Page 1

BA01581T/09/EN/03.18

71413053

2018-08-20

Valid as of version

01.00 (device version)

Products Solutions Services

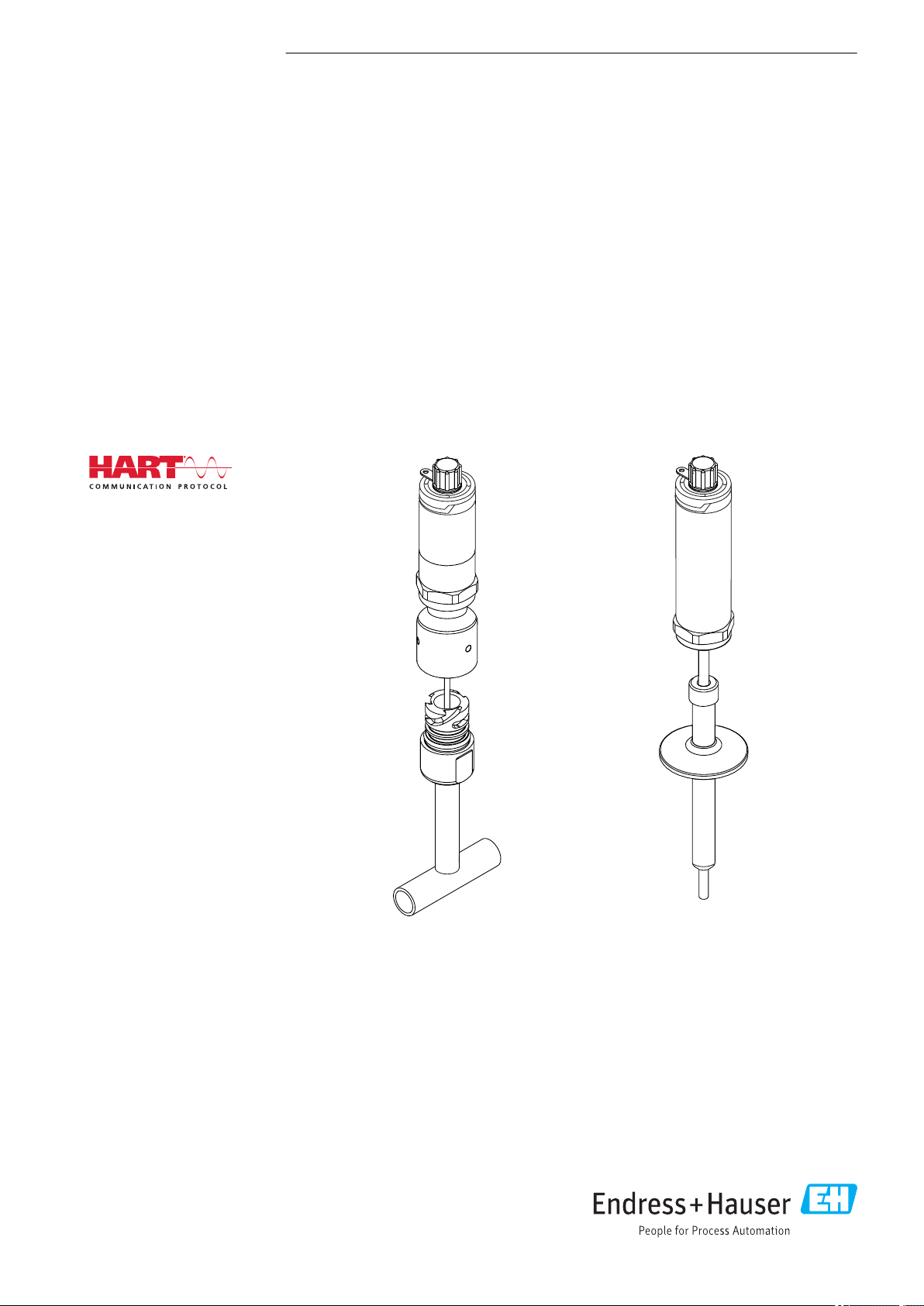

Operating Instructions

iTHERM TrustSens TM371,

TM372

Compact thermometer with self-calibration

Page 2

Page 3

iTHERM TrustSens TM371, TM372 Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Symbols .............................. 4

1.3 Documentation ........................ 5

2 Basic safety instructions ............ 6

2.1 Requirements for personnel ............... 6

2.2 Intended use .......................... 6

2.3 Operation safety ....................... 6

2.4 Product safety ......................... 6

3 Incoming acceptance and product

identification ....................... 7

3.1 Incoming acceptance .................... 7

3.2 Product identification .................... 7

3.3 Transport and storage ................... 9

4 Mounting ......................... 10

4.1 Mounting conditions ................... 10

4.2 Mounting the measuring device ........... 10

4.3 Post-mounting check ................... 13

9 Diagnostics and troubleshooting ... 35

9.1 Troubleshooting ...................... 35

9.2 Diagnostic information via LEDs ........... 35

9.3 Diagnostic information ................. 36

9.4 Overview of diagnostics events ............ 37

9.5 Diagnostic list ........................ 39

9.6 Event logbook ........................ 39

9.7 Firmware history ...................... 39

10 Maintenance ...................... 40

10.1 Cleaning ............................ 40

11 Repair ............................ 41

11.1 Spare parts .......................... 41

11.2 Return .............................. 41

11.3 Disposal ............................ 41

12 Accessories ....................... 42

12.1 Device-specific accessories ............... 42

12.2 Communication-specific accessories ........ 45

12.3 Service-specific accessories ............... 46

12.4 System components .................... 47

5 Electrical connection .............. 14

5.1 Connecting requirements ................ 14

5.2 Connecting the device .................. 14

5.3 Ensuring the degree of protection .......... 14

5.4 Post-connection check .................. 15

6 Operability ........................ 15

6.1 Overview of operation options ............ 15

6.2 Structure and function of the operating

menu .............................. 16

6.3 Access to the operating menu via an

operating tool ........................ 17

7 System integration ................ 21

7.1 Overview of device description files ......... 21

7.2 Measured variables via HART protocol ...... 21

7.3

Supported HART® commands ............. 22

8 Commissioning .................... 24

8.1 Function check ....................... 24

8.2 Switching on the measuring device ......... 24

8.3 Configuring the measuring device .......... 24

8.4 Creating a calibration report .............. 26

8.5 Protecting settings from unauthorized

access .............................. 28

8.6 Advanced settings ..................... 29

13 Technical Data .................... 47

13.1 Input ............................... 47

13.2 Output ............................. 47

13.3 Wiring ............................. 48

13.4 Performance characteristics .............. 49

13.5 Environment ......................... 53

13.6 Mechanical construction ................ 54

13.7 Certificates and approvals ............... 72

14 Operating menu and parameter

description ........................ 74

14.1 Setup menu .......................... 78

14.2 Calibration menu ...................... 79

14.3 Diagnostics menu ..................... 83

14.4 Expert menu ......................... 92

Endress+Hauser 3

Page 4

About this document iTHERM TrustSens TM371, TM372

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

4 Endress+Hauser

Page 5

iTHERM TrustSens TM371, TM372 About this document

,…,

Symbol Meaning

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.4 Tool symbols

Symbol Meaning

Open-ended wrench

A0011222

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• W@M Device Viewer (www.endress.com/deviceviewer): Enter the serial number

from nameplate

• Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2D matrix code (QR code) on the nameplate

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Brief Operating Instructions Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

1.3.2 Supplementary device-dependent documentation

Additional documents are supplied depending on the device version ordered: Always

comply strictly with the instructions in the supplementary documentation. The

supplementary documentation is an integral part of the device documentation.

Endress+Hauser 5

Page 6

Basic safety instructions iTHERM TrustSens TM371, TM372

2 Basic safety instructions

2.1 Requirements for personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Are instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Intended use

• The device is a compact thermometer for the acquisition and conversion of temperature

input signals for industrial temperature measurement.

• The manufacturer is not liable for damage caused by improper or non-intended use.

2.3 Operation safety

NOTICE

Operation safety

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repair

Due to its design, the device cannot be repaired.

However, it is possible to send the device in for examination.

‣

To ensure continued operational safety and reliability, use original spare parts and

‣

accessories from Endress+Hauser only.

2.4 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

6 Endress+Hauser

Page 7

iTHERM TrustSens TM371, TM372 Incoming acceptance and product identification

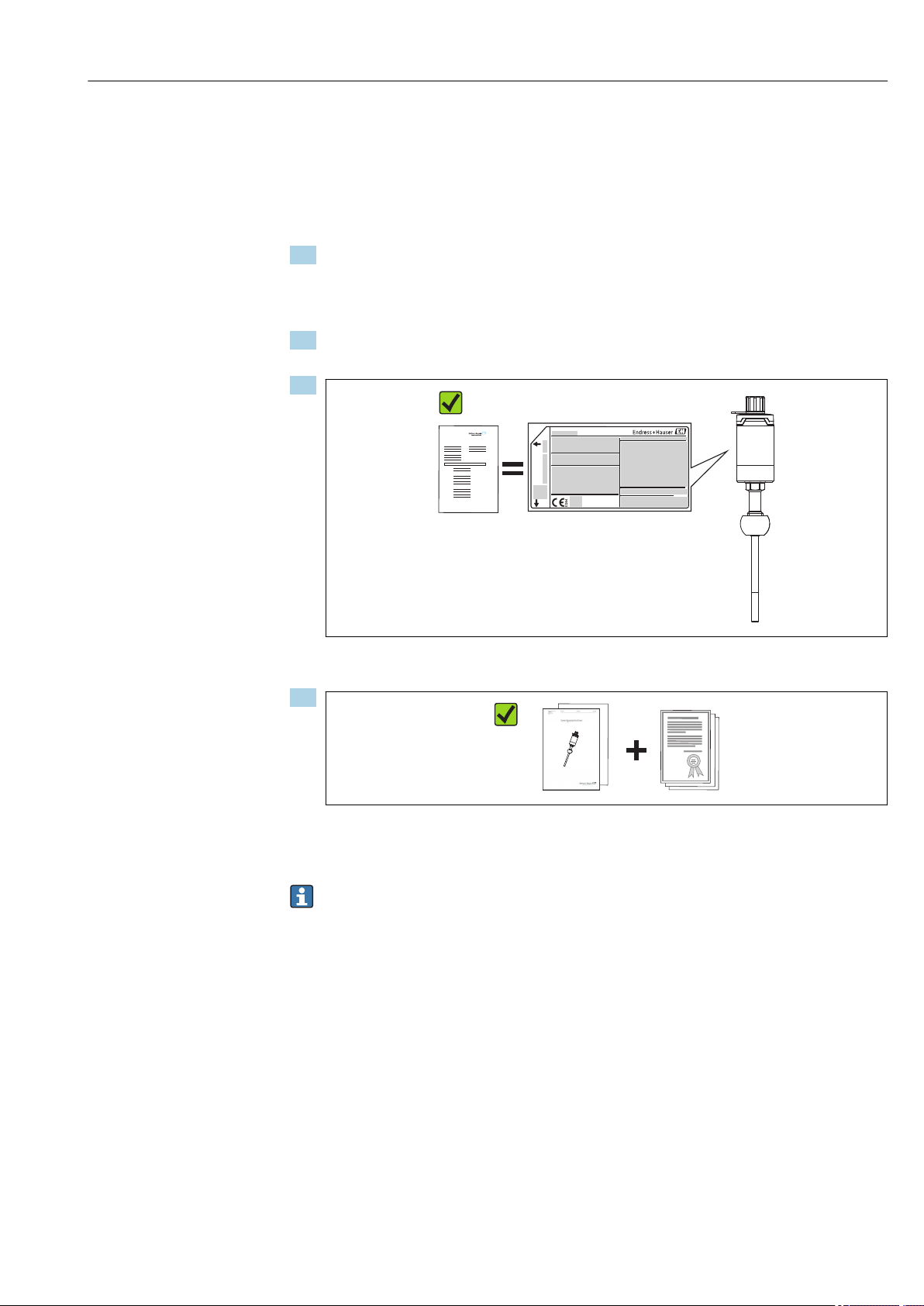

DELIVERYNOTE

TMT162

TrustSens

TM371, 372

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

1. Unpack the device carefully. Is the packaging or content damaged?

The damaged content must not be installed; in those conditions the

manufacturer cannot guarantee the original safety requirements or the material

resistance and cannot be considered as responsible for any consequent damages.

2. Is the delivery complete? Compare the scope of delivery against the information on

your order form.

3.

Do the nameplate data match the ordering information on the delivery note?

4.

Are the technical documentation and additional documents (e.g. certificates)

present?

If one of the conditions does not comply, contact your Endress+Hauser distributor.

3.2 Product identification

The following options are available for identification of the device:

• Nameplate specifications

• Enter the serial number from the nameplate in the W@M Device Viewer

(www.endress.com/deviceviewer): All data relating to the device and an overview of

the Technical Documentation supplied with the device are displayed.

A0028503

A0028522

Endress+Hauser 7

Page 8

Incoming acceptance and product identification iTHERM TrustSens TM371, TM372

Input:

1

2

3

4

5

6

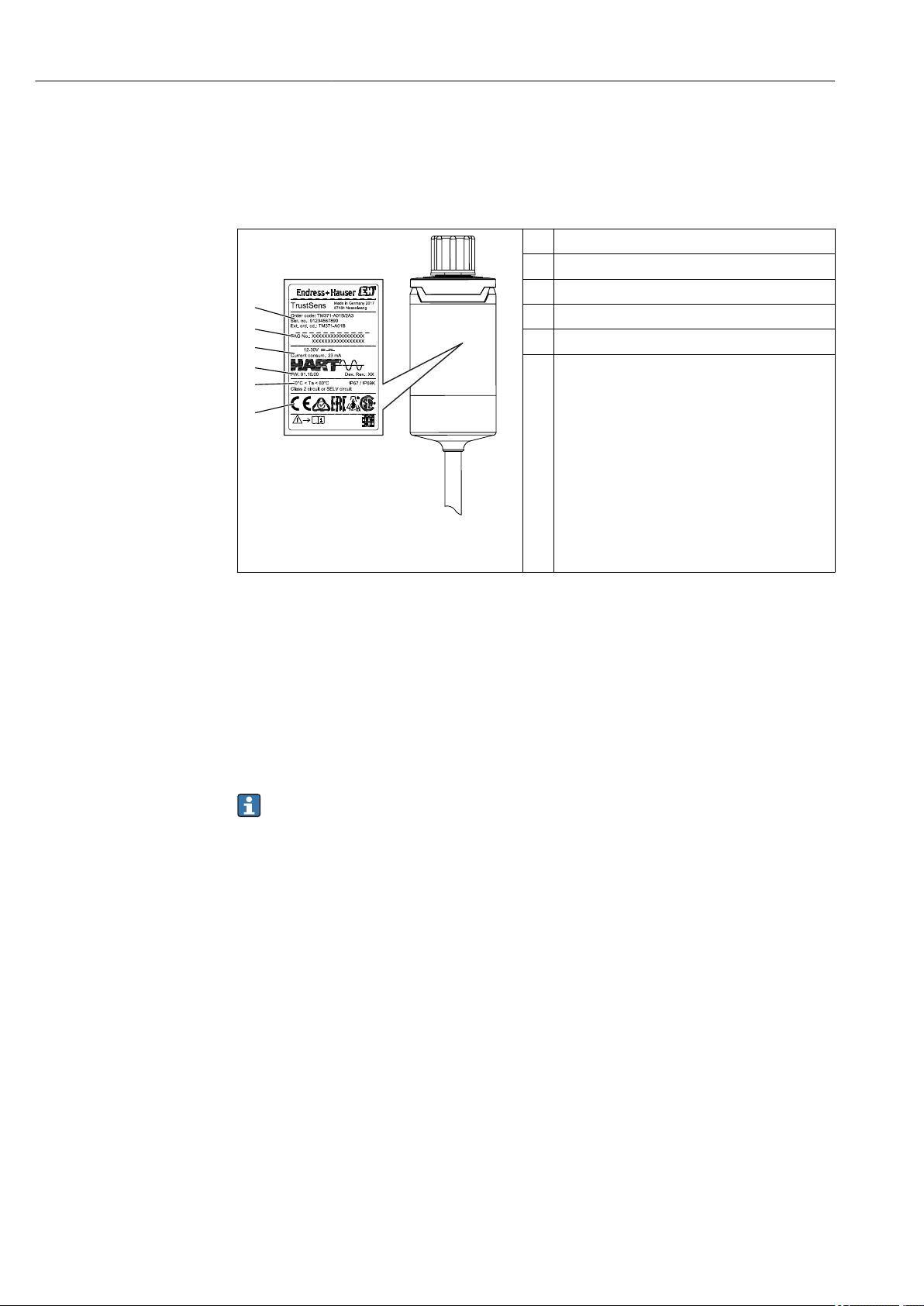

3.2.1 Nameplate

Is this the correct device?

