TI01133P/00/EN/06.18

71404630

Products Solutions Services

Technical Information

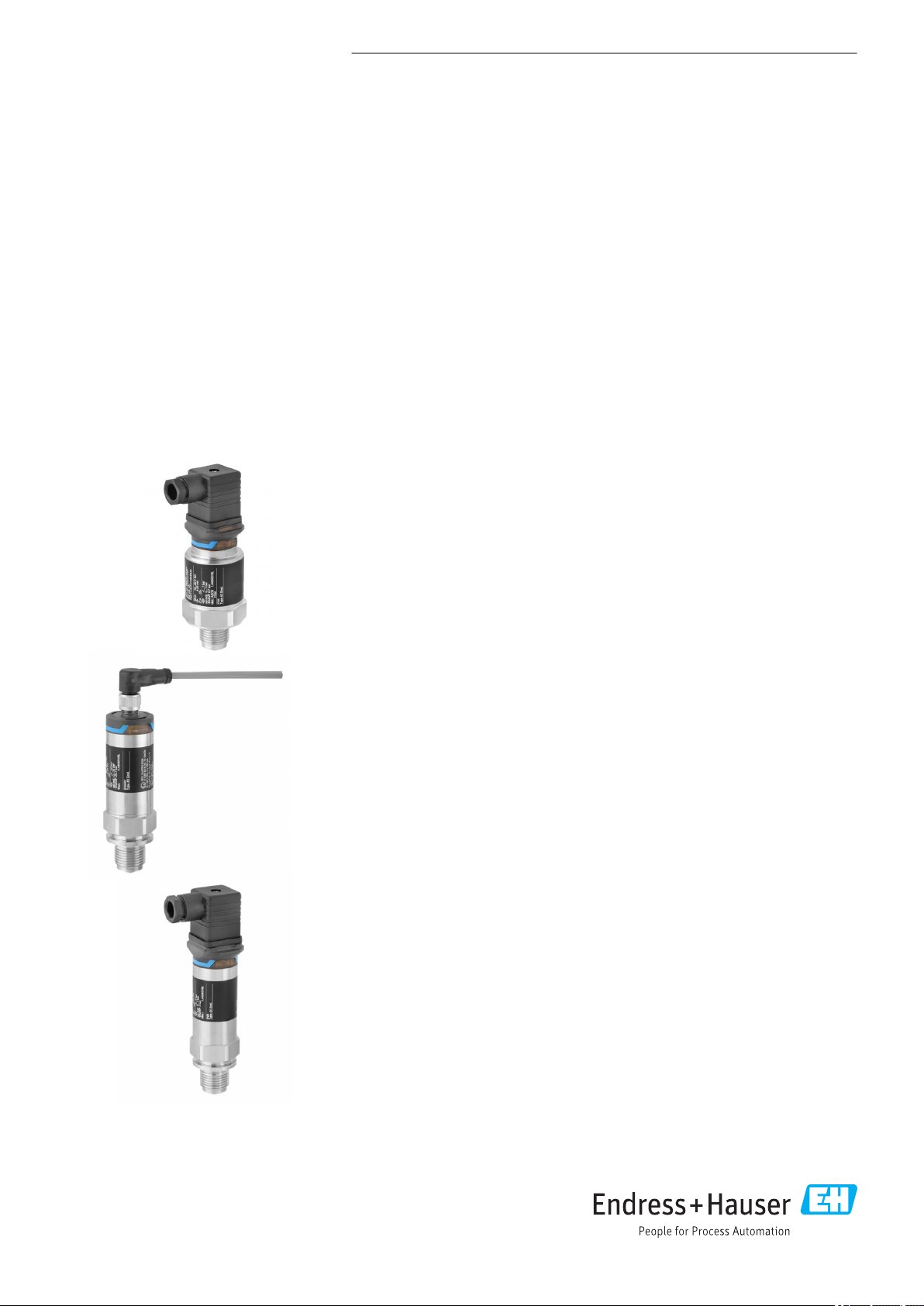

Cerabar PMC11, PMC21,

PMP11, PMP21

Process pressure measurement

Pressure transducer with ceramic and metal

sensors

Application

The Cerabar is a pressure transducer for the measurement of absolute and gauge

pressure in gases, vapors, liquids and dust. The Cerabar can be used internationally

thanks to a wide range of approvals and process connections.

Your benefits

• High reproducibility and long-term stability

• Reference accuracy: up to 0.3%

• Customized measuring ranges

– Turn down up to 5:1

– Sensor for measuring ranges up to 400 bar (6 000 psi)

• Housing and process isolating diaphragm made of 316L

Table of contents

Cerabar PMC11, PMC21, PMP11, PMP21

Document information ....................... 4

Document function ............................ 4

Symbols used ................................ 4

Documentation ............................... 5

Terms and abbreviations ........................ 6

Turn down calculation .......................... 7

Function and system design ................... 8

Measuring principle - process pressure measurement ..... 8

Measuring system ............................. 8

Device features ............................... 9

Product design .............................. 11

System integration ........................... 12

Input .................................... 13

Measured variable ............................ 13

Measuring range ............................ 13

Output .................................. 16

Output signal ............................... 16

Signal range 4 to 20 mA ........................ 16

Load (for 4 to 20 mA devices ) .................... 16

Load resistance (for 0 to 10 V devices) .............. 16

Signal on alarm 4 to 20 mA ...................... 16

Dead time, time constant ....................... 16

Dynamic behavior ............................ 17

Power supply ............................. 18

Terminal assignment .......................... 18

Supply voltage .............................. 18

Current consumption and alarm signal .............. 18

Power supply fault ............................ 19

Electrical connection .......................... 19

Cable specification ............................ 19

Residual ripple .............................. 19

Influence of power supply ....................... 19

Overvoltage protection ........................ 19

Performance characteristics of ceramic process

isolating diaphragm ........................ 20

Reference operating conditions ................... 20

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 20

Influence of the installation position ................ 20

Resolution ................................. 20

Reference accuracy ........................... 20

Thermal change of the zero output and the output span ... 20

Long-term stability ........................... 21

Switch-on time .............................. 21

Performance characteristics of metal process

isolating diaphragm ........................ 22

Reference operating conditions ................... 22

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 22

Influence of the installation position ................ 22

Resolution ................................. 22

Reference accuracy ........................... 22

Thermal change of the zero output and the output span ... 22

Long-term stability ........................... 22

Switch-on time .............................. 22

Installation ............................... 23

Installation conditions ......................... 23

Influence of the installation position ................ 23

Mounting location ............................ 23

Mounting instructions for oxygen applications ......... 24

Environment .............................. 26

Ambient temperature range ..................... 26

Storage temperature range ...................... 26

Climate class ............................... 26

Degree of protection .......................... 26

Vibration resistance ........................... 26

Electromagnetic compatibility .................... 26

Process .................................. 27

Process temperature range for devices with ceramic

process isolating diaphragm ..................... 27

Process temperature range for devices with metallic

process isolating diaphragm ..................... 27

Pressure specifications ......................... 28

Mechanical construction .................... 29

Design, dimensions ........................... 29

Electrical connection .......................... 29

Housing ................................... 30

Process connections with internal, ceramic process

isolating diaphragm ........................... 32

Process connections with internal, ceramic process

isolating diaphragm ........................... 33

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, metal process isolating

diaphragm ................................. 35

Process connections with internal, metal process isolating

diaphragm ................................. 36

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with flush-mounted, metal process

isolating diaphragm ........................... 38

Materials in contact with process .................. 39

Materials not in contact with process ............... 40

Cleaning .................................. 41

Operability ............................... 42

Plug-on display PHX20 (optional) .................. 42

Certificates and approvals ................... 43

CE mark ................................... 43

2 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

RoHS ..................................... 43

RCM-Tick marking ............................ 43

EAC conformity .............................. 43

Approval .................................. 43

Safety Instructions (XA) ........................ 43

Marine approval (pending) ...................... 44

Pressure Equipment Directive 2014/68/EU (PED) ....... 44

Other standards and guidelines ................... 44

CRN approval ............................... 45

Calibration unit .............................. 45

Calibration ................................. 45

Inspection certificates .......................... 45

Ordering information ....................... 46

Scope of delivery ............................. 46

Accessories ............................... 47

Weld-in adapter ............................. 47

Plug-on display PHX20 ......................... 47

M12 plug connectors .......................... 47

Documentation ............................ 48

Field of Activities ............................ 48

Technical Information ......................... 48

Operating Instructions ......................... 48

Brief Operating Instructions ..................... 48

Safety Instructions (XA) ........................ 48

Endress+Hauser 3

Document information

DANGER

WARNING

CAUTION

NOTICE

A

,…,

1.

