454 to +1 328 °F), typical

sensitivity above 0 °C ≈ 55 μV/K

–270 to +1 150 °C (–454 to +2 102 °F)

sensitivity above 0 °C ≈ 40 μV/K

–270 to +1 100 °C (–454 to +2 012 °F), typical

sensitivity above 0 °C ≈ 40 μV/K

–270 to +370 °C (–454 to +698 °F), typical sensitivity

above 0 °C ≈ 43 μV/K

1)

, typical

11.2 Output

11.2.1 Output signal

Generally, the measured value can be transmitted in one of two ways:

• Directly-wired sensors - sensor measured values forwarded without a transmitter.

• Via all common protocols by selecting an appropriate Endress+Hauser iTEMP

temperature transmitter. All the transmitters listed below are mounted directly in the

junction box and wired with the sensory mechanism.

11.2.2 Family of temperature transmitters

Thermometers fitted with iTEMP transmitters are an installation-ready complete solution

to improve temperature measurement by significantly increasing accuracy and reliability,

when compared to direct wired sensors, as well as reducing both wiring and maintenance

costs.

PC programmable head transmitters

They offer a high degree of flexibility, thereby supporting universal application with low

inventory storage. The iTEMP transmitters can be configured quickly and easily at a PC.

32 Endress+Hauser

Page 33

iTHERM MultiSens Flex TMS01 Technical data

Endress+Hauser offers free configuration software which can be downloaded from the

Endress+Hauser Website. More information can be found in the Technical Information.

HART® programmable head transmitters

The transmitter is a 2-wire device with one or two measuring inputs and one analog

output. The device not only transfers converted signals from resistance thermometers and

thermocouples, it also transfers resistance and voltage signals using HART

®

communication. It can be installed as an intrinsically safe apparatus in Zone 1 hazardous

areas and is used for instrumentation in the terminal head (flat face) as per DIN EN

50446. Swift and easy operation, visualization and maintenance by PC using operating

software, Simatic PDM or AMS. For more information, see the Technical Information.

PROFIBUS® PA head transmitters

Universally programmable head transmitter with PROFIBUS® PA communication.

Conversion of various input signals into digital output signals. High accuracy over the

complete ambient temperature range. Swift and easy operation, visualization and

maintenance using a PC directly from the control panel, e. g. using operating software,

Simatic PDM or AMS. For more information, see the Technical Information.

FOUNDATION Fieldbus™ head transmitters

Universally programmable head transmitter with FOUNDATION Fieldbus™

communication. Conversion of various input signals into digital output signals. High

accuracy over the complete ambient temperature range. Swift and easy operation,

visualization and maintenance using a PC directly from the control panel, e.g. using

operating software such as ControlCare from Endress+Hauser or NI Configurator from

National Instruments. For more information, see the Technical Information.

Advantages of the iTEMP transmitters:

• Dual or single sensor input (optionally for certain transmitters)

• Unsurpassed reliability, accuracy and long-term stability in critical processes

• Mathematical functions

• Monitoring of the thermometer drift, sensor backup functionality, sensor diagnostic

functions

• Sensor-transmitter matching for dual sensor input transmitter, based on Callendar/Van

Dusen coefficients

11.3 Environment

11.3.1 Ambient temperature range

Junction box Non-hazardous area Hazardous area

Without mounted transmitter –50 to +85 °C (–58 to +185 °F) –50 to +60 °C (–58 to +140 °F)

With mounted head

transmitter

With mounted multi-channel

transmitter

11.3.2 Storage temperature

Junction box

With head transmitter –50 to +95 °C (–58 to +203 °F)

With multi-channel transmitter –40 to +80 °C (–40 to +176 °F)

With DIN rail transmitter –40 to +95 °C (–40 to +203 °F)

–40 to +85 °C (–40 to +185 °F) Depends on the respective hazardous area

approval. Details see Ex documentation.

