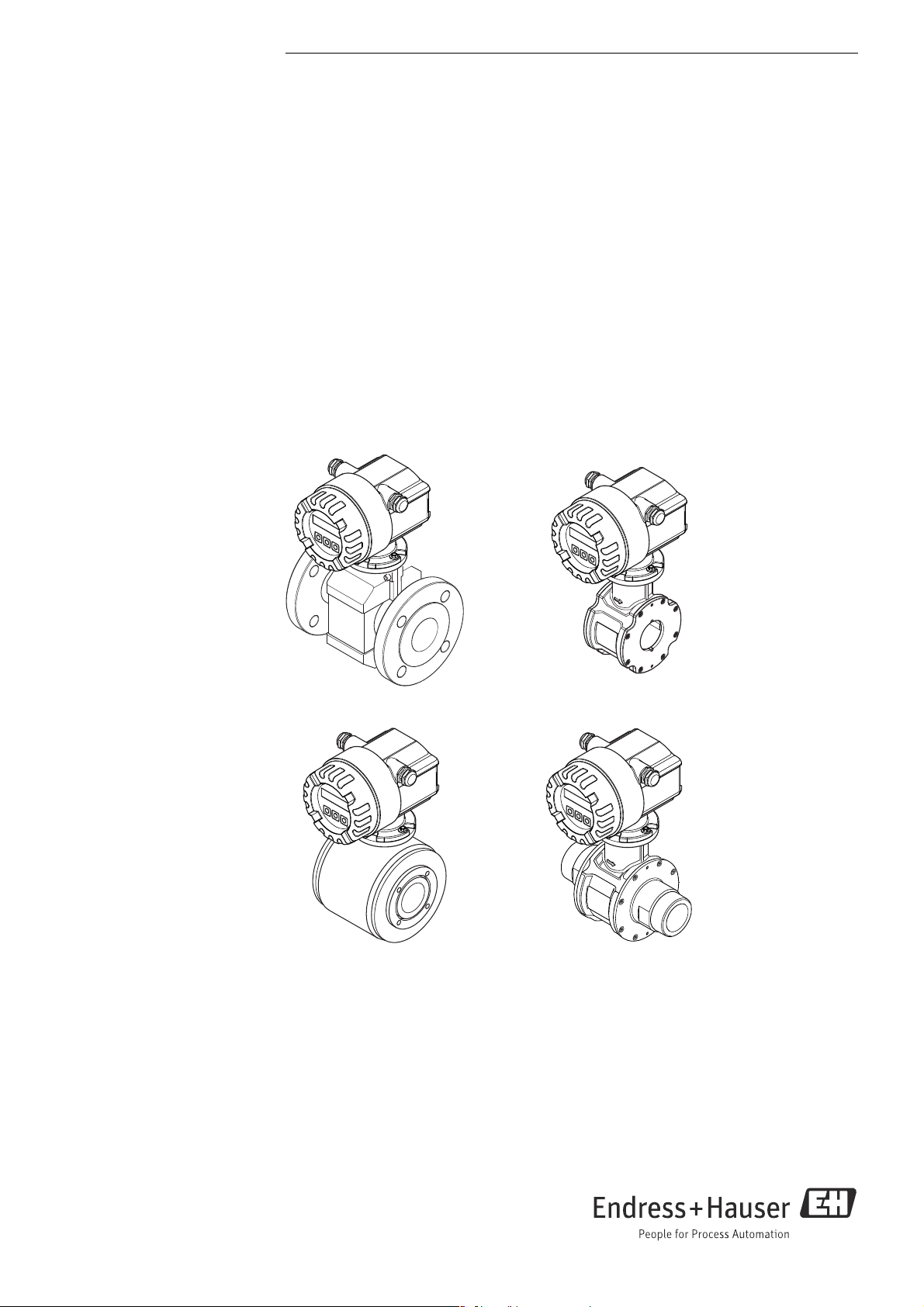

Endress+Hauser Proline Promag 10W, Proline Promag 10L, Proline Promag 10P, Proline Promag 10H, Proline Promag 10D Operating Manual

Page 1

BA00082D/06/EN/19.17

71385945

Valid as of software version

V 1.04.00 (device software)

Products Solutions Services

Operating Instructions

Proline Promag 10

HART

Electromagnetic flowmeter

6

Page 2

Products Solutions Services

Page 3

Promag 10

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety conventions and icons . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 8

2.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Incoming acceptance, transport and storage . . . . . 9

3.2 Mounting requirements . . . . . . . . . . . . . . . . . . . . 11

3.3 Installing the measuring device . . . . . . . . . . . . . 18

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 45

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1 Connecting the remote version . . . . . . . . . . . . . . 46

4.2 Connecting the measuring unit . . . . . . . . . . . . . . 52

4.3 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 54

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 57

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 58

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 59

9 Troubleshooting . . . . . . . . . . . . . . . . . . 77

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . 77

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . 78

9.3 Process error messages . . . . . . . . . . . . . . . . . . . . . 79

9.4 Process errors without messages . . . . . . . . . . . . . 80

9.5 Response of outputs to errors . . . . . . . . . . . . . . . . 81

9.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

9.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.9 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10 Technical data . . . . . . . . . . . . . . . . . . . . 87

10.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.2 Function and system design . . . . . . . . . . . . . . . . . 87

10.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.6 Performance characteristics . . . . . . . . . . . . . . . . . 92

10.7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.8 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.9 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.10 Mechanical construction . . . . . . . . . . . . . . . . . . 100

10.11 Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.12 Certificates and approvals . . . . . . . . . . . . . . . . . 114

10.13 Ordering information . . . . . . . . . . . . . . . . . . . . . 115

10.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.15 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.1 Display and operating elements . . . . . . . . . . . . . 59

5.2 Brief operating instructions on the function matrix

60

5.3 Displaying error messages . . . . . . . . . . . . . . . . . . 62

5.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Commissioning. . . . . . . . . . . . . . . . . . . . 70

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2 Switching on the measuring device . . . . . . . . . . 70

6.3 Brief commissioning guide . . . . . . . . . . . . . . . . . 70

6.4 Commissioning after installing a new electronics

board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5 Empty-pipe/full-pipe adjustment . . . . . . . . . . . . 72

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 73

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.2 Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8 Accessories . . . . . . . . . . . . . . . . . . . . . . . 74

8.1 Device-specific accessories . . . . . . . . . . . . . . . . . . 74

8.2 Communication-specific accessories . . . . . . . . . 75

8.3 Service-specific accessories . . . . . . . . . . . . . . . . . 75

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . 116

11.1 Illustration of the function matrix . . . . . . . . . . 116

11.2 Group SYSTEM UNITS . . . . . . . . . . . . . . . . . . . . 117

11.3 Group OPERATION . . . . . . . . . . . . . . . . . . . . . . . 119

11.4 USER INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . 120

11.5 Group TOTALIZER . . . . . . . . . . . . . . . . . . . . . . . 121

11.6 Group CURRENT OUTPUT . . . . . . . . . . . . . . . . . 122

11.7 Group PULSE/STATUS OUTPUT . . . . . . . . . . . . 124

11.8 Group COMMUNICATION . . . . . . . . . . . . . . . . . 129

11.9 Group PROCESS PARAMETER . . . . . . . . . . . . . 130

11.10 Group SYSTEM PARAMETER . . . . . . . . . . . . . . 132

11.11 Group SENSOR DATA . . . . . . . . . . . . . . . . . . . . . 135

11.12 Group SUPERVISION . . . . . . . . . . . . . . . . . . . . . 137

11.13 Group SIMULATION SYSTEM . . . . . . . . . . . . . . 139

11.14 Group SENSOR VERSION . . . . . . . . . . . . . . . . . . 139

11.15 Group AMPLIFIER VERSION . . . . . . . . . . . . . . . 139

11.16 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Endress+Hauser 3

Page 4

Safety instructions Promag 10

1 Safety instructions

1.1 Designated use

The measuring device described in this Operating Manual is to be used only for measuring

the flow rate of conductive fluids in closed pipes.

Most liquids can be measured as of a minimum conductivity of 50 S/cm.

Examples:

• Acids, alkalis

• Drinking water, wastewater, sewage sludge

• Milk, beer, wine, mineral water, etc.

Resulting from incorrect use or from use other than that designated the operational safety

of the measuring devices can be suspended. The manufacturer accepts no liability for

damages being produced from this.

1.2 Installation, commissioning and operation

Please note the following:

• Installation, connection to the electricity supply, commissioning and maintenance of the

device must be carried out by trained, qualified specialists authorized to perform such work

by the facility's owner-operator. The specialist must have read and understood this

Operating Manual and must follow the instructions it contains.

• The device must be operated by persons authorized and trained by the facility's owneroperator. Strict compliance with the instructions in the Operating Manual is mandatory.

• With regard to special fluids, including fluids used for cleaning, Endress+Hauser will be

happy to assist in clarifying the corrosion-resistant properties of wetted materials.

However, minor changes in temperature, concentration or in the degree of contamination

in the process may result in variations in corrosion resistance. For this reason,

Endress+Hauser does not accept any responsibility with regard to the corrosion resistance

of wetted materials in a specific application.

The user is responsible for the choice of suitable wetted materials in the process.

• If welding work is performed on the piping system, do not ground the welding appliance

through the Promag flowmeter.

• The installer must ensure that the measuring system is correctly wired in accordance with

the wiring diagrams. The transmitter must be grounded apart from when special

protective measures are taken (e.g. galvanically isolated SELV or PELV power supply)

• Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3 Operational safety

Please note the following:

• Measuring systems for use in hazardous environments are accompanied by separate Ex

documentation, which is an integral part of this Operating Manual. Strict compliance with

the installation instructions and ratings as stated in this supplementary documentation is

mandatory. The symbol on the front of this Ex documentation indicates the approval and

the certification body (e.g.

• The measuring device complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326 and NAMUR Recommendations

NE 21 and NE 43.

• Depending on the application, the seals of the process connections of the Promag H sensor

require periodic replacement.

• When hot fluid passes through the measuring tube, the surface temperature of the

housing increases. In the case of the sensor, in particular, users should expect

temperatures that can be close to the fluid temperature. If the temperature of the fluid is

high, implement sufficient measures to prevent burning or scalding.

4 Endress+Hauser

0 Europe, 2 USA, 1 Canada).

Page 5

Promag 10 Safety instructions

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to these

Operating Instructions.

1.4 Return

The measuring device must be returned if repairs or a factory calibration are required, or if

the wrong measuring device has been ordered or delivered. According to legal regulations,

Endress+Hauser, as an ISO-certified company, is required to follow certain procedures when

handling returned products that are in contact with medium.

To ensure swift, safe and professional device returns, please read the return procedures and

conditions on the Endress+Hauser website at www.services.endress.com/return-material

1.5 Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested,

and left the factory in a condition in which they are safe to operate. The devices comply with

the applicable standards and regulations in accordance with EN 61010-1 "Safety

requirements for electrical equipment for measurement, control and laboratory use".

The devices can, however, be a source of danger if used incorrectly or for anything other than

the designated use. Consequently, always pay particular attention to the safety instructions

indicated in this Operating Manual by the following icons:

#

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in

injury or a safety hazard. Comply strictly with the instructions and proceed with care.

Caution!

"

"Caution" indicates an action or procedure which, if not performed correctly, can result in

incorrect operation or destruction of the device. Comply strictly with the instructions.

!

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

Endress+Hauser 5

Page 6

Identification Promag 10

Promag 10

-20°C (-4°F) <Tamb<+60°C (+140°F)

IP67 / NEMA/Type 4XOrder Code:

Ser.No.:

TAG No.:

10PXX-XXXXXXXXXXXX

12345678901

ABCDEFGHJKLMNPQRST

20-28VAC/11-40VDC

50-60Hz

I-OUT (HART), PULSE-OUT

8VA/6W

i

EPD / MSÜ

2

3

4

5

9

8

1

N12895

6

7

2 Identification

2.1 Device designation

The flow measuring system consists of the following components:

• Promag 10 transmitter

• Promag D/E/H/L/P/W sensor

In the compact version, the transmitter and sensor form a single mechanical unit; in the

remote version they are installed separately.

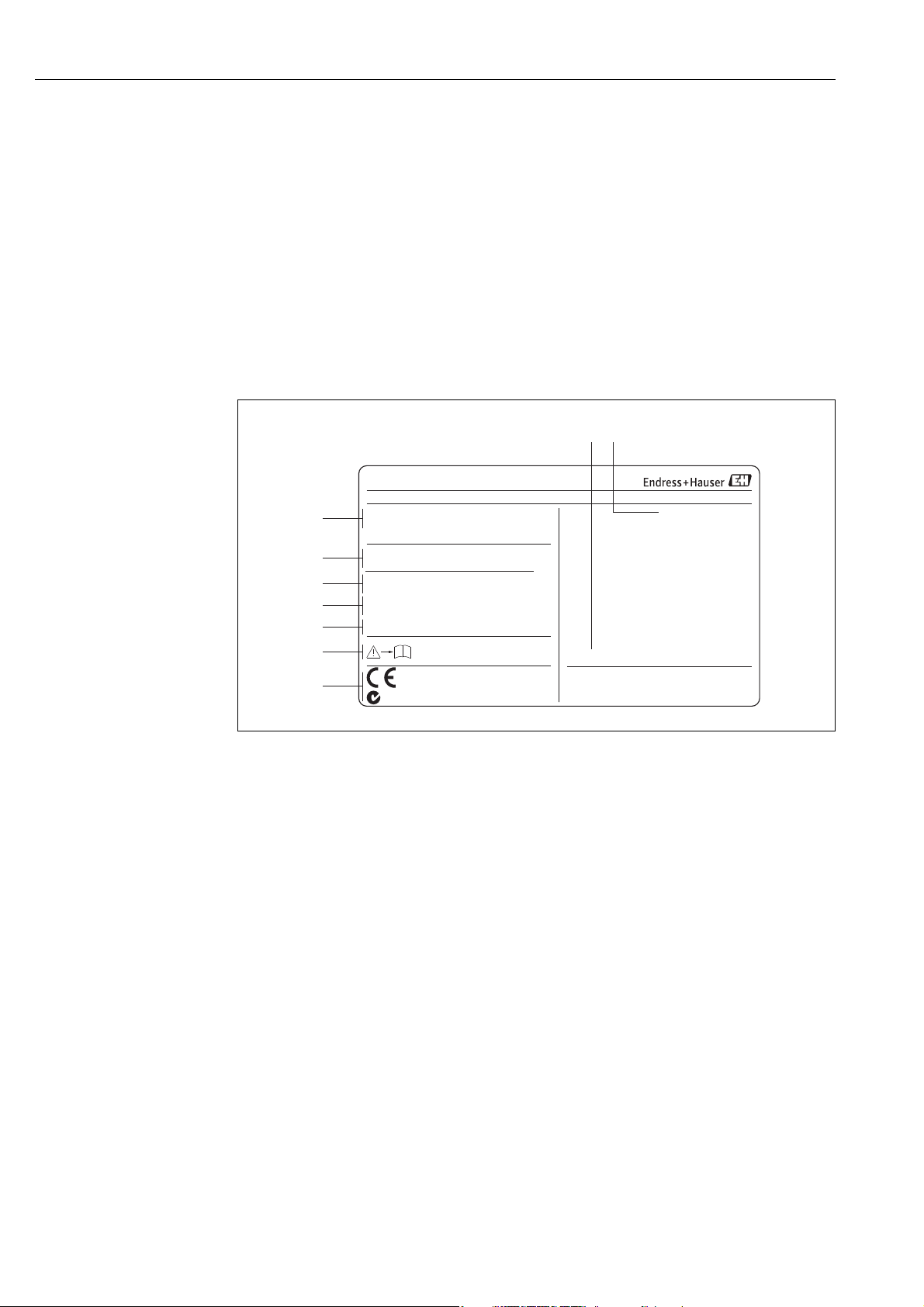

2.1.1 Nameplate of the transmitter

Fig. 1: Nameplate specifications for the "Promag 10" transmitter (example)

1 Ordering code/serial number: See the specifications on the order confirmation for the meanings of the individual letters and

digits.

2 Power supply, frequency, power consumption

3 Additional information:

EPD/MSÜ: with Empty Pipe Detection

4 Outputs available:

I-OUT (HART): with current output (HART)

PULSE-OUT: with pulse/status output

5 Reserved for information on special products

6 Observe device documentation

7 Reserved for additional information on device version (approvals, certificates)

8 Permitted ambient temperature range

9 Degree of protection

6 Endress+Hauser

A0005395

Page 7

Promag 10 Identification

-20°C (-4°F)<Tamb<+60°C (+140°F) NEMA/Type4X

50PXX-XXXXXXXXXXXX

1.0000/0000

–10 ...150°C/+14 ...300°F°C °F

PFA

12345678901 RY

ABCDEFGHJKLMNPQRST

DN100 DIN EN PN40/ pnom =PS= 40bar

EPD/MSÜ, R/B

TM:

Order Code:

Materials:

K-factor:

Ser.No.:

TAG No.:

PROMAG P

1

2

3

7

13

12

1.4435/316L

Electrodes:

0.2% CAL

4

5

6

10

1

1

i

9

8

IP67

2007

N12895

24

+

25

–

26

+

27

–

L1 (L+)

12

N (L–)

$

PULSE-OUT

fmax: 100 Hz

Passive: 30 VDC

250 mA

I-OUT (HART)

Active: 4...20 mA

RLmax. = 700 Ohm

HART

RLmin. = 250 Ohm

Supply /

Versorgung /

Tension

d’Alimentation

See operating manual

Betriebsanleitung beachten

Observer Manual d’Instruction

319740-0000

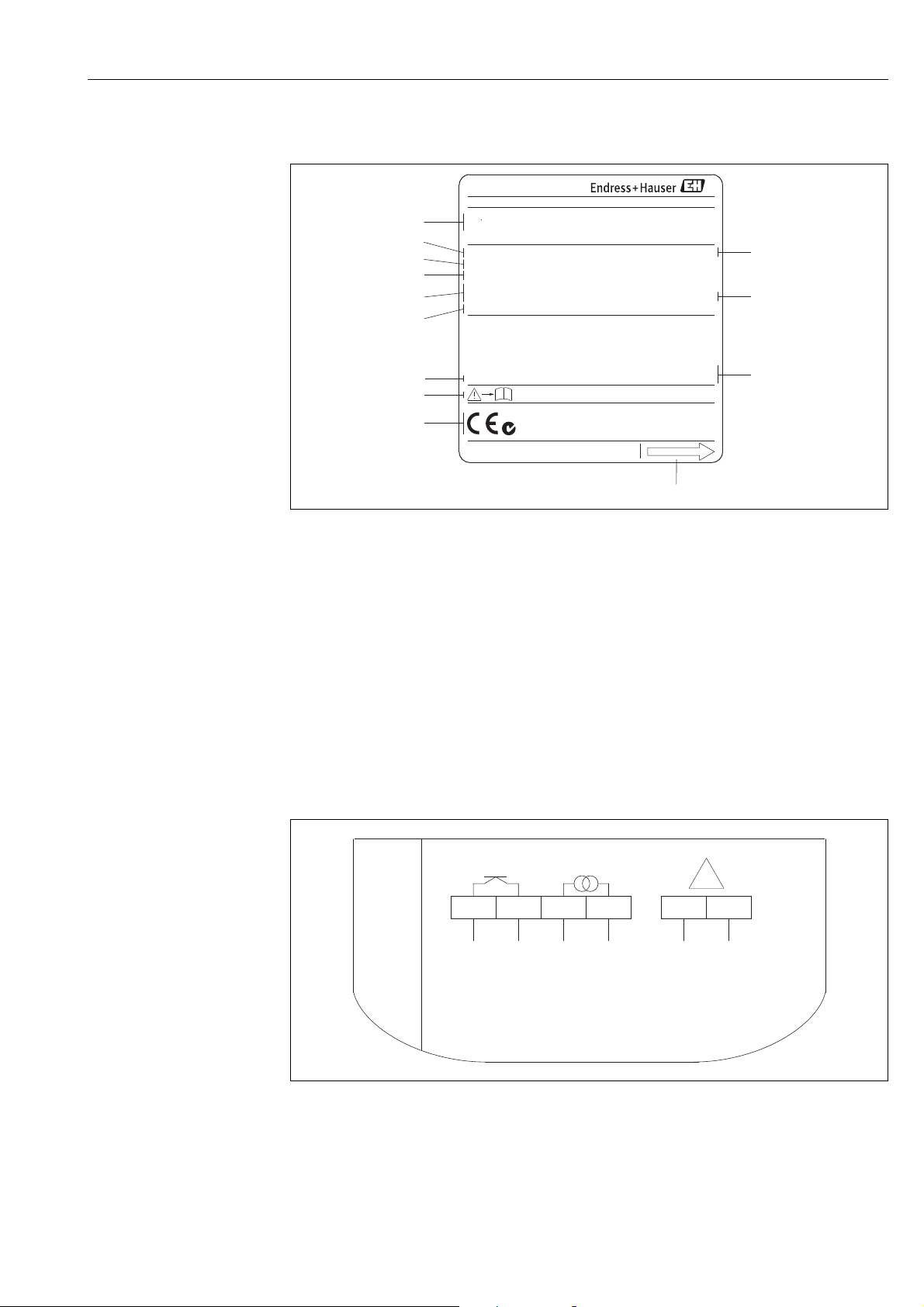

2.1.2 Nameplate of the sensor

A0004374

Fig. 2: Nameplate specifications for the "Promag" sensor (example)

1 Ordering code/serial number: See the specifications on the order confirmation for the meanings of the individual letters and

digits.

