Page 1

Product Data Document

1660DS-7c

July 17, 2007 - Page 1

Bristol® ControlWave® XFC

Gas Flow Computer

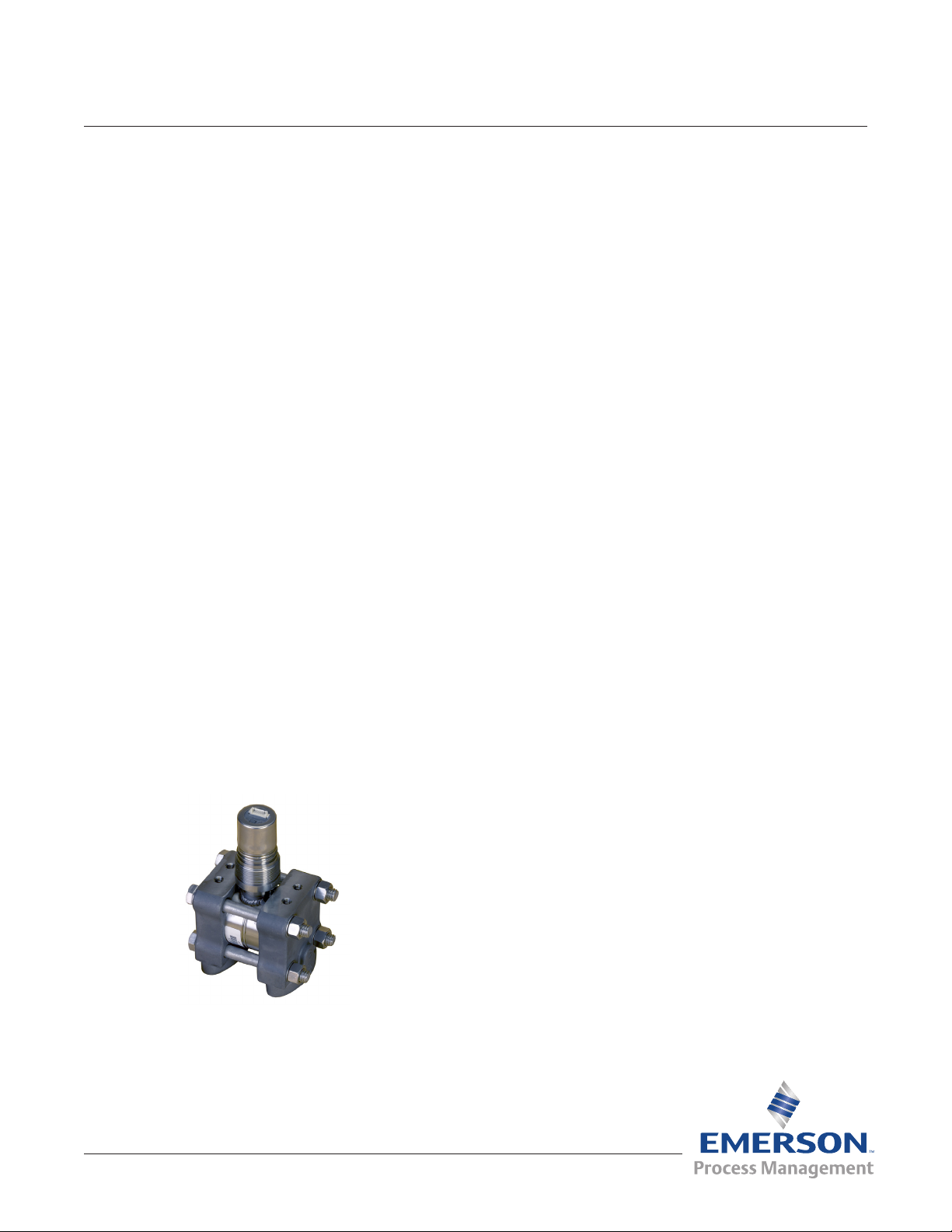

Bristol® ControlWave® XFC, from Emerson Process Management is a cost effective, competitive

solution when requirements call for a chart replace-

ment or ow computer in a compact, explosion-

proof package.

Additionally, ControlWave XFC provides extended

capabilities, such as a second meter run or plunger

lift control, while maintaining the convenience and

simplicity of an integrated, explosion-proof installation.

ControlWave XFC Overview

Hardware/Packaging Features

Smart, gauge pressure or DP/P sensor

•

assembly can be removed and replaced,

independently of the "top end" assembly.

Precision RTD interface provides very accurate

•

process temperature measurement.

Wide, 6.0 to 30.0 Vdc operating input voltage

•

range works with a broad range of power

sources.

Now available with Integral

P/T or DP/P/T Measurement

ControlWave XFC comes in a very compact,

explosion-proof package. Smart DP/P sen-

sor assembly is shown in this photo.

Very low power consumption minimizes costs of

•

solar/battery power systems.

Three serial communication ports are standard.

•

Optional I/O includes 2 DI, 2 High-speed

•

Counter inputs and 4 DO as well as an

additional 3 AI and 1 AO.

Integral 2-line LCD operates in a continuous

•

cycle mode.

Operating temperature range is -40 to 176ºF

•

(-40 to 80ºC).

Class I, Division 1 (explosion-proof) and

•

Division 2 NI approved.

Readily integrates with Emerson’s Bristol 2808

•

and 3808 MVT low power transmitters for

explosion-proof installations.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Firmware/Software Features

ControlWave XFC is pre-programmed to meet

•

API 21.1 requirements for a two-run metering

station with networking via BSAP or Modbus.

PC web style menu pages are pre-congured

•

for all user operations.

Using our ControlWave Designer, IEC 61131-3

•

programming environment, any user or third

party can modify the standard application or

create a completely customized program—and

full support from Emerson is available, every

step of the way.

Additional, standard application programs will

•

be introduced on a continual basis.

