Page 1

KA01143D/06/EN/05.15

71301568

Products Solutions Services

Brief Operating Instructions

Proline Promag P 100

Electromagnetic flowmeter

These Instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Detailed information about the device can be found in the

Operating Instructions and the other documentation:

• On the CD-ROM supplied (not included in the delivery for all

device versions).

• Available for all device versions via:

– Internet: www.endress.com/deviceviewer

– Smart phone/tablet: Endress+Hauser Operations App

Page 2

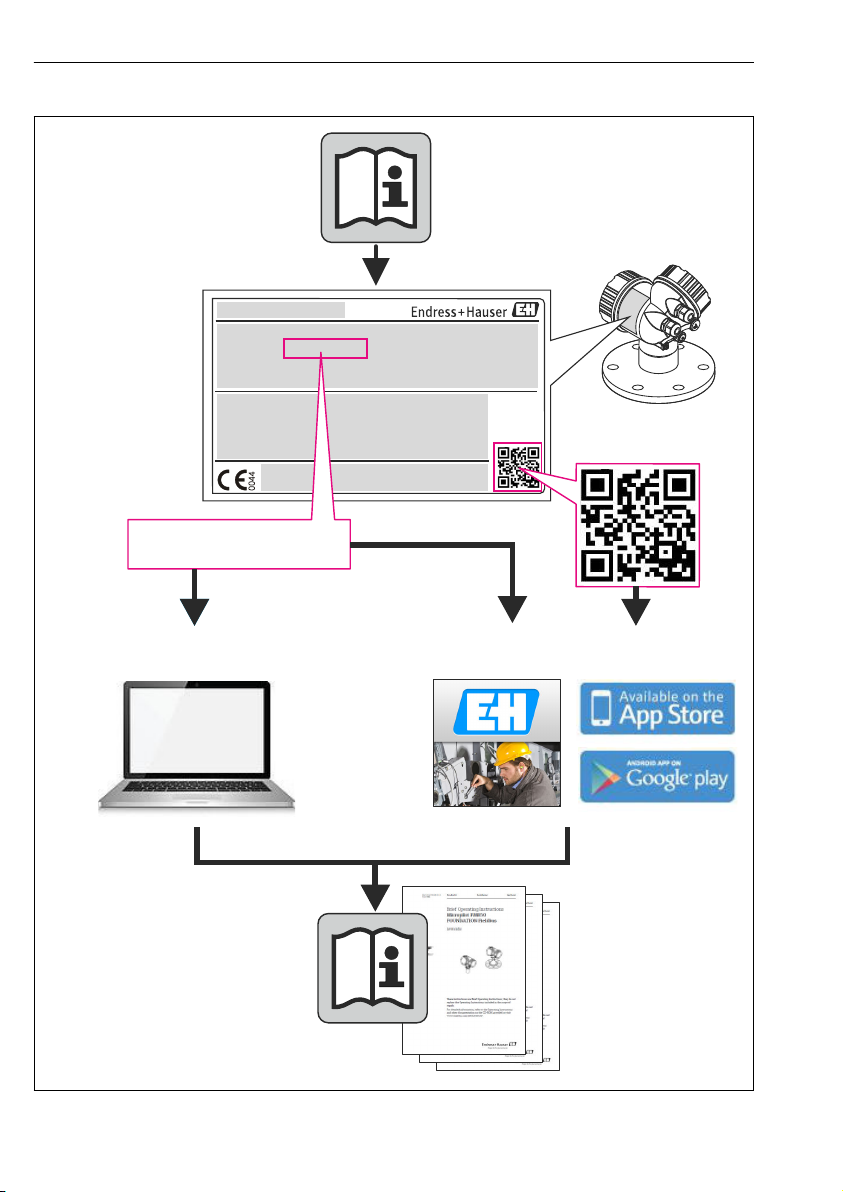

TAG No.: XXX000

Ser. No.: X000X000000

Order code 00X00-XXXX0XX0XXX

www.endress.com/deviceviewer Endress+Hauser Operations App

Serial number

Proline Promag P 100

2 Endress+Hauser

A0023555

Page 3

Proline Promag P 100 Table of contents

Table of contents

1 Document information ........................................................... 4

1.1 Symbols used ........................................................................ 4

2 Basic safety instructions ......................................................... 6

2.1 Requirements for the personnel ........................................................... 6

2.2 Designated use ....................................................................... 6

2.3 Workplace safety ...................................................................... 7

2.4 Operational safety ..................................................................... 7

2.5 Product safety ........................................................................ 7

2.6 IT security ........................................................................... 8

3 Product description .............................................................. 9

3.1 Product design ....................................................................... 9

4 Incoming acceptance and product identification ................................. 11

4.1 Incoming acceptance .................................................................. 11

4.2 Product identification ................................................................. 12

5 Storage and transport ........................................................... 12

5.1 Storage conditions .................................................................... 12

5.2 Transporting the product ............................................................... 13

6 Mounting ....................................................................... 14

6.1 Installation conditions ................................................................. 14

6.2 Mounting the measuring device .......................................................... 18

6.3 Post-installation check ................................................................. 20

7 Electrical connection ............................................................ 21

7.1 Connection conditions ................................................................. 21

7.2 Connecting the measuring device ......................................................... 29

7.3 Hardware settings .................................................................... 33

7.4 Ensuring the degree of protection ........................................................ 36

7.5 Post-connection check ................................................................. 37

8 Operation options .............................................................. 38

8.1 Structure and function of the operating menu ................................................ 38

8.2 Access to the operating menu via the Web browser ............................................ 38

8.3 Access to the operating menu via the operating tool ........................................... 42

9 System integration .............................................................. 42

10 Commissioning ................................................................. 43

10.1 Function check ...................................................................... 43

10.2 Establishing a connection via FieldCare .................................................... 43

10.3 Configuring the device address via software ................................................. 43

10.4 Configuring the measuring device ........................................................ 44

10.5 Defining the tag name ................................................................. 44

10.6 Protecting settings from unauthorized access ................................................ 44

11 Diagnostic information ......................................................... 47

Endress+Hauser 3

Page 4

Document information Proline Promag P 100

DANGER

WARNING

CAUTION

NOTICE

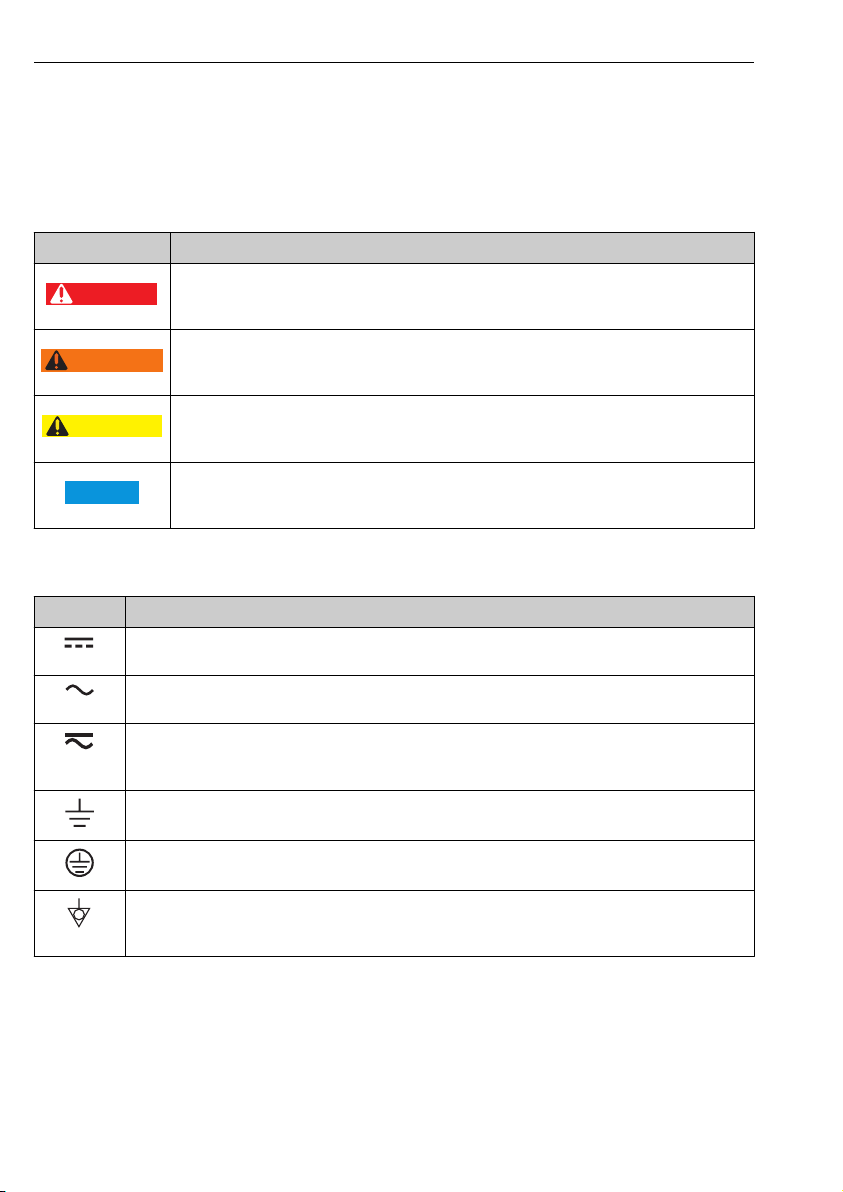

1 Document information

1.1 Symbols used

1.1.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in personal

injury.

