Page 1

Instruction Manual

90003752

1 1/2003

Instruction Manual

AK Protocol

Communication Option for

ML T 1, MLT 2, MLT 3, MLT 4, MLT 5 and CAT 200

rd

Edition 11/2003

3

www.EmersonProcess.com

Page 2

AK Protocol for ML T 1, 2, 3, 4, 5 & CAT 200 Instruction Manual

90003752

11/2003

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 10/1998 2nd Edition 11/2001

3rd Edition 1 1/2003

© 2003 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Contents

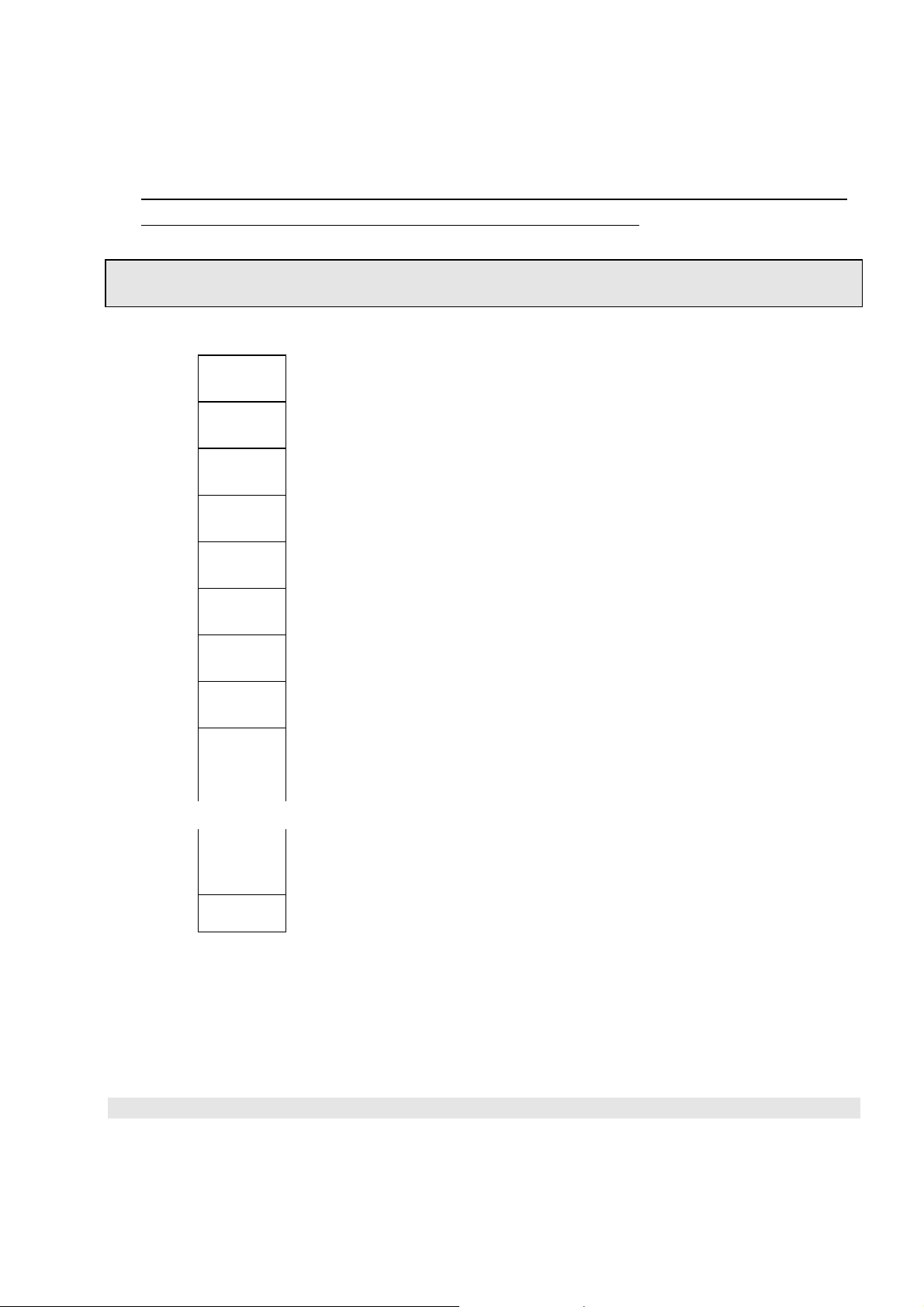

V24/RS232/485 Interface – Basics 1 - 1

I)

1 Introduction.................................................................................................1 - 1

2 Hardware....................................................................................................1 - 2

3 Protocol settings.........................................................................................1 - 3

3.1 Command telegram .............................................................................1 - 3

3.2 Response telegram..............................................................................1 - 4

3.3 Command telegram for RS485 BUS operating....................................1 - 5

3.4 Response telegram for RS485 BUS operating.....................................1 - 6

4 Specifications of data settings ....................................................................1 - 7

4.1 Head telegram (Header) ......................................................................1 - 7

4.2 Data block and error status byte..........................................................1 - 8

4.3 End of telegram....................................................................................1 - 9

4.4 Command and response telegram timing............................................1 - 10

4.5 Handling of malfunctions......................................................................1 - 10

5 Examples for potential responses to control or write commands resp.

to command telegrams with data (format) errors........................................1 - 11

6 Function sequence and error status after the receipt of the

"SRES" or "STBY" commands....................................................................1 - 19

II) V24/RS232/485 Interface – Single Analyzers and Systems 2 - 1

1 Basic Informations......................................................................................2 - 2

2 List of all Codes [Commands - Overview including page numbers]......2 - 5

2.1 Control commands...............................................................................2 - 5

2.2 Read commands..................................................................................2 - 6

2.3 Write commands..................................................................................2 - 7

3 Description of all Control Commands .........................................................2 - 8

4 Description of all Read Commands ............................................................2 - 39

5 Description of all Write Commands.............................................................2 - 85

Supplement

1 Overview about working AK commands in NGA devices ..........Supplement - 1

2 AK Service Commands..............................................................Supplement - 3

90003752(2) [AK-Commands] 11/01

AK

Page 4

AK

90003752(1) [AK-Commands] 10/98

Page 5

I) V24/RS232/485-Interface - Basics

Protocol settings of a serial interface

between a test bench control computer

and peripheral analyzers on exhaust test benches

1. Introduction

The serial interface is made for slow point to point connections (f ≤ 10 Hz). The

communication between the test bench control computer (TBCC) and the peripheral

analyzers works according to the master slave principle. That means that the peripheral

analyzers will only answer with a response telegram to the command telegram of the

TBCC. They will not send an own message.

You can distinguish two cases:

(1) Analyzers in a function unit (system)

Some analyzers are combined to a logical unit. They are connected to the TBCC via

an front-end computer. In that case the communication will not take place directly

between the TBCC and the analyzers, but between the TBCC and the front-end

computer. Each analyzer or the whole system unit will be identified by a defined

channel number:

K0 is the channel number for the whole defined system.

("Assembling command resp. assembling report")

Kn (n=1, nmax) is the channel number for each analyzer.

KV is the channel number for the front-end computer.

(2) Single analyzers

Each analyzer is connected directly to the TBCC. In that case the identification of each

analyzer will be done by the hardware connections and not by a software control. That

is why the two channel number bytes (Kn) could be deleted. But in spite of that the

channel number is generally 0 (K0) to get a uniform protocol.

The data transfer will only be done by ASCII code to get an easy handling of the protocol

with a terminal for simulation of the TBCC, the system unit and the analyzers. Therefore,

no parity check will be done as data saving.

90003752(2) [AK-Commands] 11/01

AK

1 - 1

Page 6

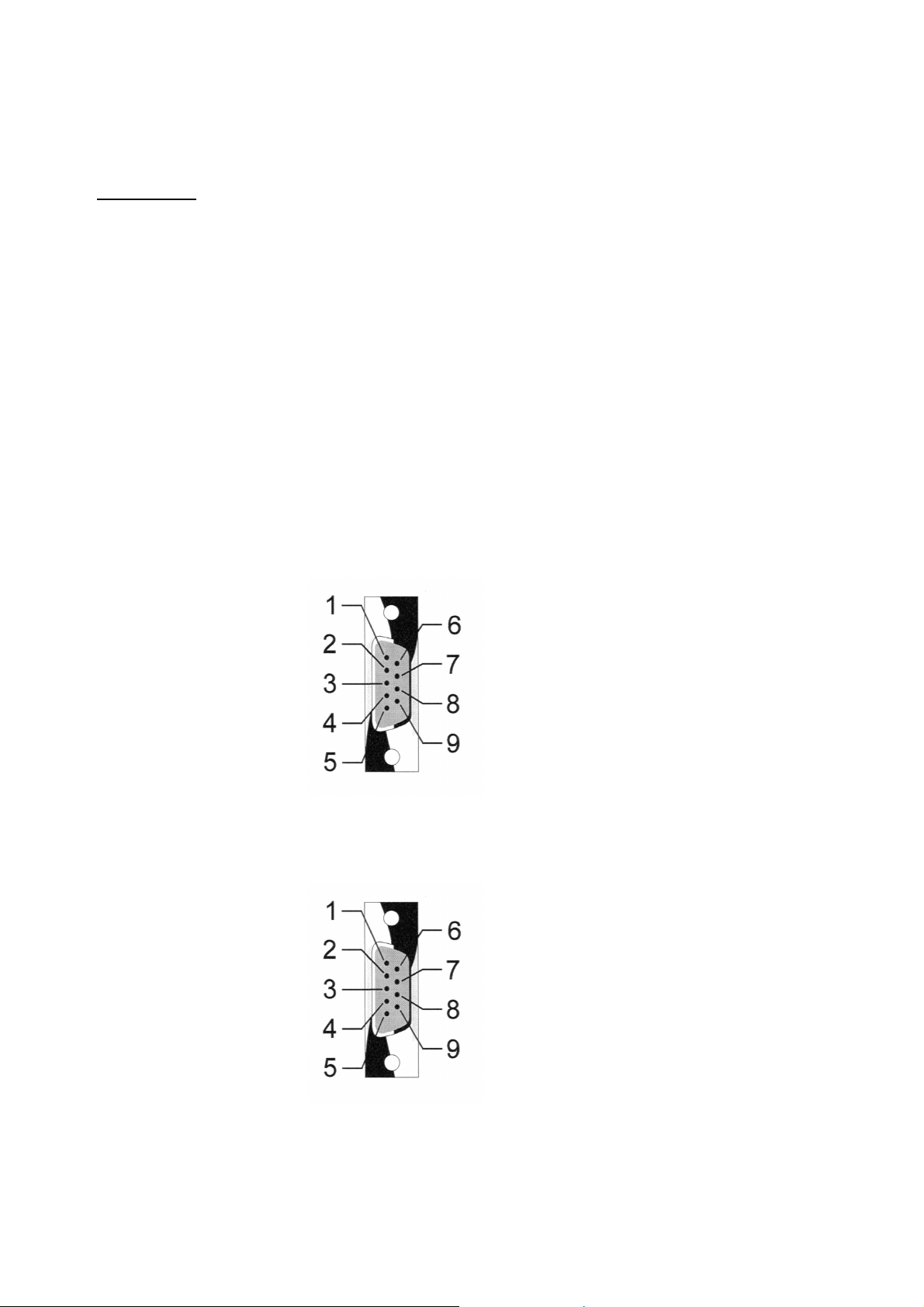

2. Hardware

1. Baud rate: 1200, 2400, 4800, 9600, 19200

2. Length of signs: 1 start bit

7 or 8 data bits

1 or 2 stop bits

3. Parity: even/odd/none

4. Operating: full duplex, no echo

5. Handshake: Xon/Xoff

6. Plug: 9 pin sub d, socket

7. Pin assignment: RS 232 module

GND

Rxd

TxD

NC

Relay 1 contact NC/NO

Relay 2 contact NC/NO

Relay 3 contact NC/NO

Relay common node

GND

RS 485 module

GND

RxDRxD+

TxD+

TxD-

1 - 2

AK

Relay 1 contact NC/NO

Relay 2 contact NC/NO

Relay 3 contact NC/NO

Relay common node

90003752(2) [AK-Commands] 10/01

Page 7

I) V24/RS232/485-Interface - Basics

3. Protocol settings

The data and command transfer protocol has the following structure:

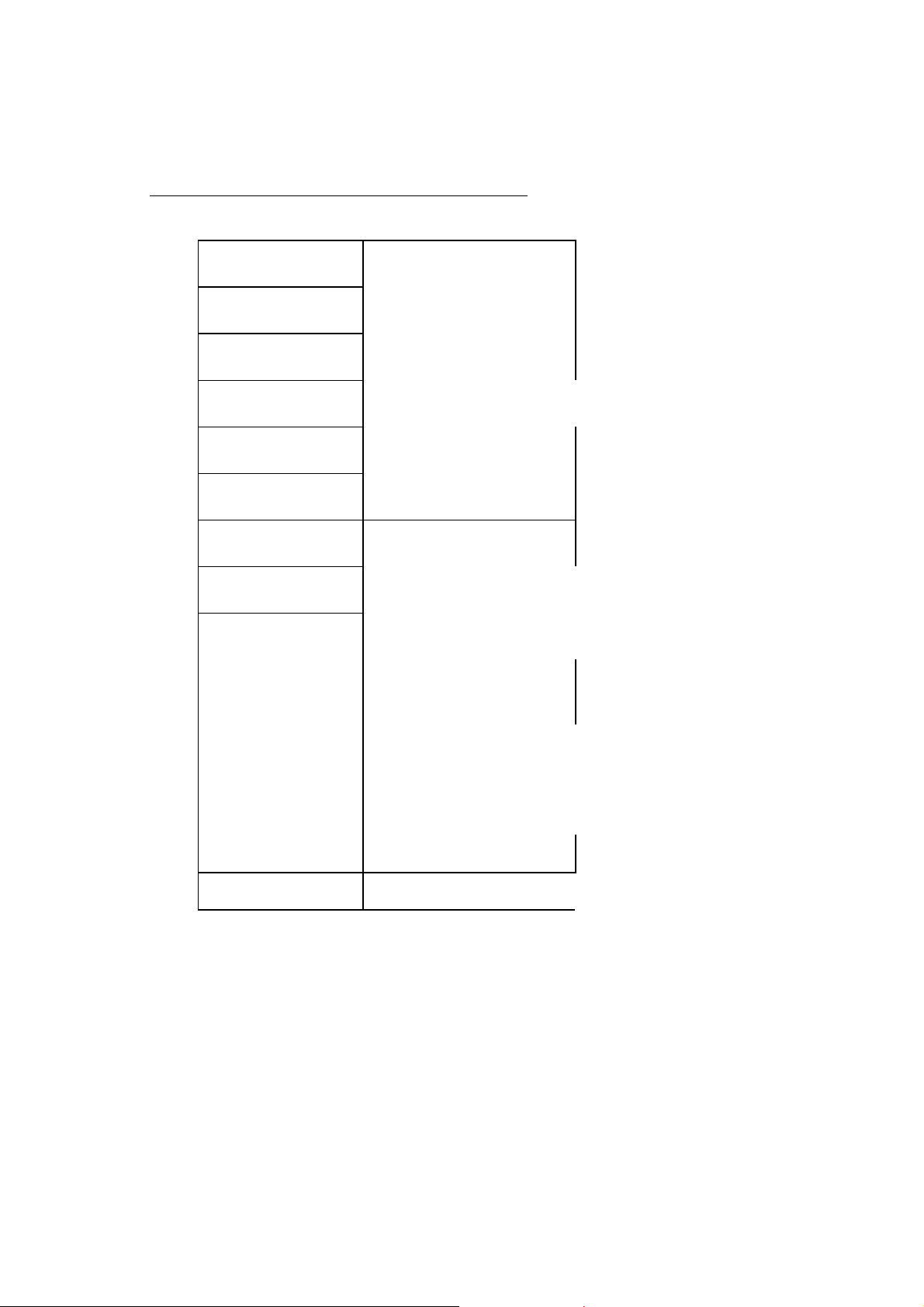

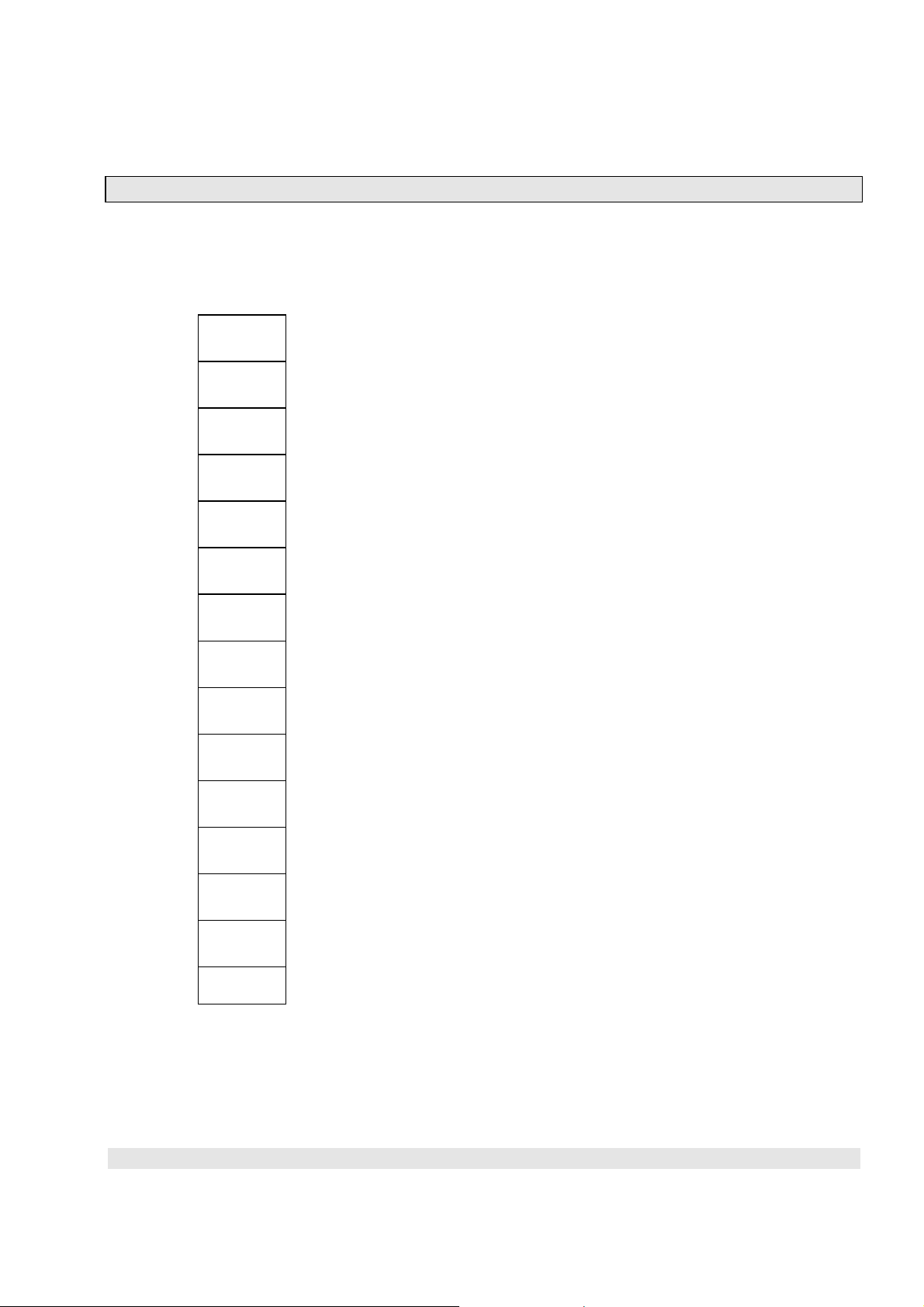

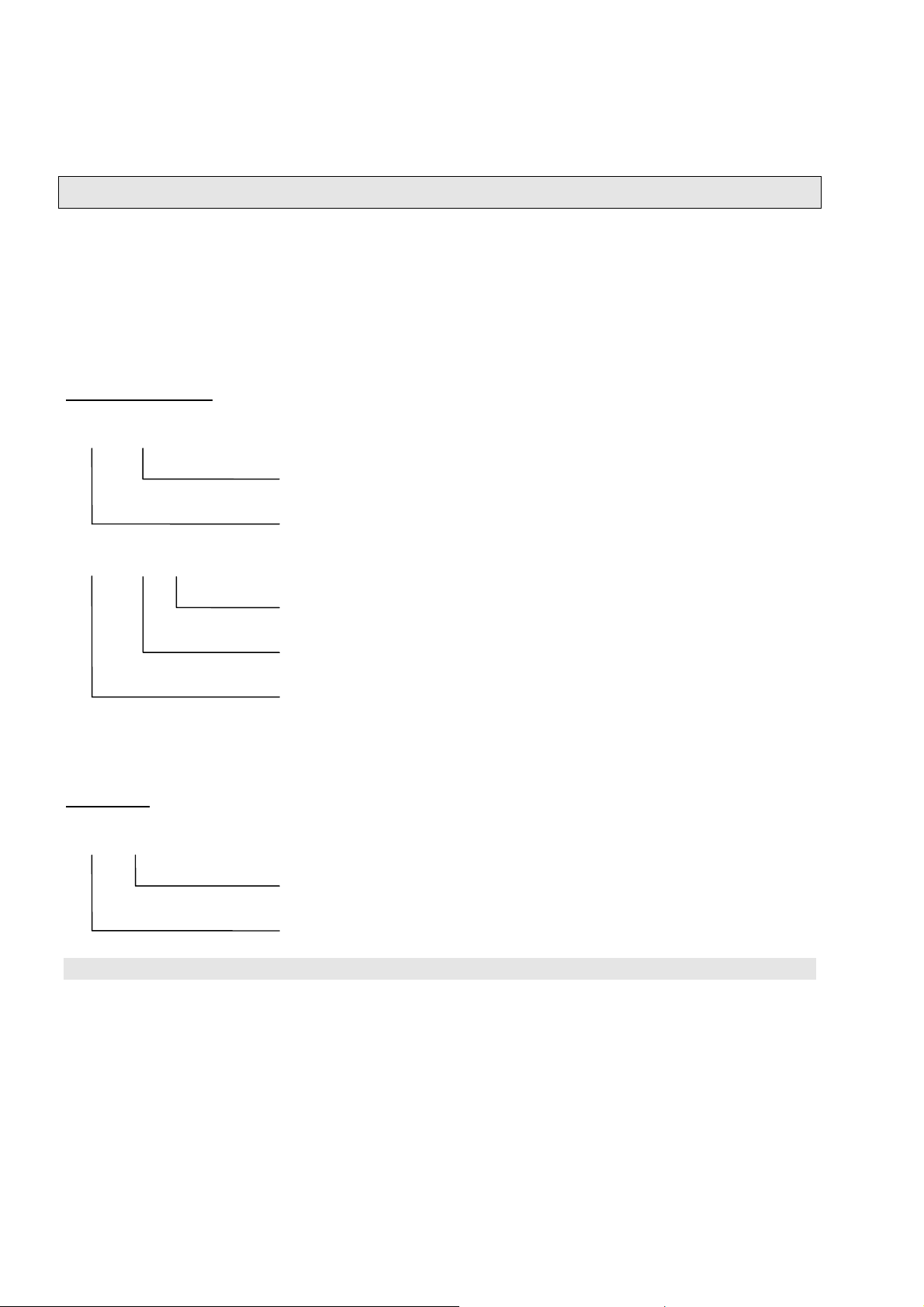

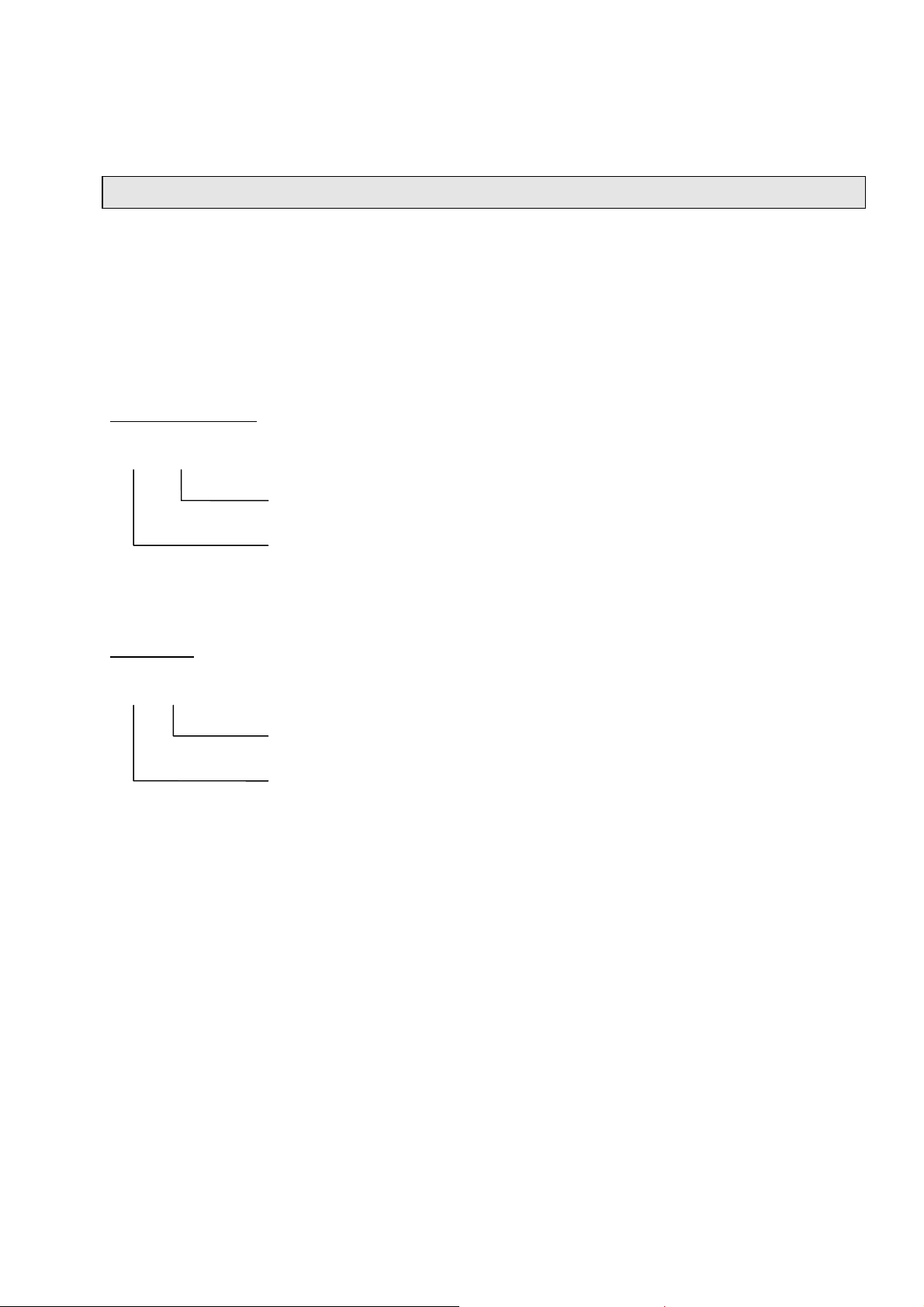

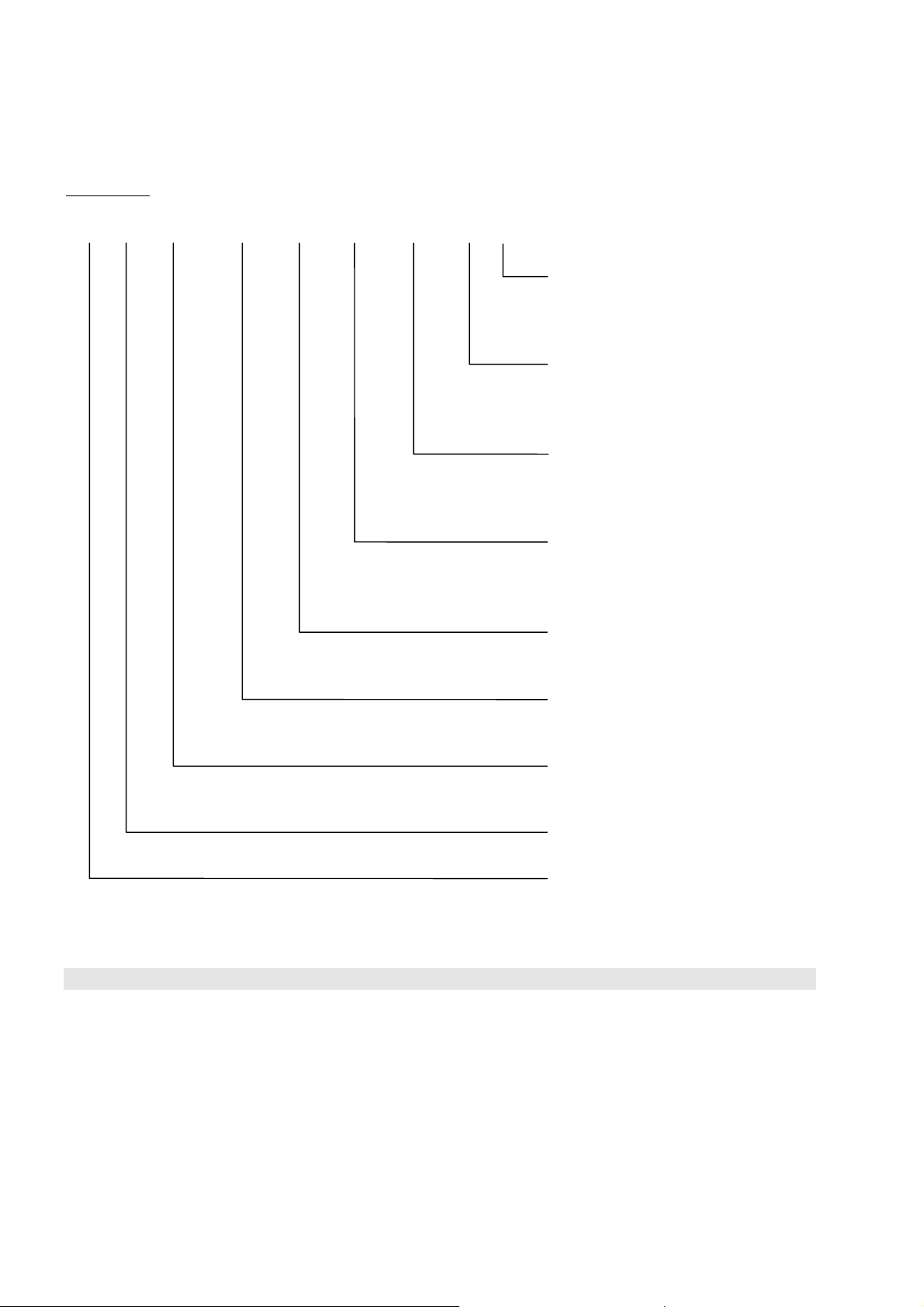

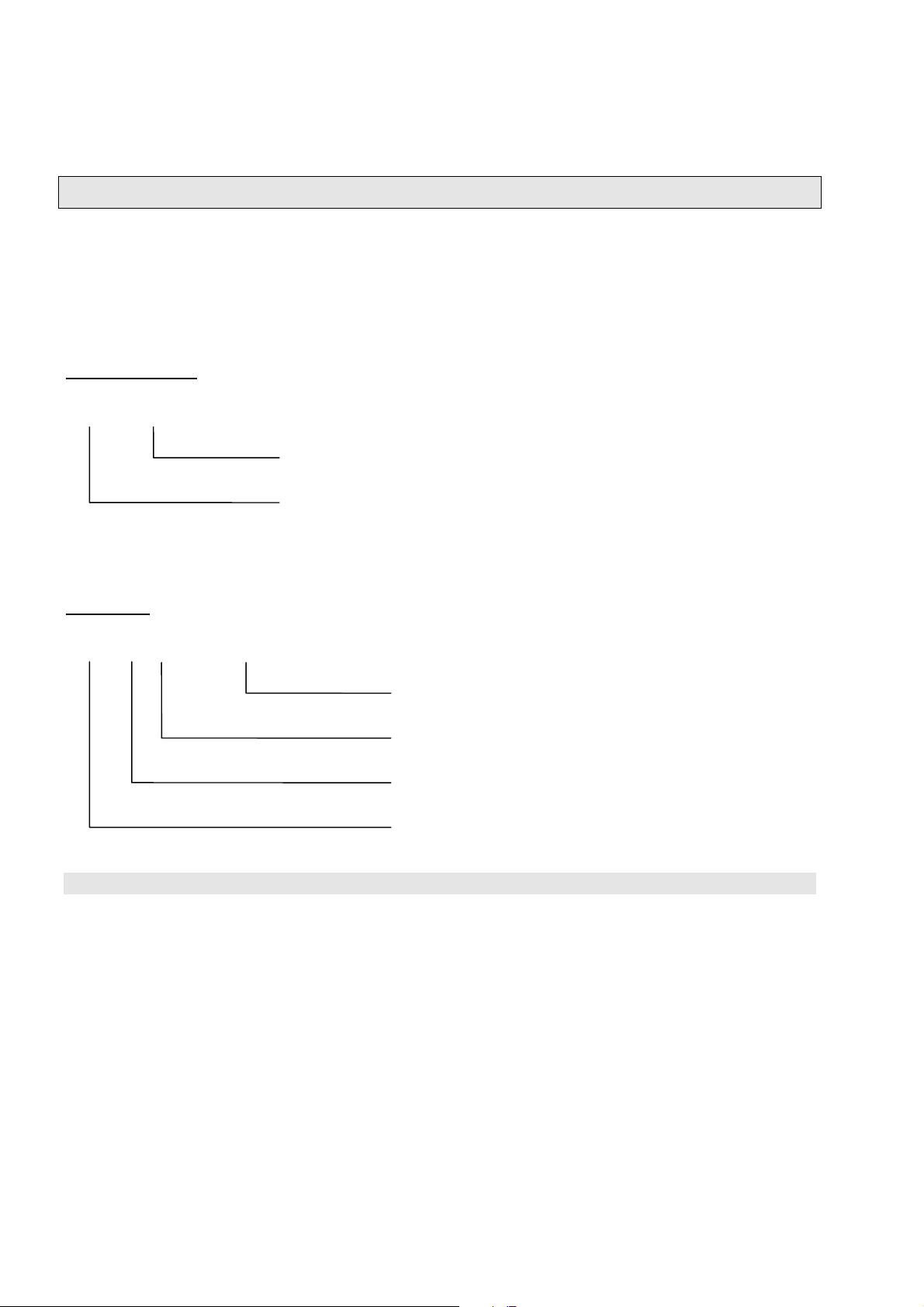

3.1. Command telegram

1. Byte STX

2. Byte DON'T CARE

3. Byte FUNCT. CODE 1

4. Byte FUNCT. CODE 2 HEAD

5. Byte FUNCT. CODE 3

6. Byte FUNCT. CODE 4

7. Byte BLANK

8. Byte "K" VARIABLE DATA

9. Byte NUMBER

(number with several

digits possible)

D

A (other data

T can also disappear,

A depending on the

function code)