Compare and check the data on the nameplate of the device against the requirements of the

measuring point:

1 Order code, serial number

2 Device TAG name

3 Supply voltage and current consumption

4 Device revision and firmware version

5 Ambient temperature

6 Approvals with symbols

A0033853

1 Nameplate of the compact thermometer

(example)

3.2.2 Scope of delivery

The scope of delivery comprises:

• Compact thermometer

• Hard copy of multi-language Brief Operating Instructions

• Ordered accessories

3.2.3 Certificates and approvals

An overview of further approvals and certifications is provided in the ’Technical data’

section. → 72

CE/EAC mark, declaration of conformity

The device meets the legal requirements of the EU/EEU guidelines. The manufacturer

confirms that the device is compliant with the relevant guidelines by applying the CE/EAC

mark.

Hygiene standard

• EHEDG certification, type EL - CLASS I. Permitted process connections in accordance

with EHEDG, see section 'Process connections' → 64

• 3-A authorization no. 1144, 3-A sanitary standard 74-06. Permitted process

connections in accordance with 3-A, see section 'Process connections' → 64

• ASME BPE, certificate of conformity can be ordered for indicated options

• FDA-compliant

• All product contact surfaces are produced without animal fats (TSE Certificate of

Suitability)

8 Endress+Hauser

Page 9

iTHERM TrustSens TM371, TM372 Incoming acceptance and product identification

Parts in contact with the medium

Parts of the thermometer in contact with the medium comply with the following European

regulations:

• (EC) No. 1935/2004, Article 3, paragraph 1, Articles 5 and 17 on materials and articles

intended to come into contact with food.

• (EC) No. 2023/2006 on good manufacturing practice for materials and articles intended

to come into contact with food.

• (EU) No. 10/2011 on plastic materials and articles intended to come into contact with

food.

3.3 Transport and storage

Pack the device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

Storage temperature –40 to +85 °C (–40 to +185 °F)

Endress+Hauser 9

Page 10

Mounting iTHERM TrustSens TM371, TM372

SW/AF 32

SW/AF 17

1

2

3

4

4 Mounting

4.1 Mounting conditions

Information about the conditions, which have to be existent at the mounting location

for a designated use, such as ambient temperature, degree of protection, climate class,

etc., as well as device dimensions - see section 'Technical Data', → 47

The immersion length of the thermometer can influence the accuracy. If the immersion

length is too small then errors in the measurement are caused by heat conduction via the

process connection. If installing into a pipe then the immersion length should ideally be

half of the pipe diameter. → 10

• Installation possibilities: Pipes, tanks or other plant components

• Orientation: no restrictions. However, self-draining in the process must be guaranteed. If

there is an opening to detect leaks at the process connection, this opening must be at the

lowest possible point.

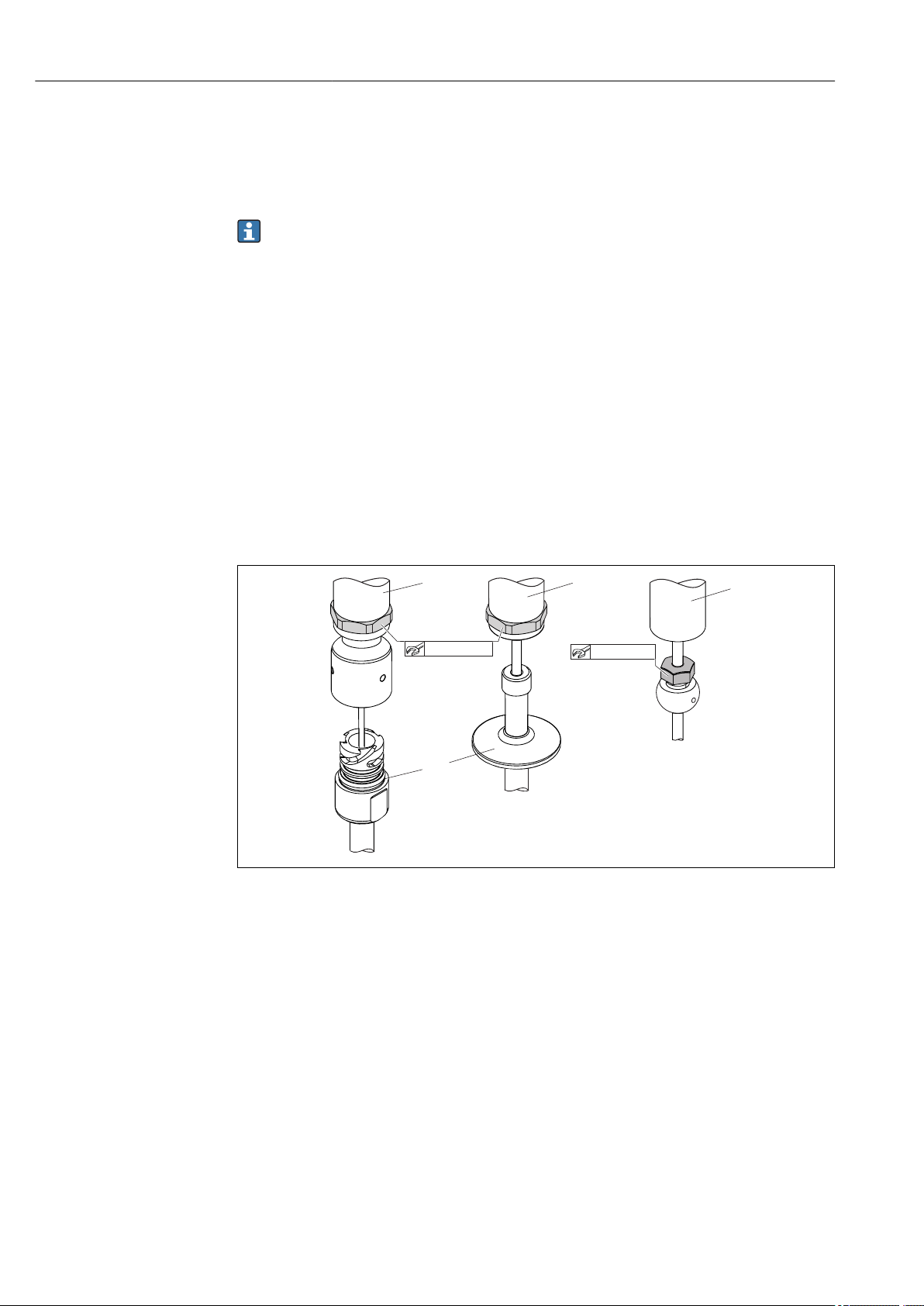

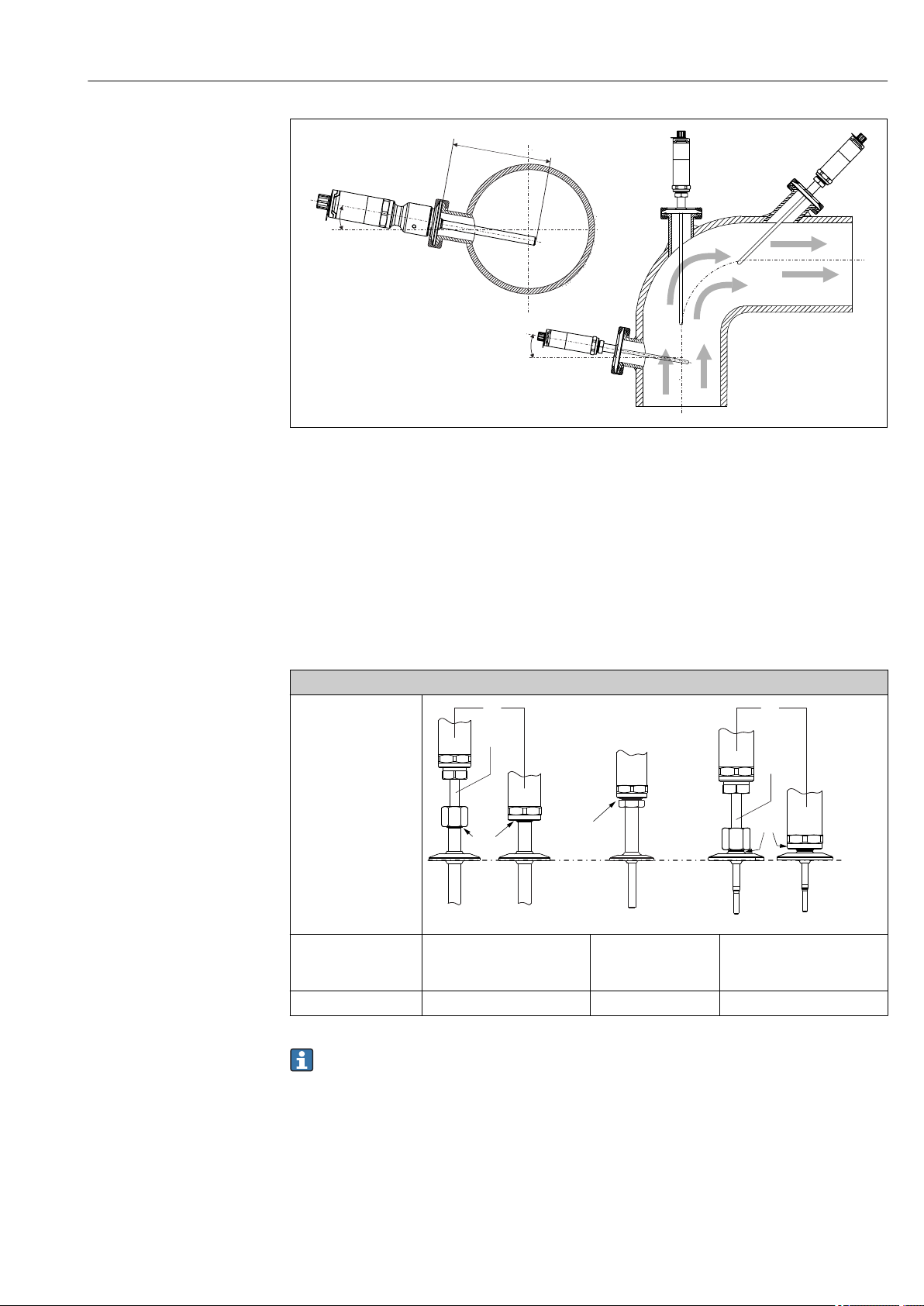

4.2 Mounting the measuring device

Required tools for mounting in an existing protection tube: Open-end wrench or mounting

socket wrench SW/AF 32

A0028639

2 Mounting process of the compact thermometer

1 Mounting of iTHERM QuickNeck connection to the existing protection tube with iTHERM QuickNeck bottom

part - no tools required

2 Hexagonal head SW/AF 32 for the mounting in an existing protection tube for M24-, G3/8"-thread

3 Adjustable compression fitting TK40 - mounting of the hexagonal screw with open-end wrench SW/AF 17

only

4 Protection tube

10 Endress+Hauser

Page 11

iTHERM TrustSens TM371, TM372 Mounting

U

≥ 3°

≥ 3°

1

2

3

4

1

2

3

4

5

M

M

M

A0031007

3 Mounting possibilities in the process

1, 2 Perpendicular to flow direction, installed at a min. angle of 3° to ensure self-draining

3 On elbows

4 Inclined installation in pipes with a small nominal diameter

U Immersion length

In the case of pipes with a small nominal diameter, it is advisable for the tip of the

thermometer to project well into the process so that it extends past the pipe axis.

Installation at an angle (4) could be another solution. When determining the immersion

length or installation depth all the parameters of the thermometer and of the medium to

be measured must be taken into account (e.g. flow velocity, process pressure).

Maximum torque

A0035951

Protection tube version TT411, 6 mm (0.24 in) (1)

TT411, 6 mm (0.24 in) and

Necktube TE411 (2)

Torque M 3 to 5 Nm (2.2 to 3.7 lbf ft) 10 Nm (7.4 lbf ft) 3 to 5 Nm (2.2 to 3.7 lbf ft)

TT411,

9 mm (0.35 in) (3)

TT411, 12.7 mm (¹⁄₂ in) (4)

TT411, 12.7 mm (¹⁄₂ in) and

Necktube TE411 (5)

When connecting the device with the protection tube: only turn the hexagonal

spanner flat on the bottom of the housing.