1.1.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

4 Endress+Hauser

Page 5

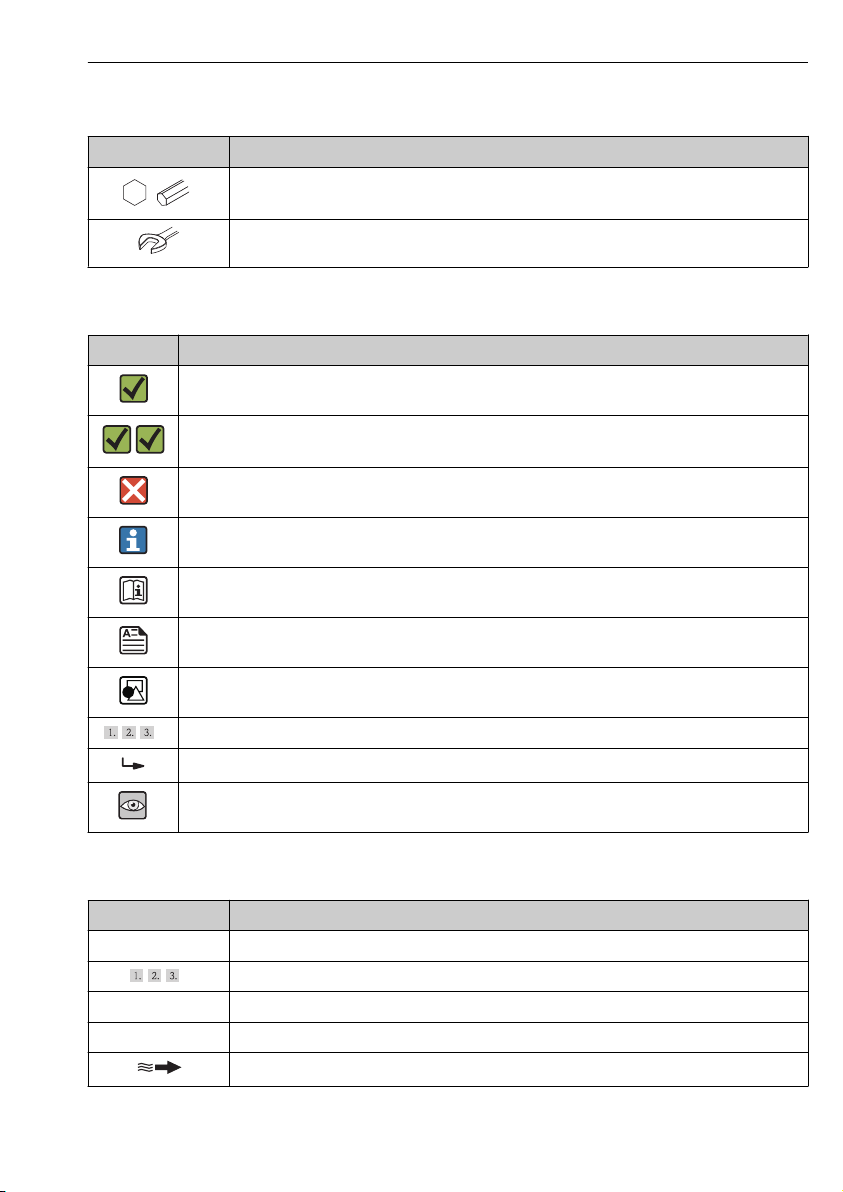

Proline Promag P 100 Document information

,…,

,…,

1.1.3 Tool symbols

Symbol Meaning

Allen key

Open-ended wrench

1.1.4 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

Preferred

Indicates procedures, processes or actions that are preferred.

Forbidden

Indicates procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Refers to the corresponding device documentation.

Reference to page

Refers to the corresponding page number.

Reference to graphic

Refers to the corresponding graphic number and page number.

Series of steps

Result of a sequence of actions

Visual inspection

1.1.5 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Flow direction

Endress+Hauser 5

Page 6

Basic safety instructions Proline Promag P 100

-

.

Symbol Meaning

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements for its tasks:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the instructions

‣

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

Following instructions and basic conditions

‣

2.2 Designated use

Application and media

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and the

‣

general conditions listed in the Operating Instructions and supplementary documentation.

Based on the nameplate, check whether the ordered device is permitted for the intended

‣

use in the hazardous area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials are

‣

adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with the

‣

relevant basic conditions specified in the associated device documentation is absolutely

essential: "Device documentation" section (Verweisziel existiert nicht, aber

@y.link.required='true').

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage caused

by improper or non-designated use.

6 Endress+Hauser

Page 7

Proline Promag P 100 Basic safety instructions

WARNING

L

Danger of breakage of the sensor due to corrosive or abrasive fluids!

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Observe the specified pressure and temperature range.

‣

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

‣

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

The external surface temperature of the housing can increase by max. 10 K due to the power

consumption of the electronic components. Hot process fluids passing through the measuring

device will further increase the surface temperature of the housing. The surface of the sensor,

in particular, can reach temperatures which are close to the fluid temperature.

Possible burn hazard due to fluid temperatures!

For elevated fluid temperature, ensure protection against contact to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

If working on and with the device with wet hands:

It is recommended to wear gloves on account of the higher risk of electric shock.

‣

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet stateof-the-art safety requirements, has been tested, and left the factory in a condition in which it

is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser confirms

this by affixing the CE mark to the device.

