Endress+Hauser Deltapilot M FMB50, Deltapilot M FMB52, Deltapilot M FMB53, Deltapilot M FMB51, Cerabar M PMC51 Brief Operating Instructions

...Page 1

KA01035P/00/EN/05.16

71316893

Products Solutions Services

Brief Operating Instructions

Deltapilot M FMB50, FMB51,

FMB52, FMB53

Hydrostatic level measurement

These Instructions are Brief Operating Instructions; they are not

a substitute for the Operating Instructions pertaining to the

device.

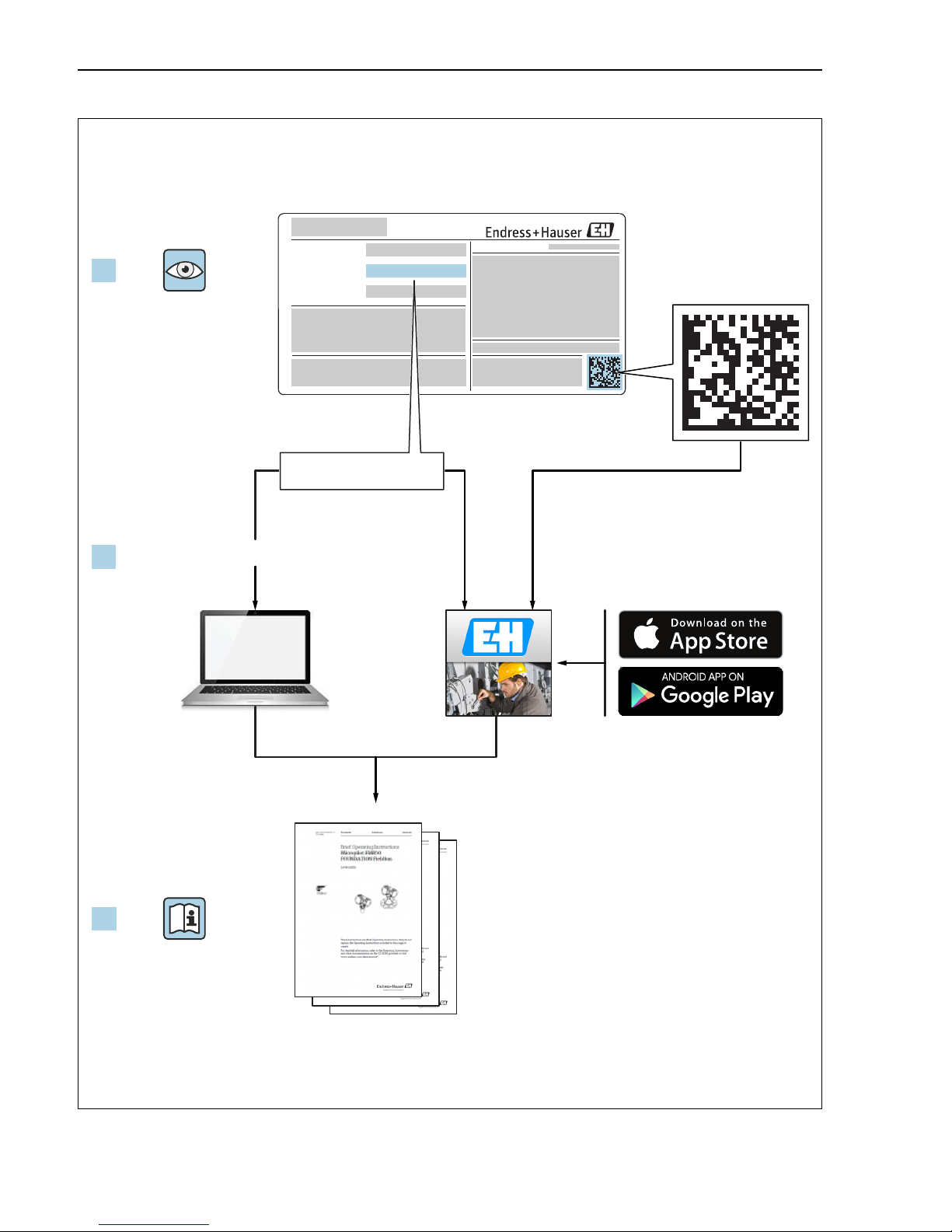

Detailed information about the device can be found in the Operating Instructions and the other documentation:

Available for all device versions via:

– Internet: www.endress.com/deviceviewer

– Smart phone/tablet: Endress+Hauser Operations App

Page 2

Deltapilot M FOUNDATION Fieldbus

1.

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer Endress+Hauser Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

2.

3.

2 Endress+Hauser

A0023555

Page 3

Deltapilot M FOUNDATION Fieldbus Table of contents

Table of contents

1 Document information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Basic safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Requirements concerning the staff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 CE mark, Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 General installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.6 Mounting of the profile seal for universal process mounting adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7 Closing the housing cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.8 Post-installation check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Connecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Connecting the measuring unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Overvoltage protection (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Operation without an operating menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Operation with an operating menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 FOUNDATION Fieldbus communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7 Commissioning without an operating menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 Position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Commissioning with an operating menu (onsite display/FieldCare) . . . . . . . . . . . . . . . . . .33

8.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Pos. zero adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.4 Level measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.5 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.6 Pressure measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Endress+Hauser 3

Page 4

Document information Deltapilot M FOUNDATION Fieldbus

DANGER

WARNING

CAUTION

NOTICE

)

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases of

the life cycle of the device: from product identification, incoming acceptance and storage, to

mounting, connection, operation and commissioning through to troubleshooting, maintenance

and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

A0011189-DE

seriousor fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

A0011190-DE

A0011191-DE

A0011192-DE

seriousor fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minoror medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personalinjury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

A grounded terminal which, as far as the

operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to

ground prior to establishing any other

connections.

4 Endress+Hauser

Equipotential connection

A connection that has to be connected to

the plant grounding system: This may be

a potential equalization line or a star

grounding system depending on

national or company codes of practice.

Page 5

Deltapilot M FOUNDATION Fieldbus Document information

1.

2.

1.2.3 Tool symbols

Symbol Meaning

Allen key

A0011221

Hexagon wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

A0015482

Reference to page

A0015484

Reference to graphic

A0015487

, , ... Series of steps

Result of a sequence of actions

A0018343

Visual inspection

A0015502

Endress+Hauser 5

Page 6

Basic safety instructions Deltapilot M FOUNDATION Fieldbus

1.

2.

t 85°C>

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3, 4, ... Item numbers

, , ... Series of steps

A, B, C, D, ... Views

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

A0019159

Connecting cable immunity to temperature change

Indicates that the connecting cables have to withstand a temperature of 85°C at least.

1.2.7 Registered trademarks

KALREZ®, VITON®, TEFLON

®

Registered label of E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered label of Ladish & Co., Inc., Kenosha, USA

FOUNDATIONTM Fieldbus

Registered trademark of the FieldComm Group, Austin, USA

GORE-TEX

®

Registered label of W.L. Gore & Associates, Inc., USA

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists: must have a relevant qualification for this specific function and

task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

6 Endress+Hauser

Page 7

Deltapilot M FOUNDATION Fieldbus Basic safety instructions

• Before beginning work, the specialist staff must have read and understood the instructions in

the Operating Instructions and supplementary documentation as well as in the certificates

(depending on the application)

• Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

• Being instructed and authorized according to the requirements of the task by the facility's

owner-operator

• Following the instructions in these Operating Instructions

2.2 Designated use

The Deltapilot M is a hydrostatic pressure sensor for measuring level and pressure.

2.2.1 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

verifying the corrosion resistance of fluid-wetted materials, but does not accept any warranty or

liability.

2.3 Workplace safety

For work on and with the device:

• Wear the required personal protective equipment according to federal/national regulations.

• Switch off the supply voltage before connecting the device.

2.4 Operational safety

Risk of injury!

‣ Operate the device in proper technical condition and fail-safe condition only.

‣ The operator is responsible for interference-free operation of the device.

‣ Only disassemble the device in pressurless condition!

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

‣ If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

‣ Carry out repairs on the device only if they are expressly permitted.

‣ Observe federal/national regulations pertaining to repair of an electrical device.

‣ Use original spare parts and accessories from Endress+Hauser only.

Endress+Hauser 7

Page 8

Identification Deltapilot M FOUNDATION Fieldbus

2.5 Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

• Based on the nameplate, check whether the ordered device is permitted for the intended use

in the hazardous area.

• Observe the specifications in the separate supplementary documentation that is an integral

part of these Instructions.

2.6 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the- art safety requirements, has been tested, and left the factory in a condition in

which they are safe to operate. It fulfills general safety requirements and legal requirements. It

also conforms to the EC directives listed in the device-specific EC declaration of conformity.

Endress+Hauser confirms this fact by applying the CE mark.

3 Identification

3.1 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer).

3.2 Scope of delivery

The scope of delivery comprises:

• Device

• Optional accessories

Documentation supplied:

• The Operating Instructions BA00384P is available on the Internet.

See: www.endress.com Download

• Brief Operating Instructions: KA01035P Deltapilot M

• Final inspection report

• Additional Safety Instructions for ATEX, IECEx and NEPSI devices

• Optional: factory calibration form, test certificates

8 Endress+Hauser

Page 9

Deltapilot M FOUNDATION Fieldbus Installation

WARNING

!

