Page 1

BA01111D/06/EN/02.15

71281882

Valid as of version

01.01.zz (Device firmware)

Products Solutions Services

Operating Instructions

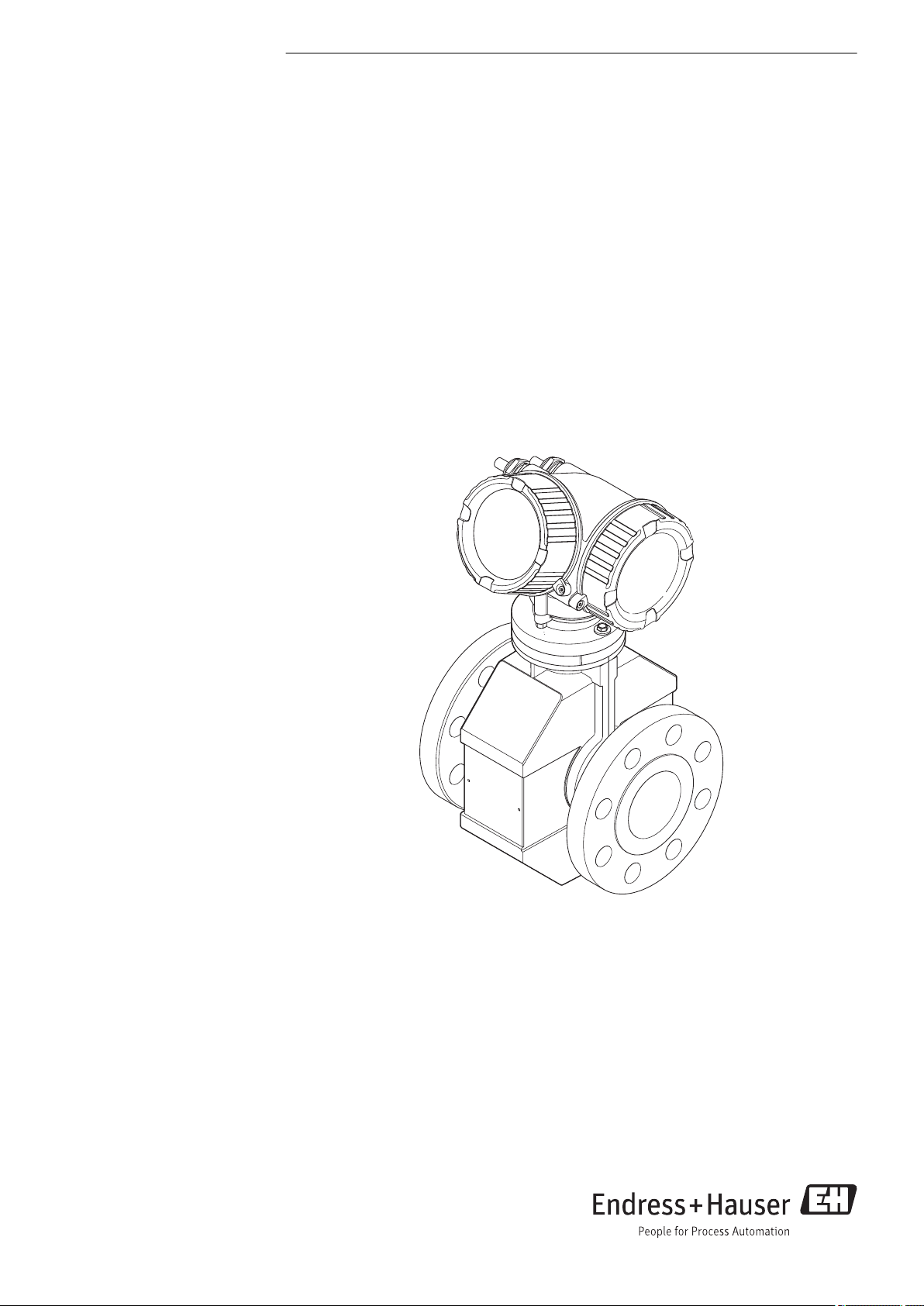

Proline Promag P 200

HART

Electromagnetic flowmeter

Page 2

Proline Promag P 200 HART

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these Instructions.

2 Endress+Hauser

Page 3

Proline Promag P 200 HART Table of contents

Table of contents

1 Document information .............. 6

1.1 Document function ..................... 6

1.2 Symbols used .......................... 6

1.2.1 Safety symbols .................. 6

1.2.2 Electrical symbols ................ 6

1.2.3 Tool symbols .................... 6

1.2.4 Symbols for certain types of

information .................... 7

1.2.5 Symbols in graphics ............... 7

1.3 Documentation ........................ 7

1.3.1 Standard documentation ........... 8

1.3.2 Supplementary device-dependent

documentation .................. 8

1.4 Registered trademarks ................... 8

2 Basic safety instructions ............ 9

2.1 Requirements for the personnel ............ 9

2.2 Designated use ........................ 9

2.3 Workplace safety ...................... 10

2.4 Operational safety ..................... 10

2.5 Product safety ........................ 10

2.6 IT security ........................... 11

3 Product description ................ 12

3.1 Product design ........................ 12

4 Incoming acceptance and product

identification ..................... 13

4.1 Incoming acceptance ................... 13

4.2 Product identification ................... 13

4.2.1 Transmitter nameplate ........... 14

4.2.2 Sensor nameplate ............... 15

4.2.3 Symbols on measuring device ...... 16

5 Storage and transport ............. 17

5.1 Storage conditions ..................... 17

5.2 Transporting the product ................ 17

5.2.1 Measuring devices without lifting

lugs ......................... 17

5.2.2 Measuring devices with lifting lugs .. 18

5.2.3 Transporting with a fork lift ........ 18

5.3 Packaging disposal ..................... 18

6 Installation ....................... 19

6.1 Installation conditions .................. 19

6.1.1 Mounting position ............... 19

6.1.2 Requirements from environment and

process ....................... 21

6.1.3 Special mounting instructions ...... 23

6.2 Mounting the measuring device ........... 23

6.2.1 Required tools .................. 23

6.2.2 Preparing the measuring device ..... 23

6.2.3 Mounting the sensor ............. 24

6.2.4 Turning the transmitter housing .... 27

6.2.5 Turning the display module ........ 28

6.3 Post-installation check .................. 28

7 Electrical connection .............. 29

7.1 Connection conditions .................. 29

7.1.1 Required tools .................. 29

7.1.2 Requirements for connecting cable ... 29

7.1.3 Terminal assignment ............. 30

7.1.4 Requirements for the supply unit .... 30

7.1.5 Preparing the measuring device ..... 31

7.2 Connecting the measuring device .......... 31

7.2.1 Connecting the transmitter ........ 31

7.2.2 Ensuring potential equalization ..... 33

7.3 Special connection instructions ............ 35

7.3.1 Connection examples ............. 35

7.4 Ensuring the degree of protection .......... 36

7.5 Post-connection check .................. 37

8 Operation options ................. 38

8.1 Overview of operation options ............ 38

8.2 Structure and function of the operating

menu .............................. 39

8.2.1 Structure of the operating menu .... 39

8.2.2 Operating philosophy ............ 40

8.3 Access to the operating menu via the local

display ............................. 41

8.3.1 Operational display .............. 41

8.3.2 Navigation view ................ 42

8.3.3 Editing view ................... 44

8.3.4 Operating elements .............. 46

8.3.5 Opening the context menu ......... 46

8.3.6 Navigating and selecting from list ... 48

8.3.7 Calling the parameter directly ...... 48

8.3.8 Calling up help text .............. 49

8.3.9 Changing the parameters ......... 50

8.3.10 User roles and related access

authorization .................. 51

8.3.11 Disabling write protection via access

code ......................... 51

8.3.12 Enabling and disabling the keypad

lock ......................... 51

8.4 Access to the operating menu via the

operating tool ........................ 52

8.4.1 Connecting the operating tool ...... 53

8.4.2 Field Xpert SFX350, SFX370 ....... 54

8.4.3 FieldCare ..................... 54

8.4.4 AMS Device Manager ............ 55

8.4.5 SIMATIC PDM .................. 55

8.4.6 Field Communicator 475 .......... 56

Endress+Hauser 3

Page 4

Table of contents Proline Promag P 200 HART

9 System integration ................ 57

9.1 Overview of device description files ......... 57

9.1.1 Current version data for the device ... 57

9.1.2 Operating tools ................. 57

9.2 Measured variables via HART protocol ...... 57

9.3 Other settings ........................ 58

9.3.1 Burst mode functionality in

accordance with HART 7

Specification ................... 58

10 Commissioning .................... 61

10.1 Function check ....................... 61

10.2 Switching on the measuring device ......... 61

10.3 Setting the operating language ............ 61

10.4 Configuring the measuring device .......... 61

10.4.1 Defining the tag name ............ 62

10.4.2 Setting the system units .......... 63

10.4.3 Configuring the current output ..... 65

10.4.4 Configuring the pulse/frequency/

switch output .................. 66

10.4.5 Configuring the local display ....... 73

10.4.6 Configuring the output

conditioning ................... 75

10.4.7 Configuring the low flow cut off ..... 76

10.4.8 Configuring empty pipe detection ... 78

10.5 Advanced settings ..................... 79

10.5.1 Carrying out a sensor adjustment .... 80

10.5.2 Configuring the totalizer .......... 80

10.5.3 Carrying out additional display

configurations .................. 82

10.5.4 Administration configuration ...... 84

10.6 Configuration management .............. 85

10.6.1 Function range of "Configuration

management" parameter .......... 86

10.7 Simulation ........................... 86

10.8 Protecting settings from unauthorized

access .............................. 88

10.8.1 Write protection via access code ..... 88

10.8.2 Write protection via write protection

switch ........................ 89

11 Operation ......................... 91

11.1 Reading the device locking status .......... 91

11.2 Adjusting the operating language .......... 91

11.3 Configuring the display ................. 91

11.4 Reading measured values ................ 91

11.4.1 Process variables ................ 91

11.4.2 Totalizer ...................... 92

11.4.3 Output values .................. 92

11.5 Adapting the measuring device to the process

conditions ........................... 93

11.6 Performing a totalizer reset .............. 93

11.7 Showing data logging ................... 94

12 Diagnostics and troubleshooting ... 97

12.1 General troubleshooting ................. 97

12.2 Diagnostic information on local display ...... 99

12.2.1 Diagnostic message .............. 99

12.2.2 Calling up remedial measures ..... 101

12.3 Diagnostic information in FieldCare ....... 101

12.3.1 Diagnostic options .............. 101

12.3.2 Calling up remedy information .... 102

12.4 Adapting the diagnostic information ...... 103

12.4.1 Adapting the diagnostic behavior ... 103

12.4.2 Adapting the status signal ........ 103

12.5 Overview of diagnostic information ....... 104

12.6 Pending diagnostic events .............. 106

12.7 Diagnostic list ....................... 107

12.8 Event logbook ....................... 107

12.8.1 Event history .................. 107

12.8.2 Filtering the event logbook ....... 108

12.8.3 Overview of information events .... 108

12.9 Resetting the measuring device .......... 109

12.9.1 Function scope of "Device reset"

parameter .................... 110

12.10 Device information ................... 110

12.11 Firmware history ..................... 112

13 Maintenance .................... 113

13.1 Maintenance tasks .................... 113

13.1.1 Exterior cleaning ............... 113

13.1.2 Interior cleaning ............... 113

13.1.3 Replacing seals ................ 113

13.2 Measuring and test equipment ........... 113

13.3 Endress+Hauser services ............... 113

14 Repair ........................... 114

14.1 General notes ....................... 114

14.2 Spare parts ......................... 114

14.3 Endress+Hauser services ............... 115

14.4 Return ............................. 115

14.5 Disposal ........................... 115

14.5.1 Removing the measuring device .... 115

14.5.2 Disposing of the measuring device .. 116

15 Accessories ...................... 117

15.1 Device-specific accessories .............. 117

15.1.1 For the transmitter ............. 117

15.1.2 For the sensor ................. 118

15.2 Communication-specific accessories ....... 118

15.3 Service-specific accessories .............. 118

15.4 System components ................... 119

16 Technical data ................... 120

16.1 Application ......................... 120

16.2 Function and system design ............. 120

16.3 Input .............................. 120

16.4 Output ............................ 121

16.5 Power supply ........................ 124

16.6 Performance characteristics ............. 125

16.7 Installation ......................... 126

16.8 Environment ........................ 127

4 Endress+Hauser

Page 5

Proline Promag P 200 HART Table of contents

16.9 Process ............................ 127

16.10 Mechanical construction ............... 129

16.11 Operability ......................... 133

16.12 Certificates and approvals .............. 135

16.13 Application packages .................. 136

16.14 Accessories ......................... 137

16.15 Documentation ...................... 137

Index ................................. 139

Endress+Hauser 5

Page 6

Document information Proline Promag P 200 HART

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols used

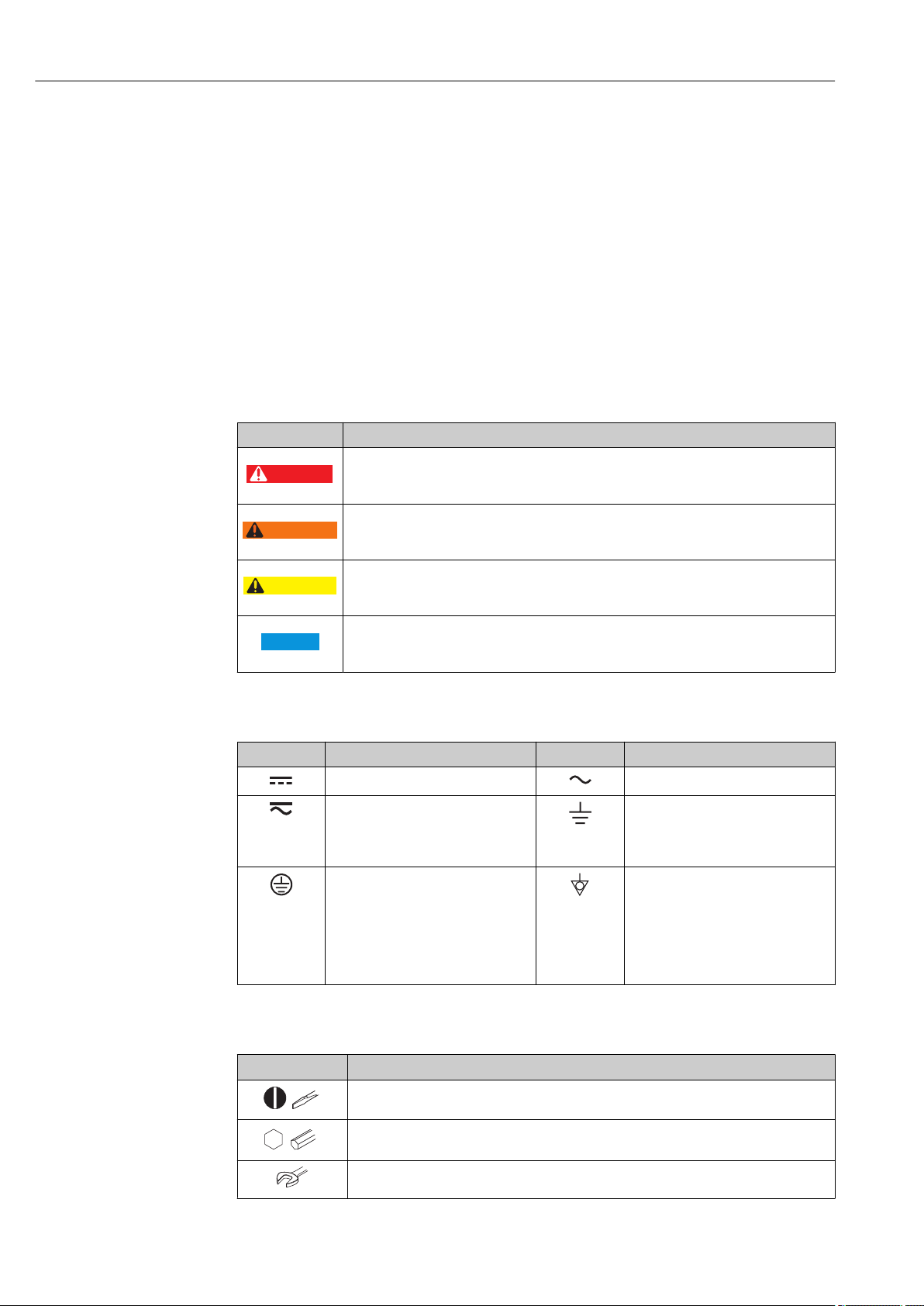

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

1.2.3 Tool symbols

Symbol Meaning

Flat blade screwdriver

Allen key

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

Open-ended wrench

6 Endress+Hauser

Page 7

Proline Promag P 200 HART Document information

,…,

,…,

-

.

