Page 1

Installation and Configuration Manual

P/N MMI-20015440, Rev. AA

July 2009

Micro Motion® 7827 Digital

Viscosity Meter

Short and Long Stem Versions

Page 2

©2009, Micro Motion, Inc. All rights reserved. Micro Motion is a registered trade name of Micro Motion, Inc., Boulder, Colorado.

The Micro Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. All other trademarks are property

of their respective owners.

Micro Motion pursues a policy of continuous development and product improvement. The specification in this document may

therefore be changed without notice. To the best of our knowledge, the information contained in this document is accurate and

Micro Motion cannot be held responsible for any errors, omissions, or other misinformation contained herein. No part of this

document may be photocopied or reproduced without prior written consent of Micro Motion.

Page 3

Contents

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 What is it? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 7827 meter measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3 What is it used for? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Installation (Short Stem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Boundary effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Standard installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Meter orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.3 Free stream installation - flanged fitting . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.4 Free stream installation - weldolet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.5 T-piece installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.6 Flow-through chamber installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Installation in the pipeline or system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Typical installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.1 Jacketed pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.2 Flow-through chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 3 Installation (Long Stem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.1 Fluid at the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.2 Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.3 Entrained gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.4 Solids contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Open-tank installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Closed-tank installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6 If the Tank is Pressurized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 4 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 EMC and cabling considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Installation and safety in hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Installation in non-hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Wiring the meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6 Connecting the 7827 to a 795x series computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6.2 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation and Configuration Manual i

Page 4

Contents

4.7 Checking the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 5 Using 7950/7951 Processing Electronics . . . . . . . . . . . . . . . . . . . . 39

5.1 Using the 7950 / 7951 Processing Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6 Calibration Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Factory calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.1 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.2 Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2.3 Primary standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2.4 Transfer standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3 In-line calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.1 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.2 Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.3 Requirements for VOS correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.1 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.2 Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5 Calibration certificate example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 7 General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 General maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Fault analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.1 Checking the Signal Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.2 Checking the power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.3 Checking the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix A Calculated Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.2 Viscosity equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.2.1 Quality factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.2.2 General viscosity equation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.3 Density equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.3.1 General density equation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.3.2 Temperature correction equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.3.3 Viscosity correction equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.3.4 Pressure correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.3.5 Velocity Of Sound correction equation. . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.3.6 Density scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.4 Kinematic viscosity equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix B Safety Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

B.1 Safety certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

ii Micro Motion 7827 Digital Viscosity Meter

Page 5

Contents

Appendix C Product Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.1 Density / temperature relationship of hydrocarbon products. . . . . . . . . . . . . . . . . . . 61

C.1.1 Crude oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.1.2 Refined products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.1.3 Platinum resistance law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

C.1.4 Density of ambient air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

C.1.5 Density of water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

C.1.6 Velocity of sound in liquids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Appendix D Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.1 General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.2 New and unused equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.3 Used equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Installation and Configuration Manual iii

Page 6

Contents

iv Micro Motion 7827 Digital Viscosity Meter

Page 7

Chapter 1

Introduction

1.1 Safety guidelines

Handle the 7827 digital viscosity meter with great care.

• Do not drop the meter.

• Do not use liquids incompatible with materials of construction.

• Do not operate the meter above its rated pressure or maximum temperature.

• Do not pressure test beyond the specified test pressure.

• Ensure all explosion-proof requirements have been applied.

• Ensure the meter and associated pipework are pressure tested to 1-1/2 times the maximum

operating pressure after installation.

• Always store and transport the meter in its original packaging, including the transit cover

secured by grub screws.

• To return a meter, refer to the Return Policy appendix for more information on the Micro

Motion return policy.

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Installation and Configuration Manual 1

Page 8

Introduction

Electronics housing

Spigot

Tines

Stem (available in varying

lengths)

Stem is sealed at both ends

and air filled

1.2 About the meter

1.2.1 What is it?

The 7827 meter is a digital viscosity meter, based on the proven tuning fork technology of Micro

Motion. It is an all-welded sensor designed to be mounted directly into a pipeline or in a tank.

Viscosity and density are determined from the resonance of the tuning fork immersed in the fluid, and

a temperature sensor (PRT) is also fitted within the meter.

The 7827 meter is available in a variety of materials, and the immersed tines can be laminated with

PFA to inhibit the build up of residues such as asphaltenes.

1.2.2 7827 meter measurements

The 7827 meter directly measures the following fluid properties:

• Line dynamic viscosity – measured in centiPoise - cP.

• Line Density – measured in kg/m

3

.

• Temperature – measured in °C or °F.

From these properties, the 7827 meter calculates:

• Line and base (referred) kinematic viscosity – measured in centiStokes - cSt.

• Line and base (referred) density – API or Matrix.

• Referral is made to 15°C, 1.013 bar; or at 60°F, 14.5 psi.

2 Micro Motion 7827 Digital Viscosity Meter

Page 9

Introduction

0dB level

-3dB level

Frequency

τ

B

τ

A

A

B

1.2.3 What is it used for?

The 7827 meter is ideally suited to applications where continuous real time measurement of viscosity

is required. The meter is particularly suited where viscosity is an indication of the behavioral

properties of the fluid, for example in applications involving spraying, coating or dipping.

Some uses are in the oil and petrochemical industry for:

•Refining

•Marine

•Power

• Heavy fuel oil (HFO) blending and bunkering

1.3 Principle of operation

The 7827 meter operates on the vibrating element principle, the element in this case being a slender

tuning fork structure which is immersed in the liquid being measured.

The tuning fork is excited into oscillation by a piezo-electric crystal internally secured at the root of

one tine, while the frequency of oscillation is detected by a second piezo-electric crystal secured at the

root of the other tine. The sensor is maintained at its first natural resonant frequency, as modified by

the surrounding fluid, by an amplifier circuit located in the electronics housing.

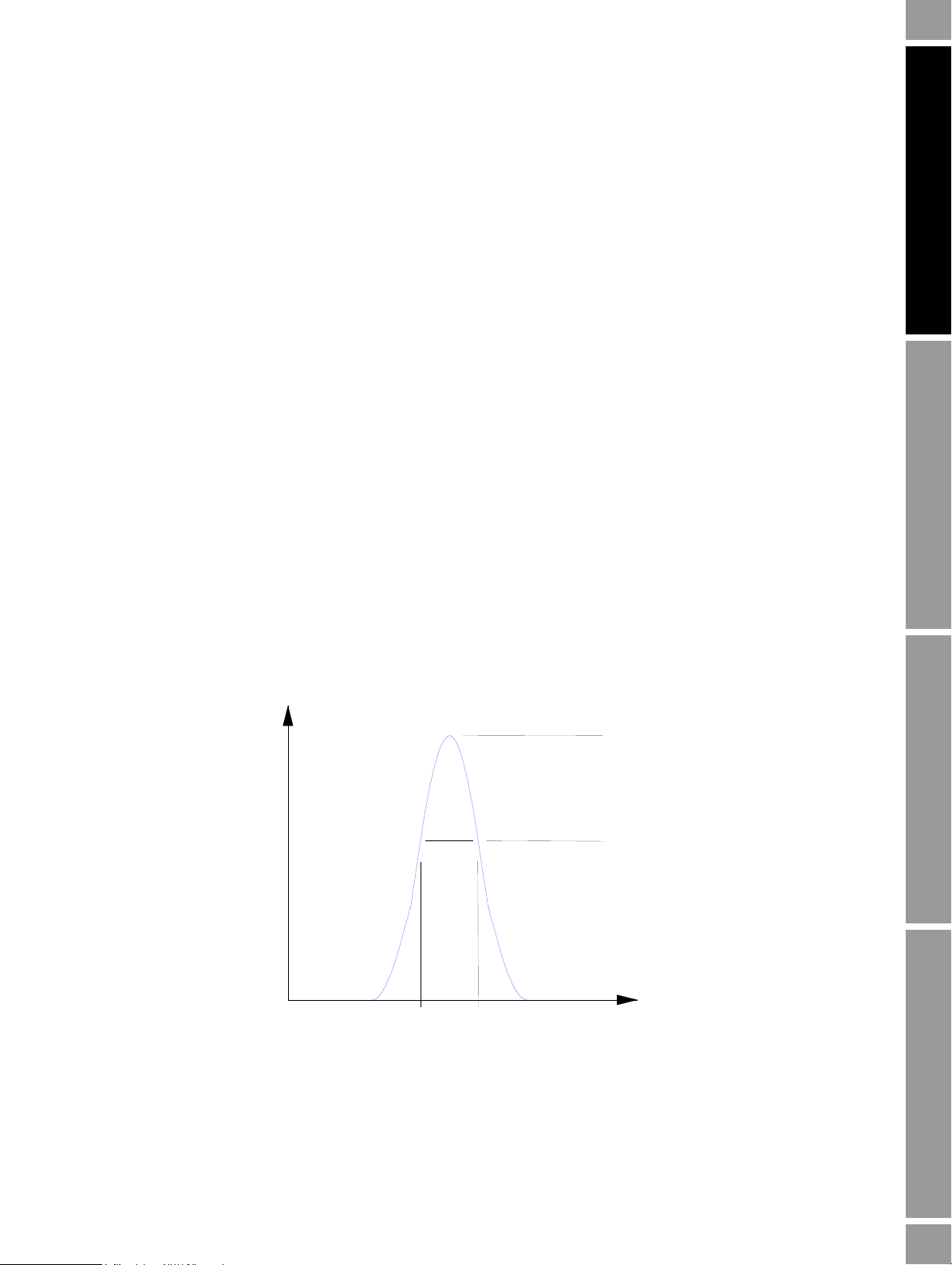

The electronics circuit actually excites the sensor into oscillation alternately at two positions on the

frequency response curve as shown in Figure 1-1. In doing this, the quality factor (Q) of the resonator

may be determined as well as the resonant frequency.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

For details of the viscosity and density calculations, see the Calculated Parameters appendix.

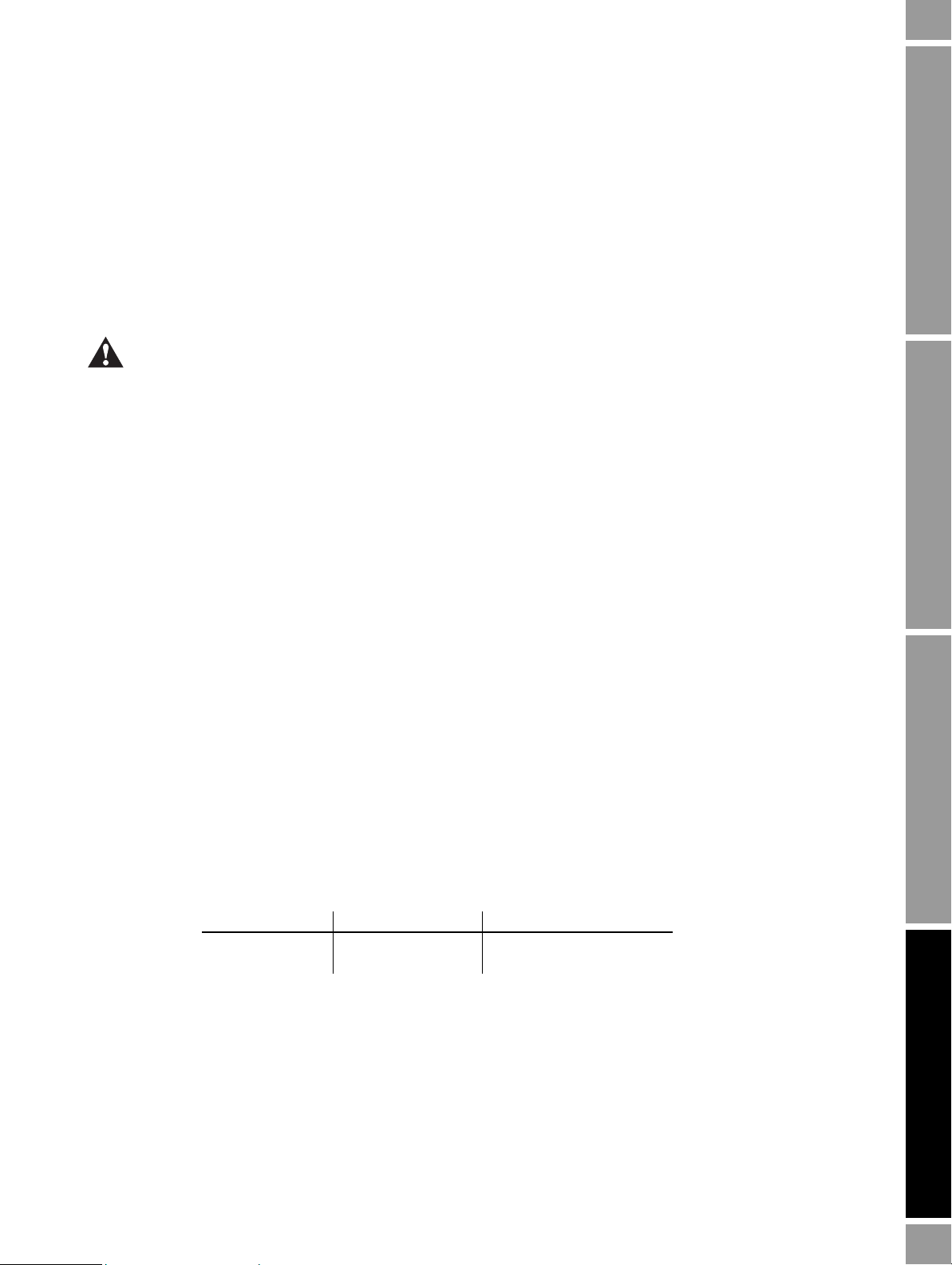

Figure 1-1 Frequency response curve showing the quality factor (Q) calculation

Response

Installation and Configuration Manual 3

Page 10

Introduction

4 Micro Motion 7827 Digital Viscosity Meter

Page 11

Chapter 2

Installation (Short Stem)

For information on installing a long-stem version of the 7827 digital viscosity meter, see Chapter 3.

2.1 Introduction

All drawings and dimensions given in this manual are given here for planning purposes only. Before

commencing fabrication, reference should always be made to the current issue of the appropriate

drawings. Contact Micro Motion for details.

For further information on handling and using the meter, see “Safety guidelines” on page 1

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

There are a variety of external factors that affect the ability of the 7827 digital viscosity meter to

operate successfully. In order to ensure that your system works correctly, the effects of these factors

must be taken into consideration when designing your installation.

There are two main aspects to consider:

• The accuracy and repeatability of the measurements

• The relevance of the measurements to the overall purpose of the system

Factors which may adversely affect accuracy and repeatability include:

• The presence of gas or bubbles within the fluid being measured

• Non-uniformity of the fluid

• The presence of solids as contaminants

• Fouling of the meter

• Temperature gradients

• Cavitations and swirls

• Operating at temperatures below the wax point of crude oils

• The correct pipe diameter that corresponds to the calibration of the meter.

In some applications, absolute accuracy is less important than repeatability. For example, in a system

where the control parameters are initially adjusted for optimum performance, and thereafter only

checked periodically.

The term achievable accuracy can be used to describe a measure of the product quality that can be

realistically obtained from a process system. It is a function of measurement accuracy, stability and

system response. High accuracy alone is no guarantee of good product quality if the response time of

the system is measured in tens of minutes, or if the measurement bears little relevance to the operation

of the system. Similarly, systems which require constant calibration and maintenance cannot achieve

good achievable accuracy.

