Page 1

TI00382P/00/EN/28.17

71374973

Products

Solutions Services

Technical Information

Deltabar S

PMD75, FMD77, FMD78

Differential pressure measurement and pressure

measurement

Differential pressure transmitter with metal

sensors

Applications

The device is used for the following measuring tasks:

• Flow measurement (volume flow or mass flow) in conjunction with differential

pressure sensors in gases, vapors and liquids

• Level, volume or mass measurements in liquids

• High process temperatures up to 400 °C (752 °F) possible with diaphragm seal

mount

• Differential pressure monitoring, e.g. of filters and pumps

Your benefits

• Very good reproducibility and long-term stability

• High reference accuracy up to 0.035 %

• Turn down up to 100:1, higher on request

• Used for flow and differential pressure monitoring up to SIL3, certified to IEC

61508 by TÜV SÜD

• High level of safety during operation thanks to function monitoring from the

measuring cell to the electronics

• The patented TempC membrane for the diaphragm seal reduces measured errors

caused by environmental and process temperature influences to a minimum

• Easy electronic replacement guaranteed with HistoROM®/M-DAT

• Uniform platform for differential pressure, hydrostatics and pressure (Deltabar S –

Deltapilot S – Cerabar S)

• Practical user navigation for quick and easy commissioning

• Extensive diagnostic functions

• Cost-effective installation with Deltabar S FMD77, capillary on low-pressure side

Page 2

Table of contents

Deltabar S PMD75, FMD77, FMD78

Document information ....................... 4

Document function ............................ 4

Symbols used ................................ 4

Documentation ............................... 5

Terms and abbreviations ........................ 6

Turn down calculation .......................... 7

Registered trademarks .......................... 7

Function and system design ................... 8

Device selection .............................. 8

Measuring principle ........................... 10

Product design .............................. 10

Communication protocol ........................ 11

Input .................................... 12

Measured variable ............................ 12

Measuring range ............................. 12

Output .................................. 14

Output Signal ............................... 14

Signal range ................................ 14

Signal on alarm .............................. 14

Load ..................................... 14

Dead time, time constant ....................... 15

Dynamic behavior, current output .................. 16

Dynamic behavior Digital output (HART electronics) ..... 16

Dynamic behavior PROFIBUS PA .................. 17

Dynamic behavior FOUNDATION Fieldbus ............ 17

Damping .................................. 18

Alarm current ............................... 18

Firmware version ............................ 18

HART protocol-specific data ..................... 18

PROFIBUS PA protocol-specific data ................ 19

FOUNDATION Fieldbus protocol-specific data .......... 19

Power supply ............................. 23

Terminal assignment .......................... 23

Supply voltage .............................. 24

Current consumption .......................... 24

Electrical connection .......................... 24

Terminals ................................. 24

Cable entries ............................... 25

Device plug ................................. 25

Cable specification ............................ 26

Start-up current ............................. 26

Residual ripple .............................. 26

Overvoltage protection (optionally for HART, PROFIBUS

PA and FOUNDATION Fieldbus) ................... 26

Influence of power supply ....................... 26

Performance characteristics of differential

pressure / pressure transmitter

(sensor module + electronics module) .......... 27

Preamble .................................. 27

Total performance of transmitter .................. 27

Reference accuracy [E1] ........................ 27

Total performance – Specification values ............. 28

Long-term stability ........................... 29

Detailed Performance Explanation and Calculation ...... 30

Total error ................................. 32

Performance characteristics - calculation

example and additional information ........... 33

Calculating the total performance in 5 steps ........... 33

Installation factors ............................ 36

Reference operating conditions ................... 37

Installation ............................... 38

General installation instructions ................... 38

Measuring arrangement ........................ 38

Measuring arrangement for devices with diaphragm seals

– FMD77 and FMD78 ......................... 38

Orientation ................................ 38

Wall and pipe mounting, transmitter (optional) ........ 39

Wall and pipe mounting, valve manifold (optional) ...... 39

"Separate housing" version ....................... 40

Turning the housing .......................... 41

Oxygen applications ........................... 42

Ultrapure gas applications ....................... 42

Applications with hydrogen ...................... 42

Environment .............................. 43

Ambient temperature range ..................... 43

Storage temperature range ...................... 43

Degree of protection .......................... 43

Climate class ............................... 43

Electromagnetic compatibility .................... 43

Vibration resistance ........................... 44

Process .................................. 45

Process temperature limits (temperature at transmitter) .. 45

Process temperature limits of capillary armoring: FMD77

and FMD78 ................................ 46

Process temperature range, seals .................. 46

Pressure specifications ......................... 47

Mechanical construction .................... 48

Device height ............................... 48

T14 housing, optional display on the side ............ 49

T15 housing, optional display on the top ............. 50

T17 housing (hygienic), optional display on the side ..... 50

Process connections PMD75 ..................... 51

Process connections PMD75 ..................... 52

Process connections PMD75 ..................... 53

Valve manifold DA63M- (optional) ................. 54

FMD77: Selecting the process connection and capillary

line ...................................... 55

FMD77 - Overview ........................... 56

Process connections FMD77 with diaphragm seal, high-

pressure side ............................... 57

Process connections FMD77 with diaphragm seal, high-

pressure side ............................... 58

Process connections FMD77 with diaphragm seal ....... 59

Process connections FMD77 with diaphragm seal ....... 61

2 Endress+Hauser

Page 3

Deltabar S PMD75, FMD77, FMD78

Process connections FMD77 with diaphragm seal ....... 63

Process connections FMD77 with diaphragm seal, low-

pressure side ............................... 63

FMD78: Selecting the process connection and capillary

line ...................................... 64

FMD78 basic device ........................... 65

Process connections FMD78 with diaphragm seal ....... 66

Process connections FMD78 with diaphragm seal ....... 67

Process connections FMD78 with diaphragm seal ....... 69

Process connections FMD78 with diaphragm seal ....... 71

Process connections FMD78 with diaphragm seal ....... 72

Process connections FMD78 with diaphragm seal ....... 74

Process connections FMD78 with diaphragm seal ....... 75

Process connections FMD78 with diaphragm seal ....... 76

Separate housing: Wall and pipe mounting with mounting

bracket ................................... 78

Materials not in contact with process ............... 79

Weight ................................... 83

Materials in contact with process .................. 83

Fill fluid ................................... 85

Operability ............................... 88

Operating concept ............................ 88

Local operation .............................. 88

Remote operation ............................ 91

HistoROM®/M-DAT (optional) ................... 92

System integration ........................... 93

Configuration data sheet ....................... 109

Accessories .............................. 112

HistoROM®/M-DAT .......................... 112

Welding flanges and welding neck ................ 112

Manifolds ................................ 112

Additional mechanical accessories ................ 112

Supplementary documentation .............. 113

Field of Activities ............................ 113

Technical Information ........................ 113

Special Documentation ........................ 113

Operating Instructions ........................ 113

Brief Operating Instructions ..................... 113

Functional safety manual (SIL) ................... 113

Overfill protection ........................... 113

Safety Instructions (XA) ....................... 113

Installation/Control Drawings ................... 114

Planning instructions, diaphragm seal systems ... 94

Applications ................................ 94

Design and operation mode ...................... 95

Differential pressure transmitter .................. 96

Diaphragm seal filling oils ....................... 97

Operating temperature range .................... 97

Response time .............................. 98

Information on cleaning ........................ 98

Installation instructions ........................ 98

Vacuum applications ......................... 102

Certificates and approvals .................. 103

CE mark .................................. 103

RCM-Tick marking ........................... 103

Ex approvals ............................... 103

EAC conformity ............................. 103

Suitable for hygiene applications ................. 103

Functional safety SIL/ IEC 61508 Declaration of

Conformity (optional) ......................... 104

Overfill protection ........................... 104

CRN approval .............................. 104

Other standards and guidelines .................. 104

Pressure Equipment Directive 2014/68/EU (PED) ...... 104

Manufacturer declarations ..................... 105

Marine approval ............................ 106

Classification of process sealing between electrical

systems and (flammable or combustible) process fluids in

accordance with ANSI/ISA 12.27.01 ............... 106

Inspection certificate ......................... 106

Calibration ................................ 107

Service .................................. 107

Ordering information ...................... 108

Scope of delivery ............................ 108

Measuring point (TAG) ........................ 108

Endress+Hauser 3

Page 4

Document information

DANGER

WARNING

CAUTION

NOTICE

A

Deltabar S PMD75, FMD77, FMD78

Document function

The document contains all the technical data on the device and provides an overview of the

accessories and other products that can be ordered for the device.

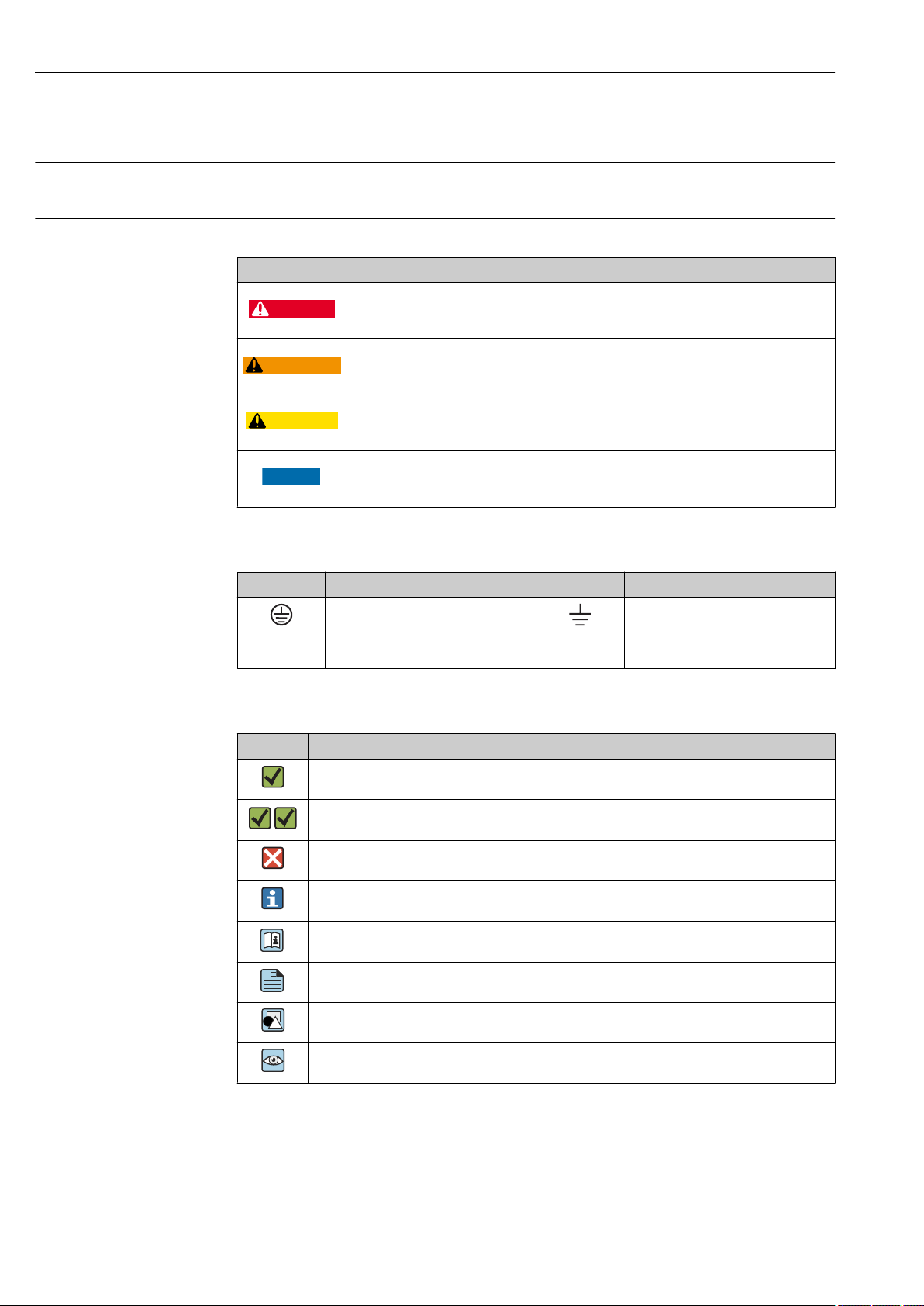

Symbols used Safety symbols

Symbol Meaning

Electrical symbols

Symbol Meaning Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Ground connection

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

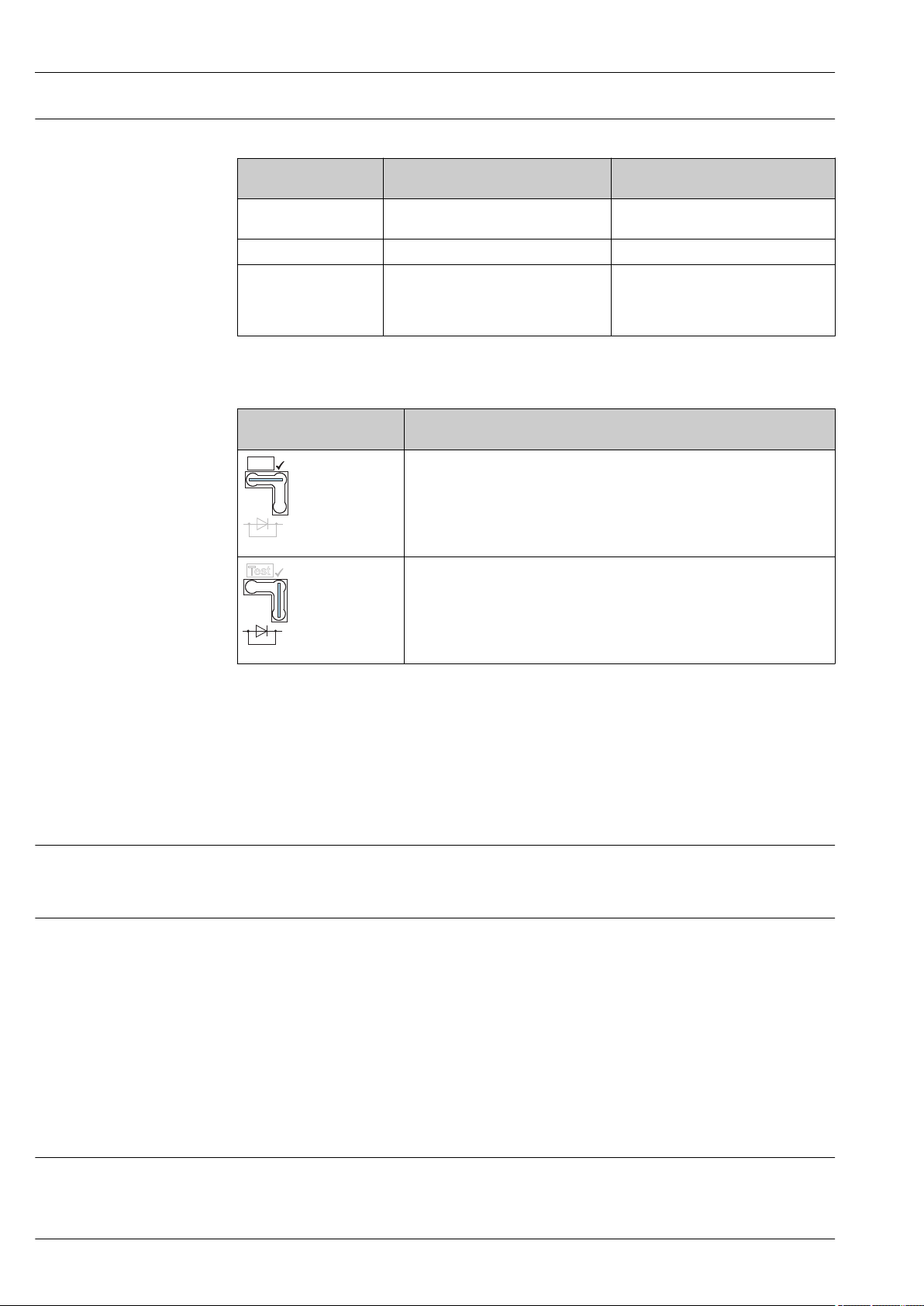

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

4 Endress+Hauser

Page 5

Deltabar S PMD75, FMD77, FMD78

,…,

1.

2.

3.

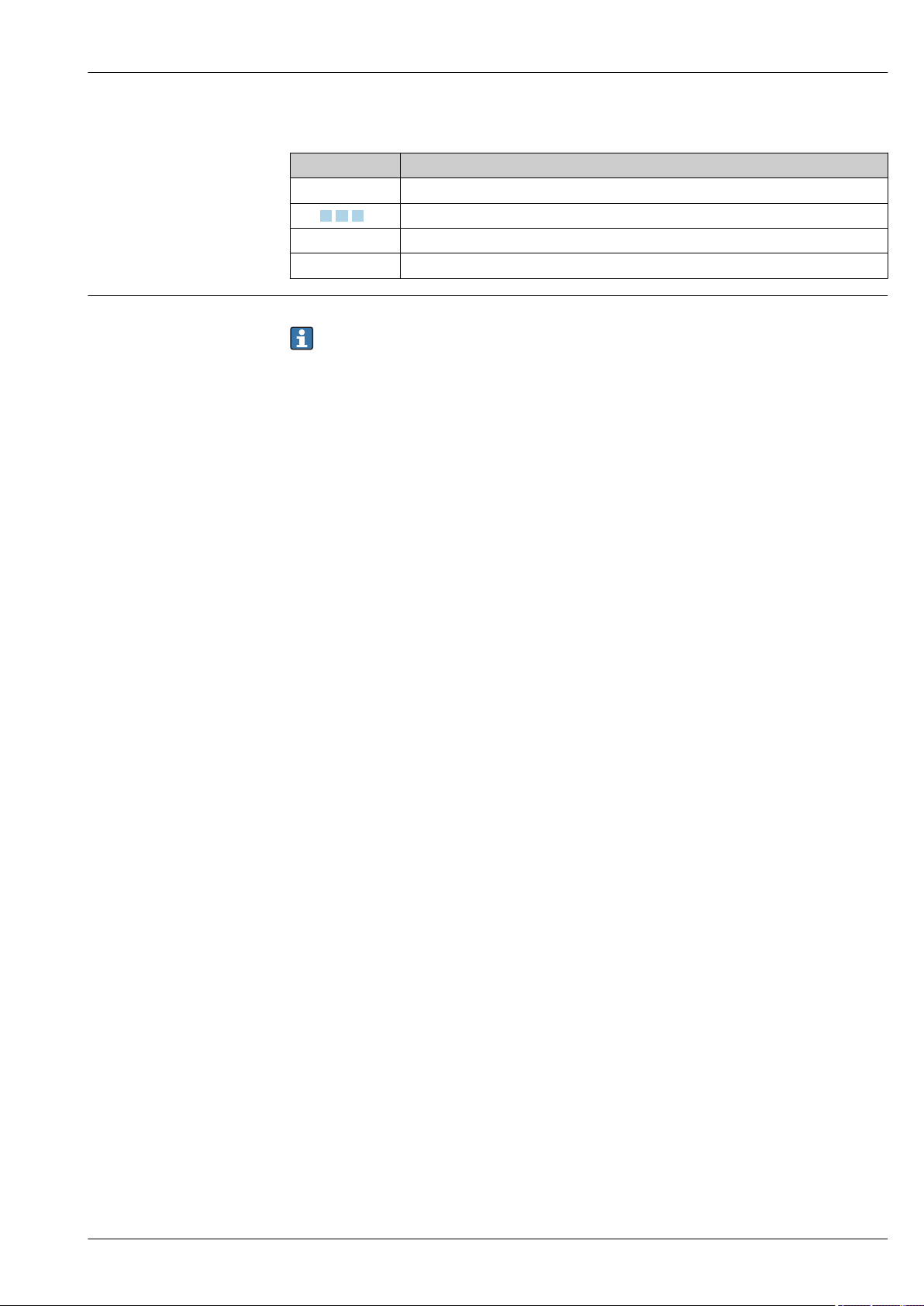

Symbols in graphics

A-A, B-B, C-C, ... Sections

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

Documentation

See chapter "Additional documentation" → 113

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com → Download

Safety Instructions (XA)