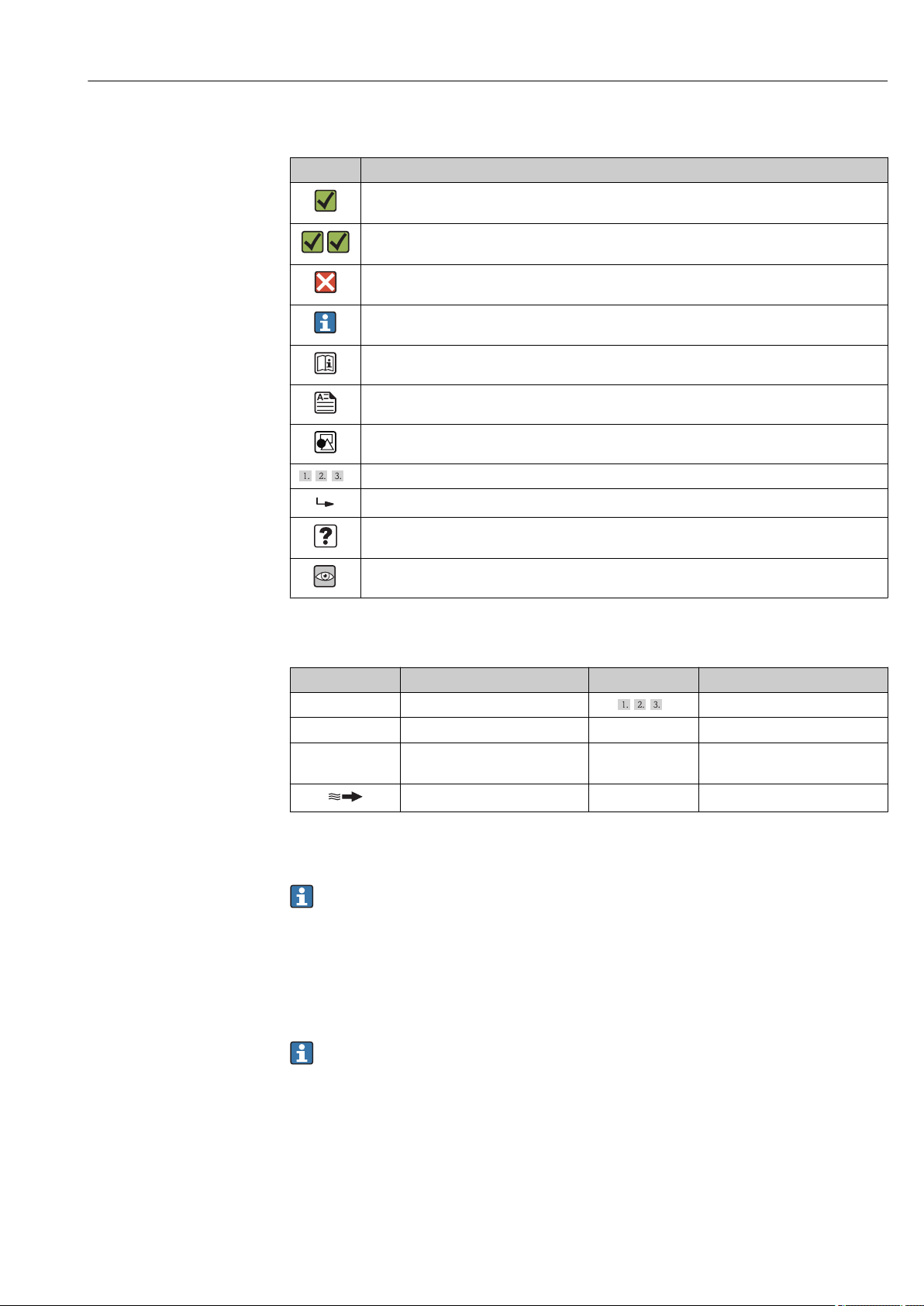

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a sequence of actions

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views A-A, B-B, C-C, ... Sections

Hazardous area

Flow direction

Series of steps

Safe area (non-hazardous area)

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The CD-ROM provided for the device (depending on the device version, the CD-ROM

might not be part of the delivery!)

• The W@M Device Viewer : Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

For a detailed list of the individual documents along with the documentation code

Endress+Hauser 7

Page 8

Document information Proline Promag P 200 HART

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Brief Operating Instructions Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

1.3.2 Supplementary device-dependent documentation

Additional documents are supplied depending on the device version ordered: Always

comply strictly with the instructions in the supplementary documentation. The

supplementary documentation is an integral part of the device documentation.

1.4 Registered trademarks

®

HART

Registered trademark of the HART Communication Foundation, Austin, USA

Applicator®, FieldCare®, Field XpertTM, HistoROM®, Heartbeat Technology

Registered or registration-pending trademarks of the Endress+Hauser Group

TM

8 Endress+Hauser

Page 9

Proline Promag P 200 HART Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

Application and media

The measuring device is only suitable for flow measurement of liquids with a minimum

conductivity of 20 μS/cm.

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and

‣

the general conditions listed in the Operating Instructions and supplementary

documentation.

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials

‣

are adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with

‣

the relevant basic conditions specified in the associated device documentation is

absolutely essential: "Documentation" section → 7.

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage

caused by improper or non-designated use.

WARNING

L

Danger of breakage of the sensor due to corrosive or abrasive fluids or from

environmental conditions!

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Keep within the specified pressure and temperature range.

‣

Endress+Hauser 9

Page 10

Basic safety instructions Proline Promag P 200 HART

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance

‣

in verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

The external surface temperature of the housing can increase by max. 10 K due to the

power consumption of the electronic components. Hot process fluids passing through the

measuring device will further increase the surface temperature of the housing. The surface

of the sensor, in particular, can reach temperatures which are close to the fluid

temperature.

Possible burn hazard due to fluid temperatures!

For elevated fluid temperature, ensure protection against contact to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

If working on and with the device with wet hands:

It is recommended to wear gloves on account of the higher risk of electric shock.

‣

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

10 Endress+Hauser

Page 11

Proline Promag P 200 HART Basic safety instructions

2.6 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 11

Page 12

Product description Proline Promag P 200 HART

1 2

3

4

5 6

7

8

9

+

E

–

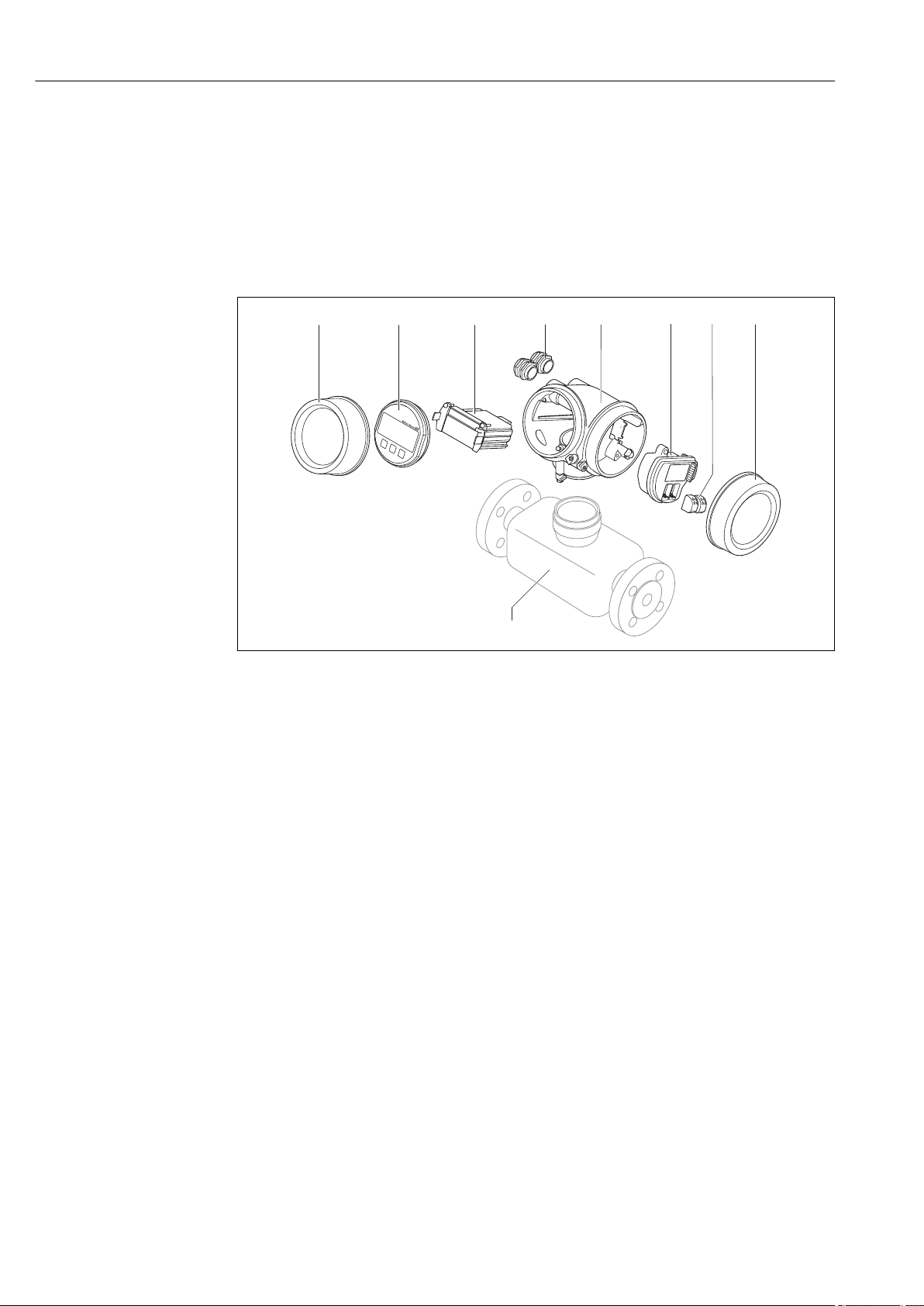

3 Product description

The device consists of a transmitter and a sensor.

One device version is available: compact version - transmitter and sensor form a

mechanical unit.

3.1 Product design

A0014056

1 Important components of a measuring device

1 Electronics compartment cover

2 Display module

3 Main electronics module

4 Cable glands

5 Transmitter housing (incl. integrated HistoROM)

6 I/O electronics module

7 Terminals (spring loaded terminals, pluggable)

8 Connection compartment cover

9 Sensor (incl. HistoROM S-DAT)

12 Endress+Hauser

Page 13

Proline Promag P 200 HART Incoming acceptance and product identification

1

+

2

1

+

2

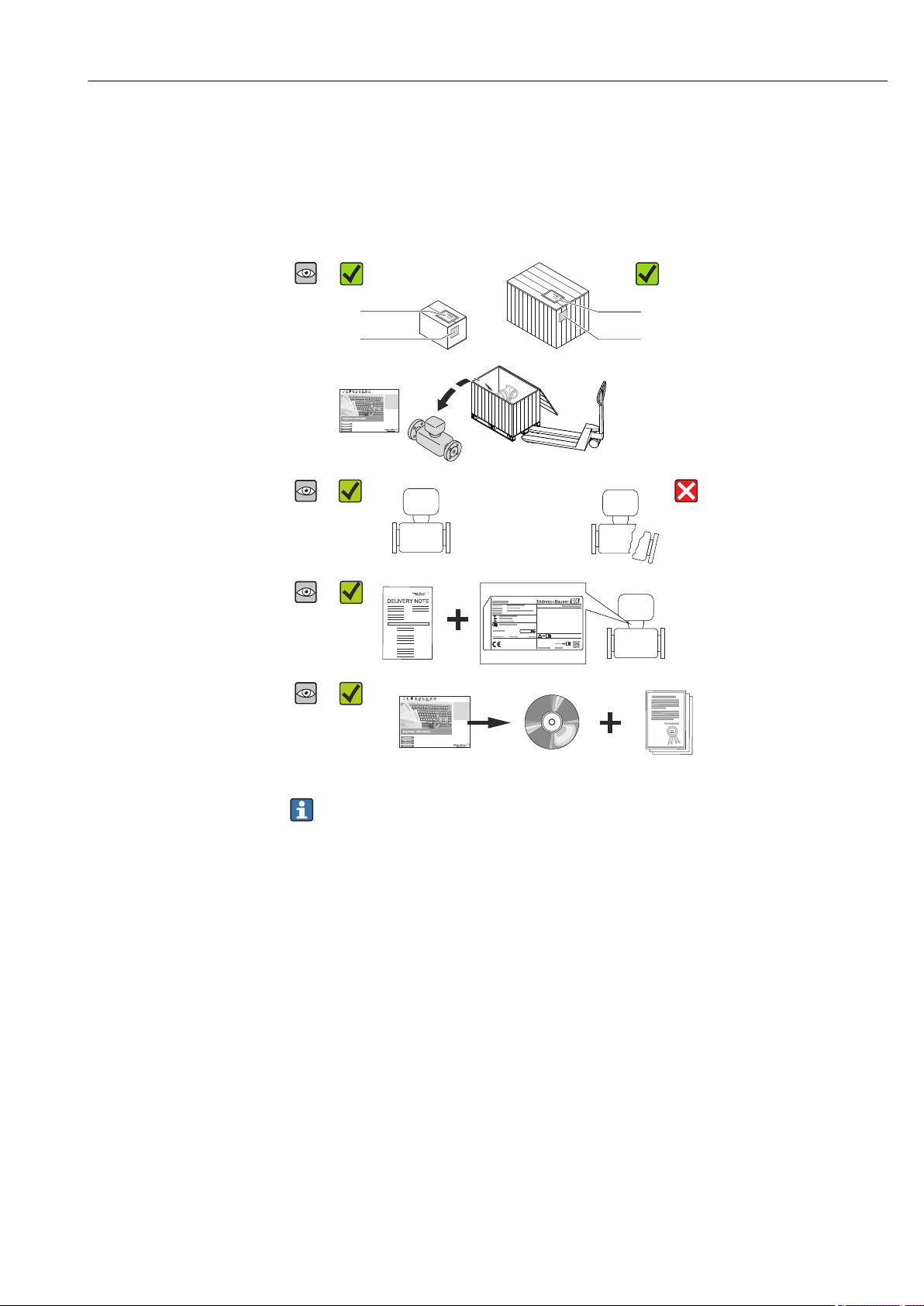

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Are the order codes on the

delivery note (1) and the

product sticker (2)

identical?

Are the goods undamaged?

Do the nameplate data

match the ordering

information on the delivery

note?

Is the CD-ROM with the

Technical Documentation

(depends on device

version) and documents

present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery!

The Technical Documentation is available via the Internet or via the Endress+Hauser

Operations App, see the "Product identification" section → 14.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App

or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information for the measuring device is displayed.

