Page 1

BA00384P/00/EN/08.16

Deltapilot M

Deltabar M

Cerabar M

71316874

Valid from software version:

01.00.zz

Products Solutions Services

Operating Instructions

Cerabar M

Deltabar M

Deltapilot M

Process pressure / Differential pressure, Flow /

Hydrostatic

Page 2

Cerabar M, Deltabar M, Deltapilot M

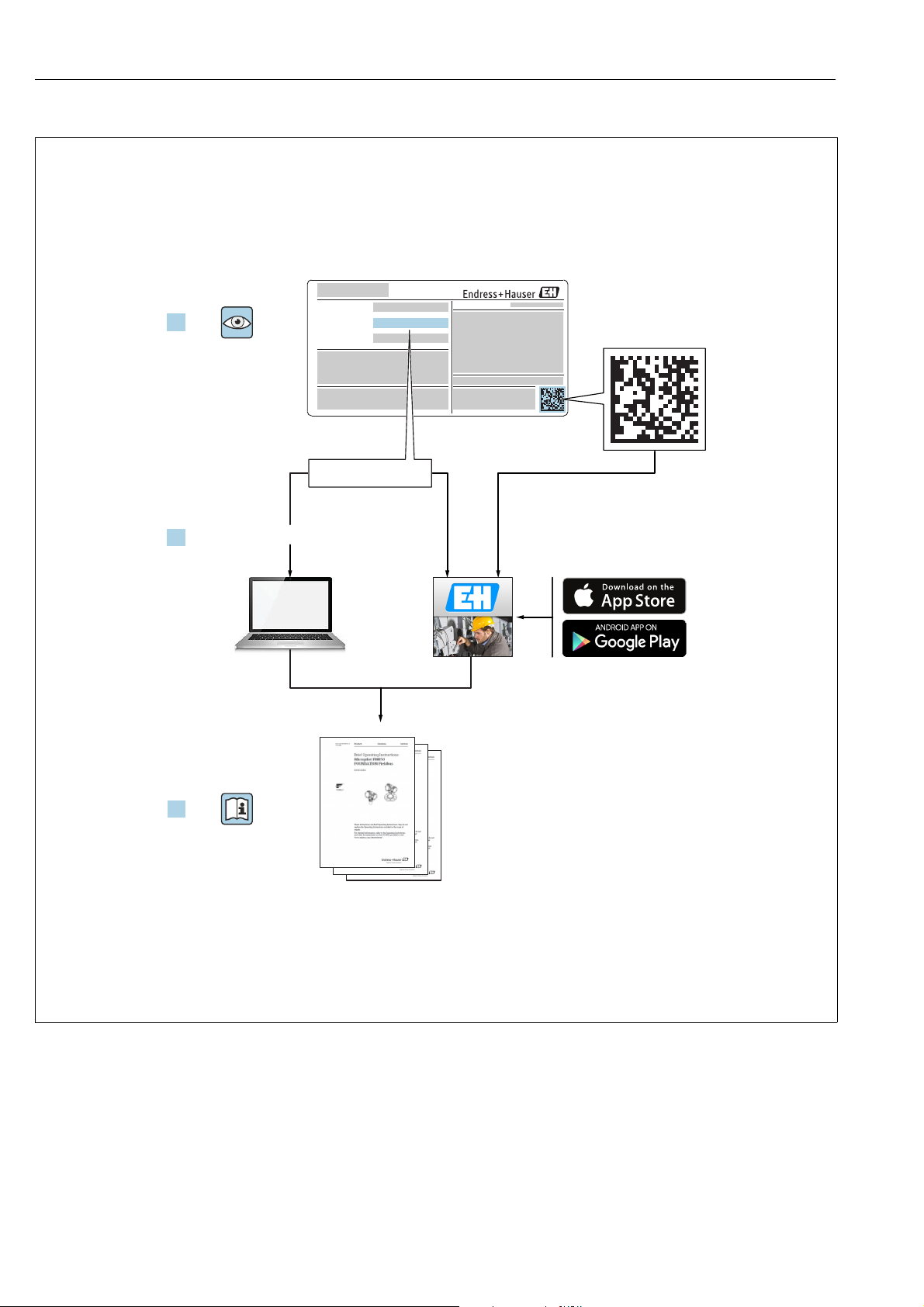

1.

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer Endress+Hauser Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

2.

3.

Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

A0023555

2 Endress+Hauser

Page 3

Cerabar M, Deltabar M, Deltapilot M

Table of contents

1 Document information . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Basic safety instructions . . . . . . . . . . . . . 6

2.1 Requirements concerning the staff . . . . . . . . . . . . . 6

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Identification . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 CE mark, Declaration of Conformity . . . . . . . . . . 11

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Storage and transport . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . 12

4.4 General installation instructions . . . . . . . . . . . . . 13

4.5 Installing Cerabar M . . . . . . . . . . . . . . . . . . . . . . . 14

4.6 Installing Deltabar M . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Installing Deltapilot M . . . . . . . . . . . . . . . . . . . . . 32

4.8 Installing profile seal for universal process adapter

37

4.9 Closing the housing cover . . . . . . . . . . . . . . . . . . 37

4.10 Post-installation check . . . . . . . . . . . . . . . . . . . . . 37

5 Electrical connection . . . . . . . . . . . . . . . 38

5.1 Connecting the device . . . . . . . . . . . . . . . . . . . . . 38

5.2 Connecting the measuring unit . . . . . . . . . . . . . . 39

5.3 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 40

5.4 Overvoltage protection (optional) . . . . . . . . . . . . 41

5.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 43

8 Commissioning with an operating menu

(onsite display/FieldCare) . . . . . . . . . . 71

8.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.3 Pos. zero adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.4 Level measurement (Cerabar M and Deltapilot M)

74

8.5 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.6 Pressure measurement . . . . . . . . . . . . . . . . . . . . . 90

8.7 Differential pressure measurement (Deltabar M) .

91

8.8 Flow measurement (Deltabar M) . . . . . . . . . . . . . 93

8.9 Level measurement (Deltabar M) . . . . . . . . . . . . . 96

8.10 Overview of the onsite display operating menu . . .

108

8.11 Description of parameters . . . . . . . . . . . . . . . . . 116

9 Commissioning with the FF

configuration program . . . . . . . . . . . . 138

9.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.2 Commissioning with FF application . . . . . . . . . 138

9.3 Scaling the OUT parameter . . . . . . . . . . . . . . . . 141

9.4 Commissioning with device application . . . . . . 142

9.5 Pos. Zero Adjust . . . . . . . . . . . . . . . . . . . . . . . . . 144

9.6 Pressure measurement . . . . . . . . . . . . . . . . . . . 145

9.7 Level measurement . . . . . . . . . . . . . . . . . . . . . . 146

9.8 Flow measurement (Deltabar M) . . . . . . . . . . . 155

9.9 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.10 Electrical differential pressure measurement with

gauge pressure sensors (Cerabar M or Deltapilot M)

161

9.11 Displaying external values on the onsite display via

FF bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

9.12 Description of parameters . . . . . . . . . . . . . . . . . 164

10 Maintenance . . . . . . . . . . . . . . . . . . . . 220

10.1 Cleaning instructions . . . . . . . . . . . . . . . . . . . . . 220

10.2 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 220

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2 Operation without an operating menu . . . . . . . 46

6.3 Operation with an operating menu . . . . . . . . . . 48

6.4 FOUNDATION Fieldbus communication protocol .

56

7 Commissioning without an operating

menu . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

7.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.2 Position adjustment . . . . . . . . . . . . . . . . . . . . . . . 69

11 Troubleshooting . . . . . . . . . . . . . . . . . 221

11.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

11.2 Response of outputs to errors . . . . . . . . . . . . . . 225

11.3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

11.4 Repair of Ex-certified devices . . . . . . . . . . . . . . 226

11.5 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

11.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

11.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

11.8 Software history . . . . . . . . . . . . . . . . . . . . . . . . . 227

12 Technical data . . . . . . . . . . . . . . . . . . . 228

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Endress+Hauser 3

Page 4

Document information Cerabar M, Deltabar M, Deltapilot M

DANGER

WARNING

CAUTION

NOTICE

)

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and storage,

to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-DE

A0011190-DE

A0011191-DE

A0011192-DE

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

seriousor fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

seriousor fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minoror medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personalinjury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

1.2.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Hexagon wrench

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line or

a star grounding system depending on

national or company codes of practice.