Endress+Hauser 11

Page 12

Mounting iTHERM TrustSens TM371, TM372

1

2

1 2

3 4

R0.4 R0.4

Sensor with

milk pipe

connection

Sensor Variventwith

connection

Shaped

gasket

Companion

connection

O-ring

Groove

slip-on nut

Centering ring

Sealing

Companion

connection

Companion

connection

Gasket

(O-ring)

Welding boss

Leak detection hole

Vessel wall

A0031022

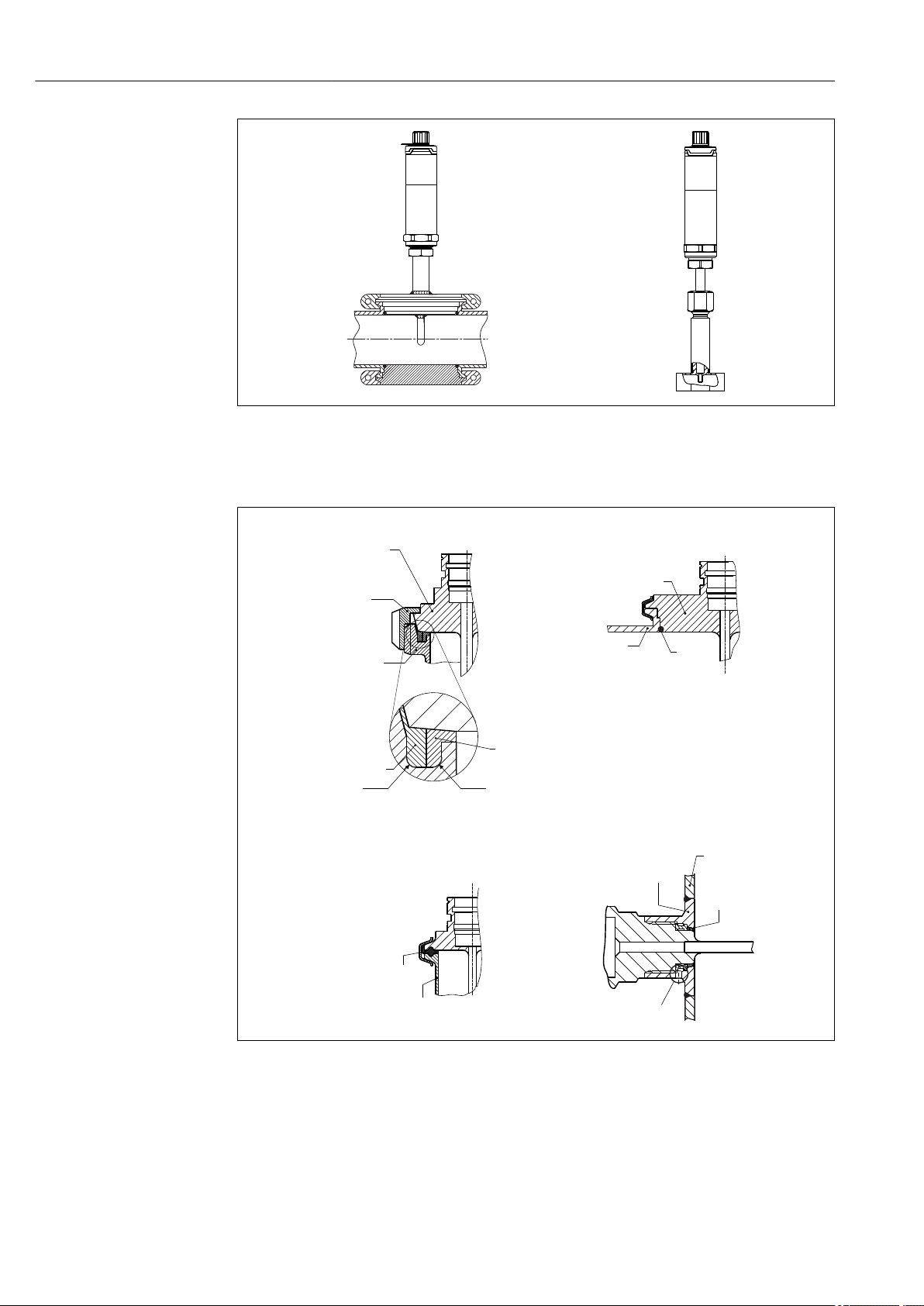

4 Process connections for thermometer installation in pipes with small nominal diameters

1 Varivent® process connection type N for DN40

2 Corner piece or T-piece (illustrated) for weld-in as per DIN 11865 / ASME BPE 2012

12 Endress+Hauser

5 Detailed installation instructions for hygiene-compliant installation

1 Sanitary connection according to DIN 11851, only in connection with EHEDG-certified and self-centering

sealing ring

2 Varivent® process connection for VARINLINE® housing

3 Clamp according to ISO 2852

4 Liquiphant-M G1" process connection, horizontal installation

A0028648-EN

Page 13

iTHERM TrustSens TM371, TM372 Mounting

The counterpieces for the process connections and the seals or sealing rings are not

included in the scope of supply for the thermometer. Liquiphant M weld-in adapters with

associated seal kits are available as accessories. → 42

Procedure in case of seal failure indicated by leak detection port:

1. Disassembling of the thermometer, validated cleaning procedure of thread and

sealing ring groove

2. Replacement of the seal or sealing ring

3. CIP after re-assembly

In the case of weld-in connections, exercise the necessary degree of care when performing

the welding work on the process side:

• Suitable welding material

• Flush-welded or with welding radius > 3.2 mm (0.13 in)

• No recesses, folds or gaps

• Honed and polished surface, Ra ≤ 0.76 µm (0.03 µin)

As a general rule, the thermometers should be installed in such a way that does not

impact their ability to be cleaned (the requirements of the 3-A Standard must be

observed). The Varivent® and Liquiphant-M weld-in adapter and Ingold (+ weld-in

adapter) connections enable flush-mounted installation.

4.3 Post-mounting check

Is the device undamaged (visual inspection)?

Is the device fixed appropriately?

Does the device comply to the measurement point specifications, such as ambient temperature, etc.?

→ 47

Endress+Hauser 13

Page 14

Electrical connection iTHERM TrustSens TM371, TM372

M12x1

1

12...30 VDC

(4...20 mA)

3

0 V

(4...20 mA)

4

2

A

B

1 (BN) +

2 (WH) nc

3 (BU) -

4 (BK) nc

1.

2.

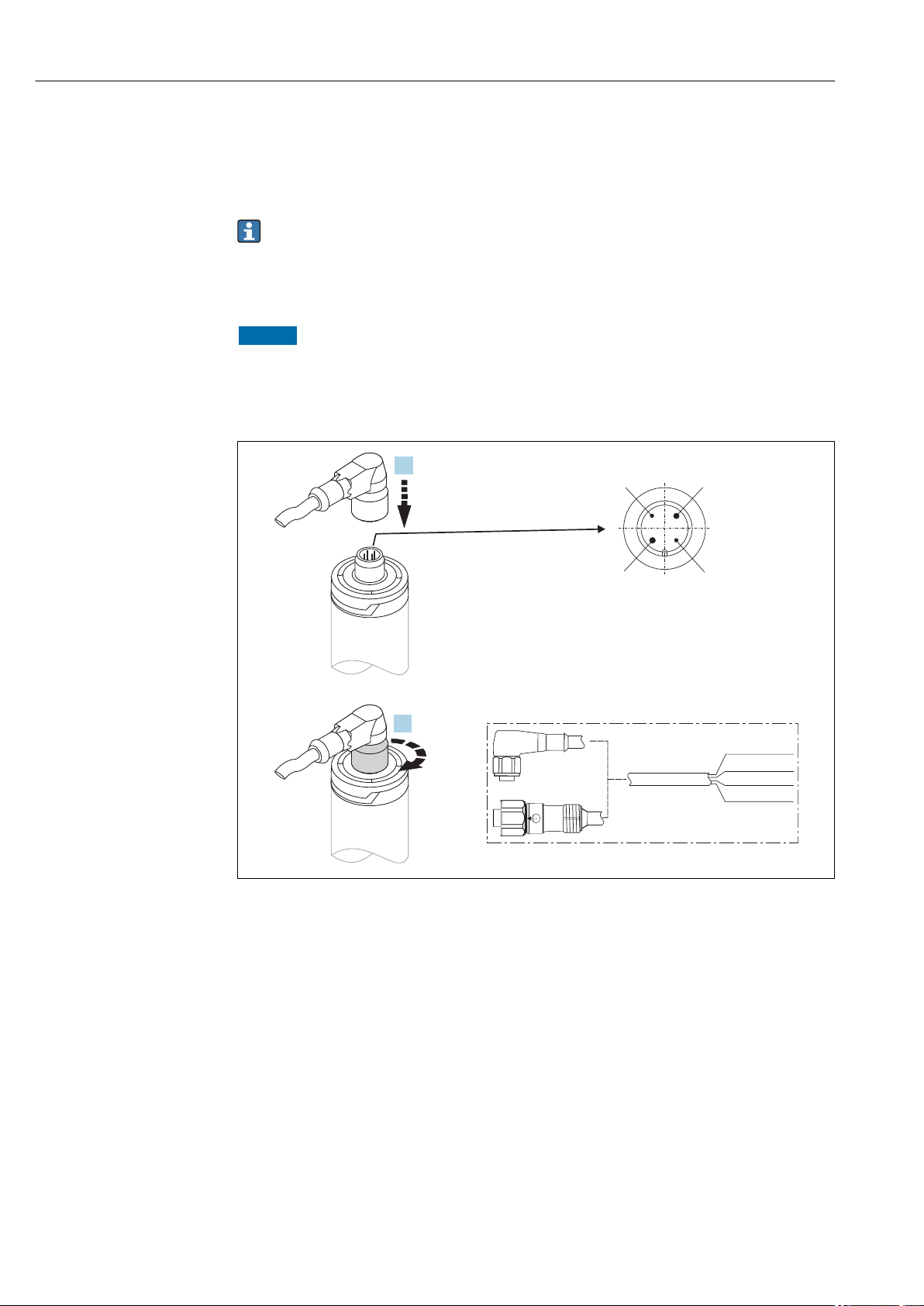

5 Electrical connection

5.1 Connecting requirements

According to the 3-A Standard electrical connecting cables must be smooth,

corrosion-resistant and easy to clean.

5.2 Connecting the device

NOTICE

To prevent damage to the device

To prevent any kind of damage from the device electronics, leave the pins 2 and 4

‣

unconnected. They are reserved for the connection of the configuration cable.

Do not tighten the M12 plug too much, in order to prevent damage to the device.

‣

A0028623

6 Cable plug M12x1 and PIN assignment of the connection socket at the device

If voltage supply is connected correctly and the measuring device is operational, the LED is

illuminated green.

5.3 Ensuring the degree of protection

The specified degree of proctection is ensured when the M12x1 cable plug is tightened. In

order to reach IP69K degree of protection, appropriate cord sets with straight or angle

plugs are available as accessories.

14 Endress+Hauser

Page 15

iTHERM TrustSens TM371, TM372 Operability

2 3

1

4 5

5.4 Post-connection check

Is the device or cable undamaged (visual check)?

Do the cables have adequate strain relief?

Does the supply voltage match the specifications on the nameplate?

6 Operability

6.1 Overview of operation options

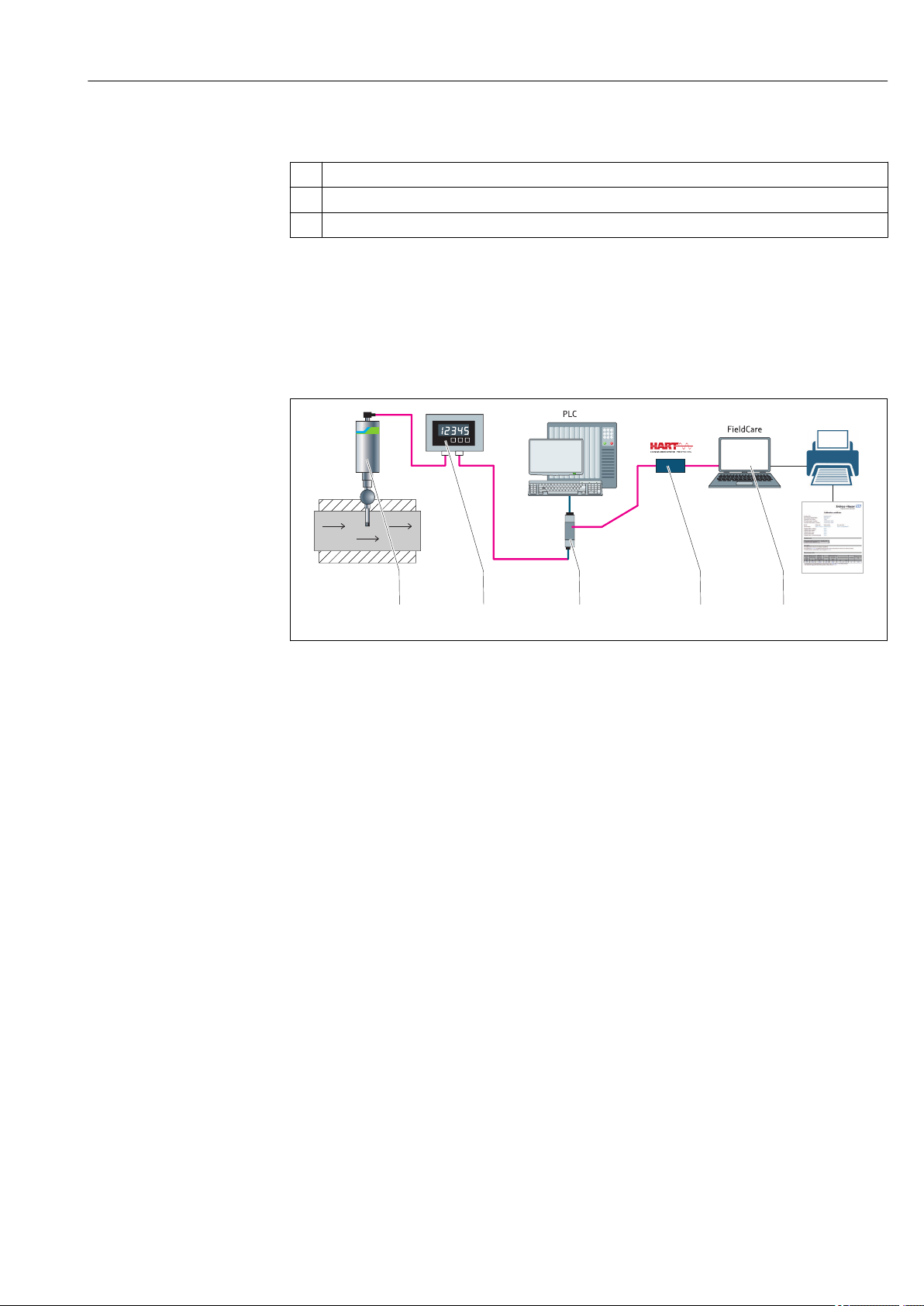

A0031089

7 Operating options of the device

1

Installed iTHERM compact thermometer with HART® communication protocol

2 RIA15 loop powered process display - It is integrated in the current loop and displays the measuring signal or

HART® process variables in digital form. The process display unit does not require an external power supply.

It is powered directly from the current loop.

3 Active barrier RN221N - The RN221N (24 V DC, 30 mA) active barrier has a galvanically isolated output for

supplying voltage to loop-powered transmitters. The universal power supply works with an input supply

voltage of 20 to 250 V DC/AC, 50/60 Hz, which means that it can be used in all international power grids.

4 Commubox FXA195 for intrinsically safe HART® communication with FieldCare via the USB interface.

5 FieldCare is a FDT-based plant asset management tool from Endress+Hauser, more details see section

'accessories'. The acquired self-calibration data is stored in the device (1) and can be read using FieldCare.

This also enables an auditable calibration certificate to be created and printed.