See the "Safety instructions" section → 113

Endress+Hauser 5

Page 6

Terms and abbreviations

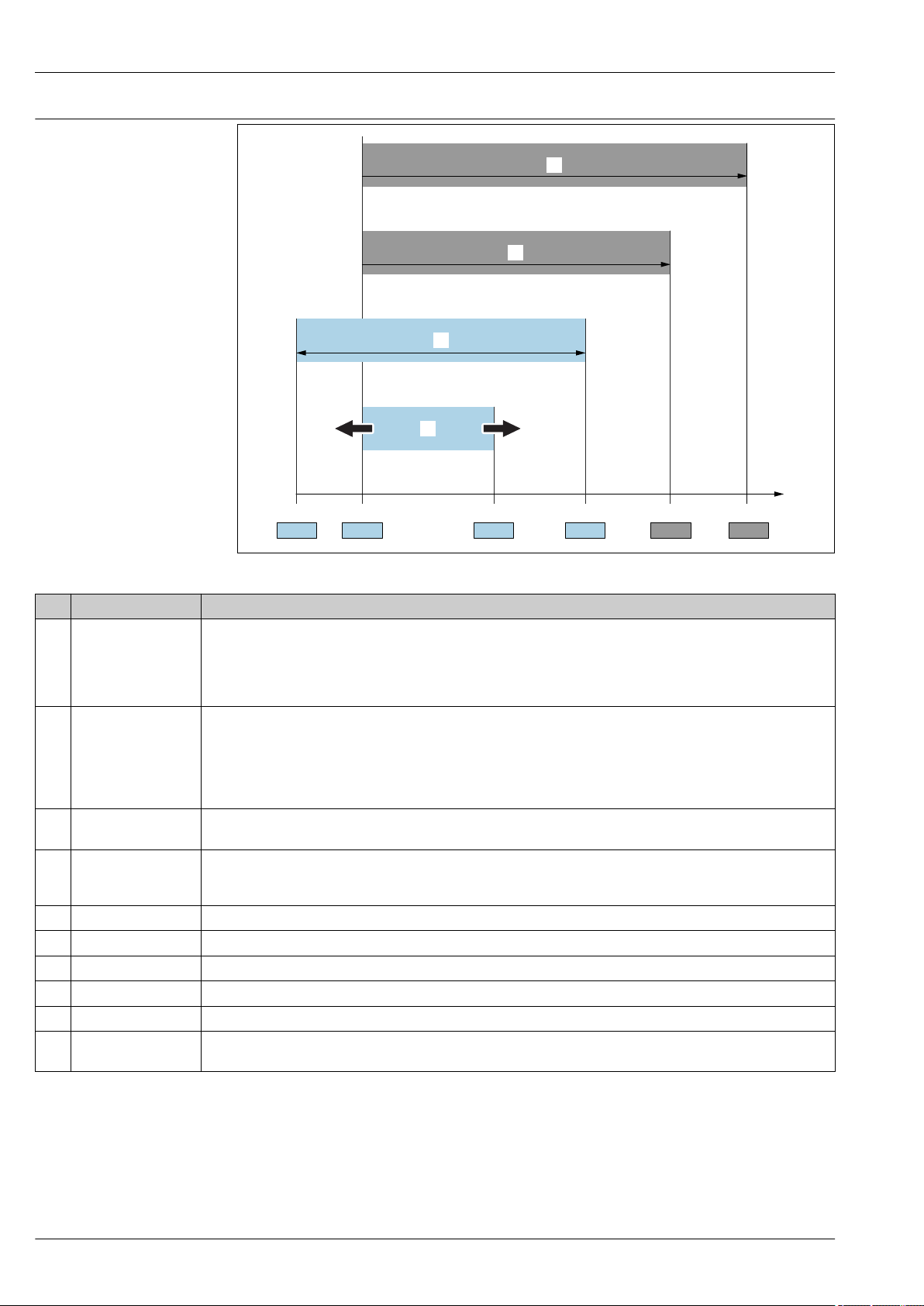

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

Deltabar S PMD75, FMD77, FMD78

A0029505

Item Term/abbreviation Explanation

1 OPL The OPL (over pressure limit = sensor overload limit) for the measuring device depends on the lowest-rated element,

with regard to pressure, of the selected components, i.e. the process connection has to be taken into consideration in

addition to the measuring cell. Also observe pressure-temperature dependency. For the relevant standards and

additional information, see the "Pressure specifications"→ 47 section.

The OPL may only be applied for a limited period of time.

2 MWP The MWP (maximum working pressure) for the sensors depends on the lowest-rated element, with regard to

pressure, of the selected components, i.e. the process connection has to be taken into consideration in addition to the

measuring cell. Also observe pressure-temperature dependency. For the relevant standards and additional

information, see the "Pressure specifications"→ 47 section.

The MWP may be applied at the device for an unlimited period.

The MWP can also be found on the nameplate.

3 Maximum sensor

measuring range

4 Calibrated/adjusted

span

p - Pressure

- LRL Lower range limit

- URL Upper range limit

- LRV Lower range value

- URV Upper range value

- TD (turn down) Turn down

Span between LRL and URL

This sensor measuring range is equivalent to the maximum calibratable/adjustable span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized spans.

Example - see the following section.

6 Endress+Hauser

Page 7

Deltabar S PMD75, FMD77, FMD78

LRV

URLURV

LRL

1 = 2

3

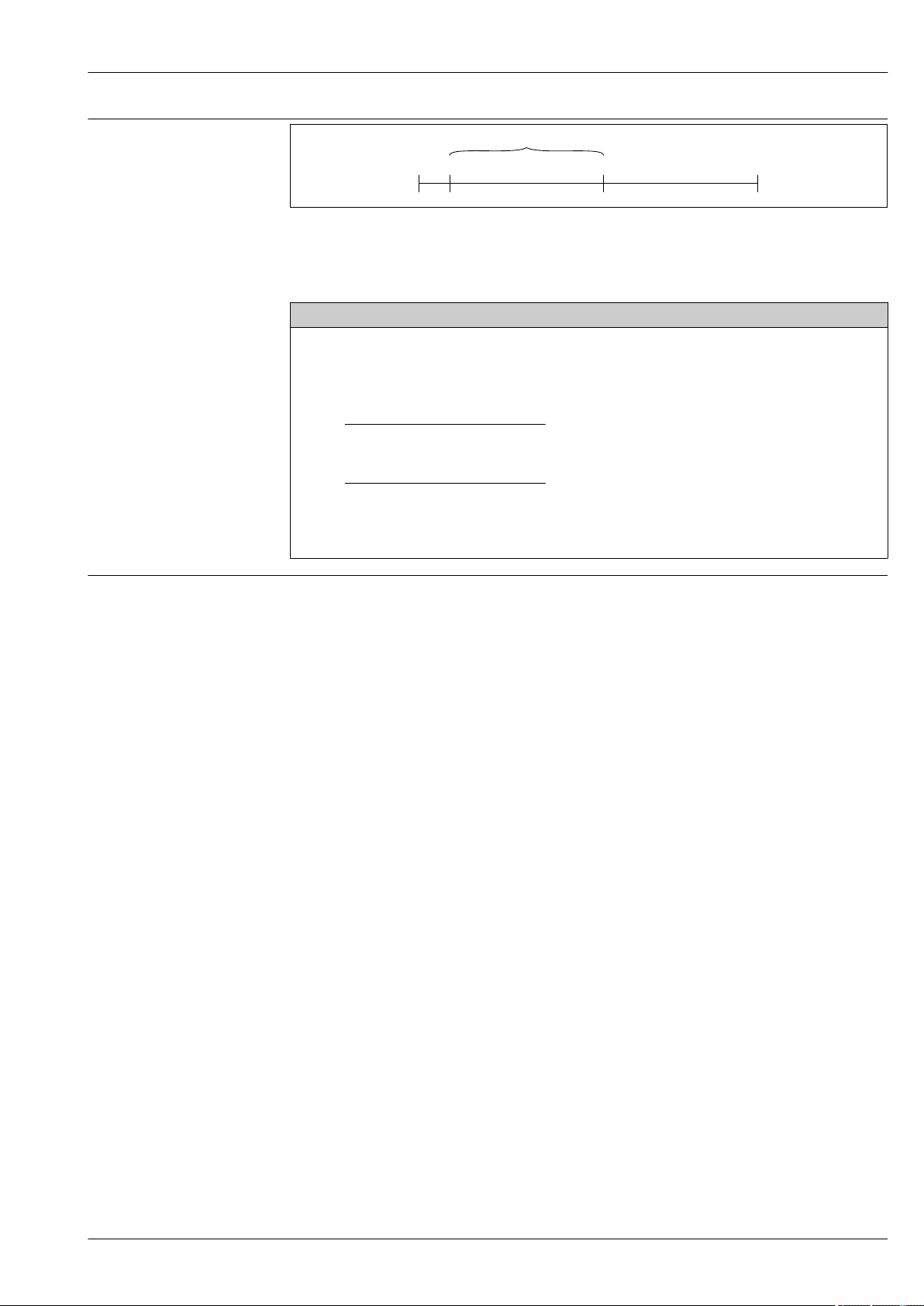

Turn down calculation

1 Calibrated/adjusted span

2 Zero point-based span

3 URL sensor

Example

• Sensor:10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

Turn down (TD):

A0029545

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD =

TD =

In this example, the TD is 2:1.

This span is based on the zero point.

Registered trademarks HART®

Registered trademark of the FieldComm Group, Austin, USA

PROFIBUS®

Registered trademark of the PROFIBUS User Organization, Karlsruhe, Germany

FOUNDATIONTMFieldbus

Registered trademark of the FieldComm Group, Austin, Texas, USA

URL

|URV - LRV|

10 bar (150 psi)

= 2

|5 bar (75 psi) - 0 bar (0 psi)|

Endress+Hauser 7

Page 8

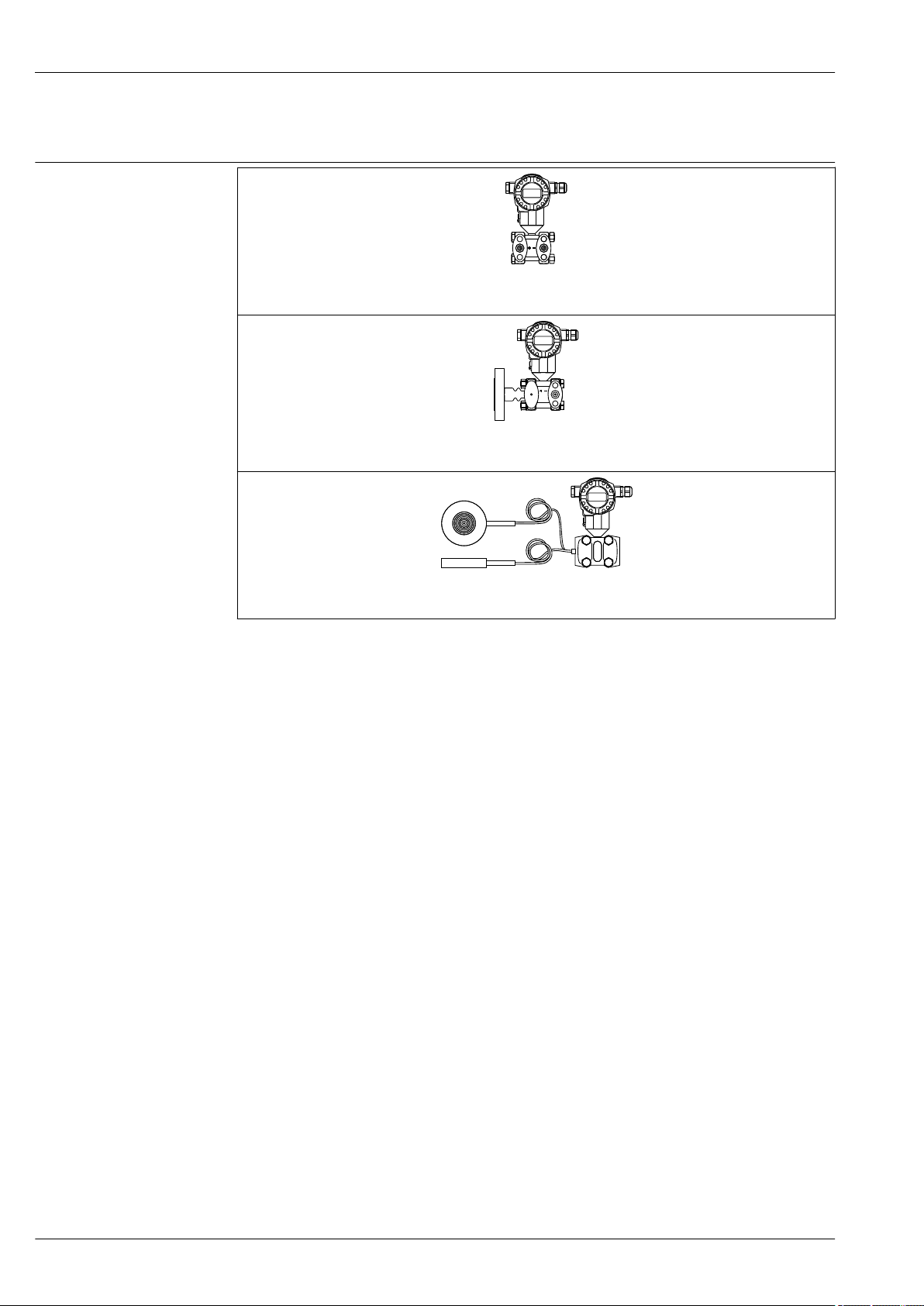

Device selection

+ –

Deltabar S PMD75, FMD77, FMD78

Function and system design

A0023922

PMD75

A0023923

FMD77 with mounted diaphragm seal

FMD78 with capillary diaphragm seals

Field of application

PMD75:

• Flow

• Level

• Differential pressure

• Pressure

FMD77:

• Level

• Differential pressure

FMD78:

• Level

• Differential pressure

Process connections

PMD75:

• 1/4 – 18 NPT

• RC 1/4

FMD77 low-pressure side (–):

• 1/4 – 18 NPT

• RC 1/4

• Alternatively available with capillary and diaphragm seal

FMD77 high-pressure side (+):

• DN 50 – DN 100

• ASME NPS 2" – 4"

• JIS 80A – 100A

FMD78:

Wide range of diaphragm seals

A0023924

8 Endress+Hauser

Page 9

Deltabar S PMD75, FMD77, FMD78

Measuring ranges

• PMD75: from –10 to +10 mbar (-0.15 to +0.15 psi) to –40 to +40 bar (-600 to +600 psi)

As gauge or absolute pressure sensor: up to 250 bar (3750 psi)

• FMD77: from –100 to +100 mbar (-1.5 to +1.5 psi) to –16 bar to +16 bar (-240 to +240 psi)

• FMD78: from –100 to +100 mbar (-1.5 to +1.5 psi) to –40 to +40 bar (-600 to +600 psi)

OPL

PMD75:

on one side: up to 420 bar (6 300 psi)

on both sides: up to 630 bar (9 450 psi)

As gauge or absolute pressure sensor: up to 375 bar (5625 psi)

FMD77:

on one side: up to 160 bar (2 400 psi)

on both sides: up to 240 bar (3 600 psi)

FMD78:

on one side: up to 160 bar (2 400 psi)

on both sides: up to 240 bar (3 600 psi)

Process temperature range(temperature at process connection)

PMD75:

–40 to +85 °C (–40 to +185 °F)

FMD77:

–70 to +400 °C (–94 to +752 °F)

(depending on the filling oil)

FMD78:

–70 to +400 °C (–94 to +752 °F)

(depending on the filling oil)

Ambient temperature range

• Without LCD display: –50 to +85 °C (–58 to +185 °F)

• With LCD display: –20 to +70 °C (–4 to +158 °F)

(extended temperature application range–50 to +85 °C (–58 to +185 °F) with limitations in optical

properties, such as display speed and contrast)

• Separate housing –20 to +60 °C (–4 to +140 °F):

• Diaphragm seal systems depending on the version

Reference accuracy

• PMD75: up to ±0.035 % of the set span

• FMD77: up to ±0.075 % of the set span

• FMD78: up to ±0.075 % of the set span

Supply voltage

Supply voltage non-Ex

• 4 to 20 mA HART: 10.5 to 45 V DC

• PROFIBUS PA and FOUNDATION Fieldbus: 9 to 32 V DC

Supply voltage Ex ia

10.5 to 30 V DC

Output

4 to 20 mA with superimposed HART protocol, PROFIBUS PA or FOUNDATION Fieldbus

Options

• HistoROM®/M-DAT memory chip

• PMD75: with blind flange on LP side for gauge and absolute pressure measurement

Specialties

PMD75:

• p

up to 420 bar (6 300 psi)

stat

• Process isolating diaphragm: tantalum

Endress+Hauser 9

Page 10

FMD77:

p

2

p

1

1

2

3

44

h =

∆

p

ρ g

+

–

–

h

A

B

For extreme medium temperatures

FMD78:

Wide range of diaphragm seals

Measuring principle Metal process isolating diaphragm

1 Measuring element

2 Middle diaphragm

3 Filling oil

4 Process isolating diaphragm

The process isolating diaphragms are deflected on both sides by the acting pressures. A filling oil

transfers the pressure to a resistance bridge (semiconductor technology). The change in the bridge

output voltage, which depends on the differential pressure, is measured and processed

Advantages:

• Standard system pressures: 160 bar (2 400 psi) up to 420 bar (6 300 psi)

• High long-term stability

• Very high single-sided overload resistance

Deltabar S PMD75, FMD77, FMD78

A0023919

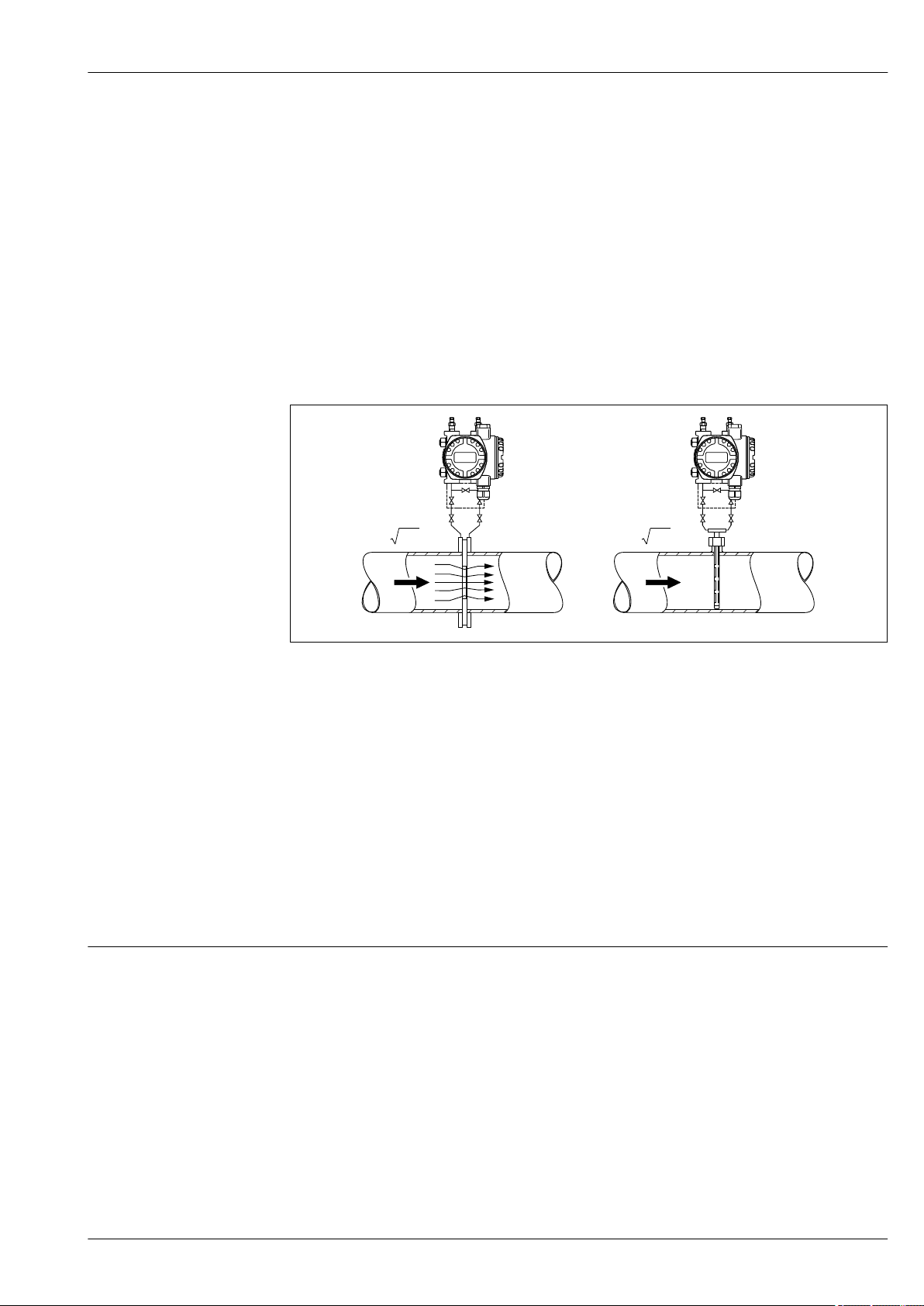

Product design Level measurement (level, volume and mass):

A Level measurement with FMD77

B Level measurement with FMD78

h Height (level)

Δp Differential pressure

ρ Density of the medium

g Gravitational constant

A0023921

10 Endress+Hauser

Page 11

Deltabar S PMD75, FMD77, FMD78

Q Q

Q ~ Q ~

∆ ∆p p

+ +

– –

p

1

p

1

p

2

p

2

A B

Your benefits

• Selection of the level operating mode which is optimum for your application in the device software

• Volume and mass measurements in any container shapes by means of a freely programmable

characteristic curve

• Choice of diverse level units with automatic unit conversion

• A customized unit can be specified.

