Page 1

BA01697D/06/EN/04.19

71426511

2019-05-01

Valid as of version

01.00.zz (Device firmware)

Products Solutions Services

Operating Instructions

Picomag

IO-Link

Electromagnetic flowmeter

Page 2

Picomag IO-Link

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these instructions.

2 Endress+Hauser

Page 3

Picomag IO-Link Table of contents

Table of contents

1 About this document ................ 5

1.1 Document function ..................... 5

1.2 Symbols used .......................... 5

1.2.1 Safety symbols .................. 5

1.2.2 Electrical symbols ................ 5

1.2.3 Communication symbols ........... 5

1.2.4 Symbols for certain types of

information .................... 5

1.2.5 Symbols in graphics ............... 6

1.3 Documentation ........................ 6

1.4 Registered trademarks ................... 6

2 Basic safety instructions ............ 7

2.1 Requirements for the personnel ............ 7

2.2 Designated use ........................ 7

2.3 Workplace safety ....................... 7

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 8

2.6 IT security ............................ 8

2.7 Device-specific IT security ................. 8

2.7.1 Access via the SmartBlue App ....... 8

2.7.2 Protecting access via a password ..... 8

2.7.3 Access via Bluetooth® wireless

technology ..................... 9

8 System integration ................ 20

8.1 Overview of device description files ......... 20

8.2 Device master file ..................... 20

9 Commissioning .................... 21

9.1 Switching ON the measuring device ........ 21

9.2 Overview of the operating menu ........... 21

9.3 Configuring the measuring device .......... 21

9.3.1 Identification .................. 21

9.3.2 Configuring system units .......... 22

9.3.3 Setting the installation direction and

measurement .................. 22

9.3.4 Configuring the IO modules ........ 23

9.3.5 Totalizer ...................... 28

9.3.6 Configuring the display ........... 29

9.3.7 Security ...................... 30

9.3.8 Data management ............... 30

9.4 Pending diagnostic events ............... 31

9.4.1 Simulation .................... 31

9.5 System ............................. 31

10 Operational ....................... 33

10.1 Offline quick view of the configuration ...... 33

3 Incoming acceptance and product

identification ..................... 10

3.1 Incoming acceptance ................... 10

3.2 Product identification ................... 10

3.2.1 Symbols on measuring device ...... 11

4 Storage and transport ............. 12

4.1 Storage conditions ..................... 12

4.2 Transporting the product ................ 12

4.3 Packaging disposal ..................... 12

5 Installation ....................... 13

5.1 Installation conditions .................. 13

5.1.1 Mounting position ............... 13

5.2 Mounting the measuring device ........... 13

6 Electrical connection .............. 15

6.1 Connection conditions .................. 15

6.1.1 Requirements for connecting cables .. 15

6.1.2 Pin assignment, device plug ........ 15

6.2 Connecting the measuring device .......... 18

6.3 Post-connection check .................. 18

7 Operation options ................. 19

7.1 Access to the operating menu via the

SmartBlue app ........................ 19

11 Diagnostics and troubleshooting ... 35

11.1 General troubleshooting ................. 35

11.2 Diagnostic information on local display ...... 36

11.2.1 Diagnostic message .............. 36

11.3 Overview of diagnostic events ............. 37

11.4 Device information .................... 38

11.5 Firmware history ..................... 38

12 Accessories ....................... 39

13 Technical data .................... 41

13.1 Input ............................... 41

13.2 Output ............................. 41

13.3 Power supply ......................... 41

13.4 Performance characteristics .............. 41

13.5 Installation .......................... 41

13.6 Environment ......................... 42

13.7 Process ............................. 42

13.8 Mechanical construction ................ 42

13.9 Operability .......................... 43

13.10 Certificates and approvals ............... 44

14 Appendix ......................... 45

14.1 Radio approvals ....................... 45

14.1.1 Europe ....................... 45

14.1.2 Canada and USA ................ 45

14.1.3 India ......................... 45

Endress+Hauser 3

Page 4

Table of contents Picomag IO-Link

14.1.4 Singapore ..................... 45

14.1.5 Thailand ...................... 46

14.1.6 Argentina ..................... 46

14.1.7 Taiwan ....................... 46

14.1.8 Brazil ........................ 46

14.1.9 South Korea ................... 47

14.1.10 Other countries ................. 47

14.2 IO-Link process data ................... 48

14.2.1 Data structure .................. 48

14.2.2 Diagnostic information ........... 48

14.3 IO-Link ISDU parameter list .............. 49

Index .................................. 57

4 Endress+Hauser

Page 5

Picomag IO-Link About this document

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

1.2.3 Communication symbols

Symbol Meaning

Bluetooth®

Wireless data transmission between devices over a short distance.

® IO-Link

Communications system for connecting intelligent sensors and actuators to an

automation system. The IO-Link technology is standardized under the description

"Single-drop digital communication interface for small sensors and actuators (SDCI)" in

the IEC 61131-9 standard.

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Endress+Hauser 5

Page 6

About this document Picomag IO-Link

A

1.

Symbol Meaning

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3.… Series of steps

Result of a step

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3, ... Item numbers

A, B, C, ... Views

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer: Enter the serial number of the measuring device

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number of the measuring

device or scan the 2-D matrix code on the measuring device.

1.4 Registered trademarks

®

Is a registered trademark. It may only be used in conjunction with products and services by

members of the IO-Link Community or by non-members who hold an appropriate license.

For more detailed information on the use of IO-Link, please refer to the rules of the IOLink Community at: www.io.link.com.

Bluetooth® wireless technology

®

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth

SIG, Inc. and any use of such marks by Endress+Hauser is under license.

Apple®

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in

the U.S. and other countries. App Store is a service mark of Apple Inc.

Android®

Android, Google Play and the Google Play logo are trademarks of Google Inc.

6 Endress+Hauser

Page 7

Picomag IO-Link Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Are instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Designated use

Application and media

The measuring device described in these Brief Operating Instructions is intended only for

flow measurement of liquids with a minimum conductivity of 20 µS/cm.

To ensure that the measuring device remains in proper condition for the operation time:

Use the measuring device only for media against which the process-wetted materials

‣

are adequately resistant.

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage

caused by improper or non-designated use.

WARNING

L

Danger of breakage due to corrosive or abrasive fluids and ambient conditions!

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Keep within the specified pressure and temperature range.

‣

Residual risks

WARNING

L

The electronics and the medium may cause the surfaces to heat up. This presents a

burn hazard!

For elevated fluid temperatures, ensure protection against contact to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

Endress+Hauser 7

Page 8

Basic safety instructions Picomag IO-Link

2.4 Operational safety

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EU

directives listed in the device-specific EU Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

2.6 IT security

Our warranty is valid only if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the settings.

IT security measures, which provide additional protection for the device and associated

data transfer, must be implemented by the operators themselves in line with their security

standards.

2.7 Device-specific IT security

2.7.1 Access via the SmartBlue App

Two access levels (user roles) are defined for the device: the Operator user role and the

Maintenance user role. The Maintenance user role is the default setting.

If a user-specific access code is not defined (in the Set access code parameter), the default

setting 0000 continues to apply and the Maintenance user role is automatically enabled.

The device's configuration data are not write-protected and can be edited at all times.

If a user-specific access code has been defined (in the Set access code parameter), all the

parameters are write-protected and the device is accessed with the Operator user role. The

previously defined access code must first be entered again before the Maintenance user

role is enabled and all the parameters can be write-accessed.

2.7.2 Protecting access via a password

Different passwords are available to protect write access to the device parameters or access

to the device via the Bluetooth® interface.

• User-specific access code

Protect write access to the device parameters via the SmartBlue app

• Bluetooth key

The password protects a connection between an operating device (e.g. smartphone,

tablet) and the device via the Bluetooth® interface.

8 Endress+Hauser

Page 9

Picomag IO-Link Basic safety instructions

General notes on the use of passwords

• The access code and Bluetooth key supplied with the device should be changed during

commissioning.

• Follow the general rules for generating a secure password when defining and managing

the access code or Bluetooth key.

• The user is responsible for the management and careful handling of the access code and

Bluetooth key.

2.7.3 Access via Bluetooth® wireless technology

Secure signal transmission via Bluetooth® wireless technology uses an encryption

method tested by the Fraunhofer Institute.

• The device is not visible via Bluetooth® wireless technology without the SmartBlue app.

• Only one point-to-point connection is established between the device and a smartphone

or tablet.

• The Bluetooth® wireless technology interface can be disabled via SmartBlue.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Picomag IO-Link

1

2

Order code:

Ser. no.:

Ext. ord. cd.:

i

i

Date:

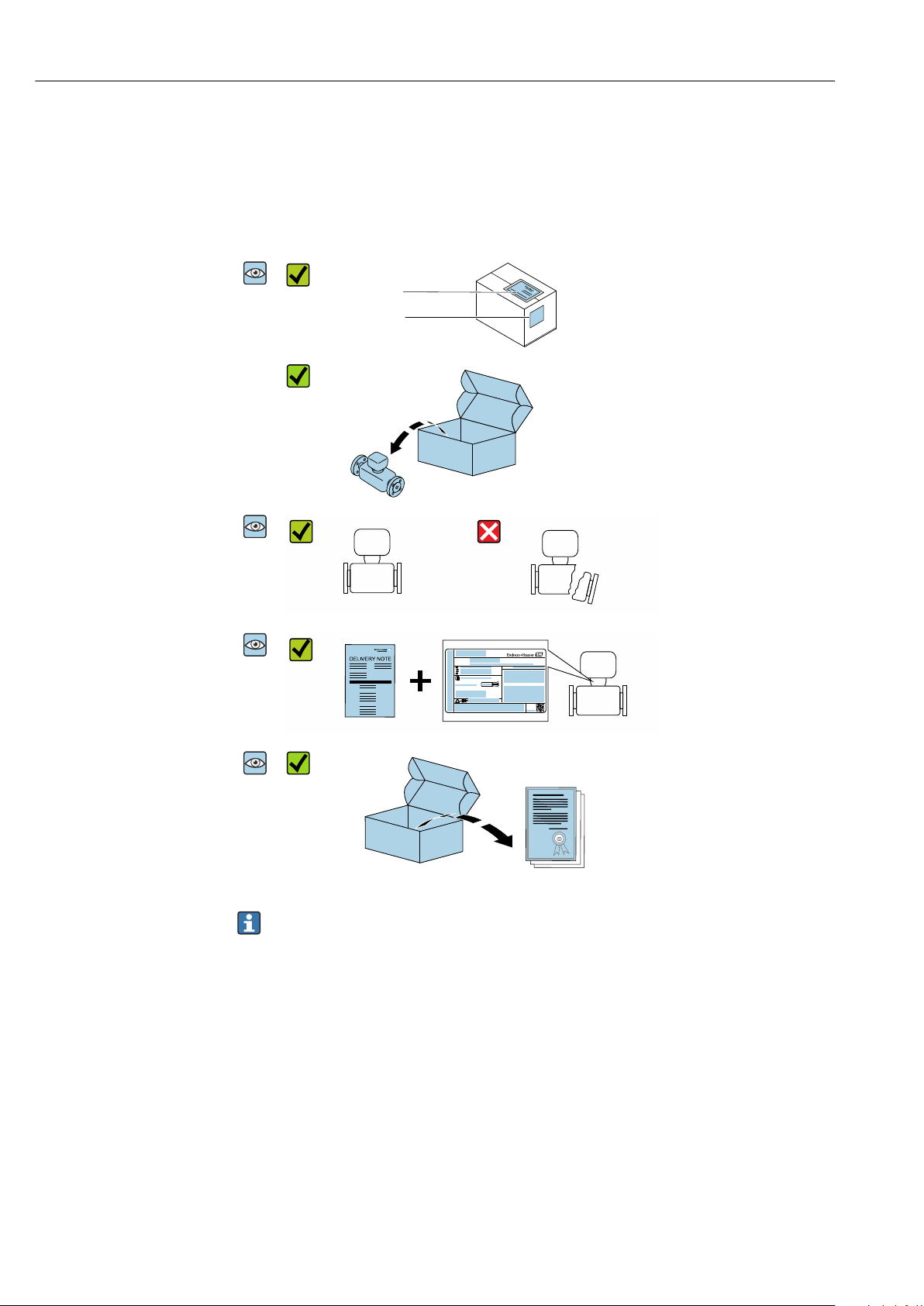

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

Are the order codes on the

delivery note (1) and the

product sticker (2) identical?

