Endress+Hauser Proline 300 Brief Operating Instructions

KA01339D/06/EN/02.18

71399867

2018-08-01

Products Solutions Services

Brief Operating Instructions

Proline 300

EtherNet/IP

Transmitter with Coriolis sensor

These instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Transmitter Brief Operating Instructions

Contain information about the transmitter.

Sensor Brief Operating Instructions → 3

Proline 300 EtherNet/IP

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

2 Endress+Hauser

A0023555

Proline 300 EtherNet/IP Brief Operating Instructions for the device

Brief Operating Instructions for the device

The device consists of a transmitter and a sensor.

The process of commissioning these two components is described in two separate manuals:

• Sensor Brief Operating Instructions

• Transmitter Brief Operating Instructions

Please refer to both Brief Operating Instructions when commissioning the device as the

contents of the manuals complement one another:

Sensor Brief Operating Instructions

The Sensor Brief Operating Instructions are aimed at specialists with responsibility for

installing the measuring device.

• Incoming acceptance and product identification

• Storage and transport

• Installation

Transmitter Brief Operating Instructions

The Transmitter Brief Operating Instructions are aimed at specialists with responsibility for

commissioning, configuring and parameterizing the measuring device (until the first

measured value).

• Product description

• Installation

• Electrical connection

• Operation options

• System integration

• Commissioning

• Diagnostic information

Additional device documentation

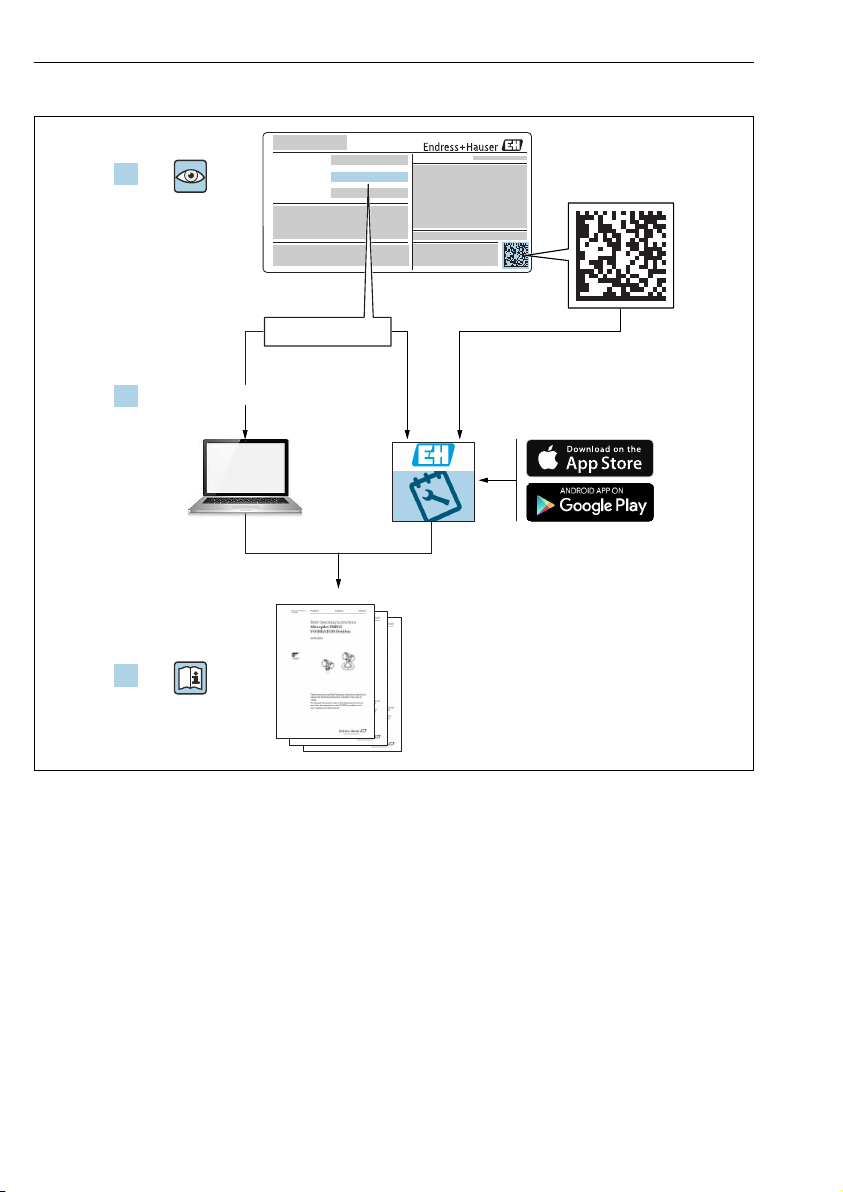

These Brief Operating Instructions are the Transmitter Brief Operating Instructions.

The "Sensor Brief Operating Instructions" are available via:

• Internet: www.endress.com/deviceviewer

• Smart phone/tablet: Endress+Hauser Operations App

Detailed information about the device can be found in the Operating Instructions and the

other documentation:

• Internet: www.endress.com/deviceviewer

• Smart phone/tablet: Endress+Hauser Operations App

Endress+Hauser 3

Table of contents Proline 300 EtherNet/IP

Table of contents

1 Document information ............................................................ 5

1.1 Symbols used ......................................................................... 5

2 Basic safety instructions .......................................................... 7

2.1 Requirements for the personnel ............................................................7

2.2 Designated use ........................................................................ 7

2.3 Workplace safety ...................................................................... 8

2.4 Operational safety ......................................................................8

