Endress+Hauser Promag 50W, Promag 50, Promag 53, Promag 53P, Promag 53W Conversion Instructions

...

NOTICE

NOTICE

EA00059D/06/A2/13.15

Products Solutions Services

71294946

Conversion Instructions

Conversion transmitter Promag 50/53 W, P, H to Promag 55 remote version

Promag 50W, P, H, 53W, P, H

Instruction is valid for the following conversion kit:

Order-Code Conversion kit

DK5UP8

1 × notice label for the sensor

1 × form data storage

1 × conversion instruction

Overview of the personnel authorized to carry out conversion

Authorization to carry out

for each.

The person who carries out conversion is responsible for safety during the work, the quality of work completed and safety of the device

after conversion.

Approval of the measuring device Group of persons authorized to carry out conversion

without approval 1, 2, 3

with approval FM/CSA Div. 2 1, 2, 3

1 Trained customer technician

2 Service technician authorized by Endress+Hauser

3 Endress+Hauser (send measuring device back to manufacturer)

conversion

depends on the approval of the measuring device. The table shows the respective group of persons

Transmitter that can be used for the conversion

The transmitter for the conversion has to be ordered seperatly. Only transmitter with the following order code can be used:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Order-Code

Transmitter

Promag

55XXX–XXXXXA, R C, S, 3 *****

Conversion transmitter Promag 50/53 W, P, H to Promag 55 remote version

Safety instructions

• Use genuine parts from Endress+Hauser only.

• In the case of Ex-certified measuring devices: Only open in

a de-energized state (once a delay of 10 minutes has elapsed

after switching off the power supply) or in environments which

do not have a potentially explosive atmosphere.

• The measuring device is energized. Danger: Risk of electric

shock! Open the measuring device in a de-energized state only.

• Before removing the device: set the process in a safe condition

and purge the pipe of dangerous materials.

• Hot surfaces! Risk of injury! Before commencing work, allow the

system and measuring device to cool down to a touchable

temperature.

• Comply with national regulations governing mounting, electrical

installation, commissioning, maintenance and conversion

procedures.

• Requirements with regard to specialized technical staff for the

mounting, electrical installation, commissioning, maintenance

and conversion of the measuring devices:

–trained in instrument safety

–familiar with the individual operation conditions of the devices

–for Ex-certified measuring devices: also trained in explosion

protection

• Follow the Operating Instructions for the device.

• Risk of damaging electronic components! Ensure you have

a working environment protected from electrostatic discharge.

• After removing the electronics cover, there is a risk of electric shock

as shock protection is removed!

Switch off the measuring device before removing internal covers.

• In the case of measuring devices in safety-related applications in

accordance with IEC 61508 or IEC 61511: After

conversion

recommission in accordance with Operating Instructions.

Document the

conversion

procedure.

• Only open housing for a brief period. Avoid the penetration of

foreign bodies, moisture or contaminants.

• Printed circuit boards for devices in categories II1G, II1D, II 2G,

II 2D, Zone 1 and Class I, Div. 1, Gp. A, B, C, D have a recess or

printed board code. Unauthorized breaking of this coding is not

permitted, as explosion protection will then be invalidated.