Endress+Hauser 7

Page 8

Basic safety instructions Proline Promag P 100

2.6 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

8 Endress+Hauser

Page 9

Proline Promag P 100 Product description

3

2

1

4

5

6

7

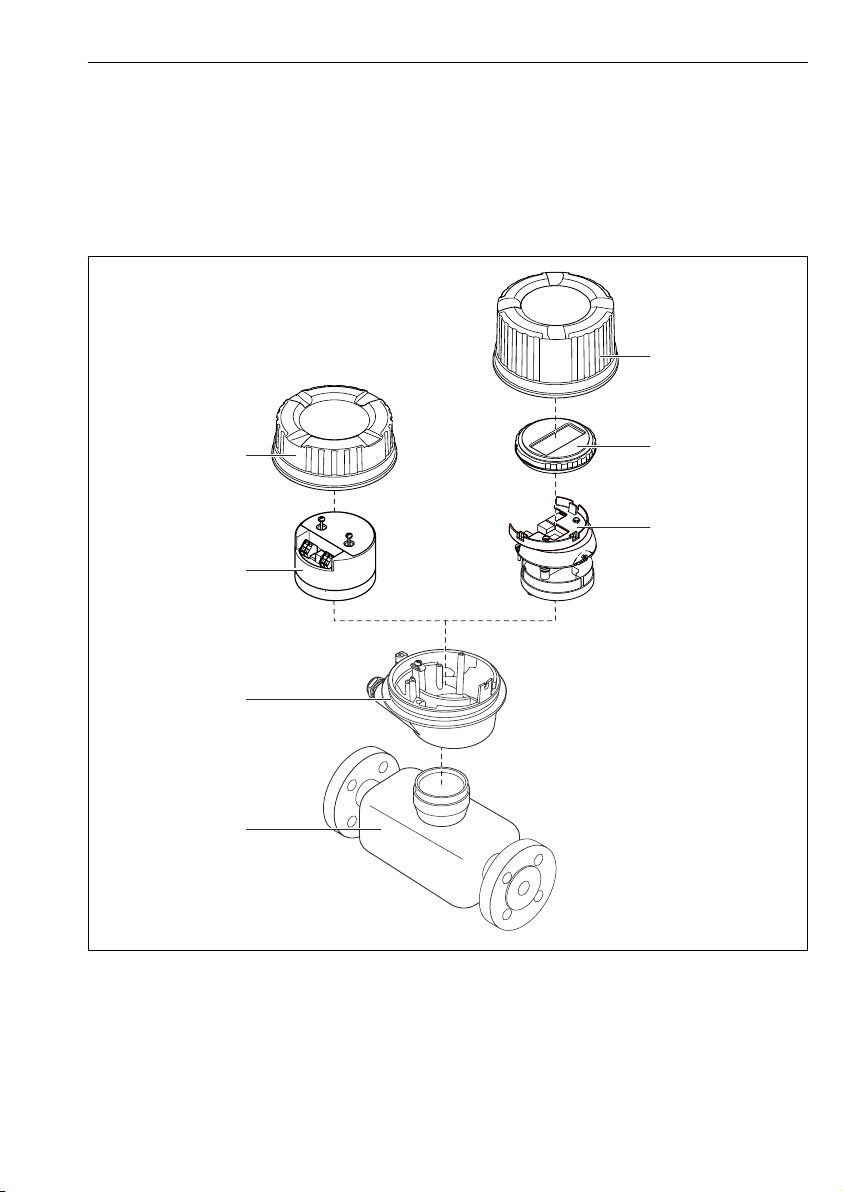

3 Product description

3.1 Product design

3.1.1 Device version with HART, EtherNet/IP and PROFIBUS DP communication types

1 Important components of a measuring device

1 Sensor

2 Transmitter housing

3 Main electronics module

4 Transmitter housing cover

A0023153

Endress+Hauser 9

Page 10

Product description Proline Promag P 100

3

2

1

4

5 Transmitter housing cover (version for optional onsite display)

6 Onsite display (optional)

7 Main electronics module (with bracket for optional onsite display)

3.1.2 Device version with Modbus RS485 communication types

2 Important components of a measuring device

1 Sensor

2 Transmitter housing

3 Main electronics module

4 Transmitter housing cover

10 Endress+Hauser

A0017609

Page 11

Proline Promag P 100 Incoming acceptance and product identification

1

+

2

1

+

2

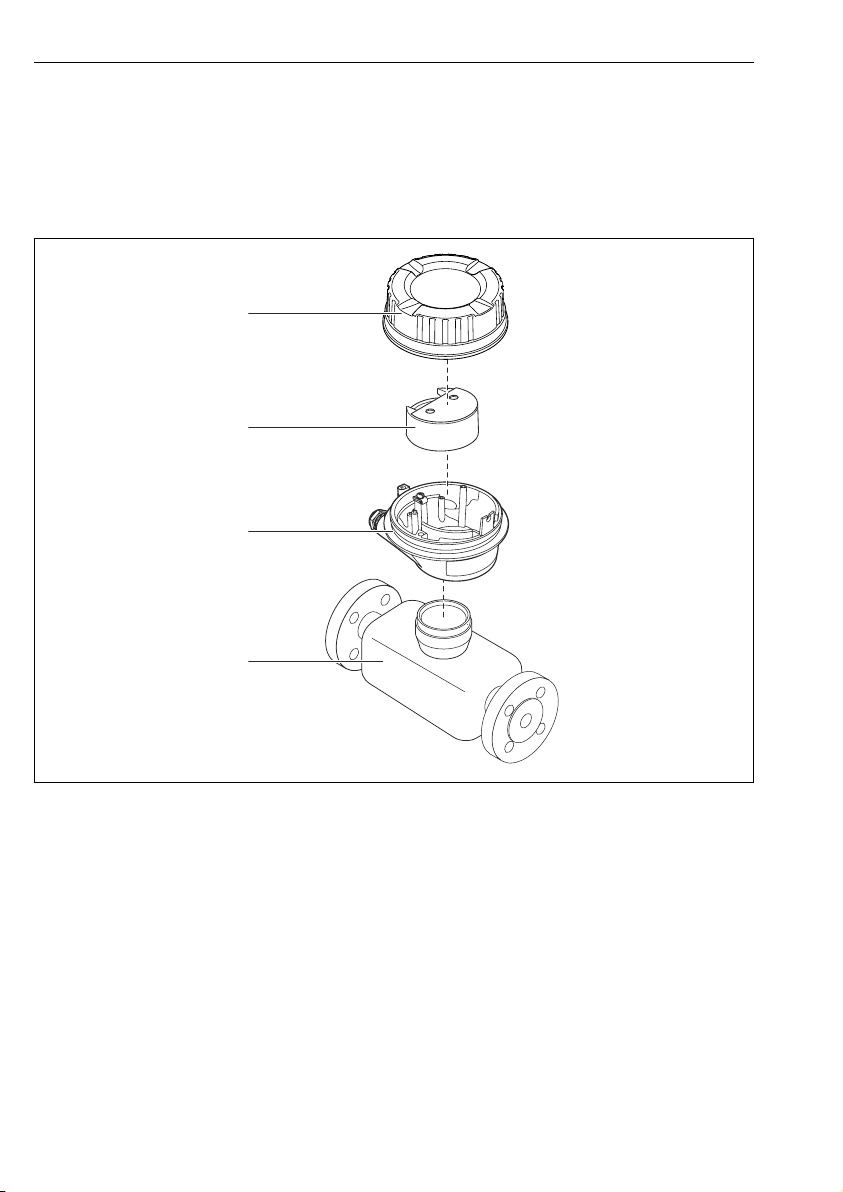

4 Incoming acceptance and product identification

4.1 Incoming acceptance

Are the order codes on the

delivery note (1) and the

product sticker (2) identical?

Are the goods undamaged?

Do the nameplate data match

the ordering information on

the delivery note?

Is the CD-ROM with the

Technical Documentation

(depends on device version)

and documents present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery! The

Technical Documentation is available via the Internet or via the Endress+Hauser

Operations App.

Endress+Hauser 11

Page 12

Storage and transport Proline Promag P 100

Order code:

Ext. ord. cd.:

Ser. no.:

Order code:

Ext. ord. cd.:

Ser. no.:

1

2

3

4

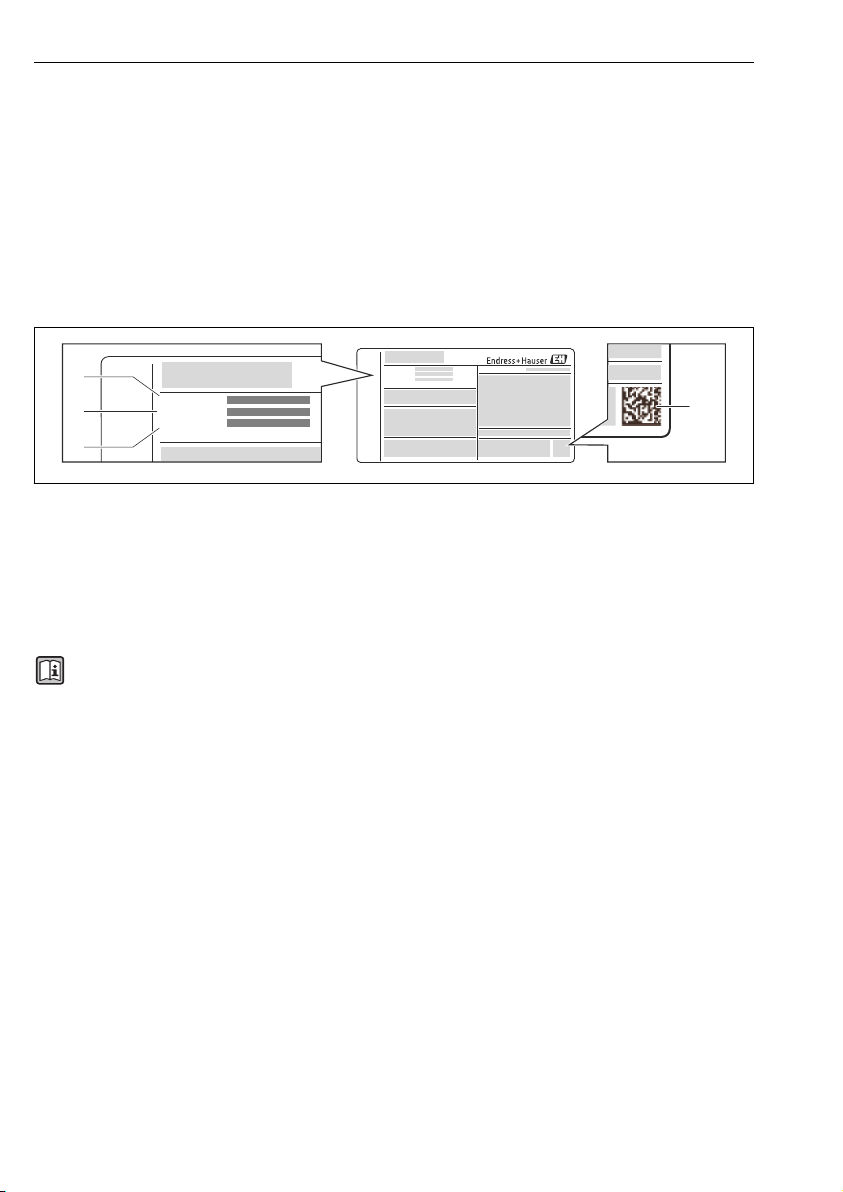

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser Operations

App: all the information for the measuring device is displayed.

A0021952

3 Example of a nameplate

1 Order code

2 Serial number (Ser. no.)

3 Extended order code (Ext. ord. cd.)

4 2-D matrix code (QR code)

For detailed information on the breakdown of the specifications on the nameplate, see

the Operating Instructions for the device .