2.

3.

Cerabar PMC11, PMC21, PMP11, PMP21

Document function

The document contains all the technical data on the device and provides an overview of the

accessories and other products that can be ordered for the device.

Symbols used Safety symbols

Symbol Meaning

Electrical symbols

Symbol Meaning Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Ground connection

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

4 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

Documentation

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com → Download

Brief Operating Instructions (KA): getting the 1st measured value quickly

These instructions contain all the essential information from incoming acceptance to initial

commissioning.

Operating Instructions (BA): your comprehensive reference

These Operating Instructions contain all the information that is required in various phases of the life

cycle of the device: from product identification, incoming acceptance and storage, to mounting,

connection, operation and commissioning through to troubleshooting, maintenance and disposal.

Safety Instructions (XA)

Depending on the approval, the following Safety Instructions (XA) are supplied with the device. They

are an integral part of the Operating Instructions.

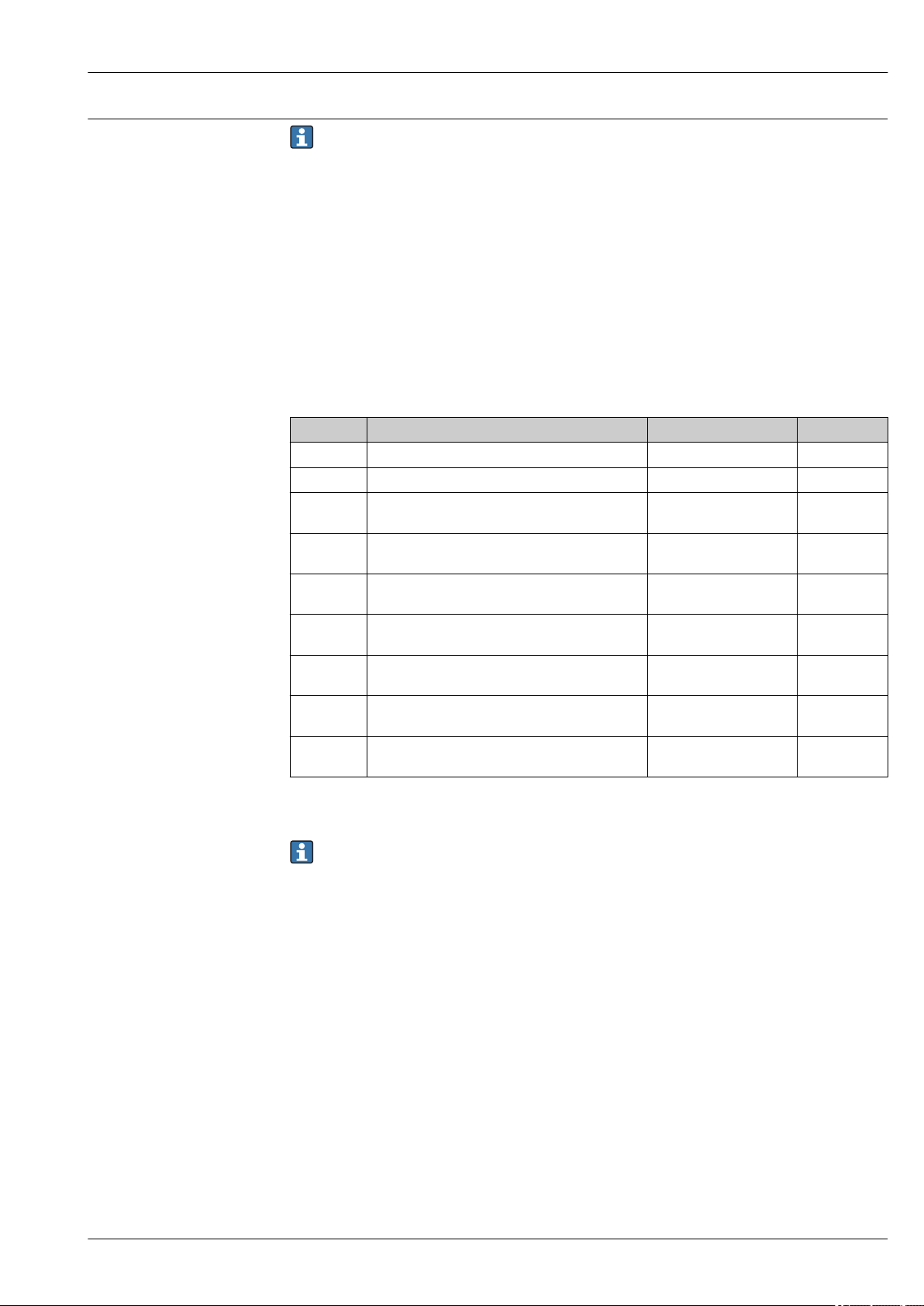

Device Directive Documentation Option

PMP21 ATEX II 1/2G Ex ia IIC T4 Ga/Gb XA01271P BA

PMC21 ATEX II 2G Ex ia IIC T4 Gb XA01271P BB

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

ATEX II 3G Ex ec IIC T4 Gc XA01533P BC

FM IS Cl. I, Div.1 Gr. A-D T4 XA01321P FA

CSA C/US IS Cl. I Div. 1 Gr. A-D XA01322P CB

EAC Ex ia IIC T4 Ga/Gb XA01540P GA

IEC Ex ia IIC T4 Ga/Gb XA01271P IA

NEPSI Ex ia IIC T4 XA01363P NA

TIIS Ex ia IIC T4 In preparation TA

1)

1) Product Configurator order code for "Approval"

The nameplate indicates the Safety Instructions (XA) that are relevant to the device.

