Endress+Hauser TH55 Specifications

TI00112R/09/EN/14.18

71404946

2018-05-31

Products

Solutions Services

Technical Information

TH53, TH54 and TH55

Thermocouple assemblies in thermowells with

spring loaded insert and enclosure for process

industry

Application

The TH53, TH54 and TH55 temperature sensors are thermocouple assemblies

installed in thermowells and designed for use in all types of process industries,

including heavy industries, due to their rugged design. They are made up of a

magnesium oxide insulated thermocouple as a measurement probe and a thermowell

made of barstock material.

The sensor assemblies can be used in process industries such as:

• Chemicals

• Petrochemicals

• Power plants

• Refineries

• Offshore platforms

Head transmitter

All Endress+Hauser transmitters are available with enhanced accuracy and reliability

compared to directly wired sensors. Instead of directly wiring your temperature

sensors to your control system, use transmitters to reduce wiring and maintenance

costs while increasing measurement accuracy.

Field transmitter

Temperature field transmitters with HART® or FOUNDATION Fieldbus™ protocol for

highest reliability in harsh industrial environments. Backlit display with large

measured value, bargraph and fault condition indication for ease of reading.

Your benefits

• One source shopping for temperature measurement solutions. World class

transmitter with integrated sensor offering for heavy process industry applications.

• Remove and install straight out of the box!

• Improved galvanic isolation on most devices (2 kV).

• Simplified model structure: Competitively priced, offers great value. Easy to order

and reorder. A single model number includes sensor, thermowell and transmitter

assembly for a complete point solution.

• All iTEMP transmitters provide long-term stability ≤ 0.05% per year.

Function and system design

K

E

E

P

T

I

G

H

T

W

H

E

N

C

I

R

C

U

I

T

A

L

I

V

E

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

°C

°F

%

K

10

0

20

30

40

50

60

70

80

90

100

!

K

E

E

P

T

I

G

H

T

W

H

E

N

C

I

R

C

U

I

T

A

L

I

V

E

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

°C

°F

%

K

10

0

20

30

40

50

60

70

80

90

100

!

Endress+Hauser

RMS 621

On

∆p (Q)

T2

T1

Deltabar S

TMT162

TMT162

TH54

flanged thermowell

TH53

tilted,

threaded

thermowell

RMS621

Heat

exchange

process

Measuring principle Thermocouples (TC)

Thermocouples are comparatively simple, robust temperature sensors which use the Seebeck effect

for temperature measurement: if two electrical conductors made of different materials are connected

at a point, a weak electrical voltage can be measured between the two open conductor ends if the

conductors are subjected to a thermal gradient. This voltage is called thermoelectric voltage or

electromotive force (emf.). Its magnitude depends on the type of conducting materials and the

temperature difference between the "measuring point" (the junction of the two conductors) and the

"cold junction" (the open conductor ends). Accordingly, thermocouples primarily only measure

differences in temperature. The absolute temperature at the measuring point can be determined

from these if the associated temperature at the cold junction is known or is measured separately and

compensated for. The material combinations and associated thermoelectric voltage/temperature

characteristics of the most common types of thermocouple are standardized in the IEC 60584 and

ASTM E230/ANSI MC96.1 standards.