Are the goods undamaged?

Do the nameplate data

match the ordering

information on the delivery

note?

Is the accompanying safety

data sheet present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery!

The Technical Documentation is available via the Internet or via the Endress+Hauser

Operations App, see the "Product identification" section .

3.2 Product identification

The following options are available for identification of the measuring device:

• The device label

• Order code with breakdown of the device features on the delivery note

• Enter the serial number on the device label in W@M Device Viewer

(www.endress.com/deviceviewer): all the information about the measuring device is

displayed.

• Enter the serial number on the device label into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the measuring device with the Endress+Hauser

10 Endress+Hauser

Operations App: all the information about the measuring device is displayed.

Page 11

Picomag IO-Link Incoming acceptance and product identification

3.2.1 Symbols on measuring device

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious

or fatal injury.

Reference to documentation

Refers to the corresponding device documentation.

Endress+Hauser 11

Page 12

Storage and transport Picomag IO-Link

4 Storage and transport

4.1 Storage conditions

Observe the following notes for storage:

Store in the original packaging to ensure protection from shock.

‣

Store in a dry place.

‣

Do not store outdoors.

‣

Storage temperature→ 42

4.2 Transporting the product

Transport the device to the measuring point in the original packaging.

Do not remove protective covers or caps installed on process connections. They

prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

4.3 Packaging disposal

All packaging materials are environmentally friendly and 100% recyclable:

Carton in accordance with European Packaging Directive 94/62EC; recyclability is

confirmed by the affixed RESY symbol.

12 Endress+Hauser

Page 13

Picomag IO-Link Installation

h

≥ 0 × DN

5 Installation

5.1 Installation conditions

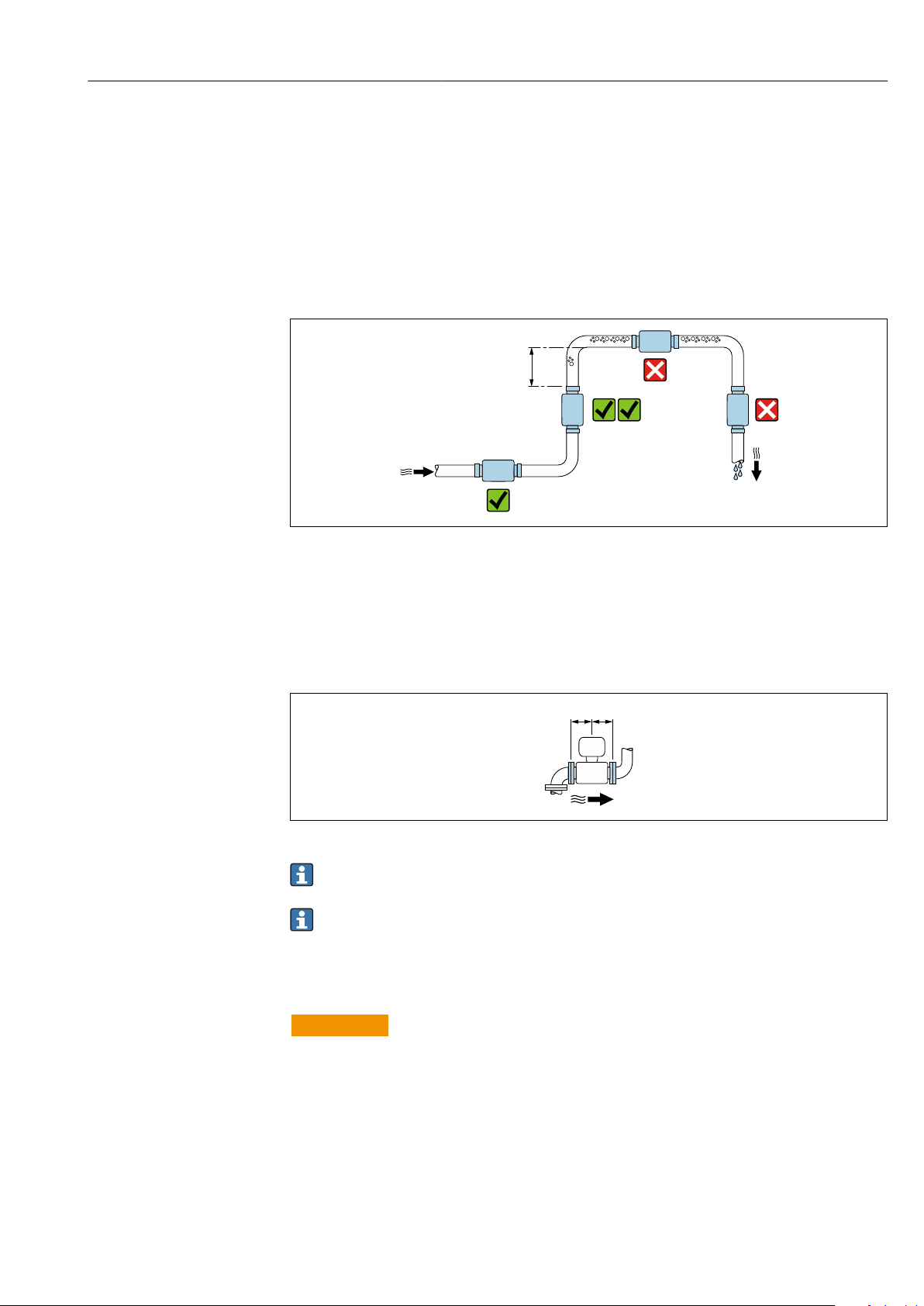

5.1.1 Mounting position

Mounting location

A0032998

Preferably install the sensor in an ascending pipe, and ensure a sufficient distance to the

next pipe elbow: h ≥ 2 × DN

Inlet and outlet runs

No inlet and outlet runs need to be considered.

A0032859

Installation dimensions: information on the dimensions and installed lengths of the

device → 42

The arrow points in the preferred direction of flow. Measurement in the other

direction is also possible.→ 22

5.2 Mounting the measuring device

WARNING

L

Burn hazard!

If medium temperatures or ambient temperatures exceed 50 °C, areas of the housing can

heat to over 65 °C.

Safeguard the housing so that it cannot be touched accidentally.

‣

Endress+Hauser 13

Page 14

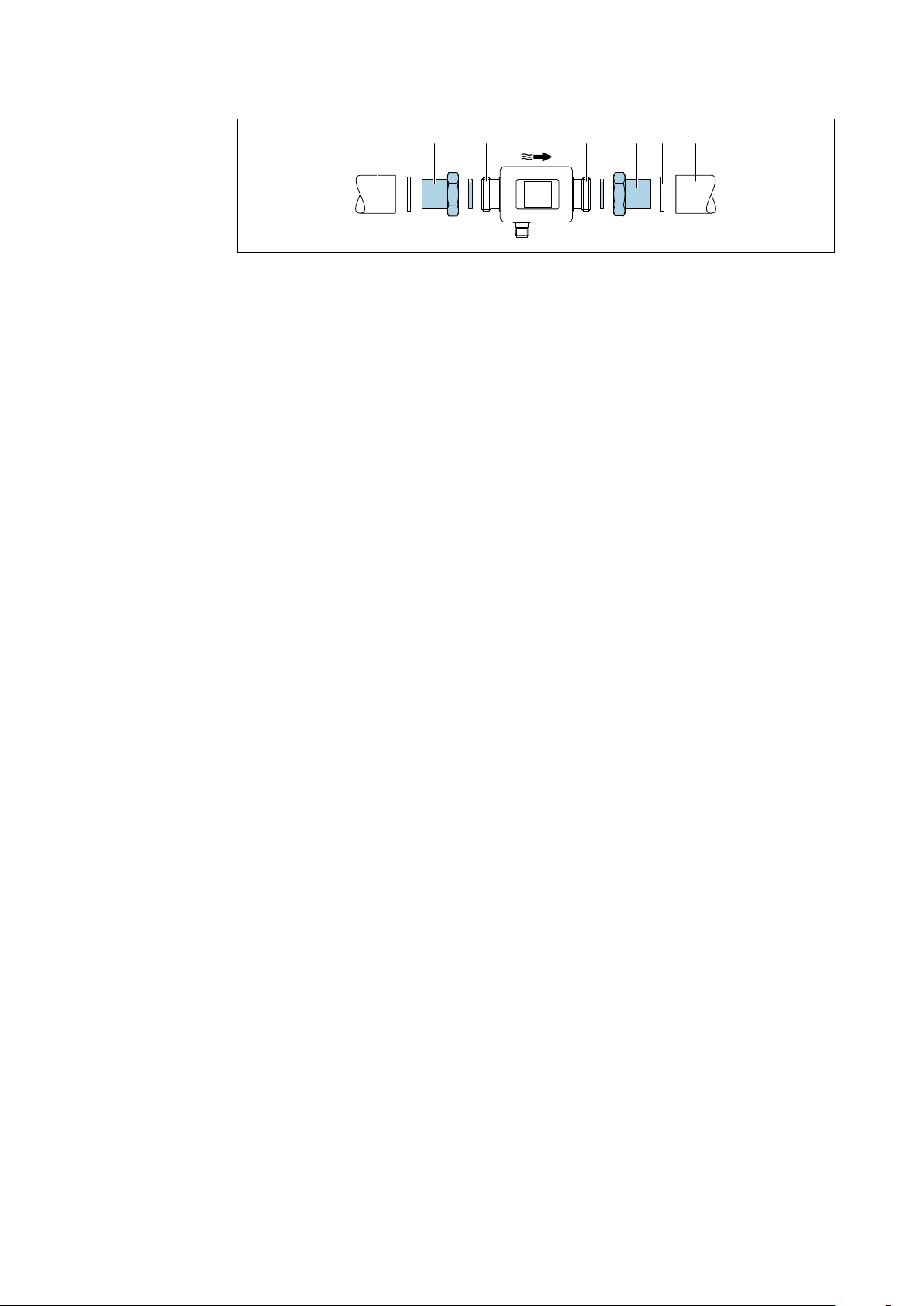

Installation Picomag IO-Link

1 12 34 45 53 2

A0033002

1 Pipe

2 Seal (not supplied)

3 Adapter: available adapters → 39

4 Seal (included in delivery)

5 Measuring device connection

14 Endress+Hauser

Page 15

Picomag IO-Link Electrical connection

A

2 WH

1 BN

4 BK

3 BU

1

2

3

4

+

-

!