2 Calibration factor with zero point

3 Nominal diameter/Pressure rating

4 Fluid temperature range

5 Materials: lining/measuring electrodes

6 Reserved for information on special products

7 Permitted ambient temperature range

8 Observe device documentation

9 Reserved for additional information on device version (approvals, certificates)

10 Calibration tolerance

11 Additional information (examples):

– EPD/MSÜ: with Empty Pipe Detection electrode

– R/B: with reference electrode

12 Degree of protection

13 Flow direction

Endress+Hauser 7

2.1.3 Nameplate, connections

Fig. 3: Nameplate specifications for transmitter (example)

A0005394

Page 8

Identification Promag 10

2.2 Certificates and approvals

The devices are designed to meet state-of-the-art safety requirements in accordance with

sound engineering practice. They have been tested and left the factory in a condition in

which they are safe to operate.

The devices comply with the applicable standards and regulations in accordance with EN

61010-1 "Safety requirements for electrical equipment for measurement, control and

laboratory use" and with the EMC requirements of IEC/EN 61326.

The measuring system described in this Operating Manual is therefore in conformity with

the statutory requirements of the EC Directives. Endress+Hauser confirms successful testing

of the device by affixing to it the CE mark.

The measuring system meets the EMC requirements of the "Australian Communications and

Media Authority (ACMA)".

2.3 Registered trademarks

KALREZ® and VITON

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP®

Registered trademark of Ladish & Co., Inc., Kenosha, USA

®

HART

Registered trademark of the HART Communication Foundation, Austin, USA

®

Applicator®, FieldCare®, Fieldcheck®

Registered or registration-pending trademarks of the Endress+Hauser Group

8 Endress+Hauser

Page 9

Promag 10 Installation

3Installation

3.1 Incoming acceptance, transport and storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following:

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches

your order.

3.1.2 Transport

The following instructions apply to unpacking and to transporting the device to its final

location:

• Transport the devices in the containers in which they are delivered.

• Do not remove the protective plates or caps on the process connections until you are ready

to install the device. This is particularly important in the case of sensors with PTFE linings.

"

#

Special notes on flanged devices

Caution!

• The wooden covers mounted on the flanges from the factory protect the linings on the

flanges during storage and transportation. In case of Promag L they are additionally used

to hold the lap joint flanges in place. Do not remove these covers until immediately before

the device in the pipe.

• Do not lift flanged devices by the transmitter housing, or the connection housing in the

case of the remote version.

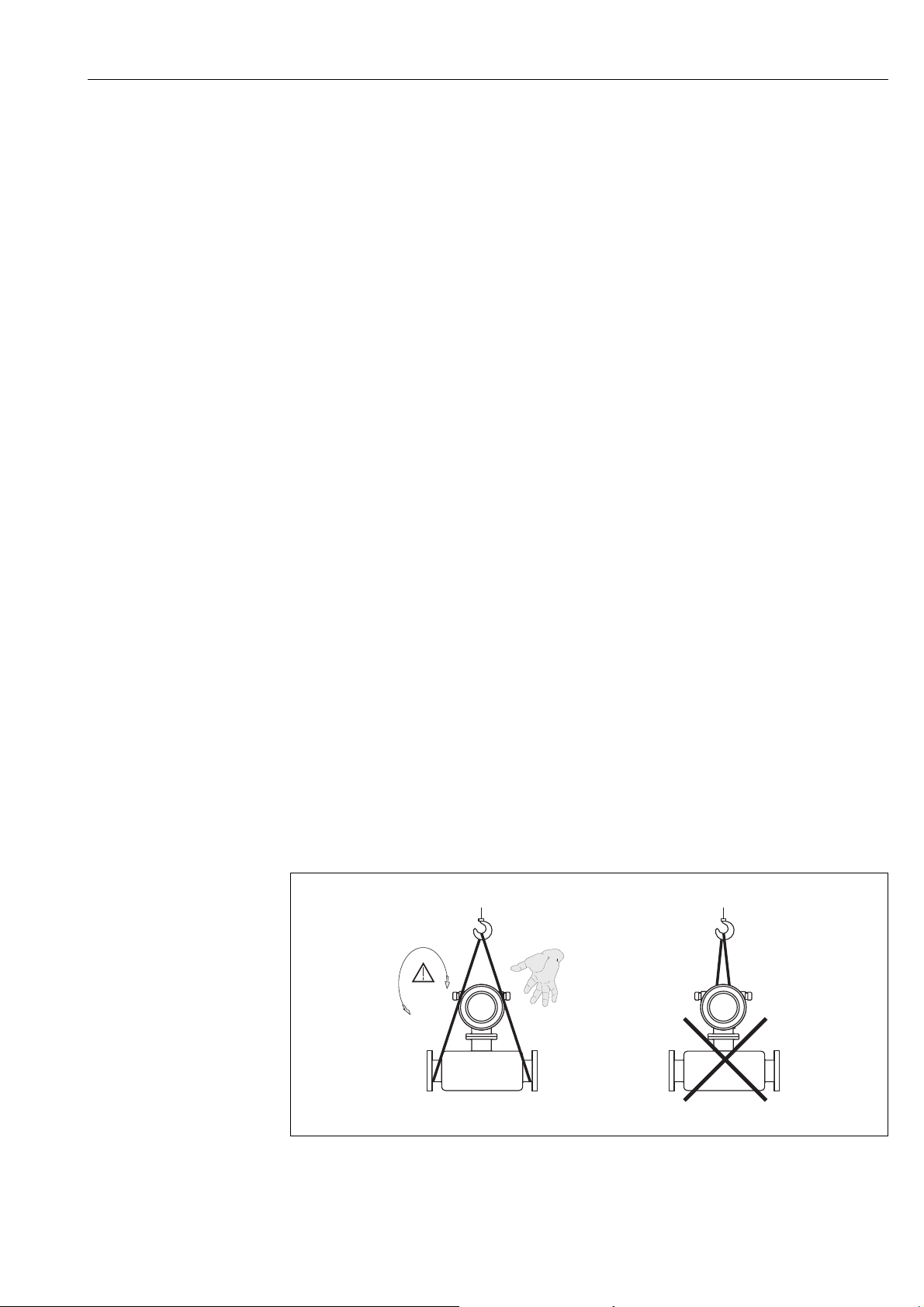

Transporting flanged devices DN ≤ 300 (12")

Use webbing slings slung round the two process connections.

Do not use chains, as they could damage the housing.

Warning!

Risk of injury if the measuring device slips. The center of gravity of the assembled measuring

device might be higher than the points around which the slings are slung.

At all times, therefore, make sure that the device does not unexpectedly turn around its axis

or slip.

A0005575

Fig. 4: Transporting sensors with DN ≤ 300 (12")

Endress+Hauser 9

Page 10

Installation Promag 10

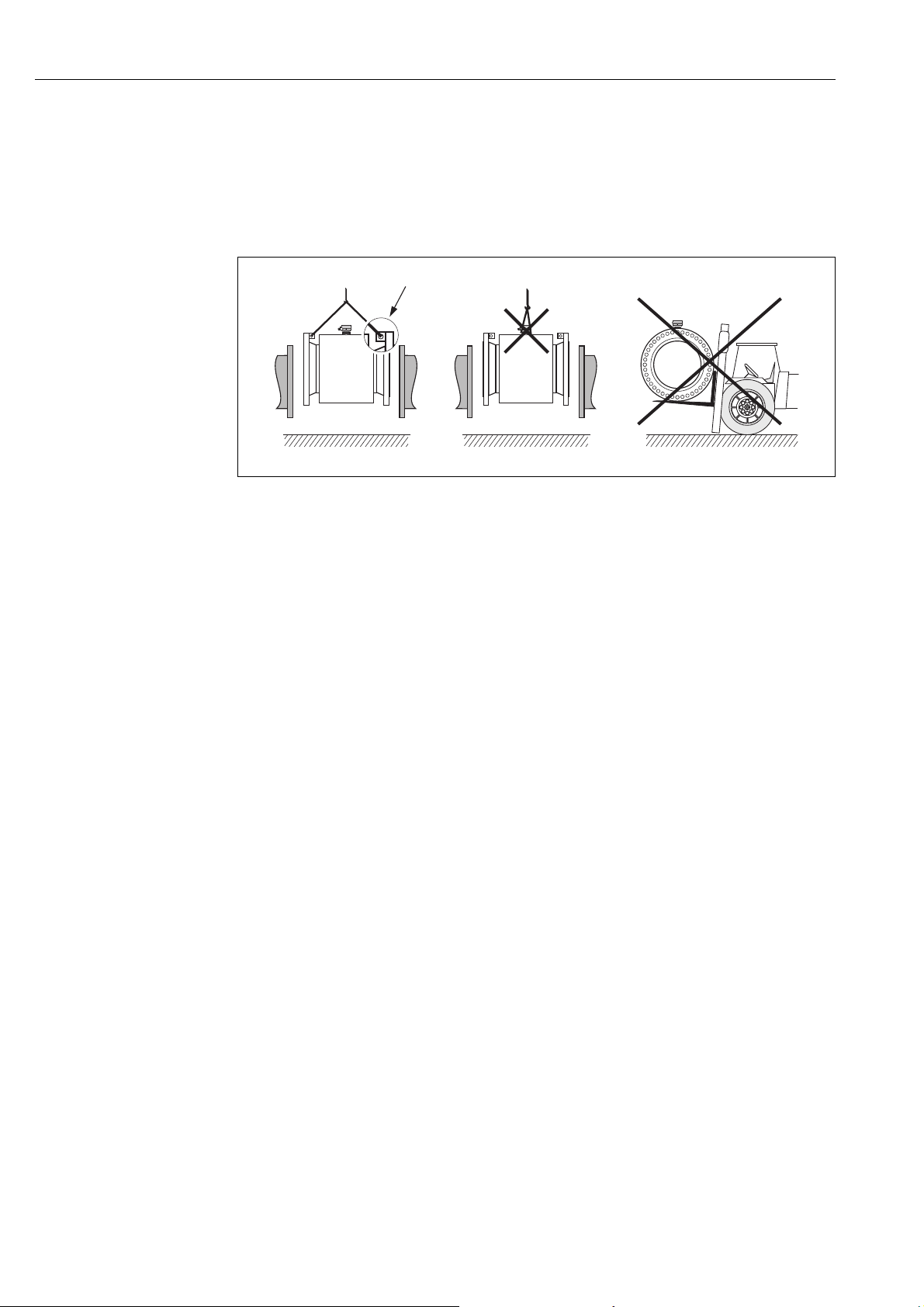

Transporting flanged devices DN ≥ 350 (14")

Use only the metal eyes on the flanges for transporting the device, lifting it and positioning

the sensor in the piping.

Caution!

"

Do not attempt to lift the sensor with the tines of a fork-lift truck beneath the metal casing.

This would buckle the casing and damage the internal magnetic coils.

A0004295

Fig. 5: Transporting sensors with DN ≥ 350 (14")

3.1.3 Storage

Please note the following:

• Pack the measuring device in such a way as to protect it reliably against impact for storage

(and transportation). The original packaging provides optimum protection.

• The storage temperature corresponds to the operating temperature range of the

measuring transmitter and the appropriate measuring sensors 92.

• Do not remove the protective plates or caps on the process connections until you are ready

to install the device. This is particularly important in the case of sensors with PTFE linings.

• The measuring device must be protected against direct sunlight during storage in order to

avoid unacceptably high surface temperatures.

• Choose a storage location where moisture does not collect in the measuring device. This

will help prevent fungus and bacteria infestation which can damage the liner.

10 Endress+Hauser

Page 11

Promag 10 Installation

h 2 x DN³

1 1

3.2 Mounting requirements

3.2.1 Dimensions

The dimensions and installation lengths of the sensor and transmitter can be found in the

"Technical Information" for the device in question. This document can be downloaded as a

PDF file from www.endress.com. A list of the "Technical Information" documents available is

provided in the "Documentation" section on 115.

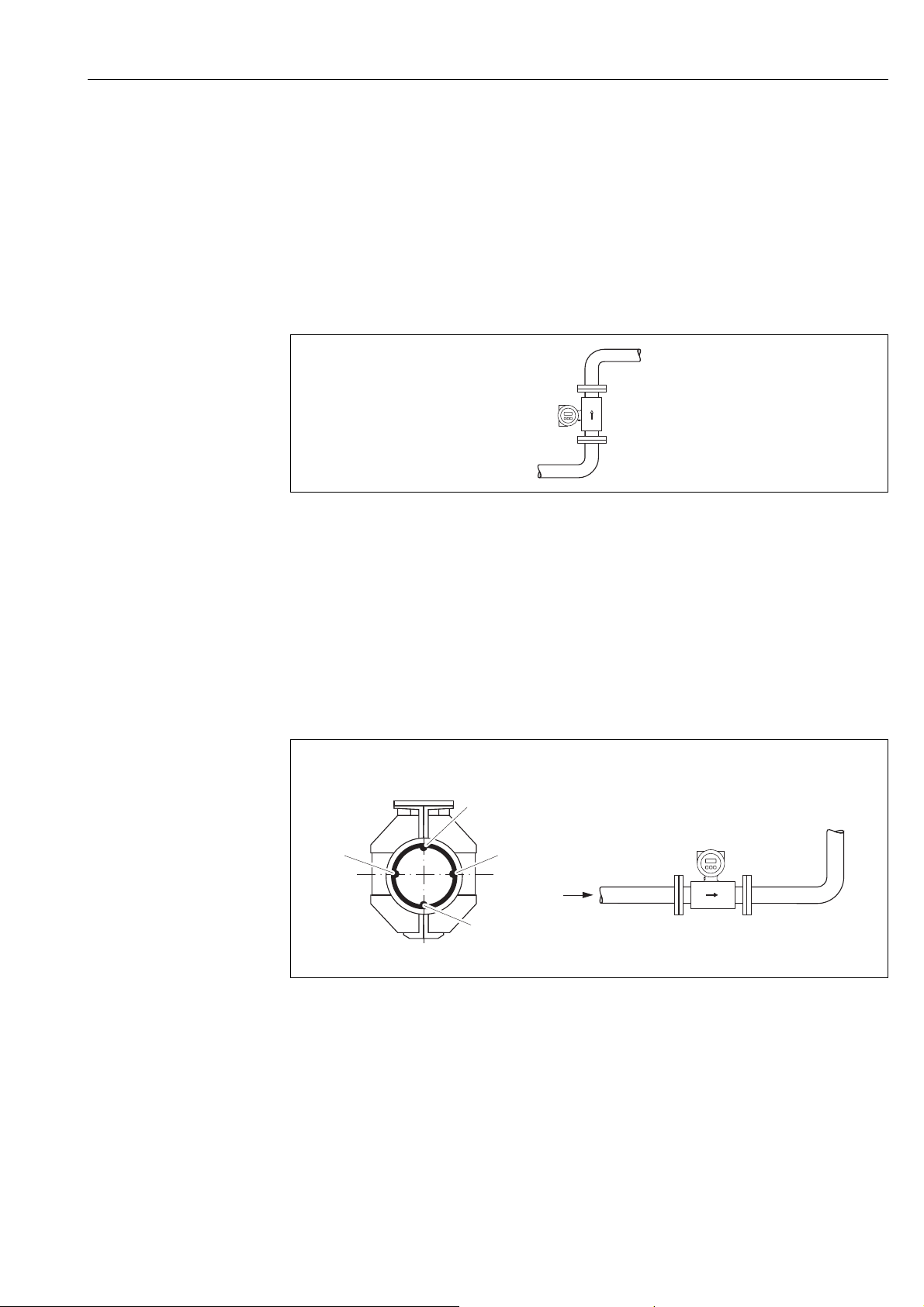

3.2.2 Mounting location

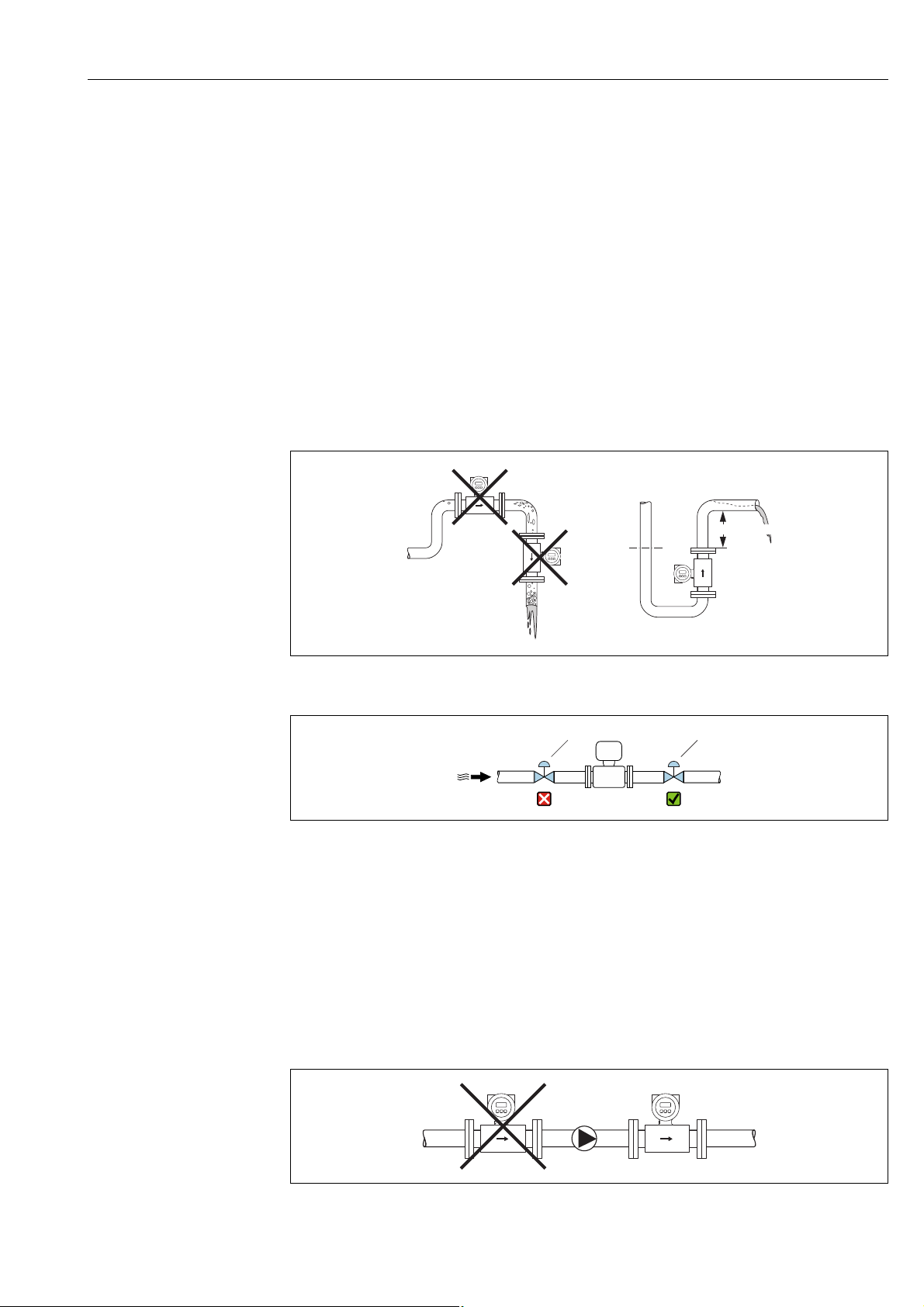

Entrained air or gas bubble formation in the measuring tube can result in an increase in

measuring errors.

