TI00095D/06/EN/16.18

71397456

Products Solutions Services

Technical Information

Proline Promag 10H

Electromagnetic flowmeter

The flowmeter for smallest flow rates with a highly cost-effective transmitter

Application

• The measuring principle is virtually independent of pressure,

density, temperature and viscosity

• For the smallest flow quantities and demanding hygienic

applications

Device properties

• Liner made of PFA

• Sensor housing made of stainless steel (3-A, EHEDG)

• Wetted materials CIP, SIP cleanable

• 2-line display with push buttons

• Device in compact or remote version

•HART

Your benefits

• Flexible installation concept – numerous hygienic process

connections

• Energy-saving flow measurement – no pressure loss due to

cross-section constriction

• Maintenance-free – no moving parts

• Cost-effective – designed for easy applications and direct

integration

• Safe operation – display provides easy readable process

information

• Fully industry compliant – IEC/EN/NAMUR

Table of contents

Proline Promag 10H

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operable flow range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Low flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection, remote version . . . . . . . . . . . . . . . . . . . . . 6

Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remote version cable specifications . . . . . . . . . . . . . . . . . . . . . . 7

Performance characteristics . . . . . . . . . . . . . . . . . . . . . .8

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 22

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Measuring tube specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fitted electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Surface roughness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 43

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

C-tick symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Sanitary compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pressure equipment directive . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Communication-specific accessories . . . . . . . . . . . . . . . . . . . . . 45

Service-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Length of connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shock and vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . 14

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure-temperature ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Medium pressure range

(nominal pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Limiting flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . 46

2 Endress+Hauser

Proline Promag 10H

Ue

I

I

B

L

V

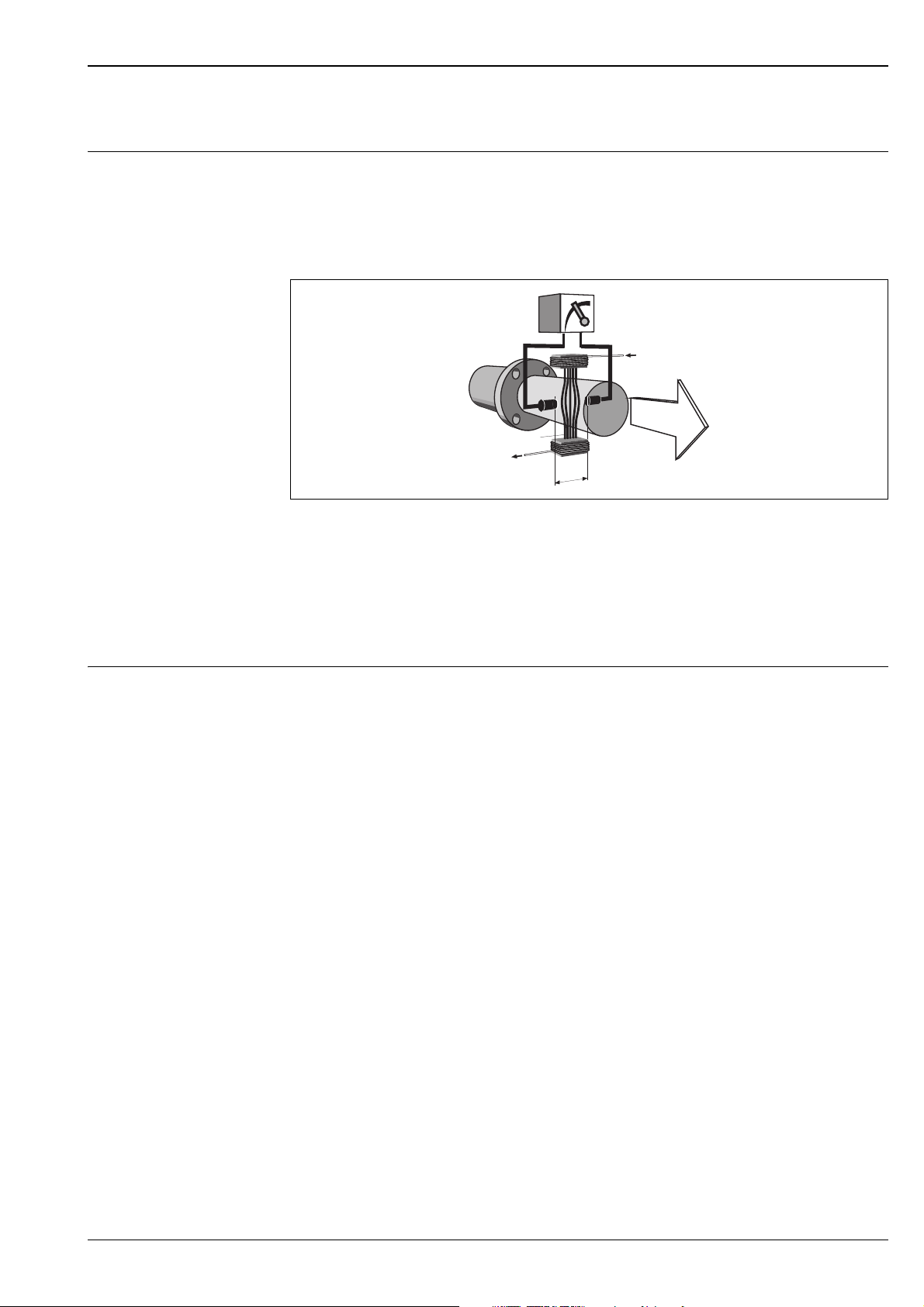

Function and system design

Measuring principle Following Faraday's law of magnetic induction, a voltage is induced in a conductor moving through a

magnetic field.

In the electromagnetic measuring principle, the flowing medium is the moving conductor.

The voltage induced is proportional to the flow velocity and is supplied to the amplifier by means of

two measuring electrodes. The flow volume is calculated by means of the pipe cross-sectional area. The

DC magnetic field is created through a switched direct current of alternating polarity.

Ue = B · L · v

Q = A · v

Ue Induced voltage

B Magnetic induction (magnetic field)

L Electrode spacing

v Flow velocity

Q Volume flow

A Pipe cross-section

I Current strength

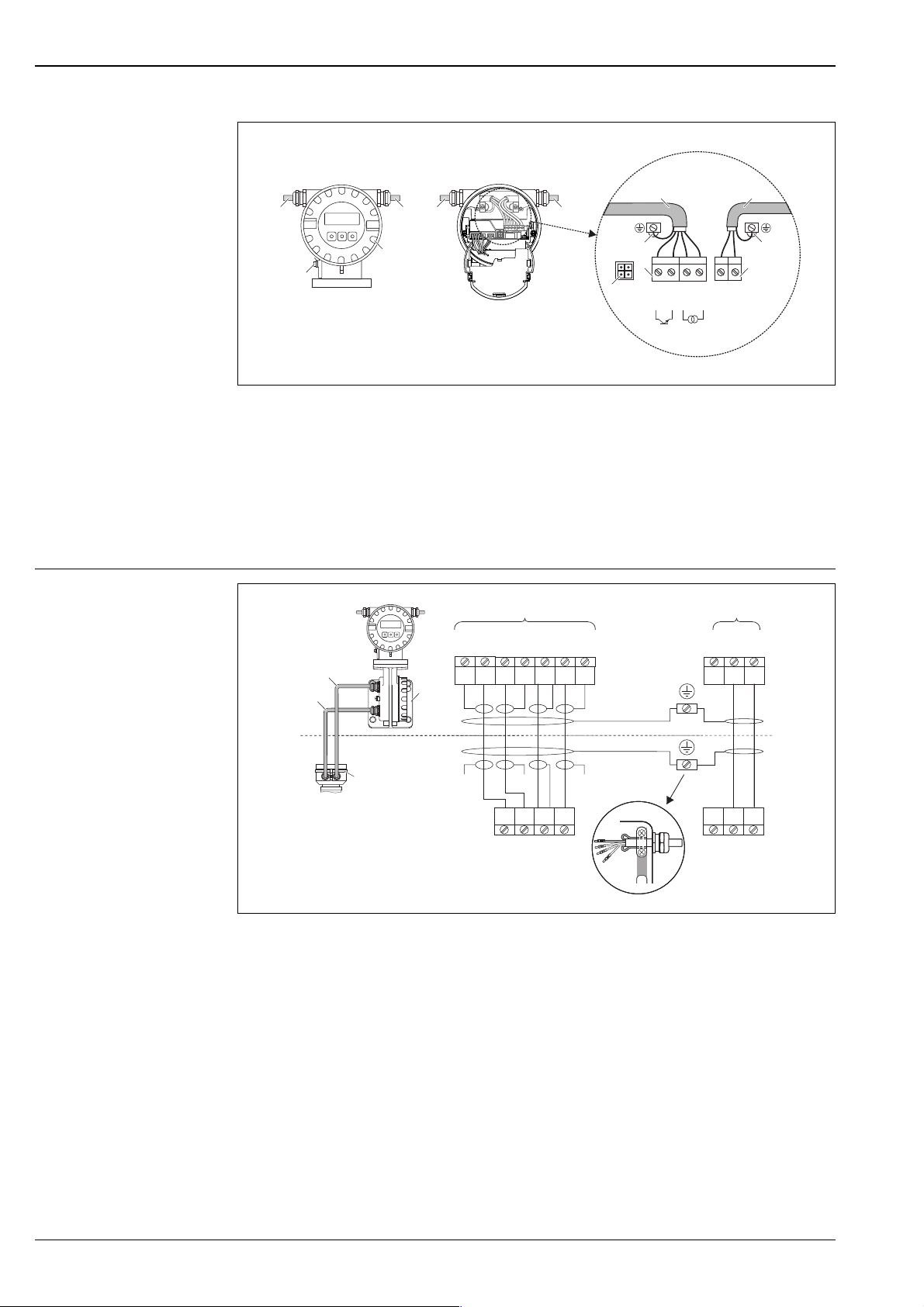

Measuring system The measuring system consists of a transmitter and a sensor.