A

B

B

A

L+

L-

IO2

IO1

6 Electrical connection

6.1 Connection conditions

6.1.1 Requirements for connecting cables

National regulations and standards apply.

Connecting cable M12 × 1 A-coded

Conductor cross-section

Temperature range –10 to +90 °C (+14 to +194 °F)

Degree of protection IP65/67, pollution degree 3

Humidity and moisture Suitable for indoor environments with up to 100% rh (wet and damp locations)

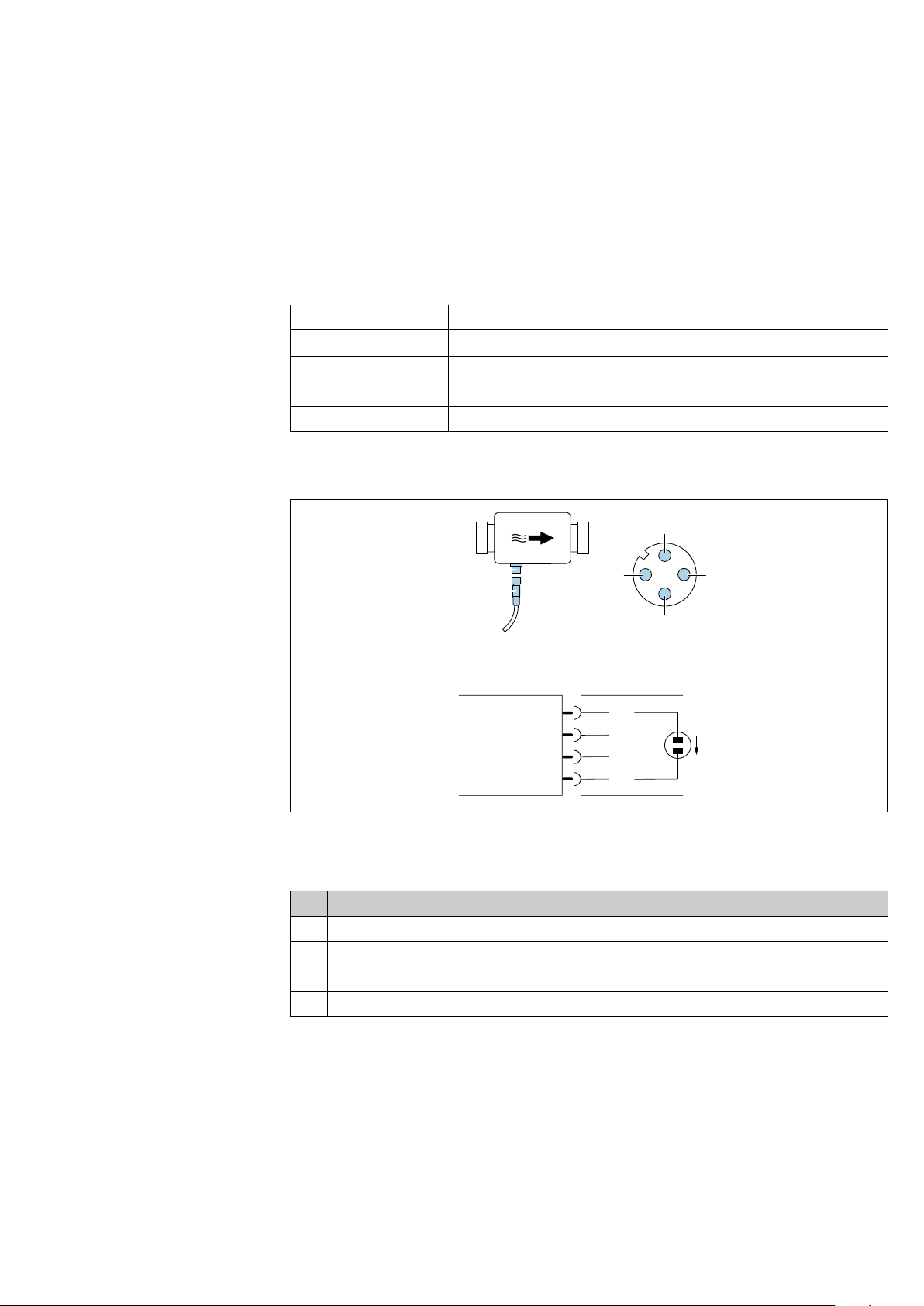

6.1.2 Pin assignment, device plug

At least 0.12 mm2 (AWG26)

A0033004

A Connector (Picomag)

B Socket (Customer side)

Pin Assignment Color Description

1 L+ Brown Supply voltage + (18 to 30 VDC/max. 3 W)

2 IO2 White Input/output 2, can be configured independently of IO1

3 L- Blue Supply voltage -

4 IO1 Black Input/output 1, can be configured independently of IO2

Endress+Hauser 15

Page 16

Electrical connection Picomag IO-Link

1

2

3

4

B

A

L+

L-

1

2

3

4

B

A

L+

L-

1

2

3

4

B

A

L+

L-

1

2

3

4

B

A

L+

L-

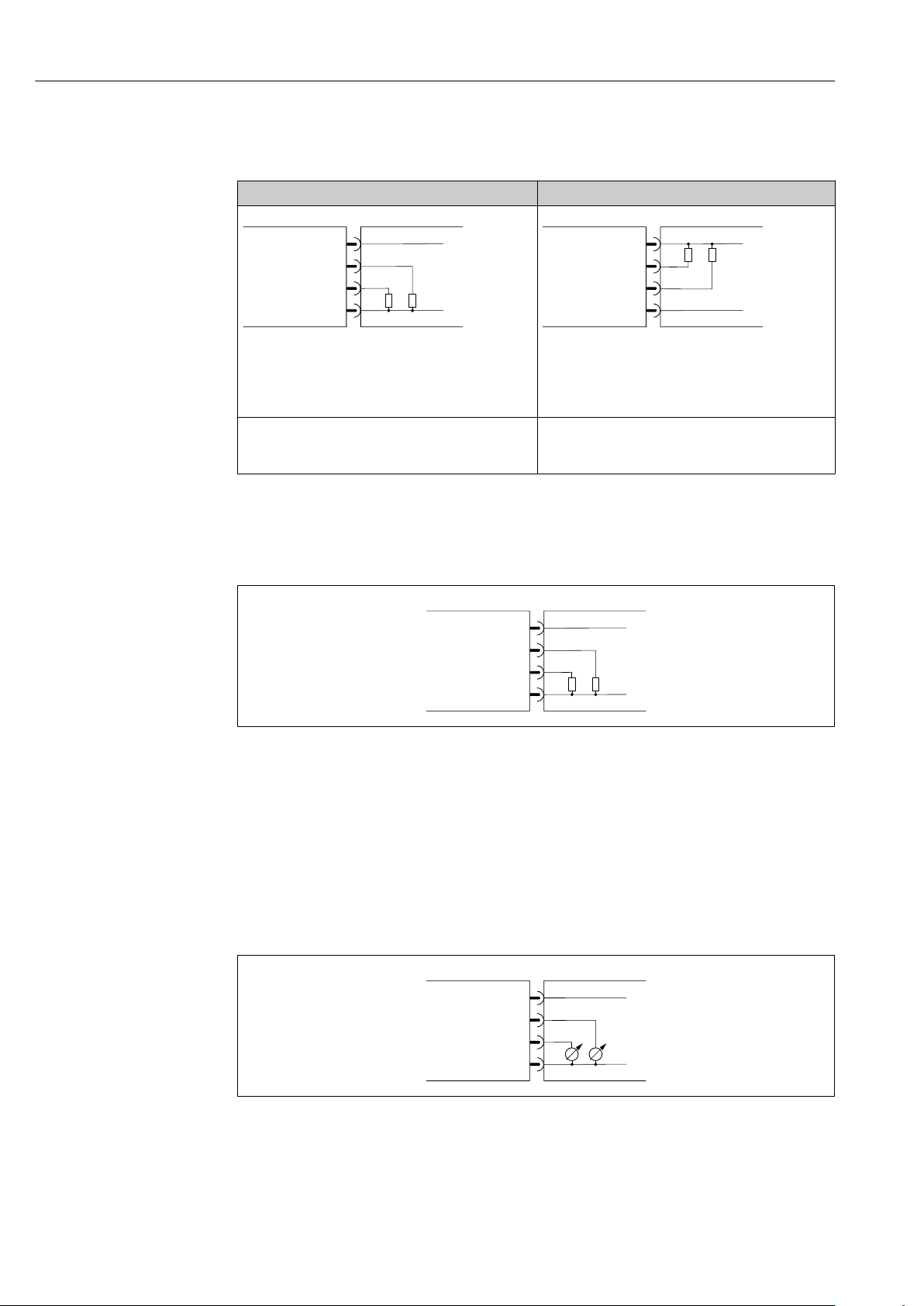

Switch output configuration version

The switching behaviour of IO1 and IO2 can be configured independently of one another.

1)

pnp

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

L- Supply voltage -

The load is switched to high side L+. The maximum

load current is 250 mA. The output is overloadresistant.

1) positive negative positive (high side switch)

2) negative positive negative (low side switch)

Pulse output configuration version

2)

npn

A0033005

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

L- Supply voltage -

The load is switched to low side L-. The maximum load

current is 250 mA. The output is overload-resistant.

A0033006

A0033005

1 Pulse output with pnp switching behaviour

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

L- Supply voltage -

The load is switched to high side L+. The maximum load current is 250 mA. The output is

overload-resistant.

Current output configuration version

A0033007

2 Current output, active, 4 to 20 mA

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

16 Endress+Hauser

L- Supply voltage -

Page 17

Picomag IO-Link Electrical connection

1

2

3

4

B

A

L+

L-

1

2

3

4

B

A

L+

L-

==

The current flows from the output to L-. The maximum load may not exceed 500 Ω. A

bigger load distorts the output signal.

