Page 1

TI01133P/00/EN/06.18

71404630

Products Solutions Services

Technical Information

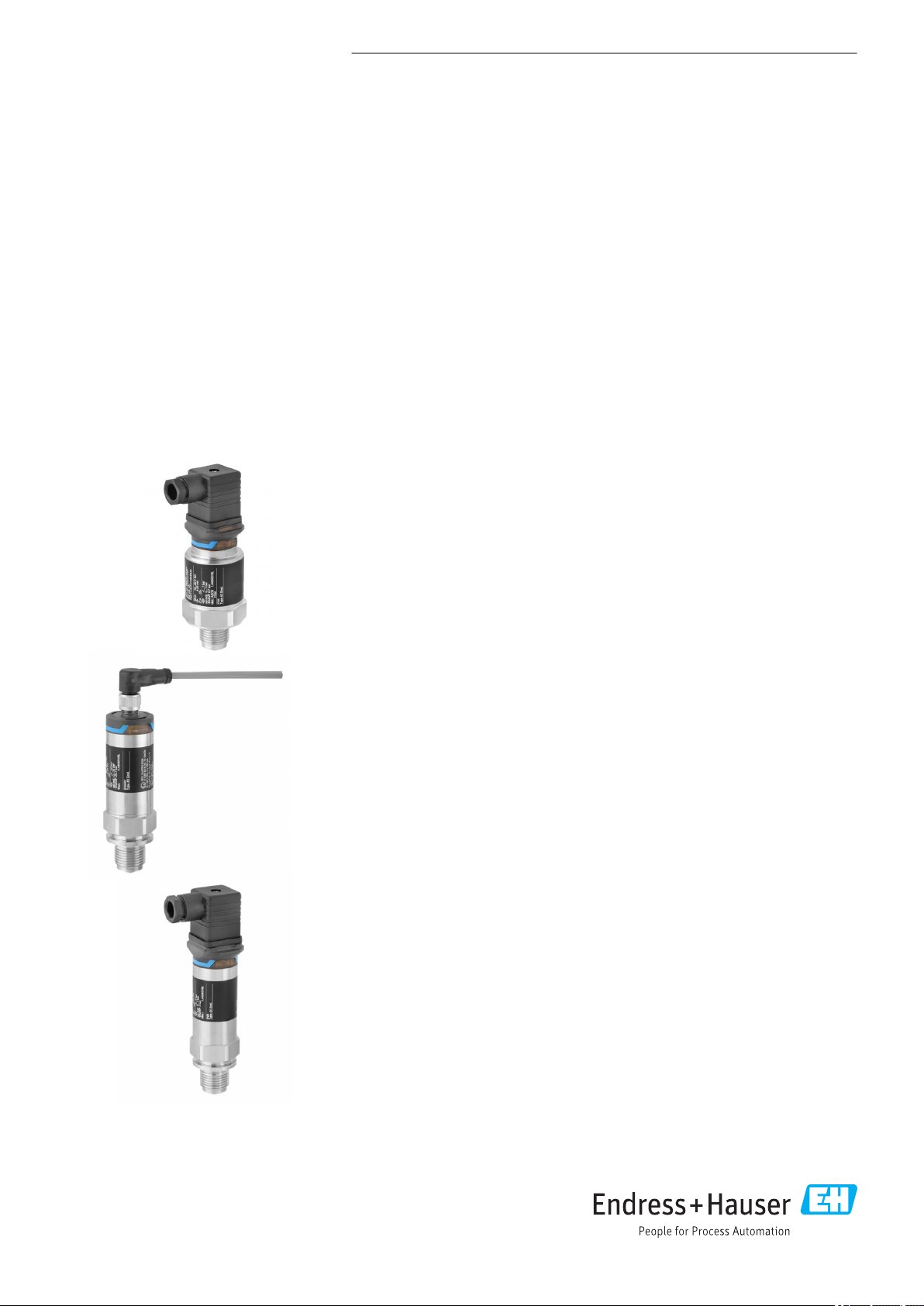

Cerabar PMC11, PMC21,

PMP11, PMP21

Process pressure measurement

Pressure transducer with ceramic and metal

sensors

Application

The Cerabar is a pressure transducer for the measurement of absolute and gauge

pressure in gases, vapors, liquids and dust. The Cerabar can be used internationally

thanks to a wide range of approvals and process connections.

Your benefits

• High reproducibility and long-term stability

• Reference accuracy: up to 0.3%

• Customized measuring ranges

– Turn down up to 5:1

– Sensor for measuring ranges up to 400 bar (6 000 psi)

• Housing and process isolating diaphragm made of 316L

Page 2

Table of contents

Cerabar PMC11, PMC21, PMP11, PMP21

Document information ....................... 4

Document function ............................ 4

Symbols used ................................ 4

Documentation ............................... 5

Terms and abbreviations ........................ 6

Turn down calculation .......................... 7

Function and system design ................... 8

Measuring principle - process pressure measurement ..... 8

Measuring system ............................. 8

Device features ............................... 9

Product design .............................. 11

System integration ........................... 12

Input .................................... 13

Measured variable ............................ 13

Measuring range ............................ 13

Output .................................. 16

Output signal ............................... 16

Signal range 4 to 20 mA ........................ 16

Load (for 4 to 20 mA devices ) .................... 16

Load resistance (for 0 to 10 V devices) .............. 16

Signal on alarm 4 to 20 mA ...................... 16

Dead time, time constant ....................... 16

Dynamic behavior ............................ 17

Power supply ............................. 18

Terminal assignment .......................... 18

Supply voltage .............................. 18

Current consumption and alarm signal .............. 18

Power supply fault ............................ 19

Electrical connection .......................... 19

Cable specification ............................ 19

Residual ripple .............................. 19

Influence of power supply ....................... 19

Overvoltage protection ........................ 19

Performance characteristics of ceramic process

isolating diaphragm ........................ 20

Reference operating conditions ................... 20

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 20

Influence of the installation position ................ 20

Resolution ................................. 20

Reference accuracy ........................... 20

Thermal change of the zero output and the output span ... 20

Long-term stability ........................... 21

Switch-on time .............................. 21

Performance characteristics of metal process

isolating diaphragm ........................ 22

Reference operating conditions ................... 22

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 22

Influence of the installation position ................ 22

Resolution ................................. 22

Reference accuracy ........................... 22

Thermal change of the zero output and the output span ... 22

Long-term stability ........................... 22

Switch-on time .............................. 22

Installation ............................... 23

Installation conditions ......................... 23

Influence of the installation position ................ 23

Mounting location ............................ 23

Mounting instructions for oxygen applications ......... 24

Environment .............................. 26

Ambient temperature range ..................... 26

Storage temperature range ...................... 26

Climate class ............................... 26

Degree of protection .......................... 26

Vibration resistance ........................... 26

Electromagnetic compatibility .................... 26

Process .................................. 27

Process temperature range for devices with ceramic

process isolating diaphragm ..................... 27

Process temperature range for devices with metallic

process isolating diaphragm ..................... 27

Pressure specifications ......................... 28

Mechanical construction .................... 29

Design, dimensions ........................... 29

Electrical connection .......................... 29

Housing ................................... 30

Process connections with internal, ceramic process

isolating diaphragm ........................... 32

Process connections with internal, ceramic process

isolating diaphragm ........................... 33

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, metal process isolating

diaphragm ................................. 35

Process connections with internal, metal process isolating

diaphragm ................................. 36

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with flush-mounted, metal process

isolating diaphragm ........................... 38

Materials in contact with process .................. 39

Materials not in contact with process ............... 40

Cleaning .................................. 41

Operability ............................... 42

Plug-on display PHX20 (optional) .................. 42

Certificates and approvals ................... 43

CE mark ................................... 43

2 Endress+Hauser

Page 3

Cerabar PMC11, PMC21, PMP11, PMP21

RoHS ..................................... 43

RCM-Tick marking ............................ 43

EAC conformity .............................. 43

Approval .................................. 43

Safety Instructions (XA) ........................ 43

Marine approval (pending) ...................... 44

Pressure Equipment Directive 2014/68/EU (PED) ....... 44

Other standards and guidelines ................... 44

CRN approval ............................... 45

Calibration unit .............................. 45

Calibration ................................. 45

Inspection certificates .......................... 45

Ordering information ....................... 46

Scope of delivery ............................. 46

Accessories ............................... 47

Weld-in adapter ............................. 47

Plug-on display PHX20 ......................... 47

M12 plug connectors .......................... 47

Documentation ............................ 48

Field of Activities ............................ 48

Technical Information ......................... 48

Operating Instructions ......................... 48

Brief Operating Instructions ..................... 48

Safety Instructions (XA) ........................ 48

Endress+Hauser 3

Page 4

Document information

DANGER

WARNING

CAUTION

NOTICE

A

,…,

1.

2.

3.

Cerabar PMC11, PMC21, PMP11, PMP21

Document function

The document contains all the technical data on the device and provides an overview of the

accessories and other products that can be ordered for the device.

Symbols used Safety symbols

Symbol Meaning

Electrical symbols

Symbol Meaning Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Ground connection

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

4 Endress+Hauser

Page 5

Cerabar PMC11, PMC21, PMP11, PMP21

Documentation

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com → Download

Brief Operating Instructions (KA): getting the 1st measured value quickly

These instructions contain all the essential information from incoming acceptance to initial

commissioning.

Operating Instructions (BA): your comprehensive reference

These Operating Instructions contain all the information that is required in various phases of the life

cycle of the device: from product identification, incoming acceptance and storage, to mounting,

connection, operation and commissioning through to troubleshooting, maintenance and disposal.

Safety Instructions (XA)

Depending on the approval, the following Safety Instructions (XA) are supplied with the device. They

are an integral part of the Operating Instructions.

Device Directive Documentation Option

PMP21 ATEX II 1/2G Ex ia IIC T4 Ga/Gb XA01271P BA

PMC21 ATEX II 2G Ex ia IIC T4 Gb XA01271P BB

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

ATEX II 3G Ex ec IIC T4 Gc XA01533P BC

FM IS Cl. I, Div.1 Gr. A-D T4 XA01321P FA

CSA C/US IS Cl. I Div. 1 Gr. A-D XA01322P CB

EAC Ex ia IIC T4 Ga/Gb XA01540P GA

IEC Ex ia IIC T4 Ga/Gb XA01271P IA

NEPSI Ex ia IIC T4 XA01363P NA

TIIS Ex ia IIC T4 In preparation TA

1)

1) Product Configurator order code for "Approval"

The nameplate indicates the Safety Instructions (XA) that are relevant to the device.