Endress+Hauser 5

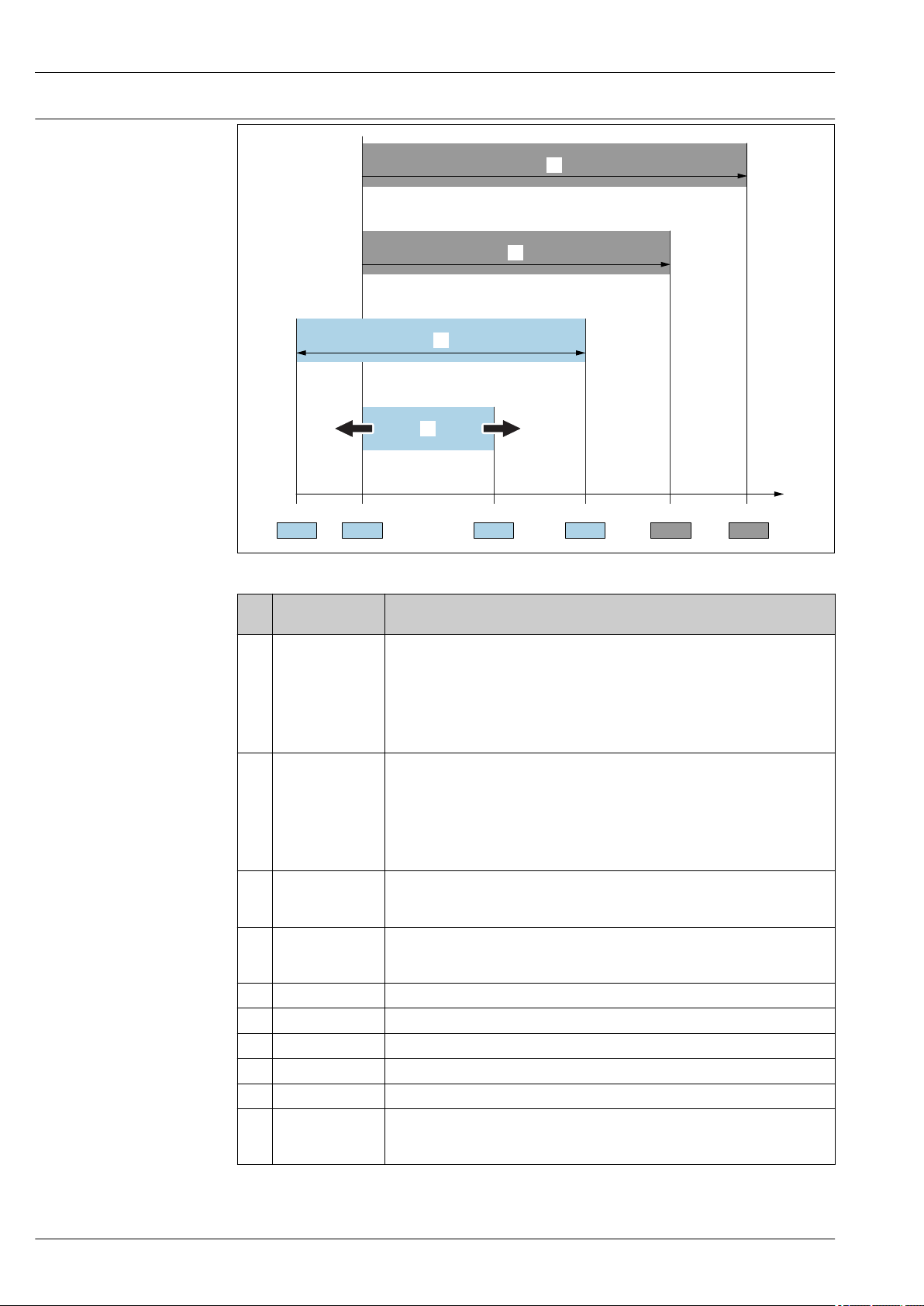

Terms and abbreviations

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

Cerabar PMC11, PMC21, PMP11, PMP21

A0029505

Item Term/

abbreviation

1 OPL The OPL (over pressure limit = sensor overload limit) for the measuring device

2 MWP The MWP (maximum working pressure) for the sensors depends on the lowest-

3 Maximum sensor

measuring range

4 Calibrated/

adjusted span

p - Pressure

- LRL Lower range limit

- URL Upper range limit

- LRV Lower range value

- URV Upper range value

- TD (turn down) Turn down

Explanation

depends on the lowest-rated element, with regard to pressure, of the selected

components, i.e. the process connection has to be taken into consideration in

addition to the measuring cell. Also observe pressure-temperature dependency. For

the relevant standards and additional notes, see the "Pressure specifications" section

→ 28 .

The OPL may only be applied for a limited period of time.

rated element, with regard to pressure, of the selected components, i.e. the process

connection has to be taken into consideration in addition to the measuring cell.

Also observe pressure-temperature dependency. For the relevant standards and

additional notes, see the "Pressure specifications" section → 28 .

The MWP may be applied at the device for an unlimited period.

The MWP can also be found on the nameplate.

Span between LRL and URL

This sensor measuring range is equivalent to the maximum calibratable/adjustable

span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized spans.

The turn down is preset at the factory and cannot be changed.

Example - see the following section.

6 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

LRV

URLURV

LRL

1 = 2

3

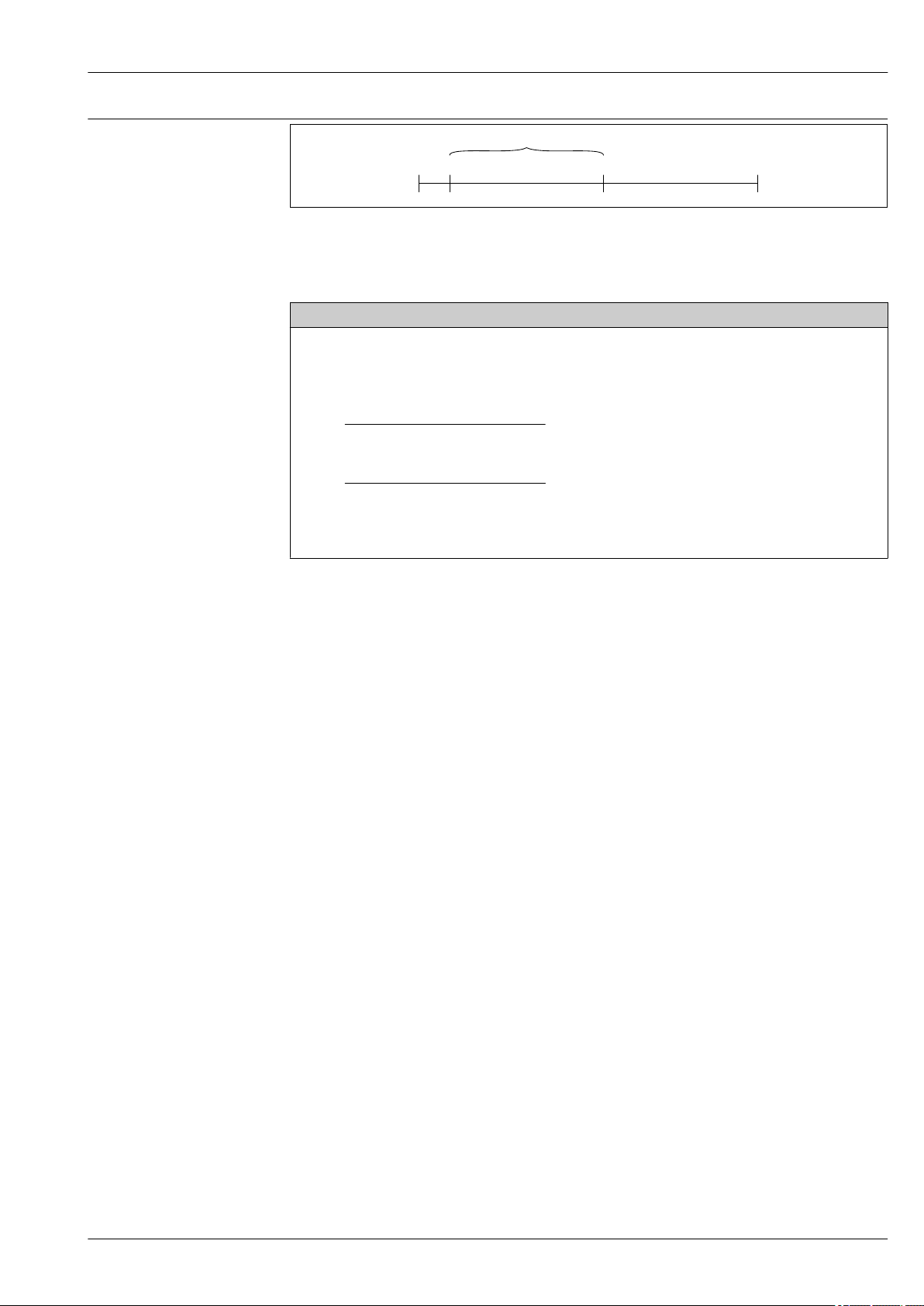

Turn down calculation

1 Calibrated/adjusted span

2 Zero point-based span

3 URL sensor

Example

• Sensor:10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

Turn down (TD):

A0029545

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD =

URL

|URV - LRV|

10 bar (150 psi)

TD =

|5 bar (75 psi) - 0 bar (0 psi)|

In this example, the TD is 2:1.

This span is based on the zero point.