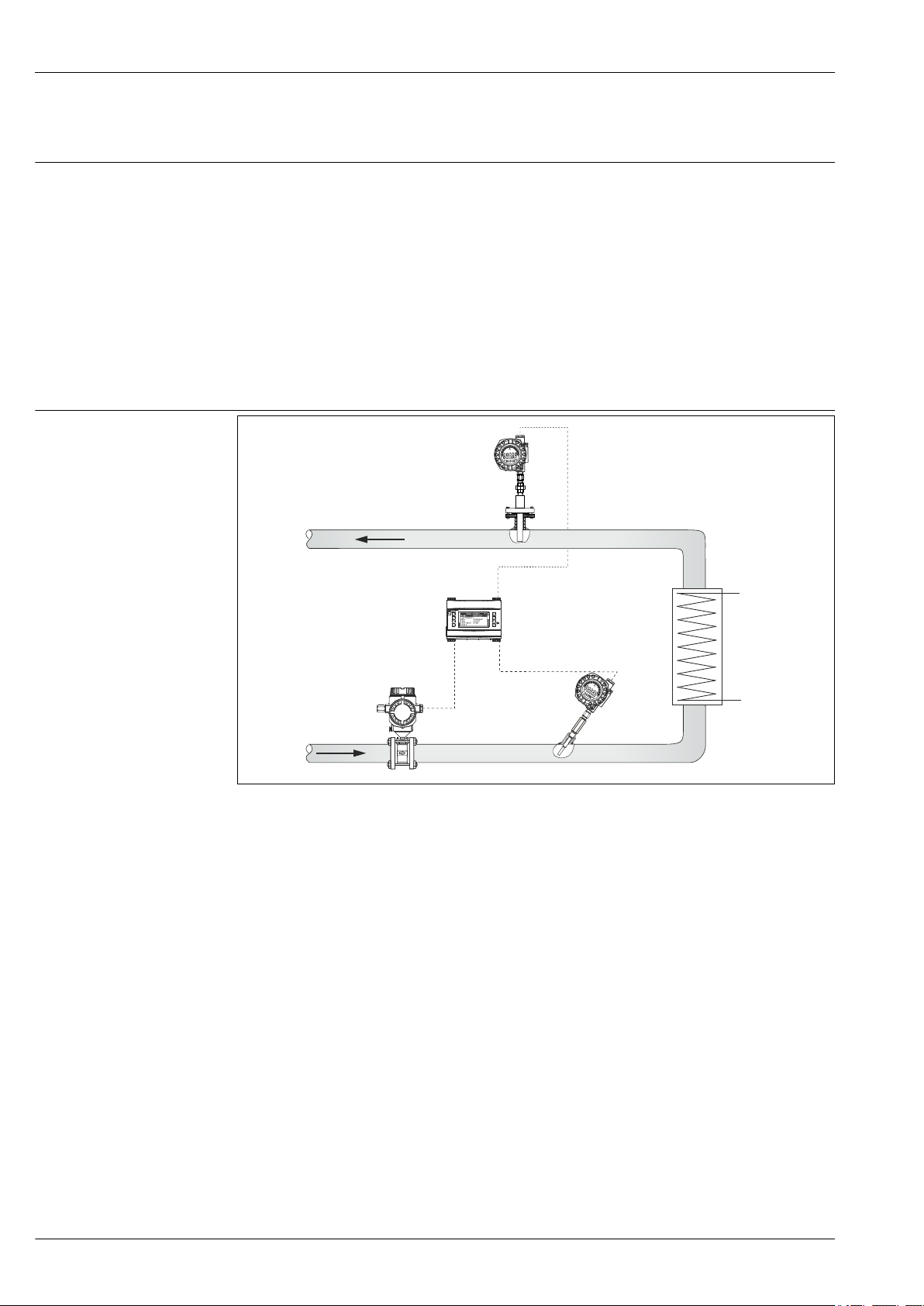

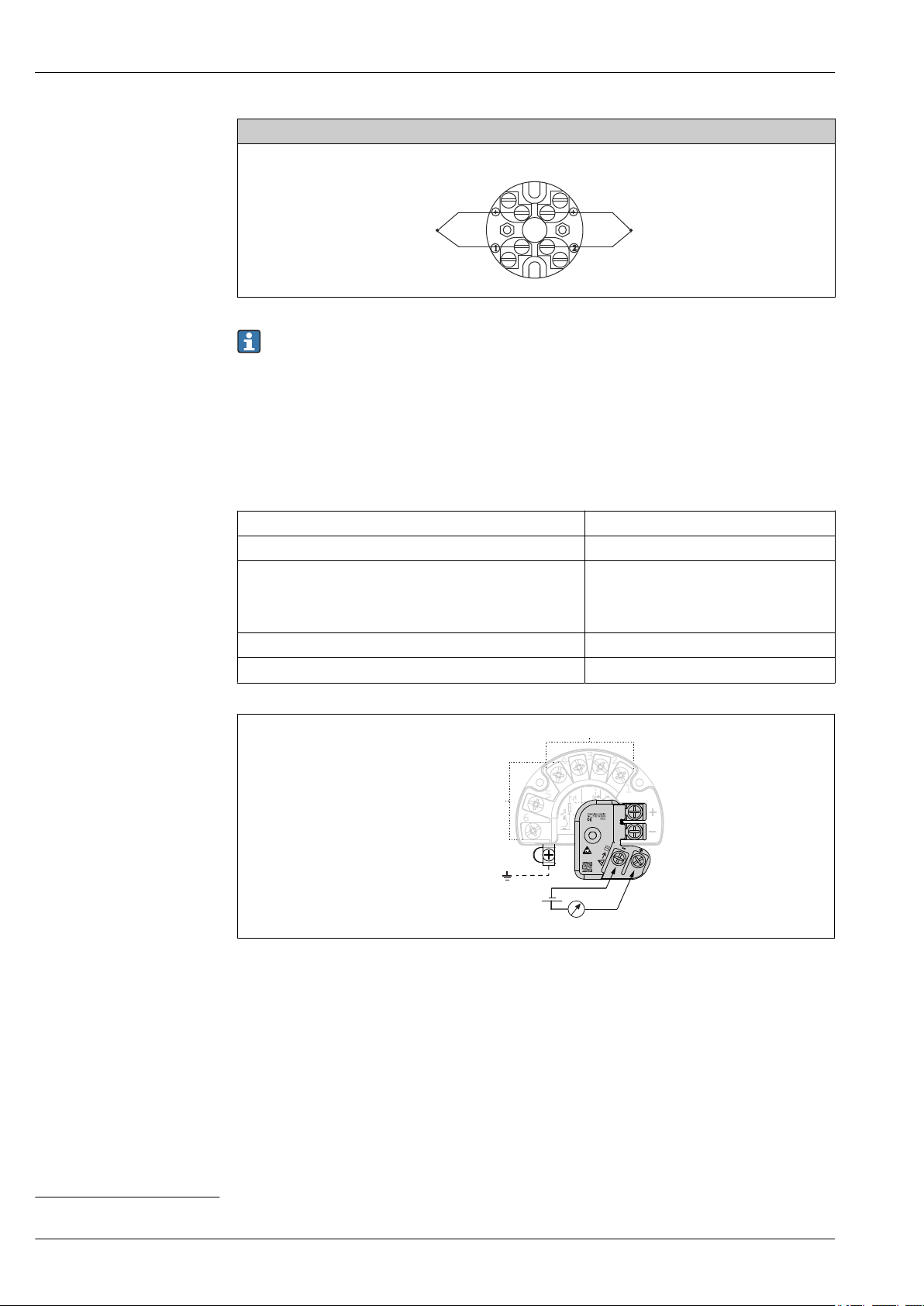

Measuring system

TH53, TH54 and TH55

A0027371-EN

1 Application example

Calculation of heat quantity which is emitted or absorbed by a water flow in a heating or cooling

system. The quantity of heat is calculated from the process variable for Δp flow (Q) and the

differential from the feed and return temperature (T2 - T1). Bidirectional energy calculations, such

as the calculating systems with changing flow direction (charging/ discharging the heat

accumulator) are also possible.