Endress+Hauser 5

Page 6

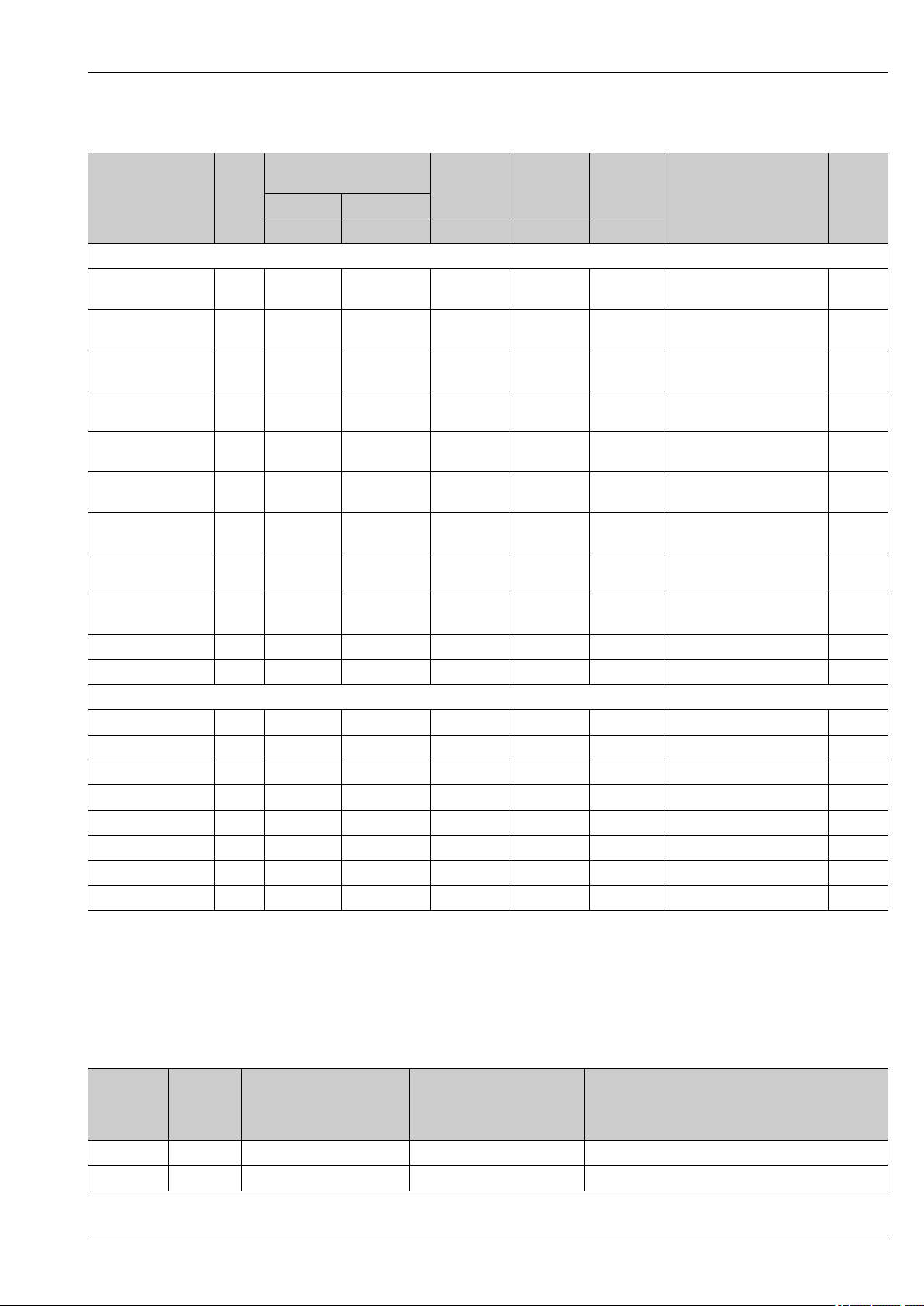

Terms and abbreviations

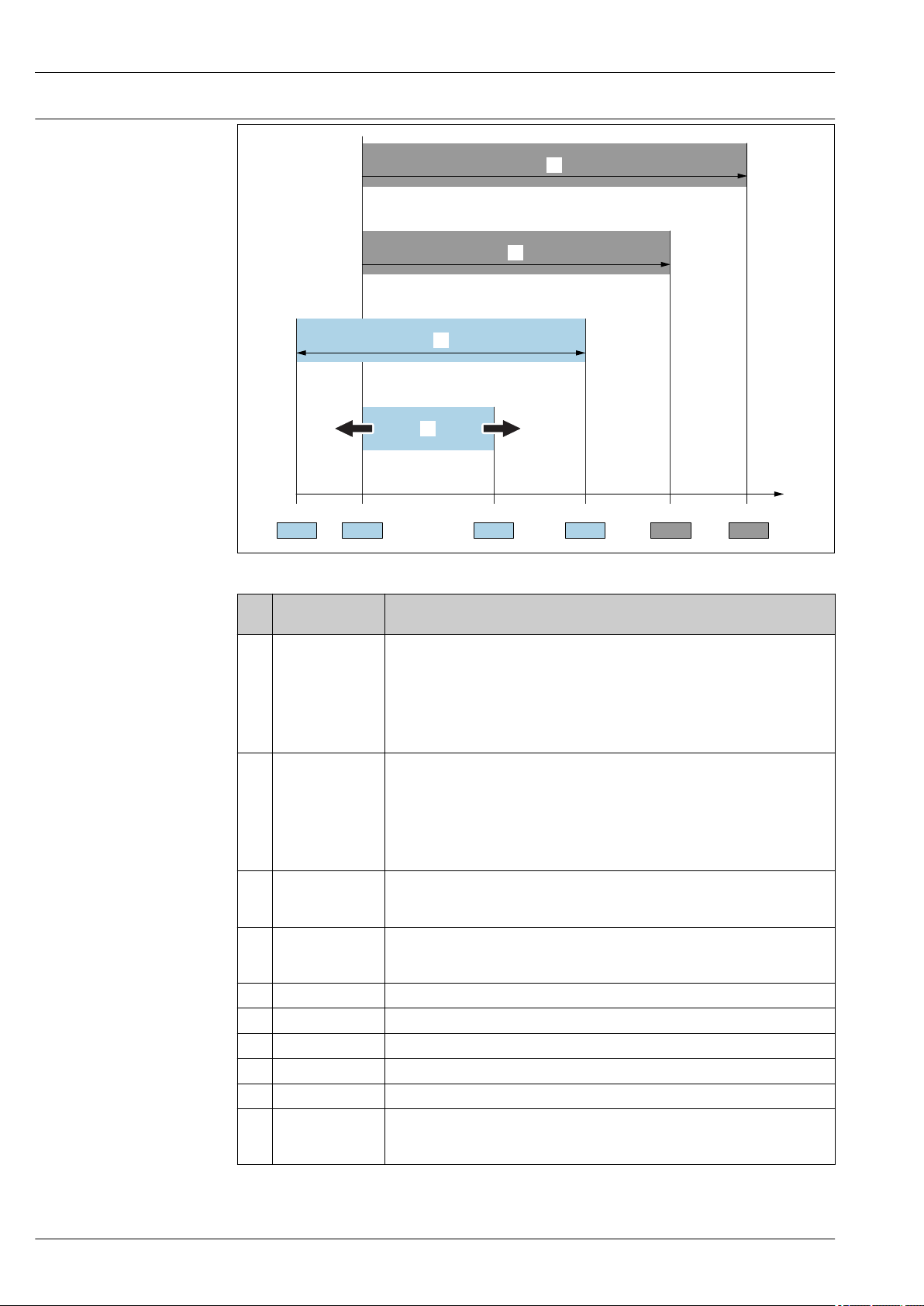

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

Cerabar PMC11, PMC21, PMP11, PMP21

A0029505

Item Term/

abbreviation

1 OPL The OPL (over pressure limit = sensor overload limit) for the measuring device

2 MWP The MWP (maximum working pressure) for the sensors depends on the lowest-

3 Maximum sensor

measuring range

4 Calibrated/

adjusted span

p - Pressure

- LRL Lower range limit

- URL Upper range limit

- LRV Lower range value

- URV Upper range value

- TD (turn down) Turn down

Explanation

depends on the lowest-rated element, with regard to pressure, of the selected

components, i.e. the process connection has to be taken into consideration in

addition to the measuring cell. Also observe pressure-temperature dependency. For

the relevant standards and additional notes, see the "Pressure specifications" section

→ 28 .

The OPL may only be applied for a limited period of time.

rated element, with regard to pressure, of the selected components, i.e. the process

connection has to be taken into consideration in addition to the measuring cell.

Also observe pressure-temperature dependency. For the relevant standards and

additional notes, see the "Pressure specifications" section → 28 .

The MWP may be applied at the device for an unlimited period.

The MWP can also be found on the nameplate.

Span between LRL and URL

This sensor measuring range is equivalent to the maximum calibratable/adjustable

span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized spans.

The turn down is preset at the factory and cannot be changed.

Example - see the following section.

6 Endress+Hauser

Page 7

Cerabar PMC11, PMC21, PMP11, PMP21

LRV

URLURV

LRL

1 = 2

3

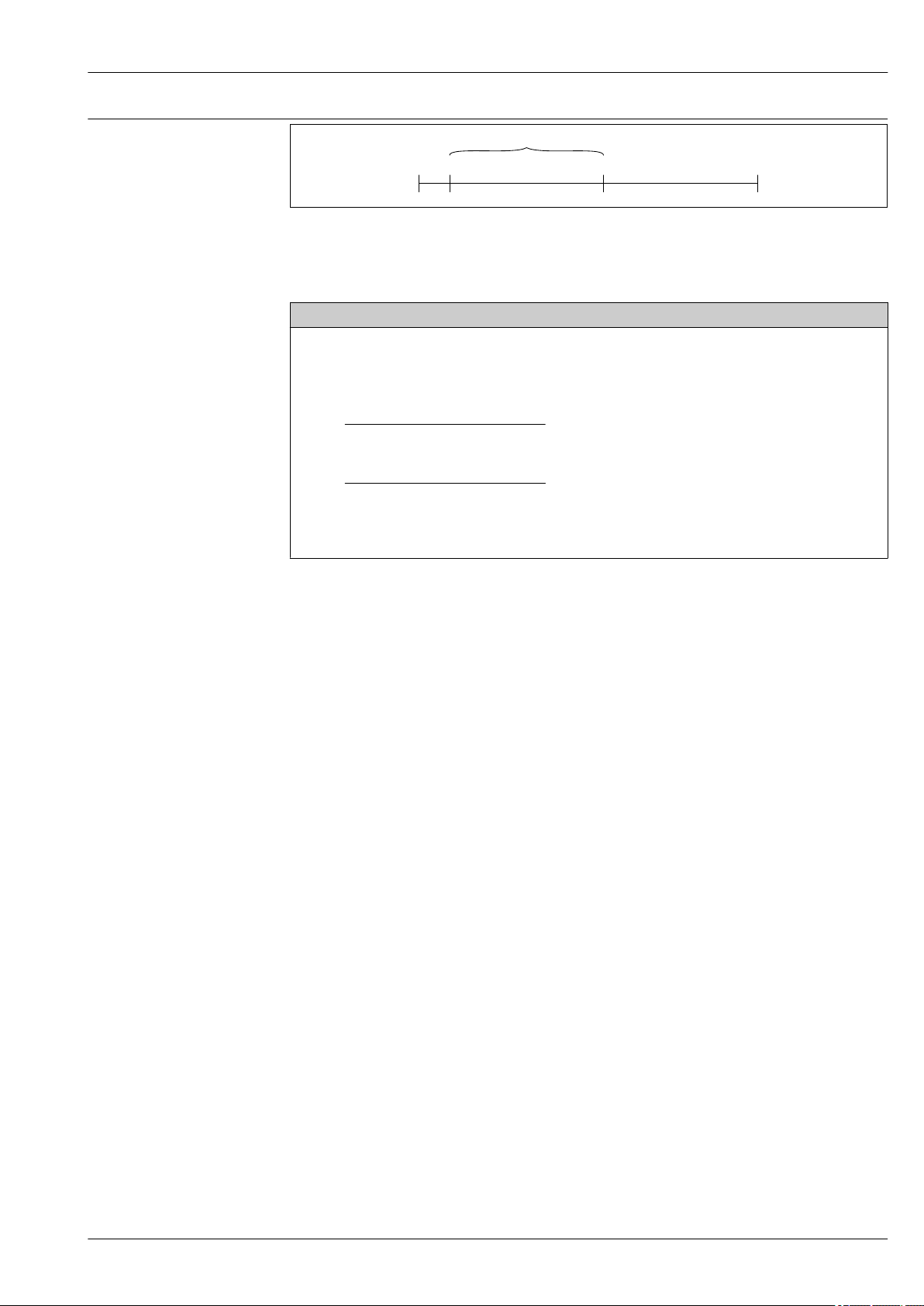

Turn down calculation

1 Calibrated/adjusted span

2 Zero point-based span

3 URL sensor

Example

• Sensor:10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

Turn down (TD):

A0029545

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD =

URL

|URV - LRV|

10 bar (150 psi)

TD =

|5 bar (75 psi) - 0 bar (0 psi)|

In this example, the TD is 2:1.

This span is based on the zero point.

= 2

Endress+Hauser 7

Page 8

Function and system design

1

2

3

4

p

p

1

3

4

2

Cerabar PMC11, PMC21, PMP11, PMP21

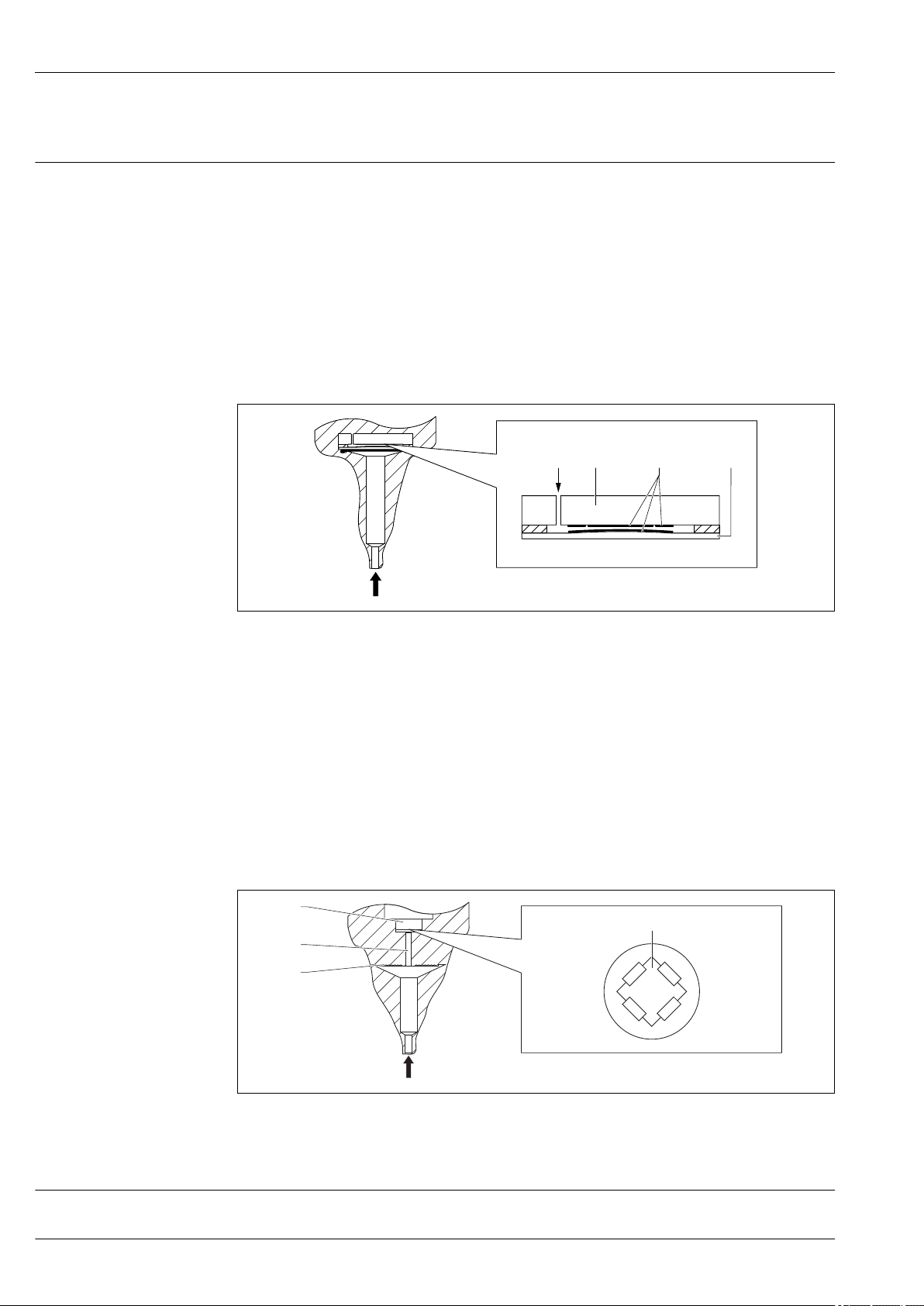

Measuring principle process pressure

measurement

Devices with ceramic process isolating diaphragm (Ceraphire®)

The ceramic sensor is an oil-free sensor, i.e. the process pressure acts directly on the robust ceramic

process isolating diaphragm and causes it to deflect. A pressure-dependent change in capacitance is

measured at the electrodes of the ceramic substrate and the process isolating diaphragm. The

measuring range is determined by the thickness of the ceramic process isolating diaphragm.

