Endress+Hauser Promag 10, Promag 50, Promag 51, Promag 53, Promag 55 Installation Instruction

...

Installation Instruction

Sensor parts remote version

Promag 10, 50, 51, 53, 55, Promass 80, 83, 84, Promag 400, Promag 800

EA00038D/06/A2/13.12

71191694

Instruction is valid for the following spare part sets:

! Note!

• The order number of the spare part set (on the packaging label) can differ from the product number (on the label directly on the spare part)!

• The order number of the relevant spare part set can be found by entering the product number of the spare part in the spare parts finder.

• We recommend that the Installation Instructions be kept with the packaging at all times.

Confirmation whether the spare part is permitted to be used with the measuring device

The spare parts set and Installation Instructions are used to replace a faulty unit with a functioning unit of the same type. Use genuine parts from

Endress+Hauser only. Only original spare parts supplied by Endress+Hauser shall be used with the measuring device. Therefore, before use, check

whether the spare part set is compatible with the measuring device.

A spare parts overview label is located in the connection compartment cover of the measuring device. If there is no label or the spare part is not

listed the appropriate spare part can also be identified via W@M Device Viewer.

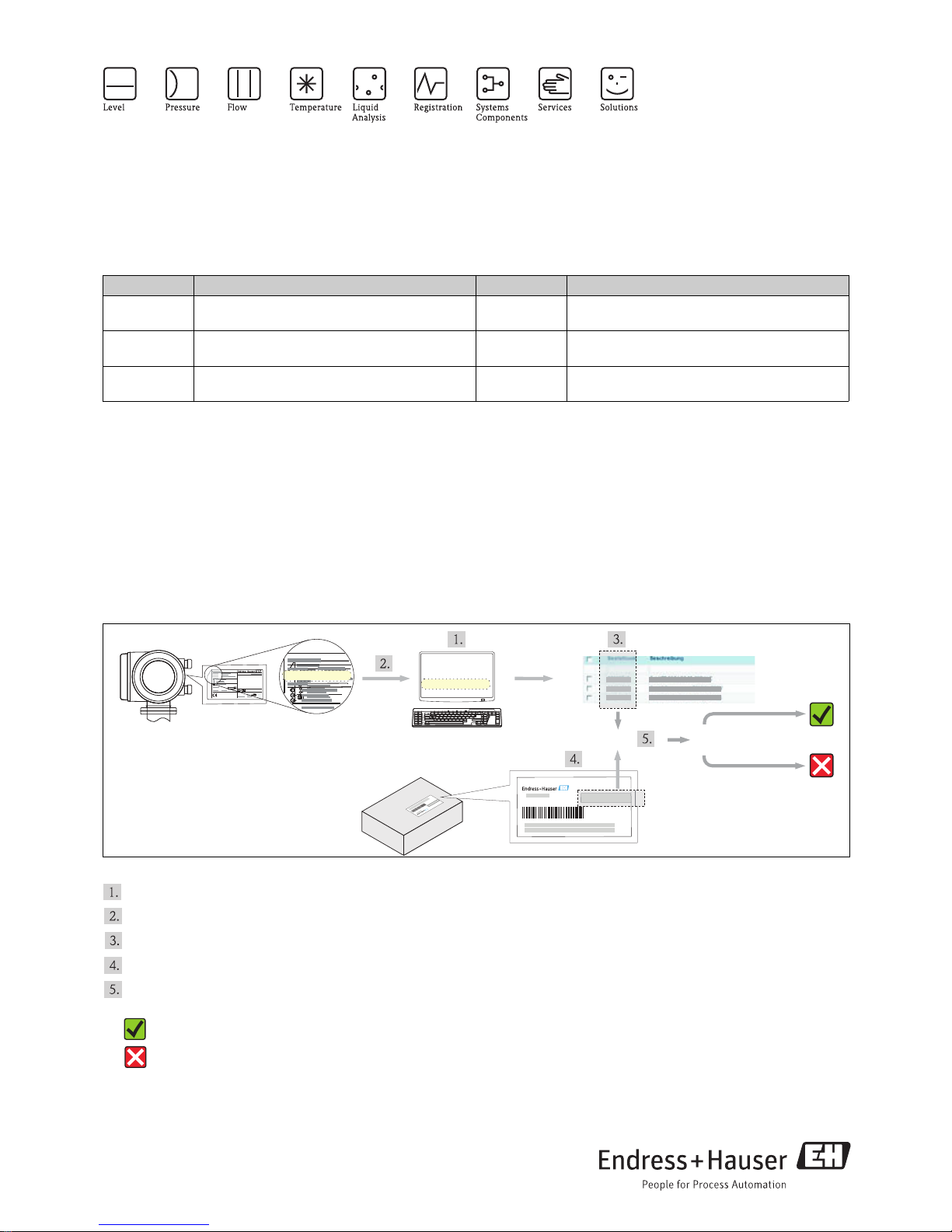

How carrying out such a check via the W@M Device Viewer is described below:

A0016264

If you have any questions, contact your Endress+Hauser service organization.