Endress+Hauser 15

Page 16

Operability iTHERM TrustSens TM371, TM372

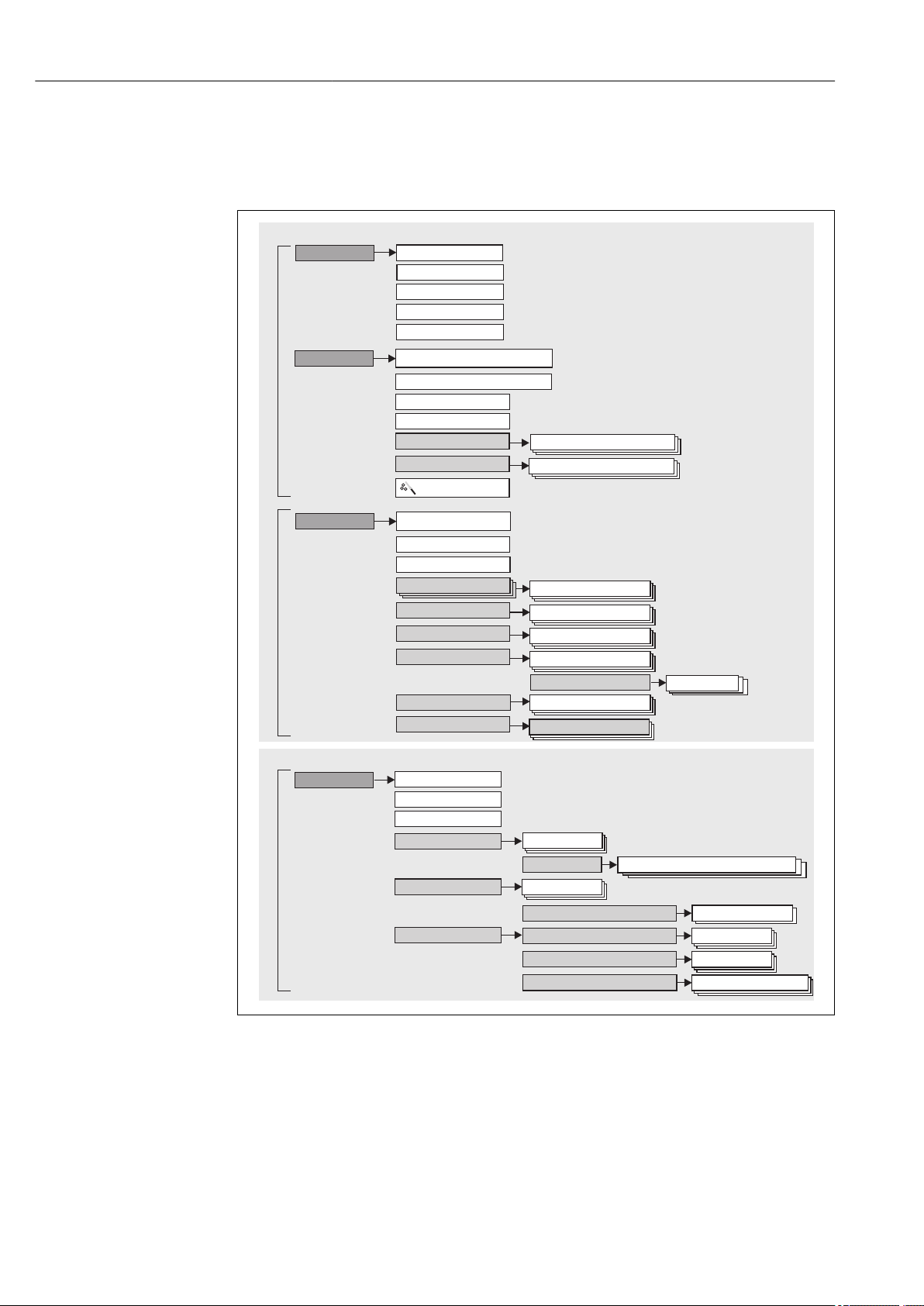

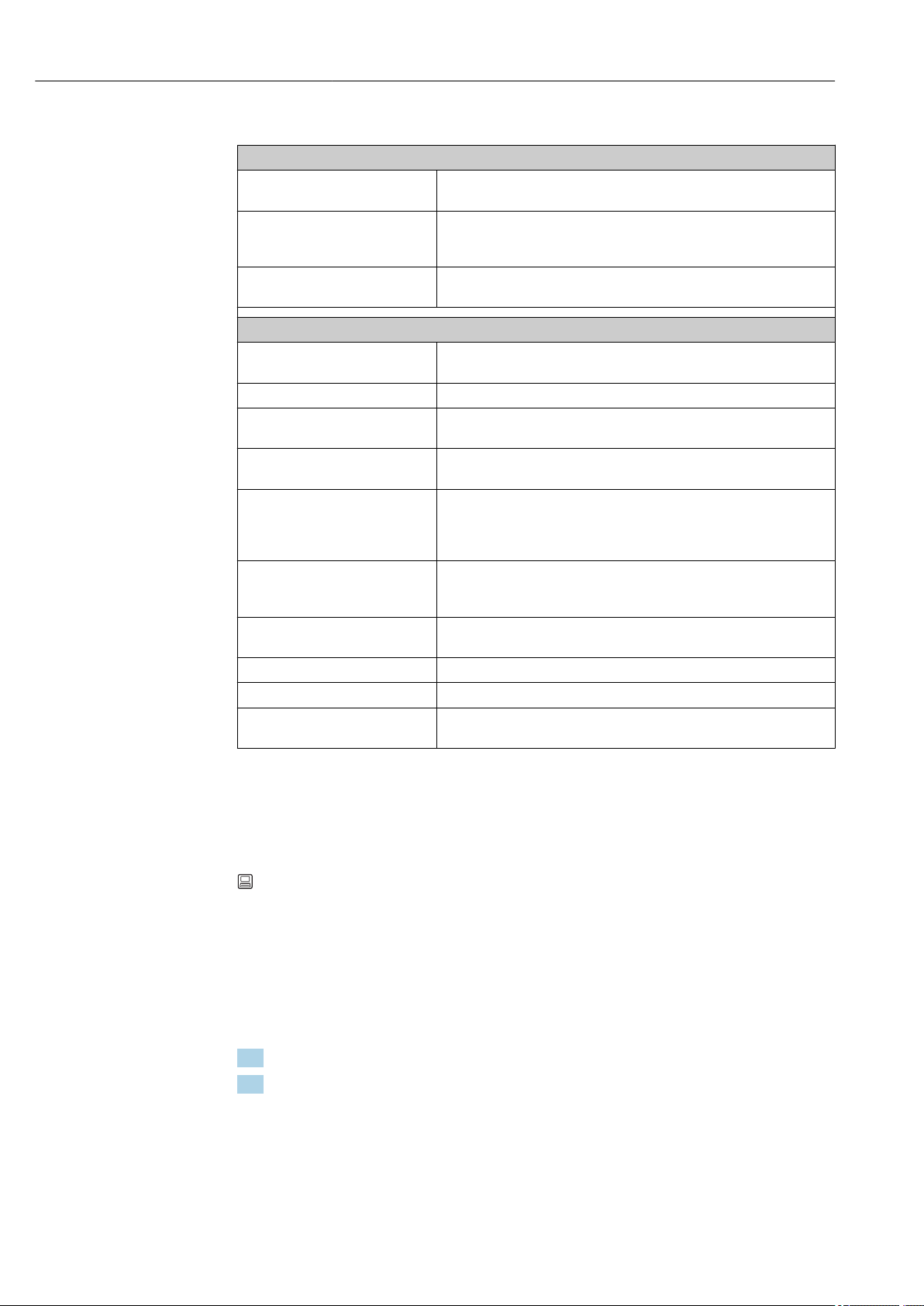

Expert

System

Communication

Operating menu for experts

Setup

Device tag

Diagnostics

Operating menu for operators and maintenances

Maintenance

Expert

Output

Unit

4 mA value

20 mA value

Actual diagnostics

Operating time

Diagnostic list

Actual diagnostics count

Enter access code

Unit

4 mA value

HART configuration

HART info

HART output

Device type

Assigncurrentoutput(PV)

Event logbook

Device information

Simulation

Previous diagnostics 1

Device tag

Min/max values

Sensor value

Measured values

Sensor min v.

Device tag

Definesoftware writeprotectioncode

Administration

Operation

Previous diagnostics 1

Loop check configuration

Loop check config.

Failure mode

Calibration

Number of self calibrations

Deviation

Limits

Interval monitoring

Self calibration monitoring

Stored self calibration points

Adjustment

Calibration report

...

Diagnostic simulation

Diagnostic settings

Access status tooling

Locking status

Lower warning value

Diagnostic behavior

6.2 Structure and function of the operating menu

6.2.1 Structure of the operating menu

A0032327-EN

16 Endress+Hauser

Page 17

iTHERM TrustSens TM371, TM372 Operability

Submenus and user roles

Certain parts of the menu are assigned to certain user roles. Each user role corresponds to

typical tasks within the lifecycle of the device.

User role Typical tasks Menu Content/meaning

Maintenance

Operator

Expert Tasks that require detailed knowledge of the function

Commissioning:

• Configuration of the measurement.

• Configuration of data processing (Measurement

range, etc.).

Reading measured values.

Calibration:

• Configuration of the warning and alarm limit values

as well as interval monitoring.

• Configuration and creation of a calibration report

(wizard).

Fault elimination:

• Diagnosing and eliminating process errors.

• Interpretation of device error messages and

correcting associated errors.

of the device:

• Commissioning measurements under difficult

conditions.

• Optimal adaptation of the measurement to difficult

conditions.

• Detailed configuration of the communication

interface.

• Error diagnostics in difficult cases.

"Setup"

"Calibration"

"Diagnostics" Contains all parameters for detecting and analyzing

"Expert" Contains all parameters of the device (including those

Contains all parameters for commissioning and

calibration:

• Setup parameters

Once values have been set for these parameters, the

measurement should generally be completely

configured.

• Calibration parameters

Contains all information and parameters for the selfcalibration, including a wizard for creating a

calibration report. This wizard is available in the

online parameterization.

errors:

• Diagnostic list

Contains up to 3 currently pending diagnostic

messages.

• Event logbook

Contains the last 5 diagnostic messages (no longer

pending).

• "Device information" submenu

Contains information for identifying the device.

• "Measured values" submenu

Contains all current measured values.

• "Simulation" submenu

Is used to simulate measured values or output values.

• Diagnostic settings

Configuration of diagnostic behavior and status

signal according to NE107

that are already in one of the other menus). The

structure of this menu is based on the function blocks

of the device:

• "System" submenu

Contains all higher-order device parameters that do

not pertain either to measurement or the measured

value communication.

• "Output" submenu

Contains all parameters for configuring the analog

current output and the loop check.

• "Communication" submenu

Contains all parameters for configuring the digital

communication interface.

6.3 Access to the operating menu via an operating tool

6.3.1 FieldCare

Function scope

FDT/DTM-based plant asset management tool from Endress+Hauser. It can configure all

smart field units in a system and help you manage them. By using the status information,

it is also a simple but effective way of checking their status and condition. Access takes

place via the HART® protocol or CDI (= Endress+Hauser Common Data Interface).

Endress+Hauser 17

Page 18

Operability iTHERM TrustSens TM371, TM372

Typical functions:

• Configuring parameters of the device

• Loading and saving device data (upload/download)

• Documentation of the measuring point

For iTHERM TrustSens thermometers, FieldCare provides convenient access to

automatically created self-calibration reports.

For details, see Operating Instructions BA00027S/04 and BA00065S/04 in the

download area on www.endress.com.

Source for device description files

See data → 21

Establishing a connection

As example: via HART® modem Commubox FXA191 (RS232) or FXA195 (USB)

1. Make sure to update the DTM library for all connected devices (e.g. FXA19x, iTHERM

TrustSens TM371).

2. Start FieldCare and create a project.

3. Go to View --> Network: Right-click on Host PC Add Device...

The Add New Device window opens.

4. Select the HART Communication option from the list and press OK to confirm.

5. Double-click on HART Communication DTM instance.

Check the Serial Interface port for the correct modem and press OK to confirm.

6. Right-click on HART Communication and select the Add Device... option in the

context menu that opens.

7. Select the desired device from the list and press OK to confirm.

The device appears in the network list.

8. Right-click on this device and select the Connect option in the context menu that

opens.

The CommDTM appears in green color.

9. Double-click on the device in the network list to establish the online connection to

the device.

The online parameterization is available.

18 Endress+Hauser

Page 19

iTHERM TrustSens TM371, TM372 Operability

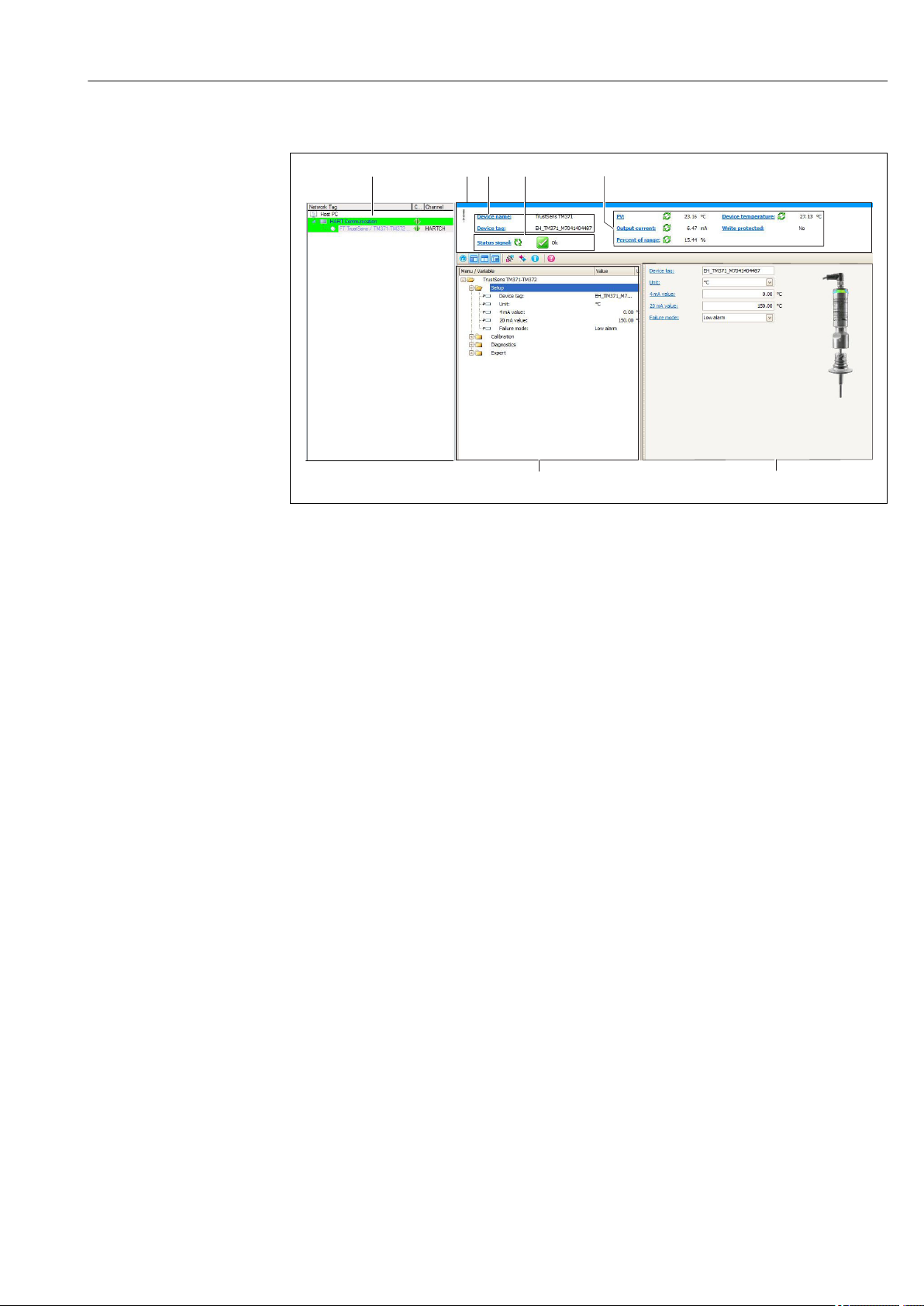

1

3

4

5

6

2

7

User interface

A0032334-EN

8 User interface with device information via HART®-communication

1 Network view

2 Header

3 Device tag and device name

4 Status area for the status signal

5 Measured values with general device information: PV, output current, percent of range, device temperature

6 Navigation area with operating menu structure

7 Display and input area

6.3.2 DeviceCare

Function scope

DeviceCare is a free configuration tool for Endress+Hauser devices. It supports devices with

the following protocols, provided a suitable device driver (DTM) is installed: HART,

PROFIBUS, FOUNDATION Fieldbus, Ethernet/IP, Modbus, CDI, ISS, IPC and PCP. The tool is

aimed at customers without a digital network in plants and workshops as well as Endress

+Hauser service technicians. The devices can be connected directly via a modem (point-topoint) or a bus system. DeviceCare is fast, easy and intuitive to use. It can run on a PC,

laptop or tablet with a Windows operating system.

