Page 1

Installation Manual

MMI-20020979, Rev AB

Micro Motion® Gas Density Meters (GDM)

Fiscal gas density measurement

May 2015

Page 2

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product. The EC declaration of

conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available on

the internet at www.micromotion.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive can be found on the internet at

www.micromotion.com/documentation.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the transmitter

configuration manual. Product data sheets and manuals are available from the Micro Motion web site at

www.micromotion.com/documentation.

Return policy

Micro Motion procedures must be followed when returning equipment. These procedures ensure legal compliance with

government transportation agencies and help provide a safe working environment for Micro Motion employees. Failure to follow

Micro Motion procedures will result in your equipment being refused delivery.

Information on return procedures and forms is available on our web support system at www.micromotion.com, or by phoning the

Micro Motion Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136 666 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Contents

Chapter 1 Planning ...........................................................................................................................1

1.1 Installation checklist .......................................................................................................................1

1.2 Best practices .................................................................................................................................2

1.3 Recommended sample flow rate ....................................................................................................3

1.4 Power requirements .......................................................................................................................4

1.5 Installation requirements for the thermo-well pocket .................................................................... 5

1.6 Recommended installations for gas density applications ................................................................6

1.7 Perform a pre-installation meter check .........................................................................................14

Chapter 2 Mounting .......................................................................................................................16

2.1 Mount the meter in the pipeline ...................................................................................................16

2.2 Connect the gas bypass lines ........................................................................................................18

2.3 Rotate the electronics on the meter (optional) .............................................................................20

2.4 Rotate the display on the transmitter (optional) ...........................................................................20

2.5 Post-installation check ................................................................................................................. 22

Chapter 3 Wiring ........................................................................................................................... 23

3.1 Available output terminals and wiring requirements .................................................................... 23

3.2 Hazardous area output wiring ...................................................................................................... 23

Chapter 4 Grounding ......................................................................................................................32

Installation Manual i

Page 4

Contents

ii Micro Motion® Gas Density Meters

Page 5

1 Planning

Topics covered in this chapter:

• Installation checklist

• Best practices

• Recommended sample flow rate

• Power requirements

• Installation requirements for the thermo-well pocket

• Recommended installations for gas density applications

• Perform a pre-installation meter check

1.1 Installation checklist

Verify the contents of the product shipment to confirm that you have all parts and

□

information necessary for the installation.

Planning

Part Quantity

Micro Motion® Gas Density Meter (GDM) 1

Accessories kit:

- M20 to 1/2-inch NPT adapter (if applicable)

- 1/2-inch NPT blanking plug

- 2.5 mm hex key

Aluminum sleeve 1

Silicon fluid 1

Thermo-well pocket kit (if applicable) 1

Calibration certificate 1

Safety instructions booklets 2

Micro Motion Product Documentation DVD 1

Make sure that all electrical safety requirements are met for the environment in

□

which the meter will be installed.

Make sure that the local ambient and process temperatures and process pressure

□

are within the limits of the meter.

Make sure that the hazardous area specified on the approval tag is suitable for the

□

environment in which the meter will be installed.

If installing the meter in a hazardous area, confirm that you have the required safety

□

barriers or galvanic isolators for your installation.

Make sure that you will have adequate access to the meter for verification and

□

maintenance.

1

Installation Manual 1

Page 6

Planning

Make sure that the process gas meets the recommended characteristics regarding

□

composition, temperature, and pressure for your installation.

Verify that you have all equipment necessary for your installation. Depending on

□

your application, you may be required to install additional parts for optimal

performance of the meter.

Follow recommended best practices for installing the GDM to account for the

□

effects of density, temperature, and pressure equilibrium.

1.2 Best practices

The following information can help you get the most from your meter.

• Handle the meter with care. Follow local practices for lifting or moving the meter.

• Ensure that the process gas is clean and dry.

• Do not use gases incompatible with the materials of construction. To prevent

corrosion of the sensing element, the process gas should be compatible with

Ni-Span-C.

• Do not expose the meter to excessive vibration (greater than 0.5 g continuously).

Vibration levels in excess of 0.5 g can affect the meter accuracy.

• Perform a Known Density Verification (KDV) check of the meter prior to installing

the meter in your system.

• Installing the meter in a bypass configuration allows you to remove the meter for

servicing or calibration without affecting the main pipeline.

• Install the meter in a thermo-well pocket to ensure the temperature of the sample

gas is equal to that of the pipeline gas. Micro Motion thermo-well pocket kits are

available for purchase.

• Minimize the length and volume of the input sample pipe to ensure an optimal

meter response time. Use 6 mm (1/4 in) instrument tubing and low-volume inlet

filters.

• Control gas flow with a needle valve mounted before or after the meter, depending

on the installation.

• Install an external coalescing filter in the sample gas inlet pipework to minimize

condensate and dust contamination.

• Verify that the filters in your system are not causing any excessive flow restrictions.

• Verify that the pressure of the process gas is approximately equal to the pipeline

pressure.

• Do not exceed more than a 10% reduction of the cross-sectional area at the point of

insertion in the pipeline to ensure minimal effect on pressure.

• Ensure that the meter and associated pipework are pressure-tested to 1½ times the

maximum operating pressure after installation.

• Install thermal insulation to the meter and the inlet and bypass-loop pipeline to

maintain temperature equilibrium between the sample and pipeline gases. Do not

insulate the transmitter (electronics) and maintain a nominal 1-in clearance

between the insulation and the transmitter housing.