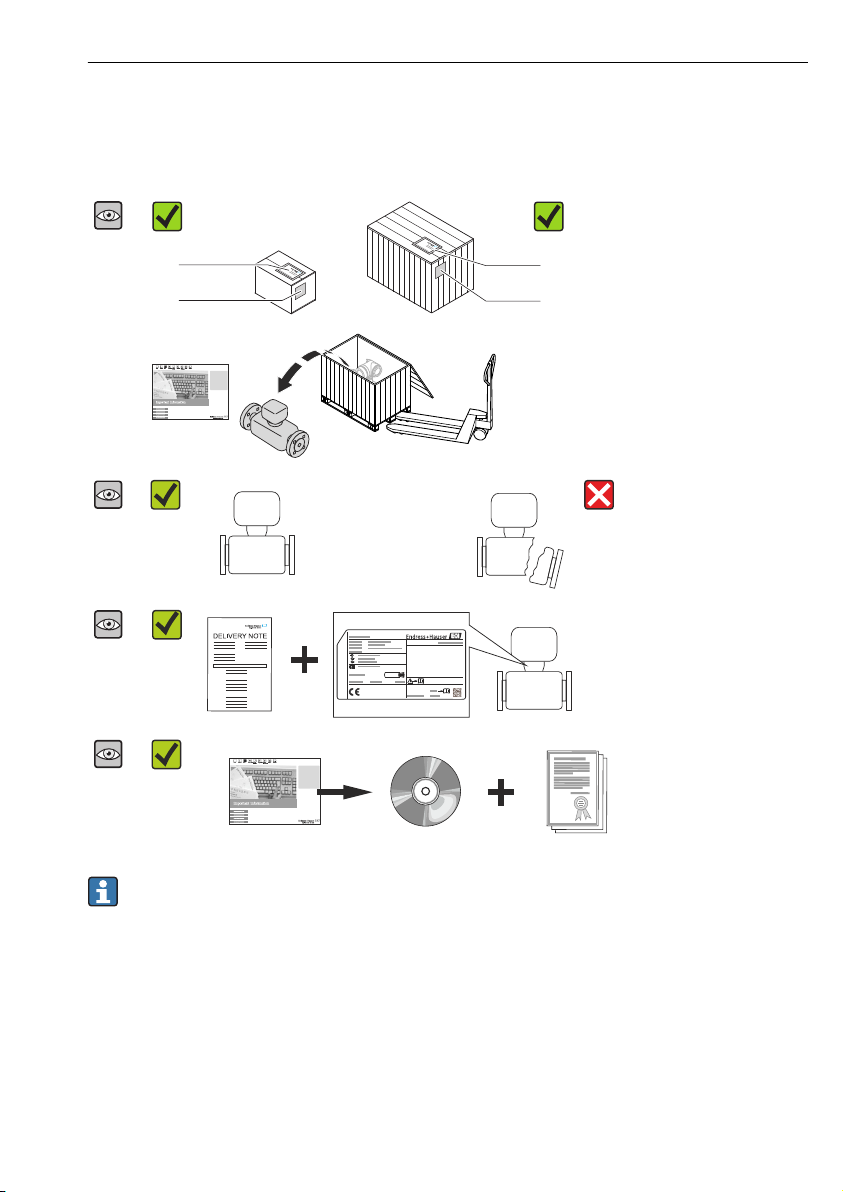

5 Storage and transport

5.1 Storage conditions

Observe the following notes for storage:

• Store in original packaging.

• Do not remove protective covers or protective caps installed on process connections.

• Protect from direct sunlight.

• Select a storage location where moisture cannot collect in the measuring device.

• Store in a dry and dust-free place.

• Do not store outdoors.

• Storage temperature→ 14

12 Endress+Hauser

Page 13

Proline Promag P 100 Storage and transport

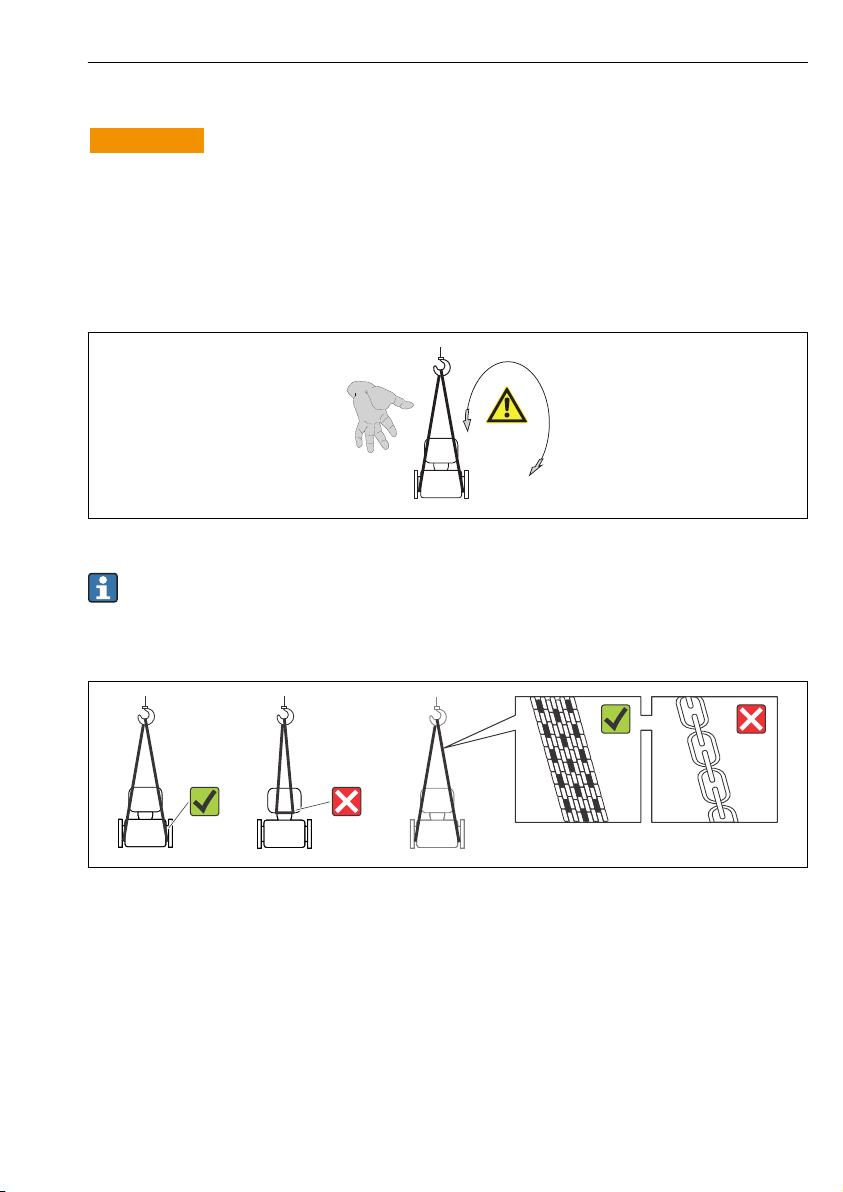

5.2 Transporting the product

WARNING

L

Center of gravity of the measuring device is higher than the suspension points of the

webbing slings.

Risk of injury if the measuring device slips.

Secure the measuring device from rotating or slipping.

‣

Observe the weight specified on the packaging (stick-on label).

‣

Observe the transport instructions on the stick-on label on the electronics compartment

‣

cover.

A0015606

• Transport the measuring device to the measuring point in the original packaging.

• Do not remove protective covers or protective caps installed on process connections.

They prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

A0015604

Endress+Hauser 13

Page 14

Mounting Proline Promag P 100

h

h

2

1

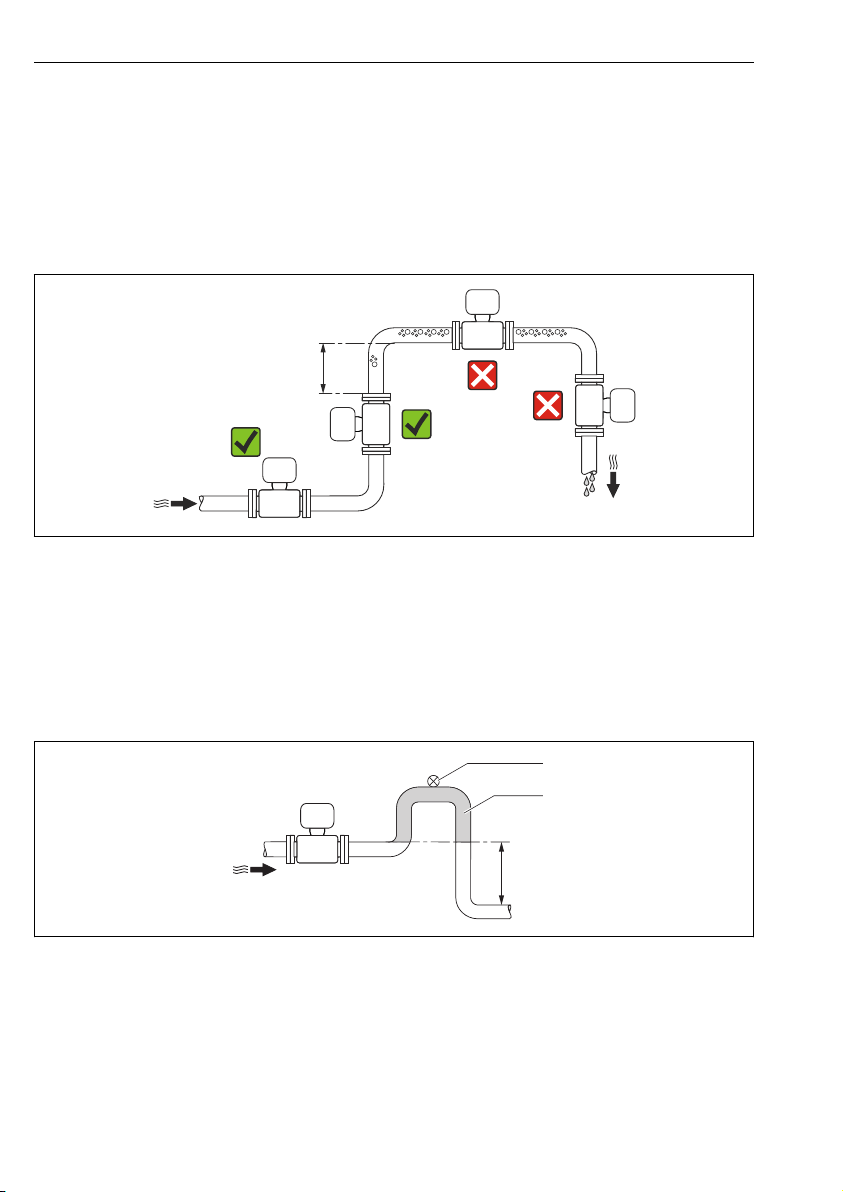

6 Mounting

6.1 Installation conditions

6.1.1 Mounting position

Mounting location

A0023343

h ≥ 2 × DN

Installation in down pipes

Install a siphon with a vent valve downstream of the sensor in down pipes whose length h ≥

5 m (16.4 ft). This precaution is to avoid low pressure and the consequent risk of damage to

the measuring tube. This measure also prevents the system losing prime.

