Page 1

TI00368C/07/EN/14.20

71478863

2020-04-30

Products

Solutions Services

Technical Information

Cleanfit COA451

Manually operated retractable assembly for water,

wastewater and process media

Application

Cleanfit COA451 is a retractable assembly for oxygen sensors with a diameter of 40

mm in:

• Wastewater treatment plants:

• Oxygen control in activated sludge basins

• Treatment and monitoring of process water

• Water works:

• Status monitoring for drinking water

• Water quality monitoring in rivers, lakes or seas

• All industrial utilities:

• Oxygen control in biological treatment

• Treatment and monitoring of process water

• Fish farming:

Oxygen monitoring for optimum growth conditions

Your benefits

• One assembly for all applications: the 'one-for-all' principle optimizes inventory

management, accelerates project handling and simplifies life cycle management.

• Easy and safe maintenance: sensor servicing and cleaning without interrupting the

process.

• Robust design: process pressure up to 10 bar (145 psi), manual operation up to

2 bar (29 psi).

• Convenient, time-saving operation: rinse water connection enables cleaning

without having to remove the sensor from the process.

Page 2

Table of contents

Function and system design ................... 3

Structure of the assembly ........................ 3

Structure of the sensor holder ..................... 3

Measuring system ............................. 5

Installation ................................ 5

Orientation ................................. 5

Installation instructions ......................... 5

Environment ............................... 6

Ambient temperature .......................... 6

Process ................................... 6

Medium temperature ........................... 6

Medium pressure ............................. 6

Pressure-temperature ratings ..................... 6

Cleanfit COA451