Advantages:

• Guaranteed overload resistance up to 40 times the nominal pressure

• The ultrapure 99.9% ceramic (Ceraphire®, see also "www.endress.com/ceraphire") ensures:

– Extremely high chemical durability

– High mechanical durability

• Can be used in absolute vacuum

• Small measuring ranges

A0020465

1 Air pressure (gauge pressure sensors)

2 Ceramic substrate

3 Electrodes

4 Ceramic process isolating diaphragm

Devices with metallic process isolating diaphragm

The process pressure deflects the metal process isolating diaphragm of the sensor and a fill fluid

transfers the pressure to a Wheatstone bridge (semiconductor technology). The pressure-dependent

change in the bridge output voltage is measured and evaluated.

Advantages:

• Can be used for high process pressures

• Fully welded sensor

• Slim, flush-mounted process connections available

A0016448

1 Silicon measuring element, substrate

2 Wheatstone bridge

3 Channel with fill fluid

4 Metal process isolating diaphragm

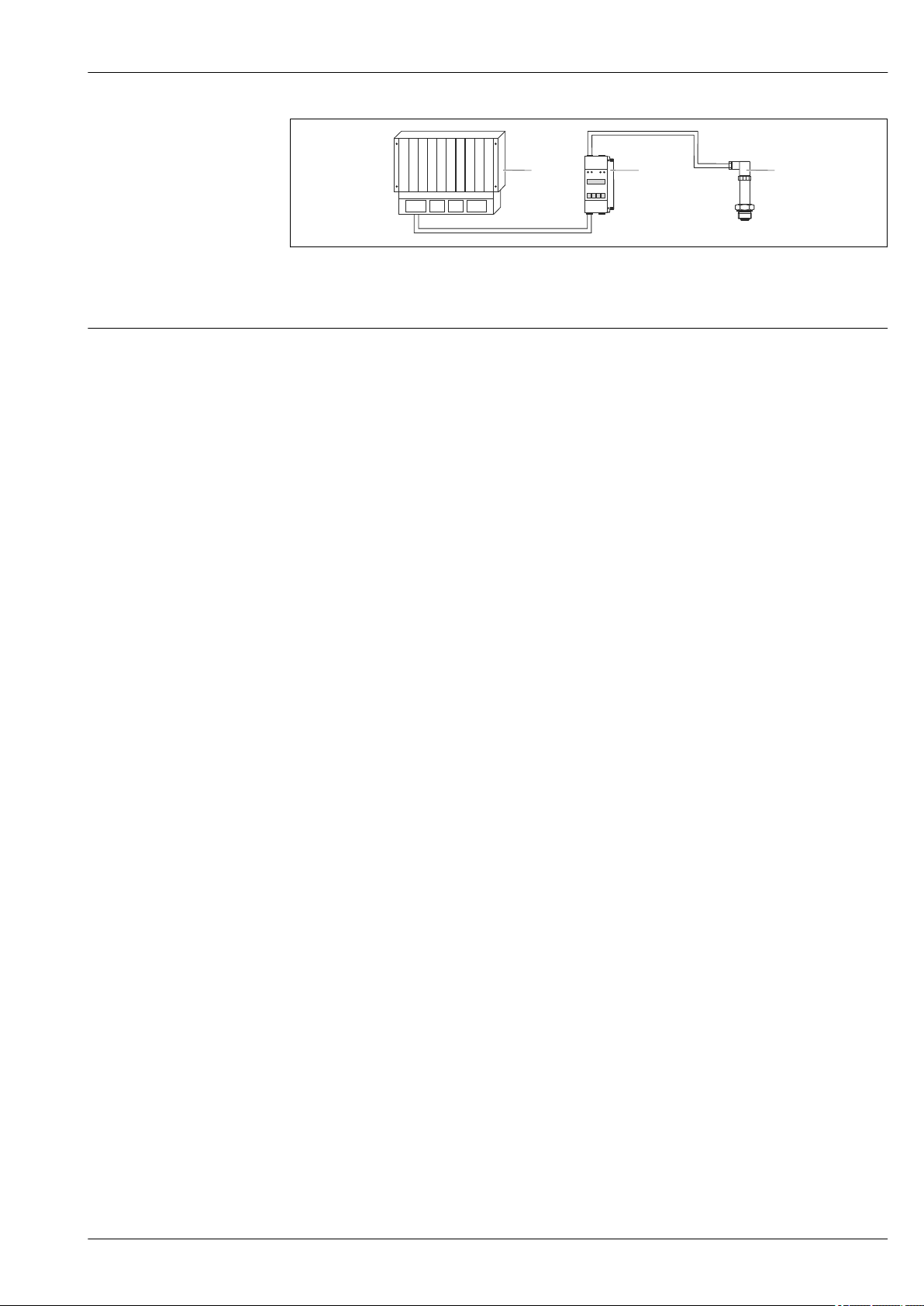

Measuring system

A complete measuring system comprises:

8 Endress+Hauser

Page 9

Cerabar PMC11, PMC21, PMP11, PMP21

1

2

3

1 PLC (programmable logic control)

2 e.g. RN221N / RMA42 (if required)

3 Pressure transducer

Device features Field of application

• PMC11: Gauge pressure

• PMP11: Gauge pressure

• PMC21: Gauge and absolute pressure

• PMP21: Gauge and absolute pressure

Process connections

PMC11:

• Thread ISO 228

• Thread ASME

• DIN 13

PMP11:

• Thread ISO 228, also flush-mount

• Thread ASME

• DIN 13

PMC21:

• Thread ISO 228

• Thread DIN 13

• Thread ASME

• Thread JIS

PMP21:

• Thread ISO 228, also flush-mount

• Thread DIN 13

• Thread ASME

• Thread JIS

A0021926

Measuring ranges

• PMC11: from –400 to +400 mbar (–6 to +6 psi) to –1 to +40 bar (–15 to +600 psi).

• PMP11: from –400 to +400 mbar (–6 to +6 psi) to –1 to +40 bar (–15 to +600 psi).

• PMC21: from –100 to +100 mbar (–1.5 to +1.5 psi) to –1 to +40 bar (–15 to +600 psi).

• PMP21: from –400 to +400 mbar (–6 to +6 psi) to –1 to +400 bar (–15 to +6 000 psi).

OPL (depends on the measuring range)

• PMC11: max. 0 to +60 bar (0 to +900 psi)

• PMP11: max. 0 to +160 bar (0 to +2 400 psi)

• PMC21: max. 0 to +60 bar (0 to +900 psi)

• PMP21: max. 0 to +600 bar (0 to +9 000 psi)

MWP

• PMC11: max. 0 to +60 bar (0 to +900 psi)

• PMP11: max. 0 to +160 bar (0 to +2 400 psi)

• PMP21: max. 0 to +600 bar (0 to +9 000 psi)

• PMC21: max. 0 to +60 bar (0 to +900 psi)

Process temperature range (temperature at process connection)

• PMC11: –25 to +85 °C (–13 to +185 °F)

• PMP11: –25 to +85 °C (–13 to +185 °F)

• PMC21: –25 to +100 °C (–13 to +212 °F)

• PMP21: –40 to +100 °C (–40 to +212 °F)

Endress+Hauser 9

Page 10

Cerabar PMC11, PMC21, PMP11, PMP21

Ambient temperature range

PMC11: –40 to +70 °C (–40 to +158 °F)

PMP11: –40 to +70 °C (–40 to +158 °F)

PMC21:

• –40 to +85 °C (–40 to +185 °F)

• Devices for hazardous areas: –40 to +70 °C (–40 to +158 °F)

PMP21:

–40 to +85 °C (–40 to +185 °F)

Reference accuracy

• PMC11: up to 0.5 %, TD 5:1, for details, see "Reference accuracy" section.

• PMP11: up to 0.5 %, TD 5:1, for details, see "Reference accuracy" section.

• PMC21: up to 0.3 %, TD 5:1, for details, see "Reference accuracy" section.

• PMP21: up to 0.3 %, TD 5:1, for details, see "Reference accuracy" section.

Supply voltage

PMC11:

• 4 to 20 mA output: 10 to 30V DC

• 0 to 10 V output: 12 to 30V DC

PMP11:

• 4 to 20 mA output: 10 to 30V DC

• 0 to 10 V output: 12 to 30V DC

PMC21:

10 to 30 V DC

PMP21:

10 to 30 V DC

Output

PMC11:

• 4 to 20 mA

• 0 to 10 V

PMP11:

• 4 to 20 mA

• 0 to 10 V

PMC21:

4 to 20 mA

PMP21:

4 to 20 mA

Material

PMC11:

• Housing made from 316L (1.4404)

• Process connections made from 316L

• Process isolating diaphragm made from Al2O3 aluminum oxide ceramic, (Ceraphire®), ultrapure

99.9 %

PMP11:

• Housing made from 316L (1.4404)

• Process connections made from 316L (1.4404)

• Process isolating diaphragm made from 316L (1.4435)

PMC21:

• Housing made from 316L (1.4404)

• Process connections made from 316L

• Process isolating diaphragm made from Al2O3 aluminum-oxide ceramic, (Ceraphire®), ultrapure

99.9 %

PMP21:

• Housing made from 316L (1.4404)

• Process connections made from 316L (1.4404)

• Process isolating diaphragm made from 316L (1.4435)

10 Endress+Hauser

Page 11

Cerabar PMC11, PMC21, PMP11, PMP21

A

B

C - 1

C - 2

D

E

D

E

Options

PMC11:

• Certificate of calibration

• Cleaned from oil+grease

PMP11:

• Certificate of calibration

• Cleaned from oil+grease

PMC21:

• Ex approvals

• Marine certificate

• Min. alarm current setting

• 3.1 Material certificates

• Certificate of calibration

• Cleaned from oil+grease

• Cleaned for O2 service

PMP21:

• Ex approvals

• Marine certificate

• Min. alarm current setting

• 3.1 Material certificates

• Certificate of calibration

• Cleaned from oil+grease

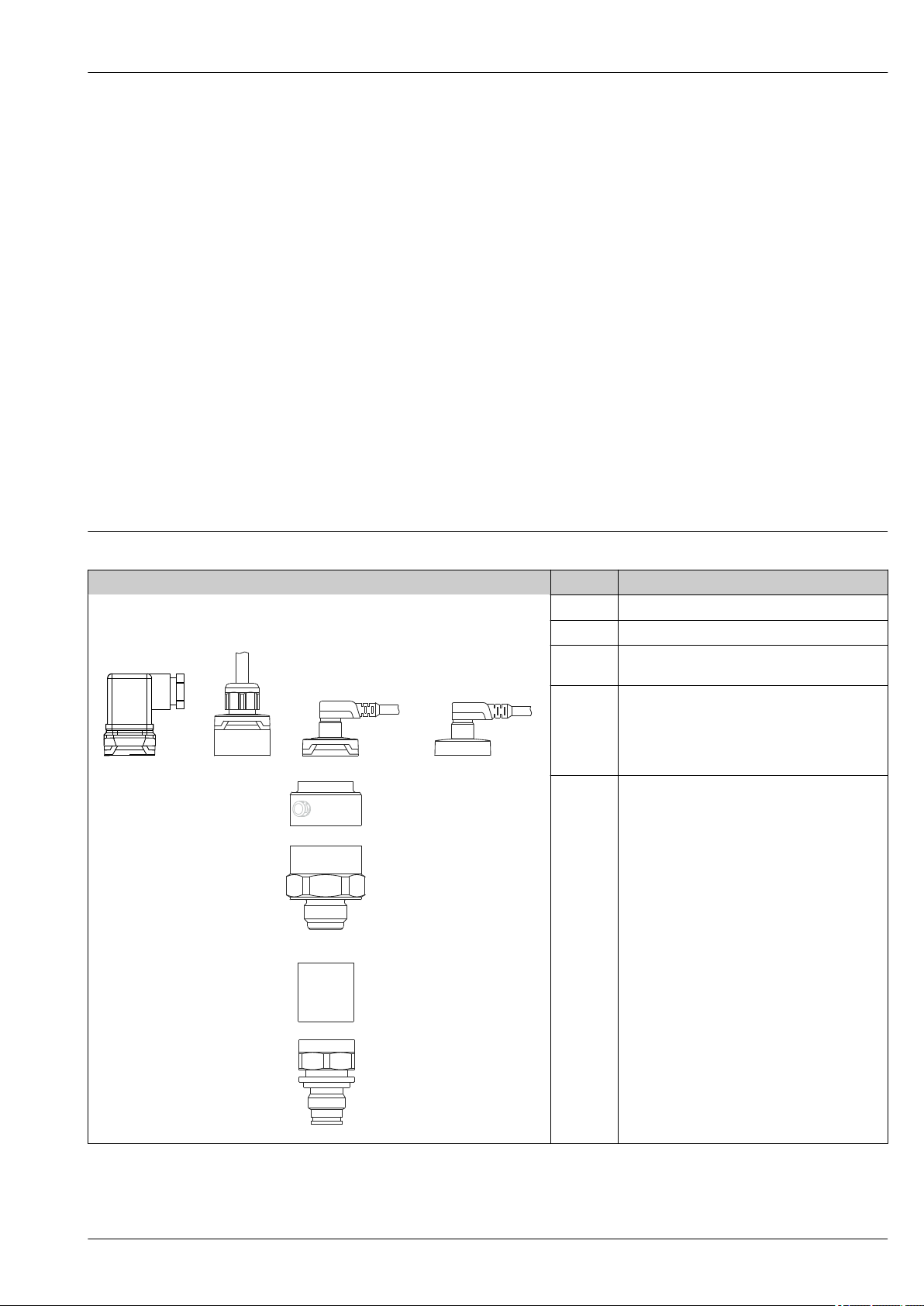

A0027232

A Valve plug

B Cable

C- 1 M12 plug

Housing cap made of plastic

C- 2 M12 plug

For Ex ec and IP69: metal housing cap

A0021987

A0027289

A0027226

D

E

Housing

Process connection (sample illustration)

Product design

Overview Position Description

A0027231

A0027215

Endress+Hauser 11

Page 12

Cerabar PMC11, PMC21, PMP11, PMP21

System integration

The device can be given a tag name (max. 32 alphanumeric characters).