Page 2

Product Data Document

1660DS-7c

July 17, 2007 - Page 2

Application Areas

ControlWave XFC is appropriate to all applications

for ow computers, including those that require

process control or extension to two meter runs, for

example:

Production wells

•

Injection wells

•

Production optimization applications

•

Off-shore platforms

•

Separation plants

•

Compressor stations

•

Storage facilities

•

Transmission metering stations

•

Distribution/LDC metering/gate stations

•

Bristol® ControlWave® XFC

Wetted parts material, stainless steel or

•

Hastelloy C

Optional manifold adapters

•

Optional mounting bracket

•

Standard application program

•

I/O conguration choices are no I/O; 2 DI, 2

•

HSC, 4 DO; and 2 DI, 2 HSC, 4 DO plus 3 AI

and 1 AO.

Specications – Package

Dimensions: Please see the diagram on page

•

14

Clearance: Please allow at least 2.5” space on

•

either side for cabling.

Dimensions: MVT Wet End: 3” H x 3¾” W x 2½”

•

D

Using the gauge pressure sensor, ControlWave

XFC provides accurate, P/T measurement for linear

meters, including positive displacement, turbine

and ultrasonic technologies. The multivariable,

DP/P sensor applies best to orice metering, where

accurate, three-variable (DP/P/T) measurement is

required.

Package Description

ControlWave XFC is ordered using a model number

specication. The complete model number specication is included toward the end of this product

data.

Standard equipment includes an explosion-proof

housing, two-board electronics assembly with 3 serial ports RTD interface, 2-line LCD, and the standard API 21.1 EFM application program. Emerson’s

Bristol smart sensor assembly, which provides

measurement of gauge pressure or differential pressure plus static pressure, is also standard equipment.

The model number additionally allows a user to

specify the following:

Weight: 12 lbs.

•

Mounting: Pipe-mounting or direct-mounting is

•

recommended; a 2” pipe-mount kit is optional.

Specications – Operating Environment

Wide operating power input voltage range of

•

6.0 to 30.0 Vdc. Shutdown sequence occurs at

5.46 Vdc nominal.

Power input surge suppression: 30V transorb

•

to ground meets ANSI/IEEE C37.90-1978.

Fuse: 0.375 A slow blow.

•

Operating Temperature Range: -40 to 176ºF

•

(-40 to 80ºC).

Operating Humidity Range: 10 to 95% RH non-

•

condensing.

Vibration Rating: Maintains proper operation

•

while subjected to a 2.0g acceleration over 10-

150 Hz and 1.0g acceleration over 150-2000

Hz.

RFI Immunity: In conformity with IEC 1000-4-3

•

Level 2 80 MHz to 1000 MHz.

Sensor upper range limits

•

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 3

Product Data Document

1660DS-7c

July 17, 2007 - Page 3

ESD: Field connected circuits meet the

•

requirements of IEC 1000-4-2 for ESD

withstand capability up to 4KV.

Nema Rating: Nema 4, 4x and 7.

•

Hazardous Area Approvals

Explosion-proof for operation in Class I, Division

•

1 Hazardous Areas: UL/CUL Approved.

Non-incendive for Class I, Division 2 Hazardous

•

areas: UL/CUL Approved.

Selection Item Descriptions and

Specications

Emerson’s Bristol Sensor Assembly

Bristol® ControlWave® XFC

can change it out and continue operating with the

"top end" electronics, including ow information,

alarms and historical archives, all intact.

Emerson recommends that users practice “depot

level” service, in other words, that the sensor assembly be removed and replaced at the user’s shop

rather than out at the site.

Each sensor assembly has a nine-digit part number,

which can be used to specify a replacement part

(please refer to the last page of this product data).

Physical Specications – MVT Assembly

Flange Material: Hastelloy C or 316 Stainless

•

Steel

Flange Bolt Material: Hastelloy C or 316

•

Stainless Steel

The sensor assembly is Selection “ABC” in the

model specication, e.g. “022” for the 100 psi gauge

pressure sensor or "142" for a 300" DP/2000 psig

static pressure multivariable sensor assembly.

Using the integral sensor assembly is the easiest

implementation for a single meter run; however, the

standard application program also allows use of

external transmitters.

Multiple-run systems can use the integral sensor

assembly for the rst run and an external, smart

multivariable transmitter, such as the Bristol 3808

MVT from Emerson(which includes the exact same

sensor assembly), for additional meter runs.

If the sensor assembly requires a repair, the user

Diaphragm Material: Hastelloy C or 316

•

Stainless Steel

Fill Medium: DC 200 Silicone

•

Flange Process Connections: ¼” NPT

•

Connects to the main electronics via a

•

dedicated SPI bus cable.

Note: Wetted parts materials, Hastelloy C or Stainless Steel, are specied in Selection “D.”

Accuracy and Performance Specications

– Gauge Pressure or Differential Pressure/

Static Pressure

Combined effects of nonlinearity,

•

nonrepeatability and hysteresis at reference

pressure and over the operating temperature

range: GP, DP and SP linear mode: ±0.075% of

Calibrated Span or 0.015% of URL, whichever

is greater.

Temperature effect on Static and Differential

•

pressure: ±0.21%URL maximum combined shift

of zero and span with an ambient temperature

change of 60ºC (108ºF)

Bristol DP/P Multivariable

Sensor Assembly

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Static Pressure Effects On Differential Pressure:

•

Zero error: ±0.1% URL, for a change in static

pressure of 1000 psi; Span error: ±0.1%

Page 4

Product Data Document

1660DS-7c

July 17, 2007 - Page 4

Bristol® ControlWave® XFC

reading, for a change in static pressure of 1000

psi

Long Term Stability at Constant Conditions:

•

±0.1% URL/Year typical

Mounting position effect: ±2 in H2O maximum,

•

which can be calibrated out.

Ripple and noise: Per ISA 50.1 Section 4.6

•

Sensor Assembly Wetted Parts Material

Selection “D” allows the user to choose the material

used in the ange bolts, anges and diaphragm in

the sensor assembly. Materials are 316 stainless

steel and Hastelloy C.

Processor/Main Electronics

The electronics assembly consists of two circuit

boards with the CPU, LCD display, communication,

dc/dc power system controller functions and the

I/O functions all installed within the explosion-proof

housing.