3.3 CE mark, Declaration of Conformity

The devices are designed to meet state-of-the-art safety requirements, have been tested and left

the factory in a condition in which they are safe to operate. The devices comply with the

applicable standards and regulations as listed in the EC Declaration of Conformity and thus

comply with the statutory requirements of the EC Directives. Endress+Hauser confirms the

conformity of the device by affixing to it the CE mark.

4 Installation

4.1 Incoming acceptance

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

4.2 Storage and transport

4.2.1 Storage

The device must be stored in a dry, clean area and protected against damage from impact (EN

837-2).

Storage temperature range:

See Technical Information for Deltapilot M TI00437P.

4.2.2 Transport

Incorrect transportation

Housing, diaphragm and capillaries may become damaged, and there is a risk of injury!

‣ Transport the measuring device to the measuring point in its original packaging or by the

process connection.

‣ Follow the safety instructions and transport conditions for devices weighing more than 18

kg (39.6 lbs).

‣ Do not use capillaries as a carrying aid for the diaphragm seals.

4.3 Installation conditions

4.3.1 Dimensions

For dimensions, please refer to the Technical Information for Deltapilot M TI00437P,

"Mechanical construction" section.

Endress+Hauser 9

Page 10

Installation Deltapilot M FOUNDATION Fieldbus

WARNING

!

WARNING

!

4.4 General installation instructions

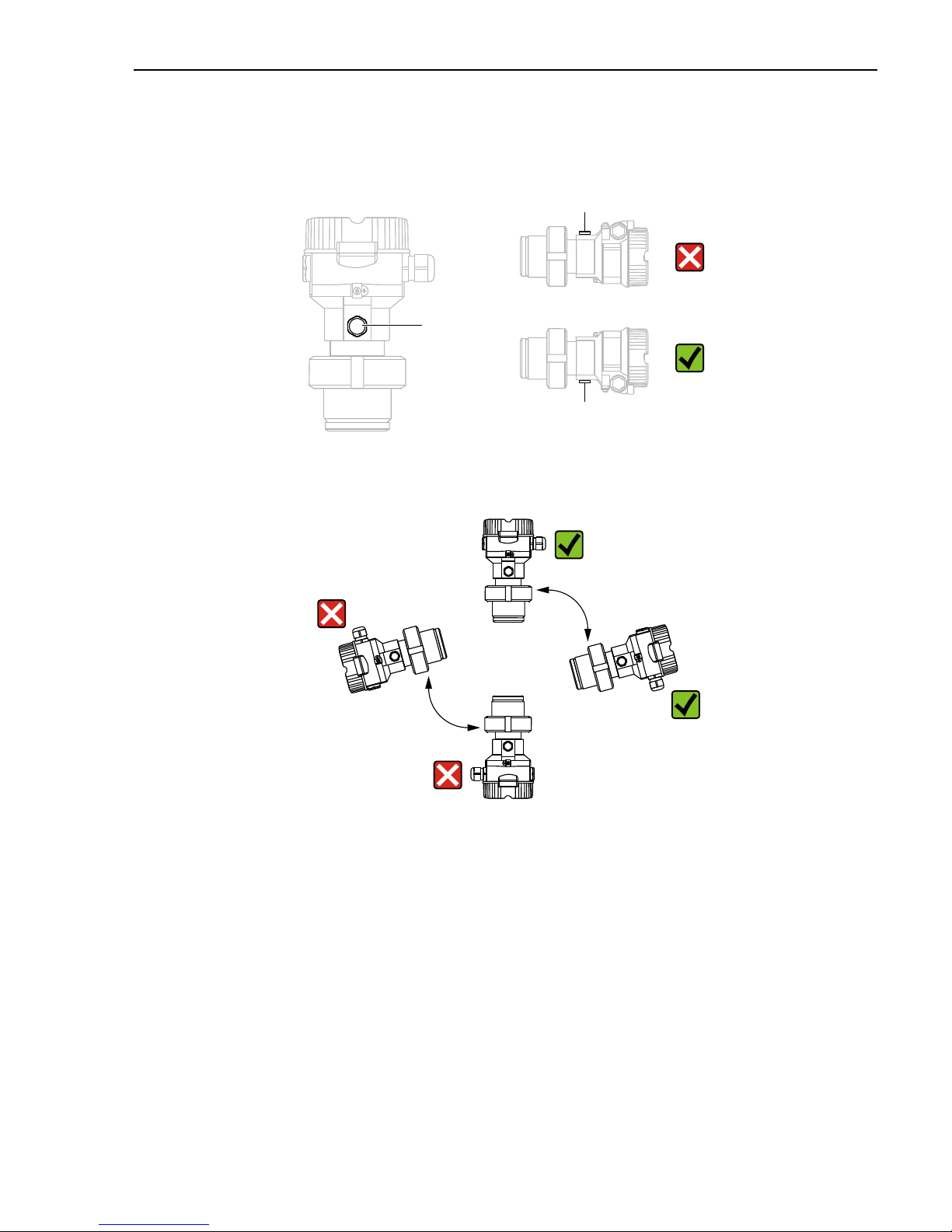

• Devices with a G 1 1/2 thread:

When screwing the device into the tank, the flat seal has to be positioned on the sealing

surface

of the process connection. To avoid additional strain on the process isolating diaphragm, the

thread should never be sealed with hemp or similar materials.

• Devices with NPT threads:

– Wrap Teflon tape around the thread to seal it.

– Tighten the device at the hexagonal bolt only. Do not turn at the housing.

– Do not overtighten the thread when screwing. Max. torque: 20 to 30 Nm (14.75 to 22.13

lbf ft)

4.4.1 Mounting sensor modules with PVDF thread

Risk of damage to process connection!

Risk of injury!

‣ Sensor modules with PVDF process connections with threaded connection must be installed

with the mounting bracket provided!

Material fatigue from pressure and temperature!

Risk of injury if parts burst! The thread can become loose if exposed to high pressure and

temperatures.

‣ The integrity of the thread must be checked regularly and the thread may need to be

re-tightened with the maximum tightening torque of 7 Nm (5.16 lbf ft). Teflon tape is

recommended for sealing the ½" NPT thread.

4.5 Installing

• Due to the orientation of the Deltapilot M, there may be a shift in the zero point, i.e. when the

container is empty or partially full, the measured value does not display zero. You can correct

this zero point shift ä 23, Section "Function of the operating elements" or ä 35,

Section 8.3 "Pos. zero adjust".

• The local display can be rotated in 90° stages.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

ä 14, Section 4.5.6 " "Wall and pipe mounting (optional)".

4.5.1 General installation instructions

• Do not clean or touch process isolating diaphragms with hard or pointed objects.

• The process isolating diaphragm in the rod and cable version is protected against mechanical

damage by a plastic cap.

10 Endress+Hauser

Page 11

Deltapilot M FOUNDATION Fieldbus Installation

1

1

1

• If a heated Deltapilot M is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the pressure

compensation (1). If this is the case, mount the Deltapilot M with the pressure compensation

(1) pointing downwards.

• Keep the pressure compensation and GORE-TEX® filter (1) free from contamination.

• The device must be installed as follows in order to comply with the cleanability requirements

of the ASME-BPE (Part SD Cleanibility).:

4.5.2 FMB50

Level measurement

• Always install the device below the lowest measuring point.

• Do not install the device at the following positions:

– in the filling curtain

– in the tank outflow

– in the suction area of a pump

– or at a point in the tank that can be affected by pressure pulses from the agitator

• The calibration and functional test can be carried out more easily if you mount the device

downstream of a shutoff device.

• Deltapilot M must be included in the insulation for media that can harden when cold.

Endress+Hauser 11

Page 12

Installation Deltapilot M FOUNDATION Fieldbus

L

E

17 (0.67)

Pressure measurement in gases

• Mount Deltapilot M with shutoff device above the tapping point so that any condensate can

flow into the process.

Pressure measurement in steams

• Mount Deltapilot M with siphon above the tapping point.

• Fill the siphon with liquid before commissioning.

The siphon reduces the temperature to almost the ambient temperature.

Pressure measurement in liquids

• Mount Deltapilot M with the shutoff device below or at the same level as the tapping point.