–40 to +85 °C (–40 to +185 °F) –40 to +70 °C (–40 to +158 °F)

Endress+Hauser 33

Page 34

Technical data iTHERM MultiSens Flex TMS01

11.3.3 Humidity

Condensation according to IEC 60068-2-33:

• Head transmitter: Permitted

• DIN rail transmitter: Not permitted

Maximum relative humidity: 95% according to IEC 60068-2-30

11.3.4 Climate class

Determined when the following components are installed into the junction box:

• Head transmitter: Class C1 according to EN 60654-1

• Multi-channel transmitter: Tested as per IEC 60068-2-30, meets the requirements

regarding class C1-C3 in accordance with IEC 60721-4-3

• Terminal blocks: Class B2 according to EN 60654-1

11.3.5 Degree of protection

• Specification for conduit: IP68

• Specification for the junction box: IP66/67

11.3.6 Electromagnetic compatibility (EMC)

Depending on the head transmitter used. For detailed information see the related

Technical Information, listed at the end of this document.

11.4 Mechanical construction

11.4.1 Design, dimensions

The overall multipoint assembly is composed of different sub-assemblies. Both linear and

3D configurations have the same features, dimensions and materials. Different inserts are

available, based upon specific process conditions, in order to have the highest accuracy and

an extended lifetime. In addition, protecting thermowells can be selected to further

increase mechanical performances and corrosion resistance, and to allow insert

replacement. Associated shielded extension cables are provided with high resistance

sheath materials to withstand different environmental conditions and to ensure steady

and noiseless signals. The transition between the inserts and the extension cable is

obtained by the usage of specially sealed bushings, ensuring the declared IP degree

protection.