CPU/System Controller specications are listed

here. For information and specications on the I/O,

please refer to the description for Selection “K,” “I/O

CONFIGURATION,” on page 6.

3 Serial Communication Ports (see below for

•

further information)

6.0 to 30.0 Vdc Power Supply with Power Fail

•

Sequencer

Two-line LCD with nine, seven-segment

•

numeric characters plus polarity on line 1 and

six, fourteen-segment alphanumeric characters

on line 2.

Information on the Serial Ports

COM1:

RS 232

•

Three wire interface

•

300 to 115.2K baud rates

•

Physical Interface is on the main termination

•

assembly.

COM2:

RS 232

•

300 to 115.2K baud rates

•

Physical Interface is on the main termination

•

assembly.

Supports RTS, CTS, DTR, and DCD modem

•

control signals

Specications for CPU/System

Controller

32-bit ARM9TDMI RISC Core Processor

•

running at 14 MHz

Serial Real Time Clock Accurate to 5 seconds/

•

month at 25 ºC

512 KB Flash Boot/Downloader

•

2 MB SRAM

•

8 MB Simultaneous Read/write Flash

•

Backup Battery for Real Time Clock and SRAM:

•

300 mA-Hour Lithium Coin Cell, 4000 Hour

Backup Time

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

RS 232 transceivers are enabled by the port’s

•

DTR.

DCD remains active in power-down mode.

•

COM3:

RS 485, 2-wire

•

300 to 115.2K baud rates

•

Physical Interface is on the main termination

•

assembly.

Page 5

Product Data Document

1660DS-7c

July 17, 2007 - Page 5

ControlWave XFC

Standard Application Program

Selection “EF” allocates two digits with the expectation that we will offer a number of standard applications in the future. Currently, the two-run M&R

program is the only one available.

ControlWave XFC is shipped with the program

(.MWT le) loaded in Flash and the Flash Conguration Program (FCP) also loaded.

For users who expect to use their own program,

ControlWave XFC can also be ordered without an

application program.

Bristol® ControlWave® XFC

The PC menu pages, calibration utility and

•

program load are all included on the BSI Cong

CD.

Standard conguration is a one-run or two-run

•

station.

Each run can be orice, turbine/PD or

•

ultrasonic.

Flow calculations include the following:

•

AGA3-1992 with selectable AGA8 Gross or

•

AGA8 Detail

AGA3-1985/NX-19

•

AGA7/NX-19

•

AGA7 with selectable AGA8 Gross or AGA8

•

Detail

Auto Adjust AGA7/NX-19

•

Auto Adjust AGA7 with selectable AGA8

•

Gross or AGA8 Detail

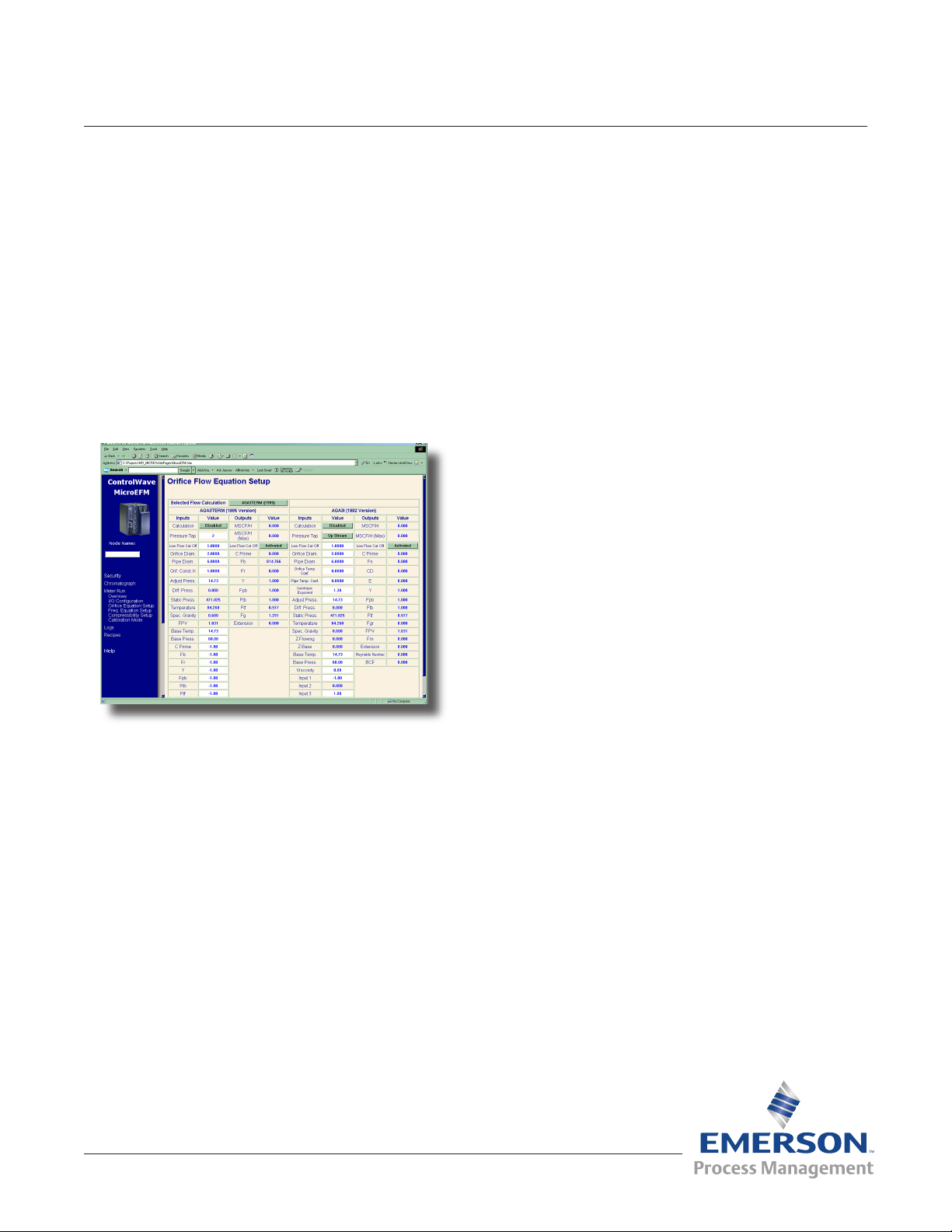

The user’s interface to the Standard Application Program

is via a series of straight-forward web style menu pages.