Endress+Hauser 13

Page 14

Incoming acceptance and product identification Proline Promag P 200 HART

Ordercode:

Ext.ord.cd.:

Ser.no.:

Date:

i

i

Patents

322540-0001

1

2

3 4 5

6

7

8

9

10 11

12

14

15

16

17

13

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The chapters "Additional standard documentation on the device" → 8 and

"Supplementary device-dependent documentation" → 8

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

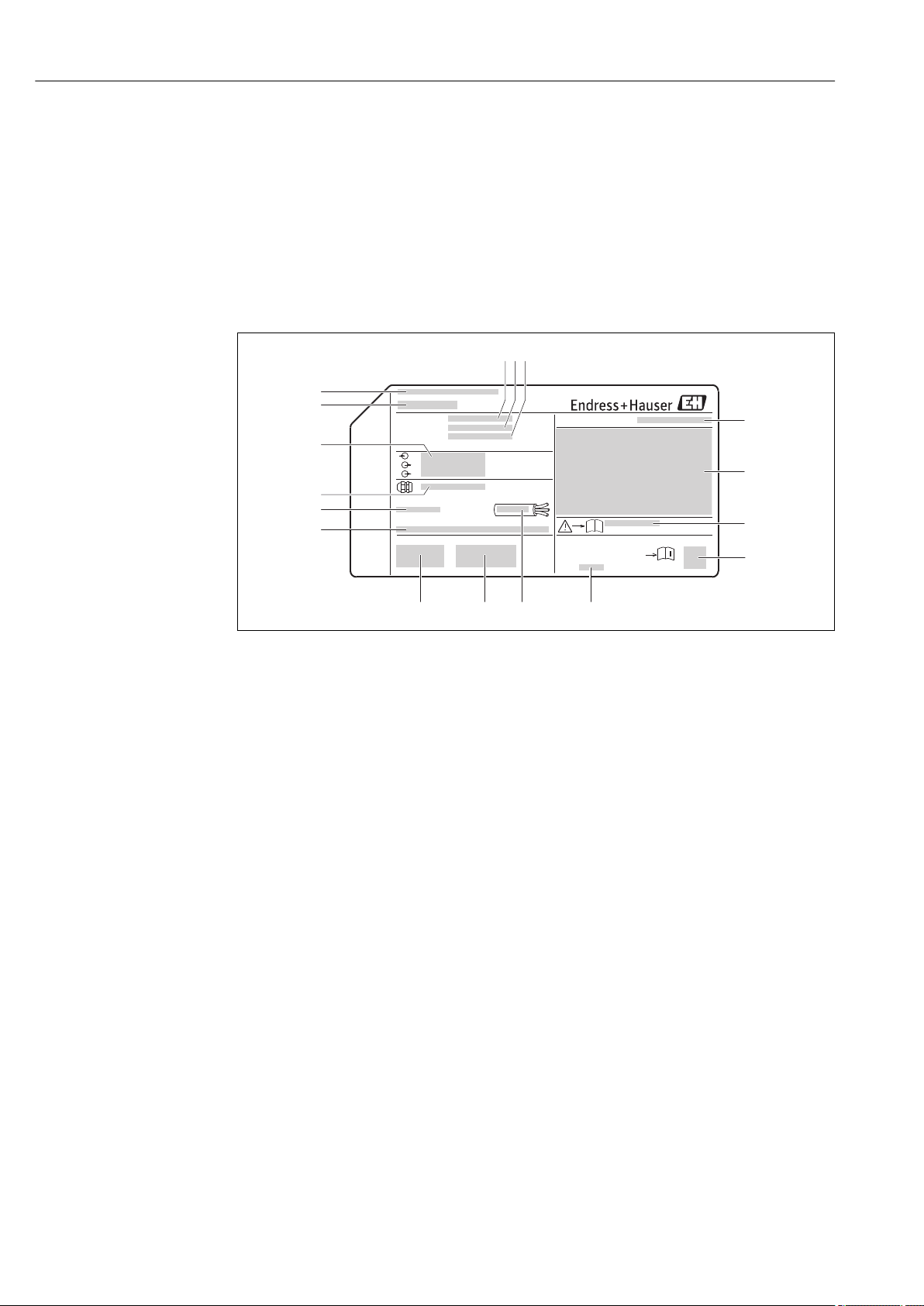

4.2.1 Transmitter nameplate

A0013906

2 Example of a transmitter nameplate

1 Manufacturing location

2 Name of the transmitter

3 Order code

4 Serial number (Ser. no.)

5 Extended order code (Ext. ord. cd.)

6 Electrical connection data, e.g. available inputs and outputs, supply voltage

7 Type of cable glands

8 Permitted ambient temperature (Ta)

9 Firmware version (FW) and device revision (Dev.Rev.) from the factory

10 CE mark, C-Tick

11 Additional information on version: certificates, approvals

12 Permitted temperature range for cable

13 Manufacturing date: year-month

14 Degree of protection

15 Approval information for explosion protection

16 Document number of safety-related supplementary documentation

17 2-D matrix code

14 Endress+Hauser

Page 15

Proline Promag P 200 HART Incoming acceptance and product identification

i

Patents

i

Material:

Tm:

Ext. ord. cd.:

Order Code:

Ser.No.:

Date:

21

3

4

5

6 7

8

9

10

11

13

12

14

15

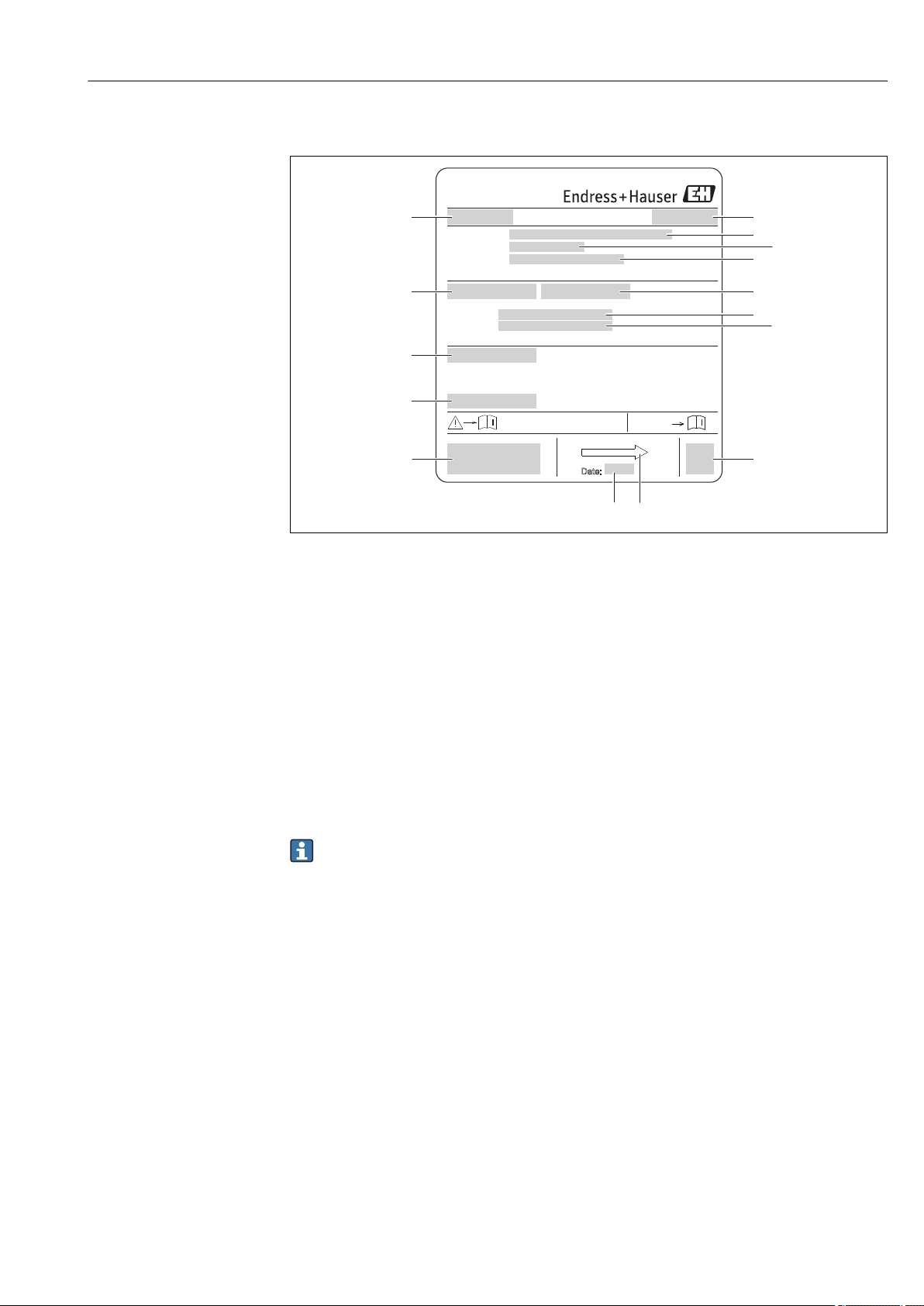

4.2.2 Sensor nameplate

3 Example of sensor nameplate

1 Name of the sensor

2 Manufacturing location

3 Order code

4 Serial number (ser. no.)

5 Extended order code (ext. ord. cd.)

6 Nominal diameter of sensor

7 Test pressure of the sensor

8 Fluid temperature range

9 Material of lining and electrodes

10 Degree of protection: e.g. IP, NEMA

11 Permitted ambient temperature (Ta)

12 2-D matrix code

13 CE mark, C-Tick

14 Flow direction

15 Manufacturing date: year-month

Order code

The measuring device is reordered using the order code.

Extended order code

• The device type (product root) and basic specifications (mandatory features) are

always listed.

• Of the optional specifications (optional features), only the safety and approvalrelated specifications are listed (e.g. LA). If other optional specifications are also

ordered, these are indicated collectively using the # placeholder symbol (e.g. #LA#).

• If the ordered optional specifications do not include any safety and approval-related

specifications, they are indicated by the + placeholder symbol (e.g. XXXXXX-ABCDE

+).

A0017186

Endress+Hauser 15

Page 16

Incoming acceptance and product identification Proline Promag P 200 HART

4.2.3 Symbols on measuring device

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious

or fatal injury.

Reference to documentation

Refers to the corresponding device documentation.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

16 Endress+Hauser

Page 17

Proline Promag P 200 HART Storage and transport

5 Storage and transport

5.1 Storage conditions

Observe the following notes for storage:

• Store in the original packaging to ensure protection from shock.

• Do not remove protective covers or protective caps installed on process connections.

They prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

• Protect from direct sunlight to avoid unacceptably high surface temperatures.

• Select a storage location where moisture cannot collect in the measuring device as

fungus and bacteria infestation can damage the lining.

• Store in a dry and dust-free place.

• Do not store outdoors.

• Storage temperature→ 127

5.2 Transporting the product

Transport the measuring device to the measuring point in the original packaging.

A0015604

Do not remove protective covers or caps installed on process connections. They

prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

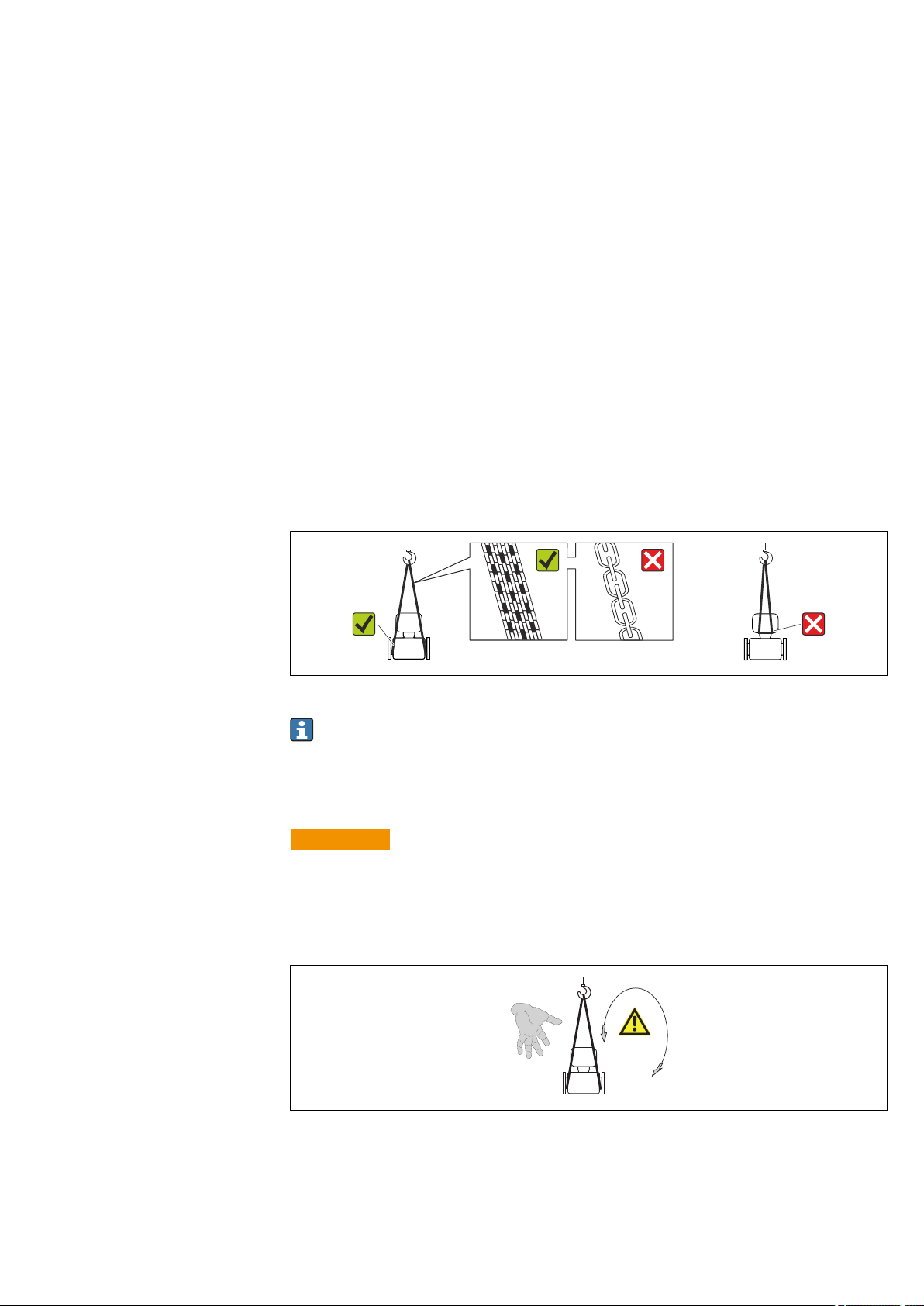

5.2.1 Measuring devices without lifting lugs

WARNING

L

Center of gravity of the measuring device is higher than the suspension points of the

webbing slings.

Risk of injury if the measuring device slips.

Secure the measuring device against slipping or turning.

‣

Observe the weight specified on the packaging (stick-on label).

‣

A0015606

Endress+Hauser 17

Page 18

Storage and transport Proline Promag P 200 HART

5.2.2 Measuring devices with lifting lugs

CAUTION

L

Special transportation instructions for devices with lifting lugs

Only use the lifting lugs fitted on the device or flanges to transport the device.

‣

The device must always be secured at two lifting lugs at least.