• Has a wide range of uses, e.g.

– for level measurement in vessels with pressure overlay

– in the event of foam formation

– in containers with agitators or screen fittings

– in the event of liquid gases

– for standard level measurement

Flow measurement

Flow measurement with Deltabar S and primary device:

Communication protocol

A Orifice plate

B Pitot tube

Q Flow

Δp Differential pressure, Δp = p1 – p

2

Your benefits

• Choice of four flow modes of operation: volume flow, corrected volume flow (European norm

conditions), standard volume flow (American standard conditions) and mass flow

• Choice of diverse flow units with automatic unit conversion

• A customized unit can be specified.

• Low flow cut off: when activated, this function suppresses small flows which can lead to large

fluctuations in the measured value.

• Contains two totalizers as standard. One totalizer can be reset to zero.

• The totalizing mode and unit can be individually set for each totalizer. This allows independent

daily and annual quantity totalizing.

• 4 to 20 mA with HART communication protocol

• PROFIBUS PA

– The Endress+Hauser devices meet the requirements of the FISCO model.

– Due to a low current consumption of 13 mA ± 1 mA, the following number of devices can be

operated on one bus segment if installing as per FISCO: up to 7 devices for Ex ia, CSA IS and FM

IS applications or up to 27 devices for all other applications e.g. in non-hazardous areas, Ex nA

etc. Further information on PROFIBUS PA can be found in Operating Instructions BA00034S

"PROFIBUS DP/PA: Guidelines for planning and commissioning" and in the PNO Guideline.

• FOUNDATION Fieldbus

– The Endress+Hauser devices meet the requirements of the FISCO model.

– Due to a low current consumption of 15.5 mA ± 1 mA, the following number of devices can be

operated on one bus segment if installing as per FISCO: up to 6 devices for Ex ia, CSA IS and FM

IS applications or up to 24 devices for all other applications e.g. in non-hazardous areas, Ex nA

etc. Further information on FOUNDATION Fieldbus, such as requirements for bus system

components, can be found in Operating Instructions BA00013S "FOUNDATION Fieldbus

Overview".

A0023920

Endress+Hauser 11

Page 12

Input

Measured variable Measured process variables

Differential pressure, pressure

Calculated process variables

• Flow rate (volume flow or mass flow)

• Absolute pressure, gauge pressure

• Level (level, volume or mass)

Measuring range

Deltabar S PMD75, FMD77, FMD78

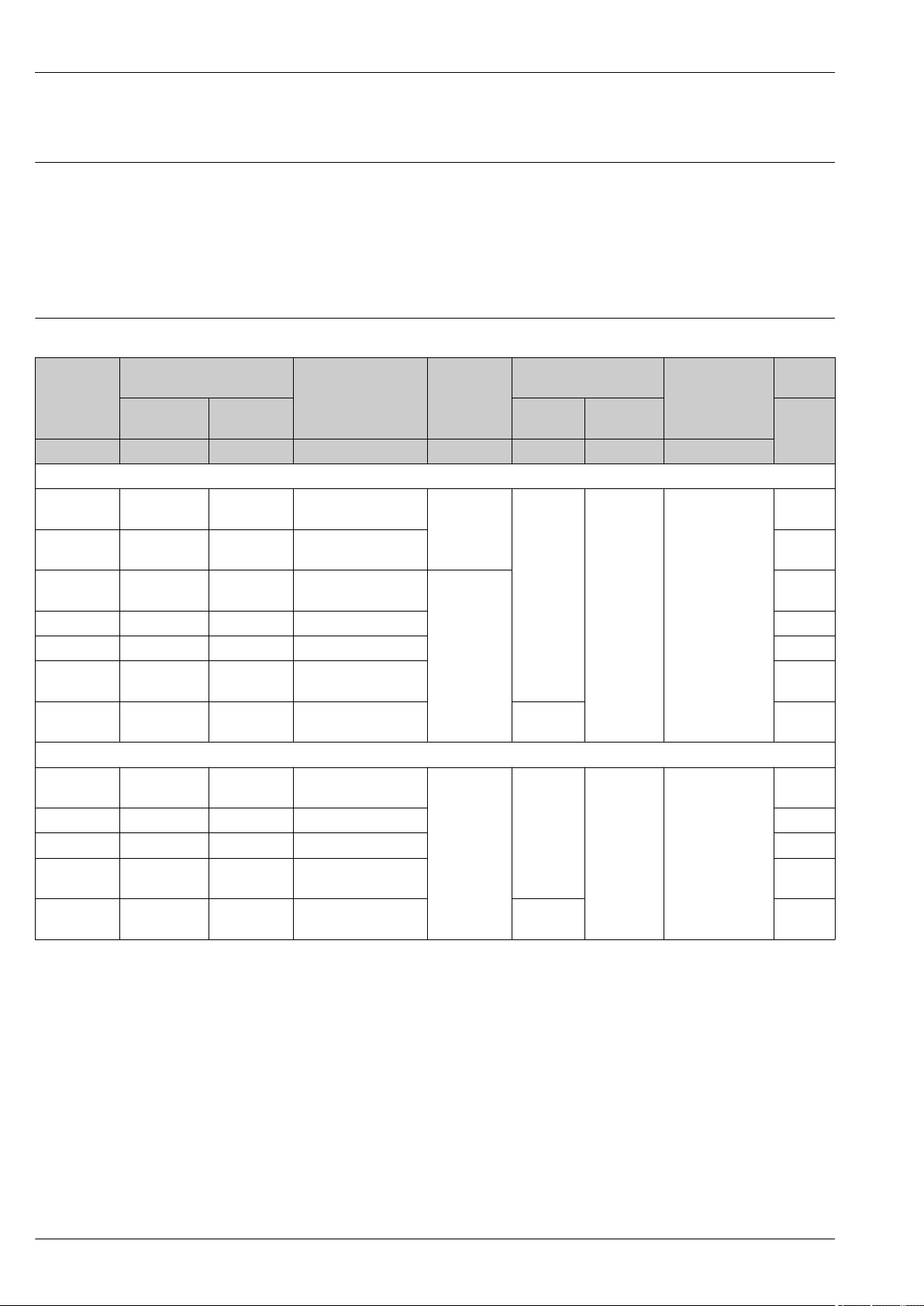

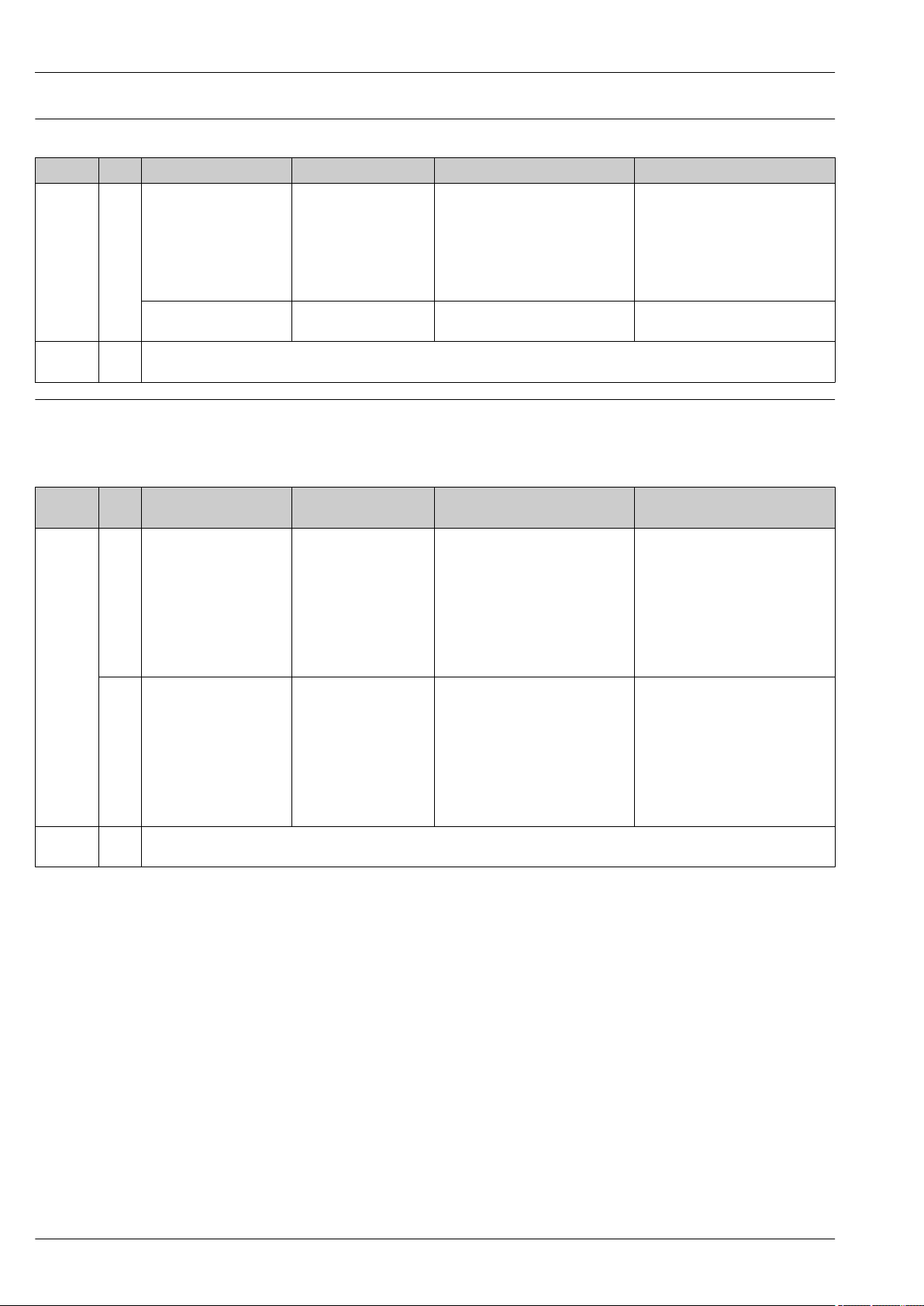

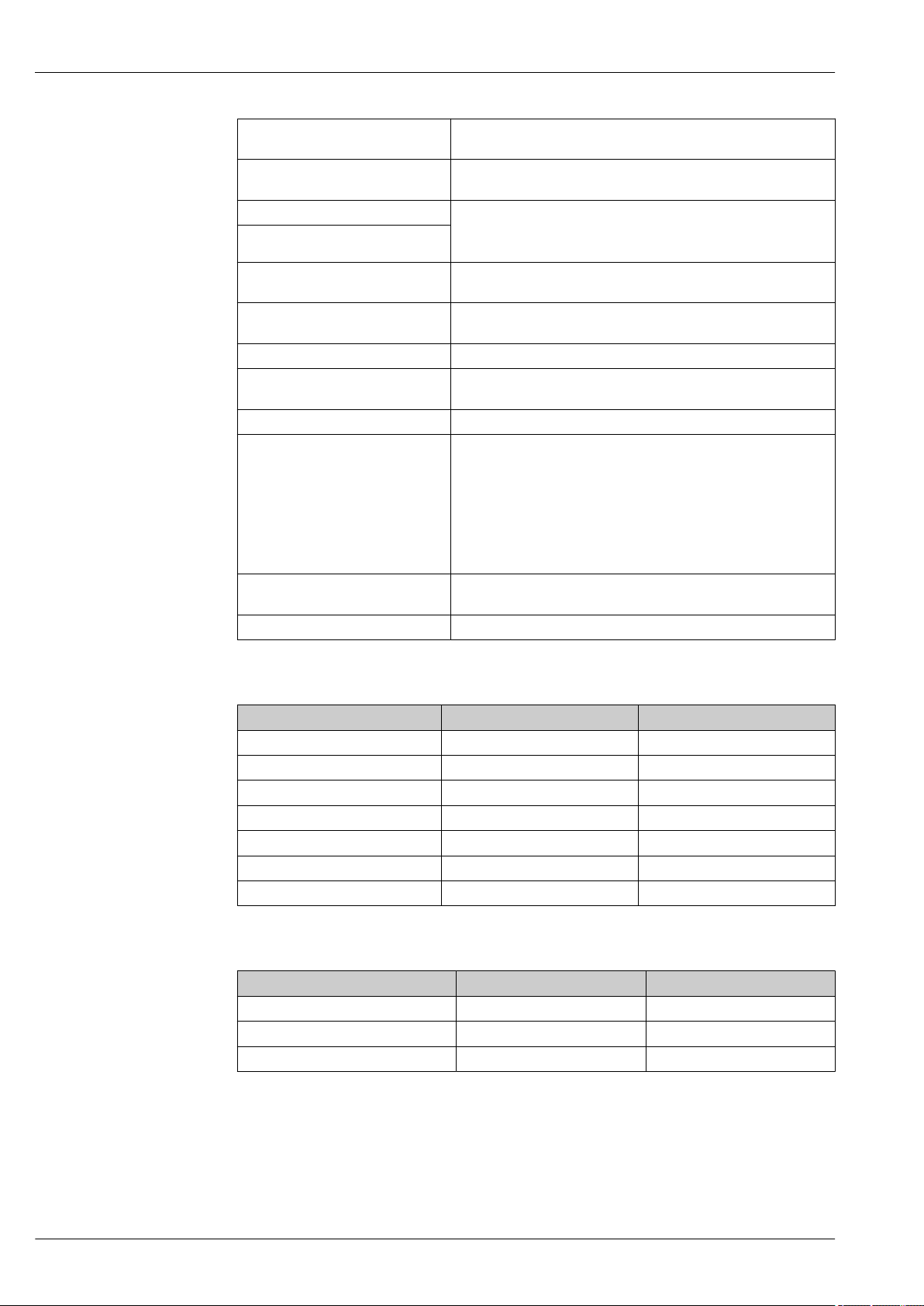

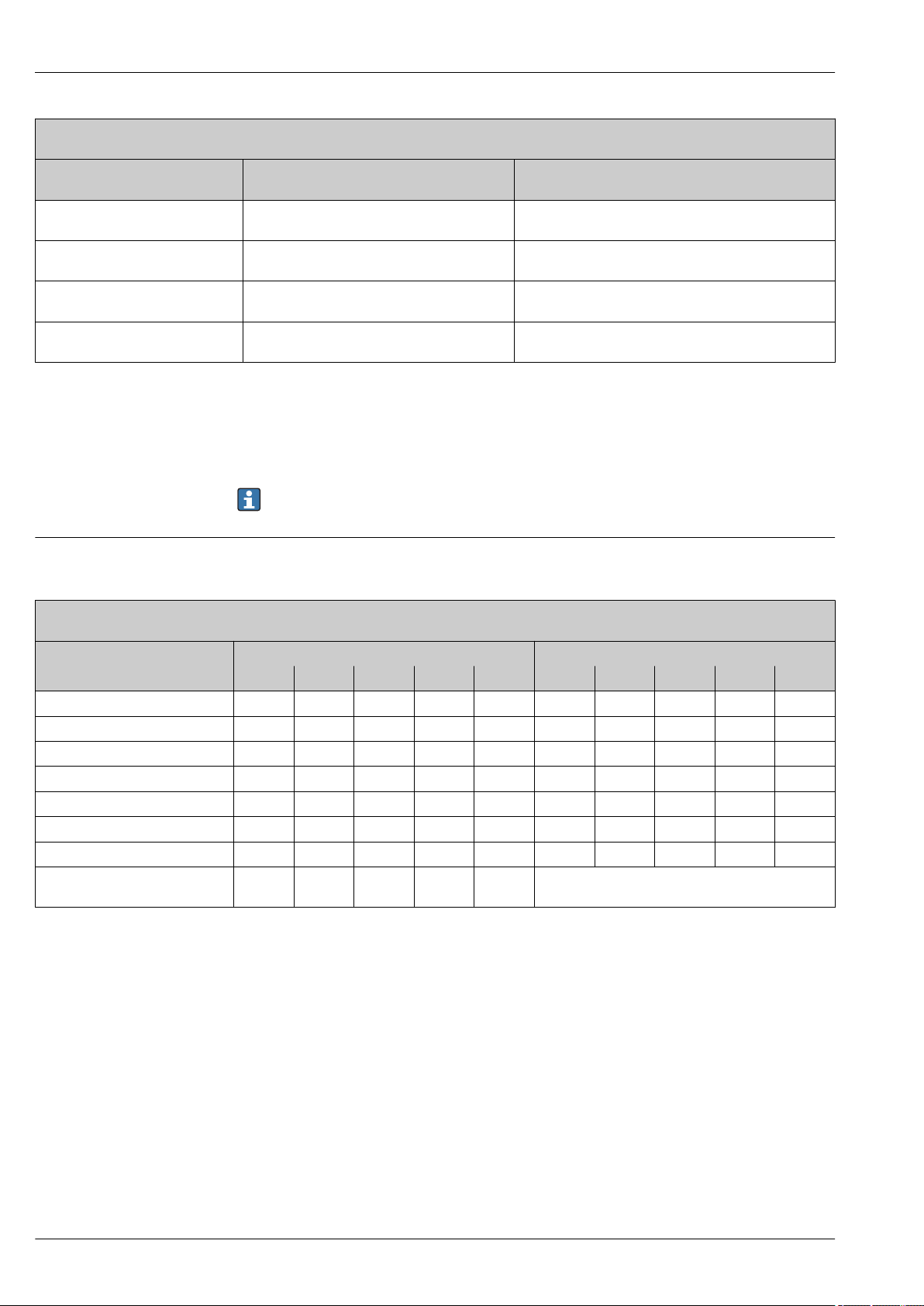

Sensor Maximum sensor measuring

range

lower (LRL) upper (URL) on one side on both

[mbar (psi)] [mbar (psi)] [mbar (psi)] [mbar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [mbar

Smallest calibratable

1)

span

MWP OPL remains stable

for a minimum of

sides

operating

pressure

abs

2)

(psi

abs

Option

PN 160

)]

FMD77, FMD78, PMD75: Option PN 160 / 16 MPa / 2400 psi

10 (0.15)

–10 (-0.15) +10 (+0.15) 0.25 (0.00375) 160 (2400) 160 (2400) 240 (3600)

7B

(PMD75 only)

30 (0.45)

–30 (-0.45) +30 (+0.45) 0.3 (0.0045) 7C

(PMD75 only)

100 (1.5) –100 (-1.5) +100 (+1.5) 1/5

(0.015/0.075)

4)

160 (2400)

500 (7.5) –500 (-7.5) +500 (+7.5) 5 (0.075) 7F

5)

7D

0.1 (0.0015)

3000 (45) –3000 (-45) +3000 (+45) 30 (0.45) 7H

16000 (240) –16000

(-240)

40000 (600) –40000

(-600)

+16000

(+240)

+40000

(+600)

160 (2.4) 7L

400 (6) "+" side

6)

:

7M

160 (2400)

PMD75: Option PN 420 / 42 MPa / 6300 psi

100 (1.5) –100 (-1.5) +100 (+1.5) 1/5

(0.015/0.075)

4)

420 (6300)

5)

420 (6300) 630 (9450)

8D

500 (7.5) –500 (-7.5) +500 (+7.5) 5 (0.075) 8F

3000 (45) –3000 (-45) +3000 (+45) 30 (0.45) 8H

16000 (240) –16000

(-240)

40000 (600) –40000

(-600)

+16000

(+240)

+40000

(+600)

160 (2.4) 8L

400 (6) "+" side

6)

:

420 (6300)

0.1 (0.0015)

8M

3)

1) Turn down > 100:1 on request

2) The minimum operating pressure indicated in the table applies to silicone oil under reference operating conditions. Min. operating pressure at

85 °C (185 °F) for silicone oil: up to 10 mbar

(0.15 psi

abs

). FMD77 and FMD78: Min. operating pressure: 50 mbar

abs

(0.75 psi

abs

; observe also

abs)

the pressure and temperature application limits of the selected filling oil → 97. For vacuum applications, follow the installation

instructions→ 102.