Designation Option

Measuring point (TAG), see additional specifications Z1

1) Product Configurator order code for "Marking"

1)

12 Endress+Hauser

Page 13

Cerabar PMC11, PMC21, PMP11, PMP21

Input

Measured variable Measured process variable

• PMC11: Gauge pressure

• PMP11: Gauge pressure

• PMC21: Gauge pressure or absolute pressure

• PMP21: Gauge pressure or absolute pressure

Calculated process variable

Pressure

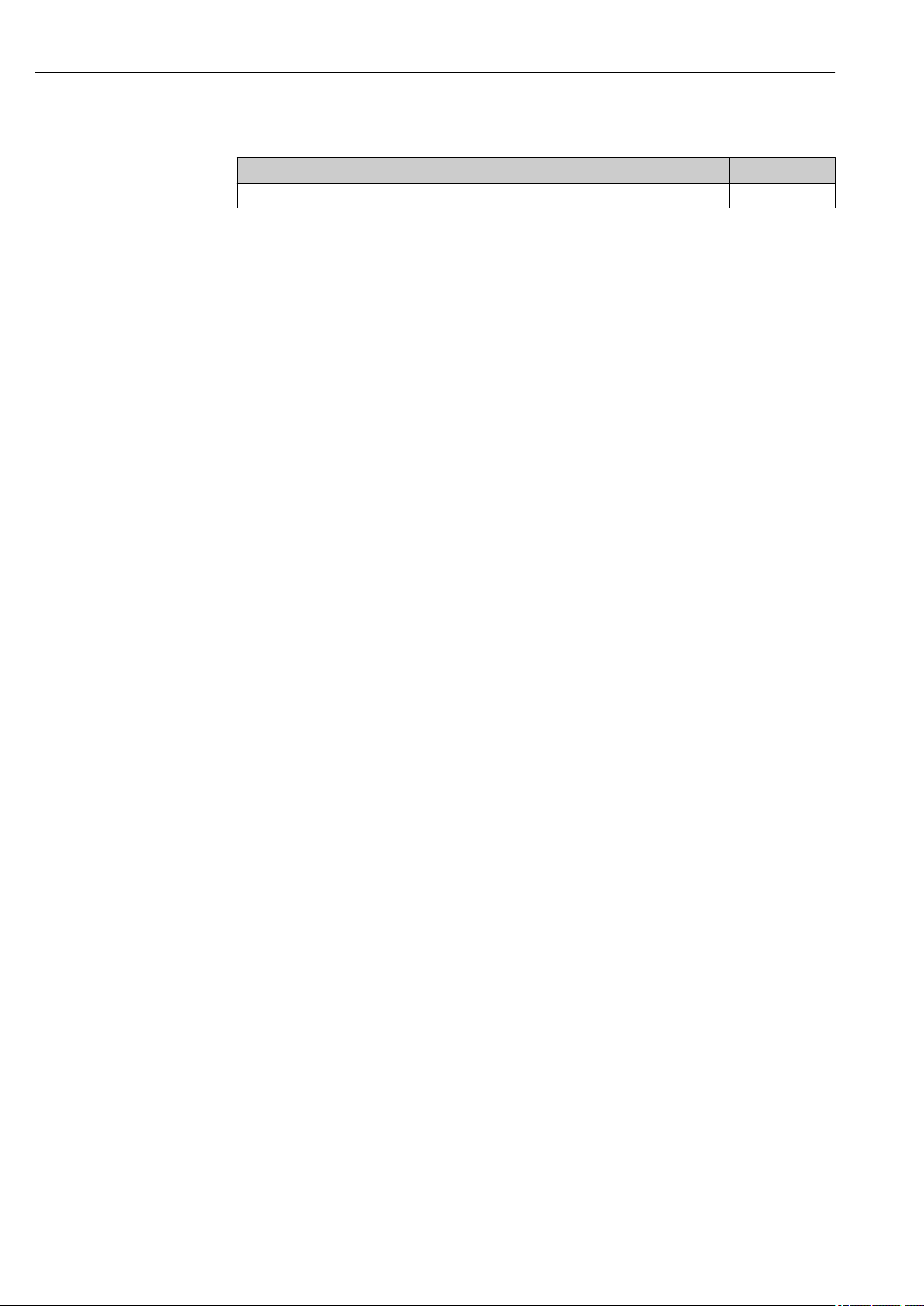

Measuring range Ceramic process isolating diaphragm

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for gauge pressure measurement

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

4)

PMC21 –0.1 (–1.5) +0.1 (+1.5) 0.02 (0.3) 2.7 (40.5) 4 (60) 0 to 100 mbar (0 to 1.5 psi) 1C

5)

PMC21 –0.25 (–4) +0.25 (+4) 0.05 (1) 3.3 (49.5) 5 (75) 0 to 250 mbar (0 to 4 psi) 1E

6)

PMC11

–0.4 (–6) +0.4 (+6) 0.08 (1.2) 5.3 (79.5) 8 (120) 0 to 400 mbar (0 to 6 psi) 1F

PMC21

1 bar (15 psi)

6)

PMC11

–1 (–15) +1 (+15) 0.2 (3) 6.7 (100.5) 10 (150) 0 to 1 bar (0 to 15 psi) 1H

PMC21

2 bar (30 psi)

6)

PMC11

–1 (–15) +2 (+30) 0.4 (6) 12 (180) 18 (270) 0 to 2 bar (0 to 30 psi) 1K

PMC21

4 bar (60 psi)

6)

PMC11

–1 (–15) +4 (+60) 0.8 (12) 16.7 (250.5) 25 (375) 0 to 4 bar (0 to 60 psi) 1M

PMC21

6 bar (90 psi)

6)

PMC11

–1 (–15) +6 (+90) 2.4 (36) 26.7 (400.5) 40 (600) 0 to 6 bar (0 to 90 psi) 1N

PMC21

10 bar (150 psi)

6)

PMC11

–1 (–15) +10 (+150) 2 (30) 26.7 (400.5) 40 (600) 0 to 10 bar (0 to 150 psi) 1P

PMC21

16 bar (240 psi)

6)

PMC11

–1 (–15) +16 (+240) 6.4 (96) 40 (600) 60 (900) 0 to 16 bar (0 to 240 psi) 1Q

PMC21

25 bar (375 psi)

6)

PMC11

–1 (–15) +25 (+375) 10 (150) 40 (600) 60 (900) 0 to 25 bar (0 to 375 psi) 1R

PMC21

40 bar (600 psi)

6)

PMC11

–1 (–15) +40 (+600) 8 (120) 40 (600) 60 (900) 0 to 40 bar (0 to 600 psi) 1S

PMC21

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

3)

Endress+Hauser 13

Page 14

Cerabar PMC11, PMC21, PMP11, PMP21

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for absolute pressure measurement

100 mbar (1.5 psi)

250 mbar (4 psi)

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

6)

PMC21 0 +0.1 (+1.5) 0.1 (1.5) 2.7 (40.5) 4 (60) 0 to 100 mbar (0 to 1.5 psi) 2C

6)

PMC21 0 +0.25 (+4) 0.25 (4) 3.3 (49.5) 5 (75) 0 to 250 mbar (0 to 4 psi) 2E

6)

PMC21 0 +0.4 (+6) 0.4 (6) 5.3 (79.5) 8 (120) 0 to 400 mbar (0 to 6 psi) 2F

6)

6)

6)

PMC21 0 +1 (+15) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 1 bar (0 to 15 psi) 2H

PMC21 0 +2 (+30) 0.4 (6) 12 (180) 18 (270) 0 to 2 bar (0 to 30 psi) 2K

PMC21 0 +4 (+60) 0.8 (12) 16.7 (250.5) 25 (375) 0 to 4 bar (0 to 60 psi) 2M

6)

PMC21 0 +10 (+150) 2 (30) 26.7 (400.5) 40 (600) 0 to 10 bar (0 to 150 psi) 2P

6)

PMC21 0 +40 (+600) 8 (120) 40 (600) 60 (900) 0 to 40 bar (0 to 600 psi) 2S

1) Highest turn down that can be set at the factory: 5:1. The turn down is preset and cannot be changed.

2) Other measuring ranges (e.g. –1 to +5 bar (–15 to 75 psi)) can be ordered with customer-specific settings (see the Product Configurator, order

code for "Calibration; Unit" option "J"). It is possible to invert the output signal (LRV = 20 mA; URV = 4 mA). Prerequisite: URV < LRV

3) Product Configurator, order code for "Sensor range"

4) Vacuum resistance: 0.7 bar (10.5 psi) abs

5) Vacuum resistance: 0.5 bar (7.5 psi) abs

6) Vacuum resistance: 0 bar (0 psi) abs

3)

Maximum turn down which can be ordered for absolute pressure and gauge pressure sensors

Devices for gauge pressure measurement

• 6 bar (90 psi), 16 bar (240 psi), 25 bar (375 psi): TD 1:1 to TD 2.5:1

• All other measuring ranges: TD 1:1 to TD 5:1

Devices for absolute pressure measurement

• 100 mbar (1.5 psi), 250 mbar (4 psi), 400 mbar (6 psi): TD 1:1

• 1 bar (15 psi): TD 1:1 to TD 2.5:1

• All other measuring ranges: TD 1:1 to TD 5:1

14 Endress+Hauser

Page 15

Cerabar PMC11, PMC21, PMP11, PMP21

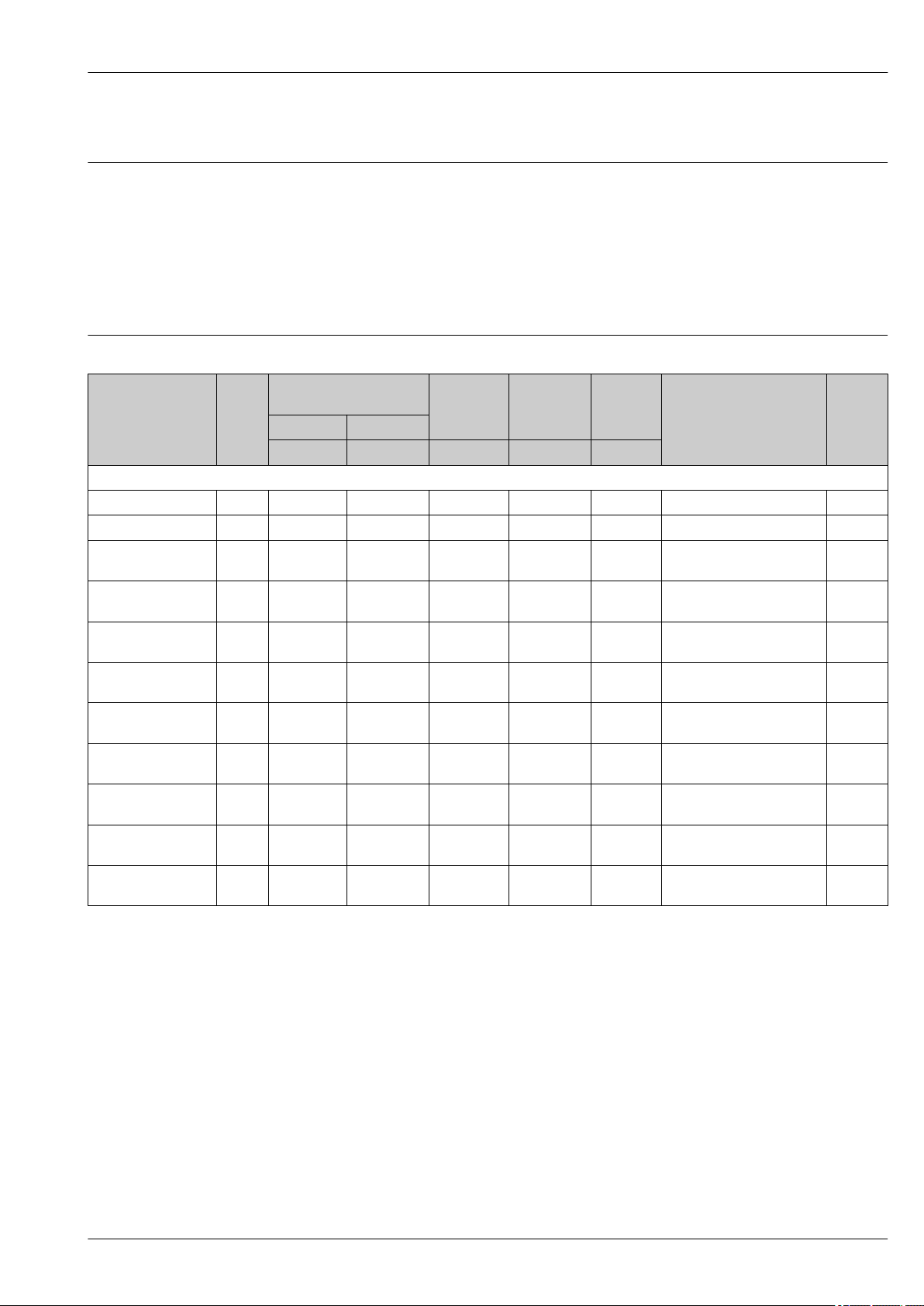

Metal process isolating diaphragm

Sensor Device Maximum

Sensor measuring range

lower (LRL) upper (URL)

[bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)] [bar (psi)]

Devices for gauge pressure measurement

400 mbar (6 psi)

4)

PMP11

–0.4 (–6) +0.4 (+6) 0.4 (6) 1 (15) 1.6 (24) 0 to 400 mbar (0 to 6 psi) 1F

PMP21

1 bar (15 psi)

4)

PMP11

–1 (–15) +1 (+15) 0.4 (6) 2.7 (40.5) 4 (60) 0 to 1 bar (0 to 15 psi) 1H

PMP21

2 bar (30 psi)

4)

PMP11

–1 (–15) +2 (+30) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 2 bar (0 to 30 psi) 1K

PMP21

4 bar (60 psi)

4)

PMP11

–1 (–15) +4 (+60) 0.8 (12) 10.7 (160.5) 16 (240) 0 to 4 bar (0 to 60 psi) 1M

PMP21

6 bar (90 psi)

4)

PMP11

–1 (–15) +6 (+90) 2.4 (36) 16 (240) 24 (360) 0 to 6 bar (0 to 90 psi) 1N

PMP21

10 bar (150 psi)

4)

PMP11

–1 (–15) +10 (+150) 2 (30) 25 (375) 40 (600) 0 to 10 bar (0 to 150 psi) 1P

PMP21

16 bar (240 psi)

