Page 1

Product Data sheets

DOC.DSE.PN.US Rev. *

0D\ 2011

El-O-Matic E and P Series

Technical data pneumatic Rack and Pinion actuators

www.El-O-matic.com

Page 2

Data sheet

A B

A B

A B

Sheet No.:

Date: June 2010

A1.102 Rev. B

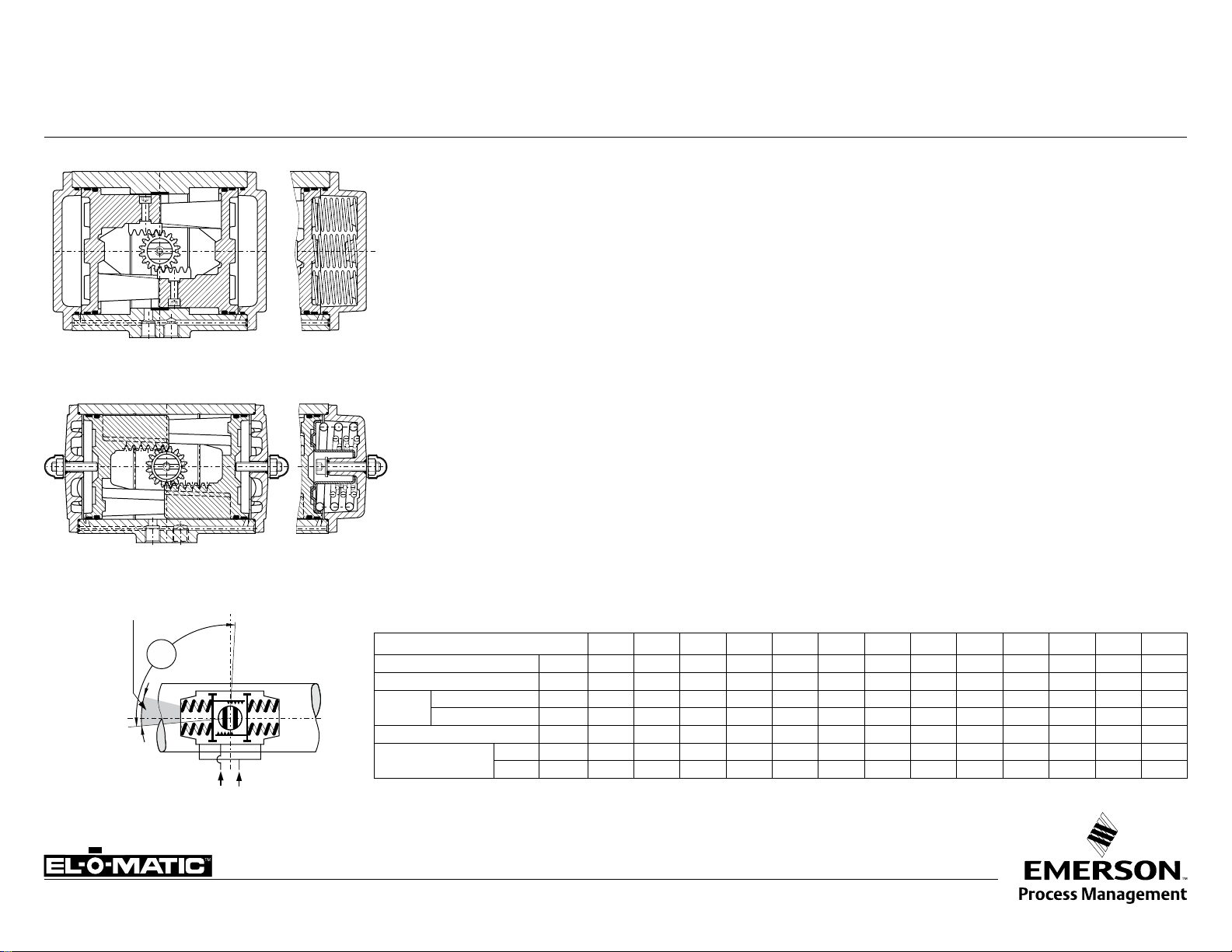

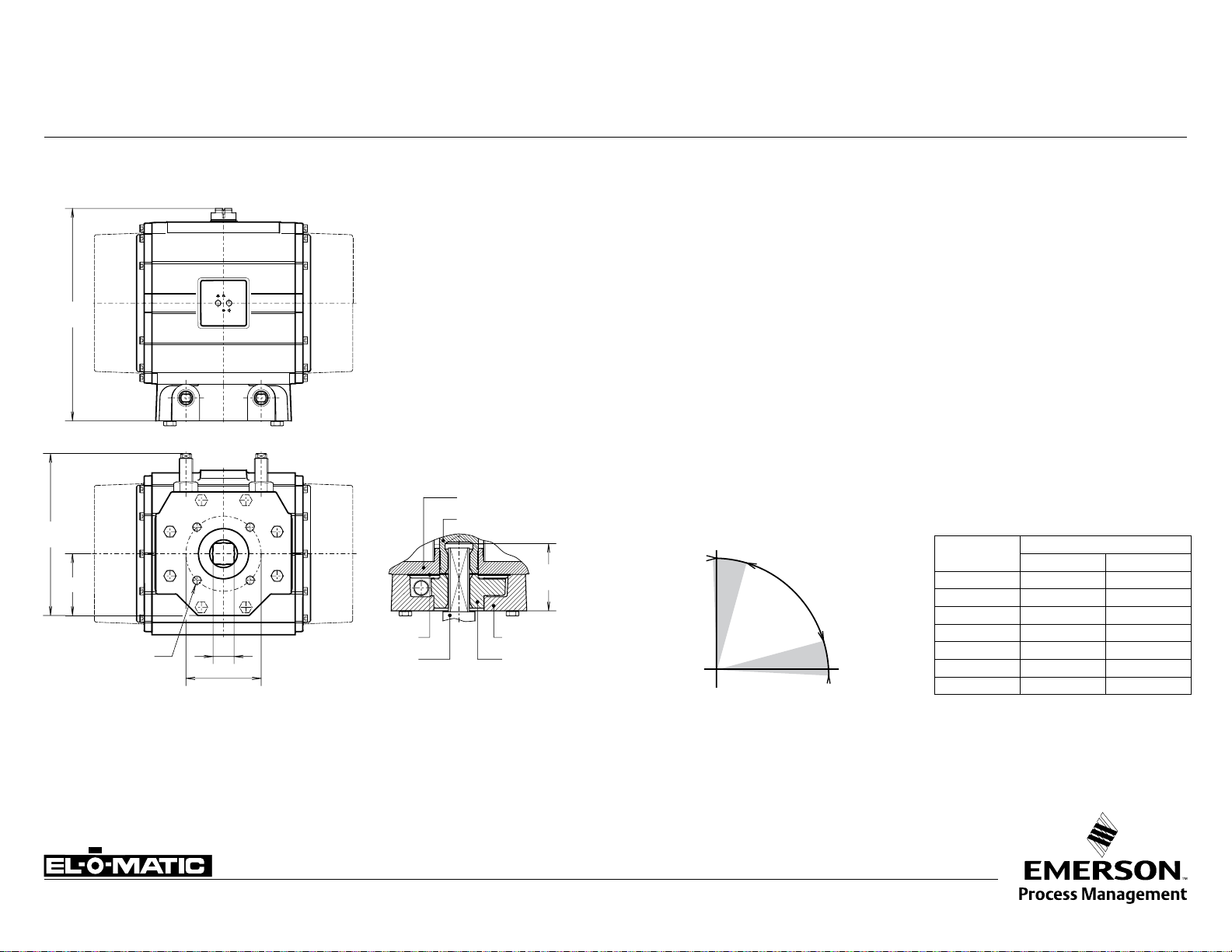

TECHNICAL DETAILS, STANDARD ACTUATOR E/P

P-series

PD = Double acting

E-series

ED = Double acting

11°

Adjustable

range*

91°

Open

*

only standard on E-Serie actuators

A B

A B

91.5°

A

PS = Spring return

ES = Spring return

-0.5° Closed

B

Specification

Pressure range : Double acting 20 to 120 psi

: Spring return 80 to 120 psi,, with max. spring set

40 to 120 psi, reduced spring

quantity

: 180° actuators 87 psi maximum

Torque : 1133 to 40,000 in.lb at 80psi supply

See torque datasheets 1.104.01 and 1.104.02

Operating media : Air, dry or lubricated and inert gasses

: For sub-zero applications take appropriate measures

Temperature : -4° to +176°F

European Directives

PED : All actuators are suiteable for use

with Group 2 gasses according to

Pressure Equippement Directive

97/23/EC

: Optional : actuators suiteable for

use with Group 1 gasses

ATEX : All basic actuators are suiteable

for use in hazardous area's

classified II 2 GD, zones 1 or 2

(Gasses) and 21 or 22 (Dust)

Lubrication : Factory lubricated for the normal life of the actuator

Construction : Suitable for indoor and outdoor installation

Finish : Polyester non-TGIC based powder coating

(see data sheet A4.204.01)

Rotation : 91.5° (-0.5° CW to 91° CCW)

Russian Approvals

El-O-Matic E and P series pneumatic actuators are

available with the GOST-R and Rostechnadzor (RTN)

approvals.

Double acting : Standard counter clockwise with port "A" pressurized

(code A, see data sheet A1.503 for other assembly

codes)

Spring return : Clockwise fail action

(code A, see data sheet A1.504 for other assembly

codes)

Note

1. Operating time is average with actuator under load

and solenoid valve fitted.

2. Air consumption is the actual free air volume at 1 atm.

3. Pressure is in barg.

Limit stops : Standard on E-series. Adjustable range 91°/80°

: Optional on P-series. See datasheet A1.501.01

: For double stroke adjustment. See datasheet

A1.501.05

ACTUATOR TYPE E12 E25 E40 E65 E100 E150 E200 E350 E600 E950 E1600 P2500 P4000

Bore inch

Stroke inch

Weight:

Operating time sec.

Air consumption at

1 atm (cu./in.)

Double acting lb.

Spring return lb.

port A stroke

port B stroke

1.8 2.2 2.8 3.1 3.6 4.1 4.3 5.7 6.9 7.9 9.1 11.8 12.8

0.5 0.6 0.7 0.9 1.0 1.2 1.5 1.5 1.7 2.0 2.5 2.2 3.2

1.3 2.9 4.0 5.3 6.8 10.5 12.8 23 43 58 94 125 191

1.5 3.7 5.3 7.9 10.1 15.2 20.1 37 61 85 145 194 291

0.4 0.5 0.7 1.1 1.2 1.8 2.3 3.6 4.5 5.4 6.9 7 12

3.1 6.1 9.8 20 21 45 49 110 177 287 445 488 824

3.7 6.7 13 22 30 40 61 116 189 299 488 568 1,068

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 3

Data sheet

Sheet No.:

Date: November 2010

A1.102.10 Rev. C

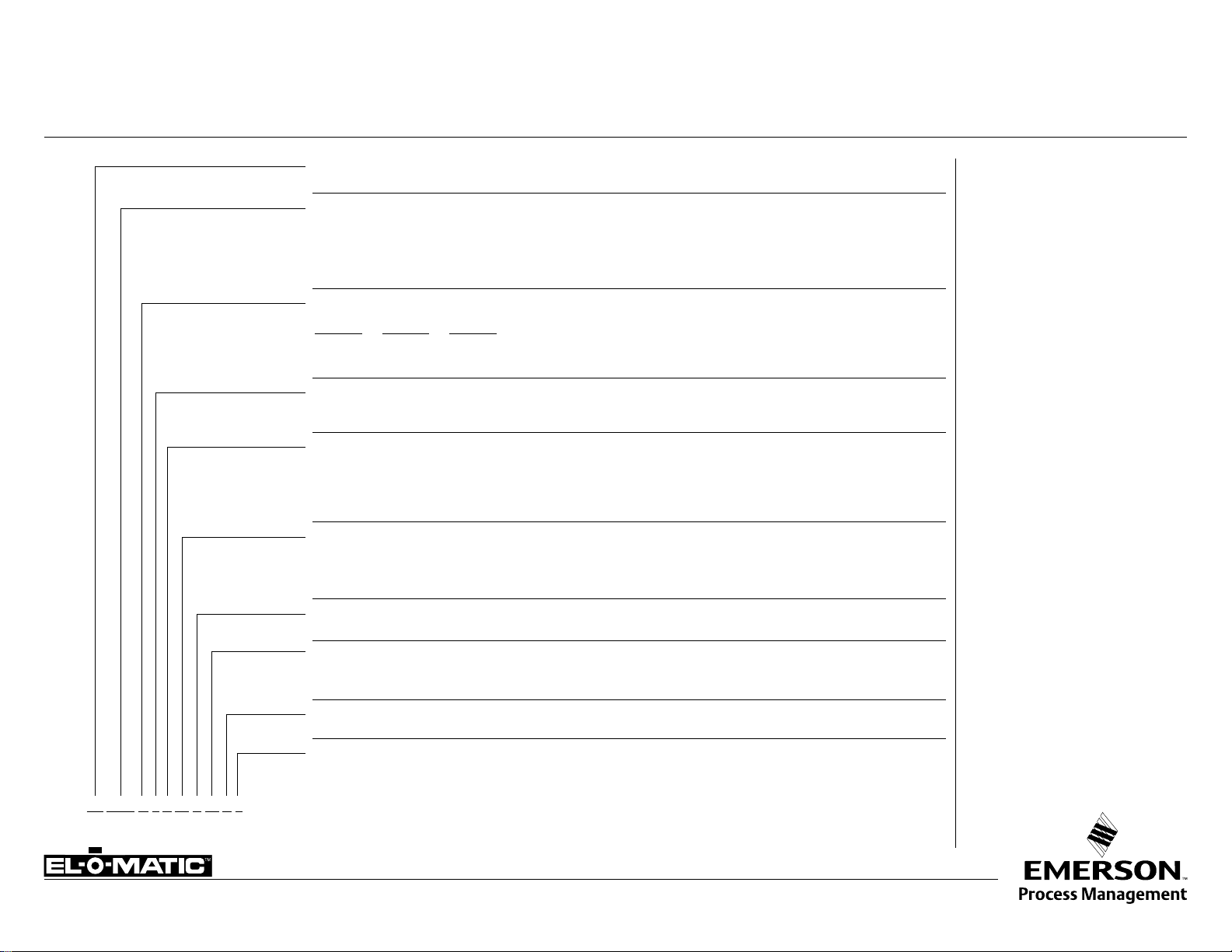

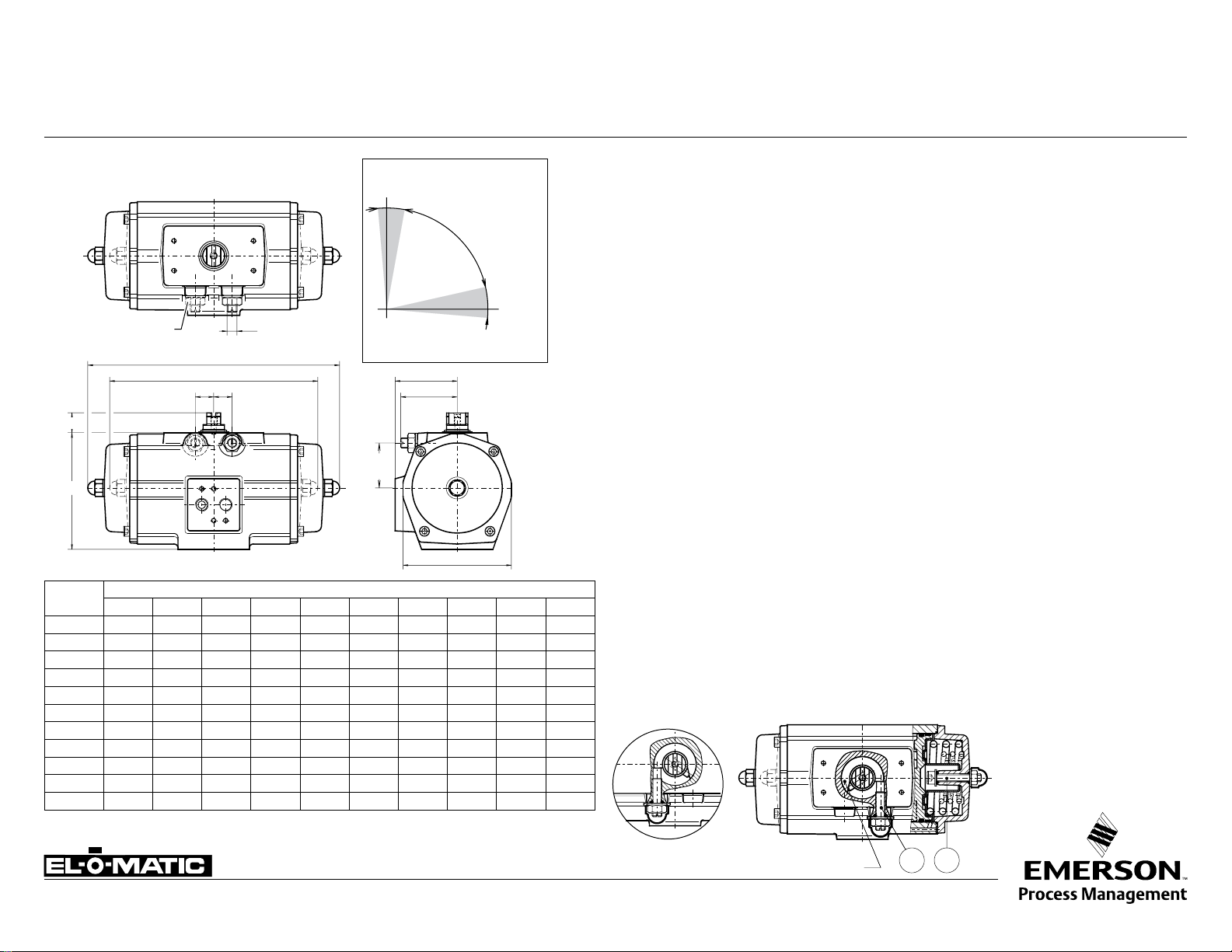

EL-O-MATIC BASIC PNEUMATIC ACTUATOR CONFIGURATION E/P

Single or Double action

ES

PS

or

= Single acting,

Actuator siz

E-series

0012 = E12 0025 = E25 0040 = E40 0065 = E65 0100 = E100 0150 = E150

0200 = E200 0350 = E 350 0600 = E600 0950 = E950 1600 = E1600

P-series

2500 = P2500 4000 = P4000

e

ED or PD

= Double acting

Valve flange

Metric Metric UNC/NPT

ISO 5211 DIN 3337 ISO 5211

M = D =

N = E = V =

O =

F =

U =

W =

Finish

Standard

CSR coating

CSR coating

(2

+ Aluminum pinion

(2

+ Stainless Steel pinion

(3

Limit stops

0 = No limit stops 1 = L1 One way limit stops 2 = Double Stroke Adjustment

Standard on P-series Standard on E-Series Standard on DSA-Series

Assemb

ly code

Code Action Rotation Mounting

A =

B =

C =

D =

ing to close clock wise in line with pipeline

Spr

Spring to close clock wise across pipeline

Spr

ing to open counter clock wise across pipeline

Spring to open counter clock wise in line with pipeline

Spring set E-serie Spring set P-serie

00 = Double acting actuator 00 = Double acting actuator

01 = Springset 1 04 = Springset 4 04 = Springset 4 10 = Springset 10

02 = Springset 2 05 = Springset 5 06 = Springset 6 12 = Springset 12

03 = Springset 3 06 = Springset 6 08 = Springset 8 14 = Springset 14

Future expansion

A = Standard

Default Insert

Size (in mm.)

- ISO or UNC 00 11 14 14 19 19 22 27 27 36 46 00 00

- DIN 00 11 14 14 17 17 22 22 27 36 46 00 00

(1

E12 E25 E40 E65 E100 E150 E200 E 350 E600 E950 E1600 P2500 P4000

See following data sheets

for more information

A1.104.01 / A1.104.02

A1.103.106 / A1.103.073 /

A1.103.102 / A1.103.103

A1.101.30 / A1.101.33 /

A4.204.01

A1.501.01/

A1.501.05

A1.503/

A1.504

A1.104.02

A1.103.073

A1.103.106

A1.103.120

Visual Indication Code

D = Disk K = Knob N = No visual indication

A1.101.70 / A1.101.71

ES 0040.M 1 A 05 A.14 N 1

Temperature range

0 = Standard TS: 80°C (176°F) -20°C ( -4°F)

1 = High temp TS: 120°C (248°F) -20°C ( -4°F)

2 = Low temp TS: 80°C (176°F) -40°C (-40°F)

(1

Actuators E12, P2500 and P4000 have no inserts. They have have a inner square the shaft

180° actuators are not covered by this configuration matrix.

(2

CSR Coating not possible in combination with Double Stroke Adjustment limit stops (DSA series).

(3

Stainless Steel Pinion not possible in combination with Double Stroke Adjustment limit stops (DSA series).

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 4

Data sheet

TM

B

A

C

D

Sheet No.:

Date: November 2009

A1.501.01 Rev. A

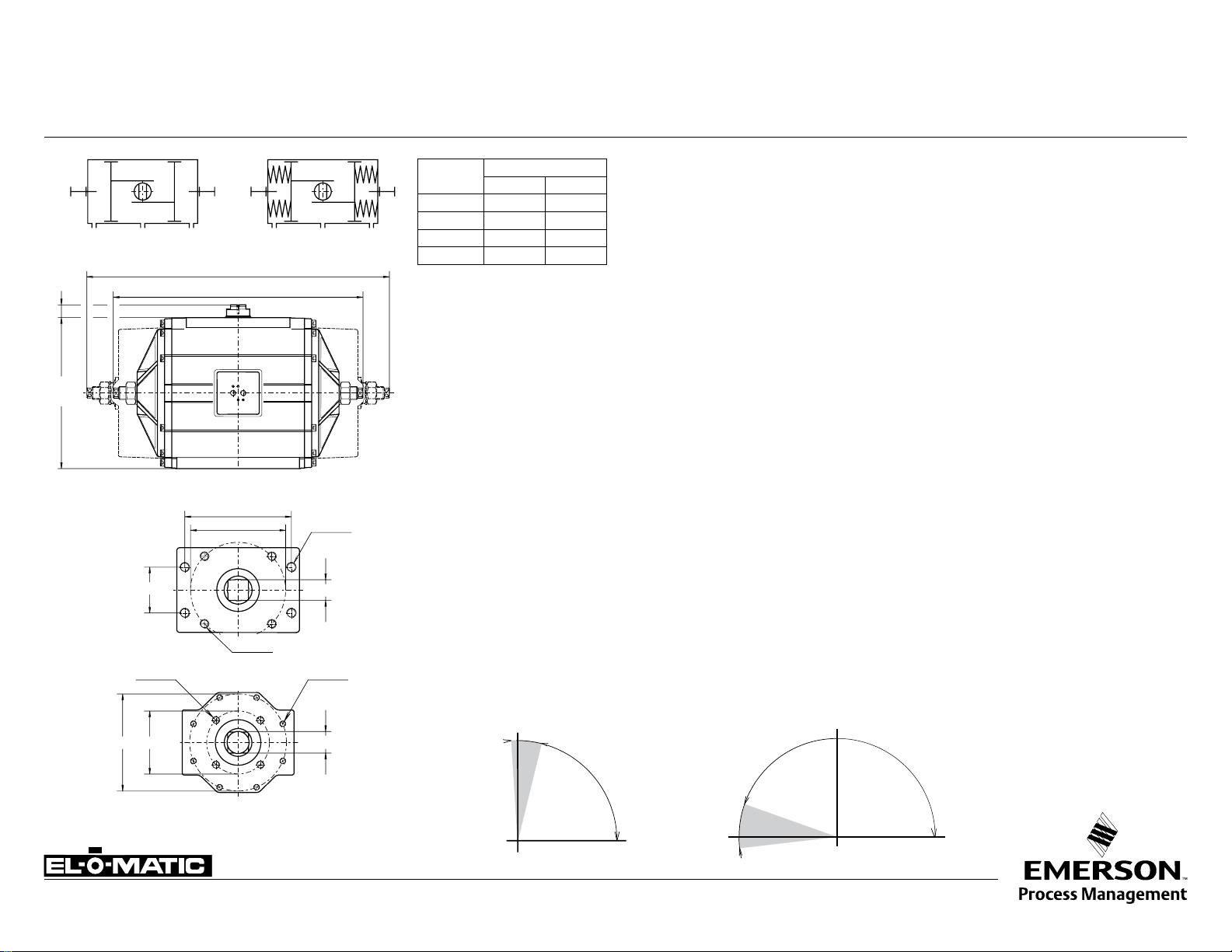

EL-O-MATIC ACTUATOR WITH ONE WAY LIMIT STOPS L1/LF

Description

Actuators with one way adjustable limit stops are used where the maximum opening (or closing)

position of the valve needs to be reduced. For instance to adjust the maximum capacity of a

remote operated valve.

Also actuators with 180° rotation are available with these stops.

Operation

DOUBLE ACTING

SPRING RETURN

Dim.

in inch

A

B

C

D

ACTUATOR TYPE

P2500 P4000

22.8 27.9

31.3 45.4

14.0 15

1.2 1.2

Stop screws are fitted to both endcaps and the screw length is such that adjustment is possible

through the specified rotation of the actuator.

The modified endcap is machined for -0.5° to +93° rotation for all P-series models.

Identification

“L1” is added to the basic part number i.e. PD2500-L1

Specification:

Pressure : Up to 120 PSI

Media : Air, dry or lubricated or non-corrosive gas

Torque (90°) : Data sheet A1.104.01 - A1.104.04

(180°) : Data sheet P-serie A1.204.01 and A1.204.02

Other dimensions : Data sheet A 1.103.XXX (90°)

: Data sheet A 1.203.011 (180°)

Temperature : -4.0° to +176°F

9.236

6.496

5/8"-11x.98

Adjustable range : 80°-93°(90°) or 160°-186° (180°)

Adjustable position (see data sheet A1.503 or A1.504)

code position

A Valve open (spring to close)

3.827

1.811

P2500

B Valve open (spring to close)

C Valve closed (spring to open)

D Valve closed (spring to open)

Note:

10x1.14

3/4"-10x1.14

5/8"-11x.98

1) Can be provided with extra long screws for full range adjustment

(identification: PD2500-LF)

2) This option in combination of a manual override gearbox is redundant

6.496

3/4"-

2.16510.000

P4000

Open

3° 10°

Adjustable range

90° actuator

Adjustable range

180° actuator

Note: Do not adjust under pressure

-20°

Closed

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

+6°

Open

Closed

Page 5

Data sheet

TM

E

Gmax.

F

WO

V

H

max.

+1° -15°

+0.5°

-15°

Sheet No.:

Date: November 2009

A1.501.03 Rev. A

LIMIT STOP PLATE DIMENSIONS LS 420

Description

These limit stop plates are used when precise control is required for both end of stroke positions.

It is possible to adjust 15° of both ends of the standard stroke.

Construction

The complete stop plate assembly may be added to the 90° P- series actuators.

The assembly is normally sandwiched between the actuator and mounting surface of the valve

or bracket. Bearing rings are used at both surfaces to provide a long life expectancy.

The unit is assembled with a drive adaptor which passes through the stop plate, into the square

actuator and provides the coupling between the two components.

This drive adaptor normally also accommodates the coupling of the valve stem.

Identification

"LS420" is added to the basic part number i.e. PD2500-LS420

Other dimensions

See data sheet A1.103.xxx

Option

Version for 180° or DIN-standard actuator

Actuator base

Drive shaft

Cover plate

Drive adaptor

Note: Cover plate only in combination with P2500

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Housing limit stop

Cam

Open

Adjustable range

90° actuators

Closed

Dim.

in inches

E

F

G

H

O

V

W

ACTUATOR TYPE

P2500 P4000

18.3 19.3

5.3 5.3

12.7 12.7

5.1 5.6

1.8 2.2

165 165

M20x30 M20x30

Page 6

Data sheet

TM

Y

A

B

C

H

I

X

J

1

LL

D

3° 10°

3°

15°

1

2

Sheet No.:

Date: November 2009

A1.501.05 Rev. A

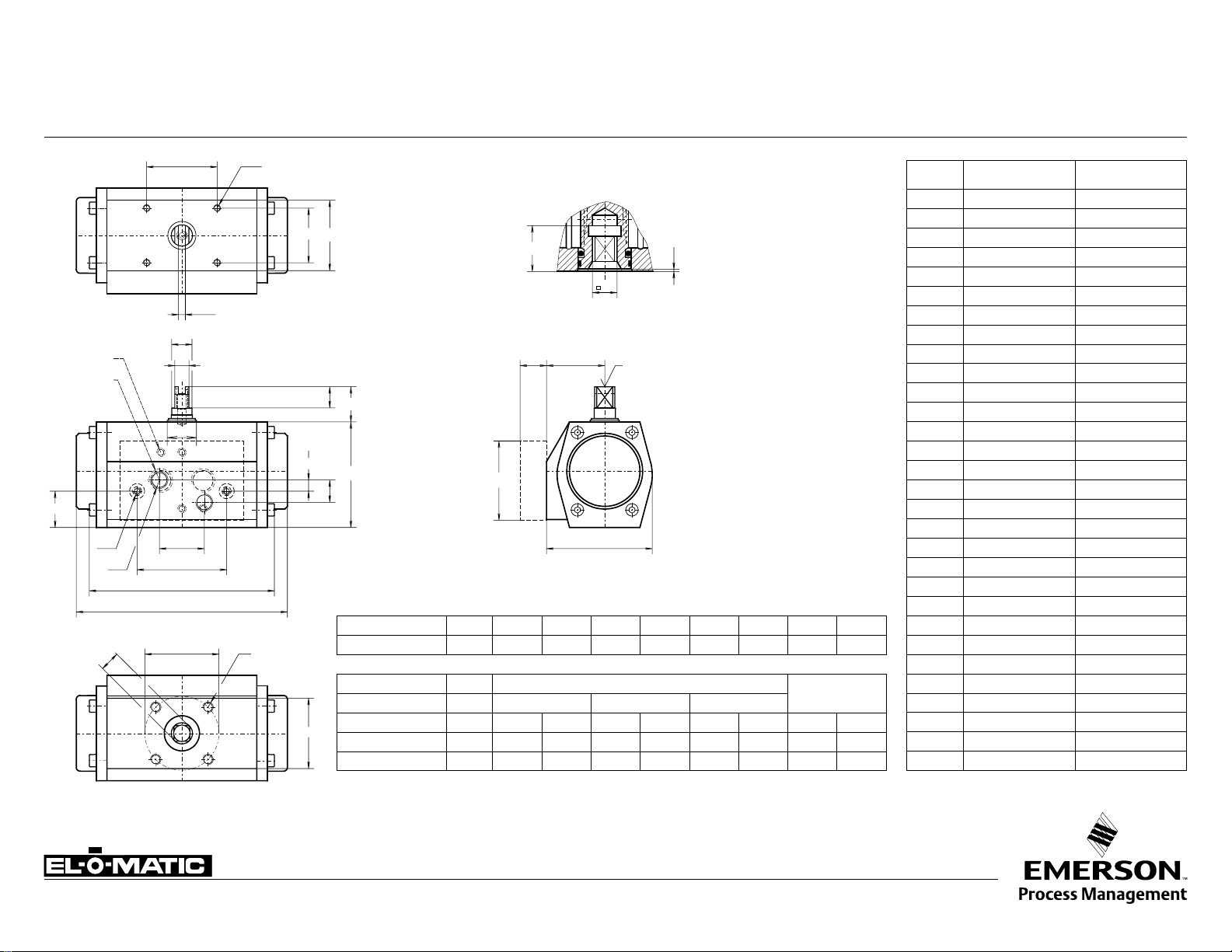

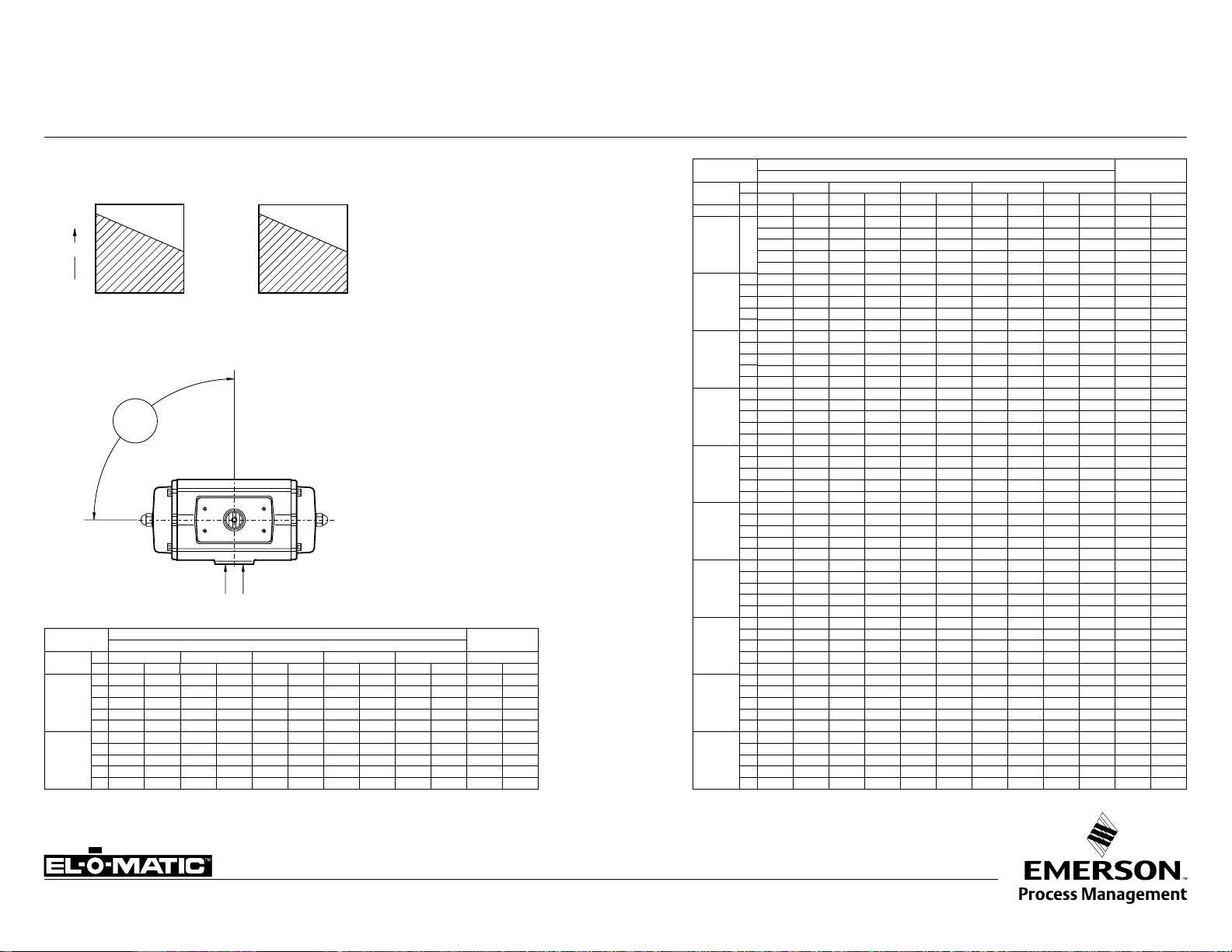

EL-O-MATIC ACTUATOR WITH DOUBLE STROKE ADJUSTMENT DSA

Open

stopscrew (2)

adjustable

range

Description

Actuators with double stroke adjustment are normally used for high performance butterfly valves

where a fine adjustment is required for the closed position. In this version adjustment is provided

at the end of the opening and closing stroke positions. DSA actuators may be double acting or

spring return, though are normally used as spring return (fail close) actuators.