Source for device description files

See data → 21

6.3.3 Field Xpert

Function scope

Field Xpert is an industrial PDA (personal digital assistant) with integrated touchscreen for

commissioning and maintaining field devices in explosion hazardous and non-hazardous

areas. It allows efficient configuration of FOUNDATION fieldbus, HART and WirelessHART

devices.

Source for device description files

See data → 21

Endress+Hauser 19

Page 20

Operability iTHERM TrustSens TM371, TM372

6.3.4 AMS Device Manager

Function scope

Program from Emerson Process Management for operating and configuring measuring

devices via the HART® protocol.

Source for device description files

See data → 21

6.3.5 SIMATIC PDM

Function scope

SIMATIC PDM is a standardized, manufacturer-independent program from Siemens for

the operation, configuration, maintenance and diagnosis of intelligent field devices via the

HART ® protocol.

Source for device description files

See data → 21

6.3.6 Field Communicator 375/475

Function scope

Industrial handheld terminal from Emerson Process Management for remote

configuration and measured value display via the HART ® protocol.

Source for device description files

See data → 21

20 Endress+Hauser

Page 21

iTHERM TrustSens TM371, TM372 System integration

7 System integration

7.1 Overview of device description files

Version data for the device

Firmware version 01.00.zz The firmware version can be found:

• on the nameplate → 1, 8

• in the operating menu: Diagnostics → Device

information → Firmware version

•

Please make sure to use the operating

instructions valid for the device. The

corresponding firmware versions for each

operating instructions can be found on its title

page.

Manufacturer ID (17) 0x11 Operating menu: Diagnostics → Device information →

Manufacturer ID

Device type 0x11CF Operating menu: Expert → Communication → HART

info → Device type

HART protocol revision 7.0 Operating menu: Expert → Communication → HART

info → HART revision

Device revision 1 • On the nameplate → 1, 8

• Operating menu: Expert → Communication → HART

info → Device revision

The suitable device driver software (DD/DTM) for the individual operating tools can be

obtained from different sources:

• www.endress.com --> Downloads --> Media Type: Software --> Software Type:

Application Software

• www.endress.com --> Products: individual product page e.g. TM371 --> Documents /

Manuals / Software: Electronic Data Description (EDD) or Device Type Manager (DTM).

• via DVD (contact your local Endress+Hauser sales center)

Endress+Hauser supports all common operating tools of different manufacturers (e.g.

Emerson Process Management, ABB, Siemens, Yokogawa, Honeywell and many more).

The Endress+Hauser operating tools FieldCare and Device care can also be obtained per

download (www. endress.com --> Downloads --> Media Type: Software --> Application

Software) or via optical data storage medium (DVD) from your local Endress+Hauser sales

center.

7.2 Measured variables via HART protocol

The measured values (device variables) are assigned to the device variables as follows:

Dynamic variable Device variable

Primary value (PV) Temperature

Secondary value (SV) Device temperature

Tertiary value (TV) Number of self-calibrations

Quaternary value (QV) Calibration deviation

Endress+Hauser 21

Page 22

System integration iTHERM TrustSens TM371, TM372

7.3

Supported HART® commands

The HART® protocol enables the transfer of measurement data and device data

between the HART® master and the field device. HART® masters such as the above

listed operating tools require an appropriate device driver software (DD or DTM) to

establish the data exchange. The data exchange is initiated via commands.

There are three different types of commands.

• Universal commands:

All HART® devices support and use universal commands. These are associated with the

following functionalities for example:

– Recognition of HART® devices

– Reading digital measured values

• Common practice commands:

Common practice commands offer functions which are supported and can be executed by

many but not all field devices.

• Device-specific commands:

These commands allow access to device-specific functions which are not HART

®

standard. Such commands access individual field device information.

Command No. Designation

Universal commands

0, Cmd0 Read unique identifier

1, Cmd001 Read primary variable

2, Cmd002 Read loop current and percent of range

3, Cmd003 Read dynamic variables and loop current

6, Cmd006 Write polling address

7, Cmd007 Read loop configuration

8, Cmd008 Read dynamic variable classifications

9, Cmd009 Read device variables with status

11, Cmd011 Read unique identifier associated with TAG

12, Cmd012 Read message

13, Cmd013 Read TAG, descriptor, date

14, Cmd014 Read primary variable transducer information

15, Cmd015 Read device information

16, Cmd016 Read final assembly number

17, Cmd017 Write message

18, Cmd018 Write TAG, descriptor, date

19, Cmd019 Write final assembly number

20, Cmd020 Read long TAG (32-byte TAG)

21, Cmd021 Read unique identifier associated with long TAG

22, Cmd022 Write long TAG (32-byte TAG)

38, Cmd038 Reset configuration changed flag

48, Cmd048 Read additional device status

Common practice commands

33, Cmd033 Read device variables

34, Cmd034 Write primary variable damping value

35, Cmd035 Write primary variable range values

40, Cmd040 Enter/Exit fixed current mode

22 Endress+Hauser

Page 23

iTHERM TrustSens TM371, TM372 System integration

Command No. Designation

42, Cmd042 Perform device reset

44, Cmd044 Write primary variable units

45, Cmd045 Trim loop current zero

46, Cmd046 Trim loop current gain

50, Cmd050 Read dynamic variable assignments

54, Cmd054 Read device variable information

59, Cmd059 Write number of response preambles

95, Cmd095 Read Device Communication Statistics

100, Cmd100 Write Primary Variable Alarm Code

516, Cmd516 Read Device Location

517, Cmd517 Write Device Location

518, Cmd518 Read Location Description

519, Cmd519 Write Location Description

520, Cmd520 Read Process Unit Tag

521, Cmd521 Write Process Unit Tag

523, Cmd523 Read Condensed Status Mapping Array

524, Cmd524 Write Condensed Status Mapping Array

525, Cmd525 Reset Condensed Status Mapping Array

526, Cmd526 Write Simulation Mode

527, Cmd527 Simulate Status Bit

Endress+Hauser 23

Page 24

Commissioning iTHERM TrustSens TM371, TM372

1

8 Commissioning

8.1 Function check

Before commissioning the device make sure that all final checks have been carried out:

• Checklist "Post-mounting check" , → 13

• Checklist "Post-connection check", → 15

8.2 Switching on the measuring device

Once the final checks have been successfully completed, it is time to switch on the supply

voltage. The device performs a number of internal test functions after power-up. This is

indicated by red LED-flashing. The device is operational after approx. 10 seconds in

normal operating mode. The LED on the device is illuminated green.

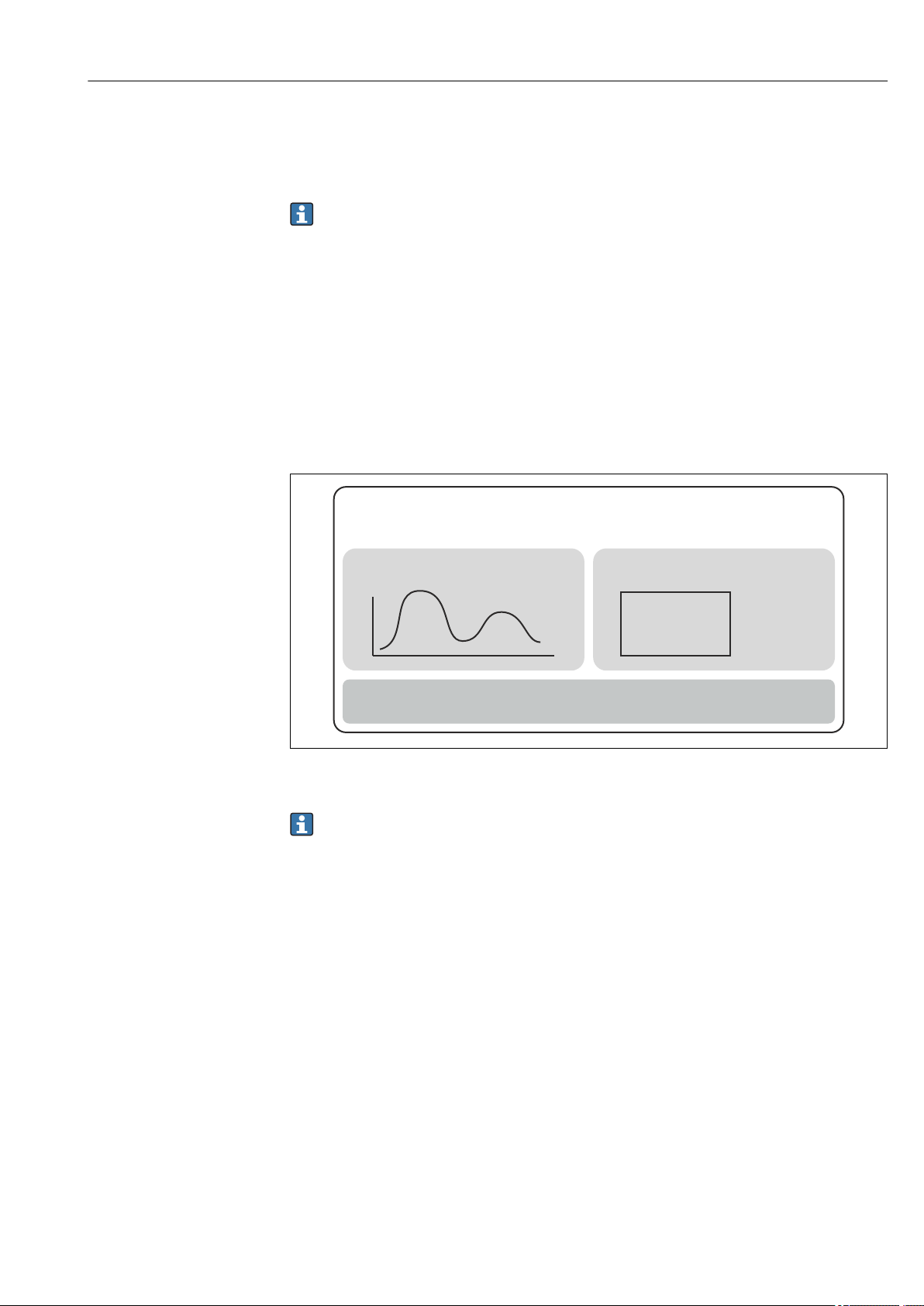

8.2.1 Display elements

1 LED signals for device status indication.

Function description of the different LED signals, see → 35

8.3 Configuring the measuring device

See 'Operating menu and parameter description'→ 74

8.3.1 Defining the measurement range

To configure the measurement range, enter the 4 mA value and the 20 mA value.

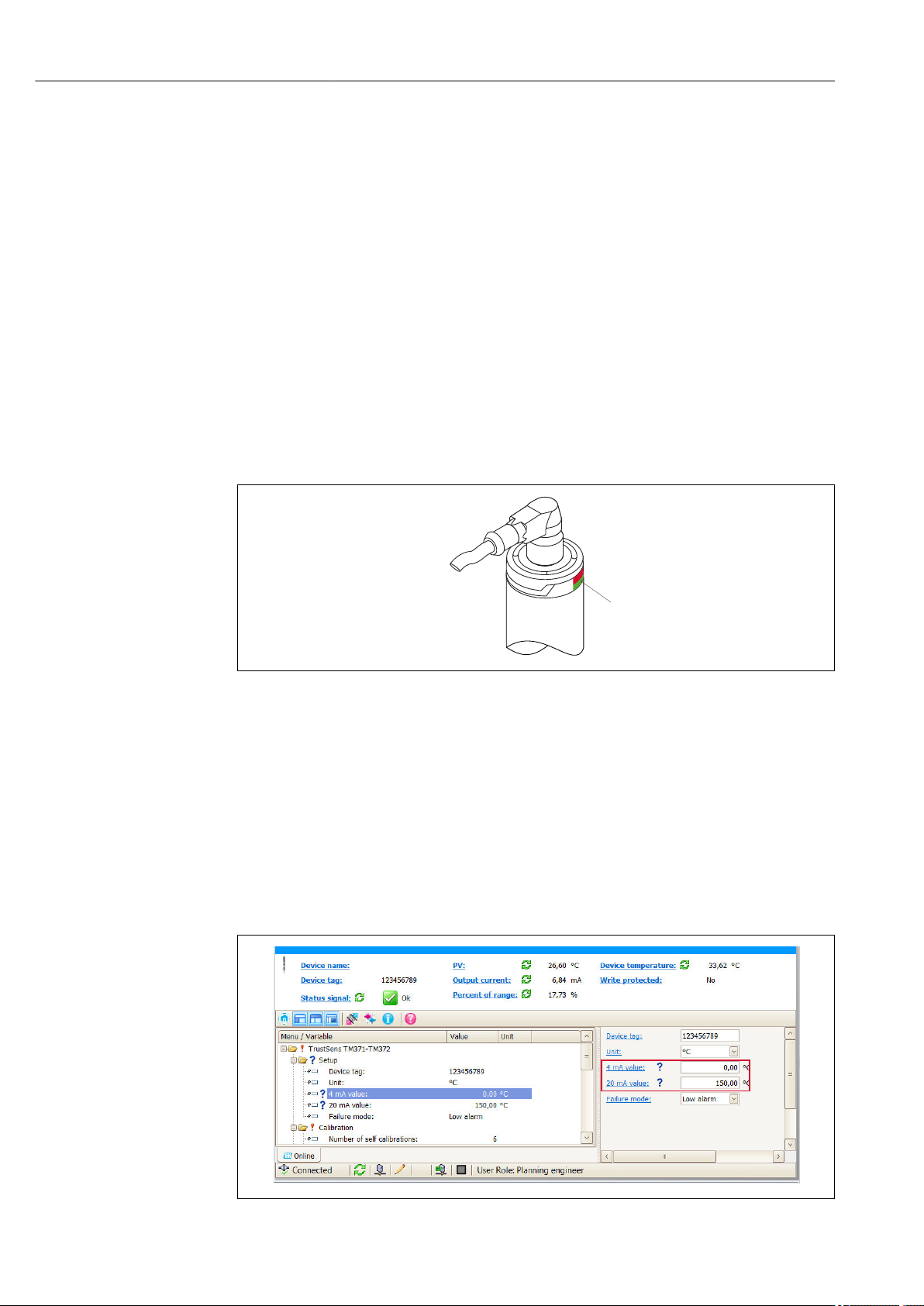

A0031589

A0034666-EN

24 Endress+Hauser

Page 25

iTHERM TrustSens TM371, TM372 Commissioning

2

1

Navigation

"Setup" menu → 4 mA value

"Setup" menu → 20 mA value

1. In the 4 mA value input window, enter the lower range value of your process

measurement range and press ENTER to confirm.