2.5 Product safety .........................................................................9

2.6 IT security ............................................................................9

2.7 Device-specific IT security ................................................................ 9

3 Product description .............................................................. 10

4 Installation ...................................................................... 11

4.1 Turning the transmitter housing .......................................................... 11

4.2 Turning the display module .............................................................. 12

4.3 Cover locking ........................................................................ 13

4.4 Transmitter post-installation check ........................................................ 13

5 Electrical connection ............................................................ 14

5.1 Connection conditions .................................................................. 14

5.2 Connecting the measuring device ......................................................... 17

5.3 Hardware settings ..................................................................... 25

5.4 Ensuring potential equalization ........................................................... 26

5.5 Ensuring the degree of protection ......................................................... 26

5.6 Post-connection check .................................................................. 27

6 Operation options ............................................................... 28

6.1 Overview of operation options ............................................................ 28

6.2 Structure and function of the operating menu ................................................ 29

6.3 Access to the operating menu via the local display ............................................. 30

6.4 Access to the operating menu via the operating tool ............................................ 33

6.5 Access to the operating menu via the Web server .............................................. 33

7 System integration .............................................................. 33

8 Commissioning .................................................................. 33

8.1 Function check ....................................................................... 33

8.2 Setting the operating language ........................................................... 34

8.3 Configuring the measuring device ......................................................... 34

8.4 Protecting settings from unauthorized access ................................................. 35

9 Diagnostic information .......................................................... 36

4 Endress+Hauser

Proline 300 EtherNet/IP Document information

DANGER

WARNING

CAUTION

NOTICE

A

1.