Order number Device component Order number Device component

50098705

Kit connection board,

1 × connection board, FS sensor

71039495

Kit connection board, FS HE Ex,

1 × connection board, FS sensor Ex HEC

71039494

Kit connection board, FS HE,

1 × connection board, FS sensor HEC

50098018

Kit connection board, FS

1 × connection board, FS sensor

50098706

Kit connection board, FS Ex,

1 × connection board, FS sensor Ex

71039497

Kit connection board, FS HE

1 × connection board, FS sensor HEC

Choose the Endress+Hauser Device Viewer via web browser: www.endress.com/deviceviewer

Enter the serial number (Ser. No.) of the device into the W@M Device Viewer (on the label of the transmitter), then click on "Spare parts".

The list of the available spare parts for the device is displayed.

Check the order number on the packaging label of the spare part set.

Check whether the order number of the spare part set is specified in the list displayed by the device viewer:

= YES, the spare part can be used.

= NO, the spare part may not be used.

www.endress.com/deviceviewer

Device Viewer

Ser. No.:

12345

i

i

Ser.No.:1234567890

Ser. No.:

12345

=

?

Sensor parts remote version

2 Endress + Hauser

Overview of the personnel authorized to carry out repairs

Authorization to carry out a repair depends on the approval of the measuring device. The table shows the respective group of persons for each.

! Note!

The person who carries out the repair is responsible for safety during the work, the quality of work completed and safety of the device after repair.

Safety instructions

• Check whether the spare part matches the identification label on the

measuring device, as explained on the first page.

• The spare parts set and Installation Instructions are used to replace

a faulty unit with a functioning unit of the same type.

Use genuine parts from Endress+Hauser only.

• In the case of Ex-certified measuring devices: Only open in

a de-energized state (once a delay of 10 minutes has elapsed after

switching off the power supply) or in environments which do not

have a potentially explosive atmosphere.

• The measuring device is energized. Danger: Risk of electric shock!

Open the measuring device in a de-energized state only.

• Before removing the device: set the process in a safe condition and

purge the pipe of dangerous materials.

• Hot surfaces! Risk of injury! Before commencing work, allow the

system and measuring device to cool down to a touchable

temperature.

• In the case of measuring devices in custody transfer, the custody

transfer status no longer applies once the lead seal has been removed.

• Comply with national regulations governing mounting, electrical

installation, commissioning, maintenance and repair procedures.

• Requirements with regard to specialized technical staff for the

mounting, electrical installation, commissioning, maintenance and

repair of the measuring devices:

–trained in instrument safety

–familiar with the individual operation conditions of the devices

–for Ex-certified measuring devices: also trained in explosion

protection

• Follow the Operating Instructions for the device.

• Risk of damaging electronic components! Ensure you have a working

environment protected from electrostatic discharge.

• After removing the electronics cover, there is a risk of electric shock

as shock protection is removed!

Switch off the measuring device before removing internal covers.

• Modifications to the measuring device are not permitted.

• In the case of measuring devices in safety-related applications in

accordance with IEC 61508 or IEC 61511: After repair recommission

in accordance with Operating Instructions. Document the repair

procedure.

• Only open housing for a brief period. Avoid the penetration of foreign

bodies, moisture or contaminants.

• Replace defective seal/gaskets with genuine parts from

Endress+Hauser only.

• If threads are damaged or defective, the measuring device must be

repaired.

• Threads (e.g. of the cover for the electronics and connection

compartments) must be lubricated. Use an acid-free, non-hardening

grease if an abrasion resistant dry lubricant is non-existent.

• If spacing is reduced or the dielectric strength of the measuring device

cannot be guaranteed during repair work, perform a test on

completion of the work (e.g. high-voltage test in accordance with the

manufacturer's instructions).

• Service connector:

–do not connect in potentially explosive atmospheres.

–only connect to Endress+Hauser service devices.

• Observe the instructions for transporting and returning the device

outlined in the Operating Instructions.

• If you have any questions, contact your E+H service organization.