2. In the 20 mA value input window, enter the upper range value of your process

measurement range and press ENTER to confirm.

8.3.2 Defining the warning limits for the self-calibration

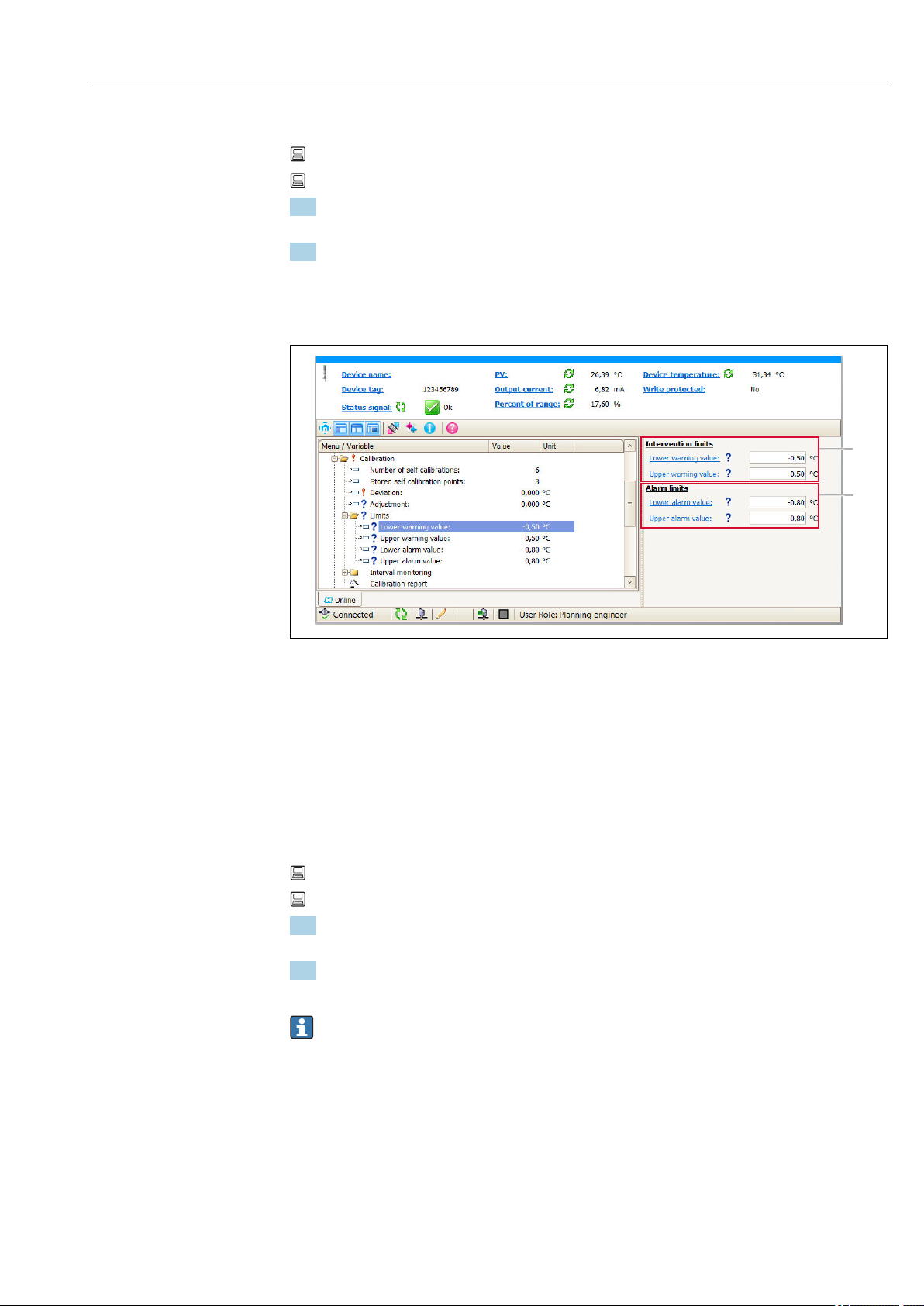

A0034668-EN

1 Values to be entered for the warning limits

2 Values to be entered for the alarm limits

Use this function to define the lower and upper warning limit. As a result of each selfcalibration the deviation between the reference sensor and the Pt100 sensor is being

determined. If this deviation exceeds the defined warning limit, the device will transmit

the defined status signal and show the defined diagnostic behavior via the LED. (Factory

setting = Warning - LED red flashes, diagnostic number 144. Measured value status =

Uncertain / Not limited).

Navigation

"Calibration" menu → Limits → Lower warning value

"Calibration" menu → Limits → Upper warning value

1. In the Lower warning value input window, enter the lower warning limit for the

self-calibration deviation and press ENTER to confirm.

2. In the Upper warning value input window, enter the upper warning limit for the

self-calibration deviation and press ENTER to confirm.

Please consider the maximum limited value range to be entered: ±0.35 °C (±0.67 °F).

→ 80

8.3.3 Defining the alarm limits for the self-calibration

Use this function to define the lower and upper alarm limit. As a result of each selfcalibration the deviation between the reference sensor and the Pt100 sensor is being

determined. If this deviation exceeds the defined alarm limit, the device will transmit the

defined status signal and show the defined diagnostic behavior via the LED. (Factory

setting = Warning - LED red flashes, diagnostic number 143. Measured value status =

Uncertain / Not limited.)

Endress+Hauser 25

Page 26

Commissioning iTHERM TrustSens TM371, TM372

1.

2.

Navigation

"Calibration" menu → Limits → Lower alarm value

"Calibration" menu → Limits → Upper alarm value

1. In the Lower alarm value input window, enter the lower limit for the self-calibration

deviation and press ENTER to confirm.

2. In the Upper alarm value input window, enter the upper warning limit for the selfcalibration deviation and press ENTER to confirm.

Please consider the maximum limited value range to be entered: ±0.35 °C (±0.67 °F).

→ 80

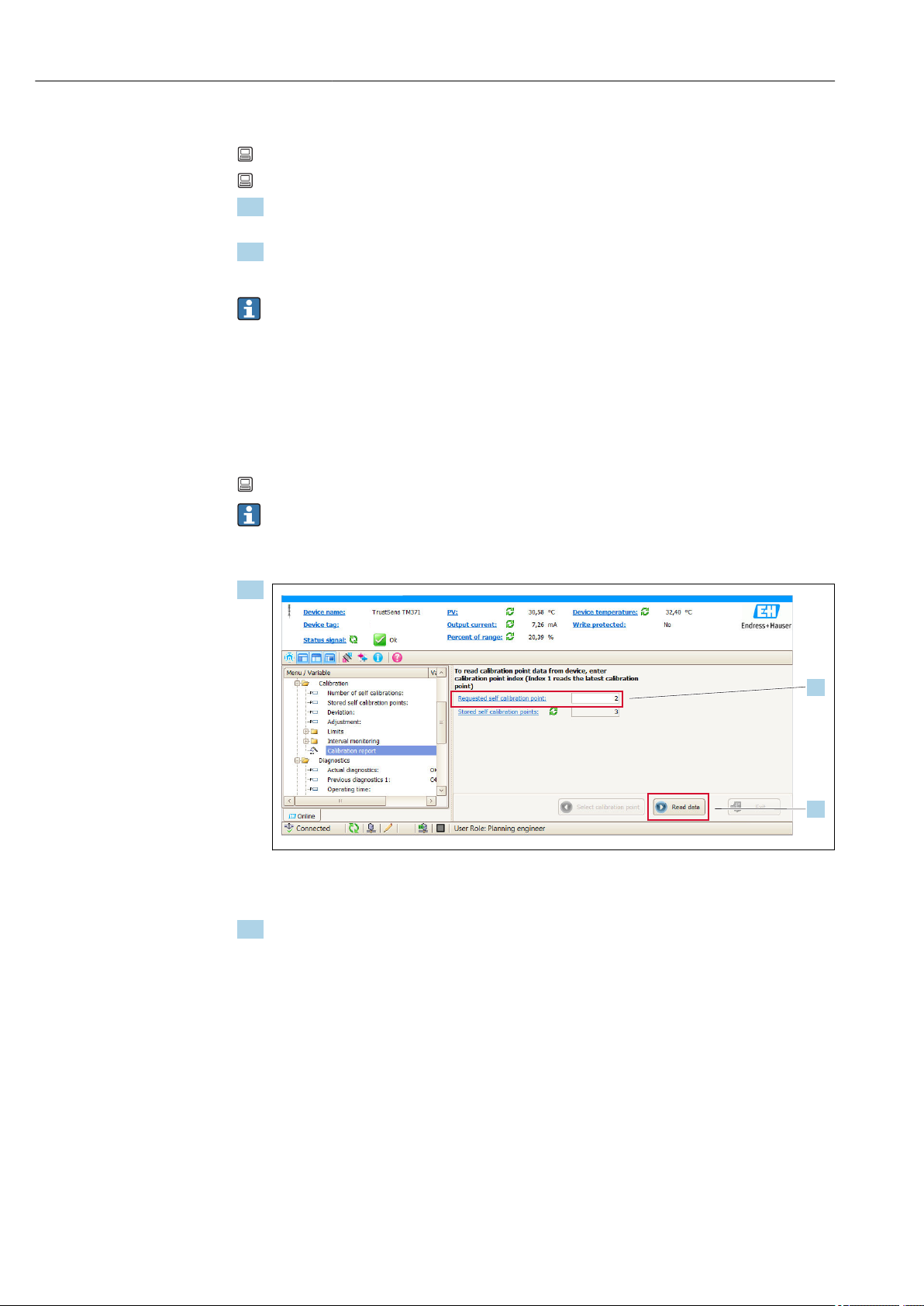

8.4 Creating a calibration report

The "calibration report" wizard guides you systematically through the process for creating a

calibration report for a pre-selected calibration point.

Navigation

"Calibration" menu → Calibration report

At least one stored self-calibration point must be in the device to start the online

wizard.

Configuration and creation of a calibration report

1.

To read the calibration point data from the device, enter the calibration point index.

Index 1 reads the latest calibration point.

2. Press READ DATA to confirm.

An overview of device information and calibration point data appears. See table

below for detailed information.

A0033678-EN

26 Endress+Hauser

Page 27

iTHERM TrustSens TM371, TM372 Commissioning

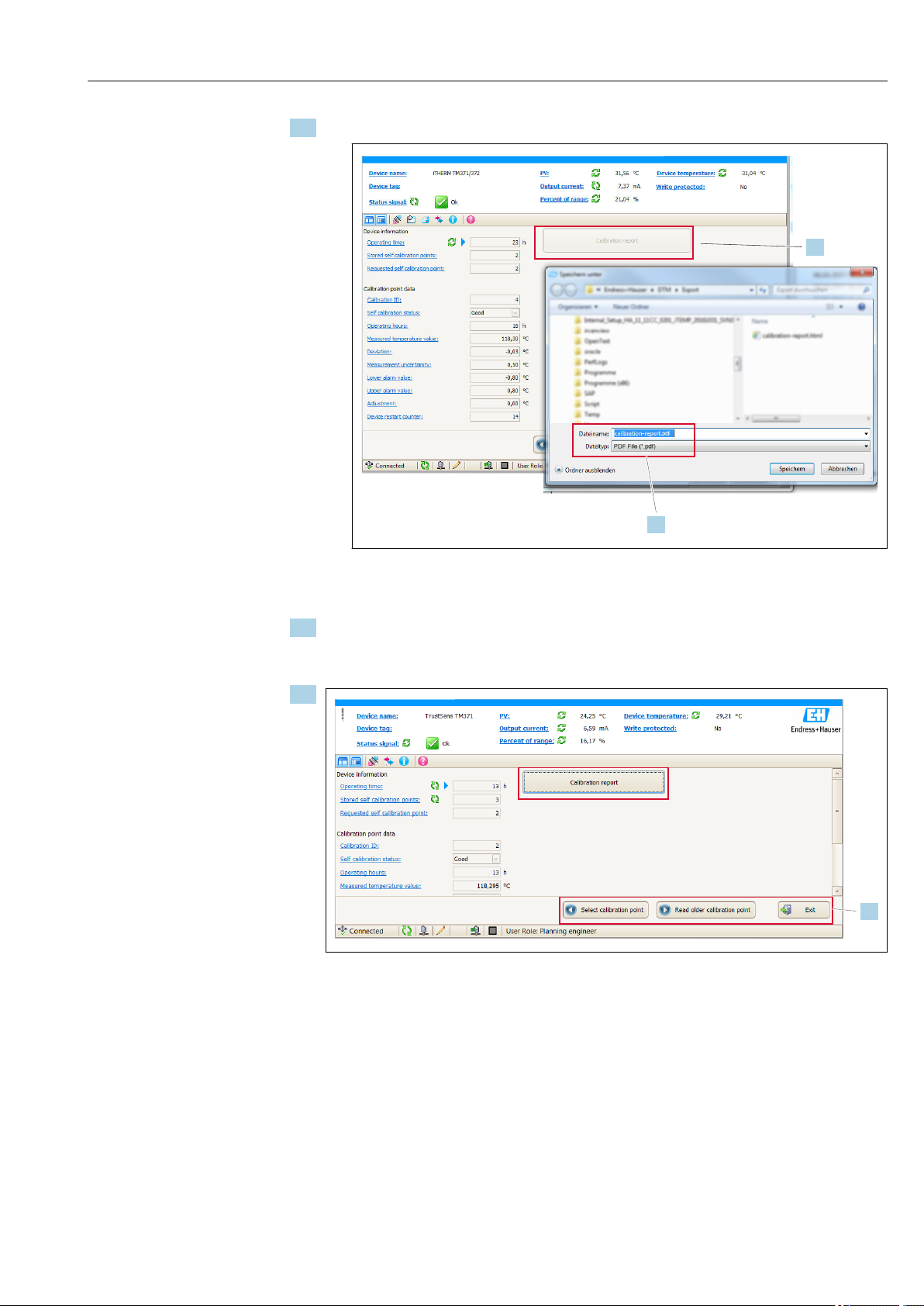

3.

4.

5.

3. Press CALIBRATION REPORT to continue.

A0033679-EN

Your file system explorer window appears. You are asked to save the calibration

report as a PDF file.

4. Enter a file name for the calibration report and select a memory location in your file

system.

The calibration report is just being saved on your file system.

5.

A0033682-EN

Either press EXIT to end the calibration report wizard, press SELECT CALIBRATION

POINT to select another stored self-calibration point or press READ OLDER

CALIBRATION POINT to switch to the previous self-calibration point.

The creation of a self-calibration report is finished. The saved PDF-file can be opened to

read or to print the calibration report.

Endress+Hauser 27

Page 28

Commissioning iTHERM TrustSens TM371, TM372

Relevant self-calibration data for creating a report

Device information

Operating time Use this function to display the total count of hours when the device was

powered.

Stored self-calibration points Displays the amount of all stored self-calibration points. This device is

able to store 350 self-calibration points. As soon as the memory would

reach its limit, the oldest self-calibration point will be overwritten.

Requested self-calibration point Enter the number of the requested self-calibration point. The latest self-

calibration point always has the number "1".

Calibration point data

Calibration ID Use this number to identify a self-calibration point. Each number is

unique and is not editable.

Self-calibration status This function shows the validity of the self-calibration point data.

Operating hours This function displays the value of the operating hours counter of the

shown self-calibration point.

Measured temperature value This function displays the measured Pt100 temperature value at that

specific time of the self-calibration.