2 Micro Motion® Gas Density Meters

Page 7

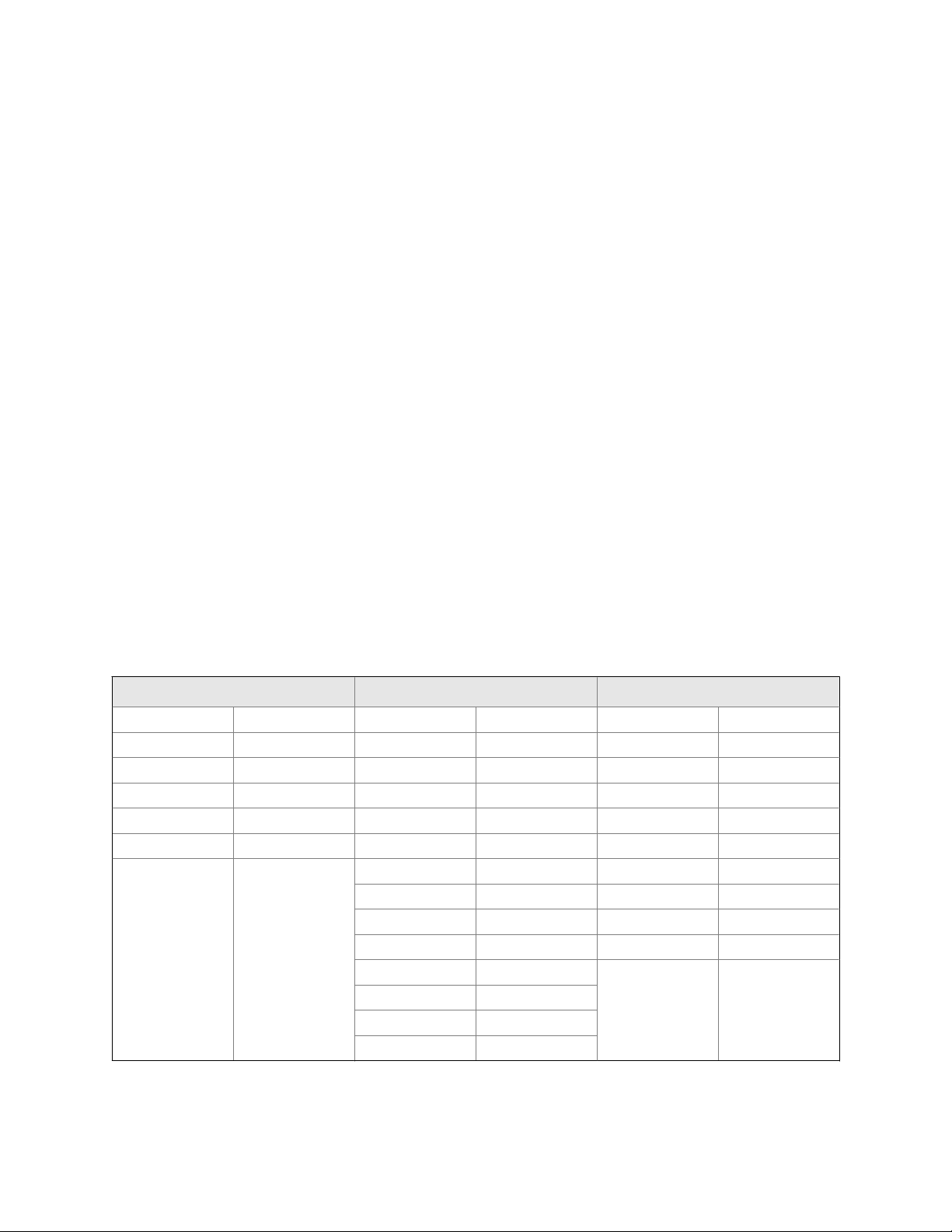

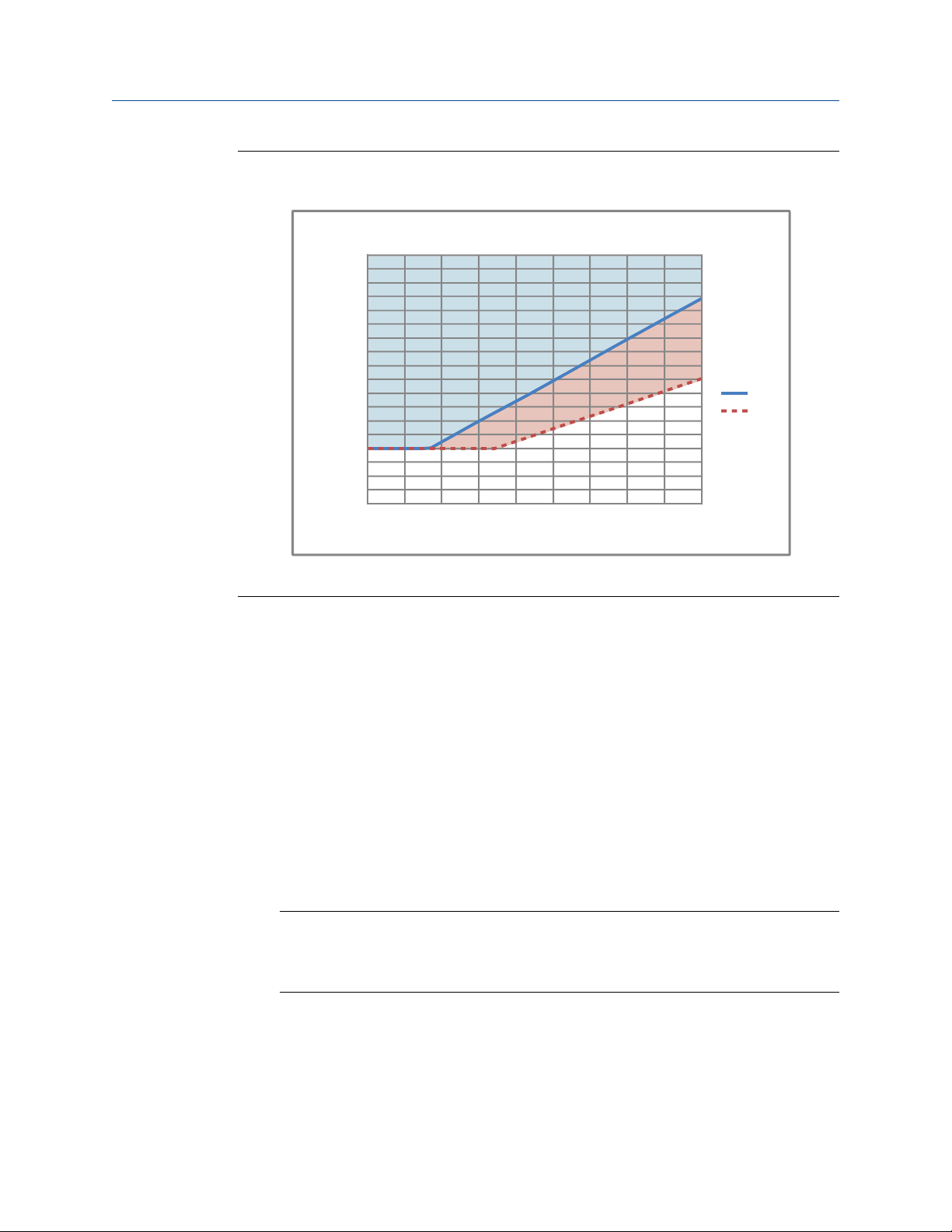

1.3 Recommended sample flow rate

Volume of gas in meter = 40 cm

3

3.5

3

2.5

2

1.5

1

.5

0

0 2 4 6 8 10

Flowrate (lt/hr)

Recommended

operating

flow rate

Volume of gas in meter = 2.44 in

3

1.2

1.0

.8

.6

.4

.2

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

Flowrate (ft3/hr)

Pressure drop (mbar)

Pressure drop (inch WC)

Recommended

operating

flow rate

Use the smallest acceptable flow rate for the process gas passing through the meter. This

ensures a sample gas flow rate that is representative of the main flow with regard to the

proportions of different gas constituents.

Micro Motion recommends a gas flow rate of 5 ±1 l/hr (0.176 ±0.35 ft3/hr), although a flow

rate between 1 to 10 l/hr (0.035 to 0.35 ft3/hr) is acceptable.

At flow rates greater than 10 l/hr (0.35 ft3/hr), the density reading can become slightly

unstable and may introduce a small density error. For natural gas with a typical application

density of approximately 0.06 g/cm3 (60 kg/m3), a pressure differential of approximately

1.66 mbar (0.67 in WC) is required to maintain a flow rate of 5 l/hr (0.176 ft3/hr) .

Pressure drop through the meterFigure 1-1:

Planning

Installation Manual 3

Page 8

300 600 900 1200 1500 1800 2100 2400 2700 3000

Distance of Installation (f t)