1 Document information

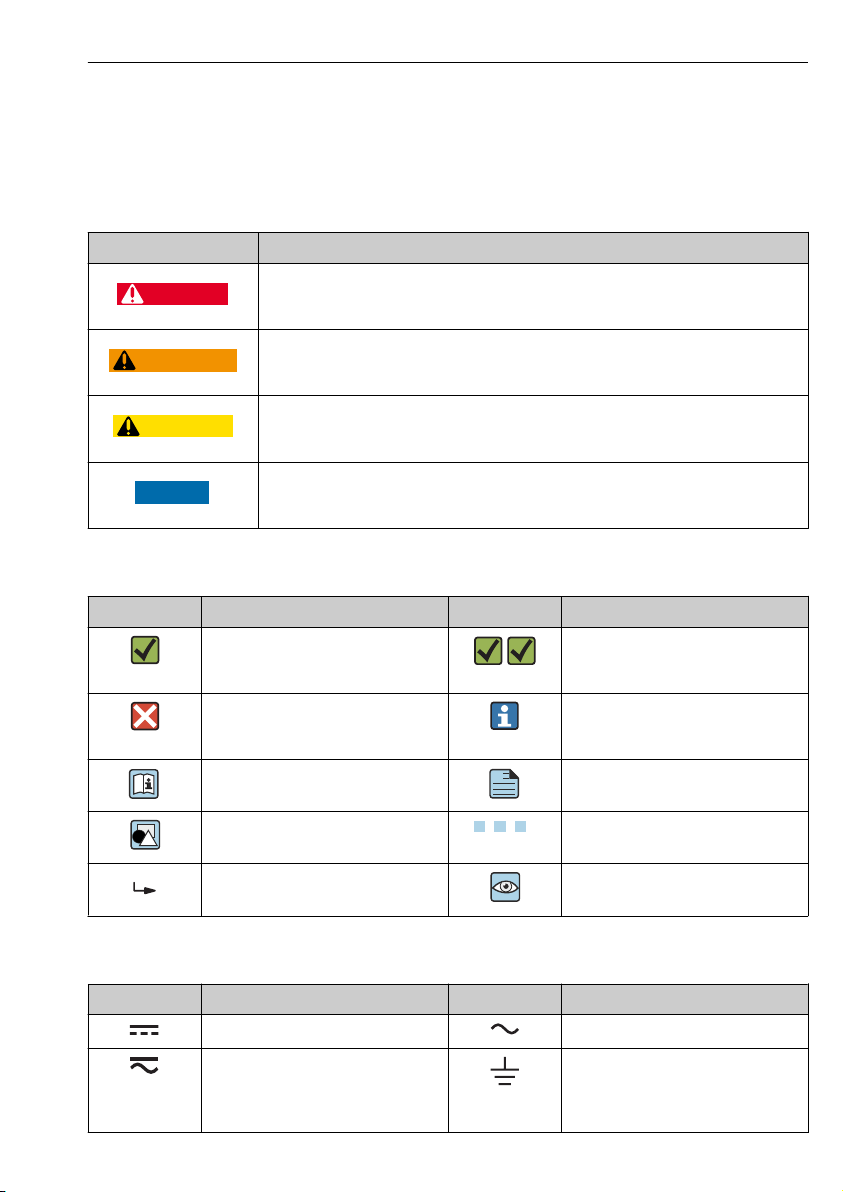

1.1 Symbols used

1.1.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2 Symbols for certain types of information

Symbol Meaning Symbol Meaning

Permitted

Procedures, processes or actions that

are permitted.

Forbidden

Procedures, processes or actions that

are forbidden.

Reference to documentation

Preferred

Procedures, processes or actions that

are preferred.

Tip

Indicates additional information.

Reference to page

Reference to graphic

Result of a step Visual inspection

, 2., 3.… Series of steps

1.1.3 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Endress+Hauser 5

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Document information Proline 300 EtherNet/IP

1.

-

.

Symbol Meaning

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

1.1.4 Communication symbols

Symbol Meaning Symbol Meaning

Wireless Local Area Network

(WLAN)

Communication via a wireless, local

network.

LED

Light emitting diode is on.

LED

Light emitting diode is off.

LED

Light emitting diode is flashing.

1.1.5 Tool symbols

Symbol Meaning Symbol Meaning

Torx screwdriver Flat blade screwdriver

Cross-head screwdriver Allen key

Open-ended wrench

1.1.6 Symbols in graphics

Symbol Meaning Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views A-A, B-B, C-C, ... Sections

Hazardous area

Flow direction

6 Endress+Hauser

, 2., 3.… Series of steps

Safe area (non-hazardous area)

Proline 300 EtherNet/IP Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements for its tasks:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the application).

Follow instructions and comply with basic conditions.

