Page 1

MON2000

Software for Gas Chromatographs

User Manual

Applies to Both:

Daniel Danalyzer On-Line Gas Chromatographs

Rosemount Analytical Process Gas Chromatographs

Part Number 3-9000-522

Revision R

JULY 2010

Page 2

Page 3

MON2000 Software for Gas Chromatographs

Manual

NOTICE

DANIEL MEASUREMENT AND CONTROL, INC. AND ROSEMOUNT ANALYTICAL

(COLLECTIVELY, “SELLER”) SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS IN

THIS MANUAL OR OMISSIONS FROM THIS MANUAL. SELLER MAKES NO WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT,

SHALL SELLER BE LIABLE FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING,

BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, ETC.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION

ONLY AND MAY BE TRADEMARKS/REGISTERED TRADEMARKS OF THESE COMPANIES.

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES

ONLY, AND WHILE EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY

ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED,

REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR

APPLICABILITY. WE RESERVE THE RIGHT TO MODIFY OR IMPROVE THE DESIGNS OR

SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

SELLER DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE

OF ANY PRODUCT. RESPONSIBILITY FOR PROPER SELECTION, USE AND MAINTENANCE OF

ANY SELLER PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

DANIEL AND THE DANIEL LOGO ARE REGISTERED TRADEMARKS OF DANIEL MEASUREMENT

AND CONTROL, INC. ROSEMOUNT AND THE ROSEMOUNT ANALYTICAL LOGO ARE

REGISTERED TRADEMARKS OF ROSEMOUNT ANALYTICAL. THE EMERSON LOGO IS A

TRADEMARK AND SERVICE MARK OF EMERSON ELECTRIC CO.

COPYRIGHT

U.S.A.

All rights reserved. No part of this work may be reproduced or copied in any form or by any

means - graphic, electronic, or mechanical — without first receiving the written permission of

Daniel Measurement and Control, Inc. Houston, Texas, U.S.A.

©

2010 BY DANIEL MEASUREMENT AND CONTROL, INC., HOUSTON, TEXAS,

Page 4

WARRANTY

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein and except as

otherwise expressly provided herein, Daniel Measurement and Control, Inc. and Rosemount

Analytical, (collectively“Seller”) warrants that the firmware will execute the programming

instructions provided by Seller, and that the Goods manufactured or Services provided by Seller

will be free from defects in materials or workmanship under normal use and care until the

expiration of the applicable warranty period. Goods are warranted for twelve (12) months from

the date of initial installation or eighteen (18) months from the date of shipment by Seller,

whichever period expires first. Consumables and Services are warranted for a period of 90 days

from the date of shipment or completion of the Services. Products purchased by Seller from a

third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by the

original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond making

a reasonable commercial effort to arrange for procurement and shipping of the Resale Products. If

Buyer discovers any warranty defects and notifies Seller thereof in writing during the applicable

warranty period, Seller shall, at its option, promptly correct any errors that are found by Seller in

the firmware or Services, or repair or replace F.O.B. point of manufacture that portion of the

Goods or firmware found by Seller to be defective, or refund the purchase price of the defective

portion of the Goods/Services. All replacements or repairs necessitated by inadequate

maintenance, normal wear and usage, unsuitable power sources, unsuitable environmental

conditions, accident, misuse, improper installation, modification, repair, storage or handling, or

any other cause not the fault of Seller are not covered by this limited warranty, and shall be at

Buyer's expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or

any other party except as may be agreed upon in writing in advance by an authorized Seller representative. All costs of dismantling, reinstallation and freight and the time and expenses of

Seller's personnel for site travel and diagnosis under this warranty clause shall be borne by Buyer

unless accepted in writing by Seller. Goods repaired and parts replaced during the warranty

period shall be in warranty for the remainder of the original warranty period or ninety (90) days,

whichever is longer. This limited warranty is the only warranty made by Seller and can be

amended only in a writing signed by an authorized representative of Seller. Except as otherwise

expressly provided in the Agreement, THERE ARE NO REPRESENTATIONS OR WARRANTIES OF

ANY KIND, EXPRESSED OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. It

is understood that corrosion or erosion of materials is not covered by our guarantee.

2.

LIMITATION OF REMEDY AND LIABILITY: SELLER SHALL NOT BE LIABLE FOR DAMAGES

CAUSED BY DELAY IN PERFORMANCE. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF

WARRANTY HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION, REPLACEMENT OR

REFUND OF PURCHASE PRICE UNDER THE LIMITED WARRANTY CLAUSE IN SECTION 1

HEREIN. IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION

(WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER

TORT OR OTHERWISE), SHALL SELLER'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS

EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR SERVICES

PROVIDED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES

THAT IN NO EVENT SHALL SELLER'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND

TO INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM

"CONSEQUENTIAL DAMAGES" SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF

ANTICIPATED PROFITS, LOSS OF USE, LOSS OF REVENUE AND COST OF CAPITAL.

Page 5

IMPORTANT INSTRUCTIONS

• Read all instructions prior to installing, operating, and servicing this product.

• Follow all warnings, cautions, and instructions marked on and supplied with this product.

• Inspect the equipment packing case and if damage exists, notify your local carrier for

liability.

• Open the packing list and carefully remove equipment and spare or replacement parts

from the case. Inspect all equipment for damage and missing parts.

• If items are damaged or missing, contact the manufacturer at 1 (713) 827-6314 for

instructions about receiving replacement parts.

• Install equipment as specified per the installation instructions and per applicable local and

national codes. All connections shall be made to proper electrical and pressure sources.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent personal injury.

• Use of this product for any purpose other than its intended purpose may result in property

damage and/or serious injury or death.

• Before opening the flameproof enclosure in a flammable atmosphere, the electrical

circuits must be interrupted.

• Repairs must be performed using only authorized replacement parts as specified by the

manufacturer. Use of unauthorized parts can affect the product's performance and place

the safe operation of the product at risk.

• When installing or servicing ATEX-certified units, the ATEX approval applies only to

equipment without cable glands. When mounting the flameproof enclosures in a

hazardous area, only flameproof cable glands certified to IEC 60079-1 must be used.

• Technical assistance is available 24 hours a day, 7 days a week

6314.

by calling 1 (713) 827-

Page 6

This page is intentionally left blank.

Page 7

TABLE OF CONTENTS

INTRODUCTION 1.1 Description of Manual ....................................1-1

Section 1 – Introduction ................................1-1

Section 2 – Installation and Startup.................1-2

Section 3 – Getting Started............................1-2

Section 4 – Control Functions.........................1-2

Section 5 – Application Functions ...................1-3

Section 6 – Chromatogram Viewer..................1-3

Section 7 – Reports.......................................1-3

Section 8 – Logs...........................................1-3

Section 9 – Data Collection ............................1-4

Section 10 – Modbus Test .............................1-4

Appendix A, PC Config Report ........................1-5

Appendix B, Component Data Table ................1-5

Appendix C, Data Computations .....................1-5

Appendix D, Analog Output

Cal. 2350A GC .............................................1-5

Appendix E, Upgrade 2350A GC

S/W and 2350 EPROMS.................................1-5

Appendix F, Modbus Reg. List for 2350A GC ...1-5

INSTALLATION AND

SETUP

1.2 Description of Online Help ..............................1-6

1.3 Description of MON2000 ...............................1-6

2.1 System Requirements ....................................2-1

2.2 Installing MON2000 ......................................2-3

2.3 Installing the CrypKey License Service for

MON2000 PLUS ...........................................2-4

2.4 Copying MON2000 to Disks ...........................2-4

2.5 Transferring a MON2000 PLUS License ...........2-6

2.6 Uninstalling MON2000................................. 2-15

2.7 Starting MON2000......................................2-17

2.8 Performing Your First Logon ......................... 2-18

Page 8

ii TABLE OF CONTENTS

MON2000

2.8.1 The Initial Logon ......................................... 2-18

2.8.2 Registering MON2000 ................................. 2-19

2.8.3 Update MON2000....................................... 2-21

2.9 Checklist for Setting Up MON2000 ............... 2-22

2.10 Communications ......................................... 2-22

2.10.1 Connect to the GC Unit ............................... 2-22

2.10.2 Disconnect from GC Unit ............................. 2-23

2.11 Customizing MON2000................................ 2-24

2.11.1 Configure Users .......................................... 2-24

2.11.2 Set Up GC Directory.................................... 2-27

2.11.3 Dial-up Connection ...................................... 2-30

2.11.4 Modem Initialization Strings/Setup................. 2-36

Black Box - Modem 325............................... 2-37

U.S. Robotics Sportster ............................... 2-38

GVC/MaxTech 28.8 Kbps Modem ................. 2-40

2.12 2350 to 2350A Retrofit Instructions .............2-41

2.13 Conversion Process ..................................... 2-43

2.14 BASIC 2350A CONFIGURATION................... 2-49

2.15 2350A Options........................................... 2-52

2.15.1 The COM4A Board ...................................... 2-52

2.15.2 2350A Modem Installation ........................... 2-55

2.15.3 2350A Ethernet Installation.......................... 2-58

2.15.4 Ethernet TCP/IP Settings .............................. 2-62

2.15.5 MON2000 TCP/IP Settings........................... 2-64

2.16 CONNECT VIA GC EXTERNAL MODEM ......... 2-66

2.16.1 Hardware Setup.......................................... 2-66

2.16.2 Select Program Settings............................... 2-68

2.16.3 Generate PC Config Report........................... 2-70

Installation and Setup JULY 2010

Page 9

TABLE OF CONTENTS iii

MON2000

2.17 Downloading an Application .........................2-72

2.18 Upgrading Flash .......................................... 2-75

2.19 Offline Edit of GC Application .......................2-76

2.19.1 File Selection ..............................................2-77

2.19.2 Upload Application ......................................2-78

2.19.3 Upload BOS................................................2-81

GETTING STARTED 3.1 Logging On...................................................3-1