Mechanical construction ...................... 7

Dimensions ................................. 7

Certificates and approvals ................... 11

CE/PED ................................... 11

Ordering information ....................... 11

Product page ............................... 11

Product Configurator .......................... 11

Scope of delivery ............................. 12

Accessories ............................... 12

Device-specific accessories ...................... 12

Service-specific accessories ...................... 14

Accessory kits ............................... 14

2

Page 3

Cleanfit COA451

1

2

3

4

5

6

8

9

7

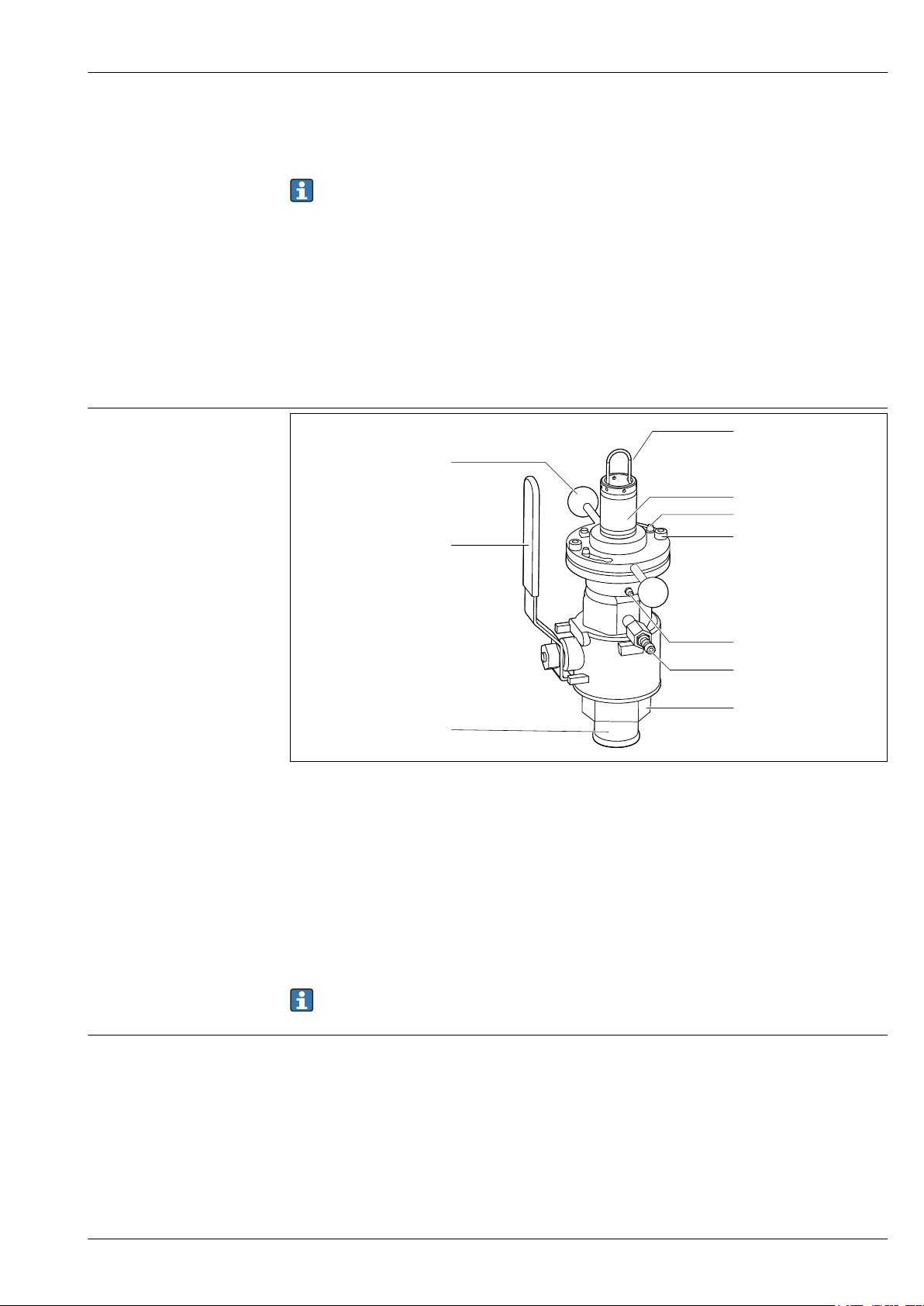

Structure of the assembly

Function and system design

The assembly is operated manually.

The vent cock or the the rinse connections (if used) are in open contact with the medium in the

measuring position and when the assembly is retracted/inserted, and are therefore exposed to

the process pressure.

The vent cock or the rinse connections (if used) must be closed when inserting/retracting the

assembly.

In the service position (sensor moved back into the assembly as far as possible and ball valve closed),

the assembly is sealed from the process by the ball valve.

This means that cleaning, calibration or sensor replacement can be performed without interrupting

the process.

The assembly can be inserted/retracted manually at process conditions up to a process pressure of

approx. 2 bar (29 psi).

A0038438

1 Assembly in operational state (ball valve open)

1 Bracket for sensor holder

2 Sensor holder

3 Bayonet lock

4 Securing screws

5 Grease nipple

6 Ball valve/valve for venting or rinse connection

7 Process connection

8 Retraction pipe

9 Hand lever for opening/closing the ball valve

10 Handles

An additional rinse chamber valve can be mounted in the locking screw opposite the vent valve.