Two versions are available:

• Compact version: Transmitter and sensor form a mechanical unit.

• Remote version: Sensor is mounted separate from the transmitter.

Transmitter:

• Promag 10 (key operation, two-line, unilluminated display)

Sensor:

• Promag H (DN 2 to 150 / ¹⁄ to 6")

A0003191

Endress+Hauser 3

Input

Measured variable Flow velocity (proportional to induced voltage)

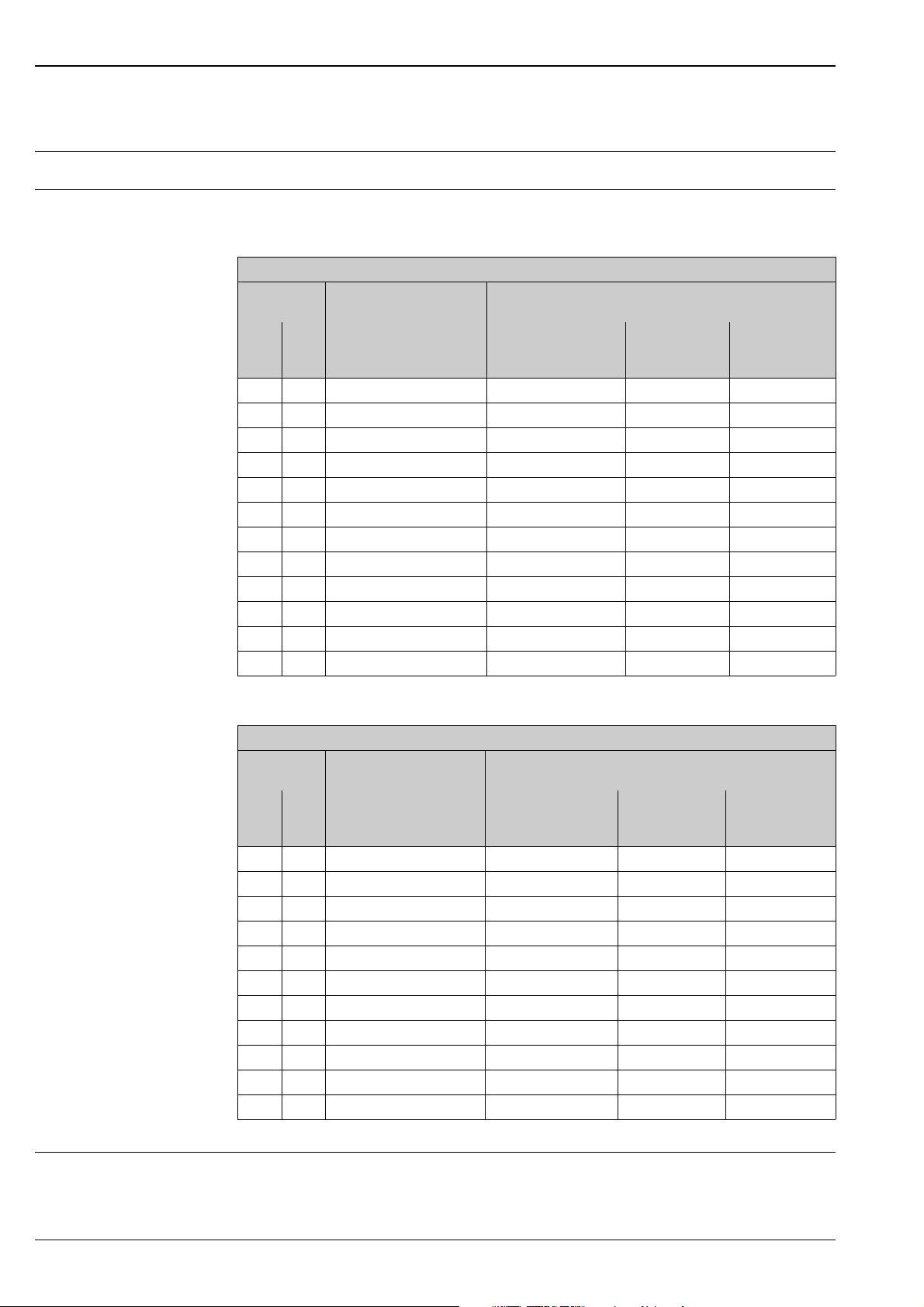

Measuring ranges Measuring ranges for liquids

Typically v = 0.01 to 10 m/s (0.03 to 33 ft/s) with the specified accuracy

Flow characteristic values (SI units)

Nominal

diameter

[mm] [inch]

2¹⁄" 0.06 to 1.8 dm³/min 0.5 dm³/min 0.005 dm³ 0.01 dm³/min

4¹⁄" 0.25 to 7 dm³/min 2 dm³/min 0.025 dm³ 0.05 dm³/min

8³⁄" 1 to 30 dm³/min 8 dm³/min 0.1 dm³ 0.1 dm³/min

15 ½" 4 to 100 dm³/min 25 dm³/min 0.2 dm³ 0.5 dm³/min

25 1" 9 to 300 dm³/min 75 dm³/min 0.5 dm³ 1 dm³/min

40 1½" 25 to 700 dm³/min 200 dm³/min 1.5 dm³ 3 dm³/min

50 2" 35 to 1100 dm³/min 300 dm³/min 2.5 dm³ 5 dm³/min

65 – 60 to 2000 dm³/min 500 dm³/min 5 dm³ 8 dm³/min

80 3" 90 to 3000 dm³/min 750 dm³/min 5 dm³ 12 dm³/min

100 4" 145 to 4700 dm³/min 1200 dm³/min 10 dm³ 20 dm³/min

125 – 220 to 7500 dm³/min 1850 dm³/min 15 dm³ 30 dm³/min

150 6" 20 to 600 m³/h 150 m³/h 0.03 m³ 2.5 m³/h

Recommended flow rate Factory settings

Min./max. full scale value

(v ~ 0.3 or 10 m/s)

Full scale value, current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulses/s)

Proline Promag 10H

Low flow cut off

(v ~ 0.04 m/s)

Flow characteristic values (US units)

Nominal

diameter

[inch] [mm]

¹⁄" 2 0.015 to 0.5 gal/min 0.1 gal/min 0.001 gal 0.002 gal/min

¹⁄" 4 0.07 to 2 gal/min 0.5 gal/min 0.005 gal 0.008 gal/min

³⁄" 8 0.25 to 8 gal/min 2 gal/min 0.02 gal 0.025 gal/min

½" 15 1.0 to 27 gal/min 6 gal/min 0.05 gal 0.10 gal/min

1" 25 2.5 to 80 gal/min 18 gal/min 0.2 gal 0.25 gal/min

1½" 40 7 to 190 gal/min 50 gal/min 0.5 gal 0.75 gal/min

2" 50 10 to 300 gal/min 75 gal/min 0.5 gal 1.25 gal/min

3" 80 24 to 800 gal/min 200 gal/min 2 gal 2.5 gal/min

4" 100 40 to 1250 gal/min 300 gal/min 2 gal 4 gal/min

– 125 60 to 1950 gal/min 450 gal/min 5 gal 7 gal/min

6" 150 90 to 2650 gal/min 600 gal/min 5 gal 12 gal/min

Operable flow range Over 1000 : 1

Recommended flow rate Factory settings

Min./max. full scale value

(v ~ 0.3 or 10 m/s)

Full scale value,

current output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulses/s)

Low flow cut off

(v ~ 0.04 m/s)

4 Endress+Hauser

Proline Promag 10H

Output

Output signal Current output

• Galvanically isolated

•Active: 4 to 20 mA, RL < 700 (for HART: RL 250 )

• Full scale value adjustable

• Temperature coefficient: typ. 2 A/°C, resolution: 1.5 A

Pulse/status output

• Galvanically isolated

• Passive: 30 V DC/250 mA

• Open collector

• Can be configured as:

– Pulse output: Pulse value and pulse polarity can be selected, max. pulse width adjustable (5 to

2000 ms), pulse frequency max. 100 Hz

– Status output: for example, can be configured for error messages, empty pipe detection, flow

recognition, limit value

Signal on alarm • Current output Failsafe mode can be selected

• Pulse output Failsafe mode can be selected

• Status output "Not conductive" in the event of fault or power supply failure

Load See "output signal"

Low flow cutoff Switch points for low flow cutoff are selectable.