3.2 Logging Off ..................................................3-3

3.3 MON2000 User Interface ...............................3-3

3.3.1 Main Window ...............................................3-4

3.3.2 GC Status Bar...............................................3-5

3.3.3 View Menu...................................................3-8

3.3.4 ToolTips.......................................................3-8

3.3.5 Data Entry and Function Features....................3-8

3.3.6 Shortcut to Save or Print Data ........................3-9

3.4 Keyboard Shortcuts.......................................3-9

3.5 Procedures Guide ........................................3-11

3.6 Keylock Switch Control................................ 3-15

3.7 Configuring Your Printer............................... 3-16

3.8 Using Online Help........................................ 3-18

3.9 Operating Modes for Model 700.................... 3-19

3.10 About MON2000 ........................................ 3-19

CONTROL FUNCTIONS 4.1 Auto Sequence .............................................4-1

4.2 Single Stream ...............................................4-2

4.3 Halt .............................................................4-3

JULY 2010 Getting Started

Page 10

iv TABLE OF CONTENTS

MON2000

4.4 Calibration....................................................4-4

4.5 Baseline Run.................................................4-5

4.6 Auto BTU Start Up and Valve Timing............... 4-7

4.6.1 Initiating an Auto BTU Start Up Run ................ 4-7

4.6.2 Starting a Valve Timing Run ......................... 4-12

4.7 GC Time .................................................... 4-13

4.7.1 View GC Time ............................................ 4-13

4.7.2 Set GC Time............................................... 4-14

4.8 Stop Now .................................................. 4-15

APPLICATION

FUNCTIONS

5.1 System ........................................................5-1

5.2 Component Data........................................... 5-6

5.2.1 Select Standard Component(s)...................... 5-10

5.2.2 Select Standard Values ................................ 5-11

5.2.3 Update Standard Component(s) .................... 5-11

5.2.4 View Raw Data........................................... 5-12

5.2.5 Sort Retention Time .................................... 5-14

5.3 Timed Events .............................................5-14

Timed Events Description............................. 5-14

Valve Events .............................................. 5-15

Integration Events ....................................... 5-15

Spectrum Gain Events ................................. 5-16

5.4 User Defined .............................................. 5-19

5.4.1 Numeric ..................................................... 5-19

5.4.2 Selection.................................................... 5-20

5.4.3 Text Strings ...............................................5-20

5.5 Calculations ............................................... 5-21

5.5.1 Control ...................................................... 5-21

5.5.2 Averages ................................................... 5-23

Application Functions JULY 2010

Page 11

MON2000

TABLE OF CONTENTS v

5.5.3 User Defined ..............................................5-25

5.6 Limit Alarms ...............................................5-27

Limit Alarms Description ..............................5-30

5.7 Discrete Alarms ..........................................5-31

5.7.1 Delayed Discrete Alarms .............................. 5-33

5.8 Streams .....................................................5-38

5.9 Analog Inputs .............................................5-44

5.10 Analog Outputs...........................................5-48

5.10.1 Analog Output Dialog Description.................. 5-48

5.10.2 Changing a Variable.....................................5-52

5.10.3 Changing the Bargraph.................................5-52

5.10.4 Performing a Manual Calibration.................... 5-53

5.10.5 Performing an Automated Calibration............. 5-54

5.11 Discrete Inputs ...........................................5-56

5.12 Discrete Outputs .........................................5-57

5.13 Valves .......................................................5-58

5.14 Temperature Control....................................5-61

5.15 FID Configuration ........................................ 5-62

5.16 LOI Status Variables .................................... 5-66

5.17 Serial Ports................................................. 5-68

5.17.1 Serial Ports Configuration .............................5-71

5.18 GC Serial Port and Cable Configurations......... 5-74

5.18.1 GC DB-9 Serial to External Modem DB-25 ...... 5-76

5.18.2 GC Phoenix Plug to External Modem DB-25 .... 5-77

5.18.3 Com ID ......................................................5-78

5.18.4 Registers....................................................5-80

JULY 2010 Application Functions

Page 12

vi TABLE OF CONTENTS

MON2000

5.18.5 Setting Optional Base Pressures.................... 5-86

5.18.6 Setting Optional Base Results ....................... 5-90

5.19 TCP/IP, Subnet, and Gateway Menu.............. 5-94

CHROMATOGRAM

VIEWER

6.1 Chromatogram Viewer Function ......................6-1

6.2 Viewing a Live Chromatogram ........................ 6-2

6.2.1 From Online GC ............................................6-2

6.2.2 From GC Archive ..........................................6-3

6.2.3 From File on Disk ..........................................6-4

6.3 Removing a Chromatogram from View............. 6-8

6.4 Saving a Chromatogram to Disk...................... 6-8

6.5 Graph Functions............................................6-9

6.5.1 Editing the Chromatogram Graph ....................6-9

6.5.2 Changing Cursor Size .................................. 6-10

6.5.3 Printing the Chromatogram........................... 6-11

6.6 Chromatogram Functions ............................. 6-11

6.6.1 Editing the Chromatogram............................ 6-12

6.6.2 Editing TEVs from CGM Viewer .................... 6-13

6.6.3 Editing Retention Times from CGM Viewer ..... 6-15

6.6.4 Editing TEVs from Cursor ............................. 6-15

6.6.5 Viewing the Chromatogram Results............... 6-16

6.6.6 Entering a Description.................................. 6-18

6.6.7 Forcing a Calibration.................................... 6-19

6.6.8 Toggling TEVs and CGM Components ........... 6-19

6.7 Viewing Baseline Data ................................. 6-20

6.8 Viewing RAW Data .....................................6-21

6.9 Display Options ..........................................6-21

Chromatogram Viewer JULY 2010

Page 13

MON2000

TABLE OF CONTENTS vii

REPORTS 7.1 Report Display ..............................................7-1

7.1.1 View Report from Live Data............................7-1

7.1.2 View Report from File ....................................7-4

7.1.3 Print Report ..................................................7-6

7.1.4 Save Report to Disk.......................................7-6

7.1.5 Report Contents............................................7-8

Analysis Report.............................................7-9

Raw Data Report......................................... 7-11

Calibration Report .......................................7-12

Final Calibration Report ................................7-13

Average Reports .........................................7-14

Sample 24-Hour Average Report ...................7-14

7.2 GC Report Request......................................7-15

7.3 GC Printer Control .......................................7-16

7.4 MON2000 Printer Control.............................7-18

7.5 Archive Data ..............................................7-20

7.5.1 View Data Model 500/Model 700..................7-21

7.5.2 Archive Export Data ....................................7-24

7.5.3 Reset.........................................................7-27

7.6 Trend Data .................................................7-28

7.6.1 Trend Data Model 700/2350A GCs .............. 7-28

7.6.2 View Live Trend Online Model 700/2350A ..... 7-29

7.6.3 View Trend from File on Disk........................ 7-32

7.6.4 Edit Graph Display.......................................7-34

7.6.5 Changing Cursor Size...................................7-34

7.6.6 Describe Trend ...........................................7-35

7.6.7 Print Trend .................................................7-35

7.6.8 Save Trend................................................. 7-36

7.6.9 Read Trend Archive .....................................7-36

7.6.10 Display Options...........................................7-37

JULY 2010 Reports

Page 14

viii TABLE OF CONTENTS

LOGS 8.1 Maintenance Log...........................................8-1

MON2000

8.2 Parameter List ..............................................8-3

8.3 Alarm Log .................................................... 8-6

8.4 Clear or Acknowledge Active Alarms ...............8-9

8.5 Event Log .................................................... 8-9

MON2000 PLUS DATA

COLLECTION/AUTO-

POLLING

9.1 Overview .....................................................9-1

9.2 Data Collection Configuration ......................... 9-3

9.2.1 Create a New Polling Control File .................... 9-6

9.2.2 Open an Existing Polling Control File................ 9-7

9.2.3 Await Command ...........................................9-9

9.2.4 Connect/Logon Command ............................ 9-10

9.2.5 Connect/No Logon Command ....................... 9-11

9.2.6 Delay (Seconds) Command........................... 9-11

9.2.7 Delay (Hours) Command .............................. 9-12

9.2.8 Disconnect Command.................................. 9-13

9.2.9 End Command ............................................9-13

9.2.10 Poll Command: Alarms................................. 9-14

9.2.11 Poll Command: Averages ............................. 9-16

9.2.12 Poll Command: CGM Archive........................ 9-19

9.2.13 Poll Command: CGM on Alarm...................... 9-21

9.2.14 Poll Command: Condition Start ..................... 9-21

9.2.15 Poll Command: Condition End....................... 9-23

9.2.16 Poll Command: Event Log ............................9-24

9.2.17 Poll Command: Maintenance Log .................. 9-26

9.2.18 Poll Command: Registers.............................. 9-28

9.2.19 Poll Command: Reports................................ 9-32

9.2.20 Repeat Command........................................ 9-34

9.2.21 Run Command............................................ 9-35

Logs JULY 2010

Page 15

MON2000

TABLE OF CONTENTS ix

9.3 Data Collection ...........................................9-35

9.3.1 Start Auto-Sequencing.................................9-36

9.3.2 Transaction Log ..........................................9-38

9.3.3 Auto-Sequencing Status............................... 9-38

9.3.4 Status Log .................................................9-39

MODBUS TEST 10.1 Starting WinMB ..........................................10-1

10.2 Establishing Communications........................ 10-2

10.2.1 Comparison of Modbus Protocols .................. 10-3

10.2.2 Set GC Com Parameters via MON2000.......... 10-4

10.2.3 Set Up Port via WinMB ................................10-5

10.3 Getting Modbus Data................................... 10-7

10.3.1 Use Single Data Type ..................................10-9

APPENDIX A, PC CONFIG

REPORT

APPENDIX B:

COMPONENT DATA

TABLE

10.3.2 Use Template (Mixed Data Types) ............... 10-10

10.4 Using Modbus Data ................................... 10-13

10.4.1 Set Log Parameters ................................... 10-14

10.4.2 Save Modbus Data .................................... 10-16

10.4.3 Assign Scale Ranges for User_Modbus......... 10-17

10.4.4 Print Modbus Data ....................................10-17

10.5 Troubleshooting Communication Errors ........ 10-18

10.6 Using Modbus Test Online Help .................. 10-19

10.6.1 How to Access .........................................10-19

10.6.2 How to Navigate ....................................... 10-20

A.1 How to Print................................................ A-1

A.2 Example Report............................................ A-2

APPENDIX C, DATA

COMPUTATIONS

JULY 2010 Modbus Test

C.1 Data Acquisition ...........................................C-1

Page 16

x TABLE OF CONTENTS

MON2000

C.2 Peak Detection .............................................C-2

C.3 Analysis Computations ..................................C-5

C.3.1 Conc. Analysis with Response Factor ..............C-5

Calibration....................................................C-5

Calc. in Mole Percent w/o Normalization ..........C-7

C.4 Post Analysis Computations ...........................C-9

C.4.1 Liquid Equivalent Computations ......................C-9

C.4.2 Heating Value Calculations .............................C-9

C.4.3 Multi-Level Calibration .................................C-17

C.4.4 Indirect Calibration .....................................C-18

APPENDIX D, ANALOG

OUTPUT CAL. FOR 2350A

APPENDIX E, UPGRADE

2350A GC S/W AND

2350 EPROMS

D.1 Calibrating by Volts .......................................D-1

D.2 Calibrating by Percentages .............................D-5

E.1 Connect to GC and Halt Analysis .................... E-1

E.2 Offline Edit to Upload App. & Rename ............. E-1

E.3 Upgrade User-Defined Applications.................. E-3

E.4 Upgrade from Disk ........................................ E-3

E.4.1 Upgrade from GC Controller ........................... E-6

E.4.2 Configure GC Connection ............................... E-9

E.5 Disconnect Power and Disassemble ............... E-10

E.6 Replace EPROMS/Reset CPU ........................ E-12

E.7 Reassembly Procedures ............................... E-13

E.8 Set-Up and Programming ............................. E-14

E.8.1 Procedure .................................................. E-14

E.8.2 Reprogramming the DiskOnChip .................... E-16

E.8.3 GC Reassembly........................................... E-17

Appendix D, Analog Output Cal. For 2350A JULY 2010

Page 17

MON2000

TABLE OF CONTENTS xi

E.9 Connect to GC for Upgraded App. ................. E-18

E.10 Guide to Standard Application Files ............... E-19

E.10.1 Importance of Standard Application Files........ E-19

E.10.2 Standard Applications v1.50 and Later .......... E-20

E.10.3 Standard Applications Prior to v1.50 ............. E-22

APPENDIX F, MODBUS

REG. LIST FOR 2350A GC

F.1 Introduction – SIM_2251 & User_Modbus ........ F-1

F.1.1 Notes on User_Modbus .................................. F-1

F.1.2 Notes on SIM_2251 Modbus .......................... F-2

F.2 User_Modbus Register List ............................. F-3

F.2.1 SIM_2251 Modbus Register List...................... F-6

JULY 2010 Appendix F, Modbus Reg. List for 2350A GC

Page 18

xii TABLE OF CONTENTS

MON2000

This page is intentionally left blank.

Appendix F, Modbus Reg. List for 2350A GC JULY 2010

Page 19

MON2000

INTRODUCTION 1-1

INTRODUCTION

Welcome to the MON2000 User Manual

(P/N 3-9000-522), a user guide that

accompanies the MON2000 software produced

by Daniel Measurement and Control, Inc., a

Division of Emerson Process Management.

Use this manual for installing the MON2000

and Modbus Test (WinMB) software programs,

getting started, checking various gas

chromatograph (GC) application settings, and

configuring and monitoring your GC system.

1.1 DESCRIPTION OF MANUAL

See the following section summaries or the

Table of Contents for more information.

Section 1 – Introduction

This section includes:

• summary listing of the manual sections

• description of the MON2000 User Guide

online help file

• description of the MON2000 software

program

_________________________________________________________________________________________

JULY 2010 Description of Manual

Page 20

1-2 INTRODUCTION

Section 2 – Installation and Startup

This section includes:

• short description of the MON2000 software

• minimum system requirements for

installing MON2000 on a 32-bit Microsoft®

Windows® platform

• installation and Startup instructions

• establishing communications and Logon

procedures

• instructions for customizing MON2000 and

setting up security

• instructions for downloading an application

and using the Offline Edit function to

change an application’s configuration

MON2000

Section 3 – Getting Started

This section includes:

• instructions on how to log on and log off

• navigation instructions for MON2000

• listing of available procedures and keyboard

shortcuts

• access and navigation instructions for the

MON2000 User Guide online help file

Section 4 – Control Functions

This section includes:

• description of available Control functions

and detailed step procedures

Description of Manual JULY 2010

Page 21

MON2000

INTRODUCTION 1-3

Section 5 – Application Functions

This section includes:

• description of available GC Application

functions and detailed step procedures

Section 6 – Chromatogram Viewer

This section includes:

• description of available Chromatogram

Viewer functions and detailed step

procedures to view, save, and print

chromatograms

Section 7 – Reports

This section includes:

• descriptions of available reports and sample

outputs

• instructions on how to generate and print a

given report

Section 8 – Logs

This section includes:

• description of Maintenance, Alarm, and

Event logs

• description of the Parameter List

• step procedures for viewing, editing, and

clearing logs

_________________________________________________________________________________________

JULY 2010 Description of Manual

Page 22

1-4 INTRODUCTION

Section 9 – Data Collection

This section includes:

• descriptions of Data Collection and AutoSequencing

• instructions on how to configure, generate

and run the Data Collection and AutoSequencing function using MON2000 PLUS

Section 10 – Modbus Test

This section includes:

• short description of the WinMB software

• minimum system requirements for

installing WinMB on a 32-bit Microsoft®

Windows® platform

MON2000

• installation and start up instructions

• description of available Modbus Test

functions and detailed step procedures

• description of the WinMB online help file

and navigation instructions

Description of Manual JULY 2010

Page 23

MON2000

INTRODUCTION 1-5

Appendix A, PC Config Report

This appendix provides a sample PC Config

Report for reference only.

Appendix B, Component Data Table

This appendix provides two sample Component

Data Tables for reference only.

Appendix C, Data Computations

This appendix discusses the various equations

and computations involved with acquisition

and analysis tasks.

Appendix D, Analog Output Cal. 2350A GC

This appendix demonstrates how to calibrate

an analog output for a 2350A GC Controller,

using the MON2000 software.

Appendix E, Upgrade 2350A GC S/W and 2350 EPROMS

This appendix describes how to upgrade the GC

software and the 2350 GC Controller EPROMS,

the 2350A WinSystems CPU,

P/C104 Bus, and DiskOnChip.

Appendix F, Modbus Reg. List for 2350A GC

This appendix explains the differences between

SIM_2251 and User_Modbus protocols, and

lists the corresponding Modbus registers used

by the 2350A GC Controller.

_________________________________________________________________________________________

JULY 2010 Description of Manual

Page 24

1-6 INTRODUCTION

1.2 DESCRIPTION OF ONLINE HELP

Use the User Guide online help file to quickly

access information regarding any MON2000

function. See Section 3.8 for more detailed

information.

1.3 DESCRIPTION OF MON2000

MON2000 is a menu-driven, Windows-based

software program designed to operate the gas

chromatograph (GCs). MON2000 runs on an

IBM-compatible personal computer (PC) and

serves as an interface between you and the GC

unit. MON2000 can run on a Windows® 95,

Windows® 98, Windows® 2000, Windows® XP

or Windows® NT operating system.

MON2000

MON2000, combined with the GC application(s), offers a complete software package for

operating and monitoring one or more GC

systems from a single PC. MON2000 includes

security features to help prevent unauthorized

access to GC data or control. MON2000 also

includes, for trouble-shooting purposes, an

auxiliary program (WinMB) to selectively poll

the GC Modbus registers (see Section 10 for

more information).

GC functions that can be initiated or controlled

by MON2000 include:

• alarm parameters

• alarm and event processing

• analog scale adjustments

•analyses

• baseline runs

• calculation assignments and configurations

• calibrations

• component assignments and configurations

When configured for RS-485

multi-drop networking,

MON2000 can interface with

up to 32 GC units, either in a

stand-alone configuration or via

a network.

When configured for

Ethernet networking MON2000

can interface with a number of

GC Units limited only by the

number of available TCP/IP

addresses.

Description of Online Help JULY 2010

Page 25

MON2000

INTRODUCTION 1-7

•diagnostics

• event sequences

• halt operations

• stream assignments and sequences

• valve activations

• timing adjustments

Reports that can be generated by MON2000

per the GC application:

• 24-Hour Averages

•Analysis

• Calibration

• Final Calibration

• Hourly Averages

• Monthly Averages

• PC Configuration

•Raw Data

• Variable Averages

• Weekly Averages

Logs that are maintained by MON2000:

•Alarm Log

•Event Log

• Parameter List

• Maintenance Log

_________________________________________________________________________________________

JULY 2010 Description of MON2000

Page 26

1-8 INTRODUCTION

MON2000

This page is intentionally left blank.

Description of MON2000 JULY 2010

Page 27

MON2000

INSTALLATION AND SETUP 2-1

INSTALLATION AND SETUP

This section lists the system requirements to

run MON2000 and provides installation

procedures as well as initial logon instructions,

communications setup, and software

configuration.

