Page 1

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

MSL600

Ultrasonic continuous sludge blanket monitor

Model Covered:

MSL600/Z0 with MSL603 transducer

MSL600

www.mobrey.com

Page 1

Page 2

MSL600

THIS MANUAL COVERS MSL600 FROM SOFTWARE VERSION 3.00 AND ABOVE

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

CONTENTS

FOR QUICK START, SEE SECTION 5 ON PAGE 20

(i) Safety precautions

Page

1. Introduction ............................................................................................................. 6

1.1 About the MSL600 ............................................................................................................................................... 6

1.2 About this Manual ............................................................................................................................................... 6

1.3 Important MSL600 features ................................................................................................................................ 7

1.3.1 Human Machine Interface ..................................................................................................................................... 7

1.3.2 Self-cleaning ......................................................................................................................................................... 7

1.4 As a system ......................................................................................................................................................... 8

2. Application planning ............................................................................................... 9

2.1 Circular clarifiers ................................................................................................................................................. 9

2.1.1 Rotating bridge ...................................................................................................................................................... 9

2.2 Rectangular clarifiers ....................................................................................................................................... 10

3. Installation ............................................................................................................. 11

3.1 Preliminary checks ........................................................................................................................................... 11

3.2 Location ............................................................................................................................................................. 11

3.3 Mounting bracket attachment .......................................................................................................................... 11

3.3.1 Bridge preparation ............................................................................................................................................... 11

3.3.2 Installing the bracket on the bridge ..................................................................................................................... 12

3.3.3 Attaching the MSL600 ......................................................................................................................................... 12

3.4 Transducer connections .................................................................................................................................. 14

3.5 Power and other electrical connections ......................................................................................................... 14

3.6 Cable extension ................................................................................................................................................. 16

4. Programming ......................................................................................................... 17

4.1 Display ............................................................................................................................................................... 17

4.2 Contrast (viewing angle) control ..................................................................................................................... 18

4.3 Keypad and Menu Navigation .......................................................................................................................... 18

4.4 Security .............................................................................................................................................................. 19

4.5 On-line/Off-line .................................................................................................................................................. 19

5. Quick start parameters ......................................................................................... 20

5.1 Tank depth - Bottom reference ........................................................................................................................ 20

5.2 Determination of tank depth ............................................................................................................................. 21

5.3 Transducer self-cleaning .................................................................................................................................. 21

5.4 mA current output parameters ......................................................................................................................... 22

5.5 Current output adjust ....................................................................................................................................... 22

Page 2

Page 3

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

5.6 Relay parameters .............................................................................................................................................. 23

5.7 Alarm .................................................................................................................................................................. 23

5.8 Transducer out-of-water time ........................................................................................................................... 23

5.9 Digital input ....................................................................................................................................................... 24

MSL600

6. Detailed operation ................................................................................................. 25

6.1 The menu structure ........................................................................................................................................... 25

6.2 Parameter editing .............................................................................................................................................. 26

6.3 Scrolling ............................................................................................................................................................. 26

6.4 Direct access ..................................................................................................................................................... 26

7. Application parameters ........................................................................................ 27

7.1 Main menu parameters ..................................................................................................................................... 27

7.1.1 Cancel password ................................................................................................................................................. 27

7.1.2 Go Online/Offline ................................................................................................................................................. 27

7.2 Installation parameters ..................................................................................................................................... 27

7.2.1 Tank Depth – P101 ............................................................................................................................................. 27

7.2.2 Xdr Tilt Time – P103 ........................................................................................................................................... 27

7.2.3 Tag No. – P242 ................................................................................................................................................... 27

7.2.4 Description – P240 .............................................................................................................................................. 28

7.3 De-sludge parameters ...................................................................................................................................... 28

7.3.1 Start On - P250 ................................................................................................................................................... 28

7.3.2 Stop On - P251 ................................................................................................................................................... 28

7.3.3 Stop If - P252 ...................................................................................................................................................... 29

7.3.4 Start Time - P253 ................................................................................................................................................ 29

7.3.5 Interval - P254 ..................................................................................................................................................... 29

7.3.6 Max Retries - P257 ............................................................................................................................................. 29

7.4 Cleaning parameters ......................................................................................................................................... 30

7.4.1 Start On - P260 ................................................................................................................................................... 30

7.4.2 Interval - P264 ..................................................................................................................................................... 30

7.4.3 Cleaning Time - P444 ......................................................................................................................................... 30

7.5 mA output parameters ...................................................................................................................................... 30

7.5.1 Lower Range Val - P400 ..................................................................................................................................... 30

7.5.2 Upper Range Val - P401 ..................................................................................................................................... 30

7.5.3 Alarm Action - P402 ............................................................................................................................................ 31

7.5.4 0/4-20mA - P403 ................................................................................................................................................. 31

7.6 Relay parameters .............................................................................................................................................. 32

7.6.1 Relay RL1 mode (P410) and RL2 mode (P420).................................................................................................. 32

7.6.2 Relay On and Off Points ..................................................................................................................................... 34

7.6.3 Relay overrides (Min ON, Max ON, and Min OFF) .............................................................................................. 34

7.7 Display parameters (HMI) ................................................................................................................................. 34

7.7.1 HMI upper, middle, and lower display options ..................................................................................................... 34

7.7.2 Backlight On/Off - P575 ...................................................................................................................................... 35

7.7.3 Clear Trend ..............................................................................................................

7.7.4 Clear Profile ........................................................................................................................................................ 35

7.8 Logging parameters .......................................................................................................................................... 36

7.8.1 Log Interval - P590 .............................................................................................................................................. 36

7.8.2

7.8.3 Data Overwrite - P592 ......................................................................................................................................... 36

Fast log - P591 .................................................................................................................................................... 36

........................................... 35

Page 3

Page 4

MSL600

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

7.8.4

7.9 Engineering parameters ................................................................................................................................... 37

7.9.1 Alg. Select – P620 ............................................................................................................................................... 37

7.9.2 Common algorithm parameters P621 to P629 .................................................................................................... 37

7.9.3 Municipal 1 parameters P630 to P637 ................................................................................................................ 40

7.9.4 Municipal 2 parameter P640 ............................................................................................................................... 42

7.10 System parameters ........................................................................................................................................... 43

7.10.1 AUTO CYCLE function ........................................................................................................................................ 43

7.10.2 DISPLAY test ...................................................................................................................................................... 43

7.10.3 Current Output test parameters P700 to P702 .................................................................................................... 43

7.10.4 LOAD DEFAULTS function ................................................................................................................................. 43

7.10.5 COMMS parameters P710 to P716 ..................................................................................................................... 44

7.10.6 SETTINGS parameters P730 to P737 and BASE UNITS selection .................................................................... 44

7.10.7 PIN parameter P740 ........................................................................................................................................... 45

7.10.8 FIXED parameters D750 to D753 ....................................................................................................................... 45

7.11 Readings and diagnostics parameters ........................................................................................................... 46

7.11.1 Readings parameters D800 to D834 ................................................................................................................... 46

7.11.2 Diagnostics parameters D835 to D852 ............................................................................................................... 47

Low Mem Alarm - P593 ....................................................................................................................................... 36

8. Technical reference ............................................................................................... 49

8.1 Transmit pulse and echo processing .............................................................................................................. 49

9. Maintenance .......................................................................................................... 49

10. Troubleshooting .................................................................................................... 49

11. Programming chart ............................................................................................... 50

12. Specification.......................................................................................................... 53

12.1 MSL600 .............................................................................................................................................................. 53

12.2 MSL603 transducer ........................................................................................................................................... 54

13. Dimensional drawings .......................................................................................... 55

14. MSL603 transducer cable extension ................................................................... 57

Figures and tables

Figure (1): MSL600 system architecture .......................................................................................................................... 9

Figure (2): Circular clarifiers – Rotating bridge ................................................................................................................. 10

Figure (3): Circular clarifiers - Static bridge ...................................................................................................................... 11

Figure (4): Rectangular clarifiers ...................................................................................................................................... 11

Figure (5): MSL600 mounting ........................................................................................................................................... 14

Figure (6): Transducer cable wiring .................................................................................................................................. 15

Figure (7): External connection terminals ......................................................................................................................... 16

Figure (8): The LCD display layout ................................................................................................................................... 18

Figure (9): Keypad layout ................................................................................................................................................. 19

Figure (10): Tank depth parameter ................................................................................................................................. 21

Figure (11): Menu structure .............................................................................................................................................. 26

Figure (12): MSL600 Bridge mounted unit ....................................................................................................................... 53

Figure (13): MSL600 and MSL603 assembly ................................................................................................................... 54

Table (A): Connection descriptions reading from left to right (all via M20 cable glands) .................................................. 16

Table (B): Relay Parameter numbers ............................................................................................................................... 32

Page 4

Page 5

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

(i) Safety precautions

BEFORE OPERATING THIS DEVICE THE MANUAL SHOULD BE READ FULLY

The following safety precautions should be observed before using this product or working on the attached cables.

x This MSL600 product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read the operating information carefully before

using the product.

x The types of product users are:

Responsible body: This is the individual or group responsible for the use and maintenance of equipment, and

for ensuring that operators are adequately trained. Operators use the product for its intended function. They

should not be allowed access to the electrical connections within the control box, and would normally only

operate the external keypad and monitor the display.

Maintenance personnel perform routine procedures on the product to keep it operating, for example, checking

the line voltage or checking electrical connections, replacing mains fuses etc. Otherwise, only service

personnel should perform them.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products.

Only properly trained service personnel may perform installation and service procedures. There are no user

serviceable parts on the main PCB section of the MSL600 product.

x Users of this product must be protected from electric shock at all times. The responsible body must ensure

that users are prevented access and/or insulated from every connection point. Product users must be trained

to protect themselves from the risk of electric shock.

x Before operating an instrument, make sure the line cord is connected to a properly grounded power

receptacle. Inspect the connecting cables for possible wear, cracks, or breaks before each use. When fuses

are used in a product, replace with same type and rating for continued protection against fire hazard.

x Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth

ground connections.

x Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. If

you are unsure about the applicability of a replacement component, call a MOBREY office for information.

Only use the MSL600 with the sensor supplied or Mobrey agreed replacement. The unit will not necessarily

work with apparently equivalent sensor units.