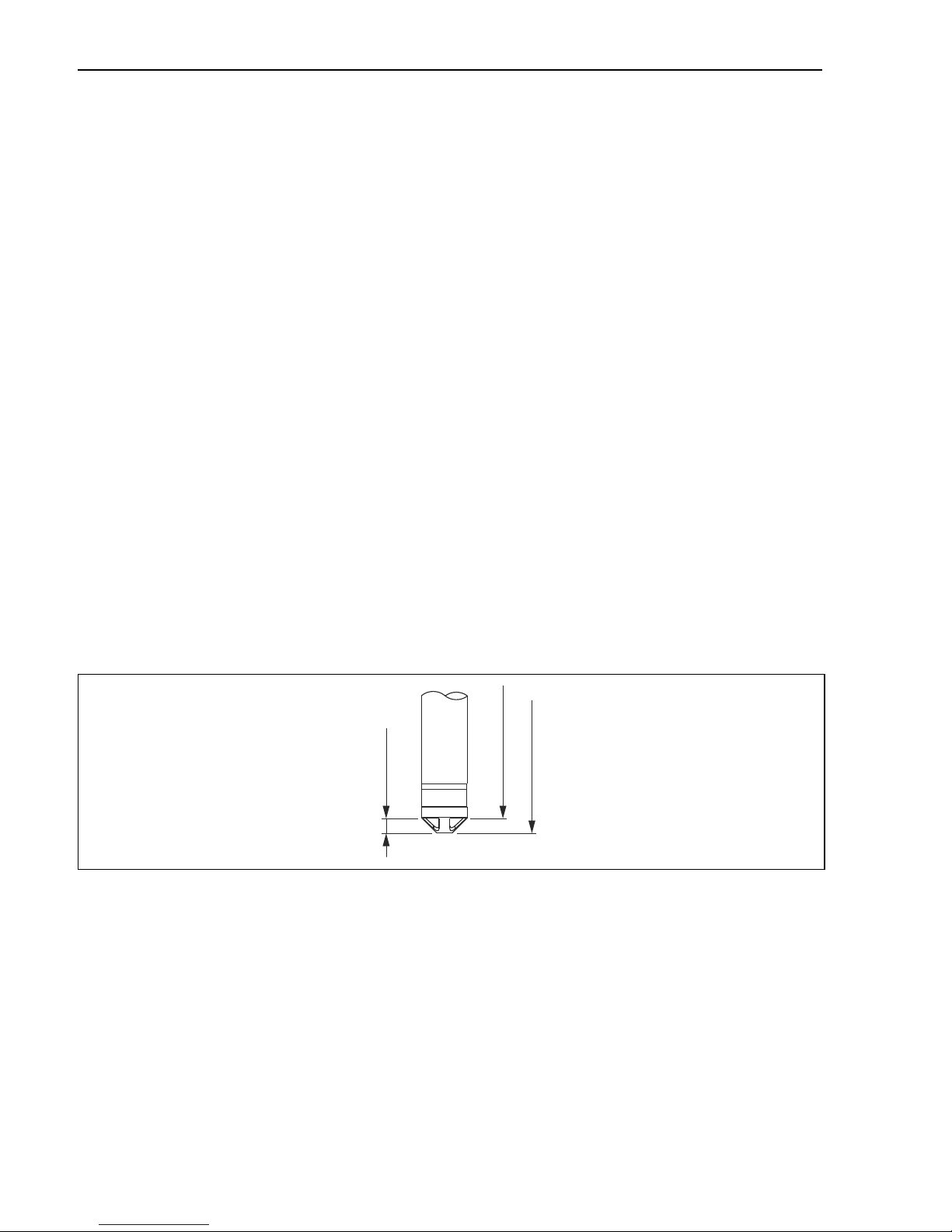

4.5.3 FMB51/FMB52/FMB53

• When mounting rod and cable versions, make sure that the probe head is located at a point

as free as possible from flow. To protect the probe from impact resulting from lateral

movement, mount the probe in a guide tube (preferably made of plastic) or secure it with a

clamping fixture.

• In the case of devices for hazardous areas, comply strictly with the safety instructions when

the housing cover is open.

• The length of the extension cable or the probe rod is based on the planned level zero point.

The height of the protective cap must be taken into consideration when designing the layout

of the measuring point. The level zero point (E) corresponds to the position of the process

isolating diaphragm.

Level zero point = E; top of the probe = L.

12 Endress+Hauser

Page 13

Deltapilot M FOUNDATION Fieldbus Installation

1

2

3

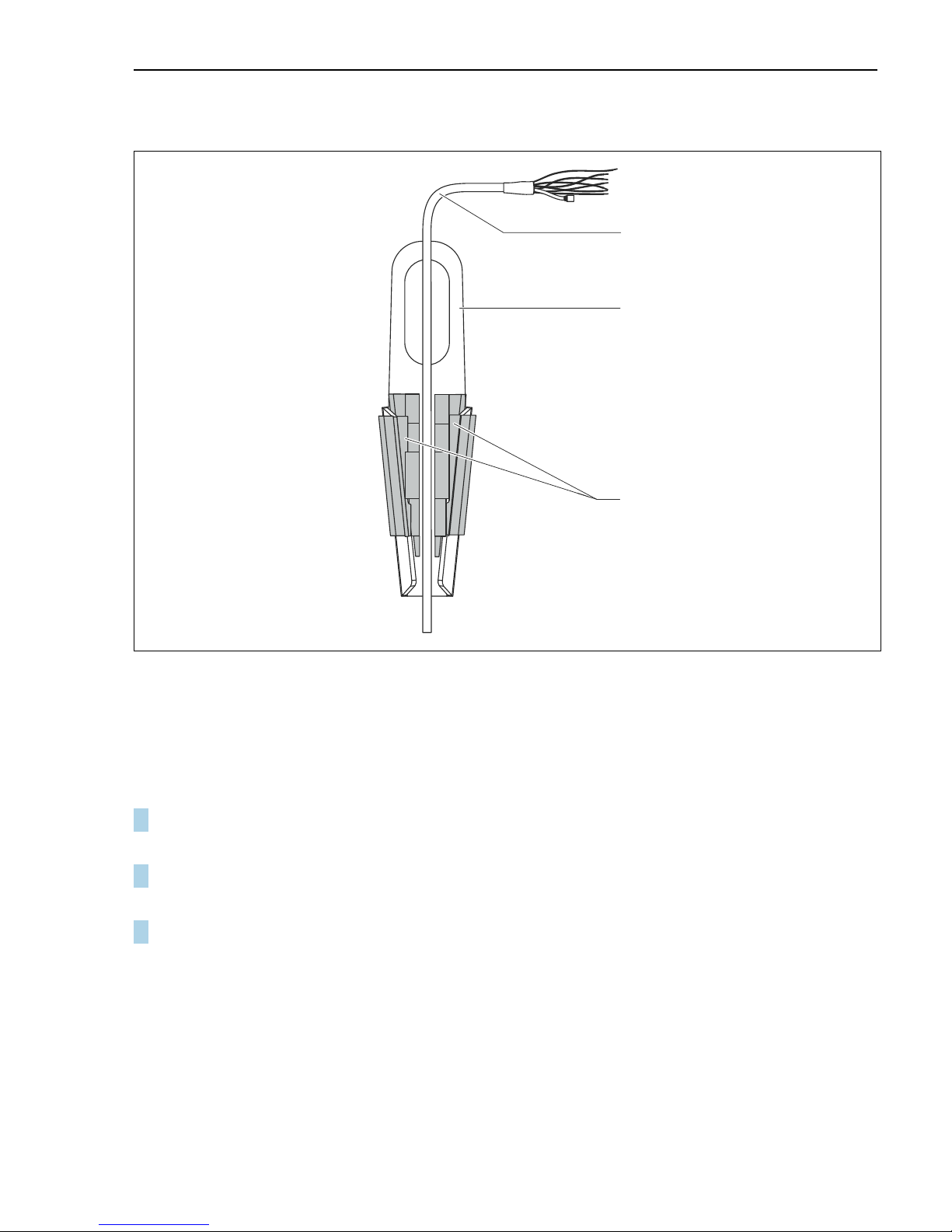

4.5.4 Mounting the FMB53 with a suspension clamp

Fig. 1: Mounting with a suspension clamp

1Extension cable

2 Suspension clamp

3 Clamping jaws

A0018793

Mounting the suspension clamp:

1. Mount the suspension clamp (item 2). When selecting the place to fix the unit, take the

weight of the extension cable (item 1) and the device into account.

2. Raise the clamping jaws (item 3). Position the extension cable (item 1) between the

clamping jaws as illustrated in Figure.

3. Hold the extension cable in position (item 1) and push the clamping jaws (item 3) back

down.

Tap the clamping jaws gently from above to fix them in place.