Avoid the following locations:

• Highest point of a pipeline. Risk of air accumulating!

• Directly upstream from a free pipe outlet in a vertical pipeline.

A0008154

Fig. 6: Mounting location

A0033017

Fig. 7: Installation of the sensor after a control valve is not recommended

1 Control valve

Installation of pumps

Do not install the sensor on the intake side of a pump. This precaution is to avoid low

pressure and the consequent risk of damage to the lining of the measuring tube. Information

on the lining's resistance to partial vacuum can be found on 96.

It might be necessary to install pulse dampers in systems incorporating reciprocating,

diaphragm or peristaltic pumps. Information on the measuring system's resistance to

vibration and shock can be found on 93.

A0003203

Fig. 8: Installation of pumps

Endress+Hauser 11

Page 12

Installation Promag 10

5 x DN

2 x DN

³

³

h

2

1

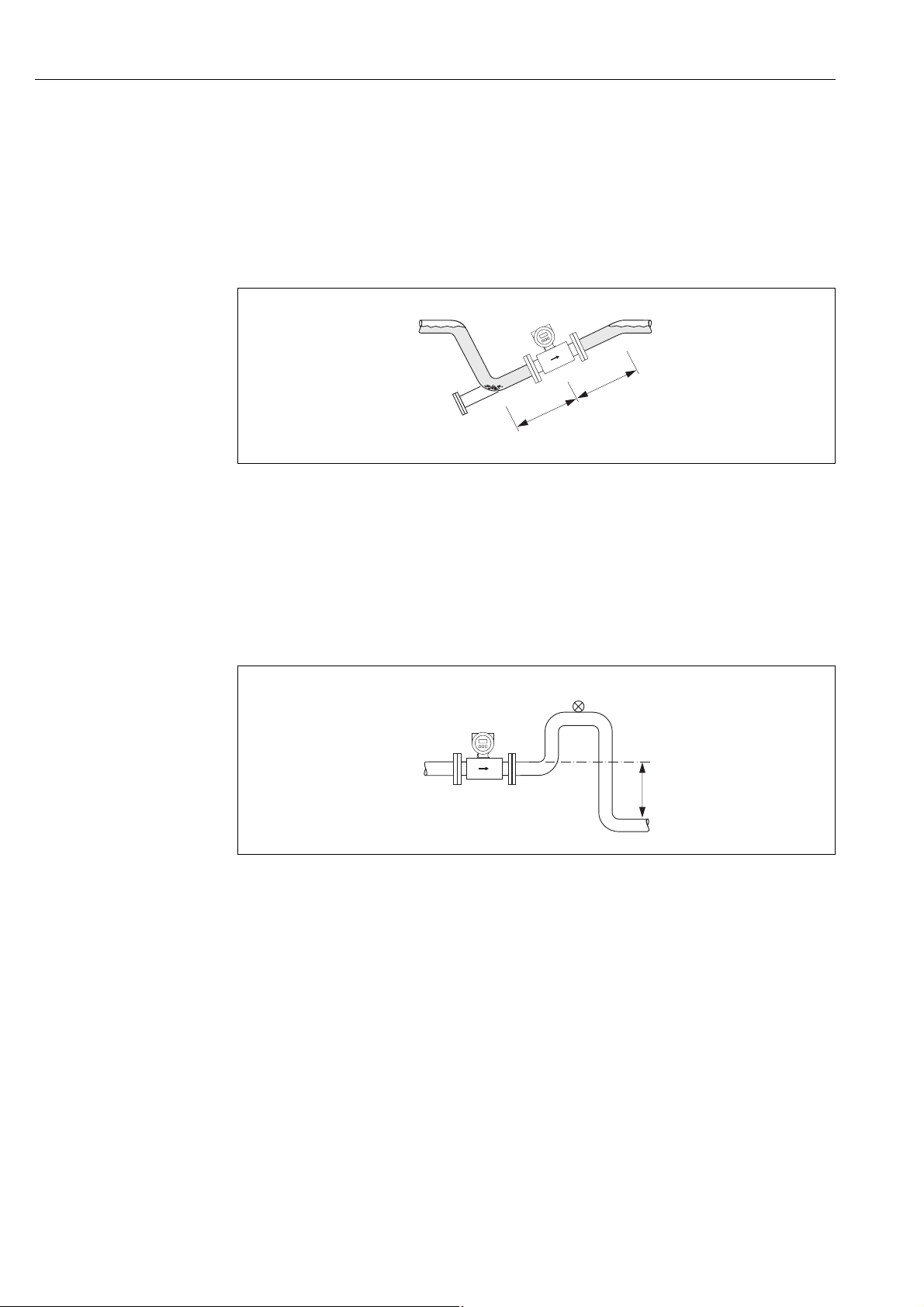

Partially filled pipes

Partially filled pipes with gradients necessitate a drain-type configuration.

The Empty Pipe Detection function (EPD 72) offers additional protection by detecting

empty or partially filled pipes.

Caution!

"

Risk of solids accumulating. Do not install the sensor at the lowest point in the drain. It is

advisable to install a cleaning valve.

A0008155

Fig. 9: Installation in a partially filled pipe

Down pipes

Install a siphon or a vent valve downstream of the sensor in down pipes whose length

h 5 m (16.4 ft). This precaution is to avoid low pressure and the consequent risk of

damage to the lining of the measuring tube.

This measure also prevents the system losing prime, which could cause air pockets.

Information on the lining's resistance to partial vacuum can be found on 96.

Fig. 10: Measures for installation in a down pipe

1Vent valve

2Pipe siphon

hLength of down pipe

A0008157

12 Endress+Hauser

Page 13

Promag 10 Installation

A

1

22

A

3

3.2.3 Orientation

An optimum orientation position helps avoid gas and air accumulations and deposits in the

measuring tube. However, Promag offers the additional Empty Pipe Detection (EPD)

function to ensure the detection of partially filled measuring tubes, e.g. in the case of

degassing fluids or varying process pressure.

Vertical orientation

This is the ideal orientation for self-emptying piping systems and for use in conjunction with

Empty Pipe Detection.

A0008158

Fig. 11: Vertical orientation

Horizontal orientation

The measuring electrode plane should be horizontal. This prevents brief insulation of the

two measuring electrodes by entrained air bubbles.

Caution!

"

Empty Pipe Detection functions correctly only when the measuring device is installed

horizontally and the transmitter housing is facing upward ( 11). Otherwise there is no

guarantee that Empty Pipe Detection will respond if the measuring tube is only partially

filled or empty.

Fig. 12: Horizontal orientation

1 EPD electrode for the detection of empty pipes (not with Promag D and Promag H (DN 2 to 8 / ¹⁄₁₂ to ³⁄₈"))

2 Measuring electrodes for signal detection

3 Reference electrode for the potential equalization (not with Promag D and H)

A0003207

Endress+Hauser 13

Page 14

Installation Promag 10

³ 5DNx

³ 2DNx

≥ 0 × DN

L

Inlet and outlet run

If possible, install the sensor upstream from fittings such as valves, T-pieces, elbows, etc.

The following inlet and outlet runs must be observed in order to meet accuracy

specifications:

•Inlet run: 5 × DN

•Outlet run: 2 × DN

Fig. 13: Inlet and outlet run standard version

Fig. 14: Optional version: w/o inlet and outlet run

3.2.4 Vibrations

Secure the piping and the sensor if vibration is severe.

Caution!

"

If vibrations are too severe, we recommend the sensor and transmitter be mounted

separately. Information on resistance to vibration and shock can be found on 93.

A0003210

A0032859

Fig. 15: Measures to prevent vibration of the device (L > 10 m (32.8 ft))

14 Endress+Hauser

A0003208

Page 15

Promag 10 Installation

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

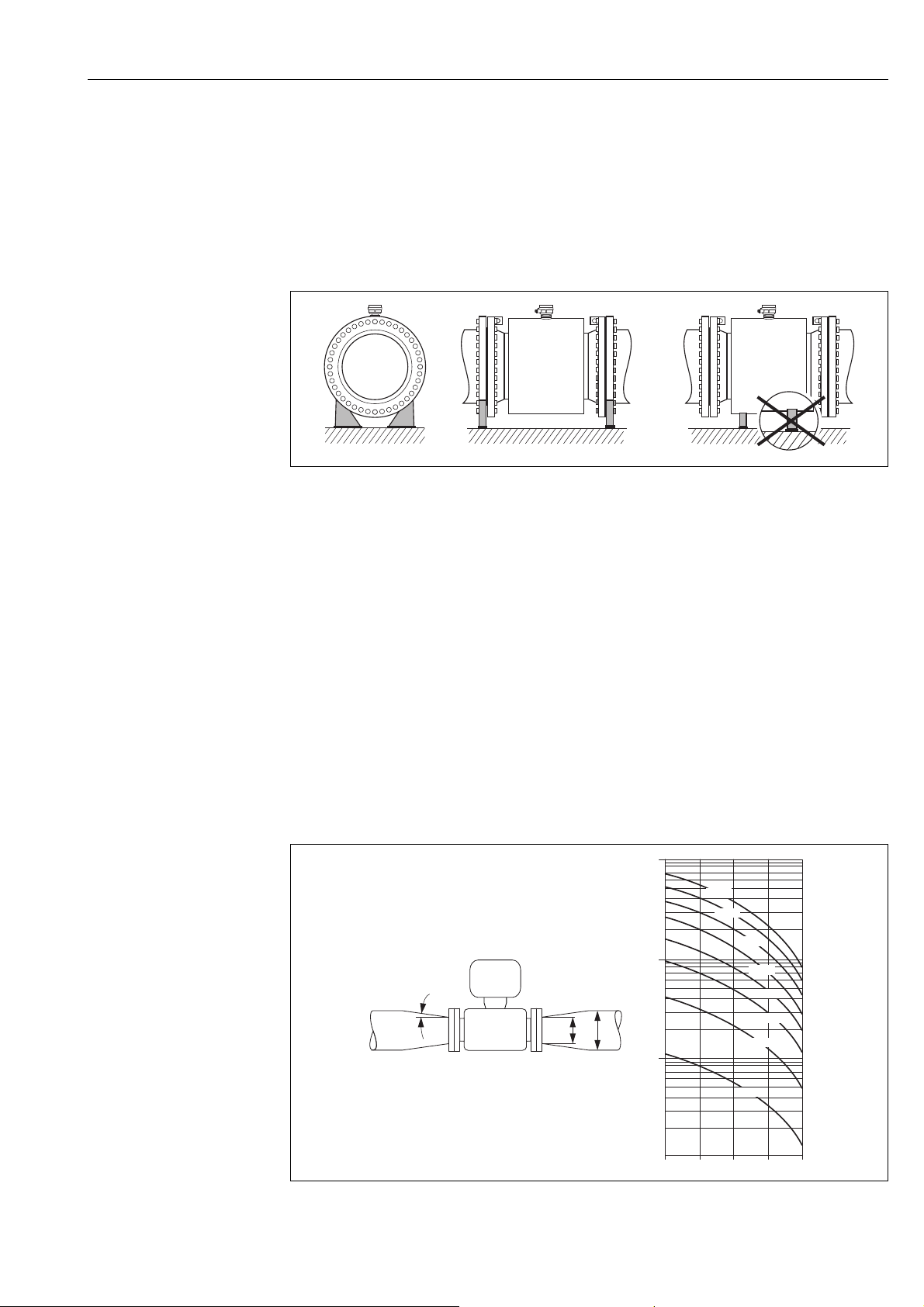

3.2.5 Foundations, supports

If the nominal diameter is DN 350 (14"), mount the sensor on a foundation of adequate

load-bearing strength.

Caution!

"

Risk of damage.

Do not support the weight of the sensor on the metal casing: the casing would buckle and

damage the internal magnetic coils.

A0003209

Fig. 16: Correct support for large nominal diameters (DN ≥ 350 / 14")

!

3.2.6 Adapters

Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor

in larger-diameter pipes.

The resultant increase in the rate of flow improves measuring accuracy with very slowmoving fluids. The nomogram shown here can be used to calculate the pressure loss caused

by reducers and expanders.

Note!

• The nomogram only applies to liquids of viscosity similar to water.

• For Promag D with threaded connection adapters can not be used

• For Promag H the selection of a pipe with larger diameter for high viscosities of the fluid

may be considered to reduce the pressure loss.

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity

(downstream from the reduction) and the d/D ratio.

Fig. 17: Pressure loss due to adapters

A0016359

Endress+Hauser 15

Page 16

Installation Promag 10

L

max

[]ft

200 6000

400

200

100

50 100 200

[m]

[ S/cm]μ

L

max

50

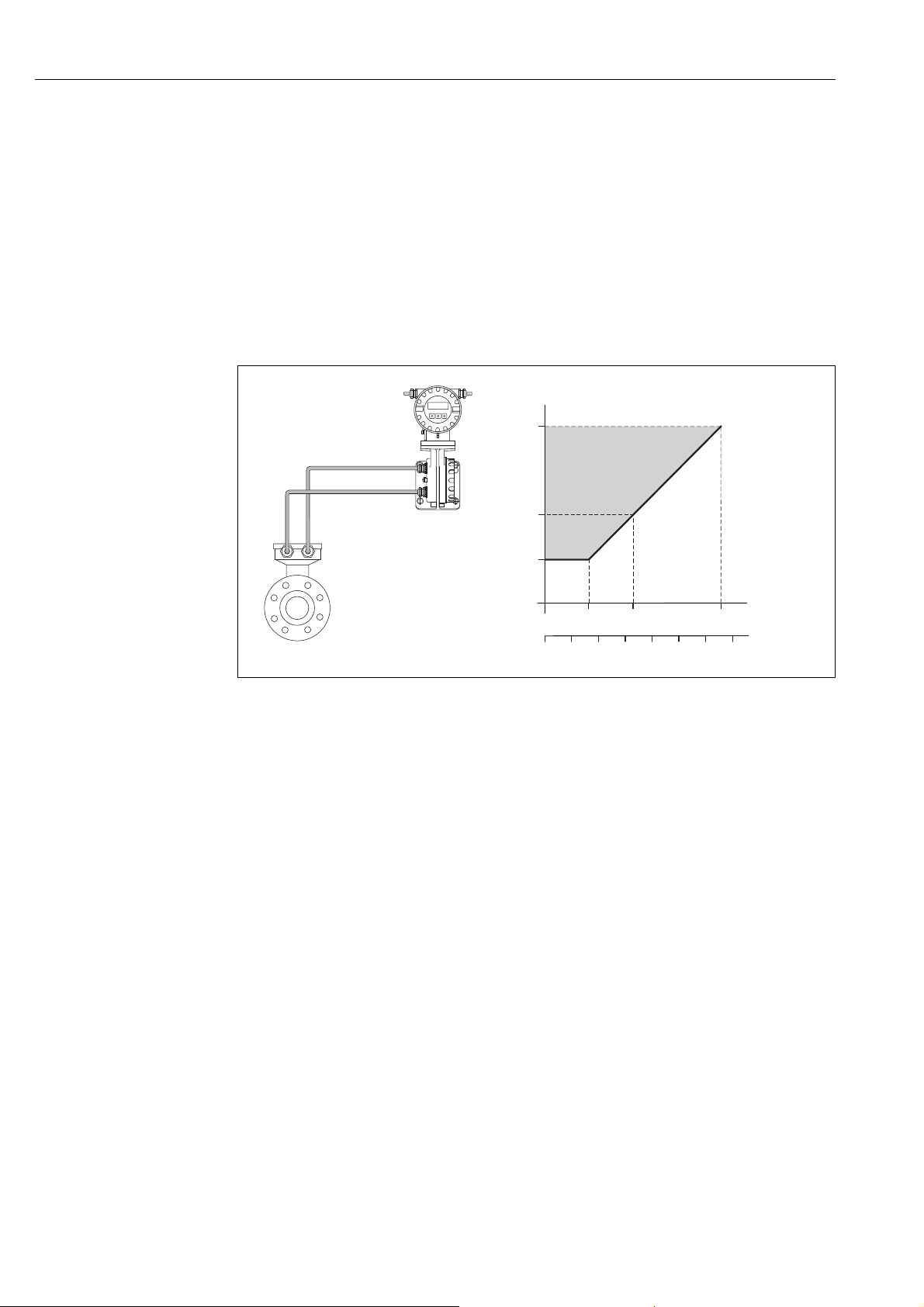

3.2.7 Length of connecting cable

In order to ensure measuring accuracy, comply with the following instructions when

installing the remote version:

• Fix cable run or lay in armored conduit. Cable movements can falsify the measuring signal

especially in the case of low fluid conductivities.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter, if necessary.

• The permitted connecting cable length L

18). A minimum conductivity of 50 S/cm is needed for all fluids.

• The maximum connecting cable length is 10 m (33 ft) when empty pipe detection (EPD

72) is switched on.

is determined by the fluid conductivity (

max

A0003214

Fig. 18: Permissible cable length for the remote version

Area shaded gray = permitted range

= connecting cable length in [m]

L

max

Fluid conductivity in [μS/cm]

16 Endress+Hauser

Page 17

Promag 10 Installation

≤≤3 ( 10)

3.2.8 Special mounting instructions

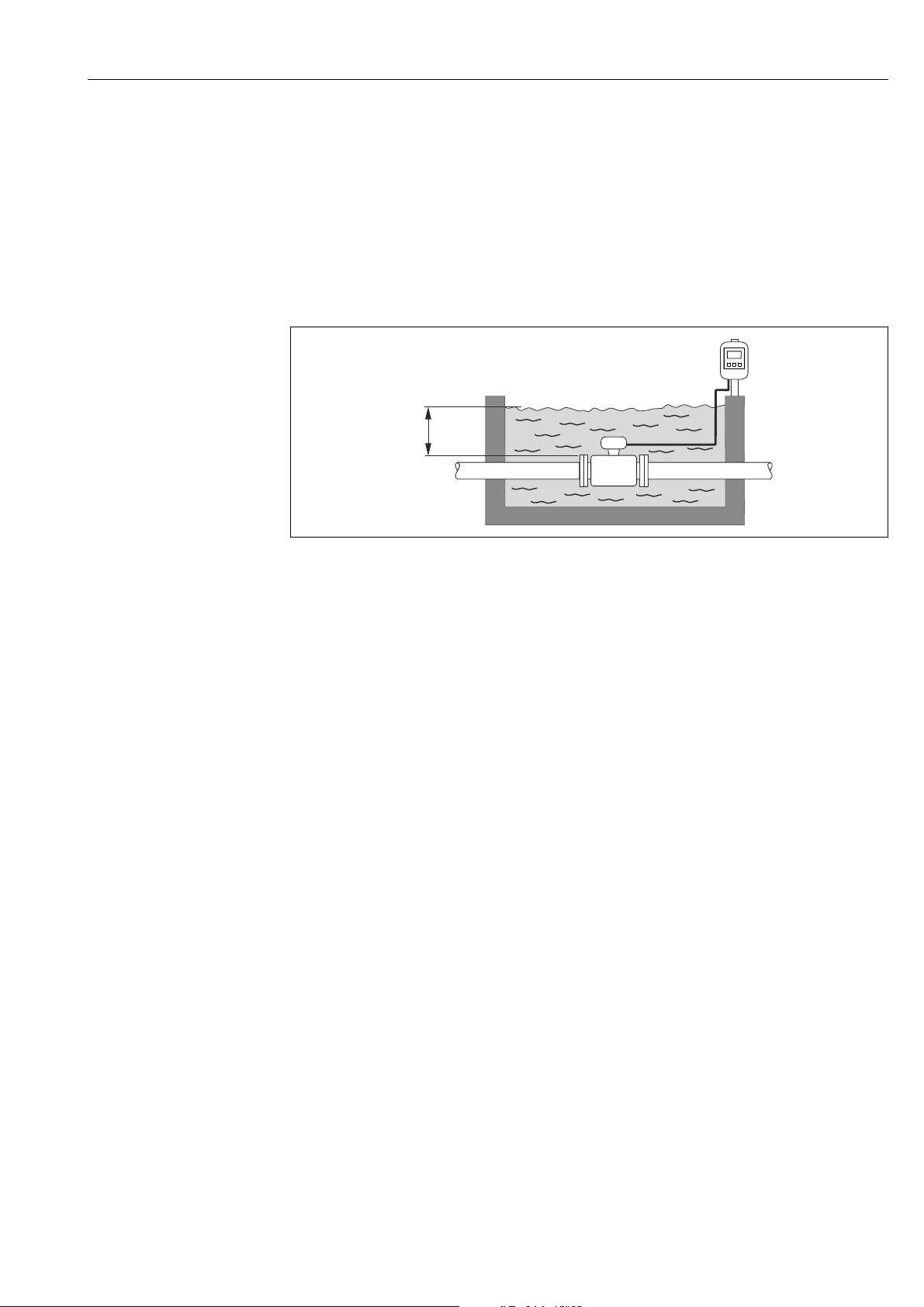

Temporary use in water for sensor Promag L

A remote version in IP67, type 6 is optionally available for temporary use in water up to 168

hours at 3 m (10 ft) or, in exceptional cases, for use up to 48 hours at 10 m (30 ft).