Operation

The closed position is adjusted by means of the stop-screw (1) located in the actuator body and

for the open position by the stop-screws (2) in the actuator end caps.

Factory option:

Fail to Open

Closed

stopscrew (1)

Identification

See data sheet A1.102.10

Specification

Pressure : Up to 120 psi

Operating media : Air, dry or lubricated or non-corrosive gas

Torque (90°) : Data sheet A1.104.01 - A1.104.02

Rotation -

- Spring return : Clock-wise on air failure.

- Double acting : Counter clock-wise with port “A” pressurised.

Other dimensions : Data sheet A1.103.XXX

Temperature : -4° to +176° F

Adjustable range : Closed position (1), -3° - 15°

Open position (2), 80° - 93°

Dim.

in inch.

A DA

B SR

C

D

H

J1

L

Y

X

X max.

E25 E40 E65 E100 E150 E200 E350 E600 E950 E1600

6.26 7.09 7.83 8.70 10.00 11.14 12.01 15.35 17.32 20.47

6.77 8.03 9.80 10.51 12.20 14.17 15.24 18.90 20.94 25.24

3.15 3.66 4.13 4.65 5.51 5.63 7.13 8.66 10.20 11.69

0.79 0.79 0.79 0.79 0.79 0.79 0.79 1.18 1.18 1.18

2.91 3.39 3.86 4.25 4.76 5.04 6.81 8.15 9.09 264.00

I

1.81 2.01 2.26 2.48 2.76 2.87 3.71 4.45 4.96 5.59

1.11 1.38 1.57 1.72 1.92 2.12 2.85 3.50 4.03 4.50

0.45 0.61 0.61 0.73 0.97 0.97 0.97 1.63 1.63 1.87

1/4"-20 5/16"-18 5/16"-19 3/8"-16 3/8"-16 1/2"-13 1/2"-13 5/8"-11 5/8"-11 3/4"-10

1.42 1.63 1.63 1.99 2.36 2.46 2.85 4.02 4.02 4.31

1.63 1.91 1.91 2.30 2.64 2.91 3.31 4.51 4.51 4.88

Actuator type

Note

1) Can be provided with extra long end-cap stop screws for full range adjustment of the “open”

position.

2) This DSA option is not required on actuators fitted with manual override gearboxes, as MO

gearboxes already incorporate this function.

Important

1) "Fail open" is factory option.

2) When assembled for “fail open” operation (code D; see data sheet A1.504), both stop-screws

(1) and (2) will adjust the closed position. There is no adjustment for the open position!

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Factory option:

"Fail open"

Stroke adjustment cam

Page 7

Data sheet

Sheet No.:

Date: May 2011

A1.103.106 Rev. D

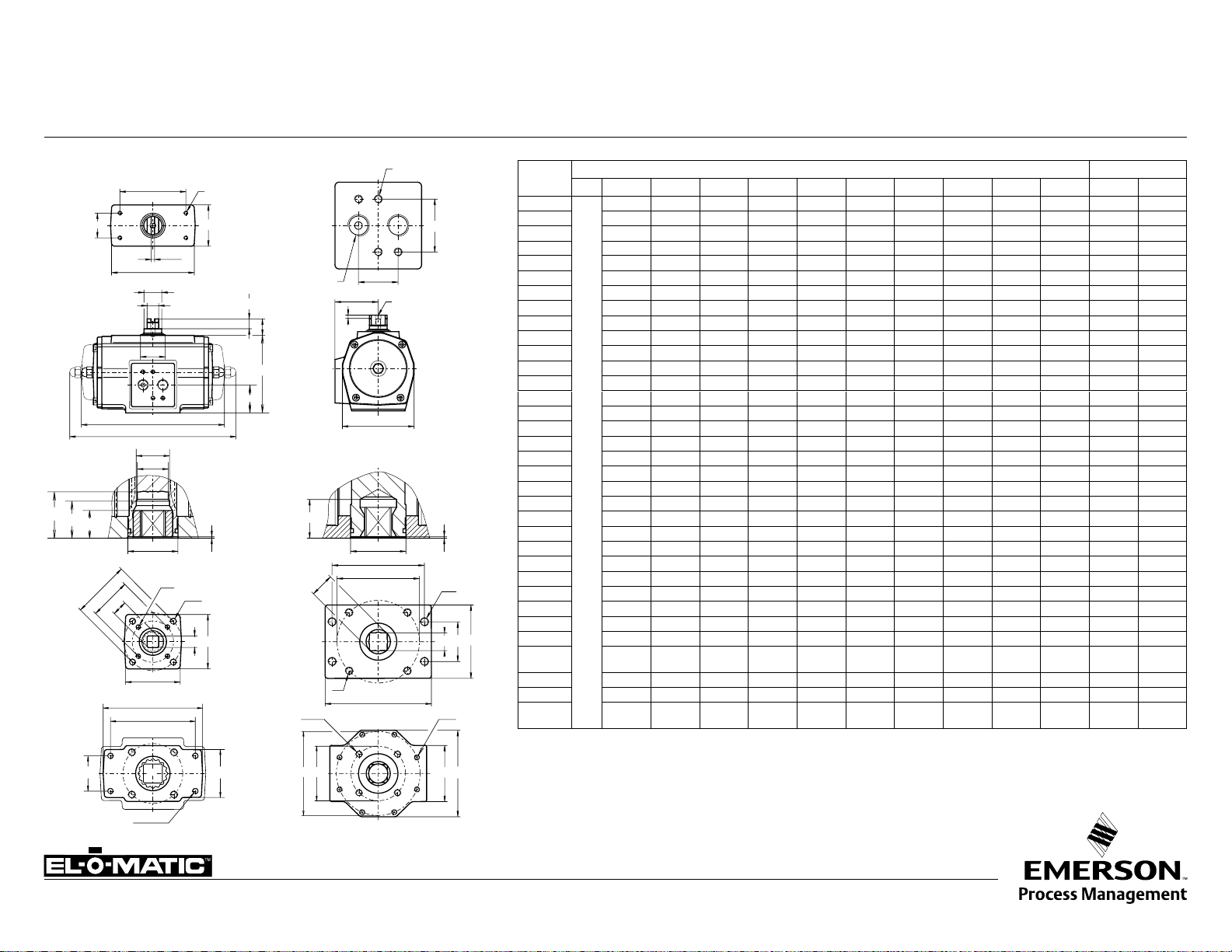

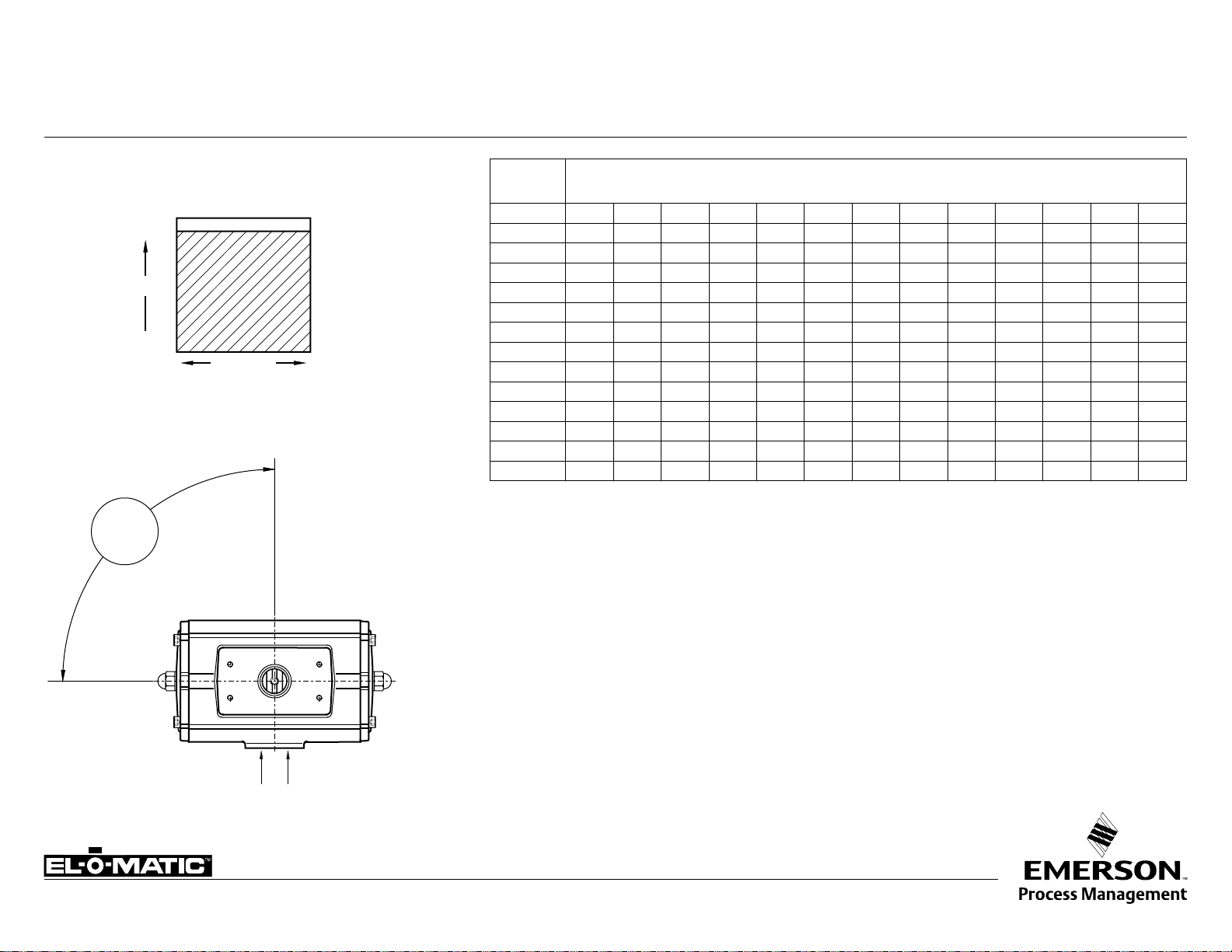

DIMENSION SHEET STANDARD ACTUATOR - ISO E/P

U1 R1

E-series

M1

M2

M3

øV1

øV

+0.02

0

øP

E25-E950

E1600

T1

S1

E

F

E2

A

B

øP2

øP1

øK

S

S

9.236

0.16

W

UNC 10-24x.31

±0.02

N

W1

R

O

UNC 10-24x.31

B

1.26

A

0.16

0.95

I

M6x.47

H

1/4”NPT

G

D

C

J

P-series

M1

W

øP

+0.02

øK

T

0

øV

W

S

±0.02

N

W2

O

U

P2500

W1

R

Dim.

in inch

A DA

B SR

C

D

E

E2

F

G

H

I

J

K

M1

M2

M3

N

O max.

O min.

P

P1

P2

R

R1

R2

S

S1

T1

U1

V

W

V1

W1

E 12 E 25 E 40 E 65 E100 E150 E200 E 350 E600 E950 E1600 P2500 P4000

For E12 dimensions see data sheet A1.103.102

6.26 7.09 7.83 8.70 10.00 11.14 12.01 15.24 16.69 20.31 14.88 19.76

6.77 8.03 9.80 10.51 12.20 14.17 15.24 18.78 20.35 25.08 22.44 32.83

3.15 3.66 4.13 4.65 5.51 5.63 7.13 8.66 10.20 11.69 14.02 14.96

0.79 0.79 0.79 0.79 0.79 0.79 0.79 1.18 1.18 1.18 1.18 1.18

0.63 0.87 0.87 0.87 1.42 1.42 1.42 2.17 2.17 2.52 2.17 2.52

0.91 1.18 1.18 1.18 1.77 1.77 1.77 2.56 2.56 2.95 2.56 3.15

0.39 0.55 0.55 0.55 0.75 0.75 0.75 1.42 1.42 1.42 1.42 1.42

0.47 0.47 0.47 0.47 0.47 0.47 0.47 0.39 0.39 0.39 0.39 0.39

2.91 3.39 3.86 4.25 4.76 5.04 6.81 8.15 9.09 10.43 13.78 14.96

1.81 2.09 2.26 2.48 2.76 2.87 3.71 4.45 4.96 5.59 7.28 7.87

1.26 1.32 1.54 1.59 1.59 1.99 2.85 3.33 4.15 4.74 7.01 7.48

0.94 1.30 1.30 1.50 2.17 2.17 2.17 2.68 2.95 3.74 3.35 4.72

1.36 1.36 1.36 1.36 1.97 1.97 1.97 2.05 2.52 3.23 2.60 3.03

- - - 1.06 - 1.46 1.46 - - - - -

0.669 0.669 0.669 0.787 0.787 1.161 1.161 1.161 1.949 2.303 - -

0.04 0.04 0.04 0.06 0.04 0.06 0.06 0.06 0.06 0.06 0.12 0.06

0.437 0.556 0.556 0.753 0.871 0.871 1.068 1.068 1.424 1.817 1.817 2.173

0.433 0.551 0.551 0.748 0.866 0.866 1.063 1.063 1.417 1.811 1.811 2.165

0.555 0.713 0.713 0.992 1.110 1.110 1.425 1.425 1.898 2.370 2.370 2.843

0.555 0.713 0.831 0.909 1.303 1.303 1.303 1.437 1.909 2.382 - -

- - - 0.988 1.264 1.264 1.264 - - - - -

2.05 2.56 2.76 2.76 3.39 3.54 4.49 4.88 5.12 6.06 6.69 6.69

1.97 1.97 1.97 2.36 2.36 2.36 2.36 3.54 3.54 4.92 6.30 6.30

- - - - - - - - - 5.20 - 10.31

2.05 2.56 2.76 2.76 3.62 3.54 4.49 4.88 5.59 11.02 11.42 11.42

3.94 3.94 3.94 3.94 3.94 3.94 3.94 6.69 6.69 8.27 9.65 9.65

3.150 3.150 3.150 3.150 3.150 3.150 3.150 5.118 5.118 5.118 5.118 5.118

1.181 1.181 1.181 1.181 1.181 1.181 1.181 1.181 1.181 1.181 1.181 1.181

F03 F05 F05 F05 F07 F07 F07 F10 F10 F16 F16 F16

1.417 1.969 1.969 1.969 2.756 2.756

10-24

1/4"-20

x.31"

F05 F07 F07 F07 F10 F10 F10 F12 F14 - - F25

1.969 2.756 2.756 2.756 4.016 4.016 4.016 4.921 5.512 - - 10.000

1/4"-20

5/16"-18

x.39"

x.39"

x.39"

1/4"-20

x.39"

5/16"-18

x.39"

Actuators E-series P-series

1/4"-20

x.39"

5/16"-18

x.39"

5/16"-18

x.39"

3/8"-16

x.63"

5/16"-18

x.39"

3/8"-16

x.63"

2.756 4.016 4.016 6.496 6.496 6.496

5/16"-18

3/8"-16

x.39"

x.63"

3/8"-16

x.63"

1/2"-13

x.79"

3/8"-16

x.63"

5/8"-11

x.98"

3/4"-10

x1.14"

- -

3/4"-10

x1.14"

3/4"-10

x1.14"

"5/8""-11

x.98"

3.827

R2

øV

R

R2

Note

øV1

1. Flange and square drive to ISO 5211

5/8”-11

x .98”

P4000

2. Top and solenoid flange to VDI/VDE 3845 (NAMUR)

3. For P-series actuators with limit stops see A1.501.01

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 8

Data sheet

TM

T

W2

U

R1

0.16

UNC10-24x .31

1/4"

E

F

G

D

K1

K

C

E2

W1

X

L

L1

A

B

J

øP

+0.02

0

øV

R

W

YI

H

1.77

0.59

M

N

±0.02

O

Sheet No.:

Date: November 2009

A1.103.102 Rev. A

DIMENSION SHEET ACTUATOR ISO E12 (90°/180°)

Dim. in

Inches

A ED

B ES

C

D

E

E2

F

G

H

I

DOUBLE ACTING TORQUE (ED)

Pressure psi 40 50 60 70 80 90 100 120

Torque 90°/180° (in.lb.)