MSL600

x To clean the instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument

only. Do not apply cleaner directly to the inside of the instrument or allow liquids to enter or spill on the

instrument.

x WARNING - If this equipment is used in a manner not specified by Mobrey, the protection provided may be

impaired. The MSL600 is regarded as permanently installed equipment and as such a switch or circuit

breaker must be included in the installation. This should be in close proximity to the equipment, it should be

marked as the disconnecting device, and it should disconnect both current carrying conductors.

x A protective earth should be used for all applications.

x The normal application of the MSL600 requires it to be mounted on a water handling plant. The installation

point and power cables associated with the MSL600 must be such that tank overflow, local flooding or pump

failure do not cause these to be submerged or subject to flows of water. Sensor and sensor cabling can be

submerged without hazard to equipment operators when correctly connected as described in this manual.

Explanation of symbols: The IEC Protective Earth Symbol is:

CHECK THAT THE POWER SUPPLY IS SUITABLE BEFORE SWITCHING POWER ON.

Internal adjustments can select mains 115 Volts AC power, which makes the equipment unsuitable for 230V AC

supplies. Check the 2 voltage selection switches compared with the available power supply.

Page 5

Page 6

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

1. Introduction

Before operating this device the manual should be read carefully paying particular attention to the safety

precautions laid out in section (i).

This instruction manual provides comprehensive information specific to the Mobrey Measurement continuous

suspended solids blanket level monitor, the MSL600.

1.1 About the MSL600

The basic MSL600 system contains an ultrasonic transducer and a bridge-mounted control unit.

The control unit is microprocessor-based and is given the designation MSL600. It is intended to be mounted on a

bridge using a specially designed and easy-to-install mounting bracket that is supplied with the system.

The system is specially adapted for use with clarifiers and thickeners containing municipal and industrial

wastewater treatment sludge. The MSL600 provides a means of sensing the presence of the sludge blanket and

measuring its depth in the clarifier. It also provides a range of current and relay outputs to the user for control and

alarm purposes.

The MSL600 uses the sonar principle, with an ultrasonic pulse transmitted under water from a partially

submerged, IP68-rated transducer (MSL603). The pulse of ultrasound is transmitted vertically down into the

clarifier tank, and then reflects from the surface of the sludge blanket. The system captures the ultrasonic echoes

received from the sludge blanket interface and determines the time-of-flight of the echo from the transducer to the

sludge blanket.

February 2012

Knowing the speed of sound in the supernatant (the system has automatic temperature compensation), the

control unit calculates the distance to the blanket interface. This distance is then subtracted from the

programmed depth of the tank to give the sludge blanket depth or interface level. This is the system’s

fundamental process variable.

1.2 About this Manual

This section introduces the user to the MSL600 system, its components and key features. The system’s mode of

operation is explained in this section.

In section 2, the manual discusses application planning where installation is primarily intended to be on municipal

and industrial wastewater clarifiers.

In section 3, the manual discusses the actual physical process of mechanical and electrical installation of the

system. This section provides a step by step procedure for easy installation of the MSL600 system on site.

In section 4, the manual introduces the basics of programming the system. This section introduces the human

machine interface (HMI), keypad and display

In section 5, the manual discusses the minimum programming steps needed for commissioning the system so

that a meaningful measurement can be made. This quick start setup section is intended to cater for the needs of

most users.

In section 6, the manual discusses in more detail the human machine interface and how the system is

programmed.

In section 7, all of the system’s parameters are discussed and their function detailed. Sections 6.0 and 7.0 are

primarily intended for the more advanced user who needs to tune the system to meet an unusual application.

In section 8, the manual discusses in detail the mode of operation of some of the key system elements. This

section is intended for the most advanced user.

Page 6

Page 7

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

Finally, sections 9 to 13 cover maintenance, troubleshooting, programming chart, technical specifications and

dimension drawings relevant to using the MSL600 system.

MSL600

1.3 Important MSL600 features

The MSL600 system incorporates several unique design features which are intended to promote trouble free

operation, give a degree of installation flexibility, and allow ease of installation.

1.3.1 Human Machine Interface

In common with other Mobrey Measurement control units, the MSL600 makes use of the Mobrey Measurement

Human Machine Interface (HMI). The HMI reflects comments and suggestions received about the need to be

easy and intuitive to use. The intention is that you should be able to program and interrogate the system using the

integral membrane keypad and Liquid Crystal Display (LCD) without the need for regular reference to this manual.

For the more experienced user, the HMI also facilitates rapid navigation of the menu structure to system parameters.

1.3.2 Self-cleaning

One of the most important features of the MSL600 is its transducer self-cleaning facility.

In the application for which the system is designed, the transducer is normally mounted in a relatively hostile

environment. In this environment, the likelihood of the transducer becoming coated or otherwise fouled is

relatively high. A fouled transducer is far less efficient at transmitting sonar pulses into the supernatant. Without

the ability to automatically clean itself, the transducer maintenance cycle would need to be more regular, and thus

increase the life cost of the system.

Experience suggests that any moving mechanical cleaning devices are themselves prone to fouling. It is for this

reason that the MSL600 uses an air purge cleaning function. Extensive experimental results show that this

method is extremely effective in keeping the face of the transducer free from any coating growth or build-up of

floating debris.

The cleaning cycle is optimised for maximum efficiency. However, you can manually initiate a cleaning cycle or

override this feature by turning it off.

1.3.3 Mounting bracket

Most clarifier tanks have railings on the walkway, rotating or moving bridge or walkway. It is recommended that

the MSL600 be mounted on these railings. The MSL600 system is supplied with a purpose designed mounting

bracket. This bracket design has been optimised to fit most designs of railing. This is intended to provide

alignment and a stable platform for the transducer and control unit.

The transducer and mounting bracket, collectively known as an MSL603, are intended to be fitted to the clarifier

before the MSL600 control unit is attached to them. This allows mechanical adjustment and fitting without the

need to worry about the electronics in the enclosure.

The transducer mounting arrangement is hinged so that the transducer can be lifted out of the water, using the

chain provided, for ease of maintenance (in most cases this will not be necessary because the transducer is selfcleaning). When installed, the transducer front face should be continually immersed in water to a depth of

approximately 75mm (3 inches). The MSL600 mounting bracket should allow sufficient adjustment for this in

most cases. Extensions and extra tubes are readily available from a number of sources to allow the mounting to

be modified – contact Mobrey Measurement Sales for assistance (see section 3.3.3 for other sources).

Note:

The MSL603 transducer can also be supplied without mounting hardware and is supplied complete with

10 metres (33 feet) of connecting cable and air hose for the self-cleaning system. This allows the installer to

provide their own mounting arrangements using suitable 25mm (1 inch) pipe or conduit. This arrangement is

normally supplied for fixed bridges or enclosed tanks where a pivoting sensor is not required.