Installation and Configuration Manual 5

Page 12

Installation (Short Stem)

long axis

short

axis

Factors which may adversely affect the relevance of the measurements could include:

• Measurement used for control purposes being made too far away from the point of control, so

that the system cannot respond properly to changes.

• Measurements made on fluid which is unrepresentative of the main flow.

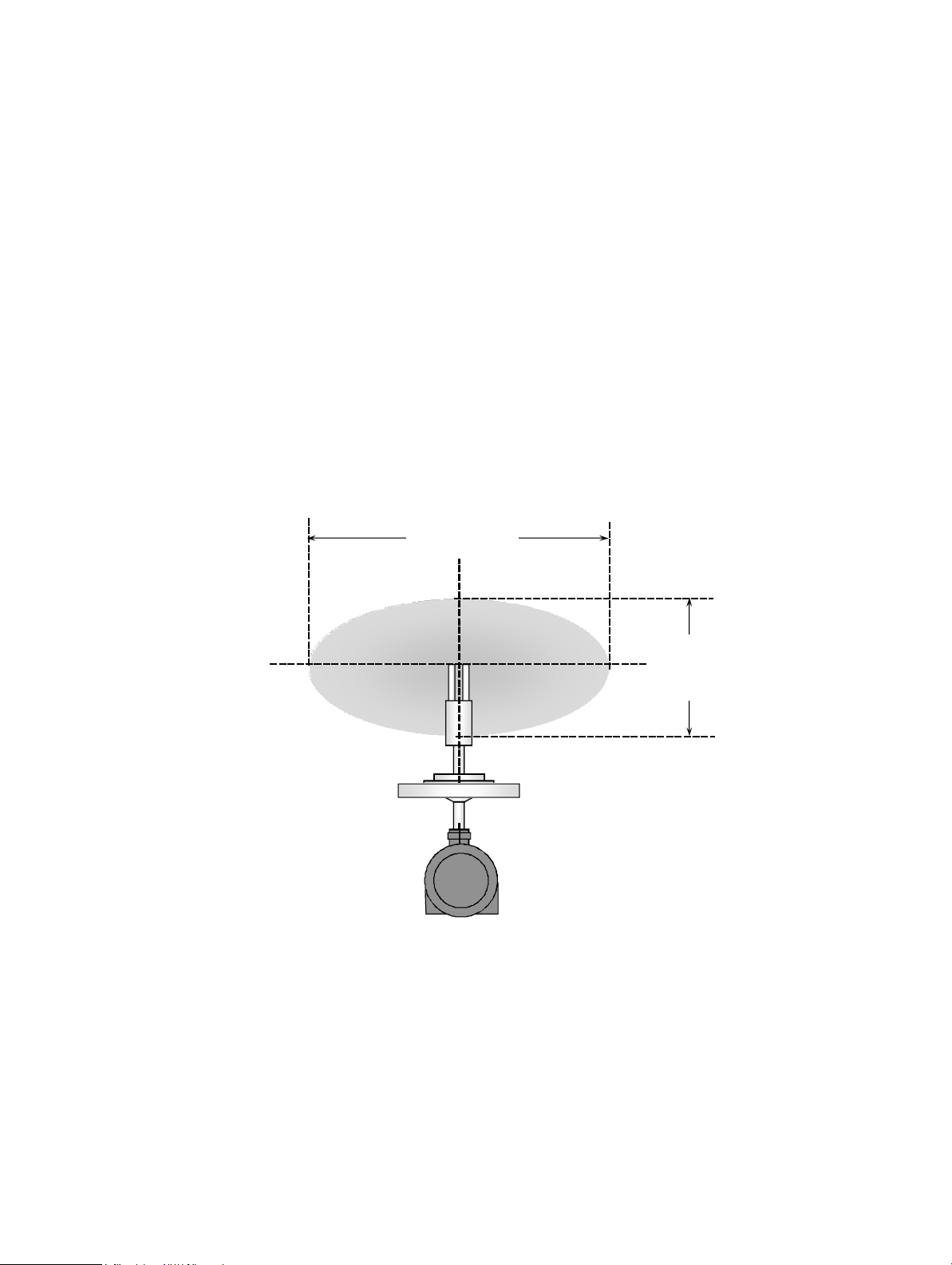

2.2 Boundary effects

Any insertion device or meter can only measure the properties of the fluid within the region of fluid to

which it is sensitive.

For practical reasons, it is helpful to consider the sensitive, or effective region, for the viscometer as

an ovoid centered on the tips of the tines with its long axis aligned with the direction in which the

tines vibrate, as shown below. The 7827 meter is insensitive to the properties of the fluid outside this

region and progressively more sensitive to fluid properties the closer the fluid is to the tines. Density

can be considered a “mass centered” effect and viscosity a “surface centered” effect in this

visualization; i.e. the measurement of density is more uniformly sensitive to the density of fluid

throughout the region while viscosity measurement is much more critically sensitive to fluid on the

surface of the tines.

If part of this volume is taken up by the pipework or fittings there is said to be a boundary effect; i.e.,

the intrusion of the pipe walls will alter the calibration. The diagram below illustrates the 7827 meter

installed in a pocket on the side of a 4" (100 mm) horizontal pipe line (viewed from above). The

effective region is completely enclosed within the pipe line and thus is completely fluid.

6 Micro Motion 7827 Digital Viscosity Meter

Page 13

Installation (Short Stem)

Top or Plan view

4” horizontal pipe

2”Schedule 40

Pocket or “T”

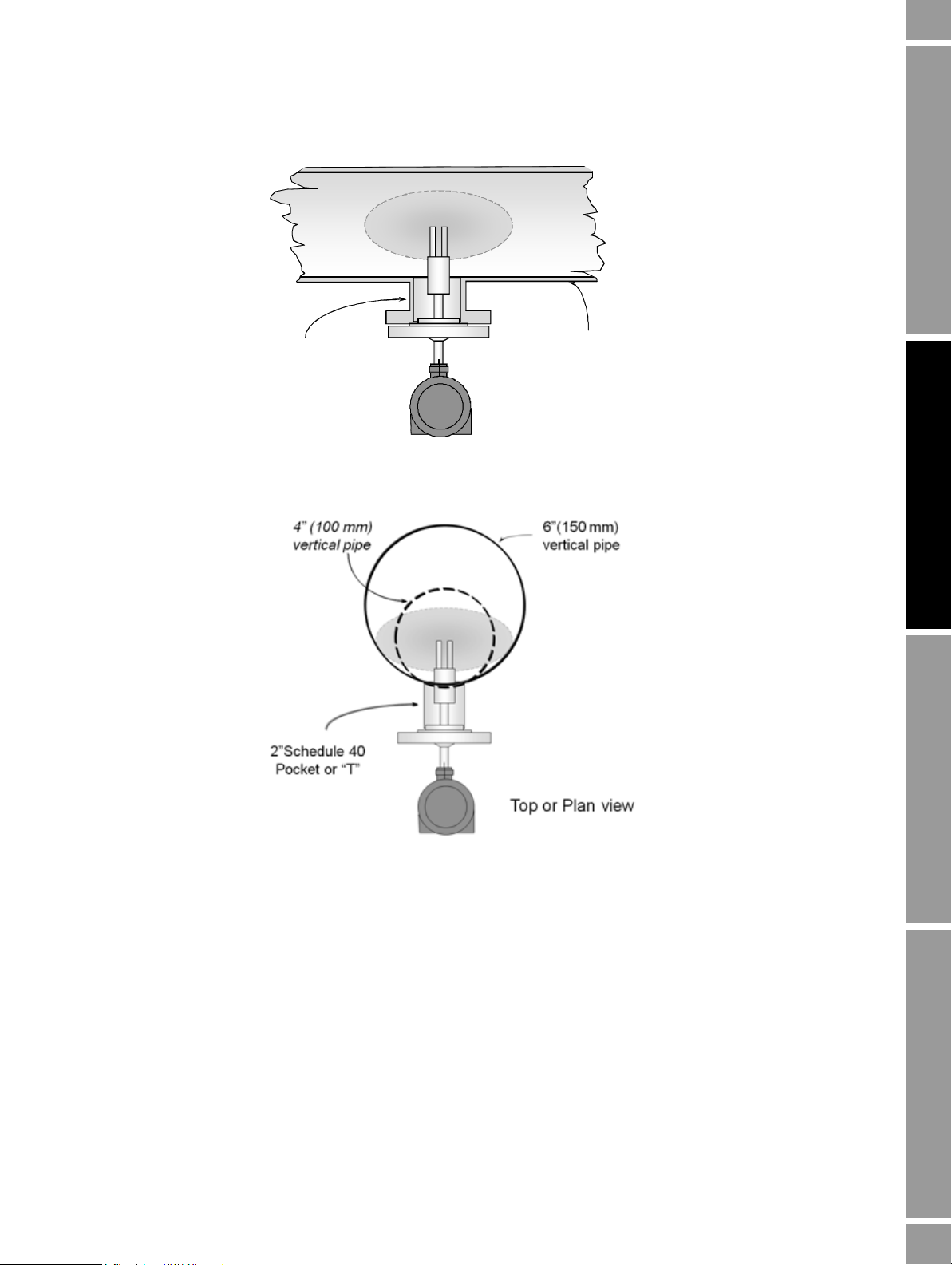

This next view shows other pipe outlines superimposed:

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Installation and Configuration Manual 7

The smaller circle represents a 4" (100 mm) vertical pipe, which because the 7827 meter orientation is

constant irrespective of pipe orientation intersects the effective region. The 6" (150 mm) pipe is the

smallest pipe diameter to completely enclose the effective region when the pipe is vertical. Thus

smaller pipe diameters can lead to a variety of different geometries which would each require a

separate calibration.

An alternative condition is shown in the next diagram where the side pocket is extended until it passes

completely through the effective region producing a “core”:

Page 14

Installation (Short Stem)

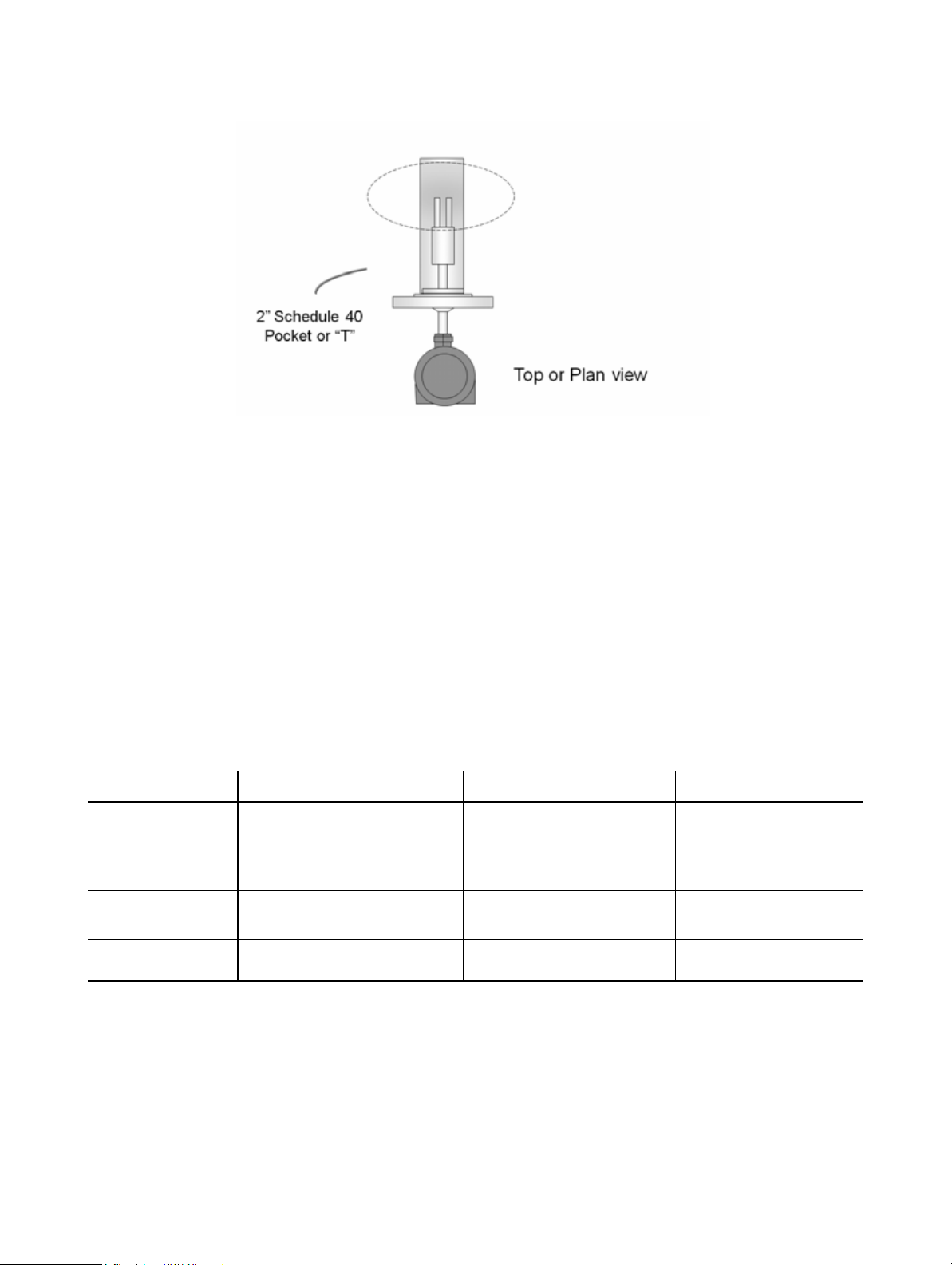

From this, it would appear that almost every installation requires a separate in situ calibration – a very

undesirable situation. The problem is resolved by providing standard calibration geometries which

can be used in all pipe work configurations and thereby allow the factory calibration conditions to be

reproduced in the process.

2.3 Standard installations

2.3.1 Overview

To overcome the need for in situ calibration for every installation, three standard installations are

proposed. If an installation conforms to one of these standards, the factory calibration of the 7827

meter is valid, and in-situ calibration unnecessary. Table 2-1summarizes the three installations. For

tank installations, consult Micro Motion.