59 74 89 104 119 134 149 179

SINGLE ACTING TORQUE (ES)

Pressure psi 60 80 100

Position - start end start end start end start end

Torque 90° (in.lb.)

Torque 180° (in.lb.)

48 23 80 55 112 87 64 41

49 25 81 57 112 88 63 40

Air stroke

Spring

stroke

J

K

K1

L

L1

M

N

Omax.

Omin.

P

R

R1

T

U

V

W

W1

W2

X

Y

90° 180°

4.06 6.10

4.65 8.50

2.36 2.36

0.79 0.79

0.63 0.63

0.91 0.91

0.39 0.39

0.47 0.47

2.36 2.36

1.30 1.30

0.83 0.83

0.50 0.50

0.25 0.25

1.00 1.00

2.00 2.00

0.65 0.65

0.039 0.039

0.358 0.358

0.354 0.354

0.476 0.476

1.57 1.57

1.57 1.57

1.57 1.57

1.22 1.22

1.654 1.654

10-24 UNCx.24" 10-24 UNCx.24"

10-24 UNCx.24" 10-24 UNCx.24"

10-24 UNCx.24" 10-24 UNCx.24"

1/8"NPT 1/8"NPT

M6x.48 M6x.48

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 9

Data sheet

Ø P2

Ø P1

M1

M2

Sheet No.:

Date: May 2011

A1.103.200 Rev. B

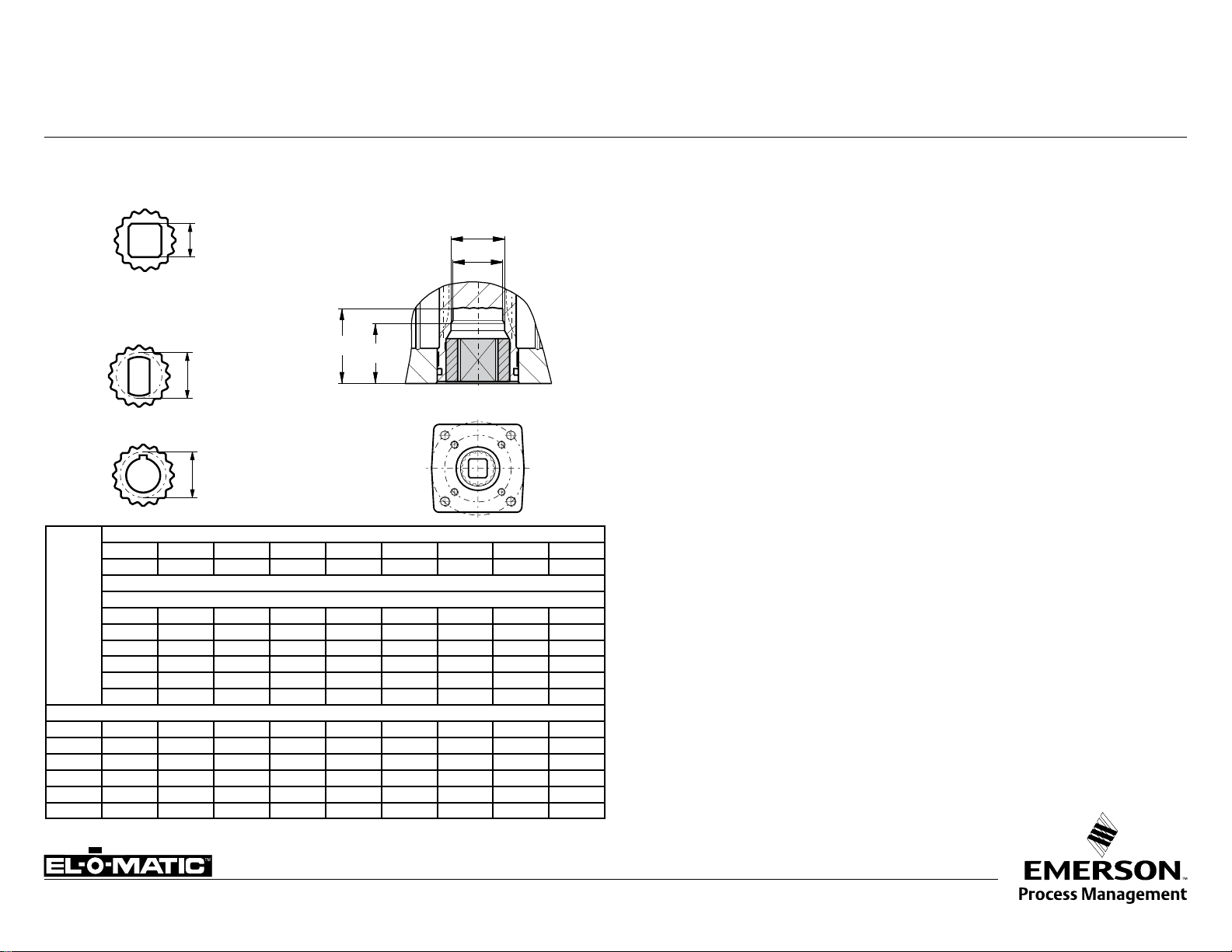

DRIVE INSERTS FOR EL-O-MATIC ACTUATORS E

Standard available

insert shapes

sq Max.

Optional available

insert shapes

D Max.

D Max.

Standard inserts with inner-square-dimensions per actuator type

E25 E40 / E65 E100 E150 E200 E350 E600 E950 E1600

0.433 0.551 0.748 0.866 0.866 1.063 1.063 1.417 1.811

Optional insert dimensions

0.354 0.394 0.472 0.551 0.551 0.551 0.551 0.866

0.394 0.472 0.551 0.630 0.630 0.630 0.630

0.63 0.669 0.669 0.669 0.669

0.748 0.748 0.748 0.748

0.945 0.945 0.866 0.866

1.063 1.063 0.945 0.945

Maximum insert dimensions

M1 1.36 1.36 1.36 1.97 1.97 1.97 2.05 2.52 3.23

M2 - - 1.06 1.46 1.46 1.46 - - P1 0.71 0.71 0.91 1.26 1.26 1.26 1.44 1.91 2.38

P2 - - 0.99 1.43 1.43 1.43 - - -

SQ max. 0.630 0.630 0.748 1.063 1.063 1.063 1.063 1.417 1.811

D max. 0.827 0.827 0.929 1.323 1.323 1.323 1.323 1.772 2.362

Insert mounting

acc. ISO 5211

Description

Most of the El-O-Matic actuators are fitted with drive inserts. This enables actuators to be

directly mounted onto suitable valves and eliminates the need for a bracket and coupling type

mounting kit. The use of direct mounts significantly cuts the cost of the valve/actuator assembly.

Standard actuators are fitted with square drive inserts in accordance with ISO 5211 (or DIN

3337), but a wide variety of other inserts are also available. Special inserts may have oversize or

undersize squares, double-D and shaft key way forms.

Drive inserts can be supplied on factory built actuators or as loose items and are easily

replaceable at distributor or end user level.

Where direct mounts are not possible, for instance on valves with exposed grand packing, the

use of inserts often simplifies the design of the mounting kit.

Material : Aluminum alloy

Finish : Anodized

The following actuator types do not have inserts.

- E12,

- P2500 and P4000

- 180° actuators

These actuators have inner square directly in the bottom of the pinion. See the following data

sheets for more information :

E12 ISO5211 A1.103.102

P2500/P4000 ISO 5211 A1.103.106

180° ISO 5211 A1.203.011

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 10

Data sheet

91.5°

-0.5°

91°

AB

Sheet No.:

Date: January 2010

A1.104.01 Rev. B

DOUBLE ACTING ACTUATOR TORQUE (In.lb.) 90°

DOUBLE ACTING TORQUE

Start End

Torque

Rotation

CLOSED

Actuator

Type Size 30 35 40 45 50 55 60 70 75 80 90 100 120

ED 12

ED 25

ED 40

ED 65

ED 100

ED 150

ED 200

ED 350

ED 600

ED 950

ED 1600

PD 2500

PD 4000

43.9 51.4 58.9 66.4 73.9 81.4 88.9 104 111 119 134 149 179

81.4 95.3 109 123 137 151 165 193 206 220 248 276 332

153 179 205 231 257 283 309 361 387 413 466 518 622

233 272 312 352 392 431 471 551 590 630 709 789 948

344 402 461 520 578 637 696 813 872 930 1048 1165 1400

551 645 739 833 927 1021 1115 1303 1397 1491 1680 1868 2244

754 883 1011 1140 1269 1398 1527 1784 1913 2042 2299 2557 3072

1310 1534 1757 1981 2205 2428 2652 3100 3323 3547 3994 4442 5337

2226 2606 2986 3366 3747 4127 4507 5267 5647 6028 6788 7548 9069

3323 3890 4458 5025 5593 6160 6728 7862 8430 8997 10132 11267 13537

5493 6431 7369 8307 9245 10183 11121 12998 13936 14874 16750 18626 22379

8774 10273 11825 13270 14768 16267 17847 20858 22363 23869 26880 29891 35912

14874 17414 19962 22495 25035 27576 30127 35210 37751 40293 45375 50458 60623

Torque of double acting actuators (in In.lb)

Supply pressure (psi)

Note

1. Emerson Process Management recommends that the valve manufacturer supply the maximum required torque

values (Including any adjustments or suggested safety factors for valve service conditions or application).

Additionally, the valve manufacturer must identify at which position(s) and direction(s) of rotation

(Counter Clock Wise or Clock Wise) these maximum requirements occur.

2. If in doubt, or you require any assistance with sizing actuators, do not hesitate to contact your

nearest Emerson's Valve Automation Division representative.

3 Pressure on port "A" opens the actuator*

4 The actuator is shown in closed position*

(* code A, data sheet A1.503)

OPEN

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 11

Data sheet

91.5°

C

F

D E

-0.5°

91°

AB

Sheet No.:

Date: January 2010

A1.104.02 Rev. B

SPRING RETURN ACTUATOR TORQUE (In.lb.) 90°

Start

Torque

Springset

Actuator

Type

PS 2500

PS 4000

C

OPEN

SINGLE ACTING TORQUE

D

End

Rotation

Counter Clockwise

SPRING STROKEAIR STROKE

E

Start

F

End

Rotation

Clockwise

Note

1. Emerson Process Management

recommends that the valve manufacturer

supply the maximum required torque values

(Including any adjustments or suggested

safety factors for valve service conditions or

application).

Additionally, the valve manufacturer must

identify at which position(s) and direction(s)

of rotation (Counter Clock Wise or Clock

Wise) these maximum requirements occur.

2. If in doubt, or you require any assistance

with sizing actuators, do not hesitate to

CLOSED

contact your nearest Emerson's Valve

Automation Division representative.

3 Pressure on port "A" opens the actuator*

4 The actuator is shown in closed position*

(* code A, data sheet A1.504)

nr.

40 60 80 100 120 (lbf/in)

C D C D C D C D C D E F

6 6881 4278 12875 10273 18869 16267 24863 22261 30858 28255 7013 4401

8 5251 1781 11245 7775 17239 13769 23233 19764 29228 25758 9351 5868

10 - - 9615 5278 15609 11272 21603 17266 27597 23260 11689 7335

12 - - 7985 2780 13979 8774 19973 14768 25967 20763 14026 8803

14 - - - - 12349 6277 18343 12271 24337 18265 16364 10270

6 11701 7310 21862 17472 32024 27633 42185 37795 52347 47956 11835 7429

8 8949 3096 19111 13257 29272 23419 39434 33580 49595 43742 15780 9905

10 - - 16359 9042 26521 19204 36682 29365 46844 39527 19725 12381

12 - - 13608 4828 23770 14989 33931 25150 44093 35312 23670 14857

14 - - - - 21018 10774 31180 20936 41341 31097 27615 17333

Air Stroke (lbf/in)

SUPPLY PRESSURE (in PSI)

Spring Stroke

Actuator

Type

ES 12

ES 25

ES 40

ES 65

ES 100

ES 150

ES 200

ES 350

ES 600

ES 950

ES 1600

Springset

nr.

40 60 80 100 120 (lbf/in)

C D C D C D C D C D E F

2 - - 48 24 80 55 111 87 143 119 63 40

71 44 130 103 189 162 248 221 306 280 62 39

2

48 8 107 67 166 126 225 185 284 244 94 59

3

4

- - 85 31 144 90 203 149 262 208 125 78

5

- - - - 121 54 180 113 239 172 156 98

6

- - - - 99 18 158 77 217 136 188 117

2 133 82 243 193 354 303 464 414 575 524 117 73

3 91 15 201 125 312 236 422 346 533 457 176 110

4 - - 159 58 270 169 380 279 491 390 234 146

5 - - - - 228 101 338 212 449 322 293 183

6 - - - - 185 34 296 144 406 255 351 220

2 196 117 365 285 533 454 701 622 870 790 186 117

3 129 10 297 178 466 347 634 515 802 683 279 176

4 - - 230 71 398 240 567 408 735 576 372 234

5 - - - - 331 133 500 301 668 470 465 292

6 - - - - 264 26 432 194 601 363 558 351

2 303 192 552 441 801 690 1050 939 1299 1188 258 161

3 211 44 460 293 709 542 958 791 1206 1039 387 242

4 - - 367 144 616 393 865 642 1114 891 516 323

5 - - - - 523 245 772 494 1021 743 646 403

6 - - - - 430 96 679 345 928 594 775 484

2 485 297 884 696 1283 1094 1681 1493 2080 1892 423 259

3 337 54 735 453 1134 852 1533 1250 1931 1649 634 388

4 - - 587 210 985 609 1384 1007 1783 1406 845 517

5 - - - - 837 366 1235 764 1634 1163 1056 647

6 - - - - 688 123 1087 522 1485 920 1268 776

2 656 406 1202 952 1747 1498 2293 2043 2838 2589 579 362

3 448 74 994 619 1539 1165 2085 1710 2631 2256 868 542

4 - - 786 287 1332 832 1877 1378 2423 1924 1158 723

5 - - - - 1124 500 1669 1045 2215 1591 1447 904

6 - - - - 916 167 1462 713 2007 1258 1736 1085

2 1105 684 2053 1632 3001 2580 3949 3528 4897 4476 1025 658

3 727 95 1675 1043 2623 1991 3571 2939 4519 3887 1537 987

4 - - 1297 455 2245 1403 3193 2351 4141 3299 2049 1317

5 - - - - 1866 814 2814 1762 3762 2710 2561 1646

6 - - - - 1488 225 2436 1173 3384 2121 3074 1975

2 1920 1183 3531 2794 5142 4405 6753 6016 8364 7628 1723 1082

3 1298 193 2909 1804 4520 3415 6131 5026 7742 6637 2585 1624

4 - - 2287 814 3898 2425 5509 4036 7120 5647 3446 2165

5 - - - - 3276 1434 4887 3046 6498 4657 4308 2706

6 - - - - 2654 444 4265 2055 5876 3666 5169 3247

2 2898 1777 5303 4182 7708 6587 10113 8992 12518 11397 2563 1587

3 1986 304 4391 2709 6796 5114 9201 7519 11606 9924 3844 2381

4 - - 3479 1236 5884 3641 8288 6046 10693 8451 5125 3175

5 - - - - 4971 2168 7376 4573 9781 6978 6407 3968

6 - - - - 4059 695 6464 3100 8869 5505 7688 4762

2 4765 2988 8741 6964 12716 10939 16692 14915 20668 18890 4193 2646

3 3244 578 7220 4554 11196 8530 15171 12505 19147 16481 6289 3970

4 - - 5699 2145 9675 6120 13650 10096 17626 14071 8385 5293

5 - - - - 8154 3711 12129 7686 16105 11662 10481 6616

6 - - - - 6633 1301 10608 5277 14584 9252 12578 7939

Air Stroke (lbf/in)