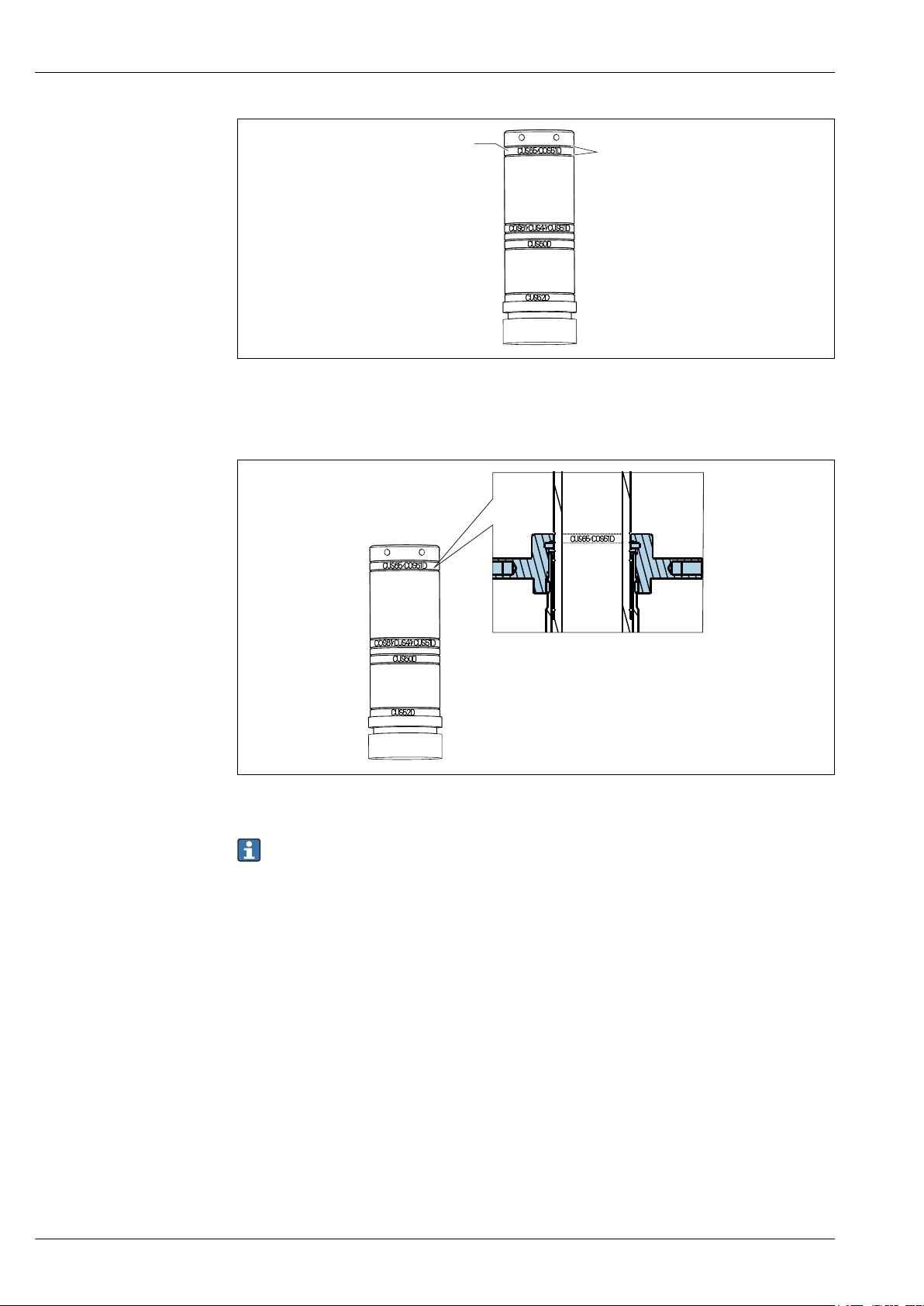

Structure of the sensor holder

The sensor holder is used to position the sensor correctly in order to ensure correct measuring

accuracy.

If the sensor is not positioned correctly, the ball valve may be blocked or the sensor may be located in

the dead space as a result.

3

Page 4

2

2 Short sensor holder

1 Mounting position of the bayonet nut to hold the relevant sensor

2 Grooves of the safety rings to mount the bayonet nut

Cleanfit COA451

A0038451

A0038479

3 Mounting position of the bayonet nut for CUS65D or COS51D

The name indicated on the holder serves as a mounting aid. The bayonet nut covers over the

marking for the selected sensor position.

4

Page 5

Cleanfit COA451

1

3

4

2

Measuring system

4 Orientations, schematic

1 Sensor (see Accessories)

2 Transmitter

3 Retractable assembly

4 Direction of flow

The orientation depends on the sensor head. Pay attention to the Operating Instructions for the

relevant sensor. An inclination of at least 15° is recommended for amperometric sensors

Make sure to avoid a siphon effect at the rinse chamber outlet. The inflow to the rinse chamber

‣

is always from below.

A0038660

Orientation

Installation

The following diagram shows different installation positions in pipes, and indicates whether they are

permitted or not.

A0038661

5 Schematic of installation positions and orientations

Ideally, the assembly should be mounted in an ascending pipe. Installation in a horizontal pipe is

‣

also possible.

• Install the sensor in places with uniform flow conditions.

• Do not install the sensor in places where air may collect or foam bubbles form or where suspended

particles may settle.