n. Byte ETX END

90003752(2) [AK-Commands] 11/01

AK

1 - 3

Page 8

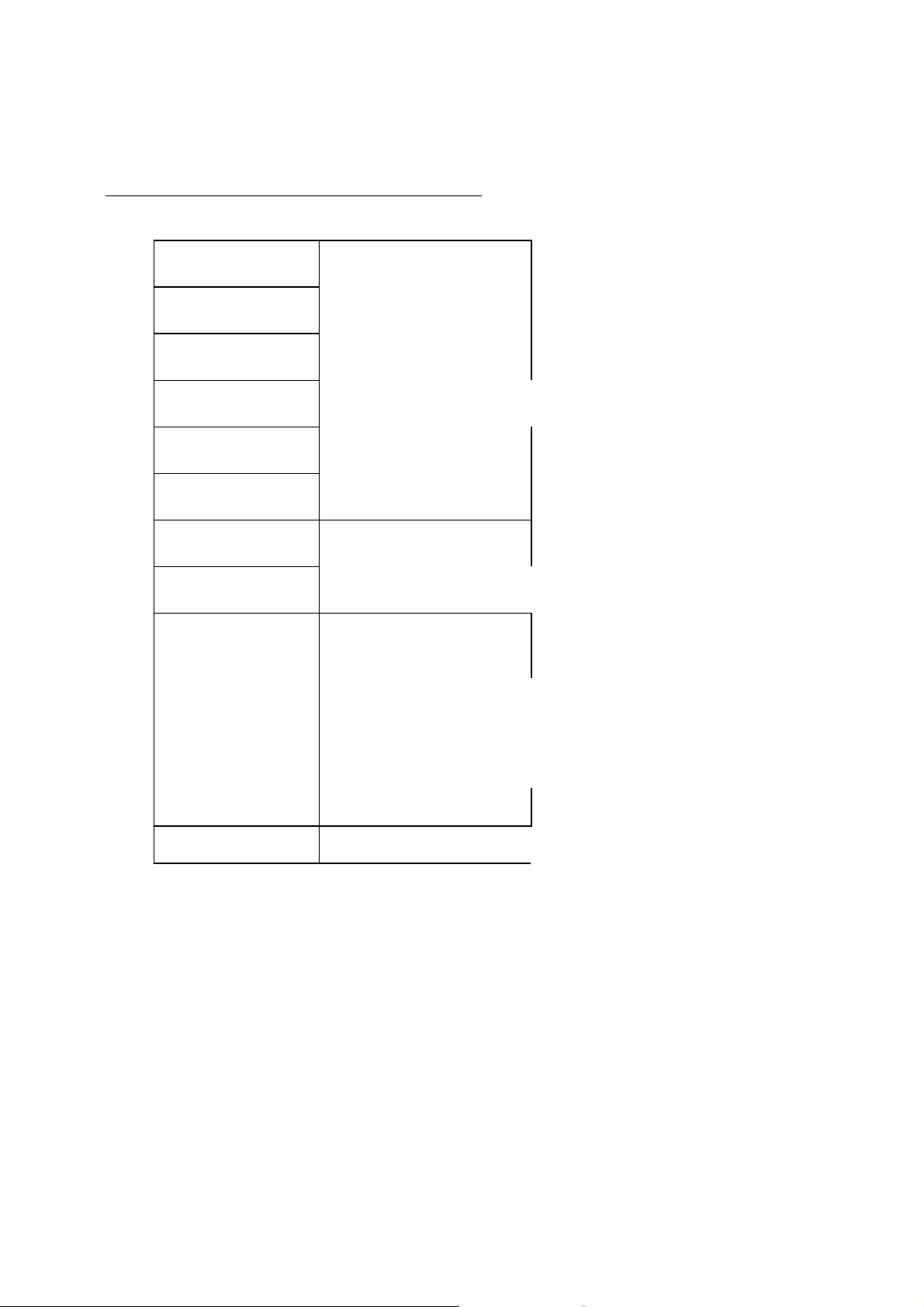

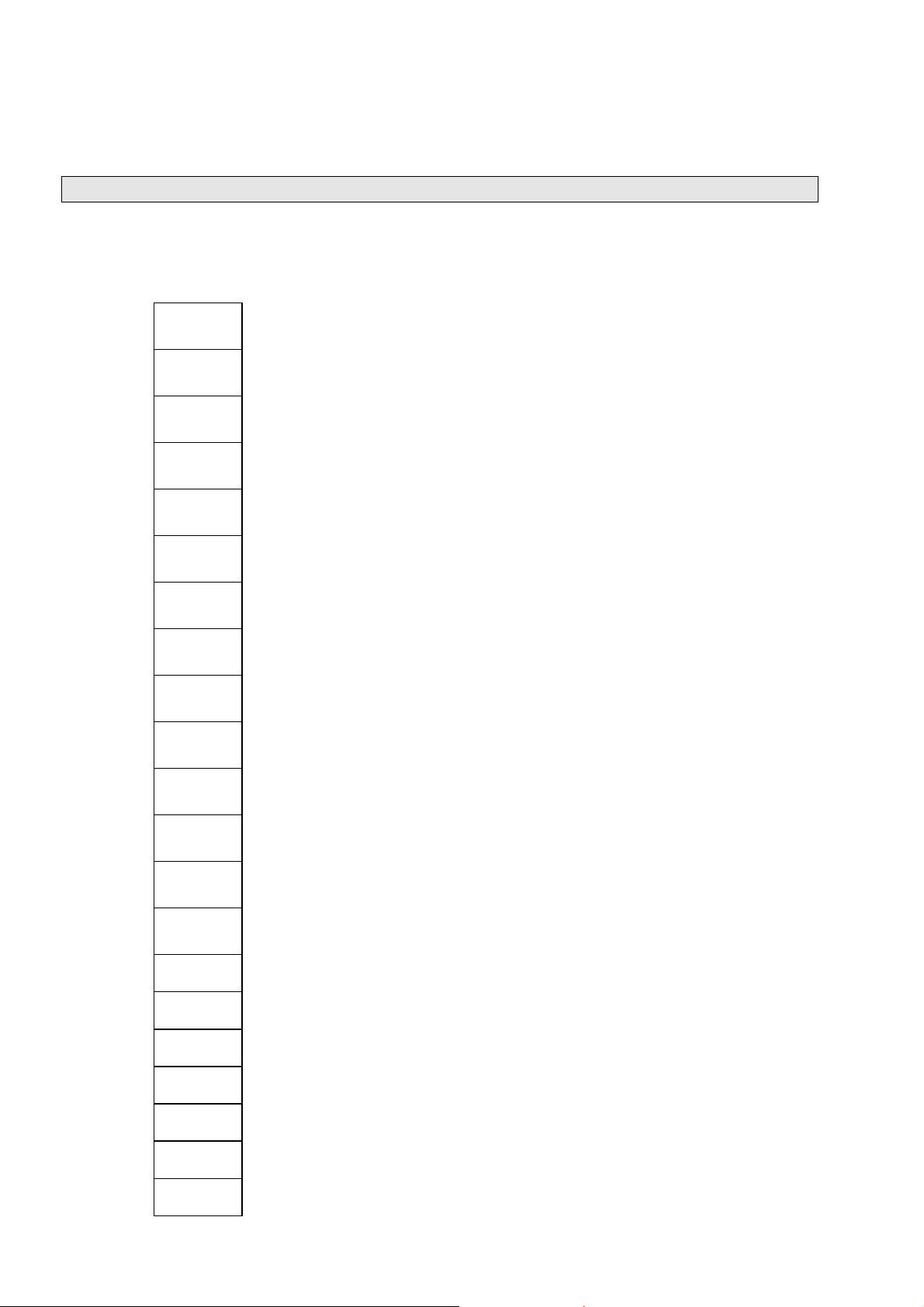

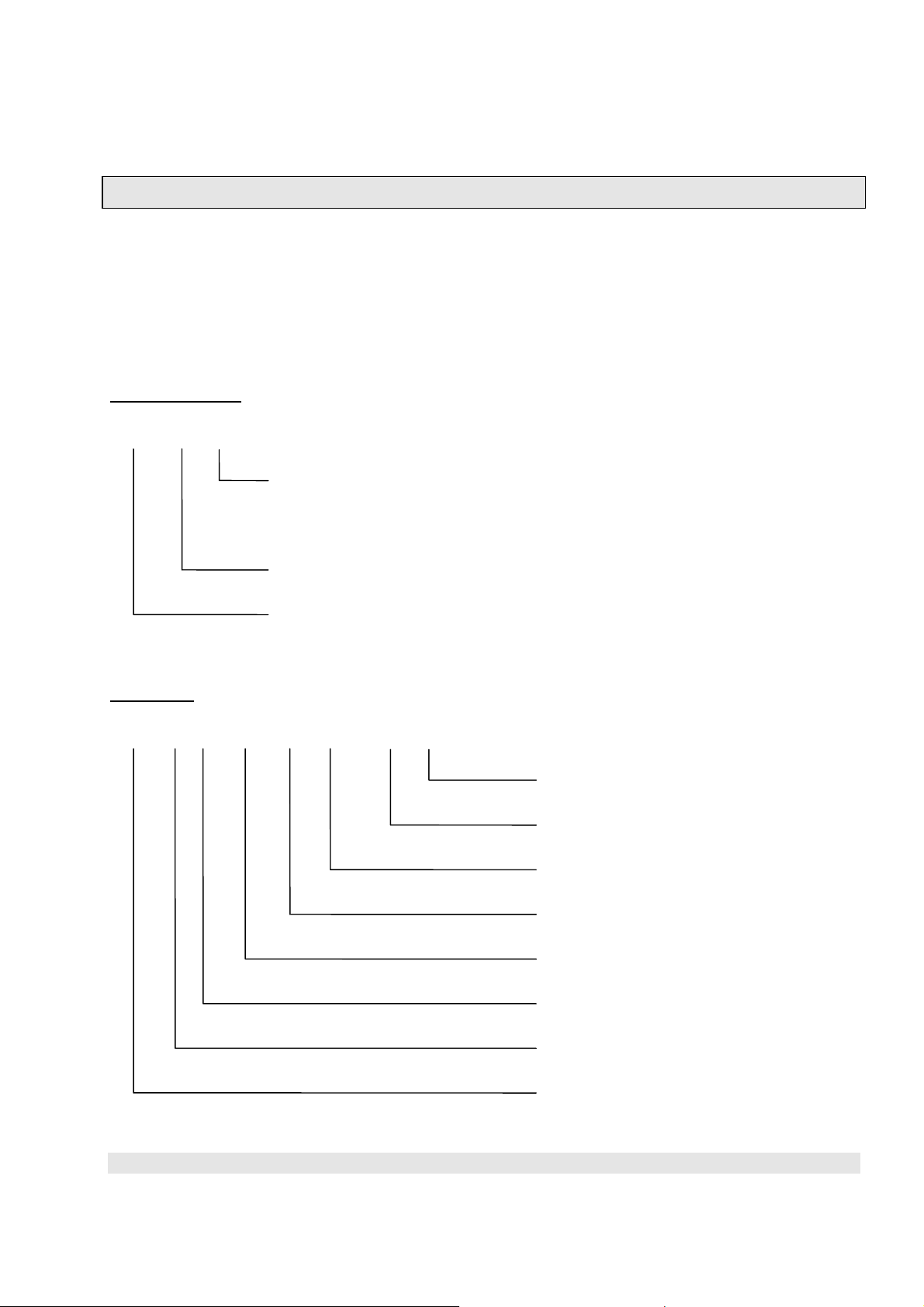

3.2. Response telegram

1. Byte STX

2. Byte DON'T CARE

3. Byte FUNCT. CODE 1

4. Byte FUNCT. CODE 2 HEAD

5. Byte FUNCT. CODE 3

6. Byte FUNCT. CODE 4

7. Byte BLANK

8. Byte ERROR STATUS

FIXED

DATA

D

A VARIABLE DATA

T (can also disappear,

A depending on the

function code)

n. Byte ETX END

1 - 4

AK

90003752(2) [AK-Commands] 10/01

Page 9

I) V24/RS232/485-Interface - Basics

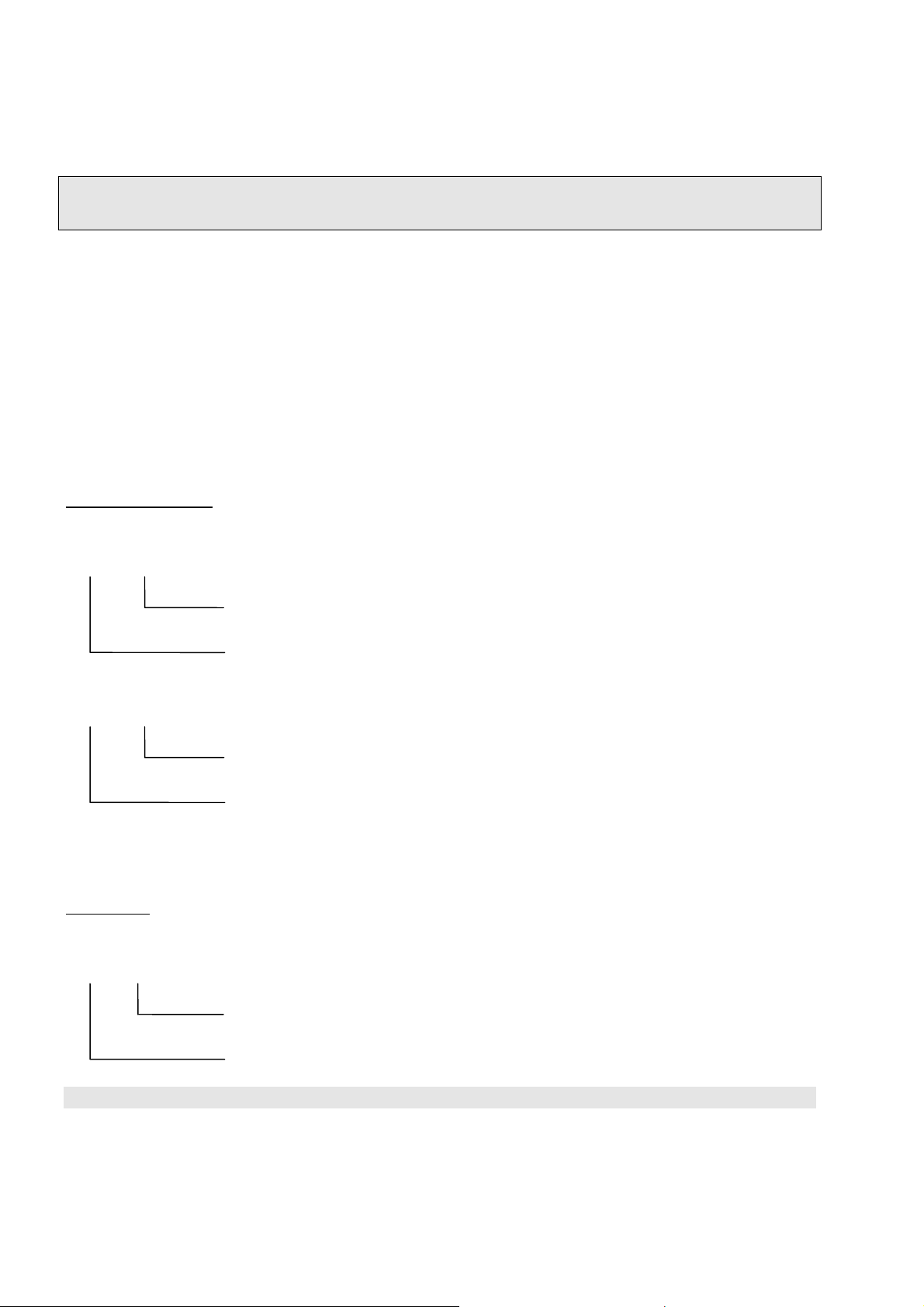

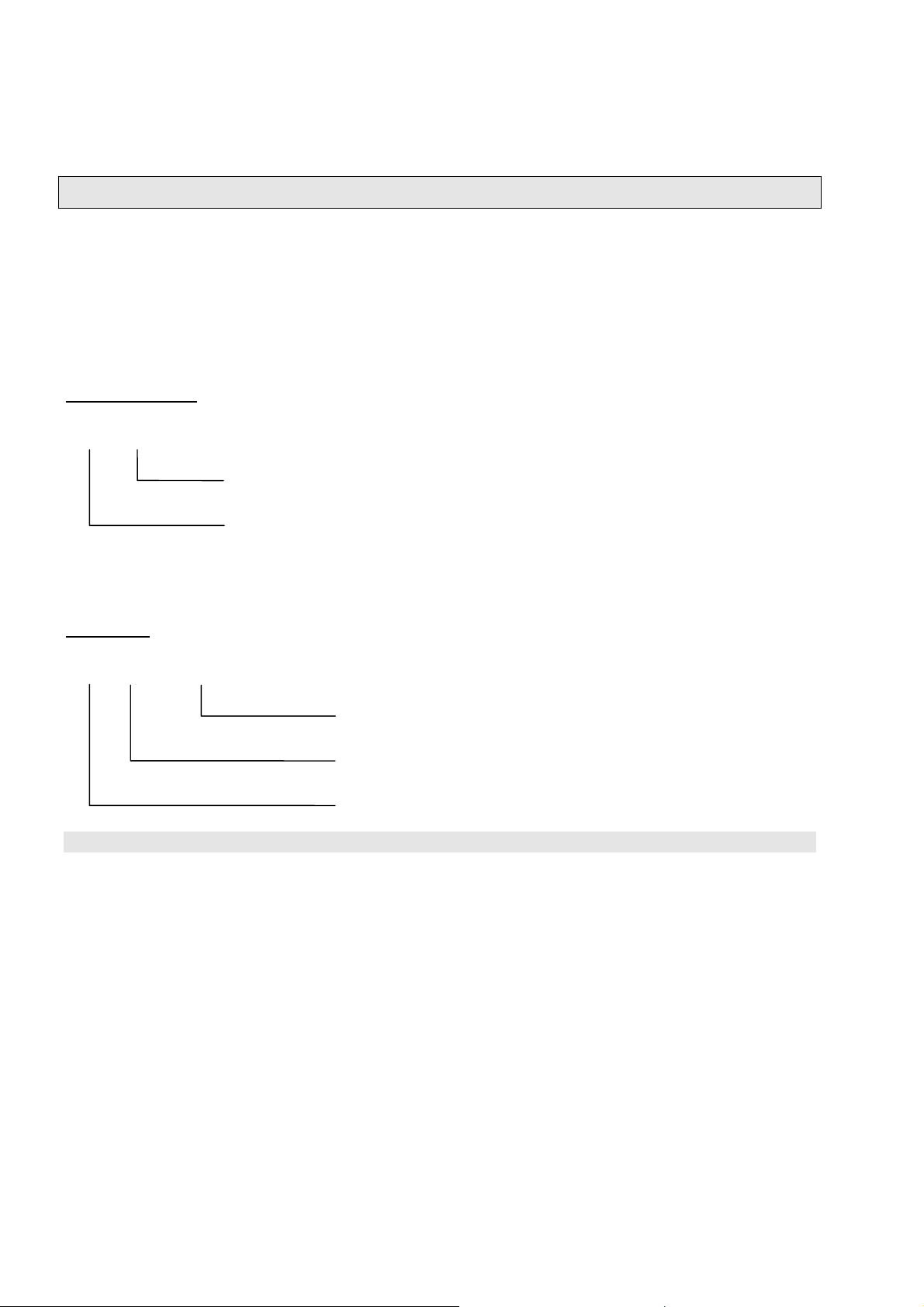

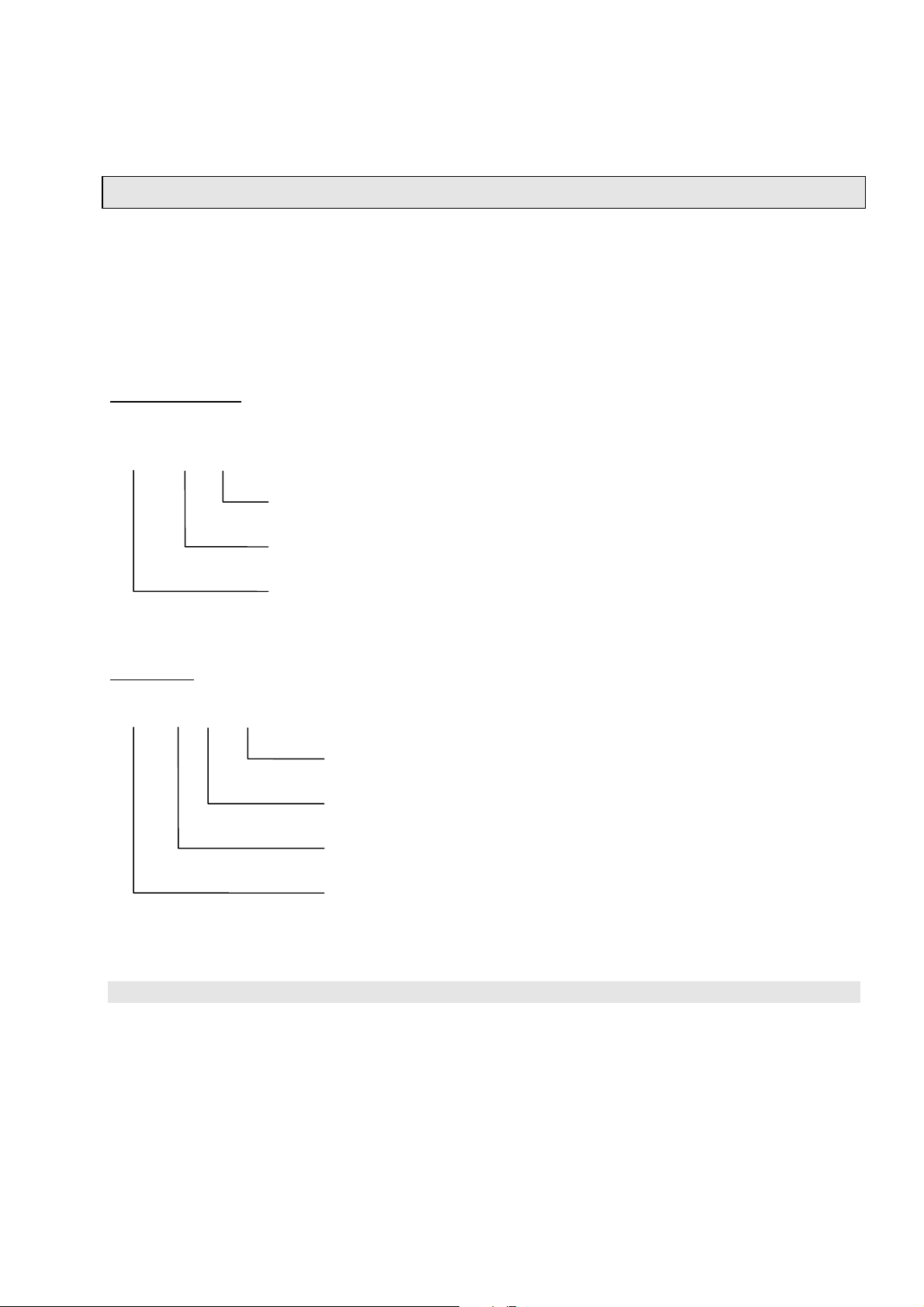

3.3. Command telegram for RS485 BUS operating

1. Byte STX

2. Byte BUS ADDRESS

3. Byte FUNCT. CODE 1

4. Byte FUNCT. CODE 2 HEAD

5. Byte FUNCT. CODE 3

6. Byte FUNCT. CODE 4

7. Byte BLANK

8. Byte "K" VARIABLE DATA

9. Byte NUMBER

(Number with several

digits possible)

D

A (other data

T can also disappear,

A depending on the

function code)

n. Byte ETX END

90003752(2) [AK-Commands] 11/01

AK

1 - 5

Page 10

3.4. Response telegram for RS485 BUS operating

1. Byte STX

2. Byte BUS ADDRESS

3. Byte FUNCT. CODE 1

4. Byte FUNCT. CODE 2 HEAD

5. Byte FUNCT. CODE 3

6. Byte FUNCT. CODE 4

7. Byte BLANK

8. Byte ERROR STATUS

FIXED

DATA

D

A VARIABLE DATA

T (can also disappear,

A depending on the

function code)

n. Byte ETX END

1 - 6

AK

90003752(2) [AK-Commands] 10/01

Page 11

I) V24/RS232/485-Interface - Basics

4. Specifications of data settings

4.1. Head telegram (Header)

The begin of each transfer is a "STX" in the first byte. Each "STX" will start a new transfer.