‣

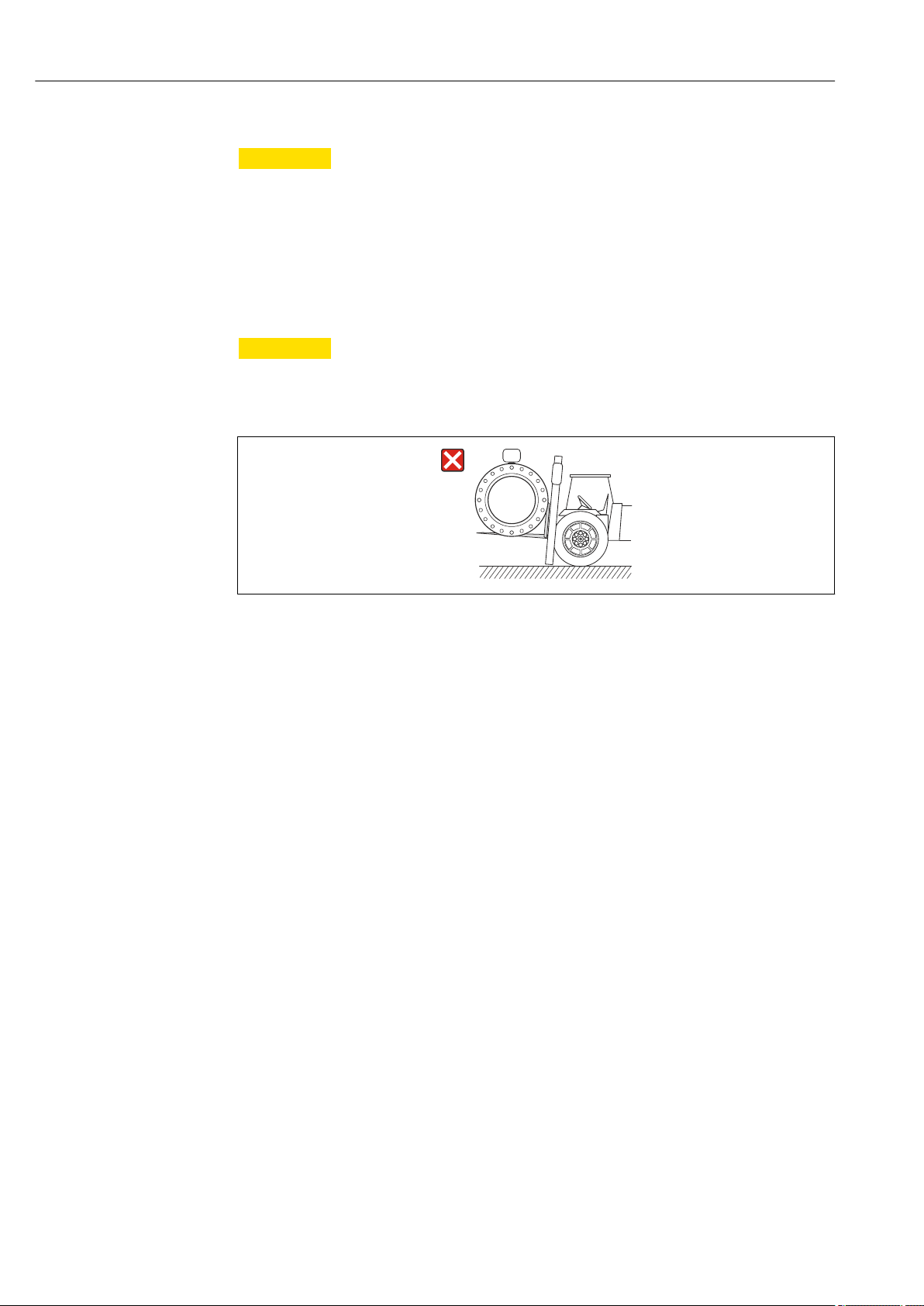

5.2.3 Transporting with a fork lift

If transporting in wood crates, the floor structure enables the crates to be lifted lengthwise

or at both sides using a forklift.

CAUTION

L

Risk of damaging the magnetic coil

If transporting by forklift, do not lift the sensor by the metal casing.

‣

This would buckle the casing and damage the internal magnetic coils.

‣

5.3 Packaging disposal

All packaging materials are environmentally friendly and 100% recyclable:

• Measuring device secondary packaging: polymer stretch film that conforms to EC

Directive 2002/95/EC (RoHS).

• Packaging:

– Wood crate, treated in accordance with ISPM 15 standard, which is confirmed by the

affixed IPPC logo.

or

– Carton in accordance with European Packaging Directive 94/62EC; recyclability is

confirmed by the affixed RESY symbol.

• Seaworthy packaging (optional): Wood crate, treated in accordance with ISPM 15

standard, which is confirmed by the affixed IPPC logo.

• Carrying and mounting hardware:

– Disposable plastic pallet

– Plastic straps

– Plastic adhesive strips

• Dunnage: Paper cushion

A0023726

18 Endress+Hauser

Page 19

Proline Promag P 200 HART Installation

h

h

2

1

6 Installation

6.1 Installation conditions

6.1.1 Mounting position

Mounting location

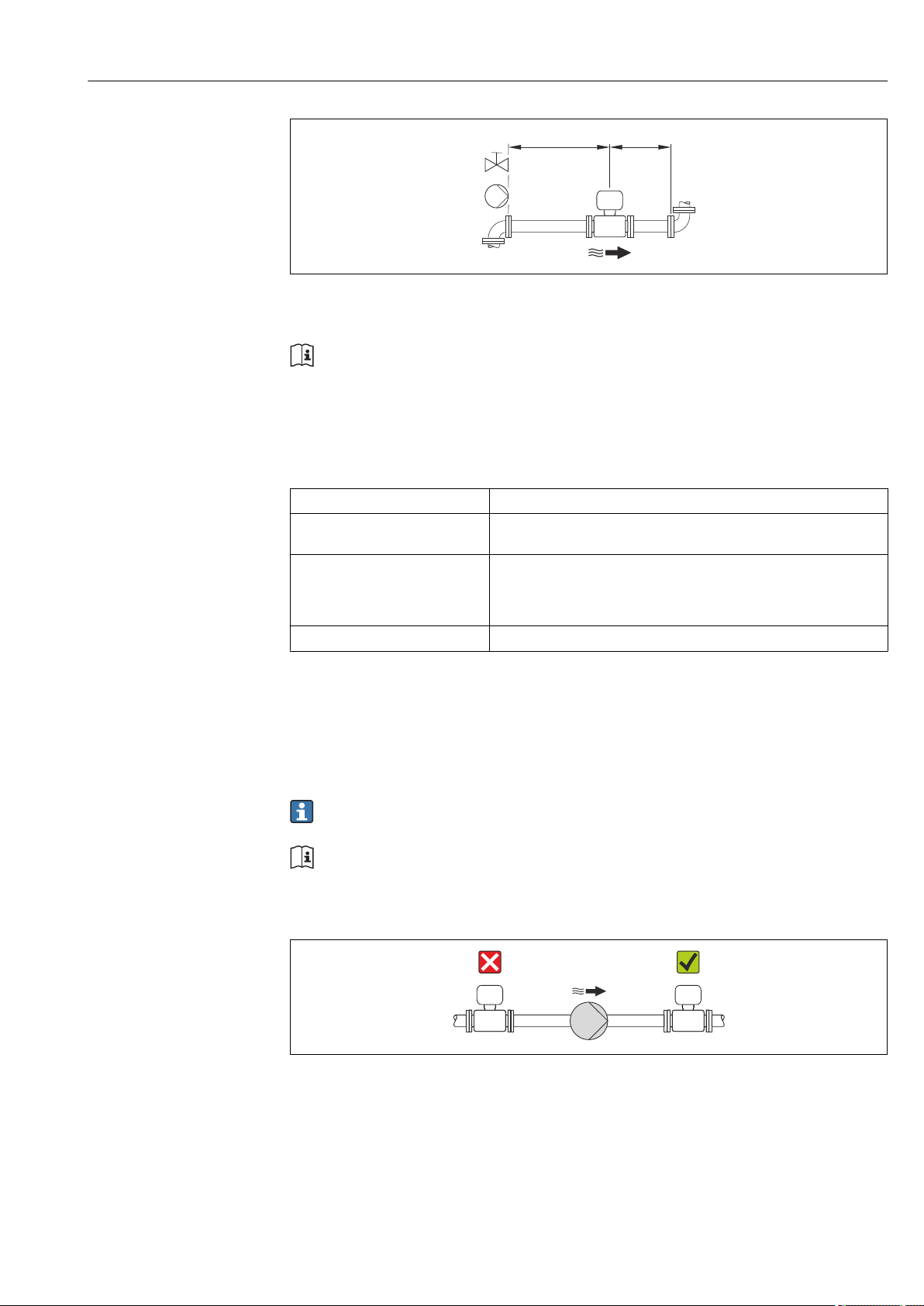

A0023343

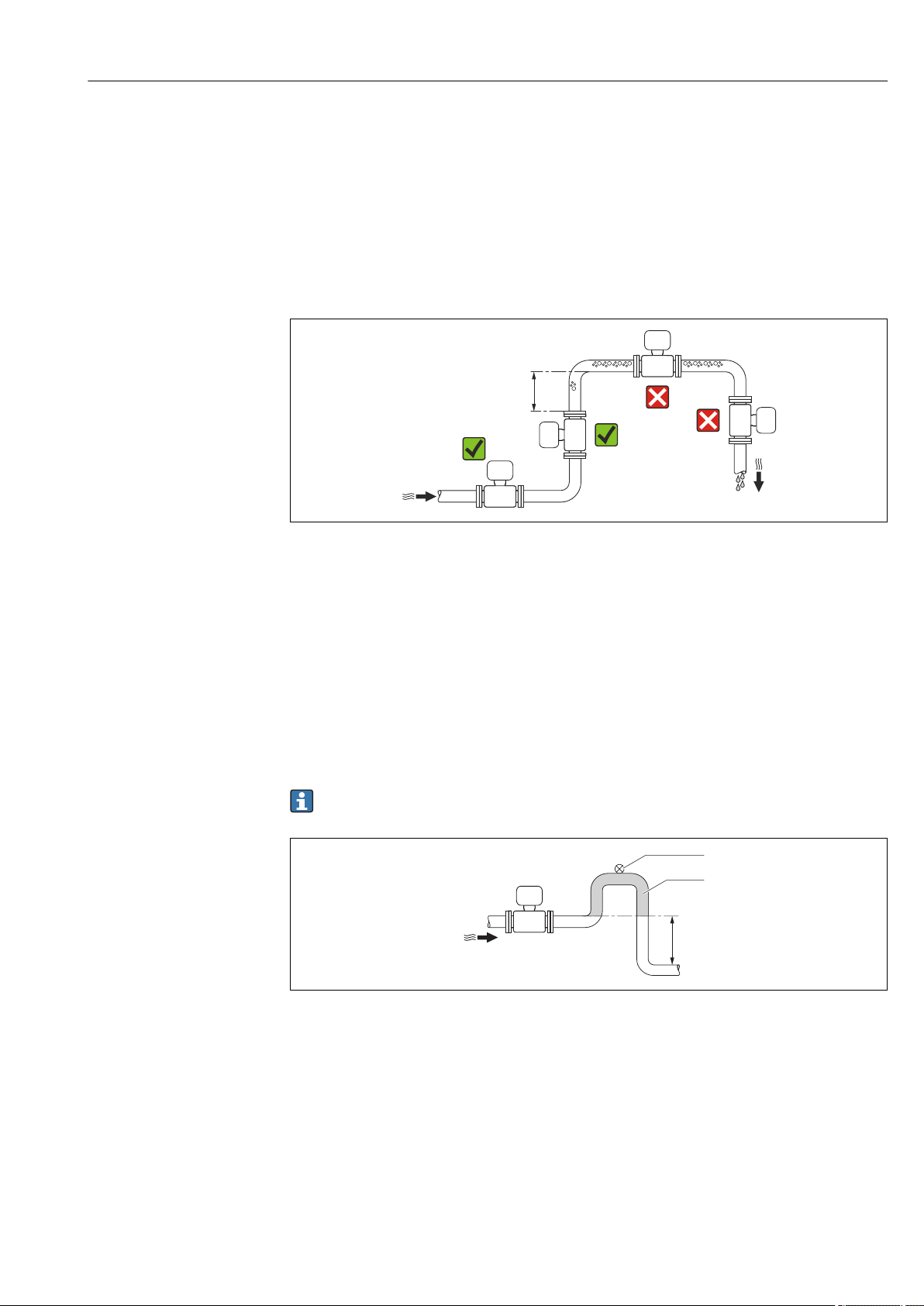

Preferably install the sensor in an ascending pipe, and ensure a sufficient distance to the

next pipe elbow: h ≥ 2 × DN

To prevent measuring errors arising from accumulation of gas bubbles in the measuring

tube, avoid the following mounting locations in the pipe:

• Highest point of a pipeline.

• Directly upstream of a free pipe outlet in a down pipe.

Installation in down pipes

Install a siphon with a vent valve downstream of the sensor in down pipes whose length h

≥ 5 m (16.4 ft). This precaution is to avoid low pressure and the consequent risk of

damage to the measuring tube. This measure also prevents the system losing prime.

For information on the liner's resistance to partial vacuum

A0017064

4 Installation in a down pipe

1 Vent valve

2 Pipe siphon

h Length of down pipe

Installation in partially filled pipes

A partially filled pipe with a gradient necessitates a drain-type configuration.

Endress+Hauser 19

Page 20

Installation Proline Promag P 200 HART

³ 5 × DN

³ 2 × DN

1

2

3

2

A0017063

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor

according to the flow direction (direction of medium flow through the piping).

An optimum orientation position helps avoid gas and air accumulations and deposits in

the measuring tube.

The measuring device also offers the empty pipe detection function to detect partially filled

measuring pipes in the event of outgassing fluids or variable process pressures.

Vertical

Optimum for self-emptying pipe systems and for use in conjunction with empty pipe

detection.

Horizontal

1 EPD electrode for empty pipe detection

2 Measuring electrodes for signal detection

3 Reference electrode for potential equalization

• The measuring electrode plane must be horizontal. This prevents brief insulation of

the two measuring electrodes by entrained air bubbles.

• Empty pipe detection only works if the transmitter housing is pointing upwards as

otherwise there is no guarantee that the empty pipe detection function will actually

respond to a partially filled or empty measuring tube.

A0015591

A0016260

Inlet and outlet runs

If possible, install the sensor upstream from fittings such as valves, T-pieces or elbows.

Observe the following inlet and outlet runs to comply with accuracy specifications:

20 Endress+Hauser

Page 21

Proline Promag P 200 HART Installation

5 × DN≥

2 × DN≥

A0016275

Installation dimensions

For the dimensions and installation lengths of the device, see the "Technical

Information" document, "Mechanical construction" section

6.1.2 Requirements from environment and process

Ambient temperature range

Transmitter –40 to +60 °C (–40 to +140 °F)

Local display –20 to +60 °C (–4 to +140 °F), the readability of the display may be

impaired at temperatures outside the temperature range.

Sensor • Process connection material, carbon steel:

–10 to +60 °C (+14 to +140 °F)

• Process connection material, stainless steel:

–40 to +60 °C (–40 to +140 °F)

Liner Do not exceed or fall below the permitted temperature range of the liner .

If operating outdoors:

• Install the measuring device in a shady location.

• Avoid direct sunlight, particularly in warm climatic regions.

• Avoid direct exposure to weather conditions.

Temperature tables

Observe the interdependencies between the permitted ambient and fluid

temperatures when operating the device in hazardous areas.

For detailed information on the temperature tables, see the separate document

entitled "Safety Instructions" (XA) for the device.

System pressure

A0015594

Endress+Hauser 21

Page 22

Installation Proline Promag P 200 HART

L

Never install the sensor on the pump suction side in order to avoid the risk of low pressure,

and thus damage to the liner.

Furthermore, install pulse dampers if reciprocating, diaphragm or peristaltic pumps

are used.

• For information on the liner's resistance to partial vacuum → 128

• For information on the shock resistance of the measuring system → 127

• For information on the vibration resistance of the measuring system → 127

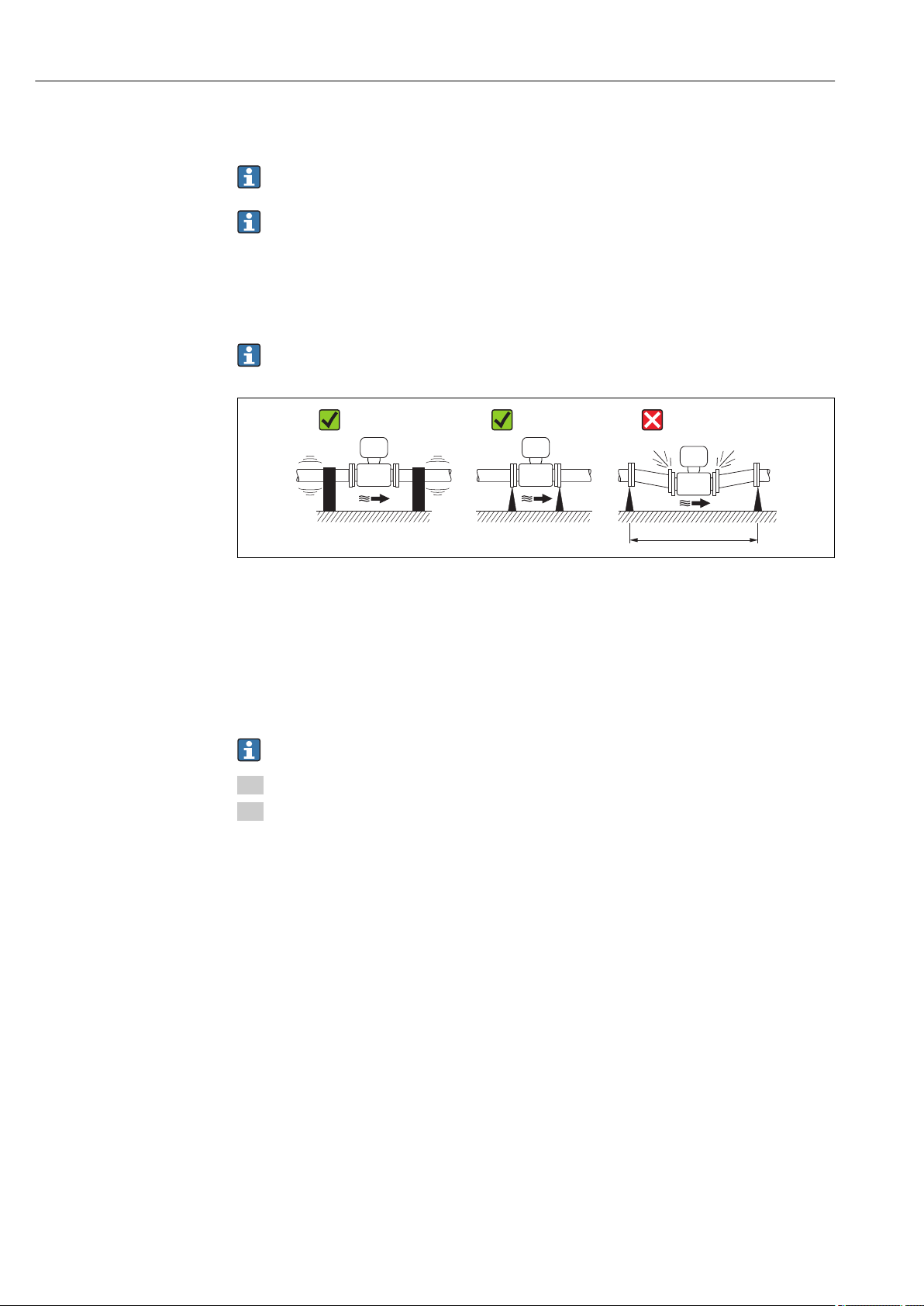

Vibrations

In the event of very strong vibrations, the pipe and sensor must be supported and fixed.