Deviation This function displays the measured Pt100 self-calibration deviation from

the reference temperature. The deviation is calculated as follows:

Self-calibration deviation = reference temperature - measured Pt100

temperature value + adjustment

Adjustment This function displays the adjustment value added to the measured Pt100

value. This influences the self-calibration deviation. → 80

New adjustment = Adjustment - deviation of last self-calibration point

Measurement uncertainty This functions displays the maximum measurement uncertainty at the

self-calibration temperature.

Lower alarm value This function displays the defined lower alarm limit value. → 81

Upper alarm value This function displays the defined upper alarm limit value. → 81

Device restart counter Displays the device restarts between now and when the displayed self-

calibration was executed.

8.5 Protecting settings from unauthorized access

Use this function to protect the device from unwanted changes.

Navigation

Expert menu → System → Administration → Define device write protection code

If the code is programmed into the device firmware it is saved in the device and the

operating tool displays the value 0 so that the defined write protection code is not openly

displayed for viewing.

User entry: 0 to 9 999

Factory default: 0 = write protection is not active.

To activate the write protection please go through the following steps:

1. Define a write protection in the Enter access code parameter.

2. Enter a code which does not correspond the the one which is defined in step 1.

The device is now write protected.

28 Endress+Hauser

Page 29

iTHERM TrustSens TM371, TM372 Commissioning

Heartbeat Diagnostics

Heartbeat Verification

Pass/Fail

}

· ......................

· ......................

· ......................

· ......................

· ......................

Heartbeat Monitoring

Heartbeat Technology

TM

Deactivate the write protection

Enter the defined code in the Enter access code parameter.

‣

The device is not write protected.

If the write protection code has been forgotten, it can be deleted or overwritten by the

service organization.

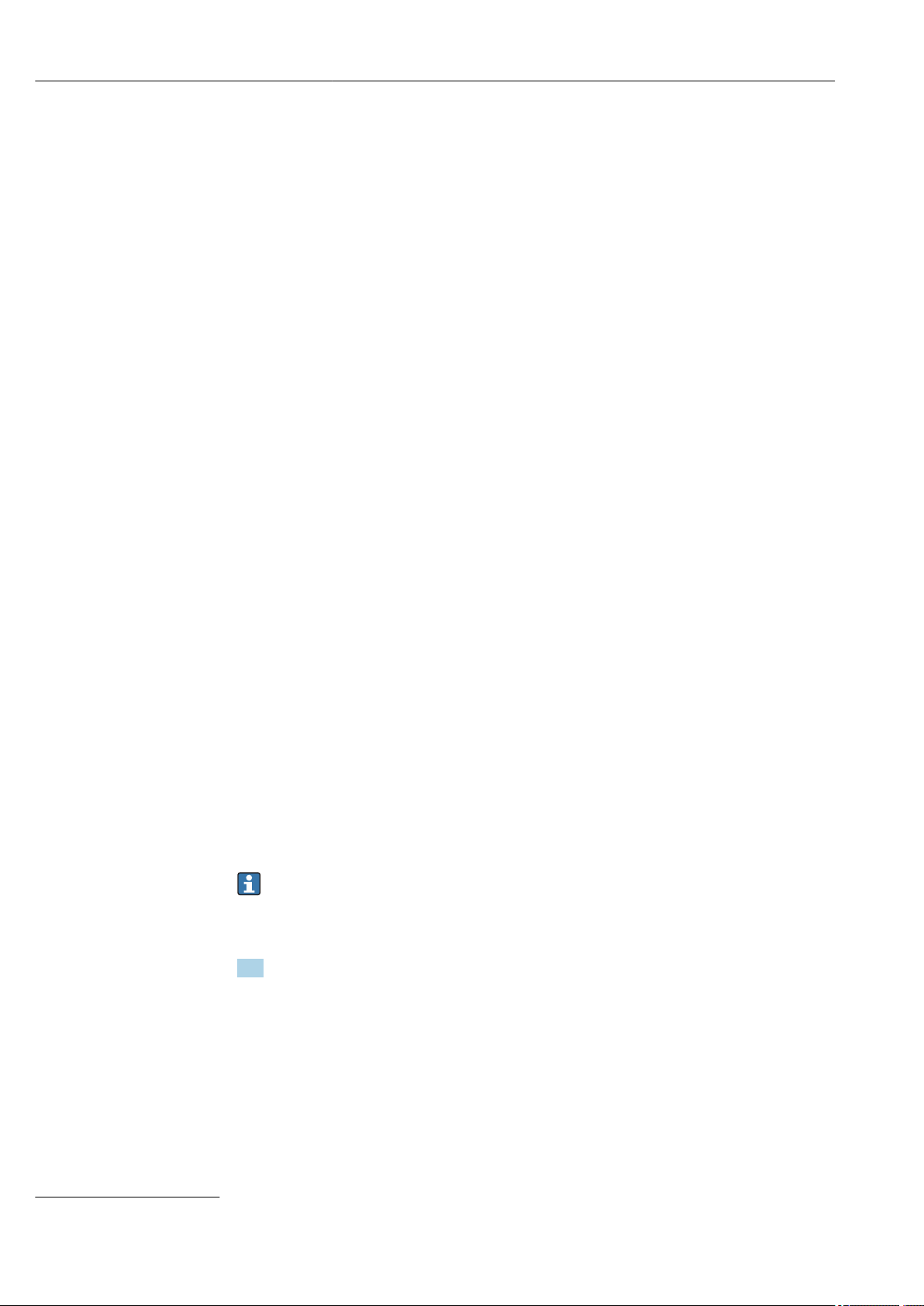

8.6 Advanced settings

The section contains a description of the additional parameters and technical data that are

available with the Heartbeat Verification and Heartbeat Monitoring application

packages.

8.6.1 Heartbeat modules

Overview

9 Heartbeat modules

The modules are available in all the device versions. The Heartbeat functionality is

available with the revised device driver software (DTM, version 1.11.zz and higher).

Short description of the modules

Heartbeat Diagnostics

Function

• Continuous self-monitoring of the device.

• Diagnostic messages output to

– a local display, optional

– an asset management system (e.g. FieldCare/DeviceCare)

– an automation system (e.g. PLC)

Advantages

• Device condition information is available immediately and processed in time.

• The status signals are classified in accordance with VDI/VDE 2650 and NAMUR

recommendation NE 107 and contain information about the cause of the error and

remedial action.

Detailed description

→ 30

A0020035

Endress+Hauser 29

Page 30

Commissioning iTHERM TrustSens TM371, TM372

Heartbeat Verification

Device functionality checked on demand

• Verification of the correct functioning of the measuring device within specifications.

• The verification result provides information about the condition of the device: "Passed" or

"Failed".

• The results are documented in a verification report.

• The automatically generated report supports the obligation to demonstrate compliance

with internal and external regulations, laws and standards.

• Verification is possible without interrupting the process.

Advantages

• No onsite presence is required to use the function.

• The DTM

1)

triggers verification in the device and interprets the results. No specific

knowledge is required on the part of the user.

• The verification report can be used to prove quality measures to a third party.

• Heartbeat Verification can replace other maintenance tasks (e.g. periodic check) or

extend the test intervals.

Detailed description

→ 31

Heartbeat Monitoring

Function

Calibration information is logged in addition to the verification parameters. 350

calibration points are saved in the device (FIFO memory).

Advantages

• Early detection of changes (trends) to ensure plant availability and product quality.

• Use of information for the proactive planning of measures (e.g. maintenance).

Detailed description

→ 33

8.6.2 Heartbeat Diagnostics

Device diagnostic messages, along with remedial measures, are displayed in the operating

tool (FieldCare/DeviceCare).

For information on using the diagnostic messages, see the "Diagnostics and

troubleshooting" section. → 35

Diagnostic message in the operating tool

1. Navigate to the "Diagnostics" menu.

The diagnostic event, along with the event text, is displayed in the Actual

diagnostics parameter.

1) DTM: Device Type Manager; controls device operation via DeviceCare, FieldCare, PACTware or a DTM-based control system.

30 Endress+Hauser

Page 31

iTHERM TrustSens TM371, TM372 Commissioning

2. On the right in the display area, hover the cursor over the "Actual diagnostics"

parameter.

A0037333-EN

A tool tip with remedy information for the diagnostic event appears.

8.6.3 Heartbeat Verification

Verification report

Creating the verification report using the wizard

The wizard to create a verification report is only available if the device is operated via

FieldCare, DeviceCare, PACTware or a DTM-based control system.

Navigation

Menu "Diagnostics → Heartbeat" → Heartbeat Verification

1. Press the Heartbeat Verification button.

The user-guided wizard appears.

2.

A0037334-EN

Endress+Hauser 31

Page 32

Commissioning iTHERM TrustSens TM371, TM372

3. Follow the instructions given by the wizard.

The wizard guides you through the entire process for creating the verification

report. The verification report can be saved in PDF and XML format.

The device must be in operation for at least 6 minutes before a verification can be

performed.

Content of the verification report

The verification report contains the results of the test objects: Passed or Failed is indicated

as the result.

Verification report: general information

Parameter Description/comments

Device information

System operator Name of the system operator; is defined when the verification report is created.

Location Location of the device within the plant; is defined when the verification report is

created.

Device tag Unique name for the measuring point so it can be identified quickly within the

plant. Is defined when commissioning the device.

Device name Displays the device name. It can also be found on the nameplate. It cannot be

changed.

Serial number Displays the serial number of the device. It can also be found on the nameplate.

It cannot be changed.

Order code Displays the order code of the device. It can also be found on the nameplate. It

cannot be changed.

Firmware version Displays the device firmware version installed. It cannot be changed.

Verification information

Operating time Indicates how long the device has been in operation up to this point.

Date/time Displays the current computer system time.

Comments Allows the user to enter optional comments, which appear in the verification

report.

Verification results

The test result for all the test

objects is given on the

subsequent pages. The

following results are possible:

• : Passed

• : Failed

Verification criteria for the test objects

Test object Verification criterion

Mainboard module

Electronics Checks the correct functioning of the electronics.

Memory content Checks the correct functioning of the data memory.

Supply voltage Checks the permitted supply voltage range.

Electronics temperature Checks the permitted electronics temperature range or device temperature

range.

32 Endress+Hauser

Page 33

iTHERM TrustSens TM371, TM372 Commissioning

Test object Verification criterion

Sensor module

Sensor Checks whether the sensor works as per the specifications.

Reference temperature Checks whether the reference sensor works as per the specifications.

Sensor drift warning limit

exceeded

Sensor drift alarm limit exceeded Checks whether the configured alarm limits are exceeded.

Sensor information

Number of self-calibrations Displays all the self-calibrations executed up to now. This value cannot be

Deviation Displays the deviation of the measured value from the reference

Adjustment of the measurement Displays the adjustment of the calibration deviation.

Monitoring parameters

Device temperature min: Displays the minimum electronics temperature measured in the past

Device temperature max: Displays the maximum electronics temperature measured in the past

Sensor min value: Displays the minimum temperature measured in the past at the sensor

Sensor max. value: Displays the maximum temperature measured in the past at the sensor

Checks whether the configured warning limits are exceeded.

reset.

temperature.

(peakhold indicator).

(peakhold indicator).

input (peakhold indicator).

input (peakhold indicator).

Summary of results

Overall

results

Displays the overall result of the verification. The verification report can be saved in PDF and XML

format. To save the report, click the Save results as PDF button or the Save results as XML

button.

If the verification fails, try again or contact the Service Organization.

8.6.4 Heartbeat Monitoring

Calibration information is logged in addition to the verification parameters.

HART variable Output Unit

PV Temperature °C/°F

SV Device temperature °C/°F

TV Calibration counter -

QV Calibration deviation °C/°F

Monitoring information can be read out and analyzed as described below:

A higher-level controller is configured in such a way that calibration deviations and the

calibration counter are saved when the calibration counter changes. This type of function

is supported by Endress+Hauser's Advanced Data Manager Memograph M RSG45, for

example. The following table provides a sample overview of the monitoring analysis using

the Field Data Manager software MS20:

Endress+Hauser 33

Page 34

Commissioning iTHERM TrustSens TM371, TM372

Time stamp Device name Category Text

25.07.2018 TrustSens 1 (example)Self-calibration EH_TM371_M7041504487: self-calibration

(ID=183)

Serial number: M7041504487

Device name: iTHERM TM371/372

Operating hours: 1626 h

Reference temperature: 118.67 °C

Measured temperature value: 118.68 °C

Deviation: 0.01 °C

Measuring uncertainty (k=2): 0.35 °C

Max. permitted deviation: -0.80 / +0.80 °C

Assessment

... ... ... ...

34 Endress+Hauser

Page 35

iTHERM TrustSens TM371, TM372 Diagnostics and troubleshooting

2

3

4

Commubox

PMC731: PIC0001

Online

1 >Group Select

2 PV 0.7 bar

HELP

SEND

HOME

1

1

9 Diagnostics and troubleshooting

9.1 Troubleshooting

Always start troubleshooting with the checklists below if faults occur after start up or

during operation. This takes you directly (via various queries) to the cause of the problem

and the appropriate remedial measures.

Due to its design, the device cannot be repaired. However, it is possible to send the

device back for examination. See the information in the "Return" section. → 41

General errors

Problem Possible cause Remedy

Device is not responding. Supply voltage range does not match

that specified on the nameplate.

M12 plug is not connected correctly,

wrong cable wiring.

Output current < 3.6 mA Device is defective. Replace the device.

HART communication is not

working.

Missing or incorrectly installed

communication resistor.

Apply correct voltage, see nameplate.

Check the wiring.

Install the communication resistor (250

Ω) correctly.

A0032326

1 TrustSens compact thermometer

2 HART® communication resistor, R =

≥ 250 Ω

3 PLC/DCS

4 Configuration examples: FieldCare

with Commubox, HART® handheld

communicator as well as via Field

Xpert SFX350/370

Commubox is not properly

Connect Commubox correctly .

connected.

9.2 Diagnostic information via LEDs

Position LEDs Function description

LED green (gn)

is illuminated

LED green (gn) is flashing

LED red (rd) and green

(gn) are flashing

alternating

A0031589

LED for device status

1

indication

LED red (rd) is flashing Presence of a diagnostic event: "Warning"

LED red (rd) is illuminated Presence of a diagnostic event: "Alarm"

Endress+Hauser 35

Voltage supply is correct. The device is

operational and the set limit values are met.

With a frequency 1 Hz: self-calibration

currently being performed.

With a frequency 5 Hz for 5 s: self-calibration

finished and valid, all process criteria were

within specifications. Calibration data stored.

Self-calibration process finished but not valid,

violation of necessary process criteria.

Calibration data not stored.

Page 36

Diagnostics and troubleshooting iTHERM TrustSens TM371, TM372

9.3 Diagnostic information

Status signal and diagnostic behavior can be configured manually.

Status signal - Digital information available via HART® communication

Letter/

symbol

F Failure The device or its periphery behaves in such a way that the measurement value is

C Function

S Out of

M Maintenance

Status signal Meaning of the status signal

no longer valid. This includes faults/failures which are caused by the process being

measured, but have an impact on the ability to perform a measurement e.g. “no

process signal” detected.

The device is deliberately serviced, configured, parameterized or is in simulation

check

specification

required

mode. A situation exists where the output signal does not represent the process

value and is therefore not valid.

The device is operating outside of its technical specifications or internal diagnostic

functions indicate that the current process conditions increase the measurement

uncertainty (i.e. during plant start-up or cleaning processes).