3) Product Configurator, order code for "Nominal range; PN"

4) Smallest calibratable span for the PMD75: 1 mbar (0.015 psi); Smallest calibratable span for the FMD77 and FMD78: 5 mbar (0.075 psi)

5) All PMD75 process connections are CRN-approved. If O-rings are used, the MWP is 315 bar (4 725 psi); if PTFE and CU seals are used, the MWP

is 120 bar (1 800 psi).

6) "–" side: 100 bar (1 500 psi)

12 Endress+Hauser

Page 13

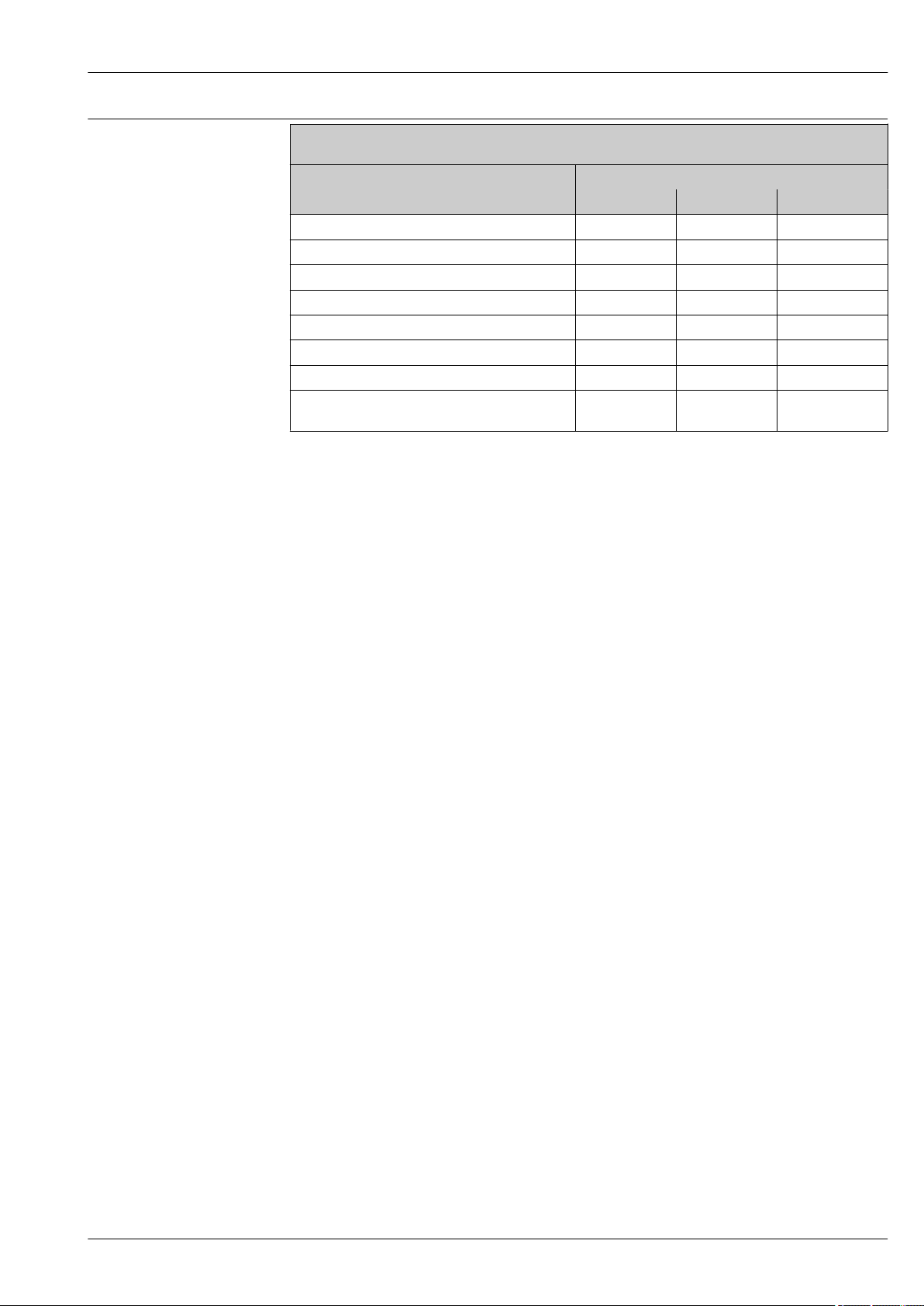

Deltabar S PMD75, FMD77, FMD78

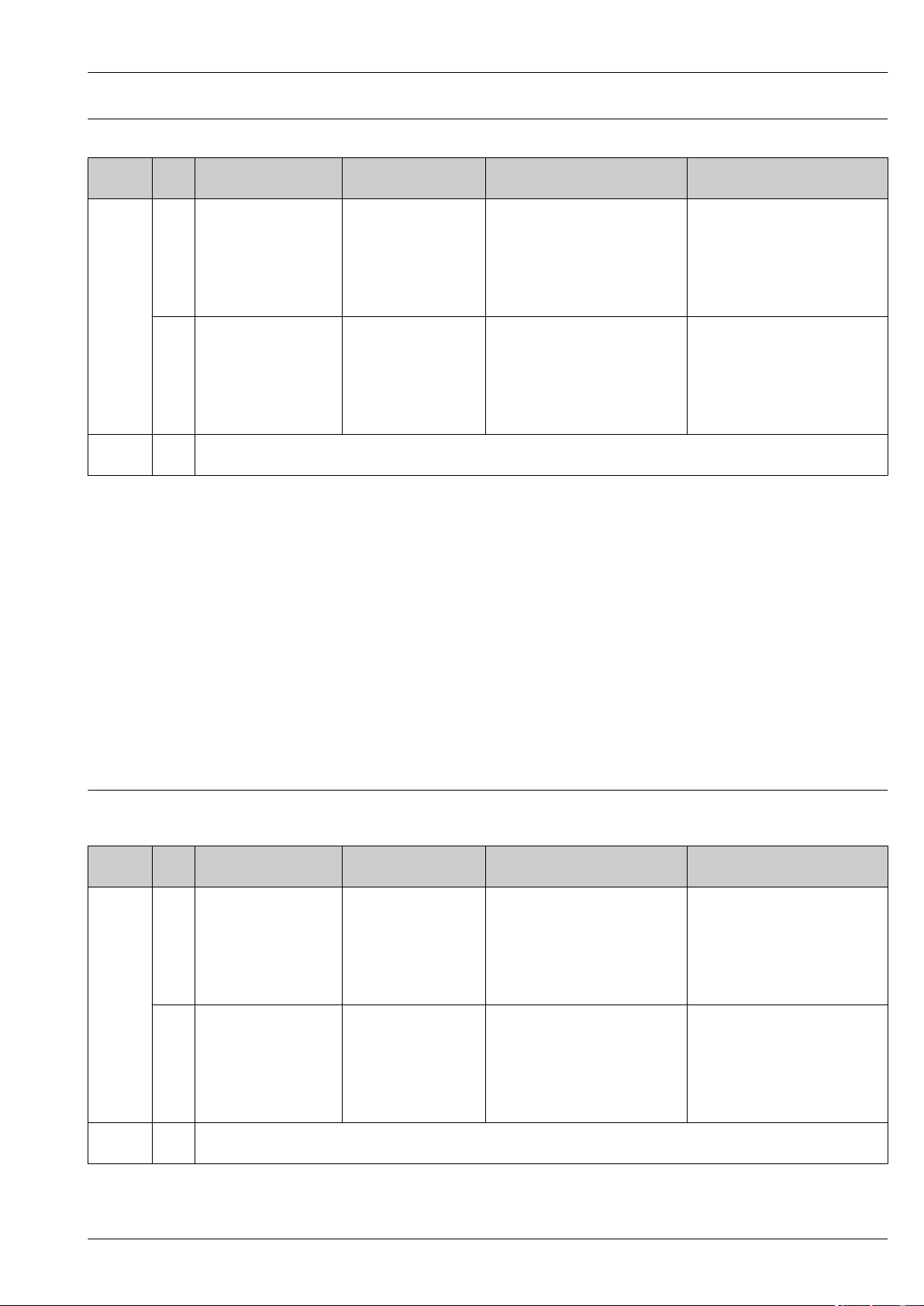

Sensor Maximum sensor measuring

range

lower (LRL) upper (URL) on one side on both

Smallest

calibratable span

MWP OPL remains stable for a

minimum of

operating pressure

Option

1)

sides

bar (psi) bar (psi) bar (psi) bar (psi) bar (psi) bar (psi) mbar

abs

(psi

abs

)

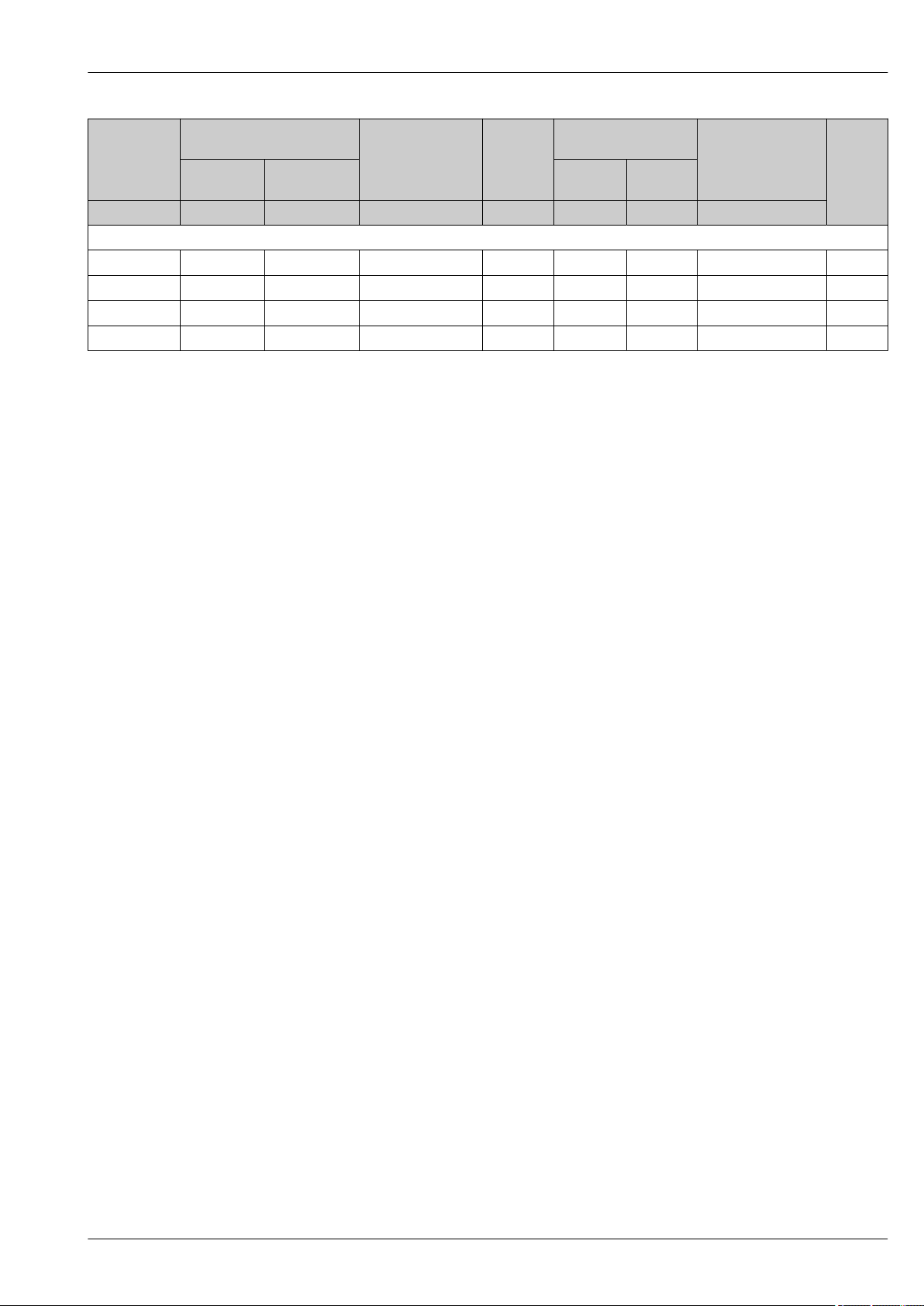

PMD75: optionally available as a gauge or absolute pressure sensor

160 (2400) rel -1 (-15) 160 (2400) 40 (600) 160 (2400) 240 (3600) -

160 (2400) abs 0 160 (2400) 4 (60) 160 (2400) 240 (3600) -

250 (3750) rel -1 (-15) 250 (3750) 40 (600) 250 (3750) 375 (5625) -

250 (3750) abs 0 250 (3750) 4 (60) 250 (3750) 375 (5625) -

3)

3)

3)

3)

10 7Q

10 7V

10 7R

10 7W

1) The minimum operating pressure indicated in the table applies to silicone oil under reference operating conditions. Min. operating pressure at

85 °C (185 °F) for silicone oil: up to 10 mbar

(0.15 psi

abs

abs

).

2) Product Configurator, order code for "Nominal range; PN"

3) Available only with blind flange on LP side.

2)

Endress+Hauser 13

Page 14

Output

on on

off off

damp.

damp.

Display Display

Sensor Sensor

HART HART

R R

FIELD COMMUNICATION PROTOCOL FIELD COMMUNICATION PROTOCOL

SW /min

SW /min

E

+

–

E

+

–

Deltabar S PMD75, FMD77, FMD78

Output Signal

• 4 to 20 mA with superimposed digital communication protocol HART, 2-wire

• Digital communication signal PROFIBUS PA (Profile 3.0), 2-wire

– Signal coding: Manchester Bus Powered (MBP): Manchester II

– Transmission rate: 31.25 KBit/s voltage mode

• Digital communication signal FOUNDATION Fieldbus, 2-wire

– Signal coding: Manchester Bus Powered (MBP): Manchester II

– Transmission rate: 31.25 KBit/s voltage mode

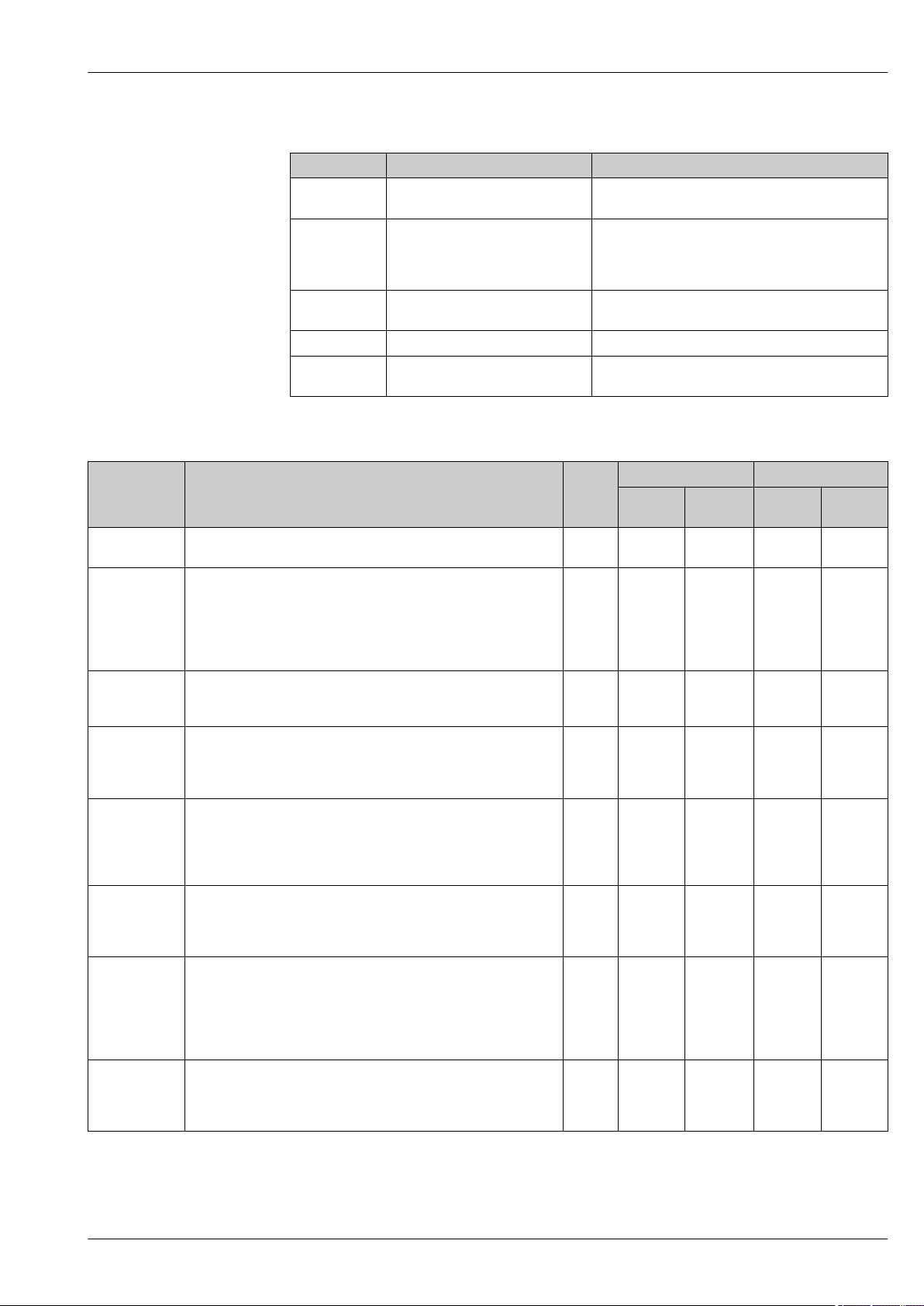

Output Internal + LCD External + LCD Internal

1)

Option

4 to 20mA HART B A C

4 to 20mA HART, Li=0 E D F

PROFIBUS PA N M O

FOUNDATION Fieldbus Q P R

1) Product Configurator, order code for "Display, operation: "

Signal range 4 to 20 mA

3.8 mA to 20.5 mA

A0021280

Signal on alarm 4 to 20 mA HART

As per NAMUR NE43.

• Max. alarm: can be set from 21 to 23 mA (factory setting: 22 mA)

• Hold measured value: last measured value is held

• Min. alarm: 3.6 mA

PROFIBUS PA

As per NAMUR NE43.

Can be set in the Analog Input Block.

Options:

• Last Valid Out Value (factory setting)

• Fail Safe Value

• Status bad

FOUNDATION Fieldbus

As per NAMUR NE43.

Can be set in the Analog Input Block.