A0017064

4 Installation in a down pipe

1 Vent valve

2 Pipe siphon

h Length of down pipe

14 Endress+Hauser

Page 15

Proline Promag P 100 Mounting

³ 5 × DN

³ 2 × DN

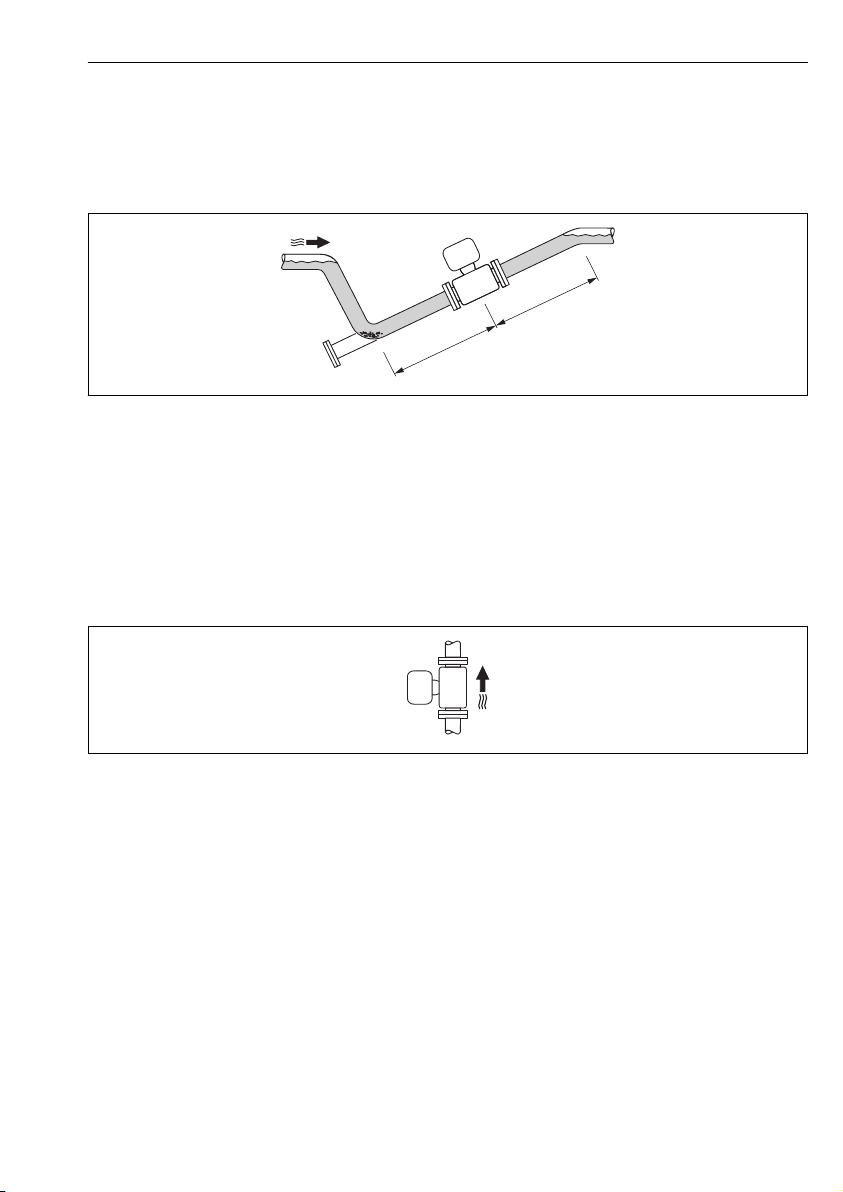

Installation in partially filled pipes

A partially filled pipe with a gradient necessitates a drain-type configuration. The empty pipe

detection (EPD) function offers additional protection by detecting empty or partially filled

pipes.

A0017063

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor according

to the flow direction.

An optimum orientation position helps avoid gas and air accumulations and deposits in the

measuring tube.

Vertical

A0015591

This is the optimum for self-emptying piping systems and for use in conjunction with empty

pipe detection.

Endress+Hauser 15

Page 16

Mounting Proline Promag P 100

1

2

3

2

5 × DN≥

2 × DN≥

Horizontal

A0016260

1 EPD electrode for empty pipe detection

2 Measuring electrodes for signal detection

3 Reference electrode for potential equalization

• The measuring electrode plane must be horizontal. This prevents brief insulation of

the two measuring electrodes by entrained air bubbles.

• The empty pipe detection only works if the transmitter housing is pointing upwards as

otherwise there is no guarantee that the empty pipe detection function will actually

respond to a partially filled or empty measuring tube.

Inlet and outlet runs

For the dimensions and installation lengths of the device, see the "Technical Information"

document, "Mechanical construction" section

6.1.2 Requirements from environment and process

Ambient temperature range

For detailed information on the ambient temperature range, see the Operating

Instructions for the device (Verweisziel existiert nicht, aber @y.link.required='true')

If operating outdoors:

• Install the measuring device in a shady location.

• Avoid direct sunlight, particularly in warm climatic regions.

• Avoid direct exposure to weather conditions.

16 Endress+Hauser

A0016275

Page 17

Proline Promag P 100 Mounting

L

Temperature tables

SI units

T

a

[°C]

30 50 95 130 150 150 150

50 – 95 130 150 150 150

60 – 95 110 110 110 110

T6

[85 °C]

T5

[100 °C]

T4

[135 °C]

T3

[200 °C]

T2

[300 °C]

T1

[450 °C]

US units

T

a

[°F]

86 122 203 266 302 302 302

122 – 203 266 302 302 302

140 – 203 230 230 230 230

T6

[185 °F]

T5

[212 °F]

T4

[275 °F]

T3

[392 °F]

T2

[572 °F]

T1

[842 °F]

System pressure

A0015594

Furthermore, install pulse dampers if reciprocating, diaphragm or peristaltic pumps are

used.

Vibrations

A0016266

5 Measures to avoid device vibrations (L > 10 m (33 ft))

Endress+Hauser 17

Page 18

Mounting Proline Promag P 100

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

Adapters

A0016359

6.2 Mounting the measuring device

6.2.1 Required tools

For sensor

For flanges and other process connections:

• Screws, nuts, seals etc. are not included in the scope of supply and must be provided by the

customer.

• Appropriate mounting tools

6.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove any protective covers or protective caps present from the sensor.

3. Remove stick-on label on the electronics compartment cover.

18 Endress+Hauser

Page 19

Proline Promag P 100 Mounting

6.2.3 Mounting the sensor

WARNING

L

Danger due to improper process sealing!

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

‣

process connections and piping.

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

‣

1. Ensure that the direction of the arrow on the sensor matches the flow direction of the

medium.

2. To ensure compliance with device specifications, install the measuring device between

the pipe flanges in a way that it is centered in the measurement section.

3. If using ground disks, comply with the Installation Instructions provided.

4. Observe required screw tightening torques → 19.

5. Install the measuring device or turn the transmitter housing so that the cable entries do

not point upwards.

A0013964

Mounting the seals

CAUTION

L

An electrically conductive layer could form on the inside of the measuring tube!

Risk of measuring signal short circuit.

Do not use electrically conductive sealing compounds such as graphite.

‣

Comply with the following instructions when installing seals:

• When mounting the process connections, make sure that the seals concerned are clean and

centered correctly.

• For DIN flanges: only use seals according to DIN EN 1514-1.

• For "PFA" lining: additional seals are always required.

• For "PTFE" lining: generally additional seals are not required.

Mounting the ground cable/ground disks

Comply with the information on potential equalization and detailed mounting instructions for

the use of ground cables/ground disks → 31.

Screw tightening torques

For detailed information on the screw tightening torques, see the "Mounting the sensor"

section of the Operating Instructions for the device

Endress+Hauser 19

Page 20

Mounting Proline Promag P 100

1.

2.

3.

4.

5.