SUPPLY PRESSURE (in PSI)

Spring Stroke

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 12

Data sheet

TM

Sheet No.:

Date: November 2009

A1.101.33 Rev. A

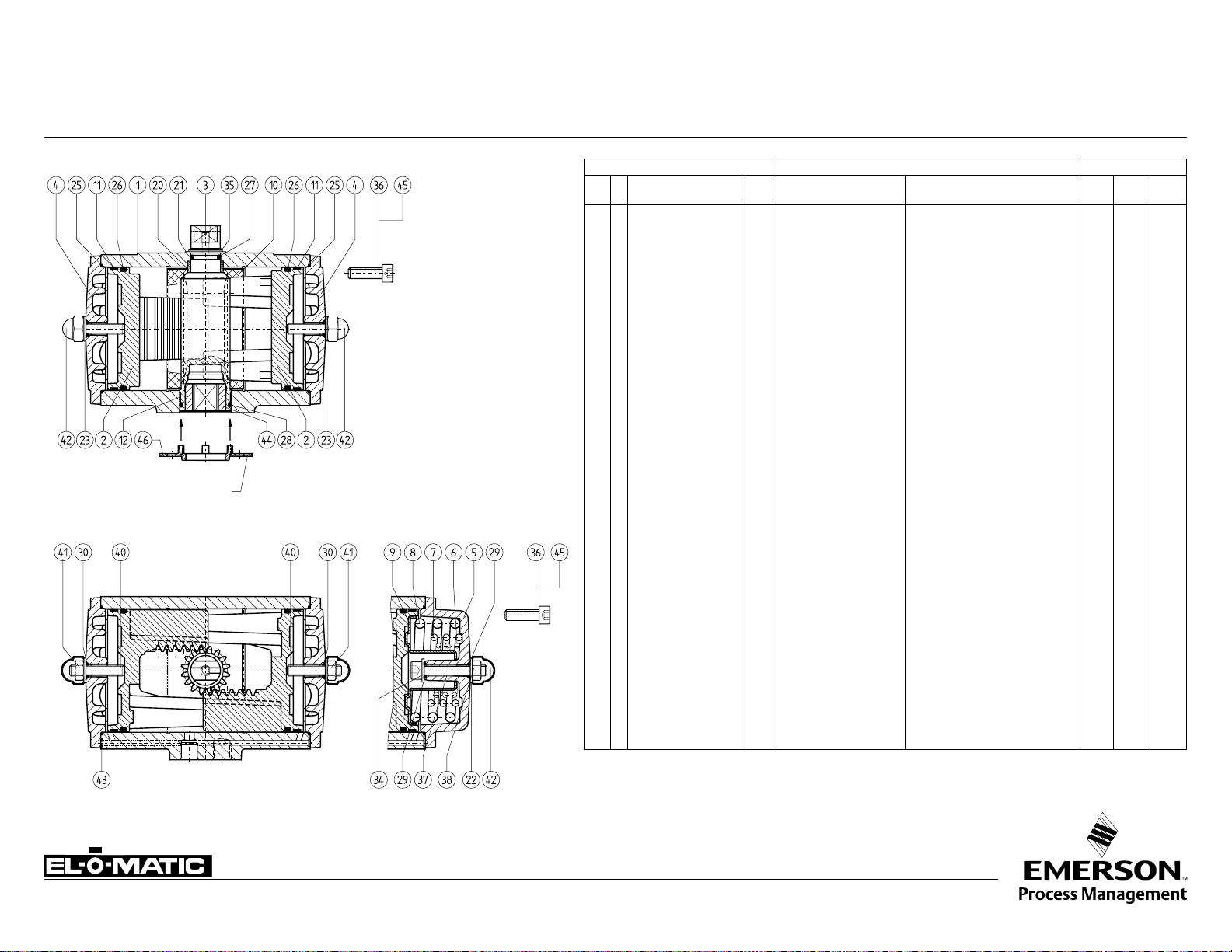

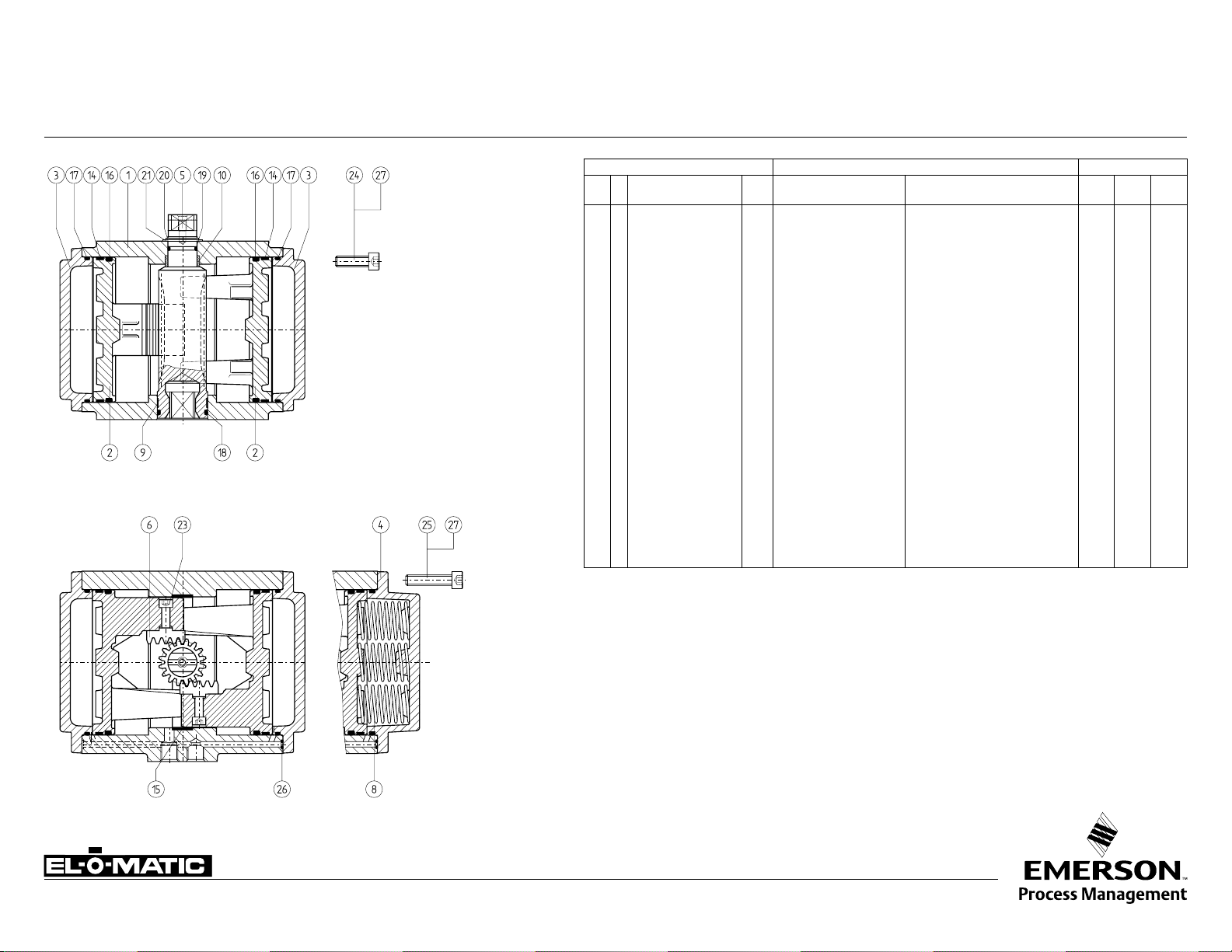

CONSTRUCTION, PARTS AND MATERIALS E-SERIE ACTUATORS E

Optional center-plate

Notes

1 Hard anodized

aluminum alloy:

AlZnMgCu1.5,

DIN 1725/1

2 Deltatone Coating

3 Anodized

4 Zinc plated and

passivated

5 CSR Coating

(see 4.204.02)

6 Stainless Steel

Sandvic 1802, SS2382

7 Stainless Steel

X35CrM017

8 No insert, adaptor

square direct in pinion

Nr. Description Qty. Description Specification Std

1 Body 1 Aluminum Alloy UNS A13600, ASTM B85 - - 5

2 Piston 2 Aluminum Alloy UNS A03560, ASTM B26 - - 3 Drive pinion 1 GAlSi10Mg, DIN 1725/2 UNS 1 77075, ASTM 7075 T6 1 6 6

4 End Cap ED 2 Aluminum Alloy UNS A13600, ASTM B85 - - 5

5 End Cap ES 2 Aluminum Alloy UNS A13600, ASTM B85 - - 5

6 Spring- inner 2 Carbon Spring Steel UNS G10860, ASTM A228 2 2 2

7 Spring- mid 2 Carbon Spring Steel UNS G10860, ASTM A228 2 2 2

8 Spring- outer 2 Carbon Spring Steel UNS G10860, ASTM A228 2 2 2

9 Spring Holder 2 Steel C45, DIN 17200 3 3 3

10 * Guide Band 1 Nylatron PA6.6 + MoS2 - - 11 * Guide Band 2 PTFE, Carbon filled PTFE + 25% C - - 12 * Bearing Bush 1 Nylatron PA6.6 + MoS2 - - 20 * Bearing Bush 1 Delrin POM - - 21 * O-ring 1 Nitrile Rubber Buna N - - -

22 * Washer ES 2 Nylon PA6 - - 23 * Washer ED 2 Nylon PA6 - - 25 * O-ring 2 Nitrile Rubber Buna N - - 26 * O-ring 2 Nitrile Rubber Buna N - - 27 * Washer 1 ZEDEX 100 K - - - 28 * O-ring 1 Nitrile Rubber Buna N - - 29 * O-ring 4 Nitrile Rubber Buna N - - 30 * O-ring 2 Nitrile Rubber Buna N - - 34 Washer ES 2 Steel C35 3 3 3

35 * Spring Clip 1 Carbon Spring Steel MIL - R-212 48B 2 7 7

36 End Cap Bolt ED/ES 8 Stainless Steel AISI 304 - - 37 Limit Stop Bolt ES 2 Stainless Steel AISI 304 - - 38 Nut 2 Stainless Steel AlSl 304 - - 40 Limit Stop Bolt ED 2 Stainless Steel AISI 304 - - 41 Nut 2 Stainless Steel AISI 304 - - 42 Nut Cover 2 Polyethylene PE - - 43 * O-ring 2 Nitrile Rubber Buna N - - 44 Insert 1 Aluminum Alloy UNS 1 6082, ASTM 6082 4 9 4

45 Threaded insert 8 Steel UNS G10430, ASTM A29 3 3 3

* Recommended spare parts (contained in Repair kits)

Parts Materials Excecutions

Remark

All materials are European origin, listed are the nearest US equivalents.

DOUBLE ACTING ED SINGLE ACTING ES

Finish

Standard : Polyester non-TGIC based powder coating

(see data sheet A4.204.01)

CSR : CSR Coating (see data sheet A4.204.02)

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

S.S.

Shaft

CSR

Page 13

Data sheet

TM

Sheet No.:

Date: November 2009

A1.101.30 Rev. A

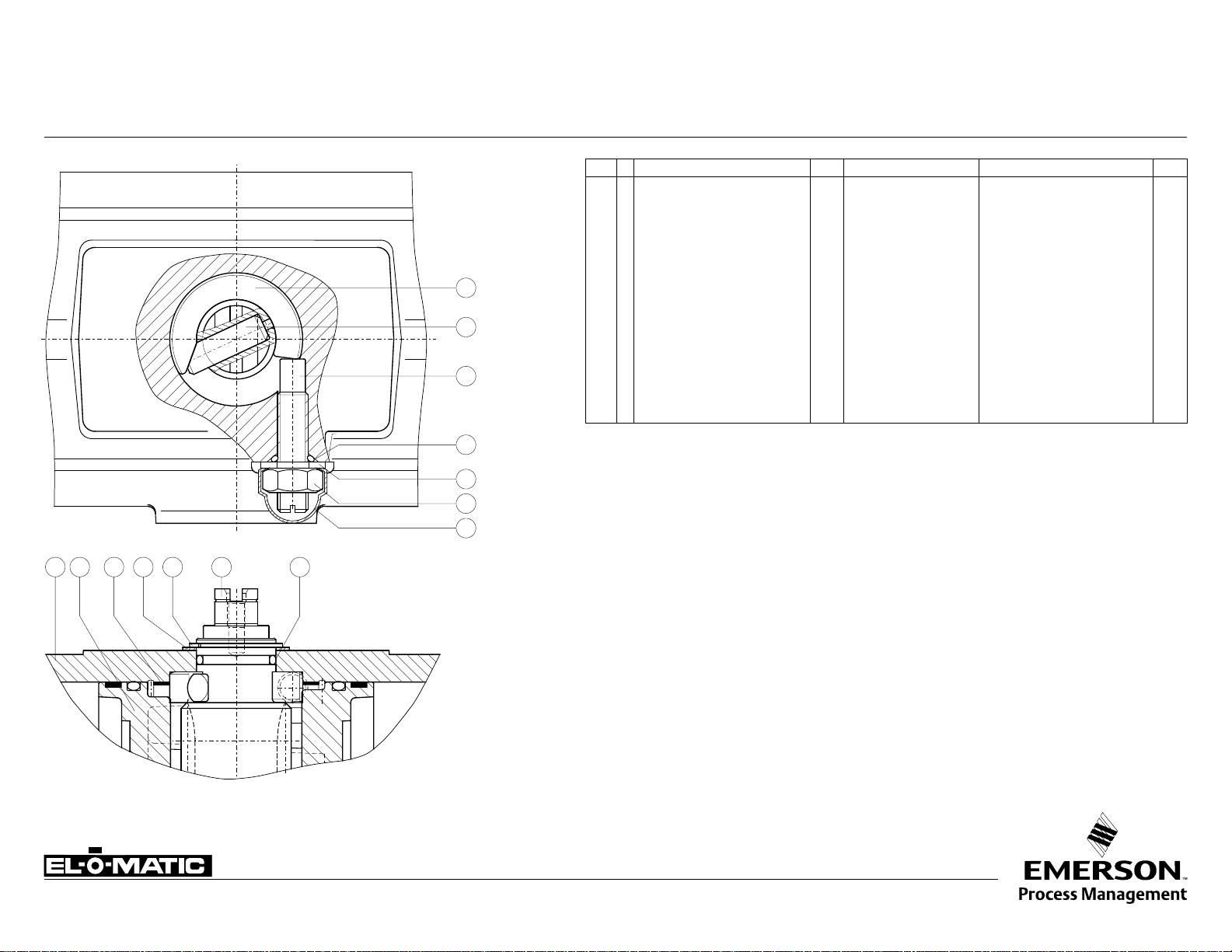

CONSTRUCTION, PARTS AND MATERIALS P-SERIE ACTUATORS P

Parts Materials Excecutions

Nr. Description Qty. Description Specification Std

1 Body 1 Aluminum Alloy UNS A13600, ASTM B85 - - 6

2 Piston 2 Aluminum Alloy UNS A03560, ASTM B26 - - 3 Endcap PDA 2 Aluminum Alloy UNS A13600, ASTM B85 - - 6

4 Endcap PSA 2 Aluminum Alloy UNS A13600, ASTM B85 - - 6

5 Drive pinion 1 Aluminum Alloy UNS 1 77075, ASTM 7075 T6 1 4 4

6 Gear Rack 2 Steel UNS G10950, ASTM A108 - - 8 Spring 14 Carbon Spring Steel UNS G10860, ASTM A228 2 2 2

9 * Bearing Bush 1 Nylatron GS PA6.6 + MoS2 - - 10 * Bearing Bush 1 Delrin POM - - 14 * Guide band 2 PTFE, Carbon filled PTFE + 25% C - - 15 * Guide band 2 PTFE, Carbon filled PTFE + 25% C - - 16 * O-ring 2 Nitrile Rubber Buna N - - 17 * O-ring 2 Nitrile Rubber Buna N - - 18 * O-ring 1 Nitrile Rubber Buna N - - 19 * O-ring 1 Nitrile Rubber Buna N - - 20 * Spring Clip 1 Carbon Spring Steel MIL - R-212 48B 2 5 5

21 * Thrust Washer 1 ZEDEX 100 K - - - 23 Bolt 4 Alloy Steel 12.9 ASTM F568 - - 24 Endcap bolt PDA 20 Alloy Steel 8.8 ASTM F568 2 4 4

25 Endcap bolt PSA 20 Alloy Steel 8.8 ASTM F568 2 4 4

26 * O-ring 2 Nitrile Rubber Buna N - - 27 Threaded insert 20 Steel UNS G10430, ASTM A29 3 3 3

* Recommended spare parts (contained in Repair kit)

S.S.