Previous transfers will be deleted, if they are not finished by "ETX". That means, only

completed telegrams may be interpreted and answered.

You can take any content for the "DON'T CARE" byte, excluding control signs or signs

reserved by the AK commands.

For the RS485 BUS operating an address byte will be used instead of the "DON'T CARE"

byte. The analyzers will only answer to this command if the bus address setup will concur

with this byte.

In the command telegram a function code will be sent to the system unit or the analyzer

with the four function bytes.

In the response telegram this function code will be sent back as an echo if the transfer is

successful. The echo will be four question marks (????), if

• the command telegram has not minimum the number of bytes of the head telegram, the

channel number in the data part and the end telegram (number of bytes = 10; using a

channel number with two digits = 11 bytes) or

• the function code has errors or is unknown.

The function code may not contain blanks.

There are three groups of function codes:

(1) Control commands

(2) Read commands

(3) Write commands

90003752(2) [AK-Commands] 11/01

AK

1 - 7

Page 12

4.2. Data block and error status byte

The data presentation is variable. A fixed format will not be used. A blank or a <CR> with

<LF> will be used as separating characters of data. The separation with <CR><LF> will

only be done, if the following complete date will have more than 60 digits. Each data set

will begin normally with a blank.

The data block of the command telegram has only variable data. These data depend on

the function code. They can disappear for some function codes excluding the channel

number. The channel number can have more than two bytes.

The data block of the response telegram is divided in fixed and variable data. The first digit

of the fixed data is a blank followed by an error status byte. The error status number will be

zero for an error free running analyzer or system unit. The error status number will be

counted up from 1 to 9 with each change in the error status. The error status number will

be zero again after the errors will be removed. Changing the status of the system will not

change the error status number. The variable data depend on the function code. They can

disappear for some function codes.

The long and variable floating point format or the E- Format are allowed to display the

digits of numbers. You can find in each analyzer protocol which of these formats may be

used. The decimal point can disappear for integers. The "+/-" sign may only be used for

negative numbers. Digits without physical meaning have to be vanished.

You can distinguish the following cases if a date with an error exists for a reading:

(1) The transfer of the date is not possible, e.g. an analyzer in a system is missing or it

cannot send a signal.

→ The date will be replaced by a "#".

(2) The date is only valid with restrictions, e.g. FID temperature too low.

→ The date will begin with a "#".

Range overflow and range underflow will be displayed in the same way. "Valid" means

that no criterions of plausibility will be considered.

Example:

You ask for a concentration value and the analyzer is in the "stand-by" mode. The date

must not be marked with "#" as "valid with restrictions", if the analyzer would work

normally in the operation mode.

1 - 8

AK

90003752(2) [AK-Commands] 10/01

Page 13

I) V24/RS232/485-Interface - Basics

If an analyzer or a system is not in the "REMOTE" status, the control and write commands

have to report "OF" ("Offline") in the data set to the. In system units the channel number

has to be reported, too.

If one analyzer is missing, a system unit has to send the channel number and "NA" ("Not

Available") to the test bench control computer with control and write commands.

A response telegram is not possible, if the test bench control computer has a direct contact

to the analyzers and one analyzer is missing or the whole system is missing. So the test

bench control computer has to realize the missing of devices by "Time Out".

If the system or the analyzer is occupied by executing a function, the new start of a control

command will lead to the response "BS" (Busy) in the data block of the response telegram.

The running function will not be disturbed. Exception: The order was a software reset.

If the data or parameters transfer is not complete (i.e. not expected format) in the

command telegram to the system or the analyzer, the test bench control computer will get

a "SE" (Syntax Error) in the data block of the following response telegram.

If the system or the analyzers cannot work with the data or the parameters of the

command telegram (data error, parameter error), the test bench control computer will get a

"DF" (data error) in the data block of the following response telegram.

4.3. End of telegram

Each transfer will end with "ETX" in the last byte.

90003752(2) [AK-Commands] 11/01

AK

1 - 9

Page 14

4.4. Command and response telegram timing

For each command telegram of the TBCC the peripheral analyzer sends a response

telegram.

It is not allowed for the TBCC to send new command telegrams before this response

telegram is received.

For most of the command telegrams this response might be sent after some milliseconds.

But for some commands the response telegram might be started to sent 2-3 seconds after

receiving the command telegram. The time starts the moment the peripheral analyzer

receives the ETX character of the command telegram.

It is not assured that the response telegram is sent without any delay between the single

characters but it might be that there are up to 2-3 seconds in between.

4.5. Handling of malfunctions

For the case of a malfunction it might be that the ETX-character of the command telegram

is not received by the peripheral analyzer. Then it will not evaluate the command telegram

and so will not send a response telegram.

In this case it is in the responsibility of the TBCC not to run into an endless loop. It has to

have a timeout of 4-5 seconds to react on this communication failure.

The TBCC may repeat the last command telegram or doing some other exception

handling.

1 - 10

AK

90003752(2) [AK-Commands] 10/01

Page 15

I) V24/RS232/485-Interface - Basics

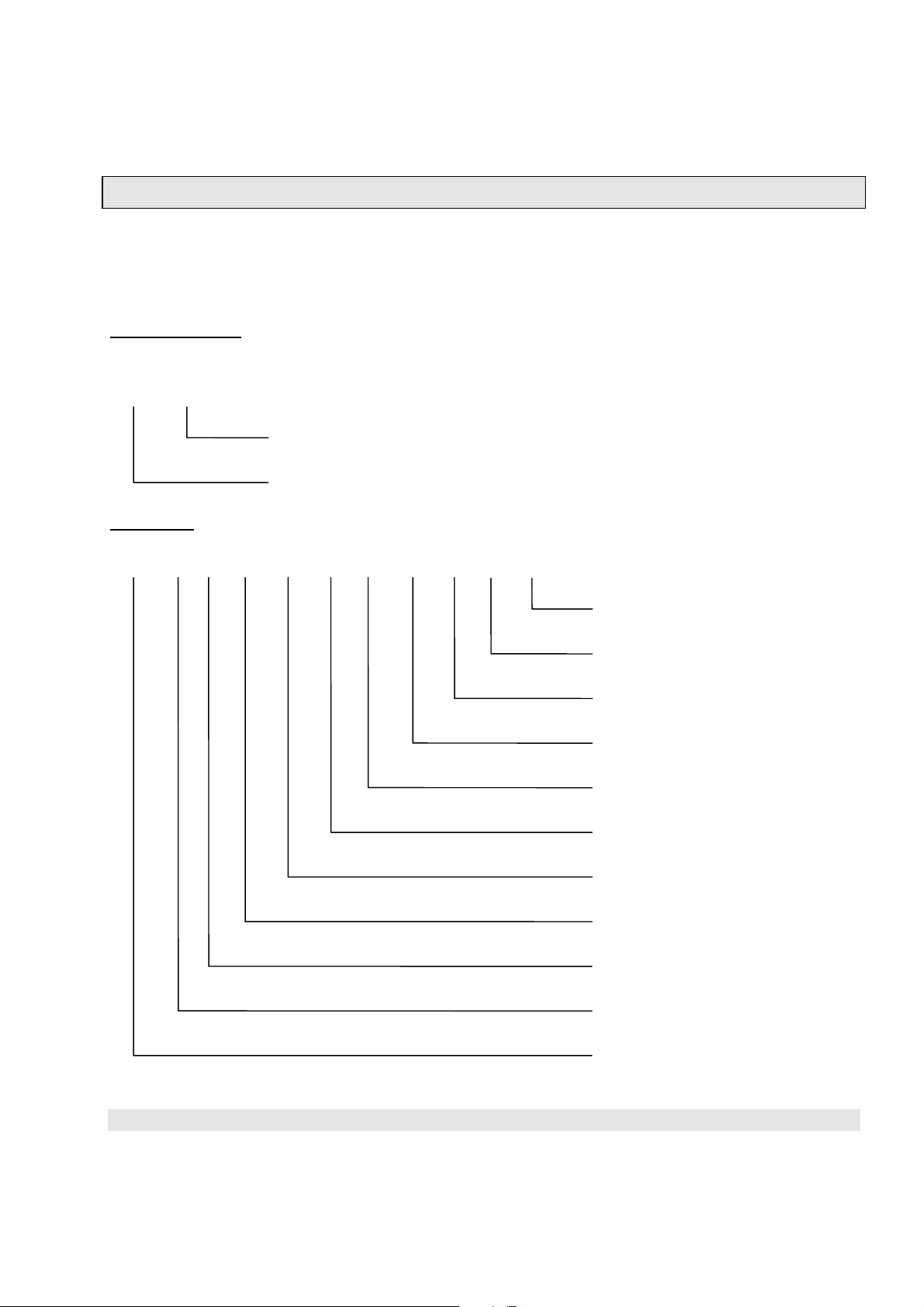

5. Examples for potential responses to control or write commands resp.

to command telegrams with data (format) errors:

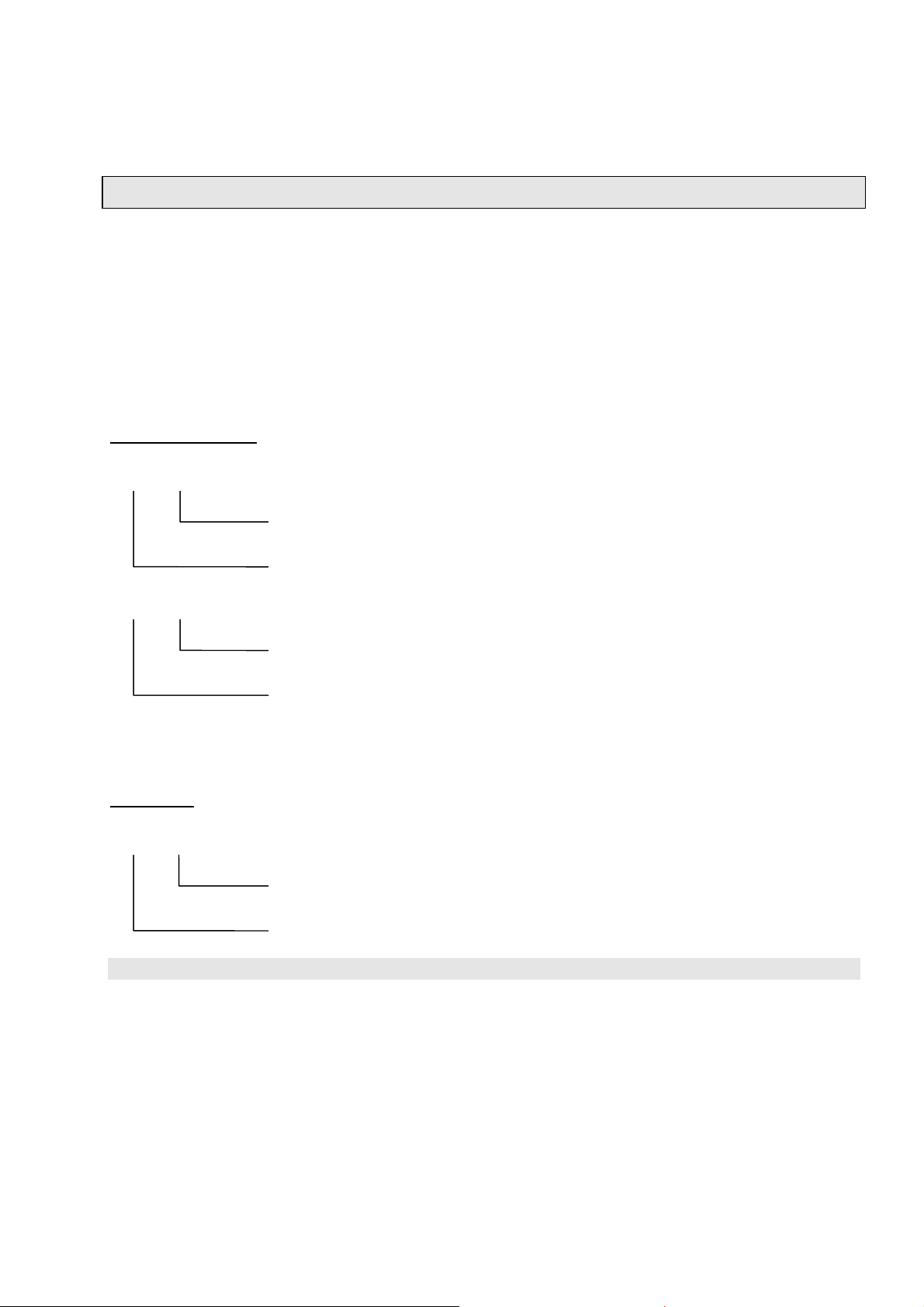

1. Analyzer and/or system unit with several analyzers "Online"

and called analyzers are existing.

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

evtl.

variable

...

.

...

Data

n. Byte ETX

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

90003752(2) [AK-Commands] 11/01

AK

1 - 11

Page 16

2. Analyzer and/or system unit with several analyzers "Offline"

and called analyzers are existing.

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte n

12. Byte BLANK

13. Byte O

14. Byte F

evtl.

variable

...

.

...

Data

n. Byte ETX

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

11. Byte: Channel number is zero: "The whole system unit offline".

Channel number is one to n: "Single analyzer offline".

1 - 12

AK

90003752(2) [AK-Commands] 10/01

Page 17

I) V24/RS232/485-Interface - Basics

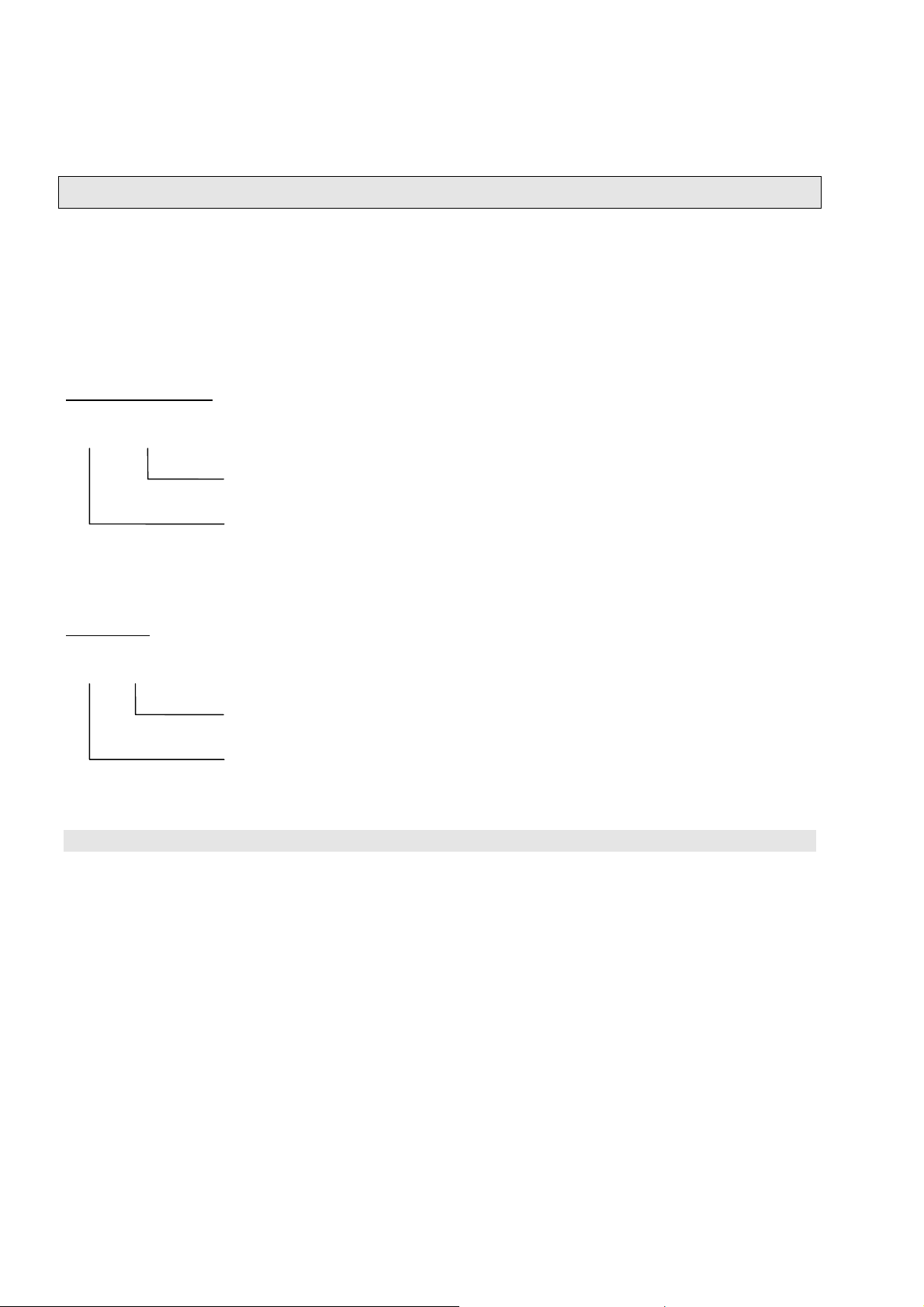

3. Called system unit "online", called single analyzer not available.

If the test bench control computer will call the devices directly and the system unit or the

analyzer are not available, you will not get any response telegram. So, the test bench

control computer will have to realize the missing of the system or of the analyzer by

"Time Out".

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte n

12. Byte BLANK

13. Byte N

14. Byte A

15. Byte ETX

Error status byte: Value is zero: Device without error

Value is not zero: Device with one or more errors

11. Byte: Channel number one to n: "Called device not available".

90003752(2) [AK-Commands] 11/01

AK

1 - 13

Page 18

4. Called system unit "offline", called single analyzer not available.

If the test bench control computer will call the devices directly and the system unit or the

analyzer are not available, you will not get any response telegram. So, the test bench

control computer will have to realize the missing of the system or of the analyzer by

"Time Out".