Overview of the Standard Application

Program

Uses pre-congured web style menu pages for

•

user readings, conguration and maintenance—

PC menu pages can be modied and new

pages congured to work with a modied

application load.

Uses the LocalView Calibration Utility for

•

calibration of all transducers, including the

integral sensor and external, Bristol transmitters

(e.g. 3808 MVT).

Allows the user to select the integral sensor

•

assembly or an external transmitter. External

transmitters can be interfaced via RS 485 or

analog inputs.

Includes an auto-selector, PID ow/pressure

•

control algorithm

Includes run switching

•

Resides on a BSAP SCADA network

•

Supports a sampler and an odorizer

•

Provides audit trail and archives

•

Includes a nominations function

•

Allows the user to select engineering units from

•

a broad variety, including English and metric

Provides energy throughput as well as

•

composition information (note that a

chromatograph is not supported by the standard

application program).

Provides control for external modems and

•

radios for power saving and other modes of

operation.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 6

Product Data Document

1660DS-7c

July 17, 2007 - Page 6

Bristol® ControlWave® XFC

Communication Port Conguration for the

Standard Application Program

COM1 – Local RS 232 port for conguration via a

PC. Flash conguration is BSAP Slave, 115.2K

baud rate.

COM2 – RS 232 Network port with Flash conguration of BSAP Slave, 9600 baud. The standard

application program is compatible with an external

communication device via RS 232.

COM3 – RS 485 port with Flash conguration of

BSAP Master at 9600 baud. The standard application program assumes that a 3808 MVT smart

multivariable transmitter is to be interfaced to this

port.

Hazardous Area Certication

Class I, Division 1 certication via the explosion

proof packaging and Class I, Division 2 certication

via non-incendive electronics are specied in selection “G.”

Manifold Adapters

ration if use of any I/O is anticipated in the future

because addition of the points requires a changeout of the I/O card—due to hazardous area certication requirements, that can be done only at the

factory.

ControlWave XFC I/O Specications

Discrete Inputs

Number of points: 2

•

Input conguration: Internally sourced dry

•

contact

Input ltering: 15 milliseconds

•

Input current: 60 uA nominal.

•

“0” state voltage: Below 1.5V

•

“1” state voltage: Above 1.5V

•

Maximum Scan Rate: once per second

•

Electrical isolation: None

•

Surge Suppression: 30V transorb between

•

signal and ground meets ANSI/IEEE C37.901978

Optional manifold adapters, which come in a set of

two, one for each ange for the DP/P sensor assembly, are available in stainless steel and specied

in selection “H.”

Mounting Bracket

An optional mounting bracket, which afxes to the

neck of the housing and allows installation on a wall

or 2” pipe, can be specied in selection “J.”

I/O Conguration

In selection “K,” the user can choose a conguration

without I/O, one with 2 DI, 2 HSC and 4 DO, and

one with 2 DI, 4 DO, 2 HSC plus 3 AI and 1 AO.

It is recommended that users select an I/O congu-

Terminations: Pluggable Terminal block

•

accommodates up to 14 gauge wire size

Discrete Outputs

Number of points: 4

•

Conguration: Open Drain MOSFET, externally

•

sourced

Maximum load current: 400 mA at 30 Vdc

•

Maximum Update Rate: once per second

•

Electrical isolation: None

•

Surge Suppression: 30V transorb between

•

signal and ground meets ANSI/IEEE C37.901978

Terminations: Pluggable Terminal block

•

accommodates up to 14 gauge wire size

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 7

Product Data Document

1660DS-7c

July 17, 2007 - Page 7

Bristol® ControlWave® XFC

High Speed Counter Inputs

Number of points: 2

•

Input Range: Internally source dry contact input

•

Frequency range: 0 – 10,000 Hz

•

Input ltering: 20 microseconds

•

One shot pulse conditioned signal to MSP

•

counter

Signal Conditioning: Debounce circuit for

•

contact closures and bandwidth limiting for

counter input

Input current: 200uA

•

“0” state voltage: Above 1.5V

•

“1” state voltage: Below 1.5V

•

Electrical isolation: None

•

Surge Suppression: 30V transorb between

•

signal and ground meets ANSI/IEEE C37.901978

Terminations: Pluggable Terminal block

•

accommodates up to 14 gauge wire size

Analog Inputs

Point Count: 3 Inputs, Single ended

•

Range: 1-5 Vdc, externally powered

•

Input Impedance: 1 M ohm

•

Filter: single pole

•

Analog Output

Point Count: One analog output

•

Range: 4-20mA Sink

•

Maximum drive for 4-20 mA output: 450 Ohms

•

Resolution: 16-bits

•

Accuracy: +/- 0.1% of full scale at 25ºC; +/-

•

0.2% of full scale from -20 to 70ºC, +/- 0.3% of

full scale; -40 to 80ºC

Maximum Update Rate: once per second

•

Surge Suppression: 9V transorb between

•

signal and ground meets ANSI/IEEE C37.901978

Terminations: Pluggable Terminal block

•

accommodates up to 16 gauge wire size

RTD Interface Information

A three-wire platinum RTD per DIN 43760 is supported. The temperature, T, in degrees Celsius is

calculated using the Resistance vs. Temperature

Tables according to the DIN EN 60751 standard for

Class A & B RTDs. The DIN EN 60751 equation is:

R(t) = R0 * (1 + At +Bt2)

Where:

A = 3.9083 * 10-3 oC-1

B = -5.775 * 10-7 oC-2

R0 = 100ohms

Accuracy +/- .1% of full scale at 25ºC; +/- .2%

•

of full scale from -20 to 70ºC; +/- .3% of full

scale from -40 to 80ºC

Maximum Scan Rate: once per second

•

Surge Suppression: 9V transorb between

•

signal and ground meets ANSI/IEEE C37.901978

Terminations: Pluggable Terminal block

•

accommodates up to 16 gauge wire size

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

In addition, the user may enter the R0, A, and B

coefcients of a custom calibrated RTD, another

platinum standard or a different material (Nickel,

Balco or Copper).