Shaft

Notes

1 Hard anodized

2 Deltatone® Coating

3 Zinc plated and passivated

4 Stainless Steel AISI 304

5 Stainless Steel, X35CrM017

6 CSR Coating (see A4.204.02)

7 P4000 has a stainless steel (AISI 304)

locking ring between spring clip (20)

and thrust washer (21)

8 P4000 has in the springs a guiding bush (PVC)

CSR

Remark

All materials are European origin, listed are the nearest US equivalents

Finish

Standard : Polyester non-TGIC based powder coating

(see data sheet A4.204.01)

DOUBLE ACTING PD SINGLE ACTING PS

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

CSR : CSR Coating (see data sheet A4.204.02)

Page 14

Data sheet

TM

5

6

8

10

12

13

14

12347

9

11

Sheet No.:

Date: November 2009

A1.101.60 Rev. A

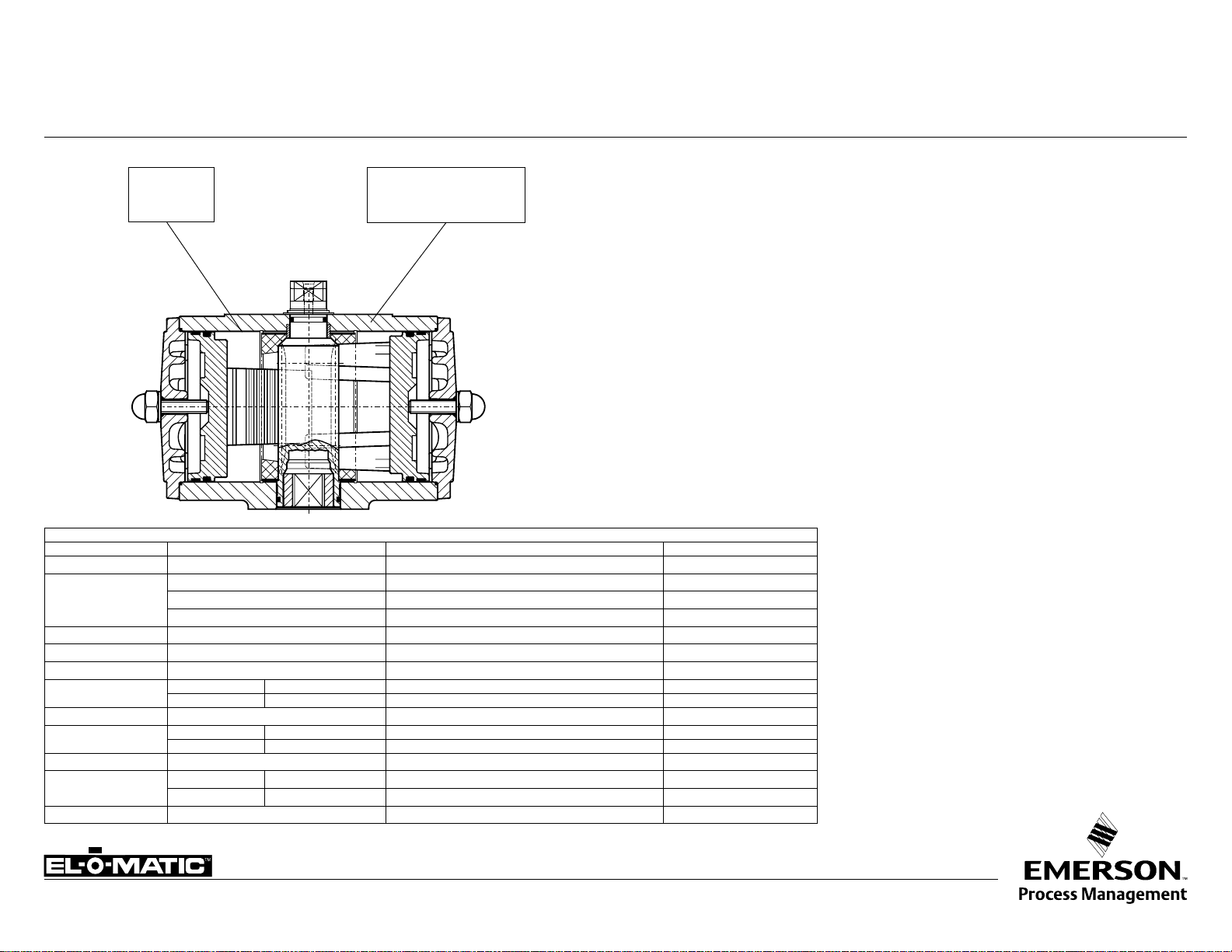

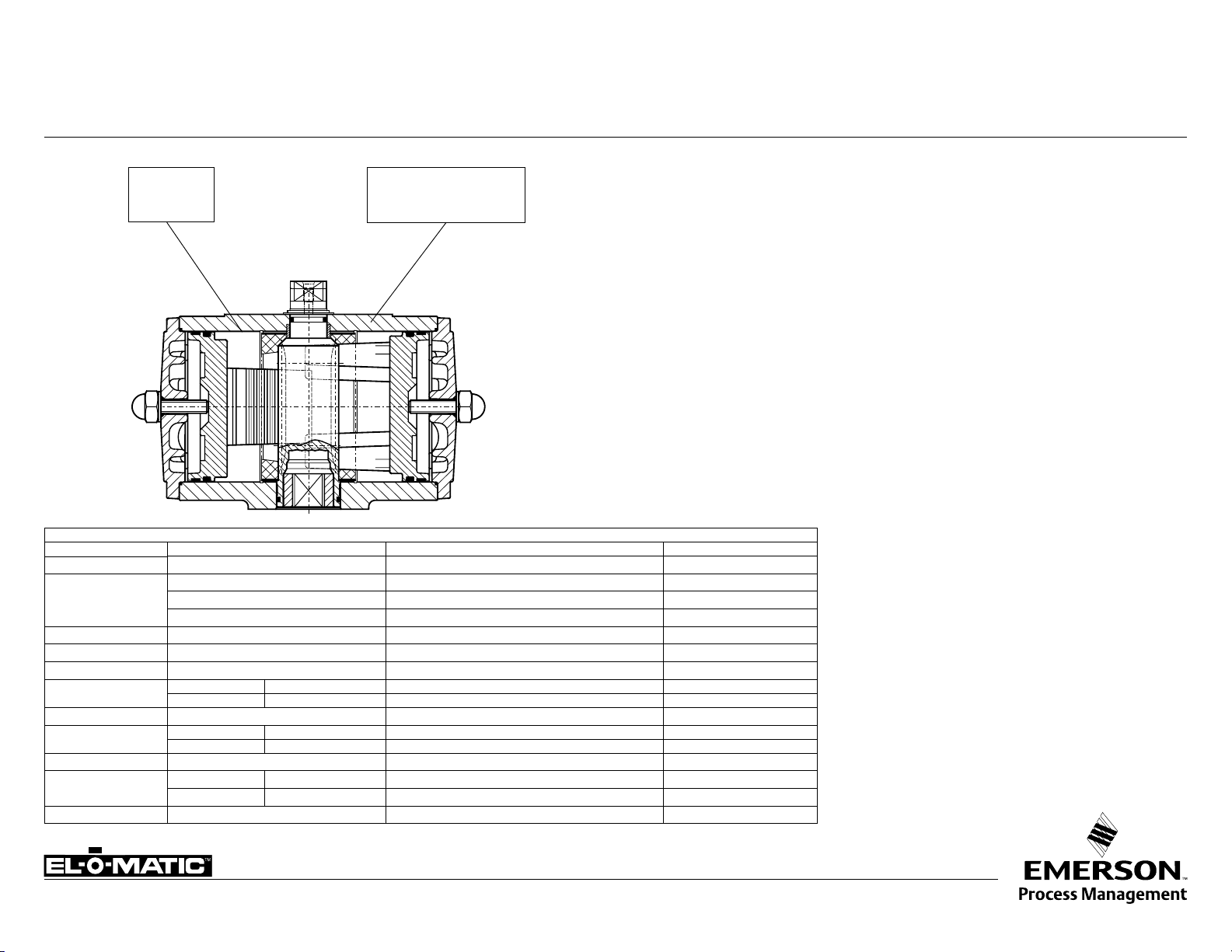

CONSTRUCTION, PARTS AND MATERIALS DSA ACTUATOR

Nr. Description Qty. Material Specification Note

1 Body DSA 1 Aluminum Alloy UNS A13600, ASTM B85 2 Piston DSA 2 Aluminum Alloy UNS A03560, ASTM B26 3 Drive pinion DSA 1 Aluminum Alloy UNS 1 77075, ASTM 7075 T6 1

4 * Guide Band DSA 1 Nylatron GS UNS A13600, ASTM B85 5 Cam for stroke adj. DSA 1 Stainless Steel UNS A13600, ASTM B85 6 Shaftpin for stroke adj. DSA 1 Chrome nickel steel UNS G10860, ASTM A228 7 * Washer 1 ZEDEX 100 K - 8 * Washer 1 Nylon UNS G10860, ASTM A228 -

9 * O-ring shaft top 1 Nitrile Rubber C45, DIN 17200 10 * O-ring limit stop bolt DSA 1 Nitrile Rubber PA6.6 + MoS2 11 Circlip 1 Carbon spring steel PTFE + 25% C 2

12 Limitstop bolt DSA 1 Stainless Steel PA6.6 + MoS2 13 Nut 1 Stainless Steel POM 14 Nut Cover 1 Polyethylene Buna N -

* Recommended spare parts (contained in Repair kits DSA)

Finish

Polyester non-TGIC based powder coating (see data sheet A4.204.01)

Note

1 Hard anodized

2 Deltatone® coating

DSA

Remark

This data sheet shows only the extra or specific parts of a DSA actuator.

For all the other parts see data sheet A1.101.33

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 15

Data sheet

Sheet No.:

Date: June 2010

A1.101.70 Rev. C

LOW TEMPERATURE ACTUATOR SPECIFICATIONS

-40°C / +80°C

-40°F / +176°F

Silicone

MVQ 70

Sealings

Materials

Part Material Specifications Remark

Housing

Drive Shaft

Piston

Sealings

Grease

Shaft bearings

Piston bearings

Bodybearings

Shaft thrust washer

End cap bolts

Springs

Castrol Optitemp TT1

Low Temperature

A double piston, rack and pinion pneumatic actuator incorporating a three point piston support

system, anti-blowout spindle and with high duty synthetic bearings at all bearing points.

Grease

This version is a standard aluminum actuator, but incorporating parts and materials suitable for

low temperature operation.

Note

When operating actuators in sub-zero temperatures (< 0°C or < 32°F) care should be taken to

counter the effects of freezing condensate inside the actuator.

Specification

Max. pressure : 120 psi (8 bar)

Torque : Standard

Media : Air or non corrosive gas

Temperature : -40°F to +176°F (-40°C to +80°C)

Finish : Polyester non-TGIC based powder coating (see data sheet A4.204.01)

Spare parts

Dedicated low temperature spare parts are available for maintenance or make a standard

actuator suiteable for low temperature operation.

Aluminum Alloy UNS A13600, ASTM B85

Aluminum Alloy UNS 1 77075, ASTM 7075 T6 Hard anodized

Steel (180° rotation) ETG100 or 42CrMo4V XM Zinc Plated type > P750

Stainless Steel Sandvic 1802, SS2382 or X35CrM017 type > E950

Aluminum Alloy UNS A03560, ASTM B26

Silicone MVQ 70 O-rings -/-

Description

Castrol Optitemp TT1

Top : Delrin POM

Bottom : Nylatron PA6.6 + MoS2

PTFE 25% Carbon filled

PTFE (“P” serie) 25% Carbon filled

Nylatron (“E” serie) PA6.6 + MoS2

ZEDEX 100 K -/-

Stainless Steel (“E” serie) AISI 304 A2

Alloy Steel (“P” serie) 8.8 DIN 912

Carbon Spring Steel UNS G10860, ASTM A228

-/-

Deltatone

Deltatone

®

coating

®

coating

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 16

Data sheet

Sheet No.:

Date: January 2010

A1.101.71 Rev. B

HIGH TEMPERATURE ACTUATOR SPECIFICATIONS

-20°C / +120°C

-4°F / +248°F

Sealings

Materials

Part Material Specifications Remark

Housing

Drive Shaft

Piston

Sealings

Grease

Shaft bearings

Piston bearings

Bodybearings

Shaft thrust washer

End cap bolts

Springs

Viton

FPM

Castrol

LMX

A double piston, rack and pinion pneumatic actuator incorporating a three point piston support

system, anti-blowout spindle and with high duty synthetic bearings at all bearing points.

Grease

This version is a standard aluminum actuator, but incorporating parts and materials suitable for

high temperature operation.

Specification

Max. pressure : 8 bar ~ 120psi

Torque : Standard

Media : Air or non corrosive gas

Temperature : -4°F to +248°F (-20°C to +120°C)

Finish : Polyester non-TGIC based powder coating (see data sheet A4.204.01)

Spare parts

Dedicated high temperature spare parts are available for maintenance or make a standard

actuator suiteable for high temperature operation.

Aluminum Alloy UNS A13600, ASTM B85

Aluminum Alloy UNS 1 77075, ASTM 7075 T6 Hard anodized

Steel (180° rotation) ETG100 or 42CrMo4V XM Zinc Plated type > P750

Stainless Steel Sandvic 1802, SS2382 or X35CrM017 type > E950

Aluminum Alloy UNS A03560, ASTM B26

Viton FPM O-rings -/Castrol LMX -/-

Top : Delrin POM

Bottom : Nylatron PA6.6 + MoS2

PTFE 25% Carbon filled

PTFE (“P” serie) 25% Carbon filled

Nylatron (“E” serie) PA6.6 + MoS2

ZEDEX 100 K -/-

Description

Stainless Steel (“E” serie) AISI 304 A2

Alloy Steel (“P” serie) 8.8 DIN 912 Deltatone

Carbon Spring Steel UNS G10860, ASTM A228 Deltatone

®

coating

®

coating

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 17

Data sheet

TM

Sheet No.:

Date: November 2009

A4.201 Rev.A

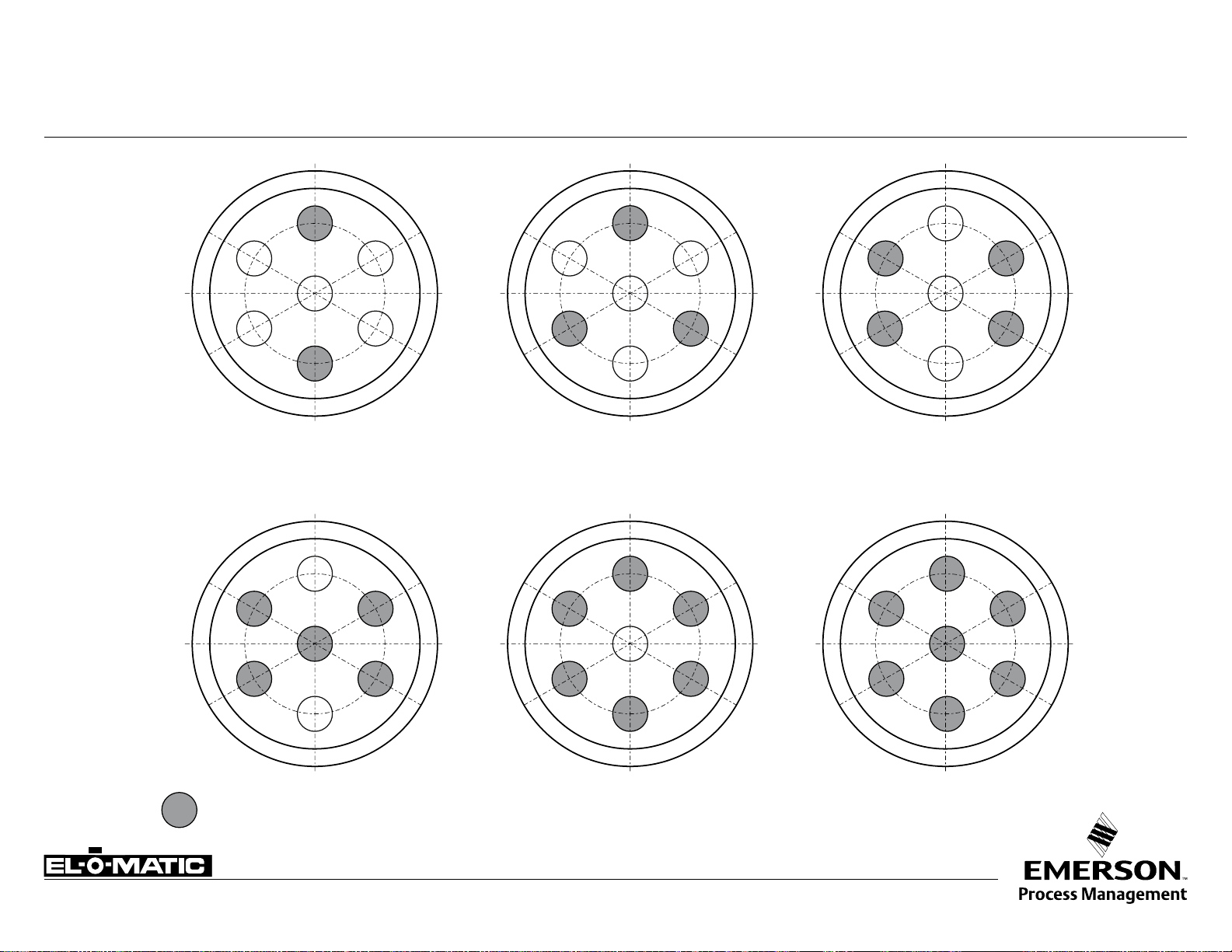

INSTALLATION OF SPRINGS OF P-SERIES ACTUATOR P

4 SPRINGS 6 SPRINGS 8 SPRINGS

10 SPRINGS 12 SPRINGS 14 SPRINGS

SPRING

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 18

Data sheet

TM

Sheet No.:

Date: November 2009

A4.202 Rev.A

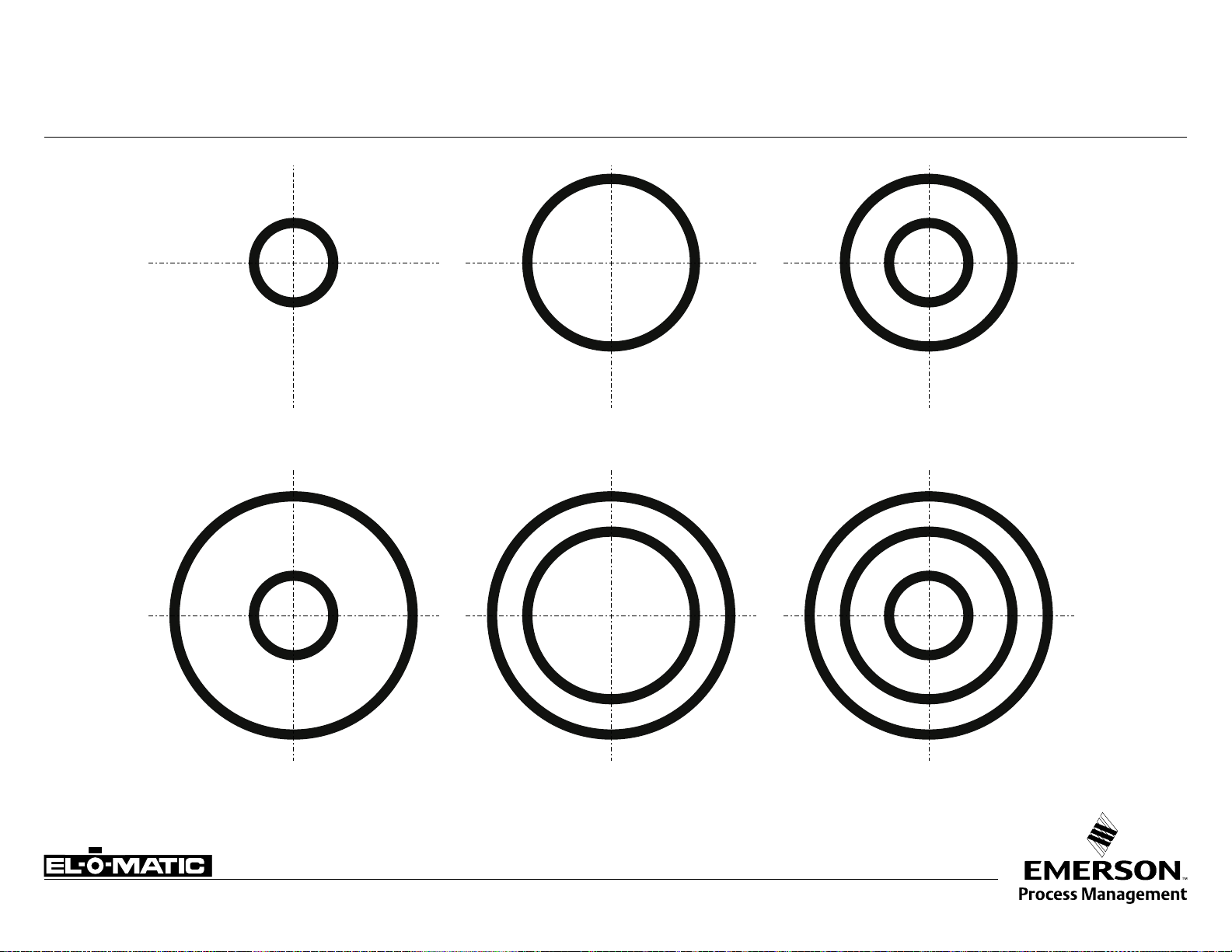

INSTALLATION OF SPRINGS OF E-SERIES ACTUATOR E

SPRING SET No. 1

inner spring

SPRING SET No. 4

inner spring

outer spring

SPRING SET No. 2

mid spring

SPRING SET No. 5

mid spring

outer spring

SPRING SET No. 3

inner spring

mid spring

SPRING SET No. 6

inner spring

mid spring

outer spring

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 19

Data sheet

TM

A

B

A

B

A

B

A

B

Sheet No.:

Date: November 2009

A1.503 Rev. A

DOUBLE ACTING ACTUATOR ASSEMBLY MODES E/P

A-port pressurized

B-port pressurized

Pistons

Shaft

STANDARD

All views are from above

Pistons are shown in inner position

MOUNTING IN LINE

(OPTIONAL L1/LF) LIMIT STOPS WILL ADJUST THE VALVE AT OPEN POSITION

(OPTIONAL L1/LF) LIMIT STOPS WILL ADJUST THE VALVE AT CLOSED POSITION

MOUNTING ACROSS LINE

PISTONS TURNED 180°

(from standard)

B-port pressurized

A

B

DC

SHAFT TURNED 90°

(from standard)

MOUNTING ACROSS LINE

MOUNTING IN LINE

SHAFT TURNED 90°

PISTONS TURNED 180°

(from standard)

A-port pressurized

B-port pressurized

B-port pressurized

A-port pressurized

A-port pressurized

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 20

Data sheet

TM

Sheet No.:

Date: November 2009

A1.504 Rev. A

SPRING RETURN ACTUATOR ASSEMBLY MODES E/P

Pistons

Shaft

All views are from above

Pistons are shown in inner position

AB

A-port pressurized

Spring stroke

Springs

STANDARD

MOUNTING IN LINE

SPRING TO CLOSE (ROTATION CW)

SPRING TO OPEN (ROTATION CCW)

MOUNTING ACROSS LINE

PISTONS TURNED 180°

(from standard)

Spring stroke

A

B

DC

A-port pressurized

Spring stroke

AB

SHAFT TURNED 90°

(from standard)

MOUNTING ACROSS LINE

MOUNTING IN LINE

SHAFT TURNED 90°

PISTONS TURNED 180°

(from standard)

Spring stroke

A-port pressurized

A-port pressurized

AB

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

AB

Page 21

Data sheet

Sheet No.:

Date: April 2011

High grade aluminum alloy,

hard anodized

(Option : Stainless steel)

A4.204.01 Rev.B

EL-O-MATIC STANDARD CORROSION PROTECTION SYSTEM

Stainless steel fasteners

Description

The corrosion protection system of standard El-O-Matic E&P series pneumatic actuators consist of the

following treatments or materials:

1 De-greasing

All aluminum parts are de-greased before the powder coating is applied by washing with an alkaline

solution to assure the best bonding between the aluminum surface and the coating.

2 Powder coating

- Polyester non-TGIC based powder coating for exterior use.

- The powder coating is applied cold using automatic electrostatic spray equipment and is cured at

minimum 190°C (374°F) offering excellent anti color fade and weather resistance.

- The powder coating thickness is 1.5 mm (37 microns) minimum, and 2 mm (50 microns) average.

- Good resistance against most chemical bases, acids, solvents, alkalis and oils at normal temperatures.

- Excellent exterior mechanical durability.

- The coating has passed a salt spray test according to ASTM B117 for 500 hours. The powder coating is

virtually solvent free, and therefore environmentally friendly.

3 High grade & hard anodized aluminum pinion

Actuators with high grade & hard anodized aluminum pinions, passed a 500 hours salt spray test.

Optional stainless steel pinions are available for a higher corrosion resistance.

4 Stainless steel or Deltatone

®

treated external steel parts

External parts are stainless steel or steel alloy with a Deltatone® treatment.

Technical data:

Coating : Polyester non-TGIC based powder coating

Powder coating:

Polyester non-TGIC based powder

coating for exterior use.

Salt spray test : DIN 50021 / ASTM B117: 500h

Color : Yellow (RAL 1007)

Materials : Housing : Aluminum alloy

: Pinion : High grade aluminum alloy, hard anodized

(Option : Stainless steel)

: Fasteners : Stainless steel or alloy steel with Deltatone® treatment

: Tagplate : Stainless steel

Application : Standard EL-O-MATIC E & P series pneumatic actuators

For Non-Standard actuators, see data sheet A4.204.05

Option : CSR coating for excellent corrosion resistance

See data sheet A4.204.02

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 22

Data sheet

CSR

Corrosion

Protected

Sheet No.:

Date: June 2009

Hard anodized aluminum

(Option : Stainless steel)

A4.204.02 Rev.B

Stainless steel fasteners

EL-O-MATIC ACTUATOR WITH CSR COATING CSR

Description

EL-O-MATIC CSR-actuators have an excellent corrosion resistance in environments where the actuator is

in contact with chemicals like caustic soda. The CSR coating itself is resistant to at least 1000 hours of salt

spray test exposure. Together with the excellent mechanical properties, the CSR coating is "the" solution for

very harsh environments.

CSR actuator housing and caps are completely coated (inside and out) with a ceramic filled fluoropolymer

based epoxy resin, impregnated by a temperature of 240°C into the aluminum surface.

Approximately 40% of the coating is impregnated into the aluminum, 60% stays on the surface of the

component as a seal.

Technical data

Coating : Ceramic filled fluoropolymer based epoxy resin

Layer thickness : 20 microns

Salt spray test : DIN 50021 / ASTM B117: 1000 hours

Max. temperature : -4° to 176°F (20° to + 80°C)

Materials : Housing : Aluminum alloy

: Shaft : Aluminum hard anodized

: (Option : Stainless steel)

: Fasteners : Stainless steel

: Tagplate : Stainless steel

Application : Optional on all EL-O-MATIC actuators

Chemical resistances

Resistance to various inorganic chemicals, organic chemicals, gasolines, oils, detergents,

etc. is generally good to excellent, but also depends on temperature and/or concentration.

Coating:

More detailed information available at data sheet A4.204.021

20 microns Ceramic filled epoxy resin

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 23

Data sheet

TM

Sheet No.:

Date: November 2009

A4.204.021 Rev.A

CHEMICAL RESISTANCE LIST FOR CSR COATING CSR

Inorganic chemicals

1 Ammonium hydroxide (10%) 2 Nitric acid (10%)

1 Calcium chloride (~50%) 3 Nitric acid (50%)

3 Chlorine 1 Hydrochloric acid (10%)

3 Chromic acid 1 Hydrochloric acid (concentrated)

3 Hydrofluoric acid (50%) 1 Sulphuric acid (50%)

1 Caustic potash solution (10%) 3 Sulphuric acid (concentrated)

1 Sodium hypochlorite (saturated) 2 Sulphur dioxide

1 Caustic soda solution (10%) 1 Sulphur hexafluoride

1 Caustic soda solution (saturated) 2 Nitric oxide

1 Phosphoric acid (10%) 1 Hydrogen peroxide (100%)

1 Phosphoric acid (50%)

Organic chemicals

3 Acetone 1 Glycerine

3 Acetonitrile 1 Hexane

3 Aniline 1 Isooctane

2 Benzene 1 Isopropanol

1 n-Butanol 1 Methanol

3 Butyl acetate 3 Methylene chloride

3 Chlorobenzene 3 Methyl ethyl ketone

3 Chloroforme 3 N.N-Dimethylformamide

3 o-Chlorophenol 3 N-Methylpyrrolidon

1 Cyclohexane 1 Oxalic acid

3 Cyclohexanone 1 Perchloroethylene

3 1,2-Dichloroethane 1 Petroleum ether

2 Diethyl ether 3 Phenol

2 Dioxane 1 Carbon bisulphide

1 Glacial acetic acid 1 Turpentine

1 Ethanol 2 Tetrachloroethane

3 Ethyl acetate 2 1,1,1-Trichloroethane

1 Ethylene glycol 1 Tetrachloromethane

1 Formaldehyde 3 Trichloroethylene

2 Freon 11 2 Toluene

2 Freon 22 1 Xylene

Fuels/lubricants

1 Two-star petrol (50°C)

1 Four-star petrol (50°C)

1 Fuel M 15 (50°C)

1 Diesel oil

1 Kerosene

1 to 2 Hypoid bevel gear oil Shell Spirax HD 90 (150°C)

1 Transmission oil Shell Spirax MA 80 (150°C)

Chemicals

1 Automatic transmission fluid Shell Dextra

11D 20-137 (150°C)

1 Engine oil, mineral, Mihag 1500-40 (150°C)

1 Engine oil, synthetic, Mobil SHC 10 W-40

3 Brake fluid Hydraulan DOT 4

1 Roller bearing grease DIN 51 825

Technical detergents

2 Genkeene

2 1,1,1- Trichloroethane

2 Triklone A

2 Perchloroethylene

Miscellaneous fluids

1 Glysantin (BASF)/water

1 Plasticizer DOP

1 Suds

1 Washing-up liquids

1 Household detergents

1 Linseed oil

1 Milk

1 Soapsuds

1 Silicone oils

1 Excellent

2 Limited resistance; it is recommended to perform field tests under the specified conditions.

3 Not recommended

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Note: This list has been composed with great care. However,

EL -O - MATIC cannot be held responsible, either for any

errors in this list or for their consequences.

Because of continued testing this list is subject to

change without notice.

Page 24

Data sheet

TM

P60 - P750

0.94

1.26

M5x.31

G1/4"

I

M6x.47

4

H

K

M1

N

±0.02

øV1

4xW

øV

8xW1

W1

øP

+0.02

0

W

W2

T

O

R

R2

S

øV

øV1

U

B

A

0.16

U1

T1

R1

S1

M5x.31

E1

F

E2

J

GD

C

2

2

3

P1100 - P4000 P4000

M5x.31

1.00

1.37

1.00

G1/2"

1.37

1

Sheet No.:

Date: November 2009

A1.203.011 Rev. A

DIMENSION SHEET STANDARD 180° ACTUATOR 180°

Dim.

in mm.

A DA

B SR

C

D

E1

E2

F

G

H

I

J

K

M1

N

O max.

O min.