Page 7

Page 8

Installation, Operation & Maintenance Manual

p

r

IP262/Z0, Rev. AB

MSL600

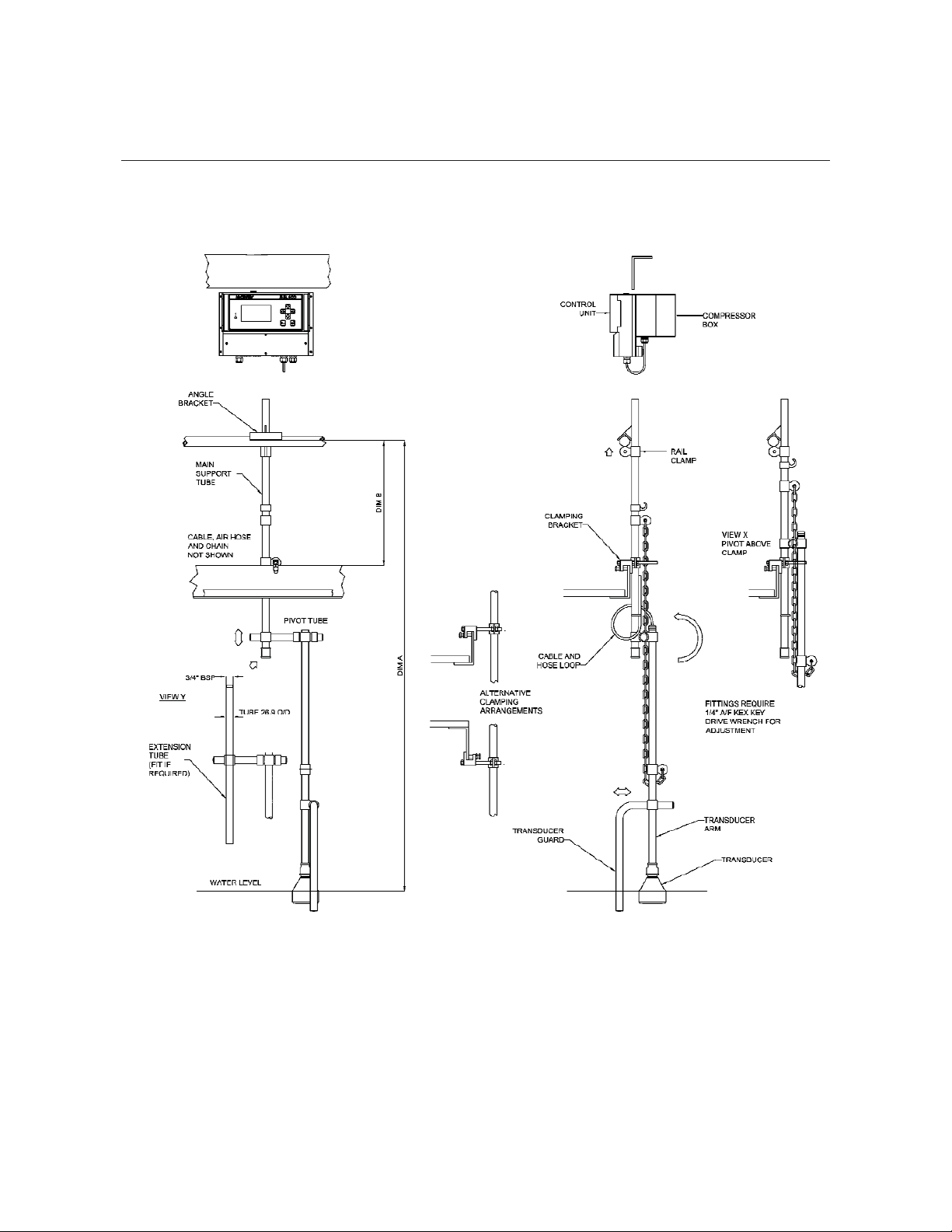

1.4 As a system

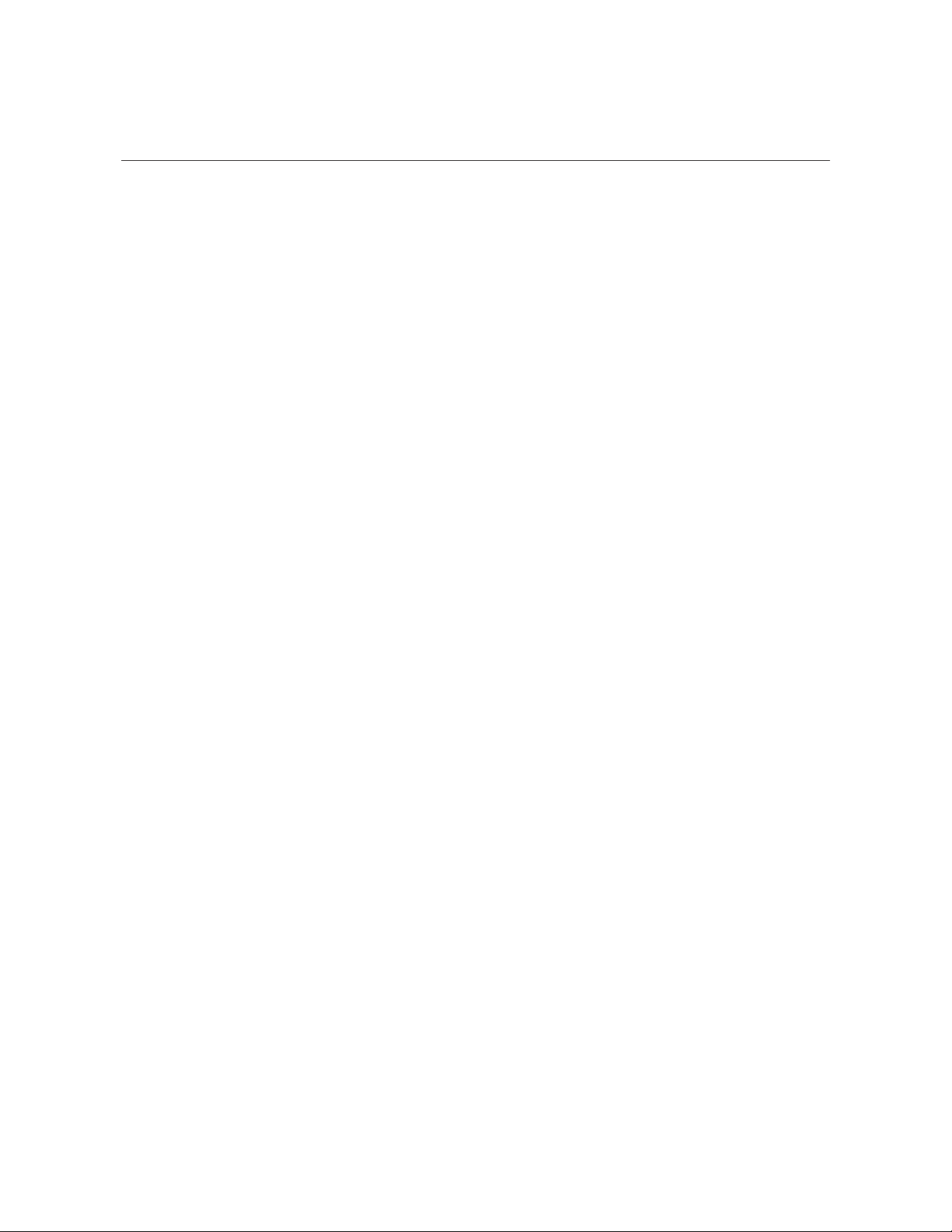

Figure (1) shows the architecture of the complete MSL600 system and where each component is intended to be

used. Install the MSL603 transducer and mounting bracket on the rotating bridge or fixed walkway over the

clarifier tank. Install the MSL600 control unit on the mounting bracket.

Figure (1): MSL600 system architecture

February 2012

Location

Fixed or rotating bridge

3 relay

outputs

RS232

4-20mA

output

MSL600 - Standalone Bridge Mount Unit

PLC/SCADA

PC or

Laptop

com

ute

Location

Control room

MSL603 Transducer

Page 8

Page 9

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

2. Application planning

The following section discusses a few practical considerations when planning an installation.

2.1 Circular clarifiers

Circular clarifiers are very common and can come with rotating or static bridges over them.

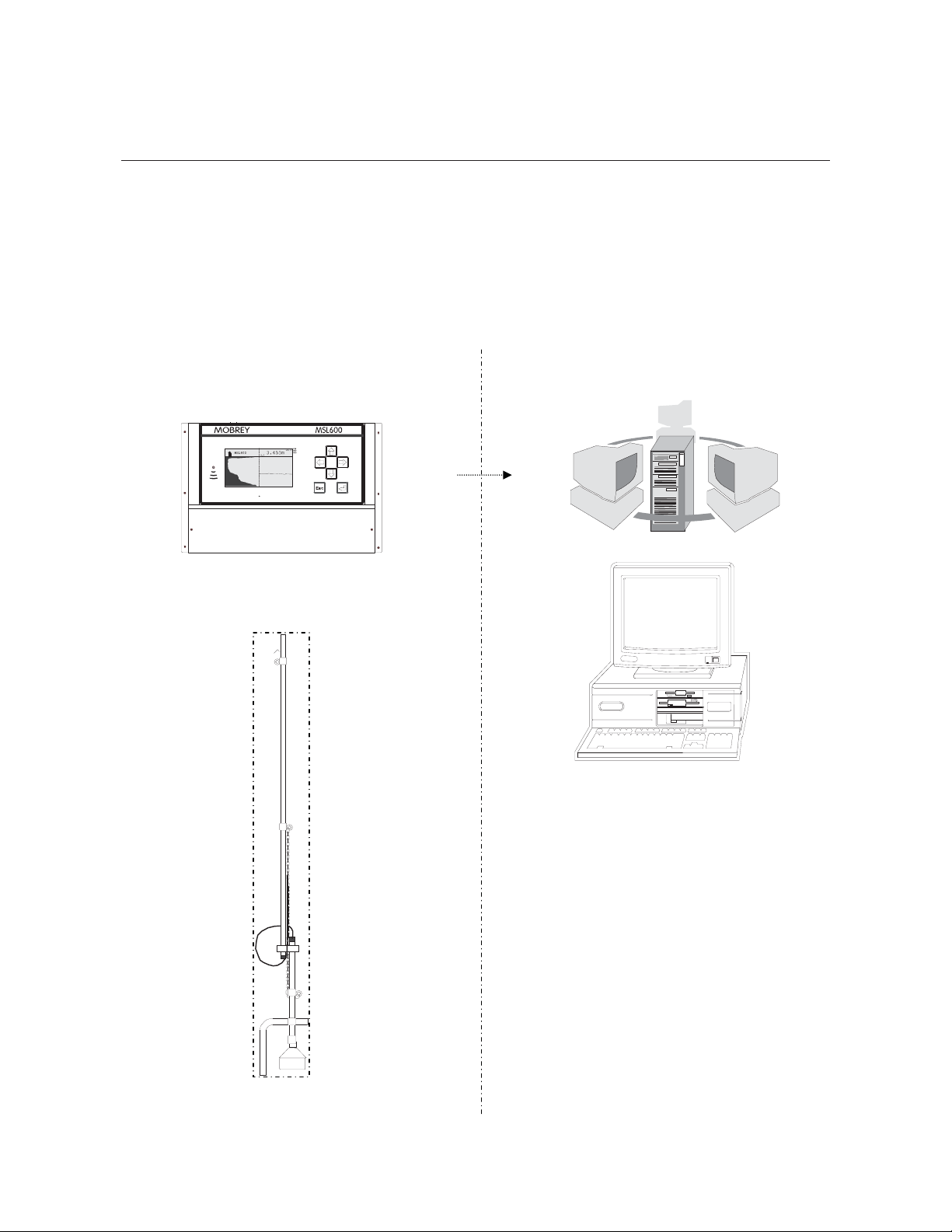

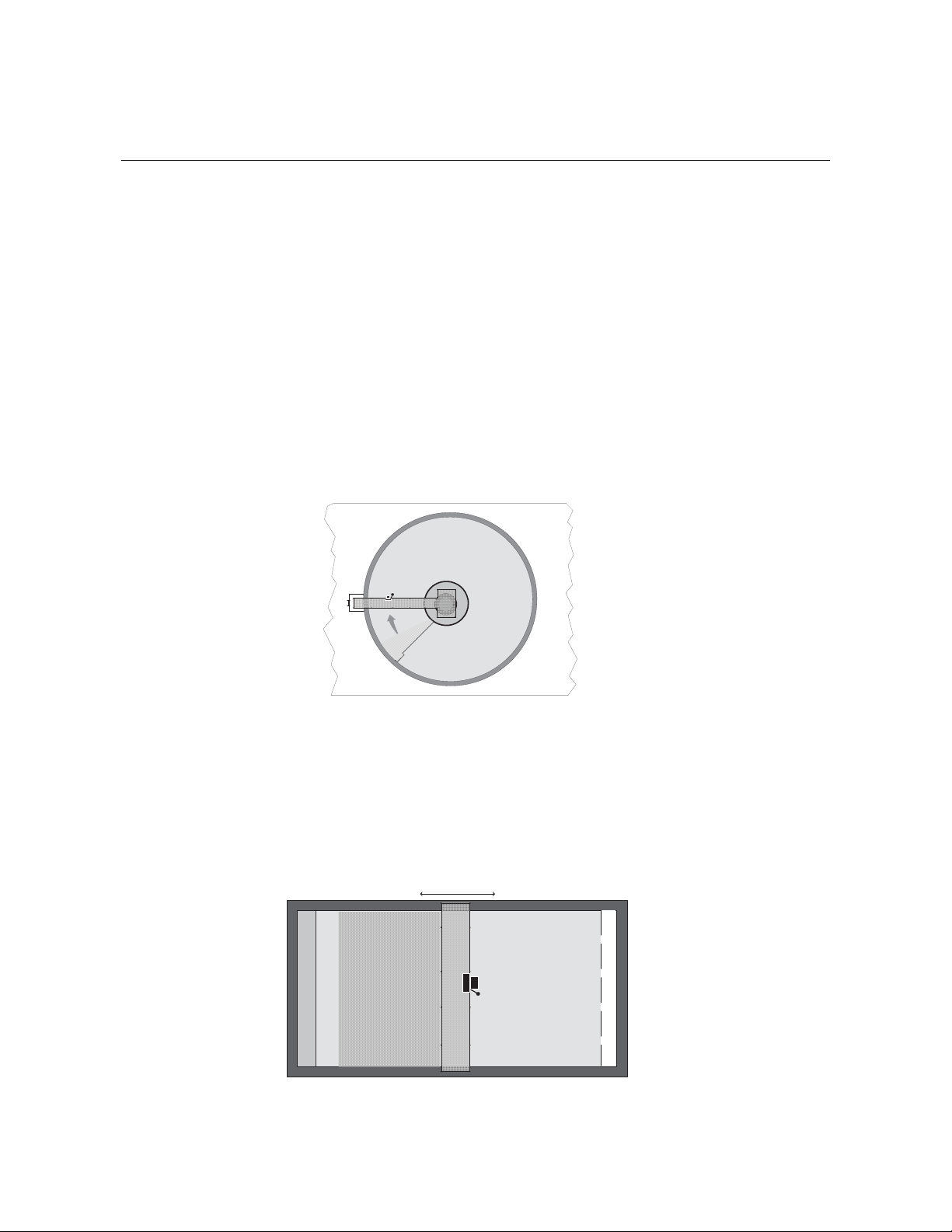

2.1.1 Rotating bridge

If the transducer is mounted on a rotating bridge then it should be positioned on the leading edge of the bridge,

see Figure (2). This places it ahead of any bow wave in the sludge blanket which may be created by trailing sub

surface scrappers that would otherwise give rise to a false indication of the blanket level.