22.8V

24V

14

15

16

17

18

19

20

21

22

23

24

25

26

AWG

Minimum Wire Gauge

Planning

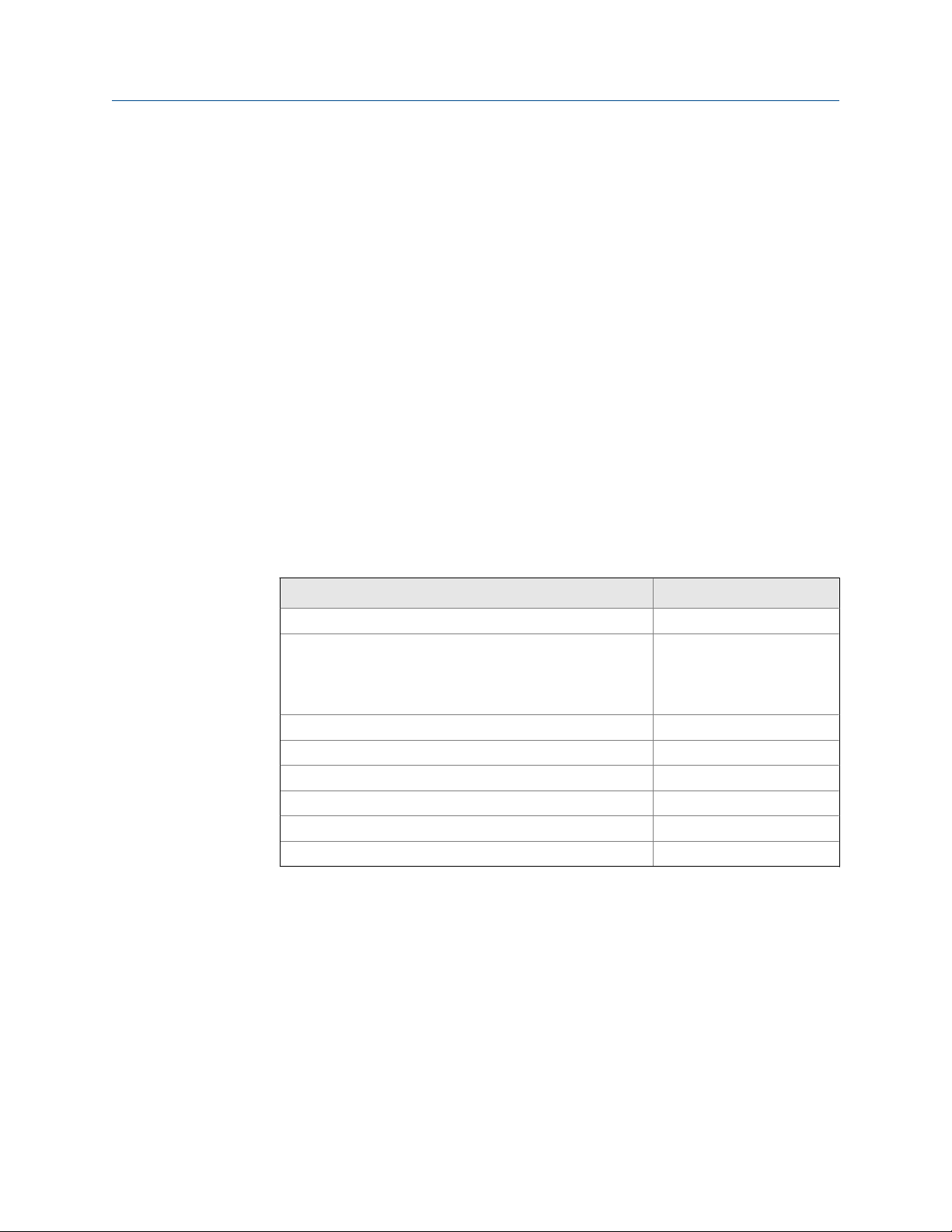

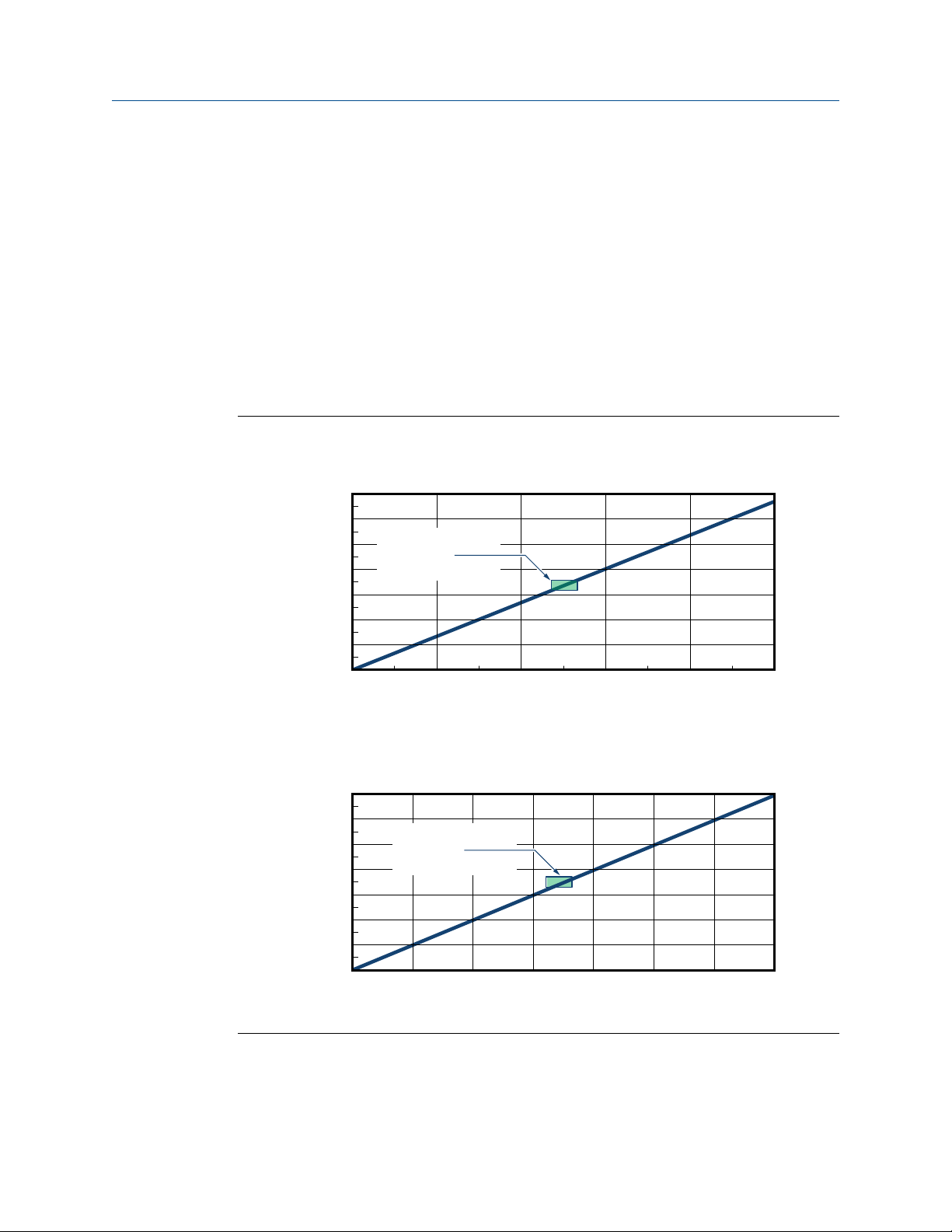

1.4 Power requirements

Following are the DC power requirements to operate the meter:

• 24 VDC, 0.45 W maximum

• Minimum 22.8 VDC with 1000 m (3280 ft) of 0.20 mm2 (18 AWG) power-supply

cable

• At startup, power source must provide a minimum of 0.5 A of short-term current at

a minimum of 19.6 V at the power-input terminals.