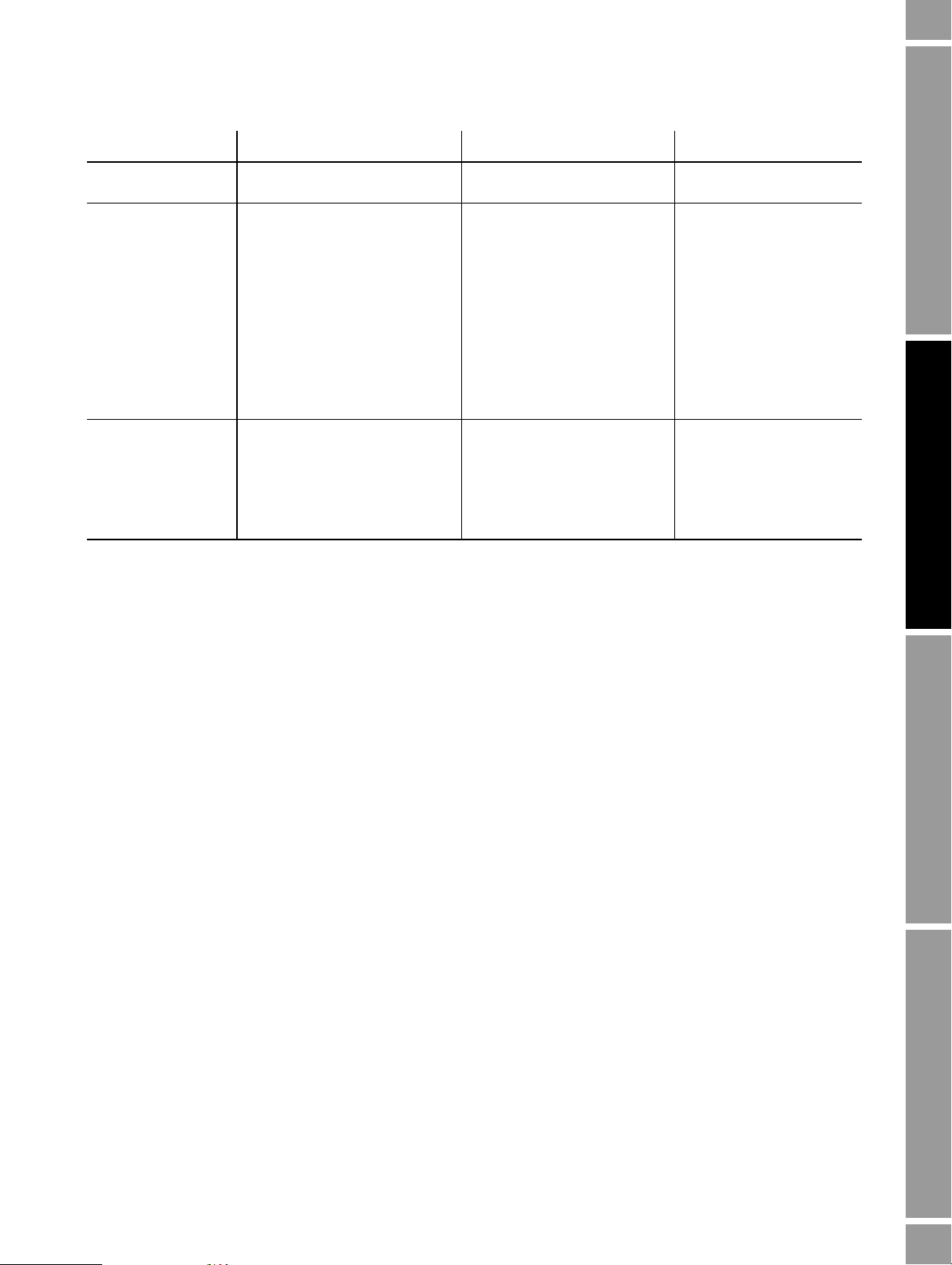

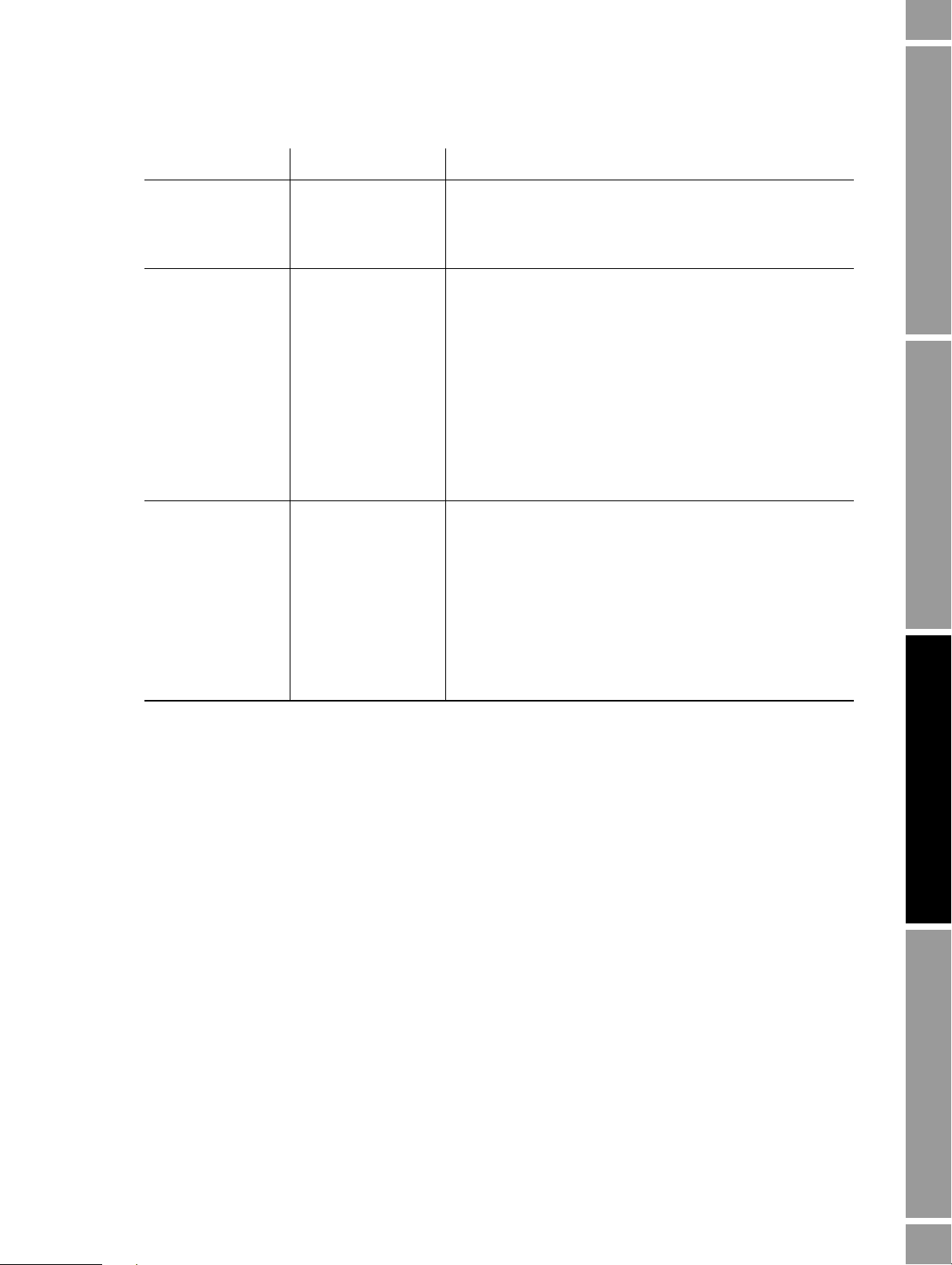

Table 2-1. Types of standard installations

Installation type Free stream T-piece Flow-through chamber

Description 7827 meter tines are inserted

Flow rate 0.3 to 0.5 m/s at the 7827 meter. 0.5 to 3 m/s at main pipe wall. 10 to 30 l/min.

Viscosity 0.5 to 12500 cP 0.5 to 100 cP 0.5 to 1000 cP

Temperature

(1)

directly into the main fluid flow.

-50 to 200°C

(-58 to 392°F)

7827 meter tines are contained

in a side pocket off the main

flow.

-50 to 200°C

(-58 to 392°F)

7827 meter tines are

contained in a flow-through

chamber in which fluid is

circulated from the main

flow.

-50 to 200°C

(-58 to 392°F)

8 Micro Motion 7827 Digital Viscosity Meter

Page 15

Installation (Short Stem)

Table 2-1. Types of standard installations continued

Installation type Free stream T-piece Flow-through chamber

Main flow pipe size 100 mm (4") horizontal

150 mm (6") vertical, or larger.

Advantages • Simple installation in large bore

pipes.

• Ideal for clean fluids and

non-waxing oils.

• Suitable for line viscosity

measurement and simple

referrals.

Not recommended

for

• Dirty fluids.

• Low or unstable flow rates.

• Where step changes in

viscosity can occur.

• For small bore pipes.

100 mm (4") horizontal or

larger.

• Simple installation in large

bore pipes.

• Ideal for clean fluids and

non-waxing oils.

• Suitable for line viscosity

measurement and simple

referrals.

• Dirty fluids

• Low or unstable flow rates.

• Where step changes in

viscosity can occur.

• for small bore pipes.

• Where temperature effects

are significant.

Any.

• Adaptable installation to

any diameter main pipe

and for tank applications.

• Ideal for flow and

temperature conditioning.

• Suitable for complex

referrals and for use with

heat exchangers.

• Suitable for step changes

in viscosity.

• Fast response.

• Ideal for analyser

cubicles.

• Uncontrolled flow rates.

• Careful system design

required to ensure

representative

measurement.

• Frequently requires the

use of a pump.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

(1)

Approval for use in hazardous areas is limited to –40 to +200°C (–40 to +392°F)

2.3.2 Meter orientation

The meter must always be installed horizontally, and orientated to allow flow in the gap between the

tines. This is irrespective of the pipe line orientation, and helps to prevent the trapping of bubbles or

solids on the meter.

Installation and Configuration Manual 9

Page 16

Installation (Short Stem)

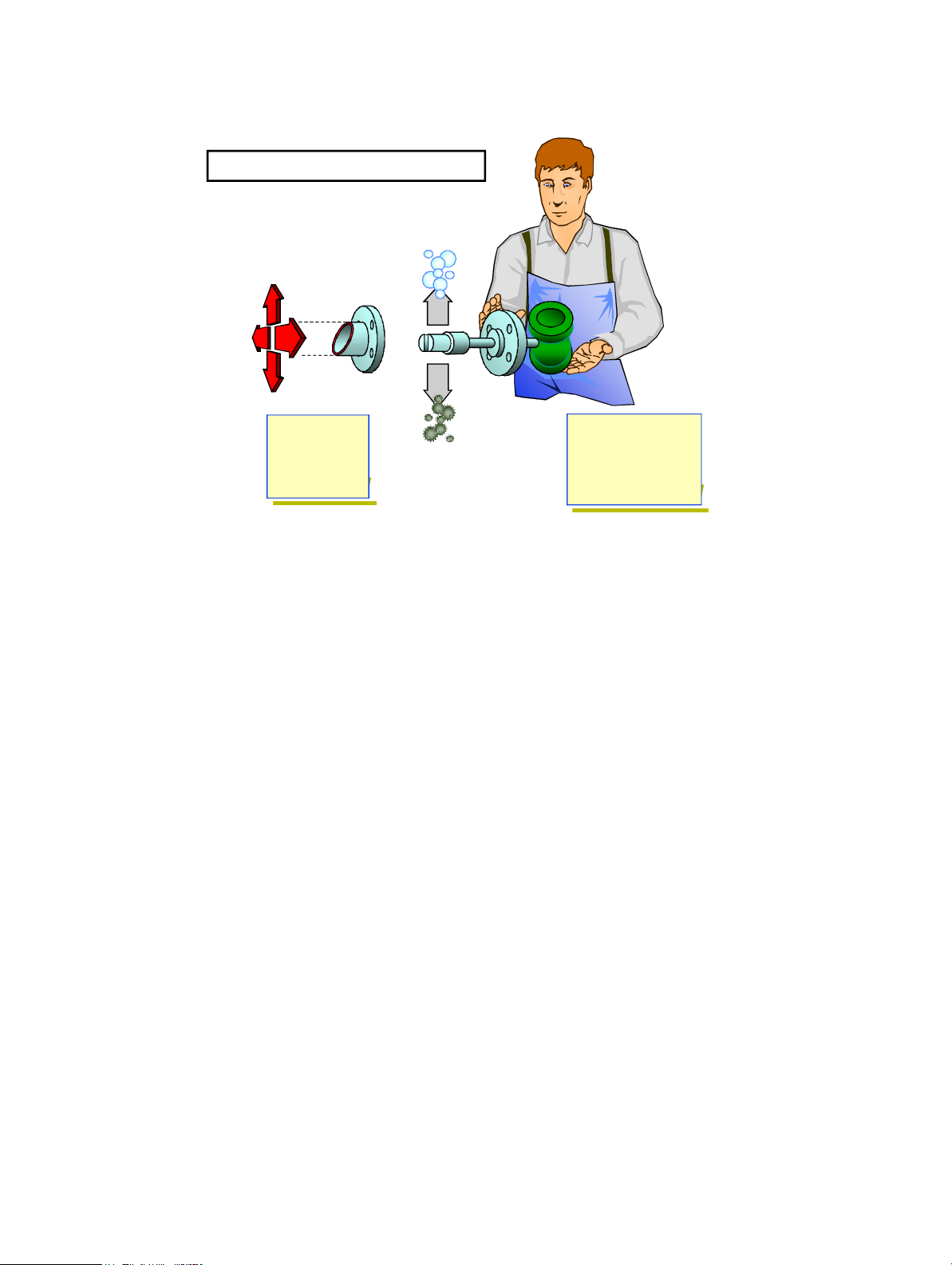

Bubbles rise!

Solids sink!

the slot

must be

vertical

.

For ALL pipe and flow directions

.

the meter

must be

horizontal

Figure 2-1 Meter orientation

Note: All drawings and dimensions given in the following sections are derived from detailed

dimensional drawings. They are given here for planning purposes only. Before commencing

fabrication, reference should always be made to the current issue of the appropriate drawings contact Micro Motion for details.

2.3.3 Free stream installation - flanged fitting

Conditions:

• Flow: 0.3 to 0.5 m/s (at the meter)

• Viscosity: 0.5 to 12,500 cP

• Temperature: -50 °C to 200 °C (–58 °F to 392 °F)

[-40 °C to 200 °C (-40 °F to 392 °F) in hazardous areas]

Note: The thermal mass of the flanges may affect the response time of the meter to temperature

changes.

The view shown below is schematic to show the dimensions of the side pocket, which is fabricated by

the end user.

10 Micro Motion 7827 Digital Viscosity Meter

Page 17

Installation (Short Stem)

circlip

4” or larger;

horizontal

6” or larger;

vertical

2.75”

(70 mm ±2 mm)

7.75”

(197 mm)

Free Stream; flanged

2” (52.3 mm)

wall thickness

at least

0.15” (3.912 mm)

2” Schedule 40

4.37”

(111 mm)

0.47” (12 mm)

PTFE

ring

circlip

PTFE

ring

circlip

PFA

ring

circlip

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

The pocket geometry must be consistent with 2" schedule 40 tube in both internal diameter and

minimum wall thickness, such as:

• Internal diameter: 2" (52.5 mm)

• Wall thickness: minimum 0.15" (3.912 mm)

Weld neck or slip-on flanges may be used, according to the flange rating selected. However, for

higher rated flanges, only slip-on flanges may give the necessary clearances.