Galvanic isolation All circuits for inputs, outputs and power supply are galvanically isolated from each other.

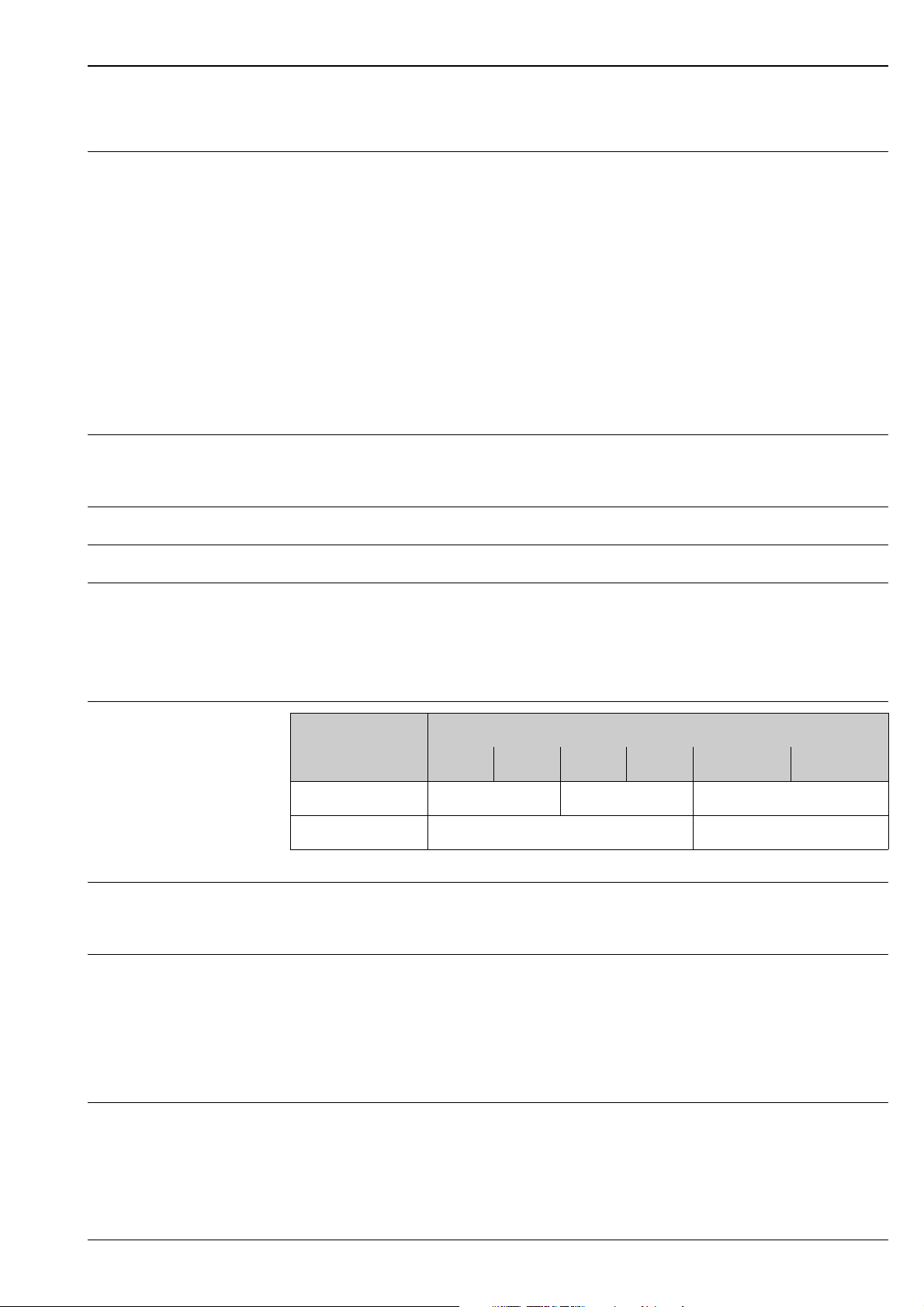

Power supply

Terminal assignment

Order code for

"Input / Output"

A Pulse/status output HART current output Power supply

Functional values Section "Output signal" Section "Supply voltage"

Supply voltage • 85 to 250 V AC, 45 to 65 Hz

• 20 to 28 V AC, 45 to 65 Hz

• 11 to 40 V DC

Power consumption • 85 to 250 V AC: < 12 VA (incl. sensor)

• 20 to 28 V AC: < 8 VA (incl. sensor)

• 11 to 40 V DC: < 6 W (incl. sensor)

Switch-on current:

• Max. 16 A (< 5 ms) for 250 V AC

• Max. 5.5 A (< 5 ms) for 28 V AC

• Max. 3.3 A (< 5 ms) for 24 V DC

24 (+) 25 (–) 26 (+) 27 (–) 1 (L1/L+) 2 (N/L–)

Terminal No.

Power supply failure Lasting min. ½ cycle frequency: EEPROM saves measuring system data

Endress+Hauser 5

Electrical connection

b

a

e

e

b

2127

–

25–26

+

24

+

L1

(L+)

N

(L-)

e

g

b

d

h

i

c

f

E1

E2

GND

E

S1

E1

E2

S2

GND

E

S

5

7

4

37

42 41

42 41

6

5

7

8437 36

n.c. n.c.

dc

n.c.

b

a

d

c

Connecting the transmitter (aluminum field housing), cable cross-section max. 2.5 mm2 (14 AWG)