4)

PMP11

–1 (–15) +16 (+240) 5 (75) 25 (375) 64 (960) 0 to 16 bar (0 to 240 psi) 1Q

PMP21

25 bar (375 psi)

4)

PMP11

–1 (–15) +25 (+375) 5 (75) 25 (375) 100 (1500) 0 to 25 bar (0 to 375 psi) 1R

PMP21

40 bar (600 psi)

4)

PMP11

–1 (–15) +40 (+600) 8 (120) 100 (1500) 160 (2400) 0 to 40 bar (0 to 600 psi) 1S

PMP21

100 bar (1 500 psi)

400 bar (6 000 psi)

4)

PMP21 –1 (–15) +100 (+1500) 20 (300) 100 (1500) 160 (2400) 0 to 100 bar (0 to 1 500 psi) 1U

4)

PMP21 –1 (–15) +400 (+6000) 80 (1200) 400 (6000) 600 (9000) 0 to 400 bar (0 to 6 000 psi) 1W

Devices for absolute pressure measurement

400 mbar (6 psi)

1 bar (15 psi)

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

40 bar (600 psi)

100 bar (1 500 psi)

400 bar (6 000 psi)

4)

PMP21 0 (0) 0.4 (+6) 0.4 (6) 1 (15) 1.6 (24) 0 to 400 mbar (0 to 6 psi) 2F

4)

4)

4)

PMP21 0 (0) 1 (+15) 0.4 (6) 2.7 (40.5) 4 (60) 0 to 1 bar (0 to 15 psi) 2H

PMP21 0 (0) 2 (+30) 0.4 (6) 6.7 (100.5) 10 (150) 0 to 2 bar (0 to 30 psi) 2K

PMP21 0 (0) 4 (+60) 0.8 (12) 10.7 (160.5) 16 (240) 0 to 4 bar (0 to 60 psi) 2M

4)

PMP21 0 (0) 10 (+150) 2 (30) 25 (375) 40 (600) 0 to 10 bar (0 to 150 psi) 2P

4)

PMP21 0 (0) +40 (+600) 8 (120) 100 (1500) 160 (2400) 0 to 40 bar (0 to 600 psi) 2S

4)

PMP21 0 (0) +100 (+1500) 20 (300) 100 (1500) 160 (2400) 0 to 100 bar (0 to 1 500 psi) 2U

4)

PMP21 0 (0) +400 (+6000) 80 (1200) 400 (6000) 600 (9000) 0 to 400 bar (0 to 6 000 psi) 2W

Lowest

calibratable

1)

span

MWP OPL Factory settings

2)

Option

3)

1) Highest turn down that can be set at the factory: 5:1. The turn down is preset and cannot be changed.

2) Other measuring ranges (e.g. –1 to +5 bar (–15 to 75 psi)) can be ordered with customer-specific settings (see the Product Configurator, order

code for "Calibration; Unit" option "J"). It is possible to invert the output signal (LRV = 20 mA; URV = 4 mA). Prerequisite: URV < LRV

3) Product Configurator, order code for "Sensor range"

4) Vacuum resistance: 0.01 bar (0.145 psi) abs

Maximum turn down which can be ordered for absolute pressure and gauge pressure sensors

Device Range 400 mbar (6 psi) 1 bar (15 psi)

6 bar (90 psi)

16 bar (240 psi)

PMP11 0.5% TD 1:1 TD 1:1 to TD 2.5:1 TD 1:1 to TD 5:1

PMP21 0.3% TD 1:1 TD 1:1 to TD 2.5:1 TD 1:1 to TD 5:1

2 bar (30 psi)

4 bar (60 psi)

10 bar (150 psi)

25 to 400 bar (375 to 6 000 psi)

Endress+Hauser 15

Page 16

Output

[ ]W

30

20

10

1068

614

U

[V]

1

R

L

max

B

2

R

L

max

£

-U 6.5V

22mA

B

I

63 %

100 %

t

t1t

2

90 %

t

3

Cerabar PMC11, PMC21, PMP11, PMP21

Output signal

Signal range 4 to 20 mA

Load (for 4 to 20 mA devices )

Designation Option

4 to 20 mA (2-wire) 1

PMC11: 0 to 10 V output (3-wire)

PMP11: 0 to 10 V output (3-wire)

1) Product Configurator, order code for "Output"

1)

2

3.8 mA to 20.5 mA

In order to guarantee sufficient terminal voltage in two-wire devices, a maximum load resistance R

(including line resistance) must not be exceeded depending on the supply voltage UB of the supply

unit.

A0029452

1 Power supply 10 to 30 V DC

2 R

UBSupply voltage

Maximum load resistance

Lmax

L

Load resistance (for 0 to 10 V devices)

Signal on alarm 4 to 20 mA

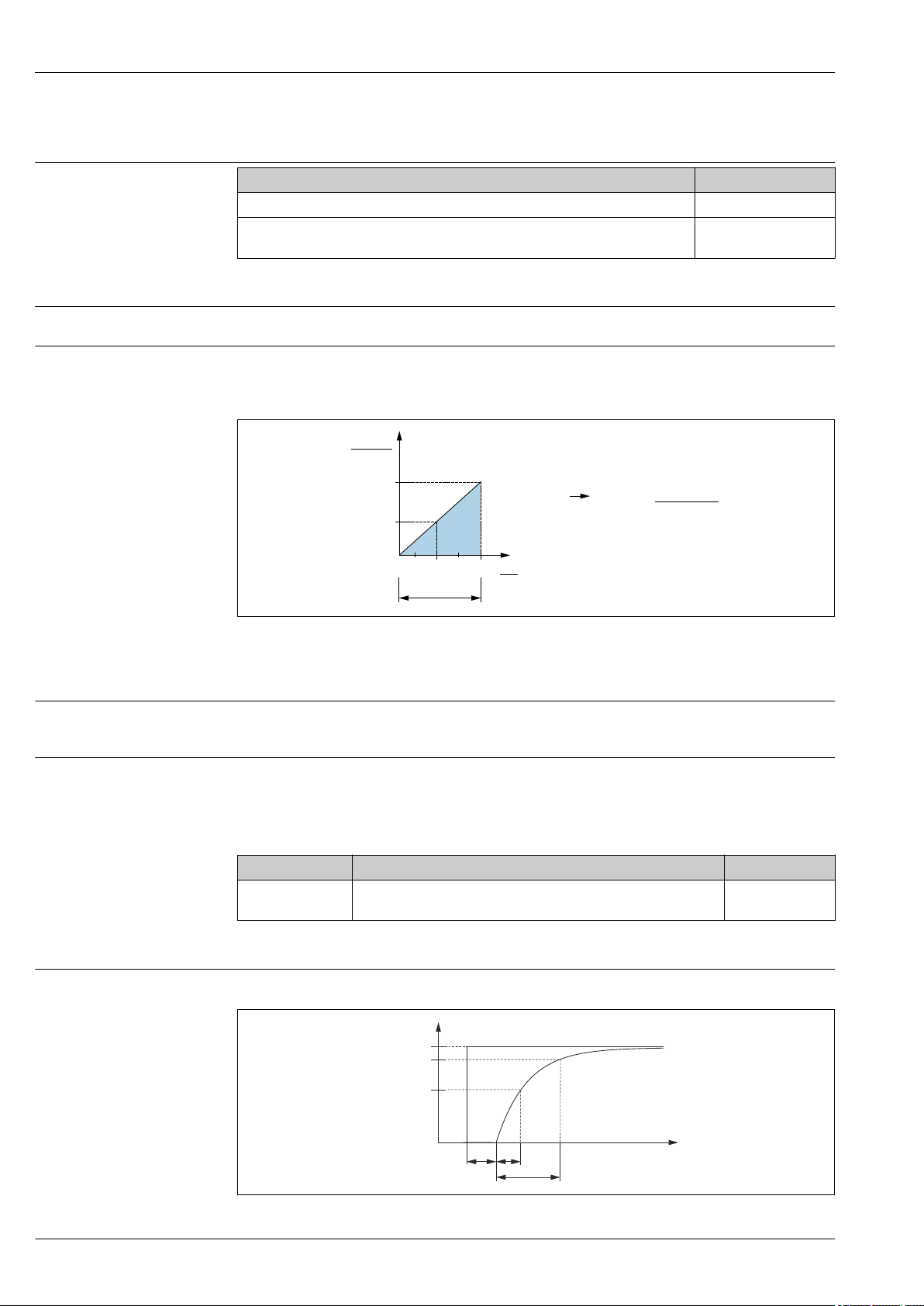

Dead time, time constant

The load resistance must be ≥ 5 [kΩ].

The response of the output to error is regulated in accordance with NAMUR NE43.

Factory setting MAX alarm: >21 mA

alarm current

Device Description Option

PMC21

PMP21

1) Product Configurator order code for "Service"

Adjusted min. alarm current IA

Presentation of the dead time and the time constant:

1)

A0019786

16 Endress+Hauser

Page 17

Cerabar PMC11, PMC21, PMP11, PMP21

Dynamic behavior

Dead time (t1) [ms] Time constant (T63), t2 [ms] Time constant (T90), t3 [ms]

6 ms 10 ms 15 ms

Endress+Hauser 17

Page 18

Cerabar PMC11, PMC21, PMP11, PMP21

L–

L+

2

1

3

0.5A

L–

L+

1

2

3

4

0.5A

L–

L+

1

2

3

(a)

0.5A

L–

L+

2

1

3

0.5A

L–

L+

1

2

3

4

0.5A

Power supply

WARNING

L

Limitation of electrical safety due to incorrect connection!

In accordance with IEC/EN61010 a separate circuit breaker must be provided for the device .

‣

When using the measuring device in hazardous areas, installation must comply with the

‣

corresponding national standards and regulations and the Safety Instructions or Installation or

Control Drawings.

All explosion protection data are given in separate documentation which is available upon

‣

request. The Ex documentation is supplied as standard with all devices approved for use in

explosion hazardous areas.

Protective circuits against reverse polarity, HF influences and overvoltage peaks are integrated.

‣

The device must be operated with a 500 mA fine-wire fuse (slow-blow).

‣

Terminal assignment

4 to 20 mA output

Device M12 plug Valve plug Cable

PMC11

PMP11

PMC21

PMP21

A0023487

A0022823

1 brown = L+

2 blue = L3 green/yellow = ground connection

(a) reference air hose

0 to 10 V output

Device M12 plug Valve plug Cable

PMC11

PMP11

A0017576

-

A0022822

A0023783

Supply voltage

Current consumption and alarm signal

18 Endress+Hauser

Electronic version Device Supply voltage

4 to 20 mA output PMC11

PMP11

PMC21

PMP21

0 to 10 V output PMC11

PMP11

Number of wires Device Normal operation Alarm signal

2 PMC11

PMP11

PMC21

PMP21

3 PMC11

PMP11

1) For MAX alarm (factory setting)

≤ 26 mA > 21 mA

< 12 mA 11 V

10 to 30 V DC

12 to 30 V DC

1)

Page 19

Cerabar PMC11, PMC21, PMP11, PMP21

Power supply fault

• Behavior in the event of overvoltage (>30 V):

The device works continuously up to 34 V DC without damage. If the supply voltage is exceeded,

the specified characteristics are no longer guaranteed.

• Behavior in the event of undervoltage:

If the supply voltage falls below the minimum value, the device switches off in a defined manner

(status same as for no power supply).

Electrical connection Degree of protection

Device Connection Degree of protection Option

PMP21

PMP21

PMP21

PMP21

PMP21

PMP21

PMC11

PMP11

PMC21

PMP21

PMC11

PMP11

PMC21

PMP21

PMC11

PMP11

PMC21

PMP21

Cable5 m (16 ft) IP66/68

Cable10 m (33 ft) IP66/68

Cable25 m (82 ft) IP66/68

M12 plug IP65 NEMA type 4X enclosure L

M12 plug IP65/67 NEMA type 4X enclosure M

Valve plug ISO4400 M16 IP65 NEMA type 4X enclosure U

Valve plug ISO4400 NPT ½ IP65 NEMA type 4X enclosure V

2)

NEMA type 4X/6P enclosure A

2)

NEMA type 4X/6P enclosure B

2)

NEMA type 4X/6P enclosure C

1)

Cable specification

Residual ripple

Influence of power supply

Overvoltage protection

1) Product Configurator order code for "Electrical connection"

2) IP 68 (1.83m H2O for 24 h)

For valve plug: < 1.5 mm2 (16 AWG) and Ø4.5 to 10 mm (0.18 to 0.39 in)

The device operates within the reference accuracy up to ±5 % of the residual ripple of the supply

voltage, within the permitted voltage range.

≤0.005 % of the URL/1 V

The device does not contain any special elements to protect against overvoltage ("wire to ground").

Nevertheless the requirements of the applicable EMC standard EN 61000-4-5 (testing voltage 1kV

EMC wire/ground) are met.

Endress+Hauser 19

Page 20

Cerabar PMC11, PMC21, PMP11, PMP21

Performance characteristics of ceramic process isolating diaphragm

Reference operating conditions

Measuring uncertainty for small absolute pressure measuring ranges

Influence of the installation position

Resolution

Reference accuracy

• As per IEC 60770

• Ambient temperature TA = constant, in the range of:+21 to +33 °C (+70 to +91 °F)

• Humidity φ = constant, in the range of 5 to 80 % rH

• Ambient pressure pA = constant, in the range of:860 to 1 060 mbar (12.47 to 15.37 psi)

• Position of measuring cell = constant, in range: horizontal ±1° (see also "Influence of the

installation position" section → 23)

• Zero based span

• Material of process isolating diaphragm: Al2O3 (aluminum-oxide ceramic, Ceraphire®)

• Supply voltage: 24 V DC ±3 V DC

• Load: 320 Ω (at 4 to 20 mA output)

The smallest extended uncertainty of measurement that can delivered by our standards is:

• in range 1 to 30 mbar (0.0145 to 0.435 psi): 0.4 % of reading

• in range < 1 mbar (0.0145 psi): 1 % of reading.

→ 23

Current output: min. 1.6 μA

The reference accuracy contains the non-linearity [DIN EN 61298-2 3.11] including the pressure

hysteresis [DIN EN 61298-23.13] and non-repeatability [DIN EN 61298-2 3.11] in accordance with

the limit point method as per [DIN EN 60770].