Endress+Hauser 13

Page 14

Installation Deltapilot M FOUNDATION Fieldbus

NOTICE

12

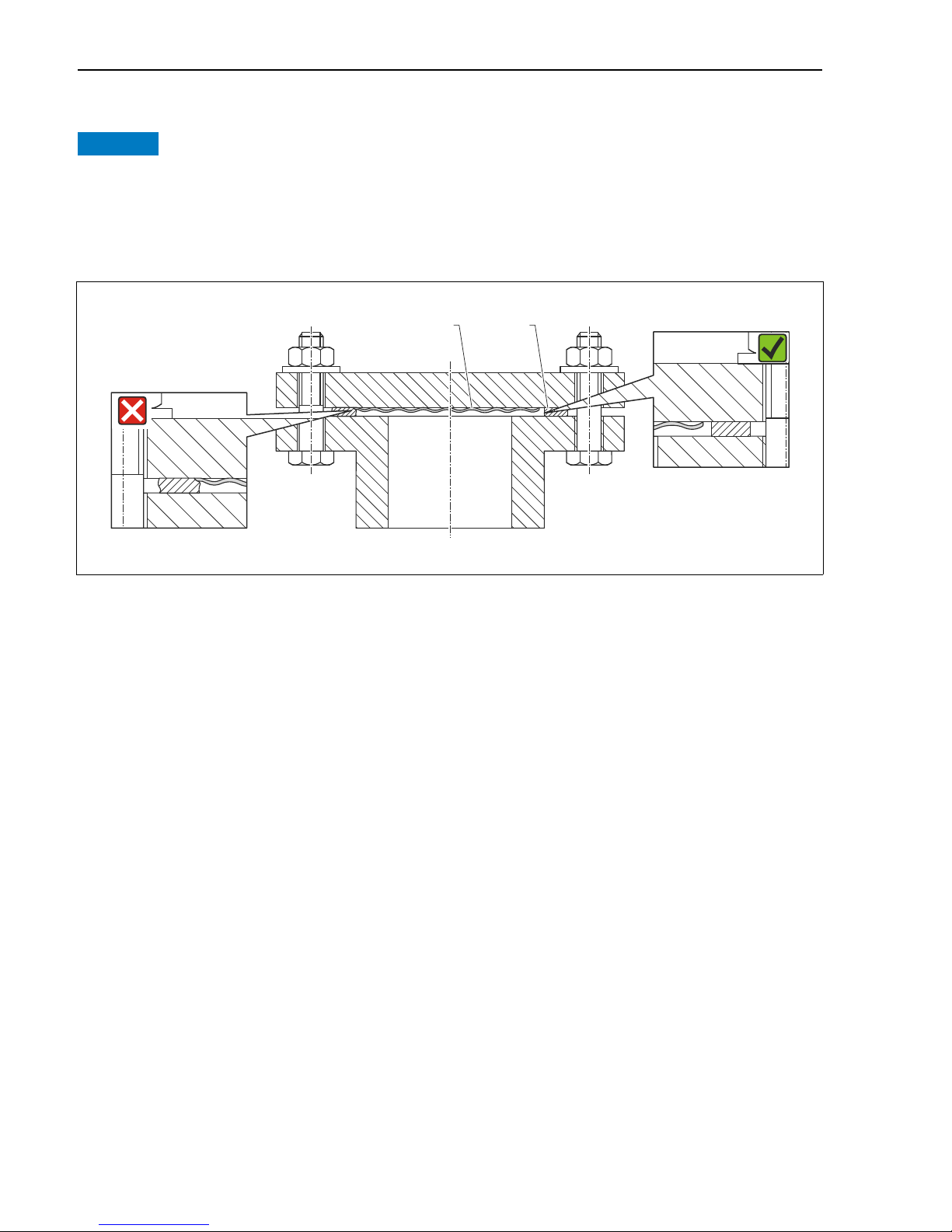

4.5.5 Seal for flange mounting

Distorted measurement results.

The seal is not allowed to press on the process isolating diaphragm as this could affect the

measurement result.

‣ Ensure that the seal is not touching the process isolating diaphragm.

Fig. 2:

1 Process isolating diaphragm

2Seal

4.5.6 Wall and pipe mounting (optional)

Mounting bracket

See operating instructions.

A0017743

14 Endress+Hauser

Page 15

Deltapilot M FOUNDATION Fieldbus Installation

r ³ 120 (4.72)

2

3

4

5

6

1

7

7

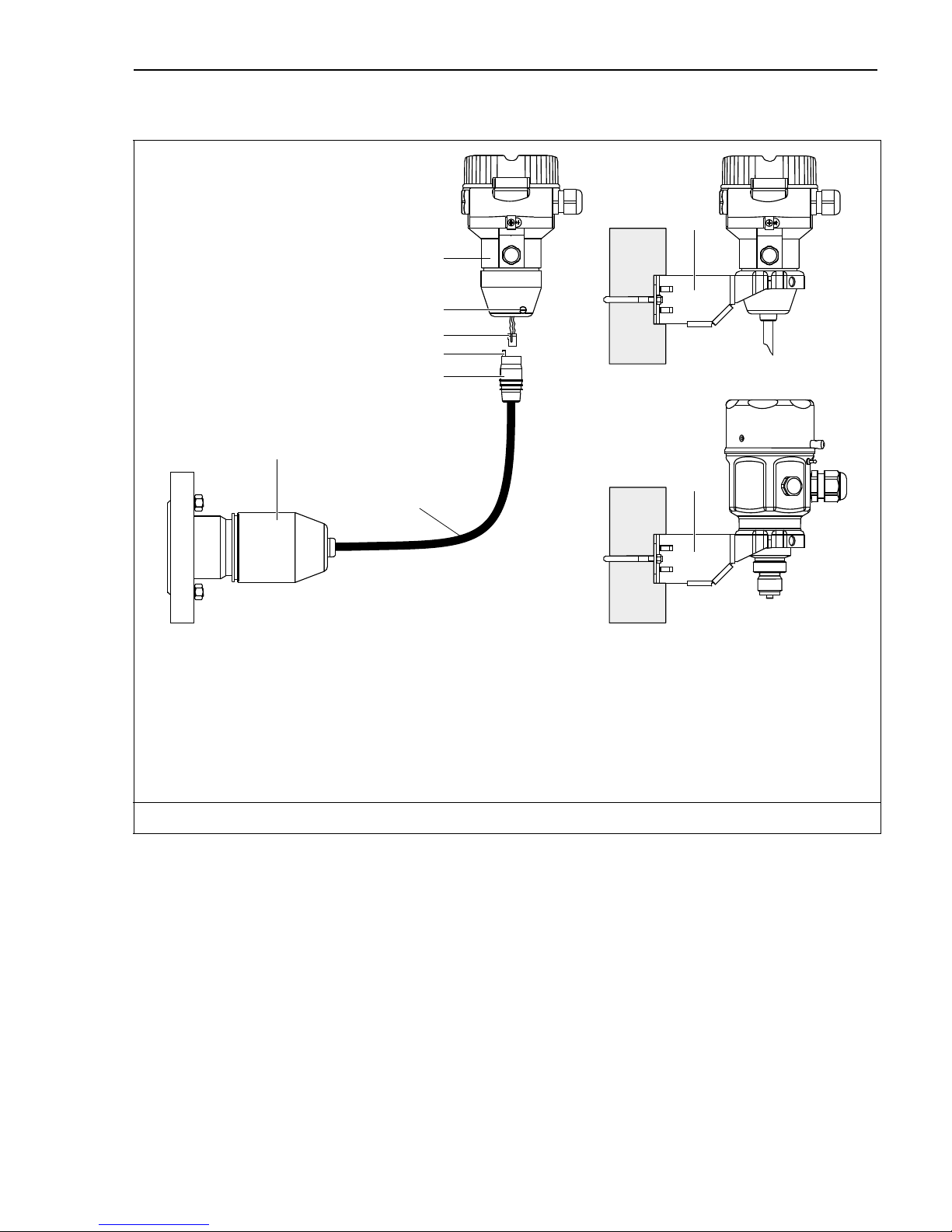

4.5.7 Assembling and mounting the "separate housing" version

Fig. 3: "Separate housing" version

1 In the case of the "separate housing" version, the sensor is delivered with the process connection and cable ready

mounted.

2 Cable with connection jack

3 Pressure compensation

4 Connector

5Locking screw

6 Housing mounted with housing adapter, included

7 Mounting bracket provided, suitable for pipe and wall mounting (for pipes from 1

Maßeinheit mm (in)

1/4

" up to 2" diameter)

Assembly and mounting

1. Insert the connector (item 4) into the corresponding connection jack of the cable (item 2).

2. Plug the cable into the housing adapter (item 6).

3. Tighten the locking screw (item 5).

4. Mount the housing on a wall or pipe using the mounting bracket (item 7).

When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at

least 5 Nm (3.69 lbf ft). Mount the cable with a bending radius (r) 120 mm (4.72 in).

Routing the cable (e.g. through a pipe)

You require the cable shortening kit.

A0028494

Endress+Hauser 15

Page 16

Installation Deltapilot M FOUNDATION Fieldbus

NOTICE

NOTICE

Order number: 71093286

For details on mounting, see SD00553P/00/A6.

4.5.8 Supplementary installation instructions

Sealing the probe housing

• Moisture must not penetrate the housing when mounting the device, establishing the

electrical connection and during operation.

• Always firmly tighten the housing cover and the cable entries.

4.6 Mounting of the profile seal for universal process mounting

adapter

For details on mounting, see KA00096F/00/A3.

4.7 Closing the housing cover

Devices with EPDM cover seal - transmitter leakiness!

Mineral-based, animal-based or vegetable-based lubricants cause the EPDM cover seal to swell

and the transmitter to become leaky.

‣ The thread is coated at the factory and therefore does not require any lubrication.

The housing cover can no longer be closed.

Damaged thread!

‣ When closing the housing cover, please ensure that the thread of the cover and housing are

free from dirt, e.g. sand.If you feel any resistance when closing the cover, check the thread

on both again to ensure that they are free from dirt.

4.7.1 Closing the cover on the stainless steel housing

Fig. 4: Closing the cover

16 Endress+Hauser

A0028497

Page 17

Deltapilot M FOUNDATION Fieldbus Electrical connection

WARNING

!

The cover for the electronics compartment is tightened by hand at the housing until the stop.

The screw serves as DustEx protection (only available for devices with DustEx approval).

4.8 Post-installation check

O Is the device undamaged (visual inspection)?

O Does the device comply with the measuring point specifications?

For example:

•Process temperature

• Process pressure

• Ambient temperature range

•Measuring range

O Are the measuring point identification and labeling correct (visual inspection)?

O Is the device adequately protected against precipitation and direct sunlight?

O Are the securing screw and securing clamp tightened securely?

5 Electrical connection

5.1 Connecting the device

Supply voltage might be connected!

Risk of electric shock and/or explosion!

‣ Ensure that no uncontrolles processes are activated in the system.

‣ Switch off the supply voltage before connecting the device.

‣ When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or Installation

or Control Drawings.

‣ A suitable circuit breaker must be provided for the device in accordance with

IEC/EN61010.

‣ Devices with integrated overvoltage protection must be grounded.