a Electronics compartment cover

bPower supply cable

c Ground terminal for power supply cable

d Terminal connector for power supply cable

e Electrode cable

f Ground terminal for electrode cable

g Terminal connector for electrode cable

h Service connector

i Ground terminal for potential equalization

Proline Promag 10H

A0003192

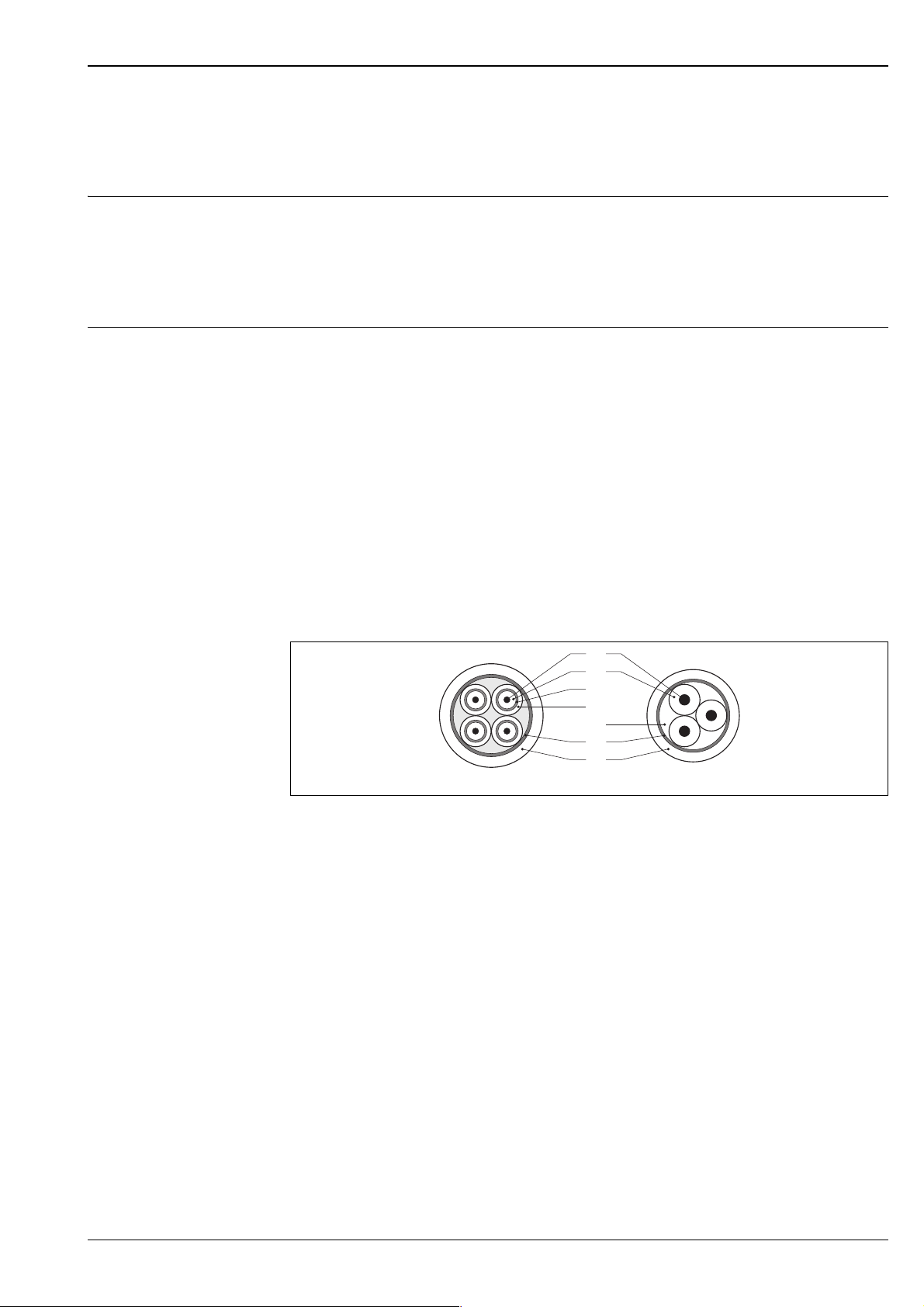

Electrical connection, remote version

Connecting the remote version

a Wall-mount housing connection compartment

b Sensor connection housing cover

c Electrode cable

d Coil current cable

n.c. Not connected, insulated cable shields

Terminal numbers and cable colours:

5/6=brown, 7/8=white, 4=green, 37/36=yellow

A0012477

!

6 Endress+Hauser

Note!

Grounding the cable shielding in the sensor takes place by means of the strain relief terminal.

Proline Promag 10H

1

2

3

4

5

6

7

a

b

Potential equalization To guarantee perfect measurement, the sensor and the fluid have to be on the same electric potential.

Potential equalization can take place by means of the metal, process connections in contact with the

medium which are mounted directly on the sensors. As a result, further measures for potential

equalization are generally not required.

Cable entries Power supply and electrode cables (inputs/outputs):

• Cable entry M20 × 1.5 (8 to 12 mm / 0.31 to 0.47")

• Thread for cable entries, ½" NPT, G ½"

Connecting cable for remote version:

• Cable entry M20 × 1.5 (8 to 12 mm / 0.31 to 0.47")

• Thread for cable entries, ½" NPT, G ½"

Remote version cable specifications

Coil current cable

• 3 × 0.75 mm

2

(18 AWG) PVC cable with common, braided copper shield ( ~ 9 mm / 0.35")

• Conductor resistance: 37 /km ( 0.011 /ft)

• Capacitance core/core, shield grounded: 120 pF/m ( 37 pF/ft)

• Operating temperature: –20 to +80 °C (–68 to +176 °F)

• Cable cross-section: max. 2.5 mm

2

(14 AWG)

• Test voltage for cable insulation: 1433 AC r.m.s 50/60 Hz or 2026 V DC

Electrode cable

• 3 × 0.38 mm2 (20 AWG) PVC cable with common, braided copper shield ( ~ 9.5 mm / 0.37") and

individual shielded cores

• With empty pipe detection (EPD): 4 × 0.38 mm

2

(20 AWG) PVC cable with common, braided copper

shield ( ~ 9.5 mm / 0.37") and individual shielded cores

• Conductor resistance: 50 /km ( 0.015 /ft)

• Capacitance core/shield: 420 pF/m ( 128 pF/ft)

• Operating temperature: –20 to +80 °C (–68 to +176 °F)

• Cable cross-section: max. 2.5 mm

2

(14 AWG)

a Electrode cable

b Coil current cable

1Core

2 Core insulation

3 Core shield

4 Core jacket

5 Core reinforcement

6 Cable shield

7 Outer jacket

Operation in zones of severe electrical interference

The measuring device complies with the general safety requirements in accordance with EN 61010

and the EMC requirements of IEC/EN 61326.

!

Note!

Grounding is by means of the ground terminals provided for the purpose inside the connection

housing. Ensure that the stripped and twisted lengths of cable shield to the ground terminal are as

short as possible.