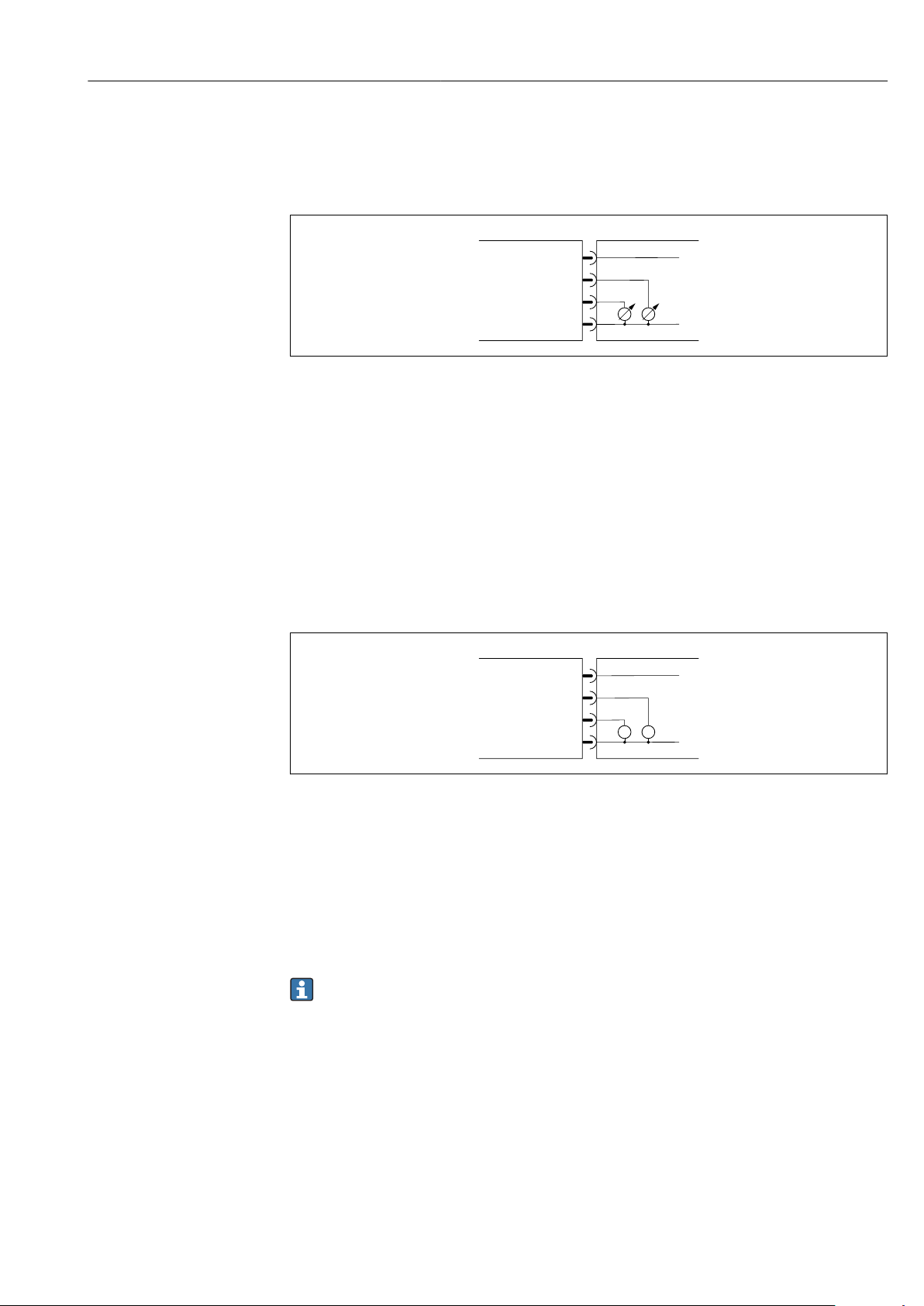

Voltage output configuration version

A0033007

3 Voltage output, active, 2 to 10 V

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

L- Supply voltage -

The voltage from the output applies to L-. The load must be at least 500 Ω. The output is

overload-resistant.

Status input configuration version

• 15 V (switch-on threshold)

• 5 V (switch-off threshold)

4 Status input

A Connector (Picomag)

B Socket (Customer side)

L+ Supply voltage +

L- Supply voltage -

Internal resistance: 7.5 kΩ

IO-Link configuration version

Option only available for output 1 in the Output 1→ 23 submenu

A0033008

The measuring device features an IO-Link communication interface with a baud rate of

38,400 and with a second IO function on pin 2. This requires an IO-Link compatible

module (IO-Link master) for operation. The IO-Link communication interface allows direct

access to the process and diagnostics data.

Endress+Hauser 17

Page 18

Electrical connection Picomag IO-Link

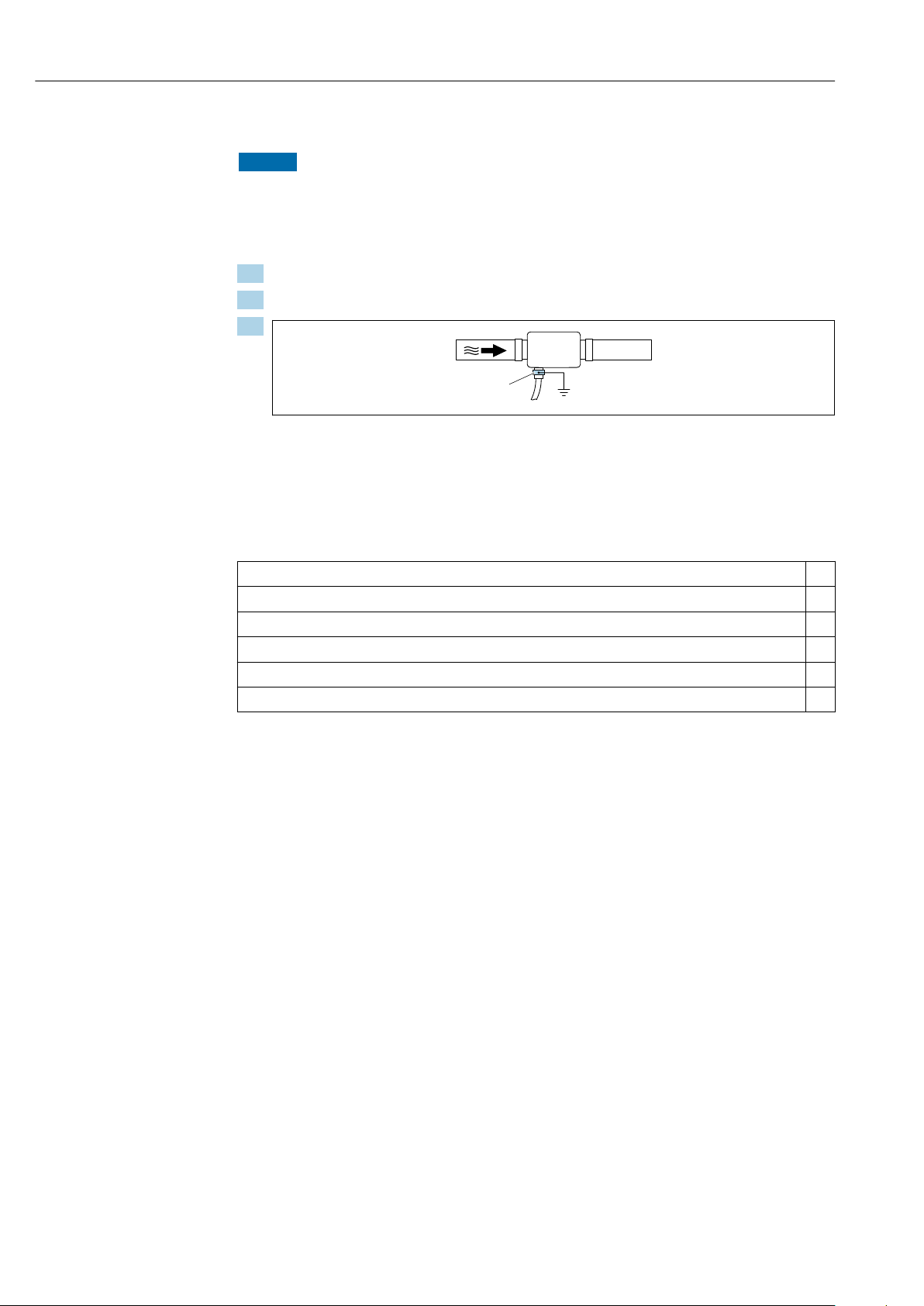

1

6.2 Connecting the measuring device

NOTICE

The measuring device may only be installed by properly trained technicians.

Comply with national and international regulations regarding the installation of

‣

electrotechnical systems.

Power supply according to EN 50178, SELV, PELV or Class 2.

‣

1. De-energize the system.

2. Connect the measuring device via the connector.

3.

A0033003

In the case of non-grounded pipes:

The device must be grounded using the ground terminal accessory.

6.3 Post-connection check

Are cables or the device undamaged (visual inspection)?

Do the cables have adequate strain relief?

Is the connector connected correctly?

Does the supply voltage match the specifications on the measuring device?

Is the pin assignment of the connector correct?

Is the potential equalization established correctly?

18 Endress+Hauser

Page 19

Picomag IO-Link Operation options

7 Operation options

7.1 Access to the operating menu via the SmartBlue app

The device can be operated and configured via the SmartBlue app. In this case, the

connection is established via the Bluetooth® wireless technology interface.

Supported functions

• Device selection in Live List and access to the device (login)

• Configuration of the device

• Access to measured values, device status and diagnostics information

The SmartBlue app is available for free download for Android devices (Google Playstore)

and iOS devices (iTunes Apple Shop) : Endress+Hauser SmartBlue

Directly to the app with the QR code:

System requirements

• Devices with iOS:

iOS9.0 or higher

• Devices with Android:

Android 4.4 KitKat or higher

Download the SmartBlue app:

1. Install and start the SmartBlue app.

A Live List shows all the devices available.

The list displays the devices with the configured tag name. The default setting for

the tag name is EH_DMA_XYZZ (XYZZ = the last 7 digits of the device serial

number).

2. For Android devices, activate GPS positioning (not necessary for devices with IOS)

3. Select the device from the Live List.

The Login dialog box opens.

Logging in:

4. Enter the user name: admin.

5. Enter the initial password: serial number of the device.

When you log in for the first time, a message is displayed advising you to change

the password.

6. Confirm your entry.

The main menu opens.

7. Optional: Change the password:

A0033202

Navigate through the various items of information about the device: swipe the screen

to the side.

Endress+Hauser 19

Page 20

System integration Picomag IO-Link

8 System integration

The measuring device has an IO-Link communication interface. The IO-Link interface

allows direct access to process and diagnostics data and enables the user to configure the

measuring device on the fly.