= 2

Endress+Hauser 7

Function and system design

1

2

3

4

p

p

1

3

4

2

Cerabar PMC11, PMC21, PMP11, PMP21

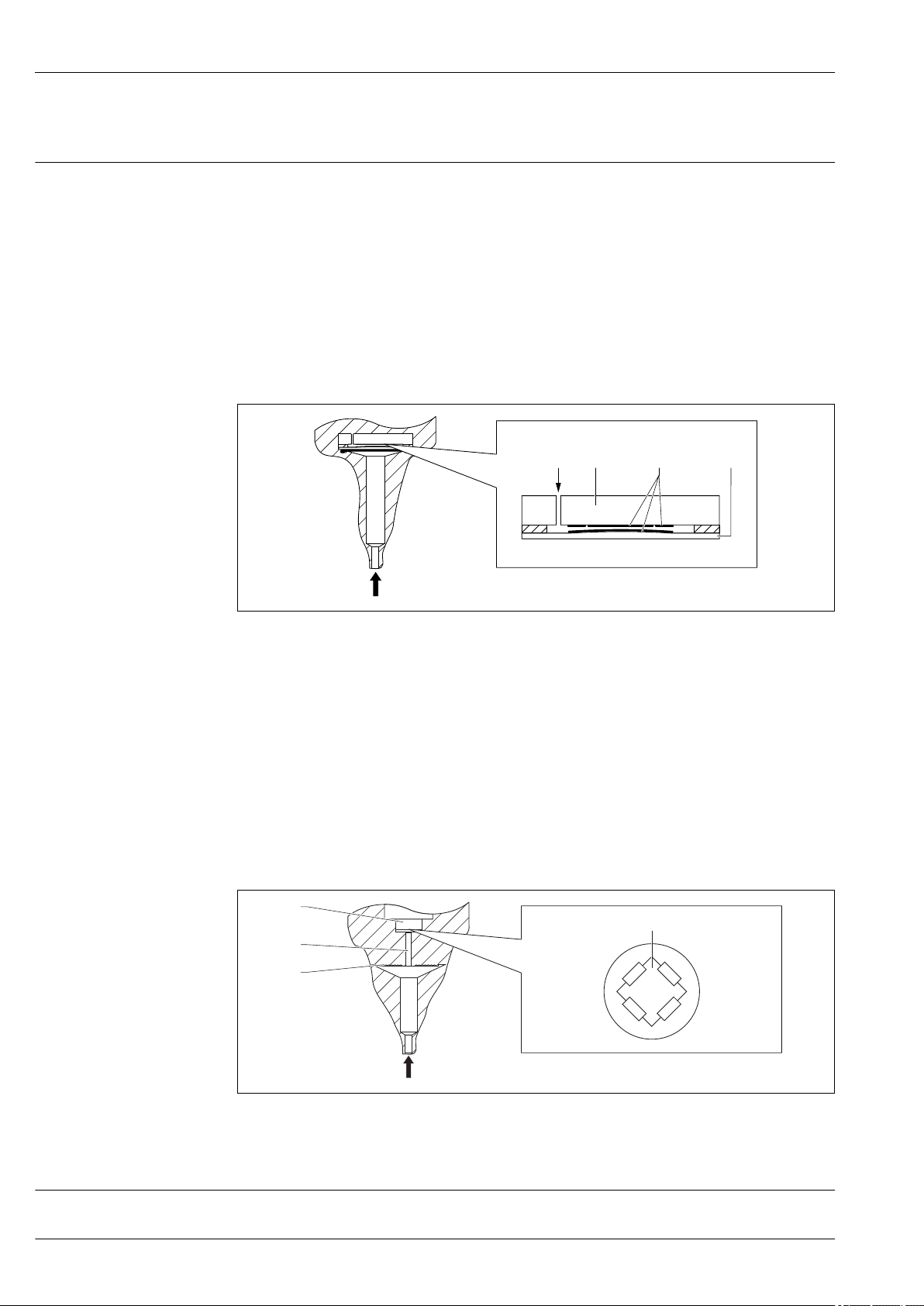

Measuring principle process pressure

measurement

Devices with ceramic process isolating diaphragm (Ceraphire®)

The ceramic sensor is an oil-free sensor, i.e. the process pressure acts directly on the robust ceramic

process isolating diaphragm and causes it to deflect. A pressure-dependent change in capacitance is

measured at the electrodes of the ceramic substrate and the process isolating diaphragm. The

measuring range is determined by the thickness of the ceramic process isolating diaphragm.

Advantages:

• Guaranteed overload resistance up to 40 times the nominal pressure

• The ultrapure 99.9% ceramic (Ceraphire®, see also "www.endress.com/ceraphire") ensures:

– Extremely high chemical durability

– High mechanical durability

• Can be used in absolute vacuum

• Small measuring ranges

A0020465

1 Air pressure (gauge pressure sensors)

2 Ceramic substrate

3 Electrodes

4 Ceramic process isolating diaphragm

Devices with metallic process isolating diaphragm

The process pressure deflects the metal process isolating diaphragm of the sensor and a fill fluid

transfers the pressure to a Wheatstone bridge (semiconductor technology). The pressure-dependent

change in the bridge output voltage is measured and evaluated.

Advantages:

• Can be used for high process pressures

• Fully welded sensor

• Slim, flush-mounted process connections available

A0016448

1 Silicon measuring element, substrate

2 Wheatstone bridge

3 Channel with fill fluid

4 Metal process isolating diaphragm

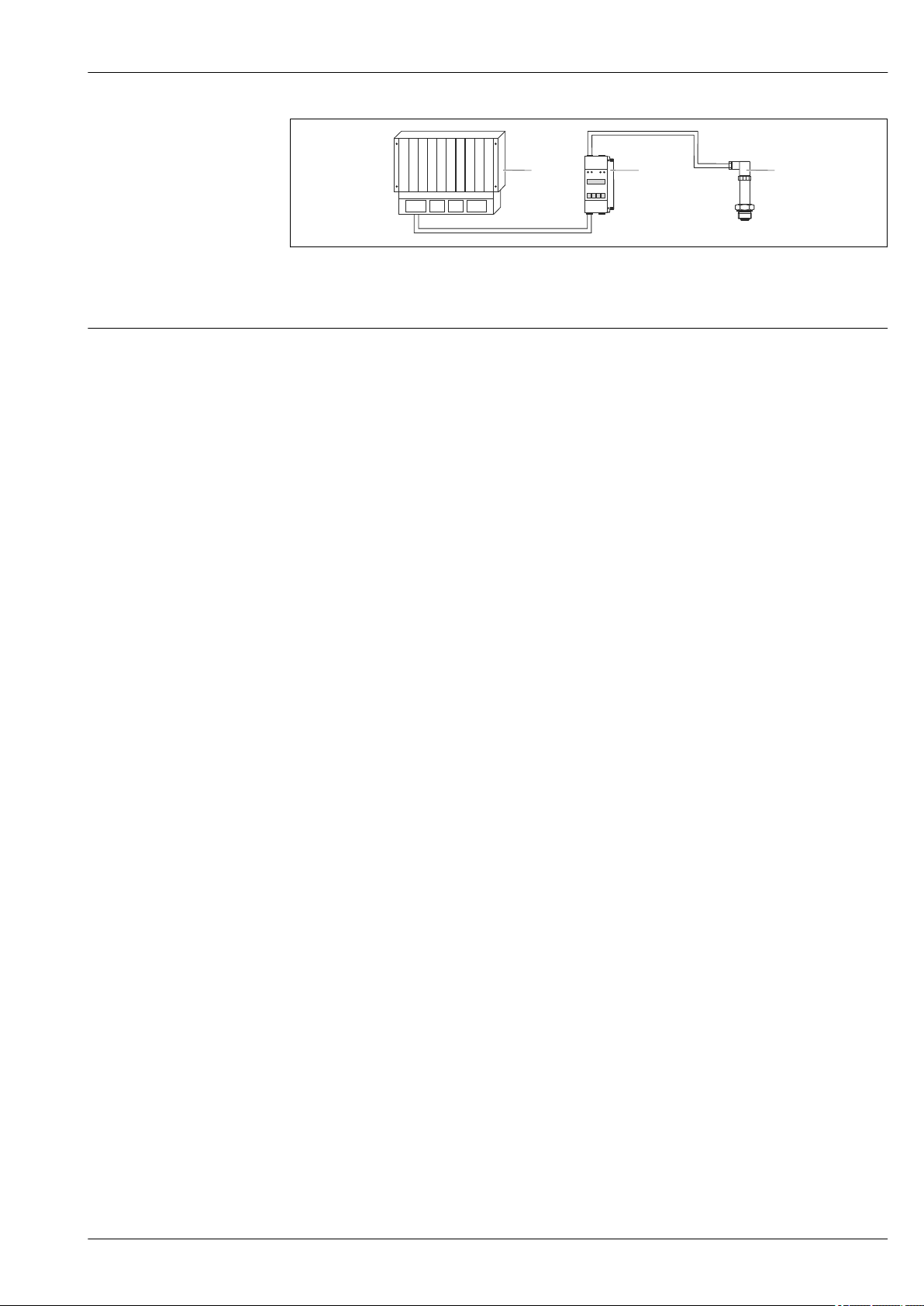

Measuring system

A complete measuring system comprises:

8 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

1

2

3

1 PLC (programmable logic control)

2 e.g. RN221N / RMA42 (if required)

3 Pressure transducer

Device features Field of application

• PMC11: Gauge pressure

• PMP11: Gauge pressure

• PMC21: Gauge and absolute pressure

• PMP21: Gauge and absolute pressure

Process connections

PMC11:

• Thread ISO 228

• Thread ASME

• DIN 13

PMP11:

• Thread ISO 228, also flush-mount

• Thread ASME

• DIN 13

PMC21:

• Thread ISO 228

• Thread DIN 13

• Thread ASME

• Thread JIS

PMP21:

• Thread ISO 228, also flush-mount

• Thread DIN 13

• Thread ASME

• Thread JIS

A0021926

Measuring ranges

• PMC11: from –400 to +400 mbar (–6 to +6 psi) to –1 to +40 bar (–15 to +600 psi).

• PMP11: from –400 to +400 mbar (–6 to +6 psi) to –1 to +40 bar (–15 to +600 psi).

• PMC21: from –100 to +100 mbar (–1.5 to +1.5 psi) to –1 to +40 bar (–15 to +600 psi).

• PMP21: from –400 to +400 mbar (–6 to +6 psi) to –1 to +400 bar (–15 to +6 000 psi).