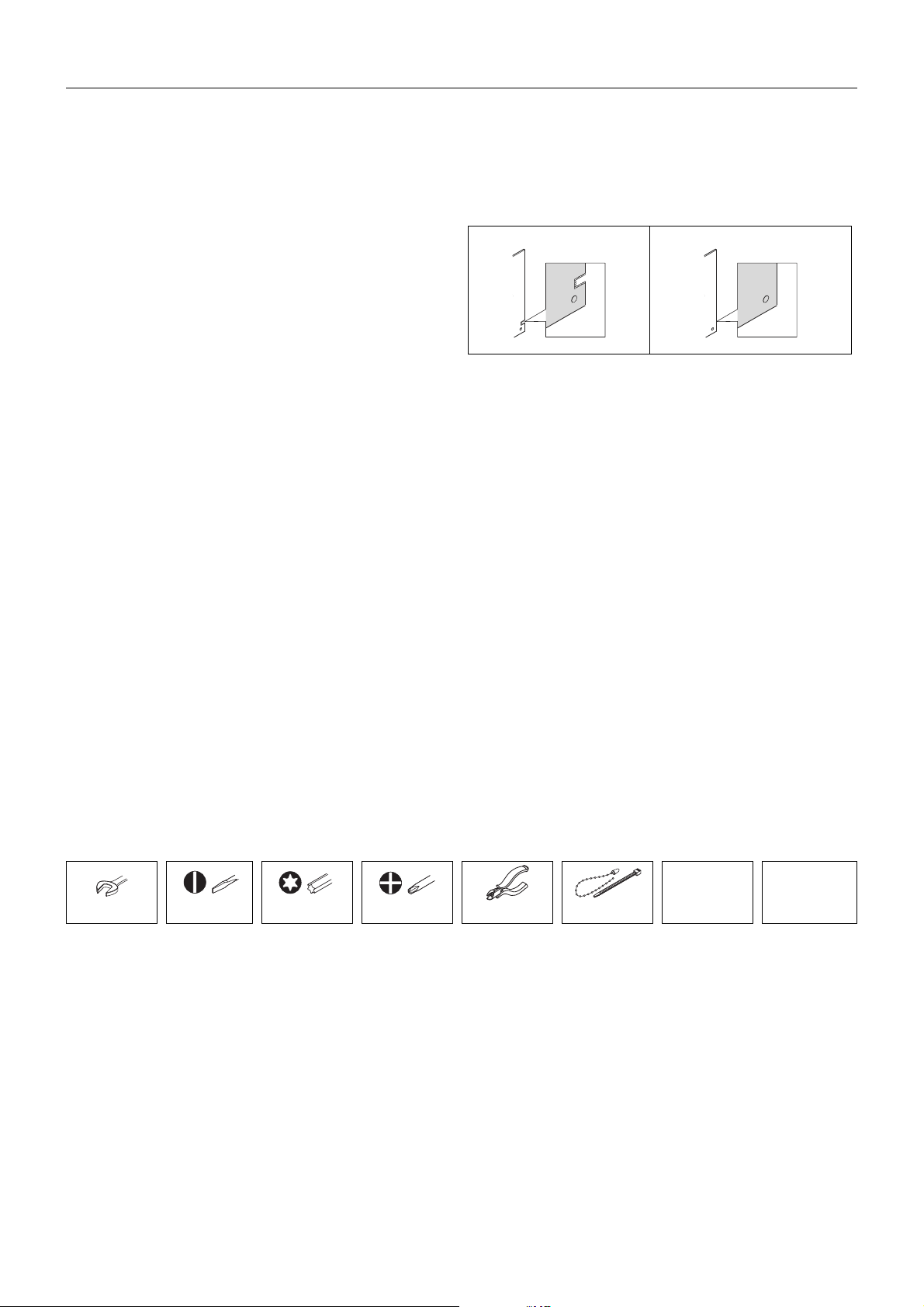

Example Coding, Ex-board

Example Coding, Non-Ex board

A0011688

A0011689

• Caution! When replacing amplifier boards, I/O boards or

submodules, ensure compatibility with existing software. The

process for reading out the software revision number is

described in the Operating Instructions (device functions). If the

software of the board is not compatible, it should be updated

using an operating software package (e.g. Field Care). In the

event of functional changes, notify the plant owner/operator.

• Replace defective seal/gaskets with genuine parts from

Endress+Hauser only.

• If threads are damaged or defective, the measuring device must

be repaired.

• Threads (e.g. of the cover for the electronics and connection

compartments) must be lubricated. Use an acid-free, non-hardening

grease if an abrasion resistant dry lubricant is non-existent.