Compared to the degree of protection of standard version IP67, type 4X enclosure, the

version IP67, type 6 enclosure was designed to withstand short-term or temporary

submergence (e.g. flooding).

Fig. 19: Temporary use in water. Engineering unit mm (ft)

A0017296

Endress+Hauser 17

Page 18

Installation Promag 10

5

1

2

3

4

3.3 Installing the measuring device

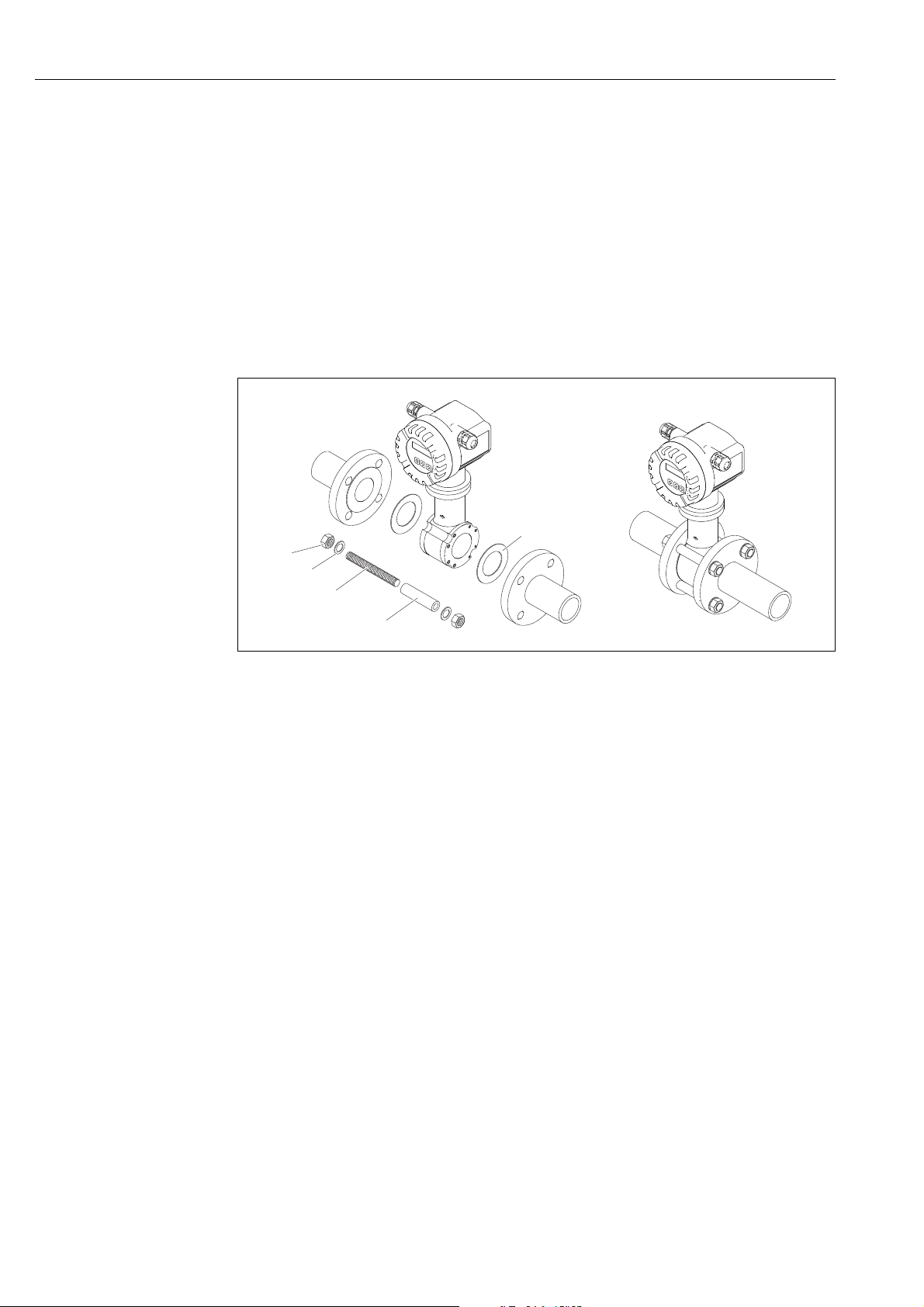

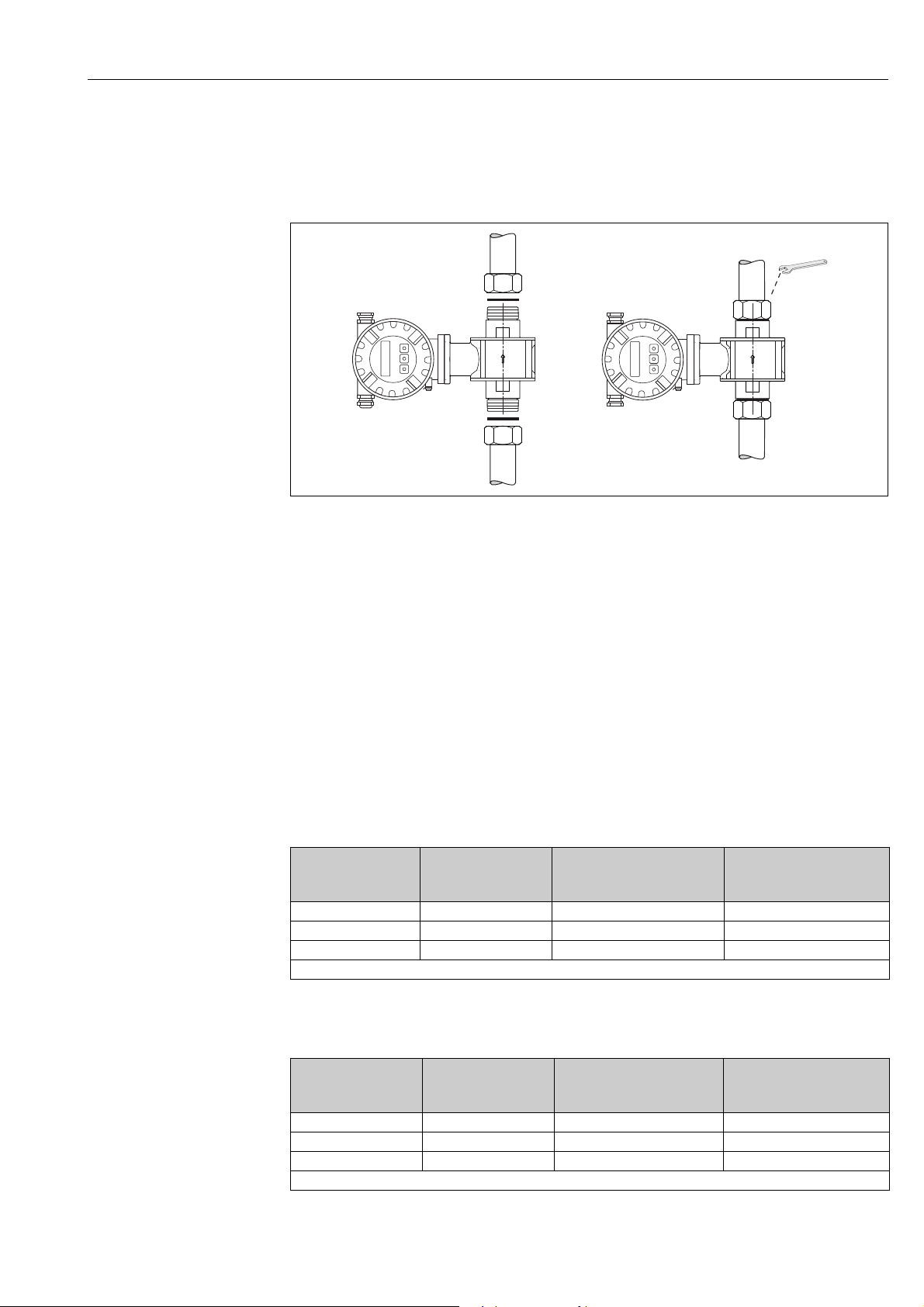

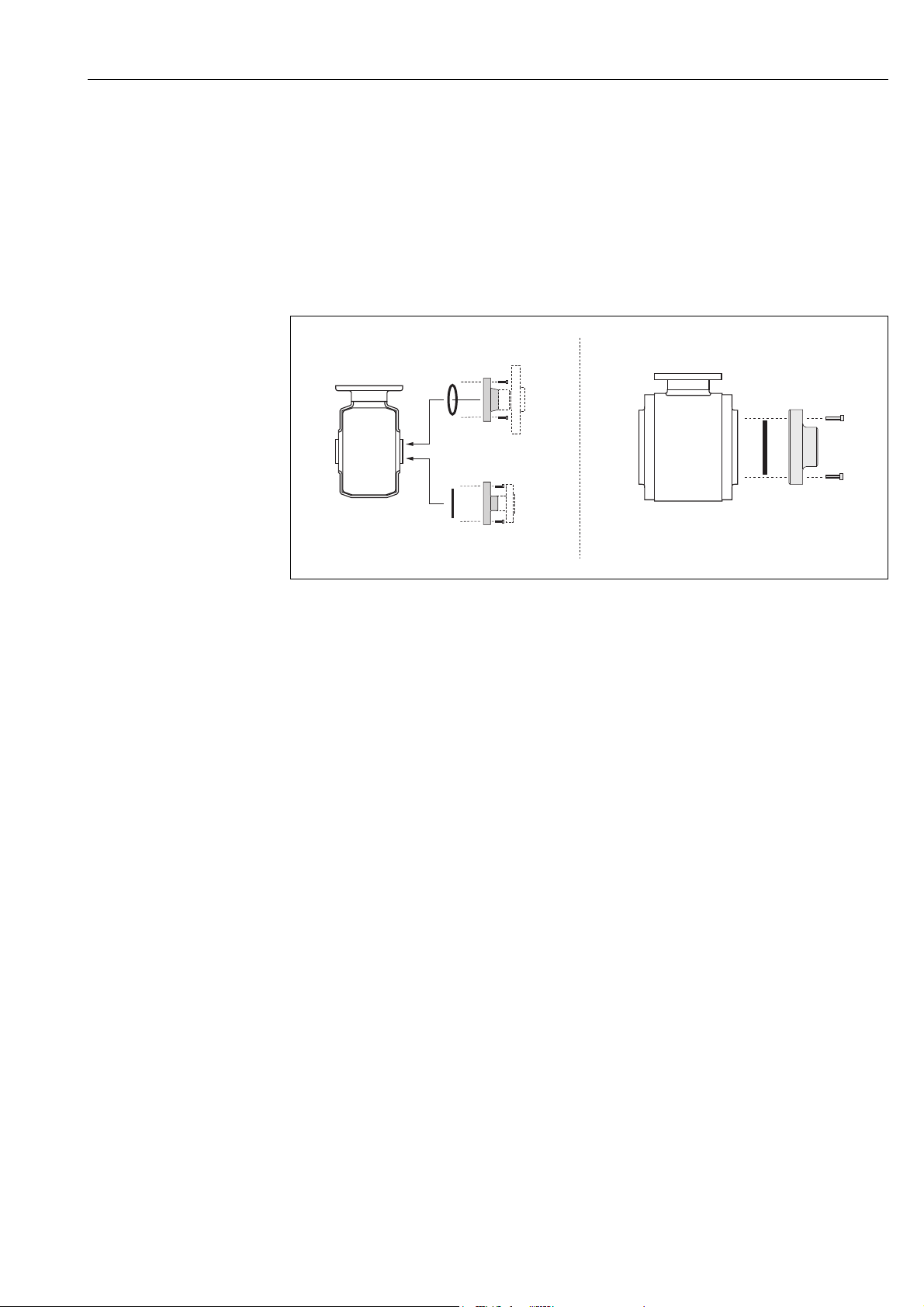

3.3.1 Installing the Promag D sensor as wafer version

The sensor is installed between the pipe flanges with a mounting kit. The device is centered

using recesses on the sensor ( 19).

!

"

Note!

A mounting kit consisting of mounting bolts, seals, nuts and washers can be ordered

separately ( 74). Centering sleeves are provided with the device if they are required for

the installation.

Caution!

When installing the transmitter in the pipe, observe the necessary torques ( 20).

a0010714

Fig. 20: Mounting the sensor Promag D as wafer version

1Nut

2Washer

3 Mounting bolt

4 Centering sleeve

5Seal

Seals

When installing the sensor make sure that the seals used do not project into the pipe crosssection.

Caution!

"

Risk of short circuit! Do not use electrically conductive sealing compounds such as graphite!

An electrically conductive layer could form on the inside of the measuring tube and shortcircuit the measuring signal.

!

18 Endress+Hauser

Note!

Use seals with a hardness rating of 70° Shore A.

Page 19

Promag 10 Installation

1

1

1

1

1

1

1

1

1

1

1

1

2

2

22

3

3

3

3

3

3

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

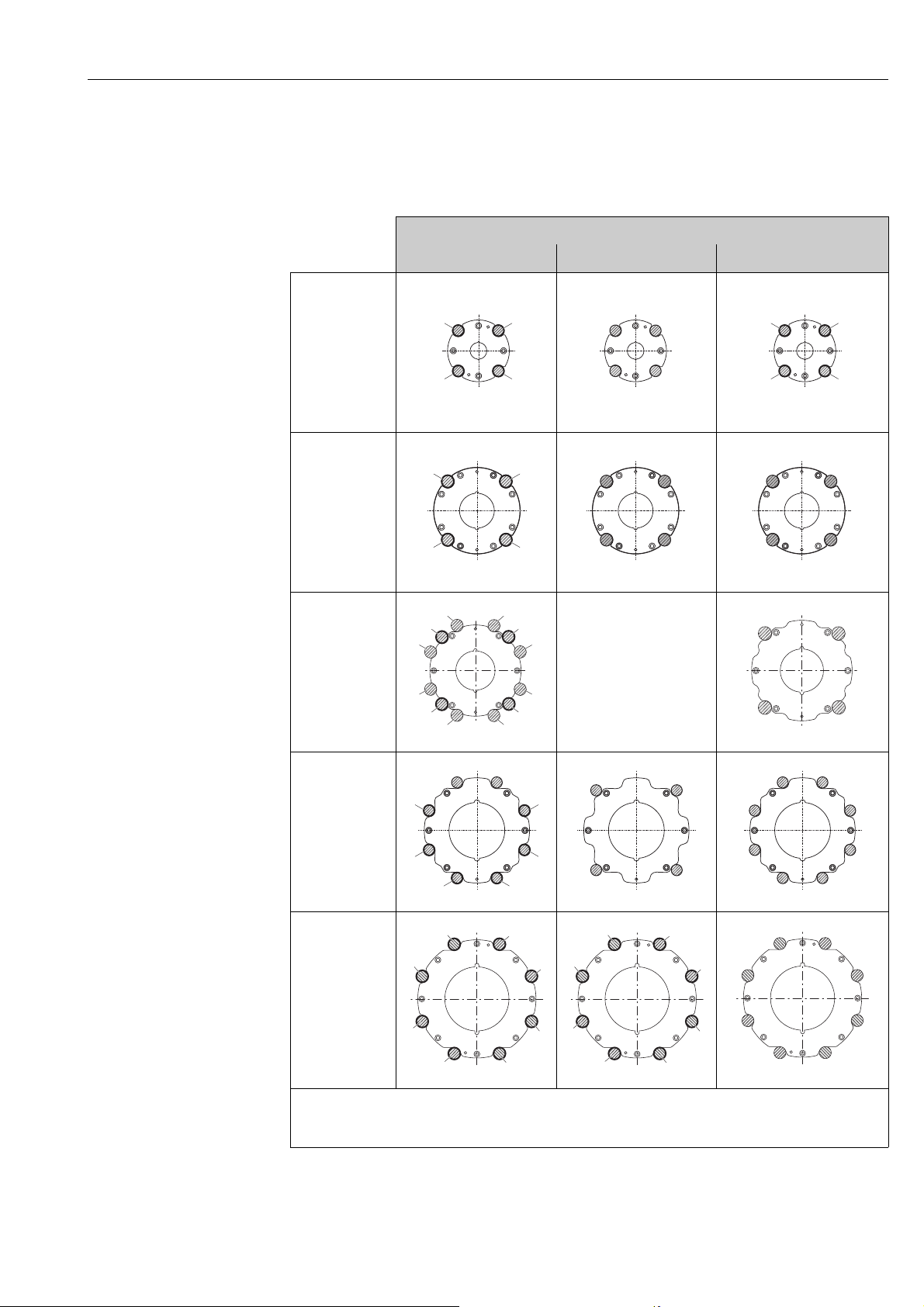

Arrangement of the mounting bolts and centering sleeves

The device is centered using recesses on the sensor. The arrangement of the mounting bolts

and the use of the centering sleeves supplied depend on the nominal diameter, the flange

standard und the pitch circle diameter.