• Avoid installation in the down pipe.

• Avoid fittings downstream from pressure reduction stages which can lead to outgassing.

Installation instructions

Install the assembly in places with uniform flow conditions. The minimum pipe diameter is DN

‣

80.

The installation instructions depend on the sensor used.

Detailed installation instructions are provided in both the Technical Information and in the

Operating Instructions for the particular sensor.

5

Page 6

Environment

8070605040

30

2010

2

4

6

8

10

29

58

87

116

p

p

[psi]

[bar]

176158140

122

104

86

6850

T[°C]

T[°F]

A

85

185

Cleanfit COA451

Ambient temperature

Medium temperature

Medium pressure

Pressure-temperature ratings

0 to 50 °C (32 to 122 °F)

Process

0 to 85 °C (32 to 185 °F)

Max. 10 bar (145 psi)

For manual insertion/retraction of the assembly, the medium pressure must not exceed 2 bar

(29 psi)! Also take the process conditions of the sensor used into consideration!

6 Pressure/temperature ratings

A Range in which the assembly can be operated manually

A0038761

6

Page 7

Cleanfit COA451

226 (8.90)

Ø 49.3

(1.94)

X0

100

(3.94)

Ø 46

(1.81)

106

(4.17)

1 (0.04)

X1

311 (12.24)

67

(2.64)

185 (7.28)

270 (10.63)

109.5 (4.31)

92 (3.62)

115.5 (4.55)

Ø 86 (3.39)

Ø 91 (3.58)

X0

Mechanical construction

Dimensions Assembly with G2 thread and weld-in adapter in measuring position (long and short stroke)

A0038481

7 Dimensions in mm (in)

X0,X1Dimensions depend on the sensor

7

Page 8

Cleanfit COA451

101 (3.98)

X2

171

(6.73)

100

(3.94)

32

(1.26)

X2

276 (10.87)

Assembly with G2 thread and weld-in adapter in service position (long and short stroke)

8 Dimensions in mm (in)

X2 Dimensions depend on the sensor

A0038630

8

Page 9

Cleanfit COA451

Ø 49.3

(1.94)

Ø 46

106 (4.17)

X0

100

(3.94)

X1

85

(3.35)

32 (1.26)

226 (8.90)

(1.81)

32

(1.26)

X2

276 (10.87)

100

(3.94)

101 (3.98)

Assembly with flange connection

9 Dimensions in mm (in)

X0,X2Dimensions depend on the sensor

Sensor X0

CUS52D 25 (0.98)

CUS50D 26 (1)

CUS41/ 16 (0.63)

CUS51D 5 (0.2)

COS61D 12 (0.47)

CUS65 21 (0.83)

COS51D 12 (0.47)

Sensor measuring

position

CUS52D 139 (5.47)

CUS50D 110 (4.33)

CUS41/CUS51D,

COS61D

CUS65, COS51D 59 (2.32)

X1

101 (3.98)

A0038651

Sensor service

position, long

CUS52D 638 (25.12)

CUS50D 609 (23.98)

X2

9

Page 10

Cleanfit COA451

9.25

(0.37)

51.4

(2.02)

60.2

(2.37)

89.5

(3.52)

COS51D

CUS65(D)

COS61(D)

CUS41(D)

CUS51D

CUS50D

CUS52D

131

(5.16)

173 (6.81)

182 (7.17)

211 (8.31)

32

(1.26)

Sensor service

position, long

CUS41/CUS51D,

COS61D

CUS65, COS51D 558 (21.97)

Sensor service

position, short

CUS52D 533 (20.98)

CUS50D 504 (19.84)

CUS41/CUS51D,

COS61D

CUS65, COS51D 453 (17.83)

X2

600 (23.62)

X2

495 (19.49)

Sensor holder with sensors

10

10 Dimensions of sensor holder with sensors in mm (in)

A0038478

Page 11

Cleanfit COA451

A

2"

32 (1.26)

a

b

B

C

Process connections

A0038650

11 Dimensions of process connections in mm (in)

A G2" female thread

B G2" female thread with weld-in adapter

C Flange DN 50 / PN 16 (as per EN 1092-1) and flange ANSI 2" / 150 lbs

a DN 50: Ø 125 (4.92), ANSI 2": Ø 120.7 (4.75)

b DN 50: Ø 165 (6.50), ANSI 2": Ø 152.4 (6.00)

Rinse connection and vent cock

Rinse connection nozzles

Connection options:

• 2 x ball valve with hose connection OD 9mm (see "Accessories"). (A ball valve is included in the

delivery for the assembly. On its own it acts as a vent cock.)