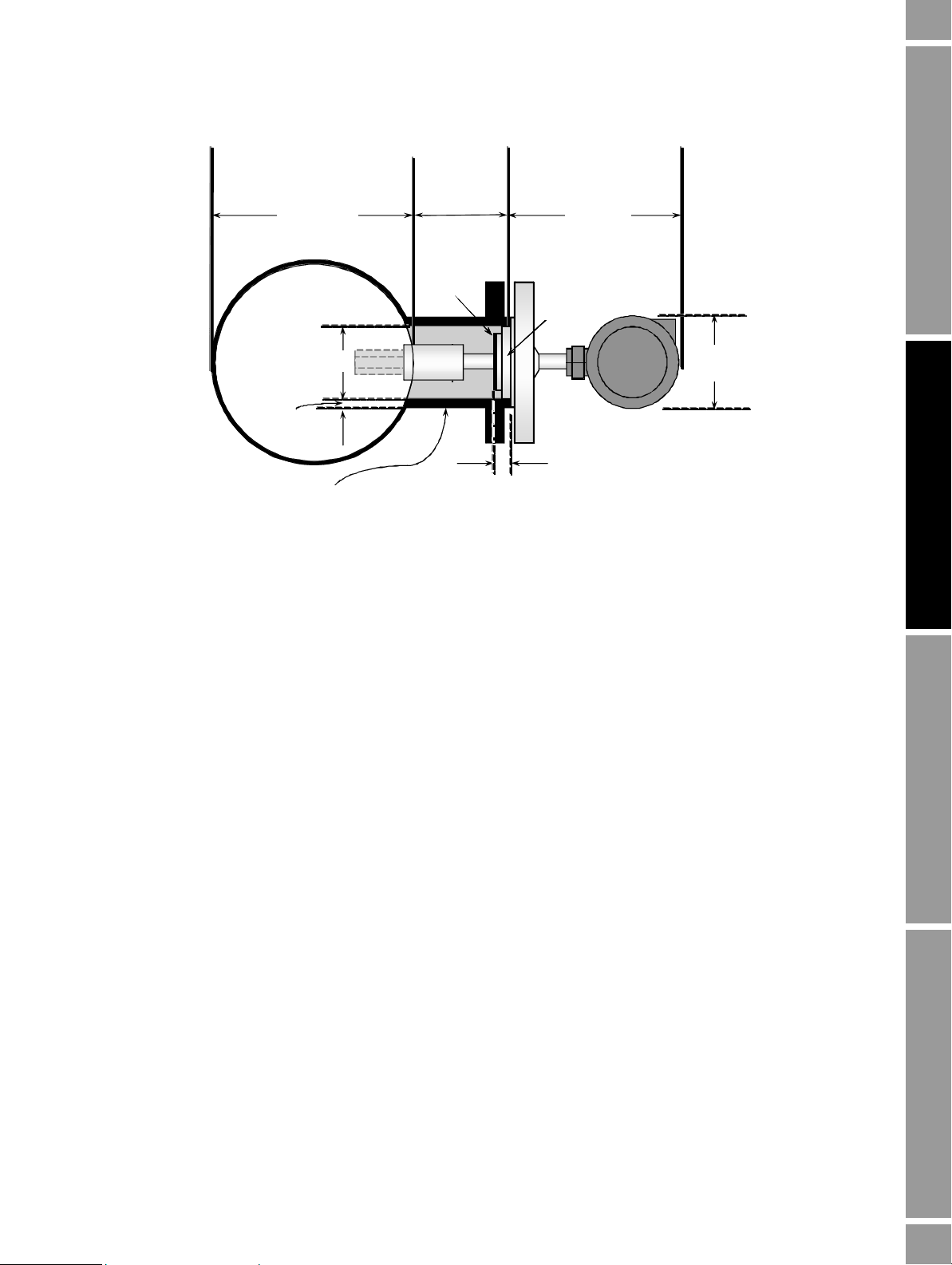

2.3.4 Free stream installation - weldolet

This is the preferred option where temperature variations are a critical factor. The reduced thermal

mass of the weldolet's taper-lock fitting renders it more able to track rapid changes in temperature.

Conditions:

• Flow: 0.3 to 0.5 m/s (at the meter)

• Viscosity: 0.5 to 12,500 cP

• Temperature: -50 °C to 200 °C (–58 °F to 392 °F)

[-40 °C to 200 °C (-40 °F to 392 °F) in hazardous areas]

The weldolet has a 1.5" taper lock fitting, and is supplied to be welded on 4", 6", 8" or 10" pipelines.

Use of the weldolet ensures that the tines of the 7827 meter are orientated correctly and are fully

inserted into the fluid stream.

Before fitting the weldolet, the pipeline must be bored through at 2.1" (52.5 mm) diameter to accept

the viscometer. The weldolet must be welded to the pipeline concentrically with the pre-bored hole.

The view shown below is a schematic to show the relevant dimensions.

Installation and Configuration Manual 11

Page 18

Installation (Short Stem)

10” (254 mm)

Horizontal: 4” or larger

Vertical: 6” or larger

Weld

4.4” (111 mm)

Free stream weldolet

to suit pipe diameter

(4, 6, 8 or 10” N.B.)

2.1” (52.5 mm)

min

Figure 2-2 Free stream 1.5" Swagelock fitting

The installation will conform generally to Schedule 40 pressure ratings. The weldolet fabrication is

rated to 100 Bar at ambient temperature.

Note: Correct installation and pressure testing of the fitting is the responsibility of the user.

2.3.5 T-piece installation

Conditions:

The thermal mass of the flanges may affect the response time of the meter to temperature changes.

Flow velocity at the pipe wall and fluid viscosity must be within the limits shown to ensure that the

fluid within the pocket is refreshed in a timely manner. This installation will not respond as rapidly as

the free-stream installation to step changes in viscosity.

The view shown is a schematic to show the dimensions of the side pocket, which is fabricated by the

end user.

• Flow: 0.5 to 3.0 m/s (at the pipe wall)

• Viscosity: 0.5 to 100 cP

• Temperature: -50 °C to 200 °C (–58 °F to 392 °F)

[-40 °C to 200 °C (-40 °F to 392 °F) in hazardous areas]

12 Micro Motion 7827 Digital Viscosity Meter

Page 19

Installation (Short Stem)

“T” piece Flanged

D

4” or larger;

horizontal

or vertical

6.9”

(175 mm ±2

mm)

7.75”

(197 mm)

2” (52.3 mm)

wall thickness

at least

0.15” (3.912 mm)

2” Schedule 40

PFA

ring

circlip

0.47” (12 mm)

4.37” (111 mm)

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

The pocket geometry must be consistent with 2" schedule 40 tube in both internal diameter and

minimum wall thickness, i.e.:

• Internal diameter: 2.1" (52.5 mm)

• Wall thickness : minimum 0.15" (3.912 mm)

Weld neck or slip-on flanges may be used, according to the flange rating selected. However, for

higher rated flanges, only slip-on flanges may give the necessary clearances.

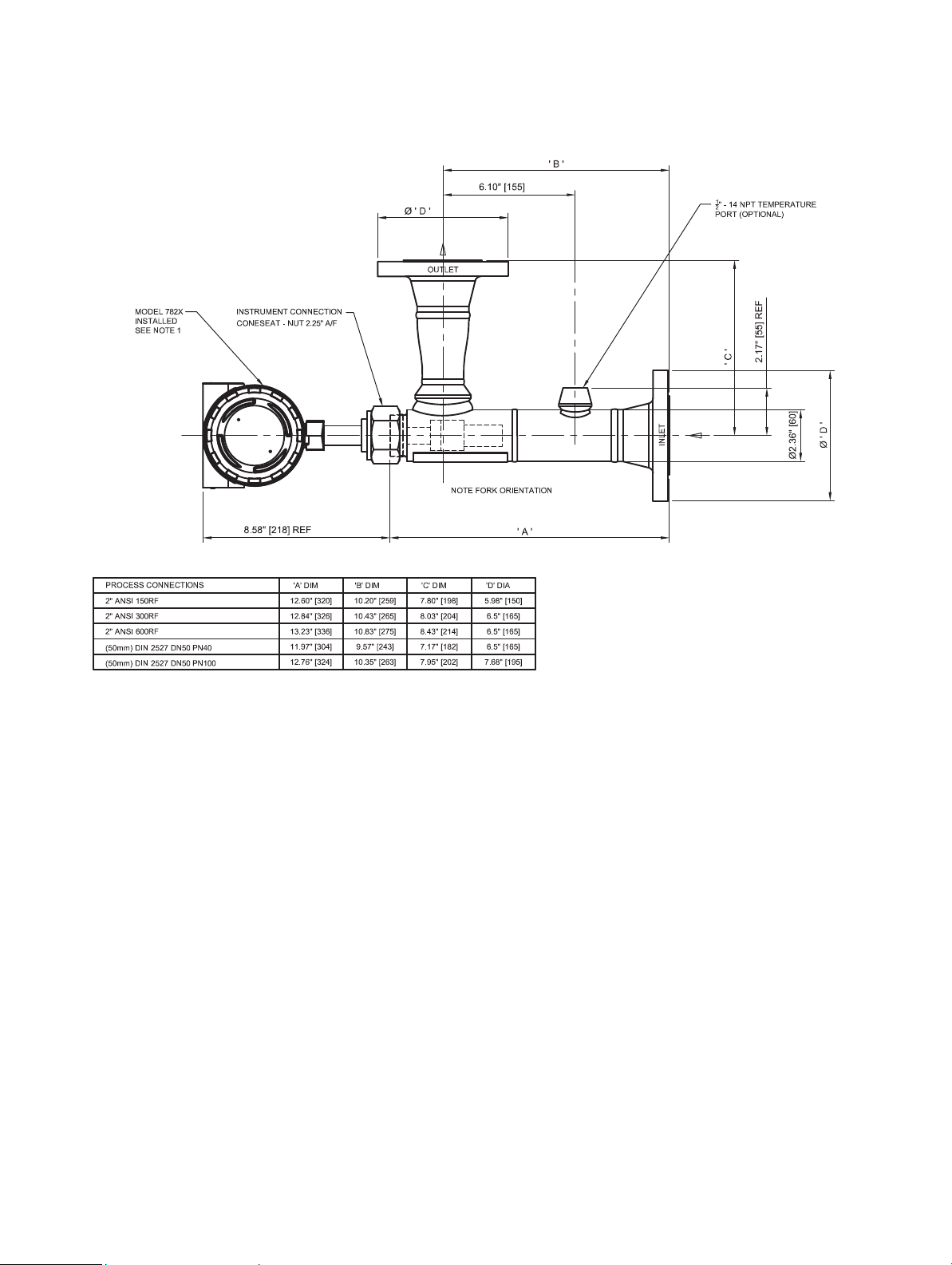

2.3.6 Flow-through chamber installation

Flow-through chambers are fabricated by Micro Motion, and are available with either weld prepared

ends or with flange or compression fittings for connection into the process pipe lines. They are

available with 1" NB, 2" NB, or 3" NB inlet and outlet pipes.

Note: The length of the inlet and outlet pipes must not be altered, otherwise the temperature response

and stability of the fitting may be adversely affected.

Conditions:

• Flow: constant, between 10 and 30 l/min for 2" sch 40 calibration bore section, 5–300 l/min

for 3" sch 80 calibration bore.

• Viscosity: 0.5 to 1000 cP

• Temperature: -50 °C to 200 °C (–58 °F to 392 °F)

[-40 °C to 200 °C (-40 °F to 392 °F) in hazardous areas]

Installation and Configuration Manual 13

• Pressure: 70 bar @ 204 °C, subject to process connections.

The PT100 is a direct insertion type, without a thermowell, and uses a ¾" Swagelok connection.

The diagram below shows an example of this type of standard installation.

Page 20

Installation (Short Stem)

Dimensions shown in inches (mm)

The three compression fittings on the flow pockets (½" drain, ¾" temp probe, and 1-½" mounting nut

for the meter) are rated to above the working pressure of the flow pocket. The fittings may be

Swagelok or Parker; both are used in manufacture.

The fittings are certified to the following standards:

• Swagelok: SO9001 / 9002, ASME,TUV,CSA,DNV

• Parker: ISO 9001 / 9002, TUV, DNV, LLOYDS

2.4 Installation in the pipeline or system

Viscosity is a highly sensitive indicator of change in a fluid – a key reason why viscosity

measurement is increasingly being chosen as a process measurement.

This sensitivity means that the measurement can be very sensitive to extraneous effects and therefore

great care must be taken to consider all the factors which affect measurement when assessing the

installation requirements.

Like many other meters, the optimum performance of the viscometer depends upon certain conditions

of the fluid and configuration of the process pipe-work. By introducing appropriate flow conditioning,

the optimum performance of the 7827 meter can be achieved at any chosen location in the process

system.

14 Micro Motion 7827 Digital Viscosity Meter

Page 21

Installation (Short Stem)

You must first select a location which serves the application objective; e.g. installed close to the point

of control. Then, consideration can be given to fluid conditioning at that point. Where the application

requirements allow a degree of tolerance in the point chosen for installation, the installation may be

able to take advantage of natural flow conditioning.

The choice of mechanical installation (free stream, “T” piece or flow-through chamber) will be

dictated partly by application needs and partly by the fluid conditions, such as:

• Condition of fluid at the sensor

• Thermal effects

• Flow rate

•Entrained gas

• Solids contamination

Fluid at the sensor

The fluid in the effective zone of the 7827 meter must be of uniform composition and at uniform

temperature. It must be representative of the fluid flow as a whole.

This is achieved either by mixing of the fluid either using a static inline mixer or taking advantage of

any natural pipe condition that tends to cause mixing, such as pump discharge, partially open valves.

The viscometer should be installed downstream where the flow is just returning to laminar flow

conditions.

Thermal effects

Avoid temperature gradients in the fluid and in the pipe work and fittings immediately upstream and

downstream of the viscometer.

Always insulate the viscometer and surrounding pipework thoroughly. Insulation must be at least

1" (25 mm) of rockwool, preferably 2" (50 mm) (or equivalent insulating heat jacket) and enclosed in

a sealed protective casing to prevent moisture ingress, air circulation, and crushing of the insulation.

Special insulation jackets are available from Micro Motion for the flow-through chambers, which,

because of the low volumetric flow rates and hence low heat flow, are more vulnerable to temperature

effects.

Avoid direct heating or cooling of the viscometer and associated pipe work upstream and downstream

that is likely to create temperature gradients. If it is necessary to provide protection against cooling

due to loss of flow, electrical trace heating may be applied, provided it is thermostatically controlled

and the thermostat is set to operate below the minimum operating temperature of the system.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Where flow-through chambers are used and where base (or referred) viscosity is required and the

behavior of the fluid is such that the temperature of the sample flow will require controlling, heat

exchangers should be fitted upstream a sufficient distance from the chamber so that the fluid

temperature is relatively stable. Insulation should be extended from the viscometer to the outlet from

the heat exchanger. Fluid heat exchangers should be controlled by modulating the flow rate of the heat

exchange fluid and not by modulating the sample flow rate.

Flow rate

Flow rates and velocities should be maintained relatively constant within the limits given. The fluid

flow provides a steady heat flow into the viscometer section, and the flow rate influences the self

cleaning of the sensor and the dissipation of bubbles and solid contaminants.

Installation and Configuration Manual 15

Page 22

Installation (Short Stem)

Where it is necessary to install the viscometer in a by-pass (either using the free stream installation in

a 4" diameter horizontal by-pass, or a flow-through chamber), flow may be maintained using pressure

drop, pitot scoop, or by a sample pump. Where a pump is used, the pump should be upstream of the

viscometer.

Entrained gas

Gas pockets can disrupt the measurement. A brief disruption in the signal caused by transient gas

pockets can be negated in the signal conditioning software, but more frequent disruptions or serious

gas entrainment must be avoided. This can be achieved by observing the following conditions:

• Keep pipe lines fully flooded at all times

• Vent any gas prior to the viscometer

• Avoid sudden pressure drops or temperature changes which may cause dissolved gases to

break out of the fluid

• Maintain a back pressure on the system sufficient to prevent gas break out (e.g. back pressure

equivalent to twice the ‘head loss’ plus twice the vapor pressure)

• Maintain flow velocity at the sensor within the specified limits.

Solids contamination

• Avoid sudden changes of velocity that may cause sedimentation.

• Install the viscometer far enough downstream from any pipework configuration which may

cause centrifuging of solids (e.g. bends).

• Maintain flow velocity at the sensor within the specified limits.

• Use filtration if necessary.