A0011222

4 Endress+Hauser

Page 5

Cerabar M, Deltabar M, Deltapilot M Document information

1.

2.

1.

2.

t 85°C>

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

A0015482

Reference to page

A0015484

Reference to graphic

A0015487

, , ... Series of steps

Result of a sequence of actions

A0018343

Visual inspection

A0015502

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

, , ... Series of steps

A, B, C, D, ... Views

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

Connecting cable immunity to temperature change

Indicates that the connecting cables have to withstand a temperature of 85°C at least.

1.2.7 Registered trademarks

KALREZ®, VITON®, TEFLON

Registered label of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered label of Ladish & Co., Inc., Kenosha, USA

FOUNDATION

TM

Fieldbus

Registered trademark of the FieldComm Group, Austin, USA

GORE-TEX

®

Registered label of W.L. Gore & Associates, Inc., USA

®

Endress+Hauser 5

Page 6

Basic safety instructions Cerabar M, Deltabar M, Deltapilot M

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner-operator

• Following the instructions in these Operating Instructions

2.2 Designated use

The Cerabar M is a pressure transmitter for measuring level and pressure.

The Deltabar M is a differential pressure transmitter for measuring differential pressure,

flow and level.

The Deltapilot M is a hydrostatic pressure sensor for measuring level and pressure.

2.2.1 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability.

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national

regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

‣ Operate the device in proper technical condition and fail-safe condition only.

‣ The operator is responsible for interference-free operation of the device.

‣ Only disassemble the device in pressurless condition!

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

‣ If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

6 Endress+Hauser

Page 7

Cerabar M, Deltabar M, Deltapilot M Basic safety instructions

‣ Carry out repairs on the device only if they are expressly permitted.

‣ Observe federal/national regulations pertaining to repair of an electrical device.

‣ Use original spare parts and accessories from Endress+Hauser only.

2.5 Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

• Based on the nameplate, check whether the ordered device is permitted for the intended

use in the hazardous area.

• Observe the specifications in the separate supplementary documentation that is an

integral part of these Instructions.

2.6 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the- art safety requirements, has been tested, and left the factory in a condition in

which they are safe to operate. It fulfills general safety requirements and legal requirements.

It also conforms to the EC directives listed in the device-specific EC declaration of conformity.

Endress+Hauser confirms this fact by applying the CE mark.

Endress+Hauser 7

Page 8

Identification Cerabar M, Deltabar M, Deltapilot M

3 Identification

3.1 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer).

3.2 Device designation

3.2.1 Nameplate

• The MWP (maximum working pressure) is specified on the nameplate. This value refers

to a reference temperature of 20°C (68°F) or 100°F (38 °C) for ANSI flanges.

• The pressure values permitted at higher temperatures can be found in the following

standards:

– EN 1092-1: 2001 Tab. 18

– ASME B 16.5a – 1998 Tab. 2-2.2 F316

– ASME B 16.5a – 1998 Tab. 2.3.8 N10276

– JIS B 2220

• The test pressure corresponds to the over pressure limit (OPL) of the device = MWP x 1.5

2)

.

• The Pressure Equipment Directive (EC Directive 97/23/EC) uses the abbreviation "PS". The

abbreviation "PS" corresponds to the MWP (maximum working pressure) of the measuring

device.

1)

1) With regard to their stability-temperature property, the materials 1.4435 and 1.4404 are grouped together

under 13EO in EN 1092-1 Tab. 18. The chemical composition of the two materials can be identical.

2) The equation does not apply for PMP51 and PMP55 with a 40 bar (600 psi) or a 100 bar (1500 psi) measuring

cell.

8 Endress+Hauser

Page 9

Cerabar M, Deltabar M, Deltapilot M Identification

ex works FW:

Dev.Rev.:

250002755-C

Ext. order code:

Ser. no.:

U=

Span

P

MWP

Order code:

Made in Germany, D-79689 Maulburg

Mat.:

250002756-E

L=

1

2

3

4

5 6 7

8 9 10

11

12

13

14

15

16

17

18

18

Pmax

Tmax

for oxygen service

Bei Sauerstoffeinsatz/

1

2

3

Aluminum housing

A0030017

Fig. 1: Nameplate

1 Device name

2 Order code (for re-orders)

3 Serial number (for identification)

4 Extended order code (complete)

5 MWP (maximum working pressure)

6 Electronic version (output signal)

7Min./max. span

8 Nominal measuring range

9 Supply voltage

10 Unit of length

11 ID number of notified body with regard to ATEX (optional)

12 ID number of notified body with regard to Pressure Equipment Directive (optional)

13 Approvals

14 Device version

15 Software version

16 Degree of protection

17 Wetted materials

18 Approval-specific information

Devices suitable for oxygen applications are fitted with an additional nameplate.

Fig. 2: Additional nameplate for devices suitable for oxygen applications

1 Maximum pressure for oxygen applications

2 Maximum temperature for oxygen applications

3 Layout identification of the nameplate

A0030019

Endress+Hauser 9

Page 10

Identification Cerabar M, Deltabar M, Deltapilot M

002757-A

p

Order code:

Ext. order code:

Ser. no.:

MWP

D-79689 Maulburg

Made in Germany,

ex works FW

U=

Dev.Rev.:

L=

Span

Mat.:

002758-C

1

2

3

4

4

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

12

002759-B

1

1

Stainless steel housing, hygienic

A0030021

Fig. 3: Nameplate for Cerabar M and Deltapilot M

1 Device name

2 Order code (for re-orders)

3 Serial number (for identification)

4 Extended order code (complete)

5 Nominal measuring range

6 MWP (maximum working pressure)

7Length data

8 Electronic version (output signal)

9 Supply voltage

10 Min./max. span

11 Wetted materials

12 Approval-specific information

13 ID number of notified body with regard to ATEX (optional)

14 ID number of notified body with regard to Pressure Equipment Directive (optional)

15 Approvals

16 Software version

17 Device version

18 Degree of protection

Devices with certificates are fitted with an additional plate.

Fig. 4: Additional nameplate for devices with certificates

1 Approval-specific information

3.2.2 Identifying the sensor type

In the case of gauge pressure sensors, the "Pos. zero adjust" parameter appears in the

operating menu ("Setup" -> "Pos. zero adjust").

In the case of absolute pressure sensors, the "Calib. offset" parameter appears in the

operating menu ("Setup" -> "Calib. offset").

A0030024

10 Endress+Hauser

Page 11

Cerabar M, Deltabar M, Deltapilot M Identification

3.3 Scope of delivery

The scope of delivery comprises:

• Device

• Optional accessories

Documentation supplied:

• The Operating Instructions BA00384P is available on the Internet.