34 Endress+Hauser

Page 35

iTHERM MultiSens Flex TMS01 Technical data

F

B

I

H

A

C

L

L

MPx

MPx

I

H

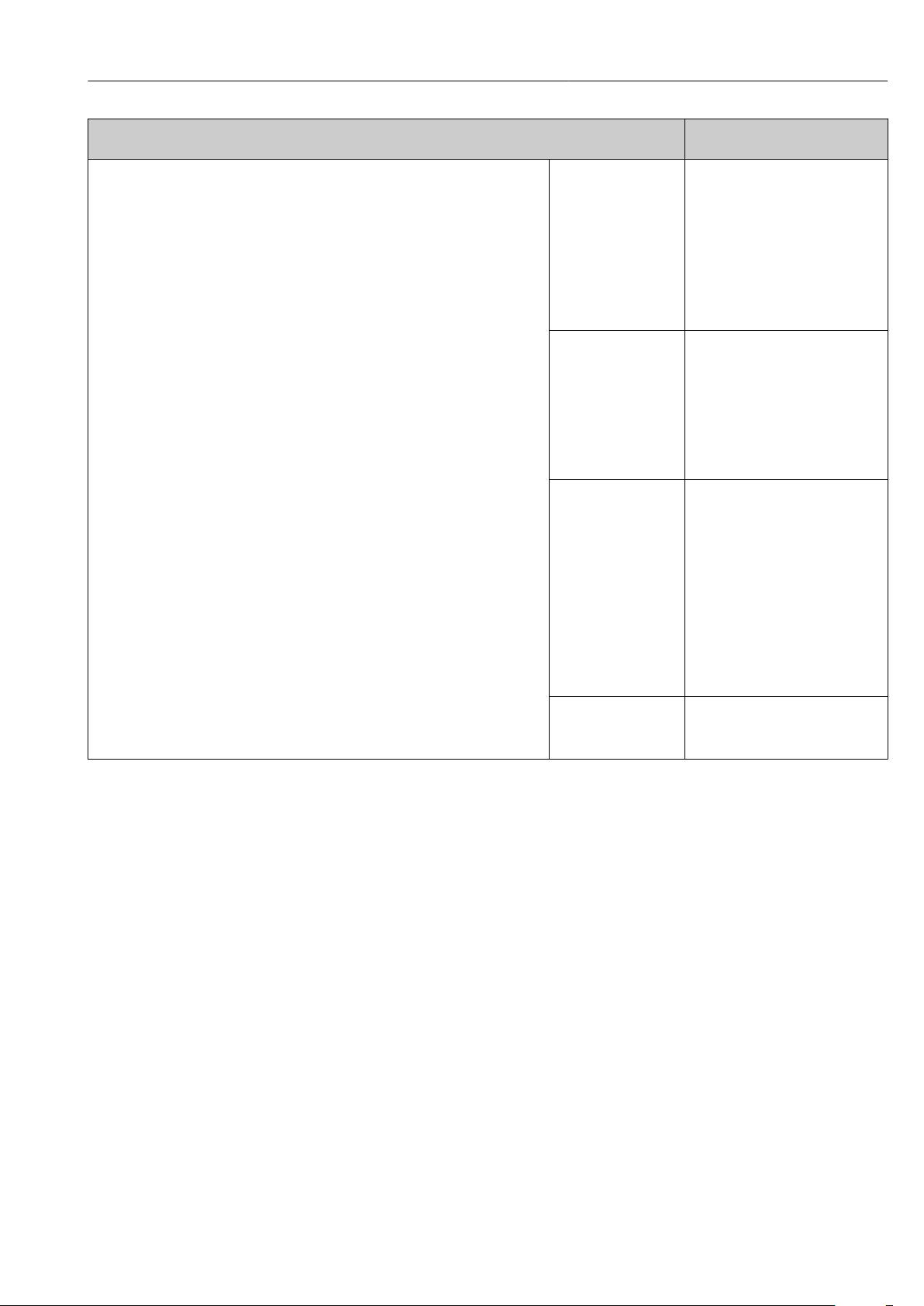

11 Design of the modular multipoint thermometer, with frame neck on the left side or with frame neck and

covers on the right side. All dimensions in mm (in)

A, B,CDimensions of the junction box, see following figure

MPx Numbers and distribution of measuring points: MP1, MP2, MP3 etc.

L

Different immersion length of sensing elements or thermowells

MPx

I, H Encumbrance of the junction box and support system

F Extension neck length

L Overall device length

Extension neck F in mm (in)

Standard 250 (9.84)

Specifically customized extension necks are available on request.

A0028080

Immersion lengths MPx of sensing elements/thermowells:

Based on customer requirements

Endress+Hauser 35

Page 36

Technical data iTHERM MultiSens Flex TMS01

A

B

C

Junction box

A0028118

1 Cable glands

2 Junction box

3 Frame

The junction box is suited for chemical agents environments. Sea water corrosion

resistance and extreme temperature variation stability is guaranteed. Ex-e Ex-i terminals

can be installed.

Possible junction box dimensions (A x B x C) in mm (in):

A B C

Stainless Steel Min. 170 (6.7) 170 (6.7) 130 (5.1)

Max. 500 (19.7) 500 (19.7) 240 (9.5)

Aluminium Min. 100 (3.9) 150 (5.9) 80 (3.2)

Max. 330 (13) 500 (19.7) 180 (7.1)

Type of specification Junction box Cable glands

Material AISI 316 NiCr Plated brass

AISI 316 / 316L

Ingress protection (IP) IP66/67 IP66

Ambient temperature range

(ATEX)

Approvals ATEX, FM, UL, CSA approval

Marking ATEX II 2GD Ex e IIC/Ex ia Ga

Cover Hinged -

Maximum sealing diameter - 6 to 12 mm (0.24 to 0.47 in)

–50 to +60 °C

(–58 to +140 °F)

for use in hazardous area

IIC Ex tb IIIC Db T6/T5/T4

UL913 Class I, Division 1

Groups B,C,D T6/T5/T4

FM3610 Class I, Division 1

Groups B,C,D T6/T5/T4

CSA C22.2 No.157 Class

I,Division 1 Groups B,C,D

T6/T5/T4

–52 to +110 °C (–61.1 to +140 °F)

-

According to the junction box approval

36 Endress+Hauser

Page 37

iTHERM MultiSens Flex TMS01 Technical data

Neck extension

The neck extension ensures the connection between the flange and the junction box. The

design has been developed to ensure several mounting layouts to deal with possible

obstacles and constraints that can be met in any plant such as the reactor’s infrastructure

(step ways, loading structures, supporting skirts, stairs, etc.) and reactor thermal

insulation. The neck extension design ensures easy access for monitoring and maintaining

inserts and extension cables. It guarantees a high stiffness connection for the junction box

and vibration loads. No closed volumes are present in the neck extension. This avoids the

accumulation of waste and potentially dangerous fluids coming from the environment that

can damage the instrumentation allowing continuous ventilation.