Ideally the transducer should be mounted between 1/3 and 2/3 of the way along from the outer (wall) edge of the

settlement tank (i.e. 1/3 to 2/3 of the radius from the inside of the tank wall).

Care should be taken to ensure that the transducer is mounted over an undisturbed section of the tank, i.e. not

too close to the tank inlet or tank wall, and away from columns of rising gas bubbles. All of these factors can

result in false sonar echoes being received. It is recommended that the transducer be mounted at least

1m (3.3 feet) from any such structures.

If a scum removing skimmer is present then the transducer should be mounted behind this.

MSL600

When locating the transducer the user must ensure that there are no permanent underwater obstructions below

the transducer, as these will give false sonar echoes and disrupt the signal. It is recommended that the

transducer be mounted at least 1m (3.3 feet) from any such structures.

Ensure that the transducer does not come into contact or collide with any scum boards, weirs or other surface

obstructions as the bridge rotates.

Figure (2): Circular clarifiers – Rotating bridge

Approximate

MSL600

mounting

position

Page 9

Page 10

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

2.1.2 Static bridge

The transducer mounting arrangement is designed to lift out of the water if it is mounted on a fixed bridge when a

moving scraper passes underneath (e.g. on a picket fence thickener). Ideally, the transducer should be mounted

1/3 to 2/3 of the way along from the outer (wall) edge of the settlement tank (i.e. 1/3 to 2/3 of the radius from the

inside of the tank wall).

If the transducer is mounted on a static bridge then it should be positioned on the trailing edge of the bridge, see

Figure (3). This gives the hinge mechanism maximum clearance from the bridge structure.

Ensure the transducer guard is facing towards the moving sweeper. The guard and hinge mechanism can be

angled slightly to meet the rotating parts at a normal incidence. This avoids the transducer guard sliding

sideways along the rotating part as it is lifted.

Always check that the parts sliding over each other will not become entangled or locked together. The rotating

mechanism on most bridges is strong enough to bend the mounting bracket if this should happen.

It is strongly recommended that a few uneventful rotations be observed before installation is completed.

Figure (3): Circular clarifiers - Static bridge

February 2012

2.2 Rectangular clarifiers

As with a rotating bridge and a circular tank, the transducer should be mounted from the leading edge of the

bridge to avoid false level readings from the disturbed bow wave in the sludge blanket as the bridge scrapes

sludge into the hopper at the end of the clarifier.

The considerations detailed in section 2.1 for rotating clarifiers should all be considered as appropriate for a

rectangular clarifier.

Figure (4): Rectangular clarifiers

Page 10

Page 11

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

MSL600

3. Installation

The following section discusses installation considerations in more detail.

3.1 Preliminary checks

Carefully unpack the MSL600 control unit, transducer, and mounting bracket arrangement from their packaging.

Check that there is no visible damage to any of the packed parts, paying particular attention to the transducer and

transducer cables, and the membrane keypad and display area on the MSL600.

Contained in the packaging should be the following:

Pack one

• 1 x MSL600 bridge mounted unit, with compressor housing containing the air compressor for self-cleaning on

a metal mounting plate (pre-assembled).

• 1 x MSL600 manual.

Pack two

• 1 x transducer assembly, and bridge mounting kit (including tool kit).

(Optional – MSL603 transducer only with 10 metres of cable and air hose)

3.2 Location

Determine the optimum location for installation of the MSL600 following the hints and tips given in section 2,

Application planning.

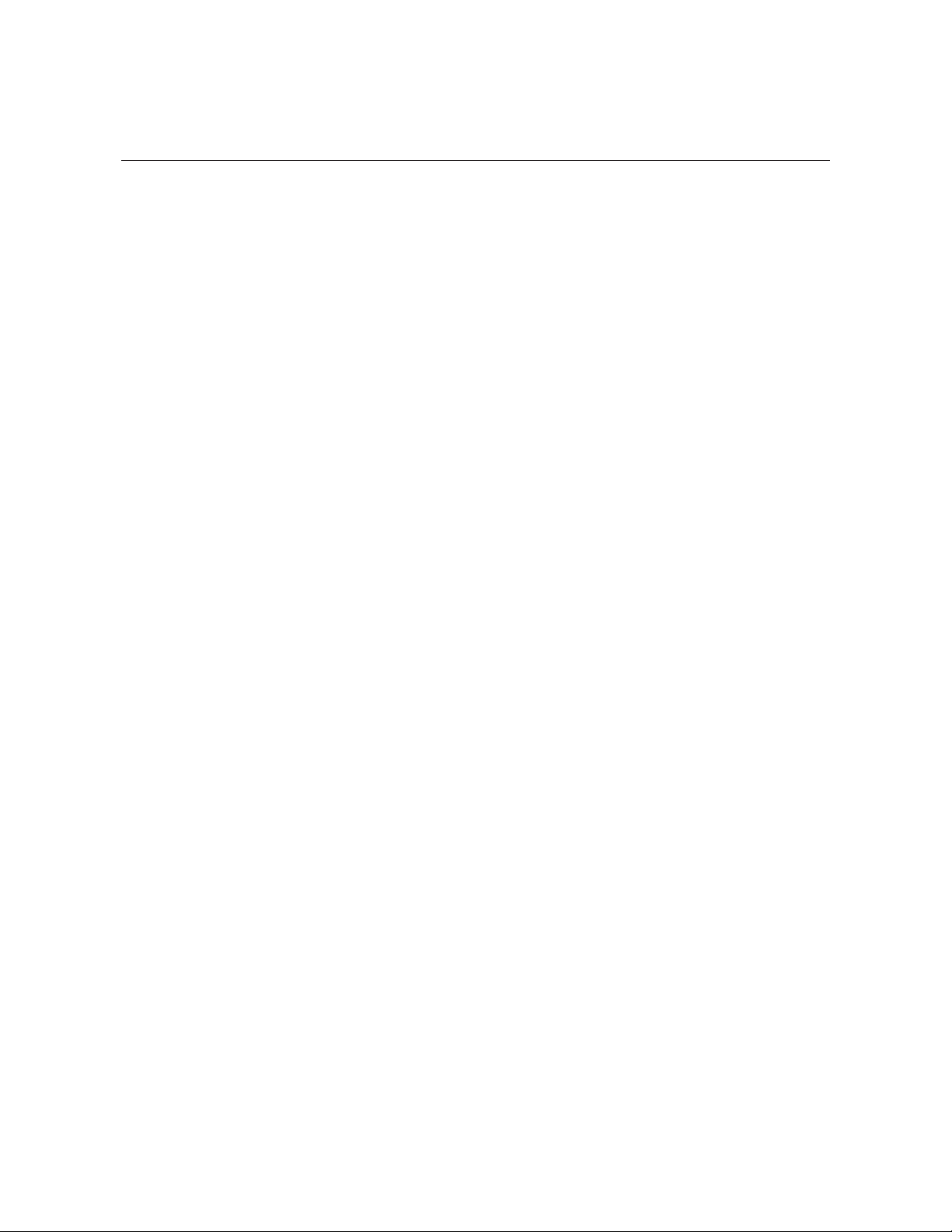

3.3 Mounting bracket attachment

The mounting bracket is specifically designed for mounting on the centre rail of the safety railing on the bridge of

any settling tank, see Figure (5). The rail can be any diameter up to 52mm (2 inches).

The bracket is also clamped to the bridge kicking board or similar supporting frame.

Adjustments can be made for different bridge heights, and the bracket can be angled to miss obstructions.

An extension arm can be added to the main support tube to extend the adjustment of the bracket further, if required.

Most adjustments are made by hexagon key and spanner, included in the supplied bridge mounting kit.

The transducer arm hangs vertically from a pivot and can be swung out of the water for cleaning and inspection.

WARNING!

The transducer is a sensitive instrument and care must be taken to prevent unnecessary impact or strain on it during installation.

3.3.1 Bridge preparation

The bracket should be prepared and initial adjustments made off the bridge. If any obstructions are present in the

installation area, the unit should be set up accordingly. This will greatly simplify any adjustments required during

mounting of the unit on the bridge. The cable and hose from the transducer should be handled with care to

prevent any sharp bending, especially in the area where they exit the transducer arm.

Check there is sufficient room between the top rail, centre rail, and any other structure for the control box to be

fitted. The space required is 430mm (17 inches) high and 360mm (14 inches) wide [see Figure (5)].

Measure the distance from the water surface to the centre rail of the safety railing (dimension A).

Measure the distance from the centre rail to the kicking board (dimension B) or similar structure.

Page 11

Page 12

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

With the bracket on the ground adjust the pivot tube up or down the main support tube until the distance between

the angle bracket and midpoint of the transducer is dimension A. Adjust the clamping bracket up or down the

main support tube to dimension B so it will be just clear of the final clamping position.

If the clamp is higher than the pivot tube this will need to be removed and reassembled in reverse order (view X).

If dimension A is too large and cannot be achieved, remove the pivot tube assembly, screw on the extension tube

and refit the pivot tube (view Y). If the pivot arm is to be set at an angle or set to the opposite hand, this should

be done at this stage.

Adjust the transducer guard so that it is at 90° to the pivot arm, projecting under the pivot arm and approximately

25mm (1 inch) below the bottom of the transducer.

If necessary move the chain attachment clamps to positions convenient for swinging the transducer out of the

water. Adjust the chain so that it is slightly slack with the unit fully extended and any excess chain is hanging on

the main support tube and not the transducer arm.

The cable and air hose can now be attached to the bottom of the main support tube with the cable ties provided.