See: www.endress.com Download

• Brief Operating Instructions: KA01032P Cerabar M / KA01029P Deltabar M / KA01035P

Deltapilot M

• Final inspection report

• Additional Safety Instructions for ATEX, IECEx and NEPSI devices

• Optional: factory calibration form, test certificates

3.4 CE mark, Declaration of Conformity

The devices are designed to meet state-of-the-art safety requirements, have been tested and

left the factory in a condition in which they are safe to operate. The devices comply with the

applicable standards and regulations as listed in the EC Declaration of Conformity and thus

comply with the statutory requirements of the EC Directives. Endress+Hauser confirms the

conformity of the device by affixing to it the CE mark.

Endress+Hauser 11

Page 12

Installation Cerabar M, Deltabar M, Deltapilot M

WARNING

!

4Installation

4.1 Incoming acceptance

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches

your order.

4.2 Storage and transport

4.2.1 Storage

The device must be stored in a dry, clean area and protected against damage from impact

(EN 837-2).

Storage temperature range:

See Technical Information for Cerabar M TI00436P / Deltabar M TI00434P / Deltapilot M

TI00437P.

4.2.2 Transport

Incorrect transportation

Housing, diaphragm and capillaries may become damaged, and there is a risk of injury!

‣ Transport the measuring device to the measuring point in its original packaging or by the

process connection.

‣ Follow the safety instructions and transport conditions for devices weighing more than

18 kg (39.6 lbs).

‣ Do not use capillaries as a carrying aid for the diaphragm seals.

4.3 Installation conditions

4.3.1 Dimensions

For dimensions, please refer to the Technical Information for Cerabar M TI00436P /

Deltabar M TI00434P / Deltapilot M TI00437P, "Mechanical construction" section.

12 Endress+Hauser

Page 13

Cerabar M, Deltabar M, Deltapilot M Installation

WARNING

!

WARNING

!

4.4 General installation instructions

• Devices with a G 1 1/2 thread:

When screwing the device into the tank, the flat seal has to be positioned on the sealing

surface

of the process connection. To avoid additional strain on the process isolating diaphragm,

the thread should never be sealed with hemp or similar materials.

• Devices with NPT threads:

– Wrap Teflon tape around the thread to seal it.

– Tighten the device at the hexagonal bolt only. Do not turn at the housing.

– Do not overtighten the thread when screwing. Max. torque: 20 to 30 Nm (14.75 to

22.13 lbf ft)

4.4.1 Mounting sensor modules with PVDF thread

Risk of damage to process connection!

Risk of injury!

‣ Sensor modules with PVDF process connections with threaded connection must be

installed with the mounting bracket provided!

Material fatigue from pressure and temperature!

Risk of injury if parts burst! The thread can become loose if exposed to high pressure and

temperatures.

‣ The integrity of the thread must be checked regularly and the thread may need to be re-

tightened with the maximum tightening torque of 7 Nm (5.16 lbf ft). Teflon tape is

recommended for sealing the ½" NPT thread.

Endress+Hauser 13

Page 14

Installation Cerabar M, Deltabar M, Deltapilot M

NOTICE

1

1

1

4.5 Installing Cerabar M

• Due to the orientation of the Cerabar M, there may be a shift in the zero point, i.e. when

the container is empty or partially full, the measured value does not display zero. You can

correct this zero point shift ä 47, Section "Function of the operating elements" or

ä 73, Section 8.3 "Pos. zero adjust".

• For PMP55, please refer to Section 4.5.2 "Installation instructions for devices with

diaphragm seals – PMP55", ä 17.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

ä 21, Section 4.5.5 "Wall and pipe mounting (optional)".

4.5.1 Installation instructions for devices without diaphragm seals –

PMP51, PMC51

Damage to the device!

If a heated Cerabar M is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the pressure

compensation (1).

‣ If this is the case, mount the Cerabar M with the pressure compensation (1) pointing

downwards.

®

• Keep the pressure compensation and GORE-TEX

• Cerabar M transmitters without diaphragm seals are mounted as per the norms for a

manometer (DIN EN 837-2). We recommend the use of shutoff devices and siphons. The

orientation depends on the measuring application.

• Do not clean or touch process isolating diaphragms with hard or pointed objects.

• The device must be installed as follows in order to comply with the cleanability

requirements of the ASME-BPE (Part SD Cleanability):

filter (1) free from contamination.

14 Endress+Hauser

Page 15

Cerabar M, Deltabar M, Deltapilot M Installation

1

2

1

1

2

2

3

4

Pressure measurement in gases

A0028473

Fig. 5: Measuring arrangement for pressure measurement in gases

1 Cerabar M

2Shutoff device

Mount the Cerabar M with the shutoff device above the tapping point so that any condensate

can flow into the process.

Pressure measurement in steams

Fig. 6: Measuring arrangement for pressure measurement in steams

1 Cerabar M

2Shutoff device

3 U-shaped siphon

4 Circular siphon

A0028474

• Mount Cerabar M with siphon above the tapping point.

• Fill the siphon with liquid before commissioning.

The siphon reduces the temperature to almost the ambient temperature.

Endress+Hauser 15

Page 16

Installation Cerabar M, Deltabar M, Deltapilot M

1

2

3

Pressure measurement in liquids

A0028491

Fig. 7: Measuring arrangement for pressure measurement in liquids

1 Cerabar M

2 Shutoff device

• Mount Cerabar M with shutoff device below or at the same level as the tapping point.

Level measurement

A0028492

Fig. 8: Measuring arrangement for level

• Always install the Cerabar M below the lowest measuring point.

• Do not mount the device in the filling curtain or at a point in the tank which could be

affected by pressure pulses from an agitator.

• Do not mount the device in the suction area of a pump.

• The calibration and functional test can be carried out more easily if you mount the device

downstream of a shutoff device.

16 Endress+Hauser

Page 17

Cerabar M, Deltabar M, Deltapilot M Installation

NOTICE

NOTICE

4.5.2 Installation instructions for devices with diaphragm seals –

PMP55

• Cerabar M devices with diaphragm seals are screwed in, flanged or clamped, depending on

the type of diaphragm seal.

• Please note that the hydrostatic pressure of the liquid columns in the capillaries can cause

zero point shift. The zero point shift can be corrected.

• Do not clean or touch the process isolating diaphragm of the diaphragm seal with hard or

pointed objects.

• Do not remove process isolating diaphragm protection until shortly before installation.

Improper handling!

Damage to the device!

‣ A diaphragm seal and the pressure transmitter together form a closed, oil-filled

calibrated system. The fill fluid hole is sealed and may not be opened.

‣ When using a mounting bracket, sufficient strain relief must be ensured for the

capillaries in order to prevent the capillary bending down (bending radius 100

(3.94 in)).

‣ Please observe the application limits of the diaphragm seal filling oil as detailed in the

Technical Information for Cerabar M TI00436P, "Planning instructions for diaphragm

seal systems" section.

In order to obtain more precise measurement results and to avoid a defect in the device,

mount the capillaries as follows:

‣ Vibration-free (in order to avoid additional pressure fluctuations)

‣ Not in the vicinity of heating or cooling lines

‣ Insulate if the ambient temperature is below or above the reference temperature

‣ With a bending radius of 100 mm (3.94 in).

‣ Do not use the capillaries as a carrying aid for the diaphragm seals!

Endress+Hauser 17

Page 18

Installation Cerabar M, Deltabar M, Deltapilot M

H1

1

2

3

4

5

A

B

0.0

2.0

4.0

6.0

8.0

10.0

12.0

50 100 300 400 500 600 700 800 900 1000200

[mbar

abs

]

[m]

Vacuum application

For applications under vacuum, Endress+Hauser recommends mounting the pressure

transmitter below the diaphragm seal. This prevents vacuum loading of the diaphragm seal

caused by the presence of fill fluid in the capillary.

When the pressure transmitter is mounted above the diaphragm seal, the maximum height

difference H1 in accordance with the illustrations below must not be exceeded.