‣

2.2 Designated use

Application and media

• The measuring device described in these Brief Operating Instructions is intended only for

flow measurement of liquids and gases.

• The measuring device described in these Brief Operating Instructions is intended only for

flow measurement of liquids.

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or where there is an

increased risk due to process pressure, are labeled accordingly on the nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Keep within the specified pressure and temperature range.

‣

Only use the measuring device in full compliance with the data on the nameplate and the

‣

general conditions listed in the Operating Instructions and supplementary documentation.

Based on the nameplate, check whether the ordered device is permitted for the intended

‣

use in the hazardous area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media to which the process-wetted materials are

‣

sufficiently resistant.

If the ambient temperature of the measuring device is outside the atmospheric

‣

temperature, it is absolutely essential to comply with the relevant basic conditions as

specified in the device documentation.

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage caused

by improper or non-designated use.

WARNING

L

Danger of breakage due to corrosive or abrasive fluids and ambient conditions!

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Keep within the specified pressure and temperature range.

‣

Endress+Hauser 7

Basic safety instructions Proline 300 EtherNet/IP

NOTICE

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

‣

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

WARNING

L

The electronics and the medium may cause the surfaces to heat up. This presents a burn

hazard!

For elevated fluid temperatures, ensure protection against contact to prevent burns.

‣

Only applies for Proline Promass A, E, F, O, X and Cubemass C

WARNING

L

Danger of housing breaking due to measuring tube breakage!

If a measuring tube ruptures, the pressure inside the sensor housing will rise according to the

operating process pressure.

Use a rupture disk.

‣

WARNING

L

Danger from medium escaping!

For device versions with a rupture disk: medium escaping under pressure can cause injury or

material damage.

Take precautions to prevent injury and material damage if the rupture disk is actuated.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

If working on and with the device with wet hands:

Due to the increased risk of electric shock, gloves must be worn.

‣

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

8 Endress+Hauser

Proline 300 EtherNet/IP Basic safety instructions

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet stateof-the-art safety requirements, has been tested, and left the factory in a condition in which it

is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EU

directives listed in the device-specific EU Declaration of Conformity. Endress+Hauser confirms

this by affixing the CE mark to the device.

2.6 IT security

Our warranty is valid only if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the settings.

IT security measures, which provide additional protection for the device and associated data

transfer, must be implemented by the operators themselves in line with their security

standards.

2.7 Device-specific IT security

The device offers a range of specific functions to support protective measures on the operator's

side. These functions can be configured by the user and guarantee greater in-operation safety

if used correctly.

For detailed information on device-specific IT security, see the Operating Instructions for

the device.

2.7.1 Access via service interface (CDI-RJ45)

The device can be connected to a network via the service interface (CDI-RJ45). Device-specific

functions guarantee the secure operation of the device in a network.

The use of relevant industrial standards and guidelines that have been defined by national

and international safety committees, such as IEC/ISA62443 or the IEEE, is recommended.

This includes organizational security measures such as the assignment of access authorization

as well as technical measures such as network segmentation.

The device can be integrated in a ring topology. The device is integrated via the terminal

connection for signal transmission (output 1) and the connection to the service interface

(CDI-RJ45) .