OPL (depends on the measuring range)

• PMC11: max. 0 to +60 bar (0 to +900 psi)

• PMP11: max. 0 to +160 bar (0 to +2 400 psi)

• PMC21: max. 0 to +60 bar (0 to +900 psi)

• PMP21: max. 0 to +600 bar (0 to +9 000 psi)

MWP

• PMC11: max. 0 to +60 bar (0 to +900 psi)

• PMP11: max. 0 to +160 bar (0 to +2 400 psi)

• PMP21: max. 0 to +600 bar (0 to +9 000 psi)

• PMC21: max. 0 to +60 bar (0 to +900 psi)

Process temperature range (temperature at process connection)

• PMC11: –25 to +85 °C (–13 to +185 °F)

• PMP11: –25 to +85 °C (–13 to +185 °F)

• PMC21: –25 to +100 °C (–13 to +212 °F)

• PMP21: –40 to +100 °C (–40 to +212 °F)

Endress+Hauser 9

Cerabar PMC11, PMC21, PMP11, PMP21

Ambient temperature range

PMC11: –40 to +70 °C (–40 to +158 °F)

PMP11: –40 to +70 °C (–40 to +158 °F)

PMC21:

• –40 to +85 °C (–40 to +185 °F)

• Devices for hazardous areas: –40 to +70 °C (–40 to +158 °F)

PMP21:

–40 to +85 °C (–40 to +185 °F)

Reference accuracy

• PMC11: up to 0.5 %, TD 5:1, for details, see "Reference accuracy" section.

• PMP11: up to 0.5 %, TD 5:1, for details, see "Reference accuracy" section.

• PMC21: up to 0.3 %, TD 5:1, for details, see "Reference accuracy" section.

• PMP21: up to 0.3 %, TD 5:1, for details, see "Reference accuracy" section.

Supply voltage

PMC11:

• 4 to 20 mA output: 10 to 30V DC

• 0 to 10 V output: 12 to 30V DC

PMP11:

• 4 to 20 mA output: 10 to 30V DC

• 0 to 10 V output: 12 to 30V DC

PMC21:

10 to 30 V DC

PMP21:

10 to 30 V DC

Output

PMC11:

• 4 to 20 mA

• 0 to 10 V

PMP11:

• 4 to 20 mA

• 0 to 10 V

PMC21:

4 to 20 mA

PMP21:

4 to 20 mA

Material

PMC11:

• Housing made from 316L (1.4404)

• Process connections made from 316L

• Process isolating diaphragm made from Al2O3 aluminum oxide ceramic, (Ceraphire®), ultrapure

99.9 %

PMP11:

• Housing made from 316L (1.4404)

• Process connections made from 316L (1.4404)

• Process isolating diaphragm made from 316L (1.4435)

PMC21:

• Housing made from 316L (1.4404)

• Process connections made from 316L

• Process isolating diaphragm made from Al2O3 aluminum-oxide ceramic, (Ceraphire®), ultrapure

99.9 %

PMP21:

• Housing made from 316L (1.4404)

• Process connections made from 316L (1.4404)

• Process isolating diaphragm made from 316L (1.4435)

10 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

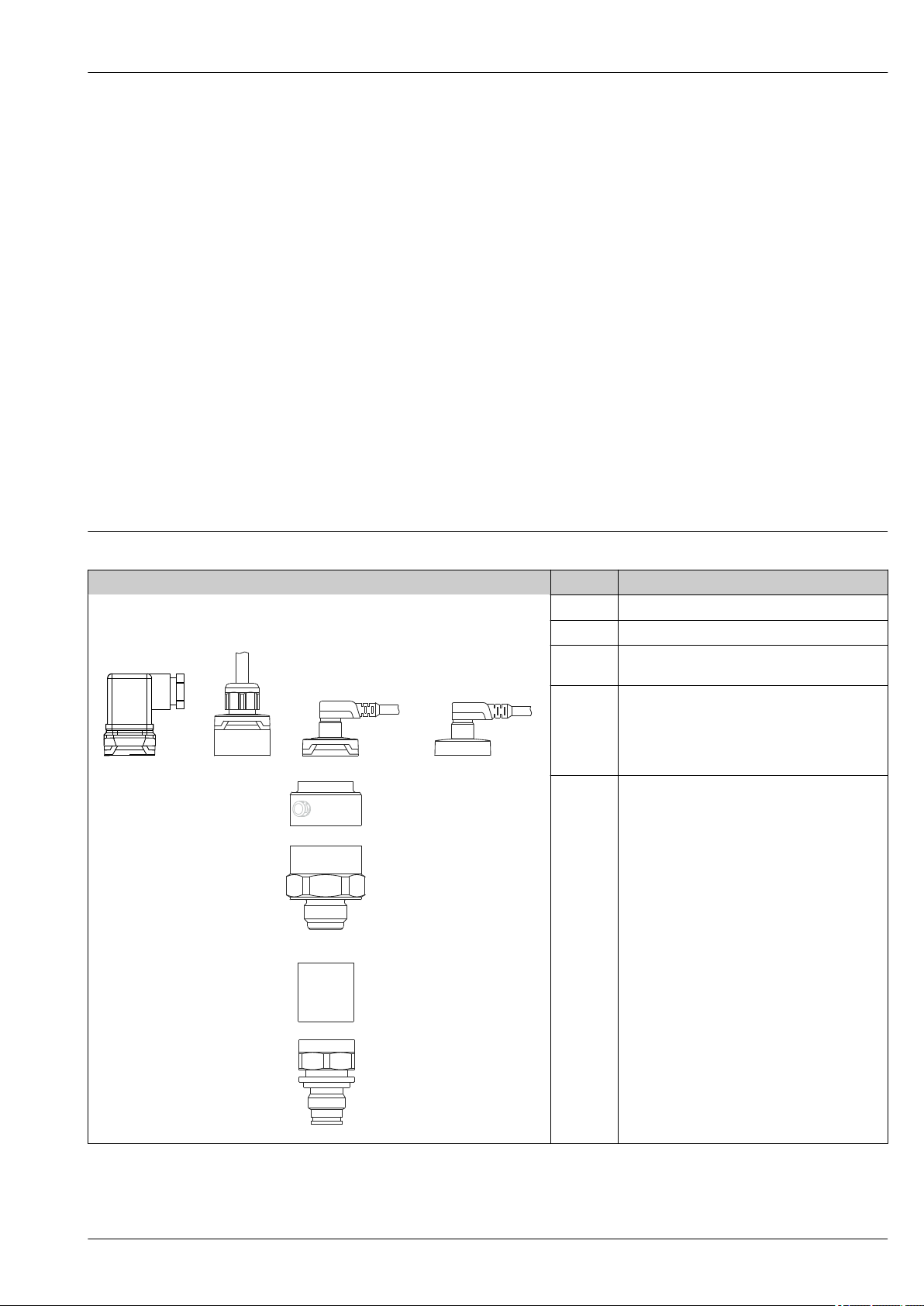

A

B

C - 1

C - 2

D

E

D

E

Options

PMC11:

• Certificate of calibration

• Cleaned from oil+grease

PMP11:

• Certificate of calibration

• Cleaned from oil+grease

PMC21:

• Ex approvals

• Marine certificate

• Min. alarm current setting

• 3.1 Material certificates

• Certificate of calibration

• Cleaned from oil+grease

• Cleaned for O2 service

PMP21:

• Ex approvals

• Marine certificate

• Min. alarm current setting

• 3.1 Material certificates

• Certificate of calibration

• Cleaned from oil+grease

A0027232

A Valve plug

B Cable

C- 1 M12 plug

Housing cap made of plastic

C- 2 M12 plug

For Ex ec and IP69: metal housing cap

A0021987

A0027289

A0027226

D

E

Housing

Process connection (sample illustration)

Product design

Overview Position Description

A0027231

A0027215

Endress+Hauser 11

Cerabar PMC11, PMC21, PMP11, PMP21

System integration

The device can be given a tag name (max. 32 alphanumeric characters).