2.1 SYSTEM REQUIREMENTS

To achieve maximum performance when

running the MON2000 software, ensure your

PC system contains the following hardware.

• PC with a 486/90MHz or higher processor

(Pentium/100MHz or higher recommended)

running either

Windows® 95 (service pack 1 or better) or later

equipment and Microsoft® Windows® operating

system.

Microsoft Internet Explorer 5.0 (or later) is required to view

spreadsheets or reports saved in HTML format.

If running Windows® 95 with the 2350A optional Ethernet

card, the user must download Socket 2 from

www.microsoft.com/windows95/downloads to utilize

MON2000’s ethernet feature.

JULY 2010 System Requirements

Page 28

2-2 INSTALLATION AND SETUP

MON2000

-Windows® 98 version 1 or later

-Windows® 2000 version 1 or later

-Windows® XP version 1 or later (see note

for system requirements)

-Windows® NT Server version 4 (service

pack 3 or later)

Use the Settings>Control Panel>System/>General Page menu to check the system version

number.

For Windows

For Windows

To use Windows

• Computer/Processor PC with 300 MHz or higher processor clock speed recommended;

• 233 MHz minimum required (single or dual processor system)

•*Intel

• Memory: 128 MB of RAM or higher recommended (64 MB minimum supported; may limit

• Hard Disk Minimum: 1.5 GB of available hard disk space.

For Windows

®

or compatible processor recommended.

performance and some features).

95, the version number should be 4.00.950A/B or later.

®

98 or Windows® 2000, the version number should be 1 or later.

®

XP you need:

®

Pentium®/CeleronTM family, or AMD-K6®/AMD AthlonTM/AMD DuronTM family,

NT4, the version number should be 4.00.1381 or later.

®

• 16 megabytes (MB) of RAM (32 MB or

higher recommended)

• 5 MB of free hard disk space

• Super VGA monitor with 800x600

resolution

• free serial port for remote/local connection

to gas chromatograph (for online operations)

• free parallel port for connection to printer

•Windows

-compatible modem (for remote

®

connection only)

• Ethernet connection (when using Ethernet

networking)

System Requirements JULY 2010

Page 29

MON2000

INSTALLATION AND SETUP 2-3

2.2 INSTALLING MON2000

To install MON2000, do the following:

If you are upgrading MON2000, you must install the new

software with same directory as the current version.

1. Either place the MON2000 CD in your

CD-ROM drive or insert Installation Disk 1

into your floppy drive.

2. Launch Windows® Explorer® by either:

• Clicking the button (see the

taskbar) to access the Programs menu

option.

• Double-clicking the Windows® Explorer®

icon on your desktop.

3. Access either your CD-ROM drive or floppy

drive.

4. Double-click the file “setup.exe”.

5. The Installation Wizard begins. Follow the

instructions provided on each screen.

Upon successful installation, Windows®

automatically creates a MON2000 icon on

your desktop.

JULY 2010 Installing MON2000

Page 30

2-4 INSTALLATION AND SETUP

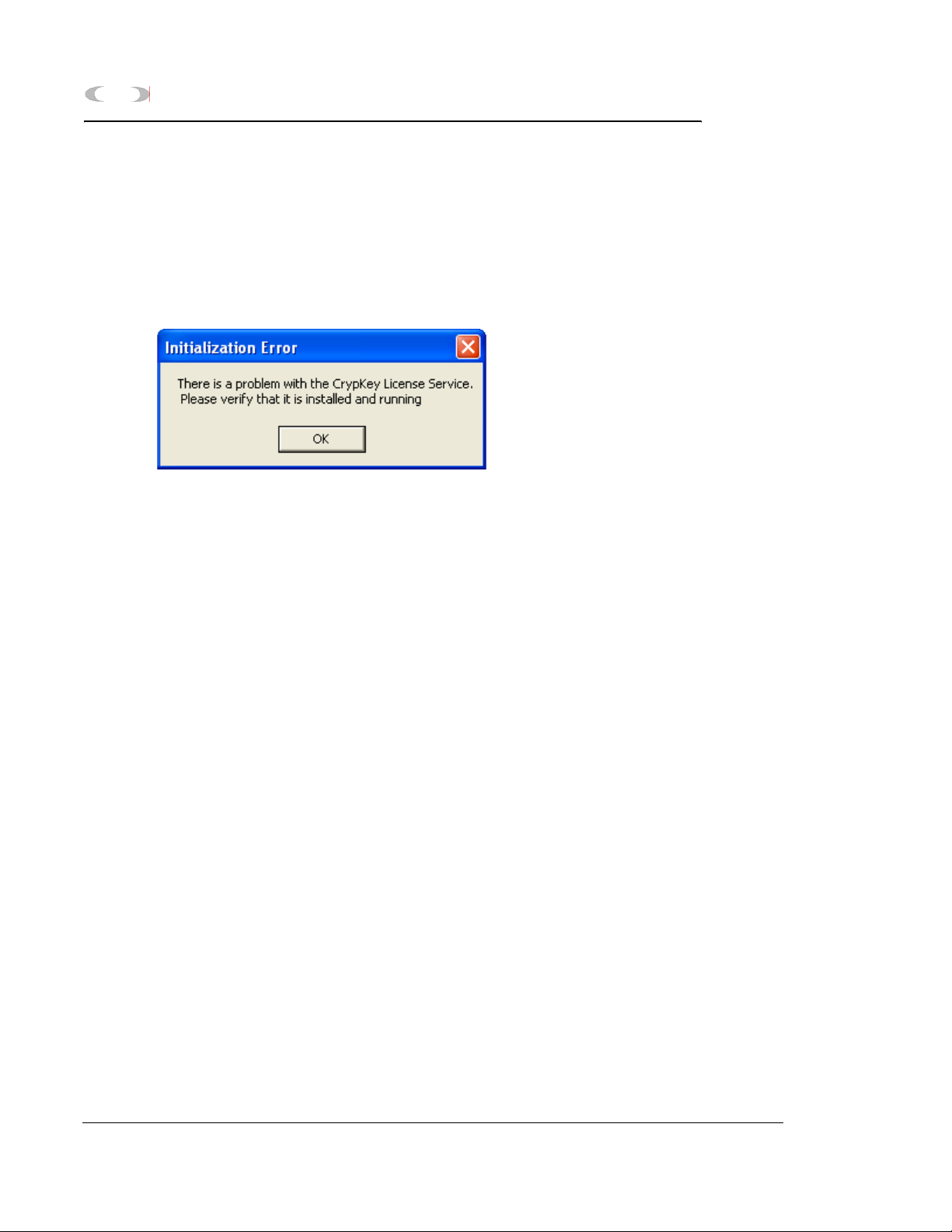

2.3 INSTALLING THE CRYPKEY LICENSE SERVICE FOR MON2000 PLUS

The CrypKey License Service must be installed

on all NT-based systems. If you try to run

MON2000 PLUS before installing the CrypKey

License Service, an error will result.

To install the CrypKey License Service, do the

following:

MON2000

1. After installing MON2000 PLUS, the

program folder should display

automatically; if it doesn’t, open Windows®

Explorer® and access the MON2000 PLUS

program folder.

2. Double-click the SETUPEX.EXE file.

MON2000 PLUS can now be started. You have

30 days to evaluate the application. Once the

trial period expires, you must obtain a license

to continue to use MON2000 PLUS.

for more information, refer to the MON2000

PLUS Quick Start Guide (3-9000-743).

2.4 COPYING MON2000 TO DISKS

Use this procedure to copy the MON2000

installation files to 3 floppy disks for future

installation.

Installing the CrypKey License Service for MON2000 PLUS JULY 2010

Page 31

MON2000

INSTALLATION AND SETUP 2-5

1. Label 3 blank formatted 3.5-inch floppy

disks “MON2000 Install Disk 1”, “MON2000

Install Disk 2”, and “MON2000 Install Disk

3”.

2. Place the MON2000 CD in your CD-ROM

drive.

3. Launch Windows® Explorer®.

4. Ensure that the Show all files option in

Windows® Explorer® is selected.

(a) Use the View > Folder Options menu to

access the Folder Options dialog.

(b) Click the View tab.

(c) In the Advanced Settings pane, find the

gray folder icon labeled Hidden Files.

(d) Click the Show all files radio button.

(e) Click the button.

5. Use the Windows

Explorer® directory tree

®

to open the MON2000 Installation Files

folder on your CD.

6. Place the “MON2000 Install Disk 1” in your

floppy drive.

JULY 2010 Copying MON2000 to Disks

Page 32

2-6 INSTALLATION AND SETUP

7. Open the Disk1 folder on your CD.

8. Copy all files from the Disk1 folder to the

“MON2000 Install Disk 1” floppy.

9. Remove the “MON2000 Install Disk 1” from

your floppy drive.

10.Repeat Steps 5 through 8 to copy the Disk2

and Disk3 folders to your “MON2000 Install

Disk 2” and “MON2000 Install Disk 3”

floppy disks.

11.Remove the MON2000 CD from your

CD-ROM drive.

2.5 TRANSFERRING A MON2000 PLUS LICENSE

To physically transfer the license file from one

computer to the other you will need a

removeable storage medium such as a 3.5-inch

floppy disk or a USB flash drive. Also, there

must be a licensed version on MON2000 PLUS

installed on the source computer and an

unlicensed version of MON2000 PLUS on the

targeted computer.

MON2000

1. On the target computer, if using a floppy

disk, insert it into the disk drive; if using a

flash drive, insert it in to a USB slot.

Transferring a MON2000 PLUS License JULY 2010

Page 33

MON2000

INSTALLATION AND SETUP 2-7

2. Start MON2000 on the target computer.

The License Configuration screen displays.

3. Select Transfer in from another

computer... from the License menu. The

JULY 2010 Transferring a MON2000 PLUS License

Page 34

2-8 INSTALLATION AND SETUP

Transfer License In (Step 1 of 3) screen

displays.