• If spacing is reduced or the dielectric strength of the measuring

device cannot be guaranteed during conversion work, perform

a test on completion of the work (e.g. high-voltage test in

accordance with the manufacturer's instructions).

• Service connector:

–do not connect in potentially explosive atmospheres.

–only connect to Endress+Hauser service devices.

• Observe the instructions for transporting and returning the

device outlined in the Operating Instructions.

• If you have any questions, contact your E+H service

organization.

Tool List

pen/ tool

Ø < 2 mm

22 mm

0.5 × 3.5 mm T20 PH2 side cutter cable tie

(0.08 inch)

2 Endress + Hauser

acid-free,

non-hardening

grease

Conversion transmitter Promag 50/53 W, P, H to Promag 55 remote version

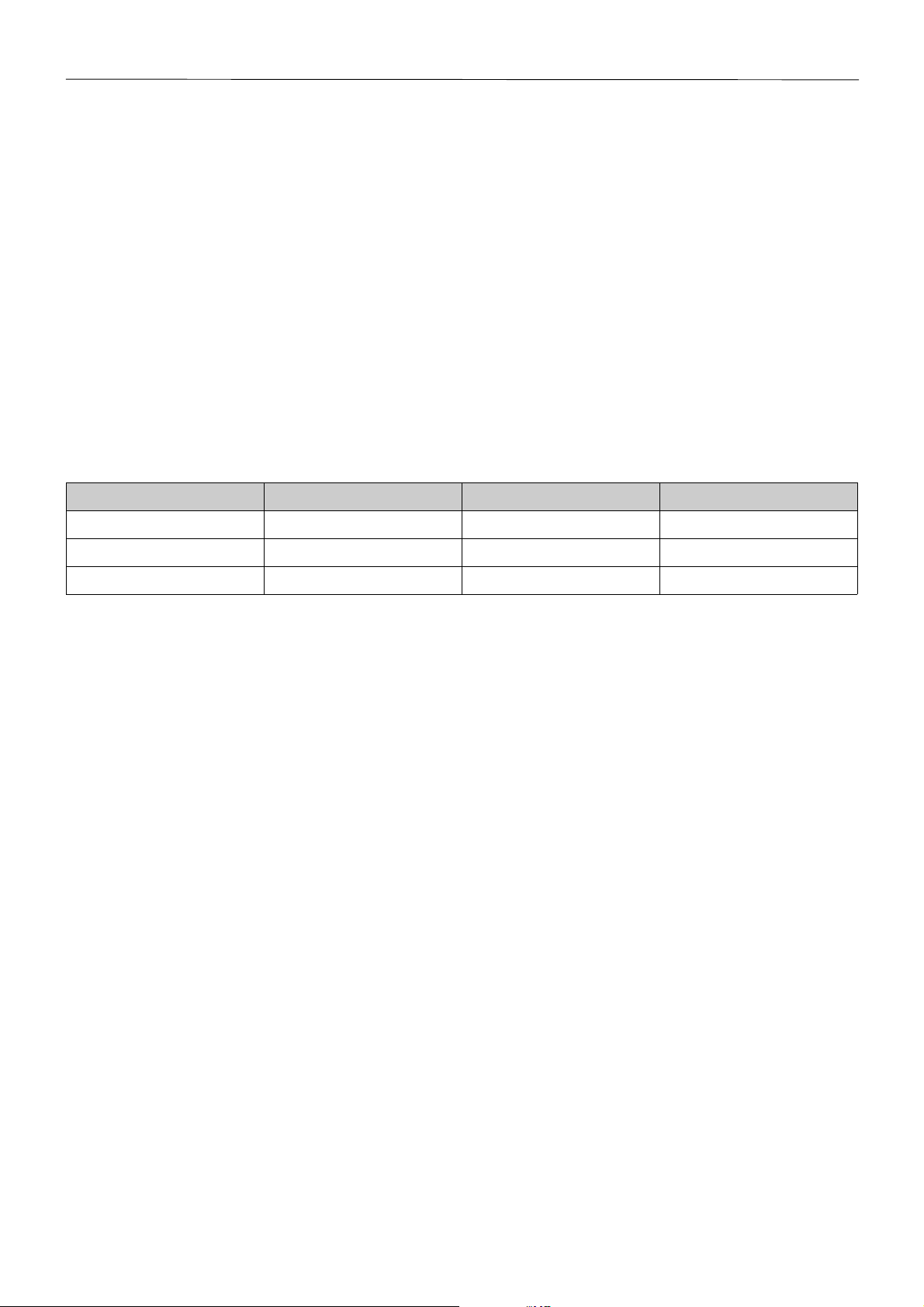

A Information about the modified device

Relevant documentation

Not only the already existing documentation, but also the documentation delivered with the transmitter will be relevant additionally,

cause of the conversion.

be

For the sensor the documentation for Promag 50, 53 is relevant.

For the transmitter the documentation for Promag 55 is relevant.

Changes and restrictions conditioned by conversion

• Accuracy

After conversion of the device an additional measured error of ± 0,2% to the measured value must be calculated.

B Preparatory operations: Save device data

• Conversion Promag 50

Select important parameter out of the application (e.g. with the aid of the Quick Setup "Commisioning" see Operating Instructions) and

fill them into the "list of parameter", chapter H. After Conversion enter the noted parameter into the new transmitter.

• Conversion Promag 53

Save the parameters of the transmitter to the T-DAT using the "T-DAT SAVE/ LOAD" function".

Replace the T-DAT into the transmitter after conversion.