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte 0

12. Byte BLANK

13. Byte O

14. Byte F

15. Byte BLANK

16. Byte K

17. Byte n

18. Byte BLANK

19. Byte N

20. Byte A

21. Byte ETX

1 - 14

AK

90003752(2) [AK-Commands] 10/01

Page 19

I) V24/RS232/485-Interface - Basics

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

11. Byte: Channel number zero: "System unit offline"

17. Byte: Channel number one to n: "Called device not available.

90003752(2) [AK-Commands] 11/01

AK

1 - 15

Page 20

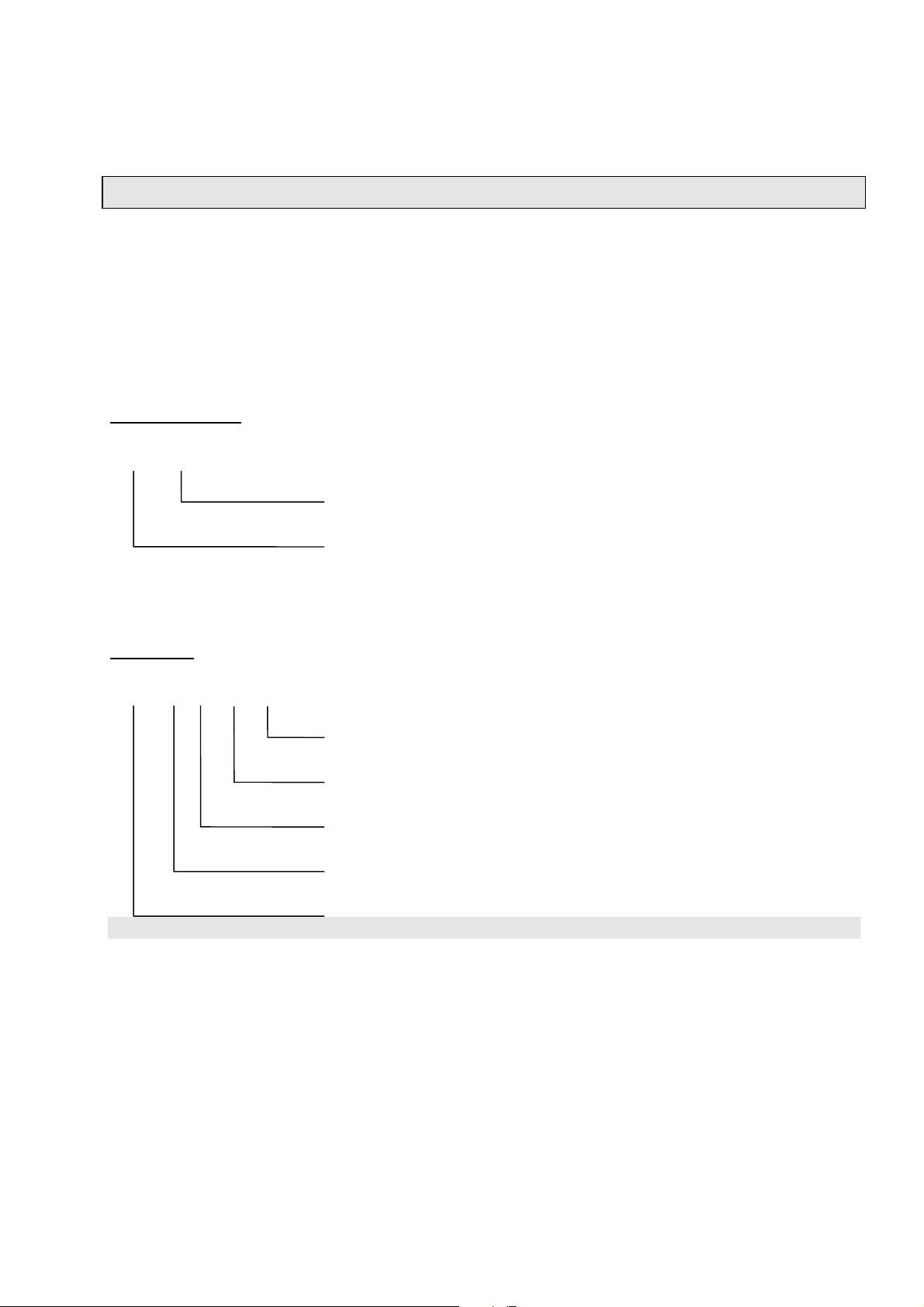

5. Called unit or channel is busy with a running function.

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte n

12. Byte BLANK

13. Byte B

14. Byte S

15. Byte ETX

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

11. Byte: Channel number is zero: "The whole unit is busy".

Channel number is one to n: "Single analyzer is busy".

1 - 16

AK

90003752(2) [AK-Commands] 10/01

Page 21

I) V24/RS232/485-Interface - Basics

6. The data are incomplete or the data do not have the expected format.

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte n

12. Byte BLANK

13. Byte S

14. Byte E

15. Byte ETX

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

90003752(2) [AK-Commands] 11/01

AK

1 - 17

Page 22

7. The data or the parameters do not have the expected size.

1. Byte STX

2. Byte

DON'T

CARE

3. Byte C

4. Byte O

5. Byte D

6. Byte E

7. Byte BLANK

8. Byte x Error status byte

9. Byte BLANK

10. Byte K

11. Byte n

12. Byte BLANK

13. Byte D

14. Byte F

15. Byte ETX

Error status byte: Value is zero: Device without error.

Value is not zero: Device with one or more errors.

1 - 18

AK

90003752(2) [AK-Commands] 10/01

Page 23

I) V24/RS232/485-Interface - Basics

6. Function sequence and error status after the receipt of the

'SRES' or 'STBY' commands

1. The test bench control computer is sending the control command SRES (Reset)

to the system unit or any single analyzer.

All running functions or procedures will be canceled. An initializing will start, that is

analogous to the switching on of the system unit or the analyzer: CPU and memory

check, regulating or controlling of required temperatures, igniting of the flame in a FID

an so on. The operation mode of the system or analyzer is "stand-by" during the

initializing, even if the device is not ready and error free. That means, the status STBY

will be reported to the read command ASTZ. The test bench control computer can only

realize with the read command ASTF (error status), if the device is ready for

measurements. The device will be ready to measure, if the essential functions of the

current measuring instruction will be error free.

Example:

The status of the system unit or analyzer is SXYZ. The test bench control computer

sends SRES:

Test bench control computer sends SRES Kn

→ System or analyzer will response SRES x

The system unit or the analyzer will cancel the status SXYZ. It will run a CPU and

memory check and it will control the temperatures. If the temperatures are out of the

allowed setpoint range, the device will regulate it. The FID will control the flame and will

try to ignite it, if necessary, and so on. The test bench control computer will read the

operation mode and the error status:

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ 0 SMAN STBY

or

Test bench control computer sends ASTZ Kn

System or analyzer will response ASTZ x SMAN STBY

Test bench control computer sends ASTF Kn

System or analyzer will response ASTF x n

The error status byte will be zero and the system or the analyzer will be ready to

measure, if all temperatures are in the allowed setpoint range, if the FID flame is

burning etc.

If these parameters are not correct, the error status byte will be different from zero. The

test bench control computer will read the operation mode and the error status as long as

the system or the analyzer will be ready to measure. The test bench control computer

will control the maximum time for this reading.

90003752(2) [AK-Commands] 11/01

AK

1 - 19

Page 24

2. The test bench control computer is sending the control command STBY (Standby) to the system unit or any single analyzer.

There are two different cases:

! If the system or the analyzer is resting, this mode will be finished. Then, it will be tried to

get the stand-by mode ready for an error free measurement. The system or the

analyzer will regulate all temperatures to the required setpoints, that were down during

the resting. The FID will control the flame burning and if necessary it will try to ignite the

flame etc. The operation mode of the system or analyzer is "stand-by" during these

checkups, even if the device is not ready and error free. That means, the status STBY

will be reported to the read command ASTZ. The test bench control computer can only

realize with the read command ASTF (error status), if the device is ready for

measurements. The device will be ready to measure, if the essential functions of the

current measuring instruction will be error free.

Example:

The system or the analyzer is resting. No error is existing. The test bench control

computer will ask for the operation mode:

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ 0 SREM SPAU

Test bench control computer sends STBY. System or analyzer shall accept the stand-by

mode:

Test bench control computer sends STBY Kn

→ System or analyzer will response STBY 0

The system or analyzer is finishing the resting. Then, it will try to get the stand-by mode

for an error free measurement. The system or analyzer will check the conditions: Are all

temperatures in the setpoint range ? Is the FID flame burning ? etc. The test bench

control computer will read the operation mode:

Status is error free:

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ 0 SREM STBY

or status has still some errors:

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ x SREM STBY

Test bench control computer sends ASTF Kn

→ System or analyzer will response ASTF x n

The error status byte will be zero and the system or the analyzer will be ready to

measure, if all temperatures are in the allowed setpoint range, if the FID flame is

burning etc.

If these parameters are not correct, the error status byte will be different from zero. The

test bench control computer will read the operation mode and the error status as long as

the system or the analyzer will be ready to measure. The test bench control computer

will control the maximum time for this reading.

1 - 20

AK

90003752(2) [AK-Commands] 10/01

Page 25

I) V24/RS232/485-Interface - Basics

# The system or the analyzer is in the operation mode SXYZ. This mode will be finished.

Then, it will be tried to get the stand-by mode ready for an error free measurement. If

there will be an error in the function SXYZ, the system or the analyzer will try to remove

this error to get the stand-by mode ready for an error free measurement (i.e. FID flame

is not burning, the FID will try to ignite). The operation mode of the system or analyzer is

"stand-by" during these check-ups, even if the device is not ready and error free. That

means, the status STBY will be reported to the read command ASTZ. The test bench

control computer can only realize with the read command ASTF (error status), if the

device is ready for measurements. The device will be ready to measure, if the essential

functions of the current measuring instruction will be error free.

Example:

The system or the analyzer is in the operation mode SXYZ. An error is existing with the

error number n, i.e. FID flame is not burning. The test bench control computer will ask

for the error status:

Test bench control computer sends ASTF Kn

→ System or analyzer will response ASTF x n

Test bench control computer sends STBY. System or analyzer shall accept the stand-by

mode and get ready for an error free measurement:

Test bench control computer sends STBY Kn

→ System or analyzer will response STBY x

The system or analyzer is finishing the operation mode SXYZ. Then, it will try to get the

stand-by mode for an error free measurement. The system or analyzer will check the

conditions and will try to remove the error, i.e. ignition of the FID flame. The test bench

control computer will read the operation mode:

Error is removed (e.g. Flame was ignited):

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ 0 SREM STBY

or

Error is still existing (e.g. Flame has not been ignited):

Test bench control computer sends ASTZ Kn

→ System or analyzer will response ASTZ x SREM STBY

Test bench control computer sends ASTF Kn

→ System or analyzer will response ASTF x n

The error status byte will be zero and the system or the analyzer will be ready to

measure, if the error is removed i.e. the FID flame is still burning.

If these parameters are not correct, the error status byte will be different from zero. The

test bench control computer will read the operation mode and the error status as long as

the system or the analyzer will be ready to measure. The test bench control computer

will control the maximum time for this reading.

90003752(2) [AK-Commands] 11/01

AK

1 - 21

Page 26

1 - 22

AK

90003752(2) [AK-Commands] 10/01

Page 27

II) V24/RS232/485 Interface - Single Analyzers and Systems

Specifications of the criterions and codes for the communication

between

• the front-end computer (system computer) of an exhaust analyzer system and the test

bench control computer.

• each analyzer of an exhaust analyzer system and the test bench control computer.

• the front-end computer (system computer) of an exhaust analyzer system and their

single devices. The following measurement systems and equipments can also be such

single devices.

• the front-end computer (system computer) of a fuel consumption analyzer and a test

bench control computer.

• the front-end computer (system computer) of an SHED measurement equipment and

the test bench control computer. (SHED: Sealed Housing for Evaporative Determination)

• the front-end computer (system computer) of a sampling system and the test bench

control computer.

The computer of an analyzer or of a system will be named as FU

(Function Unit) and the test bench control computer will be abbreviated

with TBCC.

90003752(1) [AK-Commands] 10/98

AK

2 - 1

Page 28

1. Basic Informations

You can distinguish three cases:

(1) Exhaust analyzer system:

Some analyzers are combined logically. That means, these analyzers are connected with

the TBCC via an front-end computer (system computer). The communication does not

take place directly between the TBCC and the analyzers, but it will take place via the frontend computer. The identification of each device resp. of the whole system will be done by

a channel number. K0 means the whole configured analyzer system ("assembling

command resp. assembling report"). Kn (n=1, nmax) means each physical available

analyzer. KV means the corresponding front-end computer.

Some analyzers and the sampling devices or systems (e.g. CVS equipment, particle

sampler, sampling system, etc.) are combined logically. That means, these analyzers are

connected with the TBCC via an front-end computer (system computer). The communication does not take place directly between the TBCC and the devices or systems, but it

will take place via the front-end computer. The identification of each device and system will

be done by a channel number. The handling of the analyzers will be like described above.

All the other devices or systems can only be called directly by the corresponding channel

number. The front-end computer must know the mnemonics of these devices and

systems. Furthermore, the front-end computer has to be able to send orders and read

commands to the channels resp. to send responses to the TBCC.

(2) Single exhaust analyzers (single channel analyzers):

All analyzers are connected to the TBCC individually. So, an identification of the analyzers

by the software would not be necessary, because the analyzers are identified by their

hardware connections. But to get a homogeneous protocol, the channel number will be

indicated with K0.

(3) Single exhaust analyzers (multi channel analyzers):

All analyzers are connected to the TBCC individually, but they measure more than a single

component (e.g. CO and C02). The identification by the software is necessary, because it

will call the single channels resp. components. That is why such a single analyzer will be

treated like a system.

2 - 2

AK

90003752(3) [AK-Commands] 11/03

Page 29

II) V24/RS232/485 Interface - Single Analyzers and Systems

The codes determined in this manual are valid for the communication between

• the TBCC and the front-end computer of an exhaust analyzer system.

• the front-end computer of an exhaust analyzer system and the corresponding single

devices.

• the TBCC and the single exhaust analyzers connected directly to the TBCC.

• the TBCC and other exhaust measuring or analyzing devices or equipments connected

directly to the TBCC.

The floating point format is valid for the signal transfer.

The physical units are determined as follows:

• Exhaust values: ppm

• Temperatures: K

• Pressures: Pa

• Flow: l/min

The analyzer system or each analyzer can be set to the operation mode "MANUAL"

selecting "REMOTE DISABLE" for the parameter "REMOTE EN-/DISABLE". This setup

does not depend on the previous status of the system or analyzer.

If you select "REMOTE ENABLE", the mode "MANUAL" will retain for the moment, but the

TBCC can call this operation mode with a control command. If the TBCC will setup the

system/the analyzer to "REMOTE", the system/the analyzer will execute control

commands from the TBCC. Precondition: The system/the analyzer is able to start the

function selected.

In the mode "REMOTE DISABLE", the TBCC can only send read commands. It is only

possible to read signals and status informations. If then the system or the analyzer is in the

mode "MANUAL", it will ignore the control command from the TBCC. No change of the

error status will be done in the response to the TBCC. Instead of that the response will

display "MANUAL" as first date.

The same will be valid, if the parameter is "REMOTE ENABLE", but the TBCC did switch

the system/the analyzer to the mode "MANUAL".

Otherwise, the operation mode can only be recognized by reading the status.

This is also valid during a test is running.

90003752(1) [AK-Commands] 10/98

AK

2 - 3

Page 30

If it is possible in a system to put single channels together to lines, so the following

definition will be valid:

A line is the summary of "1-x" analyzers to a logical group "y", that can be switched

physically to a gas channel "z". Each device can only be assigned to one line at the

same time. If you will try to assign a channel to another line and this channel is already

assigned, the front-end computer will send as response "DF" (data error).

The organization of each defined line will be done in the front-end computer (CODE KV

Ln ...). The order must be sent to the front-end computer "KV".

A line will be dissolved by the configuration without assignment of channels (CODE KV

Ln) or by the reset order (SRES).

All available gas inputs can be assigned to a defined line. So it is possible to assign

different lines to different gas sampling points, e.g. in front of a catalyst, behind a

catalyst. If the gas running time will change in such cases, you have to regard for it.

2 - 4

AK

90003752(3) [AK-Commands] 11/03

Page 31

II) V24/RS232/485 Interface - Single Analyzers and Systems

2. List of all Codes

2.1. Control commands

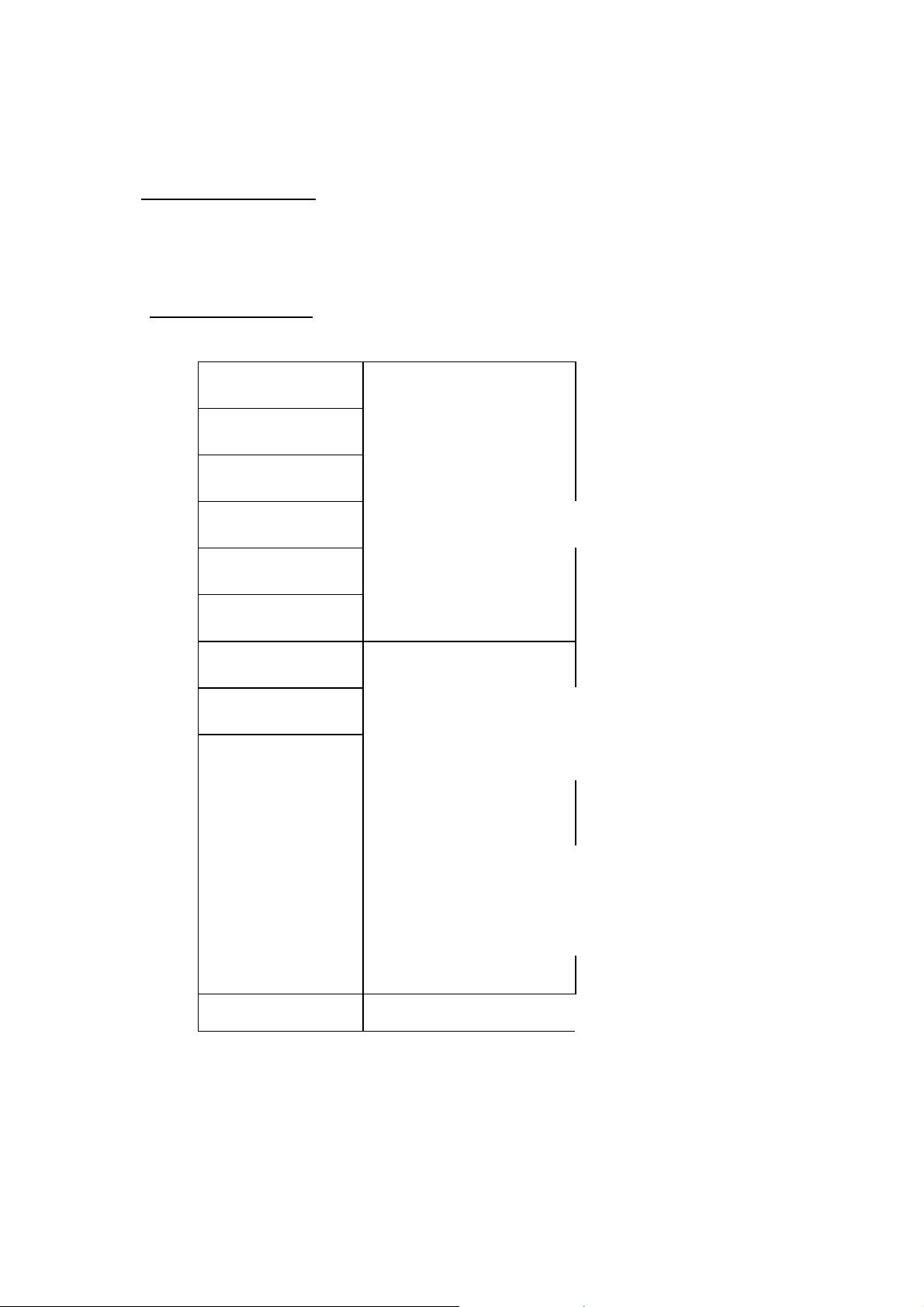

CODE Function Page

SALI Kn Mm Linearization check with spangas 2 - 8

SARA Kn Autoranging "OFF" (located range will remain) 2 - 9

SARE Kn Autoranging "ON" 2 - 9

SATK Kn Autom. calibration

(zero and span calibration + zerogas + stand-by)

SEGA Kn Spangas (spangas will flow with time limit) 2 - 15

SEMB Kn Mm Set range (1, 2, 3, 4) 2 - 16

SFRZ Kn Decimal point setup for floating point format 2 - 18

SGTS Kn Device test 2 - 19

SHDA K0 Hold mode "OFF" 2 - 20

SHDE K0 Hold mode "ON" 2 - 20

SINT Kn Start integration (integral average) 2 - 21

SLCH Kn Mm Linearization check (with gas distribution) 2 - 22

SLIN Kn Mm Linearization

(with determination of corrections and saving)

SLST Kn Set linearization step and get values 2 - 24

SMAN Kn Operation mode "Manual" 2 - 25

SMGA Kn Samplegas (will be sucked or will be on) 2 - 26

SNAB Kn Zerogas calibration 2 - 27

SNGA Kn Zerogas (zerogas will flow with time limit) 2 - 28

SPAB Kn Spangas calibration 2 - 29

SPAU Kn Pause (resting status, e.g. pumps, ozonator, deozonator, high

voltage off, gas input closed within the device)