Energy manager RMS621

Energy conservation and cost expenditures are significant issues in today's industry. Accurate flow monitoring

2 Endress+Hauser

and calculation is the basis for thorough analysis and billing of energy. This data can serve as a basis to

maximize savings potential and help in controlling operational costs on a daily basis. Endress+Hauser's energy

managers provide accurate and reliable calculations for the monitoring and control of energy consumption

(both produced and consumed) according to international standards, e.g. IAPWS-IF 97, AGA8, ISO 5167 etc.

For RMS621 details, see "Documentation".

iTEMP TMT162 Temperature Field Transmitter

Aluminum or stainless steel dual compartment explosion - proof enclosure and compact, fully potted electronics

provide the ultimate protection in harshest environments. TMT162 prevents costly plant shutdowns by

detecting corrosion on RTDs or thermocouples before it corrupts the measured value. Endress+Hauser's Field

Temperature Transmitters with backlit display and sensor backup functionality are designed with safety in

mind to keep your plant, equipment and personnel safe. More information on this can be found in the Technical

Information, see "Documentation".

TH53, TH54 and TH55

Deltabar S/Cerabar S

The evolution series of Cerabar S/Deltabar S represents a decisive step ahead in making pressure

instrumentation better and safer for the process industry. The development of new products thrives especially

on the knowledge, commitment and experience of staff members. Permanent high performance can only be

achieved if dedicated and enthusiastic people provide their ideas. Endress+Hauser's instruments are not only

supposed to distinguish themselves for customers and users by technological novelties but also by the presence

of people supporting this progress, be it in service, sales or production. More information on this can be found

in the Technical Information, see "Documentation".

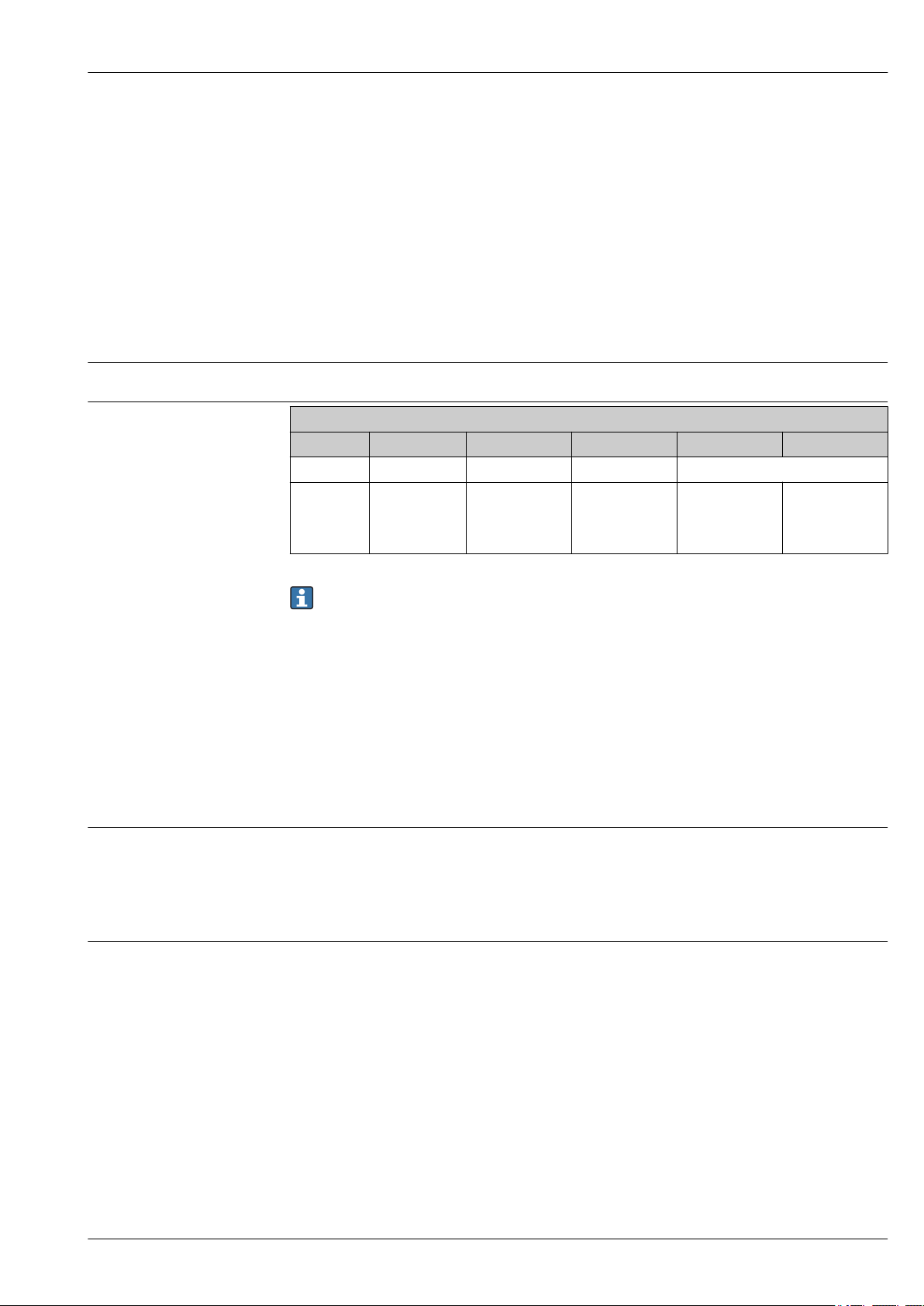

Input

Measured variable

Measurement range

Temperature (temperature-linear transmission behavior)