The cable and hose must make a 360° loop between transducer tube and main support tube to allow for flexing

when the arm is lifted. Move the transducer arm up and down and check that the cable and hose move freely

without excessive strain.

Before installing the unit on the bridge check that all the fittings associated with pivot tube are securely tightened,

including those which have not been adjusted, as these are often difficult to reach later.

3.3.2 Installing the bracket on the bridge

Before carrying the unit on to the bridge, swing the transducer arm into the up position and attach it to the main

support tube with the chain. This makes the unit more compact and easier to manage. Lift the unit over the

handrail and hook it on to the horizontal centre tube of the rail. Release the rail clamp and push it up firmly under

the rail. While pushing on the barrel of the rail clamp (not the lug) retighten the clamping screw. This will

ensure a tight fit against the rail.

Loosen the clamping bracket assembly, attach it to the kicking board or similar structure and retighten. The

studding allows the main support tube to be adjusted approximately to the vertical position. In some instances

one or both nuts between the clamps will need to be removed. Tighten all fixings.

Lower the transducer arm carefully into the water and check the water surface is approximately in line with the top

of the parallel portion of the transducer and it is clear of obstructions. Adjust the pivot arm height and angle as

necessary. It is recommended the unit be removed from the bridge to make these fine adjustments. Ensure the

cable and air hose still move freely without excessive strain when the transducer is raised and lowered.

Check that the transducer arm is hanging vertically. The transducer guard also functions as a balance arm.

To adjust, swing the arm up and loosen the transducer guard. Move the guard backwards or forwards as

appropriate and retighten. Repeat until the arm hangs vertically.

When the unit is installed and functioning correctly check all fittings are securely tightened, including those which

have not been adjusted.

3.3.3 Attaching the MSL600

The MSL600 and compressor box come attached to a back plate complete with mounting lug. Check the

clamping screw of the mounting lug is clear of the inside face and slide the complete unit onto the top of the main

support tube. Orientate the unit to the correct position and tighten the clamping screw.

February 2012

Run the cable and hose up to the control unit avoiding sharp bends and flattening of the hose. Plug the air hose

onto the air connector on the bottom of the compressor box. The unit is now ready for wiring.

Additional fittings for MSL bracket (UK only) can be obtained from:

Alvin Products Limited, Knight Works, 10-12 Hampton Street, London, SE1 6SN

Tel. 020 7708 2004, Fax. 020 7708 3044, Web site:

Fittings are ALVIN ‘KEY’ CLAMPS (Size 5 - 26.9mm dia.) Similar fittings are also available from other manufacturers.

Note: Socket head screws require 1/4” A/F Hex key clamp bracket screws require 17mm A/F spanner.

www.alvin.net

Page 12

Page 13

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

Figure (5): MSL600 mounting

MSL600

Page 13

Page 14

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

3.4 Transducer connections

The MSL600 is housed in an ABS enclosure rated to IP66. The lower section of the housing is for cable

connections and the upper part has the LCD and keypad controls.

It is not necessary, or advisable, to remove the lid of the upper part of the enclosure. There are no user

serviceable parts inside.

All field wiring connections are accessible by removing the lower lid, which is secured by four screws. Inside the

terminal area, all connections are made using screw terminals. All terminal blocks are suitable for wires 0.5mm

2

2.5mm

(26 to 12 AWG). Insulation should be stripped back 7.0mm (0.25 inches).

The transducer cable comprises of five wires, see Figure (6), the connections for which are as follows:

• White wire - Transducer signal wire. This should be connected to the terminal

block marked ‘SENSOR’ and ‘SIG’.

• Black wire - Transducer 0V wire. This should be connected to the terminal block

marked ‘SENSOR’ and ‘0V’.

• Yellow wire - Transducer screen wire. This should be connected to the terminal

block marked ‘SENSOR’ and ‘SCN’.

• Red wire - Temperature compensation positive wire. This should be connected

to the terminal block marked ‘TEMP’ and ‘IN’

February 2012

2

to

• Brown wire - Temperature compensation 0V wire. This should be connected to

the terminal block marked ‘TEMP’ and ‘0V’.

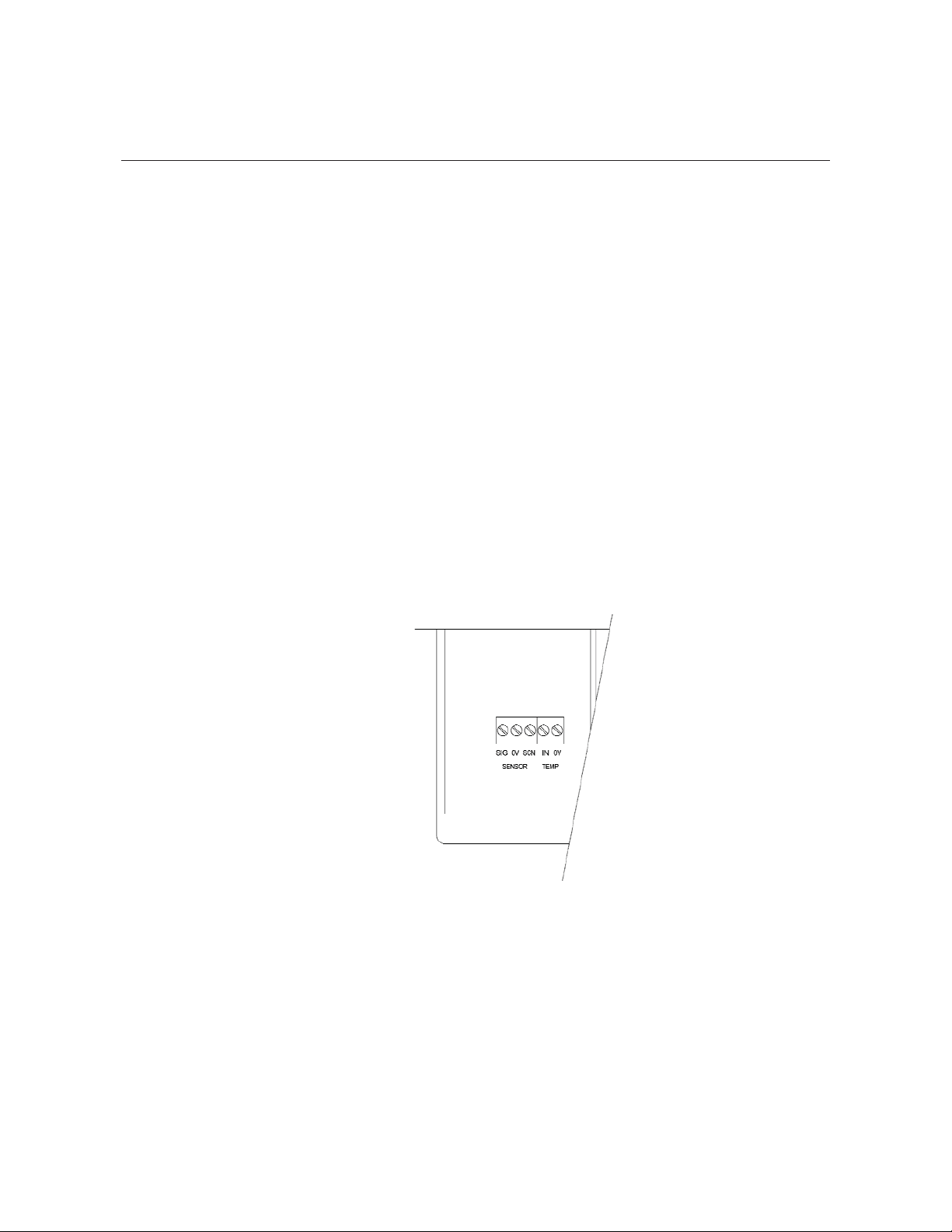

Figure (6): Transducer cable wiring

All connections to the transducer are intended to be made via the first M20 cable gland (fitted) on the left-hand

side, at the bottom of the MSL600 enclosure.

3.5 Power and other electrical connections

(See also section (i), safety precautions)

It is the responsibility of the installer to observe all local regulations and approval requirements, and to use cable

to suit the environmental requirements of the particular application.

Prior to applying power to the unit ensure that the two voltage selection switches are set to the appropriate

voltage for the installation.

In the event of a fuse needing replacement the user must ensure that the mains input fuse (F1) has a rating of

200mA (F) and the cleaning compressor (F2) has a rating of 1A(T).

Page 14

Page 15

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

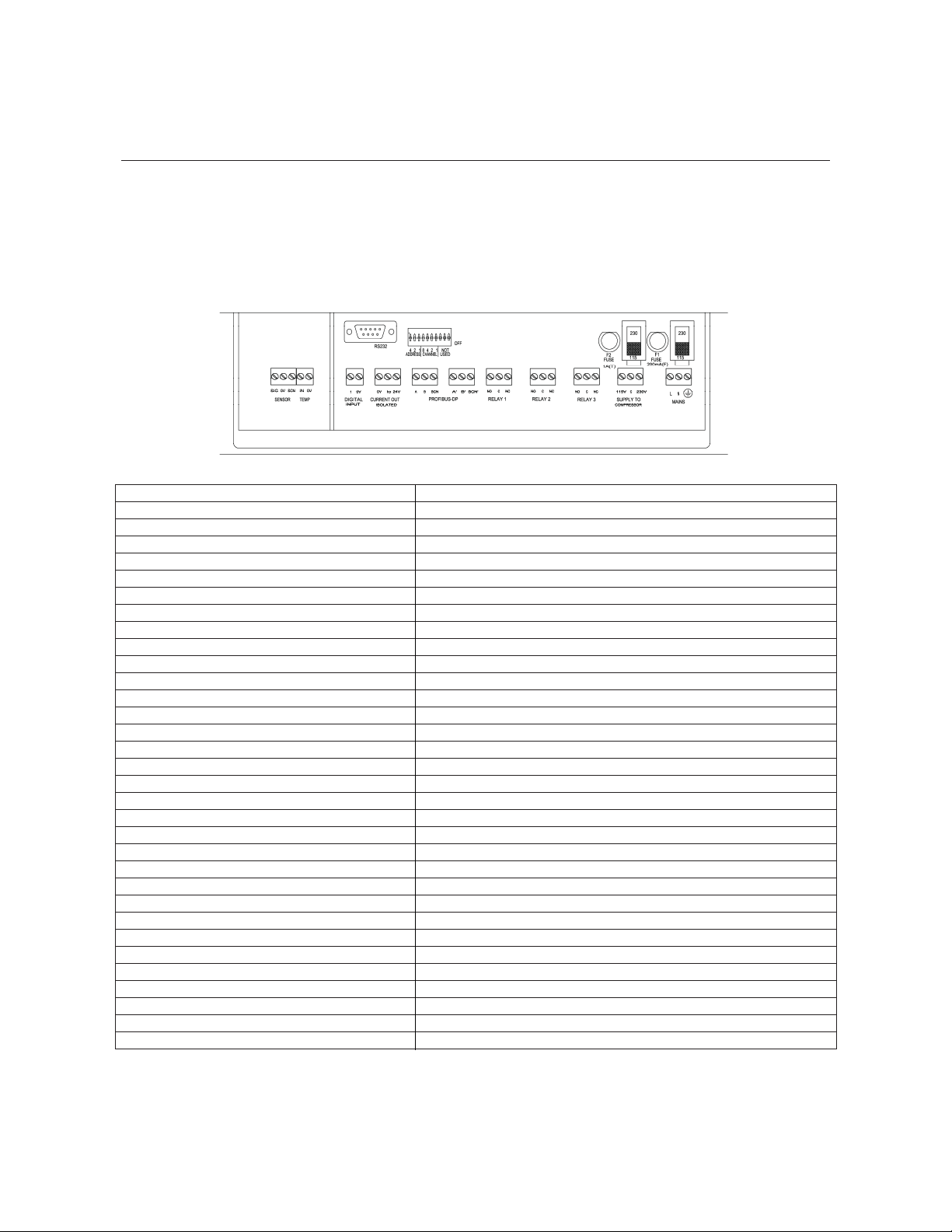

The diagram below, Figure (7) shows the layout of external connection terminals of the MSL600 with the lower

terminal housing cover removed. Table (A) gives a description of each.