SQEF Kn Mm Cross interference (only for CO analyzers) 2 - 31

SREM Kn Operation mode "Remote" 2 - 32

SRES Kn Reset (analyzer will change via initializing mode to stand-by) 2 - 33

SROF Kn Delay modus "OFF" (operation mode: signal output with/without

delay time, involved are SINT, AKON, AIKO, AIKG, analog signal)

SRON Kn Delay modus "ON" (analog to "SROF") 2 - 34

SSPL Kn Purging (purge air will be sucked or will be on) 2 - 35

ST9O Kn Set t

time step (S = fast, M = medium, L = slowly) 2 - 36

90

STBY Kn Stand-by (get ready for measurement no matter of the previous

history)

Optional:

SCAL Kn Start system calibration (only for platform) 2 - 13

SENO Kn NO measurement (operation mode CLD) 2 - 17

SNOX Kn NO

Kn:

Mm:

Response

Channel n

Range m

The response to the control commands will contain the CODE of the control command and

the error status byte (0-9).

measurement (operation mode CLD) 2 - 17

x

2 - 10

2 - 23

2 - 30

2 - 34

2 - 37

90003752(1) [AK-Commands] 10/98

AK

2 - 5

Page 32

2.2. Read commands

CODE

Function Page

AAEG Kn Spangas deviation 2 - 39

AALI Kn Mm Deviations of the last linearization checks with spangas 2 - 40

AANG Kn Zerogas deviation 2 - 41

AEMB Kn Selected range (R1, R2, R3, R4) 2 - 45

AFDA Kn CODE Zero- /spangas time (function length of calibration) 2 - 46

AFDA Kn CODE Purge time 2 - 46

AGID Kn Device identification 2 - 47

AGRW Kn m Limit 2 - 48

AIKG Kn Concentration integral average; all (in ppm) 2 - 49

AIKO Kn Concentration integral average (in ppm) 2 - 51

AKAK Kn Mm Calibration gas concentration (in ppm) 2 - 53

AKAL Kn Stored calibration corrections 2 - 54

AKFG Kn Configuration of the system 2 - 57

AKON Kn Concentration (current value in ppm) 2 - 58

ALCH Kn Mm Deviations of the last linearization checks 2 - 61

ALIK Kn Calculation of linearization curve 2 - 62

ALIN Kn Mm Linearization values in the device (X/Y = Setpoint-/raw value) 2 - 63

ALKO Kn Mm Polynomial coefficents of the linearization curve 2 - 64

ALST Kn Linearization steps 2 - 65

AM90 Kn Actual response time (t90 time) 2 - 66

AMBA Kn Mm Begin of range (in ppm) 2 - 67

AMBE Kn Mm End of range (in ppm) 2 - 68

AMBU Kn Switch levels for autoranging 2 - 69

AMDR Kn Manual adjusted pressure 2 - 70

AQEF Kn Cross interference check result (in ppm) (only for CO analyzers) 2 - 71

ASOL Kn Setpoint value with limits 2 - 72

ASTA Kn General status of the system 2 - 73

ASTF Kn Internal error status 2 - 74

ASTZ Kn Device status 2 - 76

ASYZ Kn System time (year, month, day, hour, min., sec.) 2 - 78

AT9O Kn T90 time (response time) 2 - 79

ATEM Kn m Temperature 2 - 80

ATOL Kn Mm Stability tolerances 2 - 81

AVEZ Kn Delay and synchronization time 2 - 83

AZEI Kn CODE Times (for procedures) 2 - 84

Optional:

ABST Kn Counter of operating hours 2 - 42

ADRU Kn m Pressure (for service) 2 - 43

ADUF Kn m Flow (for service) 2 - 44

AKEN Kn Device tag 2 - 56

AKOW Kn Mm Correction (zerogas calibration and gradient) 2 - 60

AUKA Kn Uncorrected analog value 2 - 82

Kn:

Mm:

Channel n

Range m

Response

The response to the read command will contain the CODE of the read command,

the error status byte (0-9) and the data.

2 - 6

AK

90003752(3) [AK-Commands] 11/03

Page 33

II) V24/RS232/485 Interface - Single Analyzers and Systems

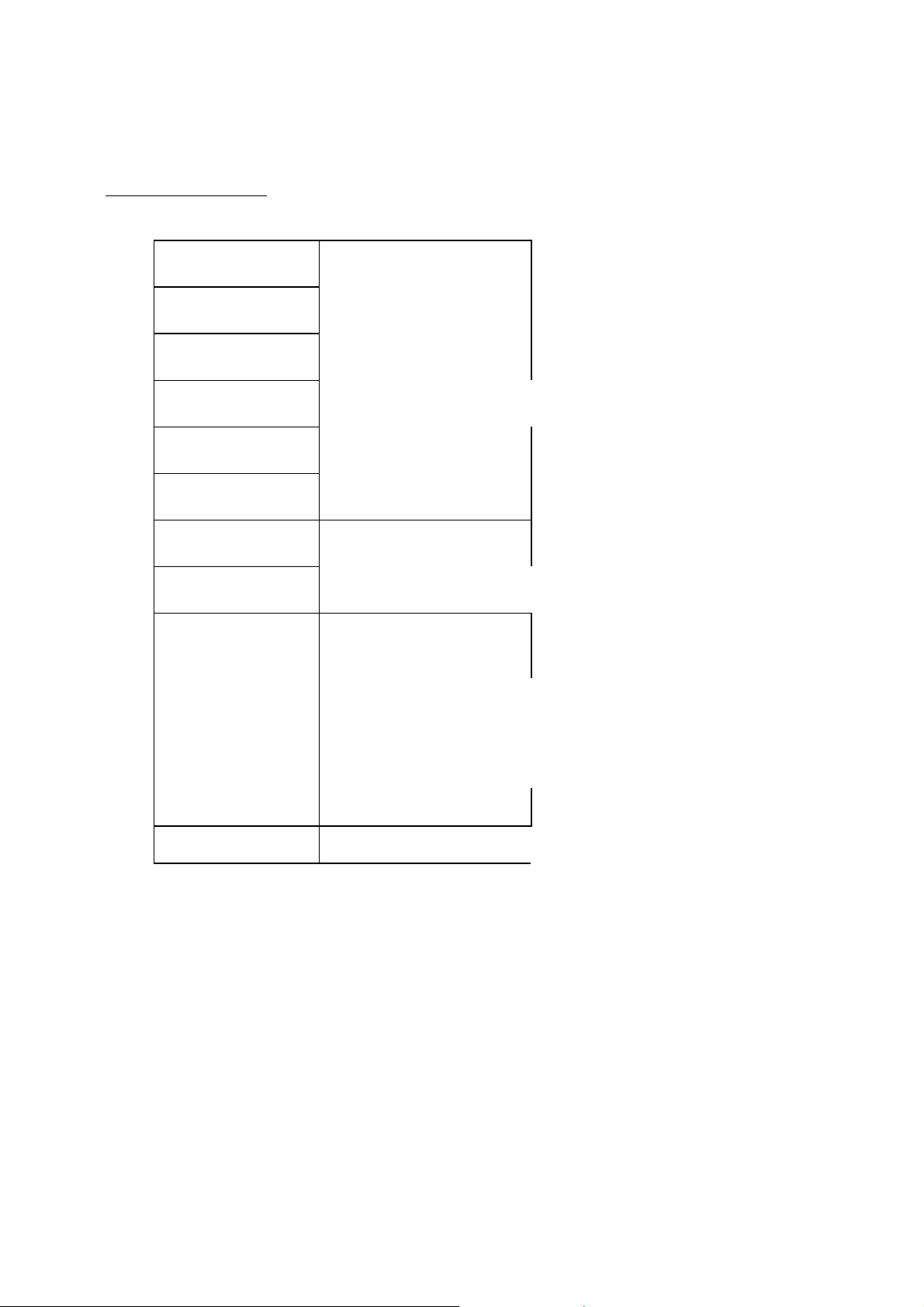

2.3. Write commands

CODE

Function Page

EFDA Kn CODE

DATA

EFDA Kn CODE Purge time 2 - 85

EGRW Kn DATA Limits 2 - 87

EKAK Kn Mm

DATA

EKFG Kn DATA Configuration of the system 2 - 90

ELIN Kn Mm

DATA

ELKO Kn DATA Polynomial coefficents of the linearization curve 2 - 92

ELST Kn DATA Linearization steps 2 - 93

EMBA Kn Mm

DATA

EMBE Kn Mm

DATA

EMBU Kn DATA Switch levels for autoranging 2 - 96

EMDR Kn DATA Manual adjusted pressure 2 - 97

ESOL Kn m DATA Setpoint value with limits 2 - 98

ESYZ Kn DATA System time (year, month, day, hour, min., sec.) 2 - 99

ET9O Kn DATA T90 time (response time) 2 -100

ETOL Kn Mm

DATA

EVEZ Kn DATA Delay and synchronization time 2 -102

EZEI Kn CODE

DATA

Optional:

EKEN Kn DATA Device tag 2 - 89

Kn:

Mm:

Channel n

Range m

Zero- /spangas time (function length of calibration) 2 - 85

Calibration gas concentration (in ppm)

Value = 0: no spangas available

Linearization values in the device (X/Y = Setpoint-/raw value) 2 - 91

Begin of range (in ppm)

Value = 0: no range defined

End of range (in ppm)

Value = 0: no range defined

Stability tolerances 2 -101

Times (for procedures) 2 -103

2 - 88

2 - 94

2 - 95

Response

The response to the write commands will contain the CODE of the write command and

the error status byte (0 - 9).

90003752(1) [AK-Commands] 10/98

AK

2 - 7

Page 34

3. Description of all Control Commands

SALI – Control command "Linearization check with spangas"

Starting this command the analyzer in a system or the single analyzer will start the

spangas flow with all available spangases one after another. It will check the setpoint

values automatically. The device will record the determined values and store the raw/

setpoint deviations. These deviations can be read with the command "AALI".

Control command

SALI Kn Mx

Function associated to channel n, range x

Code

Response

SALI 0

Error status

Code

2 - 8

AK

90003752(3) [AK-Commands] 11/03

Page 35

II) V24/RS232/485 Interface - Single Analyzers and Systems

SARA – Control command "Autoranging OFF"

SARE – Control command "Autoranging ON"

Starting the command "Autoranging ON" the analyzers in a system or the single analyzer

will select the best range for the current concentration automatically.

With the control command "SEMB" the autoranging will be stopped and the range sent

with the "SEMB" command will be selected. The command "Autoranging OFF" will stop

this function, but the found range will remain.

Control command

SARE K0

SARA K0

Function associated to the whole system unit

Code

SARE Kn

SARA Kn

Function associated to a single analyzer

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 9

Page 36

SATK – Control command "Automatic calibration"

Starting this command the analyzers in a system or the single analyzer will start a

calibration procedure to determine the correction values. The required calibration gases

and the pumps will be switched on automatically. Then, the calibration procedure will start

automatically. Such a procedure has to run until the end. It may not be canceled or

interrupted by other functions. Otherwise it is not sure that the correction values will be

valid to calculate the exhaust values of analysis. Exceptions are the commands "Reset" or

"Stand-by". After the procedure will be over the system, the analyzers in a system or the

single analyzer will have to change to the operation mode "Stand-by".