Upper Temperature limits for various thermocouple types in °C (°F)

Sheath OD Type T Type J Type E Type K Type N

⌀¼" 370 °C (700 °F) 720 °C (1 330 °F) 820 °C (1 510 °F) 1 150 °C (2 100 °F)

Maximum

element

temperature

range limits

–270 to +400 °C

(–

454 to +752 °F)

–210 to +1 200 °C

(–

346 to +2 192 °F)

–270 to +1 000 °C

(–

454 to +1 832 °F)

–270 to +1 372 °C

(–

454 to +2 500 °F)

–270 to +1 300 °C

454 to +2 372 °F)

These values are valid for single and duplex thermocouples. The temperature limits given are

intended only as a guide to the user and should not be taken as absolute values or as

guarantees of satisfactory life or performance. These types and sizes are sometimes used at

temperatures above the given limits, but usually at the expense of stability or life or both. In

other instances, it may be necessary to reduce the above limits in order to achieve adequate

service.

Thermocouples with 316 SS sheath and assemblies with 316 SS thermowells are rated for a

maximum temperature of 927 °C (1 700 °F).

Output

(–

Output signal

Generally, the measured value can be transmitted in one of two ways:

• Directly-wired sensors - sensor measured values forwarded without a transmitter.

• Via all common protocols by selecting an appropriate Endress+Hauser iTEMP temperature

transmitter. All the transmitters listed below are mounted directly in the terminal head or as field

transmitter and wired with the sensory mechanism.

Family of temperature transmitters

Thermometers fitted with iTEMP transmitters are an installation-ready complete solution to

improve temperature measurement by significantly increasing accuracy and reliability, when

compared to direct wired sensors, as well as reducing both wiring and maintenance costs.

PC programmable head transmitters

They offer a high degree of flexibility, thereby supporting universal application with low inventory

storage. The iTEMP transmitters can be configured quickly and easily at a PC. Endress+Hauser offers

free configuration software which can be downloaded from the Endress+Hauser Website. More

information can be found in the Technical Information.

HART® programmable head transmitters

The transmitter is a 2-wire device with one or two measuring inputs and one analog output. The

device not only transfers converted signals from resistance thermometers and thermocouples, it also

transfers resistance and voltage signals using HART® communication. It can be installed as an

intrinsically safe apparatus in Zone 1 hazardous areas and is used for instrumentation in the

terminal head (flat face) as per DIN EN 50446. Swift and easy operation, visualization and

Endress+Hauser 3

TH53, TH54 and TH55

maintenance using universal device configuration tools like FieldCare, DeviceCare or

FieldCommunicator 375/475. For more information, see the Technical Information.

PROFIBUS® PA head transmitters

Universally programmable head transmitter with PROFIBUS® PA communication. Conversion of

various input signals into digital output signals. High accuracy over the complete ambient

temperature range. The configuration of PROFIBUS PA functions and of device-specific parameters is

performed via fieldbus communication. For more information, see the Technical Information.

FOUNDATION Fieldbus™ head transmitters

Universally programmable head transmitter with FOUNDATION Fieldbus™ communication.

Conversion of various input signals into digital output signals. High accuracy over the complete

ambient temperature range. All transmitters are released for use in all important process control

systems. The integration tests are performed in Endress+Hauser's "System World". For more

information, see the Technical Information.

Advantages of the iTEMP transmitters:

• Dual or single sensor input (optionally for certain transmitters)

• Pluggable display (optionally for certain transmitters)

• Unsurpassed reliability, accuracy and long-term stability in critical processes

• Mathematical functions

• Monitoring of the thermometer drift, sensor backup functionality, sensor diagnostic functions

• Sensor-transmitter matching for dual sensor input transmitters, based on Callendar/Van Dusen

coefficients

Field transmitter

Field transmitter with HART® or FOUNDATION Fieldbus™ communication and backlit display. Can

be read easily from a distance, in sunlight and at night. Large measurement value, bargraph and

fault indication displayed. Benefits are: dual sensor input, highest reliability in harsh industrial

environments, mathematic functions, thermometer drift monitoring and sensor back-up

functionality, corrosion detection.