Power cable recommendations

Minimum wire gauge (AWG per feet)Figure 1-2:

4 Micro Motion® Gas Density Meters

Page 9

0.000

0.050

0.100

0.150

0.200

0.250

0.300

0.350

0.400

0.450

0.500

0.550

0.600

0.650

0.700

0.750

0.800

0.850

0.900

100 200 300 400 500 600 700 800 900 1000

Minimum Wire Area (mm

2

)

Distance of Installation (m)

Minimum Wire Area (mm2)

22.8V

24V

Planning

Minimum wire area (mm2 per meter)Figure 1-3:

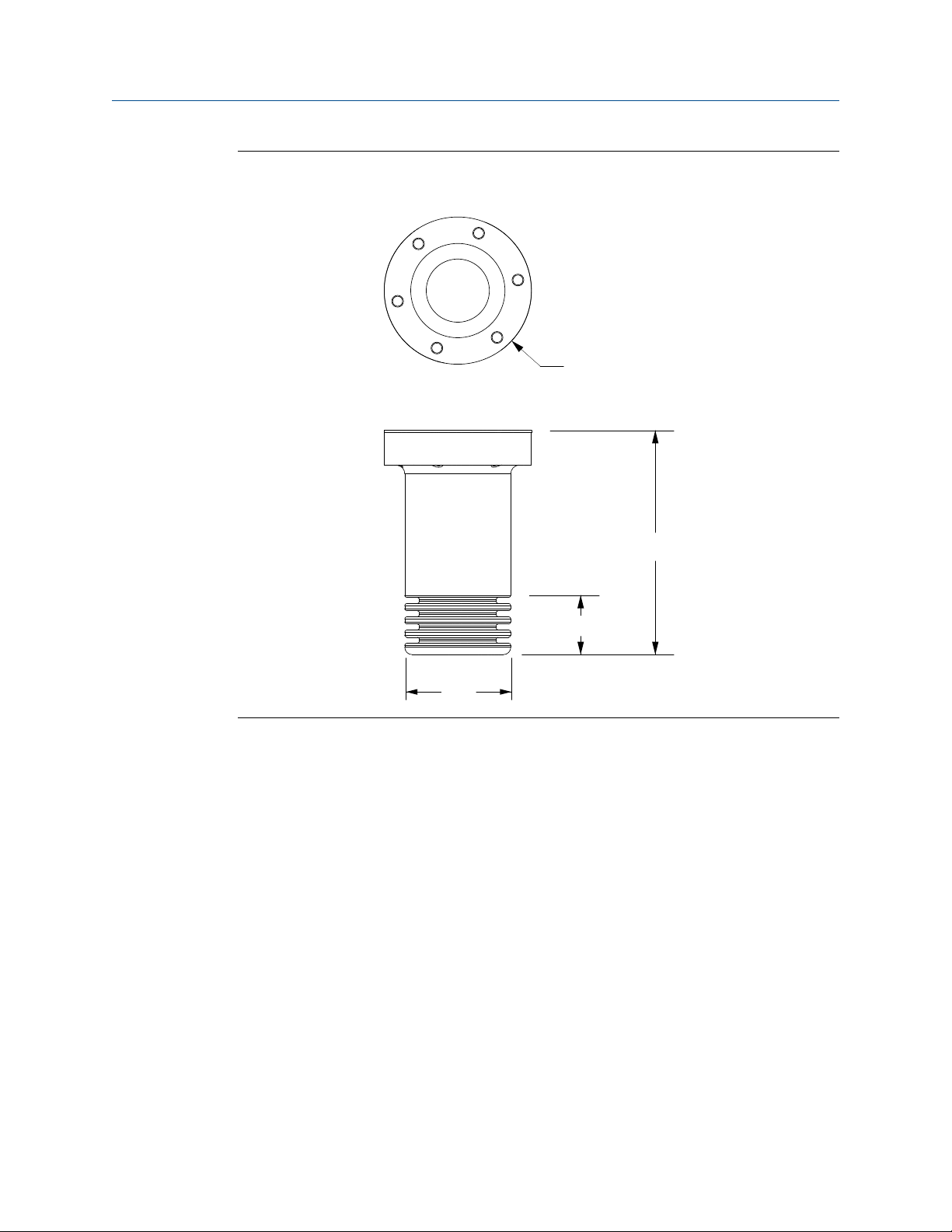

1.5 Installation requirements for the thermo-well pocket

Installation of the GDM in a thermo-well pocket helps maintain temperature equilibrium

between the sample gas and pipeline gas. Micro Motion provides thermo-well pocket

installation kits for purchase. Contact your local sales representative or Micro Motion

Customer Support at flow.support@emerson.com for more information.

A thermo-well pocket installation requires the following, before you can mount and

connect the GDM:

1. Create an aperture in the pipeline to receive the pocket (see Figure 1-4 for the pocket

Installation Manual 5

dimensions).

Important

Micro Motion recommends that you do not exceed more than a 10% reduction of the crosssectional area at the point of insertion to ensure minimal effect on pressure. Follow local

practices and guidelines for welding in hazardous areas, if applicable.

2. Install and weld the pocket in place. Be sure to follow local practices and guidelines

for welding in hazardous areas, if applicable.

Page 10

6.00

(152.30)

Ø3.94

(100.00)

1.59

(40.30)

2.83

(72.00)

Dimensions in

inches

(mm)

Planning

Micro Motion thermo-well pocket dimensionsFigure 1-4:

1.6 Recommended installations for gas density applications

Micro Motion recommends specific installations for the GDM depending on the gas

density application – as defined by international standards, ISO 5167 and AGA 3. This

information is provided for your reference only.

1.6.1 Installation in an orifice plate metering system

The orifice plate metering system is a widely used method for accurate flow measurement

of natural gas. The orifice meter is a differential pressure device in which the orifice plate

causes a pressure drop between the upstream and downstream sides. The flow rate is

determined from the dimensions of the system (as defined by international standards ISO

5167 and AGA 3), and from measurements of differential pressure and fluid density.

6 Micro Motion® Gas Density Meters

Page 11

Planning

Meter installation in a pressure recovery application

The most common location for a density device in an orifice plate metering system is

downstream from the orifice plate. This installation is commonly referred to as the

pressure recovery method. The pressure recovery method allows an optimal gas flow rate,

and provides easy access for checking filters and verifying the meter calibration.

Tip

Use 6-mm (1/4-in) instrument tubing for the gas input pipework. Use 12-mm (1/2-in) insertion

tubing for the gas return pipework.

Installation Manual 7

Page 12

STATUS

SCROLL SELECT

C

A

E

A

B

D

G

F

H

J K

I

GDM

Planning

Meter installation in pressure recovery applicationFigure 1-5:

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Pipeline diameter

G. Differential pressure transmitter

H. Density point

I. Distance is eight times the pipeline diameter

J. Thermal insulation

K. Vent/vacuum test point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

With the pressure recovery installation method:

• No bypass of the orifice plate is necessary.

• Density is measured at the downstream tapping of the orifice plate, which reduces

the significance of pressure build-up across the fine-gauge filters.

• Flow is achieved because the pressure after the orifice plate is lower than that

further downstream.

8 Micro Motion® Gas Density Meters

Page 13

Planning

• Pressure drops through the valves and filters do not affect the reading. The pressure

inside the meter and at the gas outlet is equal to the pressure at the orifice

downstream point.

• The correct expansion factor for the downstream point is used in the orifice flow

calculations.

• The measured density at the density point is used in the mass flow calculation, as

defined by ISO 5167 and AGA 3.

Meter installation in differential pressure application

An alternative to the downstream installation method is the upstream installation method,

as defined by AGA 3. This method is also known as the differential pressure method, which

is optimal for orifice plate metering. A disadvantage of this installation is that the sample

gas flow is not measured because it bypasses the orifice plate.

Installation Manual 9

Page 14

STATUS

SCROLL SELECT

E

A

A

B

D

C

F

G

H

GDM

Planning

Meter installation in differential pressure applicationFigure 1-6:

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Differential pressure transmitter

G. Thermal insulation

H. Vent/vacuum test point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

With the differential pressure installation method:

• The process gas flow bypasses the meter, but should be low enough [for example,

5 lt/hrs (0.176 ft3/hr)] to not be of significance.

• The measured density is the upstream density.

• The control valve and the flowmeter can be mounted on either side of the meter to

suit the installation and dependent on where the density point is.