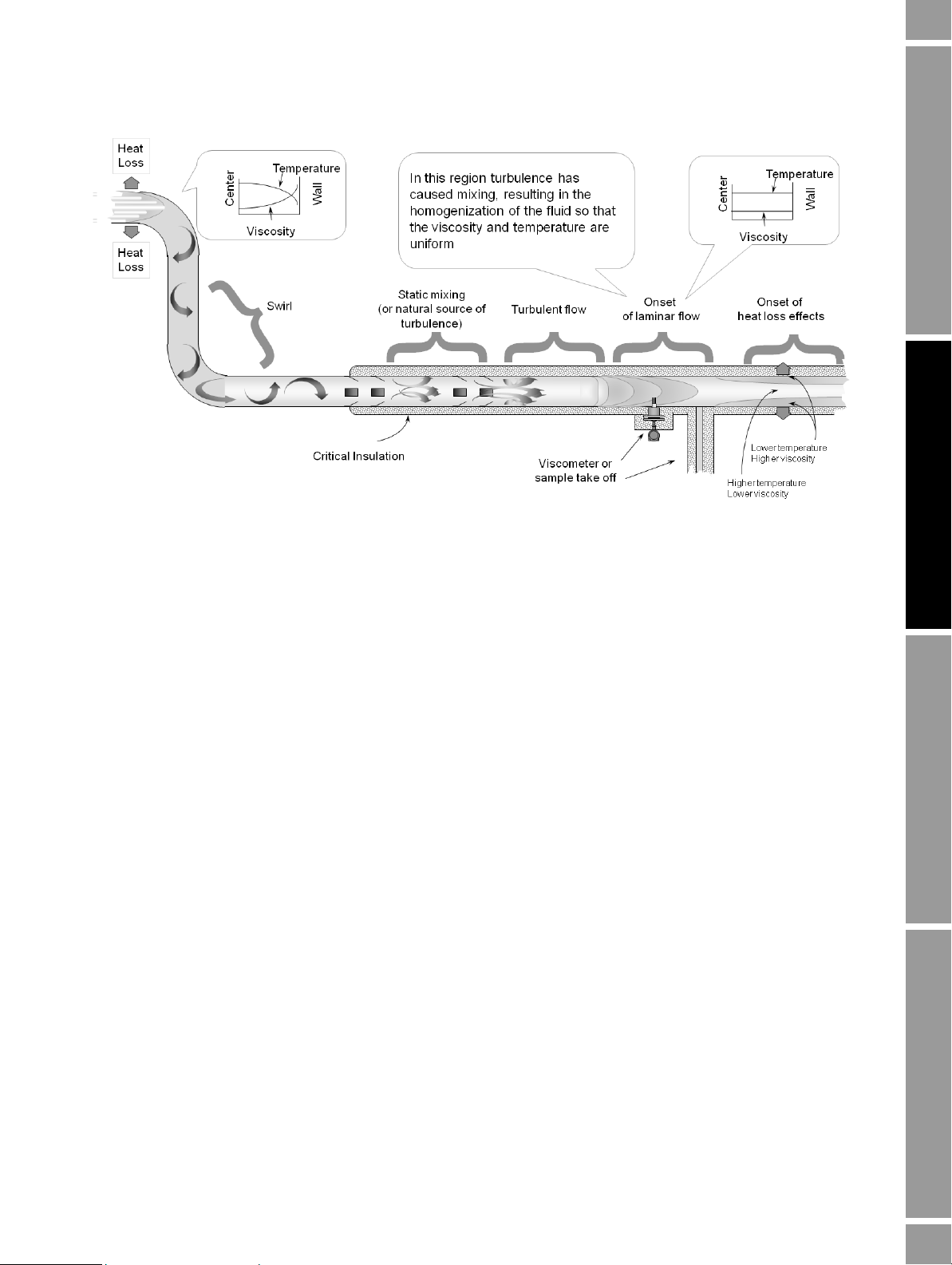

The diagram below illustrates some of the principles outlined in this section. It shows a free-stream

viscometer installation with an additional sample take off. The position of both is such that the static

mixing (which could be caused by pump discharge or partially closed valve), has negated the adverse

effects of bends and established laminar flow, and has ensured that the fluid is thoroughly mixed and

thus of uniform composition and temperature. The ideal place for a free stream or “T” piece

installation, or for the by-pass take off point is where the flow has just begun to be laminar.

Note: The insulation extends upstream and downstream far enough to prevent conduction losses in the

pipe walls from degrading the temperature conditioning of the fluid at the sensor.

16 Micro Motion 7827 Digital Viscosity Meter

Page 23

Installation (Short Stem)

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

2.5 Typical installations

The following diagrams illustrate some typical solutions for line viscosity measurement, simple base

viscosity referral and base viscosity using temperature control of the sample flow.

In all examples, the fluid flow is assumed to be uniform in composition and temperature as it enters

the viscometer section.

2.5.1 Jacketed pipeline

The diagram below shows a jacketed pipeline. The heating fluid in the jacket will cause temperature

gradients, and therefore it is discontinued through the viscometer section. If protection against cooling

due to loss of flow is required through the unjacketed section then it must be provided using electrical

trace heating.

Installation and Configuration Manual 17

Page 24

Installation (Short Stem)

Figure 2-3 Jacketed pipeline installation

Alternatively, the viscometer can be installed in a by-pass. By ensuring that the sample is mixed

where the by-pass draws off the main pipeline, it is not necessary to discontinue the main pipe line

jacket. This is shown below.

Figure 2-4 4" bypass using DP to generate constant flow at the meter

18 Micro Motion 7827 Digital Viscosity Meter

Page 25

Installation (Short Stem)

PT10 0

(optional)

Pump

10-30 l/min

Insulation

(required)

Optional drain line (½”)

either vented or

returned to process

Line or Base Viscosity: temperature not conditioned

Horizontal Pipe line

Flowmeter

(optional)

1”-2” sample lines

Always install the chamber with flow

in horizontal and flow out vertically

upwards.

Drain, to purge solids, is vertically

down and can be vented and/or

returned to line.

Side Wall Tappin g

Side Wall Tapping

with Pitot Scoop

Meter in 2”

flow-through

chamber

2.5.2 Flow-through chamber

The diagram below shows the use of a flow-through chamber. This provides a compact installation

and is particularly suited to flows of contaminated fluids, since the design of the chamber encourages

self cleaning. Because the volume flow rate is low, the heat flow is low and therefore the insulation

must be as efficient as possible. The low heat flow makes this system ideal for base (or referred)

viscosity measurement using heat exchangers.

Figure 2-5 Pumped bypass

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Installation and Configuration Manual 19

Page 26

Installation (Short Stem)

20 Micro Motion 7827 Digital Viscosity Meter

Page 27

Chapter 3

Installation (Long Stem)

For information on installing a short-stem version of the 7827 digital viscosity meter, see Chapter 2.

3.1 Introduction

All drawings and dimensions given in this manual are given here for planning purposes only. Before

commencing fabrication, reference should always be made to the current issue of the appropriate

drawings. Contact Micro Motion for details.

To protect the tines from damage, a Transit Cover is fitted prior to shipment from the factory. The Transit

Cover is held in place by 2 grub screws. Be sure to remove and store the Transit Cover prior to

installation. Re-fit the Transit Cover if storing or transporting, such as for repair. If the Transit Cover has

been lost, it can be purchased from Micro Motion.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

For further information on handling and using the meter, see “Safety guidelines” on page 1

There are a variety of external factors that affect the ability of the 7827 digital viscosity meter to

operate successfully. In order to ensure that your system works correctly, the effects of these factors

must be taken into consideration when designing your installation.

There are two main aspects to consider:

• The accuracy and repeatability of the measurements

• The relevance of the measurements to the overall purpose of the system

Factors which may adversely affect accuracy and repeatability include:

• The presence of gas or bubbles within the fluid being measured

• Non-uniformity of the fluid

• The presence of solids as contaminants

• Fouling of the meter

• Temperature gradients

• Cavitations and swirls

• Operating at temperatures below the wax point of crude oils

In some applications, absolute accuracy is less important than repeatability. For example, in a system

where the control parameters are initially adjusted for optimum performance, and thereafter only

checked periodically.

Installation and Configuration Manual 21

Page 28

Installation (Long Stem)

The term achievable accuracy can be used to describe a measure of the product quality that can be

realistically obtained from a process system. It is a function of measurement accuracy, stability and

system response. High accuracy alone is no guarantee of good product quality if the response time of

the system is measured in tens of minutes, or if the measurement bears little relevance to the operation

of the system. Similarly, systems which require constant calibration and maintenance cannot achieve

good achievable accuracy.

Factors which may adversely affect the relevance of the measurements could include:

• Measurement used for control purposes being made too far away from the point of control, so

that the system cannot respond properly to changes.

• Measurements made on fluid which is unrepresentative of the main flow.

3.2 Installation considerations

Density and viscosity is a sensitive indicator of change in a fluid - a key reason why density and

viscosity measurement is increasingly being chosen as a process measurement. However, density and

viscosity measurements can be sensitive to extraneous effects and, therefore, great care must be taken

to consider all the factors which may affect measurement when assessing the installation

requirements.

Like many other meters, the optimum performance of the viscosity meter depends upon certain

conditions of the fluid. You must first select a suitable position where the fork’s tines are always

completely immersed in the fluid. Although tolerant of solids, turbulence and bubbles, there should

be at least a 50 mm clearance from objects e.g. impellers, pipe stubs, etc.

Then consideration can be given to fluid conditioning at that point. Where the application

requirements allow a degree of tolerance in the point chosen for installation, the installation may be

able to take advantage of natural flow conditioning.

The choice of mechanical installation will be dictated partly by application needs and partly by the

fluid conditions, such as:

• Condition of fluid at the sensor.

• Flow rate.

•Entrained gas.

• Solids contamination.

3.2.1 Fluid at the sensor

The fluid in the effective zone of the long stem 7827 meter must be of uniform composition and at

uniform temperature. It must be representative of the fluid as a whole. This is achieved by taking

advantage of any natural tank condition that tends to cause mixing, such as pump discharge, partially

open valves etc.

3.2.2 Flow rate

If there is flow in the tank, the rate of flow should ideally be not more than 0.5 m

3

/s. If flow rates

exceed this, a ‘shift’ will be introduced into density and viscosity readings. The higher the flow rate

is, the larger the ‘shift’. Measurements also become ‘noisy’.

22 Micro Motion 7827 Digital Viscosity Meter

Page 29

Installation (Long Stem)

3.2.3 Entrained gas

Gas pockets can disrupt the measurement. A brief disruption in the signal caused by transient gas

pockets can be negated in the internal signal conditioning software, but more frequent disruptions or

serious gas entrainment must be avoided. This can be achieved by observing the following

conditions:

• Vent any gas prior to the viscosity meter.

• Avoid sudden pressure drops or temperature changes which may cause dissolved gases to

break out of the fluid.

3.2.4 Solids contamination

• Avoid sudden changes of velocity that may cause sedimentation.

• Install the meter far enough away from any build-up of solids.

• Maintain flow velocity at the sensor within the specified limits.

• Specify the long-stem 7827 meter with a non-stick PFA protective layer.

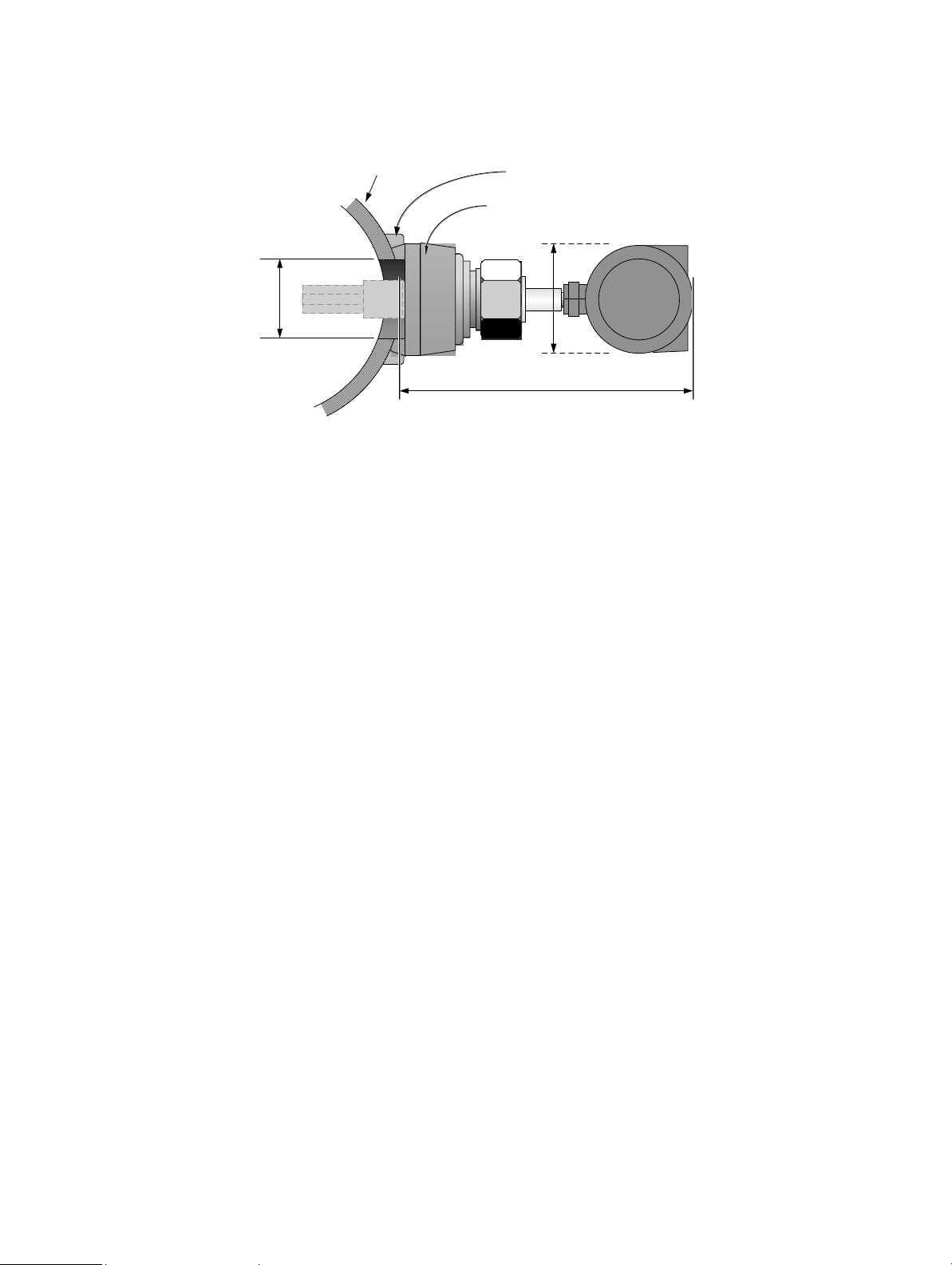

3.3 Open-tank installation

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Only the safe area model may be used in open-tank installation.

1. For open-tank installations, the long-stemmed 7827 meter is clamped to a structure (see

Figure 3-1). The position of the clamp determines the insertion depth.