‣ Protective circuits against reverse polarity, HF influences and overvoltage peaks are

integrated.

Connect the device in the following order:

1. Check that the supply voltage corresponds to the supply voltage indicated on the nameplate.

2. Switch off the supply voltage before connecting the device.

3. Remove housing cover.

4. Guide the cable through the gland. Preferably use a twisted, shielded two-wire cable.

Endress+Hauser 17

Page 18

Electrical connection Deltapilot M FOUNDATION Fieldbus

- +

1

1

2

3

4

5. Connect the device in accordance with the following diagram.

6. Screw down the housing cover.

7. Switch on the supply voltage.

FOUNDATION Fieldbus electrical connection

1 Terminals for supply voltage and signal

2 Grounding terminal

3 Supply voltage: 9 to 32 VDC (Power conditioner)

4 External ground terminal

A0029967

18 Endress+Hauser

Page 19

Deltapilot M FOUNDATION Fieldbus Electrical connection

2

1

4

3

5.1.1 Devices with 7/8" plug

PIN assignment for 7/8" connector PIN Meaning

1 Signal –

2 Signal +

3 Not assigned

4Shield

A0011176

5.2 Connecting the measuring unit

5.2.1 Supply voltage

Electronic version

FOUNDATION Fieldbus,

version for non-hazardous areas

9 to 32 V DC

For further information on the network structure and grounding and for further bus system

components such as bus cables, see the relevant documentation, e.g. Operating Instructions

BA00013S "FOUNDATION Fieldbus Overview" and the FOUNDATION Fieldbus Guideline.

5.2.2 Current consumption

16 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21.

5.2.3 Terminals

• Supply voltage and internal ground terminal: 0.5 to 2.5 mm2 (20 to 14 AWG)

2

• External ground terminal: 0.5 to 4 mm

(20 to 12 AWG)

5.2.4 Cable specification

• Endress+Hauser recommends using twisted, shielded two-wire cables.

• Cable outer diameter: 5 to 9 mm (0.2 to 0.35 in)

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2 (MBP).

Endress+Hauser 19

Page 20

Operation Deltapilot M FOUNDATION Fieldbus

on

off

Display

Zero

simulation

TMTM

F

OUNDATIONFOUNDATION

SW / P2=High

SW / Ö

damping

delta p only

5.2.5 Shielding/potential equalization

• You achieve optimum shielding against disturbances if the shielding is connected on both

sides (in the cabinet and on the device). If potential equalization currents are expected in the

plant, only ground shielding on one side, preferably at the transmitter.

• When using in hazardous areas, you must observe the applicable regulations.

Separate Ex documentation with additional technical data and instructions is included with

all Ex systems as standard.

5.3 Potential equalization

Hazardous area applications: Connect all devices to the local potential equalization.

Observe the applicable regulations.

5.4 Overvoltage protection (optional)

See operating instructions.

5.5 Post-connection check

Perform the following checks after completing electrical installation of the device:

• Does the supply voltage match the specifications on the nameplate?

• Is the device properly connected?

• Are all screws firmly tightened?

• Are the housing covers screwed down tight?

As soon as voltage is applied to the device, the green LED on the electronic insert lights up briefly

or the connected onsite display lights up.

6Operation

6.1 Operating options

6.1.1 Operation without operating menu

Operating options Explanation Graphic illustration Description

Local operation without

device display

The device is operated

using the operating key

and DIP switches on the

electronic insert.

ä 22

20 Endress+Hauser

Page 21

Deltapilot M FOUNDATION Fieldbus Operation

E

+

–

6.1.2 Operation with an operating menu

Operation with an operating menu is based on an operation concept with "user roles" ä 24.

Operating options Explanation Graphic illustration Description

Local operation

with device display

Remote operation via

FieldCare

The device is operated

using the operating keys

on the device display.

The device is operated

using the FieldCare

operating tool.

ä 26

ä 30

6.1.3 Operation via FF communication protocol

Operating options Explanation Graphic illustration Description

Remote operation via

FieldCare

Remote operation via

the NI Tool

The device is operated

using the FieldCare

operating tool.

The device is operated

using the NI Tool.

See operating

instructions

See operating

instructions

Endress+Hauser 21

Page 22

Operation Deltapilot M FOUNDATION Fieldbus

on

off

SW / P2=High

Simulation

SW /

damping

1

2

345

on

off

Display

Zero

simulation

TM

F

OUNDATION

SW / P2=High

SW /

damping

delta p only

8 765 4

1

2

3

6.2 Operation without an operating menu

6.2.1 Position of operating elements

The operating key and DIP switches are located on the electronic insert in the device.

Fig. 5: FOUNDATION Fieldbus electronic insert

A0023127

1 Operating key for position zero adjustment (Zero) or reset

2 Green LED to indicate successful operation

3 Slot for optional local display

4+5 DIP switch only for Deltabar M

6 DIP-switch for simulation mode

7 DIP switch for switching damping on/off

8 DIP switch for locking/unlocking parameters relevant to the measured value

Function of the DIP switches

Switches Symbol/

Switch position

labeling

1 The device is unlocked.

Parameters relevant to the measured value

can be modified.

"off" "on"

The device is locked.

Parameters relevant to the measured value

cannot be modified.

22 Endress+Hauser

Page 23

Deltapilot M FOUNDATION Fieldbus Operation

Switches Symbol/

labeling

"off" "on"

2damping Damping is switched off.

The output signal follows measured value

changes without any delay.

3 Simulation The simulation mode is switched off

(factory setting).

The following switches only for Deltabar M:

4SW/

5 SW/P2= High

1) The value for the delay time can be configured via the operating menu ("Setup" -> "Damping").

Factory setting: = 2 s or as per order specifications.

Switch position

Damping is switched on.

The output signal follows measured value

changes with the delay time .

The simulation mode is switched on.

Function of the operating elements

Operating key Meaning

"Zero"

pressed for at least

3seconds

Position adjustment (zero point correction)

Press key for at least 3 seconds. The LED on the electronic insert lights up briefly if the

pressure applied has been accepted for position adjustment.

See also the following Section "Performing position adjustment on site.''

1)

"Zero"

pressed for at least

12 seconds

Reset

All parameters are reset to the order configuration.

Performing position adjustment on site

• Operation must be unlocked. ä 30, Section 6.3.5 "Locking/unlocking operation".

• The device is configured at the factory for the Level measuring mode.

– Operation via FF configuration program: In the Pressure Transducer Block, you can change

the measuring mode by means of the PRIMARY_VALUE_TYPE parameter.

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

• To reconcile the parameter database, perform a "Reconcile device" (after position adjustment)

with the FF host.

Perform position adjustment:

1. Pressure is present at device.

2. Press key for at least 3 seconds.

3. If the LED on the electronic insert lights up briefly, the pressure applied has been accepted

for position adjustment.

If the LED does not light up, the pressure applied was not accepted. Observe the input

limits. For error messages, see operating instructions.

Endress+Hauser 23

Page 24

Operation Deltapilot M FOUNDATION Fieldbus

6.2.2 Locking/unlocking operation

See operating instructions.

6.3 Operation with an operating menu

6.3.1 Operation concept

The operation concept makes a distinction between the following user roles:

User role Meaning

Operator Operators are responsible for the devices during normal "operation". This is usually limited to

reading process values either directly at the device or in a control room. If the work with the

devices extends beyond value read-off tasks, the tasks involve simple, application-specific

functions that are used in operation. Should an error occur, these users simple forward the

information on the errors but do not intervene themselves.

Service

engineer/technician

Expert Experts work with the devices over the entire product life cycle, but their device requirements

Service engineers usually work with the devices in the phases following device commissioning.

They are primarily involved in maintenance and troubleshooting activities for which simple

settings have to be made at the device.

Technicians work with the devices over the entire life cycle of the product.

Thus, commissioning and advanced settings and configurations are some of the tasks they have

to carry out.

are often extremely high. Individual parameters/functions from the overall functionality of the

devices are required for this purpose time and again.

In addition to technical, process-oriented tasks, experts can also perform administrative tasks

(e.g. user administration).

"Experts" can avail of the entire parameter set.

6.3.2 Structure of the operating menu

User role Submenu Meaning/use

Operator Language Only consists of the "Language" parameter (000) where the operating language

for the device is specified.

The language can always be changed even if the device is locked.

Operator Display/operat. Contains parameters that are needed to configure the measured value display

(selecting the values displayed, display format, display contrast, etc.).

With this submenu, users can change the measured value display without

affecting the actual measurement.

24 Endress+Hauser

Page 25

Deltapilot M FOUNDATION Fieldbus Operation

User role Submenu Meaning/use

Service

engineer/technic

ian

Service

engineer/technic

ian

Setup Contains all the parameters that are needed to commission measuring

operations. This submenu has the following structure:

• Standard setup parameters

A wide range of parameters, which can be used to configure a typical

application, is available at the start. The measuring mode selected determines

which parameters are available.

After making settings for all these parameters, the measuring operation

should be completely configured in the majority of cases.

• "Extended setup" submenu

The "Extended setup" submenu contains additional parameters for more

in-depth configuration of the measurement operation to convert the

measured value and to scale the output signal.

This menu is split into additional submenus depending on the measuring

mode selected.

Diagnosis Contains all the parameters that are needed to detect and analyze operating

errors. This submenu has the following structure:

• Diagnostic list

Contains up to 10 error messages currently pending.