Insert and thermowells

Different insert and thermowell types are available. For any different requirement

that is not described here, please contact the Endress+Hauser sales department.

Thermocouple

Diameter in mm (in) Type Standard Hot junction type Sheath material

1x type K

6 (0.24)

4.5 (0.18)

3 (0.12)

2 (0.08)

1.5 (0.06)

2x type K

1x type J

2x type J

1x type N

2x type N

1x type T

2x type T

IEC 60584 /ASTM E230 Grounded/Ungrounded Alloy600 / AISI 316L

RTD

Diameter in mm (in) Type Standard Sheath material

1x Pt100 WW

3 (0.12)

6 (¹⁄₄)

2x Pt100 WW

1x Pt100 TF

2x Pt100 TF

IEC 60751 AISI 316L

Thermowells

External diameter in mm (in) Sheath material Type Thickness in mm (in)

6 (0.24)

8 (0.32)

10.2 (¹⁄₈)

AISI 316L or

AISI 321 or

AISI 347 or

Alloy 600

AISI 316L or

AISI 321 or

AISI 347 or

Alloy 600

AISI 316L or

AISI 321 or

AISI 347 or

Alloy 600

closed or open

closed or open

closed or open

1 (0.04) or

1.5 (0.06)

1 (0.04) or

1.5 (0.06) or

2 (0.08)

1.73 (0.068)

11.4.2 Weight

The weight can vary depending on the configuration: Dimension and content of the

junction box, neck length, dimensions of process connection and the number of inserts.

The approximate weight of a typically configured multipoint thermometer (number of

inserts = 12, flange size = 3", medium size junction box) = 40 kg (88 lb)

Endress+Hauser 37

Page 38

Technical data iTHERM MultiSens Flex TMS01

11.4.3 Materials

It refers to insert sheath, neck extension, junction box and all wetted parts.

The temperatures for continuous operation specified in the following table are only

intended as reference values for use of the various materials in air and without any

significant compressive load. The maximum operation temperatures are reduced

considerably in some cases where abnormal conditions such as high mechanical load occur

or in aggressive media.

Material

name

AISI

316/1.4401

AISI 316L/

1.4404

1.4435

Alloy600/

2.4816

AISI

304/1.4301

AISI 304L/

1.4307

AISI 316Ti/

1.4571

Short form Recommended

max.

temperature for

continuous use

in air

X5CrNiMo 17-12-2 650 °C (1 202 °F) • Austenitic, stainless steel

X2CrNiMo17-12-2

X2CrNiMo18-14-3

NiCr15Fe 1 100 °C

X5CrNi18-10 850 °C (1 562 °F) • Austenitic, stainless steel

X2CrNi18-9 850 °C (1 562 °F) • Good welding properties

X6CrNiMoTi17-12-2 700 °C (1 292 °F) • Addition of titanium means increased resistance

650 °C (1 202 °F) • Austenitic, stainless steel

(2 012 °F)

Properties

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorinebased and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g.

phosphoric and sulfuric acids, acetic and tartaric

acids with a low concentration)

• Increased resistance to intergranular corrosion

and pitting

• Compared to 1.4404, 1.4435 has even higher

corrosion resistance and a lower delta ferrite

content

• A nickel/chromium alloy with very good

resistance to aggressive, oxidizing and reducing

atmospheres, even at high temperatures

• Resistance to corrosion caused by chlorine gases

and chlorinated media as well as many oxidizing

mineral and organic acids, sea water etc.

• Corrosion from ultrapure water

• Not to be used in sulfur-containing atmospheres

• Well usable in water and lowly pollute waste

water

• Only at relatively low temperatures resistant to

organic acids, saline solutions, sulphates,

alkaline solutions, etc.