Designation Option

Measuring point (TAG), see additional specifications Z1

1) Product Configurator order code for "Marking"

1)

12 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

Input

Measured variable Measured process variable

• PMC11: Gauge pressure

• PMP11: Gauge pressure

• PMC21: Gauge pressure or absolute pressure

• PMP21: Gauge pressure or absolute pressure

Calculated process variable

Pressure

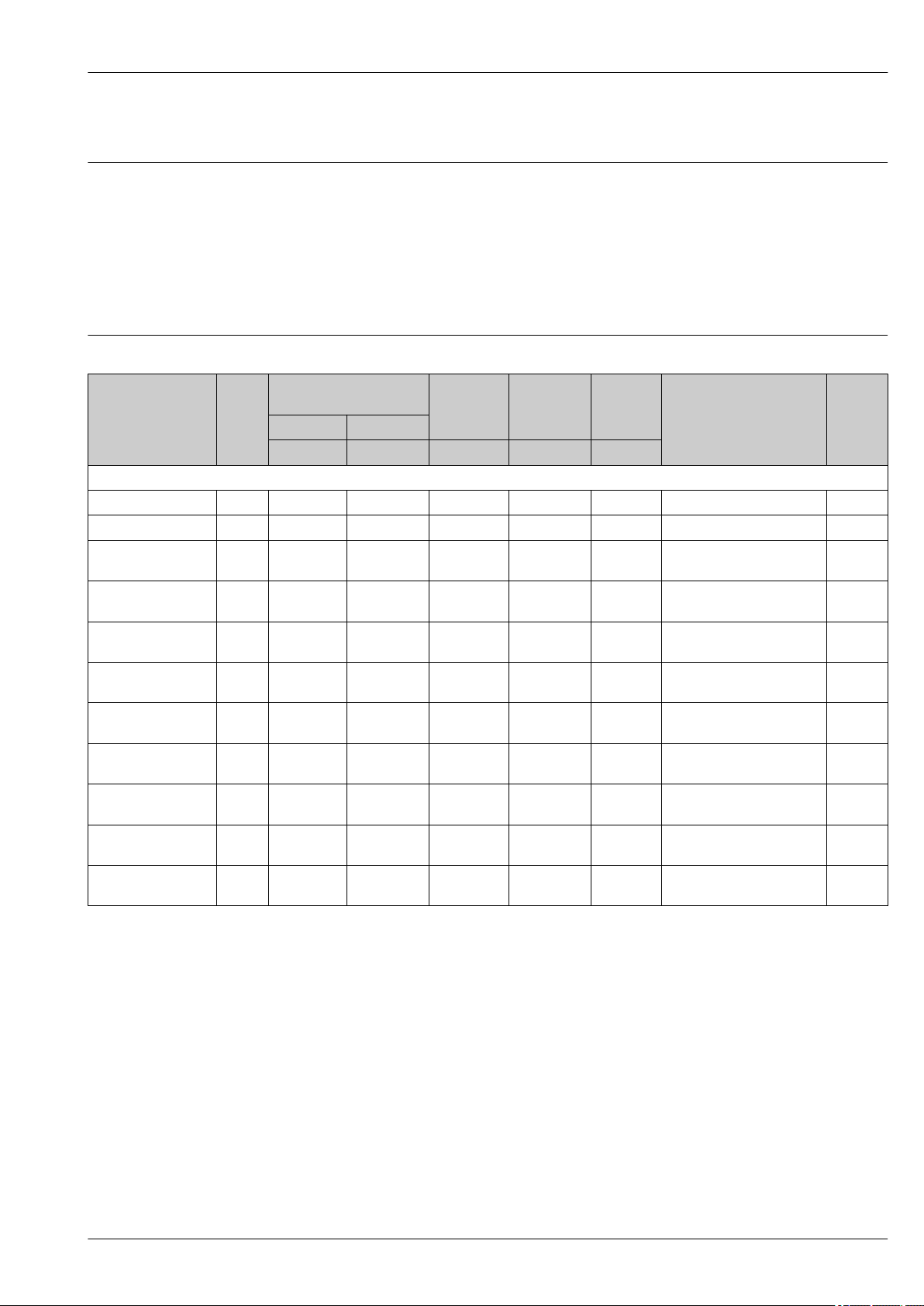

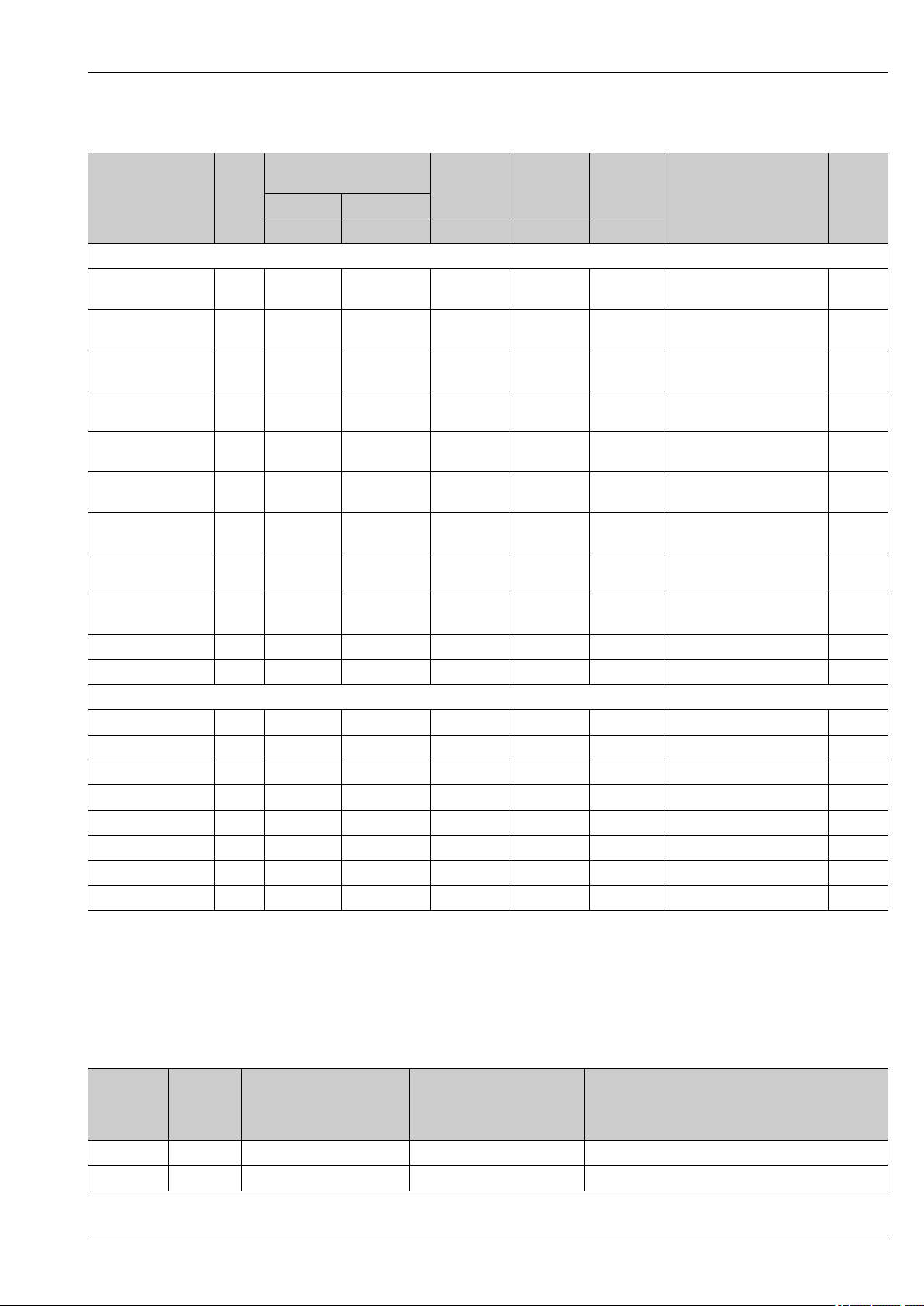

Measuring range Ceramic process isolating diaphragm

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for gauge pressure measurement

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

4)

PMC21 –0.1 (–1.5) +0.1 (+1.5) 0.02 (0.3) 2.7 (40.5) 4 (60) 0 to 100 mbar (0 to 1.5 psi) 1C

5)

PMC21 –0.25 (–4) +0.25 (+4) 0.05 (1) 3.3 (49.5) 5 (75) 0 to 250 mbar (0 to 4 psi) 1E

6)

PMC11

–0.4 (–6) +0.4 (+6) 0.08 (1.2) 5.3 (79.5) 8 (120) 0 to 400 mbar (0 to 6 psi) 1F

PMC21

1 bar (15 psi)

6)

PMC11

–1 (–15) +1 (+15) 0.2 (3) 6.7 (100.5) 10 (150) 0 to 1 bar (0 to 15 psi) 1H

PMC21

2 bar (30 psi)

6)

PMC11

–1 (–15) +2 (+30) 0.4 (6) 12 (180) 18 (270) 0 to 2 bar (0 to 30 psi) 1K

PMC21

4 bar (60 psi)

6)

PMC11

–1 (–15) +4 (+60) 0.8 (12) 16.7 (250.5) 25 (375) 0 to 4 bar (0 to 60 psi) 1M

PMC21

6 bar (90 psi)

6)

PMC11

–1 (–15) +6 (+90) 2.4 (36) 26.7 (400.5) 40 (600) 0 to 6 bar (0 to 90 psi) 1N

PMC21

10 bar (150 psi)