During the RTD calibration, the user will be able to

set the coefcients, restore the factory default for

these coefcients, and calibrate the internal Refer-

ence resistor.

RTD Input Specications

These specications are for the interface only, not

including the RTD probe or wiring (please note that

Page 8

Product Data Document

1660DS-7c

July 17, 2007 - Page 8

RTD probe interchangeability can add ±0.7°C of

uncertainty to the measurement).

RTD Conversion Accuracy: ± 0.1°C, or ± 0.1%

•

of reading, whichever is greater

Ambient temperature effect on RTD

•

measurement: ±0.01°C / ºC max

Long Term Stability at Constant Conditions:

•

±0.25ºC / month max

Accessories

Bristol® ControlWave® XFC

Bendable RTD

The user can choose a bendable RTD that is attached to the ControlWave XFC via an armored

cable of 6-foot, 15-foot or 25-foot length. The

individual wires attach to a terminal block on the

termination plate.

The RTD assembly includes a tting, which is

installed in the right-hand (when looking at the termination plate end of the instrument) conduit port.

Normally, this RTD would be used to provide the

process temperature input but the standard application program also allows the user to select an

external temperature transmitter, instead.

The bendable RTD is a “one size ts all” solution

that is perfect for most applications and excellent for

depot-level inventory situations in which the ultimate

installation (and, therefore, thermowell depth) is not

necessarily known.

The 12” probe can quickly be inserted in a

thermowell, whereupon the user can tighten the in-

cluded tting to lock it in place and bend the excess

length out of the way.

Note also that the bendable RTD assembly is approved only for use in Class I, Division 2 hazardous

areas and is not explosion proof.

Bendable RTD Assembly Part Numbers

6 Foot Cable - 621564-01-0-KIT

•

15 Foot Cable - 621564-02-8-KIT

•

25 Foot Cable - 621564-03-6-KIT

•

PC CABLES

PC cables for ControlWave XFC will be released in

the near future

STANDARD APPLICATION PROGRAM AND PC

MENU PAGES

ControlWave XFC normally comes pre-loaded

with the Standard Application Program (.pro le)

in Flash. However, the PC menu pages are not

loaded in Flash but are available either via the Emerson Process Management web site or on a CD.

The CD is the “BSI Cong” CD, which also contains

the LocalView Calibration Tool as well as a copy of

the Standard Application Program.

Note that a thermowell is required for this bendable

RTD!

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

BSI Cong CD – p/n 395575-02-8

For users wishing to modify the Standard Application Program, it is available as source code. Please

contact Emerson’s Remote Automation Solutions

Application Services department for information.

Page 9

Product Data Document

1660DS-7c

July 17, 2007 - Page 9

Bristol® ControlWave® XFC

Open Standards For Programming, Network

Conguration and Communication

Only ControlWave brings the perfect combination of

industry standards to minimize learning, engineering

and implementation costs.

By adhering to such industry standards as Ethernet,

TCP/IP, Microsoft Windows®, COM/DCOM, FTP,

OLE and ActiveX, ControlWave is able to achieve

the highest degree of openness in control system

architecture and bring the optimal process efciency

and productivity needed to ensure a successful

system implementation.

ControlWave Designer with ACCOL III

ControlWave XFC is compatible with ControlWave

PAC/RTU products, above, as well as the other mem-

bers of the ControlWave ow computer family.

Product Family Compatibility

ControlWave XFC is compatible with Emerson’s

Bristol ControlWave family. It is fully software-compatible with ControlWave GFC, ControlWave EFM,

ControlWave Micro and the ControlWave Process

Automation Controller (PAC). The ControlWave

PAC provides the highest I/O capacity and supports

up to three Ethernet ports as well as redundancy.

This family compatibility is a major benet to users

whose operations include a number of larger installations in addition to those that require ow computers. ControlWave family products are capable of all

measurement & control functions at sites such as

major, custody-transfer metering stations, compressor stations, off-shore platforms, processing plants

and storage facilities.

Users will not only appreciate the similarity in much

of the hardware but will also nd the documentation, networking and software compatibilities to be

important to their asset management.

To minimize your engineering and development

time, we have adopted the international standard for

controller programming, IEC 61131-3. ControlWave

Designer is a fully IEC 61131-3-compliant programming environment for the ControlWave family of

products. ControlWave Designer includes all ve

IEC 61131-3 process languages for batch, continu-

ous and discrete control: Function Block Diagram,

Structured Text Sequential Function Chart, Ladder

Logic Diagram and Instruction List.

ControlWave Designer includes an extensive library

of more than 200 basic IEC 61131-3 functions and

function blocks common to many IEC 61131-3

based products. These include:

Flip-ops, Counters & Timers

•

Ladder diagram functions – coils and contacts,

•

etc.

Numerical, Arithmetic & Boolean functions

•

– Sine, Cosine, Add, Sub, Square Root, And,

Or, etc.

Selection & Comparison – Min, Max, Greater

•

than, Equal, Less than, etc.

Type conversions – Integer to Real, Boolean to

•

Word, etc.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 10

Product Data Document

1660DS-7c

July 17, 2007 - Page 10

ACCOL III

In addition to the basic functions and function

blocks, ControlWave Designer brings the benet

of many years experience in measurement and

SCADA to the Bristol ACCOL III function block

library. ACCOL III includes over sixty function blocks

that are valuable for use in oil & gas and process

measurement & control applications. Further, ACCOL III is designed to take full advantage of the

signicant features offered by ControlWave.

Briey, this library includes function blocks for:

AGA gas ow and API liquids calculations

•

Audit, Archive, File Handling

•

Average, Compare, Totalize

•

Scheduling & Sequencing

•

PID & Lead/Lag

•

Bristol® ControlWave® XFC

In addition, ControlWave ensures data integrity, in

the event of a communication interruption, by storing critical time-stamped alarm and historical data

in the controller memory. This data is then securely

retrieved when communication is restored.