• Event logbook

Contains the last 10 error messages (no longer pending).

• Instrument info

Contains information on the device identification.

• Measured values

Contains all the current measured values

• Simulation

Is used to simulate pressure, level and alarm/warning.

• Reset

Expert Expert Contains all the parameters of the device (including those in one of the

submenus). The "Expert" submenu is structured by the function blocks of the

device. It thus contains the following submenus:

• System

Contains general device parameters that neither affect measurement nor

integration into a distributed control system.

• Measurement

Contains all the parameters for configuring the measurement.

• Communication

Contains all the parameters of the FOUNDATION Fieldbus interface.

• Application

Contains all the parameters for configuring the functions that go beyond the

actual measurement (e.g. totalizer).

• Diagnosis

Contains all the parameters that are needed to detect and analyze operating

errors.

For an overview of the entire operating menu: See operating instructions.

Direct access to parameters

The parameters can only be accessed directly via the "Expert" user role.

Endress+Hauser 25

Page 26

Operation Deltapilot M FOUNDATION Fieldbus

1.

2.

3.

4.

5.

6.

Parameter name Description

Direct access (119)

Entry

Menu path:

Expert Direct access

Use this function to enter a parameter code for direct access.

User input:

• Enter the desired parameter code.

Factory setting:

0

6.3.3 Operation with a device display (optional)

A 4-line liquid crystal display (LCD) is used for display and operation. The onsite display shows

measured values, dialog texts, fault messages and notice messages.

For easy operation the display can be taken out of the housing (see figure steps 1 to 3). It is

connected to the device through a 90 mm (3.54 in) cable.

The display of the device can be turned in 90° stages (see figure steps 4 to 6).

Depending on the orientation of the device, this makes it easy to operate the device and read the

measured values.

26 Endress+Hauser

A0028500

Page 27

Deltapilot M FOUNDATION Fieldbus Operation

E

+

–

F

1

6

2

57

3

4

Functions:

• 8-digit measured value display including sign and decimal point.

• Bar graph as graphic display of the current pressure measured value in relation to the set

pressure range in the Pressure Transducer Block. The pressure range is set by means of the

SCALE_IN parameter (via FF configuration program, not via onsite display).

• Three keys for operation.

• Simple and complete menu guidance as parameters are split into several levels and groups.

• Each parameter is given a 3-digit parameter code for easy navigation.

• Possibility of configuring the display to suit individual requirements and preferences, such as

language, alternating display, display of other measured values such as sensor temperature,

contrast setting.

• Comprehensive diagnostic functions (fault and warning message etc.).

Fig. 6: Display

1 Main line

2Value

3Symbol

4Unit

5Bar graph

6 Information line

7Operating keys

A0030013

The following table illustrates the symbols that can appear on the onsite display. Four symbols

can occur at one time.

Symbol Meaning

Lock symbol

The operation of the device is locked. To unlock the device, ä 30, Locking/unlocking

operation.

Endress+Hauser 27

Page 28

Operation Deltapilot M FOUNDATION Fieldbus

Symbol Meaning

Communication symbol

Data transfer via communication

Error message "Out of specification"

The device is being operated outside its technical specifications (e.g. during warmup or

cleaning processes).

Error message "Service mode"

The device is in the service mode (during a simulation, for example).

Error message "Maintenance required"

Maintenance is required. The measured value remains valid.

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid.

Simulation symbol

Simulation mode is activated. DIP switch 2 for simulation is set to "On".

See also Section 6.2.1 "Position of operating elements" and ä 30, Section 6.3.6

"Simulation".

Operating keys on the display and operating module

Operating key(s) Meaning

– Navigate downwards in the picklist

– Edit the numerical values and characters within a function

– Navigate upwards in the picklist

– Edit the numerical values and characters within a function

–Confirm entry

– Jump to the next item

– Selection of a menu item and activation of the editing mode

Contrast setting of onsite display: darker

Contrast setting of onsite display: brighter

O

S

O

S

F

and

and

F

F

ESC functions:

and

O

28 Endress+Hauser

S

– Exit the edit mode for a parameter without saving the changed value.

– You are in a menu at a selection level. Each time you press the keys simultaneously,

you go up a level in the menu.

Page 29

Deltapilot M FOUNDATION Fieldbus Operation

Operating example: Parameters with a picklist

Example: selecting "Deutsch" as the language of the menu.

Language 000 Operation

1 English "English" is set as the menu language (default value). A in front

of the menu text indicates the active option.

Deutsch

2 Deutsch Select "Deutsch" with or .

English

3 Deutsch 1. Confirm your choice with . A in front of the menu text

indicates the active option ("Deutsch" is now selected as the

English

menu language).

2. Exit the edit mode for the parameter with .

Operating example: User-definable parameters

Example: setting "Set URV" parameter from 100 mbar (1.5 psi) to 50 mbar (0.75 psi).

Set URV 014 Operation

The local display shows the parameter to be changed. The value

1100.000mbar

2 1 00 . 000 mbar

3 5 00 . 000 mbar

4500 .000 mbar

highlighted in black can be changed. The "mbar" unit is specified

in another parameter and cannot be modified here.

1. Press or to get to the editing mode.

2. The first digit is highlighted in black.

1. Use to change "1" to "5".

2. Confirm "5" with . The cursor jumps to the next position

(highlighted in black).

3. Confirm "0" with (second position).

The third position is highlighted in black and can now be edited.

550 .000 mbar

Endress+Hauser 29

1. Switch to the "" symbol with the key.

2. Use to save the new value and exit the editing mode.

See next graphic.

Page 30

Operation Deltapilot M FOUNDATION Fieldbus

Set URV 014 Operation

The new value for the upper range value is 50.0 mbar (0.75 psi).

65 .000 mbar

– You exit the edit mode for the parameter with .

– You can get back to the editing mode with or .

Operating example: Accepting the pressure present

Example: setting position adjustment

Pos. zero adjust 007 Operation

1 Abort The pressure for position adjustment is present at the device.

Confirm

2 Confirm Use or to switch to the "Confirm" option. The active option is

highlighted in black.

Abort

3Compensation

accepted!

4 Abort Exit the edit mode for the parameter with .

Confirm

Accept the pressure present as position adjustment with the

key. The device confirms the adjustment and goes back to the

"Pos. zero adjust" parameter.

6.3.4 Operation via FieldCare

See operating instructions.

6.3.5 Locking/unlocking operation

See operating instructions.

6.3.6 Simulation

See operating instructions.

6.3.7 Resetting to factory settings (reset)

See operating instructions.

30 Endress+Hauser

Page 31

Deltapilot M FOUNDATION Fieldbus Commissioning without an operating menu

WARNING

!

6.4 FOUNDATION Fieldbus communication protocol

6.4.1 Device identification and addressing

FOUNDATION Fieldbus identifies the device using its ID code and automatically assigns it a

suitable field address. The identity code cannot be changed.

The device appears in the network display once you have started the FF configuration program

and integrated the device into the network. The blocks available are displayed under the device

name.

If the device description has not yet been loaded, the blocks report "Unknown" or "(UNK)".

The devices report as follows (typical display in a configuration program after the connection

has been established):

Device name Serial number

-

-

EH_ Deltapilot_M_5X _ 00000000000000

RS_00000000000 (RB2)

TRD1_00000000000 (PCD)

DIAGNOSTIC_000000000000 (DIAGNOSTIC)

DISPLAY_00000000000 (DISP)

AI1_000000000000 (AI)

AI2_000000000000 (AI)

DI_00000000000 (DI)

DO_00000000000 (DO)

ISEL_00000000000(ISB)

PID_00000000000(PID)

ARTH_00000000000(ARB)

CHAR_00000000000(SCB)

INTG_0000000000 (ITB)

7 Commissioning without an operating menu

The device is configured at the factory for the Level measuring mode. The measuring range and

the unit in which the measured value is transmitted correspond to the specifications on the

nameplate.

Exceeding the maximum allowable working pressure!

Risk of injury due to bursting of parts! Warning messages are generated if pressure is too high.

‣ If a pressure smaller than the minimum permitted pressure or greater than the maximum

permitted pressure is present at the device, the following messages are output in succession

(depending on the setting in the "Alarm behavior" (050) parameter):

"S140 Working range P" or "F140 Working range P"

Endress+Hauser 31

Page 32

Commissioning without an operating menu Deltapilot M FOUNDATION Fieldbus

NOTICE

"S841 Sensor range" or "F841 Sensor range"

"S971 Adjustment"

Use the device only within the sensor range limits.

Shortfall of the allowable working pressure!

Output of messages if pressure is too low.

‣ If a pressure smaller than the minimum permitted pressure or greater than the maximum

permitted pressure is present at the device, the following messages are output in succession

(depending on the setting in the "Alarm behavior" (050) parameter):

"S140 Working range P" or "F140 Working range P"

"S841 Sensor range" or "F841 Sensor range"

"S971 Adjustment"

Use the device only within the sensor range limits.

7.1 Function check

Carry out a post-installation and a post-connection check as per the checklist before

commissioning the device.

• "Post-installation check" checklist ä 17

• "Post-connection check" checklist ä 20

7.2 Position adjustment

The following functions are possible by means of the key on the electronic insert:

• Position adjustment (zero point correction)

• Device reset ä 23

• Operation must be unlocked. ä 30, "Locking/unlocking operation"

• The device is configured for the "Pressure" measuring mode as standard.