Control command

SATK K0

Function associated to the whole system unit

Code

SATK K1 Kn

Function associated to channel n

Function associated to channel 1

Code

SATK Kn M3

Function associated to channel n and range 3

Code

Response

SATK 0

Error status

Code

2 - 10

AK

90003752(3) [AK-Commands] 11/03

Page 37

II) V24/RS232/485 Interface - Single Analyzers and Systems

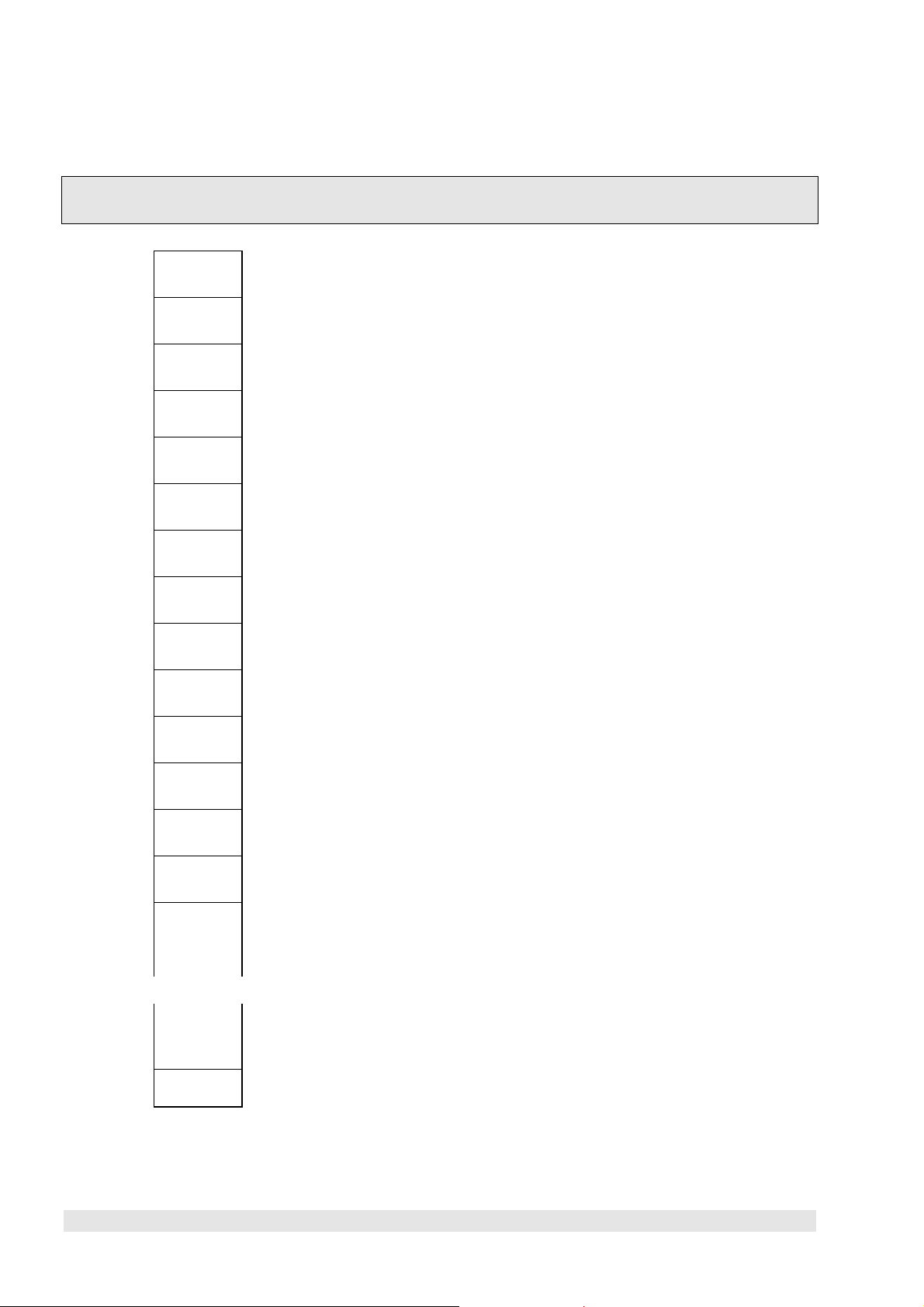

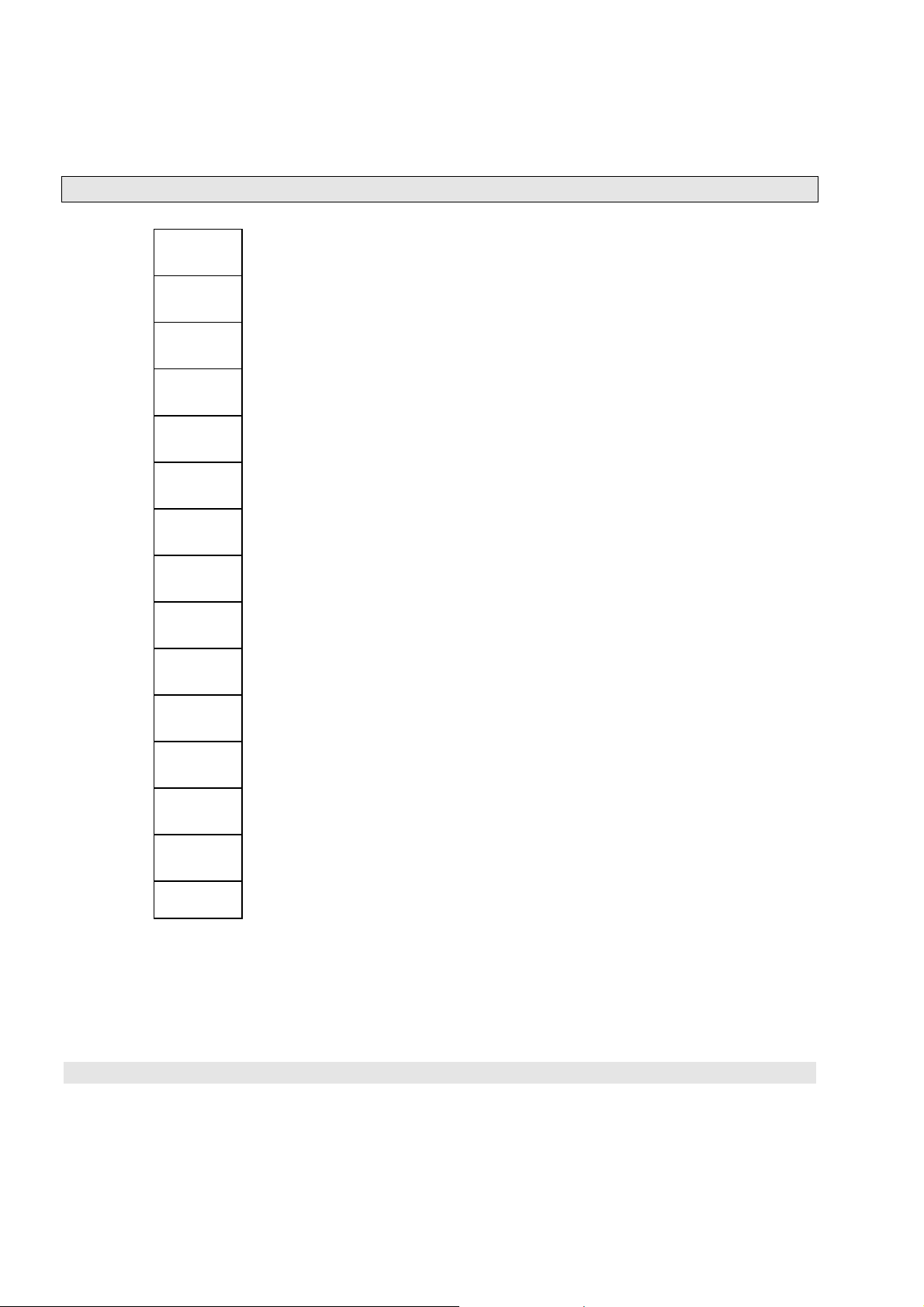

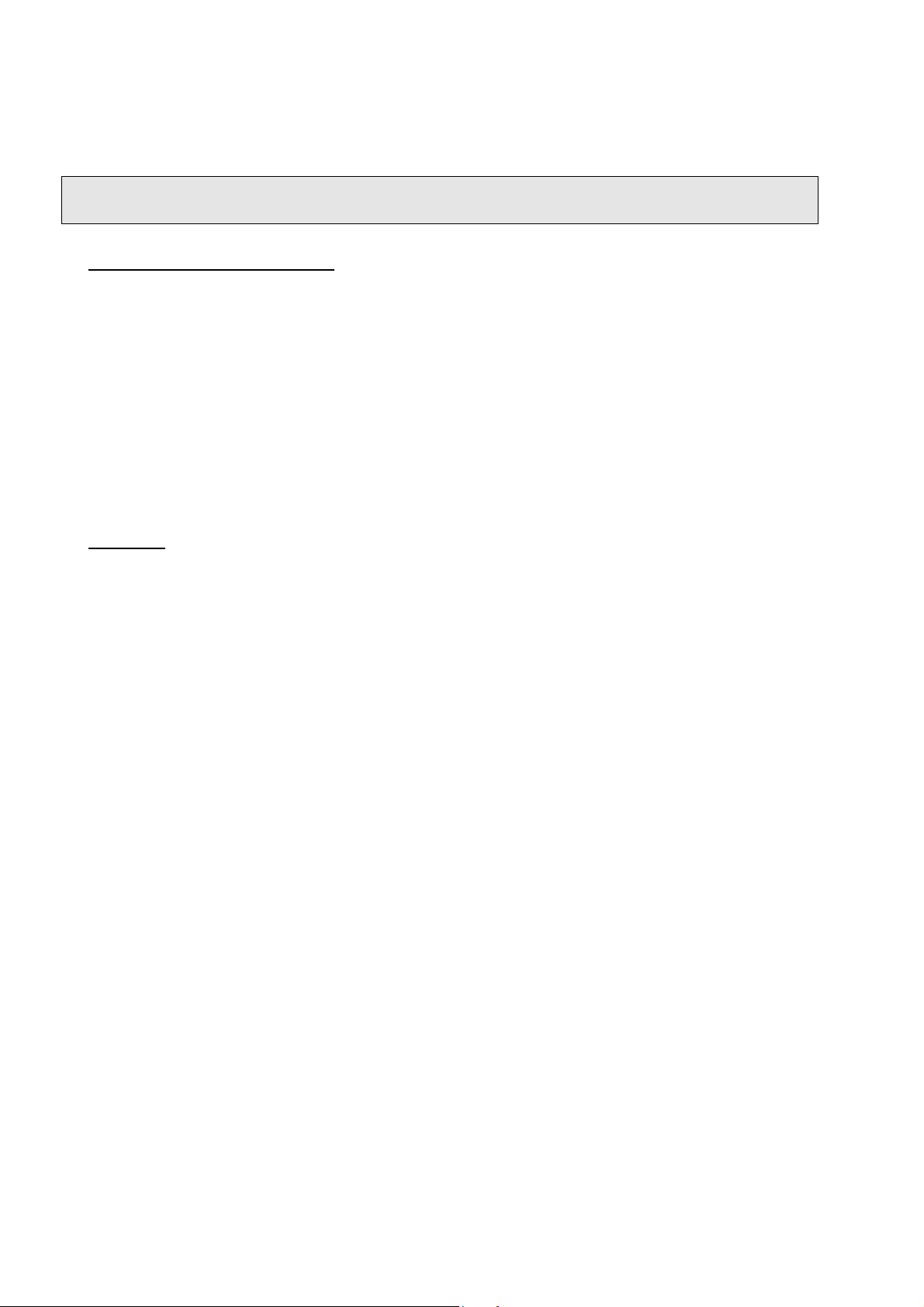

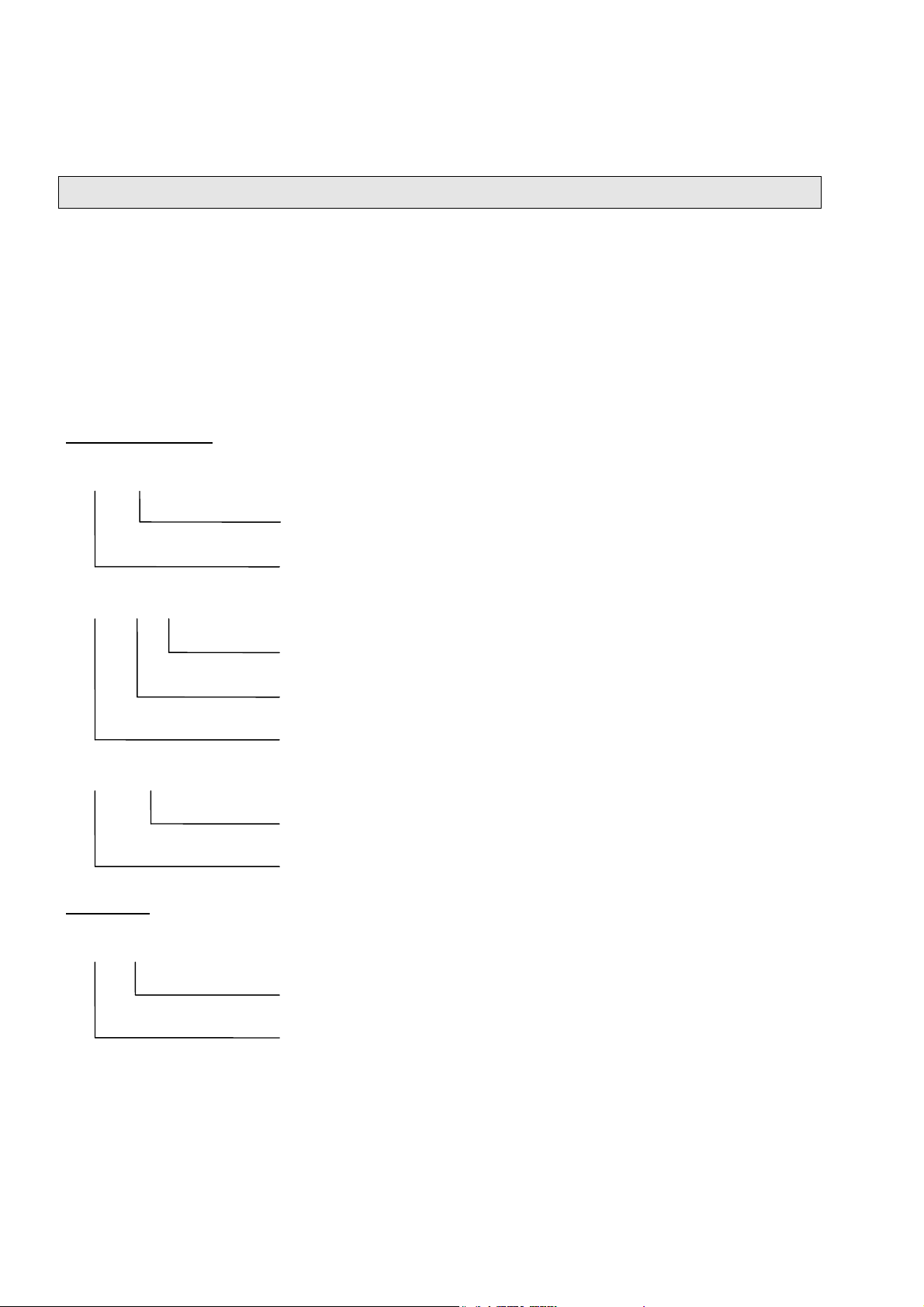

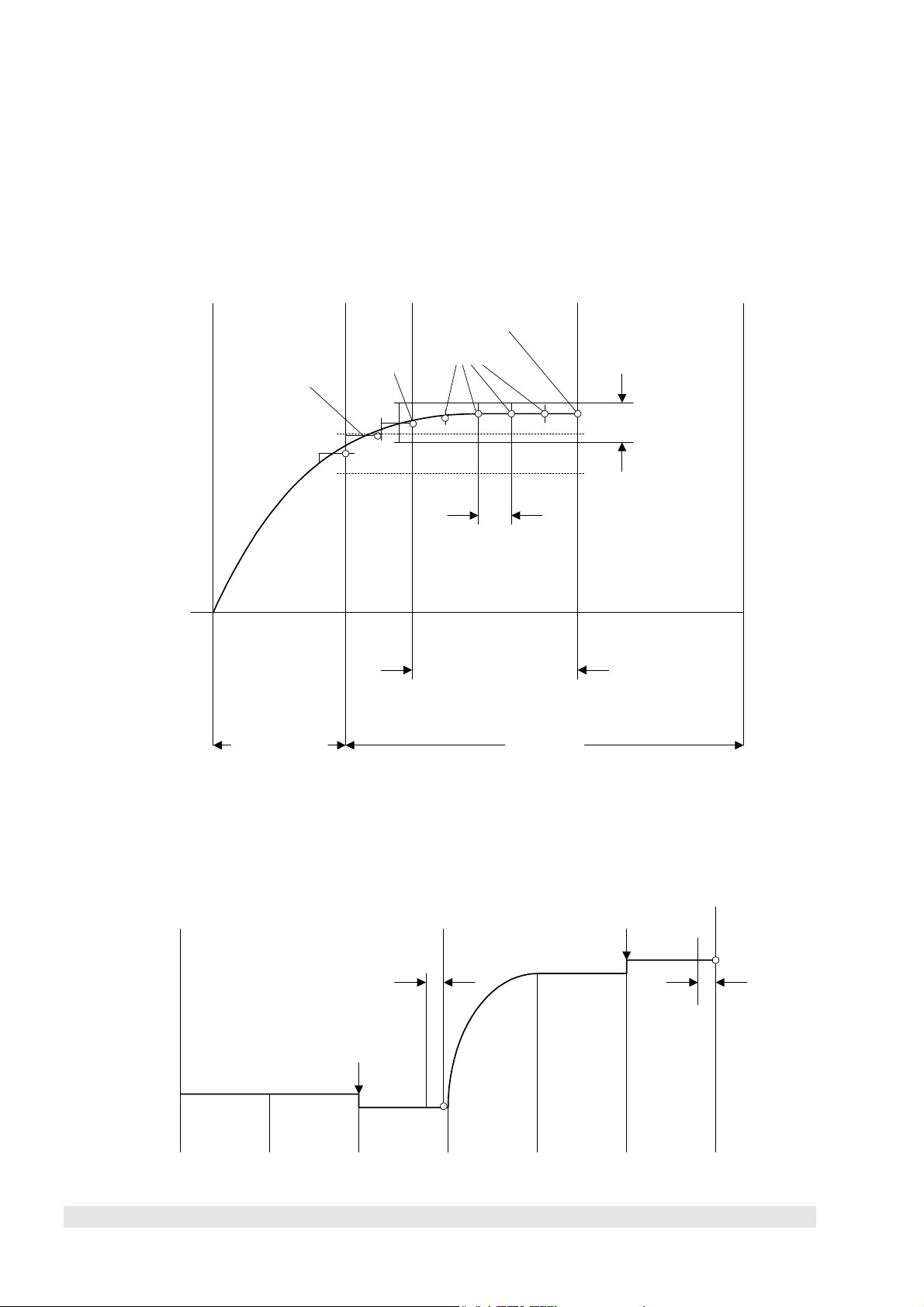

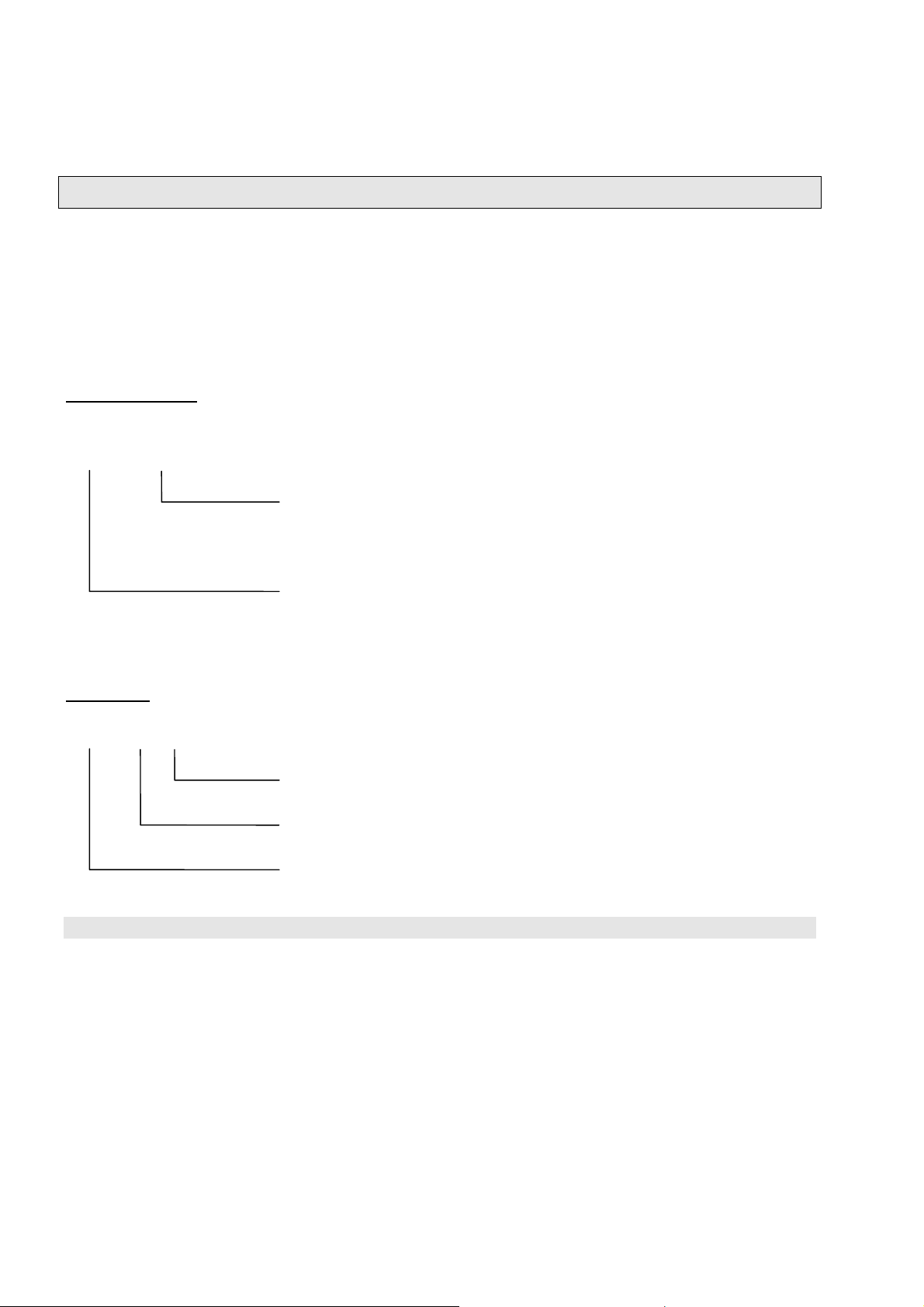

Stability control procedure

Wait dead time Tt, if

gases were switched

Start timer for time-out To

Calculate concentration

mean value K1 over time Ti

Set and start timer

for stability time

Calculate concentration

mean value Knew over time Ti

Deviation = | K1 - Knew|

Parameters:

To Time-out [xx s] (max. time for stability control)

Tt Dead time [xx s]

(Wait after gas switching)

Ti Integration time [xx,x s] (for K1, Knew)

Ts Stability time [xx s]

Tol. Tolerance [x,x % range]

No

Time out ?

No

Dev. ≥ Tol.

No

Stability

time

over ?