Deviation from normal operation, the device still works, but should be attended to

soon to ensure continued operation, e.g. build-up, corrosion, zero point

adjustment not possible or memory for data storage almost full.

1)

1) Valid for the default mappings to the diagnostic numbers

Diagnostic behavior - Analog information via current output and LED

Diagnostic behavior Meaning of the behavior

Alarm Measurement is interrupted. Mostly the measured data is invalid and the

configured failure current is set. A diagnostic message is generated.

Warning Usually, the device continues to measure. A diagnostic message is generated.

Disabled The diagnostic event is completely surpressed even if the device is not working

properly.

Diagnostics event and event text

Diagnostics event

Status signal Event number Event text

↓ ↓ ↓

Example 001 Device failure

3-digit number

The fault can be identified by means of the diagnostics event. The event text helps you by

providing information about the fault.

36 Endress+Hauser

Page 37

iTHERM TrustSens TM371, TM372 Diagnostics and troubleshooting

9.4 Overview of diagnostics events

Diagnostic events are assigned to a certain diagnostic number and a status signal. The user

can change this assignment for certain diagnostic events.

Example:

Settings Device behavior

Configuration example Diagnostic

number

Default setting 143 S Warning S Measured

Manual configuration:

Status signal S is switched to

F

Manual configuration:

diagnostic behavior

Warning is switched to

Alarm

Manual configuration:

Warning is switched to

Disabled

143 F Warning F Measured

143 S Alarm S Configured

143 S

Status

signal

1)

Diagnostic

behavior

(settings)

Disabled -

Status signal

(output via HART®

protocol)

2)

Output

current

value

value

failure

current

Last valid

measured

3)

value

PV, status LED

Measured value,

UNCERTAIN

Measured value,

UNCERTAIN

Measured value,

BAD

Last valid

measured value,

GOOD

Red is

flashing

Red is

flashing

Red is

illuminated

Green is

illuminated

1) Setting is not relevant.

2) Status signal is not indicated.

3) If there is no valid measured value, it is set to the failure current

Diagnostic

number

001 1 Device failure 1. Restart device.

004 2 Sensor defective Replace device. F

047 22 Sensor limit reached 1. Check sensor.

105 26 Manual calibration

143 21 Sensordrift Alarm

144 27 Sensordrift warning

221 29 Reference sensor

Priority Short text Remedy

2. Replace electronics.

2. Check process conditions.

1. Execute calibration and reset

interval expired

limit exceeded

limit exceeded

defective

3)

calibration interval.

2. Switch off calibration counter

1. Check self calibration alarm

limits.

2. Check value of adjustment.

3. Replace device

1. Check self calibration warning

limits.

2. Check value of adjustment.

3. Replace device

Replace device. M

Diagnostics

Not

1)

Diagnostic

behavior

from the

factory

Alarm

Warning

Status

signal

(factory

default)

F Alarm

S Warning

M Warning

S Warning

M Warning

Configurable

configurable

Configurable

Not

configurable

2)

Endress+Hauser 37

Page 38

Diagnostics and troubleshooting iTHERM TrustSens TM371, TM372

Diagnostic

number

Priority Short text Remedy

401 15 Factory reset active Factory reset in progress, please

wait.

402 16 Initialization active Initialization in progress, please

wait.

410 3 Data transfer failed 1. Check connection.

2. Repeat data transfer.

411 17 Up-/download active Up-/download in progress, please

wait.

435 5 Linearization faulty Check linearization. F

437 4 Configuration

Execute factory reset. F

incompatible

438 30 Dataset different 1. Check data set file.

2. Check device parameterization.

3. Download new device

parameterization.

485 18 Process variable

Deactivate simulation.

simulation activeSensor

491 19 Output simulation -

Deactivate simulation. C

current output

495 20 Diagnostic event

Deactivate simulation. C

simulation active

501 6 Wiring error

4)

Check wiring. F

Status

signal

(factory

default)

Configurable

1)

Diagnostic

behavior

from the

factory

Not

configurable

C

C

F

C

Warning

Warning

Alarm

Warning

Alarm

Alarm

M Warning

C Warning

Warning

Warning

Alarm

Configurable

Not

configurable

2)

531 6 Factory adjustment

missing

8 Factory adjustment

missing-Sensor

9 Factory adjustment

missing-Reference

1. Contact service organization.

2. Replace device.

sensor

10 Factory adjustment

missing-Current

output

537 11 Configuration 1. Check device configuration

2. Up- and download new

configuration

12 Configuration-Sensor 1. Check sensor configuration.

13 Configuration-

2. Check device configuration.

Reference sensor

14 Configuration-Current

output

1. Check application

2. Check the current output

parameterization

801 23 Supply voltage too low Increase supply voltage. S

825 24 Operating

temperature

1. Check ambient temperature.

2. Check process temperature.

F Alarm

F Alarm

Alarm

S

Warning

38 Endress+Hauser

Page 39

iTHERM TrustSens TM371, TM372 Diagnostics and troubleshooting

Not

1)

Diagnostic

behavior

from the

factory

Configurable

configurable

Status

Diagnostic

number

844 25 Process value out of

905 28 Self calibration

1) F, C, S, M, N can be configured

2) 'Alarm', 'Warning' and 'Disabled' can be configured

3) Reference sensor defective if temperature range of –45 to +200 °C (–49 to +392 °F) is exceeded. Temperature measurement continues, but self-

4) Leading error cause: CDI modem and loop are connected simultaneously, based on wrong connection (CDI modem or loop only) or defective cable

Priority Short text Remedy

1. Check process value.

specification

interval expired

calibration is permanently disabled.

plug.

2. Check application.

3. Check sensor.

1. Initiate self-calibration.

2. Deactivate self-calibration

interval monitoring.

3. Replace device

signal

(factory

default)

S Warning

M Warning

Configurable

configurable

2)

Not

9.5 Diagnostic list

If more than three diagnostic events occure simultaneously, only the messages with the

highest priorities are shown in the Diagnostics list. → 84 Characteristic feature of

the displayed priority is the status signal in the following order: F, C, S, M. If there are

several diagnostic events with the same status signal, the priority values from the table

above are used for ordering the diagnostic events, e.g.: F001 appears first, F501 appears

second and S047 appears last.

9.6 Event logbook

Diagnostic events that are no longer pending are shown in the Event logbook submenu.

→ 85

9.7 Firmware history

Revision history

The firmware version (FW) on the nameplate and in the Operating Instructions indicates

the device release: XX.YY.ZZ (example 01.02.01).

XX Change to main version. No longer compatible. Changes in the device

and Operating Instructions.

YY Change to functions and operation. Compatible. Changes in the

Operating Instructions.

ZZ Bug fixing. No changes to the Operating Instructions.

Date Firmware Version Modifications Documentation

09/17 01.00.zz Original firmware BA01581T/09

Endress+Hauser 39

Page 40

Maintenance iTHERM TrustSens TM371, TM372

10 Maintenance

In general, no specific maintenance is required for this device.

10.1 Cleaning

The sensor has to be cleaned as required. The cleaning can also be proceeded when the

device is installed (e.g. CIP Cleaning in Place / SIP Sterilization in Place). Care must be

taken to ensure that the sensor is not damaged during the cleaning.

The housing is resistant to typical cleaning agents from the outside. It passed the Ecolab

test.

40 Endress+Hauser

Page 41

iTHERM TrustSens TM371, TM372 Repair

11 Repair

Due to its design, the device cannot be repaired.

11.1 Spare parts

Currently available spare parts for your product can be found online at:

http://www.products.endress.com/spareparts_consumables. When ordering spare parts,

please quote the serial number of the device!

Type Order number

Plug screw fitting G1/2 1.4435 60022519

Spare Part Kit Press-Screw TK40 G1/4 d6 71215757

Spare Part Kit Press-Screw TK40 G1/2 d6 71217633

Weld-in adapter G3/4 d=50, 316L, 3.1 52018765

Weld-in adapter G3/4, d=29, 316L, 3.1 52028295

G1/2 metal to metal weld in adapter 60021387

Weld in adapter M12x1.5 316L&1.4435 71405560

O-ring 14.9x2.7 VMQ, FDA, 5 pieces 52021717

Weld-in adapter G3/4 d=55, 316L 52001052

Weld-in adapter G3/4, 316L, 3.1 52011897

O-ring 21.89x2.62 VMQ, FDA, 5 pcs. 52014473

Weld-in adapter G1, d=60, 316L 52001051

Weld-in adapter G1, d=60, 316L, 3.1 52011896

Weld-in adapter G1, d=53, 316L, 3.1 71093129

O-ring 28.17x3.53 VMQ, FDA, 5 pcs. 52014472

Adapter for Ingold connection 60017887

O-ring set for Ingold connection 60018911

Grip cap flexible yellow TPE 71275424

iTHERM TK40 compression fitting TK40-

Spare Part Kit sealing TK40 XPT0001-

iTHERM TT411 thermowell TT411-

11.2 Return

The measuring device must be returned if it is need of repair or a factory calibration, or if

the wrong measuring device has been delivered or ordered. Legal specifications require

Endress+Hauser, as an ISO-certified company, to follow certain procedures when handling

products that are in contact with the medium.

To ensure safe, swift and professional device returns, please refer to the procedure and

conditions for returning devices provided on the Endress+Hauser website at

http://www.endress.com/support/return-material

11.3 Disposal

The device contains electronic components and must therefore be disposed of as electronic

waste. Please pay particular attention to the national disposal regulations in your country.

Please seperate the different components according to their material consistence.

Endress+Hauser 41

Page 42

Accessories iTHERM TrustSens TM371, TM372

!30 (1.18)

16 (0.63)

34 (1.34)

15 (0.6)

G½”

M12x1.5

!7.6 (0.3)

!20 (0.8)

13 (0.51)

17 (0.67)

8 (0.31)

!18

(0.71)

G½”/

M12x1.5

37 (1.46)

AF22

G 1¼”

50 (1.97)

12 Accessories

12.1 Device-specific accessories

Device-specific accessories

Accessories Description

Welding boss with sealing taper (metal -

metal)

Welding boss for G½" and M12x1.5 thread

Metal-sealing; conical

Material of wetted parts: 316L/1.4435

Max. process pressure 16 bar (232 PSI)

Order number:

• 60021387 (G½")

• 71405560 (M12x1.5)

Dummy plug

A0006621

A0018236

Dummy plug for G½” or M12x1.5 conical metal-sealing welding boss

Material: SS 316L/1.4435

Order number:

• 60022519 (G½")

• 60021194 (M12x1.5)

A0009213-EN

Weld-in adapter for Ingold process

connections

Material of wetted parts: 316L/1.4435

Weight: 0.32 kg (0.7 lb)

Order number: 60017887

O-ring seal set

• Silicone O-ring in accordance with FDA CFR 21

• Maximum temperature: 230 °C (446 °F)

• Order number: 60018911

42 Endress+Hauser

A0008956

Page 43

iTHERM TrustSens TM371, TM372 Accessories

ø

26 (1.0)

25 (1.0)

ø

29 (1.1)

30 (1.2)

G

ISO 228

¾"

ø32 (1.3)

ø

50 (2.0)

26 (1.0)

21 (0.8)

ø

32 (1.3)

G ¾

ISO 228

"

26 (1.0)

ø

55 (2.2)

21 (0.8)

ø

32 (1.3)

G ¾

ISO 228

"

ø50 (2.0)

ø53 (2.1)

47.8 (1.9)

24.6 (1.0)

30°

21 (0.8)

ø41 (1.6)

G 1"

ISO 228

Weld-in adapter for FTL31/33/20,

pipe-mounting

A0008265

1) A seal is included in the delivery.

Weld-in adapter for FTL31/33/20,

vessel-mounting

G¾", d=29 mm, without flange

Material: 316L

Roughness in μm (μin): 1.5 (59.1)

Order number: 52028295 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52021717

compliant

G¾", d=50 mm, with flange

Material: 316L

Roughness in μm (μin): 0.8 (31.5)

Order number: 52018765 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52021717

compliant

EHEDG tested and 3-A marked

1)

, FDA-

1)

, FDA-

A0008810

1) A seal is included in the delivery.

Weld-in adapter for FTL50

A0008274

1) A seal is included in the delivery.

Weld-in adapter for FTL50

G¾", d=55 mm, with flange

Material: 316L

Roughness in μm (μin): 0.8 (31.5)

Order number: 52001052 (without inspection certificate

EN10204-3.1 material)

Order number: 52011897 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52014473

compliant

Order number weld-in dummy: MVT2L0692

EHEDG tested and 3-A marked

G1", d=53 mm, without flange

Material: 316L

Roughness in μm (μin): 0.8 (31.5)

Order number: 71093129 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52014472

compliant

Order number weld-in dummy: MVT2L0691

1)

, FDA-

1)

, FDA-

1) A seal is included in the delivery.

A0011927

Endress+Hauser 43

Page 44

Accessories iTHERM TrustSens TM371, TM372

ø41 (1.6)

G 1"

ISO 228

ø60 (2.4)

29.6 (1.2)

24.6 (1.0)

26 (1.02)

5 (0.2)

ø65 (2.56)

!D

20 (0.79)

35 (1.38)

Weld-in adapter for FTL50

A0008267

1) A seal is included in the delivery.

Weld-in adapter for FTL50

G1", d=60 mm, with flange

Material: 316L

Roughness in μm (μin): 0.8 (31.5)

Order number: 52001051 (without inspection certificate

EN10204-3.1 material)

Order number: 52011896 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52014472

compliant

Order number weld-in dummy: MVT2L0691

EHEDG tested and 3-A marked

G1", can be aligned

Material: 316L

Roughness in μm (μin): 0.8 (31.5)

Order number: 52001221 (without inspection certificate

EN10204-3.1 material)

Order number: 52011898 (with inspection certificate EN10204-3.1

material)

Order number seal (5-pc. set): silicone O-ring 52014424

compliant

Order number weld-in dummy: M40167

1)

, FDA-

1)

, FDA-

A0008272

1) A seal is included in the delivery.

Flexible handle cap to cover the

QuickNeck bottom part

Diameter ⌀D: 24 to 26 mm (0.94 to 1.02 in)

Material: Thermoplastic polyolefin - elastomer (TPE), free from

plasticizers

Maximum temperature: +150 °C (+302 °F)

Order number: 71275424

A0027201

Maximum process pressure for the weld-in adapters:

• 25 bar (362 PSI) at maximum 150 °C (302 °F)

• 40 bar (580 PSI) at maximum 100 °C (212 °F)

For more information on the weld-in adapters, see Technical Information (TI00426F/

00).

44 Endress+Hauser

Page 45

iTHERM TrustSens TM371, TM372 Accessories

USB

FieldCare/

DeviceCare

USB

USB

driver

1

2 (WH) nc

2

1 (BN) +

4

3 (BU) -

3

4 (BK) nc

1

2 (WH) nc

2

1 (BN) +

4

3 (BU) -

3

4 (BK) nc

A

B

USB

drivers

12.2 Communication-specific accessories

Configuration kit TXU10

Commubox FXA291

Cordset M12x1, angle plug

Configuration kit for CDI communication with PC-programmable

devices. Includes interface cable for PC with USB port and M12x1

coupling (Non-Ex area).

Order code: TXU10-BD

A0028635

Connects Endress+Hauser field devices with a CDI interface (=

Endress+Hauser Common Data Interface) and the USB port of a