• The pressure applied must be within the nominal pressure limits of the sensor. See

information on the nameplate.

Carrying out position adjustment

Pressure is present at device.

1)

Does the LED on the electronic insert light up briefly?

Yes No

32 Endress+Hauser

Press the "Zero" key for at least 3 s.

Page 33

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

WARNING

!

NOTICE

Carrying out position adjustment

Applied pressure for position adjustment has been

accepted.

1) Observe warning on commissioning

Applied pressure for position adjustment has not been

1)

accepted. Observe the input limits.

8 Commissioning with an operating menu (onsite

display/FieldCare)

The device is configured at the factory for the Level measuring mode. The measuring range and

the unit in which the measured value is transmitted correspond to the specifications on the

nameplate.

Exceeding the maximum allowable working pressure!

Risk of injury due to bursting of parts! Warning messages are generated if pressure is too high.

‣ If a pressure smaller than the minimum permitted pressure or greater than the maximum

permitted pressure is present at the device, the following messages are output in succession

(depending on the setting in the "Alarm behavior" (050) parameter):

"S140 Working range P" or "F140 Working range P"

"S841 Sensor range" or "F841 Sensor range"

"S971 Adjustment"

Use the device only within the sensor range limits.

Shortfall of the allowable working pressure!

Output of messages if pressure is too low.

‣ If a pressure smaller than the minimum permitted pressure or greater than the maximum

permitted pressure is present at the device, the following messages are output in succession

(depending on the setting in the "Alarm behavior" (050) parameter):

"S140 Working range P" or "F140 Working range P"

"S841 Sensor range" or "F841 Sensor range"

"S971 Adjustment"

Use the device only within the sensor range limits.

8.1 Function check

Carry out a post-installation and a post-connection check as per the checklist before

commissioning the device.

• "Post-installation check" checklist ä 17

• "Post-connection check" checklist ä 20

Endress+Hauser 33

Page 34

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

WARNING

!

8.2 Commissioning

Commissioning comprises the following steps:

1. Function check ( ä 33)

2. Selecting the language, measuring mode and pressure unit ( ä 34)

3. Position adjustment ( ä 35)

4. Configuring measurement:

– Pressure measurement ( ä 46 ff)

– Level measurement ( ä 36 ff)

–Linearization ( ä 46 ff)

8.2.1 Selecting the language, measuring mode and pressure unit

Language selection

Parameter name Description

Language (000)

Options

Menu path:

Main menu Language

Select the menu language for the onsite display.

Options:

• English

• Possibly another language (as selected when ordering the device)

• One further language (language of the manufacturing plant)

Factory setting:

English

Measuring mode selection

Parameter name Description

Measuring mode (005)

Options

Menu path: Setup

Measuring mode

Select the measuring mode.

The operating menu is structured differently depending on the measuring mode

selected.

Changing the measuring mode affects the span (URV)!

This situation can result in product overflow.

‣ If the measuring mode is changed, the span setting (URV) must be verified and, if

necessary, reconfigured!

Options:

• Pressure

• Level

Factory setting:

Pressure

34 Endress+Hauser

Page 35

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

Pressure unit selection

Parameter name Description

Press. eng. unit (125)

Options

Menu path: Setup Press.

eng. unit

Select the pressure unit.

If a new pressure unit is selected, all pressure-specific parameters are converted and

displayed with the new unit.

Options:

• mbar, bar

• mmH2O, mH2O,

•inH2O, ftH2O

•Pa, kPa, MPa

•psi

• mmHg, inHg

•kgf/cm

Factory setting:

mbar or bar depending on the sensor nominal measuring range, or as per order

specifications

2

8.3 Pos. zero adjust

The pressure resulting from the orientation of the device can be corrected here.

Parameter name Description

Corrected press. (172)

Display

Menu path:

Setup Corrected press.

Displays the measured pressure after sensor trim and position adjustment.

If this value is not equal to "0", it can be corrected to "0" by the position adjustment.

Pos. zero adjust (007)

(Gauge pressure sensor)

Selection

Menu path:

Setup Pos. zero adjust

Position adjustment – the pressure difference between zero (set point) and the

measured pressure need not be known.

Example:

– Measured value = 2.2 mbar (0.032 psi)

– You correct the measured value via the "Pos. zero adjust" parameter with the

"Confirm" option. This means that you are assigning the value 0.0 to the pressure

present.

– Measured value (after pos. zero adjust) = 0.0 mbar

Options

•Confirm

•Abort

Factory setting:

Abort

Endress+Hauser 35

Page 36

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

Parameter name Description

Calib. offset (192) / (008)

(absolute pressure sensor)

Entry

Menu path:

Setup Calib. offset

Position adjustment – the pressure difference between the set point and the measured

pressure must be known.

Example:

– Measured value = 982.2 mbar (14.24 psi)

– You correct the measured value with the value entered (e.g. 2.2 mbar (0.032 psi))

via the "Calib. offset" parameter. This means that you are assigning the value 980.0

(14.21 psi) to the pressure present.

– Measured value (after calib. offset) = 980.0 mbar (14.21 psi)

Factory setting:

0.0

8.4 Level measurement

8.4.1 Information on level measurement

• The limit values are not checked, i.e. the values entered must be appropriate for the sensor

and the measuring task for the device to be able to measure correctly.

• Customer-specific units are not possible.

• There is no unit conversion.

• The values entered for "Empty calib. (028)/Full calib. (031)", "Empty pressure (029)/Full

pressure (032)", "Empty height (030)/Full height (033)" must be at least 1 % apart. The value

will be rejected, and a warning message displayed, if the values are too close together.

You have a choice of two methods for calculating the level: "In pressure" and "In height". The table

in the "Overview of level measurement" section that follows provides you with an overview of

these two measuring tasks.

8.4.2 Overview of level measurement

Measuring task Level

selection

Calibration is

performed by entering

two pressure-level

value pairs.

Calibration is

performed by entering

the density and two

height-level value

pairs.

"In pressure" Via the "Unit before

"In height" – Calibration with reference

Measured

variable options

lin. (025)"

parameter: %, level,

volume or mass

units.

Description Measured value display

– Calibration with reference

pressure (wet calibration),

see ä 37

– Calibration without

reference pressure (dry

calibration), see ä 39

pressure (wet calibration),

see ä 44

– Calibration without

reference pressure (dry

calibration), see ä 41

The measured value

display and the

"Level before lin. (019)"

parameter display the

measured value.

36 Endress+Hauser

Page 37

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

B

300 mbar

3 m

A

0 mbar

0 m

8.4.3 "In pressure" level selection

Calibration with reference pressure (wet calibration)

Example:

In this example, the level in a tank should be measured in "m". The maximum level is 3 m (9.8

ft). The pressure range is due to the filling height and the density.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• The tank can be filled and emptied.

The values entered for "Empty calib. (028)/Full calib. (031)" and the pressures present at the

device must be at least 1% apart. The value will be rejected, and a warning message displayed,

if the values are too close together. Further limit values are not checked; i.e. the values entered

must be appropriate for the sensor and the measuring task so that the measuring device can

measure correctly.

Description

1 Perform "position adjustment" ä 35.

2 Select the "Level" measuring mode via the

"Measuring mode (005)" parameter.

Menu path: Setup Measuring mode (005)

3 Select a pressure unit by means of the "Press. eng.

unit (125)" parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit (125)

4 Select the "In pressure" level mode by means of the

"Level selection (024)" parameter.

Menu path: Setup Extended Setup Level

Level selection (024)

Fig. 7: Calibration with reference pressure –

A0030028

wet calibration

A See Table, Step 7.

B See Table, Step 8.

Endress+Hauser 37

Page 38

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

A

B

h

[m]

p

[mbar]

3

0

0 300

Description

5 Select a level unit by means of the "Unit before lin.

(025)" parameter, here "m" for example.

Menu path: Setup Extended Setup Level

Unit before lin. (025)

6 Select the "Wet" option by means of the "Calibration

mode (027)" parameter.

Menu path: Setup Extended Setup Level

Calibration mode (027)

7 The pressure for the lower calibration point is

present at the device, here 0 mbar for example.

Select the "Empty calib. (028)" parameter.

Menu path: Setup Extended Setup Level

Empty calib. (028)

Enter the level value, here 0 m for example. The

pressure value present is assigned to the lower level

value by confirming the value.

8 The pressure for the upper calibration point is

present at the device, here 300 mbar (4.35 psi) for

example.

Select the "Full calib. (031)" parameter.

Menu path: Setup Extended Setup Level

Full calib. (031)

Enter the level value, here 3 m (9.8 ft) for example.

The pressure value present is assigned to the upper

level value by confirming the value.

9 If calibration is performed with a medium other

than the process medium, enter the density of the

calibration medium in "Adjust density (034)".

Menu path: Setup Extended Setup Level

Adjust density (034)

10 If calibration was performed with a medium other

than the process medium, specify the density of the

process medium in the "Process density (035)"

parameter.

Menu path: Setup Extended Setup Level

Process density (035)

11 Result:

The measuring range is set for 0 to 3 m (9.8 ft).

Fig. 8: Calibration with reference pressure –

A0017658

wet calibration

C See Table, Step 7.

D See Table, Step 8.

The measured variables %, level, volume and mass are available for this level mode.

See operating instructions "Unit before lin. (025)".