P

R

R1

R2

S

S1

T

T1

U

U1

V

W

V1

W1

W2

Note

1. Flange to ISO 5211, square drive to DIN 3337

2. Top and Solenoid flange to VDI/VDE 3845 (NAMUR).

E12 P60 P150 P280 P500 P750 P1100 P2500 P4000

9.17 11.61 13.94 16.30 17.60 19.76 24.92 29.61

10.08 13.07 17.09 19.57 21.77 25.24 32.17 42.95

3.98 5.31 6.30 7.48 9.21 9.72 14.02 14.96

0.79 0.79 0.79 1.18 1.18 1.18 1.18 1.18

0.63 0.87 1.02 1.42 1.42 1.77 2.17 2.52

0.91 1.18 1.38 1.77 1.77 2.17 2.56 3.15

0.39 0.55 0.55 0.75 0.75 1.18 1.42 1.42

0.47 0.47 0.47 0.75 0.75 0.39 0.39 0.39

3.98 5.43 6.61 7.56 9.41 9.84 13.54 14.65

For E12 dimensions see A1.103.102

2.28 2.95 3.50 4.29 5.28 5.31 7.20 7.87

1.69 2.09 2.72 3.74 4.57 4.92 7.01 7.48

1.10 1.50 1.89 2.20 2.20 2.95 3.35 4.72

1.06 1.06 1.22 1.50 1.50 2.01 2.60 3.03

0.04 0.04 0.06 0.06 0.08 0.10 0.12 0.06

0.556 0.674 0.871 1.068 1.068 1.424 1.817 2.173

0.551 0.669 0.866 1.063 1.063 1.417 1.811 2.165

0.713 0.992 1.110 1.425 1.425 1.898 2.370 2.843

2.36 3.15 3.98 4.37 5.51 5.51 6.69 6.69

2.01 2.36 2.80 3.19 3.94 4.72 6.30 6.30

2.76 3.94 - - - - - 10.31

4.37 5.12 5.55 6.34 8.27 8.27 11.42 11.42

4.37 5.12 5.55 5.55 6.30 8.27 9.65 9.65

- - - - - - 9.24 -

3.15 3.15 3.15 5.12 5.12 5.12 5.12 5.12

- - - - - - 3.83 -

1.18 1.18 1.18 1.18 1.18 1.18 1.18 1.18

F05 F07 F07 F10 F10 F14 F16 F16

1.969 2.756 2.756 4.016 4.016 5.512 6.496 6.496

M6 x .35 M8 x .51 M8 x .51 M10 x .63 M10 x .63 M16 x .79 M20 x1.18 M20 x1.18

F07 F10 F10 F12 F12 - - F25

2.756 4.016 4.016 4.921 4.921 - - 10.000

M8 x .51 M10 x .63 M10 x .63 M12 x .63 M12 x .63 - - M16 x 0.98

- - - - - - M16 x 0.98 -

ACTUATOR TYPE

P1100 P2500 and P4000 have a non-NAMUR solenoid flange with 1/2" entries.

3. 180° actuators are standard equipped with "L1" limit stops. 120° or 135° rotation

is possible with optional LF-option (See data sheet A1.503.01)

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Eur ope: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 25

Data sheet

A B

182°

181° -1°

Sheet No.:

Date: June 2010

A1.204.01 Rev. C

180° DOUBLE ACTING ACTUATOR TORQUE (In.lb.) 180°

START END

TORQUE

ROTATION

Actuator

type

ED 12

PD 60

PD 150

PD 280

PD 500

PD 750

PD 1100

PD 2500

PD 4000

Note

1. Emerson Process Management recommends that the valve manufacturer supply the

maximum required torque values (Including any adjustments or suggested safety factors for

valve service conditions or application).

Additionally, the valve manufacturer must identify at which position(s) and direction(s) of

rotation (Counter Clock Wise or Clock Wise) these maximum requirements occur.

2. If in doubt, or you require any assistance with sizing actuators, do not hesitate to contact your

nearest Emerson's Valve Automation Division representative.

3. Pressure on port "A" opens the actuator*

4. The actuator is shown in closed position*

5. Do not exceed the maximum supply pressure of 6 bar / 87psi.

(*code A, data sheet A1.503)

30 40 50 60 70 80

44 59 74 89 104 119

104 139 175 210 245 281

262 351 441 530 620 709

493 662 830 999 1167 1336

872 1170 1467 1765 2063 2361

1297 1740 2182 2625 3068 3511

1912 2566 3219 3872 4525 5179

4407 5913 7418 8923 10429 11934

7440 9981 12522 15064 17605 20146

Torque (in in.lb)

Supply Pressure (PSI)

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 26

Data sheet

D E

181°

F C

-1°

A B

182°

Sheet No.:

Date: June 2010

A1.204.02 Rev. C

180° SPRING RETURN ACTUATOR TORQUE (In.lb.) 180°

C

Start

Torque

Counter Clockwise

AIR STROKE

D

End

Rotation

SPRING STROKE

E

Start

F

End

Rotation

Clockwise

Note

1. Emerson Process Management recommends that the valve manufacturer supply the maximum

required torque values (Including any adjustments or suggested safety factors for valve service

conditions or application).

Additionally, the valve manufacturer must identify at which position(s) and direction(s) of rotation

(Counter Clock Wise or Clock Wise) these maximum requirements occur.

2. If in doubt, or you require any assistance with sizing actuators, do not hesitate to contact your

nearest Emerson's Valve Automation Division representative.

3. Pressure on port "A" opens the actuator*

4. The actuator is shown in closed position*

5. Do not exceed the maximum supply pressure of 6 bar / 87psi.

(*code A, data sheet A1.504)

Actuator

type

ES12

PE60

PE150

PE280

PE500

PE750

PE1100

PE2500

PE4000

Spring

nr.

40 50 60 70 80 (in.lb.)

C D C D C D C D C D E F

2 - - 33 9 49 25 65 41 81 57 63 41

8 70 19 105 55 141 90 176 125 212 161 112 62

10 - - 88 24 123 60 159 95 194 131 141 78

12 - - - - 106 30 142 65 177 101 169 93

14 - - - - - - 124 35 160 71 197 109

8 185 76 274 165 364 255 453 344 543 433 258 150

10 - - 233 96 322 186 411 275 501 365 322 187

12 - - - - 280 117 370 206 459 296 387 225

14 - - - - 239 48 328 137 418 227 451 262

8 - - 493 193 662 361 830 530 999 698 597 303

10 - - - - 578 202 746 370 915 539 746 379

12 - - - - - - 662 211 830 379 896 455

14 - - - - - - - - 746 220 1045 531

8 - - 965 256 1263 554 1561 852 1859 1149 1134 452

10 - - - - 1138 251 1435 549 1733 847 1417 565

12 - - - - - - - - 1608 544 1701 678

14 - - - - - - - - - - 1984 791

8 - - 1470 549 1913 992 2356 1434 2799 1877 1529 641

10 - - - - 1735 583 2178 1026 2621 1469 1912 801

12 - - - - - - 2000 618 2443 1060 2294 961

14 - - - - - - - - 2265 652 2676 1121

8 1454 430 2108 1083 2761 1736 3414 2389 4067 3043 1999 1000

10 - - 1830 549 2483 1202 3136 1855 3790 2509 2499 1250

12 - - - - 2205 668 2858 1321 3512 1975 2999 1500

14 - - - - - - 2581 787 3234 1441 3499 1750

8 2625 890 4124 2389 5622 3888 7121 5386 8620 6885 4675 2934

10 - - 3309 1140 4807 2639 6306 4137 7804 5636 5844 3668

12 - - 2494 -109 3992 1390 5491 2889 6989 4387 7013 4401

14 -

8 4475 1548 7015 4088 9555 6628 12096 9169 14636 11709 7890 4952

10 - - 5639 1981 8180 4521 10720 7061 13260 9602 9863 6190

12 - - 4264 -127 6804 2414 9344 4954 11885 7494 11835 7429

14 - - - - 5428 306 7969 2847 10509 5387 13808 8667

- - - 3177 141 4676 1640 6174 3138 8182 5135

Air Stroke (in.lb.)

SUPPLY PRESSURE (PSI)

Spring

Stroke

www.El-O-matic.com

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

Page 27

Contact Us: Emerson Process Management, Valve Automation facilities at your nearest location:

North & South AmericA

18703 GH Circle

PO Box 508

Waller, TX 77484

USA

T +1 281 727 5300

F +1 281 727 5353

2500 Park Avenue West

Mansfield, OH 44906

USA

T +1 419 529 4311

F +1 419 529 3688

9009 King Palm Drive

Tampa, FL 33619

USA

T +1 813 630 2255

F +1 813 630 9449

13840 Pike Road

Missouri City, Texas 77489

USA

T +1 281 499 1561

F +1 281 499 8445

Av. Hollingsworth,

325, Iporanga Sorocaba,

SP 18087-105

Brazil

T +55 15 3238 3788

F +55 15 3228 3300

middle eASt & AfricA

P. O. Box 17033

Dubai

United Arab Emirates

T +971 4 811 8100

F +971 4 886 5465

P. O. Box 105958

Abu Dhabi

United Arab Emirates

T +971 2 697 2000

F +971 2 555 0364

P. O. Box 3911

Al Khobar 31952

Saudi Arabia

T +966 3 814 7560

F +966 3 814 7570

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

F +966 3 340 8790

P. O. Box 32281

Doha

Qatar

T +974 4 576777

F +974 4 315448

2 Monteer Road, Isando

Kempton Park, 1600

South Africa

T +27 11 974 3336

F +27 11 974 7005

europe

Asveldweg 11

7556 BR Hengelo (O)

The Netherlands

T +31 74 256 1010

F +31 74 291 0938

Siemensring 112

47877 Willich

Germany

T +49 2154 499 660

F +49 2154 499 6613

25, Rue de Villeneuve

Silic – BP 40434

94583 RUNGIS Cedex

France

T +33 1 49 79 73 00

F +33 1 49 79 73 99

Via Montello 71/73

20038 Seregno (Milan)

Italy

T +39 0362 2285 207

F +39 0362 2436 55

6 Bracken Hill

South West Industrial Estate

Peterlee SR8 2LS

United Kingdom

T +44 191 518 0020

F +44 191 518 0032

ul. Konstruktorska str 11A

02-673 Warsaw

Poland

T +48 22 4589237

F +48 22 45 89 231

C/ Francisco Gervás, 1

28108 Alcobendas – Madrid

Spain

T +34 0913 586 000

F +34 0913 589 145

Letnikovskaya Str. 10-2

115114 Moscow

Russia and FSU

T +7 495 981 98 11

F +7 495 981 98 10

ASiA pAcific

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6501 4600

F +65 6268 0028

9/F Gateway Building

No. 10 Ya Bao Road

Chaoyang District

Beijing 100020

P.R.China

T +86 10 5821 1188

F +86 10 5821 1100

No.15 Xing Wang Road

Wuqing Development Area

Tianjin 301700

P.R.China

T +86 22 8212 3300

F +86 22 8212 3308

Lot 13111, Mukim Labu

Kawasan Perindustrian Nilai

71807 Nilai, Negeri Sembilan

Malaysia

T +60 6 799 2323

F +60 6 799 9942

471 Mountain Highway

Bayswater, Victoria 3153

Australia

T +61 3 9721 0200

F +61 3 9720 0588

301 Solitaire Corporate Park

151 M.V.Road, Andheri (E)

Mumbai – 400093

Maharashtra, India

T +91 22 6694 2711

F +91 22 2825 3394

NOF, Shinagawa Konan Bldg

1-2-5, Higashi-shinagwa

Shinagwa-ku, Tokyo

140-0002 Japan

T +81 3 5769 6873

F +81 3 5769 6902

© 2010 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. “Brand mark listing” are marks of one of the Emerson Process Management family of companies.

All other marks are property of their respective owners.

The contents of this publication are presented for information purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

EL-O-MATIC

®

is a registered trademark of EL-O-MATIC B.V.

www.El-O-matic.com

Page 28

Electro-Pneumatic Positioner F20

Installation and Operation

Manual

English

Deutsch

Nederlands

DOC,F20,EDN Rev. : -

Accredited by the

Dutch Council for

Certification

Page 29

Contents (English)

1.0 Introduction.................................................................. 4

1.1 Product Description F20 ....................................... 4

1.2 Operating Principles .............................................. 6

2.0 Installation - Rotary Actuators ................................... 8

2.1 Mechanical Installation - Rotary Actuators ............. 8

2.2 Pneumatic Connections ....................................... 10

2.2.1 Double acting ....................................................... 1 0

2.2.2 Single acting ........................................................ 10

3.0 Installation - Linear Actuators .................................. 12

3.1 Mechanical Installation - Linear Actuators ........... 12

3.1.1 Installation sequence ........................................... 12

3.2 Pneumatic Connections ....................................... 14

3.2.1 Double acting ....................................................... 1 4

3.2.2 Single acting ........................................................ 14

4.0 Electrical Connections - Initial Setup....................... 16

4.1 Electrical Connections ......................................... 16

4.2 Initial Setup - Zero, Range and Sensitivity ........... 16

4.3 Zero Setting ......................................................... 16

4.4 Range Setting ...................................................... 16

4.5 Sensitivity Setting................................................. 16

4.6 Split range setting ................................................ 18

5.0 Failure Modes............................................................. 20

5.1 Failure Modes - Double acting ............................. 20

5.1.1 Changes for Reverse Acting ................................ 20

5.2 Failure Modes - Single Acting (Spring return) ...... 22

5.2.1 Changes for Reverse Acting ................................ 22

6.0 General specifications .............................................. 24

6.1 Certificates .......................................................... 25

7.0 PTF20 option.............................................................. 26

7.1 Introduction .......................................................... 26

7.2 Installation ............................................................ 26

Inhalt (Deutsch)

1.0 Einführung ............................................................................. 5

1.1 Produktbeschreibung F20 .............................................. 5

1.2 Arbeitsweise ................................................................... 7

2.0 Einbau Drehantriebe............................................................. 9

2.1 Mechanischer Einbau - Drehantriebe ........................... 9

2.2 Pneumatikanschlüsse ................................................... 11

2.2.1 Doppeltwirkende Ausführung ..................................... 1 1

2.2.2 Einfachwirkend Ausführung ........................................ 1 1

3.0 Einbau - Hubantriebe ......................................................... 13

3.1 Mechanischer Einbau - Hubantriebe ........................... 13

3.1.1 Montageablauf ............................................................. 13

3.2 Pneumatikanschlüsse ................................................... 15

3.2.1 Doppeltwirkende Ausführung ..................................... 1 5

3.2.2 Einfachwirkende Ausführung ...................................... 15

4.0 Elektrische Anschlüsse - Anfangseinstellungen ................ 17

4.1 Elektrische Anschlüsse................................................. 17

4.2 Anfangseinstellungen - Null, Bereich und Totzone ..... 17

4.3 Nullpunkteinstellung.................................................... 17

4.4 Bereicheinstellung........................................................ 17

4.5 Einstellung der Empfindlichkeit .................................. 17

4.6 Einstellung für geteilten Eingangsbereich / Split range 19

5.0 Ausfallarten ......................................................................... 21

5.1 Ausfallarten Doppeltwirkend ....................................... 21

5.1.1 Umschaltung auf umgekehrte Wirkung....................... 21

5.2 Ausfallarten - Einfachwirkend (Federrückführung) .... 23

5.2.1 Umschaltung auf umgekehrte Wirkung....................... 23

6.0 Allgemeine technische Daten .............................................. 24

6.1 Zertificate ..................................................................... 25

7.0 Optionsbaugruppe PTF20 .................................................. 27

7.1 Einführung ................................................................... 27

7.2 Einbau .......................................................................... 27

Inhoud (Nederlands)

1.0 Introductie .................................................................... 5

1.1 Produktomschrijving F20 ....................................... 5

1.2 Werkingsprincipes ................................................. 7

2.0 Montage op roterende aandrijvingen......................... 9

2.1 Montage op roterende aandrijvingen ..................... 9

2.2 Pneumatische aansluitingen ................................ 11

2.2.1 Dubbelwerkende uitvoering ................................. 1 1

2.2.2 Enkelwerkende uitvoering .................................... 11

3.0 Montage - lineaire aandrijvingen .............................. 13

3.1 Montage - lineaire aandrijvingen.......................... 13

3.1.1 Montagevolgorde ................................................. 13

3.2 Pneumatische aansluitingen ................................ 15

3.2.1 Dubbelwerkende uitvoering ................................. 1 5

3.2.2 Enkelwerkende uitvoering .................................... 15

4.0 Elektrische aansluitingen - Initiële instelling .......... 17

4.1 Elektrische aansluitingen ..................................... 17

4.2 Initiële instelling - nulpunt, bereik en gevoeligheid 17

4.3 Nulpunt instellen .................................................. 17

4.4 Instellen van het bereik ........................................ 17

4.5 Instellen van de gevoeligheid ............................... 17

4.6 Instellen voor gesplitst bereik ............................... 19

5.0 Storingen.................................................................... 21

5.1 Storingen - dubbelw erkend .................................. 21

5.1.1 Wijzigingen voor omgekeerde werking ................ 2 1

5.2 Storingen- enke lwerkend (v eerretour) ................. 23

5.2.1 Wijzigingen voor omgekeerde werking ................ 2 3

6.0 Algemene specificaties ............................................. 24

6.1 Certifikaten .......................................................... 25

7.0 Optie PTF20................................................................ 27

7.1 Inleiding ............................................................... 27

7.2 Installatie .............................................................. 27

2 DOC,F20,EDN Rev.: -

Page 30

Warning

The device may only be operated by craftsmen who are familiar with the mounting, the installation and operation of this product.

Craftsmen as mentioned in this installation and operation manual are persons who, on the basis of their crafts education, their knowledge and experience

as well their knowledge of the applicable standards can judge the to them commissioned labour and can recognise the possible dangers.

To work on the device in an explosion proof execution, the craftsmen must have an education or instruction respectively the legitimacy to work on

explosion proof devices in explosion hazardous areas.

Dangers due to the control valve of the flow media, the working pressure and the moving parts have to be avoided by appropriate measures. Professional

transport and storage of the device is required.