MON2000

4. Click Browse to select a disk path to the

removeable storage medium that holds the

license file. Click OK to accept your

selection.

Transferring a MON2000 PLUS License JULY 2010

Page 35

MON2000

INSTALLATION AND SETUP 2-9

5. Click Next. The Transfer License In (Step 2

of 3) screen displays.

6. Remove the removeable storage medium

from the targeted computer and insert it

into the source computer.

7. Launch MON2000 PLUS on the source

computer. When the startup screen

displays, press Enter. The License

JULY 2010 Transferring a MON2000 PLUS License

Page 36

2-10 INSTALLATION AND SETUP

Configuration screen displays with the

message “Unlimited license”.

MON2000

8. Select Transfer out to another

computer... from the License menu of the

Transferring a MON2000 PLUS License JULY 2010

Page 37

MON2000

INSTALLATION AND SETUP 2-11

License Configuration screen. The Transfer

License Out (Step 1 of 2) screen displays.

9. Click Browse to select a disk path to the

removeable storage medium that holds the

license file. Click OK to accept your

selection.

JULY 2010 Transferring a MON2000 PLUS License

Page 38

2-12 INSTALLATION AND SETUP

10.Click Next. The Transfer License Out (Step

2 of 2) screen displays.

MON2000

Transferring a MON2000 PLUS License JULY 2010

Page 39

MON2000

INSTALLATION AND SETUP 2-13

11.Click Finish. MON2000 PLUS on the

source computer is no longer licensed.

12.Remove the removeable storage medium

from the source computer and reinsert it

into targeted computer.

JULY 2010 Transferring a MON2000 PLUS License

Page 40

2-14 INSTALLATION AND SETUP

13.On the targeted computer, click Next on the

Transfer License In (Step 2 of 3) screen. The

Transfer License In (Step 3 of 3) screen

displays.

MON2000

Transferring a MON2000 PLUS License JULY 2010

Page 41

MON2000

INSTALLATION AND SETUP 2-15

14.Click Finish. The License Configuration

screen displays.

MON2000 PLUS is now licensed for unlimited

use on the targeted computer.

2.6 UNINSTALLING MON2000

To uninstall MON2000 using Windows® 95,

Windows® 98, Windows® 2000 or Windows®

NT,

1. Click the button (see the taskbar).

JULY 2010 Uninstalling MON2000

Page 42

2-16 INSTALLATION AND SETUP

2. Click Settings and then Control Panel. The

Control Panel dialog appears.

3. Double-click the Add/Remove Programs

icon.

MON2000

If using Windows XP, click the Start button, then

Add/Remove Programs.

4. The Add/Remove Program Properties dialog

appears.

5. Select MON2000 and click the

button.

Uninstalling MON2000 JULY 2010

Page 43

MON2000

INSTALLATION AND SETUP 2-17

6. Windows® displays the following

confirmation dialog.

7. Click the button to continue.

Windows® deletes the program files only.

Any files shared by other programs or

created by the user are not deleted.

Click the button to abort and

return to the Add/Remove Program

Properties dialog.

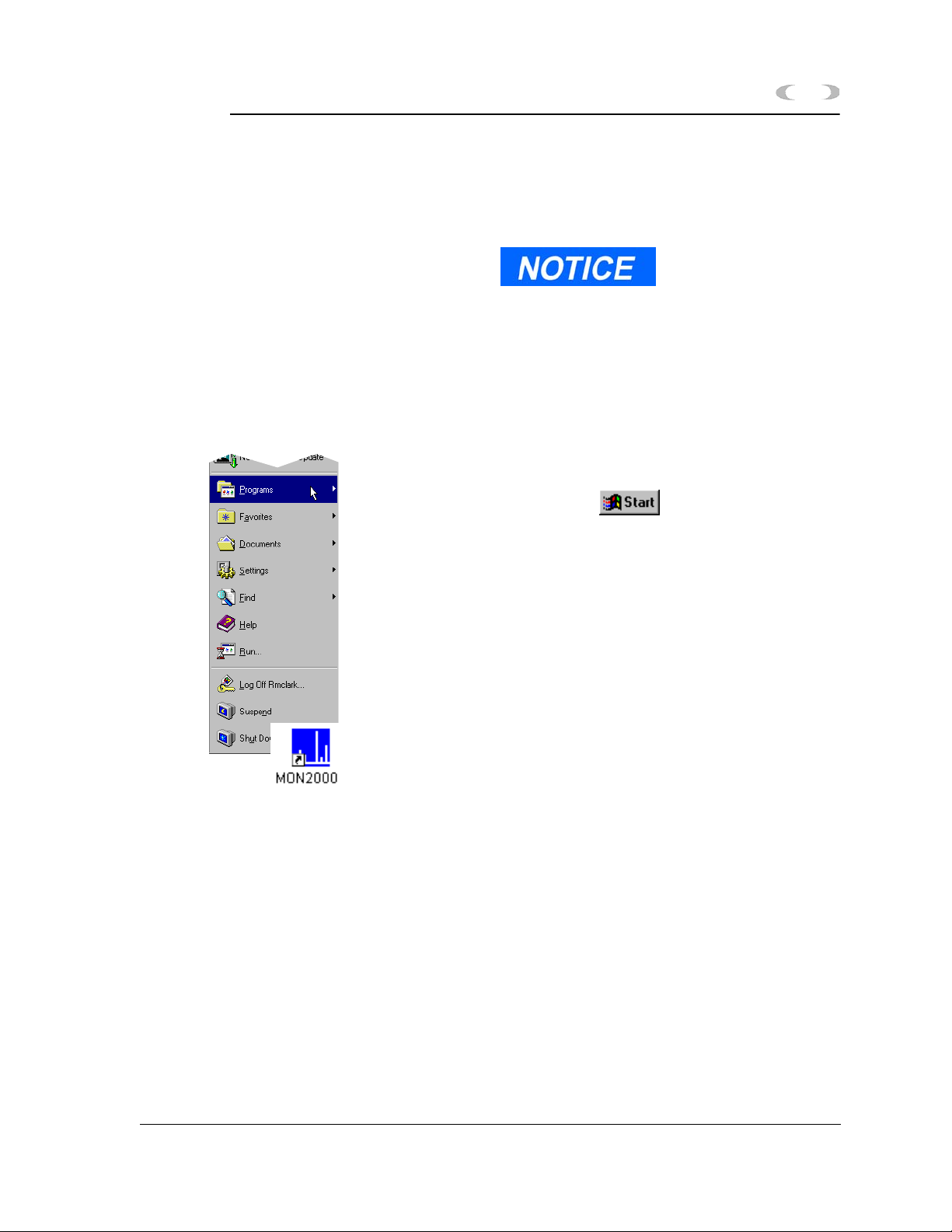

2.7 STARTING MON2000

To start MON2000 after a successful

installation,

Use the Windows® Start menu (Start >

Programs >MON2000 menu) by clicking the

button.

Double-click the MON2000 icon automatically

created on your desktop during installation.

You cannot access the MON2000 functions

until you are successfully logged on.

To start MON2000 directly from the executable

file, use the directory you specified when

installing MON2000. Note that c:\Program

JULY 2010 Starting MON2000

Page 44

2-18 INSTALLATION AND SETUP

Files\MON2000\MON2000 is the default

setting.

2.8 PERFORMING YOUR FIRST LOGON

2.8.1 The Initial Logon

MON2000

Each new GC unit is shipped with one super

user named “Emerson”. After logon, ensure

that this user name appears in the Users list as

a super user (see Section 2.11.1).

To log on for the first time,

1. Start the MON2000 software program by

clicking the desktop icon or by using the

Windows

Start menu (see Section 2.7).

®

2. Click in the User Name data field.

3. Type emerson. Note that the user name is

not case-sensitive.

A PIN is not required for

the initial logon.

Performing Your First Logon JULY 2010

Page 45

MON2000

INSTALLATION AND SETUP 2-19

4. When you have successfully logged on, the

MON2000 main window appears.

2.8.2 Registering MON2000

After your have successfully performed your

initial logon (see Section 2.8.1), MON2000

automatically prompts you to register your

copy of MON2000 software. An active Internet

connection is required for registration.

Registering your MON2000 software allows

you to receive information about free updates

and related products. A direct link to the

Emerson Internet website is provided via the

File > Update MON2000 menu.

You may choose to postpone registration. You

can register at any time via the File > Register

MON2000 menu.

JULY 2010 Registering MON2000

Page 46

2-20 INSTALLATION AND SETUP

1. Use the File>Register MON2000 menu.

Follow the prompts in the Register

MON2000 dialog to input your name,

MON2000 serial number (located inside the

CD jewel case), and other relevant

information.

2. Click the button to continue.

MON2000

3. Choose the desired registration method by

clicking the corresponding radio button.

4. Click the button.

You must have an active

internet connection to

register via the website.

Registering MON2000 JULY 2010

Page 47

MON2000

INSTALLATION AND SETUP 2-21

2.8.3 Update MON2000

Provided there is an active internet connection

to the computer on which MON2000 is

installed, clicking the File>Update MON2000

submenu sends the user to the Emerson®

Chromatograph Controllers website

(www.emersonprocess.com/daniel/products/GC/

Controllers/Productdetail.htm).

Updating the software

requires a previously installed,

registered copy of MON2000.

Use the File>Update MON2000 menu to

download the latest versions of MON2000 and

the BOS software programs.

To download the latest versions of the software,

1. Use the computer on which MON2000 is

installed and connect to the Internet.

Minimize the Internet window.

2. From MON2000, select the File>Update

MON2000 menu. This opens the Emerson

Chromatograph Controllers website

(www.emersonprocess.com/daniel/products/

GC/Controllers/Productdetail.htm).