Endress+Hauser 9

Product description Proline 300 EtherNet/IP

5

4

Nicht unter

Spannung öffnen

Do not open when

energized

Ne pas ouvrir

sous tension

Power

I/O

N

i

c

h

t

u

n

t

e

r

a

r

e

ö

f

f

n

e

n

D

i

s

p

l

a

y

+

E

ESC

–

1

2

3

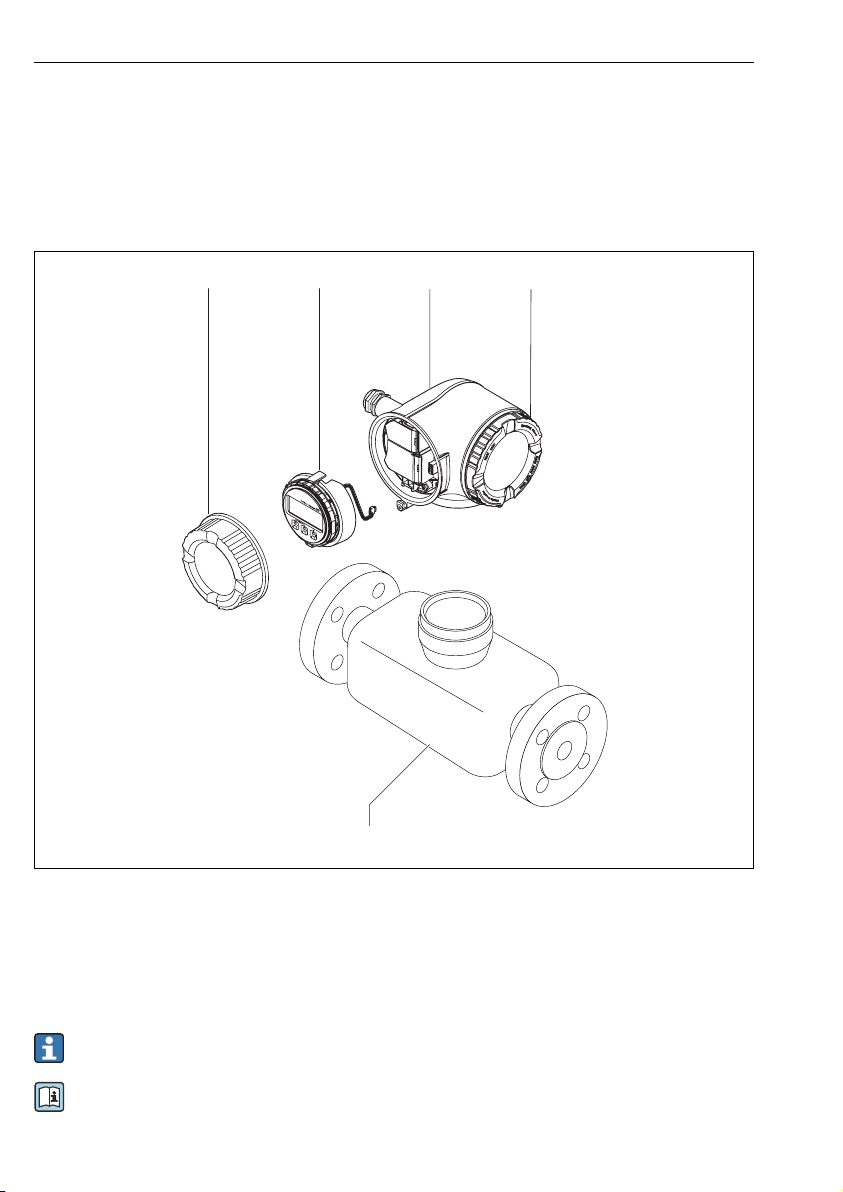

3 Product description

The device consists of a Proline 300 transmitter and a Proline Promass or Cubemass

Coriolis sensor.

The device is available as a compact version:

The transmitter and sensor form a mechanical unit.

A0029586

1 Connection compartment cover

2 Display module

3 Transmitter housing

4 Electronics compartment cover

5 Sensor

Use of the device with the remote display and operating module DKX001 → 24.

For detailed information on the product description, see the Operating Instructions for

the device

10 Endress+Hauser

Proline 300 EtherNet/IP Installation

N

i

c

h

t

u

n

t

e

r

a

r

e

ö

f

f

n

e

n

+

E

ESC

–

1.

2.

N

i

c

h

t

u

n

t

e

r

a

r

e

ö

f

f

n

e

n

+

E

ESC

–

3.

3 mm 4 mm

4.