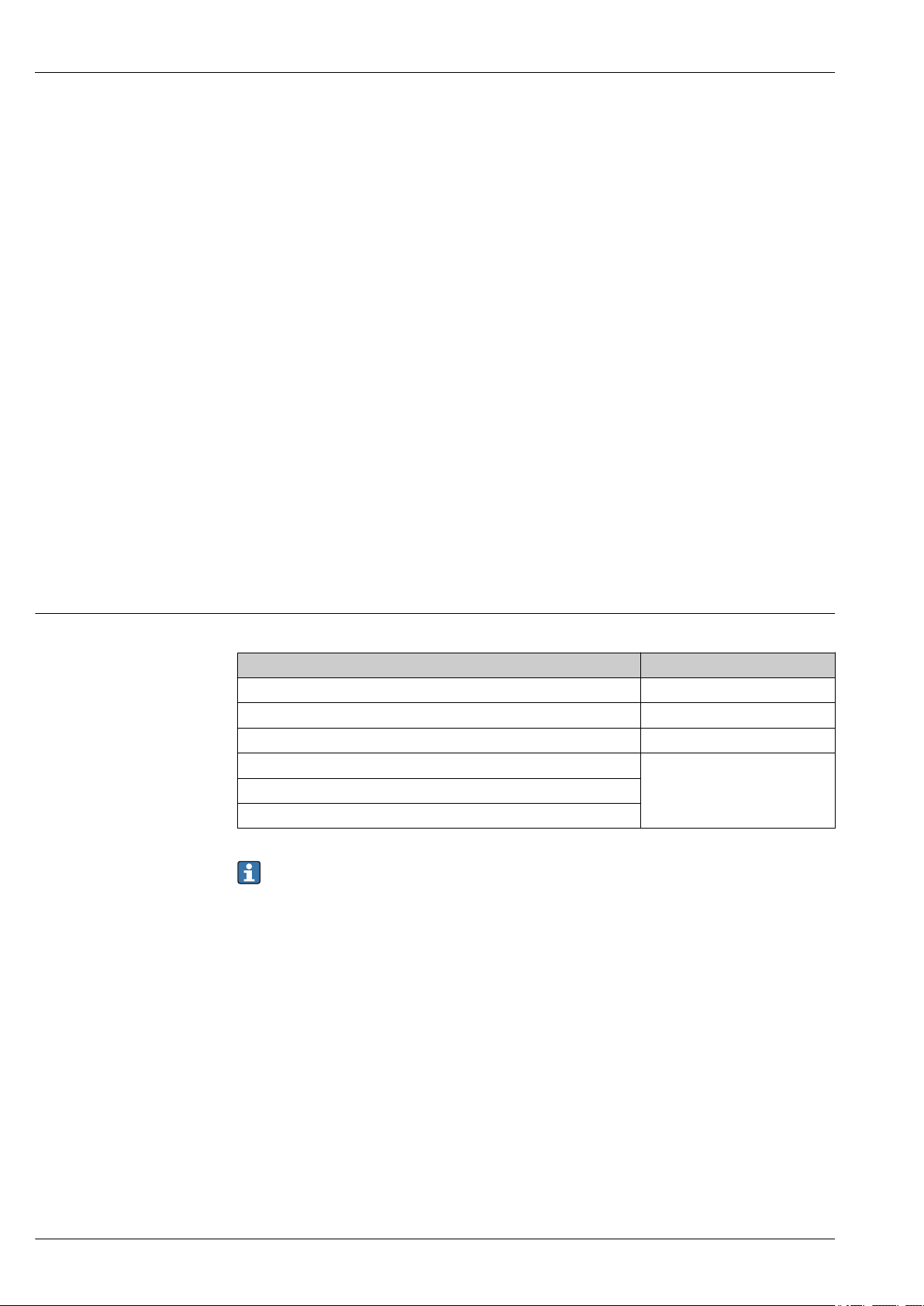

Galvanic isolation

Galvanic isolation of Endress+Hauser iTEMP transmitters

Transmitter type Sensor

TMT181 PCP Û = 3.75 kV AC

TMT182 HART® U = 2 kV AC

TMT162 HART® Field transmitter U = 2 kV AC

TMT82 HART®

U = 2 kV ACTMT84 PA

TMT85 FF

In applications where fast response time is needed, grounded thermocouples are recommended.

This thermocouple design may cause a ground loop. This can be avoided by using iTEMP

transmitters with high galvanic isolation.

4 Endress+Hauser

TH53, TH54 and TH55

1

2

11.5...35 V

11.5...30 V Ex

4

6

TC

mA

4...20 mA

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor

input 2

Sensor

input 1

Bus connection

and supply voltage

Display connection

TC

TC

+

-

1

2

3

4

5

6

+

-

3

4

S1

3

S2

-

+

+

-

#

Sensor 1

Sensor 2 (not TMT142)

Power supply

field transmitter and

analog output 4 to 20 mA,

or bus connection

1

6

2

5

TC

TC

Sensor 1

Sensor 2 (not TMT142)