Note:

When wiring of the unit is finished, ensure that the terminal housing cover is replaced the correct way up, i.e. with

the bevelled edge uppermost otherwise the IP rating of the enclosure may be compromised.

Figure (7): External connection terminals

SENSOR TEMP (see note 1)

SIG Transducer sonar signal (white)

0V Transducer zero volts (black)

SCN Transducer screen (yellow)

IN Temperature compensation signal (red)

0V Temperature zero volts (brown)

DIGITAL INPUT (see note 2)

1 Digital input signal

0V Digital input zero volts

CURRENT OUT ISOLATED

0V Current output zero

Io Current out

24V 24V source for current output (Not normally used)

RELAY 1 (de-energised state)

NO Normally open

C Common

NC Normally closed

RELAY 2 (de-energised state)

NO Normally open

C Common

NC Normally closed

RELAY 3 (de-energised state)

NO Normally open

C Common

NC Normally closed

COMPRESSOR (Factory wired)

115V (White) 115V supply for the cleaning compressor

C (Purple) Common for the cleaning compressor

230V (Orange) 230V supply for the cleaning compressor

MAINS

L Live terminal for mains supply

N Neutral terminal for mains supply

E Earth terminal for mains supply

MSL600

Table (A): Connection descriptions reading from left to right (all via M20 cable glands)

Page 15

Page 16

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

3.6 Cable extension

The transducer is connected using ALPHA XTRA-GUARD4 P/N45272. The standard cable length is 10 metres.

This cable comprises of two twisted pairs with an overall screen and drain. The brown and red wires from the

transducer should be connected to one twisted pair. The black and white wire from the transducer should be

connected to the other twisted pair. The yellow from the transducer should be connected to the drain wire which

must be terminated at the screen (SCN) terminal on the PCB.

Fitting instructions for extending the MSL603 transducer cable are in section 14.

Note 1:

The standard 10 metres of cable should be sufficient for most installations. The maximum recommended

additional extension is 20m. Use only cable conforming to the specification given above and ensure any

connections are made using high grade screened connectors. For suitable specification connectors refer to

Mobrey Measurement customer support. It is the responsibility of the installer to ensure that any extension to the

cable must be suitable for its working environment.

Note 2:

The digital input, if used must be connected to switch relay contacts which are insulated to IEC6010 category III

(4kV impulse) with no exposed live parts.

February 2012

Page 16

Page 17

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

4. Programming

The following sections introduce the main display and use of the keypad (MSL600 only) for programming the

MSL600. Password protection to prevent unauthorized access is also discussed.

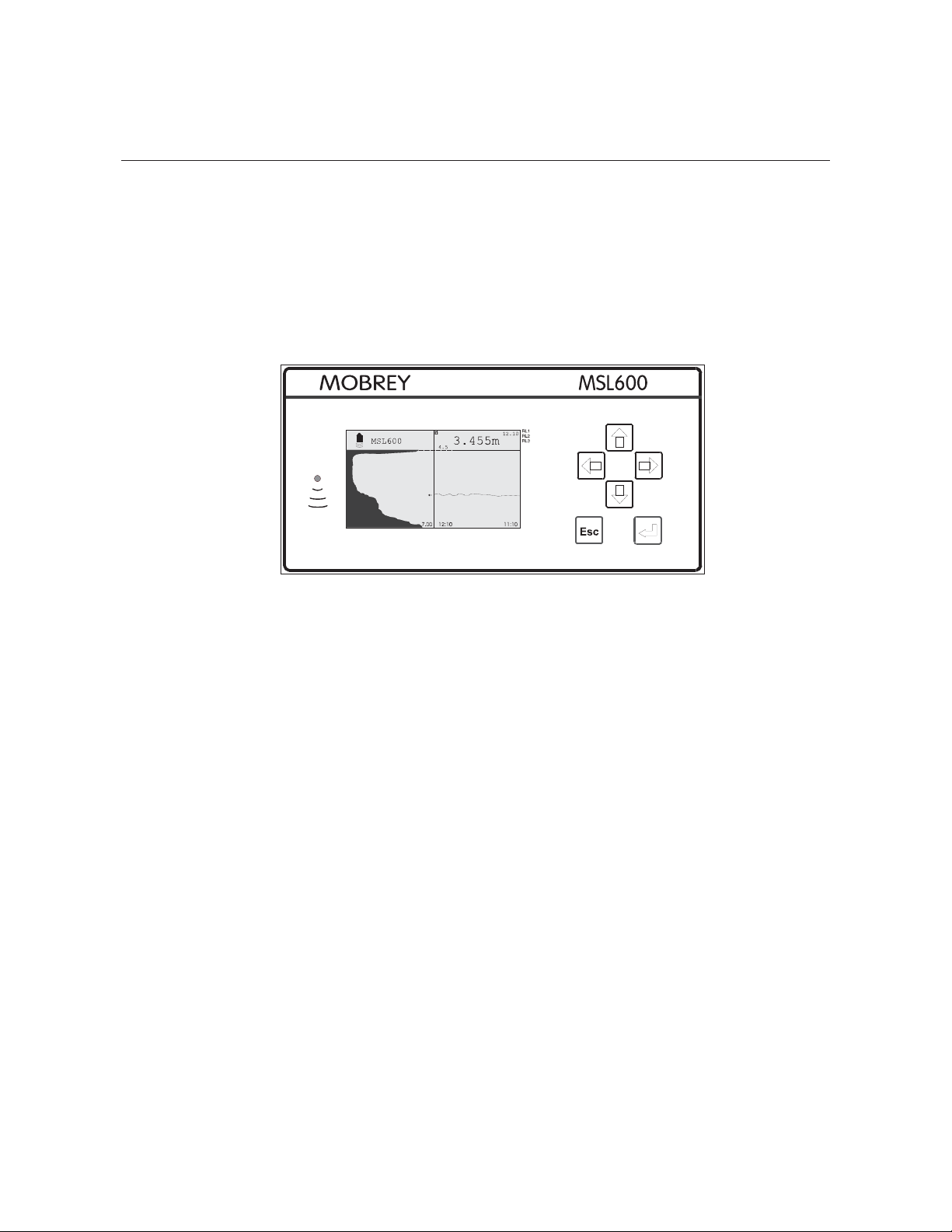

4.1 Display

The display is a 240 x 128 dot matrix LCD module with full graphics capability and LED back light. The LCD is

split into four parts, see Figure (8).

Figure (8): The LCD display layout

MSL600

• Upper left – In the upper left of the display is an icon representing the transducer and the unit tag

number. The tag number is user programmable via the HMI.

• Upper right – The HMI information is displayed in the upper right of the display. The HMI uses 4 lines

• Lower left – The lower left of the display shows the sonar echo profile from which the blanket position

is determined.

• Lower right – The lower right of the display shows the blanket level trend at minute intervals over the

last hour.

When the display is in the normal mode, trending is active and the m and o keys enable the user to view the last

12 hours of data, an hour at a time backwards and forwards respectively. The views are labelled with their start

and finish times. The sonar echo profile recorded at the corresponding start time is also displayed.

After reaching the oldest data the o key is inoperative. Where no data has been recorded there is a gap in the

trend line. A zero value is represented by a line a single-pixel thick. Pressing Esc returns to the real time normal

display.

Note: Do not confuse this trending with data logging which is discussed in more detail later.

The LCD has a back light for operator convenience. This has one of 3 modes selectable using the HMI:

• On permanently unless internal temperature too high, in which case automatically off.

• Off permanently unless internal temperature is too low, in which case automatically on.

• Auto - i.e. off until keypad is actuated, in which case on and stay on for, typically, 5 minutes - on for only 10

seconds if internal temperature too high.

The LCD on the MSL600 is supplemented by a single red LED which indicates the health of the unit. The LED

flashes every 2 seconds (½Hz) to indicate normal operation, whilst a steady illumination or no illumination

indicates a problem.

x 20 characters with each character 7 x 5 dots. In normal operation, the actual blanket

level is displayed here.

Page 17

Page 18

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

February 2012

4.2 Contrast (viewing angle) control

When the system is making measurements in normal mode the screen contrast or viewing angle can be adjusted.

Whilst holding down the Esc key press either the n or p key

Esc and - increases (darkens) the contrast and Esc and p decreases (lightens) the contrast.