• For information on the shock resistance of the measuring system → 127

• For information on the vibration resistance of the measuring system → 127

A0016266

5 Measures to avoid device vibrations (L > 10 m (33 ft))

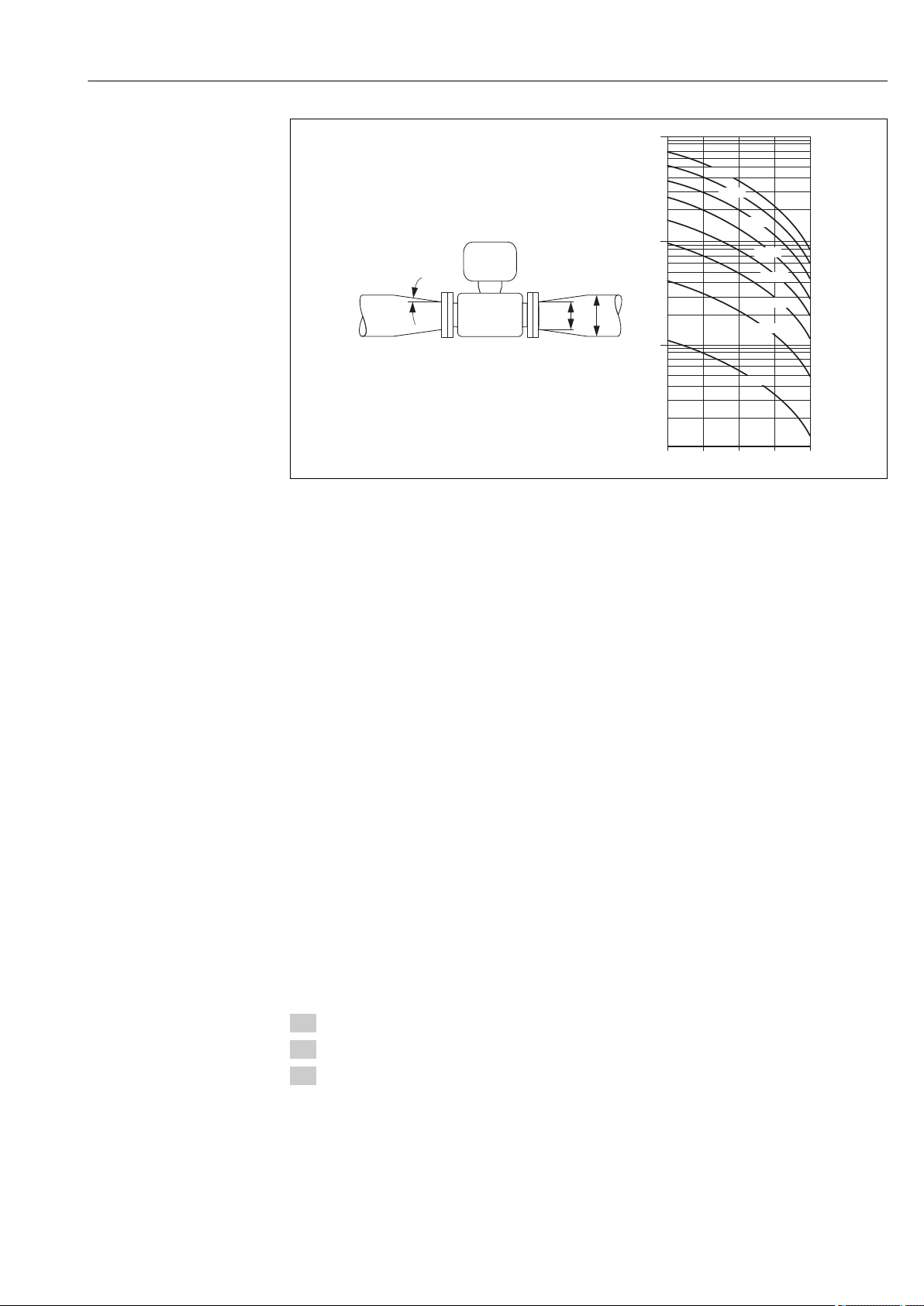

Adapters

Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor

in larger-diameter pipes. The resultant increase in the rate of flow improves measuring

accuracy with very slow-moving fluids. The nomogram shown here can be used to

calculate the pressure loss caused by reducers and expanders.

The nomogram only applies to liquids with a viscosity similar to that of water.

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity

(downstream from the reduction) and the d/D ratio.

22 Endress+Hauser

Page 23

Proline Promag P 200 HART Installation

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

A0016359

6.1.3 Special mounting instructions

Display protection

To ensure that the optional display protection can be easily opened, maintain the

‣

following minimum head clearance: 350 mm (13.8 in)

6.2 Mounting the measuring device

6.2.1 Required tools

For transmitter

• For turning the transmitter housing: Open-ended wrench8 mm

• For opening the securing clamps: Allen key3 mm

For sensor

For flanges and other process connections:

• Screws, nuts, seals etc. are not included in the scope of supply and must be provided by

the customer.

• Appropriate mounting tools

6.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove any protective covers or protective caps present from the sensor.

3. Remove stick-on label on the electronics compartment cover.

Endress+Hauser 23

Page 24

Installation Proline Promag P 200 HART

6.2.3 Mounting the sensor

WARNING

L

Danger due to improper process sealing!

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

‣

process connections and piping.

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

‣

1. Ensure that the direction of the arrow on the sensor matches the flow direction of

the medium.

2. To ensure compliance with device specifications, install the measuring device

between the pipe flanges in a way that it is centered in the measurement section.

3. If using ground disks, comply with the Installation Instructions provided.

4. Observe required screw tightening torques → 24.

5. Install the measuring device or turn the transmitter housing so that the cable entries

do not point upwards.

A0013964

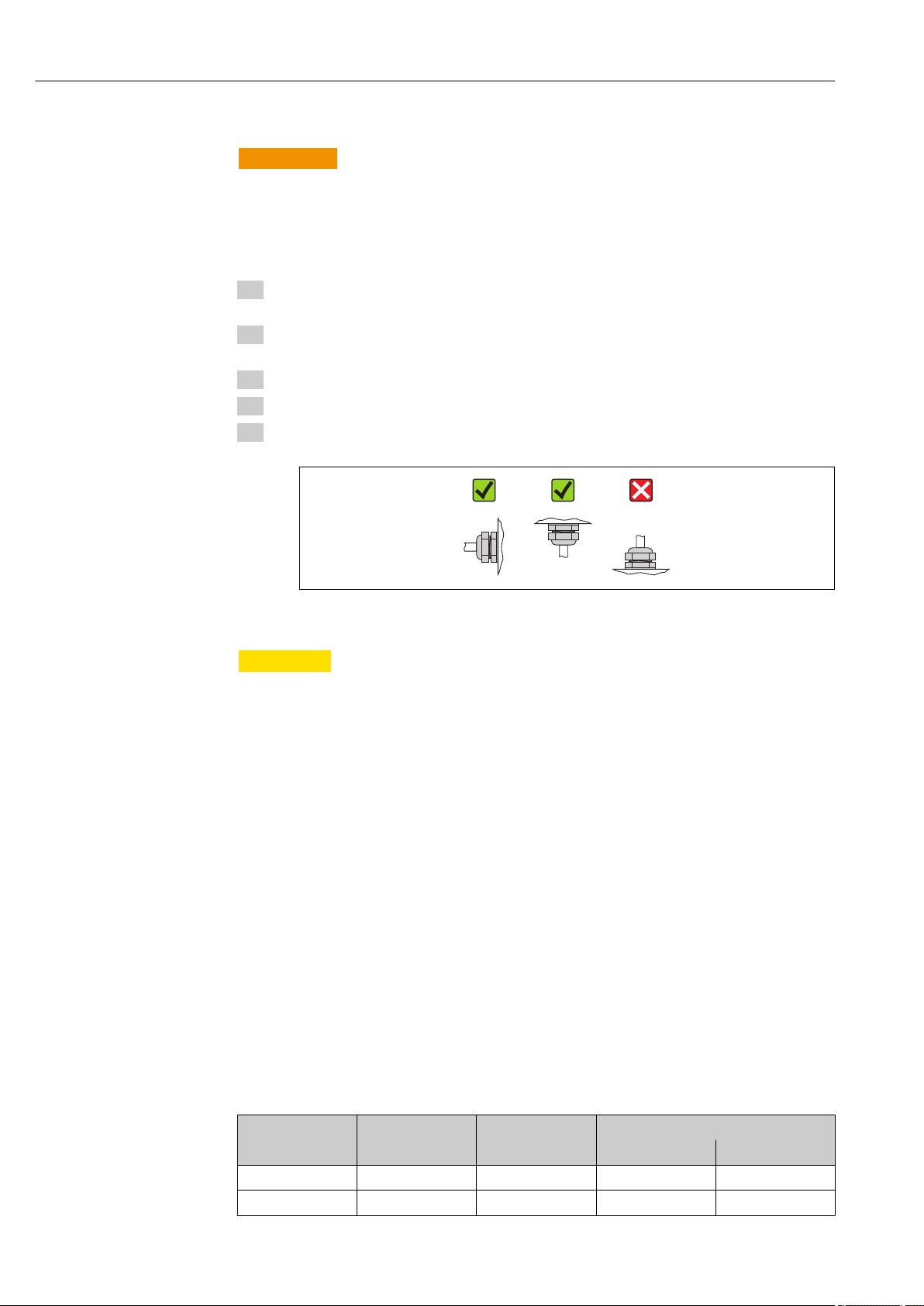

Mounting the seals

CAUTION

L

An electrically conductive layer could form on the inside of the measuring tube!

Risk of measuring signal short circuit.

Do not use electrically conductive sealing compounds such as graphite.

‣

Comply with the following instructions when installing seals:

• Make sure that the seals do not protrude into the piping cross-section.

• For DIN flanges: only use seals according to DIN EN 1514-1.

• For "PFA" lining: generally additional seals are not required.

• For "PTFE" lining: generally additional seals are not required.

Mounting the ground cable/ground disks

Comply with the information on potential equalization and detailed mounting instructions

for the use of ground cables/ground disks → 33.

Screw tightening torques

Please note the following:

• The screw tightening torques listed below apply only to lubricated threads and to pipes

not subjected to tensile stress.

• Tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

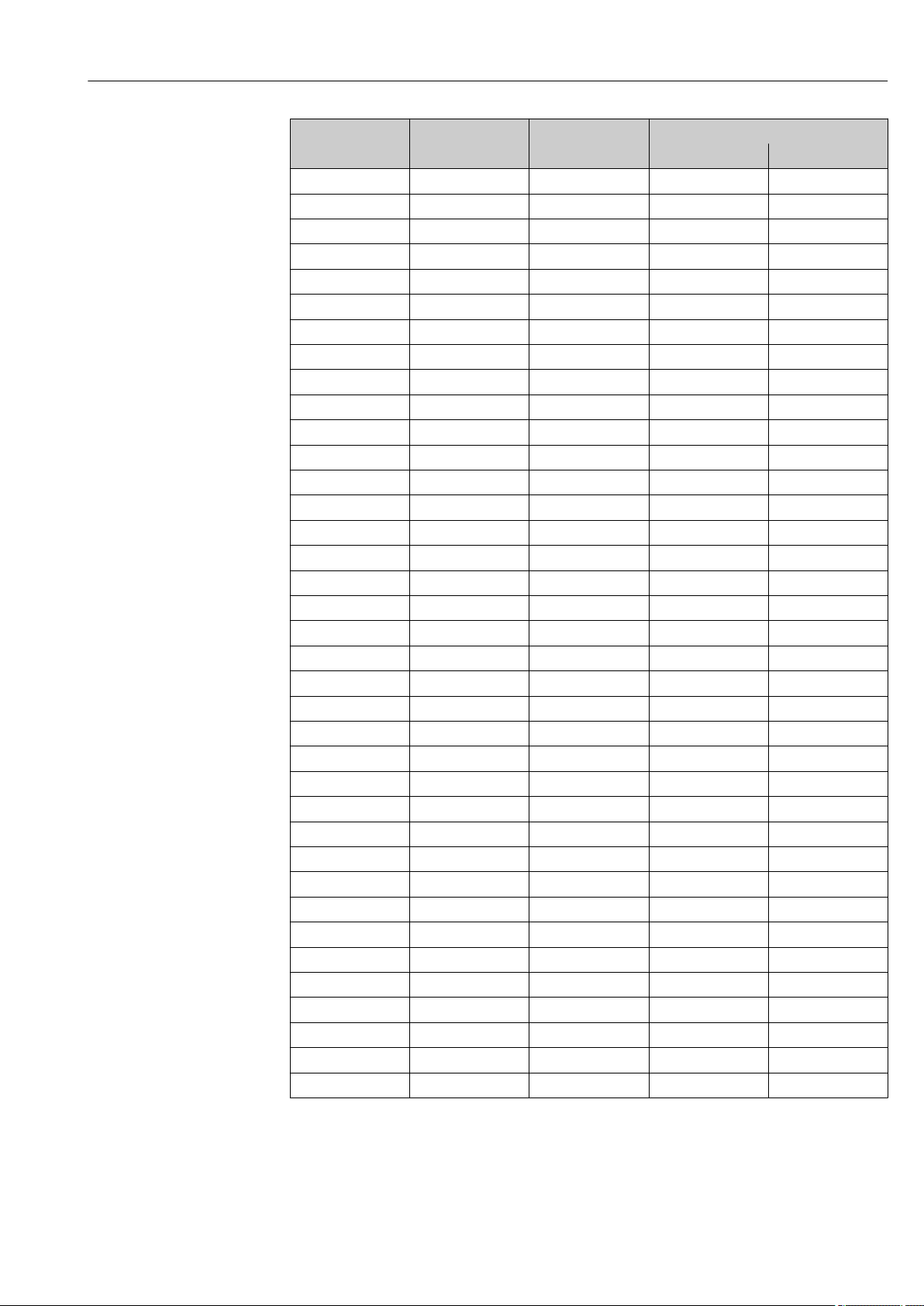

Screw tightening torques for EN 1092-1 (DIN 2501), PN 40/25

Nominal diameter Pressure rating Threaded fasteners Max. screw tightening torque [Nm]

[mm] [bar] [mm] PTFE PFA

15 PN 40 4 × M12 11 –

25 PN 40 4 × M12 26 20

24 Endress+Hauser

Page 25

Proline Promag P 200 HART Installation

Nominal diameter Pressure rating Threaded fasteners Max. screw tightening torque [Nm]