6.

7.

4.

4.

3 mm

6.2.4 Turning the display module

The display module can be turned to optimize display readability.

Aluminum housing version, AlSi10Mg, coated

6.3 Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure (refer to the section on "Pressure-temperature ratings" in the "Technical Information"

document on the CD-ROM provided)

• Ambient temperature

• Measuring range

Has the correct orientation for the sensor been selected ?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the direction of flow of the fluid through the piping ?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Have the fixing screws been tightened with the correct tightening torque?

20 Endress+Hauser

A0023192

Page 21

Proline Promag P 100 Electrical connection

7 Electrical connection

The measuring device does not have an internal circuit breaker. For this reason, assign

the measuring device a switch or power-circuit breaker so that the power supply line can

be easily disconnected from the mains.

7.1 Connection conditions

7.1.1 Required tools

• For cable entries: Use corresponding tools

• For securing clamp (on aluminum housing): Allen screw3 mm

• For securing screw (for stainless steel housing): open-ended wrench 8 mm

• Wire stripper

• When using stranded cables: crimping tool for ferrule

7.1.2 Requirements for connecting cable

The connecting cables provided by the customer must fulfill the following requirements.

Electrical safety

In accordance with applicable federal/national regulations.

Permitted temperature range

• –40 °C (–40 °F) to +80 °C (+176 °F)

• Minimum requirement: cable temperature range ≥ ambient temperature +20 K

Power supply cable

Standard installation cable is sufficient.

Signal cable

Current output

For 4-20 mA HART: Shielded cable recommended. Observe grounding concept of the plant.

Pulse/frequency/switch output

Standard installation cable is sufficient.

PROFIBUS DP

The IEC 61158 standard specifies two types of cable (A and B) for the bus line which can be

used for every transmission rate. Cable type A is recommended.

Cable type A

Characteristic impedance 135 to 165 Ωat a measuring frequency of 3 to 20 MHz

Cable capacitance <30 pF/m

Wire cross-section

Cable type Twisted pairs

Endress+Hauser 21

>0.34 mm2 (22 AWG)

Page 22

Electrical connection Proline Promag P 100

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shielding Copper braided shielding or braided shielding with foil shield. When grounding the

cable shield, observe the grounding concept of the plant.

Modbus RS485

The EIA/TIA-485 standard specifies two types of cable (A and B) for the bus line which can be

used for every transmission rate. Cable type A is recommended.

Cable type A

Characteristic impedance 135 to 165 Ωat a measuring frequency of 3 to 20 MHz

Cable capacitance <30 pF/m

Wire cross-section

Cable type Twisted pairs

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shielding Copper braided shielding or braided shielding with foil shield. When grounding the

>0.34 mm2 (22 AWG)

cable shield, observe the grounding concept of the plant.

EtherNet/IP

The standard ANSI/TIA/EIA-568-B.2 Annex specifies CAT 5 as the minimum category for a

cable used for EtherNet/IP. CAT 5e and CAT 6 are recommended.

For more information on planning and installing EtherNet/IP networks, please refer to

the "Media Planning and Installation Manual. EtherNet/IP" of the ODVA Organization.

Cable diameter

• Cable glands supplied:

M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• Spring terminals:

Wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

22 Endress+Hauser

Page 23

Proline Promag P 100 Electrical connection

L

L

26

27

+

_

24

25

1

2

+

_

+

_

1

2

3

7.1.3 Terminal assignment

Transmitter

Connection version 4-20 mA HART with pulse/frequency/switch output

Order code for "Output", option B

Depending on the housing version, the transmitters can be ordered with terminals or device

plugs.

A0016888

6 Terminal assignment 4-20 mA HART with pulse/frequency/switch output

1 Power supply: DC 24 V

2 Output 1: 4-20 mA HART (active)

3 Output 2: pulse/frequency/switch output (passive)

Terminal number

Order code for

"Output"

Option B DC 24 V 4-20 mA HART (active) Pulse/frequency/switch

Order code for "Output":

Option B: 4-20 mA HART with pulse/frequency/switch output

Endress+Hauser 23

Power supply Output 1 Output 2

2 (L-) 1 (L+) 27 (–) 26 (+) 25 (–) 24 (+)

output (passive)

Page 24

Electrical connection Proline Promag P 100

L

L

26

27BA

1

2

+

_

1

2

PROFIBUS DP connection version

For use in the non-hazardous area and Zone 2/Div. 2.

Order code for "Output", option L

Depending on the housing version, the transmitters can be ordered with terminals or device

plugs.

A0022716

7 PROFIBUS DP terminal assignment

1 Power supply: DC 24 V

2 PROFIBUS DP

Terminal number

Order code for

"Output"

Option L DC 24 V B A

Order code for "Output":

Option L: PROFIBUS DP, for use in non-hazardous areas and Zone 2/div. 2

24 Endress+Hauser

Power supply Output

2 (L-) 1 (L+) 26 (RxD/TxD-P) 27 (RxD/TxD-N)

Page 25

Proline Promag P 100 Electrical connection

L

L

26

27AB

1

2

+

_

1

2

Modbus RS485 connection version

Order code for "Output", option M

Depending on the housing version, the transmitters can be ordered with terminals or device

plugs.

A0019528

8 Modbus RS485 terminal assignment

1 Power supply: DC 24 V

2 Modbus RS485

Terminal number

Order code for

"Output"

Option M DC 24 V Modbus RS485

Order code for "Output":

Option M: Modbus RS485

Power supply Output

2 (L-) 1 (L+) 27 (B) 26 (A)

Endress+Hauser 25

Page 26

Electrical connection Proline Promag P 100

L

L

1

2

+

_

1

2

1

2

4

3

5

EtherNet/IP connection version

Order code for "Output", option N

Depending on the housing version, the transmitters can be ordered with terminals or device

plugs.

A0017054

9 EtherNet/IP terminal assignment

1 Power supply: DC 24 V

2 EtherNet/IP

Terminal number

Order code for

"Output"

Option N DC 24 V EtherNet/IP

Order code for "Output":

Option N: EtherNet/IP

Power supply Output

2 (L-) 1 (L+) Device plug M12x1

7.1.4 Pin assignment, device plug

Supply voltage

For all connection versions (device side)

Pin Assignment Coding Plug/socket

1 L+ DC 24 V A Plug

2

3

4 L- DC 24 V

5 Grounding/shielding

A0016809

26 Endress+Hauser

Page 27

Proline Promag P 100 Electrical connection

3

2

4

1

5

3

2

4

1

5

3

2

4

1

5

4-20 mA HART with pulse/frequency/switch output

Device plug for signal transmission (device side)

Pin Assignment Coding Plug/socket

1 + 4-20 mA HART (active) A Socket

2 - 4-20 mA HART (active)

3 + Pulse/frequency/switch output (passive)

4 - Pulse/frequency/switch output (passive)

5 Grounding/shielding

A0016810

PROFIBUS DP

For use in the non-hazardous area and Zone 2/Div. 2.

Device plug for signal transmission (device side)

Pin Assignment Coding Plug/socket

1 B Socket

2 A PROFIBUS DP

3

4 B PROFIBUS DP

5 Grounding/shielding

A0016811

MODBUS RS485

Device plug for signal transmission (device side)

Pin Assignment Coding Plug/socket

1 B Socket

2 A Modbus RS485

3

4 B Modbus RS485

5 Grounding/shielding

A0016811

Endress+Hauser 27

Page 28

Electrical connection Proline Promag P 100

3

2

4

1

EtherNet/IP

Device plug for signal transmission (device side)

Pin Assignment Coding Plug/socket

1 + Tx D Socket

2 + Rx

3 - Tx

4 - Rx

A0016812

7.1.5 Shielding and grounding

The shielding and grounding concept requires compliance with the following:

• Electromagnetic compatibility (EMC)

• Explosion protection

• Personal protection equipment

• National installation regulations and guidelines

• Observe cable specification → 21.

• Keep the stripped and twisted lengths of cable shield to the ground terminal as short as

possible.

• Seamless cable shielding.

Grounding of the cable shield

To comply with EMC requirements:

• Ensure the cable shield is grounded to the potential matching line at multiple points.

• Connect every local ground terminal to the potential matching line.

NOTICE

In systems without potential matching, the multiple grounding of the cable shield causes

mains frequency equalizing currents!

Damage to the bus cable shield.

Only ground the bus cable shield to either the local ground or the protective ground at one

‣

end.

7.1.6 Preparing the measuring device

1. Remove dummy plug if present.

2.

NOTICE

Insufficient sealing of the housing!

Operational reliability of the measuring device could be compromised.

Use suitable cable glands corresponding to the degree of protection.

‣

If measuring device is delivered without cable glands:

Provide suitable cable gland for corresponding connecting cable → 21.

3. If measuring device is delivered with cable glands:

Observe cable specification → 21.

28 Endress+Hauser

Page 29

Proline Promag P 100 Electrical connection

1 2

A

7.2 Connecting the measuring device

NOTICE

Limitation of electrical safety due to incorrect connection!

For use in potentially explosive atmospheres, observe the information in the device-specific

‣

Ex documentation.