4 Installation

For detailed information about mounting the sensor, see the Sensor Brief Operating

Instructions → 3

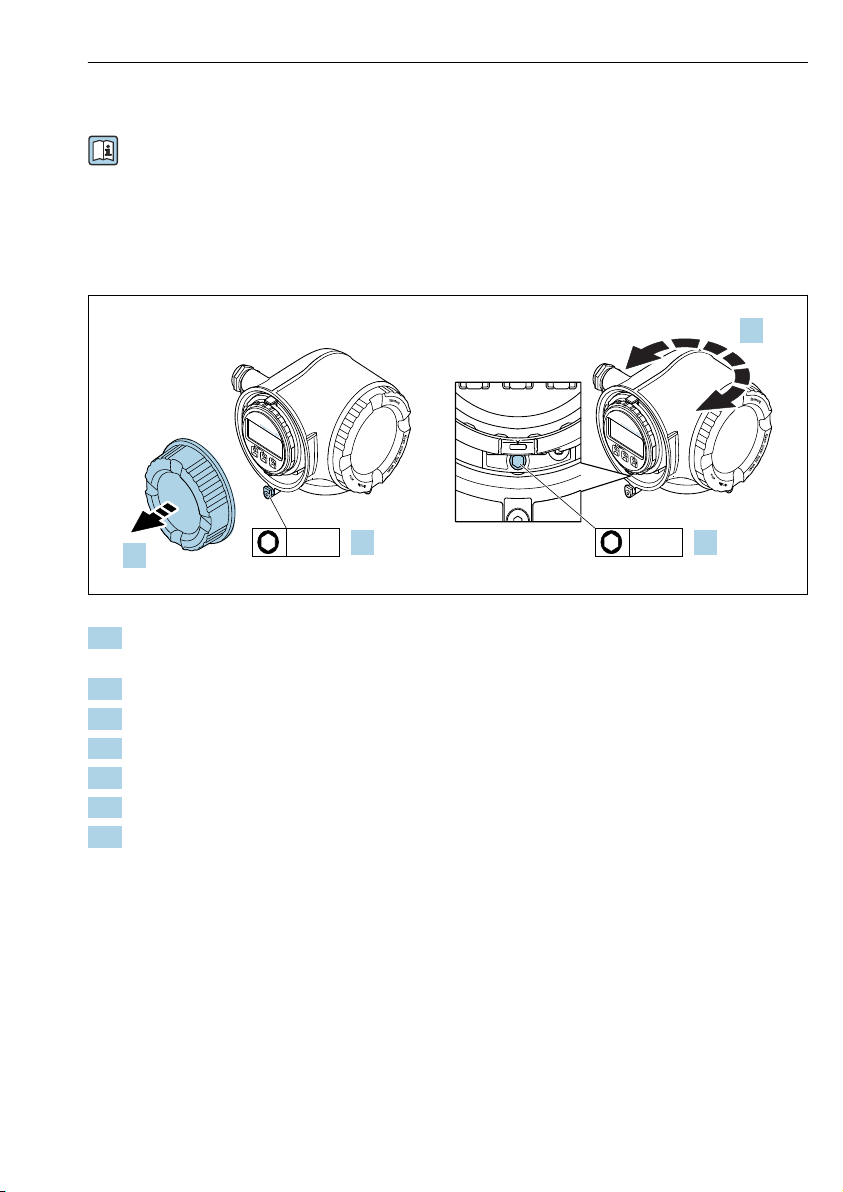

4.1 Turning the transmitter housing

To provide easier access to the connection compartment or display module, the transmitter

housing can be turned.

A0029993

1. Depending on the device version: Loosen the securing clamp of the connection

compartment cover.

2. Unscrew the connection compartment cover.

3. Release the fixing screw.

4. Turn the housing to the desired position.

5. Firmly tighten the securing screw.

6. Screw on the connection compartment cover

7. Depending on the device version: Attach the securing clamp of the connection

compartment cover.

Endress+Hauser 11

Installation Proline 300 EtherNet/IP

N

i

c

h

t

u

n

t

e

r

a

r

e

ö

f

f

n

e

n

+

E

ESC

–

1.

2.