[mm] [bar] [mm] PTFE PFA

32 PN 40 4 × M16 41 35

40 PN 40 4 × M16 52 47

50 PN 40 4 × M16 65 59

1)

65

65 PN 40 8 × M16 43 40

80 PN 16 8 × M16 53 48

80 PN 40 8 × M16 53 48

100 PN 16 8 × M16 57 51

100 PN 40 8 × M20 78 70

125 PN 16 8 × M16 75 67

125 PN 40 8 × M24 111 99

150 PN 16 8 × M20 99 85

150 PN 40 8 × M24 136 120

200 PN 10 8 × M20 141 101

200 PN 16 12 × M20 94 67

200 PN 25 12 × M24 138 105

250 PN 10 12 × M20 110 –

250 PN 16 12 × M24 131 –

250 PN 25 12 × M27 200 –

300 PN 10 12 × M20 125 –

300 PN 16 12 × M24 179 –

300 PN 25 16 × M27 204 –

350 PN 10 16 × M20 188 –

350 PN 16 16 × M24 254 –

350 PN 25 16 × M30 380 –

400 PN 10 16 × M24 260 –

400 PN 16 16 × M27 330 –

400 PN 25 16 × M33 488 –

450 PN 10 20 × M24 235 –

450 PN 16 20 × M27 300 –

450 PN 25 20 × M33 385 –

500 PN 10 20 × M24 265 –

500 PN 16 20 × M30 448 –

500 PN 25 20 × M33 533 –

600 PN 10 20 × M27 345 –

1)

600

600 PN 25 20 × M36 731 –

PN 16 8 × M16 43 40

PN 16 20 × M33 658 –

1) Designed acc. to EN 1092-1 (not to DIN 2501)

Endress+Hauser 25

Page 26

Installation Proline Promag P 200 HART

Screw tightening torques for ASME B16.5, Class 150/300

Nominal diameter Pressure rating Threaded fasteners Max. screw tightening torque [Nm]

([lbf · ft])

[mm] [in] [psi] [in] PTFE PFA

15 ½ Class 150 4 × ½ 6 (4) – (–)

15 ½ Class 300 4 × ½ 6 (4) – (–)

25 1 Class 150 4 × ½ 11 (8) 10 (7)

25 1 Class 300 4 × 5/8 14 (10) 12 (9)

40 1 ½ Class 150 4 × ½ 24 (18) 21 (15)

40 1 ½ Class 300 4 × ¾ 34 (25) 31 (23)

50 2 Class 150 4 × 5/8 47 (35) 44 (32)

50 2 Class 300 8 × 5/8 23 (17) 22 (16)

80 3 Class 150 4 × 5/8 79 (58) 67 (49)

80 3 Class 300 8 × ¾ 47 (35) 42 (31)

100 4 Class 150 8 × 5/8 56 (41) 50 (37)

100 4 Class 300 8 × ¾ 67 (49) 59 (44)

150 6 Class 150 8 × ¾ 106 (78) 86 (63)

150 6 Class 300 12 × ¾ 73 (54) 67 (49)

200 8 Class 150 8 × ¾ 143 (105) 109 (80)

250 10 Class 150 12 × 7/8 135 (100) – (–)

300 12 Class 150 12 × 7/8 178 (131) – (–)

350 14 Class 150 12 × 1 260 (192) – (–)

400 16 Class 150 16 × 1 246 (181) – (–)

450 18 Class 150 16 × 1 1/8 371 (274) – (–)

500 20 Class 150 20 × 1 1/8 341 (252) – (–)

600 24 Class 150 20 × 1 ¼ 477 (352) – (–)

Screw tightening torques for JIS B2220, 10/20K

Nominal diameter Pressure rating Threaded fasteners Max. screw tightening torque [Nm]

[mm] [bar] [mm] PTFE PFA

25 10K 4 × M16 32 27

25 20K 4 × M16 32 27

32 10K 4 × M16 38 –

32 20K 4 × M16 38 –

40 10K 4 × M16 41 37

40 20K 4 × M16 41 37

50 10K 4 × M16 54 46

50 20K 8 × M16 27 23

65 10K 4 × M16 74 63

65 20K 8 × M16 37 31

80 10K 8 × M16 38 32

80 20K 8 × M20 57 46

100 10K 8 × M16 47 38

100 20K 8 × M20 75 58

26 Endress+Hauser

Page 27

Proline Promag P 200 HART Installation

max.350°

8mm

8mm

Nominal diameter Pressure rating Threaded fasteners Max. screw tightening torque [Nm]

[mm] [bar] [mm] PTFE PFA

125 10K 8 × M20 80 66

125 20K 8 × M22 121 103

150 10K 8 × M20 99 81

150 20K 12 × M22 108 72

200 10K 12 × M20 82 54

200 20K 12 × M22 121 88

250 10K 12 × M22 133 –

250 20K 12 × M24 212 –

300 10K 16 × M22 99 –

300 20K 16 × M24 183 –

Screw tightening torques for AS 2129, Table E

Nominal diameter Threaded fasteners Max. screw tightening torque

[Nm]

[mm] [mm] PTFE

25 4 × M12 21

50 4 × M16 42

Screw tightening torques for AS 4087, PN 16

Nominal diameter Threaded fasteners Max. screw tightening torque

[Nm]

[mm] [mm] PTFE

50 4 × M16 42

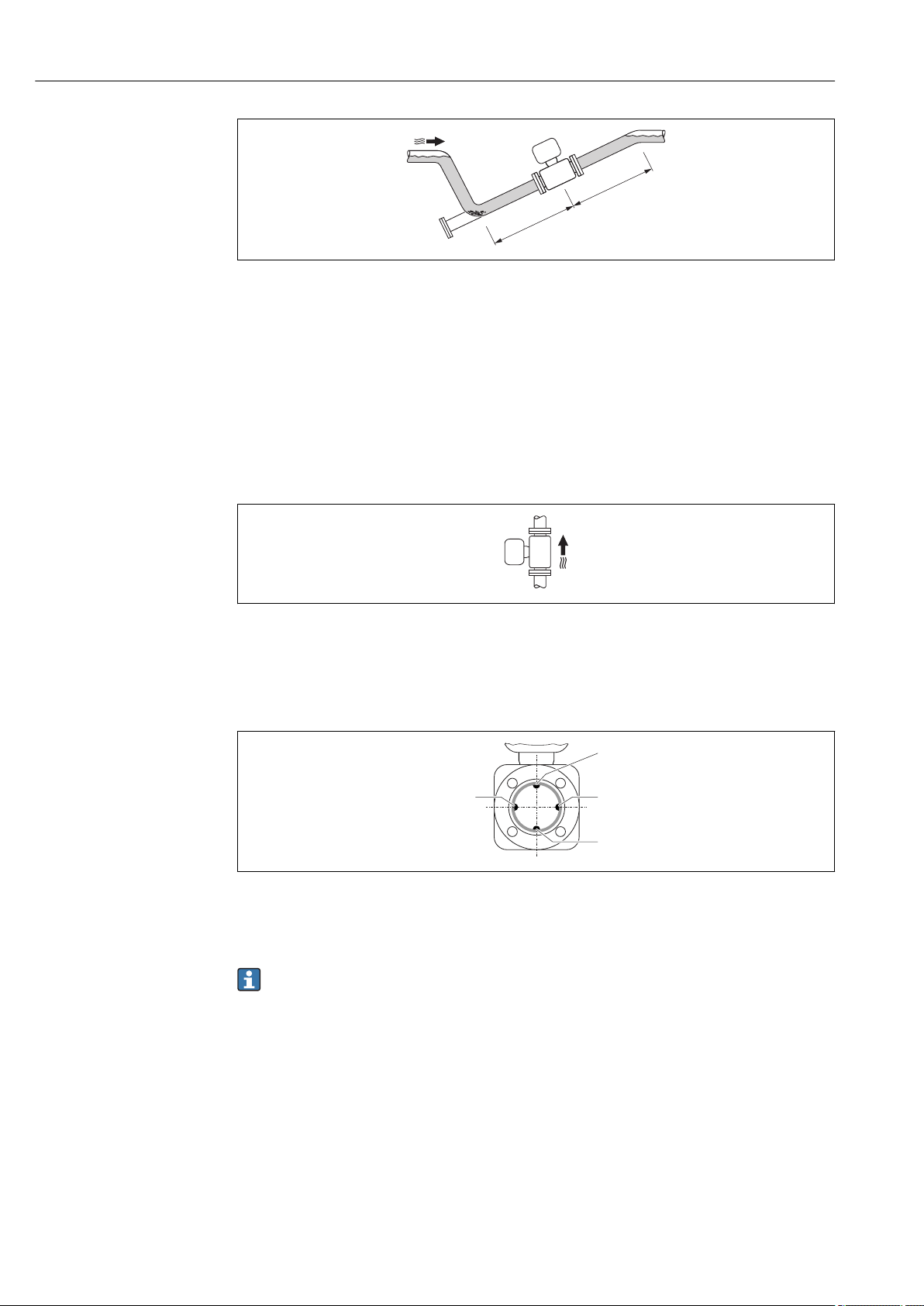

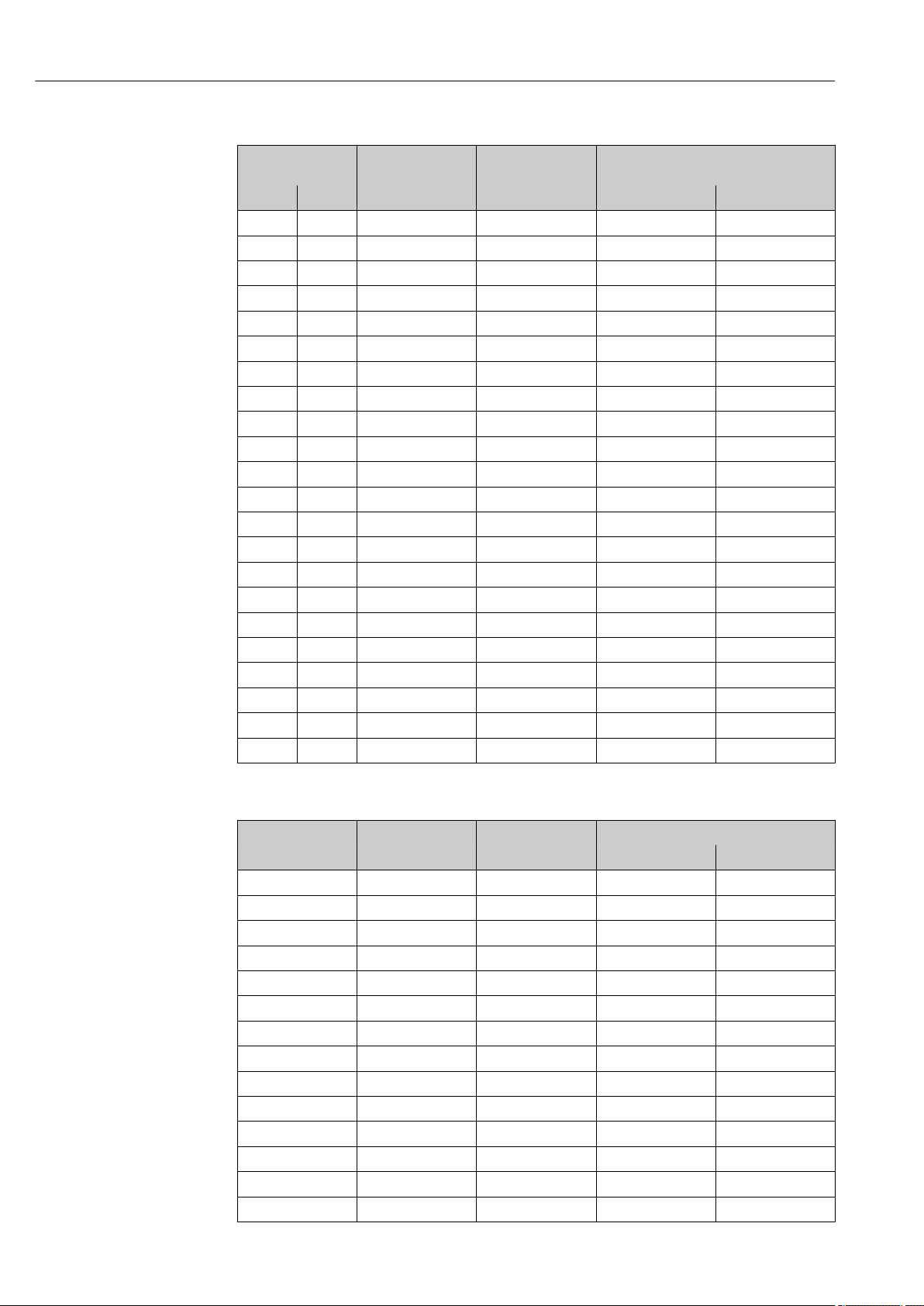

6.2.4 Turning the transmitter housing

To provide easier access to the connection compartment or display module, the transmitter

housing can be turned.

A0013713

1. Release the fixing screw.

2. Turn the housing to the desired position.

3. Firmly tighten the securing screw.

Endress+Hauser 27

Page 28

Installation Proline Promag P 200 HART

+

E

–

1

3mm

6.2.5 Turning the display module

The display module can be turned to optimize display readability and operability.

A0013905

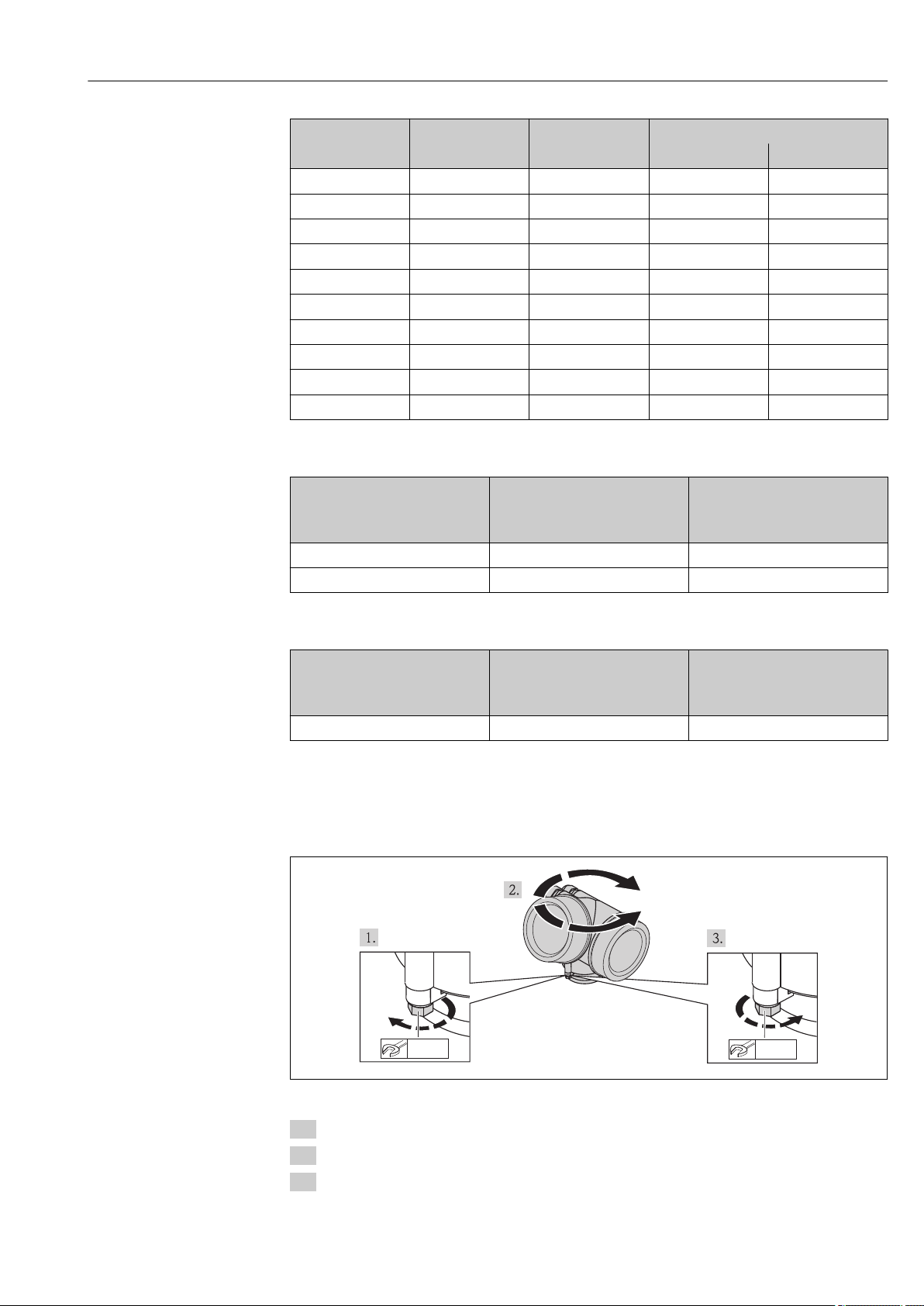

1. Loosen the securing clamp of the electronics compartment cover using an Allen key.

2. Unscrew cover of the electronics compartment from the transmitter housing.

3. Optional: pull out the display module with a gentle rotational movement.

4. Rotate the display module into the desired position: Max. 8 × 45° in each direction.

5. Without display module pulled out:

Allow display module to engage at desired position.