Options:

• Last Good Value

• Fail Safe Value (factory setting)

• Wrong Value

Load 4 to 20 mA HART

In order to guarantee sufficient terminal voltage in two-wire devices, a maximum load resistance R

(including line resistance) must not be exceeded depending on the supply voltage U0 of the supply

unit. In the following load diagrams, observe the position of the jumper and the explosion protection:

14 Endress+Hauser

Page 15

Deltabar S PMD75, FMD77, FMD78

U – 11.5 V

23 mA

[ ]W

30

20

11.5

40 45

1239

1456

804

369

Test

£

B

U – 10.5 V

R

L

max

23 mA

£

30

20

10.5

U U

[V] [V]

40 45

1282

1500

847

413

[ ]W

R

L

max

Test

3

A

1

2

1

2

R

L

max

3

R

L

max

I

63 %

100 %

t

t1t

2

90 %

t

3

A Jumper for 4 to 20 mA test signal set to "Non-test" position

B Jumper for 4 to 20 mA test signal set to "Test" position

1 Power supply 10.5 (11.5) to 30 V DC for 1/2 G Ex ia, 1GD Ex ia, 1/2 GD Ex ia, FM IS, CSA IS, IECEx ia, NEPSI

2 Power supply 10.5 (11.5) to 45 V DC for devices for non-hazardous areas, 1/2 D, 1/3 D, 2 G Ex d, 3 G Ex nA,

3 R

U Supply voltage

Ex ia

FM XP, FM DIP, FM NI, CSA XP, CSA dust ignition-proof, NEPSI Ex d

maximum load resistance

Lmax

A0019988

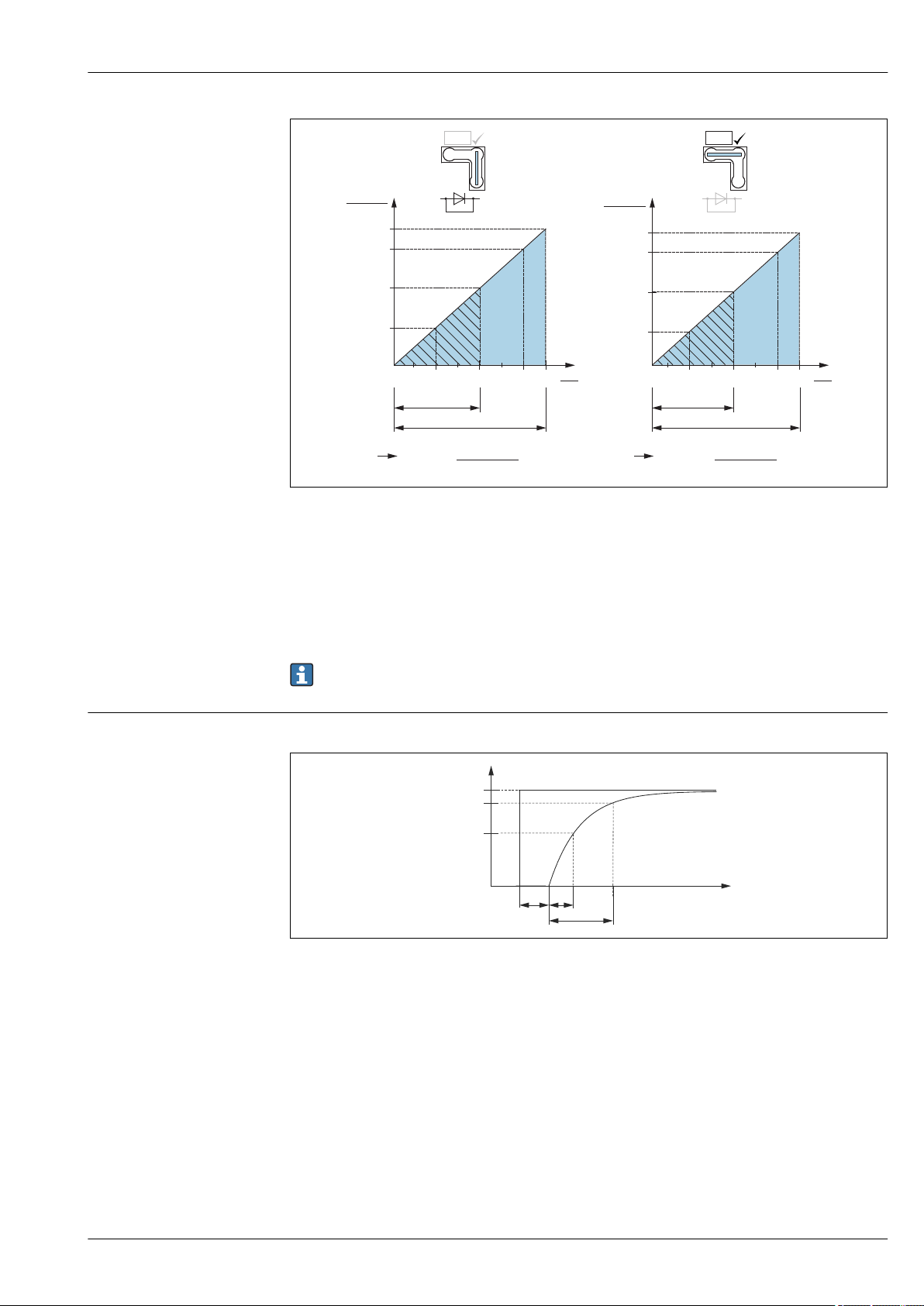

Dead time, time constant

When operating via a handheld terminal or via a PC with an operating program, a minimum

communication resistance of 250 Ω must be taken into account.

Presentation of the dead time and the time constant:

A0019786

Endress+Hauser 15

Page 16

Deltabar S PMD75, FMD77, FMD78

Dynamic behavior, current output

Type Measuring cell Dead time (t1) [ms] Time constant T63 (t2) [ms] Time constant T90 (t3) [ms]

PMD75 max. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

• 160 bar (2 400 psi)

• 250 bar (3 750 psi)

FMD77,

FMD78

max. Dependent on the diaphragm seal

Dynamic behavior Digital output (HART electronics)

A typical burst rate of 300 ms results in the following behavior:

45 • 450

• 450

• 60

• 45

• 40

• 60

• 60

50 40 90

• 1040

• 1040

• 138

• 104

• 92

• 138

• 138

Type Measuring cell Dead time (t1) [ms] Dead time (t1) [ms] +

Time constant T63 (t2) [ms]

PMD75 min. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

• 160 bar (2 400 psi)

• 250 bar (3 750 psi)

max. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

• 160 bar (2 400 psi)

• 250 bar (3 750 psi)

FMD77,

FMD78

max. Dependent on the diaphragm seal

205 • 655

• 655

• 265

• 250

• 245

• 265

• 265

• 295

• 295

1005 • 1455

• 1455

• 1065

• 1050

• 1045

• 1065

• 1065

• 1095

• 1095

Dead time (t1) [ms] +

Time constant T90 (t3) [ms]

• 1200

• 1200

• 298

• 264

• 252

• 298

• 298

• 300

• 300

• 2000

• 2000

• 1098

• 1064

• 1052

• 1098

• 1098

• 1100

• 1100

Reading cycle

• Acyclic: max. 3/s, typically 1/s (depending on command # and number of preambles)

• Cyclic (burst): max. 3/s, typically 2/s

The device commands the BURST MODE functionality for cyclical value transmission via the HART

communication protocol.

Cycle time (update time)

Cyclic (burst): min. 300 ms

Response time

• Acyclic: min. 330 ms, typically 590 ms (depending on command # and number of preambles)

• Cyclic (burst): min. 160 ms, typically 350 ms (depending on command # and number of

preambles)

16 Endress+Hauser

Page 17

Deltabar S PMD75, FMD77, FMD78

Dynamic behavior

A typical PLC cycle time of 1 s results in the following behavior:

PROFIBUS PA

Type Measuring cell Dead time (t1) [ms] Dead time (t1) [ms] +

Time constant T63 (t2) [ms]

PMD75 min. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

max. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

FMD77,

FMD78

max. Dependent on the diaphragm seal

80 • 530

• 530

• 140

• 125

• 120

• 140

• 140

1280 • 1730

• 1730

• 1340

• 1325

• 1320

• 1340

• 1340

Reading cycle (PLC)

• Acyclic: Typically 25/s

• Cyclic: Typically 30/s (depending on the number and type of the function blocks used in the

closed-control loop)

Dead time (t1) [ms] +

Time constant T90 (t3) [ms]

• 1075

• 1075

• 173

• 139

• 127

• 173

• 173

• 2275

• 2275

• 1373

• 1339

• 1327

• 1373

• 1373

Cycle time (update time)

min. 200 ms

The cycle time in a bus segment in cyclic data communication depends on the number of devices, on

the segment coupler used and on the internal PLC cycle time. A new measured value can be

determined up to five times a second.

Response time

• Acyclic: Approx. 60 ms to 70 ms (depending on Min. Slave Interval)

• Cyclic: Approx. 10 ms to 13 ms (depending on Min. Slave Interval)

Dynamic behavior FOUNDATION Fieldbus

Type Measuring cell Dead time (t1) [ms] Dead time (t1) [ms] +

PMD75 min. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

max. • 10 mbar (0.15 psi)

• 30 mbar (0.45 psi)

• 100 mbar (1.5 psi)

• 500 mbar (7.5 psi)

• 3 bar (45 psi)

• 16 bar (240 psi)

• 40 bar (600 psi)

FMD77,

FMD78

max. Dependent on the diaphragm seal

A typical configuration for the macro cycle time (host system) of 1 s results in the following

behavior:

Time constant T63 (t2) [ms]

90 • 540

• 540

• 150

• 135

• 130

• 150

• 150

1090 • 1540

• 1540

• 1150

• 1135

• 1130

• 1150

• 1150

Dead time (t1) [ms] +

Time constant T90 (t3) [ms]

• 1085

• 1085

• 183

• 149

• 137

• 183

• 183

• 2085

• 2085

• 1183

• 1149

• 1137

• 1183

• 1183

Endress+Hauser 17

Page 18

Deltabar S PMD75, FMD77, FMD78

Reading cycle

• Acyclic: Typically 10/s

• Cyclic: max. 10/s (dependent on the number and type of function blocks used in a closed-control

loop)

Cycle time (update time)

Cyclic: Min. 100 ms

Response time

• Acyclic: Typically 100 ms (for standard bus parameter settings)

• Cyclic: max. 20 ms (for standard bus parameter settings)

Damping

Alarm current

Firmware version

A damping affects all outputs (output signal, display):

• via local display, handheld terminal or PC with operating program, continuous from 0 to 999 s

• Also for HART and PROFIBUS PA: Via DIP switch on the electronic insert,

switch position "on" = set value and "off"

• Factory setting: 2 s

Designation Option

Min alarm current J

HART burst mode PV J

Min alarm current + HART burst mode PV J

1) Product Configurator, "Additional options 1" and "Additional options 2" ordering feature

Designation Option

02.20.zz, HART 7, DevRev22 72

02.11.zz, HART 5, DevRev21 73

04.00.zz, FF, DevRev07 74

04.01.zz, PROFIBUS PA, DevRev03 75

02.10.zz, HART 5, DevRev21 76

03.00.zz, FF, DevRev06 77

04.00.zz, PROFIBUS PA 78

02.30.zz, HART 7 In preparation

1)

1)

1) Product Configurator, order code for "Firmware version"

HART protocol-specific data

Manufacturer ID 17 (11 hex)

Device type code 23 (17 hex)

Device revision • 21 (15 hex) - SW version 02.1y.zz - HART specification 5

• 22 (16 hex) - SW version 02.2y.zz - HART specification 7

HART specification • 5

• 7

DD revision • 4 (Russian in language selection) for device revision 21

• 3 (Dutch in language selection) for device revision 21

• 1 for device revision 22

Device description files (DTM, DD) Information and files at:

• www.endress.com

• www.fieldcommgroup.org

HART load Min. 250 Ω

18 Endress+Hauser

Page 19

Deltabar S PMD75, FMD77, FMD78

HART device variables The measured values are assigned to the device variables as follows:

Supported functions • Burst mode

Measured values for PV (primary variable)

• Pressure

• Flow

• Level

• Tank content

Measured values for SV, TV (second and third variable)

• Pressure

• Totalizer

Measured values for QV (fourth variable)

Temperature

• Additional transmitter status

• Device locking

• Alternative operating modes

PROFIBUS PA protocolspecific data

Manufacturer ID 17 (11 hex)

Identification number 1542 hex

Profile version 3.0

• SW version 03.00.zz

• SW version 04.00.zz

3.02

SW version 04.01.zz ( device revision 3)

Compatibility with SW version 03.00.zz and higher.

GSD revision • 4 (SW version 3.00.zz and 4.00.zz)

• 5 (device revision 3)

DD revision • 1 (SW version 3.00.zz and 4.00.zz)

• 1 (device revision 3)

GSD file Information and files at:

DD files

Output values Measured value for PV (via Analog Input Function Block)

Input values Input value sent from PLC, can be shown on display

Supported functions • Identification & maintenance Simplest device identifier on the

• www.endress.com

• www.profibus.org

• Pressure

• Level

• Flow

• Tank content

Measured value for SV

• Pressure

• Temperature

Measured value for QV

Totalizer

control system and nameplate

• Condensed status (only with Profile Version 3.02)

• Automatic ID number adjustment and switchable to the following ID

numbers (only with Profile Version 3.02):

– 9700: Profile-specific transmitter identification number with the

"Classic" or "Condensed" status".

– 1504: Compatibility mode for the old Deltabar S generation

(FMD230, FMD630, FMD633, PMD230, PMD235).

– 1542: Identification number of the new Deltabar S generation

( FMD77, FMD78, PMD75).

• Device locking: The device can be locked by hardware or software.

FOUNDATION Fieldbus protocol-specific data

Manufacturer ID 452B48 hex

Device type 1009 hex

Device revision • 6 - SW version 03.00.zz

• 7 - SW version 04.00.zz (FF-912)

Endress+Hauser 19

Page 20

Deltabar S PMD75, FMD77, FMD78

DD revision • 3 (device revision 6)

• 2 (device revision 7)

CFF revision • 4 (device revision 6)

• 1 (device revision 7)

DD files Information and files at:

CFF files

Device tester version (ITK version) • 5.0 (device revision 6)

Number of ITK test campaign • IT054700 (Device Revision 6)

Link Master (LAS) capable Yes

Choice of "Link Master" and "Basic

Device"

Node address Factory setting: 247 (F7 hex)

Supported functions Field diagnostics profile (only with FF912)

Number of VCRs • 44 (device revision 6)

Number of link objects in VFD 50

• www.endress.com

• www.fieldcommgroup.org

• 6.01 (device revision 7)

• IT085400 (Device Revision 7)

Yes, factory setting is Basic Device

The following methods are supported:

• Restart

• Configure error as warning or alarm

• HistoROM

• Peakhold

• Alarm info

• Sensor trim

• 24 (device revision 7)

Virtual communication references (VCRs)

Device revision 6 Device revision 7

Permanent entries 44 1

Client VCRs 0 0

Server VCRs 5 10

Source VCRs 8 43

Sink VCRs 0 0

Subscriber VCRs 12 43

Publisher VCRs 19 43

Link settings

Device revision 6 Device revision 7

Slot time 4 4

Min. Inter PDU delay 12 10

Max. response delay 10 10

20 Endress+Hauser

Page 21

Deltabar S PMD75, FMD77, FMD78

Transducer Blocks

Block Content Output values

TRD1 Block Contains all parameters related to

Service Block Contains service information • Pressure after damping (channel 3)

Dp Flow Block Contains flow and totalizer

Diagnostic Block Contains diagnostic information Error code via DI channels (channel 0 to 16)

Display Block Contains parameters to configure

Function blocks

the measurement

parameter

the onsite display

• Pressure, flow or level (channel 1)

• Process temperature (channel 2)

• Pressure peakhold indicator (channel 4)

• Counter for max. pressure transgressions (channel

5)

Totalizer 1 (channel 6)

No output values

Block Content Number

blocks

Resource Block This block contains all the data that uniquely identifies the device; it

is an electronic version of a nameplate for the device.

Analog Input

Block 1

Analog Input

Block 2

Analog Input

Block 3

Digital Input

Block

Digital Output

Block

PID Block This block is used as a proportional-integral-derivative controller and

Arithmetic

Block

Input Selector

Block

Signal

Characterizer

Block

The AI Block receives the measuring data from the Sensor Block,

(selectable via a channel number) and makes the data available to

other function blocks at its output. Enhancement: Digital outputs for

process alarms, fail safe mode

This block contains the discrete data of the Diagnose Block (selectable

via a channel number 0 to 16) and provides them for other blocks at

the output.

This block converts the discrete input and thus initiates an action

(selectable via a channel number) in the DP Flow Block or in the

Service Block. Channel 1 resets the counter for max. pressure

transgressions.

can be used universally for closed-loop-control in the field. It enables

cascade mode and feedforward control. Input IN can be indicated on

the display. The selection is performed in the Display Block

(DISPLAY_MAIN_LINE_CONTENT).

This block is designed to permit simple use of popular measurement

math functions. The user does not have to know how to write

equations. The math algorithm is selected by name, chosen by the

user for the function to be performed.

The Input Selector Block facilitates the selection of up to four inputs

and generates an output based on the configured action. This block

normally receives its inputs from AI Blocks. The block performs

maximum, minimum, average and ‘first good’ signal selection. Inputs

IN1 to IN4 can be indicated on the display. The selection is performed

in the Display Block (DISPLAY_MAIN_LINE_CONTENT).

The Signal Characterizer Block has two sections, each with an output

that is a non-linear function of the respective input. The non-linear

function is generated by a single look-up table with 21 arbitrary x-y

pairs.

1 enhanced enhanced

3 45 ms 45 ms

1 40 ms 30 ms standard enhanced

1 60 ms 40 ms standard enhanced

1 120 ms 70 ms standard enhanced

1 50 ms 40 ms standard enhanced

1 35 ms 35 ms standard enhanced

1 30 ms 40 ms standard enhanced

Execution time Functionality

Device

Revision 6

Device

Revision 7

(without

trend and

alarm

reports)

Device

Revision 6

enhanced enhanced

Device

Revision 7

Endress+Hauser 21

Page 22

Deltabar S PMD75, FMD77, FMD78

Block Content Number

blocks

Integrator Block The Integrator Block integrates a variable as a function of the time or

accumulates the counts from a Pulse Input Block. The block can be

used as a totalizer that counts up until a reset, or as a batch totalizer

whereby the integrated value is compared against a target value

generated before or during the control routine and generates a binary

signal when the target value is reached.

Analog Alarm

Block

This block contains all process alarm conditions (working like a

comparator) and represents them at the output.

1 35 ms 40 ms standard enhanced

1 35 ms 35 ms standard enhanced

Additional function block information:

Instantiatable function blocks YES YES

Number of additional instantiatable function blocks 9 4

Execution time Functionality

Device

Revision 6

Device

Revision 7

Device

Revision 6

Device

Revision 7

22 Endress+Hauser

Page 23

Deltabar S PMD75, FMD77, FMD78

4... 20mA

Test

Test

Test

4... 20mA Test

1

8

6

7

2

3

4

5

1

4

5

2

3

Power supply

WARNING

L

Electrical safety is compromised by an incorrect connection!

When using the measuring device in hazardous areas, the relevant national standards and

‣

regulations as well as the Safety Instructions or Installation or Control Drawings must also be

observed.→ 113.

All explosion protection data are given in separate documentation which is available upon

‣

request. The Ex documentation is supplied as standard with all Ex devices→ 113.

Devices with integrated overvoltage protection must be grounded→ 26.

‣

Protective circuits against reverse polarity, HF influences and overvoltage peaks are integrated.