• Impervious to intergranular corrosion

• High ductility, excellent drawing, forming, and

spinning properties

to intergranular corrosion even after welding

• Broad range of uses in the chemical,

petrochemical and oil industries as well as in coal

chemistry

• Can only be polished to a limited extent, titanium

streaks can form

38 Endress+Hauser

Page 39

iTHERM MultiSens Flex TMS01 Technical data

1

2

3

Material

name

AISI

321/1.4541

AISI

347/1.4550

Short form Recommended

max.

temperature for

continuous use

in air

X6CrNiTi18-10 815 °C (1 499 °F) • Austenitic stainless steel

X6CrNiNb10-10 800 °C (1 472 °F) • Austenitic stainless steel

11.4.4 Process connection

Properties

• High resistance to intergranular corrosion even

after welding

• Good welding characteristics, suitable to all

standard welding methods

• It is used in many sectors of the chemical

industry, petrochemical, and pressurized vessels

• Good resistance to a wide variety of

environments in the chemical, textile, oilrefining, dairy and food industries

• Added niobium makes this steel impervious to

intergranular corrosion

• Good weldability

• Main applications are furnace fire walls, pressure

vessels, welded structures, turbine blades

A0028122

12 Flange as process connection

1 Flange

2 Compression fittings

3 Eyebolt

Standard process connection flanges are designed according to the following standards:

Standard

ASME 1½”, 2”, 3”, 4”, 6”, 8” 150#, 300#, 600# AISI 316, 316L, 304, 304L, 316Ti,

EN DN40, DN50, DN80, DN100,

1) Flanges according to GOST standard are available on request.

1)

Size Rating Material

PN10,PN16, PN40, PN63,

DN150, DN200

PN100

321, 347

Compression fittings

The compression fittings are welded or threaded into the flange to ensure tightness to the

process connection. Dimensions are coherent with the insert dimensions. Compression

fittings comply with the highest standards of reliability in terms of materials and

performances required.

Material AISI 316/316H

Endress+Hauser 39

Page 40

Technical data iTHERM MultiSens Flex TMS01

11.5 Certificates and approvals

11.5.1 CE Mark

The complete assembly is provided with individual components CE marked, to ensure safe

use in hazardous areas and pressurized environments.

11.5.2 Hazardous area approvals

The Ex approval applies to individual components like junction box, cable glands,

terminals. For further details on the available Ex versions (ATEX, UL, FM, CSA, IEC-EX,

NEPSI, EAC-EX), please contact your nearest Endress+Hauser sales organization. All

relevant data for hazardous areas can be found in separate Ex documentation.

ATEX Ex ia inserts are available only for diameters ≥ 1.5 mm (0.6 in). For further details

contact an Endress+Hauser technician.

11.5.3 Certification HART

The HART® temperature transmitter is registered by the FieldComm Group. The device

meets the requirements of the HART® Communication Protocol Specifications.

11.5.4 Certification FOUNDATION Fieldbus

The FOUNDATION Fieldbus™ temperature transmitter has successfully passed all test

procedures and is certified and registered by the Fieldbus Foundation. The device thus

meets all the requirements of the following specification:

• Certified according to FOUNDATION Fieldbus™ specification

• FOUNDATION Fieldbus™ H1

• Interoperability Test Kit (ITK), up to date revision status (device certification no.

available on request): the device can also be operated with certified devices of other

manufacturers

• Physical layer conformance test of the FOUNDATION Fieldbus™

11.5.5 Certification PROFIBUS® PA

The PROFIBUS® PA temperature transmitter is certified and registered by the PNO

(PROFIBUS® Nutzerorganisation e. V.), PROFIBUS user organization. The device meets all

the requirements of the following specifications:

• Certified according to FOUNDATION Fieldbus™ specification

• Certified in accordance with PROFIBUS® PA Profile (the up to date profile version is

available on request)

• The device can also be operated with certified devices of other manufacturers

(interoperability)

11.5.6 Other standards and guidelines

• EN 60079: ATEX certification for hazardous areas

• IEC 60529: Degree of protection of housing (IP code)

• IEC 60584 and ASTM E230/ANSI MC96.1: Thermocouples

11.5.7 Material certification

The material certificate 3.1 (according to EN 10204) can be requested separately. The