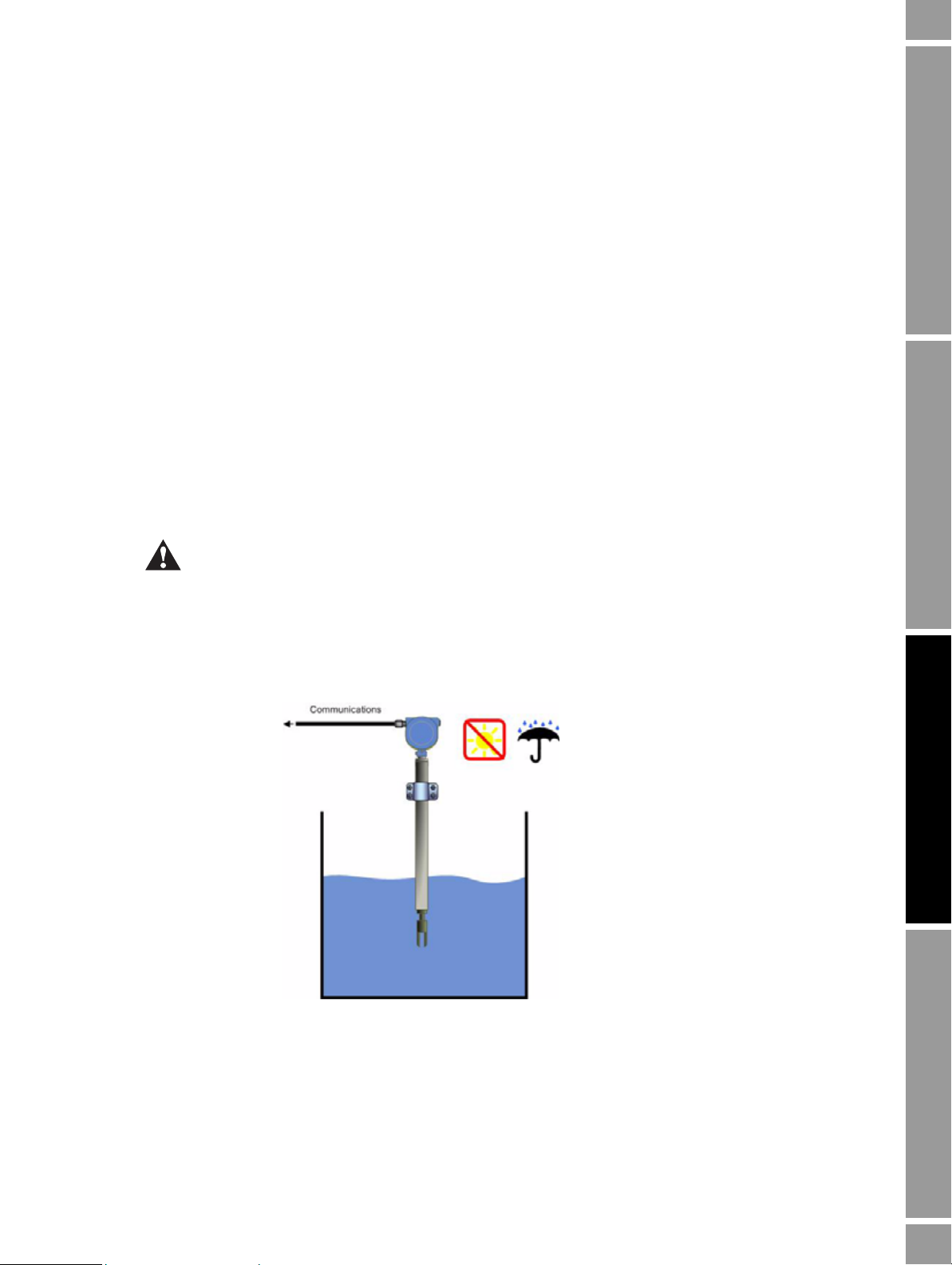

Figure 3-1 Open-tank installation

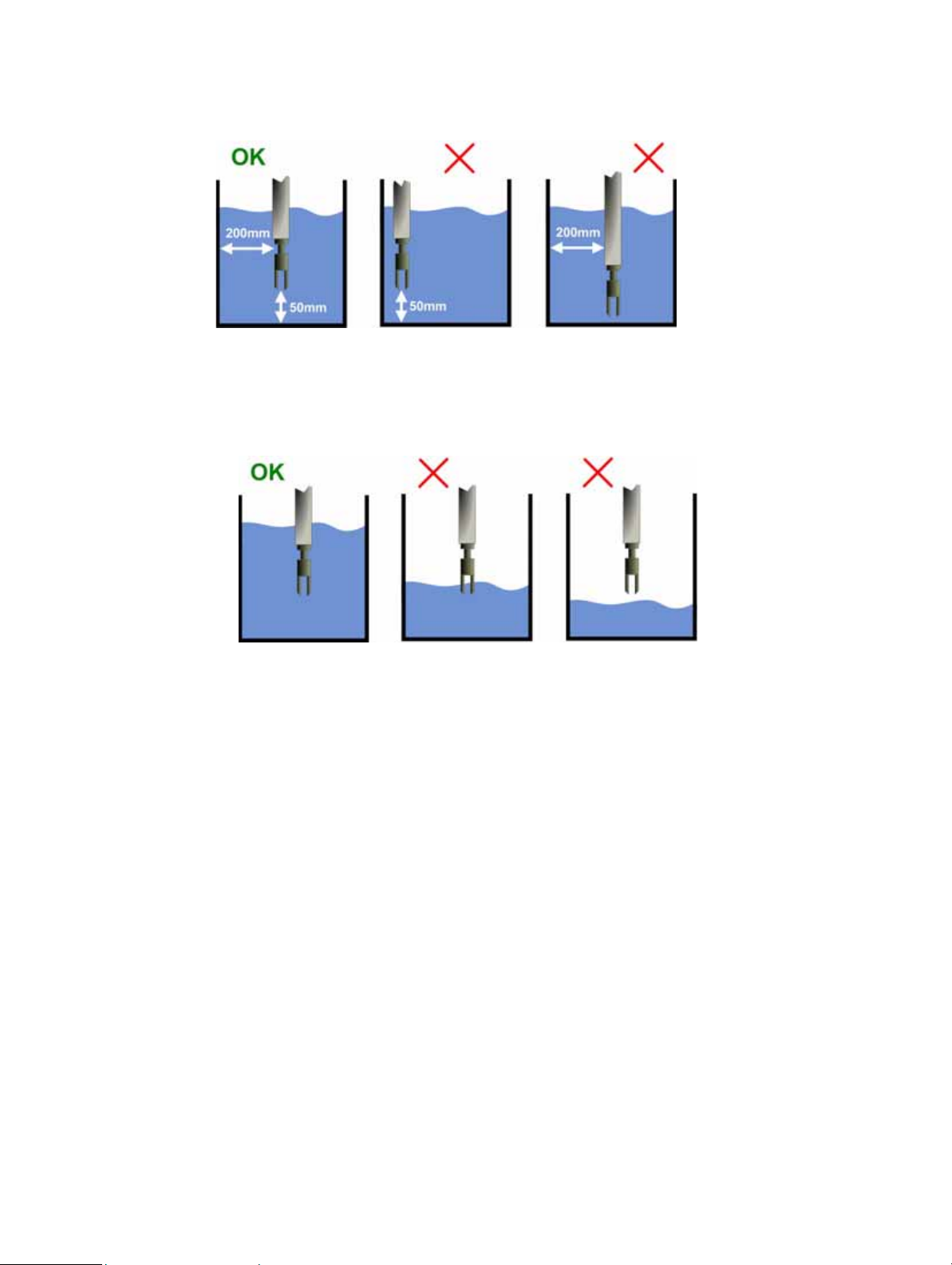

2. Keep the tines away from the tank wall (see Figure 3-2).

Installation and Configuration Manual 23

Page 30

Installation (Long Stem)

Figure 3-2 Keeping tines away from the tank wall (Open-tank)

3. Keep the tines immersed in fluid (see Figure 3-3).

Figure 3-3 Keeping tines immersed (Open-tank)

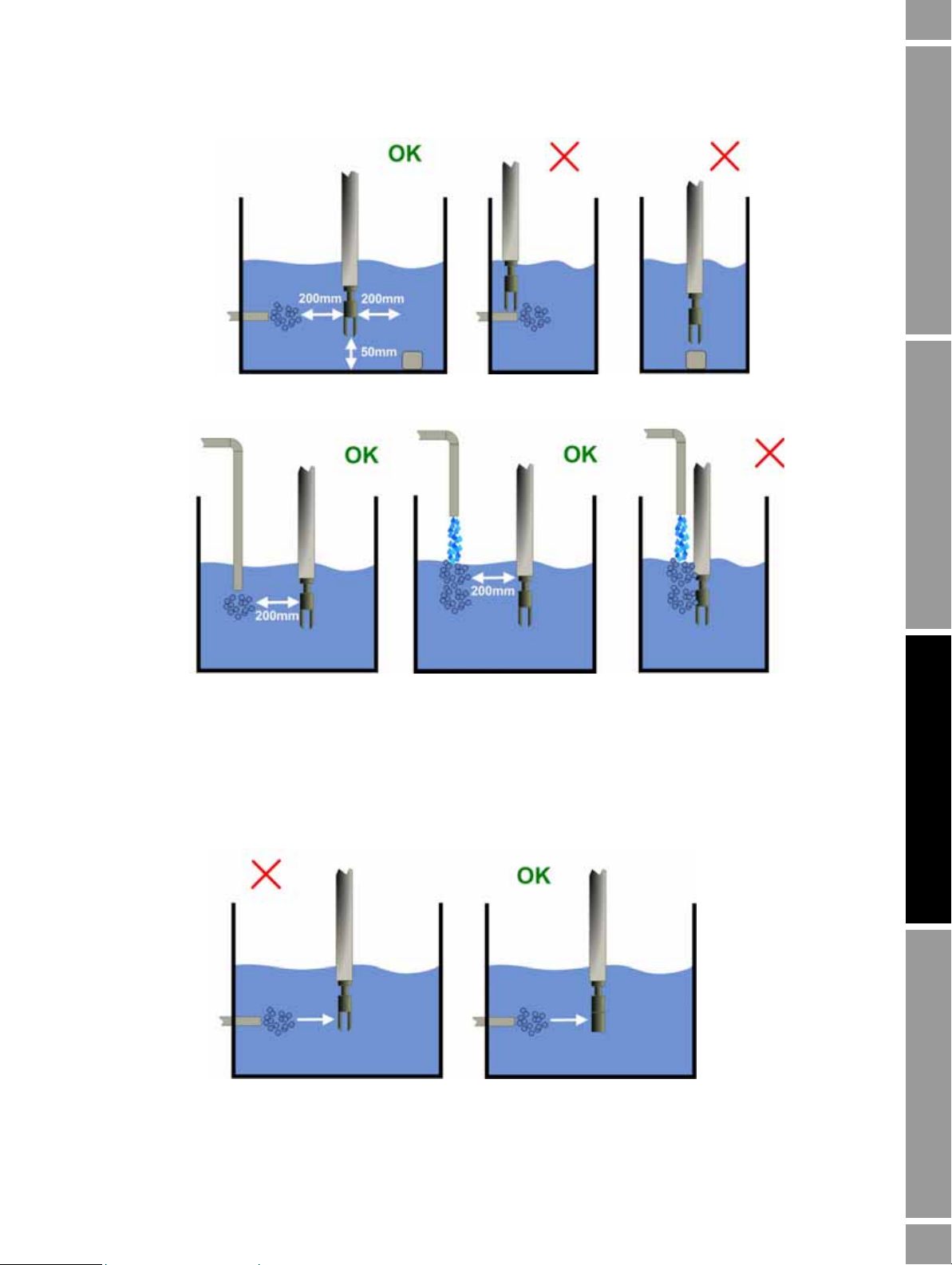

4. Keep tines away from objects and disturbed flow (see Figure 3-4).

24 Micro Motion 7827 Digital Viscosity Meter

Page 31

Installation (Long Stem)

Figure 3-4 Keeping tines away from objects and disturbed flow (open tank)

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

5. If there is flow, align the tines such that the flow is directed towards the gap between the tines

(see Figure 3-5).

Figure 3-5 Aligning the tines in flow (Open-tank)

6. Keep away from deposit build-up (see Figure 3-6).

Installation and Configuration Manual 25

Page 32

Installation (Long Stem)

Figure 3-6 Avoid deposit build-up (Open-tank)

3.4 Closed-tank installation

1. For closed-tank installations, the long-stemmed 7827 meter should have a factory fitted flange

attachment. (This is an option that is specified as a code in the part number – see a list of the

product options in the product data sheet available at www.micromotion.com.) (See

Figure 3-7).

Figure 3-7 Closed-tank installation

2. To vary the insertion depth, a standoff section with flange (not supplied) can be used (see

Figure 3-8).

26 Micro Motion 7827 Digital Viscosity Meter

Page 33

Installation (Long Stem)

Figure 3-8 Use of standoff section (not supplied)(closed-tank)

3. Keep the tines immersed in fluid (see Figure 3-9).

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Figure 3-9 Keeping tines immersed (closed tank)

4. Keep the tines away from the tank wall (see Figure 3-10).

Figure 3-10 Keeping away from tank wall (closed tank)

5. Allow for flexing of the tank lid, preventing the long-stemmed 7827 meter from being pushed

towards a tank wall or into the path of disturbed flow (see Figure 3-11).

Installation and Configuration Manual 27

Page 34

Installation (Long Stem)

Figure 3-11 Allowing for tank lid flexing (closed tank)

6. Keep tines away from objects and disturbed flow (see Figure 3-12).

Figure 3-12 Keeping tines away from objects and disturbed flow (Closed-tank)

7. If there is flow, align the tines such that the flow is directed towards the gap in the tines (see

Figure 3-13)

28 Micro Motion 7827 Digital Viscosity Meter

Page 35

Installation (Long Stem)

Figure 3-13 Aligning the tines in flow (closed tank)

8. Keep away from deposit build-up (see Figure 3-14).

Figure 3-14 Avoid deposit build-up (closed tank)

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

3.5 Calibration

The log-stemmed 7827 meter is factory calibrated and no further calibration is necessary. The

calibration is traceable to UK National Standards through the Micro Motion UKAS-approved

laboratory.

For calibration range, see the 7827 digital viscosity meter product data sheet available at

www.micromotion.com.

3.6 If the Tank is Pressurized

1. Once the installation has been prepared, and before installing the 7827 meter, fit a blanking

flange or compression nut to the 7827 meter mounting, and pressurize and flush the system.

2. Isolate the system, depressurize and remove the blanking flange or compression nut.

3. Install the 7827 meter.

4. Slowly pressurize the system and check for leaks, particularly if the normal operating

temperature is high, or the sensor has been fitted cold; tighten as necessary.

Installation and Configuration Manual 29

Page 36

Installation (Long Stem)

5. Once the system has stabilized and is leak free, fit the insulation material, remembering also to

insulate any flanges.

30 Micro Motion 7827 Digital Viscosity Meter

Page 37

Electrical Connections

Chapter 4

Electrical Connections

For installations in hazardous areas:

• For ATEX installations, the electrical installation must strictly adhere to the safety information

given in the ATEX safety instructions booklet shipped with this manual. See Section 1.1 for

important information.

• For installations in USA and Canada, the electrical installation must strictly adhere to the Electrical

Codes and a conduit seal is required within 2” (50 mm) of the enclosure.

4.1 Introduction

This chapter shows you how to wire up the 7827 digital viscosity meter and then connect it to the

Micro Motion

®

795x series of computers.

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Note: Only Micro Motion signal converters and flow computers are able to interpret the signals from

the 7827 meter; it cannot be connected to equipment from other manufacturers.