38 Endress+Hauser

Page 39

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

B

1000 l

450 mbar

A

0 l

50 mbar

r=1

g

cm

3

8.4.4 "In pressure" level selection

Calibration without reference pressure (dry calibration)

Example:

In this example, the volume in a tank should be measured in liters. The maximum volume of

1000 liters (264 gal) corresponds to a pressure of 450 mbar (6.53 psi). The minimum volume

of 0 liters corresponds to a pressure of 50 mbar (0.72 psi) since the device is mounted below the

start of the level measuring range.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the pressure and volume values for the lower and upper

calibration point must be known.

• The values entered for "Empty calib. (028)/Full calib. (031)", "Empty pressure (029)/Full

pressure (032)" must be at least 1% apart. The value will be rejected, and a warning message

displayed, if the values are too close together. Further limit values are not checked; i.e. the

values entered must be appropriate for the sensor and the measuring task so that the

measuring device can measure correctly.

• Due to the orientation of the device, there may be pressure shifts in the measured value, i.e.

when the container is empty or partly filled, the measured value is not zero. For information

on how to perform position adjustment, see ä 35, "Pos. zero adjust".

Description

1 Select the "Level" measuring mode via the

"Measuring mode (005)" parameter.

Menu path: Setup Measuring mode (005)

2 Select a pressure unit by means of the "Press. eng.

unit (125)" parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit (125)

3 Select the "In pressure" level mode by means of the

"Level selection (024)" parameter.

Menu path: Setup Extended Setup Level

Level selection (024)

4 Select a volume unit by means of the "Unit before

lin. (025)" parameter, here "l" (liter) for example.

Menu path: Setup Extended Setup Level

Unit before lin. (025)

Fig. 9: Calibration without reference pressure –

A0030030

dry calibration

A See Table, Step 7.

C See Table, Step 8.

B See Table, Step 9.

D See Table, Step 10.

Endress+Hauser 39

Page 40

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

A

B

C

D

V

[l]

p

[mbar]

1000

0

50450

Description

5 Select the "Dry" option by means of the "Calibration

mode (027)" parameter.

Menu path: Setup Extended Setup Level

Calibration mode (027)

6 "Adjust density (034)" contains the factory setting

1.0, but this value can be changed if required. The

entered value pairs must correspond to this density.

Menu path: Setup Extended Setup Level

Adjust density (034)

7 Enter the volume value for the lower calibration

point via the "Empty calib. (028)" parameter, here 0

liters for example.

Menu path: Setup Extended Setup Level

Empty calib. (028)

8 Enter the pressure value for the lower calibration

point via the "Empty pressure (029)" parameter,

here 50 mbar (0.72 psi) for example.

Menu path: Setup Extended Setup Level

Empty pressure (029)

9 Enter the volume value for the upper calibration

point via the "Full calib. (031)" parameter, here

1000 liters (264 gal) for example.

Menu path: Setup Extended Setup Level

Full calib. (031)

10 Enter the pressure value for the upper calibration

point via the "Full pressure (032)" parameter, here

450 mbar (6.53 psi) for example.

Menu path: Setup Extended Setup Level

Full pressure (032)

11 If calibration was performed with a medium other

than the process medium, specify the density of the

process medium in the "Process density (035)"

parameter.

Menu path: Setup Extended Setup Level

Process density (035)

Fig. 10: Calibration with reference pressure –

A0031028

wet calibration

E See Table, Step 7.

F See Table, Step 8.

G See Table, Step 9.

H See Table, Step 10.

12 Result:

The measuring range is set for 0 to 1000 l (264

gal).

The measured variables %, level, volume and mass are available for this level mode.

See operating instructions "Unit before lin. (025)".

40 Endress+Hauser

Page 41

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

8.4.5 "In height" level selection

Calibration without reference pressure (dry calibration)

Example:

In this example, the volume in a tank should be measured in liters. The maximum volume of

1000 liters (264 gal) corresponds to a level of 4.5 m (14.8 ft). The minimum volume of 0 liters

corresponds to a level of 0.5 m (1.6 ft) since the device is mounted below the start of the level

measuring range.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the height and volume values for the lower and upper

calibration point must be known.

• The values entered for "Empty calib. (028)/Full calib. (031)", "Empty height (030)/Full height

(033)" must be at least 1% apart. The value will be rejected, and a warning message displayed,

if the values are too close together. Further limit values are not checked; i.e. the values

entered must be appropriate for the sensor and the measuring task so that the measuring

device can measure correctly.

• Due to the orientation of the device, there may be pressure shifts in the measured value, i.e.

when the container is empty or partly filled, the measured value is not zero. For information

on how to perform position adjustment, see ä 35, "Pos. zero adjust".

Endress+Hauser 41

Page 42

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

C

1000 l

4.5 m

B

0 l

0.5 m

r=1

g

cm

3

A

Description

1 Select the "Level" measuring mode via the

"Measuring mode (005)" parameter.

Menu path: Setup Measuring mode (005)

2 Select a pressure unit via the "Press. eng. unit (125)"

parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit (125)

3 Select the "In height" level mode via the "Level

selection (024)" parameter.

Menu path: Setup Extended Setup Level

Level selection (024)

4 Select a volume unit via the "Unit before lin. (025)"

parameter, here "l" (liter) for example.

Menu path: Setup Extended Setup Level

Unit before lin. (025)

5 Select a level unit by means of the "Height unit

(026)" parameter, here "m" for example.

Menu path: Setup Extended Setup Level

Height unit (026)

6 Select the "Dry" option by means of the "Calibration

mode (027)" parameter.

Menu path: Setup Extended Setup Level

Calibration mode (027)

Fig. 11: Calibration without reference pressure –

dry calibration

A See Table, Step 7.

B See Table, Steps 8 and 9.

C See Table, Steps 10 and 11..

A0031027

7 Enter the density of the medium via the "Adjust

density (034)" parameter, here "1 g/cm

example.

Menu path: Setup Extended Setup Level

Adjust density (034)

3

" (1 SGU) for

42 Endress+Hauser

Page 43

Deltapilot M FOUNDATION Fieldbus Commissioning with an operating menu (onsite display/FieldCare)

A

h

p

g=×r

h

p

g=×r

r=1

g

cm

3

B

D

CE

V

[l]

h

[m]

h

[m]

p

[mbar]

1000

4.5

0

0.5

0.5

50

4.5

450

Description

8 Enter the volume value for the lower calibration

point via the "Empty calib. (028)" parameter, here 0

liters for example.

Menu path: Setup Extended Setup Level

Empty calib. (028)

9 Enter the height value for the lower calibration

point via the "Empty height (030)" parameter, here

0.5 m (1.6 ft) for example.

Menu path: Setup Extended Setup Level

Empty height (030)

10 Enter the volume value for the upper calibration

point via the "Full calib. (031)" parameter, here

1000 liters (264 gal) for example.

Menu path: Setup Extended Setup Level

Full calib. (031)

11 Enter the height value for the upper calibration

point via the "Full height (033)" parameter, here 4.5

m (14.8 ft) for example.

Menu path: Setup Extended Setup Level

Full height (033)

12 If the process uses a medium other than that on

which the calibration was based, the new density

must be specified in the "Process density (035)"

parameter.

Menu path: Setup Extended Setup Level

Process density (035)

13 Result:

The measuring range is set for 0 to 1000 l (264

gal).

Fig. 12: Calibration with reference pressure –

A0031066

wet calibration

A See Table, Step 7.

B See Table, Step 8.

C See Table, Step 9.

D See Table, Step 10.

E See Table, Step 11.

The measured variables %, level, volume and mass are available for this level mode operating

instructions "Unit before lin. (025)".

Endress+Hauser 43

Page 44

Commissioning with an operating menu (onsite display/FieldCare) Deltapilot M FOUNDATION Fieldbus

C

1000 l

4.5 m

B

0 l

0.5 m

r=1

g

cm

3

A

8.4.6 "In height" level selection

Calibration with reference pressure (wet calibration)

Example:

In this example, the volume in a tank should be measured in liters. The maximum volume of

1000 liters (264 gal) corresponds to a level of 4.5 m (14.8 ft). The minimum volume of 0 liters

corresponds to a level of 0.5 m (1.6 ft) since the device is mounted below the start of the level

measuring range.

3

The density of the medium is 1 g/cm

(1 SGU).

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• The tank can be filled and emptied.

The values entered for "Empty calib. (028)/Full calib. (031)" and the pressure values present at

the device must be at least 1% apart. The value will be rejected, and a warning message

displayed, if the values are too close together. Further limit values are not checked; i.e. the

values entered must be appropriate for the sensor and the measuring task so that the measuring

device can measure correctly.

Description

1 Perform position adjustment. See ä 35.

2 Select the "In height" level mode via the "Level

selection (024)" parameter.

Menu path: Setup Extended Setup Level

Level selection (024)

3 Select the "Level" measuring mode via the

"Measuring mode (005)" parameter.

Menu path: Setup Measuring mode (005)

4 Select a pressure unit via the "Press. eng. unit (125)"

parameter, here "mbar" for example.

Menu path: Setup Press. eng. unit (125)

5 Select a volume unit via the "Unit before lin. (025)"

parameter, here "l" (liter) for example.

Menu path: Setup Extended Setup Level

Unit before lin. (025)

Fig. 13: Calibration with reference pressure –

A0031027

wet calibration

A See Table, Step 8.

B See Table, Step 9.

C See Table, Step 10.

44 Endress+Hauser

Page 45