A0023994

Fig. 9: Installation above the lower diaphragm seal

The maximum height difference depends on the density of the filling oil and the smallest

ever pressure that is permitted to occur at the diaphragm seal (empty vessel), see illustration

below:

Fig. 10: Diagram of maximum installation height above the lower diaphragm seal for vacuum applications depending on the

A Height difference H1

B Pressure at diaphragm seal

1 Low temperature oil

2 Vegetable oil

3 Silicone oil

4 High-temperature oil

5Inert oil

pressure at the diaphragm seal on the positive side

18 Endress+Hauser

A0023986-en

Page 19

Cerabar M, Deltabar M, Deltapilot M Installation

T

p

T

a

+212

+176+140+104+68+32-4-40-76

+400

+350

+300

+250

+200

+150

+100

+50

0

-50

-100

+752

+662

+572

+482

+392

+302

+212

+122

+32

-58

-148

[°C]

[°F]

[°C][°F]

+100+80+60+40+20

0

-20-40-60

A

B

1

2

A

DE FG

C

B

Mounting with temperature isolator

Endress+Hauser recommends the use of temperature isolators in the event of constant

extreme medium temperatures which lead to the maximum permissible electronics

temperature of +85 °C (+185°F) being exceeded.

Depending on the filling oil used, diaphragm seal systems with temperature isolators can be

used for maximum temperatures of up to 400 °C (+752 °F). For the temperature

application limits, see technical Information, "Diaphragm seal filling oils" section.

To minimize the influence of rising heat, Endress+Hauser recommends the device be

mounted horizontally or with the housing pointing downwards. The additional installation

height also brings about a maximum zero point shift of 21 mbar (0.315 psi) due to the

hydrostatic column in the temperature isolator. You can correct this zero point shift at the

device.

The temperature restrictions are lowest with an insulation height of 30 mm (1.18 inch).

Full insulation exhibits virtually the same behavior as no insulation!

The temperature limits with an insulation height of 30 mm (1.18 inch) are illustrated in the

following graphic.

Fig. 11:

A Ambient temperature:

B Process temperature: max. 400 °C (752 °F), depending on the filling oil used

C Device with temperature isolator, material 316L (1.4404)

D Without isolation

E Maximum isolation

F 30 mm (1.18. inch) isolation

G Without isolation, maximum isolation, 30 mm (1.18. inch) isolation

1 Isolation heigth 30 mm (1.18. inch)

2Isolation material

85 °C (185 °F)

Endress+Hauser 19

A0031354

Page 20

Installation Cerabar M, Deltabar M, Deltapilot M

NOTICE

12

A

B

12

4.5.3 Seal for flange mounting

Corrupted measurement results.

The seal is not allowed to press against the process isolating diaphragm as this could affect

the measurement result.

‣ Ensure that the seal is not touching the process isolating diaphragm.

A0017743

Fig. 12:

1 Process isolating diaphragm

2Seal

4.5.4 Thermal insulation – PMP55

The PMP55 may only be insulated up to a certain height. The maximum permitted

insulation height is indicated on the devices and applies to an insulation material with a heat

conductivity 0.04 W/(m x K) and to the maximum permitted ambient and process

temperature. The data were determined under the most critical application "quiescent air".

A0020474

Fig. 13: Maximum permitted insulation height, here indicated on a PMP55 with a flange

A Ambient temperature:

B Process temperature: max. 400 °C (752°F), depending on the diaphragm seal filling oil used

1 Maximum permitted insulation height

2 Insulation material

70 °C (158°F)

20 Endress+Hauser

Page 21

Cerabar M, Deltabar M, Deltapilot M Installation

122 (4.8)

52 (2.05)

86 (3.39)

70 (2.76)

140 (5.51)

158 (6.22)

175 (6.89)

ø6 (0.24)

ø42...60 (1.65...2.36)

4.5.5 Wall and pipe mounting (optional)

Endress+Hauser offers a mounting bracket for installation on pipes or walls (for pipe

diameters from 1 ¼" to 2").

A0028493

Engineering unit mm (in)

Please note the following when mounting:

• Devices with capillary tubes: mount capillaries with a bending radius 100 mm (3.94 in).

• When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at

least 5 Nm (3.69 lbs ft).

Endress+Hauser 21

Page 22

Installation Cerabar M, Deltabar M, Deltapilot M

r ³120 (4.72)

2

3

4

5

6

1

7

7

4.5.6 Assembling and mounting the "separate housing" version

Fig. 14: "Separate housing" version

1 In the case of the "separate housing" version, the sensor is delivered with the process connection and cable ready mounted.

2 Cable with connection jack

3 Pressure compensation

4 Connector

5Locking screw

6 Housing mounted with housing adapter, included

7 Mounting bracket provided, suitable for pipe and wall mounting (for pipe diameters from 1 ¼" up to 2")

Engineering unit mm (in)

Assembly and mounting

1. Insert the connector (item 4) into the corresponding connection jack of the cable

(item 2).

2. Plug the cable into the housing adapter (item 6).

3. Tighten the locking screw (item 5).

4. Mount the housing on a wall or pipe using the mounting bracket (item 7).

When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of

at least 5 Nm (3.69 lbs ft).

Mount the cable with a bending radius (r) 120 mm (4.72 in).

Routing the cable (e.g. through a pipe)

You require the cable shortening kit.

Order number: 71093286

For details on mounting, see SD00553P/00/A6.

A0028494

22 Endress+Hauser

Page 23

Cerabar M, Deltabar M, Deltapilot M Installation

A1

ø7.95 (0.31)

ø2.5 (0.1)

5 (0.2)

12 3

s1 a0.8

4.5.7 PMP51, version prepared for diaphragm seal mount –

welding recommendation

A0028495

Fig. 15: Version XSJ: prepared for diaphragm seal mount

1 Hole for fill fluid

2Bearing

3Setscrew

A1 See the "Welding recommendation" table below

Engineering unit mm (in)

Consecutive seam

no.

A1

for sensors

40 bar (600 psi)

Endress+Hauser recommends welding on the diaphragm seal as follows for the "XSJ prepared for diaphragm seal mount" version in feature 110 "Process connection" in the order

code up to, and including, 40 bar (600 psi) sensors: the total welding depth of the fillet weld

is 1 mm (0.04 in) with an outer diameter of 16 mm (0.63 in). Welding is performed

according to the WIG method.

Sketch/welding groove shape,

dimension as per DIN 8551

Information on filling

The diaphragm seal must be filled as soon as it has been welded on.

• After welded into the process connection, the sensor asse mbly must be p rop erl y fil led wit h

a filling oil and sealed gas-tight with a sealing ball and lock screw.

Once the diaphragm seal has been filled, at the zero point the device display should not

exceed 10% of the full scale value of the cell measuring range. The internal pressure of the

diaphragm seal must be corrected accordingly.

• Adjustment / calibration:

– The device is operational once it has been fully assembled.

– Perform a reset. The device must then be calibrated to the process measuring range as

described in the Operating Instructions.

Base material matching Welding method

Adapter made of AISI 316L

(1.4435) to be welded to

diaphragm seal made of

AISI 316L (1.4435 or 1.4404)

A0024811

DIN EN ISO 24063

141 PB Inert gas

Welding

position

Inert gas,

additives

Ar/H 95/5

Additive:

ER 316L Si

(1.4430)

Endress+Hauser 23

Page 24

Installation Cerabar M, Deltabar M, Deltapilot M

NOTICE

1

4.6 Installing Deltabar M

Incorrect handling!

Damage of the device!

‣ Disassembly of the screws with item number (1) is not permissible under any

circumstances and will result in loss of warranty.