4.2 EMC and cabling considerations

To meet the EC Directive for EMC (Electromagnetic Compatibility) it is recommended that the meter

be connected using a suitable instrumentation cable and earthed through the meter body and

pipework. The instrumentation cable should have an individual screen, foil or braid over each twisted

pair and an overall screen to cover all cores. Where permissible, the screen should be connected to

earth at both ends. Note that for intrinsic safety, termination of the screen to earth in the hazardous

area is not generally permitted.

To electrically connect the 7827 to a Micro Motion 795x series computer you will need the following:

• Minimum of 7-core screened twisted pairs with overall screen

• 795x connector plugs:

7950 7951 Klippon 7951 D-type (Cannon)

2 off 10-way 2 off 10-way 2 off 25-way

1 off 4-way 1 off 4-way 1 off 4-way

• 1/2" NPT to M20 x 1 Exd IIC-rated gland adaptor

• M20 x 1 Exd IIC-rated cable gland

• 1/2" NPT Exd IIC-rated blanking plug

• Hex drive, 2.5 mm AF (2.0 mm AF stainless steel enclosure)

• Electrical screwdriver, 3 mm drive

• Wire strippers

• Gland spanners / drives

Installation and Configuration Manual 31

Page 38

Electrical Connections

GRUB

4.3 Installation and safety in hazardous areas

For installations in hazardous areas:

• For ATEX installations, the electrical installation must strictly adhere to the safety information

given in the ATEX safety instructions booklet shipped with this manual. See Section 1.1 for

important information.

• For installations in USA and Canada, the electrical installation must strictly adhere to the Electrical

Codes and a conduit seal is required within 2” (50 mm) of the enclosure.

The 7827 meter is explosive proof and can be installed in a hazardous area without the use of

intrinsically safe barriers (or isolators). However, it is still necessary to observe the rules of

compliance with current standards concerning flameproof equipment:

• The meter electronics housing covers must be tightened securely and locked into position by

their locking screws.

• The electrical conduit must be fitted with an appropriate explosion-proof cable gland.

• If any electrical conduit entry port is not used it must be blanked off using the appropriate

explosion-proof plug, with the plug entered to a depth of at least five threads.

• The spigot must be locked into place.

• The cabling used to wire the 7827 to the signal converter/flow computer must be of the

appropriate Exd rating.

4.4 Installation in non-hazardous areas

Typically the 7827 meter will operate over cable lengths up to 2 km from a 24 V supply.

Micro Motion recommend cables similar to BS 5308 or RS 368.

4.5 Wiring the meter

1. Open the Terminal Board side of the

meter’s electronics housing by

undoing the grub screw and

unscrewing the lid anticlockwise.

UNDO THIS CAP

SCREW

32 Micro Motion 7827 Digital Viscosity Meter

Page 39

Electrical Connections

HOLE

1/2" NPT PLUG Ex d IIC

1/2" TO M20 x 1 ADAPTOR

M20 x 1 CABLE GLAND

Exd IIC

T

TB3 T B 1

TB2

200 mm OF UN S CREEN ED WIR E

TERMINAL BOARD

A

CABLE GLAND

SU

G

PR T

SIGNAL -

SIGNAL +

SUPPLY -

SUPPLY +

PRT POWER +

PRT SIGNAL +

PRT SIGNAL -

PRT POWER -

k

Note: “S upply-”

& “Signal -” are

linked internally

NEST WIRES

PRT

Term 1

SUPPLY SIG

+ - + -

2. The meter is normally mounted

horizontally such that the 1/2” NPT

holes are on a vertical plane. This

minimizes water ingress. Identify the

1/2" NPT hole which is lowest and

attach the multi-core cable to it.

3. Assemble the adaptor, cable gland and

cable so that the multi-core cable is

gripped leaving 200 mm of free,

unscreened wire to connect to the

terminal blocks.

4. Fix the 1/2" NPT plug to the un-used

hole.

5. The adjacent diagram shows all the

electrical connections to the meter

terminal block. Refer to Section 4.6

for connections to the 795x.

/2" NPT

HOLE

SUPP LY SIG

1/2" NPT

PR

PPLY SI

xd IIC

DAP T OR

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Installation and Configuration Manual 33

6. When you have screwed the wires into

the correct terminals, carefully tuck

the wires around the electronics, and

tighten the cable gland.

Fi gure 3. 1: Electrical connections to 7827 main termi nal bloc

erm 8

Page 40

Electrical Connections

7. Screw the housing cap on fully and

tighten the locking grub screw using

the 2.5 mm AF hex drive.

4.6 Connecting the 7827 to a 795x series computer

4.6.1 Overview

The 7827 requires a 795x series computer (Signal Converter or Flow Computer) with liquid-based

application software for it to be functional. This section provides a guide to possible wiring

connections between the 7827 and the 795x. Configuration of the 795x is outside the scope of this

manual. For this task, refer to the 795x operating manual that was supplied with the 795x instrument.

795x computers are available as a 7950 Wall Mount unit or 7951 Panel Mount unit. Each type of unit

has a different position and layout for the physical connections. There is even a choice of two

connection panels for the 7951 - Klippon or D-type (Cannon).

TIGHTEN

CAP

TIGHTEN

GRUB

:

795x Connectors used

7950 10-way Klippon

7951 25-way D-type (Cannon) or 10-way Klippon

Note: The choice of rear panel connectors for the 7951 is done prior to ordering the unit so that it is

manufactured to satisfy the customers connector requirement.

This section has diagrams of connections, involving the 7827, for the full 795x range:

• 7950 Signal Converter

• 7950 Flow Computer

• 7951 Signal Converter

• 7951 Flow Computer

Note: “Signal Converter” and “Flow Computer” are terms that are often used to identify the basic

purpose of the 795x application software. Refer to the supplied 795x operating manual if in doubt

about identification.

Use this table to quickly find the appropriate connection diagrams.

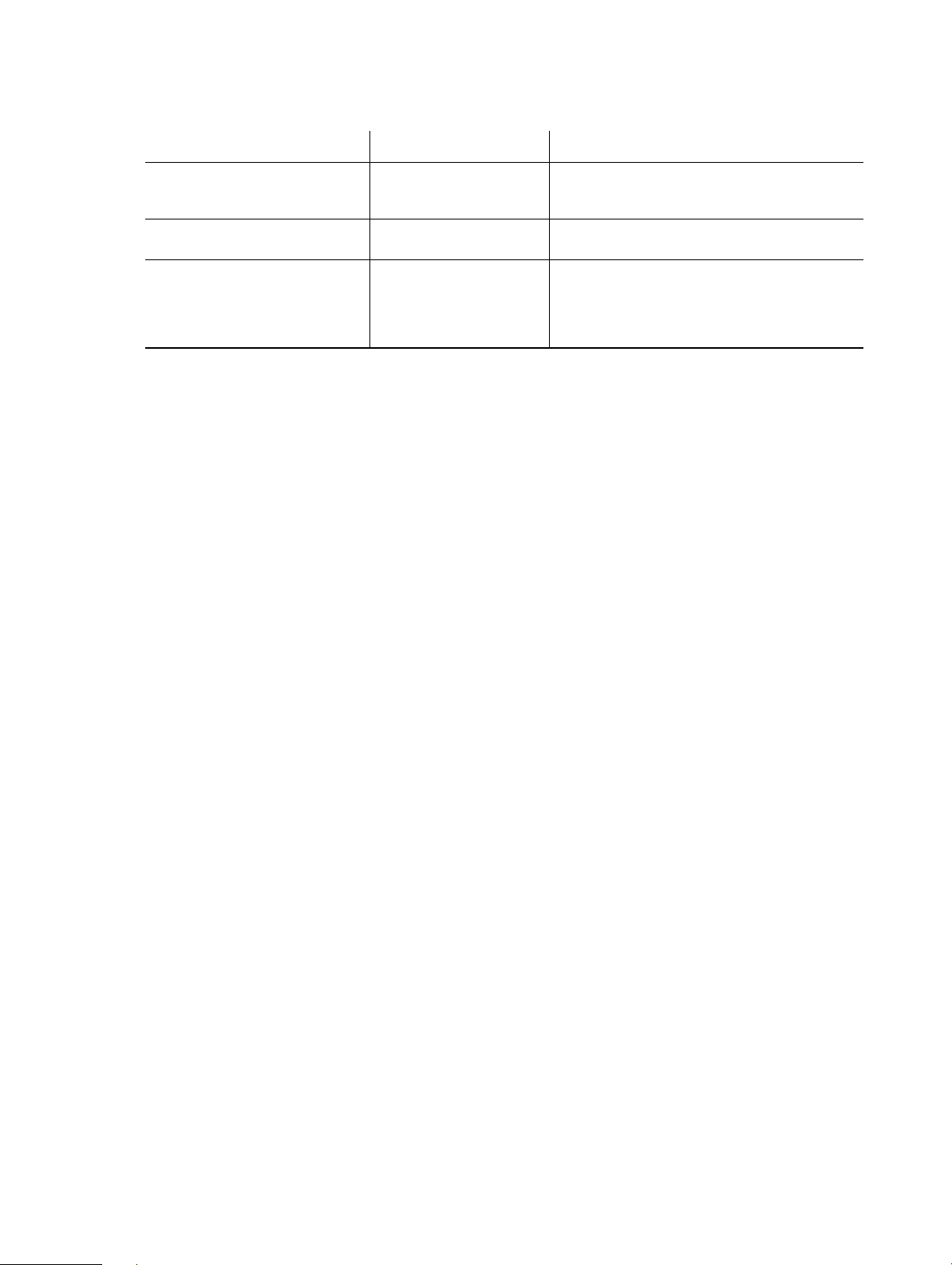

795x Figure No. of 7827s

7950 Signal Converter Figure 4-1 1

34 Micro Motion 7827 Digital Viscosity Meter

Page 41

Electrical Connections

Signal -

PRT Signal -

PRT Signal +

PRT Power +

PRT Power -

0V Supply

S i gn al +

+24V Power

Sig +

PL12/4

PL12/3

PL12/2

PL12/

PL9/8

PL9/6

5

p

p

Signal -

PRT Signal -

PRT Signal +

PRT Power +

PRT Power -

0V Supply

S i gn al +

+24V Power

Sig +

PL7/4

PL7/3

PL7/2

PL7/1

PL5/10

PL5/3

PL5/9

PL5/4

SK 6 /24

SK 6 /22

p

1

p

g

y

7950 Flow Computer Figure 4-2 2

7951 Signal Converter Figure 4-1 1

7951 Flow Computer Figure 4-3 2

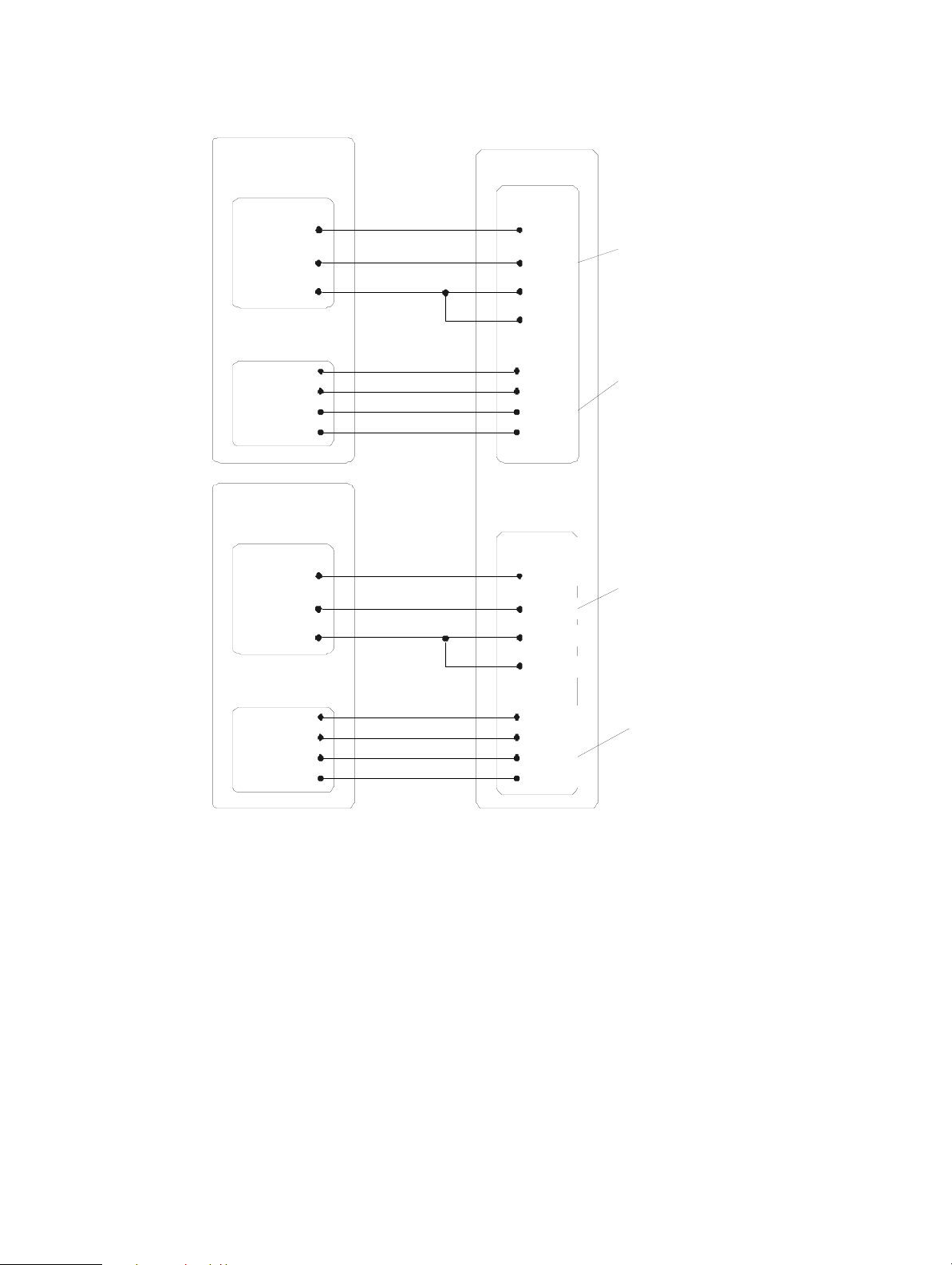

4.6.2 Connection diagrams

Figure 4-1 Connecting a 7827 to a 7950/51 Signal Converter

7827

7950

Klippon

Supply +

PL9/

Viscosity using

Density input #2

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

ins on a 7950

Supply -

PT100

PRT

7827

PL9/7

PRT In pu t #1

ins on a 7950

7951

Klippon D-type

Supply +

SK 6 /16

Viscosity using

Density input #2

ins on a 795

Supply -

SK 6 /17

PT100

Note :

The "Si

internall

external link.