Power supply

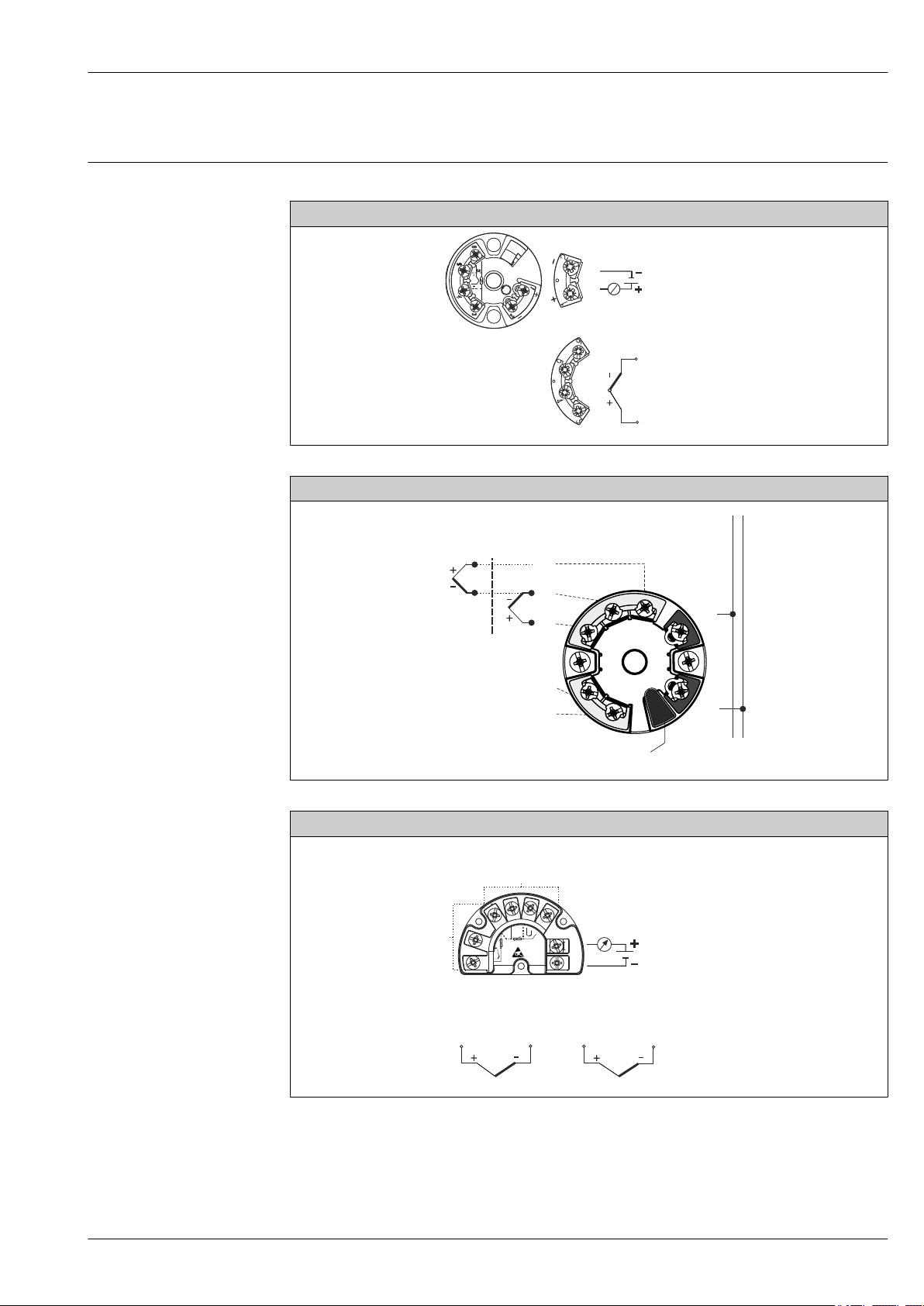

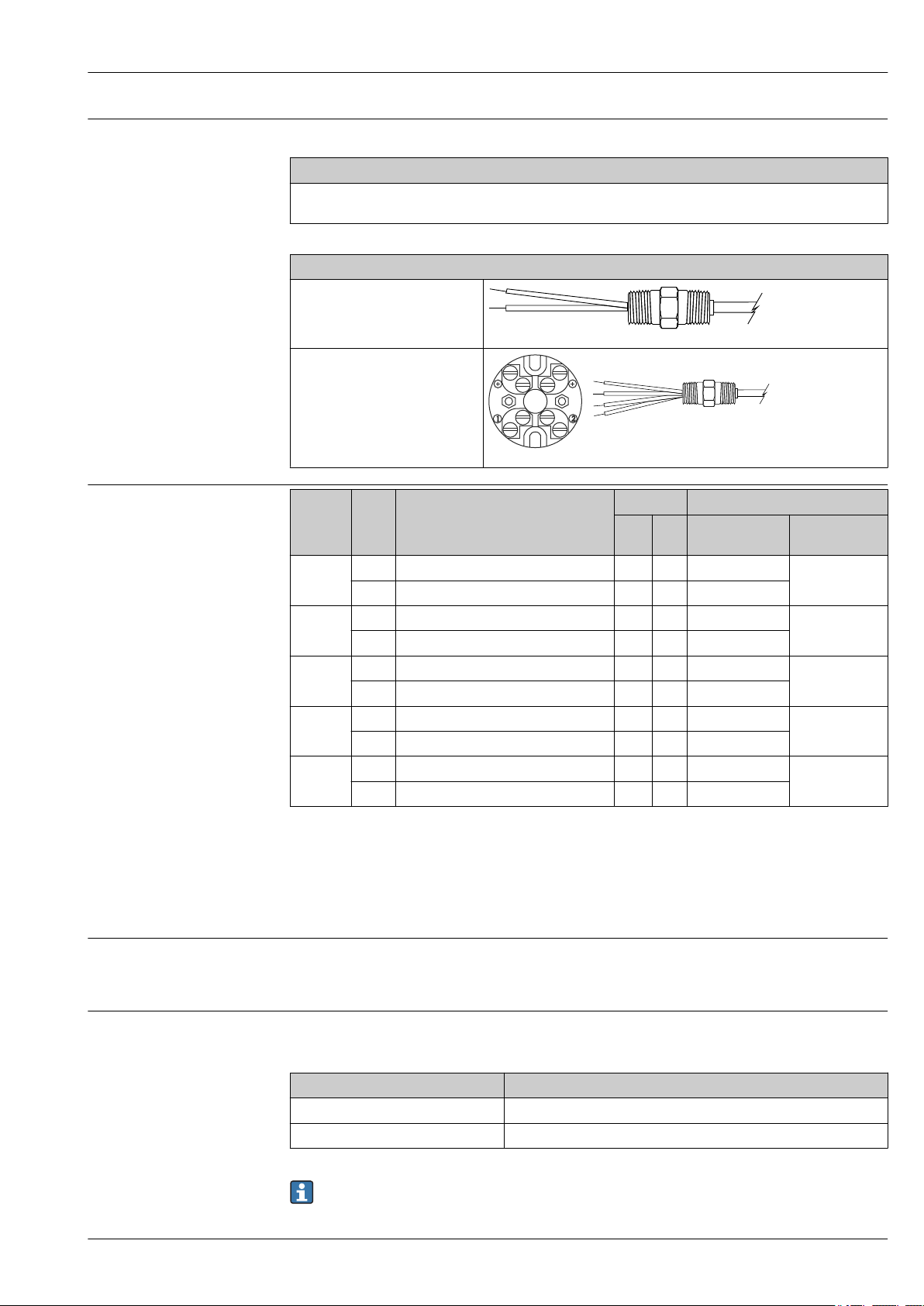

Terminal assignment

Type of sensor connection

Head transmitter mounted TMT18x (single input)