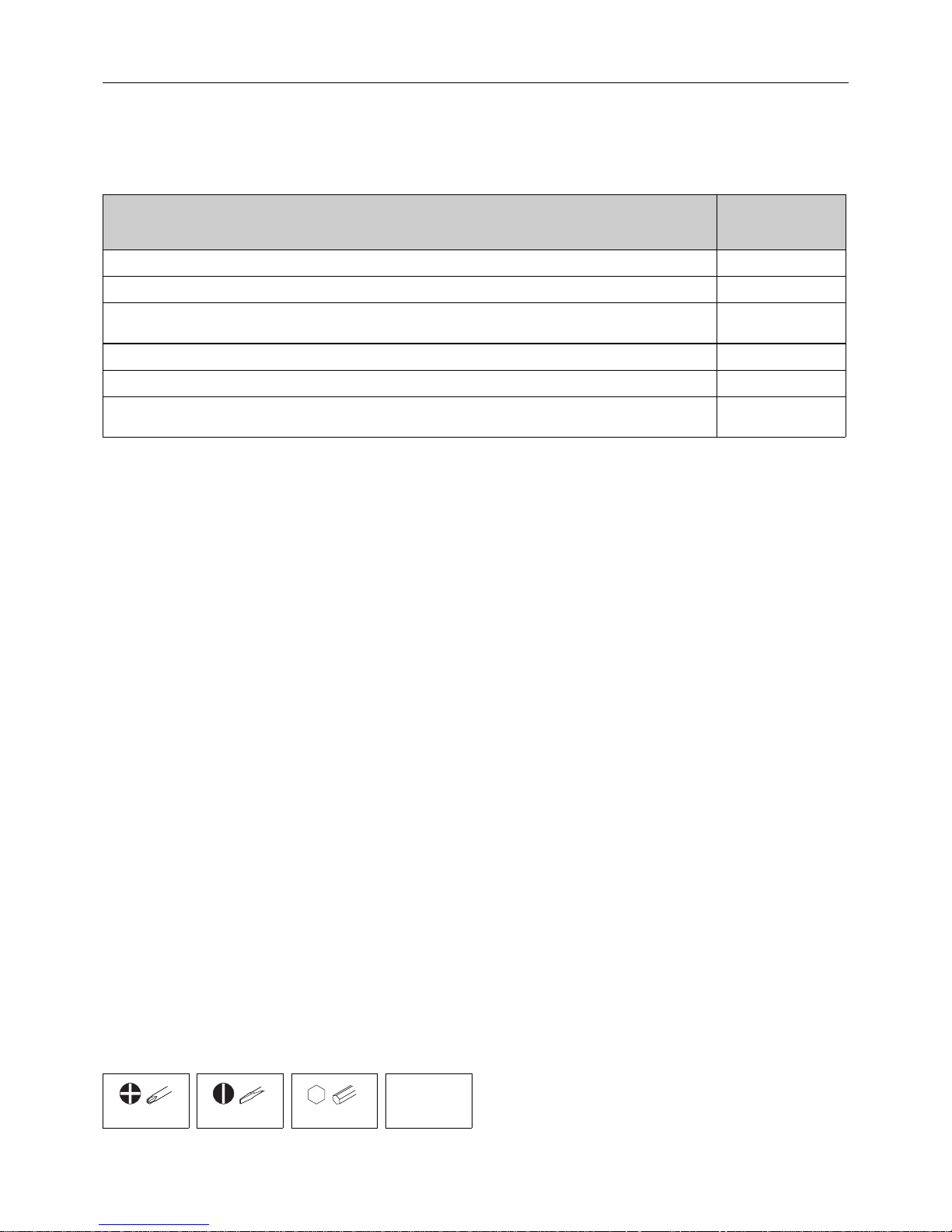

Tool List

Approval of the measuring device

Group of persons

authorized to carry

out repairs

Device without approval with spare part set: 50098705, 71039494, 50098018, 71039497 1, 2, 3

Device with approval ATEX II3G, FM/CSA Div. 2, with spare part set: 50098705, 71039494, 50098018, 71039497 1, 2, 3

Device with approval ATEX II2G, II1/2G, II2D, FM/CSA Div. 1, TIIS Zone 1, NEPSI Zone 1

with spare part set: 50098705, 71039494, 50098018, 71039497

–

Device without approval with spare part set: 50098706, 71039495 –

Device with approval ATEX II3G,

FM/CSA Div. 2, NEPSI Zone 2, with spare part set: 50098706, 71039495 –

Device with approval ATEX II2G, II1/2G, II2D, FM/CSA Div. 1, TIIS Zone 1, NEPSI Zone 1,

with spare part set: 50098706, 71039495

2, 3

1 Trained customer technician

1*Trained customer technician, trained by Endress+Hauser (for repairs carried out on devices with type approval)