PRT

-" connection on the 7827 is not shown since it is

linked to the "Supply -" connection. There is no need

Installation and Configuration Manual 35

SK 7 /14

SK 7 /15

SK 7 /16

SK 7 /17

PRT Input #1

ins on a 7951

Page 42

Electrical Connections

Signal -

PRT Signal -

PRT Signal +

PRT Power +

PRT Power -

0V Supply

Signal +

+24V Power

Sig +

PL13/8

PL13/7

PL13/6

PL13/5

PL10/8

PL10/6

PL10/7

4

p

p

Signal -

PRT Signal -

PRT Signal +

PRT Power +

PRT Power -

0V Supply

Signal +

+24V Power

Sig +

PL13/4

PL13/3

PL13/2

PL13/

PL10/4

PL10/2

PL10/3

p

p

g

y

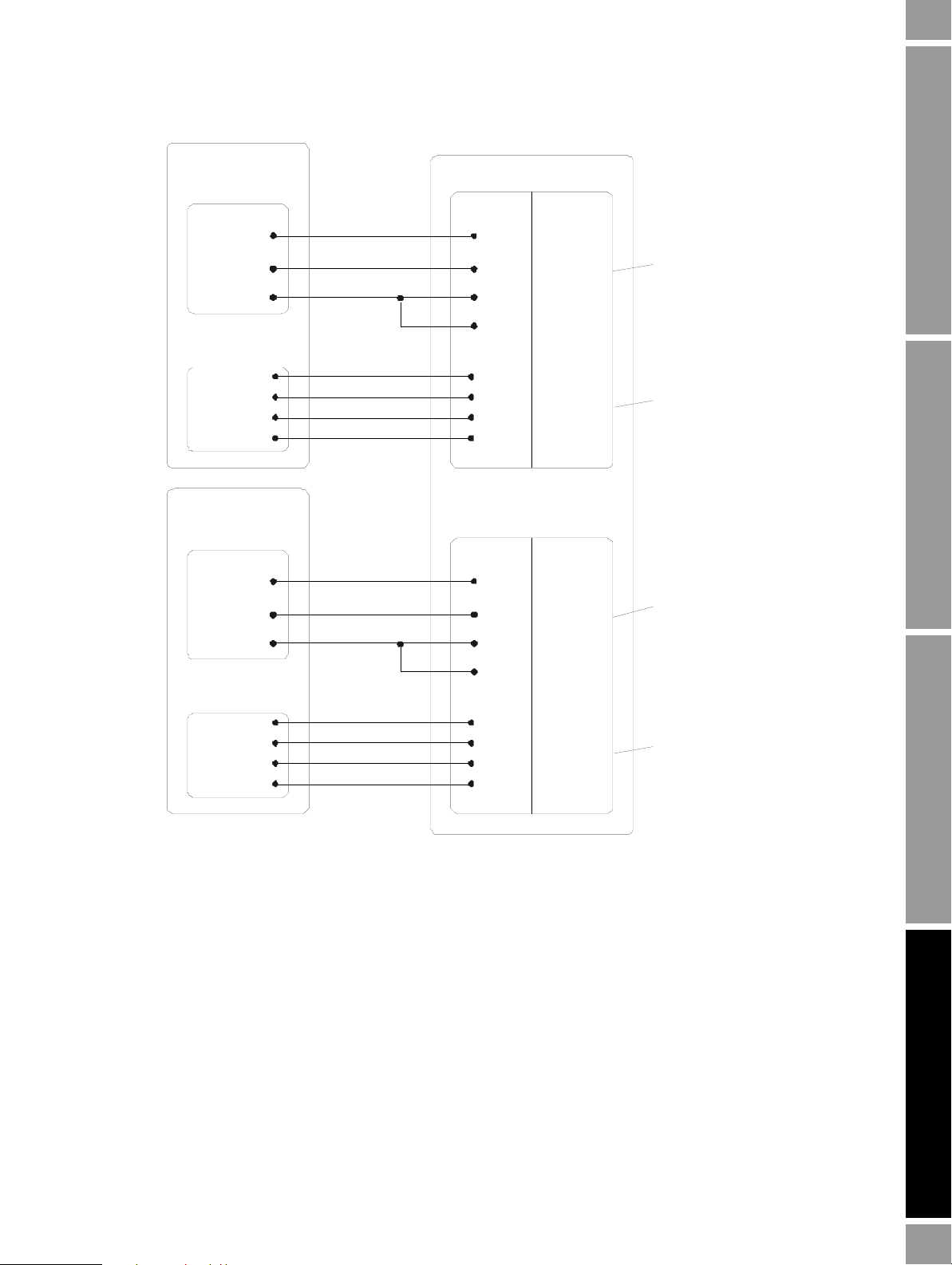

Figure 4-2 Connecting two 7827 meters to a 7950 Flow computer

7827

7950

Klippon

Supply +

PL10/

Viscosity 'A' using

Density input #3

ins on the 7950

Supply -

Integrated PT100

PRT Input #3

PRT

7827

Supply +

Klippon

PL10/5

ins on the 7950

Viscosity 'B' using

Density input #

ins on the 7950

Supply -

No te :

The "Si

internall

external link.

n t eg r a t e d PT 1 00

PRT

-" connection on the 7827 is not shown since it is

linked to the "Supply -" connection. There is no need

PRT Input #4

ins on the 7950

36 Micro Motion 7827 Digital Viscosity Meter

Page 43

Electrical Connections

PRT Signal -

PRT Signal +

PRT Power +

0V Supply

S i gn al +

+24V Power

Sig +

PL8/8

PL8/7

5

PL5/10

PL5/7

PL5/8

SK8/ 8

SK8/ 7

5

SK 6/24

SK 6/20

SK 6/21

p

p

Sig nal -

PRT Signal -

PRT Signal +

PRT Power +

PRT Power -

0V Supply

S i gn al +

+24V Power

Sig +

PL8/4

PL8/3

PL8/2

PL8/1

PL5/10

PL5/5

SK8/ 4

SK8/ 3

SK8/ 2

SK8/ 1

SK 6/24

SK 6/18

p

p

g

y

Figure 4-3 Connecting two 7827 meters to a 7951 Flow computer

7827

7951

Klippon D-type

Supply +

PL5/9

SK 6/22

Viscosity 'A' using

Density input #3

ins on the 7951

Supply -

PL5/6

SK 6/19

Integrated PT100

PRT Input #3

PRT

7827

ins on the 7951

Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction Installation (Short Stem) Electrical ConnectionsInstallation (Long Stem)Introduction

Klippon D-type

PL5/9

SK 6/22

Viscosity 'B' using

Density input #4

ins on the 7951

Supply +

Supply -

Integrated PT100

PRT

No te :

-" connection on the 7827 is not shown since it is

linked to the "Supply -" connection. There is no need

The "Si

internall

external link.

4.7 Checking the installation

After installation, the following procedure will indicate to a high degree of confidence that the meter

is operating correctly.

PRT Power -

Sig nal -

PL8/

PL8/6

SK8/

SK8/ 6

PRT Input #4

ins on the 7951

Installation and Configuration Manual 37

Page 44

Electrical Connections

Electrical checks

Measure the current consumption and the supply voltage at the meter amplifier. They should be

within the following limits:

• Current: 40 mA to 70 mA (Measured in series at the “SUPPLY +” terminal)

• Voltage: 22.8 V to 25.2 V (Measured between” SUPPLY +” and “SUPPLY -” terminals)

Functionality checks

1. When the meter is powered up, a small audible continuous ringing sound can be heard with a

“Ping” occurring at 1 second intervals.

2. With the meter clean and dry, and with the tines shielded from the wind, operate it in air and

check that the meter frequency output (τ

density air point check. If the ambient conditions are not at 20°C (±2°C), use the formula

below to calculate the resulting time period:

The result (τ

certificate to within ±0.5 μsec.

Note: The air check point is found in the Density Calibration section of the Viscometer calibration

certificate.

), is as specified on the meter calibration certificate

B

•t

@ 20°C = tB@ ambient temp – [ 0.11 * ( ambient temp - 20 ) ]

B

) from this equation should now correspond to the air check on the calibration

B

The τ

value can be easily monitored by a 795x computer with the “Health Check” facility.

B

Perform the following 795x front panel keyboard sequence if this facility is required:

a. Press the bottom-right grey MAIN MENU key.

b. Use the DOWN-ARROW key (at the left of the display) to page down through the menu

options until “Health Check” (or similar) appears.

c. Select the “Health check” option using the appropriate blue key at the right side of the

display.

d. Use the blue DOWN-ARROW key (at the left side) to page down through the menu

options until “Time period inputs” (or similar) appears.

e. Select the relevant “Time Period i/p 2”, “Time Period i/p 3” or “Time Period i/p 4” option

according to the physical connections made to the 795x (as advised in Section 4.6).

f. Refer to the supplied 795x operating manual for information about front panel key

operations and navigating the menu structure.

38 Micro Motion 7827 Digital Viscosity Meter

Page 45

Chapter 5

Using 7950/7951 Processing Electronics

5.1 Using the 7950 / 7951 Processing Electronics

For details on connecting the 7827 meter to the Micro Motion signal converters and flow computers,

refer to the appropriate 795x operating manual.

Calibration Check General MaintenanceUsing 795X Processing Electronics

Installation and Configuration Manual 39

Page 46

Using 7950/7951 Processing Electronics

40 Micro Motion 7827 Digital Viscosity Meter

Page 47

Chapter 6

Calibration Check

6.1 Introduction

The following information details the calibration method and performance of the 7827 digital

viscosity meter and covers the following:

• Factory calibration

• In-line calibration

• Performance

6.2 Factory calibration

Calibration Check General MaintenanceUsing 795X Processing Electronics

6.2.1 Viscosity

The 7827 meter is calibrated against fluids characterized with prime standards, prior to leaving the

factory. The meter may be calibrated over one or a combination of four viscosity ranges detailed

below:

• Range: Viscosity range (cP)

• Ultra-low: 0.5 - 10 cP

• Low: 1 - 100 cP

• Medium: 100 - 1,000 cP

• High: 1,000 - 12,500 cP

The 7827 meter’s default calibration is in “free stream” conditions, where the effect of solid

boundaries is negligible on the output of the meter. The calibration may also be performed in a

“tee-piece,” in which case the part number above is succeeded by a “T”.

Note: A high-range unit cannot be ordered with a tee-piece calibration.

Hygienic units can be calibrated in a 3” hygienic bore if required.

Three fluids are used to establish the general viscosity equation's constants for each viscosity range

required. See the Calculated Parameters appendix.

The instrument-under-test is immersed into the calibration fluid which has been previously

characterized for viscosity and density with prime standards. Great attention is paid to temperature

equalization and fluid homogeneity within the tank before the calibration data is taken. This

procedure is repeated for each calibration fluid and for each viscosity calibration range required.

Once the meter has been passed through the necessary fluids, a factory calibration certificate is

produced from the measurement data.

Installation and Configuration Manual 41

Page 48

Calibration Check

A fourth fluid is used as an overcheck to verify the calibration for each viscosity range. Each check is

monitored by the Micro Motion Quality Assurance Department.

6.2.2 Density

The 7827 meter is calibrated within the standard shroud against Transfer Standard instruments

traceable to National Standards, prior to leaving the factory. Three fluids ranging in density from 1 to

1000 kg/m

are derived from the air point and material properties.

The calibration procedure relies on units being immersed in fluids whose density is defined by

Transfer Standards. Great attention is paid to producing temperature equilibrium between the fluid,

the unit under test and the Transfer Standard. In this way, accurate calibration coefficients covering

the required density range can be produced.

All instruments are over-checked on water to verify the calculation. The check is monitored by the

Micro Motion Quality Assurance Department.

Where viscosity correction is concerned, the temperature measurement from each viscosity

calibration fluid taken is translated into density through a previous characterization of the fluid using

prime standards. This method is used to assess the density offset due to viscosity for each viscosity

calibration range not including the 1 to 100 cP range, as the viscosity effect only becomes significant

at viscosities greater than 100 cP.

3

are used to establish the general density equation constants. The temperature coefficients

Once the meter has been calibrated with the necessary fluids a factory calibration certificate is

produced from the measurement data.

6.2.3 Primary standards

The fluids used in the viscosity calibration have been characterized for viscosity and density versus

temperature in between 15°C and 25°C. This is done using BS/U “U-tube” capillary viscosity meters

for kinematic viscosity measurement and pyknometers for density measurements. Both of these

methods are Primary Measurement Systems conforming to BS188 and BS733 Part 1 respectively.

The calibration of the calibration fluids is performed under closely controlled laboratory conditions.

A calibration certificate is issued. Calibrations are repeated, typically every six months, producing a

well documented history of the fluid.

6.2.4

Transfer standards

The Transfer Standard instruments used in the density calibration are selected instruments which are

calibrated by the British Calibration Service Laboratory and certified.

Transfer Standard calibration uses a number of density-certified liquids, one of which is water. The

densities of these reference liquids are obtained using the Primary Measurement System whereby

glass sinkers of defined volume are weighed in samples of the liquids.

Calibration of the Transfer Standard instruments is performed under closely controlled laboratory

conditions. A calibration certificate is issued. Calibrations are repeated, typically every six months,

producing a well-documented density standard.

42 Micro Motion 7827 Digital Viscosity Meter

Page 49

Calibration Check

V1' = V1 + Q2 * ( η

actual

- η

calc

)

6.3 In-line calibration

6.3.1 Viscosity

The 7827 meter is calibrated to operate in installations where the boundary formed by the surrounding

metalwork is at a distance away where it does not influence the viscosity reading from the meter. If

the installation is such that an error in viscosity is seen due to the proximity of the metalwork to the

tines, an in-line calibration is needed to correct for this source of error.

To perform an in-line calibration it is necessary to know the actual dynamic viscosity and temperature

of the calibrating fluid along with both time periods from the meter. The fluid dynamic viscosity at

these operating conditions may be determined by using a suitable conventional viscometer/rheometer

or by measuring the fluid's kinematic viscosity and multiplying by the fluid's actual density (in g/cc).

The procedure for calculating the new calibration coefficients V1' for the particular viscosity range

currently selected is that shown below:

• where V1' = New V1 calibration coefficient for current viscosity range and installation only

Calibration Check General MaintenanceUsing 795X Processing Electronics

• V1 = Original V1 calibration coefficient for current viscosity range

• Q = meter quality factor value in calibration fluid and installation

• η

• η

= Actual fluid viscosity (measured from a standard) – (cP)

actual

= Calculated fluid viscosity (using original coefficients and Q below) – (cP)

calc

Note: The value of V1' is now used in the general viscosity equation in the 795x replacing the original

values of V1 on the calibration certificate for this application only and for this viscosity range only.

If the process viscosity is variable, the calibration should be tested at the maximum, minimum, and

mid-point values of the process viscosity range, to check that the V1 correction is sufficient.

6.3.2 Density

The 7827 meter is calibrated to operate in installations where the boundary formed by the surrounding

metalwork is at a distance away where it does not influence the density reading from the meter. If the

installation is such that an error in density is seen due to the proximity of the metalwork to the tines,

an in-line calibration is needed to correct for this source of error.

To perform an in-line calibration it is necessary to know the actual density and temperature of the

calibrating fluid along with the time period B from the meter. The fluid density at these operating

conditions may be determined by using using one of the methods outlined below:

For stable liquids

Draw off a sample of the liquid into a suitable container, at the same time note the density and the

operating temperature. Measure the density of the sample under defined laboratory conditions using a

hydrometer or other suitable equipment.

Note: It is essential that you have a good understanding of the physical properties (temperature

coefficient, etc.) of the liquid and that tables of such data are available when using this method.

Installation and Configuration Manual 43

Page 50

Calibration Check

For unstable or high-pressure vapor liquids

A pressure pyknometer can be used. The pressure pyknometer and its associated pipework can be

coupled to the pipeline so that a sample of the product flows through it. When equilibrium is reached,

the meter density reading is noted as the pyknometer is isolated from the sample flow. The

pyknometer is removed for weighing to establish the product density. This density result is now

compared with the reading from the meter.

For further details on these procedures, reference should be made to:

Energy Institute: HM7. Density, sediment and water. Section 1: General

guidance on test methods (formerly PMM Part VII, S1)

1st ed 1996 ISBN 978-0-85293-154-7