7.2.1 Connecting the transmitter

The connection of the transmitter depends on the following order codes:

• Housing version: compact or ultra-compact

• Connection version: device plug or terminals

A0019824

10 Device versions and connection versions

A Housing version: compact, aluminum coated

1 Cable entry or device plug for signal transmission

2 Cable entry or device plug for supply voltage

Endress+Hauser 29

Page 30

Electrical connection Proline Promag P 100

10 (0.4)

mm (in)

1 2

3

3 mm

A0019823

11 Device versions with connection examples

1 Cable

2 Device plug for signal transmission

3 Device plug for supply voltage

Depending on the housing version disconnect the local display from the main electronics

module: Operating Instructions for the device .

Connect the cable in accordance with the terminal assignment or the device plug pin

‣

assignment .

30 Endress+Hauser

Page 31

Proline Promag P 100 Electrical connection

DN 300≤ DN 350≥

7.2.2 Ensuring potential equalization

CAUTION

L

Electrode damage can result in the complete failure of the device!

Make sure that the fluid and sensor have the same electrical potential.

‣

Pay attention to internal grounding concepts in the company.

‣

Pay attention to the pipe material or grounding.

‣

Connection examples for standard situations

Metal, grounded pipe

A0016315

12 Potential equalization via measuring tube

Connection example in special situations

Unlined and ungrounded metal pipe

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable

13 Potential equalization via ground terminal and pipe flanges

Endress+Hauser 31

Copper wire, at least6 mm2 (0.0093 in2)

A0016317

Page 32

Electrical connection Proline Promag P 100

+

–

Plastic pipe or pipe with insulating liner

This connection method also applies in situations where:

• The customary potential equalization is not used

• Equalizing currents are present

Ground cable

Copper wire, at least6 mm2 (0.0093 in2)

14 Potential equalization via ground terminal and ground disks

Pipe with a cathodic protection unit

This connection method is only used if the following two conditions are met:

• Metal pipe without liner or pipe with electrically conductive liner

• Cathodic protection is integrated in the personal protection equipment

Ground cable

Copper wire, at least6 mm2 (0.0093 in2)

A0016318

A0016319

Prerequisite: The sensor is installed in the pipe in a way that provides electrical insulation.

1. Connect the two flanges of the pipe to one another via a ground cable.

2. Guide the shield of the signal lines through a capacitor.

3. Connect the measuring device to the power supply such that it is floating in relation to

the protective ground (isolation transformer).

32 Endress+Hauser

Page 33

Proline Promag P 100 Electrical connection

OFF ON

1

2

3

4

5

6

7

8

9

10

1

2

4

8

16

32

64

128

- Write protection

- Default Ethernet

network settings

IP 192.168.1.212

IP Address setting

(last octet)

7.3 Hardware settings

7.3.1 Setting the device address

EtherNet/IP

The IP address of the measuring device can be configured for the network via DIP switches.

Addressing data

IP address and configuration options

1st octet 2nd octet 3rd octet 4th octet

192. 168. 1. XXX

↓ ↓

Can only be configured via software addressing Can be configured via

IP address range 1 to 254 (4th octet)

IP address broadcast 255

Addressing mode ex works Software addressing; all DIP switches for hardware addressing are set to OFF.

IP address ex works DHCP server active

software addressing

and hardware

addressing

For device addressing via software → 43

Setting the address

Endress+Hauser 33

A0017913

Page 34

Electrical connection Proline Promag P 100

OFF ON

1

2

3

4

5

6

7

8

9

10

1

2

4

8

16

32

64

- Write protection

- Not used

PROFIBUS

address

- Software addressing

Set the desired IP address using the corresponding DIP switches on the I/O electronics

‣

module.

Hardware addressing with the configured IP address is enabled after 10 s.

PROFIBUS DP

The address must always be configured for a PROFIBUS DP/PA device. The valid address

range is between 1 and 126. In a PROFIBUS DP/PA network, each address can only be

assigned once. If an address is not configured correctly, the device is not recognized by the

master. All measuring devices are delivered from the factory with the device address 126 and

with the software addressing method.

Setting the address

A0021265

15 Addressing using DIP switches on the I/O electronics module

1. Disable software addressing via DIP switch 8 (OFF).

2. Set the desired device address via the corresponding DIP switches.

Example → 15, 34: 1 + 16 + 32 = device address 49

The device demands rebooting after 10 s. After rebooting, hardware addressing is

enabled with the configured IP address.

7.3.2 Enabling the terminating resistor

PROFIBUS DP

To avoid incorrect communication transmission caused by impedance mismatch, terminate

the PROFIBUS DP cable correctly at the start and end of the bus segment.

34 Endress+Hauser

Page 35

Proline Promag P 100 Electrical connection

390 Ω

DIP 1

5V

26

27

220 Ω

DIP 2

0V

390 Ω

DIP 3

OFF ON

1

2

3

4

Bus polarisation

Bus termination

Bus polarisation

Not used

4.

1.

2.

3.

• If the device is operated with a baud rate of 1.5 MBaud and under:

For the last transmitter on the bus, terminate via DIP switch 2 (bus termination) and DIP

switch 1 and 3 (bus polarization). Setting: ON – ON – ON → 16, 35.

• For baud rates > 1.5 MBaud:

Due to the capacitance load of the user and the line reflections generated as a result, ensure

that an external bus terminator is used.

It is generally advisable to use an external bus terminator as the entire segment can fail

if a device that is terminated internally is defective.

A0021274

16 Termination using DIP switches on the I/O electronics module (for baud rates < 1.5 MBaud)

Modbus RS485

To avoid incorrect communication transmission caused by impedance mismatch, terminate

the Modbus RS485 cable correctly at the start and end of the bus segment.

Endress+Hauser 35

Page 36

Electrical connection Proline Promag P 100

2 - Not used

1 - Write protection

4 - Bus termination

3 - Not used

OFFON

26

27AB

220 W

If the transmitter is used in the non-hazardous area or Zone 2/Div. 2

A0017610

17 Terminating resistor can be enabled via DIP switch on the main electronics module

7.4 Ensuring the degree of protection

The measuring device fulfills all the requirements for the IP66/67 degree of protection, Type

4X enclosure.

To guarantee IP66/67 degree of protection, Type 4X enclosure, carry out the following steps

after the electrical connection:

1. Check that the housing seals are clean and fitted correctly. Dry, clean or replace the

seals if necessary.

2. Tighten all housing screws and screw covers.

3. Firmly tighten the cable glands.

4. To ensure that moisture does not enter the cable entry, route the cable so that it loops

down before the cable entry ("water trap").

A0013960

5. Insert dummy plugs into unused cable entries.

36 Endress+Hauser

Page 37

Proline Promag P 100 Electrical connection

7.5 Post-connection check

Are cables or the device undamaged (visual inspection)?

Do the cables comply with the requirements → 21?

Do the cables have adequate strain relief?

Are all the cable glands installed, firmly tightened and leak-tight? Cable run with "water trap" → 36 ?

Depending on the device version: are all the device plugs firmly tightened → 29?

• Does the supply voltage match the specifications on the transmitter nameplate ?

• For device version with Modbus RS485 intrinsically safe: does the supply voltage match the

specifications on the nameplate of the Safety Barrier Promass 100 ?

Is the terminal assignment or the pin assignment of the device plug correct?

• If supply voltage is present, is the power LED on the electronics module of the transmitter lit green

→ 9?

• For device version with Modbus RS485 intrinsically safe, if supply voltage is present, is the power LED

on the Safety Barrier Promass 100 lit → 9?

Is the potential equalization established correctly → 31?

Depending on the device version, is the securing clamp or fixing screw firmly tightened?

Endress+Hauser 37

Page 38

Operation options Proline Promag P 100

!

Expert

Operating menu for experts

Language

Operation

Setup

Diagnostics

Operating menu for operators and maintenances

Operator

Maintenance

task-oriented

function-oriented

Expert

8 Operation options

8.1 Structure and function of the operating menu

8.1.1 Structure of the operating menu

18 Schematic structure of the operating menu

8.1.2 Operating philosophy

The individual parts of the operating menu are assigned to certain user roles. Each user role

corresponds to typical tasks within the device lifecycle.

For detailed information about the operating philosophy of the device, see the Operating

A0014058-EN

Instructions for the device (Verweisziel existiert nicht, aber @y.link.required='true').

8.2 Access to the operating menu via the Web browser

This type of access is available with the following device version:

Order code for "Output", option N: EtherNet/IP

38 Endress+Hauser

Page 39

Proline Promag P 100 Operation options

OFF ON

1

2

3

4

5

6

7

8

9

10

1

2

4

8

16

32

64

128

- Write protection

- Default Ethernet

network settings

IP 192.168.1.212

IP Address setting

(last octet)

8.2.1 Function range

Thanks to the integrated Web server the device can be operated and configured via a Web

browser.

8.2.2 Prerequisites

Hardware

Connecting cable Standard Ethernet cable with RJ45 connector

Computer RJ45 interface

Measuring device: Web server must be enabled; factory setting: ON

IP address If the IP address of the device is not known, communication with the Web server

can be established via the standard IP address 192.168.1.212.

The DHCP function is enabled in the device at the factory, i.e. the device expects

an IP address to be assigned by the network. This function can be disabled and

the device can be set to the standard IP address 192.168.1.212: set switch DIP

switch No. 10 from OFF → ON.