3. From the Emerson Chromatograph

Controller website, you can download the

latest MON2000 and BOS updates, view

and/or download catalogs, brochures,

equipment specification sheets, product

manuals, drawings, application notes, and

white papers. Other links to products and

services are also available.

JULY 2010 Update MON2000

Page 48

2-22 INSTALLATION AND SETUP

2.9 CHECKLIST FOR SETTING UP MON2000

To ensure optimum performance,

• Configure your system security (see

Section 2.11.1).

Verify that you have assigned a password to

the super user, and/or created a secure

system Admin account.

• Configure how MON2000 will save your

analytic and diagnostic information (see

Section 2.16.2).

• Establish communications between

MON2000 and the GC unit (see Section 2.10

and Section 5.17).

MON2000

2.10 COMMUNICATIONS

MON2000 can communicate to the GC unit

locally via a serial port cable, Ethernet

connection, or remotely via a modem. If

performing a remote connection, ensure that

you have configured the PC modem first.

To configure the communication and serial port

settings for the GC unit, see Section 5.17.

2.10.1 Connect to the GC Unit

1. Use the File > Connect menu or click the

toolbar icon to access the Select GC for

Connect menu.

2. Double-click the desired GC unit.

Checklist for Setting Up MON2000 JULY 2010

Page 49

MON2000

If another user is already

connected to the GC, the unit

will “lock out” the second user.

When a PC connection is

active, the GC Controller front

panel will indicate a “System

Lockout”. This status times out

after 10 minutes.

INSTALLATION AND SETUP 2-23

3. MON2000 appears the connection status

dialog while dialing the selected unit.

The messages “Reading dictionary”,

“Reading GC Application data”’ and “Logon”

appears in the status bar and an

information screen appears.

Once connected, the name of the GC unit

displays in the lower left hand corner of the

MON2000 main window.

2.10.2 Disconnect from GC Unit

Use this process to terminate an active PC

connection to a GC unit.

The menu-driven procedure for disconnecting

is completely optional. MON2000 intelligently

and automatically disconnects when you exit

MON2000 or connect to a second GC

Controller.

1. Use the File > Disconnect menu or click the

toolbar icon to access this function.

2. MON2000 automatically terminates all

open connections.

JULY 2010 Disconnect from GC Unit

Page 50

2-24 INSTALLATION AND SETUP

A Terminating communications message

appears in the status bar.

If MON2000 does not detect an active

connection to terminate, an “Invalid

selection or not downloaded” message

appears.

2.11 CUSTOMIZING MON2000

Use the following functions to customize users,

the directory of GC applications, and PC

communications parameters.

2.11.1 Configure Users

Use this function to create new user accounts

or edit the existing account data. An extra level

of security is assigned to the File>Users

submenu. The File>Users submenu can only be

accessed by first entering a Password into a

dialog box titled 'Enter Administrator

Password'. After gaining access to the Users

dialog, the operator then has the ability to

create new user accounts or edit existing

account data. This feature is not available to

the 'Regular' and 'Read Only' user.

MON2000

1. Use the File > Users menu to access this

function.

2. The Enter Administrator Password dialog

box appears.

Note that the default password admin is

not case sensitive. This password is used as

a security measure to deny unauthorized

Customizing MON2000 JULY 2010

Page 51

MON2000

INSTALLATION AND SETUP 2-25

users access to the MON2000 Users

submenu, which allows Super users to add,

edit, or change security levels.

Click the button. Then the Users

dialog appears.

3. Use the File>Change Administrator menu

to change the Administrator password.

The Change Administrator Password dialog

box appears.

Insert the old password, enter the new

password and confirm the change.

Then, click the button to apply

your changes.

JULY 2010 Configure Users

Page 52

2-26 INSTALLATION AND SETUP

4. To configure a new user or edit existing user

parameters,

(a) Click the appropriate Name cell and type

the desired user name.

Note that the user name is not casesensitive but punctuation (e.g., commas

or spaces) is preserved.

(b) Click the appropriate Type cell and use

the provided combo box to select the

desired security level. Note that there

should be at least one Super user.

(c) Click the appropriate PIN cell and type

the desired PIN for this user. Note that

the PIN is limited to 12 numeric

characters.

MON2000

Super users can write changes

to the GC unit, configure

MON2000, and access the

Users function.

Regular and Read only users

can only view data.

If no PIN is entered, the user can log on

to the MON2000 software program or

the GC unit (via the front panel) with

the assigned user name – that is, no

password will be required.

5. To write user data to the online GC unit,

(a) Click the or press

the F2 key.

(b) MON2000 writes the data to the GC

Controller.

6. Click the button to apply your

changes and return to the main screen.

Click the button to exit and

return to the main screen without applying

your changes.

Configure Users JULY 2010

Page 53

MON2000

INSTALLATION AND SETUP 2-27

2.11.2 Set Up GC Directory

Do not delete any currently

used applications from the GC

Directory. If an entry is

inadvertently deleted, you

may need to reinstall the

application software for that

GC.

This function allows you to set up a directory

listing of all GC units MON2000 can control for

this application. From the GC Directory, you

can configure the PC serial port communication

parameters for a specific GC unit.

Data entered in the GC Directory is stored in

the “Gcdir.dat” file (...\GC\BIN\). The Station

Name is the user assigned name to a GC

location. As GC applications are installed,

MON2000 adds the application name to the GC

Directory.

The GC unit name shown in the GC Status Bar

of the MON2000 main window is entered via

the System dialog (see Section 5.1).

To edit the GC directory,

1. Use the File > GC Directory menu to access

this function.

2. The GC Directory dialog appears.

JULY 2010 Set Up GC Directory

Page 54

2-28 INSTALLATION AND SETUP

3. Press the F1 key to open the MON2000

Application help file for detailed

information about these settings.

MON2000

4. MON2000 is configured with two default

directories:

• Default 1: parameters are set for 9600

baud rate

5. Default 2: parameters are set for 19200

baud rate.

6. Click the appropriate Com ID cell and type

the Modbus communication identification

number (set by DIP switch positions on the

Set Up GC Directory JULY 2010

Page 55

MON2000

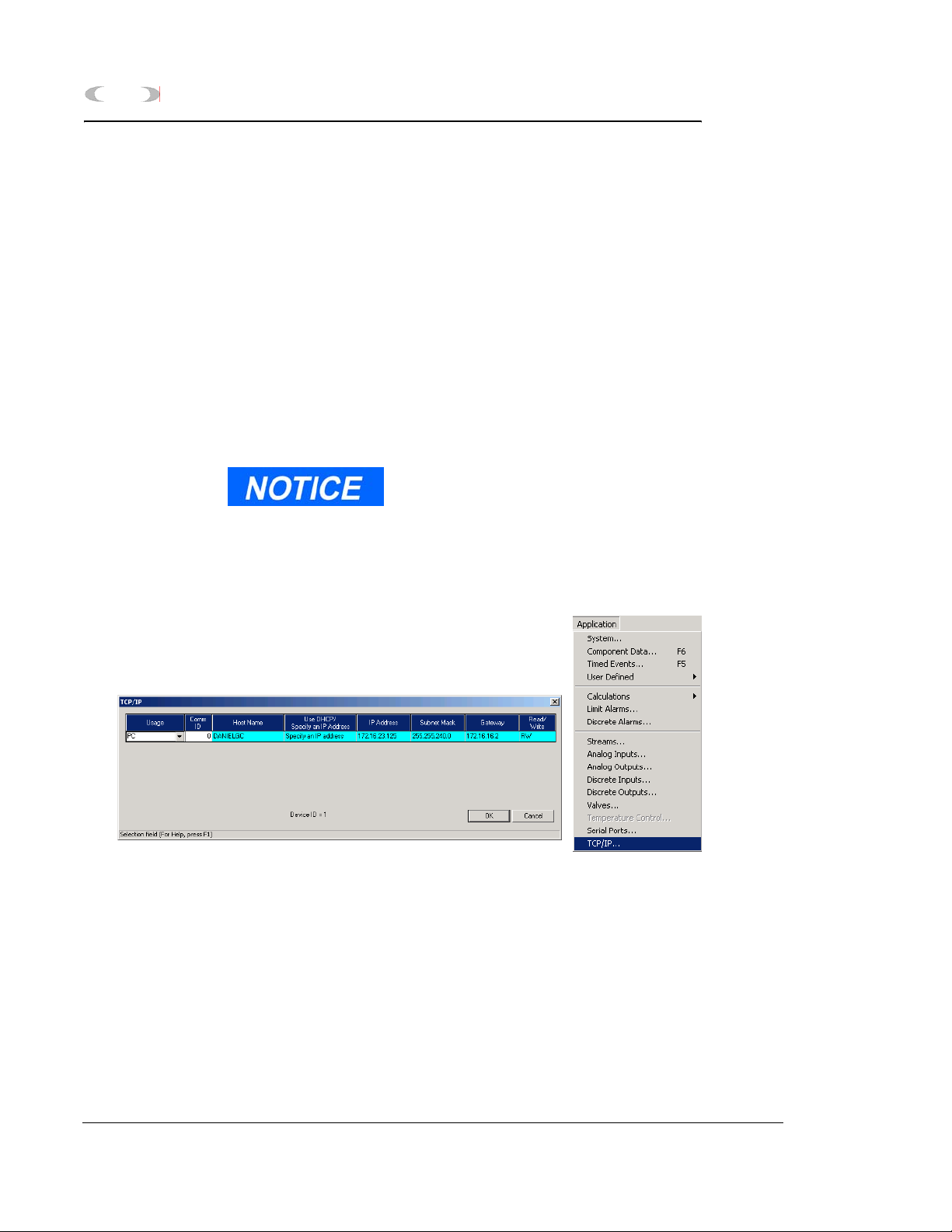

INSTALLATION AND SETUP 2-29

GC Controller system interface board) for

the GC unit.

To successfully connect to the GC unit, the

COM IDs specified via the File>GC

Directory and the Application>Serial Ports

dialogs must match. See Section 5.17.1 for

more information.