Properties:

• IO-Link Specification: Version 1.1

• IO-Link Smart Sensor Profile 2nd Edition

• SIO mode: yes

• Speed: COM2 (38.4 kBaud)

• Minimum cycle time: 10 ms

• Process data width: 120 bit

• IO-Link data storage: yes

• Block configuration: no

• Device operational: The measuring device is operational 4 seconds after the supply

voltage is applied

More information on IO-Link is available at www.io-link.com

Overview of the entire IO-Link ISDU parameter list → 49

8.1 Overview of device description files

Current version data for the device

Firmware version 01.01.zz • On the title page of the Operating Instructions

• On the device label

• Firmware version system parameter

Release date of firmware version 05.2019 ---

Profile version • 1.1

• Smart Sensor Profile

---

8.2 Device master file

In order to integrate field devices into a digital communication system, the IO-Link system

needs a description of the device parameters, such as output data, input data, data format,

data volume and supported transmission rate.

These data are available in the device master file (IODD

Master via generic modules when the communication system is commissioned.

The IODD can be downloaded as follows:

• Endress+Hauser: www.endress.com

• IODDfinder: ioddfinder.io-link.com

1)

) which is provided to the IO-Link

1) IO Device Description

20 Endress+Hauser

Page 21

Picomag IO-Link Commissioning

9 Commissioning

9.1 Switching ON the measuring device

Once the supply voltage has been switched on, the measuring device adopts the normal

mode after a maximum of 4 s. During the start-up phase, the outputs are in the same state

as the measuring device in the switched-off state.

9.2 Overview of the operating menu

Overview of the operating menu

Guidance

Diagnostics

System

▸ Identification

▸ System units

▸ Sensor

▸ Output 1

▸ Output 2

▸ Totalizer

▸ Display

▸ Security

▸ Data management

▸ Actual diagnostics

▸ Simulation

→ 21

→ 22

→ 22

→ 23

→ 23

→ 28

→ 29

→ 30

→ 30

→ 31

→ 31

▸ Data management

▸ Firmware

→ 31

→ 31

9.3 Configuring the measuring device

9.3.1 Identification

The device tag and the user level can be changed in the Identification submenu.

Navigation

Menu: "Guidance" → Identification

Endress+Hauser 21

Page 22

Commissioning Picomag IO-Link

9.3.2 Configuring system units

In the System units submenu, you can configure the units of all measured values.

Navigation

Menu: "Guidance" → System units

Parameter overview with brief description

Parameter Description Selection Factory setting

Volume flow unit Select volume flow unit. • l/s, m³/h, l/min, l/h

• gal/min (us), fl. oz/min

Volume unit Select volume unit. • ml, l, m³

• fl. oz (us), gal (us)

Temperature unit Select temperature unit. • °C

• °F

Totalizer unit Select totalizer unit. • l, m³

• 1 000 l, 1 000 m

• fl. oz (us), gal (us)

• 1 000 gal (us)

Conductivity unit Select the unit for conductivity. • µS/cm

• S/m

• ms/cm

3

l/min

ml

°C

m³

µS/cm

9.3.3 Setting the installation direction and measurement

The Sensor submenu contains parameters for specific settings of the measuring device.

Navigation

Menu: "Guidance" → Sensor

Parameter overview with brief description

Parameter Description Selection/input Factory setting

Installation

direction

On value Enter the on value for low

Damping Enter the time constant for

Select the installation

direction.

flow cut off.

damping the flow

measured value.

• Flow in arrow direction (forwards)

Positive flow measurement in the direction of the arrow.

• Flow against arrow direction (backwards)

Positive flow measurement in the opposite direction of the

arrow.

Positive floating point number

A flow measured value that is less than the value of the on

value forces the display to zero. In the event of plant

downtime, this prevents the totalizer from continuing to

totalize even though there is no flow.

0 to 10 s 0 s

Flow in arrow direction (forwards)

Depends on the nominal diameter:

DN 15 (½"):

0.05 l/min (0.013 gal/min)

DN 20 (¾"):

0.1 l/min (0.026 gal/min)

DN 25 (1"):

0.2 l/min (0.052 gal/min)

DN 50 (2"): 1.5 l/min (0.4 gal/min)

22 Endress+Hauser

Page 23

Picomag IO-Link Commissioning

9.3.4 Configuring the IO modules

The measuring device has two signal inputs or signal outputs that can be configured

independently of one another:

• Current output→ 23

• Pulse output→ 24

• Switch output→ 25

• Voltage output→ 26

• Status input → 28

Navigation

Menu: "Guidance" → Output 1

Menu: "Guidance" → Output 2

Parameter overview with brief description

Parameter Description Selection Factory setting

Output 1 Select the operating mode of output 1. • Pulse output

• Current output

• Switch output

• Voltage output

• Digital input

• IO-Link

• Off

Output 2 Select the operating mode of output 2. • Current output

• Switch output

• Voltage output

• Digital input

• Off

IO-Link

Off

Configuring the current output

The Current output submenu contains all the parameters that must be configured for the

configuration of the current output.

The output is used to output process variables by analog means in the form of a 4-20 mA

current.

Navigation

Menu: "Guidance" → Output 1 → Current output

Menu: "Guidance" → Output 2 → Current output

Parameter overview with brief description

Parameter Description Selection/input Factory setting

Assign current output Select process variable for current output. • Off

• Volume flow

• Temperature

• Conductivity

4 mA value Enter 4 mA value. Floating point number with sign 0 l/min

20 mA value Enter 20 mA value. Floating point number with sign Depends on the nominal diameter:

Volume flow

DN 15 (½"): 25 l/min (6.6 gal/min)

DN 20 (¾"): 50 l/min (13.2 gal/min)

DN 25 (1"): 100 l/min (26.4 gal/min)

DN 50 (2"): 750 l/min (198.1 gal/min)

Endress+Hauser 23

Page 24

Commissioning Picomag IO-Link

A = 0

B

Q

mA

20

16

12

8

4

A = 0

B

Q

mA

20

16

12

8

4

Unidirectional flow measurement (Q), conductivity measurement

A0035753

A Lower range value = 0

B Upper range value

Q Flow

• Current I is linearly interpolated between lower range value (A) and upper range value

(B).

• The output range ends at 20.5 mA.

Bidirectional flow measurement (Q), temperature measurement (T)

A0035754

A Lower range value

B Upper range value

Q Flow

• Current I is linearly interpolated between lower range value (A) and upper range value

(B).

• Rather than having a hard upper and lower limit, the output range ends at 20.5 mA at

the top end and at 3.8 mA at the bottom end.

Configuring the pulse output

The Pulse output submenu contains all the parameters that must be configured for the

configuration of the pulse output.

Navigation

Menu: "Guidance" → Output 1

24 Endress+Hauser

Page 25

Picomag IO-Link Commissioning

Menu: "Guidance" → Output 2

Parameter overview with brief description

Parameter Description User entry Factory setting

Value per pulse Enter the value for the pulse output. Floating point number with sign

Depends on the nominal diameter:

DN 15 (½"): 0.5 ml

DN 20 (¾"): 1.0 ml

DN 25 (1"): 2.0 ml

DN 50 (2"): 10.0 ml

The current pulse repetition frequency is calculated from the current flow and the

configured pulse value:

Pulse repetition frequency = flow/pulse value

Example

• Flow: 300 ml/min

• Pulse value: 0.001 l

• Pulse repetition frequency = 5 000 Pulse/s

The pulse output only outputs positive flow components in the set installation direction.

Negative flow components are ignored and not balanced.

Configuring the switch output

The Switch output submenu contains all the parameters that must be configured for the

configuration of the switch output.

Navigation

Menu: "Guidance" → Output 1

Menu: "Guidance" → Output 2

Parameter overview with brief description

Parameter Description Selection/input

Polarity Select the switching

behavior.

Switch output

function

• NPN (low-side-switch)

Switches load to low side to L-

• PNP (high-side-switch)

Switches load to high side to L+

• Off

The switch output is permanently switched off (open, non-conductive).

• On

The switch output is permanently switched on (closed, conductive).

• Diagnostic behavior

The output switches when an event with the status signal F occurs

• Limit volume flow

Indicates if a specified limit value is reached for the process variable.

• Limit temperature

Indicates if a specified limit value is reached for the process variable.

• Limit conductivity. Indicates if a specified limit value is reached for the process

variable.

• Limit volume totalizer Range volume totalizer

• Range volume flow

• Range temperature

• Range conductivity

• Range volume totalizer

• Empty pipe detection

Output switches off if empty pipe detection is activated.

Factory

setting

PNP (highside-switch)

Off

Endress+Hauser 25

Page 26

Commissioning Picomag IO-Link

1

0

A

B

t

C

1.1

1.2

Q / T

Q / T

1

0

A

B

t

C

2.1

2.2

Q / T

1

0

A

t

D D

3.1

3.2

B

B

A

Q / T

1

0

A

B

t

D D

4.1

4.2

A

B

Parameter Description Selection/input

Switch-on value Enter the measured

value for the switch-on

value.

Switch-off value Enter the measured

value for the switch-off

value.

Floating point number with sign 1 000 m³/h

Floating point number with sign 1 000 m³/h

Limit switched on Limit switched off

A0034163

1.1 Input variables

1.2 Switch output

A Switch-on value

B Switch-off value

C Hysteresis

Range switched on Range switched off

Factory

setting

A0034164

2.1 Input variables

2.2 Switch output

A Switch-on value

B Switch-off value

C Hysteresis

A0034165

3.1 Input variables

3.2 Switch output

A On-value (lower range limit)

B Off-value (upper range limit)

D Window

4.1 Input variables

4.2 Switch output

A On-value (lower range limit)

B Off-value (upper range limit)

D Window

Configuring the voltage output

The Voltage output submenu contains all the parameters that must be configured for the

configuration of the voltage output.

Navigation

26 Endress+Hauser

Menu: "Guidance" → Output 1

A0034166

Page 27

Picomag IO-Link Commissioning

A = 0

B

Q

V

10

8

6

4

2

0

B

Q

V

10

8

4

2

A

6

Menu: "Guidance" → Output 2

Parameter overview with brief description

Parameter Description Selection/input Factory setting

Assign voltage output Select process variable for voltage output. • Off

• Volume flow

• Temperature

• Conductivity

2 V value Enter the lower range value. Floating point number with sign 0 l/min

10 V value Enter the upper range value. Floating point number with sign Depends on the nominal diameter:

Volume flow

DN 15 (½"): 25 l/min

DN 20 (¾"): 50 l/min

DN 25 (1"): 100 l/min

DN 50 (2"): 750 l/min

Unidirectional flow measurement (Q), conductivity measurement

A0032995

A Lower range value = 0

B Upper range value

Q Flow

• Voltage U is linearly interpolated between lower range value (A) and upper range value

(B).

• The output range ends at 10.25 V.

Bidirectional flow measurement (Q), temperature measurement (T)

A0032996

A Lower range value

B Upper range value

Endress+Hauser 27

Q Flow

Page 28

Commissioning Picomag IO-Link

• Voltage U is linearly interpolated between lower range value (A) and upper range value

(B).

• Rather than having a hard upper and lower limit, the output range ends at 10.25 V at

the top end and at 1.9 V at the bottom end.

Configuring the status input

The Digital input submenu contains all the parameters that must be configured for the

configuration of the digital input.

The input is used to control an action with an external voltage signal. The minimum pulse

duration is 100 ms.