• Once the DIP switch has been activated, the device must be restarted

before the device uses the standard IP address.

• If the standard IP address (DIP switch No. 10 = ON) is used, there is no

connection to the EtherNet/IP network.

Software of the computer

Web browsers supported • Microsoft Internet Explorer (min. 8.x)

Recommended operating systems • Windows XP

Endress+Hauser 39

• Mozilla Firefox

• Google chrome

• Windows 7

A0017965

Page 40

Operation options Proline Promag P 100

User rights for TCP/IP settings User rights required for TCP/IP settings (e.g. for changes to IP address, subnet

Computer configuration • JavaScript is enabled

mask)

• If JavaScript cannot be enabled, enter http://XXX.XXX.X.XXX/basic.html in the

address line of the Web browser, e.g. http://192.168.1.212/basic.html. A

fully functional but simplified version of the operating menu structure starts

in the Web browser.

8.2.3 Establishing a connection

Configuring the Internet protocol of the computer

The following information refers to the default Ethernet settings of the device.

IP address of the device: 192.168.1.212 (factory setting)

IP address 192.168.1.XXX; for XXX all numerical values except: 0, 212 and 255 → e.g.

Subnet mask 255.255.255.0

Default gateway 192.168.1.212 or leave cells empty

192.168.1.213

1. Switch on the measuring device and connect to the computer via the cable .

2. If a 2nd network card is not used: all the applications on the notebook should be closed,

or all the applications that require the Internet or network, such as e-mail, SAP

applications, Internet or Windows Explorer, i.e. close all open Internet browsers.

3. Configure the properties of the Internet protocol (TCP/IP) as defined in the table above.

Starting the Web browser

1. Enter the IP address of the Web server in the address line of the Web browser:

192.168.1.212

2. If the IP address of the measuring device is known, enter the defined device address in

the address line of the Web browser. If it is unknown, set DIP switch No. 10 to ON,

restart the device and enter the standard IP address: 192.168.1.212 → 39.

The login page appears.

40 Endress+Hauser

Page 41

Proline Promag P 100 Operation options

Device tag

Webserv.language

English

Ent. access code

Access stat.tool Maintenance

12

OK

2 4

6

5

1 32 4

6

5

1 32 4

6

5

1 32 4

6

5

1 32 4

6

5

1 3

A0017362

1 Device tag → 44

2 Picture of device

8.2.4 Logging on

Access code 0000 (factory setting); can be changed by customer → 44

8.2.5 User interface

1

Picture of device

2

Function row with 6 functions

3

Device tag

4

Header

5

Working area

6

Navigation area

Endress+Hauser 41

A0017757-EN

Page 42

System integration Proline Promag P 100

Header

The following information appears in the header:

• Device tag → 44

• Device status with status signal

• Current measured values

Function row

Functions Meaning

Measured values The measured values of the device are displayed

Menu Access to the operating menu structure of the device, same as for the operating tool

Device status Displays the diagnostic messages currently pending, listed in order of priority

• Data exchange between PC and measuring device:

– Upload the configuration from the device (XML format, create configuration back-up)

– Save the configuration to the device (XML format, restore configuration)

Data management

Network

configuration

Logout End the operation and call up the login page

– Export the event list (.csv file)

– Export parameter settings (.csv file, create documentation of the measuring point

configuration)

– Export the Heartbeat verification log (PDF file, only available with the "Heartbeat

Verification" application package)

• Upload the device driver for system integration from the device

Configuration and checking of all the parameters required for establishing the connection to the

device:

• Network settings (e.g. IP address, MAC address)

• Device information (e.g. serial number, firmware version)

8.3 Access to the operating menu via the operating tool

For detailed information about access to the operating menu via operating tool, refer to

the Operating Instructions for the device (Verweisziel existiert nicht, aber

@y.link.required='true').

9 System integration

For information on system integration, see the Operating Instructions for the device

(Verweisziel existiert nicht, aber @y.link.required='true').

Applies only to device version with EtherNet/IP communication type

A detailed description of how to integrate the device into an automation system (e.g.

from Rockwell Automation) is available as a separate document: www.endress.com →

Select country → Automation → Digital Communication → Feldbus device

integration → EtherNet/IP

42 Endress+Hauser

Page 43

Proline Promag P 100 Commissioning

10 Commissioning

10.1 Function check

Before commissioning the device, make sure that the post-installation and post-connection

checks have been performed.

• "Post-installation check" checklist → 20

• "Post-connection check" checklist → 37

10.2 Establishing a connection via FieldCare

• For FieldCare connection → 42

• For establishing a connection via FieldCare

10.3 Configuring the device address via software

In the "Communication" submenu the device address can be set.

Navigation

"Setup" menu → Communication → Device address

10.3.1 Ethernet network and Web server

When delivered, the measuring device has the following factory settings:

IP address 192.168.1.212

Subnet mask 255.255.255.0

Default gateway 192.168.1.212

• If hardware addressing is active, software addressing is disabled.

• If a switch is made to hardware addressing, the address configured via software

addressing is retained for the first 9 places (the first three octets).

If the IP address of the device is not known, the device address currently configured can

be read out: Operating Instructions for the device

10.3.2 PROFIBUS network

At time of delivery, the measuring device has the following factory setting:

Device address 126

If hardware addressing is active, software addressing is blocked → 33

Endress+Hauser 43

Page 44

Commissioning Proline Promag P 100

10.4 Configuring the measuring device

The Setup menu with its submenus is used for fast commissioning of the measuring device.

The submenus contain all the parameters required for configuration, such as parameters for

measurement or communication.

Submenu Meaning

System units Configuring the units for all measured values

Medium selection Defining the medium

Communication Configuration of the digital communication interface

Low flow cut off Configuring the low flow cut off

10.5 Defining the tag name

To enable fast identification of the measuring point within the system, you can enter a unique

designation using the Device tag parameter and thus change the factory setting.

Navigation

"Setup" menu → Device tag

Parameter overview with brief description

Parameter Description User entry Factory setting

Device tag Enter the name for the

measuring point.

Max. 32 characters, such as

letters, numbers or special

characters (e.g. @, %, /).

Promag

10.6 Protecting settings from unauthorized access

The following options exist for protecting the configuration of the measuring device from

unintentional modification after commissioning:

• Write protection via access code for Web browser → 44

• Write protection via write protection switch → 45

10.6.1 Write protection via access code

With the customer-specific access code, access to the measuring device via the Web browser is

protected, as are the parameters for the measuring device configuration.

Navigation

"Setup" menu → Advanced setup → Administration → Define access code

Structure of the submenu

Define access code

44 Endress+Hauser

→

Define access code

Confirm access code

Page 45

Proline Promag P 100 Commissioning

ON OFF

1 = Write protection

2 = Not used

Defining the access code via the Web browser

1. Navigate to the Enter access code parameter.

2. Define a max. 4-digit numeric code as an access code.

3. Enter the access code again to confirm the code.

The Web browser switches to the login page.

If no action is performed for 10 minutes, the Web browser automatically returns to the

login page.

The user role with which the user is currently logged on via the Web browser is indicated

by the Access status tooling parameter. Navigation path: Operation → Access status

tooling

10.6.2 Write protection via write protection switch

The write protection switch makes it possible to block write access to the entire operating

menu with the exception of the following parameters:

• External pressure

• External temperature

• Reference density

• All parameters for configuring the totalizer

The parameter values are now read only and cannot be edited any more:

• Via service interface (CDI)

• Via HART protocol

• Via Modbus RS485

• Via service interface (CDI-RJ45)

• Via Ethernet network

• Via PROFIBUS DP

For device version with HART communication type

A0022571

For device version with Modbus RS485 communication type

Endress+Hauser 45

Page 46

Commissioning Proline Promag P 100

OFFON

1 - Write protection

2 - Not used

3 - Not used

4 - Bus termination

OFF ON

1

2

3

4

5

6

7

8

9

10

1

2

4

8

16

32

64

128

- Write protection

- Default Ethernet

network settings

IP 192.168.1.212

IP Address setting

(last octet)

A0017954

For device version with EtherNet/IP communication type

A0017915

For device version with PROFIBUS DP communication type

46 Endress+Hauser

Page 47

Proline Promag P 100 Diagnostic information

OFF ON

1

2

3

4

5

6

7

8

9

10

1

2

4

8

16

32

64

- Write protection

- Not used

PROFIBUS

address

- Software addressing

A0021262

Setting the write protection switch on the electronics module to the ON position enables

‣

the hardware write protection.

If hardware write protection is enabled, the Hardware locked option is displayed in

the Locking status parameter.

11 Diagnostic information

Any faults detected by the measuring device are displayed on the home page of the operating

tool once the connection has been established and on the home page of the web browser once

the user has logged on.

Remedial measures are provided for each diagnostic event to ensure that problems can be

rectified quickly.

• Web browser: Remedial measures are displayed in red on the home page next to the

diagnostic event.

• FieldCare: Remedial measures are displayed on the home page in a separate field below the

diagnostic event.

Endress+Hauser 47

Page 48

www.addresses.endress.com

Loading...

Loading...