C Overview data storage (Histo-ROM) and F-CHIP

Data storage Colour Promag 50 to Promag 55 Promag 53 to Promag 55

S-DAT blue Re-assembly Re-assembly

T-DAT black New Re-assembly

F-CHIP (Optional) red New New

Endress + Hauser 3

Conversion transmitter Promag 50/53 W, P, H to Promag 55 remote version

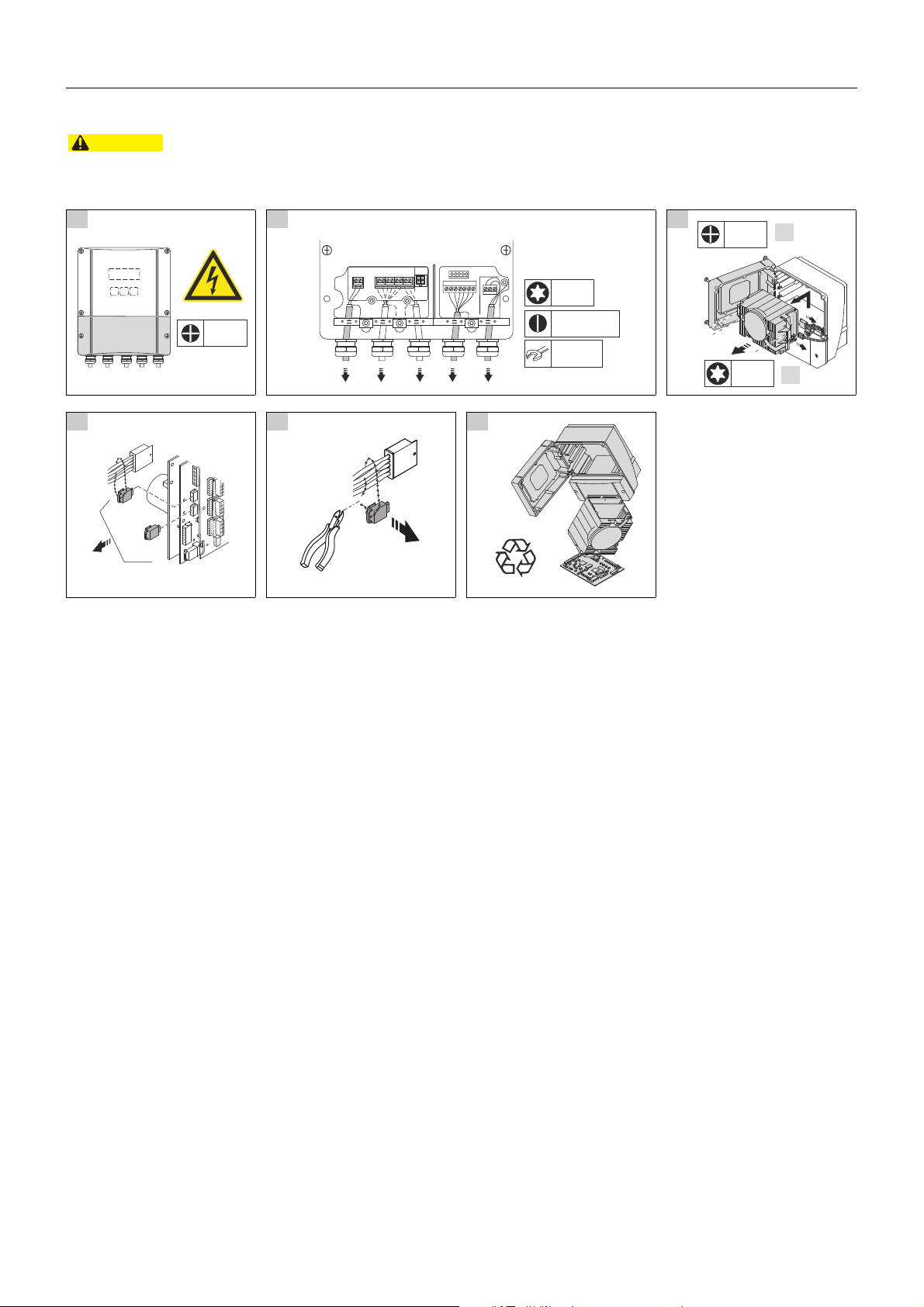

CAUTION

PH2

0.5 × 3.5

T20

22 mm

T20

1.

2.