6. With display module pulled out:

Feed the cable into the gap between the housing and main electronics module and

plug the display module into the electronics compartment until it engages.

7. Reverse the removal procedure to reassemble the transmitter.

6.3 Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure (refer to the section on "Pressure-temperature ratings" in the "Technical

Information" document)

• Ambient temperature

• Measuring range

Has the correct orientation for the sensor been selected ?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the direction of flow of the fluid through the

piping ?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Have the fixing screws been tightened with the correct tightening torque?

28 Endress+Hauser

Page 29

Proline Promag P 200 HART Electrical connection

7 Electrical connection

The measuring device does not have an internal circuit breaker. For this reason,

assign the measuring device a switch or power-circuit breaker so that the power

supply line can be easily disconnected from the mains.

7.1 Connection conditions

7.1.1 Required tools

• For cable entries: Use corresponding tools

• For securing clamp: Allen key 3 mm

• Wire stripper

• When using stranded cables: crimping tool for ferrule

• For removing cables from terminal: flat blade screwdriver ≤3 mm (0.12 in)

7.1.2 Requirements for connecting cable

The connecting cables provided by the customer must fulfill the following requirements.

Electrical safety

In accordance with applicable federal/national regulations.

Permitted temperature range

• –40 °C (–40 °F) to +80 °C (+176 °F)

• Minimum requirement: cable temperature range ≥ ambient temperature +20 K

Signal cable

Current output

For 4-20 mA HART: Shielded cable recommended. Observe grounding concept of the

plant.

Pulse/frequency/switch output

Standard installation cable is sufficient.

Cable diameter

• Cable glands supplied:

M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• Plug-in spring terminals for device version without integrated overvoltage protection:

wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Screw terminals for device version with integrated overvoltage protection: wire crosssections 0.2 to 2.5 mm2 (24 to 14 AWG)

Endress+Hauser 29

Page 30

Electrical connection Proline Promag P 200 HART

–

4

+

1

–

2

+

3

1

2

3

+

1

–

2

–

4

+

3

1

2

3

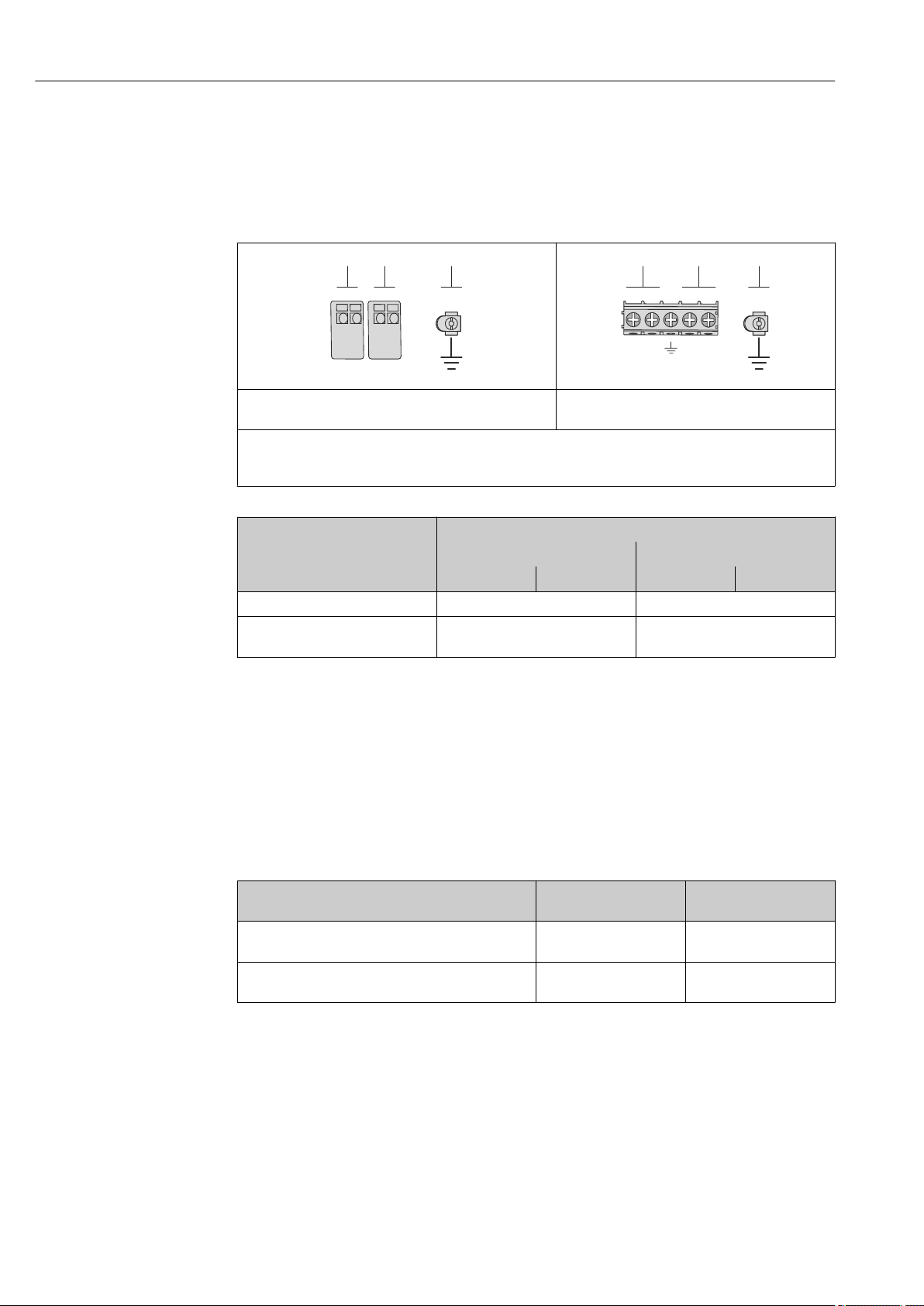

7.1.3 Terminal assignment

Transmitter

4-20 mA HART connection version with additional outputs

A0013570

Maximum number of terminals, without integrated

overvoltage protection

1

Output 1 (passive): supply voltage and signal transmission

2

Output 2 (passive): supply voltage and signal transmission

3

Ground terminal for cable shield

Order code for "Output" Terminal numbers

Output 1 Output 2

1 (+) 2 (-) 3 (+) 4 (-)

Option A 4-20 mA HART (passive) -

Option B

1) Output 1 must always be used; output 2 is optional.

1)

4-20 mA HART (passive)

Maximum number of terminals, with integrated

overvoltage protection

Pulse/frequency/switch output

(passive)

A0018161

7.1.4 Requirements for the supply unit

Supply voltage

Transmitter

An external power supply is required for each output. The following supply voltage values

apply for the 4-20 mA HART current output:

Order code for "Output"

Option A

Option B

switch output

1) External supply voltage of the power supply unit with load.

2) For device versions with SD03 local display: The terminal voltage must be increased by DC 2 V if

1) 2)

: 4-20 mA HART For 4 mA: ≥ DC 18 V

1) 2)

: 4-20 mA HART, pulse/frequency/

backlighting is used.

Minimum terminal

voltage

For 20 mA: ≥ DC 14 V

For 4 mA: ≥ DC 18 V

For 20 mA: ≥ DC 14 V

Maximum terminal

voltage

DC 35 V

DC 35 V

Load

Load for current output: 0 to 500 Ω, depending on the external supply voltage of the power

supply unit

30 Endress+Hauser

Page 31

Proline Promag P 200 HART Electrical connection

0

100

200

300

400

500

14

16 18 20

22 24

26 28 30 32

U [V]

s

R [ ]bW

1.1 1.21

34 36

Calculation of the maximum load

Depending on the supply voltage of the power supply unit (US), the maximum load (RB)

including line resistance must be observed to ensure adequate terminal voltage at the

device. In doing so, observe the minimum terminal voltage

• For US = 18 to 18.9 V: RB ≤ (US - 18 V): 0.0036 A

• For US = 18.9 to 24.5 V: RB ≤ (US - 13.5 V): 0.022 A

• For US = 24.5 to 30 V: RB ≤ 500 Ω

1 Operating range

1.1 For order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/frequency/switch

output" with Ex i

1.2 For order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/frequency/switch

output" with non-Ex and Ex d

Sample calculation

Supply voltage of the power supply unit: US = 19 V

Maximum load: RB ≤ (19 V - 13.5 V): 0.022 A = 250 Ω

7.1.5 Preparing the measuring device

1. Remove dummy plug if present.

2. NOTICE! Insufficient sealing of the housing! Operational reliability of the measuring

device could be compromised. Use suitable cable glands corresponding to the degree

of protection.

If measuring device is delivered without cable glands:

Provide suitable cable gland for corresponding connecting cable .

3. If measuring device is delivered with cable glands:

Observe cable specification .

A0013563

7.2 Connecting the measuring device

NOTICE

Limitation of electrical safety due to incorrect connection!

Have electrical connection work carried out by correspondingly trained specialists only.

‣

Observe applicable federal/national installation codes and regulations.

‣

Comply with local workplace safety regulations.

‣

For use in potentially explosive atmospheres, observe the information in the device-

‣

specific Ex documentation.

7.2.1 Connecting the transmitter

Endress+Hauser 31

Page 32

Electrical connection Proline Promag P 200 HART

10(0.4)

mm(in)

20 mm3mm

mm (in)

213 4

3 (0.12)

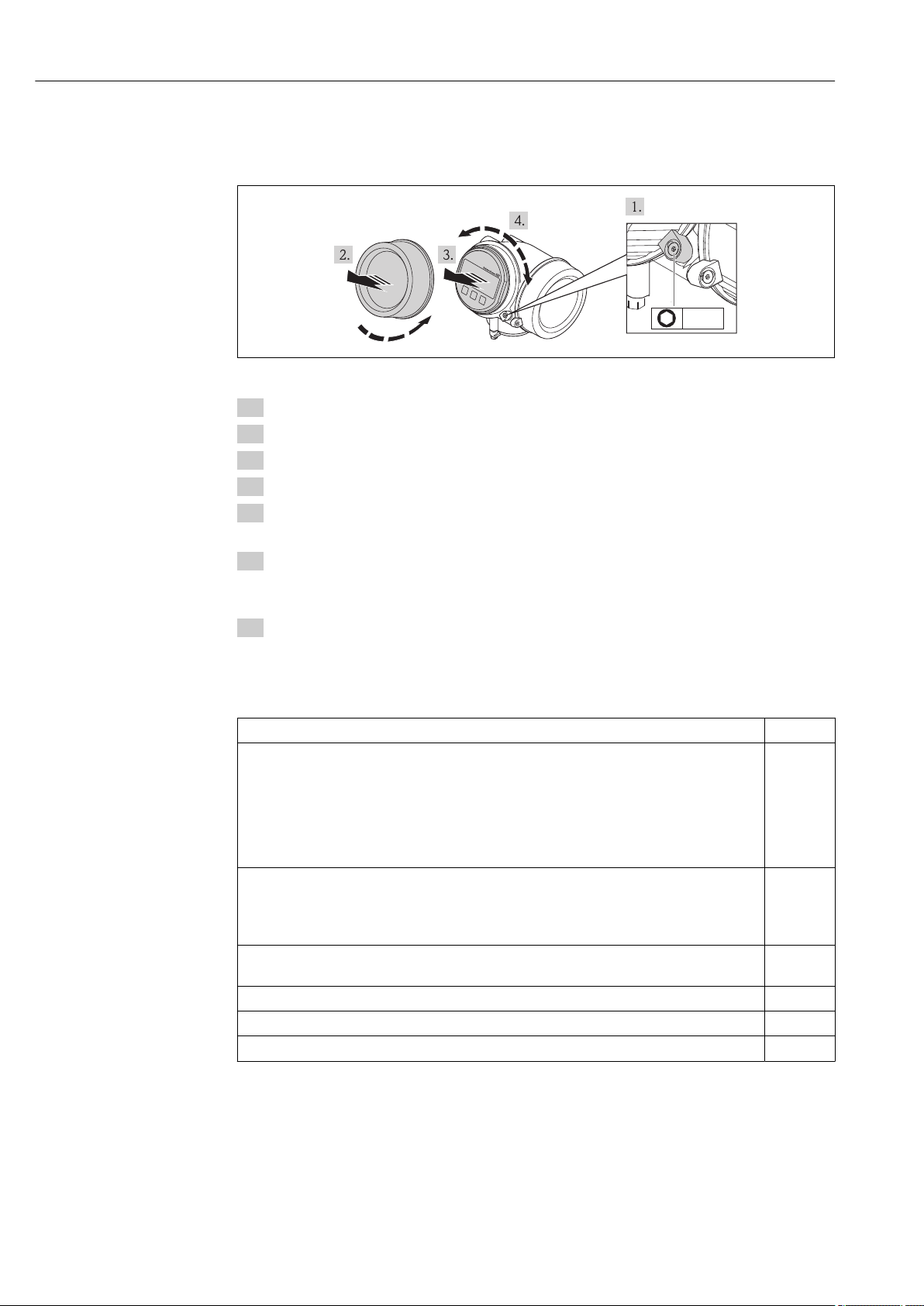

Connection via terminals

A0013836

1. Loosen the securing clamp of the connection compartment cover.

2. Unscrew the connection compartment cover.

3. Push the cable through the cable entry . To ensure tight sealing, do not remove the

sealing ring from the cable entry.

4. Strip the cable and cable ends. In the case of stranded cables, also fit ferrules.

5. Connect the cable in accordance with the terminal assignment . For HART

communication: when connecting the cable shielding to the ground terminal, observe

the grounding concept of the facility.

6. Firmly tighten the cable glands.

7. WARNING! Housing degree of protection may be voided due to insufficient sealing of

the housing. Screw in the screw without using any lubricant. The threads on the

cover are coated with a dry lubricant.

Reverse the removal procedure to reassemble the transmitter.

Removing a cable

To remove a cable from the terminal, use a flat-blade screwdriver to push the slot

‣

between the two terminal holes while simultaneously pulling the cable end out of the

terminal.

32 Endress+Hauser

A0013835

Page 33

Proline Promag P 200 HART Electrical connection

DN 300≤ DN 350≥

7.2.2 Ensuring potential equalization

Requirements

CAUTION

L

Electrode damage can result in the complete failure of the device!

Same electrical potential for the fluid and sensor

‣

Company-internal grounding concepts

‣

Pipe material and grounding

‣

For devices intended for use in hazardous locations, please observe the guidelines in

the Ex documentation (XA).

Connection examples for standard situations

Metal, grounded pipe

6 Potential equalization via measuring tube

Connection example in special situations

Unlined and ungrounded metal pipe

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable

7 Potential equalization via ground terminal and pipe flanges

Copper wire, at least6 mm2 (0.0093 in2)

A0016315

A0016317

Endress+Hauser 33

1. Connect both sensor flanges to the pipe flange via a ground cable and ground them.

2. If DN ≤ 300 (12"): Mount the ground cable directly on the conductive flange coating

of the sensor with the flange screws. If DN ≥ 350 (14"): Mount the ground cable

directly on the metal transport bracket. Observe torques → 24.

3. Connect the connection housing of the transmitter or sensor to ground potential by

means of the ground terminal provided for the purpose.