Device % of the calibrated span to the maximum turn down

Reference accuracy Non-linearity

2)

PMC11

PMC21 ±0.3 ±0.1 ±0.1

±0.5 ±0.1 ±0.1

1)

Non-repeatability

Thermal change of the zero output and the output span

1) The non-linearity for the 40 bar (600 psi) sensor can be up to ± 0.15% of the calibrated span up to the

maximum turn down.

2) For devices with 0 to 10 V output, a non-linearity of up to max. 0.3 V can occur for signal values below

0.03 V.

Overview of the turn down ranges → 14

Measuring ranges Turn down Device % of URL

100 mbar (1.5 psi)to

40 bar (600 psi)

1) For the 100 mbar (1.5 psi) and 250 mbar (4 psi) measuring ranges, the following applies: In the event of

heat effects on the initial reference conditions, an additional deviation of max. 0.3 mbar (4.5 psi) from the

zero point or the output span is possible.

Measuring cell –20 to +85 °C (–4 to +185 °F) –40 to –20 °C (–40 to –4 °F)

% of URL for TD 1:1

<1 bar (15 psi) <1 <1.2

≥ 1 bar (15 psi) <0.8 <1

1:1 to TD 5:1 PMC11 ±0.5

PMC21 ±0.3

+85 to +100 °C (+185 to +212 °F)

1)

20 Endress+Hauser

Page 21

Cerabar PMC11, PMC21, PMP11, PMP21

Long-term stability

Switch-on time

1 year 5 years 8 years

% of URL

±0.2 ±0.4 ±0.45

≤2 s (For small measuring ranges, pay attention to the thermal compensation effects.)

Endress+Hauser 21

Page 22

Cerabar PMC11, PMC21, PMP11, PMP21

Performance characteristics of metal process isolating diaphragm

Reference operating conditions

Measuring uncertainty for small absolute pressure measuring ranges

Influence of the installation position

Resolution

Reference accuracy

• As per IEC 60770

• Ambient temperature TA = constant, in the range of:+21 to +33 °C (+70 to +91 °F)

• Humidity φ = constant, in the range of 5 to 80 % rH

• Ambient pressure pA = constant, in the range of:860 to 1 060 mbar (12.47 to 15.37 psi)

• Position of measuring cell = constant, in range: horizontal ±1° (see also "Influence of the

installation position" section → 23)

• Zero based span

• Process isolating diaphragm material: AISI 316L (1.4435)

• Filling oil: synthetic oil polyalphaolefin FDA 21 CFR 178.3620, NSF H1

• Supply voltage: 24 V DC ±3 V DC

• Load: 320 Ω (at 4 to 20 mA output)

The smallest extended uncertainty of measurement that can delivered by our standards is:

• in the range 1 to 30 mbar (0.0145 to 0.435 psi): 0.4 % of reading

• in the range < 1 mbar (0.0145 psi): 1 % of reading.

→ 23

Current output: min. 1.6 μA

The reference accuracy contains the non-linearity [DIN EN 61298-2 3.11] including the pressure

hysteresis [DIN EN 61298-23.13] and non-repeatability [DIN EN 61298-2 3.11] in accordance with

the limit point method as per [DIN EN 60770].

Device % of the calibrated span to the maximum turn down

Reference accuracy Non-linearity Non-repeatability

1)

PMP11

PMP21 ±0.3 ±0.1 ±0.1

±0.5 ±0.1 ±0.1

Thermal change of the zero output and the output span

Long-term stability

Switch-on time

1) For devices with 0 to 10 V output, a non-linearity of up to max. 0.3 V can occur for signal values below

0.015 V.

Overview of the turn down ranges → 15

Measuring cell –20 to +85 °C (–4 to +185 °F) –20 to –40 °C (–4 to –40 °F)

+85 to +100 °C (+185 to +212 °F)

% of the calibrated span for TD 1:1

<1 bar (15 psi) <1 <1.2

≥ 1 bar (15 psi) <0.8 <1

Device 1 year 5 years 8 years

% of URL

PMP11

PMP21

±0.2 ±0.4 ±0.45

≤2 s

22 Endress+Hauser

Page 23

Cerabar PMC11, PMC21, PMP11, PMP21

C

A

B

1

2

Installation

Installation conditions

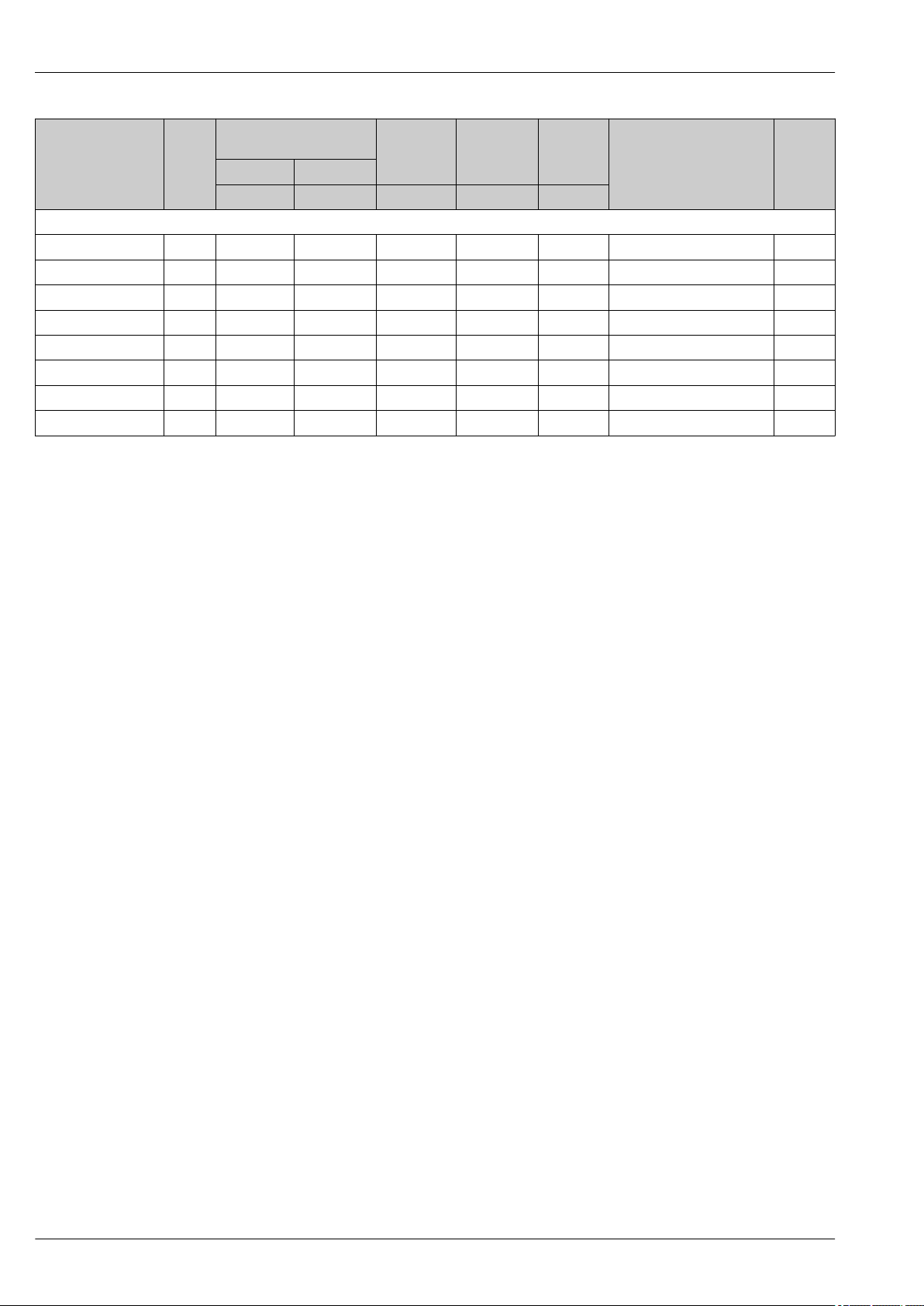

Influence of the installation position

• Moisture must not penetrate the housing when mounting the device, establishing the electrical

connection and during operation.

• Point the cable and connector downwards where possible to prevent moisture from entering (e.g.

rain or condensation water).

Any orientation is possible. However, the orientation may cause a zero point shift i.e. the measured

value does not show zero when the vessel is empty or partially full.

A0024708

Type Process isolating

diaphragm axis is

horizontal (A)

PMP11

PMP21

PMC11, PMC21

< 1 bar (15 psi)

PMC11, PMC21

≥1 bar (15 psi)

Calibration position, no

effect

Calibration position, no

effect

Calibration position, no

effect

Process isolating diaphragm

pointing upwards (B)

Up to +4 mbar (+0.058 psi) Up to –4 mbar (–0.058 psi)

Up to

+0.3 mbar (+0.0044 psi)

Up to +3 mbar (+0.0435 psi) Up to –3 mbar (–0.0435 psi)

Process isolating diaphragm

pointing downwards (C)

Up to

–0.3 mbar (–0.0044 psi)

Mounting location Pressure measurement

Pressure measurement in gases

Mount the device with shutoff device above the tapping point so that any condensate can flow into

the process.

1 Device

2 Shutoff device

Pressure measurement in vapors

For pressure measurement in vapors, use a siphon. The siphon reduces the temperature to almost

ambient temperature. Mount the device with a shutoff device at the same height as the tapping

point.

Advantage:

only minor/negligible heat effects on the device.

Note the max. permitted ambient temperature of the transmitter!

A0021904

Endress+Hauser 23

Page 24

Cerabar PMC11, PMC21, PMP11, PMP21

1

2

3

1

2

1 Device

2 Shutoff device

3 Siphon

Pressure measurement in liquids

Mount the device with a shutoff device at the same height as the tapping point.

A0024395

1 Device

2 Shutoff device

Level measurement

• Always install the device below the lowest measuring point.

• Do not install the device at the following positions:

– In the filling curtain

– In the tank outlet

– in the suction area of a pump

– Or at a point in the tank which could be affected by pressure pulses from the agitator.

A0024399

A0024405

Mounting instructions for oxygen applications

Oxygen and other gases can react explosively to oils, grease and plastics, such that, among other

things, the following precautions must be taken:

• All components of the system, such as measuring devices, must be cleaned in accordance with the

BAM requirements.

• Dependent on the materials used, a certain maximum temperature and a maximum pressure for

oxygen applications must not be exceeded.

• The following table lists devices (devices only, not accessories or enclosed accessories), which are

suitable for gaseous oxygen applications.

24 Endress+Hauser

Page 25

Cerabar PMC11, PMC21, PMP11, PMP21

Device p

for oxygen applications T

max

for oxygen applications Option

max

PMC21 40 bar (600 psi) –10 to +60 °C (+14 to +140 °F) HB

1) Product Configurator, order code for "Service"

1)

Endress+Hauser 25

Page 26

Environment

Cerabar PMC11, PMC21, PMP11, PMP21

Ambient temperature range

Storage temperature range

Climate class

Degree of protection

Device Ambient temperature range

PMC11

PMP11

PMC21

PMP21

PMC21

PMP21

1) Exception: the following cable is designed for an ambient temperature range of

–25 to +70 °C (–13 to +158 °F): Product Configurator order code for "Enclosed accessories" option "RZ".

–40 to +70 °C (–40 to +158 °F)

–40 to +85 °C (–40 to +185 °F)

Devices for hazardous areas: –40 to +70 °C (–40 to +158 °F)

1)

–40 to +85 °C (–40 to +185 °F)

Device Climate class Note

PMC11

PMP11

PMC21

PMP21

Device Connection Degree of protection Option

PMP21

PMP21

PMP21

PMP21

PMP21

PMP21

PMC11

PMP11

PMC21

PMP21

PMC11

PMP11

PMC21

PMP21

PMC11

PMP11

PMC21

PMP21

Class 3K5 Air temperature: –5 to +45 °C (+23 to +113 °F),

relative humidity: 4 to 95 %

satisfied according to IEC 721-3-3 (condensation not possible)

Cable5 m (16 ft) IP66/68

Cable10 m (33 ft) IP66/68

Cable25 m (82 ft) IP66/68

M12 plug IP65 NEMA type 4X enclosure L

M12 plug IP65/67 NEMA type 4X enclosure M

Valve plug ISO4400 M16 IP65 NEMA type 4X enclosure U

Valve plug ISO4400 NPT ½ IP65 NEMA type 4X enclosure V

2)

NEMA type 4X/6P enclosure A

2)

NEMA type 4X/6P enclosure B

2)

NEMA type 4X/6P enclosure C

1)

1) Product Configurator order code for "Electrical connection"

2) IP 68 (1.83m H2O for 24 h)

Vibration resistance

Electromagnetic compatibility

Test standard Vibration resistance

IEC 60068-2-64:2008 Guaranteed for 5 to 2000Hz: 0.05g2/Hz

• Interference emission as per EN 61326-1 equipment B

• Interference immunity as per EN 61326-1 (industrial environment)

• NAMUR recommendation EMC (NE21)

• Maximum deviation: 1.5% with TD 1:1

For more details please refer to the Declaration of Conformity.

26 Endress+Hauser

Page 27

Cerabar PMC11, PMC21, PMP11, PMP21

Process

Process temperature range for devices with ceramic process isolating diaphragm

Device Process temperature range

PMC11 –25 to +85 °C (–13 to +185 °F)

PMC21 –25 to +100 °C (–13 to +212 °F)

PMC21 for oxygen applications –10 to +60 °C (+14 to +140 °F)

• For saturated steam applications, use a device with a metal process isolating diaphragm, or

provide a siphon for temperature isolation when installing.

• Pay attention to the process temperature range of the seal. See also the following table.

Seal Notes Process temperature range Option

FKM - –20 to +100 °C (–4 to +212 °F) A

FKM Cleaned for oxygen service –10 to +60 °C (+14 to +140 °F) A

EPDM 70 - –25 to +100 °C (–13 to +212 °F) J

1) Product Configurator, order code for "Seal"

2) Product Configurator, order code for "Service"

1)

1)

1)

and HB

2)

Applications with changes in temperature

Frequent extreme changes in temperatures can temporarily cause measuring errors. Temperature

compensation takes place after a few minutes. Internal temperature compensation is faster the

smaller the change in temperature and the longer the time interval.