‣

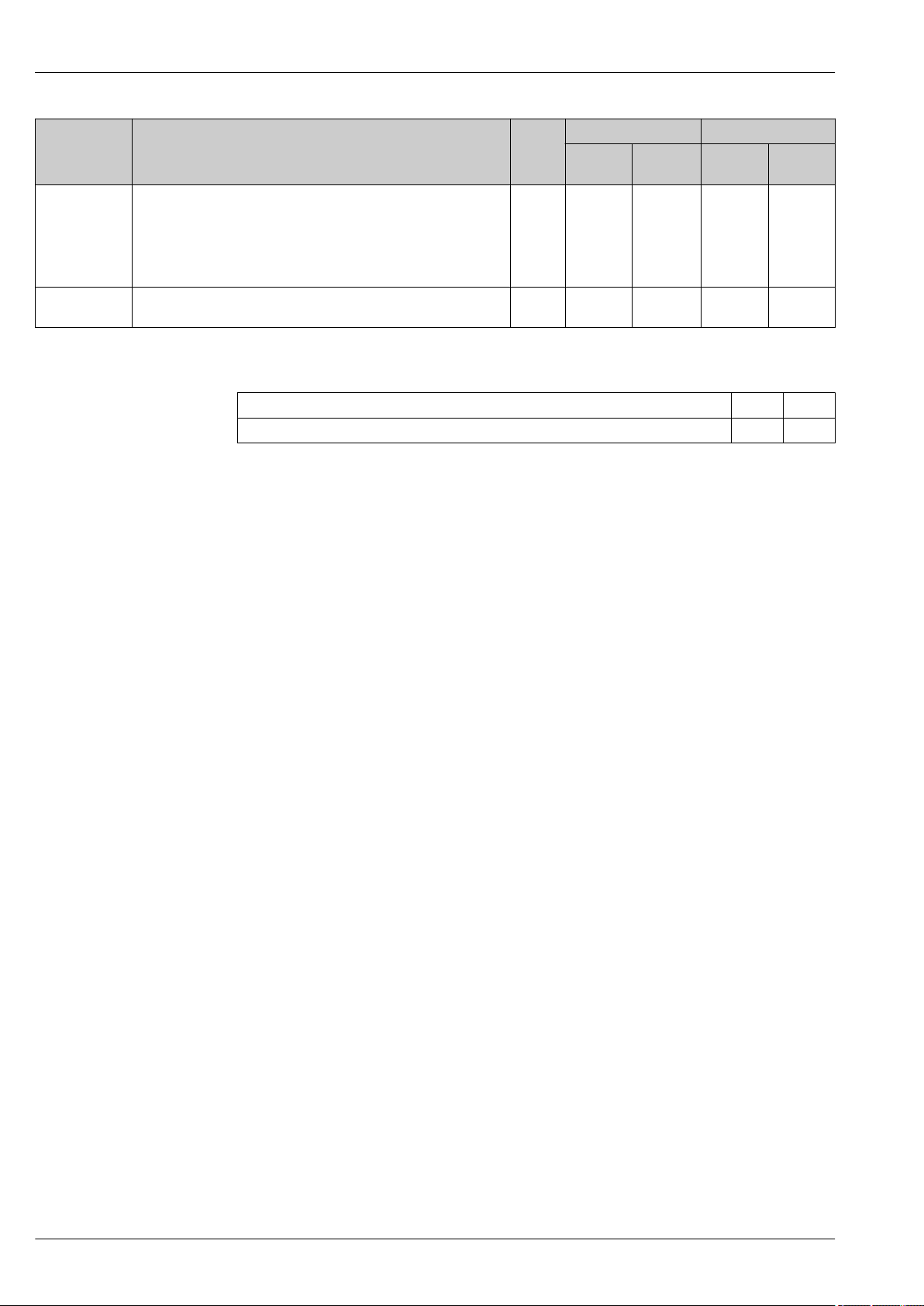

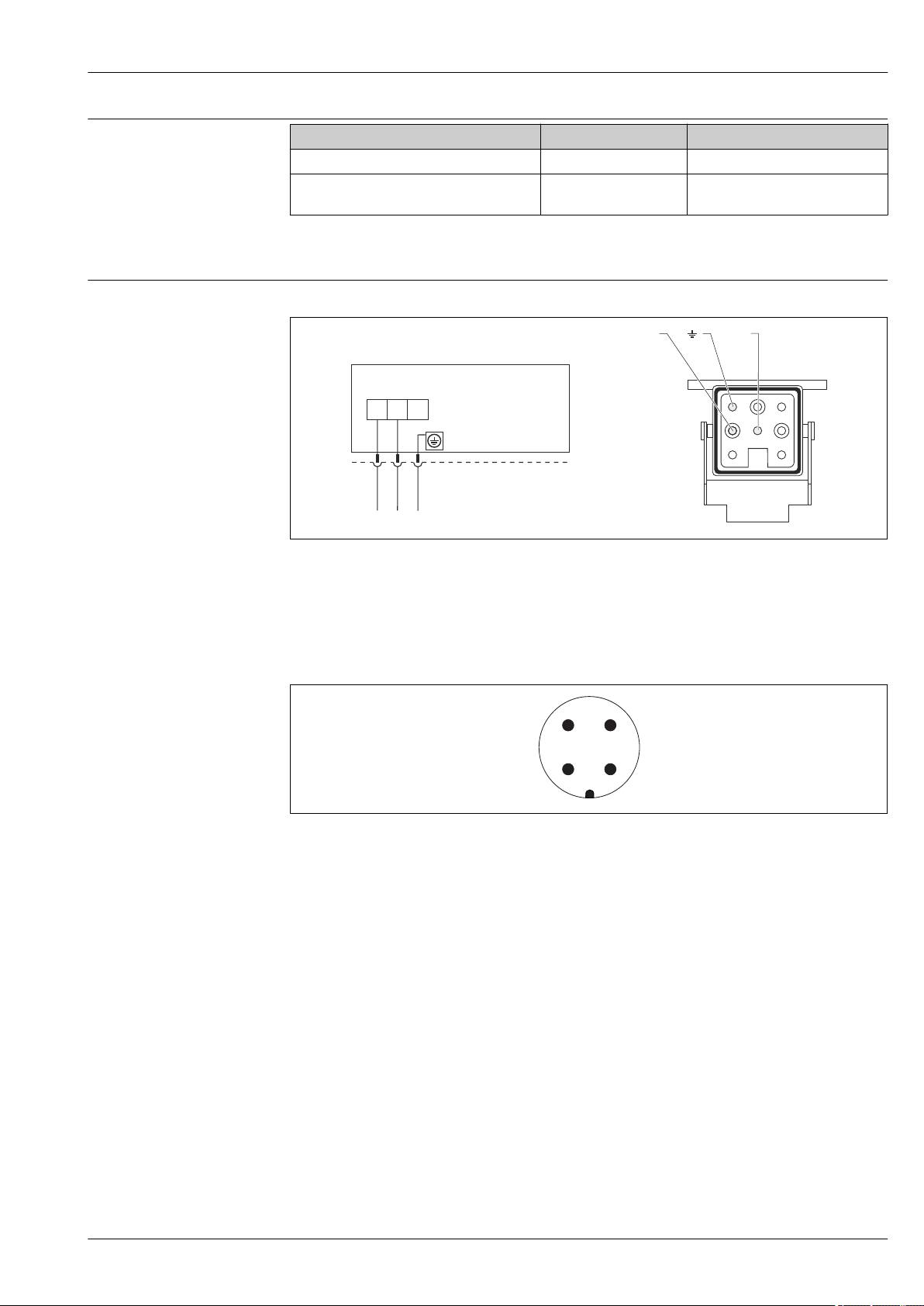

Terminal assignment 4 to 20 mA HART

A0019989

1 Housing

2 Supply voltage

3 4 to 20 mA

4 Devices with integrated overvoltage protection are labeled "OVP" (overvoltage protection) here.

5 External ground terminal

6 4 to 20 mA test signal between positive and test terminal

7 Internal ground terminal

8 Jumper for 4 to 20 mA test signal

PROFIBUS PA and FOUNDATION Fieldbus

A0020158

1 Housing

2 Supply voltage

3 Devices with integrated overvoltage protection are labeled "OVP" (overvoltage protection) here.

4 External ground terminal

5 Internal ground terminal

Endress+Hauser 23

Page 24

Supply voltage 4 to 20 mA HART

Test

Test

Deltabar S PMD75, FMD77, FMD78

Electronic version Jumper for 4 to 20 mA test signal in

"Test" position (delivery status)

Version for nonhazardous area

Intrinsically safe 11.5 to 30 V DC 10.5 to 30 V DC

• Other types of

protection

• Devices without

certificate

11.5 to 45 V DC 10.5 to 45 V DC

11.5 to 45 V DC

(versions with 35 V DC plug-in

connection)

Jumper for 4 to 20 mA test signal in

"Non-test" position

10.5 to 45 V DC

(versions with 35 V DC plug-in

connection)

Measuring a 4 to 20 mA test signal

Jumper position for test

signal

Description

• Measurement of 4 to 20 mA test signal via the positive and test terminal:

Possible. (Thus, the output current can be measured without interruption via

the diode.)

• Delivery status

• Minimum supply voltage: 11.5 V DC

A0019992

• Measurement of 4 to 20 mA test signal via positive and test terminal: Not

possible.

• Minimum supply voltage: 10.5 V DC

PROFIBUS PA

• Version for non-hazardous areas: 9 to 32 V DC

• Ex ia: 10.5 to 30 V DC

FOUNDATION Fieldbus

• Version for non-hazardous areas: 9 to 32 V DC

• Ex ia: 10.5 to 30 V DC

Current consumption

• PROFIBUS PA: 13 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21

• FOUNDATION Fieldbus: 15.5 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause

21

Electrical connection PROFIBUS PA

The digital communication signal is transmitted to the bus via a two-wire connection. The bus also

provides the power supply. For further information on the network structure and grounding, and for

further bus system components such as bus cables, see the relevant documentation, e.g. Operating

Instructions BA00034S "PROFIBUS DP/PA: Guidelines for planning and commissioning" and the

PNO Guideline.

FOUNDATION Fieldbus

The digital communication signal is transmitted to the bus via a two-wire connection. The bus also

provides the power supply. For further information on the network structure and grounding and for

further bus system components such as bus cables, see the relevant documentation, e.g. Operating

Instructions BA00013S "FOUNDATION Fieldbus Overview" and the FOUNDATION Fieldbus Guideline.

A0019993

Terminals

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

• External ground terminal: 0.5 to 4 mm2 (20 to 12 AWG)

24 Endress+Hauser

Page 25

Deltabar S PMD75, FMD77, FMD78

Han7D

–

+

+ –

–

+

1

5

4

6

7

8

2

3

A B

2

1

3

4

Cable entries

Approval Cable gland Clamping area

Standard, II 1/2 G Ex ia, IS Plastic M20x1.5 5 to 10 mm (0.2 to 0.39 in)

ATEX II 1/2 D, II 1/3 D, II 1/2 GD Ex ia,

II 1 GD Ex ia, II 3 G Ex nA

For additional technical data, see section on housing → 49

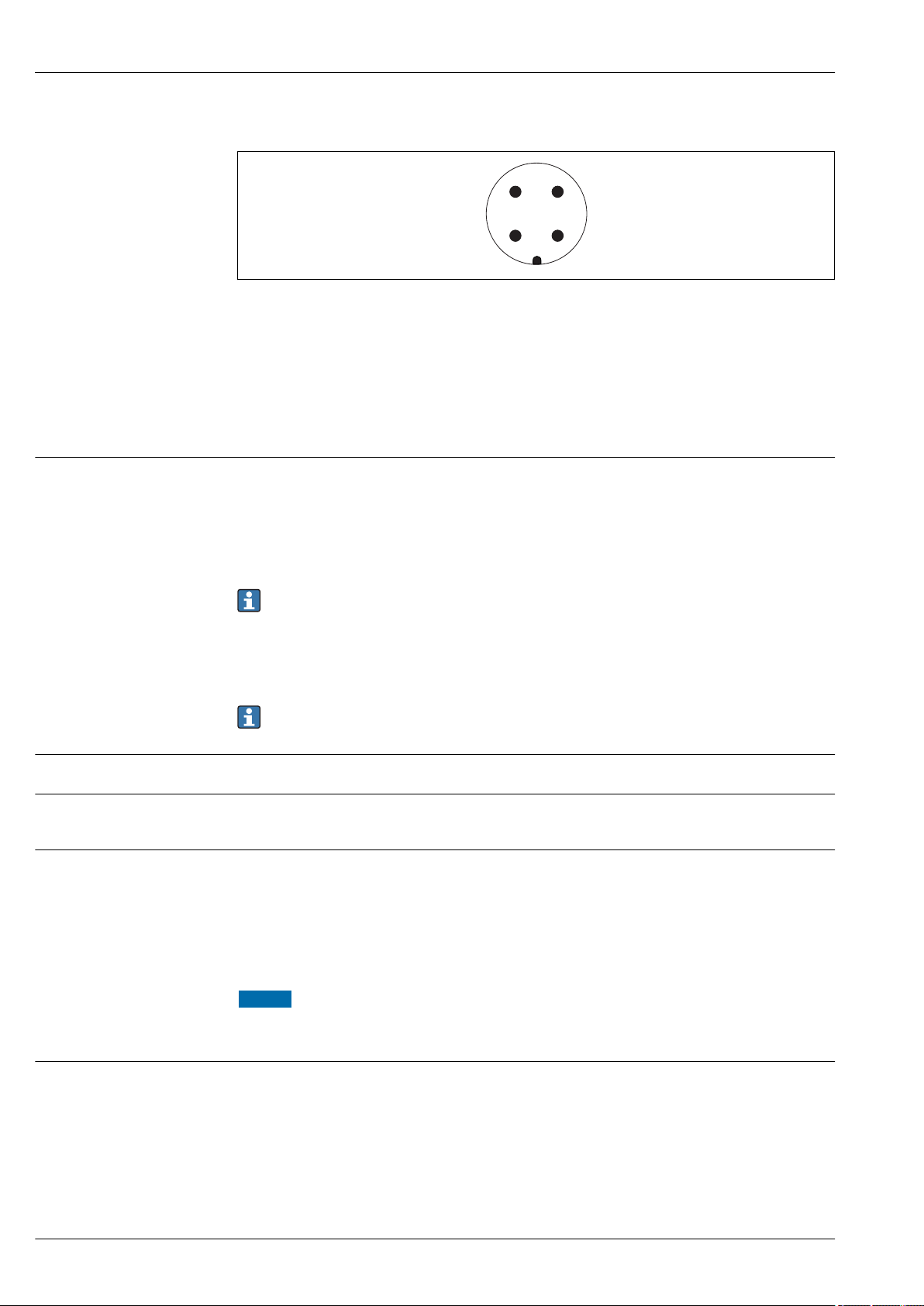

Device plug Devices with Harting plug Han7D

A Electrical connection for devices with Harting plug Han7D

B View of the plug-in connection on the device

Metal M20x1.5 (Ex e) 7 to 10.5 mm (0.28 to 0.41 in)

A0019990

Material: CuZn, gold-plated plug-in jack and plug

Devices with M12 plug

1 Signal +

2 Not assigned

3 Signal –

4 Ground

Endress+Hauser offers the following accessories for devices with an M12 plug:

Plug-in jack M 12x1, straight

• Material: Body PA; coupling nut CuZn, nickel-plated

• Degree of protection (fully locked): IP67

• Order number: 52006263

Plug-in jack M 12x1, elbowed

• Material: Body PBT/PA; coupling nut GD-Zn, nickel-plated

• Degree of protection (fully locked): IP67

• Order number: 71114212

Cable 4x0.34 mm2 (20 AWG) with M12 socket, elbowed, screw plug, length 5 m (16 ft)

• Material: Body PUR; coupling nut CuSn/Ni; cable PVC

• Degree of protection (fully locked): IP67

• Order number: 52010285

A0011175

Endress+Hauser 25

Page 26

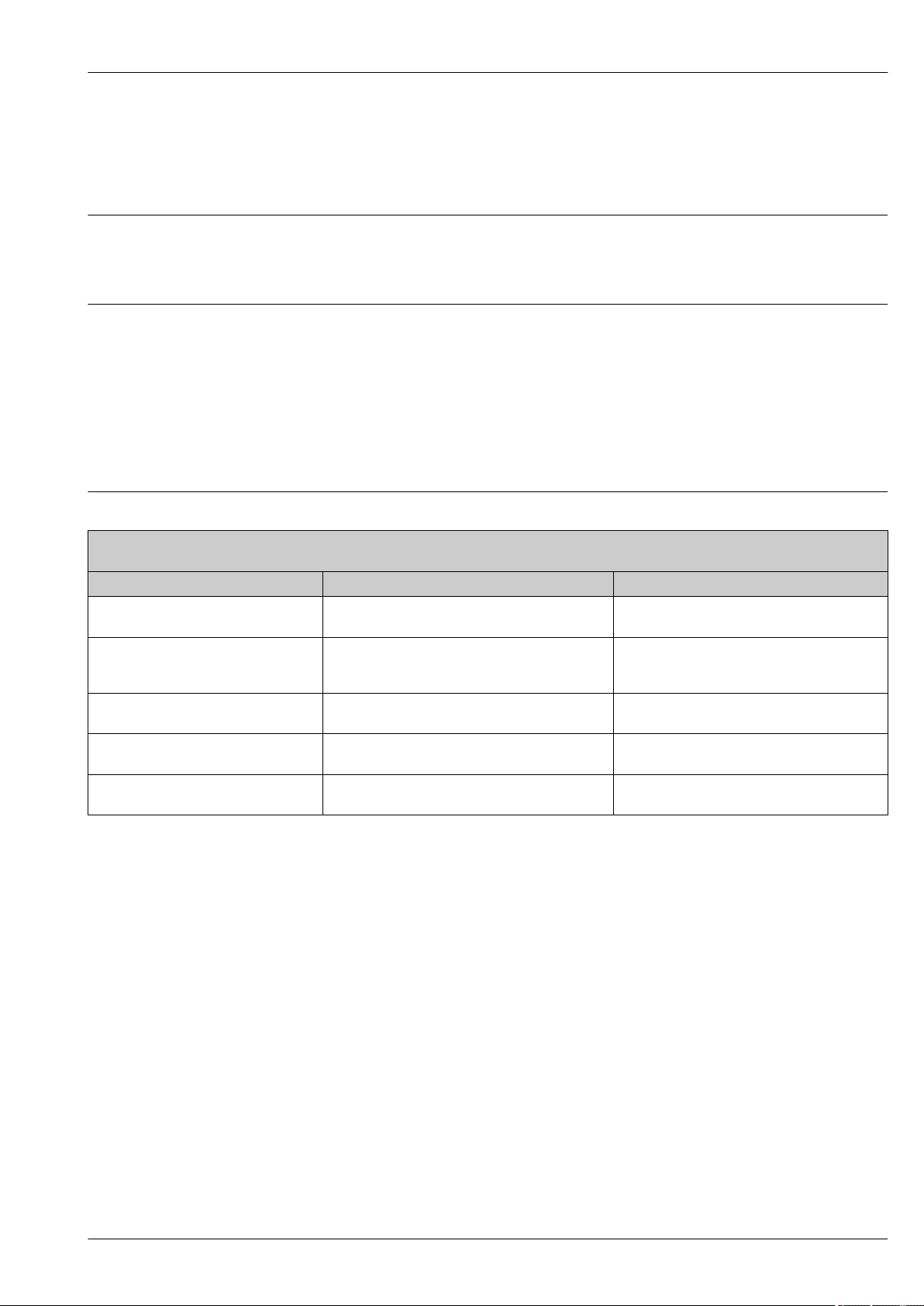

Devices with 7/8" plug

4

2

3

1

1 Signal –

2 Signal +

3 Not assigned

4 Shielding

External thread: 7/8 - 16 UNC

• Material: 316L (1.4401)

• Degree of protection: IP68

Cable specification HART

• Endress+Hauser recommends using shielded, twisted-pair two-wire cables.

• Cable outer diameter: 5 to 9 mm (0.2 to 0.35 in) depending on the cable entry used → 25

Deltabar S PMD75, FMD77, FMD78

A0011176

Start-up current

Residual ripple

Overvoltage protection (optionally for HART, PROFIBUS PA and FOUNDATION Fieldbus)

PROFIBUS PA

Use a twisted, shielded twin-core cable, preferably cable type A.

For further information regarding cable specifications, see the Operating Instructions

BA00034S "PROFIBUS DP/PA: Guidelines for planning and commissioning", the PNO guideline

2.092 "PROFIBUS PA User and Installation Guideline" and IEC 61158-2 (MBP).

FOUNDATION Fieldbus

Use a twisted, shielded twin-core cable, preferably cable type A.

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2 (MBP).

12 mA

Without influence on 4 to 20 mA signal up to ±5% residual ripple within the permitted voltage

range [according to HART hardware specification HCF_SPEC-54 (DIN IEC 60381-1)].

• Overvoltage protection:

– Nominal functioning DC voltage: 600 V

– Nominal discharge current: 10 kA

• Surge current check î = 20 kA satisfied as per DIN EN 60079-14: 8/20 μs

• Arrester AC current check I = 10 A satisfied

Ordering information: Product Configurator, order code for "Additional options 1" or Additional

options 2", option "M"

NOTICE

Device could be destroyed!

Devices with integrated overvoltage protection must be grounded.

‣

Influence of power supply

≤0.0006 % of URL/1 V

26 Endress+Hauser

Page 27

Deltabar S PMD75, FMD77, FMD78

Performance characteristics of differential pressure / pressure transmitter (sensor module + electronics module)

Preamble

The performance characteristic of the dP transmitter refers to "Accuracy of the transmitter". The

factors influencing accuracy can be divided into two groups

• Total performance of transmitter → 28

• Installation dependent influencing factors → 36

Total performance of transmitter

Reference accuracy [E1]

PMD75: Reference accuracy E1 as %

The specifications refer to the calibrated span/Upper Range Value (URV).