10 Micro Motion® Gas Density Meters

Page 15

Tip

To avoid excessive pressure drops in your sample pipeline, be sure to monitor the condition of the

filters. Do this by varying the sample flow rate and monitoring the magnitude of the resultant density

changes. Pressure drops through the filters can cause density errors if they become too large.

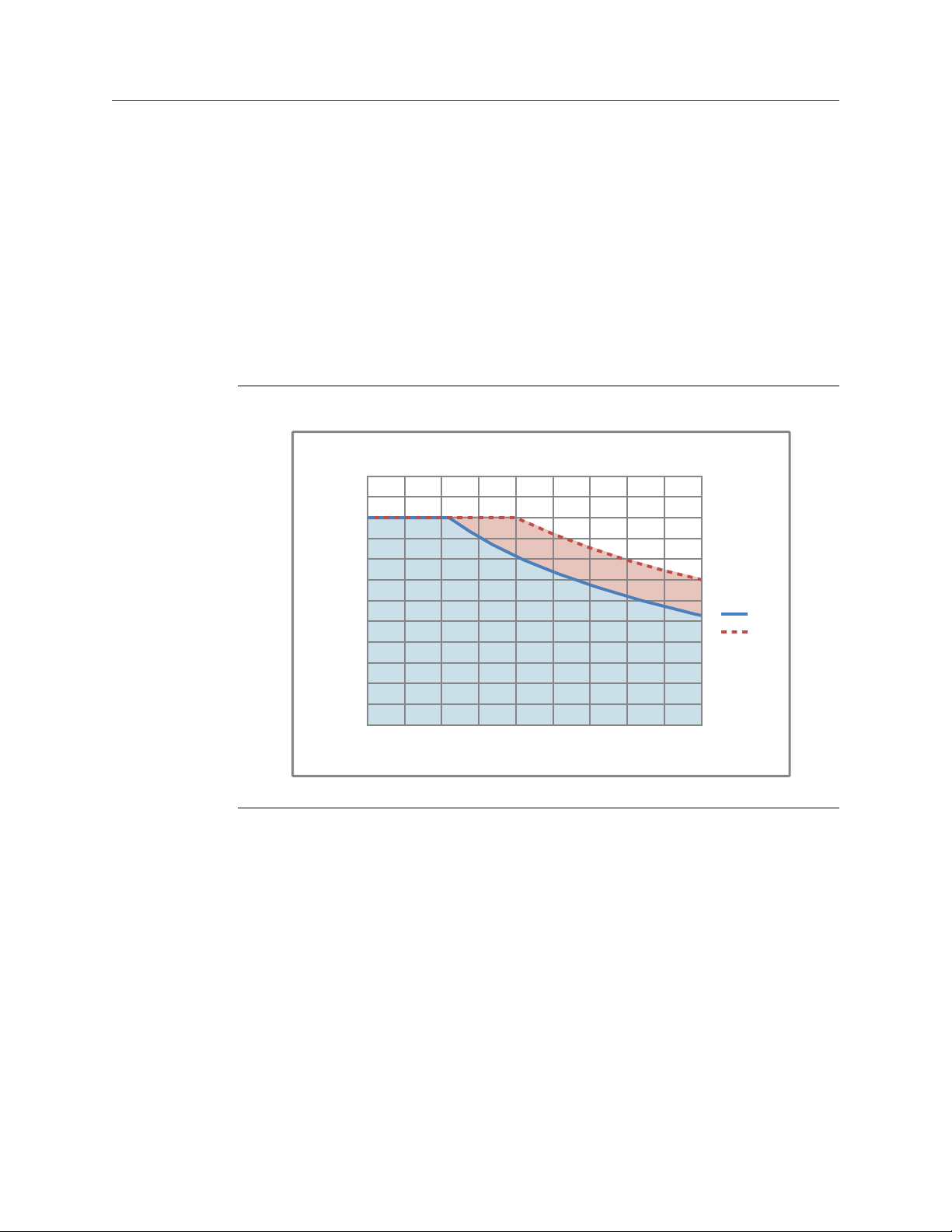

1.6.2 Meter installation in a vented gas application

The vented gas method allows the gas to be vented to flare or, in some cases, to

atmosphere. With this method, the full-pipe pressure is available as a pressure drop. For

high-pressure applications, a two-stage letdown system may be required to prevent icing.

CAUTION!

Because the full-pipe pressure is available as a pressure drop, ensure that the flow is

adequately controlled by the control valve.

Planning

Installation Manual 11

Page 16

STATUS

SCROLL SELECT

A

B

D

F

A

E

C

G

H

GDM

GDM

I

Planning

Meter installation in a vented gas applicationFigure 1-7:

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Pressure regulator

G. Thermal insulation

H. Vent/vacuum test point

I. Low-pressure vent system connection point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

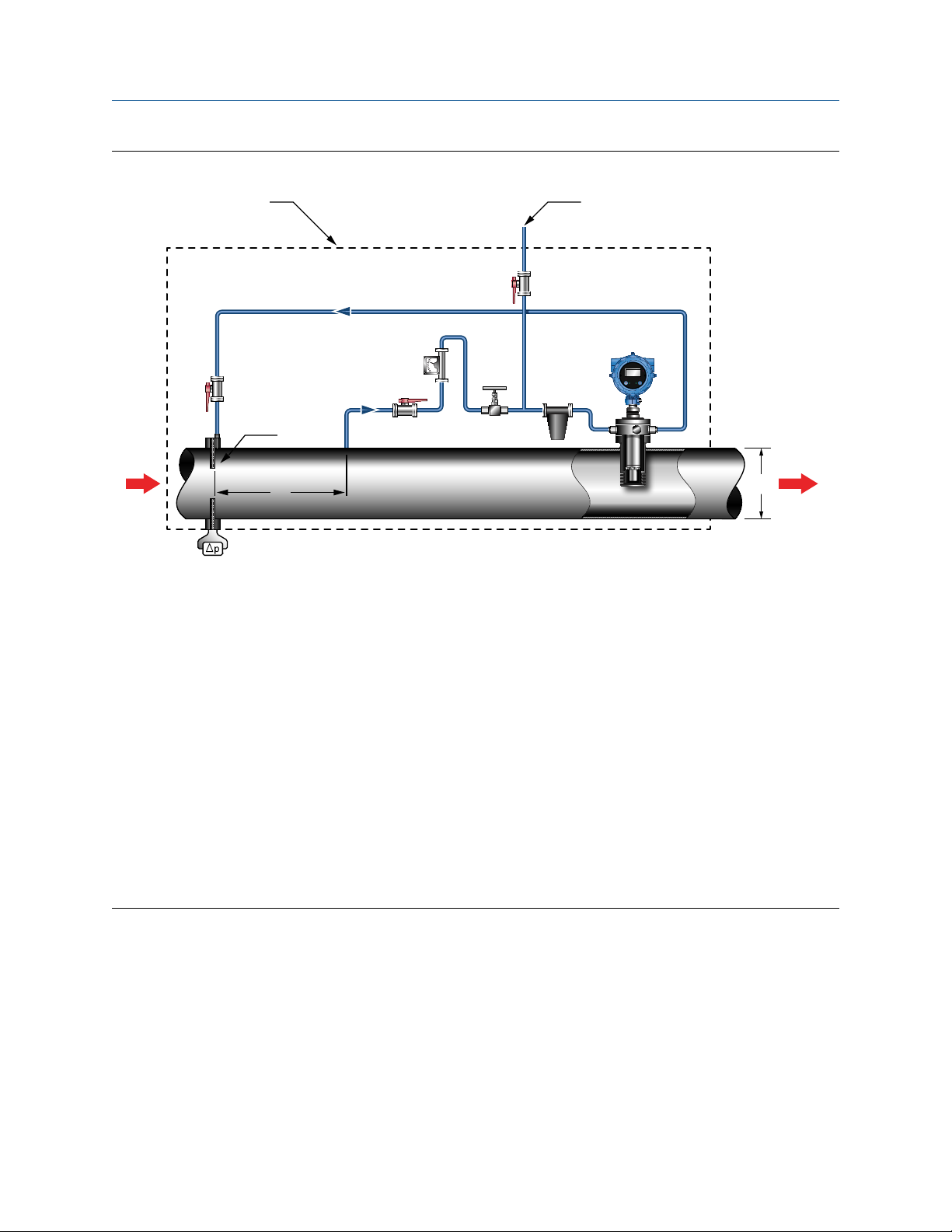

1.6.3 Meter installation in an ultrasonic meter application

To use the GDM with a full-bore ultrasonic meter, Micro Motion recommends that you

install a Rosemount Annubar® flowmeter downstream from the ultrasonic meter as a

means to provide differential pressure.