N

i

c

h

t

u

n

t

e

r

a

r

e

ö

f

f

n

e

n

+

E

ESC

–

3.

3 mm

+

E

ESC

–

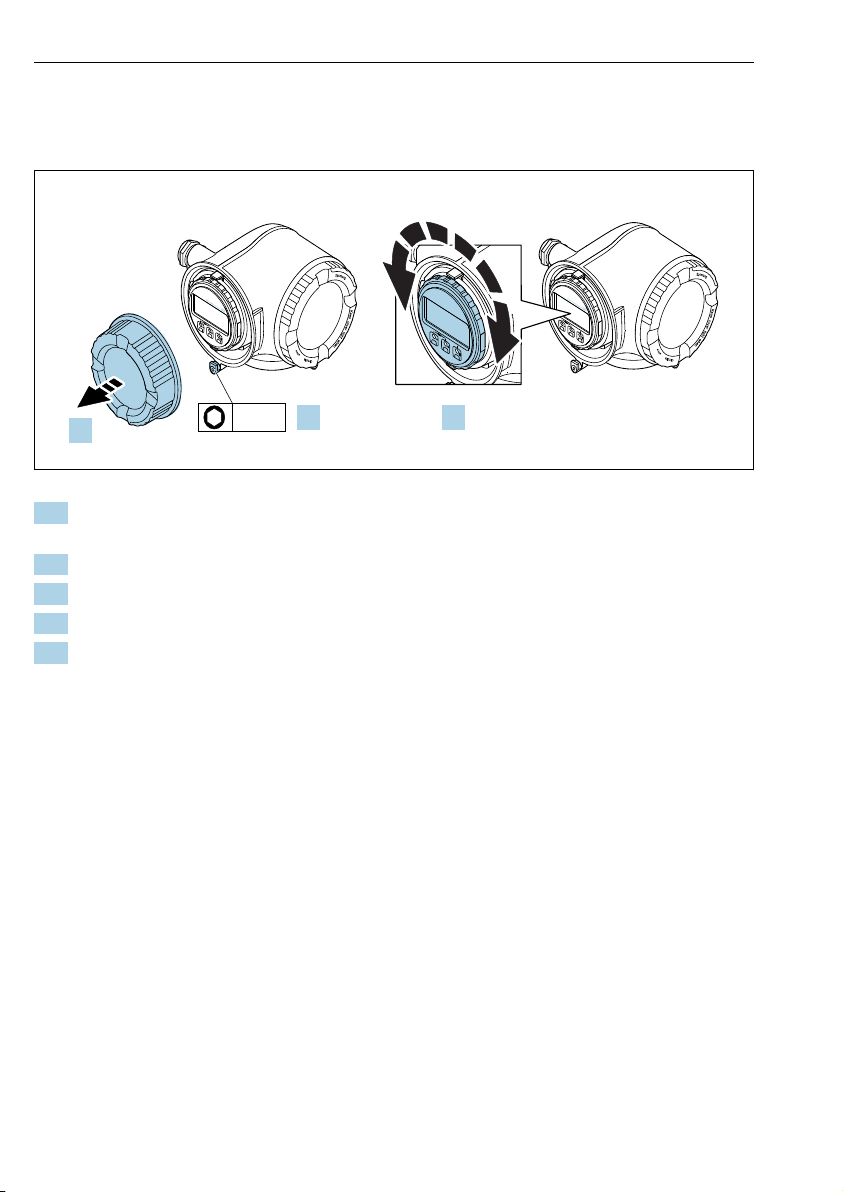

4.2 Turning the display module

The display module can be turned to optimize display readability and operability.

A0030035

1. Depending on the device version: Loosen the securing clamp of the connection

compartment cover.

2. Unscrew the connection compartment cover.

3. Turn the display module to the desired position: max. 8 × 45° in each direction.

4. Screw on the connection compartment cover.

5. Depending on the device version: Attach the securing clamp of the connection

compartment cover.

12 Endress+Hauser

Loading...

Loading...