6)

PMC11

–1 (–15) +10 (+150) 2 (30) 26.7 (400.5) 40 (600) 0 to 10 bar (0 to 150 psi) 1P

PMC21

16 bar (240 psi)

6)

PMC11

–1 (–15) +16 (+240) 6.4 (96) 40 (600) 60 (900) 0 to 16 bar (0 to 240 psi) 1Q

PMC21

25 bar (375 psi)

6)

PMC11

–1 (–15) +25 (+375) 10 (150) 40 (600) 60 (900) 0 to 25 bar (0 to 375 psi) 1R

PMC21

40 bar (600 psi)

6)

PMC11

–1 (–15) +40 (+600) 8 (120) 40 (600) 60 (900) 0 to 40 bar (0 to 600 psi) 1S

PMC21

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

3)

Endress+Hauser 13

Cerabar PMC11, PMC21, PMP11, PMP21

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for absolute pressure measurement

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

6)

PMC21 0 +0.1 (+1.5) 0.1 (1.5) 2.7 (40.5) 4 (60) 0 to 100 mbar (0 to 1.5 psi) 2C

6)

PMC21 0 +0.25 (+4) 0.25 (4) 3.3 (49.5) 5 (75) 0 to 250 mbar (0 to 4 psi) 2E

6)

PMC21 0 +0.4 (+6) 0.4 (6) 5.3 (79.5) 8 (120) 0 to 400 mbar (0 to 6 psi) 2F

6)

6)

6)

PMC21 0 +1 (+15) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 1 bar (0 to 15 psi) 2H

PMC21 0 +2 (+30) 0.4 (6) 12 (180) 18 (270) 0 to 2 bar (0 to 30 psi) 2K

PMC21 0 +4 (+60) 0.8 (12) 16.7 (250.5) 25 (375) 0 to 4 bar (0 to 60 psi) 2M

6)

PMC21 0 +10 (+150) 2 (30) 26.7 (400.5) 40 (600) 0 to 10 bar (0 to 150 psi) 2P

6)

PMC21 0 +40 (+600) 8 (120) 40 (600) 60 (900) 0 to 40 bar (0 to 600 psi) 2S

1) Highest turn down that can be set at the factory: 5:1. The turn down is preset and cannot be changed.

2) Other measuring ranges (e.g. –1 to +5 bar (–15 to 75 psi)) can be ordered with customer-specific settings (see the Product Configurator, order

code for "Calibration; Unit" option "J"). It is possible to invert the output signal (LRV = 20 mA; URV = 4 mA). Prerequisite: URV < LRV

3) Product Configurator, order code for "Sensor range"

4) Vacuum resistance: 0.7 bar (10.5 psi) abs

5) Vacuum resistance: 0.5 bar (7.5 psi) abs

6) Vacuum resistance: 0 bar (0 psi) abs

3)

Maximum turn down which can be ordered for absolute pressure and gauge pressure sensors

Devices for gauge pressure measurement

• 6 bar (90 psi), 16 bar (240 psi), 25 bar (375 psi): TD 1:1 to TD 2.5:1

• All other measuring ranges: TD 1:1 to TD 5:1

Devices for absolute pressure measurement

• 100 mbar (1.5 psi), 250 mbar (4 psi), 400 mbar (6 psi): TD 1:1

• 1 bar (15 psi): TD 1:1 to TD 2.5:1

• All other measuring ranges: TD 1:1 to TD 5:1

14 Endress+Hauser

Cerabar PMC11, PMC21, PMP11, PMP21

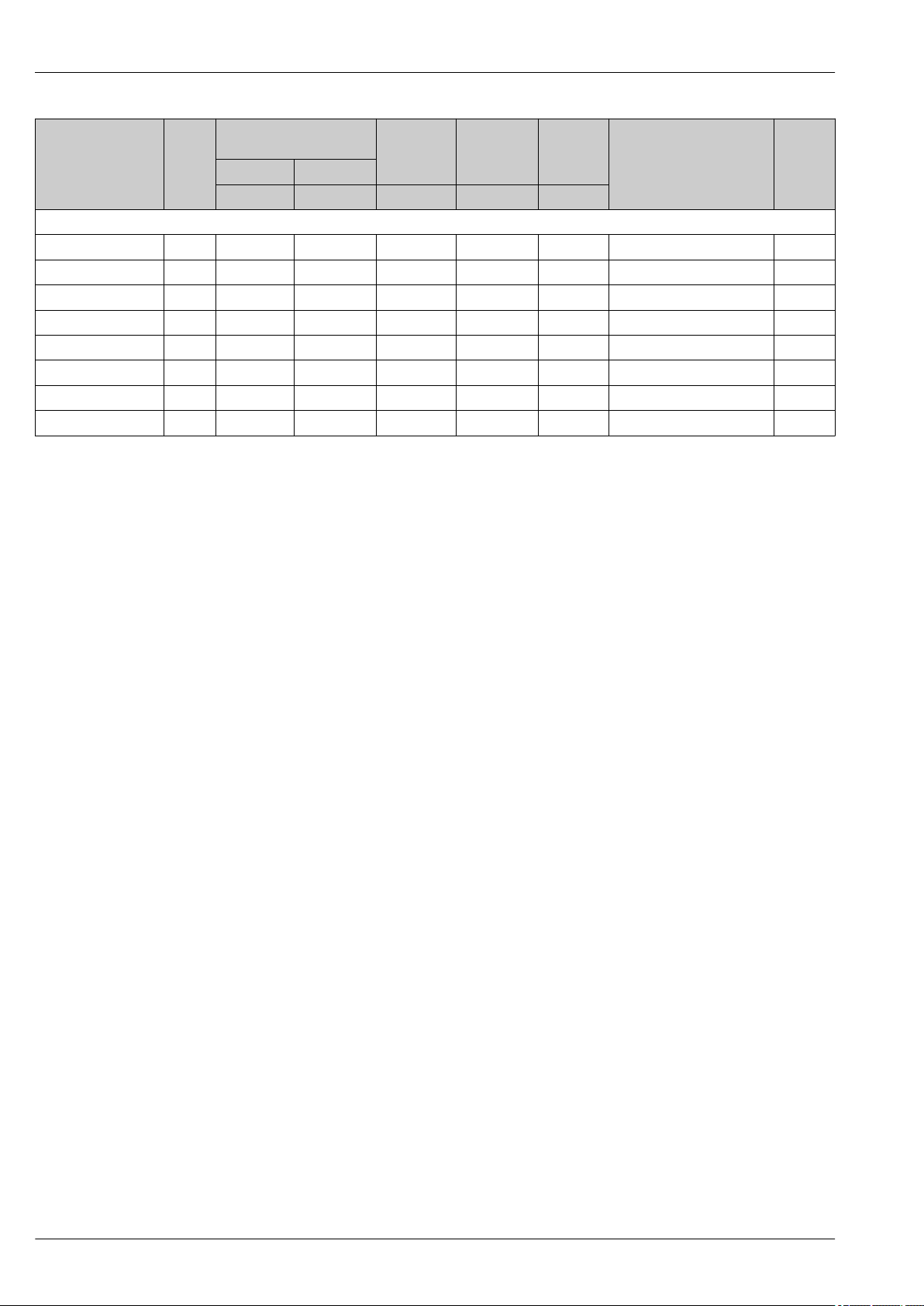

Metal process isolating diaphragm

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for gauge pressure measurement

400 mbar (6 psi)

4)

PMP11

–0.4 (–6) +0.4 (+6) 0.4 (6) 1 (15) 1.6 (24) 0 to 400 mbar (0 to 6 psi) 1F

PMP21

1 bar (15 psi)

4)

PMP11

–1 (–15) +1 (+15) 0.4 (6) 2.7 (40.5) 4 (60) 0 to 1 bar (0 to 15 psi) 1H

PMP21

2 bar (30 psi)

4)

PMP11

–1 (–15) +2 (+30) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 2 bar (0 to 30 psi) 1K

PMP21

4 bar (60 psi)

4)

PMP11

–1 (–15) +4 (+60) 0.8 (12) 10.7 (160.5) 16 (240) 0 to 4 bar (0 to 60 psi) 1M

PMP21

6 bar (90 psi)

4)

PMP11

–1 (–15) +6 (+90) 2.4 (36) 16 (240) 24 (360) 0 to 6 bar (0 to 90 psi) 1N

PMP21

10 bar (150 psi)

4)

PMP11

–1 (–15) +10 (+150) 2 (30) 25 (375) 40 (600) 0 to 10 bar (0 to 150 psi) 1P

PMP21

16 bar (240 psi)

4)