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division , are wholly owned subsidiaries of Emerson Electric Co. doing business as Remote Auto-

mation Solutions (“RAS”), a division of Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co. All other marks are property of their

respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as war-

ranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or

specications of such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available upon request. RAS does not assume responsibility for

the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product remains solely with the purchaser and end-user.

Emerson Process Management

Remote Automation Solutions

Watertown, CT 06795 USA T 1 (860) 945-2200

Mississauga, ON 06795 Canada T 1 (905) 362-0880

Worcester WR3 8YB UK T 44 (1) 905-856950

Website: www.EmersonProcess.com/Remote

Page 11

Product Data Document

1660DS-7c

July 17, 2007 - Page 11

Bristol® ControlWave® XFC

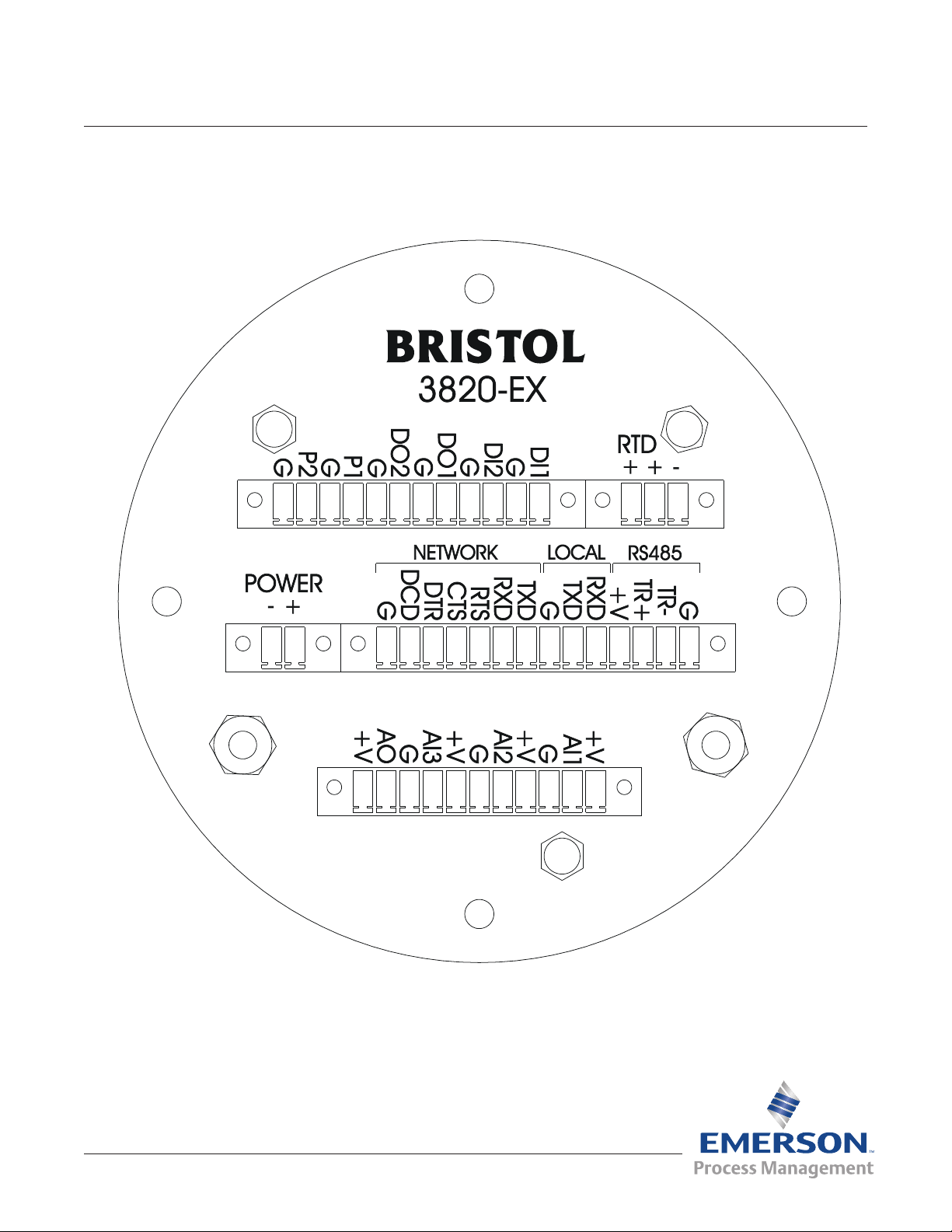

ControlWave XFC Termination Panel - No I/O (note that all three serial ports and the RTD

input are always available, regardless of the I/O selection.)