Navigation

Menu: "Guidance" → Output 1

Menu: "Guidance" → Output 2

Parameter overview with brief description

Parameter Description Selection Factory setting

Active level Select the switching behavior of the digital input. • High

Input reacts to high level

• Low

Input reacts to low level

Assign status input Select the function for the status input. • Off

• Reset totalizer

Resets the totalizer

• Flow override

– Flow measured value = 0

– Does not affect the temperature measurement

High

Reset totalizer

9.3.5 Totalizer

The totalizer can be reset with the Reset totalizer submenu.

Navigation

Menu: "Guidance" → Totalizer

Parameter overview with brief description

Parameter Description Display/options Factory setting

Volume totalizer Enter value. Floating point number with sign 0 m

Reset totalizer Reset the totalizer. • Cancel

The totalizer is not reset.

• Reset + totalize

The totalizer is reset.

3

Cancel

28 Endress+Hauser

Page 29

Picomag IO-Link Commissioning

A

A

A

9.3.6 Configuring the display

The Display submenu contains all the parameters that can be configured for the

configuration of the onsite display.

Navigation

Menu: "Guidance" → Display

Parameter overview with brief description

Parameter Description Selection/input Factory setting

Format display Select how measured values are

shown on the display.

Rotation display Select local display rotation. • Auto (automatic)

Display value 1st line + display value 2nd line:

• Volume flow + temperature

• Volume flow + totalizer

• Temperature + totalizer

• Volume flow + conductivity

• Totalizer + conductivity

• Temperature + conductivity

4 display values:

Volume flow + temperature + totalizer + conductivity

2 display values (multiplex):

Volume flow +totalizer / temperature + conductivity

• The display rotates automatically depending on the installation position

• 0°

• Can be read in the horizontal installation position with flow from left to

right

Volume flow +

temperature

Auto

A0033013

• 90°

• Can be read in the vertical installation position with flow from bottom to

top

A0033014

• 180°

• Can be read in the horizontal installation position with flow from right to

left

A0033015

Endress+Hauser 29

Page 30

Commissioning Picomag IO-Link

A

Parameter Description Selection/input Factory setting

• 270°

• Can be read in the vertical installation position with flow from top to

bottom

A0033016

Backlight Set the intensity of the

backlighting.

0 to 100 % 50 %

9.3.7 Security

The Security submenu contains all the parameters required to define a new access code

and to configure the Bluetooth connection.

Navigation

Menu: "Guidance" → Security

Parameter overview with brief description

Parameter Description Entry/selection/display

Define access code Enter a user-specific access code to restrict write access to

parameters.

Bluetooth Enable or disable the Bluetooth® wireless technology

interface.

If the interface is disabled, it can only be re-enabled

by tapping the device.

Change Bluetooth

password

Change Bluetooth password Character string comprising numbers, letters and

Max. 4-digit string of numbers 0000

• Disable

– Disable the interface.

– The connection to the measuring device is

torn down.

• Enable

special characters

Enable Bluetooth by tapping the device

1. Activate Bluetooth by tapping on the housing three times.

2. Establish a connection to the device via the SmartBlue app.

9.3.8 Data management

Export configuration as report

The device configuration can be exported as a PDF report and saved in the mobile terminal

or forwarded with this function.

Save configuration to file

The device configuration is saved in the app. The saved device configuration can be

transferred to another Picomag using the System → "Load configuration from app"

function.

Navigation

Menu: "Guidance" → Data management

Factory

setting

Enable

-

30 Endress+Hauser

Page 31

Picomag IO-Link Commissioning

9.4 Pending diagnostic events

Navigation

Menu: "Diagnostics"

Parameter overview with brief description

Parameter Prerequisite Description Display

Actual diagnostic A diagnostic event has occurred. Displays the current diagnostic event along with the

diagnostic information.

If two or more messages occur simultaneously, the

message with the highest priority is shown on the

display.

Simulation process

variable

Volume flow value Enter the value for volume flow

Temperature value Enter the value for temperature

Conductivity value Enter the value for conductivity

Enable variables for the simulation of

the process variables.

simulation.

simulation.

simulation

• Off

Variables are disabled.

• On

Variables are enabled.

Positive floating point number –

Positive floating point number –

Positive floating point number –

Symbol for

diagnostic behavior,

diagnostic code and

short message.

-

9.4.1 Simulation

The Simulation submenu enables you to simulate, without a real flow situation, various

process variables in the process and the device alarm mode and to verify downstream

signal chains (switching valves or closed-control loops).

Navigation

Menu: "Diagnostics"

Parameter overview with brief description

Parameter Description Selection/input

Simulation process

variable

Volume flow value Enter the value for volume flow simulation. Positive floating point number –

Temperature value Enter the value for temperature simulation. Positive floating point number –

Conductivity value Enter the value for conductivity simulation Positive floating point number –

Activate the simulation of process variables. • Off

Simulation is deactivated.

• On

Simulation is activated.

Deactivate the simulation again once the test has

been performed.

Factory

setting

Off

9.5 System

The System submenu contains all the parameters that can be used for the administration

of the device.

Navigation

Endress+Hauser 31

Page 32

Commissioning Picomag IO-Link

Menu: "System"

Parameter overview with brief description

Parameter Description Entry/selection/display Factory setting

Access status tooling Displays the access status. • Operator

• Maintenance

Enter access code Enter the access code.

Restrict write access to parameters in order to protect the device

configuration from unauthorized modification.

Device reset Reset the entire device configuration or some of the configuration to a

defined state.

Export configuration as

report

Save configuration to file The device configuration is saved in the app. The saved device

Load Configuration from file The saved device configuration can be uploaded to a new device with

Reset Device - - -

Firmware version - - -

Firmware update - - -

The device configuration can be exported as a PDF report and saved in

the mobile device or forwarded with this function.

configuration can be transferred to another Picomag using the System

→ "Load configuration from file" function.

this function.

Max. 4-digit string of

numbers

• Cancel

• To factory defaults

• Restart device

- -

- -

- -

Maintenance

0000

Cancel

32 Endress+Hauser

Page 33

Picomag IO-Link Operational

Xxxxx

2

1

3

4 5

6

I01:

I02:

BT:

SNo:

SW:

PIN4

PIN2

/

/

/

/

/

7

8

9

11

12

13

10

10 Operational

10.1 Offline quick view of the configuration

Tap the top of the housing (e.g. the arrow indicating the flow direction) with your knuckles

or an object to display an overview of preconfigured parameters.

A0036432

5 Information in the status layout, overview of the preconfigured parameters

1 I/O area

2 Bluetooth area

3 Identification area

4 I/O type 1

5 I/O current value type 1

6 I/O type 2

7 I/O current value type 2

8 I/O assignment type 1

9 I/O assignment type 2

10 Bluetooth module status

11 Bluetooth connection status

12 Serial number

13 Software version

I/O area (in brackets: item number → 5, 33)

I/O type ( 4, 6) I/O assignment (8, 9) I/O current value (5, 7)

S-Out • Alrt

• LimQ

• LimT

• LimV

• Lims

• WinQ

I-Out • s

• Q

• T

U-Out • s

• Q

• T

S-In • RsT

• Ovrd

P-Out Q PNPOn PNPOff

IO-L PD • Dis.

Endress+Hauser 33

Off – –

• WinT

• WinV

• Wins

• EPD

• Off

• On

Off xx.x mA

Off xx.x V

Off Low High

• PNPOn

• PNPOff

• Start

• NPNOn

• NPNOff

• Preop.

• Oper.

Page 34

Operational Picomag IO-Link

Bluetooth area (in brackets: item number → 5, 33)

Bluetooth module status (12) Bluetooth connection status (13)

On Dis./Con.

Off Dis.

34 Endress+Hauser

Page 35

Picomag IO-Link Diagnostics and troubleshooting

11 Diagnostics and troubleshooting

11.1 General troubleshooting

For local display

Error Possible causes Solution

Local display dark and no output

signals

For output signals

Error Possible causes Solution

Device shows correct value on local

display, but signal output is

incorrect, though in the valid range.

Device measures incorrectly. Configuration error or device is

Supply voltage does not match the

value indicated on the nameplate.

The polarity of the supply voltage is

wrong.

The connecting cables are not

connected correctly.

Configuration error Check and correct the parameter

operated outside the application.

Apply the correct supply voltage

→ 41.

Correct the polarity.

Check the cable connection and

correct if necessary.

configuration.

1. Check and correct parameter

configuration.

2. Observe limit values specified in

the "Technical Data".

For access

Error Possible causes Solution

Measuring device not in

smartphone or tablet live list

No communication with device via

SmartBlue app

Login via SmartBlue app not

possible

Device cannot be operated via

SmartBlue app

No write access to parameters Current user role has limited access

Bluetooth communication is

disabled

No Bluetooth connection Enable Bluetooth function on

Device is being put into operation

for the first time

Incorrect password entered Enter correct password.

Password forgotten Contact Endress+Hauser Service.

authorization

1. Check whether the Bluetooth

logo is visible on the local display or

not.

2. Re-enable Bluetooth

communication by tapping the

device three times.

smartphone or tablet.

The device is already connected

with another smartphone/tablet.

Enter initial password (device serial

number) and change.

1. Check user role

2. Enter correct customerspecific access code → 19.

Endress+Hauser 35

Page 36

Diagnostics and troubleshooting Picomag IO-Link

Xxxxxxx

F 1 8 0

T E M P . C I R C . F A I L .

Xxxxxxx

C 4 4 6

I / O 1 O V E R L O A D

Xxxxxxx

S 9 6 2

E M P T Y P I P E

?

?

?

11.2 Diagnostic information on local display

11.2.1 Diagnostic message

Faults detected by the self-monitoring system of the measuring device are displayed as a

diagnostic message in alternation with the operational display.

Diagnostic message

Alarm Function check Warning

A0033011

A0033010

If two or more diagnostic events are pending simultaneously, only the message of the

diagnostic event with the highest priority is shown.

Status signals

The status signals provide information on the state and reliability of the device by

categorizing the cause of the diagnostic information (diagnostic event).

The status signals are categorized according to VDI/VDE 2650 and NAMUR

Recommendation NE 107: F = Failure, C = Function Check, S = Out of Specification

Symbol Meaning

Failure

An operating error has occurred. The measured value is no longer valid.

Function check

The device is in simulation mode.

Out of specification

The device is being operated:

• Outside its technical specification limits (e.g. outside the process temperature range)

• Outside of the configuration carried out by the user (e.g. maximum flow in parameter 20 mA value)

A0033009

Diagnostic behavior

Diagnostic message Meaning

Alarm

• Measurement is interrupted.

• Signal outputs and totalizers assume the defined alarm condition.

• A diagnostic message is generated.

Function check

Process measured values are simulated to test the outputs/wiring.

• IO1/IO2 overload

• Flow override is active

Warning

• Measurement is resumed.

• Measuring operation with limited accuracy

• The signal outputs and totalizers are not affected.

• A diagnostic message is generated.