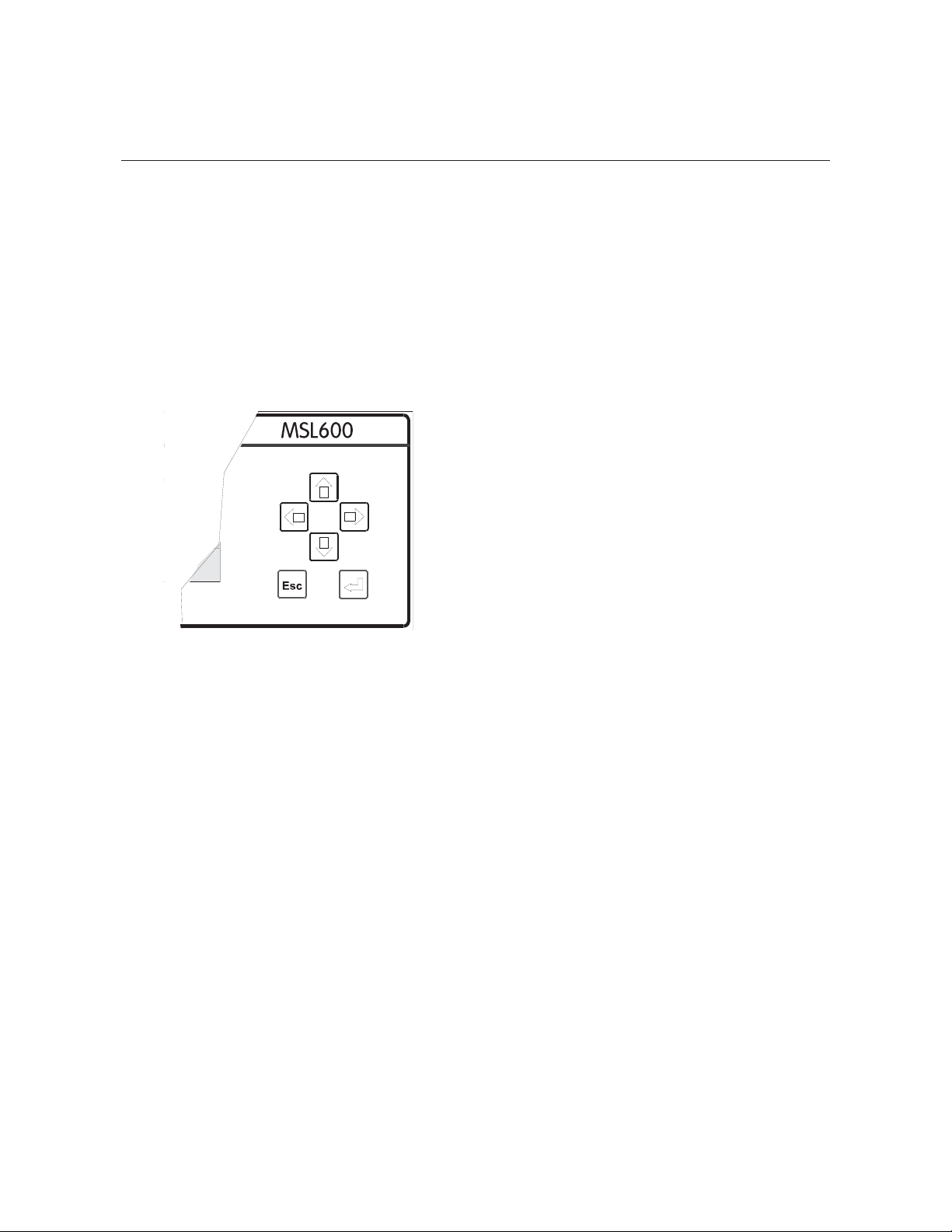

4.3 Keypad and Menu Navigation

Data entry and interrogation is normally achieved using the integral membrane keypad on the MSL600 front

panel, see Figure (9).

Figure (9): Keypad layout

The keypad comprises 6 keys:

• Cursor keys (npmo)

• Enter key ()

• Escape key (Esc)

The four arrow keys allow navigation around the HMI menu structure and the Esc and keys allow movement

from one menu level to the next. Each time a key is pressed an audible “beep” is heard. This “beep” can be

turned off via the HMI if required.

To access the main menu (from the normal display, see section 4.1) press .

To access a menu option, highlight the option using the np keys and press .

To change a parameter the padlock in the on line/off line menu must be open. This is done by highlighting “Go off

Line” in the main menu and pressing . Press again and the padlock will open. Press again and the padlock

will close.

By pressing Esc repeatedly, the screen will always return to the normal display. Alternatively, pressing and

holding Esc for a few seconds will result in jumping straight back to the Main Menu screen.

If any key other than Esc is held pressed for more than 1 second then it auto repeats. This is particularly useful for

fast scrolling through parameters. Although the display does not show every parameter whilst fast scrolling (it is

only refreshed every 500ms), the key beep (if enabled) is actuated for each parameter.

Movement through the menu structure using the arrows is shown by the titles being highlighted and flashing, i.e.

reversed to showing clear letters on a black background and vice versa. Pressing with the title highlighted

enters that part of the menu.

Page 18

Page 19

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

4.4 Security

The HMI includes a password system which may be used to protect parameters from unauthorised changes and

also to prevent the system from being switched between On and Off-line mode.

The password is in the form of a 4-digit code (or PIN). When the user has entered the correct PIN then the

password is said to be open (else closed). The PIN is a 4-digit code, value 0000 to 9999.

Once the password is open then all parameters may be edited.

A PIN of 0000 means that the password is disabled, i.e. no password is required to edit parameters.

Examining the PIN locally shows “- - - -” unless set to 0000.

When prompting for entering of PIN, the display shows “- - - -”.

A PIN is set or entered by scrolling each of the 4 digits using the m and o arrows to select the digit and n and p

arrows to select the value for each digit.

No PIN is required to navigate the menus or to simply examine parameter values.

Attempting to change a parameter value prompts for the entering of the PIN (if it is not already open). If the

parameter affects outputs, and if On-line, then after entering the PIN the user is offered go Off-line.

MSL600

If the password is open then the main menu offers the option “Cancel Password” as the default (highest priority)

option. Closing the password does not affect the On line/Off-line status.

The password is automatically closed after 5 minutes without any key press; this does not affect the

On line/Off-line status.

4.5 On-line/Off-line

This feature allows the MSL600 outputs, i.e. its relays and current output to be frozen. Also, when On-line, the

editing of all parameters which may affect these outputs is inhibited.

Off-line inhibits relays and current output.

On-line inhibits the editing of all parameters that may affect the outputs. These include relay, current output and

alarm parameters.

The On line/Off-line state is shown by the padlock symbol at the top left-hand corner of the HMI display (padlock

closed represents On-line).

Go On line/Off-line by selecting the appropriate item in the main menu. As the mode is toggled, a large image of

the Padlock symbol opens and closes. Attempting to edit any parameter can only be performed with the unit

Off-line.

If the system password is closed then the system will prompt for a password, once correctly entered then it

changes as requested.

NOTE: There is no time-out on On-line or Off-line.

Page 19

Page 20

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

5. Quick start parameters

The system leaves the factory with default values in all the parameters. These values, after installation, allow

immediate operation without any further programming. However, it is recommended for best operation that the

following parameters should be programmed.

In order to get meaningful measurements from the MSL600 in the minimum time only the following parameters

need to be adjusted.

5.1 Tank depth - Bottom reference

An accurate knowledge of the tank depth is a key parameter for the system.

The tank depth is the distance from the front face of the transducer to the bottom of the tank directly under the

transducer [see Figure (10)]. Where the tank bottom slopes, as is often the case, the sludge blanket level, Xm

indicated by the system is therefore relative to this zero reference level.

February 2012

Sludge blanket interface Xm

Figure (10): Tank depth parameter

The maximum tank depth that the system will measure is 7.000m (23.00 feet), the minimum is 1.000m (3.3 feet),

do not confuse this with the transducer blanking distance which is discussed elsewhere and is 0.3m (1 foot) by

default.

The tank depth value is stored in the system and used in subsequent calculations. The factory default is 7.000m

(23.00 feet), corresponding to the maximum depth of tank for which the system is specified.

When the unit is powered on for the first time the system makes measurements using this default. It will be

obvious that until the user enters a measured value certain functions, such as current output and displayed

blanket level will not be correct for the installation.

Tank depth

0m tank depth

Page 20

Page 21

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

MSL600

5.2 Determination of tank depth

The ultimate blanket level measurement accuracy depends upon the accuracy of the value entered for the tank

depth. It is always recommended that this be determined for every installation by the user using a measuring rod

or similar. Alternatively, the user can obtain a workable estimate of the tank depth by adjusting the tank depth

value Off line using the HMI and positioning the bottom echo at the bottom of the profile display.

This only works if a bottom echo is visible and the user must be sure that the echo he is positioning does actually

correspond to the tank bottom. To do this, follow the procedure below:

1. From the normal display, press .

2. The main menu will appear on the upper right of the display.

3. Highlight the Go Off line menu option and press . The padlock will open.

4. Press Esc to return to the main menu.

5. Use the n and p keys highlight the INSTALLATION menu option and press .

6. Highlight the Tank depth option and press .

7. To edit the depth press .

8. Use the n and p keys to increment and decrement the highlighted digit.

9. Use the m and o keys to move from one digit to the next.

10. When editing has finished press to save the value.

11. The large echo (in most cases this represents the bottom of the tank that the transducer is positioned over)

12. Repeat steps 7 to 11 as necessary.

13. When this echo appears at the bottom of the display the tank depth is set.

14. ESC to return to main menu.

on the lower left display will move.

Please note that to avoid confusing echoes this procedure should be carried out when there is no significant

sludge blanket in the tank.

5.3 Transducer self-cleaning

The transducer self-cleaning is pre-programmed for optimal performance. However, the cleaning cycle can be

changed by following the procedure set out below.

In order to access the transducer cleaning parameters follow the following programming sequence:

1. Press to access the main menu.

2. The main menu will appear on the upper right of the display.

3. Highlight the Go Off line menu option and press . The padlock will open.

4. Press Esc to return to the main menu.

5. Use the n and p keys to highlight the SETUP menu option and press .

6. Highlight the DUTY (mode) menu option and press .

7. Highlight the CLEANING menu option and press .

8. Highlight the Start On menu option and press .

9. Use the n and p keys to highlight the required option and press .

Three options are available;

• Auto Clean - This is the default option and means that the MSL600 will automatically carry out a cleaning

cycle for 10 seconds on the hour every hour.

• Manual 5s - This allows the user to manually activate a 5 second cleaning cycle at any time after which the

cycle returns to its previous setting (note, the unit must be on line to carry out this process).

• Off - The unit will not perform any cleaning cycles.

Page 21

Page 22

Installation, Operation & Maintenance Manual

MSL600

5.4 mA current output parameters

The operation of the current output is programmed by four parameters and is always controlled by the sludge

blanket level.

The current output parameters are found in SETUP – OUTPUT – CURRENT OUTPUT.

The parameters are as follows:

x Low range val (Lower range value)

This parameter allows the user to reference the programmed minimum current output (0 or 4mA) to any point

in the programmed blanket level measurement range.

The default condition is that the programmed minimum current corresponds to 0m (0 feet), the tank bottom.

x Up range val (Upper range value)

This parameter allows the user to reference the maximum 20mA current output to any point in the

programmed blanket level measurement range.