Endress+Hauser 7

A0003194

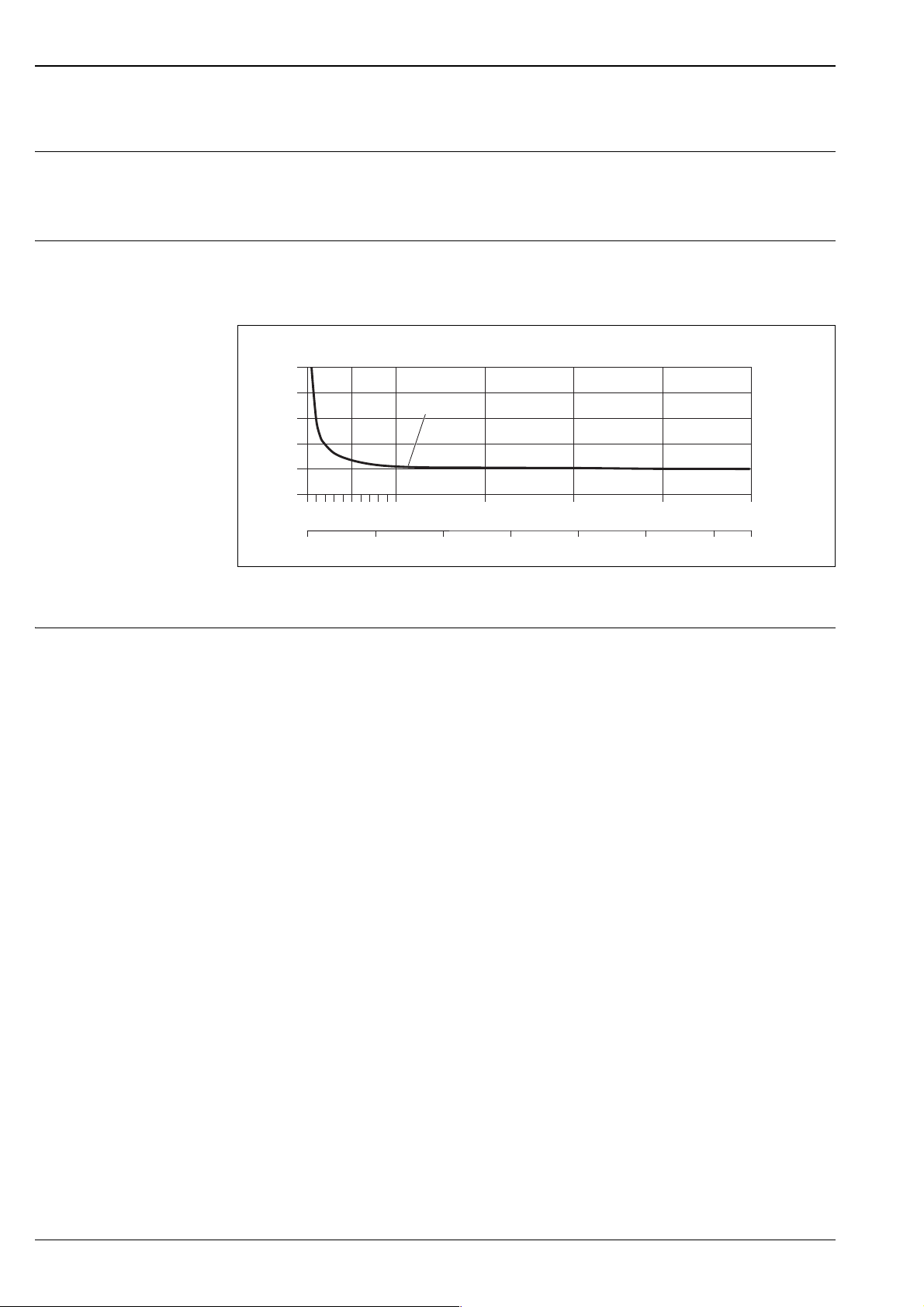

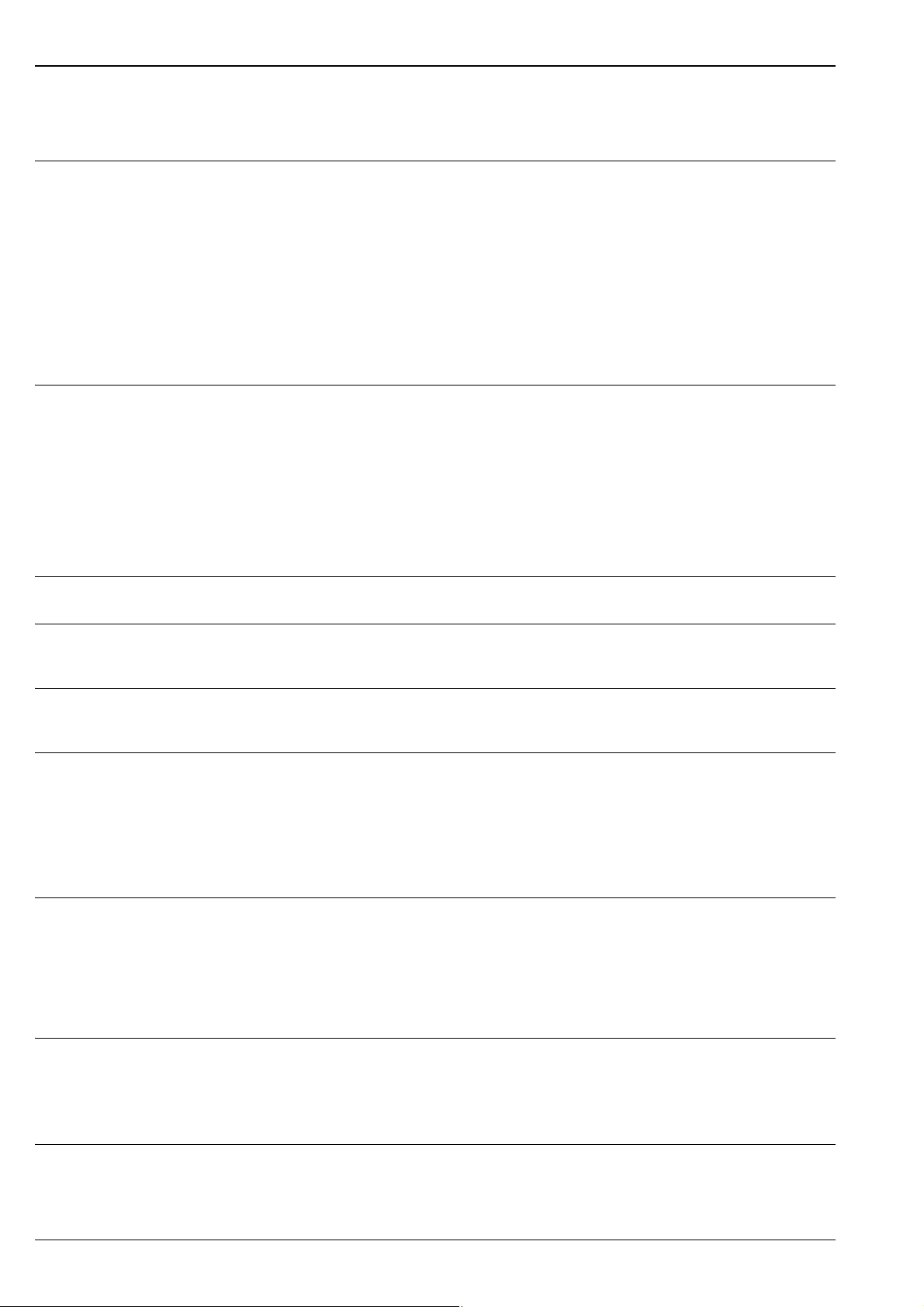

Performance characteristics

2.5

[%]

2.0

1.5

1.0

0.5

0

0.5 %

0

1

2 4 6 8 10 [m/s]

v

5 10 15 20 25 30 32 [ft/s]0

Proline Promag 10H

Reference operating conditions

• Error limits following DIN EN 29104, future ISO 20456

• Water, typically +15 to +45°C (+59 to +113 °F); 0.5 to 7 bar (73 to 101 psi)

• Specification as per calibration protocol

• Data on the measured error based on accredited calibration rigs traced back to ISO 17025

Maximum measured error • Pulse output: ±0.5% o.r. ± 2 mm/s (o.r. = of reading)

• Current output: also typically ± 5 A

Fluctuations in the supply voltage do not have any effect within the specified range.

Max. measured error in % of reading

A0003200

Repeatability Max. ±0.2% o.r. ± 2 mm/s (o.r. = of reading)