PMP11

–1 (–15) +16 (+240) 5 (75) 25 (375) 64 (960) 0 to 16 bar (0 to 240 psi) 1Q

PMP21

25 bar (375 psi)

4)

PMP11

–1 (–15) +25 (+375) 5 (75) 25 (375) 100 (1500) 0 to 25 bar (0 to 375 psi) 1R

PMP21

40 bar (600 psi)

4)

PMP11

–1 (–15) +40 (+600) 8 (120) 100 (1500) 160 (2400) 0 to 40 bar (0 to 600 psi) 1S

PMP21

100 bar (1 500 psi)

400 bar (6 000 psi)

4)

PMP21 –1 (–15) +100 (+1500) 20 (300) 100 (1500) 160 (2400) 0 to 100 bar (0 to 1 500 psi) 1U

4)

PMP21 –1 (–15) +400 (+6000) 80 (1200) 400 (6000) 600 (9000) 0 to 400 bar (0 to 6 000 psi) 1W

Devices for absolute pressure measurement

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

100 bar (1 500 psi)

400 bar (6 000 psi)

4)

PMP21 0 (0) 0.4 (+6) 0.4 (6) 1 (15) 1.6 (24) 0 to 400 mbar (0 to 6 psi) 2F

4)

4)

4)

PMP21 0 (0) 1 (+15) 0.4 (6) 2.7 (40.5) 4 (60) 0 to 1 bar (0 to 15 psi) 2H

PMP21 0 (0) 2 (+30) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 2 bar (0 to 30 psi) 2K

PMP21 0 (0) 4 (+60) 0.8 (12) 10.7 (160.5) 16 (240) 0 to 4 bar (0 to 60 psi) 2M

4)

PMP21 0 (0) 10 (+150) 2 (30) 25 (375) 40 (600) 0 to 10 bar (0 to 150 psi) 2P

4)

PMP21 0 (0) +40 (+600) 8 (120) 100 (1500) 160 (2400) 0 to 40 bar (0 to 600 psi) 2S

4)

PMP21 0 (0) +100 (+1500) 20 (300) 100 (1500) 160 (2400) 0 to 100 bar (0 to 1 500 psi) 2U

4)

PMP21 0 (0) +400 (+6000) 80 (1200) 400 (6000) 600 (9000) 0 to 400 bar (0 to 6 000 psi) 2W

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

3)

1) Highest turn down that can be set at the factory: 5:1. The turn down is preset and cannot be changed.

2) Other measuring ranges (e.g. –1 to +5 bar (–15 to 75 psi)) can be ordered with customer-specific settings (see the Product Configurator, order

code for "Calibration; Unit" option "J"). It is possible to invert the output signal (LRV = 20 mA; URV = 4 mA). Prerequisite: URV < LRV

3) Product Configurator, order code for "Sensor range"

4) Vacuum resistance: 0.01 bar (0.145 psi) abs

Maximum turn down which can be ordered for absolute pressure and gauge pressure sensors

Device Range 400 mbar (6 psi) 1 bar (15 psi)

6 bar (90 psi)

16 bar (240 psi)

PMP11 0.5% TD 1:1 TD 1:1 to TD 2.5:1 TD 1:1 to TD 5:1

PMP21 0.3% TD 1:1 TD 1:1 to TD 2.5:1 TD 1:1 to TD 5:1

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

25 to 400 bar (375 to 6 000 psi)

Endress+Hauser 15

Output

[ ]W

30

20

10

1068

614

U

[V]

1

R

L

max

B

2

R

L

max

£

-U 6.5V

22mA

B

I

63 %

100 %

t

t1t

2

90 %

t

3

Cerabar PMC11, PMC21, PMP11, PMP21

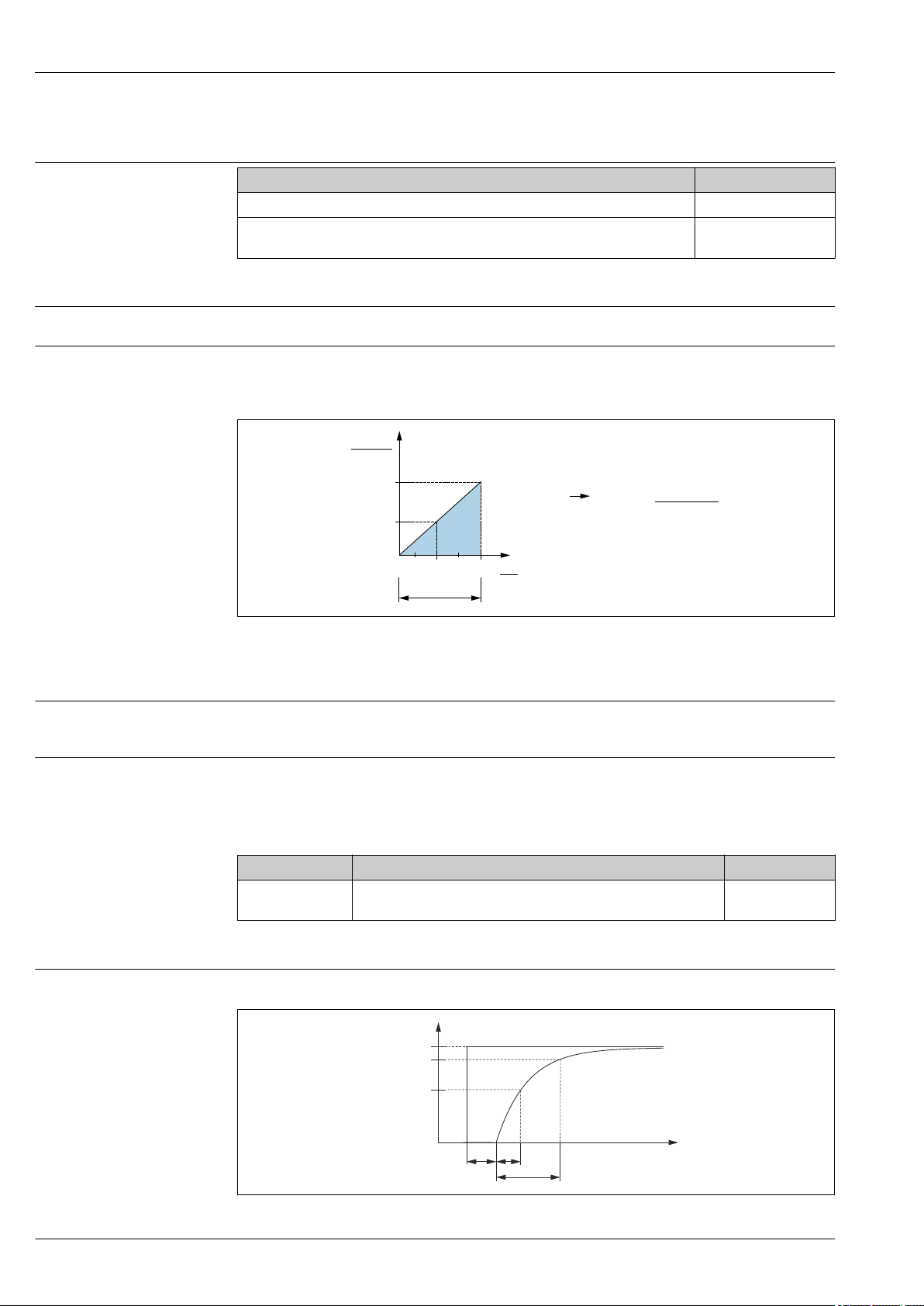

Output signal

Signal range 4 to 20 mA

Load (for 4 to 20 mA devices )

Designation Option

4 to 20 mA (2-wire) 1

PMC11: 0 to 10 V output (3-wire)

PMP11: 0 to 10 V output (3-wire)

1) Product Configurator, order code for "Output"

1)

2

3.8 mA to 20.5 mA

In order to guarantee sufficient terminal voltage in two-wire devices, a maximum load resistance R

(including line resistance) must not be exceeded depending on the supply voltage UB of the supply

unit.

A0029452

1 Power supply 10 to 30 V DC

2 R

UBSupply voltage

Maximum load resistance

Lmax

L

Load resistance (for 0 to 10 V devices)

Signal on alarm 4 to 20 mA

Dead time, time constant

The load resistance must be ≥ 5 [kΩ].

The response of the output to error is regulated in accordance with NAMUR NE43.

Factory setting MAX alarm: >21 mA

alarm current

Device Description Option

PMC21

PMP21

1) Product Configurator order code for "Service"

Adjusted min. alarm current IA

Presentation of the dead time and the time constant:

1)

A0019786

16 Endress+Hauser

Loading...

Loading...