7. Click the Comments cell to enter any helpful

information regarding a particular GC unit,

such as location or purpose.

8. Use the dynamic pull-down menus to select

the desired PC Port, Baud Rate, Data Bits,

Stop Bits, Parity, and Handshaking

settings.

The following parameters support an auto-detect

setting: Baud Rate, Data Bits, Stop Bits, Parity,

Protocol.

Set any of these parameters to “?” (autodetect) and

MON2000 will conform to the settings used by the GC

unit.

9. Use the provided cells to input RTS On

Delay, RTS Off Delay, and Extra Delay

values.

The Extra Delay field accepts numerical

values (0 to 9000 milliseconds) for

additional time to be added to the current

communication timeout delay.

10.Use the Protocol pull-down menu to select

the desired Modbus communications

protocol.

11.If you plan to connect remotely to the GC

unit via a modem or Ethernet connection,

use the Connection Type (Direct/Remote)

JULY 2010 Set Up GC Directory

Page 56

2-30 INSTALLATION AND SETUP

pull-down menu for a “Direct Connect”

option or a previously configured modem.

2.11.3 Dial-up Connection

Use this command to run the Dial-up dialog to

configure the GC Controller modem. The

default properties from Windows® Control

Panel are used so you must ensure that the

modem connects at the GC Controller’s

configured baud rate. It may be necessary to

enter a modem initialization string.

The Direct Connect option allows you to connect from the PC

to the GC Controller via a serial port, per its default settings.

MON2000

If you select a modem, the modem property dialog appears,

allowing you to change its attributes.

To configure the modem and make a

connection,

1. Use the File>GC Directory menu, and the

GC Directory appears.

2. Click the Station Name data field and click

the Modem Properties button or press the

F2 button.

Dial-up Connection JULY 2010

Page 57

MON2000

INSTALLATION AND SETUP 2-31

3. The Modem Properties dialog appears and

the General Data Connection Modem

Preferences are activated.

The General Data default settings are:

Table 2-1 General Data Connection Preferences

Port Speed

Data Protocol

Compression

Flow Control

19200

Disabled

Disabled

None

JULY 2010 Dial-up Connection

Page 58

2-32 INSTALLATION AND SETUP

4. Click the Advanced tab to configure the

Hardware settings.

MON2000

The Advanced Data default settings are:

Table 2-2 Advanced Data Connection Preferences

Data Bits

Parity

Stop Bits

8

None

1

5. Click the button to apply your

changes, or click the button to

discard the changes and return to the GC

Directory dialog.

Dial-up Connection JULY 2010

Page 59

MON2000

INSTALLATION AND SETUP 2-33

6. Next, from the GC Directory dialog, scroll

over to configure the following parameters:

The Baud Rate, Data Bits, and Stop Bits parameters

were configured above.

Table 2-3 GC Directory Dialog Default Settings

Heading Pull-down Menu Selection

PC Port COM1, COM2,COM3

Handshaking None

RTS On Delay 0

RTS On Delay 0

Extra Delay 0 (See note)

Connection Type

(Direct/Remote)

Telephone Complete number

Server Type IP Address

Retries

• Modem

• IP Address

IC Multiplier 10

Direct Connection

Modem

(Area Code) (XXX-XXXX)

XXX.XX.XX.XXX

(10 digits)

5

3

JULY 2010 Dial-up Connection

Page 60

2-34 INSTALLATION AND SETUP

The Extra Delay is enabled for Ethernet connections.

The default value is “0” and the default 30 seconds timeout is used. If

the value is changed to greater than “0”, the value is used as the

timeout. The entered value is multiplied by 10 inside MON2000,

therefore the maximum timeout is 100,000 ms or 100 seconds (ex: If

timeout value needs to be 15 seconds, the user should enter 1,500).

MON2000

Dial-up Connection JULY 2010

Page 61

MON2000

INSTALLATION AND SETUP 2-35

7. Click the button to accept the

changes. While connecting, MON2000 dials

the number, attempts to connect via the

selected modem and displays progress

messages. A message box appears when a

connection has been made or if the attempt

to connect fails.

Once a connection has been established and

while MON2000 remains connected via the

modem, the Connect button is disabled and

the Disconnect button is enabled.

If the connection fails at any time,

MON2000 displays a message in the GC

Status bar that it has been disconnected.

You can end the connection from the

File>Disconnect menu, by clicking the

disconnect icon on the MON2000 toolbar, or

by exiting MON2000.

If you are using the Modbus RTU protocol, the values for baud

rate, data bits, stop bits, and parity must match the settings

you configured in the Modem Properties dialog.

These values are required to correctly calculate character

timing.

When you start MON2000 after the

parameters are established, you can connect

to the GC via the File>Connect menu or by

clicking the Connection icon on the

MON2000 toolbar.

JULY 2010 Dial-up Connection

Page 62

2-36 INSTALLATION AND SETUP

2.11.4 Modem Initialization Strings/Setup

This section provides “examples” of modem

initialization strings and setups that have been

tested and proven operable. This string of text

characters, known as 'AT commands', has

special meaning to the PC modem and is used

by the modem for every telephone connection

made to a selected GC unit.

To edit or enter a modem initialization string,

use the button and use the Control

Panel > Modems > General > Properties >

Connection > Advanced to access the Advanced

Modem Connection Settings dialog. Enter the

modem initialization string in the Extra

Settings field.

MON2000

Modem Initialization Strings/Setup JULY 2010

Page 63

MON2000

INSTALLATION AND SETUP 2-37

By default, MON2000 provides a modem

initialization string that serves the purpose for

most Hayes-compatible modems. Therefore, in

most cases, you need not enter a different

string.

However, for some modems, you may want to

consult the following pages which document

initialization strings and modem setups that

have been field-tested.

The default initialization string that MON2000 provides is

sent to the PC modem first. Then the custom initialization

string you provide is sent. In this manner, MON2000 sets the

modem parameters that it requires, while you can customize

the modem's operation to respond to special conditions.

Once the optimum modem initialization string has been

determined, it should need no further revision unless a

different brand or model of modem is installed.

Black Box - Modem 325

During development of the GC Controller, a

Black Box Modem 325 was used to test modem

communications with the GC unit. For that test

and that modem, the modem initialization was

set as follows:

\N0\C0\Q0 (where 0 = zero)

JULY 2010 Modem Initialization Strings/Setup

Page 64

2-38 INSTALLATION AND SETUP

Interpretation of the AT commands for that

particular modem was as follows:

• \N0 = normal mode; no error control; data

is buffered (versus ‘direct mode,’ ‘reliable

mode, ’or ‘auto reliable mode’)

• \C0 = disable auto reliable buffer (versus

‘buffer data for 4 seconds or 200 characters’)

• \Q0 = disable flow control (versus ‘enable

XON/XOFF flow control,’ ‘enable unilateral

CTS flow control,’ or ‘enable bilateral CTS/

RTS flow control’)

U.S. Robotics Sportster

The following setup for U.S. Robotics Sportster

28.8 Kbps external FAX-modems was verified

at the GC assembly and checkout lab:

MON2000

• At the GC Controller, the modem DIP

switches were set to 5 and 8 UP, the rest

DOWN.

• At the PC, the modem DIP switches were

set to 2, 4, 6, and 7 UP, the rest DOWN.

Modem Initialization Strings/Setup JULY 2010

Page 65

INSTALLATION AND SETUP 2-39

MON2000

With these switch settings, initialization string

&F was required. See Table 2-4 for further

explanation of these switch settings and the

parameters they control.

Table 2-4 DIP Switch Settings for U.S. Robotics Sportster Modem

Switch Function At GC At PC

1 UP (off) – Normal DTR; computer must provide

DTR signal for modem to accept commands.

DOWN (on) – Modem ignores DTR.

2 UP (off) – Verbal (word) results.

DOWN (on) – Numeric results.

3 UP (off) – Suppress result codes.

DOWN (on) – Enable result codes.

4 UP (off) – Display keyboard commands.

DOWN (on) – Suppress echo.

5 UP (off) – Modem answers on first ring or higher.

DOWN (on) – Disable auto answer.

6 UP (off) – Modem sends carrier detect (CD) signal

on connect, and drops CD on disconnect.

DOWN (on) – CD always on.

7 UP (off) – For power-on and ATZ reset, the Y or Y1

configuration is used from user-defined nonvolatile

memory (NVRAM).

DOWN (on) – For power-on and ATZ reset, the

generic template, &F0, is used from read only

memory (ROM).

8 UP (off) – Disable AT command set recognition.

DOWN (on) – Enable AT command set recognition.

JULY 2010 Modem Initialization Strings/Setup

Page 66

2-40 INSTALLATION AND SETUP

GVC/MaxTech 28.8 Kbps Modem

The following setup for GVC 28.8 Kbps

external Voice/Data/FAX modems was verified

at Daniel Canada. At the GC Controller:

To make these settings for the modem at the GC Controller,

you will need to use a terminal program (such as ProComm o

other commercial modem software) to input the “AT”

commands to the modem before connecting it to the GC

Controller.

AT&F5 Factory default with v.42bis flow control

disabled (must be first).

ATB8 9600 baud

MON2000

Or

ATB11 19200 baud

AT&D0 Modem ignores DTR (not necessary if using a

cable that incorporates the DTR signal from

the Controller).

ATM0 Turn OFF speaker.

ATS0=n n is number of rings for auto answer (e.g.,

ATS0=1, ATS0=2, etc.).

AT&C0 Force carrier detect high

AT%C0 Turn OFF compression.

If compression is turned ON with AT%C1,

or OFF with AT%C0, then the modem at

other end should match.

AT&W0 Write to stored profile “0” (zero).

AT&Y0 Use stored profile “0” (zero) when turned on.