8 Endress+Hauser

Proline Promag 10H

h2DN³´

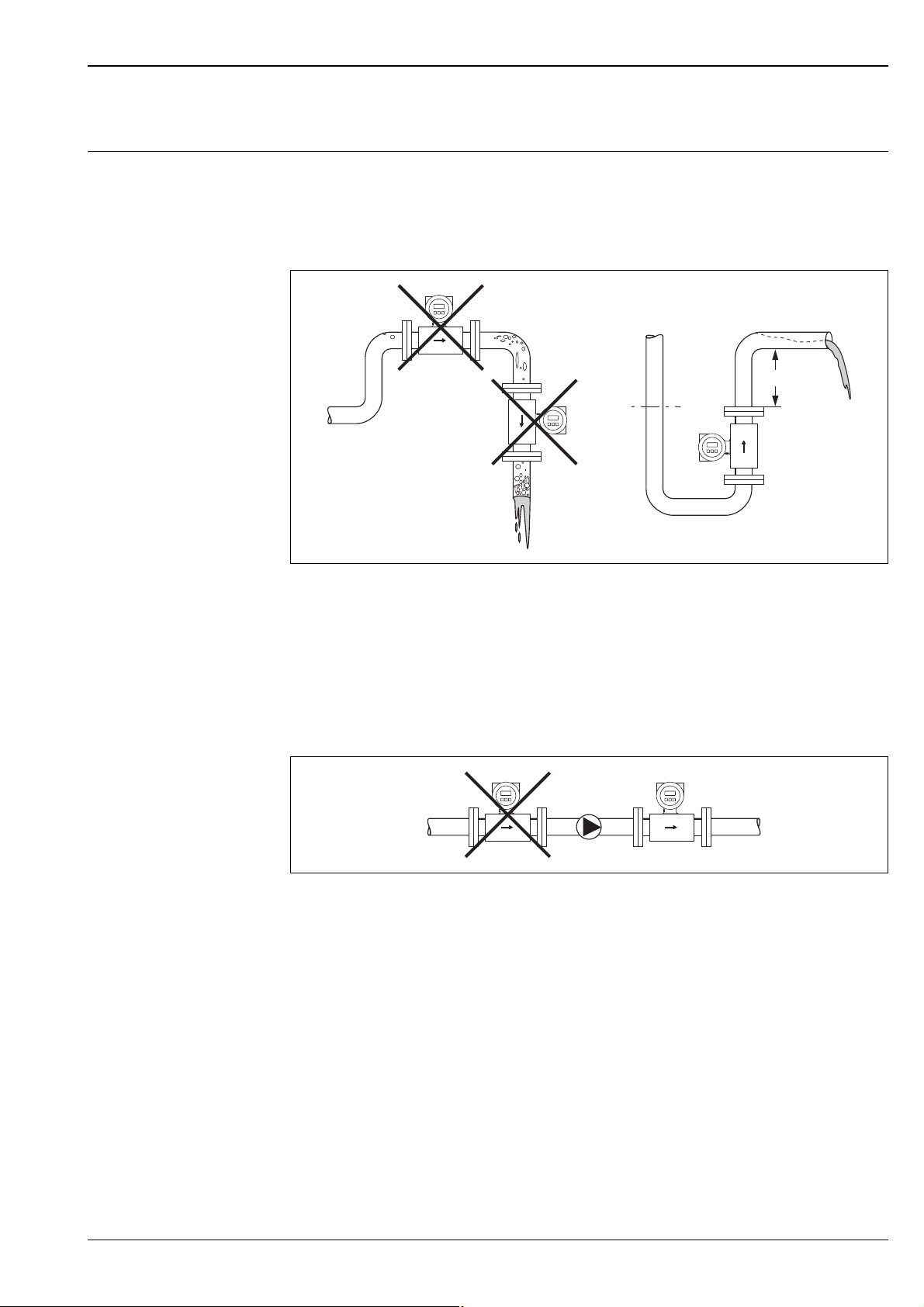

Installation

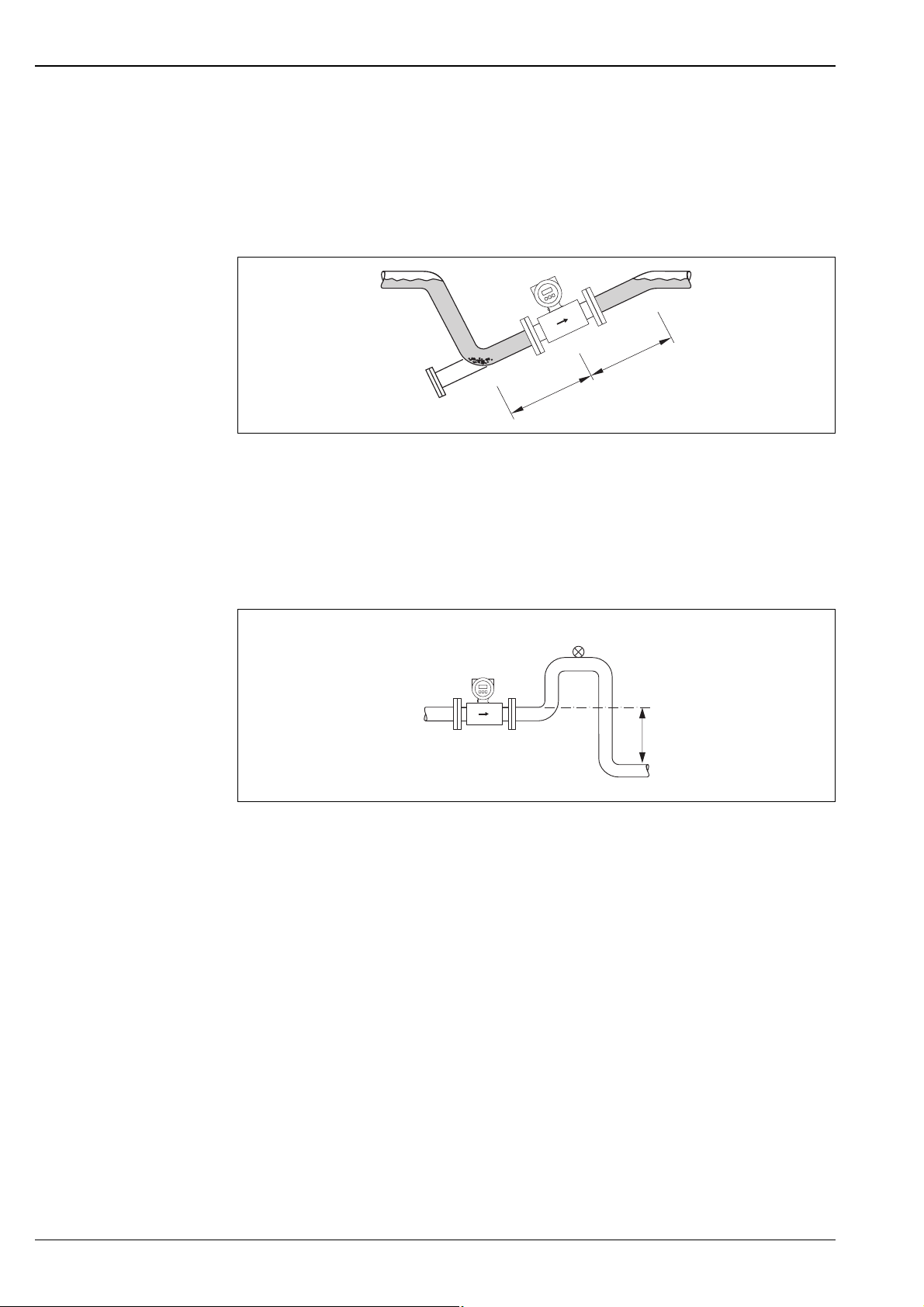

Mounting location Entrained air or gas bubble formation in the measuring tube can result in an increase in measuring

errors.

Avoid the following installation locations in the pipe:

• Highest point of a pipeline. Risk of air accumulating!

• Directly upstream from a free pipe outlet in a vertical pipeline.

A0003202

Mounting location

Installation of pumps

Sensors may not be installed on the pump suction side. This precaution is to avoid low pressure and the

consequent risk of damage to the lining of the measuring tube. Information on the pressure tightness

of the measuring tube lining 20, Section "Pressure tightness".

It might be necessary to install pulse dampers in systems incorporating reciprocating, diaphragm or

peristaltic pumps. Information on the shock and vibration resistance of the measuring system 14,

Section "Shock and vibration resistance".

A0003203

Installation of pumps

Endress+Hauser 9

!

³´5DN

³ 2

´ DN

h

2

1

Proline Promag 10H

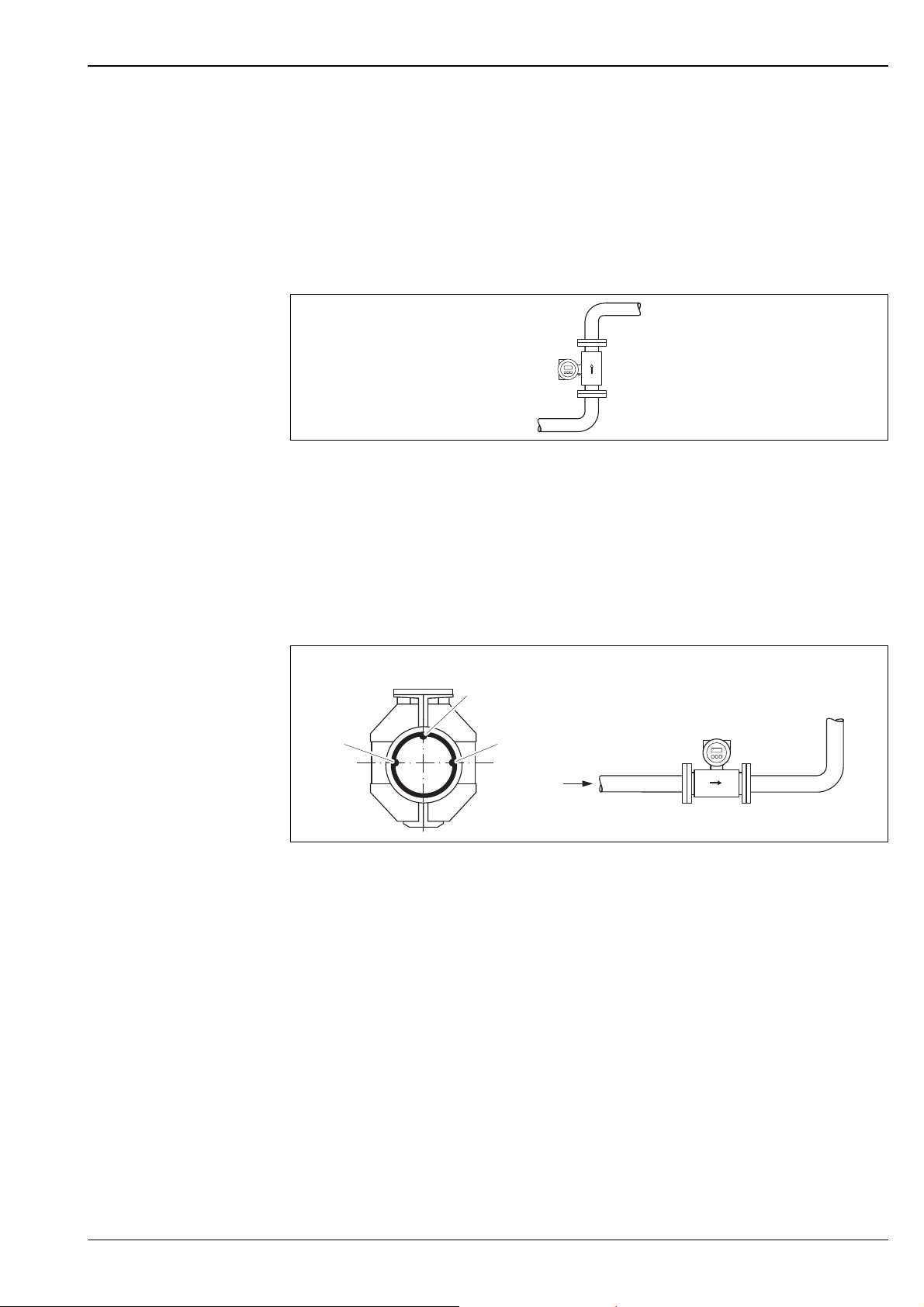

Partially filled pipes

Partially filled pipes with gradients necessitate a drain-type configuration.

The empty pipe detection function (EPD) provides additional security in detecting empty or partially

filled pipes.

Note!

Risk of solids accumulating. Do not install the sensor at the lowest point in the drain. It is advisable to

install a cleaning valve.

A0003204

Installation with partially filled pipes

Down pipes

Install a siphon or a vent valve downstream of the sensor in down pipes h 5 m (16.4 ft). This

precaution is to avoid low pressure and the consequent risk of damage to the lining of the measuring

tube. This measure also prevents the liquid current stopping in the pipe which could cause air locks.