36 Endress+Hauser

Page 37

Picomag IO-Link Diagnostics and troubleshooting

Diagnostics behavior of outputs

Output Diagnostic behavior

Switch output • Setting for reporting events with the status signal F

• Switch output is switched on if an event occurs

• No further response to events with other status signals

Pulse output • Pulse output stops if events with the status signal F occur

• No further response to events with other status signals

Totalizer • Totalizing stops if events with the status signal F occur

• No further response to events with other status signals

Current output • 3.5 mA output to report events with the status signal F

• No further response to events with other status signals

Voltage output • 1.75 V output to report events with the status signal F

• No further response to events with other status signals

IO-Link • All events reported to the Master

• Events read and processed further by the Master

11.3 Overview of diagnostic events

Diagnostic

event

181 Coil. circ. fail. Coil/frequency failure

180 Temp. circ.

201 Device fail. No communication to

283 Memory fail. CRC failure Reset to factory settings. F

446 I/O 1

447 I/O 2

485 Simulation

453 Flow override Flow override active (via

441 I-Out 1 range I-output 1 at range limit Adjust parameter or process. S

444 U-Out 1

443 P-Out 1

442 I-Out 2 range I-output 2 at range limit Adjust parameter or process. S

445 U-Out 2

962 Empty pipe Pipe is completely or

834 Temperat.

841 Flow range Flow rate outside the

Event text Reason Remedial measures

Replace the measuring

fail.

overload

overload

act.

range

range

range

range

Coil current PWM

outside tolerance range

Temperature sensor

open circuit/shortcircuit

ADC/Nordic/BMA

Overload at output 1 Increase load impedance. C

Overload at output 2 Increase load impedance. C

Measured value

simulation active (via

remote configuration)

auxiliary input)

U-output 1 at range

limit

P-output 1 at range

limit

U-output 2 at range

limit

partially empty

Medium temperature

outside the permitted

range

permitted range

device.

Replace the measuring

device.

Replace the measuring

device.

– C

– C

Adjust parameter or process. S

Adjust parameter or process. S

Adjust parameter or process. S

Adjust the process. S

Adjust the process. S

Adjust the process. S

Status signal [ex-

factory]

F

F

F

Endress+Hauser 37

Page 38

Diagnostics and troubleshooting Picomag IO-Link

11.4 Device information

The Device info submenu contains all parameters that display different information for

device identification.

Navigation

Menu: "System" → Device info

Parameter overview with brief description

Parameter Description User interface

Device name Displays the name of the measuring device. Picomag

Device tag Shows name of measuring point. Max. 32 characters, such as letters, numbers or special characters (e.g. @,

%, /).

Serial number Displays the serial number of the measuring device. Max. 11-digit character string comprising letters and numbers.

Firmware version Displays the device firmware version installed. Character string in the format xx.yy.zz

Extended order code Displays the extended order code. Character string composed of letters, numbers and certain punctuation

marks (e.g. /).

The following information is shown on the display by tapping once on the housing:

• Status and values for output 1

• Status and values for output 2

• Bluetooth status (On/Off)

• Serial number

• Software version

11.5 Firmware history

Release

date

09.2017 01.00.zz Original firmware Operating

05.2019 01.01.zz • Conductivity

Firmware

version

Firmware

changes

measurement

• Export configuration

report

• Save/load

configuration

• Bug fix

Documentation type Documentation

Instructions

Operating

Instructions

BA01697D/06/EN/01.17

BA01697D/06/EN/02.17

BA01697D/06/EN/03.17

BA01697D/06/EN/04.19

38 Endress+Hauser

Page 39

Picomag IO-Link Accessories

12 Accessories

Various accessories are available for the device, and can be ordered with the device or at a

later stage from Endress+Hauser. An up-to-date overview of accessories is available from

your local Endress+Hauser Sales Center or on the product page of the Endress+Hauser

website: www.endress.com.

Adapter set

Order number Description

71355698 G½" to G³⁄₈" external thread

71355699 G½" to R³⁄₈" external thread

71355700 G½" to NPT³⁄₈" external thread

71355701 G½" to G½" internal thread

71355702 G½" to R½" external thread

71355703 G½" to NPT½" external thread

71355704 G½" to ½" TriClamp

71355705 G³⁄₄" to R³⁄₄" external thread

71355706 G³⁄₄" to NPT³⁄₄" external thread

71355707 G³⁄₄" to G³⁄₄" internal thread

71355708 G³⁄₄" to R³⁄₄" TriClamp

71355709 G1" to R1" external thread

71355710 G1" to NPT1" external thread

71355711 G1" to G1" internal thread

71355712 G1" to 1" TriClamp

71355713 G2" to R1" external thread

71355714 G2" to R2" external thread

71355715 G2" to NPT1½" external thread

71355716 G2" to NPT2" external thread

71355717 G2" to G1½" external thread

71355718 G2" to G2" internal thread

71355719 G2" to 2" TriClamp

71355720 G2" to 2" Victaulic

71399930 G2" to 54mm press fitting

Cable set

Order number Description

71349260 2m/6.5ft, straight, 4x0.34, M12, PUR

71349261 5m/16.4ft, straight, 4x0.34, M12, PUR

71349262 10m/32.8ft, straight, 4x0.34, M12, PUR

71349263 2m/6.5ft, 90 degrees, 4x0.34, M12, PUR

71349264 5m/16.4ft, 90 degrees, 4x0.34, M12, PUR

71349265 10m/32.8ft, 90 degrees, 4x0.34, M12, PUR

Endress+Hauser 39

Page 40

Accessories Picomag IO-Link

Seal set

Order number Description

71354741 DMA15 Cent.3820

71354742 DMA20 Cent.3820

71354745 DMA25 Cent.3820

71354746 DMA50 Cent.3820

Ground terminal set

Order number Description

71345225 Ground terminal

40 Endress+Hauser

Page 41

Picomag IO-Link Technical data

13 Technical data

13.1 Input

Measured variables • Volume flow

• Temperature

• Totalizer

• Conductivity

Measuring range DN 15 (½"): 0.05 to 25 l/min (0.013 to 6.6 gal/min)

DN 20 (¾"): 0.1 to 50 l/min (0.026 to 13.2 gal/min)

DN 25 (1"): 0.2 to 100 l/min (0.052 to 26.4 gal/min)

DN 50 (2"):1.5 to 750 l/min (0.4 to 198.1 gal/min)

Digital input • High or low active

• Switch-on level 15 V

• Switch-off level 5 V

• Internal resistance 7.5 kOhm

13.2 Output

Output Max. load

Current output 500 Ω

Load must not be greater

Voltage output 500 Ω

Load resistance must not be smaller

Signal on alarm • Status signal (as per NAMUR Recommendation NE 107)

• Plain text display with remedial action

Switch output • Switching behaviour: pnp or npn

• Max. load 250 mA

13.3 Power supply

Supply voltage range 18 to 30 VDC (SELV, PELV, Class 2)

Power consumption Max. 3 W [w/o outputs IO1 and IO2, 120 mA (+ 2× 250 mA with

I/Os)]

13.4 Performance characteristics

Volume flow measurement

Maximum measured error ±0.8 % o.r.±0.2 % o.f.s.

Repeatability ±0.2 % o.r.

Response time The response time depends on the configuration (damping).

Medium temperature measurement

Maximum measured error ±2.5 °C

Repeatability ±0.5 °C

Conductivity measurement

Repeatability ±5 %o.r.±5 µS/cm

13.5 Installation

→ 13

Endress+Hauser 41

Page 42

Technical data Picomag IO-Link

B

A

C D

E

F

G

H

I

= =

K

13.6 Environment

Ambient temperature range –10 to +60 °C (+14 to +140 °F)

Storage temperature –25 to +85 °C (–13 to +185 °F)

Degree of protection IP65/67, pollution degree 3

Humidity and moisture Suitable for indoor environments with up to 100% rh (wet and damp

locations)

Operating altitude up to 2 000 m

Shock resistance 20 g (11 ms) in accordance with IEC/EN60068-2-27

Vibration resistance Acceleration up to 5 g (10 to 2 000 Hz) in accordance with IEC/

EN60068-2-6

Electromagnetic compatibility (EMC) According to IEC/EN61326 and/or IEC/EN55011 (Class A)

13.7 Process

Medium temperature range • –10 to +70 °C (+14 to +158 °F)

• Permissible short-term temperature, maximum one hour:

85 °C (185 °F)

Repetition after 4 hours at the earliest

Medium properties Liquid, conductivity > 10 µS/cm

Pressure Max. 16 bar

rel

13.8 Mechanical construction

A0033012

Dimensions in SI units

DN A

[mm]B[mm]C[mm]D[mm]

15 110 73 40.5 69.5 M12 × 1 43 G½" 56 56 24

20 110 73 40.5 69.5 M12 × 1 43 G³⁄₄" 56 56 27

25 110 73 40.5 69.5 M12 × 1 43 G1" 56 56 27

50 200 113 80 120 M12 × 1 58 G2" 86 86 52

Dimensions in US units

E F

[mm]

G H

[mm]I[mm]K[mm]

DN A

[in]B[in]C[in]

15 4.33 2.87 1.59 2.74 M12 × 1 43 G½" 2.2 2.2 24

20 4.33 2.87 1.59 2.74 M12 × 1 43 G³⁄₄" 2.2 2.2 27

D

[in]

E F

[in]

G H

[in]

I

[in]

K

[mm]

42 Endress+Hauser

Page 43

Picomag IO-Link Technical data

28.56

23.6

l / min

°C

Xxxxxxx

1

2

3

4 5 6

DN A

[in]B[in]C[in]

25 4.33 2.87 1.59 2.74 M12 × 1 43 G1" 2.2 2.2 27

50 7.87 4.45 3.15 4.72 M12 × 1 58 G2" 3.39 3.39 52

D

[in]

E F

[in]

G H

[in]

I

[in]

K

[mm]

Weight in SI units

DN [kg]

15 0.34

20 0.35

25 0.36

50 1.55

Weight in US units

DN Weight

[lbs]

15 0.75

20 0.77

25 0.79

50 3.42

Materials

Component Material

Measuring tube PEEK

Electrodes, temperature sensor 1.4435/316L

Process connection 1.4404/316L

Housing 1.4404/316L, 1.4409/CF3M

Seal FKM

Display window Polycarbonate

13.9 Operability

Local display The device has an onsite display:

A0032991

1 Tag name (configurable)

2 Measured variable 1 (configurable), with sign

3 Measured variable 2 (configurable), with sign

4 Active Bluetooth connection

5 Active I/O-Link connection

6 Device status

Display element

4 measured variables can be displayed (volume flow, temperature, totalizer, conductivity).

Endress+Hauser 43

Page 44

Technical data Picomag IO-Link

Operation • Via Bluetooth® wireless technology

• Via IO-Link

Digital communication Via IO-Link

SmartBlue app The device has a Bluetooth® wireless technology interface and can be operated and

configured using the SmartBlue app.

• The range under reference conditions is 10 m (33 ft)

• Incorrect operation by unauthorized persons is prevented by means of encrypted

communication and password encryption.