The following diagram shows a Rosemount Annubar meter installed to provide differential

pressure for the measurement system. This type of installation method does not require

sample gas to be vented to atmosphere. The Annubar and GDM must be installed a

specific distance downstream from the ultrasonic meter in your pipeline. Refer to all

manufacturer guidelines for best practices or recommendations for installing the meters in

your system.

12 Micro Motion® Gas Density Meters

Page 17

STATUS

SCROLL SELECT

E

C

A

B

D

A

G

H

F

GDM

Planning

Meter installation in an ultrasonic meter applicationFigure 1-8:

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Annubar flowmeter

G. Thermal insulation

H. Vent/vacuum test point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

1.6.4 Meter installation with a turbine flow meter

The following diagram shows a meter measurement system with a gas turbine flowmeter

installation. Refer to manufacturer guidelines for best practices or recommendations for

installing the meter in your system.

Installation Manual 13

Page 18

STATUS

SCROLL SELECT

A

B

D

A

E

C

H

F

G

GDM

Planning

Meter installation with a turbine flow meterFigure 1-9:

A. Meter isolation valves

B. Flowmeter

C. Venting valve

D. Flow control needle valve

E. Filter

F. Turbine flowmeter

G. Thermal insulation

H. Vent/vacuum test point

Note

Do not insulate the transmitter (electronics) and maintain a nominal 1-in clearance between the insulation and the transmitter

housing.

1.7 Perform a pre-installation meter check

1. Remove the meter from the box.

14 Micro Motion® Gas Density Meters

Page 19

CAUTION!

MTL7728P+

3

4

1

2

Handle the meter with care. Follow all corporate, local, and national safety regulations

for lifting and moving the meter.

2. Visually inspect the meter for any physical damage.

If you notice any physical damage to the meter, immediately contact Micro Motion

Customer Support at flow.support@emerson.com.

3. Position and secure the meter in a vertical position with the flow arrow pointing

upward.

4. Connect the power wiring, and power up the meter.

Remove the back transmitter housing cover to access the PWR terminals.

Power supply wiring terminalsFigure 1-10:

Planning

5. Perform a Known Density Verification (KDV) check.

Use the Known Density Verification procedure to match the current meter

calibration with the factory calibration. If the meter passes the test, then it has not

drifted or changed during shipment.

For more information on performing a KDV check, see the configuration and use

manual that shipped with the product.

Installation Manual 15

Page 20

Mounting

2 Mounting

Topics covered in this chapter:

• Mount the meter in the pipeline

• Connect the gas bypass lines

• Rotate the electronics on the meter (optional)

• Rotate the display on the transmitter (optional)

• Post-installation check

2.1 Mount the meter in the pipeline

Prerequisites

Important

Micro Motion recommends that you install the meter in a thermo-well pocket to maintain

temperature equilibrium between the sample gas and the pipeline gas. For ease of maintenance, you

can insert and remove the meter from the pocket as needed. See Section 1.5 for more information on

the pocket installation.

The following parts are recommended for installation in a pipeline.

• Micro Motion ® Gas Density Meter (GDM)

• Thermo-well pocket kit, which includes:

- Thermo-well pocket

- Anti-vibration gaskets

- Aluminum sleeve

- Silicone fluid

- Mounting screws

16 Micro Motion® Gas Density Meters

Page 21

STATUS

SCROLL SELECT

C

D

E

B

A

Mounting

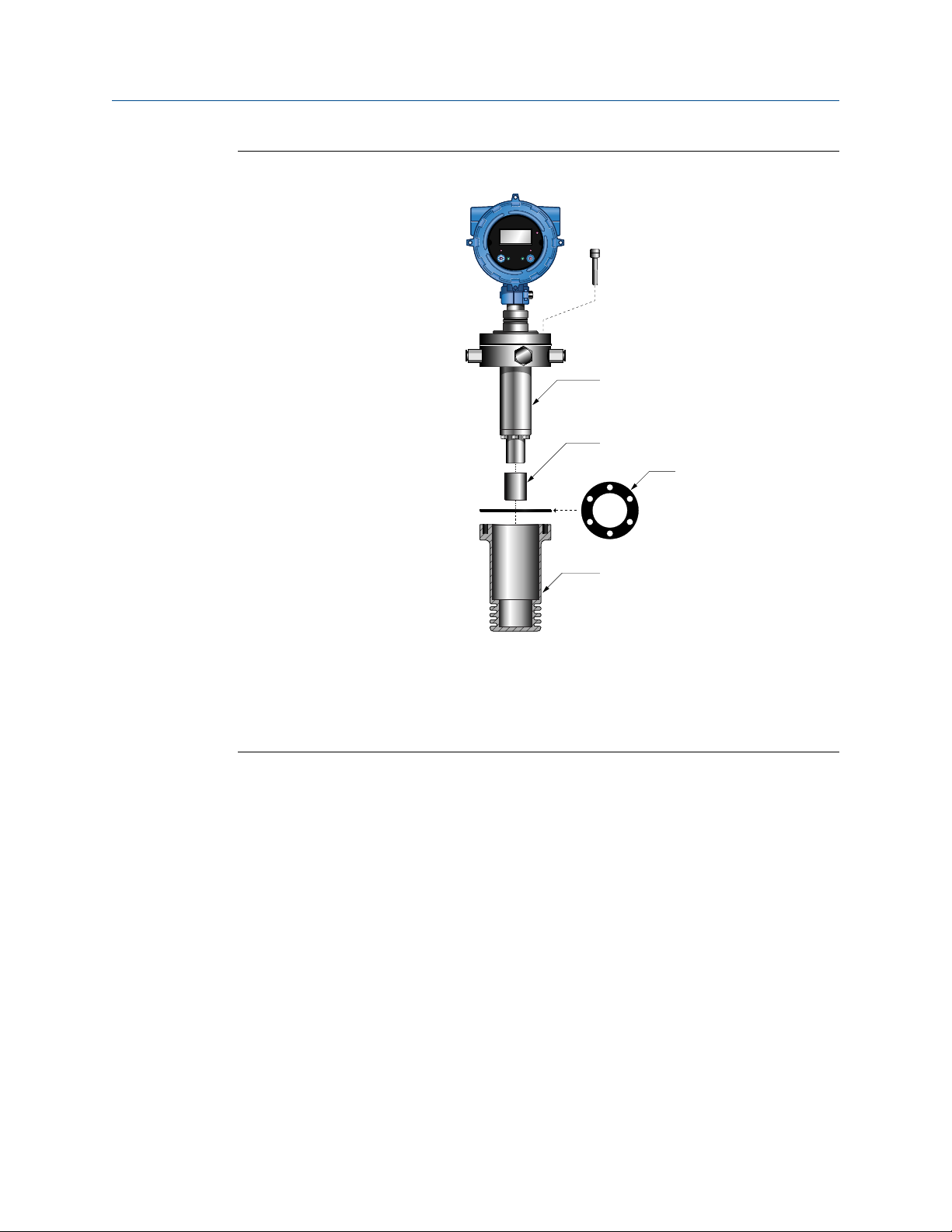

Meter installation piecesFigure 2-1:

A. M8 socket-head cap screw (for mounting)

B. Meter housing

C. Aluminum sleeve (cylinder)

D. Anti-vibration gasket

E. Thermo-well pocket

Procedure

1. (Recommended) Install the thermo-well pocket in the aperture created in the

pipeline and weld it into place.