2 Service technician authorized by Endress+Hauser

3 Endress+Hauser (send measuring device back to manufacturer)

PH2 0.5 × 3.5 3 mm, 8 mm

acid-free,

non hardening

grease

Sensor parts remote version

Endress + Hauser 3

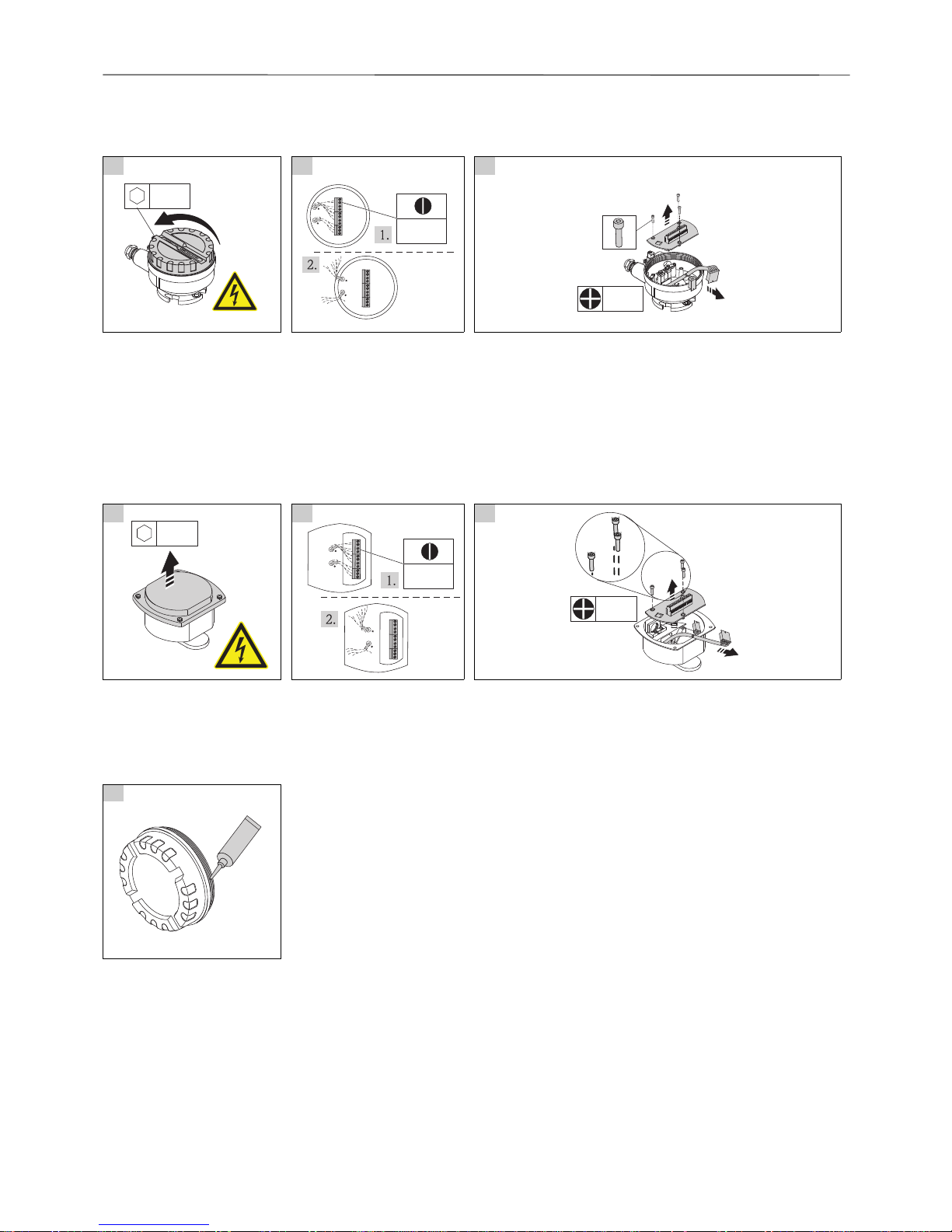

Field housing remote version

A Replacing connection board

! Note! Promass:

Non-Ex-certified measuring devices: Terminal strip is green!

Ex-certified measuring devices: Terminal strip is blue!

! Note! For wiring diagram see connection compartment cover.

Stainless Steel housing remote version

A Replacing connection board

B Re-assembly

Re-assembly is carried out in reverse order, unless otherwise instructed.

The following must be noted:

1 2 3

A0012995 A0013016 A0013017

3 mm

4

567

8

9

1

114

4

01

2

1

2

4

567

8

9

1

114

4

01

2

1

2

0.5 ×3.5

Ph2

1 2 3

A0013023 A0013025 A0013026

8 mm

4

5678911

144

01

212

4

5678911

144

01

212

0.5 ×3.5

Ph2

1

A0011687

Loading...

Loading...