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 12

Product Data Document

1660DS-7c

July 17, 2007 - Page 12

Bristol® ControlWave® XFC

ControlWave XFC Termination Panel - With Digital I/O

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 13

Product Data Document

1660DS-7c

July 17, 2007 - Page 13

Bristol® ControlWave® XFC

ControlWave XFC Termination Panel - With Full I/O Complement

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 14

Product Data Document

1660DS-7c

July 17, 2007 - Page 14

Bristol® ControlWave® XFC

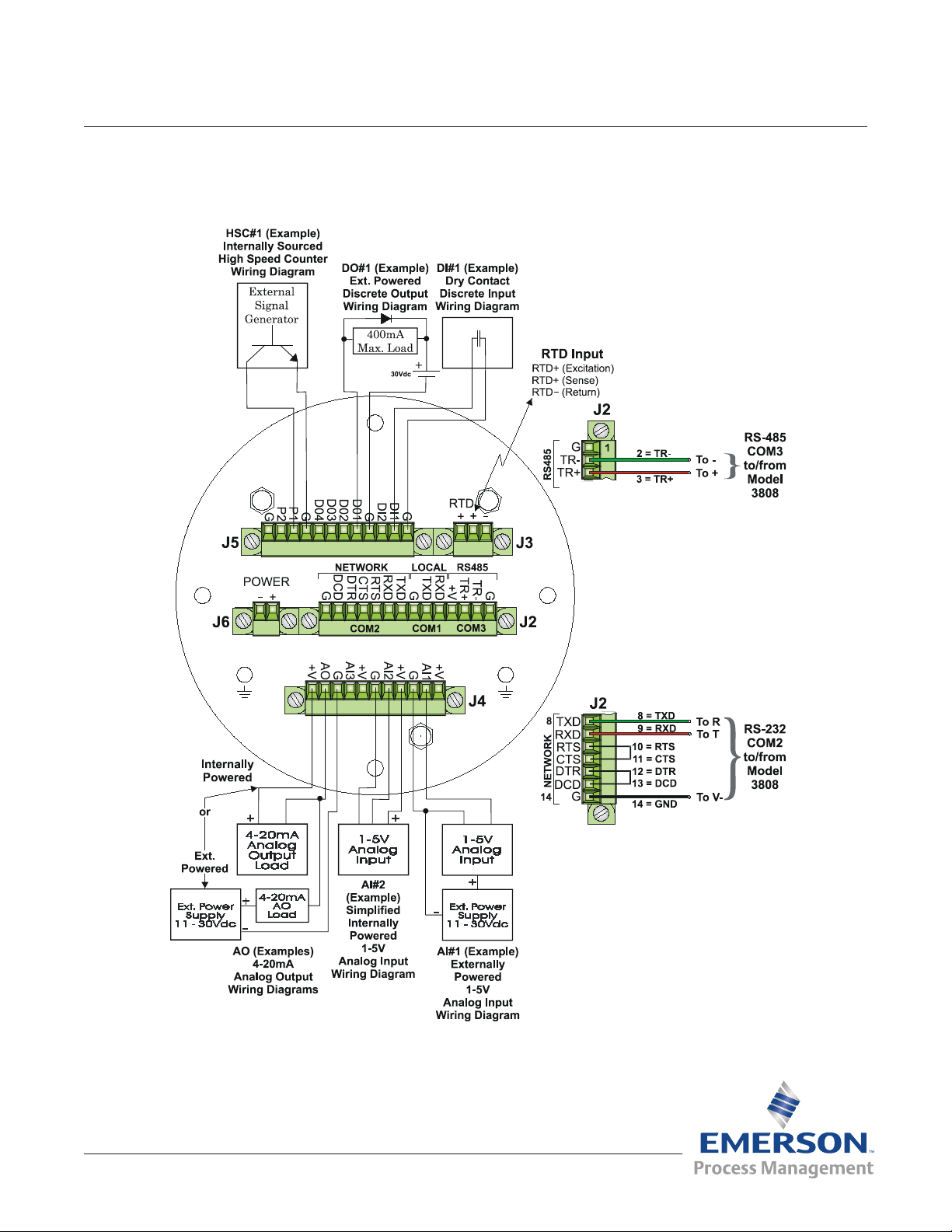

ControlWave XFC Termination Wiring Showing the full I/O conguration

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 15

Product Data Document

1660DS-7c

July 17, 2007 - Page 15

Dimensions

Bristol® ControlWave® XFC

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 16

Product Data Document

1660DS-7c

July 17, 2007 - Page 16

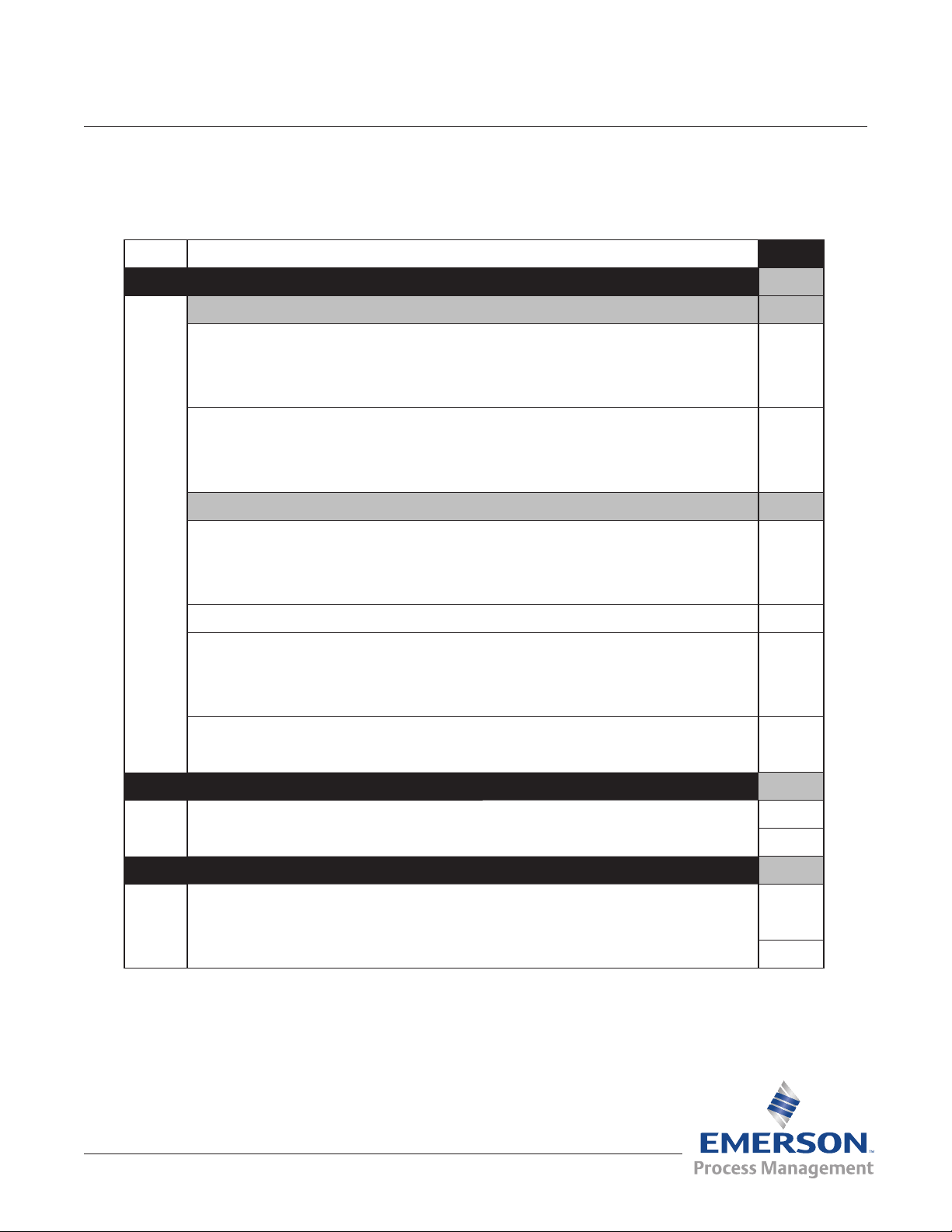

Model Number Specication

A B C - D - EF - G - H - J - K - L

Model Number: 3820-EX-10A- _ _ _ - _ - _ _ - _ - _ - _ - _ - _

DESCRIPTION CODE

A B C Integral Transducer Assembly - Either Gauge Pressure or DP/P A B C

Gauge Pressure Transducers URL (psig - unless indicated otherwise)

300 inH2O 0 1 4

25 0 2 0

100 0 2 2

300 0 2 3

1000 0 2 5

2000 0 2 8

DP/P Transducers - DP URL (inH2O) / Static Pressure URL (psig)

Bristol® ControlWave® XFC

10 150 / 1000 1 2 1

150 / 2000 1 2 2

150 / 500 1 2 3

100 / 2000 1 3 2

300 / 1000 1 4 1

300 / 2000 1 4 2

300 / 4000 1 4 4

25 PSID / 2000 2 0 2

25 PSID / 4000 2 0 4

D Wetted Parts Material D

20 316 Stainless Steel 1

Hastelloy C 2

E F Application Program E F

None 0 0

30 Standard, 1 - 2 Run M&R Program 0 1

Standard, 1 - 2 Run M&R Program, Industry Canada Approved 02

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 17

Product Data Document

1660DS-7c

July 17, 2007 - Page 17

G Certication G

None 0

40 UL Class I, Division 1 Explosion Proof and Class I, Division 2 Non-incendive 1

H Manifold Adapters H

None 0

50 316 Stainless Steel (note: manifold adapters are not available in Hastelloy) 1

J Mounting Bracket J

None 0

60 With Neck Mounting Bracket 1

K I/O Conguration K

No I/O Note: All congurations, here, 0

70 Digital Only 2 DI, 4 DO, 2 HSC include three communication 1

2 DI, 4 DO, 2 HSC + 3 AI and 1 AO ports and RTD input. 2

Bristol® ControlWave® XFC

L RTD / Cable Assembly L

None Please refer to the notes, 0

With RTD and 6-foot Cable below, concerning the RTD / 1

80 With RTD and 15-foot Cable Cable Assemblies. 2