Information on the pressure tightness of the measuring tube lining 20, Section "Pressure

tightness".

A0008157

Installation measures for vertical pipes

1Vent valve

2Pipe siphon

h Length of the down pipe

10 Endress+Hauser

Proline Promag 10H

A

1

22

A

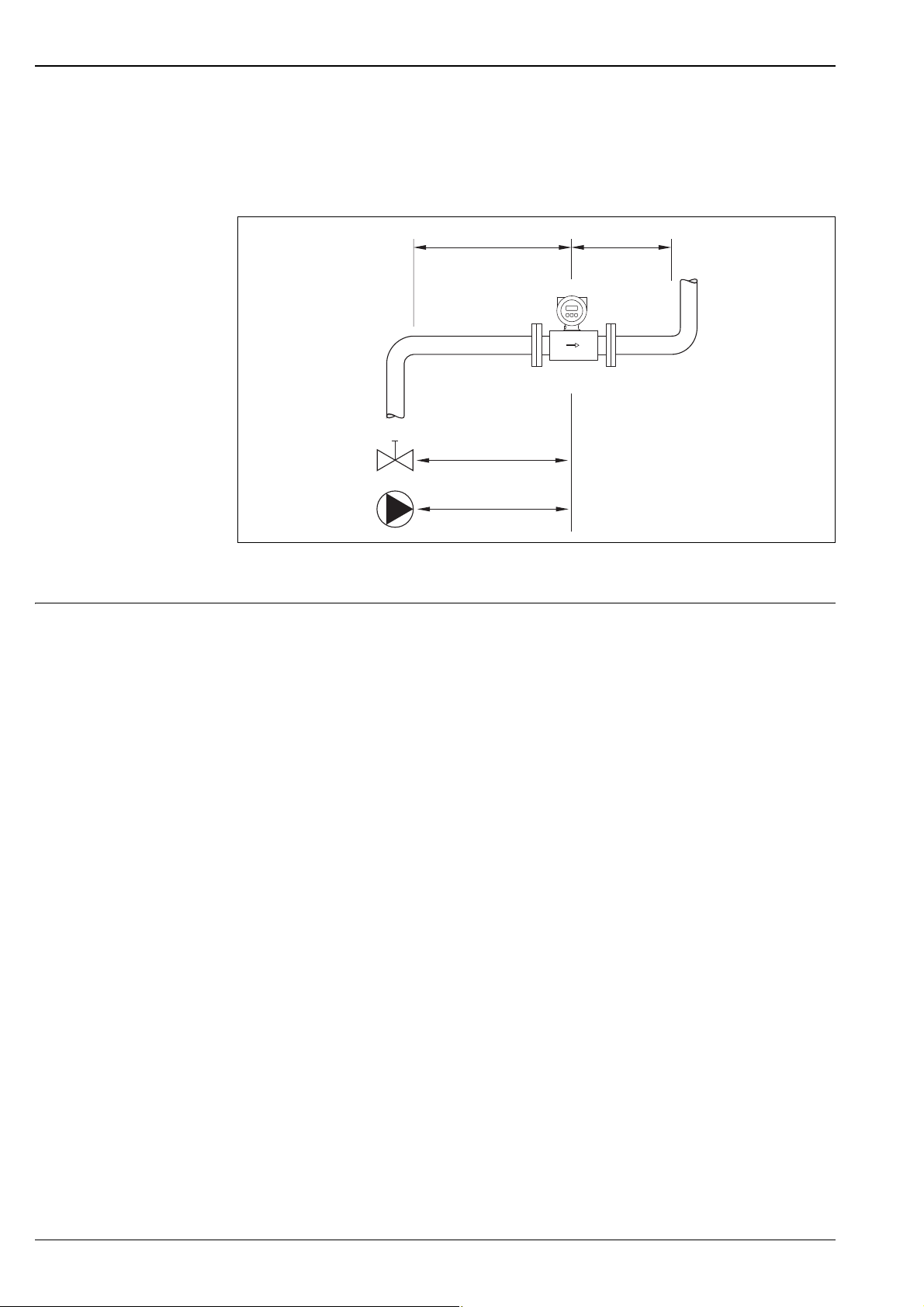

Orientation An optimum orientation position helps avoid gas and air accumulations and deposits in the measuring

tube. The measuring device also offers the additional empty pipe detection function (EPD) for the

detection of partially filled measuring tubes, e.g. in the case of degassing fluids or varying process

pressures.

Vertical orientation

This is the ideal orientation for self-emptying piping systems and for use in conjunction with empty

pipe detection.

A0008158

Vertical orientation

!

Horizontal orientation

The measuring electrode axis should be horizontal. This prevents brief insulation of the two measuring

electrodes by entrained air bubbles.

Note!

Empty pipe detection only works correctly with horizontal orientation if the transmitter housing is

facing upwards. Otherwise there is no guarantee that empty pipe detection will respond if the

measuring tube is only partially filled or empty.

A0005593

Horizontal orientation

1 EPD electrode for empty pipe detection (not for DN 2 to 8/ ¹⁄₁₂ to 5/16")

2 Measuring electrodes for signal detection

Endress+Hauser 11

Proline Promag 10H

³ 5DNx

³ 2DNx

Inlet and outlet runs If possible, install the sensor well clear of assemblies such as valves, T-pieces, elbows etc.

Note the following inlet and outlet runs to comply with measuring accuracy specifications:

• Inlet run: 5 × DN

•Outlet run: 2 × DN

A0003210

Inlet and outlet runs

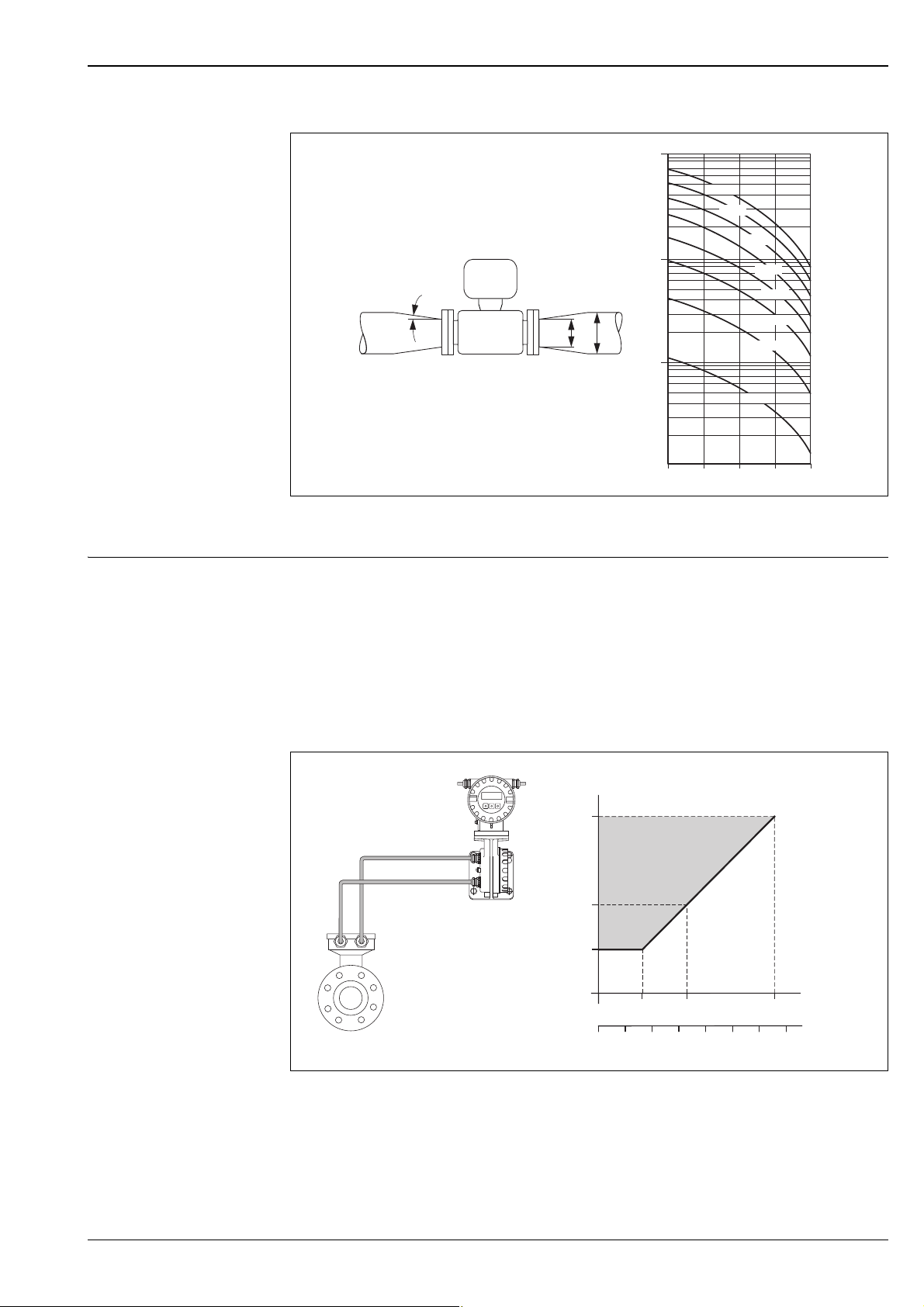

Adapters Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor in larger-

diameter pipes. The resultant increase in the rate of flow improves measuring accuracy with very slowmoving fluids. The nomogram shown here can be used to calculate the pressure loss caused by reducers

and expanders.

