Endress+Hauser Oxymax W COS71 Technical Information

Technical Information

Oxymax W COS71

Potentiostatic amperometric three-electrode sensor

Long-term stable sensor for trace measurement

Application

Continuous measurement of the dissolved oxygen

concentration plays an important role in monitoring boiler feed

water:

• Trace quantities

Oxygen may only be present in trace quantities. Excessive

concentrations of oxygen can result incorrosion damage in the

circuit.

• Thermal resp. chemical degassing

Boiler feed water is thermally and chemically degassed to

achieve oxygen-free water. This state must be maintained in

service under process conditions.

• Laboratory measurement vs. continuous process monitoring

Spot laboratory measurements to measure oxygen involve a

risk of error due to sampling errors. Continuous measurement

directly in the process eliminates this risk and provides

reliable information about the state of the medium at any

time.

Your benefits

• Maximum measurement accuracy:

– Longterm-stable measurement thanks to potentiostatic

amperometric three-electrode system

– Long maintenance intervals

– Intelligent sensor self monitoring

• Calibration to any transmitter or location and subsequent

installation at measuring point (in digital mode with Liquisys

M COM 223/253) as calibration data is stored in the sensor

• Membrane covered sensor, i.e.:

air

selectivity

2

– high O

– Minimum maintenance effort

– Minimum calibration effort thanks to simple calibration in

TI286C/07/en/02.07

51506697

Oxymax W COS71

Function and system design

Measuring principle The oxygen molecules diffused through the membrane are reduced to hydroxide ions (OH-) at the cathode.

Silver is oxidized to silver ions (Ag+) at the anode (this forms a silver halogenide layer).

A current flows due to the electron donation at the cathode and the electron acceptance at the anode. Under

constant conditions, this flow is proportional to the oxygen content of the medium.

This current is converted in the transmitter and indicated on the display as an oxygen concentration in mg/l,

as a saturation index in % SAT or as an oxygen partial pressure in hPa.

Potentiostatic amperometric three-electrode system

The high-impedance, current-free reference electrode plays an important role.

The formation of a silver bromide or silver chloride coating on the anode uses up the bromide or chloride ions

dissolved in the electrolyte

In the case of conventional membrane-covered sensors working with the two-electrode system, this causes an

increase in signal drift.

This is not the case with the three-electrode system:

The change in bromide or chloride concentration is registered by the reference electrode and an internal control

circuit holds the working electrode potential constant. The advantages of this principle are significantly

increased accuracy of the signal and considerably extended calibration intervals.