4.6.1 Installation position

• Due to the orientation of the Deltabar M, there may be a shift in the measured value, i.e.

when the container is empty, the measured value does not display zero. You may correct

this zero point shift by a position adjustment in one of the following ways:

– via the operation keys on the electronics module ( ä 47, "Function of the operating

elements")

– via the operating menu ( ä 73, "Pos. zero adjust")

• General recommendations for routing the impulse piping can be found in DIN 19210

"Methods for measurement of fluid flow; differential piping for flow measurement devices"

or the corresponding national or international standards.

• Using a three-valve or five-valve manifold allows for easy commissioning, installation and

maintenance without interrupting the process.

• When routing the impulse piping outdoors, ensure that sufficient anti-freeze protection is

used, e.g. by using pipe heat tracing.

• Install the impulse piping with a monotonic gradient of at least 10%.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls ( ä 29, "Wall

and pipe-mounting (option)").

Installation position for flow measurement

For more information about differential pressure flow measurement refer to following

documents:

• Differential pressure flow measurements with orifices: Technical Information TI00422P

• Differential pressure flow measurement with Pitot tubes: Technical Information TI00425P

24 Endress+Hauser

Page 25

Cerabar M, Deltabar M, Deltapilot M Installation

+

–

3

4

2

1

+

–

1

4

5

3

2

7

6

Flow measurement in gases

A0029783

Measuring layout for flow measurement in gases

1 Orifice plate or pitot tube

2 Shut-off valves

3Deltabar M

4 Three-valve manifold

• Mount the Deltabar M above the measuring point so that the condensate which may be

present, can run off into the process piping.

Flow measurement in steam

Measuring layout for flow measurement in steam

1 Orifice plate or pitot tube

2 Condensate traps

3 Shut-off valves

4 Deltabar M

5 Three-valve manifold

6Separator

7 Drain valves

A0029784

• Mount the Deltabar M below the measuring point.

• Mount the condensate traps at the same level as the tapping points and at the same

distance to the Deltabar M.

• Prior to commissioning, fill the impulse piping to the height of the condensate traps.

Endress+Hauser 25

Page 26

Installation Cerabar M, Deltabar M, Deltapilot M

+

–

1

3

4

2

6

5

–

+

min.

p

atm

5

4

p

atm

2

3

1

Flow measurement in liquids

A0029785

Measuring layout for flow measurement in liquids

1 Orifice plate or pitot tube

2 Shut-off valves

3Deltabar M

4 Three-valve manifold

5Separator

6 Drain valves

• Mount the Deltabar M below the measuring point so that the impulse piping is always

filled with liquid and gas bubbles can run back into the process piping.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Installation position for level measurement

Level measurement in an open container

A0029787

Measuring layout for level measurement in open containers

1 The low-pressure side is open to atmospheric pressure

2Deltabar M

3 Three-valve manifold

4Separator

5 Drain valve

• Mount the Deltabar M below the lower measuring connection so that the impulse piping

is always filled with liquid.

• The low-pressure side is open to atmospheric pressure.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

26 Endress+Hauser

Page 27

Cerabar M, Deltabar M, Deltapilot M Installation

–

+

min.

5

4

2

1

3

–

max.

–

+

min.

5

6

3

4

–

max.

2

1

Level measurement in a closed container

A0029790

Measuring layout for level measurement in a closed container

1 Shut-off valves

2 Deltabar M

3 Three-valve manifold

4Separator

5 Drain valves

• Mount the Deltabar M below the lower measuring connection so that the impulse piping

is always filled with liquid.

• Always connect the low-pressure side above the maximum level.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Level measurement in a closed container with superimposed steam

A0029791

Measuring layout for level measurement in a container with superimposed steam

1 Condensate trap

2 Shut-off valves

3 Deltabar M

4 Three-valve manifold

5Separator

6 Drain valves

• Mount the Deltabar M below the lower measuring connection so that the impulse piping

is always filled with liquid.

• Always connect the low-pressure side above the maximum level.

• A condensate trap ensures constant pressure on the low-pressure side.

Endress+Hauser 27

Page 28

Installation Cerabar M, Deltabar M, Deltapilot M

+

1

2

3

4

1

5

6

3

4

+

2

• When measuring in media with solid parts, such as dirty liquids, installing separators and

drain valves is useful for capturing and removing sediment.

Installation position for differential pressure measurement

Differential pressure measurement in gases and steam

A0029792

Measuring layout for differential pressure measurement in gases and steam

1Deltabar M

2 Three-valve manifold

3 Shut-off valves

4 e.g. filter

• Mount the Deltabar M above the measuring point so that the condensate which may be

present, can run off into the process piping.

Differential pressure measurement in liquids

A0029798

Measuring layout for differential pressure measurement in liquids

1 e.g. filter

2 Shut-off valves

3Deltabar M

4 Three-valve manifold

5Separator

6 Drain valves

• Mount the Deltabar M below the measuring point so that the impulse piping is always

filled with liquid and gas bubbles can run back into the process piping.

• When measuring in media with solid parts, such as dirty liquids, installing separators and

28 Endress+Hauser

drain valves is useful for capturing and removing sediment.

Page 29

Cerabar M, Deltabar M, Deltapilot M Installation

4.6.2 Wall and pipe-mounting (option)

Endress+Hauser offers the following mounting brackets for installing the device on pipes or

walls:

Standard design Heavy duty design

A0031326 A0031327

When using a valve block, the block's dimensions must be taken into account.

Bracket for wall and pipe mounting including retaining bracket for pipe mounting and two

nuts.

material of the screws used to secure the device depend on the order code.

Technical data (e.g. dimensions or order numbers for screws) see accessory document

SD01553P/00/EN.

Please note the following when mounting:

• To prevent the mounting screws from scoring, lubricate them with a multi-purpose grease

prior to mounting.

• In the case of pipe mounting, the nuts on the bracket must be tightened uniformly with a

torque of at least 30 Nm (22.13 lbf ft).

• For installation purposes, only use the screws with item number (2) (see the following

diagram).

Endress+Hauser 29

Page 30

Installation Cerabar M, Deltabar M, Deltapilot M

NOTICE

1

1

2

2

2

1

Incorrect handling!

Damage of the device!

‣ Disassembly of the screws with item number (1) is not permissible under any

circumstances and will result in loss of warranty.

A0024167.eps

30 Endress+Hauser

Page 31

Cerabar M, Deltabar M, Deltapilot M Installation

1

1

2

4

3

1

2

3

3

4

C

A

B

4

Typical installation arrangements

A0023109

Abb. 16:

A Impulse line vertical, version V1, alignment 90°

B Impulse line horizontal, version H1, alignment 180°

C Impulse line horizontal, version H2, alignment 90°

1 Deltabar M

2 Adapter plate

3 Mounting bracket

4 Pressure line

Endress+Hauser 31

Page 32

Installation Cerabar M, Deltabar M, Deltapilot M

1

1

1

4.7 Installing Deltapilot M

• Due to the orientation of the Deltapilot M, there may be a shift in the zero point, i.e. when

the container is empty or partially full, the measured value does not display zero. You can

correct this zero point shift ä 47, Section "Function of the operating elements" or

ä 73, Section 8.3 "Pos. zero adjust".

• The local display can be rotated in 90° stages.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

ä 21, Section 4.5.5 "Wall and pipe mounting (optional)".

4.7.1 General installation instructions

• Do not clean or touch process isolating diaphragms with hard or pointed objects.

• The process isolating diaphragm in the rod and cable version is protected against

mechanical damage by a plastic cap.

• If a heated Deltapilot M is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the

pressure compensation (1). If this is the case, mount the Deltapilot M with the pressure

compensation (1) pointing downwards.