For further information please contact your local Endress+Hauser Sales Center.

Process temperature range for devices with metallic process isolating diaphragm

Device Process temperature range

PMP11 –25 to +85 °C (–13 to +185 °F)

PMP21 –40 to +100 °C (–40 to +212 °F)

Applications with changes in temperature

Frequent extreme changes in temperatures can temporarily cause measuring errors. Internal

temperature compensation is faster the smaller the change in temperature and the longer the time

interval.

For further information please contact your local Endress+Hauser Sales Center.

Endress+Hauser 27

Page 28

Cerabar PMC11, PMC21, PMP11, PMP21

Pressure specifications

WARNING

L

The maximum pressure for the measuring device depends on the lowest-rated element with

regard to pressure.

For pressure specifications, see the "Measuring range" section and the "Mechanical construction"

‣

section.

The Pressure Equipment Directive (2014/68/EU) uses the abbreviation "PS". The abbreviation "PS"

‣

corresponds to the MWP (maximum working pressure) of the measuring device.

MWP (maximum working pressure): The MWP (maximum working pressure) is specified on the

‣

nameplate. This value is based on a reference temperature of +20 °C (+68 °F) and may be applied

to the device for an unlimited period of time. Observe the temperature dependency of the MWP.

OPL (over pressure limit): The test pressure corresponds to the over pressure limit of the sensor

‣

and may only be applied temporarily to ensure that the measurement is within the specifications

and no permanent damage develops. In the case of sensor range and process connections where

the over pressure limit (OPL) of the process connection is smaller than the nominal value of the

sensor, the device is set at the factory, at the very maximum, to the OPL value of the process

connection. If you want to use the entire sensor range, select a process connection with a higher

OPL value.

Oxygen applications: In oxygen applications, the values for "p

‣

may not be exceeded .

Devices with ceramic process isolating diaphragm: avoid steam hammering! Steam hammering

‣

can cause zero point drifts. Recommendation: Residue (water droplets or condensation) may

remain on the process isolating diaphragm following CIP cleaning and can result in local steam

hammering the next time steam cleaning takes place. In practice, drying the process isolating

diaphragm (e.g. by blowing) has proved to prevent steam hammering.

max

and T

for oxygen applications

max

28 Endress+Hauser

Page 29

Cerabar PMC11, PMC21, PMP11, PMP21

A

D

B

C

A

D

B

C

20.5 (0.81)

M12x1

20.5 (0.81)

M12x1

34 (1.34)

51 (2.01)

27 (1.06)

45 (1.77)

r ³ 102 (4.02)

Mechanical construction

• The following dimensions have been rounded up to whole measurements.

• Exact dimensions are available in the Product Configurator on the Endress+Hauser website:

www.endress.com → Product finder → On the product page, click the "Configure" button to the

right of the product photo.

Design, dimensions Device height

The device height is calculated from

• the height of the electrical connection

• the height of the housing and

• the height of the individual process connection.

The individual heights of the components are listed in the following sections. To calculate the device

height simply add up the individual heights of the components. Where applicable also take into

consideration the installation distance (space that is used to install the device). You can use the

following table for this purpose:

Section Page Height Example

Electrical connection → 29 (A)

Housing height → 30 (B)

Process connection height → 32

→ 35

Installation distance - (D)

(C)

A0027252

A0022829

Electrical connection

A

A0024426

Engineering unit mm (in)

Position Designation Material Weight kg (lbs) Device Option

A M12 plug IP65

(Additional dimensions → 47)

A M12 plug IP65/67

(Additional dimensions → 47)

B M12 plug IP66/67 Housing cap made of metal 0.030 (0.07) PMC21

Endress+Hauser 29

B

Housing cap made of plastic 0.012 (0.03) PMC11

Housing cap made of plastic 0.012 (0.03) PMC21

A0024427

C

PMP11

PMP21MPlug connector with cable

PMP21

D

A0024428

A0024429

1)

L

can be ordered as an accessory → 47

In the case of Ex ec type of protection,

the housing cap is made of metal.

Page 30

Cerabar PMC11, PMC21, PMP11, PMP21

25 (0.98)

A

ø40.5 (1.59)

34 (1.34)

65 (2.56)

B C

ø31.5 (1.24)

ø31.5 (1.24)

ø33 (1.3)

Position Designation Material Weight kg (lbs) Device Option

C M16 valve plug Plastic PPSU 0.060 (0.14) PMC11

PMP11

PMC21

PMP21

C NPT ½ valve plug Plastic PPSU 0.060 (0.14) PMC11

PMP11

PMC21

PMP21

D Cable5 m (16 ft) PUR (UL94V0) 0.280 (0.62) PMC21

PMP21

D Cable10 m (33 ft) PUR (UL94V0) 0.570 (1.26) PMC21

PMP21

D Cable25 m (82 ft) PUR (UL94V0) 1.400 (3.09) PMC21

PMP21

1) Product Configurator, order code for "Electrical connection"

U

V

A

B

C

Housing

1)

A0022243

Engineering unit mm (in)

A0027288

Engineering unit mm (in)

30 Endress+Hauser

Page 31

Cerabar PMC11, PMC21, PMP11, PMP21

Position Device Material Weight kg (lbs)

A PMC11

B (up to 100 bar (1 500 psi)) PMP11

C (400 bar (6 000 psi)) PMP11

Stainless steel 316L 0.150 (0.33)

PMC21

Stainless steel 316L 0.090 (0.20)

PMP21

Stainless steel 316L 0.090 (0.20)

PMP21

Endress+Hauser 31

Page 32

Cerabar PMC11, PMC21, PMP11, PMP21

13 (0.51)

45.5 (1.79)

2 (0.08)

ø3 (0.12)

ø5 (0.2)

ø9.5 (0.37)

G ¼" A

2 (0.08)

41

ø23 (0.91)

46 (1.81)

15.5 (0.61)

13 (0.51)

G ¼"

41

3 (0.12)

ø17.5 (0.69)

ø6 (0.24)

ø3 (0.12)

G ½" A

53.5 (2.11)

20 (0.79)

3 (0.12)

41

ø17.5 (0.69)

G ½" A

23 (0.91)

53.5 (2.11)

3 (0.12)

ø11.4 (0.45)

41

Process connections with internal, ceramic process isolating diaphragm

Thread ISO 228 G

A

C

B

A0022237

A0022236

D

A0022238

Engineering unit mm (in)

Device Position Designation Material Weight Option

kg (lbs)

• PMC11

• PMC21

• PMC11

• PMC21

• PMC11

• PMC21

• PMC11

• PMC21

1) Product Configurator, order code for "Process connection"

A Thread ISO 228 G ¼" A, EN 837 316L 0.160 (0.35) WTJ

B Thread ISO 228 G ¼" (female) 316L 0.180 (0.40) WAJ

C Thread ISO 228 G ½" A, EN 837 316L 0.180 (0.40) WBJ

D Thread ISO 228 G ½" A, bore11.4 mm (0.45 in) 316L 0.180 (0.40) WWJ

A0022239

1)

32 Endress+Hauser

Page 33

Cerabar PMC11, PMC21, PMP11, PMP21

13 (0.51)

ø3 (0.12)

NPT ¼"

43.5 (1.71)

41

55.5 (2.19)

NPT ¼"-18

ø21.4 (0.84)

NPT ½"-18

41

25 (0.98)

ø11.4 (0.45)

ø21.4 (0.84)

NPT ½"-18

ø17.3 (0.68)

55.5 (2.19)

25 (0.98)

41

Process connections with internal, ceramic process isolating diaphragm

Thread ASME

A

C

B

A0022242

A0022241

A0022240

Engineering unit mm (in)

Device Position Designation Material Weight Approval Option

kg (lbs)

• PMC11

• PMC21

• PMC11

• PMC21

• PMC11

• PMC21

1) Product Configurator, order code for "Process connection"

A ASME ¼" MNPT, bore3 mm (0.12 in) 316L 0.160 (0.35) CRN VUJ

B ASME ½" MNPT, ¼" FNPT (female) 316L 0.190 (0.42) CRN VXJ

C ASME ½" MNPT, bore11.4 mm (0.45 in) 316L 0.190 (0.42) CRN VWJ

1)

Endress+Hauser 33

Page 34

Cerabar PMC11, PMC21, PMP11, PMP21

53.5 (2.11)

20 (0.79)

3 (0.12)

3 (0.12)

ø18 (0.71)

M20x1.5

ø17.5 (0.69)

ø6 (0.24)

ø3 (0.12)

41

ø21.4 (0.84)

55.5 (2.19)

23 (0.91)

ø11.4 (0.45)

R ½"

ø17.3 (0.68)

41

Process connections with internal, ceramic process isolating diaphragm

Thread DIN13

Engineering unit mm (in)

Device Designation Material Weight Option

kg (lbs)

• PMC11

• PMC21

DIN 13 M20 x 1.5, EN 837, bore 3 mm (0.12 in) 316L 0.180 (0.40) X4J

A0022234

1)

Process connections with internal, ceramic process isolating diaphragm

1) Product Configurator, order code for "Process connection"

Thread JIS B0203

Engineering unit mm (in)

Device Designation Material Weight Option

kg (lbs)

PMC21 JIS B0203 R 1/2 (male) 316L 0.180 (0.40) ZJJ

1) Product Configurator, order code for "Process connection"

A0022235

1)

34 Endress+Hauser

Page 35

Cerabar PMC11, PMC21, PMP11, PMP21

13 (0.51)

C

2 (0.08)

ø3 (0.12)

ø5 (0.2)

ø9.5 (0.37)

G ¼" A

2 (0.08)

SW/AF

ø23 (0.91)

C

13 (0.51)

G ¼"

SW/AF

3 (0.12)

ø17.5 (0.69)

ø6 (0.24)

ø3 (0.12)

G ½" A

C

20 (0.79)

ø18 (0.71)

3 (0.12)

SW/AF

ø17.5 (0.69)

G ½" A

20 (0.79)

C

3 (0.12)

ø11.4 (0.45)

SW/AF

Process connections with internal, metal process isolating diaphragm

Thread ISO 228 G

A

C

B

A0021960

A0021959

D

Engineering unit mm (in)

Position Device Description Material Nominal value

to 100 bar (1 500 psi)

Weight Height C SW/AFWeight Height C SW/

kg (lbs) kg (lbs)

A PMP11

PMP21

B PMP11

PMP21

C PMP11

PMP21

D PMP11

PMP21

1) Product Configurator, order code for "Process connection"

Thread ISO 228 G ¼" A, EN 837 316L 0.200 (0.44) 57 (2.24) 32 0.240 (0.53) 69 (2.72) 27 WTJ

Thread ISO 228 G ¼" (female) 316L 0.220 (0.49) 57 (2.24) 32 0.260 (0.57) 69 (2.72) 27 WAJ

Thread ISO 228 G ½" A, EN 837 316L 0.220 (0.49) 65 (2.56) 32 0.270 (0.60) 77 (3.03) 27 WBJ

Thread ISO 228 G ½" A,

bore11.4 mm (0.45 in)

316L 0.220 (0.49) 62 (2.44) 32 0.260 (0.57) 74 (2.91) 27 WWJ

A0021962

Nominal value

400 bar (6 000 psi)

AF

A0021963

Option

1)

Endress+Hauser 35

Page 36

Cerabar PMC11, PMC21, PMP11, PMP21

C

ø13.7 (0.54)

ø3 (0.12)

NPT ¼"-14

12 (0.47)

13 (0.51)

SW/AF

C

25 (0.98)

NPT ½"-18

NPT ¼"-14

ø17.3 (0.68)

ø21.4 (0.84)

SW/AF

ø11.4 (0.45)

ø21.4 (0.84)

C

25 (0.98)

NPT ½"-18

ø17.3 (0.68)

SW/AF

Process connections with internal, metal process isolating diaphragm

Thread ASME

A

C

B

A0021965

A0021964

Engineering unit mm (in)

Position Device Designation Material Nominal value

A PMP11

PMP21

B PMP11

PMP21

C PMP11

PMP21

1) Product Configurator, order code for "Process connection"

ASME ¼" MNPT,

bore3 mm (0.12 in)

ASME ½" MNPT, ¼" FNPT

(female)

ASME ½" MNPT,

bore11.4 mm (0.45 in)

316L 0.200 (0.44) 55 (2.17) 32 0.240 (0.53) 67 (2.64) 27 CRN VUJ

316L 0.230 (0.51) 67 (2.64) 32 0.260 (0.57) 79 (3.11) 27 CRN VXJ

316L 0.230 (0.51) 67 (2.67) 32 0.270 (0.60) 79 (3.11) 27 CRN VWJ

A0021966

Nominal value

to 100 bar (1 500 psi)

Weight Height C SW/AFWeight Height C SW/

kg (lbs) kg (lbs)

400 bar (6 000 psi)

AF

Approval Option

1)

36 Endress+Hauser

Page 37

Cerabar PMC11, PMC21, PMP11, PMP21

C

20 (0.79)

3 (0.12)

3 (0.12)

M20x1.5

ø17.5 (0.69)

ø6 (0.24)

ø3 (0.12)

SW/AF

ø21.4 (0.84)

C

23 (0.91)

ø11.4 (0.45)

R ½"

ø17.3 (0.68)

SW/AF

Process connections with

Thread DIN13

internal, metal process

isolating diaphragm

Engineering unit mm (in)

Description Device Material Nominal value

to 100 bar (1 500 psi)

Weight Height C SW/AFWeight Height C SW/

kg (lbs) kg (lbs)

DIN 13 M20 x 1.5, EN 837, bore 3 mm (0.12 in) PMP11

PMP21

316L 0.220 (0.49) 65 (2.56) 32 0.260 (0.57) 77 (3.03) 27 X4J

Nominal value

400 bar (6 000 psi)

AF

A0021968

Option

1)

1) Product Configurator, order code for "Process connection"

Process connections with

Thread JIS B0203

internal, metal process

isolating diaphragm

A0021970

Engineering unit mm (in). Diameter of process isolating diaphragm: 17.2 mm (0.68 in)