Page 34

Electrical connection Proline Promag P 200 HART

+

–

Plastic pipe or pipe with insulating liner

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable

8 Potential equalization via ground terminal and ground disks

Copper wire, at least6 mm2 (0.0093 in2)

1. Connect the ground disks to the ground terminal via the ground cable.

2. Connect the ground disks to ground potential.

Pipe with a cathodic protection unit

This connection method is only used if the following two conditions are met:

• Metal pipe without liner or pipe with electrically conductive liner

• Cathodic protection is integrated in the personal protection equipment

Ground cable

Copper wire, at least6 mm2 (0.0093 in2)

A0016318

A0016319

Prerequisite: The sensor is installed in the pipe in a way that provides electrical insulation.

1. Connect the two flanges of the pipe to one another via a ground cable.

2. Guide the shield of the signal lines through a capacitor.

3. Connect the measuring device to the power supply such that it is floating in relation

to the protective ground (isolation transformer).

34 Endress+Hauser

Page 35

Proline Promag P 200 HART Electrical connection

2

3

4...20 mA

41

+

-

5

+

-

1

+

_

12345

2

+

–

+

–

3

7.3 Special connection instructions

7.3.1 Connection examples

Current output 4-20 mA HART

A0015511

9 Connection example for 4-20 mA HART current output (passive)

1 Automation system with current input (e.g. PLC)

2 Active barrier for power supply with integrated resistor for HART communication (≥ 250 Ω)(e.g. RN221N)

Connection for HART operating devices → 134

Observe the maximum load → 30

3 Cable shield, observe cable specifications

4 Analog display unit: observe maximum load → 30

5 Transmitter

Pulse/frequency output

10 Connection example for pulse/frequency output (passive)

1 Automation system with pulse/frequency input (e.g. PLC)

2 Power supply

3 Transmitter: observe input values

A0016801

Endress+Hauser 35

Page 36

Electrical connection Proline Promag P 200 HART

1

+

_

+

_

2

+

_

3

3

4...20 mA

5

1

+

-

3

6

+

–

+

+

–

+

–

+

–

+

–

–

2

4

4

7

+

-

Switch output

A0016802

11 Connection example for switch output (passive)

1 Automation system with switch input (e.g. PLC)

2 Power supply

3 Transmitter: observe input values

HART input

A0016029

12 Connection example for HART input with a common negative

1 Automation system with HART output (e.g. PLC)

2 Resistor for HART communication (≥ 250 Ω): observe maximum load → 31

3 Active barrier for power supply (e.g. RN221N)

4 Cable shield, observe cable specifications

5 Analog display unit: observe maximum load → 31

6 Pressure transmitter (e.g. Cerabar M, Cerabar S): see requirements

7 Transmitter

7.4 Ensuring the degree of protection

The measuring device fulfills all the requirements for the IP66/67 degree of protection,

Type 4X enclosure.

To guarantee IP66/67 degree of protection, Type 4X enclosure, carry out the following

steps after the electrical connection:

36 Endress+Hauser

1. Check that the housing seals are clean and fitted correctly. Dry, clean or replace the

seals if necessary.

2. Tighten all housing screws and screw covers.

3. Firmly tighten the cable glands.

Page 37

Proline Promag P 200 HART Electrical connection

4. To ensure that moisture does not enter the cable entry, route the cable so that it

loops down before the cable entry ("water trap").

A0013960

5. Insert dummy plugs into unused cable entries.

7.5 Post-connection check

Are cables or the device undamaged (visual inspection)?

Do the cables comply with the requirements ?

Do the cables have adequate strain relief?

Are all the cable glands installed, firmly tightened and leak-tight? Cable run with "water trap"

→ 36 ?

Depending on the device version: are all the device plugs firmly tightened ?

Does the supply voltage match the specifications on the transmitter nameplate ?

Is the terminal assignment correct ?

If supply voltage is present, do values appear on the display module?

Is the potential equalization established correctly → 33?

Are all housing covers installed and firmly tightened?

Is the securing clamp tightened correctly?

Endress+Hauser 37

Page 38

Operation options Proline Promag P 200 HART

1

2 3

4 5

S

C

8 Operation options

8.1 Overview of operation options

A0015607

1 Local operation via display module

2 Computer with operating tool (e.g. FieldCare, AMS Device Manager, SIMATIC PDM)

3 Field Xpert SFX350 or SFX370

4 Field Communicator 475

5 Control system (e.g. PLC)

38 Endress+Hauser

Page 39

Proline Promag P 200 HART Operation options

!

Expert

System

Sensor

Communication

Application

Diagnostics

Access status display

Output

Operating menu for experts

Language

Operatation Language

Parameter 1

Setup

Submenu 1

Submenu n

Device tag

Advanced setup

Enter access code

Parameter 1

Parameter n

Submenu 1

Submenu n

Diagnostics

Parameter 1

Parameter n

Submenu 1

Submenu n

Operating menu for operators and maintenances

Parameter n

Operator

Maintenance

Task-oriented

Function-oriented

Expert

Wizard 1 / Parameter 1

Wizard n / Parameter n

Parameter n

Intput

8.2 Structure and function of the operating menu

8.2.1 Structure of the operating menu

For an overview of the operating menu with menus and parameters

Endress+Hauser 39

13 Schematic structure of the operating menu

A0018237-EN

Page 40

Operation options Proline Promag P 200 HART

8.2.2 Operating philosophy

The individual parts of the operating menu are assigned to certain user roles (operator,

maintenance etc.). Each user role contains typical tasks within the device lifecycle.

Menu User role and tasks Content/meaning

Language task-oriented Role "Operator", "Maintenance"

Operation • Configuring the operational display (e.g. display format,

Setup "Maintenance" role

Diagnostics "Maintenance" role

Tasks during operation:

• Configuring the operational display

• Reading measured values

Commissioning:

• Configuration of the measurement

• Configuration of the inputs and

outputs

Fault elimination:

• Diagnostics and elimination of

process and device errors

• Measured value simulation

Defining the operating language

display contrast)

• Resetting and controlling totalizers

Wizards for fast commissioning:

• Configuring the outputs

• Configuring the operational display

• Defining the output conditioning

• Empty pipe detection

• Configuring the low flow cut off

"Advanced setup" submenu:

• For more customized configuration of the measurement

(adaptation to special measuring conditions)

• Configuration of totalizers

• Configuration of electrode cleaning (optional)

• Administration (define access code, reset measuring device)

Contains all parameters for error detection and analyzing

process and device errors:

• "Diagnostic list" submenu

Contains up to 5 currently pending diagnostic messages.

• "Event logbook" submenu

Contains up to 20 or 100 (order option " Extended

HistoROM") event messages that have occurred.

• "Device information" submenu

Contains information for identifying the device.

• "Measured values" submenu

Contains all current measured values.

• "Data logging" submenu (order option "Extended

HistoROM")

Storage and visualization of up to 1000 measured values

• "Heartbeat Technology" submenu

The functionality of the device is checked on demand and the

verification results are documented.

• "Simulation" submenu

Is used to simulate measured values or output values.

Expert function-oriented Tasks that require detailed knowledge

of the function of the device:

• Commissioning measurements under

difficult conditions

• Optimal adaptation of the

measurement to difficult conditions

• Detailed configuration of the

communication interface

• Error diagnostics in difficult cases

Contains all the parameters of the device and makes it possible

to access these parameters directly using an access code. The

structure of this menu is based on the function blocks of the

device:

• "System" submenu

Contains all higher-order device parameters that do not

pertain either to measurement or the measured value

communication.

• "Sensor" submenu

Configuration of the measurement.

• "Input" submenu

Configuration of the input.

• "Output" submenu

Configuration of the outputs.

• "Communication" submenu

Configuration of the digital communication interface.

• "Application" submenu

Configuration of the functions that go beyond the actual

measurement (e.g. totalizer).

• "Diagnostics" submenu

Error detection and analysis of process and device errors and

for device simulation and Heartbeat Technology.

40 Endress+Hauser

Page 41

Proline Promag P 200 HART Operation options

X X X X X X XX X

4

2

1

3

5

l/h

1120.50

F

8.3 Access to the operating menu via the local display

8.3.1 Operational display

A0016502

1

Operational display

2

Device tag

3

Status area

4

Display area for measured values (4-line)

5

Operating elements → 46

Status area

The following symbols appear in the status area of the operational display at the top right:

• Status signals→ 99

– F: Failure

– C: Function check

– S: Out of specification

– M: Maintenance required

• Diagnostic behavior→ 100

– : Alarm

– : Warning

• : Locking (the device is locked via the hardware )

• : Communication (communication via remote operation is active)

Display area

In the display area, each measured value is prefaced by certain symbol types for further

description:

Measured variable Measurement channel

number

↓ ↓ ↓

Example

Diagnostic behavior

Appears only if a diagnostics

event is present for this

measured variable.

Measured variables

Symbol Meaning

Volume flow

Mass flow

Endress+Hauser 41

Page 42

Operation options Proline Promag P 200 HART

4

2

1

3

5

/../Operation

0091-1

Access stat.disp

Operator

Locking status

Display

S

4

2

1

5

3

/../Curr. output 1

Assign curr.

Volume flow

Totalizer

The measurement channel number indicates which of the three totalizers is

displayed.

Output

The measurement channel number indicates which of the two current outputs is

displayed.

Measurement channel numbers

Symbol Meaning

Measurement channel 1 to 4

The measurement channel number is displayed only if more than one channel is present for the same measured

variable type (e.g. totalizer 1-3).

Diagnostic behavior

The diagnostic behavior pertains to a diagnostic event that is relevant to the displayed measured variable.

For information on the symbols → 100

The number and display format of the measured values can be configured via the

"Format display" parameter → 73. "Operation" menu → Display → Format

display

8.3.2 Navigation view

In the submenu In the wizard

A0013993-EN

1

Navigation view

2

Navigation path to current position

3

Status area

4

Display area for navigation

5

Operating elements → 46

Navigation path

The navigation path - displayed at the top left in the navigation view - consists of the

following elements:

A0016327-EN

• In the submenu:

Display symbol for menu

• In the wizard:

Display symbol for wizard

↓ ↓ ↓

Examples / ../ Display

Omission symbol for

operating menu levels in

between

/ ../ Display

Name of current

• Submenu

• Wizard

• Parameter

42 Endress+Hauser

Page 43

Proline Promag P 200 HART Operation options

For more information about the menu icons, refer to the "Display area" section

→ 43

Status area

The following appears in the status area of the navigation view in the top right corner:

• Of the submenu

– The direct access code for the parameter you are navigating to (e.g. 0022-1)

– If a diagnostic event is present, the diagnostic behavior and status signal

• In the wizard

If a diagnostic event is present, the diagnostic behavior and status signal

• For information on the diagnostic behavior and status signal → 99

• For information on the function and entry of the direct access code → 48

Display area

Menus

Symbol Meaning

Operation

Appears:

• In the menu next to the "Operation" selection

• At the left in the navigation path in the "Operation" menu

Setup

Appears:

• In the menu next to the "Setup" selection

• At the left in the navigation path in the "Setup" menu

Diagnostics

Appears:

• In the menu next to the "Diagnostics" selection

• At the left in the navigation path in the "Diagnostics" menu

Expert

Appears:

• In the menu next to the "Expert" selection

• At the left in the navigation path in the "Expert" menu

Submenus, wizards, parameters

Symbol Meaning

Submenu

Wizard

Parameters within a wizard

No display symbol exists for parameters in submenus.

Locking

Symbol Meaning

Parameter locked

When displayed in front of a parameter name, indicates that the parameter is locked.

• By a user-specific access code

• By the hardware write protection switch

Endress+Hauser 43

Page 44

Operation options Proline Promag P 200 HART

3

2

1

4

3

4

0

1 2

9

5

6

8

7

20

…

0

9

.

–

Wizard operation

Symbol Meaning

Switches to the previous parameter.

Confirms the parameter value and switches to the next parameter.

Opens the editing view of the parameter.

8.3.3 Editing view

Numeric editor Text editor

A0013941 A0013999

1

Editing view

2

Display area of the entered values

3

Input mask

4

Operating elements → 46

Input mask

The following input symbols are available in the input mask of the numeric and text editor:

Numeric editor

Symbol Meaning

Selection of numbers from 0 to 9.

Inserts decimal separator at the input position.

Inserts minus sign at the input position.

Confirms selection.

Moves the input position one position to the left.

Exits the input without applying the changes.

Clears all entered characters.

44 Endress+Hauser

Page 45

Proline Promag P 200 HART Operation options

Aa1

XYZ

ABC

_

…

xyz

abc

_

…

~&

"'^

_

…

_

Text editor

Symbol Meaning

Toggle

• Between upper-case and lower-case letters

• For entering numbers

• For entering special characters

Selection of letters from A to Z.

Selection of letters from a to z.

Selection of special characters.

Confirms selection.

Switches to the selection of the correction tools.

Exits the input without applying the changes.

Clears all entered characters.

Correction symbols under

Symbol Meaning

Clears all entered characters.

Moves the input position one position to the right.

Moves the input position one position to the left.

Deletes one character immediately to the left of the input position.

Endress+Hauser 45

Page 46

Operation options Proline Promag P 200 HART

+

+

+

++

8.3.4 Operating elements

Key Meaning

Minus key

In a menu, submenu

Moves the selection bar upwards in a choose list.

With a Wizard

Confirms the parameter value and goes to the previous parameter.

With a text and numeric editor

In the input mask, moves the selection bar to the left (backwards).

Plus key

In a menu, submenu

Moves the selection bar downwards in a choose list.

With a Wizard

Confirms the parameter value and goes to the next parameter.

With a text and numeric editor

Moves the selection bar to the right (forwards) in an input screen.

Enter key

For operational display

• Pressing the key briefly opens the operating menu.

• Pressing the key for 2 s opens the context menu.

In a menu, submenu

• Pressing the key briefly:

– Opens the selected menu, submenu or parameter.

– Starts the wizard.

– If help text is open, closes the help text of the parameter.

• Pressing the key for 2 s for parameter:

If present, opens the help text for the function of the parameter.

With a Wizard

Opens the editing view of the parameter.

With a text and numeric editor

• Pressing the key briefly:

– Opens the selected group.

– Carries out the selected action.

• Pressing the key for 2 s confirms the edited parameter value.

Escape key combination (press keys simultaneously)

In a menu, submenu

• Pressing the key briefly:

– Exits the current menu level and takes you to the next higher level.

– If help text is open, closes the help text of the parameter.

• Pressing the key for 2 s returns you to the operational display ("home position").

With a Wizard

Exits the wizard and takes you to the next higher level.

With a text and numeric editor

Closes the text or numeric editor without applying changes.

Minus/Enter key combination (press the keys simultaneously)

Reduces the contrast (brighter setting).

Plus/Enter key combination (press and hold down the keys simultaneously)

Increases the contrast (darker setting).

Minus/Plus/Enter key combination (press the keys simultaneously)

For operational display

Enables or disables the keypad lock (only SD02 display module).

8.3.5 Opening the context menu

Using the context menu, the user can call up the following menus quickly and directly from

the operational display:

46 Endress+Hauser

Page 47

Proline Promag P 200 HART Operation options

• Setup

• Conf. backup disp.

• Simulation

Calling up and closing the context menu

The user is in the operational display.

1. Press for 2 s.

The context menu opens.

A0016326-EN

2. Press + simultaneously.

The context menu is closed and the operational display appears.

Calling up the menu via the context menu

1. Open the context menu.

2. Press to navigate to the desired menu.

3. Press to confirm the selection.

The selected menu opens.

Endress+Hauser 47

Page 48

Operation options Proline Promag P 200 HART

X X X X X XXX X

20.50

0104-1

2 s

0091-1

0098-1

0098-1

0098-1

X X X X X XXX X

10.50

19.00

XX

XX

XXXX

Operation

Operation

Setup

Main menu

English

Main menu

Format display

/ ../Display

Contrast display

Display intervall

1 value, max.

Setup

Access stat.disp

/ ../Operation

Display

Locking status

1 value, max.

/ ../Format display

2 values

Val. large+2val.

Bargr. + 1 value

Locking status

/ ../Operation

Display

1 value, max.

/ ../Format display

2 values

Val. large+2val.

Bargr. + 1 value

Operator

Language

Language

8.3.6 Navigating and selecting from list

Different operating elements are used to navigate through the operating menu. The