The default condition is that 20mA corresponds automatically to the programmed tank depth parameter less

the top blanking distance. This level is programmed by the tank depth parameter which by default is set to be

7.000m (23.00 feet). The 20mA level for default settings therefore corresponds to a sludge blanket level of

6.7m (22.1 feet)

x Alarm action

This parameter is selectable from a list and determines the action to be taken by the current output under

alarm conditions.

The allowed actions are:

• Go to 3.6mA

• Go to 21mA

• Hold last reading

IP262/Z0, Rev. AB

February 2012

x 0/4-20mA (0-20mA or 4-20mA setting)

This parameter sets the current output range from a list to be either 0-20 or 4-20mA.

5.5 Current output adjust

The current output is calibrated in the factory and should not require any adjustment.

However, if required, it is possible to adjust the 4mA and 20mA points using a calibrated meter. This is done by

following the procedure detailed below:

1. Connect a milliammeter to the terminal block marked CURRENT OUT ISOLATED between the 0V and the I

connections.

2. Put the system off line so that the ‘Go Off line?’ padlock is open.

3. Access the SETUP – SYSTEM – TEST – CURRENT OUTPUT menu.

4. Select either the “4mA out adjust” or the “20mA out adjust” and press .

5. Read the actual current on the calibrated meter.

6. Enter this value in the chosen parameter and press .

7. Check that the actual current is now exactly 4mA or 20mA.

For diagnostic purposes the current output can be driven to any value between 4mA and 20mA by accessing

SETUP – SYSTEM – TEST – CURRENT OUTPUT – Set current.

With a suitable meter connected to the current output terminals a value can programmed on the control unit and

the same value will appear on the meter.

This programmed current will remain until the ‘Go On line?’ padlock is closed.

O

Page 22

Page 23

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

MSL600

5.6 Relay parameters

The MSL600 offers various options for operating its relays. There are 2 relays that are programmable to different

modes, these modes are:

• Alarm

• Set point operation

• De-sludge

• On

• Off

• None

• Fault

• Slg Lev Limits (Sludge Level Limits)

The mode of operation is selected through the SETUP – OUTPUT – RELAY – Relay Mode menu.

The default mode for Relay 1 is set point operation and for Relay 2 default mode is alarm. Relay 3 is permanently

assigned to fault mode (see section 7.6 for further details).

5.7 Alarm

There are six different alarm conditions in the SETUP - OUTPUT - ALARM menu. Each alarm condition can be

set to operate a relay, or drive the current output, or both, or neither to the following states:

• Current output – 3.6mA, 21mA or Hold as defined in “Alarm action” in the CURRENT OUTPUT menu.

• Relay outputs – The relays energise in the alarm condition if they are programmed in Alarm mode.

The relays or current output must be set up for alarm action for this function to operate. The available alarm

actions are shown in the list below:

• Out of limits

• Current saturated

• Memory filling

• Digital Input

• Max Retries

• Xdr tilted

• Dirty supernatant

• Noise Alarm

5.8 Transducer out-of-water time

Certain installations make use of a picket fence thickener or a variety of rotating scrappers and scum boards.

These rotating arms at the surface of the liquid will periodically lift the articulated transducer out of the liquid as

they sweep by.

The transducer includes a (non-mercury) mechanical tilt switch. This is used to indicate when the transducer is

being tilted and lifted out of the water. The MSL600 uses this information to determine whether valid sonar echo

profile data is being received. If not then measurement will pause and outputs will be held until the arm is vertical

again.

When the transducer is tilted a timer is started. The time for which the transducer has been tilted is compared to

a maximum allowed value, programmed by the user. If this time is exceeded then an alarm condition can be

flagged. It is possible to program an alarm relay to respond to this flag. This is intended to detect problems if the

fence should stop under the transducer, etc. The time for which the transducer has been tilted is available as a

Monitor readings parameter (D833).

When the arm returns to the vertical the timer is re-set to zero and if allocated the alarm cancelled.

If the transducer has been out of water for greater than the time allowed then its temperature may be significantly

different to that of the supernatant.

Page 23

Page 24

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

The transducer may take up to 1 hour to reach thermal equilibrium. Therefore, it may take some time to restore

accurate blanket level readings. When the arm tilts out of the supernatant the MSL600 holds the last supernatant

temperature reading from the transducer. When the transducer falls back into the supernatant the MSL600 starts

to make measurements again.

When the MSL600 measures the supernatant temperature at the transducer, as long as the temperature is within

the programmed normal limits for a supernatant then the system uses this measured temperature for speed of

sound compensation.

If the measured temperature is outside of these limits then the MSL600 uses the last held temperature reading.

This state will continue until a valid temperature reading is again obtained from the transducer in the supernatant.

The upper and lower temperature points are programmable as HMI Engineering parameters. The default values

are -5 to +40°C (23 to 104 deg F). The lower temperature should always be less than the upper and valid entries

should be limited to temperatures between -40°C and +85°C (-40 to 185 deg F).

Because the tilt switch is sensitive to vibration as well as angle it is de-bounced in software. An engineering

parameter exists in the HMI to allow this function to be turned on and off, in the case of for example a particularly

vibration prone bridge.

5.9 Digital input

Parameter P340 is used to assign the status of the digital input to an alarm relay if desired. This allows the user

to stop measurement whilst the blanket is known to be disturbed and meaningful results would not be obtained.

E.g. during high in-flow or when top water level falls below the transducer face and normal measurements can’t

be performed.

February 2012

When the digital input is active all measurements continue as normal and the LED still flashes. The sonar pulse

echo display continues to update with live data. However, the blanket level is held at its last value. The trend

graph continues to update, relays and current output remain active, and logging continues using the held blanket

level.

Digital input active means either a short across the terminals, i.e. from a contact closure or a PLC driving low, i.e.

going to ‘0’.

Page 24

Page 25

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

MSL600

6. Detailed operation

The following sections go into programming the system in more detail.

6.1 The menu structure

From the normal display, pressing the key will enter the menu system, see Figure (11). A full menu structure is

shown in section 11.

Main menu item

Go On line ?

INSTALLATION Tank Depth

Xdr Tilt Time

Tag No.

Description

SETUP DUTY (Mode) DE-SLUDGE

CLEANING

Digital i/p action

OUTPUT CURRENT OUTPUT

RELAY

ALARM

FAULT

DISPLAY

LOGGING

ENGINEERING

SYSTEM TEST

COMMS

SETTINGS

PIN

FIXED

MONITOR READINGS

DIAGNOSTICS

DIRECT Pxxx

Dxxx

Figure (11): Menu structure

The top-level menu contains the list of available menu items:

Menu Item Description

Go On-line (Go off-line) Allows programming when off line

INSTALLATION Installation parameters

SETUP Setup parameters

MONITOR Diagnostic and performance type parameters

DIRECT Allows direct access to parameters

Page 25

Page 26

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

To move up and down the list, use the n and p arrows until the required menu item is highlighted, then use the

key to enter that menu option.

The presence of additional menu items off the screen is indicated by up and down arrows on the right hand side

of the display.

The next level of the menu is then displayed and the required option can again be selected as above.

February 2012

6.2 Parameter editing

Once the required parameter is displayed, select it and press the key (note that menu groups are in upper case

letters, parameters are in upper and lower case).

Note also that there are two parameter types:

• Read/Write - these parameters are normally preceded by a “P” - e.g. P200. They may be modified by the user.

• Read Only - these parameters are normally preceded by a “D” - e.g. D800. They are either fixed within the

MSL600 or produced by data processing and thus may not be modified by the user. Examples are Software

Revision and Serial Number.

The desired parameter may now be modified. Numeric values are edited one digit at a time, the m and okeys

select each digit by highlighting them and the n and p keys increment and decrement each digit.

Alternatively, some parameters are in the form of a list. These are edited in a similar way, selecting with the

key and using the n and p keys to scroll through the list.

When the displayed value is correct, press the key to store the value.

6.3 Scrolling

When a parameter is displayed but no digit is highlighted, the n and p keys will scroll to the next parameter in

numeric order. This provides an alternative method of accessing parameters without using the menu facility.

6.4 Direct access

It is possible to access the parameters directly from the main menu if the parameter number is known.

From the normal display press the key to display the main menu on the top right hand side of the display.

Use the arrow keys to scroll down until the menu option DIRECT is highlighted and press the key.

Highlight either Pxxx or Dxxx

(Pxxx are user configurable parameters and Dxxx are non-configurable diagnostic parameters).

Enter the parameter number to be edited and press

If an invalid number is entered then the next lowest parameter is displayed.

.

Page 26

Page 27

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012

7. Application parameters

The following section details each parameter.

7.1 Main menu parameters

The following functions are available at the top level of the menu structure.

Note: A full menu structure is shown in section 11.

7.1.1 Cancel password

This is a dynamic parameter; it only appears when password has been opened. This parameter allows the user

to cancel the need for password entry before access to parameter editing is allowed.

7.1.2 Go Online/Offline

This is a dynamic parameter; it changes according to whether the system is online or offline. The padlock icon

will be displayed in a corresponding open or closed state.

7.2 Installation parameters

The following parameters are intended primarily for use during system installation.

MSL600

7.2.1 Tank Depth – P101

The tank depth is the distance from the front face of the transducer to the bottom of the tank directly under the

transducer and is the user programmable range for zero blanket level.

Parameter values (Metric) Parameter values (Imperial)

Default Min Max Default Min Max

7.000m 1.000m 7.000m 23.00 ft 3.30 ft 23.00 ft

7.2.2 Xdr Tilt Time – P103

This is the maximum time for which transducer can be out of the water before the system registers a fault.

The parameter is either disabled by entering a value of zero or programmed with a value in minutes.

The default is a value of 0 minutes, disabled.

Parameter values:

Default Min Max

0 (Disabled) 1 15

7.2.3 Tag No. – P242

This is a user defined alpha-numeric parameter. Any string up to 8 characters long may be entered using the keypad.

This will usually correspond to the instrument’s asset number or some other such identifier on the user’s schedule.

The following characters are allowed:

!”#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_

Parameter values:

Default Min Max

MSL600 - -

Page 27

Page 28

Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

MSL600

7.2.4 Description – P240

This is a user defined alpha-numeric parameter. Any string up to 12 characters long may be entered using the

keypad. This will usually be a description of the application.

The following characters are allowed:

!”#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_

Parameter values:

Default Min Max

CLARIFIER1 - -

7.3 De-sludge parameters

The following parameters relate to the de-sludge function and are found in the setup menu.

Note that minimum and maximum parameters relating to time are 00:00 and 23:59 respectively. Minimum and

maximum parameters relating to sludge level are 0.000 to 7.000m (0.00 to 23.00 feet)