Process connection

EN (DIN) ASME JIS

DN 25 to 40

(1 to 1 ½")

A0010896 A0010824 A0010896

DN 50 (2")

DN 65 (–)

DN 80 (3")

DN 100 (4")

A0010897 A0010825 A0010825

–––––––––––––––––

A0012170

A0010898 A0010827 A0010826

A0012171

Endress+Hauser 19

A0012168 A0012168 A0012169

1 = Mounting bolts with centering sleeves

2 = EN (DIN) flanges: 4-hole with centering sleeves

3 = EN (DIN) flanges: 8-hole without centering sleeves

Page 20

Installation Promag 10

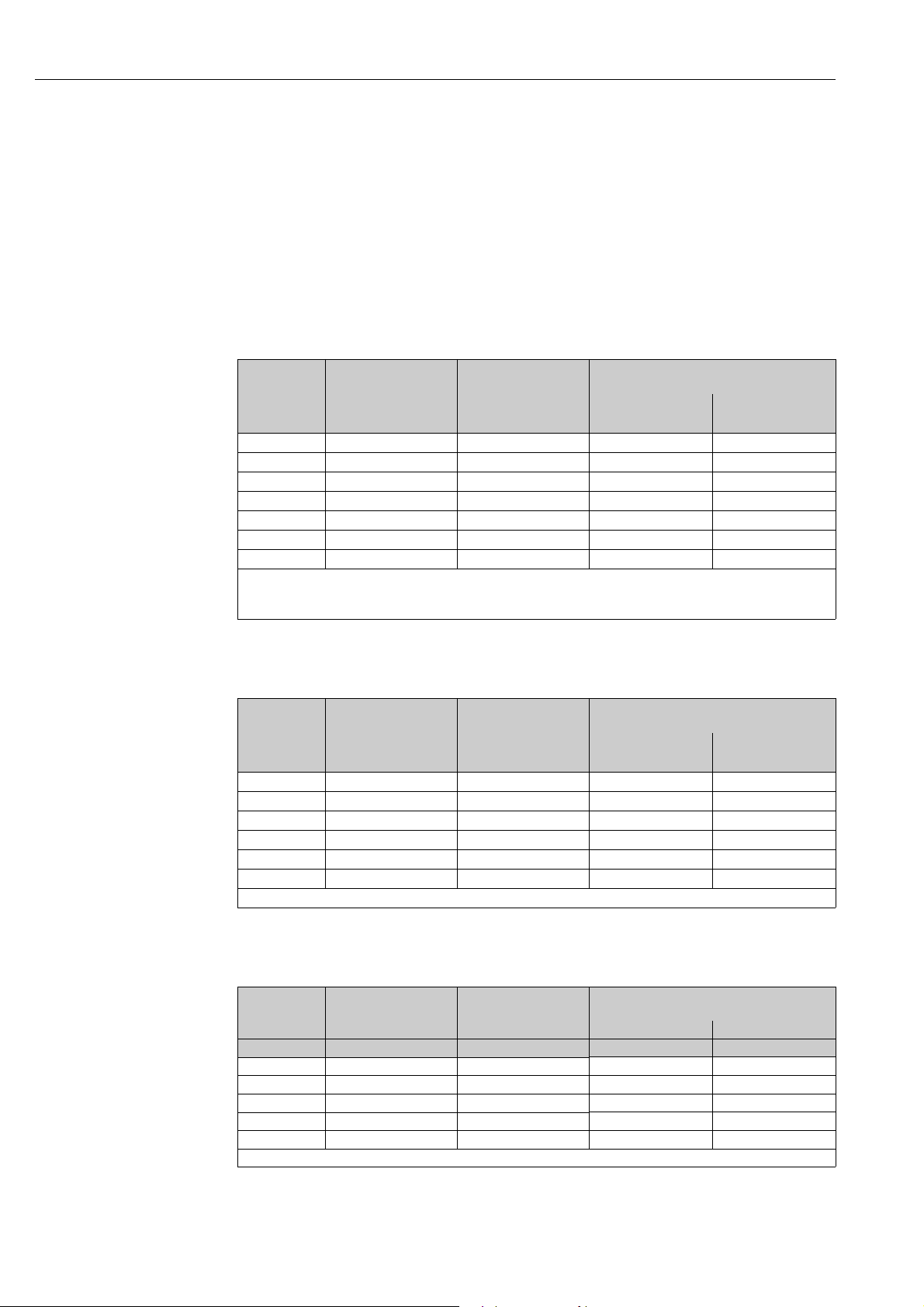

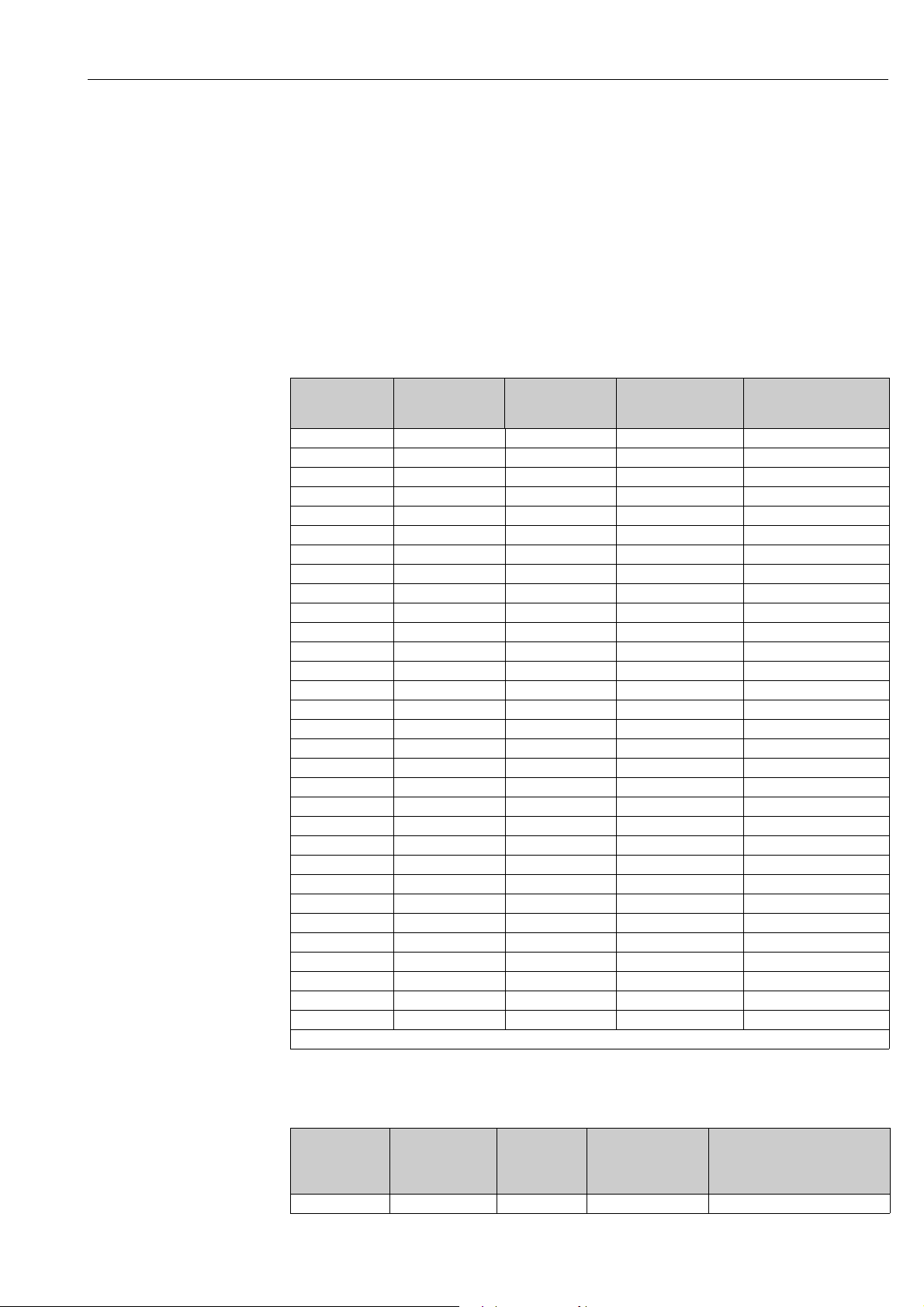

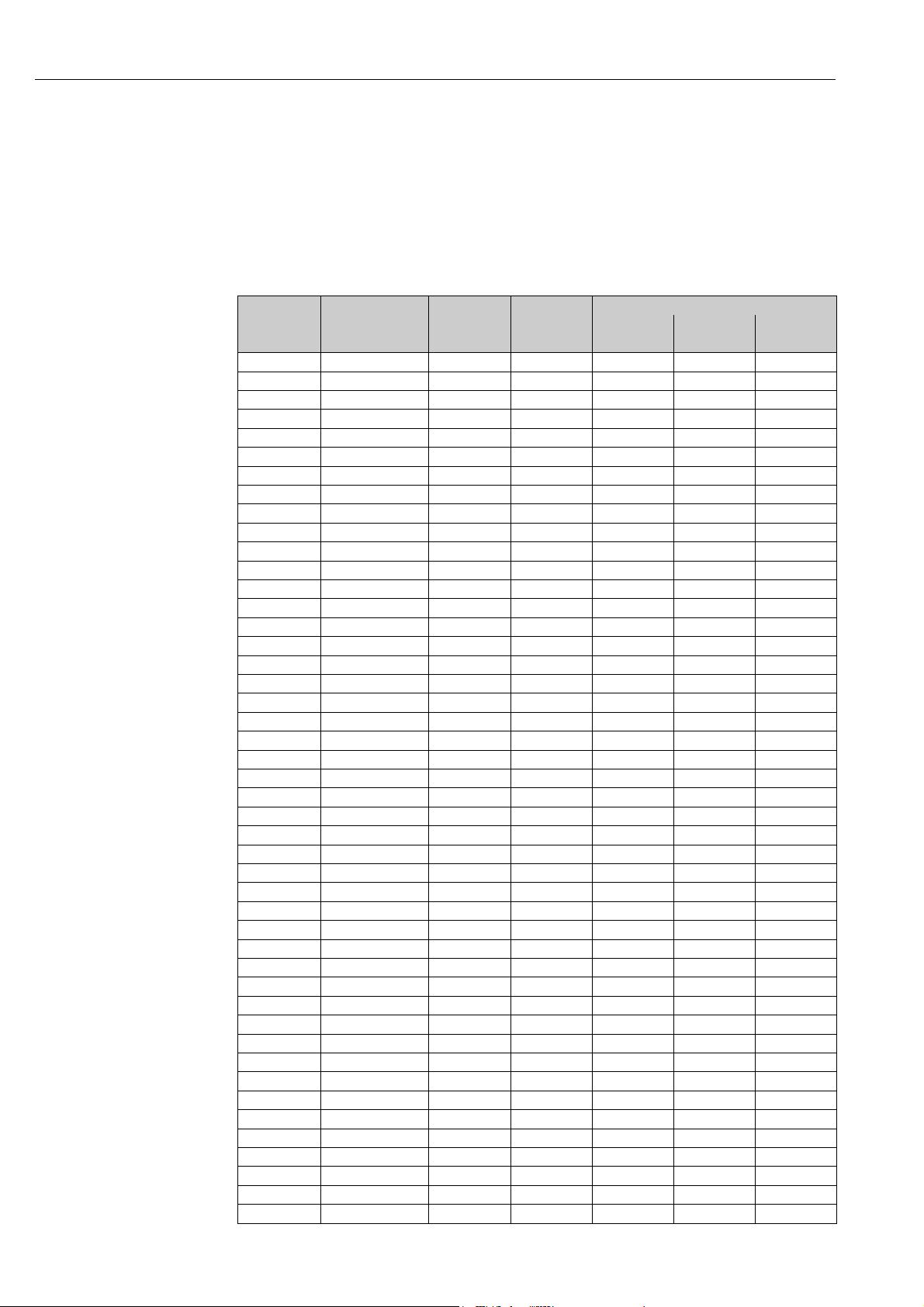

Screw tightening torques (Promag D as wafer version)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

The tightening torques apply to situations where an EPDM soft material flat seal (e.g. 70°

Shore A) is used.

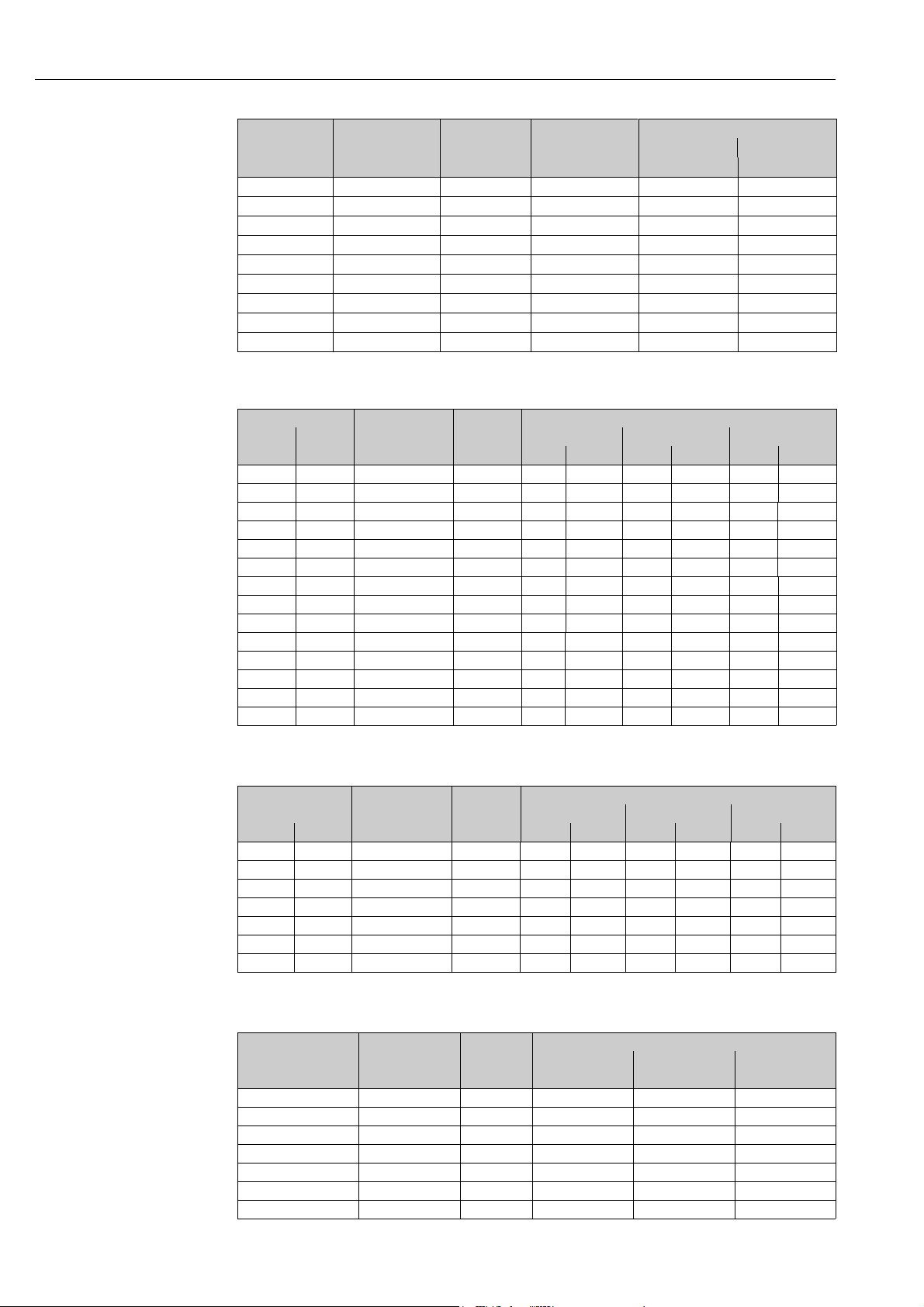

Promag D as wafer version screw tightening torques, mounting bolts and centering sleeves for

EN 1092-1 (DIN 2501), PN 16

Nominal

diameter

[mm] [mm] [mm] [Nm] [Nm]

25 4 × M12 × 145 54 19 19

40 4 × M16 × 170 68 33 33

50 4 × M16 × 185 82 41 41

65¹ 4 × M16 × 200 92 44 44

65

80 8 × M16 × 225 116 36 36

100 8 × M16 × 260 147 40 40

EN (DIN) flanges: 4-hole with centering sleeves

EN (DIN) flanges: 8-hole without centering sleeves

A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

8 × M16 × 200 –

Centering sleeve

length

Tightening torque

with a process flange with a

smooth seal face raised face

29 29

Promag D as wafer version screw tightening torques, mounting bolts and centering sleeves for

JIS B2220, 10K

Nominal

diameter

[mm] [mm] [mm] [Nm] [Nm]

25 4 × M16 × 170 54 24 24

40 4 × M16 × 170 68 32 25

50 4 × M16 × 185 – * 38 30

65 4 × M16 × 200 – * 42 42

80 8 × M16 × 225 – * 36 28

100 8 × M16 × 260 – * 39 37

* A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

Centering sleeve

length

Tightening torque

with a process flange with a

smooth seal face raised face

Promag D as wafer version screw tightening torques, mounting bolts and centering sleeves for

ASME B16.5, Class 150

Nominal

diameter

[inch] [inch] [inch] [lbf · ft] [lbf · ft]

1" 4 × UNC ½ " × 5.70" – * 14 7

1 ½" 4 × UNC ½ " × 6.50" – * 21 14

2" 4 × UNC 5/8" × 7.50" – * 30 27

3" 4 × UNC 5/8" × 9.25" – * 31 31

4" 8 × UNC 5/8" × 10.4" 5.79 28 28

* A centering sleeve is not required. The device is centered directly via the sensor housing.

Mounting bolts

Centering sleeve

length

Tightening torque

with a process flange with a

smooth seal face raised face

20 Endress+Hauser

Page 21

Promag 10 Installation

3.3.2 Installing the Promag D sensor with threaded connection

The sensor can be installed into the pipe with common threaded connections.

Caution!

"

When installing the transmitter in the pipe, observe the necessary torques ( 20).

A0029328

Fig. 21: Installing the Promag D sensor with threaded connection

Seals

The purchaser is responsible for the choice of the seals. Common seals can be used for the

threaded connections.

Caution!

"

Risk of short circuit! Do not use electrically conductive sealing compounds such as graphite!

An electrically conductive layer could form on the inside of the measuring tube and shortcircuit the measuring signal.

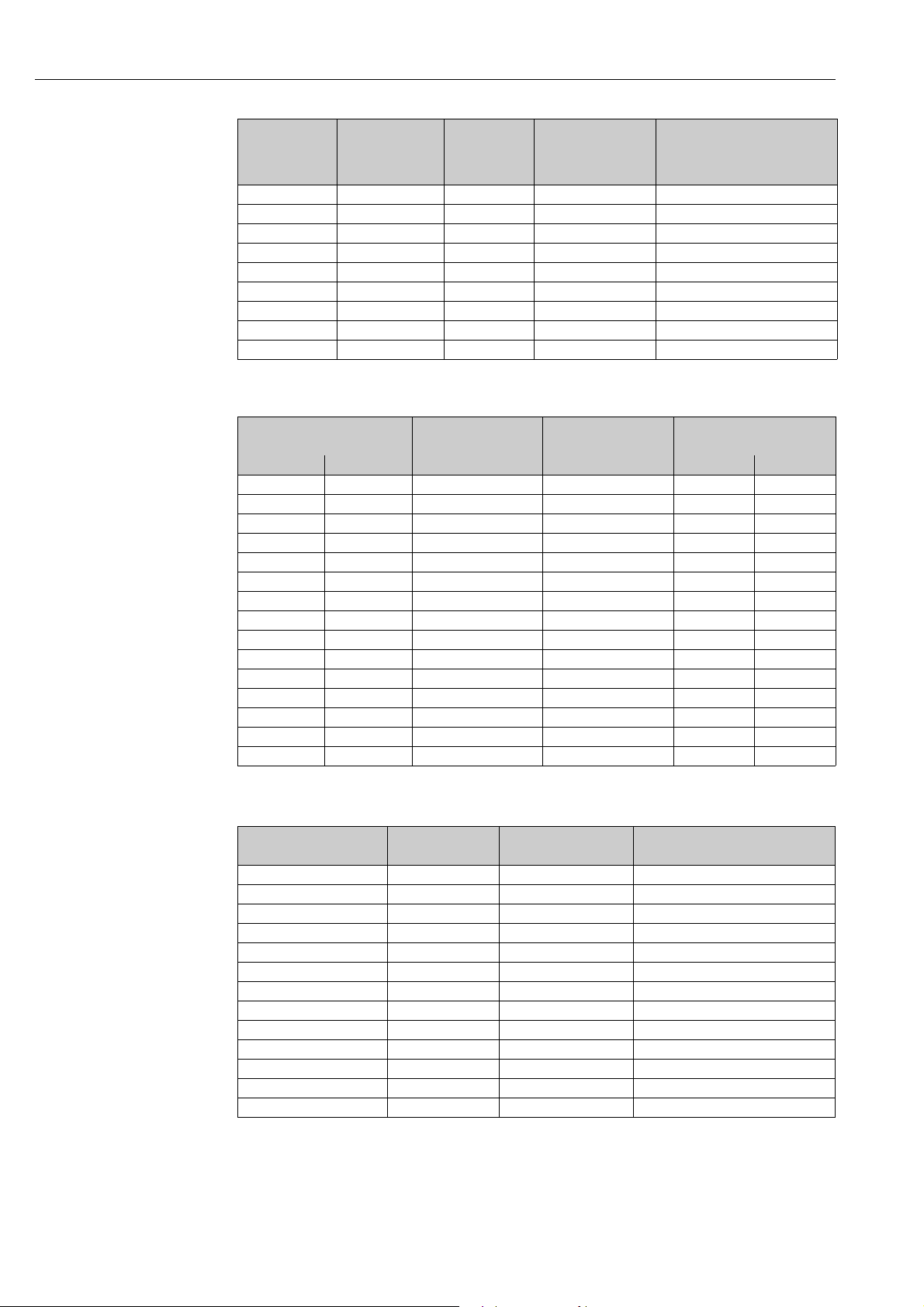

Screw tightening torques (Promag D with threaded connection)

The tightening torques listed below are for lubricated threads only.