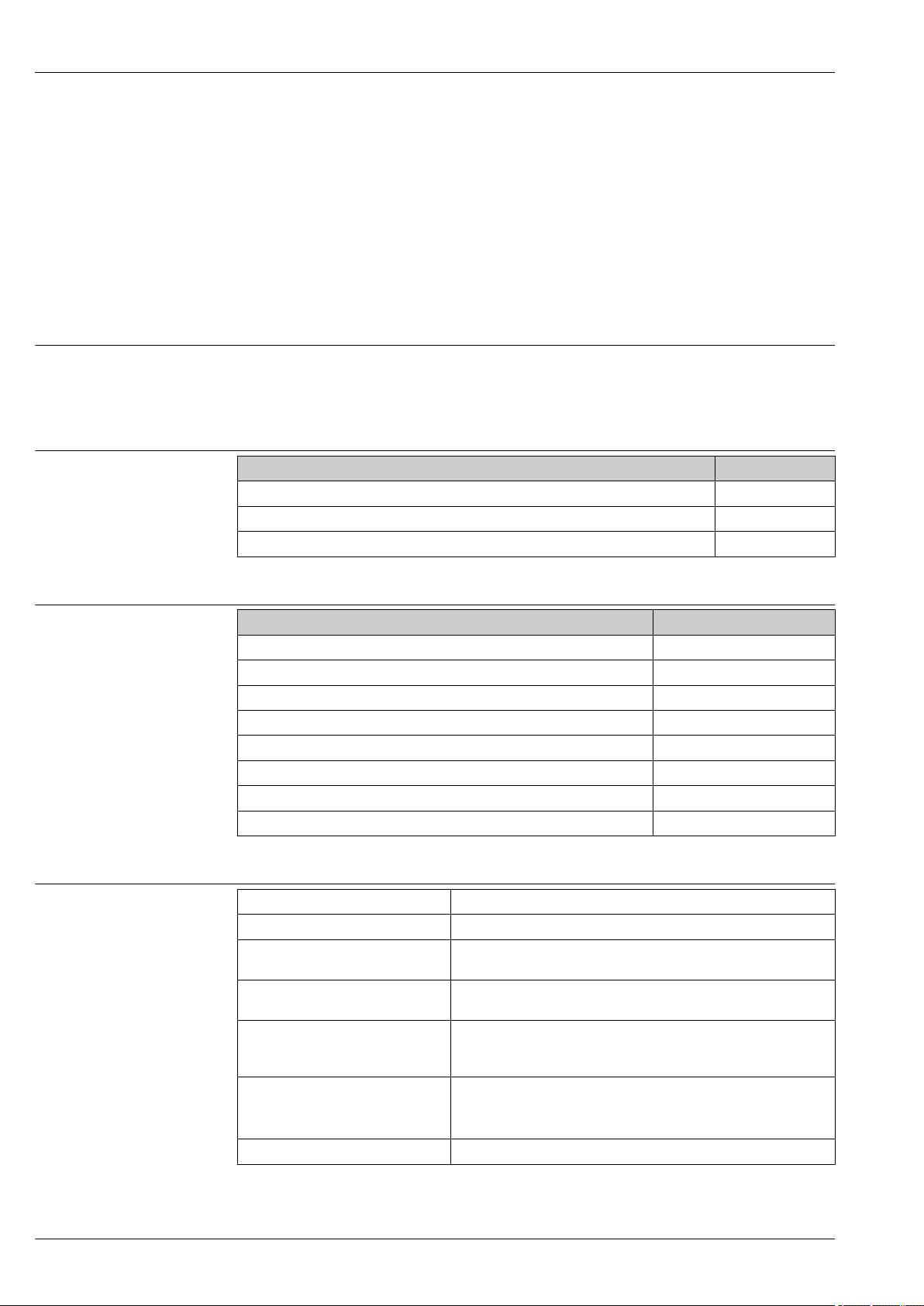

Measuring cell Standard Platinum

10 mbar (0.15 psi)

30 mbar (0.45 psi)

100 mbar (1.5 psi)

500 mbar (7.5 psi), 3 bar (45 psi)

16 bar (240 psi), 40 bar (600 psi)

160 bar (2 400 psi) rel/abs ,

250 bar (3 750 psi) rel/abs

Transmitter→ 28 total performance comprises the reference accuracy, the ambient temperature

effect and the static pressure and is calculated using the following formula:

Total performance = ± √ ( (E1)² + (E2)² + (E3)² )

E1 = Reference accuracy → 27

E2 = Ambient temperature effect per ±28 °C (50 °F) (corresponds to the range of

–3 to +53 °C (+27 to +127 °F)) → 30

E3 = Static pressure effect → 31

1)

• TD 1:1

• TD > 1:1

• TD ≤ 3:1

• TD > 3:1

• TD ≤ 5:1

• TD > 5:1

• TD ≤ 15:1

• TD > 15:1==

• TD ≤ 5:1

• TD > 5:1

==±0.075

±0.075 · TD

==±0.075

±0.025 · TD

==±0.05

±[0.009 · TD + 0.005]

±0.05

±[0.0015 · TD + 0.0275]

==±0.10

±0.02 · TD

• TD 1:1

• TD > 1:1

• TD 1:1

• TD > 1:1 to TD ≤ 3:1

• TD > 3:1

TD ≥ 1:1 = ±0.04

TD ≥ 1:1 = ±0.035

-

==±0.05

±0.075 · TD

==±0.05

±0.075

±0.025 · TD

1) Reference accuracy comprises the non-linearity [DIN EN 61298-2] including the hysteresis [DIN EN 61298-2] and the non-repeatability [DIN EN

61298-2] in accordance with the limit point method as per [DIN EN 60770]. Reference accuracy for standard up to TD 100:1, for platinum up to

TD 5:1. Valid for all membrane materials.

Endress+Hauser 27

Page 28

Deltabar S PMD75, FMD77, FMD78

FMD77/FMD78: Reference accuracy as %

The specifications refer to the calibrated span / upper range value (URV)

Measuring cell FMD77 FMD77 with capillary on low-pressure side and

100 mbar (1.5 psi)

500 mbar (7.5 psi)

3 bar (45 psi), 16 bar (240 psi)

40 bar (600 psi)

1) Reference accuracy comprises the non-linearity [DIN EN 61298-2] including the hysteresis [DIN EN 61298-2] and the non-repeatability [DIN EN

61298-2] in accordance with the limit point method as per [DIN EN 60770]. Reference accuracy for standard up to TD 100:1. The specifications

refer to the calibrated span / upper range value (URV).

2) FMD77/FMD78: No diaphragm seal errors are taken into account. Diaphragm seal errors can be calculated separately in the Applicator

diaphragm seal calculation module. Link to online tool Applicator: www.endress.com/applicator → Sizing Diaphragm Seal

1)

2)

.

FMD78

• TD ≤ 5:1

• TD > 5:1

• TD ≤ 15:1

• TD > 15:1==

• TD ≤ 15:1

• TD > 15:1==

- • TD ≤ 15:1

==±0.10

±0.02 · TD

±0.075

±[0.0015 · TD + 0.053]

±0.075

±[0.0015 · TD + 0.053]

• TD ≤ 5:1

• TD > 5:1

• TD ≤ 5:1

• TD > 5:1

• TD ≤ 15:1

• TD > 15:1

• TD > 15:1

==±0.15

±0.03 · TD

==±0.15

±0.03 · TD

==±0.1

±[0.006 · TD + 0.01]

==±0.1

±[0.006 · TD + 0.01]

Please refer to the next chapter “Detailed performance explanation and calculation” for further

explanations on "Ambient temperature effect" as well as "Static pressure effect" .

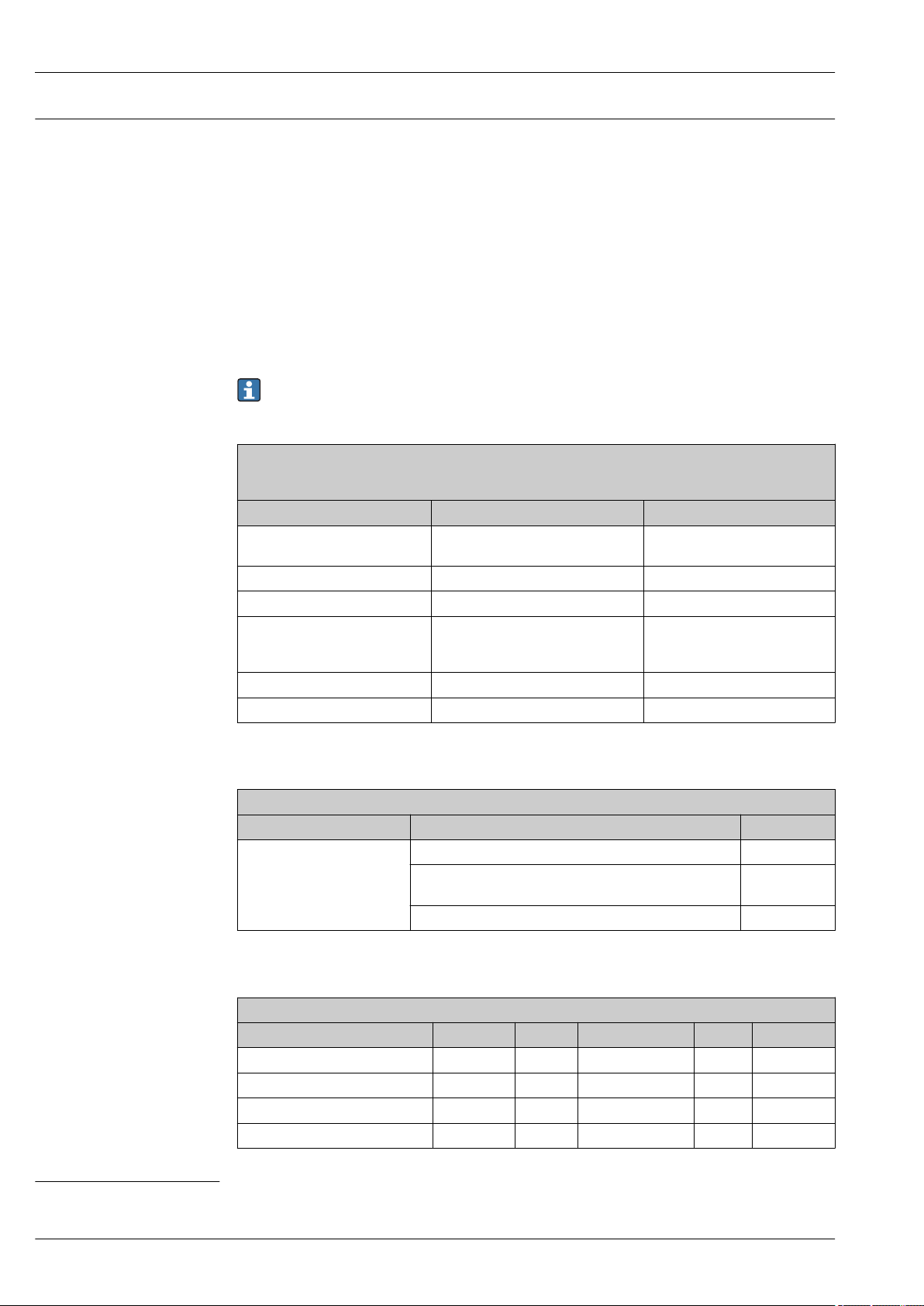

Total performance – Specification values

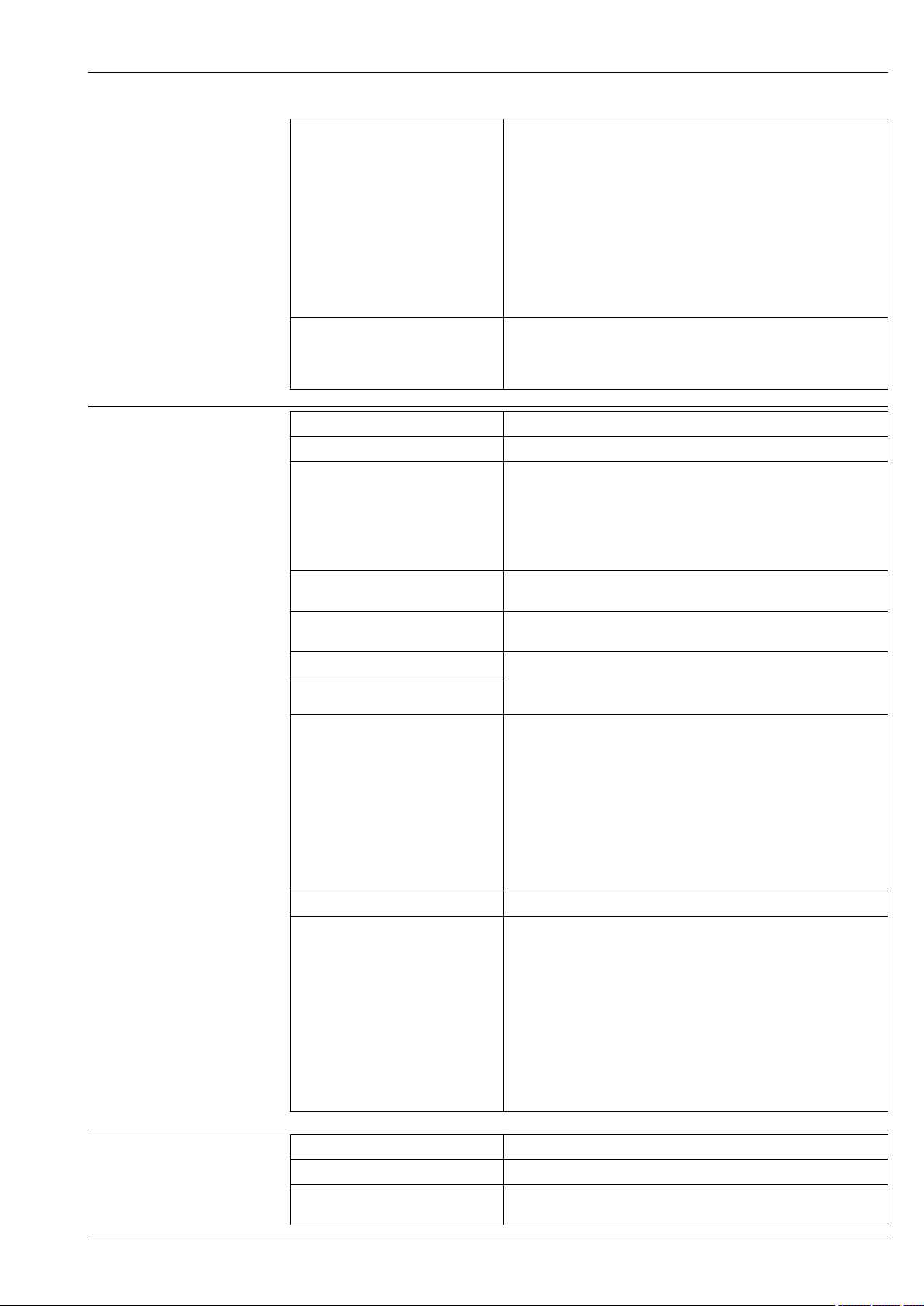

PMD75: total performance as %

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Standard

TD 1:1 TD 2:1 TD 3:1 TD 4:1 TD 5:1 TD 1:1 TD 2:1 TD 3:1 TD 4:1 TD 5:1

10 mbar (0.15 psi) ±0.30 ±0.52 ±0.74 ±0.96 ±1.18 ±0.26 ±0.44 ±0.61 ±0.78 ±0.96

30 mbar (0.45 psi) ±0.26 ±0.41 ±0.56 ±0.72 ±0.88 ±0.24 ±0.38 ±0.52 ±0.67 ±0.81

100 mbar (1.5 psi) ±0.20 ±0.27 ±0.34 ±0.41 ±0.49 ±0.20 ±0.26 ±0.33 ±0.40 ±0.47

500 mbar (7.5 psi) ±0.11 ±0.14 ±0.17 ±0.20 ±0.23 ±0.10 ±0.13 ±0.16 ±0.19 ±0.22

3 bar (45 psi) ±0.14 ±0.18 ±0.23 ±0.28 ±0.33 ±0.11 ±0.13 ±0.16 ±0.18 ±0.20

16 bar (240 psi) ±0.12 ±0.16 ±0.20 ±0.25 ±0.30 ±0.10 ±0.12 ±0.14 ±0.16 ±0.18

40 bar (600 psi) ±0.12 ±0.16 ±0.20 ±0.25 ±0.30 ±0.10 ±0.12 ±0.14 ±0.16 ±0.18

160 bar (2 400 psi) rel/abs

250 bar (3 750 psi) rel/abs

1) The specification values apply to the temperature range per ±28 °C (50 °F) (corresponds to the range of –3 to +53 °C (+27 to +127 °F)) for all

measuring cells. The specifications apply to a static pressure of 7 bar (105 psi) for measuring cells of 10 mbar (0.15 psi) to 500 mbar (7.5 psi),

for larger measuring cells of 70 bar (1 050 psi). The specification values apply to the analog output (i.e. including electronics errors). The

specification values apply to membrane material AISI 316L (1.4435), Alloy C .

±0.17 ±0.20 ±0.24 ±0.28 ±0.32 -

1)

Platinum

1)

28 Endress+Hauser

Page 29

Deltabar S PMD75, FMD77, FMD78

Long-term stability

PMD75/FMD77/FMD78: long-term stability as %

The specifications refer to the upper range limit (URL)

Measuring cell Standard & platinum

10 mbar (0.15 psi) ± 0.200 ± 0.280 ± 0.310

30 mbar (0.45 psi) ± 0.200 ± 0.280 ± 0.310

100 mbar (1.5 psi) ± 0.080 ± 0.140 ± 0.270

500 mbar (7.5 psi) ± 0.025 ± 0.050 ± 0.075

3 bar (45 psi) ± 0.038 ± 0.075 ± 0.150

16 bar (240 psi) ± 0.025 ± 0.110 ± 0.210

40 bar (600 psi) ± 0.050 ± 0.070 ± 0.100

160 bar (2 400 psi) rel/abs

250 bar (3 750 psi) rel/abs

1) FMD77FMD78: No diaphragm seal errors are taken into account. Diaphragm seal errors can be calculated

separately in the Applicator diaphragm seal calculation module. Link to online tool Applicator:

www.endress.com/applicator → Sizing Diaphragm Seal

1)

.

1 year 5 years 10 years

± 0.050 ± 0.070 ± 0.100

Endress+Hauser 29

Page 30

Deltabar S PMD75, FMD77, FMD78

Detailed Performance Explanation and Calculation

To calculate the total performance outside the temperature range of –3 to +53 °C (+27 to +127 °F) or

for a membrane material other than 1.4435/316L or Alloy C 276, please refer to the following

sections: "Ambient temperature effect", "Static pressure effect" and "Calculating the total

performance"

1)

.

Ambient temperature effect [E2]

• E2 = (E2M · CF1 · CF2) + E2E + E2

LT

• E2M = Main temperature error

• CF1 = Temperature range correction factor

• CF2 = Membrane material correction factor (thermal)

• E2E = Electronics error for analog output

• E2LT = low temperature error

E2M - Main temperature error

The output changes due to the effect of ambient temperature [IEC 61298-3] with respect to

reference temperature [DIN 16086]. The values specify the maximum error due to min./max.

ambient or process temperature conditions.

PMD75/FMD77/FMD78: main temperature error E2M as % per ±28 °C (50 °F) (corresponds to the range

of –3 to +53 °C (+27 to +127 °F))

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Standard Platinum

10 mbar (0.15 psi),

30 mbar (0.45 psi)

100 mbar (1.5 psi) ± (0.07 · TD + 0.07) ± (0.07 · TD + 0.07)

500 mbar (7.5 psi) ± (0.03 · TD + 0.017) ± (0.03 · TD + 0.017)

3 bar (45 psi),

16 bar (240 psi),

40 bar (600 psi)

160 bar (2 400 psi) rel/abs ± (0.042 · TD + 0.04) -

250 bar (3 750 psi) rel/abs ± (0.022 · TD + 0.04) -

± (0.14 · TD + 0.04) ± (0.14 · TD + 0.04)

± (0.012 · TD + 0.017) ± (0.012 · TD + 0.017)

CF1 - Temperature range correction factor

PMD75/FMD77/FMD78: correction factor CF

Measuring cell Temperature range Factor, CF

For all measuring cells 25 °C ± 28 °C (–3 to +53 °C (+27 to +127 °F)) 1

–32 to –4 °C (–26 to +25 °F) and

+54 to +85 °C (+129 to +185 °F)

–50 to –33 °C (–58 to –27 °F) 2.3

1

2

CF2 - Membrane material correction factor (thermal) (only for PMD75)

PMD75: correction factor CF

Measuring cell AISI 316L Alloy C Gold-Rhodium Monel Tantalum

10 mbar (0.15 psi) 1.0 1.0 2.5 2.8 2.3

30 mbar (0.45 psi) 1.0 1.0 2.5 2.8 2.3

100 mbar (1.5 psi) 1.0 1.0 1.1 1.1 1.1

500 mbar (7.5 psi) 1.0 1.0 1.8 1.8 1.8

1) FMD77FMD78: No diaphragm seal errors are taken into account. Diaphragm seal errors can be calculated separately in the Applicator

diaphragm seal calculation module. Link to online tool Applicator: www.endress.com/applicator → Sizing Diaphragm Seal

2

1

30 Endress+Hauser

Page 31

Deltabar S PMD75, FMD77, FMD78

PMD75: correction factor CF

Measuring cell AISI 316L Alloy C Gold-Rhodium Monel Tantalum

3 bar (45 psi) 1.0 1.0 3.1 3.1 3.1

16 bar (240 psi) 1.0 1.0 4.7 4.7 4.7

40 bar (600 psi) 1.0 1.0 3.1 3.1 3.1

160 bar (2 400 psi) rel/abs

250 bar (3 750 psi) rel/abs

2

1.0 1.0 - - -

E2E - Electronics error

PMD75/FMD77/FMD78: electronics error E2E as %

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Electronics Temperature range Error

For all measuring cells Analog output (4 to 20 mA) –50 to +85 °C (–58 to +185 °F) 0.05

Digital output (HART) –50 to +85 °C (–58 to +185 °F) 0

Digital output (PA/FF) –40 to +85 °C (–40 to +185 °F) 0

1) The additional electronics error that occurs in the temperature range –50 to –41 °C (–58 to –42 °F) is

covered by E2LT.