!

Note!

• The nomogram only applies to liquids of viscosity similar to that of water.

• For high viscosities of the fluid the selection of a pipe with larger diameter may be considered to

reduce the pressure loss.

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity (downstream from

the reduction) and the d/D ratio.

12 Endress+Hauser

Proline Promag 10H

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

L

max

[]ft

200 6000

400

200

100

50 100 200

[m]

[ S/cm]µ

L

max

50

A0016359

Pressure loss due to adapters

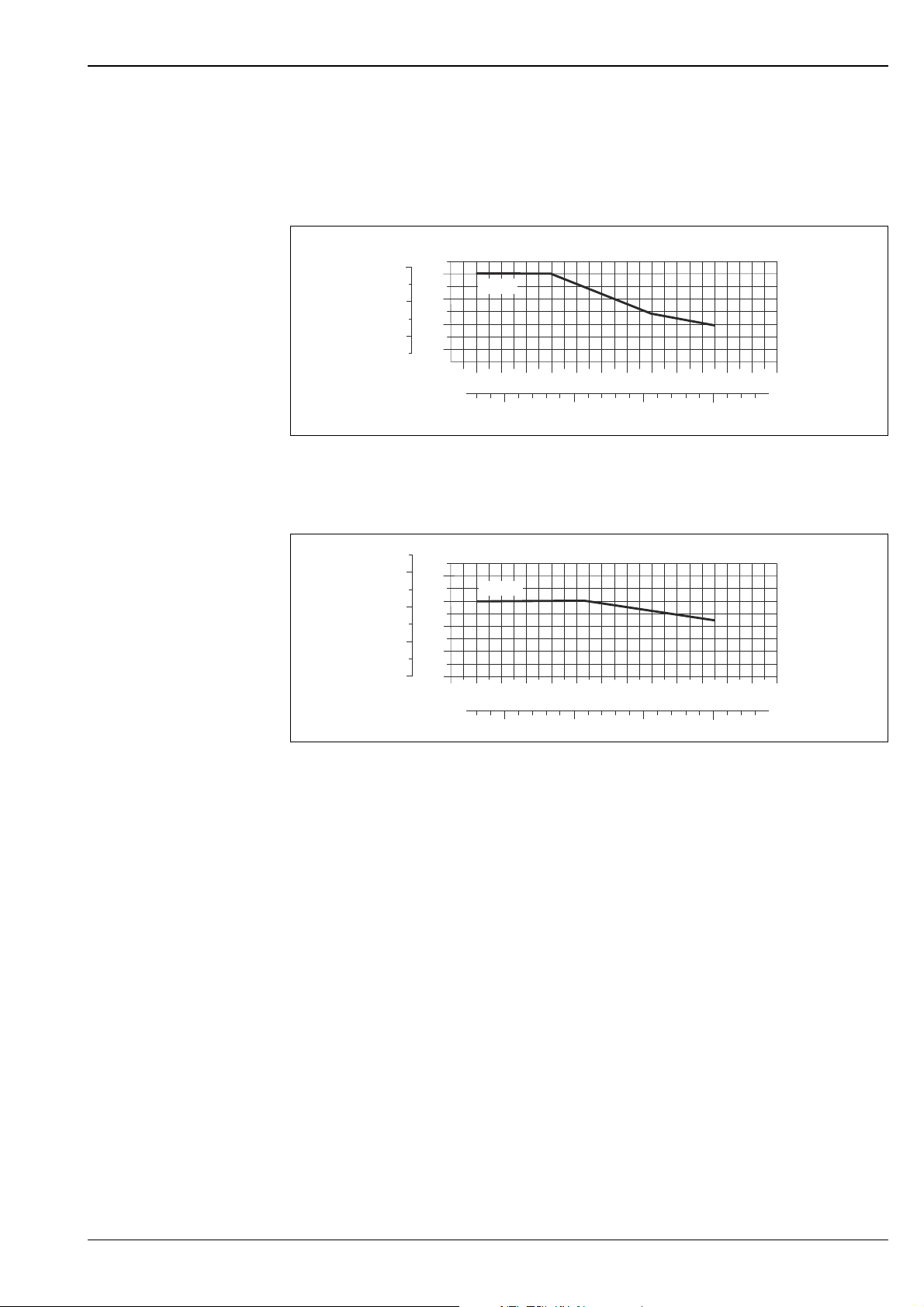

Length of connecting cable When mounting the remote version, please note the following to achieve correct measuring results:

• Fix cable run or lay in armored conduit. Cable movements can falsify the measuring signal especially

in the case of low fluid conductivities.

• Route the cable well clear of electrical machines and switching elements.

• If necessary, ensure potential equalization between sensor and transmitter.

• The permitted cable length L

is determined by the fluid conductivity.

max

A minimum conductivity of 50 S/cm is needed for all fluids.

• When the empty pipe detection function is switched on (EPD), the maximum connecting cable

length is 10 m (33 ft).

Permitted length of connecting cable for remote version

Area marked in gray = permitted range; L

= length of connecting cable in [m] ([ft]); fluid conductivity in [μS/cm]

max

A0003214

Endress+Hauser 13

Proline Promag 10H

Environment

Ambient temperature range • Transmitter: –20 to +60 °C (–4 to +140 °F)

Note!

!

At ambient temperatures below –20 °C (–4 °F), the readability of the display may be impaired.

• Sensor: –40 to +60 °C (–40 to +140 °F)

!

Storage temperature The storage temperature corresponds to the operating temperature range of the measuring

!

Note!

• The permitted temperature range of the measuring tube lining may not be undershot or overshot

( 14, Section "Medium temperature range").

• Install the device at a shady location. Avoid direct sunlight, particularly in warm climatic regions.

• The transmitter must be mounted separate from the sensor if both the ambient and fluid

temperatures are high.

transmitter and the appropriate measuring sensors.

Note!

• The measuring device must be protected against direct sunlight during storage in order to avoid

unacceptably high surface temperatures.

• A storage location must be selected where moisture does not collect in the measuring device. This

will help prevent fungus and bacteria infestation which can damage the liner.

• If protecting caps or protective covers are mounted, these must not be removed before mounting the

device.

Degree of protection • Standard: IP 67 (NEMA 4X) for transmitter and sensor.

Shock and vibration resistance

Interior cleaning • CIP cleaning

Electromagnetic compatibility (EMC)

Acceleration up to 2 g following IEC 68-2-6

•SIP cleaning

• As per IEC/EN 61326 and NAMUR recommendation NE 21

• Emission: to limit value for industry EN 55011

Process

Medium temperature range Sensor:

• DN 2 to 150 (¹⁄ to 6"): –20 to +150 °C (–4 to +302 °F)

Seals:

• EPDM: –20 to +150 °C (–4 to 302 °F)

• Viton (FKM): –20 to +150 °C (–4 to 302 °F)

• Kalrez: –20 to +150 °C (–4 to 302 °F)

Conductivity The minimum conductivity is: 50 S/cm

!

Pressure-temperature ratings

14 Endress+Hauser

Note!

In the remote version, the necessary minimum conductivity also depends on the cable length

( 13, Section "Length of connecting cable").

The following diagrams contain pressure-temperature ratings (reference curves) for flange materials

with regard to the medium temperature.

Proline Promag 10H

25

35

30

40

[bar][psi]

-40

-20

020

40 60 80 100120140160180 [°C]

360 [°F]

0-40 100 200 300

400

500

600

PN40

0

5

15

10

20

[bar][psi]

-40

-20

020

40 60 80 100120140160180 [°C]

360 [°F]

0-40 100 200 300

100

200

300

0

Cl150

Process connections with O-ring seal, 2 to 25 (¹⁄₁₂ to 1")

Process connection: coupling according to ISO 228 (DIN 2999), NPT;

flange according to EN 1092-1 (DIN 2501)

Process connection material: stainless steel, 1.4404 (316L)

A0021191-EN

Process connection: flange according to ASME B16.5

Process connection material: stainless steel, 1.4404 (316L)

A0021192-EN

Endress+Hauser 15