Promag D with threaded connection screw tightening torques, mounting bolts and width

across flat for EN 1092-1 (DIN 2501), PN 16

Nominal diameter

[mm] [mm/inch] [Nm]

25 G 1" 28/1.1 20

40 G 1 ½" 50/1.97 50

50 G 2" 60/2.36 90

The purchaser is responsible for the choice of the seals

Threaded

connection

Width across flat Max. tightening torque

Promag D with threaded connection screw tightening torques, mounting bolts and width

across flat for ASME B16.5, Class 150

Nominal diameter

[in] [mm/inch] [Nm]

1" NPT 1" 28/1.1 20

1 ½" NPT 1 ½" 50/1.97 50

2" NPT 2" 60/2.36 90

The purchaser is responsible for the choice of the seals

Threaded

connection

Width across flat Max. tightening torque

Endress+Hauser 21

Page 22

Installation Promag 10

3.3.3 Installing the Promag E sensor

Caution!

"

• The protective covers mounted on the two sensor flanges guard the PTFE, which is turned

over the flanges. Consequently, do not remove these covers until immediately before the

sensor is installed in the pipe.

• The covers must remain in place while the device is in storage.

• Make sure that the lining is not damaged or removed from the flanges.

!

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the

customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on 23

• If grounding disks are used, follow the mounting instructions which will be enclosed with

the shipment

Fig. 22: Installing the Promag E sensor

Seals

Comply with the following instructions when installing seals:

• PTFE lining No seals are required!

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

"

Risk of short circuit! Do not use electrically conductive sealing compounds such as graphite!

An electrically conductive layer could form on the inside of the measuring tube and shortcircuit the measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an

accessory ( 74).

• Information on potential equalization and detailed mounting instructions for the use of

ground cables can be found on 54

a0004296

22 Endress+Hauser

Page 23

Promag 10 Installation

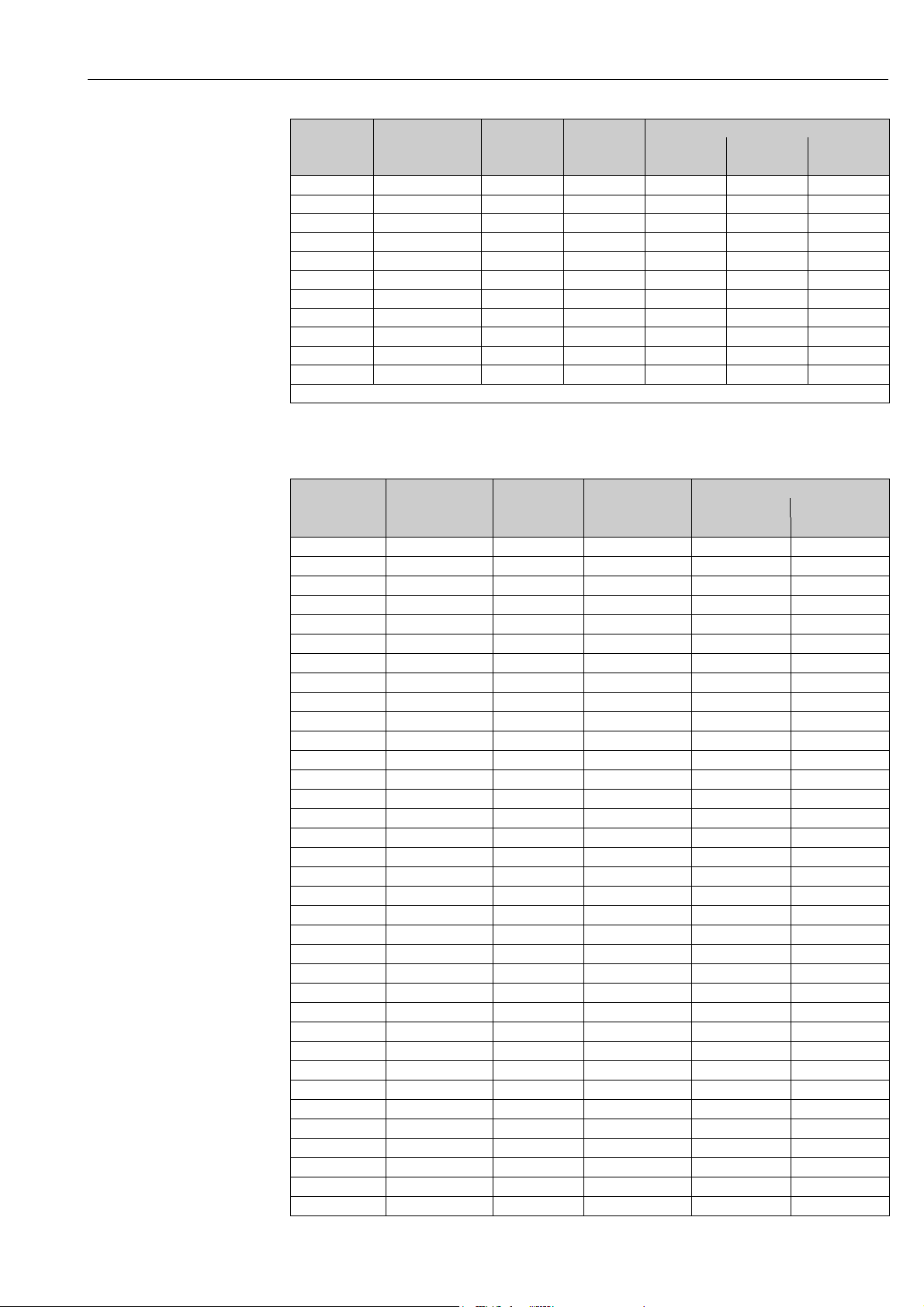

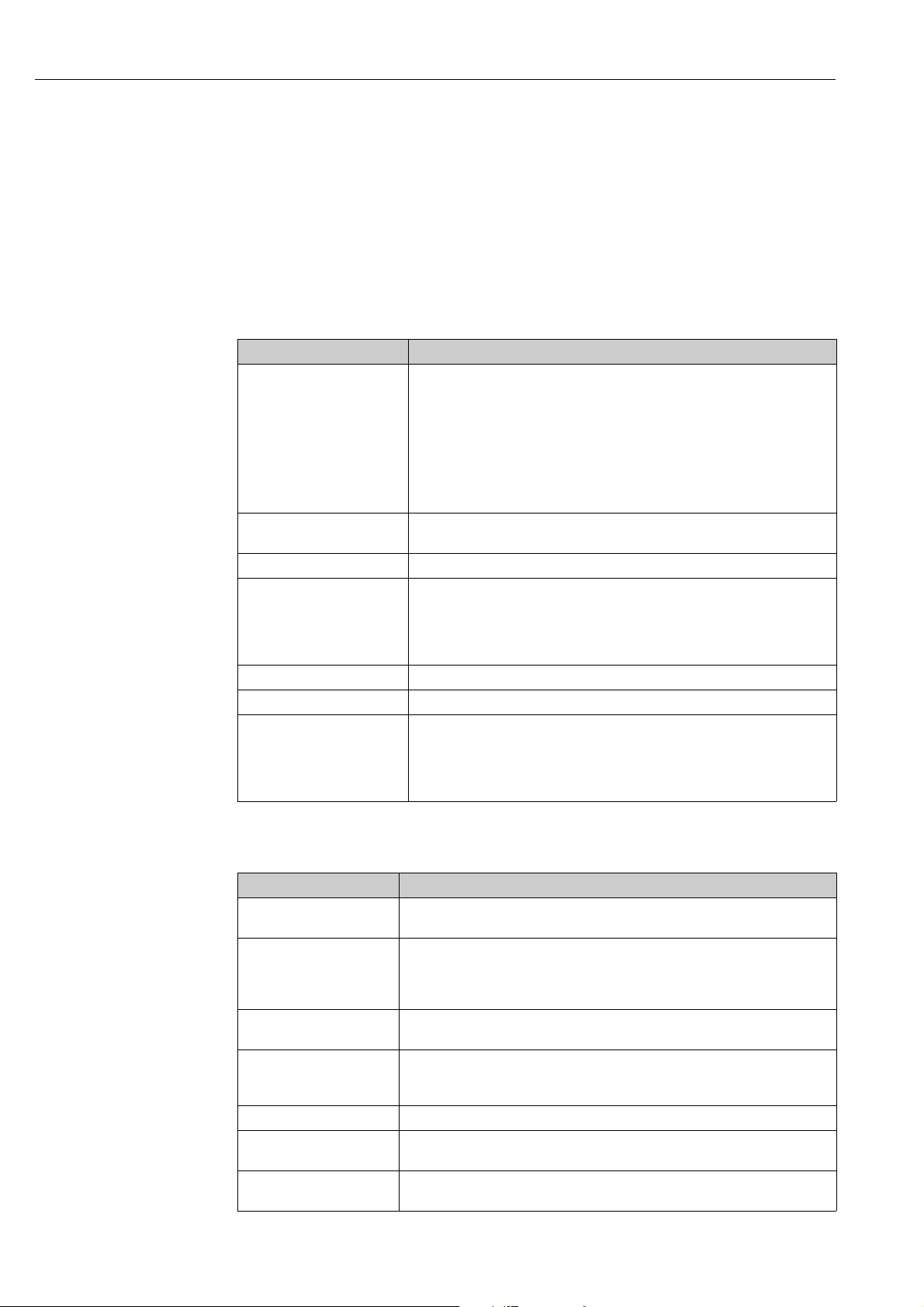

Tightening torques for threaded fasteners (Promag E)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Tightening torques for:

•EN (DIN) 23

•ASME 24

•JIS 24

Promag E screw tightening torques for EN 1092-1 (DIN 2501), PN 6/10/16/40

Nominal

diameter

[mm]

15 PN 40 4 × M 12 16 11

25 PN 40 4 × M 12 18 26

32 PN 40 4 × M 16 18 41

40 PN 40 4 × M 16 18 52

50 PN 40 4 × M 16 20 65

65 * PN 16 8 × M 16 18 43

80 PN 16 8 × M 16 20 53

100 PN 16 8 × M 16 20 57

125 PN 16 8 × M 16 22 75

150 PN 16 8 × M 20 22 99

200 PN 10 8 × M 20 24 141

200 PN 16 12 × M 20 24 94

250 PN 10 12 × M 20 26 110

250 PN 16 12 × M 24 26 131

300 PN 10 12 × M 20 26 125

300 PN 16 12 × M 24 28 179

350 PN 6 12 × M 20 22 200

350 PN 10 16 × M 20 26 188

350 PN 16 16 × M 24 30 254

400 PN 6 16 × M 20 22 166

400 PN 10 16 × M 24 26 260

400 PN 16 16 × M 27 32 330

450 PN 6 16 × M 20 22 202

450 PN 10 20 × M 24 28 235

450 PN 16 20 × M 27 40 300

500 PN 6 20 × M 20 24 176

500 PN 10 20 × M 24 28 265

500 PN 16 20 × M 30 34 448

600 PN 6 20 × M 24 30 242

600 PN 10 20 × M 27 28 345

600 * PN 16 20 × M 33 36 658

* Designed acc. to EN 1092-1 (not to DIN 2501)

EN (DIN)

Pressure rating

Threaded

fasteners

Flange thickness

[mm]

Max. tightening

torque PTFE

[Nm]

Promag E screw tightening torques for EN 1092-1, PN 6/10/16, P245GH/stainless-steel;

Calculated according to EN 1591-1:2014 for flanges according to EN 1092-1:2013

Nominal

diameter

[mm]

350 PN 10 16 × M 20 26 60

EN (DIN)

Pressure rating

Threaded

fasteners

Flange thickness

[mm]

Nom. tightening torque

PTFE

[Nm]

Endress+Hauser 23

Page 24

Installation Promag 10

Nominal

diameter

[mm]

350 PN 16 16 × M 24 30 115

400 PN 10 16 × M 24 26 90

400 PN 16 16 × M 27 32 155

450 PN 10 20 × M 24 28 90

450 PN 16 20 × M 27 34 155

500 PN 10 20 × M 24 28 100

500 PN 16 20 × M 30 36 205

600 PN 10 20 × M 27 30 150

600 PN 16 20 × M 33 40 310

EN (DIN)

Pressure rating

Threaded

fasteners

Flange thickness

[mm]

Nom. tightening torque

PTFE

[Nm]

Promag E screw tightening torques for ASME B16.5, Class 150

Nominal diameter ASME Threaded fasteners Max. tightening torque

PTFE

[mm] [inch] [Nm] [lbf · ft]

15 ½" Class 150 4 × ½" 6 4

25 1" Class 150 4 × ½" 11 8

40 1 ½" Class 150 4 × ½" 24 18

50 2" Class 150 4 × 5/8" 47 35

80 3" Class 150 4 × 5/8" 79 58

100 4" Class 150 8 × 5/8" 56 41

150 6" Class 150 8 × ¾" 106 78

200 8" Class 150 8 × ¾" 143 105

250 10" Class 150 12 × 7/8" 135 100

300 12" Class 150 12 × 7/8" 178 131

350 14" Class 150 12 × 1" 260 192

400 16" Class 150 16 × 1" 246 181

450 18" Class 150 16 × 1 ¹⁄" 371 274

500 20" Class 150 20 × 1 ¹⁄" 341 252

600 24" Class 150 20 × 1 ¼" 477 352

Pressure rating

Promag E screw tightening torques for JIS B2220, 10/20K

Nominal diameter JIS Threaded fasteners Max. tightening torque PTFE

[mm] Pressure rating [Nm]

15 20K 4 × M 12 16

25 20K 4 × M 16 32

32 20K 4 × M 16 38

40 20K 4 × M 16 41

50 10K 4 × M 16 54

65 10K 4 × M 16 74

80 10K 8 × M 16 38

100 10K 8 × M 16 47

125 10K 8 × M 20 80

150 10K 8 × M 20 99

200 10K 12 × M 20 82

250 10K 12 × M 22 133

300 10K 16 × M 22 99

24 Endress+Hauser

Page 25

Promag 10 Installation

A

B

C

DN 2…25

( / "…1")

1

12

DN 40…100

(1½"…4")

3.3.4 Installing the Promag H sensor

The sensor is supplied to order, with or without pre-installed process connections. Preinstalled process connections are secured to the sensor with 4 or 6 hex-head threaded

fasteners.

Caution!

"

The sensor might require support or additional attachments, depending on the application

and the length of the piping run. When plastic process connections are used, the sensor must

be additionally supported mechanically. A wall-mounting kit can be ordered separately from

Endress+Hauser as an accessory ( 74).

a0004301

Fig. 23: Promag H process connections

A = DN 2 to 25 / process connections with O-ring

– Flanges (EN (DIN), ASME, JIS ),

–External thread

B = DN 2 to 25 / process connections with aseptic gasket seal

– Weld nipples (EN 10357 (DIN 11850), ODT/SMS)

– Tri-Clamp L14AM7

– Coupling (DIN 11851, DIN 11864-1, SMS 1145 (only DN 25)

– Flange DIN 11864-2

C = DN 40 to 150 / process connections with aseptic gasket seal

– Weld nipples (EN 10357 (DIN 11850), ODT/SMS)

– Tri-Clamp L14AM7

– Coupling (DIN 11851, DIN 11864-1, SMS 1145)

– Flange DIN 11864-2

Seals

When installing the process connections, make sure that the seals are clean and correctly

centered.

Caution!

"

• With metal process connections, you must fully tighten the screws. The process

connection forms a metallic connection with the sensor, which ensures a defined

compression of the seal.

• With plastic process connections, note the max. torques for lubricated threads (7 Nm / 5.2

lbf ft). With plastic flanges, always use seals between connection and counter flange.

• The seals must be replaced periodically, depending on the application, particularly in the

case of gasket seals (aseptic version)!

The period between changes depends on the frequency of cleaning cycles, the cleaning

temperature and the fluid temperature. Replacement seals can be ordered as accessories

74.

Endress+Hauser 25

Page 26

Installation Promag 10

Welding the transmitter into the piping (weld nipples)

Caution!

"

Risk of destroying the measuring electronics. Make sure that the welding machine is not

grounded via the sensor or the transmitter.

1. Tack-weld the sensor into the pipe. A suitable welding jig can be ordered separately as

an accessory ( 74).

2. Loosen the screws on the process connection flange and remove the sensor, complete

with the seal, from the pipe.

3. Weld the process connection to the pipe.

4. Reinstall the sensor in the pipe. Make sure that everything is clean and that the seal is

correctly seated.

!

Note!

• If thin-walled foodstuffs pipes are not welded correctly, the heat could damage the

installed seal. It is therefore advisable to remove the sensor and the seal prior to welding.

• The pipe has to be spread approximately 8 mm to permit disassembly.

Cleaning with pigs

If pigs are us ed for cleaning, it is essential to take the inside diameters of the measuri ng tube

and process connection into account. All the dimensions and lengths of the sensor and

transmitter are provided in the separate documentation "Technical Documentation".

26 Endress+Hauser

Page 27

Promag 10 Installation

3.3.5 Installing the Promag L sensor

Caution!

"

• The protective covers mounted on the two sensor flanges (DN 25 to 300 / 1 to 12") are

used to hold the lap joint flanges in place and to protect the PTFE liner during

transportation. Consequently, do not remove these covers until immediately before the

sensor is installed in the pipe.

• The covers must remain in place while the device is in storage.

• Make sure that the lining is not damaged or removed from the flanges.

!

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the

customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on 28

• If grounding disks are used, follow the mounting instructions which will be enclosed with

the shipment

• To comply with the device specification, a concentrical installation in the measuring

section is required

Fig. 24: Installing the Promag L sensor

Seals

Comply with the following instructions when installing seals:

• Hard rubber lining additional seals are always necessary.

• Polyurethane lining no seals are required.

• PTFE lining no seals are required.

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

"

Risk of short circuit!

Do not use electrically conductive sealing compounds such as graphite! An electrically

conductive layer could form on the inside of the measuring tube and short-circuit the

measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an

accessory ( 74).