• Keep the pressure compensation and GORE-TEX

®

filter (1) free from contamination.

• The device must be installed as follows in order to comply with the cleanability

requirements of the ASME-BPE (Part SD Cleanibility).:

32 Endress+Hauser

Page 33

Cerabar M, Deltabar M, Deltapilot M Installation

4.7.2 FMB50

Level measurement

A0028492

Fig. 17: Measuring arrangement for level

• Always install the device below the lowest measuring point.

• Do not install the device at the following positions:

– in the filling curtain

– in the tank outflow

– in the suction area of a pump

– or at a point in the tank that can be affected by pressure pulses from the agitator

• The calibration and functional test can be carried out more easily if you mount the device

downstream of a shutoff device.

• Deltapilot M must be included in the insulation for media that can harden when cold.

Pressure measurement in gases

• Mount Deltapilot M with shutoff device above the tapping point so that any condensate

can flow into the process.

Pressure measurement in steams

• Mount Deltapilot M with siphon above the tapping point.

• Fill the siphon with liquid before commissioning.

The siphon reduces the temperature to almost the ambient temperature.

Pressure measurement in liquids

• Mount Deltapilot M with the shutoff device below or at the same level as the tapping point.

Endress+Hauser 33

Page 34

Installation Cerabar M, Deltabar M, Deltapilot M

L

E

17 (0.67)

1

2

3

4.7.3 FMB51/FMB52/FMB53

• When mounting rod and cable versions, make sure that the probe head is located at a point

as free as possible from flow. To protect the probe from impact resulting from lateral

movement, mount the probe in a guide tube (preferably made of plastic) or secure it with

a clamping fixture.

• In the case of devices for hazardous areas, comply strictly with the safety instructions

when the housing cover is open.

• The length of the extension cable or the probe rod is based on the planned level zero point.

The height of the protective cap must be taken into consideration when designing the

layout of the measuring point. The level zero point (E) corresponds to the position of the

process isolating diaphragm.

Level zero point = E; top of the probe = L.

4.7.4 Mounting the FMB53 with a suspension clamp

A0018793

Fig. 18: Mounting with a suspension clamp

1Extension cable

2 Suspension clamp

3 Clamping jaws

Mounting the suspension clamp:

1. Mount the suspension clamp (item 2). When selecting the place to fix the unit, take the

weight of the extension cable (item 1) and the device into account.

2. Raise the clamping jaws (item 3). Position the extension cable (item 1) between the

clamping jaws as illustrated in Figure.

3. Hold the extension cable in position (item 1) and push the clamping jaws (item 3) back

34 Endress+Hauser

down.

Tap the clamping jaws gently from above to fix them in place.

Page 35

Cerabar M, Deltabar M, Deltapilot M Installation

NOTICE

12

122 (4.8)

52 (2.05)

86 (3.39)

70 (2.76)

140 (5.51)

158 (6.22)

175 (6.89)

ø6 (0.24)

ø42...60 (1.65...2.36)

4.7.5 Seal for flange mounting

Distorted measurement results.

The seal is not allowed to press on the process isolating diaphragm as this could affect the

measurement result.

‣ Ensure that the seal is not touching the process isolating diaphragm.

A0017743

Fig. 19:

1 Process isolating diaphragm

2Seal

4.7.6 Wall and pipe mounting (optional)

Mounting bracket

Endress+Hauser offers a mounting bracket for installing on pipes or walls (for pipes from 1

1/4

" up to 2" diameter).

Maßeinheit mm (in)

In the case of pipe mounting, the nuts on the bracket must be tightened uniformly with a

torque of at least 5 Nm (3.69 lbf ft).

Endress+Hauser 35

A0028493

Page 36

Installation Cerabar M, Deltabar M, Deltapilot M

r ³120 (4.72)

2

3

4

5

6

1

7

7

4.7.7 Assembling and mounting the "separate housing" version

Fig. 20: "Separate housing" version

1 In the case of the "separate housing" version, the sensor is delivered with the process connection and cable ready mounted.

2 Cable with connection jack

3 Pressure compensation

4 Connector

5Locking screw

6 Housing mounted with housing adapter, included

7 Mounting bracket provided, suitable for pipe and wall mounting (for pipes from 1

Maßeinheit mm (in)

1/4

" up to 2" diameter)

Assembly and mounting

1. Insert the connector (item 4) into the corresponding connection jack of the cable (item

2).

2. Plug the cable into the housing adapter (item 6).

3. Tighten the locking screw (item 5).

4. Mount the housing on a wall or pipe using the mounting bracket (item 7).

When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of

at least 5 Nm (3.69 lbf ft).

Mount the cable with a bending radius (r) 120 mm (4.72 in).

Routing the cable (e.g. through a pipe)

You require the cable shortening kit.

Order number: 71093286

For details on mounting, see SD00553P/00/A6.

A0028494

4.7.8 Supplementary installation instructions

Sealing the probe housing

• Moisture must not penetrate the housing when mounting the device, establishing the

electrical connection and during operation.

• Always firmly tighten the housing cover and the cable entries.

36 Endress+Hauser

Page 37

Cerabar M, Deltabar M, Deltapilot M Installation

NOTICE

NOTICE

4.8 Installing profile seal for universal process adapter

For mounting details, see KA00096F/00/A3.

4.9 Closing the housing cover

Devices with EPDM cover seal - transmitter leakiness!

Mineral-based, animal-based or vegetable-based lubricants cause the EPDM cover seal to

swell and the transmitter to become leaky.

‣ The thread is coated at the factory and therefore does not require any lubrication.

The housing cover can no longer be closed.

Damaged thread!

‣ When closing the housing cover, please ensure that the thread of the cover and housing

are free from dirt, e.g. sand.If you feel any resistance when closing the cover, check the

thread on both again to ensure that they are free from dirt.

4.9.1 Closing the cover on the stainless steel housing

A0028497

Fig. 21: Closing the cover

The cover for the electronics compartment is tightened by hand at the housing until the stop.

The screw serves as DustEx protection (only available for devices with DustEx approval).

4.10 Post-installation check

O Is the device undamaged (visual inspection)?

O Does the device comply with the measuring point specifications?

For example:

• Process temperature

• Process pressure

• Ambient temperature range

•Measuring range

O Are the measuring point identification and labeling correct (visual inspection)?

O Is the device adequately protected against precipitation and direct sunlight?

O Are the securing screw and securing clamp tightened securely?

Endress+Hauser 37

Page 38

Electrical connection Cerabar M, Deltabar M, Deltapilot M

WARNING

!

- +

1

1

2

3

4

5 Electrical connection

5.1 Connecting the device

Supply voltage might be connected!

Risk of electric shock and/or explosion!

‣ Ensure that no uncontrolles processes are activated in the system.

‣ Switch off the supply voltage before connecting the device.

‣ When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or

Installation or Control Drawings.

‣ A suitable circuit breaker must be provided for the device in accordance with

IEC/EN61010.

‣ Devices with integrated overvoltage protection must be grounded.

‣ Protective circuits against reverse polarity, HF influences and overvoltage peaks are

integrated.

Connect the device in the following order:

1. Check that the supply voltage corresponds to the supply voltage indicated on the

nameplate.