2. Pour the supplied silicon fluid (an amount of 20 cm3) into the interior of the pocket.

3. Place one 5-mm anti-vibration gasket on top of the pocket.

Align the anti-vibration gasket holes with the bolt holes on the pocket.

4. Place the aluminum sleeve over the end of the meter housing.

5. Insert the meter housing into the pocket.

6. Secure the meter into place, using the supplied mounting screws.

Installation Manual 17

Page 22

STATUS

SCROLL SELECT

Dimensions in inches (mm)

3.74 (95)

Mounting

Typical installation in pipeline (with thermo-well pocket)Figure 2-2:

2.2 Connect the gas bypass lines

Once you have mounted the meter in the pipeline, you are ready to connect the gas

bypass lines.

Adjacent to the gas connection ports, the meter provides two filters to ensure optimal

performance of the meter sensing element.

• 2 micron filter for the inlet connection

• 90 micron filter for the outlet connection

The outlet filter provides additional protection if reverse gas flow occurs. This filter

arrangement is best suited for density measurement at the process gas return point.

Procedure

Connect the process gas bypass lines to the gas inlet/outlet ports.

18 Micro Motion® Gas Density Meters

Page 23

Gas inlet/outlet connectorsFigure 2-3:

STATUS

SCROLL SELECT

C

BA

A. Process gas outlet

B. Process gas inlet

C. Filter

Mounting

Installation Manual 19

Page 24

A

Mounting

2.3 Rotate the electronics on the meter (optional)

You can rotate the transmitter on the meter up to 90°.

1. Using a 4 mm hex key, loosen the cap screw that holds the transmitter in place.

Component to secure transmitter in placeFigure 2-4:

A. M5 socket-head cap screw

2. Rotate the transmitter clockwise to the desired orientation up to 90°.

3. Secure the cap screw in place and tighten to 60 lb·in (6.8 N·m).

2.4 Rotate the display on the transmitter (optional)

The display on the transmitter electronics module can be rotated 90° or 180° from the

original position.

20 Micro Motion® Gas Density Meters

Page 25

Display componentsFigure 2-5:

B

C

D

A

D

E

A. Transmitter housing

B. Sub-bezel

C. Display module

D. Display screws

E. Display cover

Mounting

Procedure

1. If the meter is powered up, power it down.

2. Turn the display cover counterclockwise to remove it from the main enclosure.

3. Carefully loosen (and remove if necessary) the semi-captive display screws while

holding the display module in place.

4. Carefully pull the display module out of the main enclosure until the sub-bezel pin

terminals are disengaged from the display module.

Note

If the display pins come out of the board stack with the display module, remove the pins and

reinstall them.

5. Rotate the display module to the desired position.

6. Insert the sub-bezel pin terminals into the display module pin holes to secure the

display in its new position.

7. If you have removed the display screws, line them up with the matching holes on the

sub-bezel, then reinsert and tighten them.

8. Place the display cover onto the main enclosure.

9. Turn the display cover clockwise until it is snug.

10. If appropriate, power up the meter.

Installation Manual 21

Page 26

Mounting

2.5 Post-installation check

After you complete the installation of the meter, pressure test the meter and associated

pipework to 1½ times the maximum operating pressure.

22 Micro Motion® Gas Density Meters

Page 27

3 Wiring

Topics covered in this chapter:

• Available output terminals and wiring requirements

• Hazardous area output wiring

3.1 Available output terminals and wiring

requirements

Three pairs of wiring terminals are available for transmitter outputs. These outputs vary

depending on your transmitter output option ordered. The Analog (mA), Time Period

Signal (TPS), and Discrete (DO) outputs require external power, and must be connected to

an independent 24 VDC power supply.

The screw connectors for each output terminal accept a maximum wire size of 14 AWG

(2.5 mm2).

Wiring

Important

• Output wiring requirements depend on the hazardous area classification of the environment

in which the meter is installed. It is your responsibility to verify that this installation meets all

corporate, local, and national safety requirements and electrical codes.

• If you will configure the meter to poll an external temperature or pressure device, you must

wire the mA output to support HART communications. You may use either HART/mA singleloop wiring or HART multi-drop wiring.

Transmitter outputsTable 3-1:

Output channels

Transmitter version

Analog 4–20 mA + HART 4–20 mA Modbus/RS-485

Time period signal (TPS) 4–20 mA + HART Time Period Sig-

Fixed 4–20 mA (tem-

A B C

nal (TPS)

Time period sig-

perature)

nal (TPS)

3.2 Hazardous area output wiring

Modbus/RS-485

Disabled

Micro Motion provides safety barrier and galvanic isolator installation kits for wiring the

meter in a hazardous environment. These kits provide the appropriate barriers or isolators

depending on the outputs available and approvals required.

Installation Manual 23

Page 28

Wiring

Information provided about wiring the safety barriers and galvanic isolators is intended as

an overview. You should wire the meter according to the standards that are applicable at

your site.

CAUTION!

• Meter installation and wiring should be performed by suitably trained personnel only in

accordance with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

3.2.1 Hazardous area entity parameters

DANGER!

Hazardous voltage can cause severe injury or death. To reduce the risk of hazardous voltage,

shut off power before wiring the meter.

DANGER!

Improper wiring in a hazardous environment can cause an explosion. Install the meter only in

an area that complies with the hazardous classification tag on the meter.

Input entity parameters

Input entity parameters: all connectionsTable 3-2:

4–20 mA /Discrete

Output/Time Period

Parameter Power supply

Voltage (Ui) 30 VDC 30 VDC 18 VDC

Current (Ii) 484 mA 484 mA 484 mA

Power (Pi) 2.05 W 2.05 W 2.05 W

Internal capacitance

(Ci)

Internal inductance (Li) 0.0 H 0.0 H 0.0 H

0.0 pF 0.0 pF 0.0011 pF

Signal RS-485

RS-485 output and cable parameters

All connections to the meter receive their power from the connected intrinsically safe

barrier. All cable parameters are derived from the output parameters of these devices. The

RS-485 connection also receives power from the connected barrier (MTL7761AC),

although this connection has specific output and cable parameters.

24 Micro Motion® Gas Density Meters

Page 29

RS-485 output and cable entity parameters (MTL7761AC)Table 3-3:

Input parameters

Voltage (Ui) 18 VDC

Current (Ii) 100 mA

Internal capacitance (Ci) 1 nF

Internal inductance (Li) 0.0 H

Output parameters

Voltage (Uo) 9.51 VDC

Current (instantaneous) (Io) 480 mA

Current (steady state) (I) 106 mA

Power (Po) 786 mW

Internal resistance (Ri) 19.8 Ω

Cable parameters for Group IIC

External capacitance (Co) 85 nF

External inductance (Lo) 154 µH

External inductance/resistance ratio (Lo/Ro) 31.1 µH/Ω

Wiring

Cable parameters for Group IIB

External capacitance (Co) 660 nF

External inductance (Lo) 610 µH

External inductance/resistance ratio (Lo/Ro) 124.4 µH/Ω

Hazardous area

voltage

Hazardous area

current

The meter entity parameters require the selected barrier’s opencircuit voltage to be limited to less than 30 VDC (Vmax = 30 VDC).