PH2

S-DAT

T-DAT

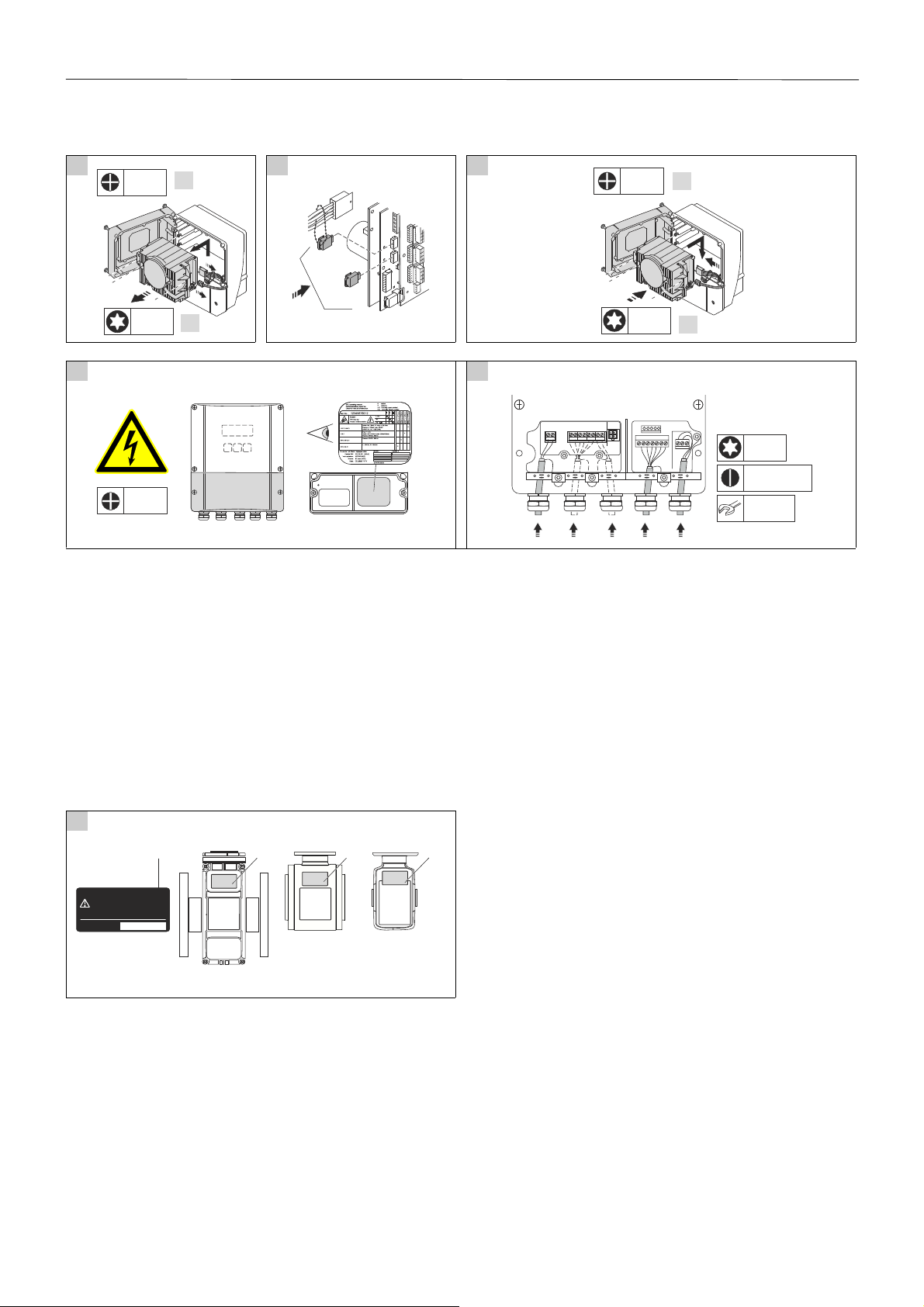

D Disassambling the transmitter Promag 50, 53

Cut off the power of the device bevore conversion. Only switch on power after conclusion of all works.

1 2 3

A0011958 A0011959 A0011684

4 5 6

A0011383 A0014762 A0011960

4 Endress + Hauser

Conversion transmitter Promag 50/53 W, P, H to Promag 55 remote version

T20

1.

2.

PH2

S-DAT

T-DAT

T20

1.

2.

PH2

PH 2

0.5 × 3.5

T20

22 mm

H

DN 40...100

(1 ...4")

1/2

H

DN 2...25

(1/12"...4")

W/P/S

1

1

1

Instrument modified,

for the new Order-Code specifications of the

transmitter, see nameplate on transmitter.

für die neue Order-Code-Ausprägungen des

Messumformers ist dasTypenschild auf

dem Messumformer zu beachten

Gerät wurde umgebaut,

Instrument modifié,

pour les nouvelles spécifications du code de

commande du transmetteur, observez

l’etiquette signalétique sur le transmetteur

Date of modification:

Umbaudatum:

Date de modification:

1

E Assembly the transmitter

1 2 3

A0011684 A0014645 A0011961

4 5

A0011963 A0011964

F Commissioning the device

• The measuring period and especially the integration time, depending on pipe diameter and the main frequency (50Hz/60Hz), have

to be set according to the table in chapter I. (Some parameter requiere the service code)

• Fill in the added form "Storage" and send it to the given adress for archiving (Data storage in the data base of Endress+Hauser).

• When Promag 50 is converted: Enter the data from the parameter list.

• When Promag 53 is converted: Function T-DAT SAFE/LOAD

→ use LOAD Selection.

• If necessary make an empty-pipe/full-pipe adjustment according to the description in the Operating Instructions.

• The conversion is complete.

G Changing the identification

1

A0014774

1. After conversion the label has to be changed!

Affix the notice label (1) as indicated in the graphic.

Endress + Hauser 5

Loading...

Loading...