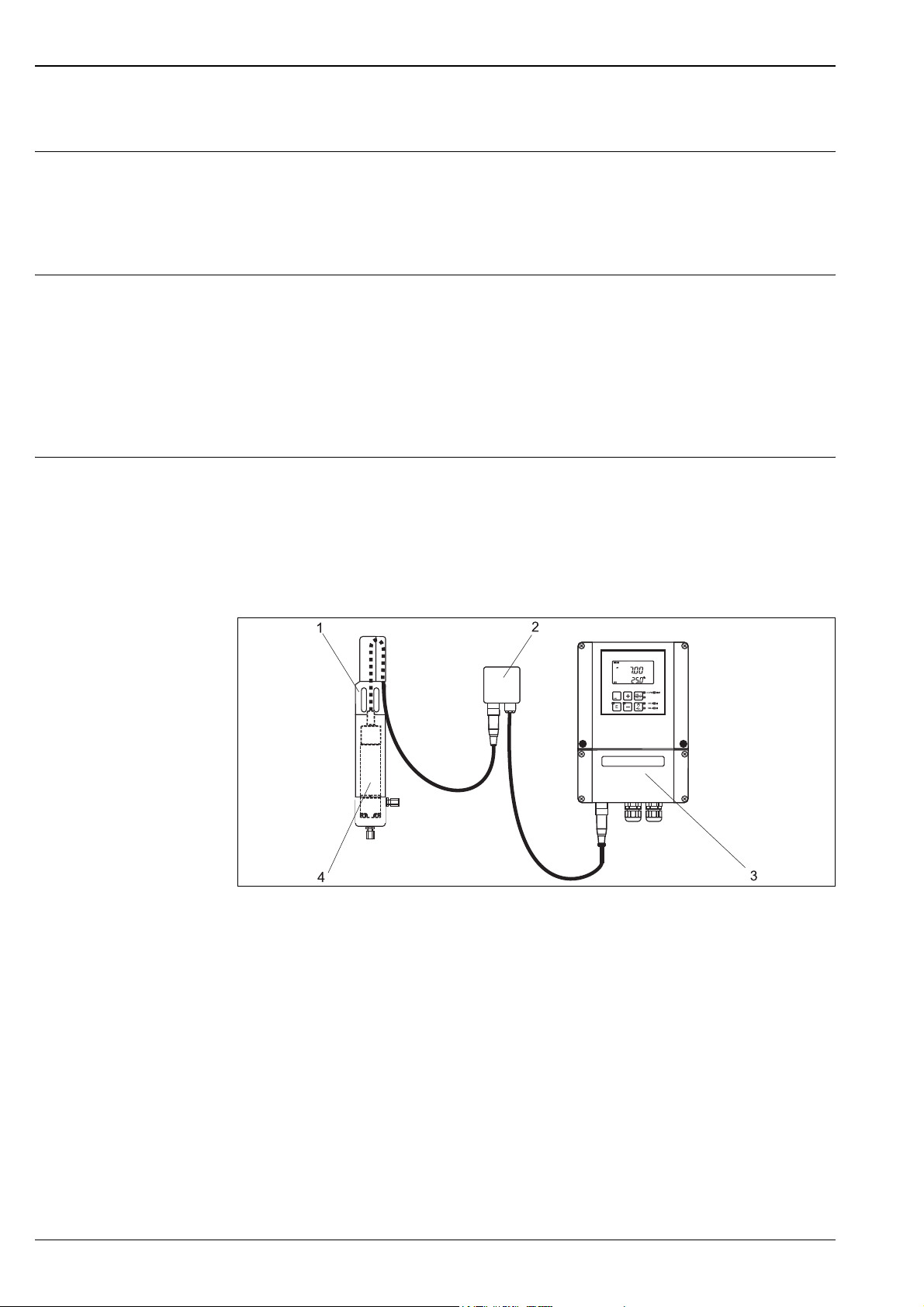

Measuring system A complete measuring system comprises at least:

• Oxygen sensor

• Transmitter, e.g. Liquisys M COM223/253-WX/WS

• Special measuring cable

• Assembly, e.g. flow assembly COA260 or retractable assembly COA451

Optional:

• Junction box VS (with cable extension)

Measuring system (example)

1 Flow assembly

2 Junction box VS (optional)

3 Transmitter Liquisys M COM253

4 Oxygen sensor

a0004102

2 Endress+Hauser

Oxymax W COS71

Input

Measured variable dissolved oxygen [mg/l, ppm, % SAT or hPa]

Measuring range with Liquisys M COM223/253-WX/WS:

0.001 to 20.000 mg/l

0.0 to 200.0 % SAT

0 to 400 hPa

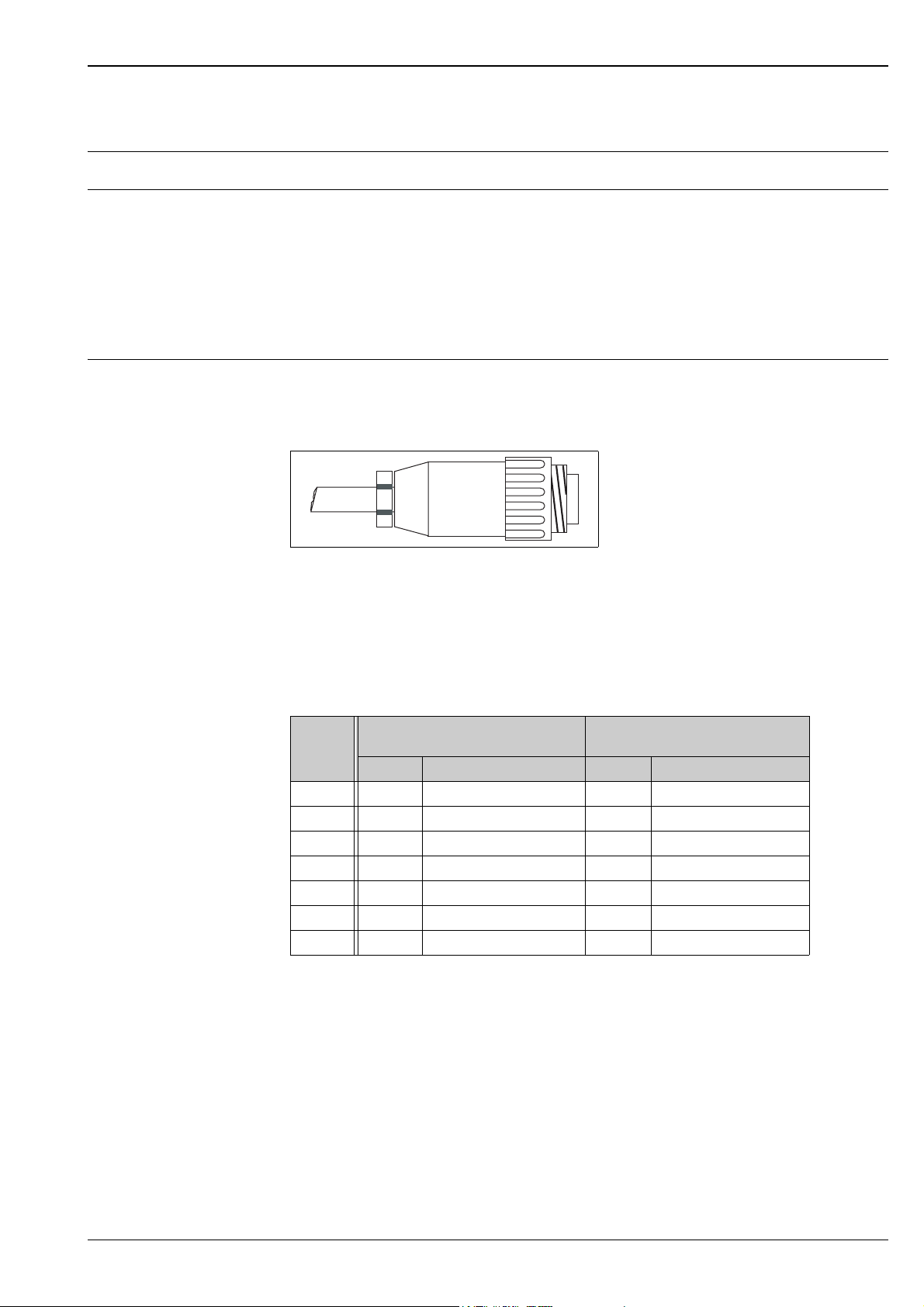

Wiring

Electrical connection Direct connection to the transmitter (field device)

Connect the sensor directly to the transmitter (COM253-WX/WS) by using the special measuring cable with

SXP plug.

SXP plug

a0004118

Direct connection to the transmitter (panel mounting device)

• Remove the SXP connector (transmitter side!) from the cable.

• Refer to the following table for the cable assignment and the assigned terminals for

Liquisys M COM223-WX/WS.

• Please note that the cable assignment changes depending on the sensor version (fixed cable or TOP68

connection).

Terminal

COM223

87 YE +U

0GY0V WH0V

96 PK NTC (analog) or Com. (digital) GN Communication (digital)

97 BU NTC (analog) or Com. (digital) BN Communication (digital)

88 BN –U

19 GN Alarm

18 WH Sensor signal

Sensor with fixed cable (OMK) Sensor with TOP68 connection

(CYK71)

Core Assignment Core Assignment

B

B

YE +U

Koax innen –U

B

B

Endress+Hauser 3

Loading...

Loading...