Description Device Material Nominal value

JIS B0203 R ½" (male) PMP21 316L 0.230 (0.51) 65 (2.56) 32 0.260 (0.57) 77 (3.03) 27 ZJJ

1) Product Configurator, order code for "Process connection"

to 100 bar (1 500 psi)

Weight Height C SW/AFWeight Height C SW/

kg (lbs) kg (lbs)

Nominal value

400 bar (6 000 psi)

AF

Option

1)

Endress+Hauser 37

Page 38

Process connections with

7 (0.28)

ø31.5 (1.24)

ø18 (0.71)

2 (0.08)

C

ø26 (1.02)

3.5 (0.14)

1

SW/AF

G ½" A

7 (0.28)

ø31.5 (1.24)

ø18 (0.71)

ø26 (1.02)

21 (0.83)

48 (1.89)

32

2

1

G ½" A

flush-mounted, metal

process isolating diaphragm

Cerabar PMC11, PMC21, PMP11, PMP21

Thread ISO 228 G

A0021971

1 FKM form seal, pre-mounted

Engineering unit mm (in). Diameter of process isolating diaphragm: 17.2 mm (0.68 in)

Device Designation Material Nominal value

to 100 bar (1 500 psi)

Weight Height C SW/AFWeight Height C SW/

kg (lbs) kg (lbs)

PMP11

PMP21

1) Product Configurator, order code for "Process connection"

Thread ISO 228 G ½" A

DIN3852, shape E

316L 0.140 (0.31) 41 (1.61) 32 0.120 (0.26) 35 (1.38) 32 WJJ

Nominal value

400 bar (6 000 psi)

AF

Option

1)

1 FKM form seal, pre-mounted

2 FKM O-ring, pre-mounted

Engineering unit mm (in). Diameter of process isolating diaphragm: 17.2 mm (0.68 in)

1)

Device

PMP11

PMP21

1) Suitable for weld-in adapter 52002643 and 52010172

2) Product Configurator, order code for "Process connection"

Designation Material Weight Option

Thread ISO 228 G ½" A

O-ring seal, flush-mounted

316L 0.150 (0.33) WUJ

kg (lbs)

38 Endress+Hauser

A0022802

2)

Page 39

Cerabar PMC11, PMC21, PMP11, PMP21

Materials in contact with process

NOTICE

Device components in contact with the process are listed in the "Mechanical construction" and

‣

"Ordering information" sections.

TSE Certificate of Suitability

The following applies to all device components in contact with the process:

• They do not contain any materials derived from animals.

• No additives or operating materials derived from animals are used in production or processing.

Process connections

Endress+Hauser supplies a threaded connection made of stainless steel in accordance with AISI 316L

(DIN/ EN material number 1.4404 or 1.4435). With regard to their stability-temperature property,

the materials 1.4404 and 1.4435 are grouped together under 13E0 in EN 1092-1: 2001 Tab. 18.

The chemical composition of the two materials can be identical.

Process isolating diaphragm

Description Material

Ceramic process

isolating diaphragm

Metal process

isolating diaphragm

Al2O3 aluminum-oxide ceramic, Ceraphire® FDA, ultrapure 99.9 % (see also

www.endress.com/ceraphire)

The US Food & Drug Administration (FDA) has no objections to the use of ceramics

made from aluminum oxide as a surface material in contact with foodstuffs. This

declaration is based on the FDA certificates of our ceramic suppliers.

AISI 316L (DIN/EN material number 1.4435)

Seals

See the specific process connection.

Endress+Hauser 39

Page 40

Cerabar PMC11, PMC21, PMP11, PMP21

5

2

4

3

1

3

6

8 97

8 97

Materials not in contact with process

Housing

A0027299

A0025117

A0027301

A0027300

Item number Component part Material

1 Valve plug • Seal: NBR

• Plug: PA

• Screw: V2A

2 Cable • Pressure screw: PVDF

• Seal: TPE-V

• Cable: PUR (UL 94 V0)

3 Design element PBT/PC

4 Connection PPSU

5 M12 plug Plastic: PPSU

6 M12 plug 316L (1.4404)

For Ex ec: metal housing cap

7 Pressure compensation

element

8 Housing 316L (1.4404)

9 Nameplates Plastic foil (attached to housing) or directly lasered onto the

PMP11: PBT/PC

PMP21 standard: PBT/PC

PMP21 with Ex ec approval: 316L (1.4404)

housing

Filling oil

Device Filling oil

PMP11

PMP21

Synthetic oil polyalphaolefin FDA 21 CFR 178.3620, NSF H1

40 Endress+Hauser

Page 41

Cerabar PMC11, PMC21, PMP11, PMP21

Cleaning

Device Description Option

PMC11

PMP11

PMC21

PMP21

PMC21 Cleaned for oxygen service HB

1) Product Configurator, order code for "Service"

Cleaned from oil+grease HA

1)

Endress+Hauser 41

Page 42

Operability

Cerabar PMC11, PMC21, PMP11, PMP21

Plug-on display PHX20 (optional)

Devices with valve plug can be fitted with the optional local display PHX20.

Designation Option

Plug-on display PHX20, IP65 RU

1) Product Configurator, order code for "Accessories"

1)

A 1-line liquid crystal display (LCD) is used. The local display shows measured values, fault messages

and information messages. The device display can be turned in 90° steps. Depending on the

orientation of the device, it is therefore easy to read the measured values.

Technical data

Display: 4-digit, red LED display

Digit height: 7.62 mm; programmable decimal point setting

Display range: -1999...9999

Accuracy: 0.2% of span ±1 digit

Electrical connection: to transmitter with 4 to 20 mA output and elbow plug DIN 43 650, with

reverse polarity protection

Power supply for display: not required, self-powered by the current loop

Voltage drop: ≤ 5 V (corresponds to load: max. 250 Ω)

Conversion rate: 3 measurements per second

Damping: 0.3 to 20 s (configurable)

Data backup: non-volatile EEPROM

Error message: • HI: Overranging

• LO: Underranging

Programming: via 2 buttons, menu-guided, scaling of display range, decimal point,

damping, error message

Degree of protection: IP 65

Effect of temperature on display: 0.1% / 10 K

Electromagnetic compatibility

(EMC):

Permitted current load: max. 60 mA

Ambient temperature: 0 to +60 °C (+32 to +140 °F)

Housing material: Plastic Pa6 GF30, blue

Order number: 52022914

Interference emission as per EN 50081, interference immunity as per EN

50082

Front screen made of PMMA, red

42 Endress+Hauser

Page 43

Cerabar PMC11, PMC21, PMP11, PMP21

Certificates and approvals

CE mark

RoHS

RCM-Tick marking

EAC conformity

Approval

Safety Instructions (XA)

The device meets the legal requirements of the relevant EC directives. Endress+Hauser confirms that

the device has been successfully tested by applying the CE mark.

The measuring system complies with the substance restrictions of the Restriction on Hazardous

Substances Directive 2011/65/EU (RoHS 2).

The supplied product or measuring system meets the ACMA (Australian Communications and Media

Authority) requirements for network integrity, interoperability, performance characteristics as well

as health and safety regulations. Here, especially the regulatory arrangements for electromagnetic

compatibility are met. The products are labelled with the RCM- Tick marking on the name plate.

A0029561

The PMC21, PMP21 and PMP23 devices meet the legal requirements of the applicable EAC

directives. These are listed in the corresponding EAC Declaration of Conformity along with the

standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

CSA C/US General Purpose

Depending on the approval, the following Safety Instructions (XA) are supplied with the device. They

are an integral part of the Operating Instructions.

Device Directive Documentation Option

PMP21 ATEX II 1/2G Ex ia IIC T4 Ga/Gb XA01271P BA

PMC21 ATEX II 2G Ex ia IIC T4 Gb XA01271P BB

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

1) Product Configurator order code for "Approval"

ATEX II 3G Ex ec IIC T4 Gc XA01533P BC

FM IS Cl. I, Div.1 Gr. A-D T4 XA01321P FA

CSA C/US IS Cl. I Div. 1 Gr. A-D XA01322P CB

EAC Ex ia IIC T4 Ga/Gb XA01540P GA

IEC Ex ia IIC T4 Ga/Gb XA01271P IA

NEPSI Ex ia IIC T4 XA01363P NA

TIIS Ex ia IIC T4 In preparation TA

The nameplate indicates the Safety Instructions (XA) that are relevant to the device.

1)

Endress+Hauser 43

Page 44

Cerabar PMC11, PMC21, PMP11, PMP21

Marine approval (pending)

Pressure Equipment Directive 2014/68/EU (PED)

Device Designation Option

PMC21

PMP21

PMC21

PMP21

PMC21

PMP21

1) Product Configurator, order code for "Additional approval"

DNV GL LE

ABS LF

RINA LV

1)

Pressure equipment with allowable pressure ≤ 200 bar (2 900 psi)

Pressure equipment (with a maximum allowable pressure PS ≤ 200 bar (2 900 psi)) can be classified

as pressure accessories in accordance with Pressure Equipment Directive 2014/68/EU. If the

maximum allowable pressure is ≤ 200 bar (2 900 psi) and the pressurized volume of the pressure

equipment is ≤ 0.1 l, the pressure equipment is subject to the Pressure Equipment Directive (cf.

Pressure Equipment Directive 2014/68/EU, Article 4, point 3). The Pressure Equipment Directive

only requires that the pressure equipment shall be designed and manufactured in accordance with

the "sound engineering practice of a Member State".

Reasons:

• Pressure Equipment Directive (PED) 2014/68/EU Article 4, point 3

• Pressure equipment directive 2014/68/EU, Commission's Working Group "Pressure", Guideline

A-05 + A-06

Note:

A partial examination shall be performed for pressure instruments that are part of safety equipment

for the protection of a pipe or vessel from exceeding allowable limits (safety accessory in accordance

with Pressure Equipment Directive 2014/68/EU, Article 2, point 4).

Pressure equipment with allowable pressure > 200 bar (2 900 psi)

Pressure equipment designated for application in every process fluid having a pressurized volume of

<0.1 l and a max. allowable pressure PS > 200 bar (2 900 psi) shall satisfy the essential safety

requirements set out in Annex I of the Pressure Equipment Directive 2014/68/EU. According to

Article 13 pressure equipment shall be classified by category in accordance with Annex II. The

conformity assessment of the pressure equipment shall be determined by the category I under

consideration of the above-mentioned low pressurized volume. These devices shall be provided with

CE marking.

Reasons:

• Pressure Equipment Directive 2014/68/EU, Article 13, Annex II

• Pressure equipment directive 2014/68/EU, Commission's Working Group "Pressure", Guideline

A-05

Note:

A partial examination shall be performed for pressure instruments that are part of safety equipment

for the protection of a pipe or vessel from exceeding allowable limits (safety accessory in accordance

with Pressure Equipment Directive 2014/68/EU, Article 2, point 4).

The following also applies:

PMP21 with threaded connection and internal process isolating diaphragm PN > 200 :

Suitable for stable gases in group 1, category I, module A

Other standards and guidelines

The applicable European guidelines and standards can be found in the relevant EU Declarations of

Conformity. The following standards were also applied:

DIN EN 60770 (IEC 60770):

Transmitters for use in industrial process control systems Part 1: Methods for performance

evaluation

44 Endress+Hauser

Page 45

Cerabar PMC11, PMC21, PMP11, PMP21

Methods for evaluating the performance of transmitters for control and regulation in industrial

process control systems.

DIN 16086:

Electrical pressure measuring instruments, pressure sensors, pressure transmitters, pressure

measuring instruments, concepts, specifications on data sheets

Procedure for writing specifications in data sheets for electrical pressure measuring instruments,

pressure sensors and pressure transmitters.

EN 61326-X:

EMC product family standard for electrical equipment for measurement, control and laboratory use.

EN 60529:

Degrees of protection provided by enclosures (IP code)

NAMUR - User association of automation technology in process industries.

NE21 - Electromagnetic Compatibility (EMC) of Industrial Process and Laboratory Control

Equipment.

NE43 - Standardization of the Signal Level for the Failure Information of Digital Transmitters.

NE44 - Standardization of Status Indicators on PCT Instruments with the Help of Light Emitting

Diodes

NE53 - Software of Field Devices and Signal-processing Devices with Digital Electronics

CRN approval

Calibration unit

Calibration

Inspection certificates

A CRN approval is available for some device versions. A CRN-approved process connection with a

CSA approval must be ordered for a CRN-approved device. The CRN-approved devices are assigned

the registration number 0F18141.5C.

Ordering information: Product Configurator, order code for "Process connection" (the CRN process

connections are indicated appropriately in the "Mechanical construction" section.)

Designation Option

Sensor range; % A

Sensor range; mbar/bar B

Sensor range; kPa/MPa C

Sensor range; psi F

Customer-specific; see additional spec. J

1) Product Configurator, order code for "Calibration; unit"

Designation Option

3-point certificate of calibration F3

1) Product Configurator order code for "Calibration"

Device Designation Option

PMC21

PMP21

3.1 Material documentation, wetted metal parts, EN10204-3.1 inspection certificate JA

1)

1)

1)

1) Product Configurator, order code for "Test, Certificate"

Endress+Hauser 45

Page 46

Cerabar PMC11, PMC21, PMP11, PMP21

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Scope of delivery

• Measuring device

• Optional accessories

• Brief Operating Instructions

• Certificates

46 Endress+Hauser

Page 47

Cerabar PMC11, PMC21, PMP11, PMP21

53 (2.09)

ø

20

(0.8)

27

(1.06)

40 (1.57)³

35

(1.38)

28

(1.1)

20 (0.79)

Accessories

Weld-in adapter

Device Description Option

PMP21 Weld-in adapter G½, 316L QA 52002643

PMP21 Weld-in adapter G½, 316L 3.1 EN10204-3.1 material,

PMP21 Weld-in tool adapter G½, brass QC 52005082

PMP21 Weld-in adapter G1/2, 316L, for G1/2 A DIN 3852 QM 71389241

PMP21 Weld-in adapter G1/2, 316L, 3.1, for G1/2 A DIN 3852,

1) Product Configurator, order code for "Enclosed accessories"

Various weld-in adapters are available for installation in vessels or pipes.