With RTD and 25-foot Cable 3

NOTES: RTD/CABLE ASSEMBLIES

If selected in "L" above, the RTD/Cable assembly will be shipped in the same box as the

ControlWave XFC. Due to UL restrictions, they cannot be shipped "pre-connected."

IMPORTANT: These particular RTD assemblies are not explosion-proof but are approved

for Class I, Division 2 hazardous areas. For explosion-proof RTD components, please

refer to the "Electronic Transmitters" section of the price book.

To specify a ControlWave XFC that is approved by Industry Canada for custody transfer

installations, please use the following model number and attachment number:

3820-EX-10A-142-102-10020

3820-A-1

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 18

Product Data Document

1660DS-7c

July 17, 2007 - Page 18

Spare Parts for ControlWave XFC

DESCRIPTION PART NUMBER

Electronics Assemblies or Boards

CPU Board Assembly 400068-010

I/O Board Assembly, No I/O

(corresponds to selection K=0) 400075-03-2

I/O Board Assembly, 2DI, 4DO, 2HSC

(corresponds to K=1) 400075-02-4

I/O Board Assembly, 2DI, 4DO, 2HSC, 3

AI, 1 AO (corresponds to K=2) 400075-01-6

DP/P Transducer Assemblies - 316 SS, No Vent

150" / 1000 psi

150" / 2000 psi the replacement component but 396531-02-4

150" / 500 psi does not include the internal 396531-03-2

100" / 2000 psi cable. 396531-04-0

300" / 1000 psi 396531-05-9

300" / 2000 psi 396531-06-7

300" / 4000 psi 396531-08-5

25 psid / 2000 psi 396531-07-5

25 psid / 4000 psi 396531-09-1

DP/P Transducer Assemblies - Hastelloy, No Vent

150" / 1000 psi 396533-01-9

150" / 2000 psi 396533-02-7

150" / 500 psi 396533-03-5

100" / 2000 psi 396533-04-3

300" / 1000 psi 396533-05-1

Bristol® ControlWave® XFC

The transducer assembly

includes 396531-01-6

300" / 2000 psi 396533-06-0

300" / 4000 psi 396533-08-6

25 psid / 2000 psi 396533-07-8

25 psid / 4000 psi 396533-09-4

Gauge Pressure Transducer Assemblies - See Next Page

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 19

Product Data Document

1660DS-7c

July 17, 2007 - Page 19

Spare Parts for ControlWave XFC - Continued

DESCRIPTION PART NUMBER

Gauge Pressure Transducer Assemblies - 316 SS

300" 396536-02-6

25 psi 396536-04-2

100 psi 396536-06-9

300 psi 396536-07-7

1000 psi 396536-09-3

2000 psi 396536-12-3

Gauge Pressure Transducer Assemblies - Hastelloy

300" 396538-02-9

25 psi 396538-04-5

100 psi 396538-06-1

300 psi 396538-07-0

1000 psi 396538-09-6

2000 psi 396538-12-6

Internal MVT Cable 396667-01-5

Bristol® ControlWave® XFC

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Loading...

Loading...