• Information on potential equalization and detailed mounting instructions for the use of

ground cables can be found on 54.

a0004296

Endress+Hauser 27

Page 28

Installation Promag 10

Screw tightening torques (Promag L)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Promag L screw tightening torques for EN 1092-1 (DIN 2501), PN 6/10/16

Nominal EN (DIN) Threaded Flange Max. tightening torques

diamter Pressure rating fasteners thickness Hard rubber Polyurethane PTFE

[mm] [mm] [Nm] [Nm] [Nm]

25 PN 10/16 4 × M 12 18 - 6 11

32 PN 10/16 4 × M 16 18 - 16 27

40 PN 10/16 4 × M 16 18 - 16 29

50 PN 10/16 4 × M 16 18 - 15 40

65* PN 10/16 8 × M 16 18 - 10 22

80 PN 10/16 8 × M 16 20 - 15 30

100 PN 10/16 8 × M 16 20 - 20 42

125 PN 10/16 8 × M 16 22 - 30 55

150 PN 10/16 8 × M 20 22 - 50 90

200 PN 16 12 × M 20 24 - 65 87

250 PN 16 12 × M 24 26 - 126 151

300 PN 16 12 × M 24 28 - 139 177

350 PN 6 12 × M 20 22 111 120 350 PN 10 16 × M 20 26 112 118 350 PN 16 16 × M 24 30 152 165 400 PN 6 16 × M 20 22 90 98 400 PN 10 16 × M 24 26 151 167 400 PN 16 16 × M 27 32 193 215 450 PN 6 16 × M 20 22 112 126 450 PN 10 20 × M 24 28 153 133 500 PN 6 20 × M 20 24 119 123 500 PN 10 20 × M 24 28 155 171 500 PN 16 20 × M 30 34 275 300 600 PN 6 20 × M 24 30 139 147 600 PN 10 20 × M 27 28 206 219 -

600* PN 16 20 × M 33 36 415 443 -

700 PN 6 24 × M 24 24 148 139 700 PN 10 24 × M 27 30 246 246 700 PN 16 24 × M 33 36 278 318 800 PN 6 24 × M 27 24 206 182 800 PN 10 24 × M 30 32 331 316 800 PN 16 24 × M 36 38 369 385 900 PN 6 24 × M 27 26 230 637 900 PN 10 28 × M 30 34 316 307 900 PN 16 28 × M 36 40 353 398 -

1000 PN 6 28 × M 27 26 218 208 1000 PN 10 28 × M 33 34 402 405 1000 PN 16 28 × M 39 42 502 518 1200 PN 6 32 × M 30 28 319 299 1200 PN 10 32 × M 36 38 564 568 1200 PN 16 32 × M 45 48 701 753 1400 PN 6 36 × M 33 32 430 - 1400 PN 10 36 × M 39 42 654 - 1400 PN 16 36 × M 45 52 729 - 1600 PN 6 40 × M 33 34 440 - 1600 PN 10 40 × M 45 46 946 - -

28 Endress+Hauser

Page 29

Promag 10 Installation

Nominal EN (DIN) Threaded Flange Max. tightening torques

diamter Pressure rating fasteners thickness Hard rubber Polyurethane PTFE

[mm] [mm] [Nm] [Nm] [Nm]

1600 PN 16 40 × M 52 58 1007 - 1800 PN 6 44 × M 36 36 547 - 1800 PN 10 44 × M 45 50 961 - 1800 PN 16 44 × M 52 62 1108 - 2000 PN 6 48 × M 39 38 629 - 2000 PN 10 48 × M 45 54 1047 - 2000 PN 16 48 × M 56 66 1324 - 2200 PN 6 52 × M 39 42 698 - 2200 PN 10 52 × M 52 58 1217 - 2400 PN 6 56 × M 39 44 768 - 2400 PN 10 56 × M 52 62 1229 - -

* Designed acc. to EN 1092-1 (not to DIN 2501)

Promag L screw tightening torques for EN 1092-, PN 6/10/16, P245GH/stainless-steel;

Calculated according to EN 1591-1:2014 for flanges according to EN 1092-1:2013

Nominal

diameter

[mm] [mm] [Nm] [Nm]

350 PN 6 12 × M 20 22 60 75

350 PN 10 16 × M 20 26 70 80

400 PN 6 16 × M 20 22 65 70

400 PN 10 16 × M 24 26 100 120

400 PN 16 16 × M 27 32 175 190

450 PN 6 16 × M 20 22 70 90

450 PN 10 20 × M 24 28 100 110

500 PN 6 20 × M 20 24 65 70

500 PN 10 20 × M 24 28 110 120

500 PN 16 20 × M 30 36 225 235

600 PN 6 20 × M 24 30 105 105

600 PN 10 20 × M 27 30 165 160

600 PN 16 20 × M 33 40 340 340

700 PN 6 24 × M 24 30 110 110

700 PN 10 24 × M 27 35 190 190

700 PN 16 24 × M 33 40 340 340

800 PN 6 24 × M 27 30 145 145

800 PN 10 24 × M 30 38 260 260

800 PN 16 24 × M 36 41 465 455

900 PN 6 24 × M 27 34 170 180

900 PN 10 28 × M 30 38 265 275

900 PN 16 28 × M 36 48 475 475

1000 PN 6 28 × M 27 38 175 185

1000 PN 10 28 × M 33 44 350 360

1000 PN 16 28 × M 39 59 630 620

1200 PN 6 32 × M 30 42 235 250

1200 PN 10 32 × M 36 55 470 480

1200 PN 16 32 × M 45 78 890 900

1400 PN 6 36 × M 33 56 300 1400 PN 10 36 × M 39 65 600 1400 PN 16 36 × M 45 84 1050 1600 PN 6 40 × M 33 63 340 1600 PN 10 40 × M 45 75 810 1600 PN 16 40 × M 52 102 1420 1800 PN 6 44 × M 36 69 430 -

EN(DIN)

pressure rating

Threaded

fastener

Flange

thickness

Nom. tightening torques

Hard rubber Polyurethane

Endress+Hauser 29

Page 30

Installation Promag 10

Nominal

diameter

[mm] [mm] [Nm] [Nm]

1800 PN 10 44 × M 45 85 920 1800 PN 16 44 × M 52 110 1600 2000 PN 6 48 × M 39 74 530 2000 PN 10 48 × M 45 90 1040 2000 PN 16 48 × M 56 124 1900 2200 PN 6 52 × M 39 81 580 2200 PN 10 52 × M 52 100 1290 2400 PN 6 56 × M 39 87 650 2400 PN 10 56 × M 52 110 1410 -

EN(DIN)

pressure rating

Threaded

fastener

Flange

thickness

Nom. tightening torques

Hard rubber Polyurethane

Promag L screw tightening torques for ASME B16.5, Class 150

Nominal diameter ASME Threaded Max. tightening torque

Pressure rating fasteners Hard rubber Polyurethane PTFE

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft] [Nm] [lbf · ft]

25 1" Class 150 4 × 5/8" - - 5 4 14 13

40 1 ½" Class 150 8 × 5/8" - - 10 17 21 15

50 2" Class 150 4 × 5/8" - - 15 11 40 29

80 3" Class 150 4 × 5/8" - - 25 18 65 48

100 4" Class 150 8 × 5/8" - - 20 15 44 32

150 6" Class 150 8 × ¾" - - 45 33 90 66

200 8" Class 150 8 × ¾" - - 65 48 87 64

250 10" Class 150 12 × 7/8" - - 126 93 151 112

300 12" Class 150 12 × 7/8" - - 146 108 177 131

350 14" Class 150 12 × 1" 135 100 158 117 - 400 16" Class 150 16 × 1" 128 94 150 111 - 450 18" Class 150 16 × 1 ¹⁄" 204 150 234 173 - -

500 20" Class 150 20 × 1 ¹⁄" 183 135 217 160 - -

600 24" Class 150 20 × 1 ¼" 268 198 307 226 - -

Promag L screw tightening torques for AWWA, Class D

Nominal diameter AWWA Threaded Max. tightening torque

Pressure rating fasteners Hart rubber Polyurethane PTFE

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft] [Nm] [lbf · ft]

700 28" Class D 28 × 1 ¼" 247 182 292 215 - 750 30" Class D 28 × 1 ¼" 287 212 302 223 - 800 32" Class D 28 × 1 ½" 394 291 422 311 - 900 36" Class D 32 × 1 ½" 419 309 430 317 - -

1000 40" Class D 36 × 1 ½" 420 310 477 352 - 1050 42" Class D 36 × 1 ½" 528 389 518 382 - 1200 48" Class D 44 × 1 ½" 552 407 531 392 - -

Promag L screw tightening torques for AS 2129, Table E

Nominal diameter AS 2129 Threaded Max. tightening torque

Pressure rating fasteners Hard rubber Polyurethane PTFE

[mm] [Nm] [Nm] [Nm]

350 Table E 12 × M 24 203 - 400 Table E 12 × M 24 226 - 450 Table E 16 × M 24 226 - 500 Table E 16 × M 24 271 - 600 Table E 16 × M 30 439 - 700 Table E 20 × M 30 355 - 750 Table E 20 × M 30 559 - -

30 Endress+Hauser

Page 31

Promag 10 Installation

Nominal diameter AS 2129 Threaded Max. tightening torque

Pressure rating fasteners Hard rubber Polyurethane PTFE

[mm] [Nm] [Nm] [Nm]

800 Table E 20 × M 30 631 - -

900 Table E 24 × M 30 627 - 1000 Table E 24 × M 30 634 - 1200 Table E 32 × M 30 727 - -

Promag L screw tightening torques for AS 4087, PN16

Nominal diameter AS 4087 Threaded Max. tightening torque

Pressure rating fasteners Hard rubber Polyurethane PTFE

[mm] [Nm] [Nm] [Nm]

350 PN 16 12 × M 24 203 - 375 PN 16 12 × M 24 137 - 400 PN 16 12 × M 24 226 - 450 PN 16 12 × M 24 301 - 500 PN 16 16 × M 24 271 - 600 PN 16 16 × M 27 393 - 700 PN 16 20 × M 27 330 - 750 PN 16 20 × M 30 529 - 800 PN 16 20 × M 33 631 - -

900 PN 16 24 × M 33 627 - 1000 PN 16 24 × M 33 595 - 1200 PN 16 32 × M 33 703 - -

Endress+Hauser 31

Page 32

Installation Promag 10

3.3.6 Installing the Promag P sensor

Caution!

"

• The protective covers mounted on the two sensor flanges guard the PTFE, which is turned

over the flanges. Consequently, do not remove these covers until immediately before the

sensor is installed in the pipe.

• The covers must remain in place while the device is in storage.

• Make sure that the lining is not damaged or removed from the flanges.

!

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the

customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on 32

• If grounding disks are used, follow the mounting instructions which will be enclosed with

the shipment

Fig. 25: Installing the Promag P sensor

Seals

Comply with the following instructions when installing seals:

• PTFE lining No seals are required!

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

"

Risk of short circuit! Do not use electrically conductive sealing compounds such as graphite!

An electrically conductive layer could form on the inside of the measuring tube and shortcircuit the measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an

accessory ( 74).

• Information on potential equalization and detailed mounting instructions for the use of

ground cables can be found on 54

Tightening torques for threaded fasteners (Promag P)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

a0004296

32 Endress+Hauser

Page 33

Promag 10 Installation

Tightening torques for:

•EN (DIN) 33

•ASME 34

•JIS 34

• AS 2129 35

• AS 4087 35

Promag P screw tightening torques for EN 1092-1 (DIN 2501), PN 10/16/25/40

Nominal diameter EN (DIN)

Pressure rating

bar

[mm] [mm] [Nm]

25 PN 40 4 × M 12 18 26

32 PN 40 4 × M 16 18 41

40 PN 40 4 × M 16 18 52

50 PN 40 4 × M 16 20 65

65 * PN 16 8 × M 16 18 43

65 PN 40 8 × M 16 22 43

80 PN 16 8 × M 16 20 53

80 PN 40 8 × M 16 24 53

100 PN 16 8 × M 16 20 57

100 PN 40 8 × M 20 24 78

125 PN 16 8 × M 16 22 75

125 PN 40 8 × M 24 26 111

150 PN 16 8 × M 20 22 99

150 PN 40 8 × M 24 28 136

200 PN 10 8 × M 20 24 141

200 PN 16 12 × M 20 24 94

200 PN 25 12 × M 24 30 138

250 PN 10 12 × M 20 26 110

250 PN 16 12 × M 24 26 131

250 PN 25 12 × M 27 32 200

300 PN 10 12 × M 20 26 125

300 PN 16 12 × M 24 28 179

300 PN 25 16 × M 27 34 204

350 PN 10 16 × M 20 26 188

350 PN 16 16 × M 24 30 254

350 PN 25 16 × M 30 38 380

400 PN 10 16 × M 24 26 260

400 PN 16 16 × M 27 32 330

400 PN 25 16 × M 33 40 488

450 PN 10 20 × M 24 28 235

450 PN 16 20 × M 27 40 300

450 PN 25 20 × M 33 46 385

500 PN 10 20 × M 24 28 265

500 PN 16 20 × M 30 34 448

500 PN 25 20 × M 33 48 533

600 PN 10 20 × M 27 28 345

600 * PN 16 20 × M 33 36 658

600 PN 25 20 × M 36 58 731

* Designed acc. to EN 1092-1 (not to DIN 2501)

Threaded

fasteners

Flange

thickness

Max. tightening

torque

PTFE

Endress+Hauser 33

Page 34

Installation Promag 10

Promag P screw tightening torques for EN 1092-1, PN 10/16/25, P245GH/stainless-steel;

Calculated according to EN 1591-1:2014 for flanges according to EN 1092-1:2013

Nominal

diamter

[mm]

350 PN 10 16 × M 20 26 60

350 PN 16 16 × M 24 30 115

350 PN 25 16 × M 30 38 220

400 PN 10 16 × M 24 26 90

400 PN 16 16 × M 27 32 155

400 PN 25 16 × M 33 40 290

450 PN 10 20 × M 24 28 90

450 PN 16 20 × M 27 34 155

450 PN 25 20 × M 33 46 290

500 PN 10 20 × M 24 28 100

500 PN 16 20 × M 30 36 205

500 PN 25 20 × M 33 48 345

600 PN 10 20 × M 27 30 150

600 PN 16 20 × M 33 40 310

600 PN 25 20 × M 36 48 500

EN (DIN)

pressure rating

Threaded

fasteners

Flange thickness

[mm]

Nom. tightening torques

PTFE

[Nm]

Promag P screw tightening torques for ASME B16.5, Class 150/300

Nominal diameter ASME Threaded fasteners Max. tightening torque

PTFE

[mm] [inch] [Nm] [lbf · ft]

25 1" Class 150 4 × ½" 11 8

25 1" Class 300 4 × 5/8" 14 10

40 1 ½" Class 150 4 × ½" 24 18

40 1 ½" Class 300 4 × ¾" 34 25

50 2" Class 150 4 × 5/8" 47 35

50 2" Class 300 8 × 5/8" 23 17

80 3" Class 150 4 × 5/8" 79 58

80 3" Class 300 8 × ¾" 47 35

100 4" Class 150 8 × 5/8" 56 41

100 4" Class 300 8 × ¾" 67 49

150 6" Class 150 8 × ¾" 106 78

150 6" Class 300 12 × ¾" 73 54

200 8" Class 150 8 × ¾" 143 105

250 10" Class 150 12 × 7/8" 135 100

300 12" Class 150 12 × 7/8" 178 131

350 14" Class 150 12 × 1" 260 192

400 16" Class 150 16 × 1" 246 181

450 18" Class 150 16 × 1 ¹⁄" 371 274

500 20" Class 150 20 × 1 ¹⁄" 341 252

600 24" Class 150 20 × 1 ¼" 477 352

Pressure rating

Promag P screw tightening torques for JIS B2220, 10/20K

Nominal diameter JIS Pressure Threaded fasteners Max. tightening torque PTFE

[mm] rating [Nm]

25 10K 4 × M 16 32

25 20K 4 × M 16 32

32 10K 4 × M 16 38

32 20K 4 × M 16 38

40 10K 4 × M 16 41

40 20K 4 × M 16 41

50 10K 4 × M 16 54

34 Endress+Hauser

Page 35

Promag 10 Installation

Nominal diameter JIS Pressure Threaded fasteners Max. tightening torque PTFE

[mm] rating [Nm]

50 20K 8 × M 16 27

65 10K 4 × M 16 74

65 20K 8 × M 16 37

80 10K 8 × M 16 38

80 20K 8 × M 20 57

100 10K 8 × M 16 47

100 20K 8 × M 20 75

125 10K 8 × M 20 80

125 20K 8 × M 22 121

150 10K 8 × M 20 99

150 20K 12 × M 22 108

200 10K 12 × M 20 82

200 20K 12 × M 22 121

250 10K 12 × M 22 133

250 20K 12 × M 24 212

300 10K 16 × M 22 99

300 20K 16 × M 24 183

Promag P tightening torques for JIS B2220, 10/20K

Nominal

diameter

[mm] [Nm] [Nm]

350 10K 16 × M 22 109 109

350 20K 16 × M 30 x3 217 217

400 10K 16 × M 24 163 163

400 20K 16 × M 30 x3 258 258

450 10K 16 × M 24 155 155

450 20K 16 × M 30 x3 272 272

500 10K 16 × M 24 183 183

500 20K 16 × M 30 x3 315 315

600 10K 16 × M 30 235 235

600 20K 16 × M 36 x3 381 381

JIS Pressure

rating

Threaded

fasteners

Nom. tightening torques

Hard rubber Polyurethane

Promag P screw tightening torques for AS 2129, Table E

Nominal diameter

[mm]

25 Table E 4 × M 12 21

50 Table E 4 × M 16 42

AS 2129

Pressure rating

Threaded

fasteners

Max. tightening torque

Promag P screw tightening torques for AS 4087, PN16

PTFE

[Nm]

Nominal diameter

[mm]

50 PN 16 4 × M 16 42

AS 4087

Pressure rating

Threaded

fasteners

Max. tightening torque

PTFE

[Nm]

Endress+Hauser 35

Page 36

Installation Promag 10

3.3.7 Installing the Promag W sensor

!

Note!

Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the

customer.

The sensor is designed for installation between the two piping flanges.

• Observe in any case the necessary screw tightening torques on 37

• If grounding disks are used, follow the mounting instructions which will be enclosed with

the shipment

a0004296

Fig. 26: Installing the Promag W sensor

Seals

Comply with the following instructions when installing seals:

• Hard rubber lining additional seals are always necessary.

•Polyurethane lining no seals are required.

• For DIN flanges, use only seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Caution!

"

Risk of short circuit!

Do not use electrically conductive sealing compounds such as graphite! An electrically

conductive layer could form on the inside of the measuring tube and short-circuit the

measuring signal.

Ground cable

• If necessary, special ground cables for potential equalization can be ordered as an

accessory ( 74).

• Information on potential equalization and detailed mounting instructions for the use of

ground cables can be found on 54

36 Endress+Hauser

Page 37

Promag 10 Installation

Screw tightening torques (Promag W)

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Always tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Tightening torques for:

•EN (DIN) 37

•JIS 40

•ASME 39

• AWWA 41

• AS 2129 41

• AS 4087 42

Promag W screw tightening torques for EN 1092-1 (DIN 2501), PN 6/10/16/25/40

Nominal

diameter

[mm] [mm] [Nm] [Nm]

25 PN 40 4 × M 12 18 - 15

32 PN 40 4 × M 16 18 - 24

40 PN 40 4 × M 16 18 - 31

50 PN 40 4 × M 16 20 48 40

65* PN 16 8 × M 16 18 32 27

65 PN 40 8 × M 16 22 32 27

80 PN 16 8 × M 16 20 40 34

80 PN 40 8 × M 16 24 40 34

100 PN 16 8 × M 16 20 43 36

100 PN 40 8 × M 20 24 59 50

125 PN 16 8 × M 16 22 56 48

125 PN 40 8 × M 24 26 83 71

150 PN 16 8 × M 20 22 74 63

150 PN 40 8 × M 24 28 104 88

200 PN 10 8 × M 20 24 106 91

200 PN 16 12 × M 20 24 70 61

200 PN 25 12 × M 24 30 104 92

250 PN 10 12 × M 20 26 82 71

250 PN 16 12 × M 24 26 98 85

250 PN 25 12 × M 27 32 150 134

300 PN 10 12 × M 20 26 94 81

300 PN 16 12 × M 24 28 134 118

300 PN 25 16 × M 27 34 153 138

350 PN 6 12 × M 20 22 111 120

350 PN 10 16 × M 20 26 112 118

350 PN 16 16 × M 24 30 152 165

350 PN 25 16 × M 30 38 227 252

400 PN 6 16 × M 20 22 90 98

400 PN 10 16 × M 24 26 151 167

400 PN 16 16 × M 27 32 193 215

400 PN 25 16 × M 33 40 289 326

450 PN 6 16 × M 20 22 112 126

450 PN 10 20 × M 24 28 153 133

450 PN 16 20 × M 27 40 198 196

450 PN 25 20 × M 33 46 256 253

500 PN 6 20 × M 20 24 119 123

500 PN 10 20 × M 24 28 155 171

500 PN 16 20 × M 30 34 275 300

EN (DIN)

pressure rating

Threaded

fasteners

Flange thick-

ness

Max. tightening torque

Hard rubber Polyurethane

Endress+Hauser 37

Page 38

Installation Promag 10

Nominal

diameter

[mm] [mm] [Nm] [Nm]