Modem Initialization Strings/Setup JULY 2010

Page 67

MON2000

INSTALLATION AND SETUP 2-41

At the PC, use &F5%C1M0 which indicates

a factory default with v.42bis flow control

disabled / compression ON / speaker OFF.

2.12 2350 TO 2350A RETROFIT INSTRUCTIONS

The 2350A GC Controller CPU assembly has

been designed to include all digital I/O and

COM3 and COM4 serial ports. This eliminates

the requirement (and additional cost) for an I/O

assembly or DSPI/O assembly.

In addition, BOS is now resident in the

DiskOnChip, instead of an EPROM set. The

DiskOnChip provides additional expanded

memory for archiving data, instead of having to

purchase a memory expansion board assembly.

The BOS file in the DiskOnChip may be

upgraded in the field through MON2000.

Optional boards may be plugged directly into

the PC/104 Bus (connectors J19 and J20) on the

CPU board assembly. The COM4A board

provides four additional serial ports (COM5

through COM8). A modem board and/or

Ethernet board may be also be plugged directly

into the PC/104 Bus for additional

communications requirements.

JULY 2010 2350 to 2350A Retrofit Instructions

Page 68

2-42 INSTALLATION AND SETUP

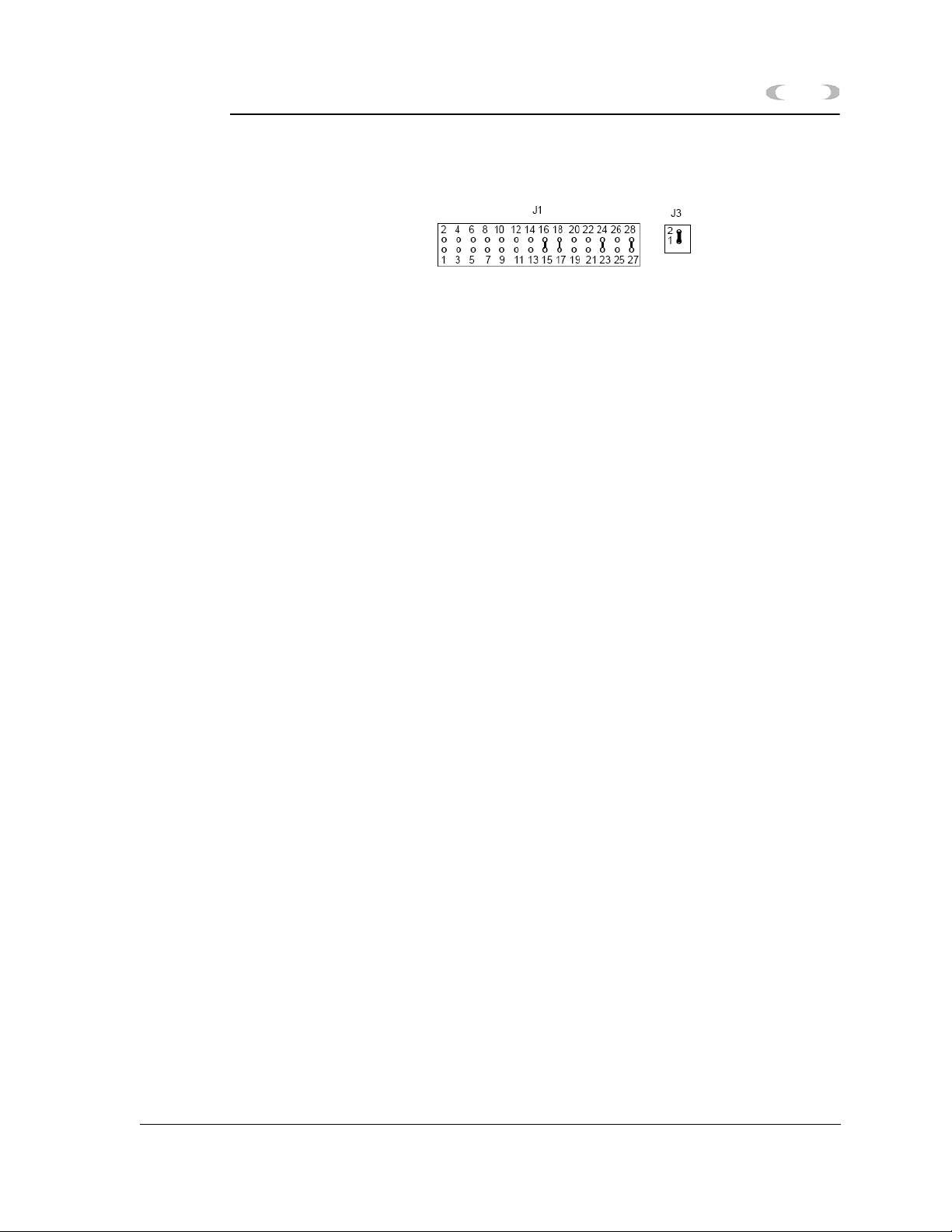

The PC/104 Bus is designed to allow any

combination of option boards to be installed in

any order, with the exception of the CSA

approved Radicom modem board which must be

the top board in the assembly. (see Figure 2-1).

MON2000

Figure 2-1 2350A Controller Card Cage Assembly

If you are using the CSA approved Radicom modem;

ensure that it is the top card in the card cage assembly.

The connection configuration of the Radicom modem

requires installation at the top of the assembly.

2350 to 2350A Retrofit Instructions JULY 2010

Page 69

INSTALLATION AND SETUP 2-43

MON2000

2.13 CONVERSION PROCESS

Use the following process to retrofit a 2350 GC

Controller to a 2350A GC Controller.

1. At the GC Controller site, remove the

Controller enclosure's front panel.

SERIOUS PERSONAL INJURY OR DEATH POSSIBLE

Before removing the unit cover from the GC Controller, make certain the power supply

switch is OFF and the AC power cord is disconnected. Observe all safety precautions

when you are working in a hazardous environment.

Failure to observe all safety precautions could result in serious injury or death.

(a) For the explosion-proof Controller, the

front panel is secured by 16 screws.

Remove those screws first.

(b) Then carefully lower the front panel on

its bottom hinges. The front panel is

heavy, so make sure it does not drop and

cause damage.

(c) For the rack mount Controller, the rear

of the enclosure is open; it allows access

for most field wiring procedures without

removing the enclosure.

2. Locate the GC Controller's Terminal Board

for Field Wiring (TB). The TB is attached to

the GC Controller's card cage assembly,

facing the enclosure's front panel. (In the

rack mount Controller, the TB faces

outward toward the rear of the enclosure.)

3. Loosen the six screws that secure the TB.

Then unplug the TB from its connections at

the back, top of the board.

JULY 2010 Conversion Process

Page 70

2-44 INSTALLATION AND SETUP

4. Lower the TB down and out of the way, held

in place by its ground straps at the bottom

of the board. This exposes the Card Cage

Assembly.

5. Loosen the four screws that secure the Card

Cage Assembly to the chassis. Then remove

the Card Cage Assembly away from its

chassis mount so that it is easy to work on.

6. Locate the System Interface and Driver

board. It is mounted to the top of the Card

Cage Assembly.

7. Remove all cables connected to the System

Interface Board (P/N 3-2350-005,

P/N 3-2350-022, or P/N 3-2350-023).

8. Remove the I/O48 Board assembly (drawing

P/N BE-12973) and cables from the top slot

of the Cage Card Assembly. This board is

not used on the 2350A GC Controller.

MON2000

9. Remove the CPU Board assembly (P/N CE-

19281) and cables from the second slot of

the card cage assembly. This board is not

used on the 2350A GC Controller.

Conversion Process JULY 2010

Page 71

MON2000

INSTALLATION AND SETUP 2-45

10.Remove the DSPI/O board assembly

(drawing P/N CE-12976) and cables from

the third slot of the card cage assembly.

This board is not used on the 2350A GC

Controller.

11.Remove any other optional boards, such as

memory expansion boards and associated

cables. These parts are not used on the

2350A GC Controller.

12.Leave the Analog Board assembly (drawing

P/N BE-18044) with attached cable in the

card cage. This board is used on the 2350A

basic configuration.

13.Change the fuse in the in-line fuse holder

from 1 amp to the 2.5 amp, Slo-Blo fuse

provided. The fuse is located in the cable (P/

N 2-3-2350-069) between the power supply

and the System Interface Board.

14.Ensure that DIP Switches 6, 7, and 8 of S1

are all in the "OFF" position. If the 2350A is

powered up with S8 in the OFF position, it

will delete the current application

(commonly called a "Cold Start").

15.To inspect or change the GC Controller's

COM ID setup at the GC Controller site,

locate the DIP switch as described in the

following steps.

SERIOUS PERSONAL INJURY OR DEATH POSSIBLE

Before removing the unit cover from the GC Controller, make certain the power

supply switch is OFF and the AC power cord is disconnected. Observe all safety

precautions when you are working in a hazardous environment.

Failure to observe all safety precautions could result in serious injury or death.

16.For the explosion-proof Controller, the front

panel is secured by 16 screws. Remove those

screws first.

JULY 2010 Conversion Process

Page 72

2-46 INSTALLATION AND SETUP

(a) Then carefully lower the front panel on

its bottom hinges. The front panel is

heavy, so make sure it does not drop and

cause damage. The DIP switch is located

on the lower left side of the front panel

(see Figure G-2).

MON2000

Figure 2-2 Explosion-Proof Controller Dip Switch

Conversion Process JULY 2010

Page 73

MON2000

INSTALLATION AND SETUP 2-47

17.For rack mount and panel mount

Controllers, use a flat head screw driver to

remove the access panel on the right side of

the card cage assembly (see Figure 2-3).

Figure 2-3 Right Side View Rack and Panel Mount Units

18.Inspect or change the DIP switch settings as

necessary.

(a) See Table 2-5 as a guide.

(b) Make sure you record in the GC