A0026046

Head mounted transmitter TMT8x (dual input)

Endress+Hauser 5

A0012699-EN

Field mounted transmitter

A0026944-EN

TH53, TH54 and TH55

1

2

-

-

+

+

Sensor 2

Sensor 1

4

+

-

1

2

3

5

6

+

-

3

4

S1

3

S2

-

+

+

-

!

+

Sensor 2

Sensor 1

-

Bus connection and

supply voltage

Terminal block mounted

A0026045-EN

The blocks and transmitters are shown as they sit inside the heads in reference to the conduit

opening.

Integrated overvoltage protection

The integrated overvoltage protection module can be ordered as an optional extra

protects the electronics from damage from overvoltage. Overvoltage occurring in signal cables (e.g.

4 to 20 mA, communication lines (fieldbus systems) and power supply is diverted to ground. The

functionality of the transmitter is not affected as no problematic voltage drop occurs.

Connection data:

1)

. The module

Maximum continuous voltage (rated voltage) UC = 42 V

Nominal current I = 0.5 A at T

Surge current resistance

• Lightning surge current D1 (10/350 µs)

• Nominal discharge current C1/C2 (8/20 µs)

• I

• In = 5 kA (per wire)

DC

amb.

= 1 kA (per wire)

imp

= 80 °C (176 °F)

In = 10 kA (total)

Temperature range –40 to +80 °C (–40 to +176 °F)

Series resistance per wire 1.8 Ω, tolerance ±5 %

2 Electrical connection of the overvoltage protection

A0033027-EN

Grounding

The device must be connected to the potential equalization. The connection between the housing and the local

ground must have a minimum cross-section of 4 mm2 (13 AWG) . All ground connections must be secured

tightly.