• The Bluetooth® wireless technology interface can be deactivated.

13.10 Certificates and approvals

Currently available certificates and approvals can be called up via the product

configurator.

CE mark The device meets the legal requirements of the applicable EU Directives. These are listed in

the corresponding EU Declaration of Conformity along with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

Radio approval The measuring device has radio approval.

For detailed information regarding radio approval, see appendix → 45

Pressure Equipment Directive

listing The measuring device is UL-listed.

CULUS

Devices not bearing this marking (PED) are designed and manufactured according to good

engineering practice. They meet the requirements of Article 4 paragraph 3 of the Pressure

Equipment Directive 2014/68/EU. The range of application is indicated in tables 6 to 9 in

Annex II of the Pressure Equipment Directive 2014/68/EU.

44 Endress+Hauser

Page 45

Picomag IO-Link Appendix

Complies with

IMDA Standards

DA 103787

14 Appendix

14.1 Radio approvals

14.1.1 Europe

This device meets the requirements of the Telecommunications Directive RED

2014/53/EU:

• EN 300 328 V2.1.1

• EN 301 489-1 V1.9.2

• EN 301 489-17 V2.2.1

• EN 62311: 2008

14.1.2 Canada and USA

English

This device complies with Part 15 of the FCC Rules and with Industry Canada licenceexempt RSS standard(s).

Operation is subject to the following two conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications made to this equipment not expressly approved by

Endress+Hauser Flowtec AG may void the user's authorization to operate this

equipment.

Français

Le présent appareil est conforme aux CNR d'industrie Canada applicables aux appareils

radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes :

• L'appareil ne doit pas produire de brouillage, et

• L'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Les changements ou modifications apportées à cet appareil non expressément

approuvée par Endress+Hauser Flowtec AG peut annuler l'autorisation de l'utilisateur

d'opérer cet appareil.

14.1.3 India

ETA Certificate No: ETA - 1707/18-RLO(NE)

14.1.4 Singapore

A0035905

Complies with IMDA Standards

DA 103787

Endress+Hauser 45

Page 46

Appendix Picomag IO-Link

04 -1 -07311366 8

14.1.5 Thailand

เครื่องโทรคมนาคมและอุปกรณนี้ มีความสอดคลองตามขอกำหนดของ กสทช.

(This telecommunication equipment is in compliance with NBTC requirements.)

14.1.6 Argentina

CNC ID: C-22455

14.1.7 Taiwan

低功率電波輻射性電機管理辦法

第十二條 經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得擅自變更頻

率、加大功率或變更原設計之特性及功能。

第十四條 低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象時,應改善

至無干擾時方得繼續使用。前項合法通信,指依電信法規定作業之無線電通信。低功率射

頻電機須忍受合法通信或工業、科學及醫療用電波輻射性電機設備之干擾。

產品名稱 Endress + Hauser

產品型號 Picomag

產地 瑞士

製造商 Endress + Hauser Flowtec AG

14.1.8 Brazil

A0037714

Modelo: Picomag Atendimento à Regulamenta ção Anatel Este equipamento não tem

direito à proteção contra interferência prejudicial e não pode causar interferência em

sistemas devidamente autorizados. Este produto está homologado pela Anatel, de acordo

com os procedimentos regulamentados pela Resolução 242/2000, e atende aos requisitos

técnicos aplicados. Para maiores informações, consulte o site da ANATEL

www.anatel.gov.br

ANATEL: 04366-18-07311

46 Endress+Hauser

Page 47

Picomag IO-Link Appendix

14.1.9 South Korea

인증

KC

적합성평가정보

R-C-EH7-Picomag

상호 : 한국엔드레스하우저 주식회사

기자재명칭(모델명): 특정소출력 무선기기(무선데이터통신시스템용무선기기)

/ Picomag

제조국 및 제조국가 : Endress+Hauser Flowtec AG / 프랑스

제조년월 : 제조년월로 표기

*사용자안내문

이 기기는 업무용 환경에서 사용할 목적으로 적합성평가를 받은 기기로서 가정용 환

경에서 사용하는 경우 전파간섭의 우려가 있습니다.

14.1.10 Other countries

Other national approvals are available on request.

Endress+Hauser 47

Page 48

Appendix Picomag IO-Link

14.2 IO-Link process data

14.2.1 Data structure

Bit

number

Data Conductivity in µS/cm Totalizer in l Volume flow in l/s Temperature

Data

type

119

111

103

to

to

to 9695to

112

104

32-bit single-precision

floating-point number

(IEEE 754)

87

to

88

80

32-bit single-

precision floating-

point number (IEEE

79

to

72

754)

71

64

63

55

47

39

31

23 to1615 to87 to 0

to

to

to

to

to

to

56

48

40

32

24

in ¹⁄₁₀ °C

32-bit single-precision

floating-point number

(IEEE 754)

16-bit two's

complement

Data structure of the status bits 7 to 0

Bit Description

0 Switches once per sampling rate

1 Reserved

2 Current status S-Out 1

3 Current status S-Out 2

4 Reserved

5 Reserved

6 Reserved

7 Reserved

Status

8-bit

14.2.2 Diagnostic information

Diagnostic code Display text Coding

Status

NE 107

F 181 COIL CIRC.FAIL. 0x5000 0 2

F 180 TEMP.CIRC.FAIL. 0x5000 0 3

F 201 DECICE FAIL. 0x5000 0 4

F 283 MEMORY FAIL. 0x8C00 0 5

C 446 I/O 1 OVERLOAD 0x180C 1 6

C 447 I/O 2 OVERLOAD 0x180C 1 7

C 485 SIMULATION ACT. 0x8C01 1 8

C 453 FLOW OVERRIDE 0x180D 1 9

S 441 I-OUT 1 RANGE 0x180A 1 10

S 444 U-OUT 1 RANGE 0x1809 1 11

S 443 P-OUT 1 RANGE 0x180B 1 12

S 442 I-OUT 2 RANGE 0x180A 1 13

S 445 U-OUT 2 RANGE 0x1809 1 14

S 962 EMPTY PIPE 0x180E 1 15

S 834 TEMPERAT. RANGE 0x8C20 1 16

S 841 FLOW RANGE 0x8C20 1 17

Diagnostic number

– SYSTEM OK 0x0000 1 1

(hex)

PDValid

Validity

Priority

48 Endress+Hauser

Page 49

Picomag IO-Link Appendix

14.3 IO-Link ISDU parameter list

The individual parts of a parameter description are described in the following section:

Designation ISDU

(dec)

Device Tag

First 10 characters displayed

(starting from left)

Device Name 0x0012 18 16 (max.) string r Picomag

Device ID1 0x0009 9 1 uint r 0x01

Device ID2 0x000A 10 1 uint r 0x01

Device ID3 0x000B 11 1 uint r 0x00

Vendor Name 0x0010 16 32 (max.) string r Endress+Hauser

Vendor ID1 0x0007 7 1 uint r 0x00

Vendor ID2 0x0008 8 1 uint r 0x11

Device Serial No.

e.g. (YMXXXXZZ)

Firmware Version

e.g. 01.00.00

Order code

e.g. DMA15-AAAAA1

Device Type 0x0100 256 2 uint r 0x94FF

Actual Diagnostics

e.g. C485 (= SIMULATION ACT.)

Last Diagnostics

e.g. S962 (= EMPTY PIPE)

Simulation Proc. Var. 0x015F 351 2 uint r/w enable=1

Sim.Proc.Var.Value Volumeflow

Unit selection list from Unit

Volumeflow

Sim.Proc.Var.Value

Temperature

Unit selection list from Unit

Temperature

Sim.Proc.Var.Value Conductivity

Unit selection list from Unit

Conductivity

Volumeflow

Current volume flow measured

value

Temperature

Current temperature measured

value

Conductivity

Current conductivity measured

value

Totalizer

Current totalizer measured value

0x0018 24 32 (max.) string r/w EH_DMA_XXZZ

0x0015 21 11 (max.) string r see nameplate

0x0017 23 8 (max.) string r

0x0102 258 18 (max.) string r see nameplate

0x0104 260 4 string r

0x0105 261 4 string r

0x0166 358 4 float r/w 0.0 -10⁶

0x0168 360 4 float r/w 0.0 -10⁴

0x0167 359 4 float r/w 0.0 0

0x0161 353 4 float r

0x0163 355 4 float r

0x0164 365 4 float r

0x0169 361 4 float r/w 0.0

ISDU

(hex)

Size

(Byte)

Identification

Diagnostics

Measured Values

Data type Access Value range Factory setting Range

disable=0

limits

10⁶

10⁴

10⁶

Endress+Hauser 49

Page 50

Appendix Picomag IO-Link

Designation ISDU

(dec)

ISDU

(hex)

Size

(Byte)

Data type Access Value range Factory setting Range

System Units

Unit Volumeflow 0x0226 550 2 uint r/w l/s=0

l/h=5

fl. oz/min=4

m³/h=1

l/min=2

Usgpm=3

Unit Volume 0x0227 551 2 uint r/w ml=0

USozf=1

l=2

m³=3

Usgal=4

Unit Temperature 0x0228 552 2 uint r/w °C=0

°F=1

Unit Conductivity 0x0229 553 2 uint r/w µS/cm=0

S/m=1

mS/cm=2

Unit Totalizer 0x016B 363 2 uint r/w USozf=1

l=2

m³=3

Usgal=4

kl=5

Ml=6

kUsg=7

Sensor

Install. Direction

In relation to direction of arrow on

0x015E 350 2 uint r/w forward=0

reverse=1

the device

Low Flow Cut Off

0x0160 352 4 float r/w 0.4/0.75/1.2/5.0

The flow rate below the selected

value is zero

Unit selection list from Unit

Volumeflow

Damping

0x01A4 420 4 float r/w 0 s 0

Volume flow damping via the PT1

element

Unit: s

Output 1

Operating Mode

IO-Link is set if connected to a

master

0x01F4 500 2 uint r/w P-Out=0

I-Out=1

S-In=2

S-Out=3

IO-Link=4

U-Out=5

off=6

Current output I-Out 1

I - OUT Assign 0x0258 600 2 uint r/w off=0

volume flow=1

temperature=2

conductivity=4

Q-Start-Value

1)

ASP

for volume flow

0x0259 601 4 float r/w 0 l/min -9.9·10⁹

Unit selection list from Unit

Volumeflow

Q-End-Value

2)

AEP

for volume flow

0x025A 602 4 float r/w 25/50/100/750

Unit selection list from Unit

Volumeflow

l/min

ml

°C

µS/cm=0

m³

forward

l/min

IO-Link

volume flow

l/min

limits

0

10⁶

100

9.9·10⁹

-9.9·10⁹

9.9·10⁹

50 Endress+Hauser

Page 51

Picomag IO-Link Appendix

Designation ISDU

(dec)

T-Start-Value

1)

ASP

for temperature

0x025F 607 4 float r/w -10 °C -9.9·10⁹

ISDU

(hex)

Size

(Byte)