2. Switch off the supply voltage before connecting the device.

3. Remove housing cover.

4. Guide the cable through the gland. Preferably use a twisted, shielded two-wire cable.

5. Connect the device in accordance with the following diagram.

6. Screw down the housing cover.

7. Switch on the supply voltage.

38 Endress+Hauser

FOUNDATION Fieldbus electrical connection

1 Terminals for supply voltage and signal

2 Grounding terminal

3 Supply voltage: 9 to 32 VDC (Power conditioner)

4 External ground terminal

A0029967

Page 39

Cerabar M, Deltabar M, Deltapilot M Electrical connection

2

1

4

3

5.1.1 Devices with 7/8" plug

PIN assignment for 7/8" connector PIN Meaning

1Signal –

2Signal +

3 Not assigned

4Shield

A0011176

5.2 Connecting the measuring unit

5.2.1 Supply voltage

Electronic version

FOUNDATION Fieldbus,

version for non-hazardous areas

9 to 32 V DC

For further information on the network structure and grounding and for further bus system

components such as bus cables, see the relevant documentation, e.g. Operating Instructions

BA00013S "FOUNDATION Fieldbus Overview" and the FOUNDATION Fieldbus Guideline.

5.2.2 Current consumption

16 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21.

5.2.3 Terminals

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

• External ground terminal: 0.5 to 4 mm

2

(20 to 12 AWG)

5.2.4 Cable specification

• Endress+Hauser recommends using twisted, shielded two-wire cables.

• Cable outer diameter: 5 to 9 mm (0.2 to 0.35 in)

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2

(MBP).

Endress+Hauser 39

Page 40

Electrical connection Cerabar M, Deltabar M, Deltapilot M

5.2.5 Shielding/potential equalization

• You achieve optimum shielding against disturbances if the shielding is connected on both

sides (in the cabinet and on the device). If potential equalization currents are expected in

the plant, only ground shielding on one side, preferably at the transmitter.

• When using in hazardous areas, you must observe the applicable regulations.

Separate Ex documentation with additional technical data and instructions is included

with all Ex systems as standard.

5.3 Potential equalization

Hazardous area applications: Connect all devices to the local potential equalization.

Observe the applicable regulations.

40 Endress+Hauser

Page 41

Cerabar M, Deltabar M, Deltapilot M Electrical connection

1

2

3

4

+

-

+

-

rt

sw

+

-

A

B

5.4 Overvoltage protection (optional)

Devices showing version "NA" in feature 610 "Mounted accessories" in the order code are

equipped with a surge arrester (see Technical Information "Ordering information" section").

The surge arrester is mounted at the factory on the housing thread for the cable gland and

is approx. 70 mm (2.76 in) in length (take additional length into account when installing).

The device is connected as specified in the following graphic. For details refer to

TI001013KEN, XA01003KA3 and BA00304KA2.

5.4.1 Wiring

Fig. 22:

A Without direct shield grounding

B With direct shield grounding

1 Incoming connection cable

2 HAW569-DA2B

3 Unit to be protected

4 Connection cable

A0023111

Endress+Hauser 41

Page 42

Electrical connection Cerabar M, Deltabar M, Deltapilot M

NOTICE

10 (0.4)

10 (0.4)

5 (0.2)

5 (0.2)

15 (0.6)

7 (0.28)

min. 1.5 mm² (16 AWG)

max. 1.5 mm² (16 AWG)

max. 2.5 mm² (14 AWG)

max. 3.75 Nm (2.77 lbf ft)

1

2

2

3

3

A

B

0.4 Nm (0.30 lbf ft)

+

+

5.4.2 Installation

Fig. 23:

A Without shield grounding

B With shield grounding

1 See NOTICE below

2Red

3Black

Engineering unit mm (in)

Screw connection glued at factory!

Damage to the device and/or surge arrester!

‣ When releasing/tightening the union nut use a wrench to hold the screw steady so it

does not turn.

A0028499

42 Endress+Hauser

Page 43

Cerabar M, Deltabar M, Deltapilot M Electrical connection

5.5 Post-connection check

Perform the following checks after completing electrical installation of the device:

• Does the supply voltage match the specifications on the nameplate?

• Is the device properly connected?

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

As soon as voltage is applied to the device, the green LED on the electronic insert lights up

briefly or the connected onsite display lights up.

Endress+Hauser 43

Page 44

Operation Cerabar M, Deltabar M, Deltapilot M

on

off

Display

Zero

simulation

TMTM

F

OUNDATIONFOUNDATION

SW / P2=High

SW / Ö

dampingdamping

delta p only

E

+

–

6Operation

6.1 Operating options

6.1.1 Operation without operating menu

Operating options Explanation Graphic illustration Description

Local operation

without device display

The device is operated using

the operating key and DIP

switches on the electronic

insert.

ä 46

6.1.2 Operation with an operating menu

Operation with an operating menu is based on an operation concept with "user roles"

ä 48.

Operating options Explanation Graphic illustration Description

Local operation

with device display

Remote operation via

FieldCare

The device is operated using

the operating keys on the

device display.

The device is operated using

the FieldCare operating tool.

ä 49

ä 53

44 Endress+Hauser

Page 45

Cerabar M, Deltabar M, Deltapilot M Operation

6.1.3 Operation via FF communication protocol

Operating options Explanation Graphic illustration Description

Remote operation via

FieldCare

The device is operated using

the FieldCare operating tool.

ä 57

Remote operation via

the NI Tool

The device is operated using

the NI Tool.

ä 138

Endress+Hauser 45

Page 46

Operation Cerabar M, Deltabar M, Deltapilot M

on

off

SW / P2=High

Simulation

SW /

damping

1

2

345

on

off

Display

Zero

simulation

TM

F

OUNDATION

SW / P2=High

SW /

damping

delta p only

87654

1

2

3

6.2 Operation without an operating menu

6.2.1 Position of operating elements

The operating key and DIP switches are located on the electronic insert in the device.

A0023127

Fig. 24: FOUNDATION Fieldbus electronic insert

1 Operating key for position zero adjustment (Zero) or reset

2 Green LED to indicate successful operation

3 Slot for optional local display

4+5 DIP switch only for Deltabar M

Switch 5: "SW/Square root"; used to control the output characteristics

Switch 4: "SW/P2-High"; used to determine the high-pressure side

6 DIP-switch for simulation mode

7 DIP switch for switching damping on/off

8 DIP switch for locking/unlocking parameters relevant to the measured value

Function of the DIP switches

SwitchesSymbol/

labeling

"off" "on"

1 The device is unlocked.

Parameters relevant to the measured

value can be modified.

2damping Damping is switched off.

The output signal follows measured value

changes without any delay.

3 Simulation The simulation mode is switched off

(factory setting).

The following switches only for Deltabar M:

4SW/ The output characteristics is defined by

the setting in the operating menu.

• "Setup" -> "Measuring mode"

• "Setup" -> "Extended setup" ->

5 SW/P2= High The high-pressure (+/HP) side is defined

by the setting in the operating menu.

("Setup" -> "High Press. Side")

Switch position

The device is locked.

Parameters relevant to the measured

value cannot be modified.

Damping is switched on.

The output signal follows measured value

changes with the delay time .

The simulation mode is switched on.

The measuring mode is "flow" and the

output characteristics is "Square root"

regardless of the settings in the operating

menu.

The high-pressure side (+/HP) is

allocated to the P2 pressure connection

regardless of the setting in the operating

menu.

1)

1) The value for the delay time can be configured via the operating menu ("Setup" -> "Damping").

Factory setting: = 2 s or as per order specifications.

46 Endress+Hauser

Page 47

Cerabar M, Deltabar M, Deltapilot M Operation

Function of the operating elements

Operating key Meaning

"Zero"

pressed for at least

3seconds

"Zero"

pressed for at least

12 seconds

Position adjustment (zero point correction)

Press key for at least 3 seconds. The LED on the electronic insert lights up briefly if the

pressure applied has been accepted for position adjustment.

See also the following Section "Performing position adjustment on site.''

Reset

All parameters are reset to the order configuration.