500 PN 25 20 × M 33 48 317 360

600 PN 6 20 × M 24 30 139 147

600 PN 10 20 × M 27 28 206 219

600 * PN 16 20 × M 33 36 415 443

600 PN 25 20 × M 36 58 431 516

700 PN 6 24 × M 24 24 148 139

700 PN 10 24 × M 27 30 246 246

700 PN 16 24 × M 33 36 278 318

700 PN 25 24 × M 39 46 449 507

800 PN 6 24 × M 27 24 206 182

800 PN 10 24 × M 30 32 331 316

800 PN 16 24 × M 36 38 369 385

800 PN 25 24 × M 45 50 664 721

900 PN 6 24 × M 27 26 230 637

900 PN 10 28 × M 30 34 316 307

900 PN 16 28 × M 36 40 353 398

900 PN 25 28 × M 45 54 690 716

1000 PN 6 28 × M 27 26 218 208

1000 PN 10 28 × M 33 34 402 405

1000 PN 16 28 × M 39 42 502 518

1000 PN 25 28 × M 52 58 970 971

1200 PN 6 32 × M 30 28 319 299

1200 PN 10 32 × M 36 38 564 568

1200 PN 16 32 × M 45 48 701 753

1400 PN 6 36 × M 33 32 430 398

1400 PN 10 36 × M 39 42 654 618

1400 PN 16 36 × M 45 52 729 762

1600 PN 6 40 × M 33 34 440 417

1600 PN 10 40 × M 45 46 946 893

1600 PN 16 40 × M 52 58 1007 1100

1800 PN 6 44 × M 36 36 547 521

1800 PN 10 44 × M 45 50 961 895

1800 PN 16 44 × M 52 62 1108 1003

2000 PN 6 48 × M 39 38 629 605

2000 PN 10 48 × M 45 54 1047 1092

2000 PN 16 48 × M 56 66 1324 1261

* Designed acc. to EN 1092-1 (not to DIN 2501)

EN (DIN)

pressure rating

Threaded

fasteners

Flange thick-

ness

Max. tightening torque

Hard rubber Polyurethane

Promag W screw tightening torques for EN 1092-1, PN 6/10/16/25, P245GH/stainlesssteel; Calculated according to EN 1591-1:2014 for flanges according to EN 1092-1:2013

Nominal

diameter

[mm] [mm] [Nm] [Nm]

350 PN 6 12 × M 20 22 60 75

350 PN 10 16 × M 20 26 70 80

350 PN 16 16 × M 24 30 125 135

350 PN 25 16 × M 30 38 230 235

400 PN 6 16 × M 20 22 65 70

400 PN 10 16 × M 24 26 100 120

400 PN 16 16 × M 27 32 175 190

400 PN 25 16 × M 33 40 315 325

450 PN 6 16 × M 20 22 70 90

450 PN 10 20 × M 24 28 100 110

EN (DIN)

Pressure rating

Threaded

fasteners

Flange thickness Nom. tightening torque

Hard rubber Polyurethane

38 Endress+Hauser

Page 39

Promag 10 Installation

Nominal

diameter

[mm] [mm] [Nm] [Nm]

450 PN 16 20 × M 27 34 175 190

450 PN 25 20 × M 33 46 300 310

500 PN 6 20 × M 20 24 65 70

500 PN 10 20 × M 24 28 110 120

500 PN 16 20 × M 30 36 225 235

500 PN 25 20 × M 33 48 370 370

600 PN 6 20 × M 24 30 105 105

600 PN 10 20 × M 27 30 165 160

600 PN 16 20 × M 33 40 340 340

600 PN 25 20 × M 36 48 540 540

700 PN 6 24 × M 24 30 110 110

700 PN 10 24 × M 27 35 190 190

700 PN 16 24 × M 33 40 340 340

700 PN 25 24 × M 39 50 615 595

800 PN 6 24 × M 27 30 145 145

800 PN 10 24 × M 30 38 260 260

800 PN 16 24 × M 36 41 465 455

800 PN 25 24 × M 45 53 885 880

900 PN 6 24 × M 27 34 170 180

900 PN 10 28 × M 30 38 265 275

900 PN 16 28 × M 36 48 475 475

900 PN 25 28 × M 45 57 930 915

1000 PN 6 28 × M 27 38 175 185

1000 PN 10 28 × M 33 44 350 360

1000 PN 16 28 × M 39 59 630 620

1000 PN 25 28 × M 52 63 1300 1290

1200 PN 6 32 × M 30 42 235 250

1200 PN 10 32 × M 36 55 470 480

1200 PN 16 32 × M 45 78 890 900

1400 PN 6 36 × M 33 56 300 1400 PN 10 36 × M 39 65 600 1400 PN 16 36 × M 45 84 1050 1600 PN 6 40 × M 33 63 340 1600 PN 10 40 × M 45 75 810 1600 PN 16 40 × M 52 102 1420 1800 PN 6 44 × M 36 69 430 1800 PN 10 44 × M 45 85 920 1800 PN 16 44 × M 52 110 1600 2000 PN 6 48 × M 39 74 530 2000 PN 10 48 × M 45 90 1040 2000 PN 16 48 × M 56 124 1900 -

EN (DIN)

Pressure rating

Threaded

fasteners

Flange thickness Nom. tightening torque

Hard rubber Polyurethane

Promag W screw tightening torques for ASME B16.5, Class 150/300

Nominal

diameter

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft]

25 1" Class 150 4 × ½" - - 7 5

25 1" Class 300 4 × 5/8" - - 8 6

40 1 ½" Class 150 4 × ½" - - 10 7

40 1 ½" Class 300 4 × ¾" - - 15 11

50 2" Class 150 4 × 5/8" 35 26 22 16

50 2" Class 300 8 × 5/8" 18 13 11 8

80 3" Class 150 4 × 5/8" 60 44 43 32

ASME Threaded Max. tightening torque

fasteners

Pressure rating

Hard rubber Polyurethane

Endress+Hauser 39

Page 40

Installation Promag 10

Nominal

diameter

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft]

80 3" Class 300 8 × ¾" 38 28 26 19

100 4" Class 150 8 × 5/8" 42 31 31 23

100 4" Class 300 8 × ¾" 58 43 40 30

150 6" Class 150 8 × ¾" 79 58 59 44

150 6" Class 300 12 × ¾" 70 52 51 38

200 8" Class 150 8 × ¾" 107 79 80 59

250 10" Class 150 12 × 7/8" 101 74 75 55

300 12" Class 150 12 × 7/8" 133 98 103 76

350 14" Class 150 12 × 1" 135 100 158 117

400 16" Class 150 16 × 1" 128 94 150 111

450 18" Class 150 16 × 1 ¹⁄" 204 150 234 173

500 20" Class 150 20 × 1 ¹⁄" 183 135 217 160

600 24" Class 150 20 × 1 ¼" 268 198 307 226

ASME Threaded Max. tightening torque

fasteners

Pressure rating

Hard rubber Polyurethane

Promag W screw tightening torques for JIS B2220, 10/20K

Nominal diameter JIS Threaded

Pressure rating Hard rubber Polyurethane

[mm] [Nm] [Nm]

25 10K 4 × M 16 - 19

25 20K 4 × M 16 - 19

32 10K 4 × M 16 - 22

32 20K 4 × M 16 - 22

40 10K 4 × M 16 - 24

40 20K 4 × M 16 - 24

50 10K 4 × M 16 40 33

50 20K 8 × M 16 20 17

65 10K 4 × M 16 55 45

65 20K 8 × M 16 28 23

80 10K 8 × M 16 29 23

80 20K 8 × M 20 42 35

100 10K 8 × M 16 35 29

100 20K 8 × M 20 56 48

125 10K 8 × M 20 60 51

125 20K 8 × M 22 91 79

150 10K 8 × M 20 75 63

150 20K 12 × M 22 81 72

200 10K 12 × M 20 61 52

200 20K 12 × M 22 91 80

250 10K 12 × M 22 100 87

250 20K 12 × M 24 159 144

300 10K 16 × M 22 74 63

300 20K 16 × M 24 138 124

fasteners

Max. tightening torque

Promag W screw tightening torques for JIS B2220, 10/20K

Nominal

diameter

[mm] [Nm] [Nm]

350 10K 16 × M 22 109 109

350 20K 16 × M 30x3 217 217

400 10K 16 × M 24 163 163

400 20K 16 × M 30x3 258 258

450 10K 16 × M 24 155 155

450 20K 16 × M 30x3 272 272

JIS Pressure

rating

Threaded fas-

teners

Nom. tightening torque

Hard rubber Polyurethane

40 Endress+Hauser

Page 41

Promag 10 Installation

Nominal

diameter

[mm] [Nm] [Nm]

500 10K 16 × M 24 183 183

500 20K 16 × M 30x3 315 315

600 10K 16 × M 30 235 235

600 20K 16 × M 36x3 381 381

700 10K 16 × M 30 300 300

750 10K 16 × M 30 339 339

JIS Pressure

rating

Threaded fas-

teners

Nom. tightening torque

Hard rubber Polyurethane

Promag W screw tightening torques for AWWA C2074, Class D

Nominal diameter AWWA Threaded Max. tightening torque

Pressure

[mm] [inch] [Nm] [lbf · ft] [Nm] [lbf · ft]

700 28" Class D 28 × 1 ¼" 247 182 292 215

750 30" Class D 28 × 1 ¼" 287 212 302 223

800 32" Class D 28 × 1 ½" 394 291 422 311

900 36" Class D 32 × 1 ½" 419 309 430 317

1000 40" Class D 36 × 1 ½" 420 310 477 352

- 42" Class D 36 × 1 ½" 528 389 518 382

1200 48" Class D 44 × 1 ½" 552 407 531 392

- 54" Class D 44 × 1 ¾" 730 538 633 467

- 60" Class D 52 × 1 ¾" 758 559 832 614

- 66" Class D 52 × 1 ¾" 946 698 955 704

1800 72" Class D 60 × 1 ¾" 975 719 1087 802

- 78" Class D 64 × 2" 853 629 786 580

2000 - Class D 64 × 2" 853 629 786 580

rating

fasteners

Hard rubber Polyurethane

Promag W screw tightening torques for AS 2129, Table E

Nominal diameter

[mm]

50 Table E 4 × M 16 32

80 Table E 4 × M 16 49

100 Table E 8 × M 16 38

150 Table E 8 × M 20 64

200 Table E 8 × M 20 96

250 Table E 12 × M 20 98

300 Table E 12 × M 24 123

350 Table E 12 × M 24 203

400 Table E 12 × M 24 226

450 Table E 16 × M 24 226

500 Table E 16 × M 24 271

600 Table E 16 × M 30 439

700 Table E 20 × M 30 355

750 Table E 20 × M 30 559

800 Table E 20 × M 30 631

900 Table E 24 × M 30 627

1000 Table E 24 × M 30 634

1200 Table E 32 × M 30 727

AS 2129

Pressure rating

Threaded

fasteners

Max. tightening torque

Hard rubber

[Nm]

Endress+Hauser 41

Page 42

Installation Promag 10

Promag W screw tightening torques for AS 4087, PN16

Nominal diameter

[mm]

50 Table E 4 × M 16 32

80 PN 16 4 × M 16 49

100 PN 16 4 × M 16 76

150 PN 16 8 × M 20 52

200 PN 16 8 × M 20 77

250 PN 16 8 × M 20 147

300 PN 16 12 × M 24 103

350 PN 16 12 × M 24 203

375 PN 16 12 × M 24 137

400 PN 16 12 × M 24 226

450 PN 16 12 × M 24 301

500 PN 16 16 × M 24 271

600 PN 16 16 × M 27 393

700 PN 16 20 × M 27 330

750 PN 16 20 × M 30 529

800 PN 16 20 × M 33 631

900 PN 16 24 × M 33 627

1000 PN 16 24 × M 33 595

1200 PN 16 32 × M 33 703

AS 4087

Pressure rating

Threaded

fasteners

Max. tightening torque

Hard rubber

[Nm]

42 Endress+Hauser

Page 43

Promag 10 Installation

Esc

E

-

+

Esc

E

-

+

3

5

6

1

2

4

4 x 45°

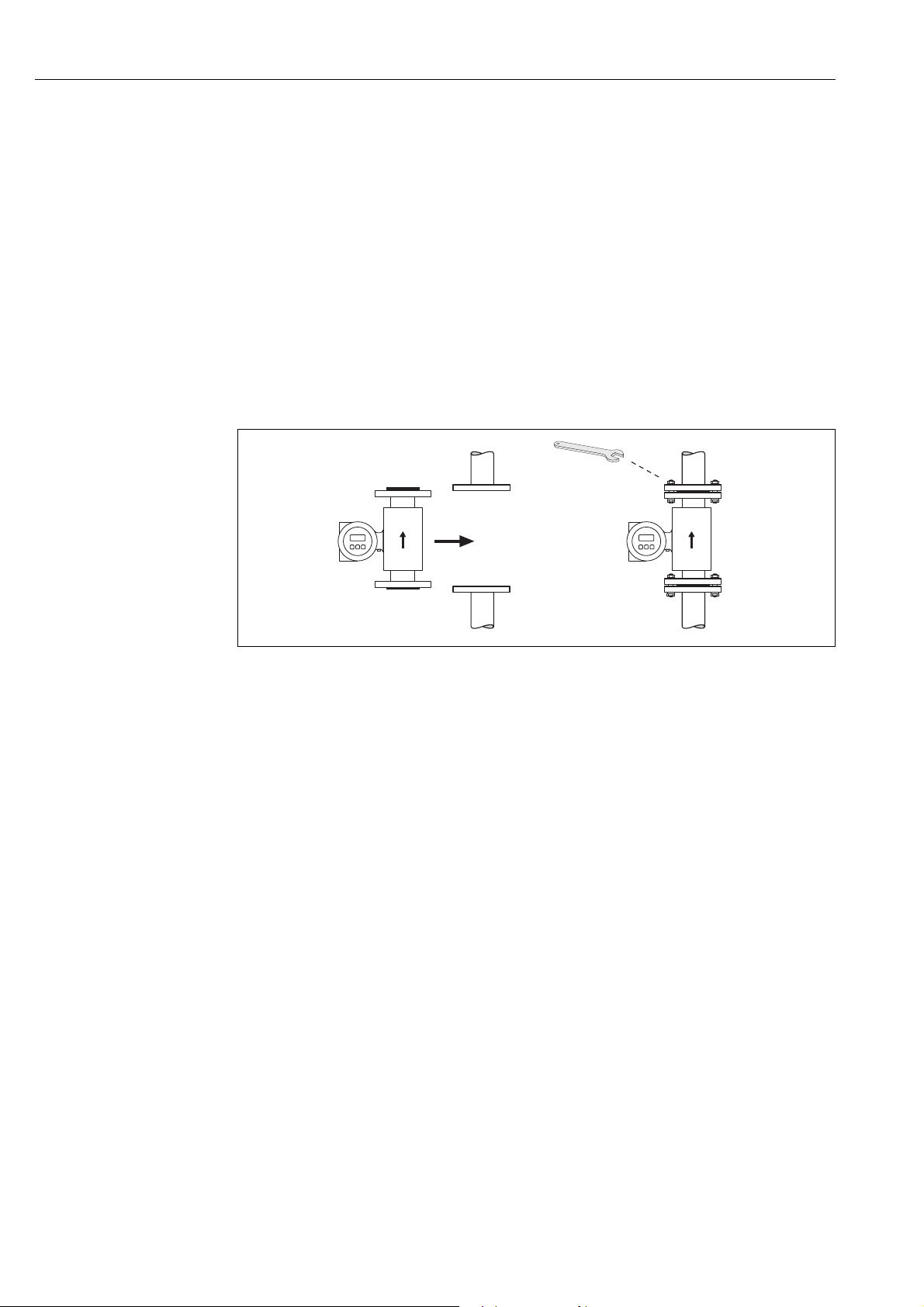

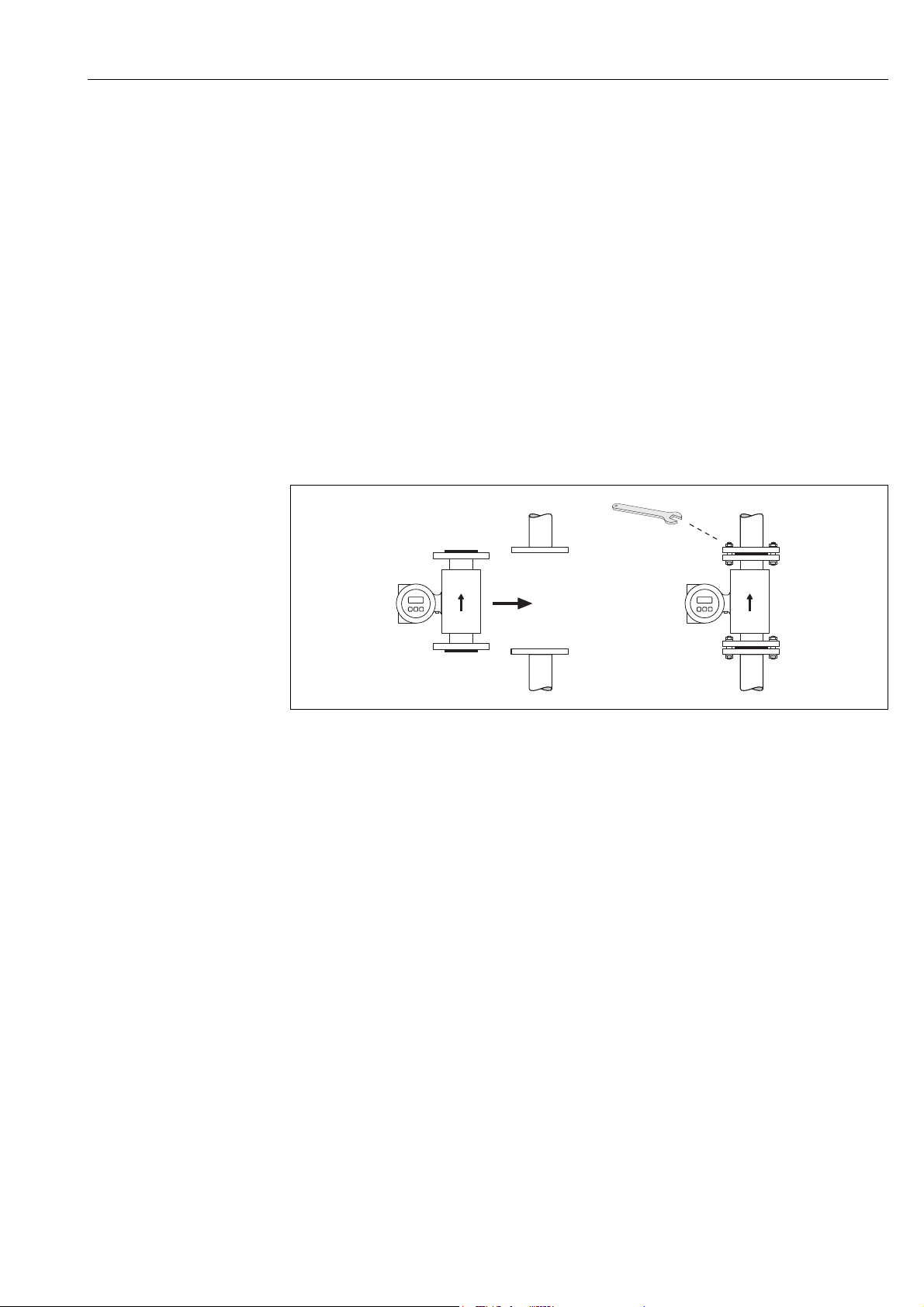

3.3.8 Turning the transmitter housing

1. Loosen the two securing screws.

2. Turn the bayonet lock as far as it will go.

3. Carefully lift the transmitter housing:

– Promag D: approx. 10 mm (0.39 in) above the securing screws

– Promag E/H/L/P/W: to the stop

4. Turn the transmitter housing to the desired position:

– Promag D: max. 180° clockwise or max. 180° counterclockwise

– Promag E/H/L/P/W: max. 280° clockwise or max. 20° counterclockwise

5. Lower the housing into position and re-engage the bayonet catch.

6. Retighten the two securing screws.

Fig. 27: Turning the transmitter housing

3.3.9 Turning the onsite display

1. Unscrew cover of the electronics compartment from the transmitter housing.

2. Remove the display module from the transmitter retaining rails.

3. Turn the display to the desired position (max. 4 × 45° in each direction).

4. Fit the display back onto the retaining rails.

5. Screw the cover of the electronics compartment firmly back onto the transmitter

housing.

a0005393

Fig. 28: Turning the local display

Endress+Hauser 43

A0003237

Page 44

Installation Promag 10

248 ±2

(9.76 ±0.08)

238 (9.37)

AB

ANSCHLUSSKLEMMEN - FIELD TERMINALS

3.3.10 Mounting the transmitter (remote version)

The transmitter can be mounted in the following ways:

•Wall mounting