1) Available for the field transmitter with HART® 7 specification

6 Endress+Hauser

TH53, TH54 and TH55

1

2

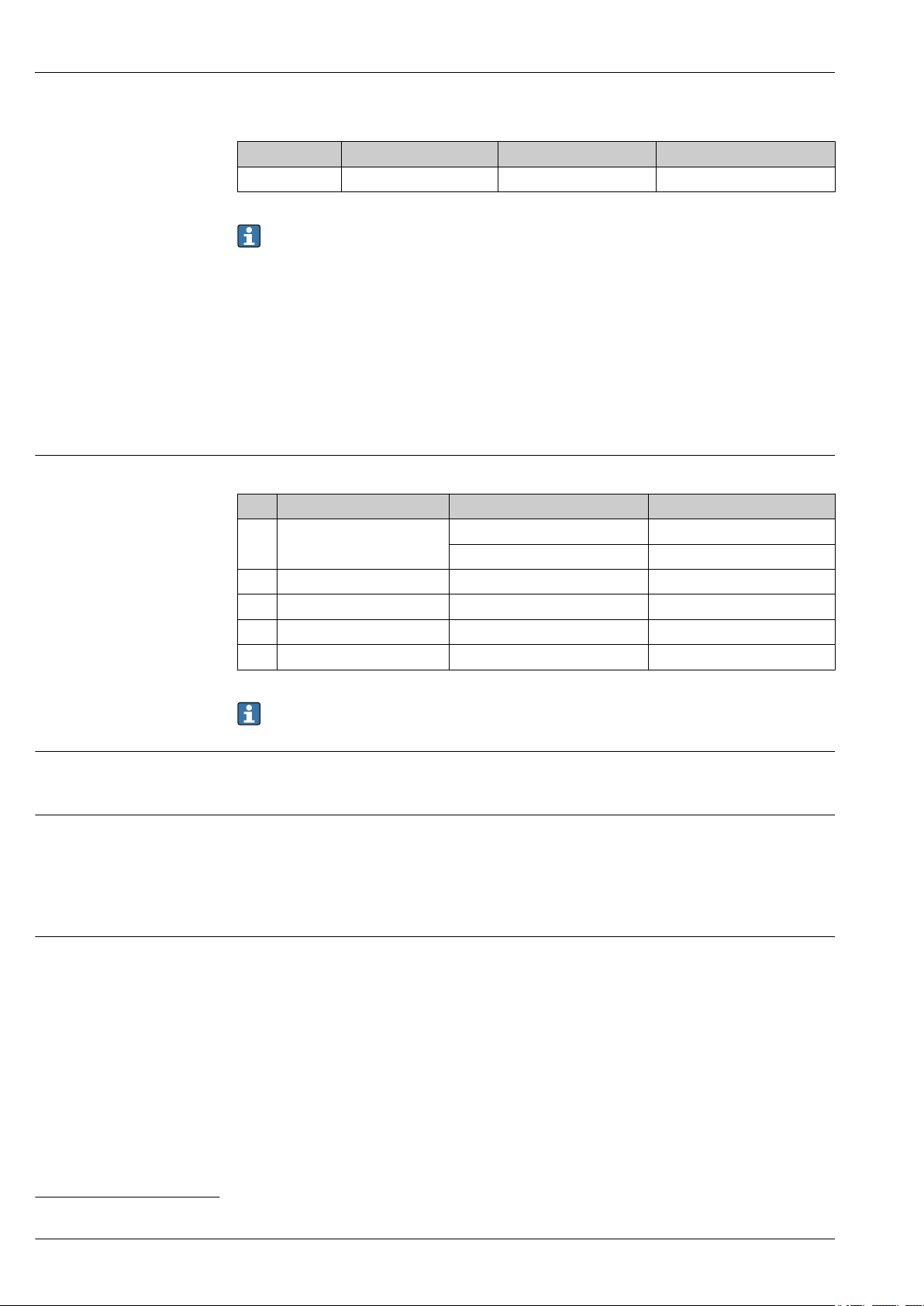

Wire specifications

Thermocouple color codes according to ASTM E-230

Thermocouple grade, TFE insulated 20AWG, 7 strands with stripped ends

Electrical connection

Flying leads, standard 139.7 mm (5.5 in) for wiring in connection head, head mounted transmitter or terminal

block mounted, and for wiring with TMT162 or TMT142 assemblies

Design of leads

Flying leads 139.7 mm (5.5 in)

with stripped ends

A0027297

Connection with terminal block (4

pole) with stripped ends

A0027298

T.C. Type POS

E EP (+) Nickel - 10% chromium X Purple Brown

J JP (+) Iron X White Brown

K KP (+) Nickel - 10% chromium X Yellow Brown

T TP (+) Copper X Blue Brown

N NP (+) Nickel - 14% chromium - 1.5% silicon X Orange Brown

Material MAGNETIC Insulation

NEG

EN (-) Copper - 45% nickel (constantan) X Red

JN (-) Copper - 45% nickel (constantan) X Red

KN (-) Nickel - 5% (aluminum, silicon)

TN (-) Copper - 45% nickel (constantan) X Red

NN (-) Nickel - 4.5% silicon - 0.1% magnesium X Red

1)

YES NO Single conductor Overall T.C.

X Red

wire

1) Silicon, or aluminum and silicon may be present in combination with other elements.

Performance characteristics

Reference conditions

Response time

Endress+Hauser 7

These data are relevant for determining the accuracy of the temperature transmitters used. More

information on this can be found in the Technical Information of the iTEMP temperature

transmitters.

63% response time per ASTM E839

Thermocouple assembly TH55 without thermowell

Junction style Thermocouple insert ⌀¹⁄₄"

Grounded 1.3 s

Ungrounded 2.9 s

Response time for the sensor assembly without transmitter.

TH53, TH54 and TH55

Response time examples for thermocouples assemblies with thermowell TH53 and TH54

Construction Stepped thermowell Tapered thermowell ³⁄₄" straight thermowell

Time 15 s 20 s 25 s

Response times for thermocouple assemblies with thermowell are provided for general design

guidance without transmitter.

When the temperature of a process media changes, the output signal of a Thermocouple assembly

follows this change after a certain time delay. The physical cause is the time related to heat transfer

from the process media through the thermowell and the insert to the sensor element

(thermocouple). The manner in which the reading follows the change in temperature of the

assembly over time is referred to as the response time. Variables that influence or impact the

response time are:

• Wall thickness of thermowell

• Spacing between thermocouple insert and thermowell

• Sensor packing

• Process parameters such as media, flow velocity, etc.

Maximum measured error

Transmitter long-term stability

Insulation resistance

Thermocouples corresponding to ASTM E839

Type Temperature range Standard tolerance (IEC class 2) Special tolerance (IEC class 1)

[°C] whichever is greater [°C] whichever is greater

E 0 to 870 °C (32 to 1 600 °F)

J 0 to 760 °C (32 to 1 400 °F) ±2.2 or ±0.75% ±1.1 or ±0.4%

K 0 to 1 260 °C (32 to 2 300 °F) ±2.2 or ±0.75% ±1.1 or ±0.4%

T 0 to 370 °C (32 to 700 °F) ±1 or 0.75% ±0.5 or ±0.4%

N 0 to 1 260 °C (32 to 2 300 °F) ±2.2 or ±0.75% ±1.1 or ±0.4%

±1.7 or ±0.5% ±1 or ±0.4%

For measurement errors in °F, calculate using equation above in °C, then mulitply the outcome

by 1.8.

≤ 0.1 °C (0.18 °F) / year or ≤ 0.05 % / year

Data under reference conditions; % relates to the set span. The larger value applies.

Insulation resistance for MgO insulated thermocouples with ungrounded hot junction between

terminals and probe sheath, test voltage 500 VDC.

1000 MΩ at 25 °C (77 °F)

These values for insulation resistance also apply between each thermocouple wire at single and

duplex constructions with ungrounded hot junction.

Calibration specifications

The manufacturer provides an option to provide comparison temperature calibrations from

–20 to 300 °C (–4 to 572 °F)

2)

on the International Temperature Scale of 1990. Calibrations are

traceable to standards maintained by the National Institute of Standards and Technology (NIST).

Calibration services are in conformance with ASTM E220, IEC 17025 and ANSI/NCSL Z540-1-1994.

The report of calibration is referenced to the serial number of the assembly.

Three point calibrations are provided, given that the specified temperatures are within the

recommended range and the minimum length requirements are met as specified. The minimum

length is based on the overall length "x" of the spring loaded insert.

2) Other ranges may be available on request.

8 Endress+Hauser

Loading...

Loading...