1)

E2LT - low temperature error

PMD75/FMD77/FMD78: low temperature error E2LT as %

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Temperature range Problem

For all measuring cells –40 to +85 °C (–40 to +185 °F) 0

–50 to –41 °C (–58 to –42 °F) 1.5

Static pressure effect [E3]

• E3 = E3M · CF

3

• E3M = main static pressure error (E3M = zero point error + span error)

• CF3 = Membrane material correction factor (static pressure)

E3M - Main static pressure error

Static pressure effect refers to the effect on the output due to changes in process static pressure.

It is the difference between the output at each static pressure and the output at atmospheric

pressure [IEC 61298-3]. It is the combination of influence of the operating pressure on the zero

point and span.

PMD75/FMD77/FMD78: main static pressure error E3M as %

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Standard Platinum

on the zero point

10 mbar (0.15 psi) ± 0.15 · TD

per 7 bar (105 psi)

30 mbar (0.45 psi) ± 0.70 · TD

per 70 bar (1 050 psi)

100 mbar (1.5 psi) ± 0.203 · TD

per 70 bar (1 050 psi)

500 mbar (7.5 psi) ± 0.07 · TD

per 70 bar (1 050 psi)

1)

on the span on the zero point

± 0.035

per 7 bar (105 psi)

± 0.14

per 70 bar (1 050 psi)

± 0.15

per 70 bar (1 050 psi)

± 0.10

per 70 bar (1 050 psi)

± 0.07 · TD

per 7 bar (105 psi)

± 0.25 · TD

per 70 bar (1 050 psi)

± 0.077 · TD

per 70 bar (1 050 psi)

± 0.028 · TD

per 70 bar (1 050 psi)

1)

on the span

± 0.035

per 7 bar (105 psi)

± 0.14

per 70 bar (1 050 psi)

± 0.15

per 70 bar (1 050 psi)

± 0.10

per 70 bar (1 050 psi)

Endress+Hauser 31

Page 32

Deltabar S PMD75, FMD77, FMD78

PMD75/FMD77/FMD78: main static pressure error E3M as %

The specifications refer to the calibrated span/Upper Range Value (URV).

Measuring cell Standard Platinum

on the zero point

3 bar (45 psi) ± 0.049 · TD

per 70 bar (1 050 psi)

16 bar (240 psi),

40 bar (600 psi)

160 bar (2 400 psi) rel/abs

± 0.049 · TD

per 70 bar (1 050 psi)

- - - -

1)

on the span on the zero point

± 0.05

per 70 bar (1 050 psi)

± 0.02

per 70 bar (1 050 psi)

± 0.021 · TD

per 70 bar (1 050 psi)

± 0.021 · TD

per 70 bar (1 050 psi)

250 bar (3 750 psi) rel/abs

1) The influence of the operating pressure on the zero point can be corrected. Please refer to operating instructions and chapter Commissioning →

Position adjustment.

CF3 – Membrane material correction factor (static pressure) (applicable only to PMD75)

1)

on the span

± 0.05

per 70 bar (1 050 psi)

± 0.02

per 70 bar (1 050 psi)

PMD75: membrane material correction factor CF3

3

Measuring cell AISI 316L Alloy C Gold-Rhodium Monel Tantalum

10 mbar (0.15 psi) 1.0 1.0 1.0 1.4 2.1

30 mbar (0.45 psi) 1.0 1.0 1.5 2.0 3.1

100 mbar (1.5 psi) 1.0 1.0 2.5 2.5 2.5

500 mbar (7.5 psi) 1.0 1.0 1.2 1.2 1.8

3 bar (45 psi) 1.0 1.0 2.1 2.1 2.8

16 bar (240 psi) 1.0 1.0 3.0 3.0 4.0

40 bar (600 psi) 1.0 1.0 3.0 3.0 4.0

160 bar (2 400 psi) rel/abs

- - - - -

250 bar (3 750 psi) rel/abs

Total error

Total error = total performance + long-term stability

Total performance as % of the set span with TD 1:1 → 28

Long-term stability as % of the upper range limit (URL) → 29

PMD75: total error as %

The specifications refer to the upper range limit (URL).

Measuring cell Standard

1)

Platinum

1 year 5 years 10 years 1 year 5 years 10 years

10 mbar (0.15 psi) ± 0.50 ± 0.58 ± 0.61 ± 0.46 ± 0.54 ± 0.57

30 mbar (0.45 psi) ± 0.46 ± 0.54 ± 0.57 ± 0.44 ± 0.52 ± 0,55

100 mbar (1.5 psi) ± 0.28 ± 0.34 ± 0,47 ± 0.28 ± 0.34 ± 0,47

500 mbar (7.5 psi) ± 0.14 ± 0.16 ± 0.19 ± 0,13 ± 0.15 ± 0.18

3 bar (45 psi) ± 0.17 ± 0.21 ± 0.29 ± 0.15 ± 0.19 ± 0.26

16 bar (240 psi) ± 0.14 ± 0.23 ± 0.33 ± 0.12 ± 0.21 ± 0.31

40 bar (600 psi) ± 0.17 ± 0.19 ± 0.22 ± 0.15 ± 0.17 ± 0.20

160 bar (2 400 psi) rel/abs

± 0.22 ± 0.24 ± 0,27 -

250 bar (3 750 psi) rel/abs

1)

1) The specification values apply to the temperature range per ±28 °C (50 °F) (corresponds to the range of –3 to +53 °C (+27 to +127 °F)) for all

measuring cells. The specifications apply to a static pressure of 7 bar (105 psi) for measuring cells of 10 mbar (0.15 psi) to 500 mbar (7.5 psi),

for larger measuring cells of 70 bar (1 050 psi). The specification values apply to the analog output (i.e. including electronics errors). The

specification values apply to membrane material AISI 316L (1.4435), Alloy C .

32 Endress+Hauser

Page 33

Deltabar S PMD75, FMD77, FMD78

Performance characteristics - calculation example and additional information

Calculating the total performance in 5 steps

Data (Example)

Measuring Conditions / Device configuration

dP range (URV) 8 bar (116 psi)

Min./ Max. temp. differential pressure transmitter

(ambient/process)

Membrane material AISI 316L

Reference accuracy (± 0.05%) Standard

PMD75 - suitable measuring cell

(upper range limit, URL)

Static pressure 35 bar (508 psi)

Output Signal 4 to 20 mA

Ambient temp.:0 to 45 °C (32 to 113 °F)

Max. Process temp.:50 °C (122 °F)

16 bar (240 psi) with TD 2:1

Formula

Total performance = ± √ ( (E1)² + (E2)² + (E3)² )

E1 = Reference accuracy → 27

E2 = Ambient temperature effect per ±28 °C (50 °F) (corresponds to the range of

–3 to +53 °C (+27 to +127 °F)) → 30

E3 = Static pressure effect → 31

Calculation

Step 1: Calculating the turn down → 7

Turn down (TD) = URL/|URV - LRV| = 16 bar (240 psi)/8 bar (116 psi)

= TD = 2:1

Step 2: Calculating the reference accuracy (E1) → 27

For the measuring conditions,

Reference accuracy, E1 = ± 0.05 (% of the set span)

= ± (0.05/100) · 8 bar (116 psi)

= ±0.0040 bar (0.0580 psi)

E1 = ± 0.05 (% of the set span)

(or) ±0.0040 bar (0.0580 psi)

Endress+Hauser 33

Page 34

Deltabar S PMD75, FMD77, FMD78

A

B

C

0.0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

[%]

-40

-40

-30

-22

-10

+140+32

+10

+50

+20

+68

+30

+86

+40

+104

+50

+122

+60

+140

+70

+158

+80

+176

+90

+194

-20

-4

[°C]

[°F]

D

Step 3: Calculation of the ambient temperature effect [E2 = (E2M · CF1 · CF2) + E2E + E2LT] → 30

For the measuring conditions,

Main temperature error, E2

Temperature correction factor, CF

Membrane material correction factor, CF

Electronics error , E2

Low temperature error E2

Ambient temperature effect, E2 = ± [(0.012 · TD + 0.017) · 1 · 1] +0.05

M

1

2

E

LT

=

± (0.012 · TD + 0.017) % of the set span

= 1

= 1

= 0.05 %

= 0 %

= ± [(0.012 · 2 + 0.017) · 1 · 1] + 0.05

= ± 0.091 (% of the set span)

= ± (0.091/100) · 8 bar (116 psi)

= ±0.0073 bar (0.10585 psi)

E2 = ± 0.091 (% of the set span)

(or) ±0.0073 bar (0.10585 psi)

A Error (% of the set span)

B Temperature

C Measuring membrane made from 316L or Alloy C

D Ambient temperature effect: 0.091 (% of the set span) (E2 at 50 °C (122 °F))

34 Endress+Hauser

A0031069

Page 35

Deltabar S PMD75, FMD77, FMD78

A

B

0.00

0.20

0.40

0.60

0.80

[%]

3

45

4

60

6907

1058120913510150111651218013195142101522516240

5

75

[bar]

[psi]

TD 2:1

TD 5:1

TD 4:1

TD 3:1

TD 1:1

C

Step 4: Calculating the static pressure effect (E3 = E3M · CF3) → 31

For the measuring conditions,

Main static pressure error, E3

Error factor dependent on membrane material, CF

Static pressure effect, E3 = ± (0.049 · TD + 0.02) · (35/70) · CF3 (% of the set span)

Step 5: Calculation of total performance

Total performance = ± √ ((E1)² + (E2)² + (E3)² )

Total performance, in mbar = ± √ ((0.004)² + (0.0073)² + (0.0047)² )

Total performance, in % of the set span = ± √ ((0.05)2 + (0.091)2 + (0.059)2)

Total performance = ± 0.119 (% of the set span)

M

3

= ± 0.0095 bar (0.13775 psi) or 9.5 mbar (0.13775 psi)

~ 0.119 % of 8 bar (116 psi)

(or)

= ± 0.119 (% of the set span)

(or) ±0.0095 bar (0.13775 psi)

=± (0.049 · TD) on the zero point and

± 0.02 on the span (% of the set span)

per 70 bar (1 015 psi)

= [± (0.049 · TD) on the zero point and

± 0.02 on the span] · (35/70) (% of the set span)

per 35 bar (507.50 psi)

= 1

= ± (0.049 · 2 + 0.02) · (0.5) · 1

= ± 0.059 (% of the set span)

= ± (0.059/100) · 8 bar (116 psi)

= ±0.0047 bar (0.06815 psi)

E3 = ± 0.059 (% of the set span)

(or) ±0.0047 bar (0.06815 psi)

E1 = Reference accuracy

E2 = Ambient temperature effect per ±28 °C (50 °F) (corresponds to the range of

–3 to +53 °C (+27 to +127 °F))

E3 = Static Pressure Effect

A Error (% of the set span)

B Set span [bar]

C Standard measuring cell

A0031070

Endress+Hauser 35

Page 36

Deltabar S PMD75, FMD77, FMD78

C

B

C

A

A

PMD75 FMD77

B

90°

90°

90°

90°

+

-

+

-

+

-

+

-

+

-

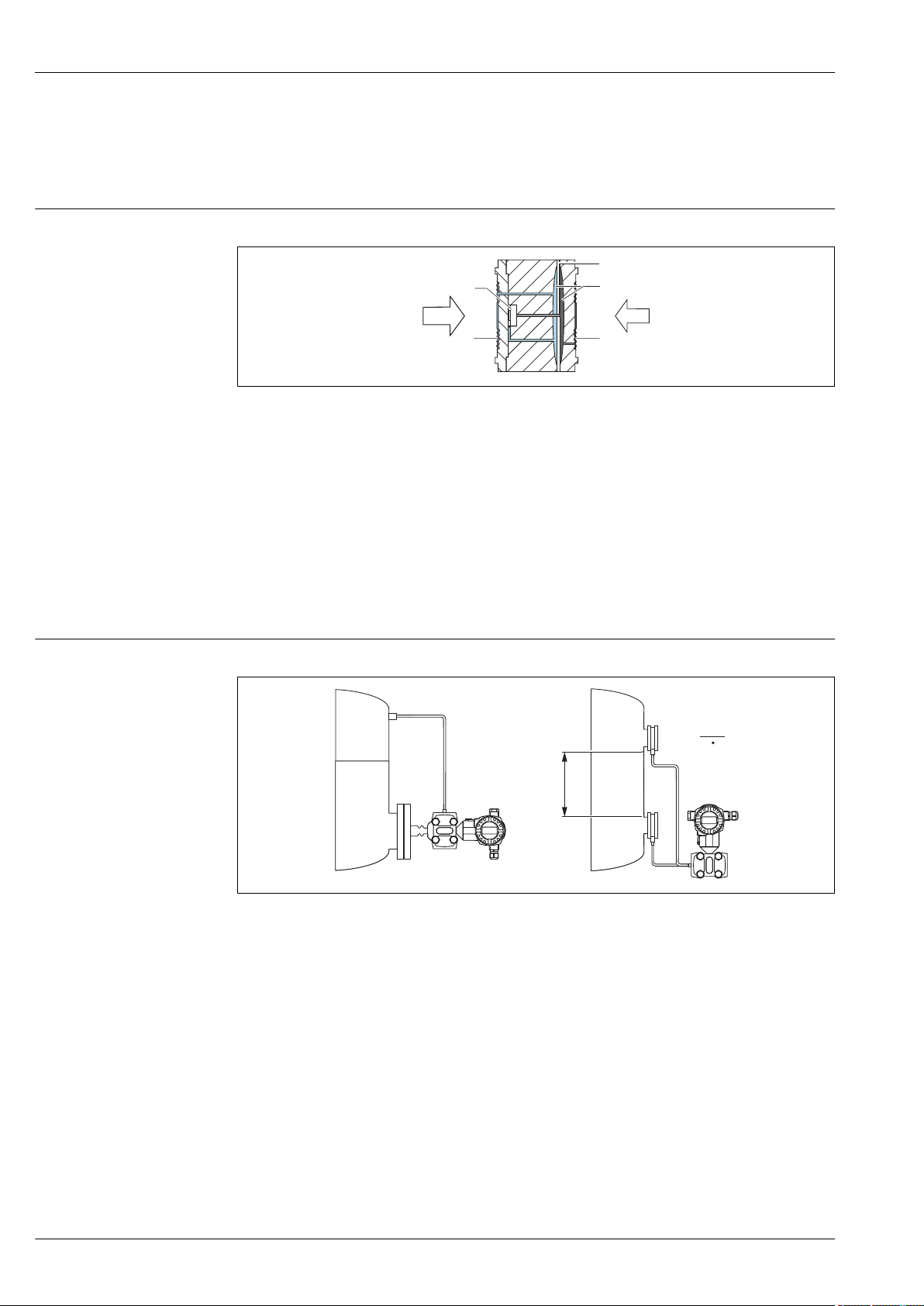

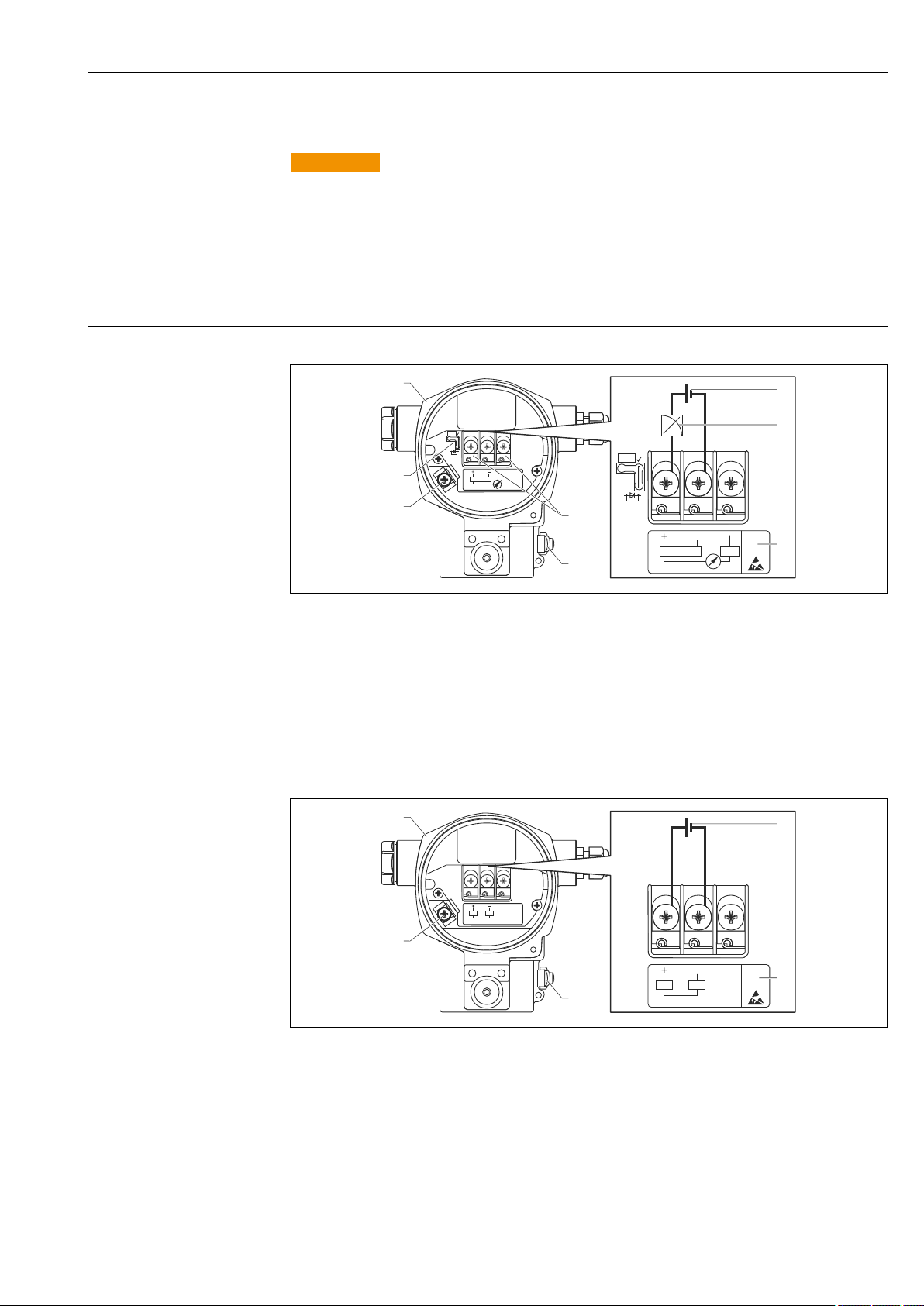

Installation factors

Some of the influencing factors are:

• Influence of installation position → 36

• Vibration effects → 36

Influence of installation position

A0031035

Device Calibration position (A) Device rotated vertically downwards (B) Device rotated vertically upwards (C)

PMD75 and silicone oil No additional error <+4 mbar (+0.06 psi)

The value is doubled for inert oil.

FMD77 and silicone oil No additional error <+32 mbar (+0.46 psi)

The value is doubled for inert oil.

<–4 mbar (–0.06 psi)

The value is doubled for inert oil.

<–32 mbar (–0.46 psi)

The value is doubled for inert oil.

A position-dependent zero point shift can be corrected. Please refer to operating instructions

chapter Commissioning → Position adjustment.

Vibration effects

Device/accessory Measuring cells Housing Test standard Vibration resistance

10 mbar (0.15 psi),

30 mbar (0.45 psi)

T14 stainless steel

T15 aluminum

IEC 61298-3

T17 aluminum

T14 aluminum IEC 61298-3

≤ 0.15% URL to 10 to 38 Hz:

±0.35 mm (0.0138 in);

38 to 2000 Hz: 2 g in all 3 planes

≤ 0.15% URL to 10 to 60 Hz:

±0.21 mm (0.0083 in);

60 to 2000 Hz: 3 g in all 3 planes

PMD75

T14 stainless steel

T15 aluminum

≥100 mbar (1.5 psi)

T14 aluminum IEC 61298-3

IEC 61298-3