The meter entity parameters require the selected barrier’s shortcircuit currents to sum to less than 484 mA (Imax = 484 mA) for all

outputs.

Hazardous area

capacitance

The capacitance (Ci) of the meter is 0.0011 μF. This value added to

the wire capacitance (Ccable) must be lower than the maximum

allowable capacitance (Ca) specified by the safety barrier. Use the

following equation to calculate the maximum length of the cable

between the meter and the barrier: Ci + Ccable ≤ Ca

Hazardous area

inductance

The inductance (Li) of the meter is 0.0 μH. This value plus the field

wiring inductance (Lcable), must be lower than the maximum

allowable inductance (La) specified by the safety barrier. The

following equation can then be used to calculate the maximum cable

length between the meter and the barrier: Li + Lcable ≤ La

Installation Manual 25

Page 30

Wiring

3.2.2 Wire all available outputs using safety barriers

Micro Motion provides a safety barrier installation kit for wiring the meter in a hazardous

area. Contact your local sales representative or Micro Motion Customer Support at

flow.support@emerson.com for more information on ordering a barrier kit.

CAUTION!

• Meter installation and wiring should be performed by suitably trained personnel only in

accordance with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

The safety barrier kit provides barriers for connecting all of the available meter outputs.

Use the provided barriers with the designated output.

Output(s) Barrier

4–20 mA MTL7728P+

• 4–20 mA

• Time Period Signal (TPS)

• Discrete

Modbus/RS-485 MTL7761AC

Power MTL7728P+

MTL7728P+

Procedure

Wire the barriers to the appropriate output terminal and pins.

26 Micro Motion® Gas Density Meters

Page 31

Bus

Bar

Hazardous Area

Non-Hazardous Area

MTL7761AC

RS-485 A

RS-485 B

3

4

1

2

24 VDC

24 VDC

MTL7728P+

24 VDC

3

4

1

2

MTL7728P+

3

4

1

2

250 Ω

MTL7728P+

3

4

1

2

HART

Device

Signal

Device

See

note

mA1+

HART

RS-485

PWR

mA2/

TPS/DO

A

B

Wiring

Hazardous area mA/DO/TPS output wiring using safety barriersFigure 3-1:

Note

The recommended resistance will vary depending on your Channel B output. For mA outputs, 250 Ω is the recommended

resistance. For TPS or Discrete outputs, 500–1000 Ω is the recommended resistance.

3.2.3 Wire Analog outputs using galvanic isolators

Micro Motion provides a galvanic isolator installation kit specific to wiring the Analog

version of the meter in a hazardous area. Contact your local sales representative or

Micro Motion Customer Support at flow.support@emerson.com for more information on

ordering an isolator kit for your meter.

Installation Manual 27

Page 32

Wiring

CAUTION!

• Meter installation and wiring should be performed by suitably trained personnel only in

accordance with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

The galvanic isolator kit (Analog version) provides isolators for connecting the following

outputs. Use the provided isolators with the designated output.

Note

The RS-485 barrier is not isolated.

Output(s) Isolator

4–20 mA + HART MTL5541

4–20 mA MTL5541

Modbus/RS-485 MTL7761AC

Power MTL5523

Procedure

Wire the isolators to the appropriate output terminal and pins.

28 Micro Motion® Gas Density Meters

Page 33

mA1+

HART

PWR

mA2

Hazardous Area

Non-Hazardous Area

MTL7761AC

RS-485 A

RS-485 B

3

4

1

2

MTL5541

2

1

14

13

12

11

MTL5523

2

1

24 VDC

14

13

12

11

24 VDC

LINK

250 Ω

MTL5541

2

1

14

13

12

11

24 VDC

250 Ω

A

B

HART

Device

Signal

Device

Wiring

Hazardous area output wiring using galvanic isolators (mA outputs option)Figure 3-2:

3.2.4 Wire Time Period Signal (TPS) or Discrete output options using galvanic isolators

Micro Motion provides a galvanic isolator installation kit specific to wiring the Time Period

Signal (TPS) and Discrete versions of the meter in a hazardous area. Contact your local

sales representative or Micro Motion Customer Support at flow.support@emerson.com for

more information on ordering an isolator kit for your meter.

CAUTION!

• Meter installation and wiring should be performed by suitably trained personnel only in

accordance with the applicable code of practice.

• Refer to the hazardous area approvals documentation shipped with your meter. Safety

instructions are available on the Micro Motion Product Documentation DVD and

accessible on the Micro Motion website at www.micromotion.com.

The galvanic isolator kit (TPS/Discrete version) provides isolators for connecting the

following outputs. Use the provided isolators with the designated output.

Installation Manual 29

Page 34

mA1+

HART

PWR

SIG

Hazardous Area

Non-Hazardous Area

MTL7761AC

MTL5532

RS-485 A

RS-485 B

5

3

4

1

2

1

11

12

13

14

4

1 kΩ

MTL5541

2

1

14

13

12

11

MTL5523

2

1

24 VDC

24 VDC

14

13

24 VDC

1 kΩ

250 Ω

A

B

HART

Device

Signal

Device

Wiring

Note

The RS-485 barrier is not isolated.

Output(s) Isolator

4–20 mA + HART MTL5541

• Time Period Signal (TPS)

• Discrete

Modbus/RS-485 MTL7761AC

Power MTL5523

Procedure

1. Wire the isolators to the appropriate output terminal and pins.

Hazardous area output wiring using galvanic isolators (TPS and Discrete output options)Figure 3-3:

MTL5532

2. Set the isolator switch settings for the TPS/DO connection (MTL5532 isolator). You

must set the isolator switches appropriately for Pins 1 through 5 (see Table 1).

30 Micro Motion® Gas Density Meters

Page 35

1 2 3 4

OFF

ON

Wiring

The switches are located on the side of the isolator, and must be set to either Off (the

up position) or On (the down position).

MTL5532 switch location (plus ON/OFF switch position)Figure 3-4:

MTL5532 switch settingsTable 3-4:

Switch ON/OFF?

1 ON

2 OFF

3 OFF

4 OFF

Installation Manual 31

Page 36

Grounding

4 Grounding

The meter must be grounded according to the standards that are applicable at the site.

The customer is responsible for knowing and complying with all applicable standards.

Prerequisites

Micro Motion suggests the following guides for grounding practices:

• In Europe, EN 60079-14 is applicable to most installations, in particular Sections

12.2.2.3 and 12.2.2.4.

• In the U.S.A. and Canada, ISA 12.06.01 Part 1 provides examples with associated

applications and requirements.

• For IECEx installations, IEC 60079-14 is applicable.

If no external standards are applicable, follow these guidelines to ground the meter:

• Use copper wire, 18 AWG (0.75 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

CAUTION!

Ground the meter to earth, or follow ground network requirements for the facility. Improper

grounding can cause measurement error.

Procedure

Check the joints in the pipeline.

- If the joints in the pipeline are ground-bonded, the sensor is automatically grounded

and no further action is necessary (unless required by local code).

- If the joints in the pipeline are not grounded, connect a ground wire to the grounding

screw located on the sensor electronics.

32 Micro Motion® Gas Density Meters

Page 37

Grounding

Installation Manual 33

Page 38

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.micromotion.com

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

*MMI-20020979*

MMI-20020979

Rev AB

2015

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

©

2015 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Process

Management family of companies. All other marks are property of

their respective owners.

Loading...

Loading...