Performing position adjustment on site

• Operation must be unlocked. ä 54, Section 6.3.5 "Locking/unlocking operation".

• The device is configured at the factory for the Pressure measuring mode (Cerabar,

Deltabar) or Level measuring mode (Deltapilot).

– Operation via FF configuration program: In the Pressure Transducer Block, you can

change the measuring mode by means of the PRIMARY_VALUE_TYPE parameter.

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

• To reconcile the parameter database, perform a "Reconcile device" (after position

adjustment) with the FF host.

Perform position adjustment:

1. Pressure is present at device.

2. Press key for at least 3 seconds.

3. If the LED on the electronic insert lights up briefly, the pressure applied has been

accepted for position adjustment.

If the LED does not light up, the pressure applied was not accepted. Observe the input

limits. For error messages, ä 221, Section 11.1 "Messages".

6.2.2 Locking/unlocking operation

Once you have entered all the parameters, you can lock your entries against unauthorized

and undesired access.

If operation is locked by means of the DIP switch, you can only unlock operation again by

means of the DIP switch. If operation is locked by means of the operating menu, you can only

unlock operation again using the operating menu.

Locking/unlocking via DIP switches

DIP switch 1 on the electronic insert is used to lock/unlock operation.

ä 46, "Function of the DIP switches".

Endress+Hauser 47

Page 48

Operation Cerabar M, Deltabar M, Deltapilot M

6.3 Operation with an operating menu

6.3.1 Operation concept

The operation concept makes a distinction between the following user roles:

User role Meaning

Operator Operators are responsible for the devices during normal "operation". This is usually limited

Service engineer/

technician

Expert Experts work with the devices over the entire product life cycle, but their device

to reading process values either directly at the device or in a control room. If the work with

the devices extends beyond value read-off tasks, the tasks involve simple, applicationspecific functions that are used in operation. Should an error occur, these users simple

forward the information on the errors but do not intervene themselves.

Service engineers usually work with the devices in the phases following device

commissioning.

They are primarily involved in maintenance and troubleshooting activities for which simple

settings have to be made at the device.

Technicians work with the devices over the entire life cycle of the product.

Thus, commissioning and advanced settings and configurations are some of the tasks they

have to carry out.

requirements are often extremely high. Individual parameters/functions from the overall

functionality of the devices are required for this purpose time and again.

In addition to technical, process-oriented tasks, experts can also perform administrative

tasks (e.g. user administration).

"Experts" can avail of the entire parameter set.

6.3.2 Structure of the operating menu

User role Submenu Meaning/use

Operator Language Only consists of the "Language" parameter (000) where the operating

language for the device is specified.

The language can always be changed even if the device is locked.

Operator Display/operat. Contains parameters that are needed to configure the measured value display

(selecting the values displayed, display format, display contrast, etc.).

With this submenu, users can change the measured value display without

affecting the actual measurement.

Service

engineer/

technician

Setup Contains all the parameters that are needed to commission measuring

operations. This submenu has the following structure:

• Standard setup parameters

A wide range of parameters, which can be used to configure a typical

application, is available at the start. The measuring mode selected

determines which parameters are available.

After making settings for all these parameters, the measuring operation

should be completely configured in the majority of cases.

• "Extended setup" submenu

The "Extended setup" submenu contains additional parameters for more indepth configuration of the measurement operation to convert the

measured value and to scale the output signal.

This menu is split into additional submenus depending on the measuring

mode selected.

48 Endress+Hauser

Page 49

Cerabar M, Deltabar M, Deltapilot M Operation

User role Submenu Meaning/use

Service

engineer/

technician

Expert Expert Contains all the parameters of the device (including those in one of the

Diagnosis Contains all the parameters that are needed to detect and analyze operating

errors. This submenu has the following structure:

• Diagnostic list

Contains up to 10 error messages currently pending.

• Event logbook

Contains the last 10 error messages (no longer pending).

• Instrument info

Contains information on the device identification.

• Measured values

Contains all the current measured values

• Simulation

Is used to simulate pressure, level, flow and alarm/warning.

• Reset

submenus). The "Expert" submenu is structured by the function blocks of the

device. It thus contains the following submenus:

• System

Contains general device parameters that neither affect measurement nor

integration into a distributed control system.

• Measurement

Contains all the parameters for configuring the measurement.

• Communication

Contains all the parameters of the FOUNDATION Fieldbus interface.

• Application

Contains all the parameters for configuring the functions that go beyond

the actual measurement (e.g. totalizer).

• Diagnosis

Contains all the parameters that are needed to detect and analyze

operating errors.

For an overview of the entire operating menu: ä 108 ff.

Direct access to parameters

The parameters can only be accessed directly via the "Expert" user role.

Parameter name Description

Direct access (119)

Entry

Menu path:

Expert Direct access

Use this function to enter a parameter code for direct access.

User input:

• Enter the desired parameter code.

Factory setting:

0

6.3.3 Operation with a device display (optional)

A 4-line liquid crystal display (LCD) is used for display and operation. The onsite display

shows measured values, dialog texts, fault messages and notice messages.

For easy operation the display can be taken out of the housing (see figure steps 1 to 3). It is

connected to the device through a 90 mm (3.54 in) cable.

The display of the device can be turned in 90° stages (see figure steps 4 to 6).

Depending on the orientation of the device, this makes it easy to operate the device and read

the measured values.

Endress+Hauser 49

Page 50

Operation Cerabar M, Deltabar M, Deltapilot M

1.

2.

3.

4.

5.

6.

E

+

–

F

1

6

2

57

3

4

A0028500

Functions:

• 8-digit measured value display including sign and decimal point.

• Bar graph as graphic display of the current pressure measured value in relation to the set

pressure range in the Pressure Transducer Block. The pressure range is set by means of the

SCALE_IN parameter (via FF configuration program, not via onsite display).

•Three keys for operation.

• Simple and complete menu guidance as parameters are split into several levels and groups.

• Each parameter is given a 3-digit parameter code for easy navigation.

• Possibility of configuring the display to suit individual requirements and preferences, such

as language, alternating display, display of other measured values such as sensor

temperature, contrast setting.

• Comprehensive diagnostic functions (fault and warning message etc.).

A0030013

Fig. 25: Display

1 Main line

2Value

3Symbol

4Unit

5Bar graph

6 Information line

7Operating keys

50 Endress+Hauser

Page 51

Cerabar M, Deltabar M, Deltapilot M Operation

The following table illustrates the symbols that can appear on the onsite display. Four

symbols can occur at one time.

Symbol Meaning

Lock symbol

The operation of the device is locked. To unlock the device, ä 54, Locking/

unlocking operation.

Communication symbol

Data transfer via communication

Square root symbol (only Deltabar M)

Active measuring mode "Flow measurement"

Error message "Out of specification"

The device is being operated outside its technical specifications (e.g. during warmup

or cleaning processes).

Error message "Service mode"

The device is in the service mode (during a simulation, for example).

Error message "Maintenance required"

Maintenance is required. The measured value remains valid.

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid.

Simulation symbol

Simulation mode is activated. DIP switch 2 for simulation is set to "On".

See also Section 6.2.1 "Position of operating elements" and ä 54, Section 6.3.6

"Simulation".

Operating keys on the display and operating module

Operating key(s) Meaning

– Navigate downwards in the picklist

– Edit the numerical values and characters within a function

– Navigate upwards in the picklist

– Edit the numerical values and characters within a function

–Confirm entry

–Jump to the next item

– Selection of a menu item and activation of the editing mode

Contrast setting of onsite display: darker

O

O

S

F

and

F

Contrast setting of onsite display: brighter

and

S

O

and

F

S

ESC functions:

– Exit the edit mode for a parameter without saving the changed value.