• Customer's own rinse connections with G1/8 external thread

• 2 x G1/8 (internal)

Vent cock

Ball valve with hose connection OD 9 mm

CE/PED

Weight

Depending on version: 8 to 11 kg (17.6 to 24.3 lbs)

Materials

Wetted: Viton (seals)

Stainless steel 1.4404 (AISI 316 L)

Nickel-plated brass (vent cock or rinse connection)

Not wetted: Stainless steel 1.4404 (AISI 316 L)

Certificates and approvals

The assembly has been manufactured according to good engineering practice as per Article 4,

Paragraph 3 of the Pressure Equipment Directive 2014/68/EU and is therefore not required to bear

the CE label.

Ordering information

Product page

Product Configurator

www.endress.com/CUA451

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

11

Page 12

Cleanfit COA451

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

Scope of delivery

The delivery comprises:

• Assembly in the version ordered

• Operating Instructions

Accessories

Device-specific accessories Sensors

Oxymax COS41

• Oxygen sensor for drinking water and industrial water measurement, amperometric measuring

principle

• Material: POM

• Product Configurator on the product page: www.endress.com/cos41

Technical Information TI00248C

Oxymax COS51D

• Amperometric sensor for dissolved oxygen

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos51d

Technical Information TI00413C

Oxymax COS61

• Optical oxygen sensor for drinking water and industrial water measurement

• Measuring principle: quenching

• Material: stainless steel 1.4571 (AISI 316Ti)

• Product Configurator on the product page: www.endress.com/cos61

Technical Information TI00387C

12

Oxymax COS61D

• Optical oxygen sensor for drinking water and industrial water measurement

• Measuring principle: quenching

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos61d

Technical Information TI00387C

Welding socket

Welding socket

• Welding socket for pipe diameter from 80 mm, with combination flange DN 50 / ANSI 2":

• Bores for DN 50 flange: 4 x 90° Ø18 on bolt circle Ø125 (4.92)

• Bores for ANSI 2" flange: 4 x 90° Ø19 on bolt circle Ø121 (4.75)

• Flange seal, 4 screws M16x60, 4 M16 nuts including washers,

• Stainless steel 1.4571 (AISI 316 Ti)

• Order No. 50080249

Page 13

Cleanfit COA451

D

D

D

D

M16x60

75 (2.95)

93 (3.66)

Ø 165 (6.50)

2"

50

(1.97)

3.6 (0.14)

A0038764

12 Welding socket, dimensions in mm (in)

D Markings for bores, DN 50 flange

Welding nipple

• Welding nipple for 2" thread

• Stainless steel 1.4404 (AISI 316 L)

• Order No. 71448684

A0038763

13 Welding nipple, dimensions in mm (in)

Welding rinse socket DN 65

• For automatic spray cleaning of CUS51D/31/41 sensors in pipes and vessels:

• Bores for DN 50 flange: 4 x 90° Ø18 on bolt circle Ø125

• Bores for ANSI 2" flange: 4 x 90° Ø19 on bolt circle Ø121

• Rinse connection: male thread R¼

• With removable rinse nozzle

• Up to 6 bar (87 psi), 80 °C (176 °F)

• Order No. 51500912

13

Page 14

Cleanfit COA451

D

D

D

D

118 (4.65)

54 (2.13)

Ø 70

33

66 (2.6)

Ø 165 (6.50)

18 (0.71)

(2.76)

(1.3)

Service-specific accessories

Accessory kits

14 Welding rinse socket, dimensions in mm (in)

D Markings for bores, DN 50 flange

Ball valve for rinse chamber

• As rinse connection complementing or replacing the vent cock supplied;

• Order No. 51512982

O-ring set

• Viton + FPM

• Order No. 51512981

A0038762

14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...