Yes

Signal stable

Signal = Knew

Yes

Yes

Signal not

stable

K1 = Knew

90003752(1) [AK-Commands] 10/98

AK

2 - 11

Page 38

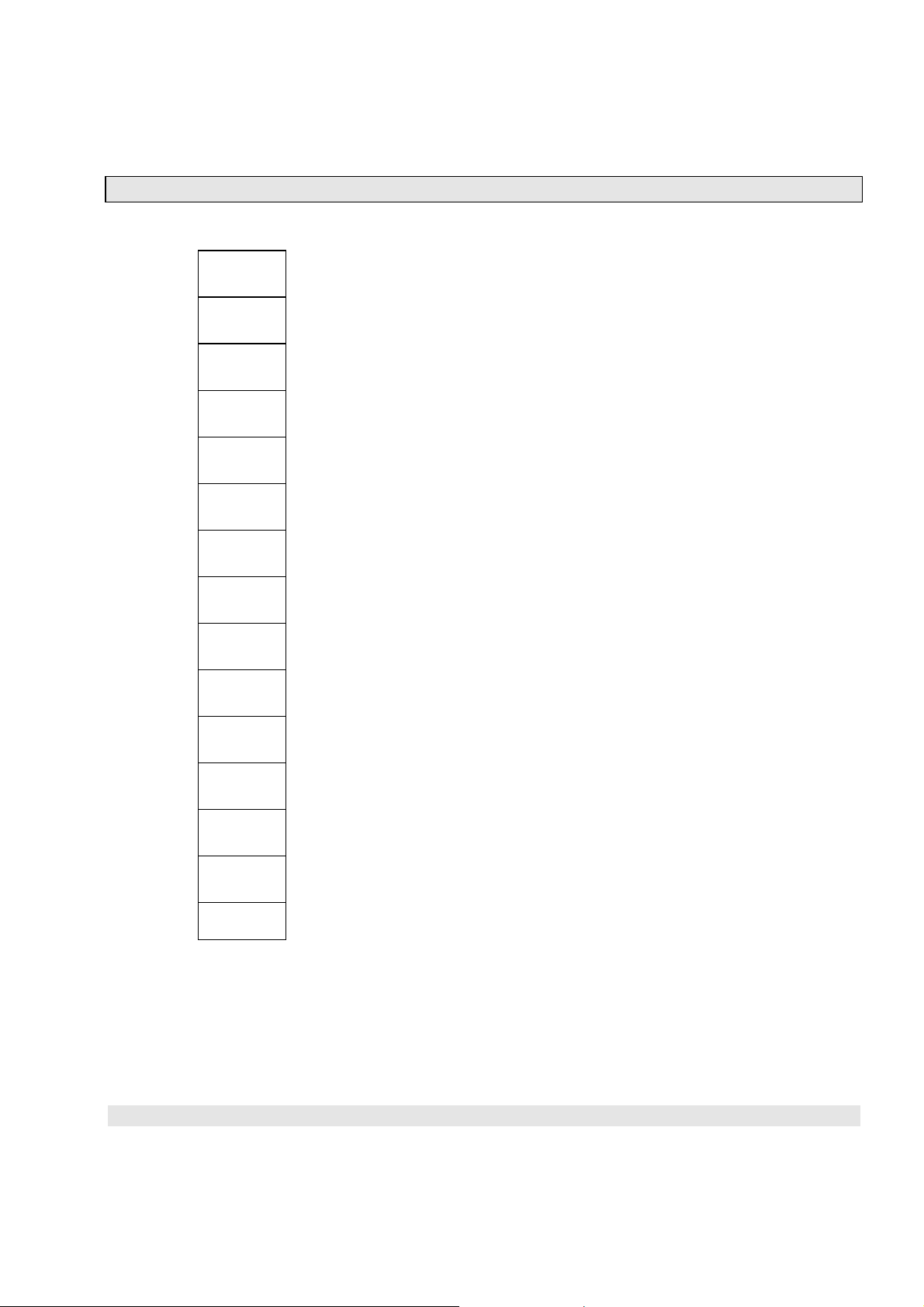

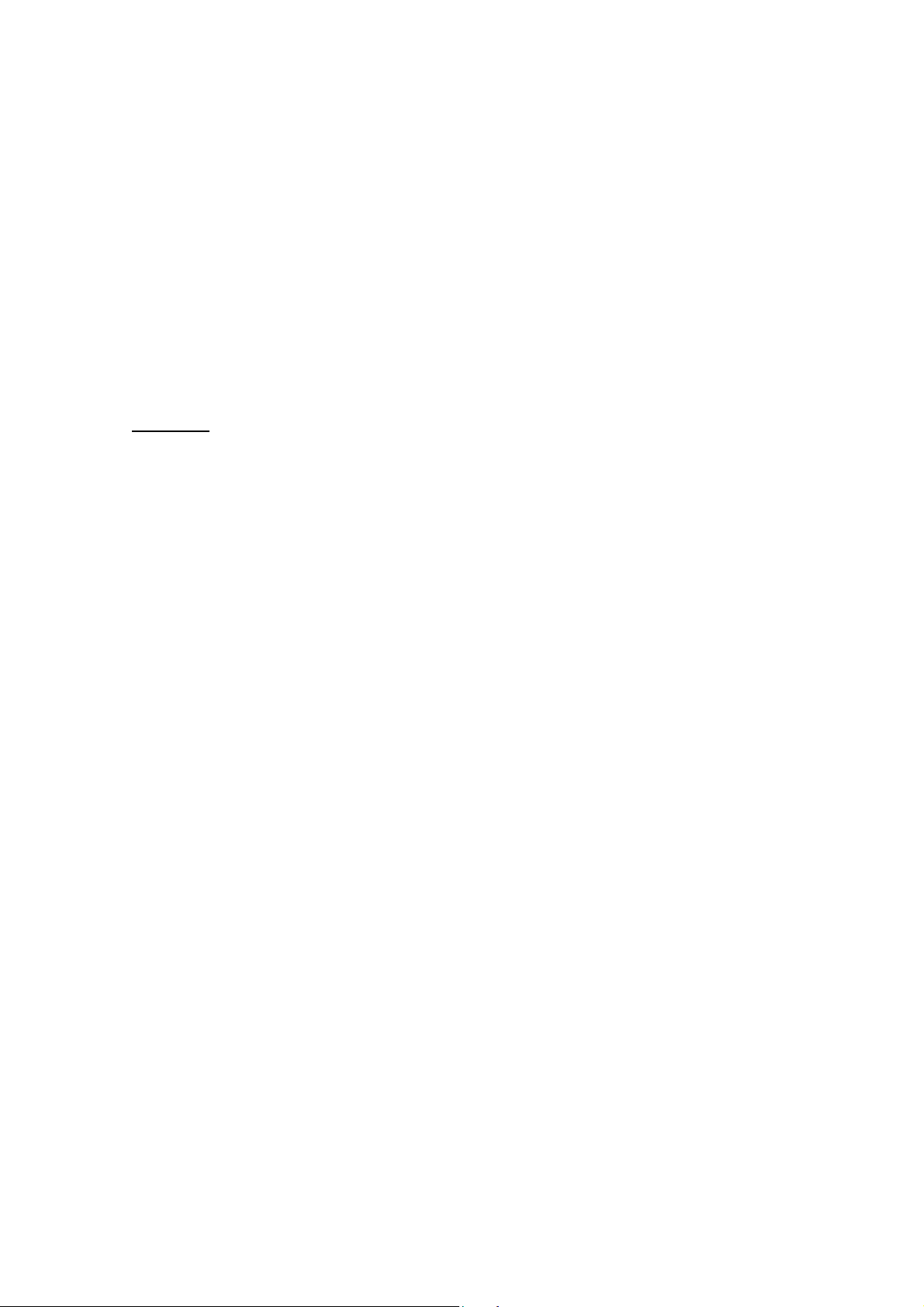

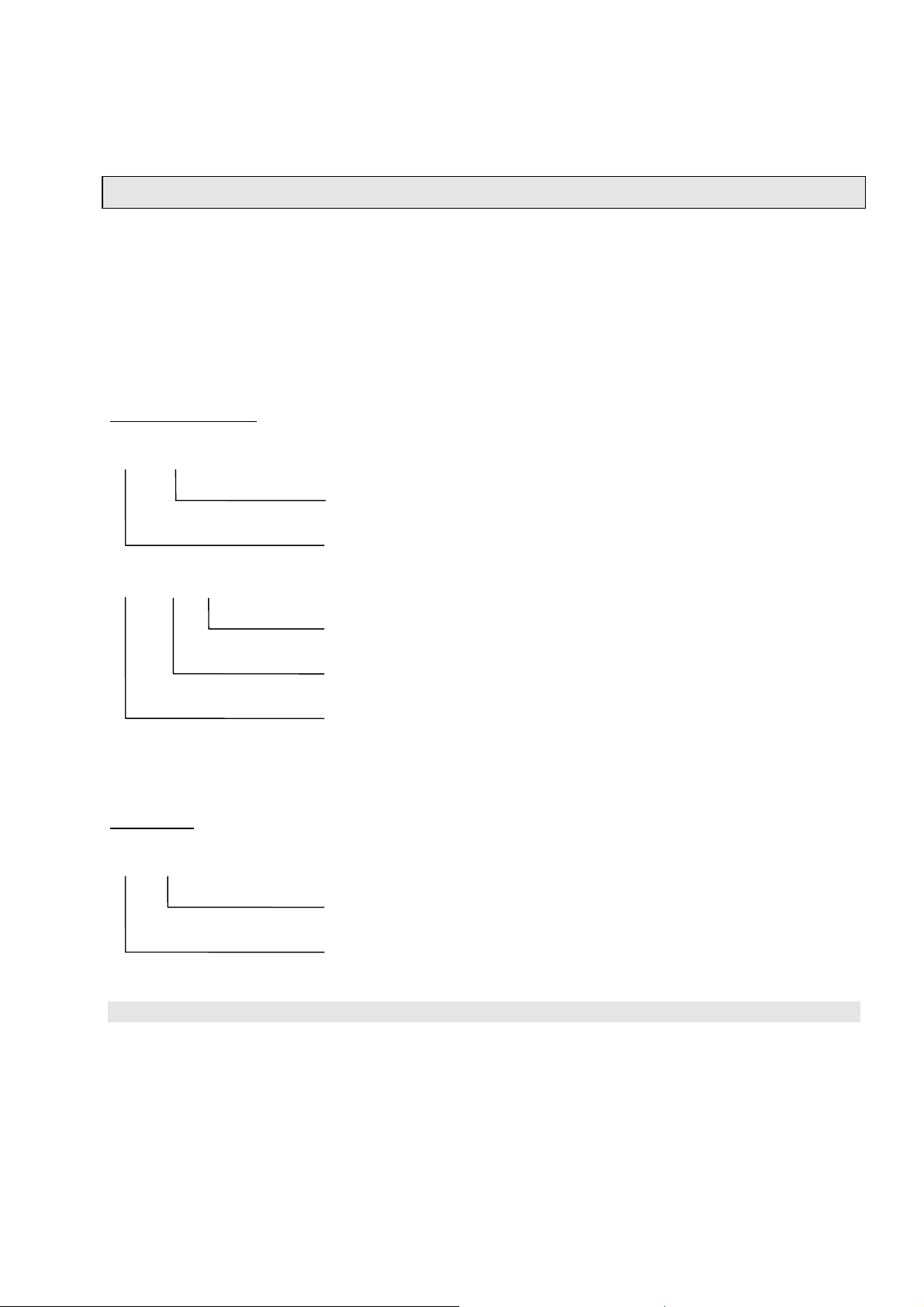

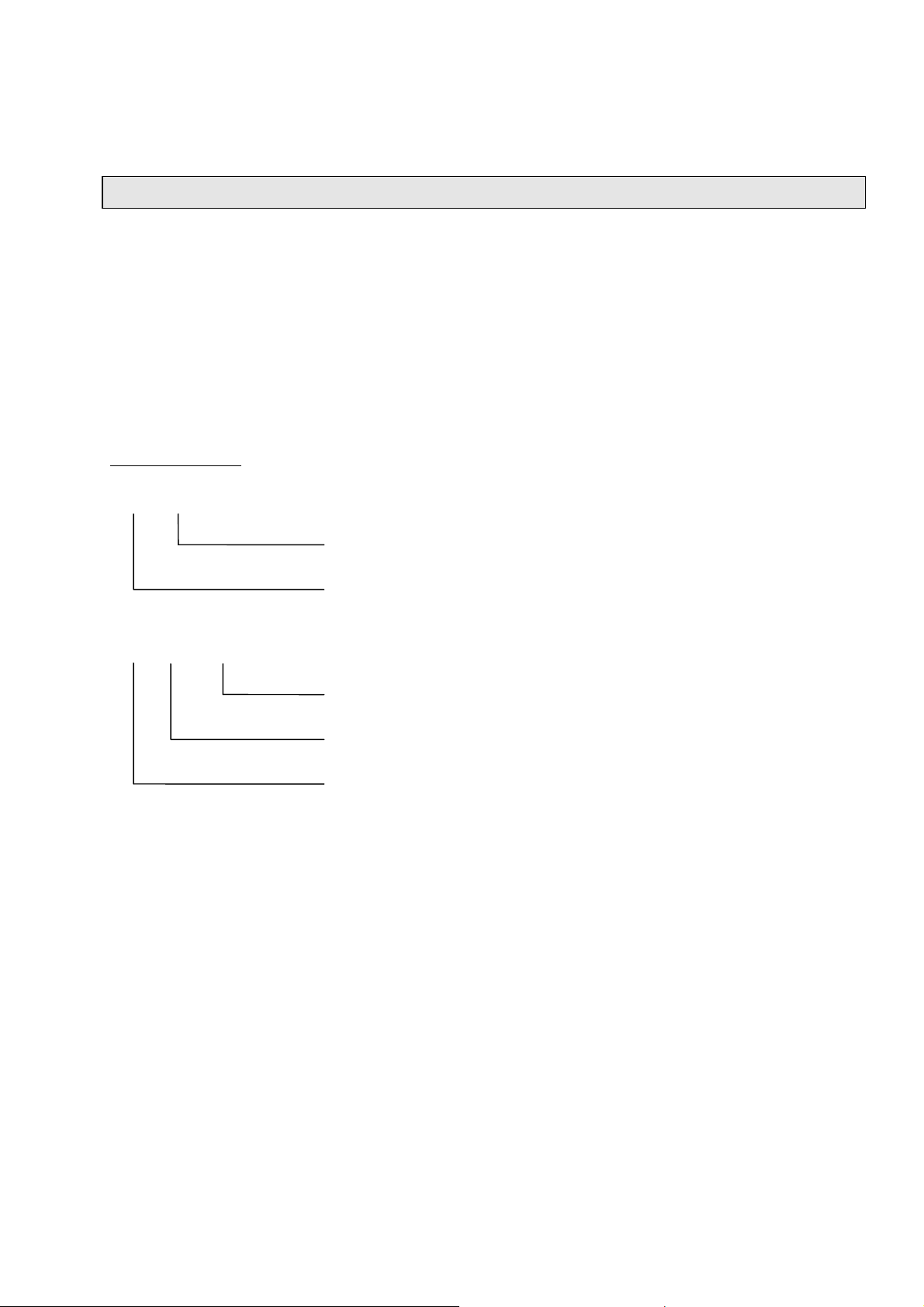

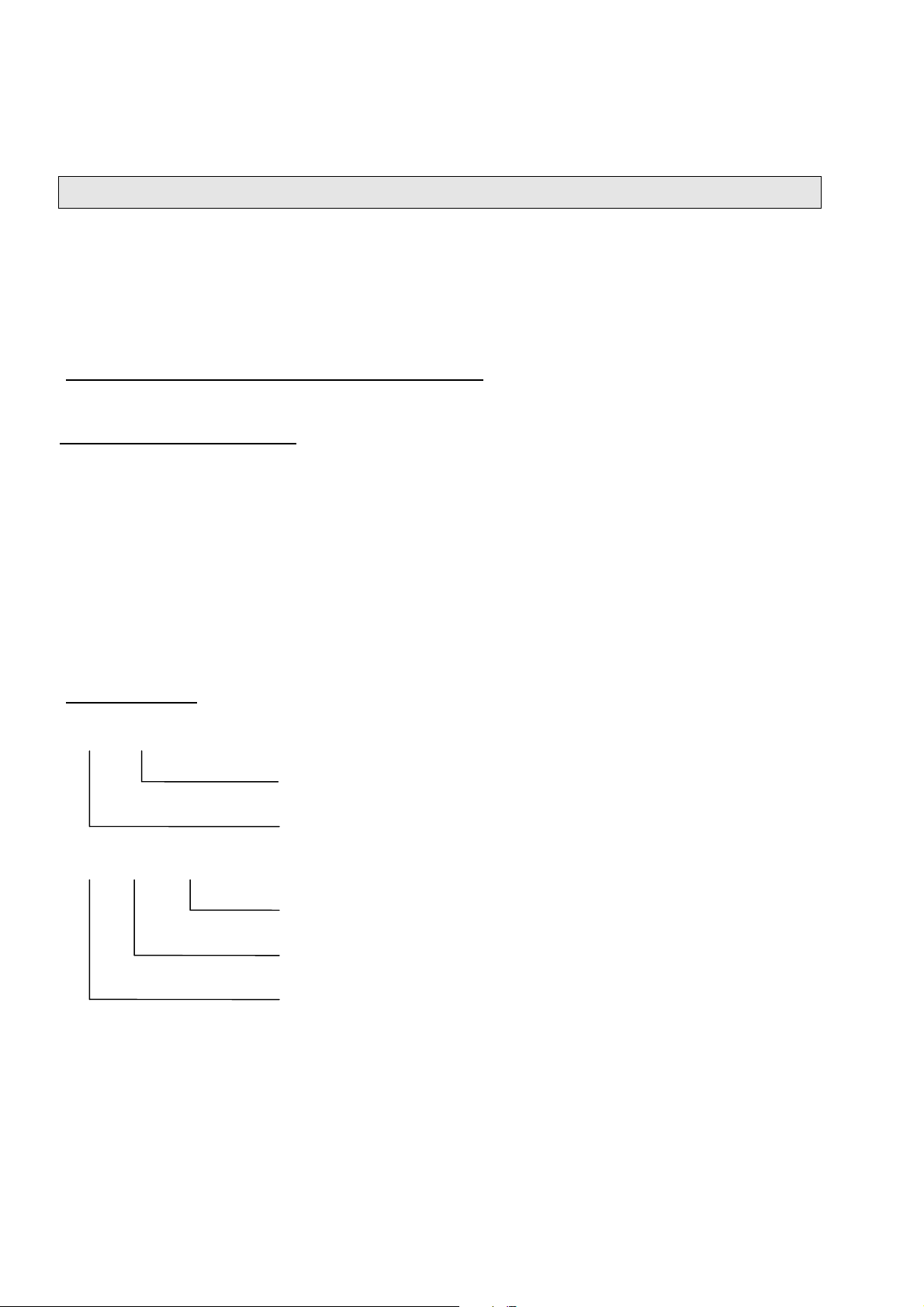

Stability control

Begin of

gas flow

Begin of

stability

control

Knew

K1

New begin

of stability

control

K1

Signal = Knew

Knew

2 * Deviation

Ti

Stability time Ts

Dead time Tt Time-out

Stability controlled procedure of the zero/span calibration

Begin of the

function SATK

Calibration

Dead time Stability

time

Average over Ti,

Read with AANG

Ti Ti

Dead timeStability

time

Calibration

Stability

time

Stability

Average over Ti,

Read with AAEG

time

2 - 12

AK

90003752(3) [AK-Commands] 11/03

Page 39

II) V24/RS232/485 Interface - Single Analyzers and Systems

Only for platform: SCAL – Control command "Start system calibration"

To control the system calibration procedures the commands "SCAL", "STBY" and "ASTZ"

have to be used. With "SCAL" the procedures will be started. For more exact description of

procedures see also the "documentation of system calibration".

Starting condition: All attached analyzer module are in the stand-by mode ("AK STBY")

and the variable "CALSTAT" is "0".

Otherwise the response is "BUSY" (BS).

Control command

SCAL Kx m (n)

Optional parameters

Type of system calibration

Function associated to channel x

Code

m Kx n

0 = ZERO-CAL K0 n = 1: switch into test mode

1 = ZERO/SPAN-CAL K0

2 = PROGRAM K0 else: switch into normal mode

3 = TEST ZERO-GAS K1...999 time-out in sec

4 = TEST SPAN-GAS1 K1...999 time-out in sec

5 = TEST SPAN-GAS2 K1...999 time-out in sec

6 = TEST SPAN-GAS3 K1...999 time-out in sec

7 = TEST SPAN-GAS4 K1...999 time-out in sec

8 = TEST CLOSE GASES K1...999 time-out in sec

If optional parameter "n" is not in the command string the appropriate variable will not be

changed.

Stop command

90003752(1) [AK-Commands] 10/98

AK

2 - 13

Page 40

STBY K0

Function associated to the whole system unit

Code

Only using the channel number 0 (K0) will stop running "SYSCAL" procedure. Besides, all

procedures of the other analyzer modules will be stopped.

Response

SCAL 0

Error status

Code

Read command

ASTZ K0

Read of the whole FU

Code

With the command "ASTZ K0" it will be checked, if a system calibration is running or not.

"SCAL" will be sent back for a running system calibration. If no system calibration is

running this string will be missed.

2 - 14

AK

90003752(3) [AK-Commands] 11/03

Page 41

II) V24/RS232/485 Interface - Single Analyzers and Systems

SEGA – Control command "Spangas"

Starting this command the analyzers in a system or the single analyzer will switch on the

calibration valve to spangas and switch on the required pumps. This function will only

check the end point. It will not correct the calibration. If continuous line recorders will be

available, the paper transport will also be switched on.

Control command

SEGA K0

Function associated to the whole system unit

Code

SEGA K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SEGA 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 15

Page 42

SEMB – Control command "Set range"

Starting this command the analyzers in a system or the single analyzer will set the range

that is named in the data. If the function "Autoranging" is running at that moment, it will be

stopped and the named range will be selected.

Control command

SEMB K1 M4 Kn M2

Function associated to channel n range 2

Function associated to channel 1 range 4

Code

Response

SEMB 0

Error status

Code

2 - 16

AK

90003752(3) [AK-Commands] 11/03

Page 43

II) V24/RS232/485 Interface - Single Analyzers and Systems

Only for CLD module: SENO/SNOX – Control command "Operation mode CLD"

Starting the command "SENO" the CLD analyzers in a system or the single CLD analyzer

will start the NO measurement. The command "SNOX" will start the NOx measurement.

Control command

SENO Kn

Function associated to channel n

Code for NO measurement

SNOX Kn

Function associated to channel n

Code for NOx measurement

Response

SENO 0

Error status

Code for NO measurement

SNOX 0

Error status

Code for NOx measurement

90003752(1) [AK-Commands] 10/98

AK

2 - 17

Page 44

SFRZ – Control command "Decimal point setup for floating point format"

E

N

With this command the format of real numbers will be setup.

This command will have an effect to the output of all real numbers. It is not possible to vary

it for different channels.

Control command

SFRZ K0 n

Parameter

Function associated to the whole system unit

Code

Description of parameter “n”

n = 1..9: n = number of digits after decimal point in normal floating point

format.

(f-notation of C-language's printf)

n = 11..19: (n-10) = is the maximum number of significant digits of either normal

floating point format or E-format, whichever is shorter.

(g-notation of C-language's printf).

Factory setting: n = 16 (= default).

Default is used if no other value for n is specified by a SFRZ

command.

n = 10 will set n = default

Response

SFRZ 0

Error status

Code

xample:

umber: 1234567.821

n = 2

Æ

1234567.82

n = 13

n = 15

Æ

1.23E06

Æ

1234600

2 - 18

AK

90003752(3) [AK-Commands] 11/03

Page 45

II) V24/RS232/485 Interface - Single Analyzers and Systems

SGTS – Control command "Device test"

Starting this command the analyzers in a system or the single analyzer will switch off the

calibration gas and the samplegas. That means, all gas tubes to the analyzer device will

be closed and the pumps will be switched off. Then, the device can be checked via a gas

input that is located directly in front of the device.

Control command

SGTS K0

Function associated to the whole system unit

Code

SGTS K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SGTS 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 19

Page 46

SHDE – Control command "Hold status ON"

SHDA – Control command "Hold status OFF"

We have the possibility to activate the "Hold"-feature not only per calibration. We can do

this also by AK-Command "SHDE". With the command "SHDA" we have the possibility to

deactivate an activated "Hold" again. Starting the command "SHDE" will switch on the

"hold status". So it is possible to start the "Hold"-feature directly by AK command and not

only per calibration. With the "SHDA" command the "Hold status" will be deactivated.

Control command

SHDE K0

SHDA K0

Function associated to the whole system unit

Code

Response

SHDE 0

SHDA 0

Error status

Code

2 - 20

AK

90003752(3) [AK-Commands] 11/03

Page 47

II) V24/RS232/485 Interface - Single Analyzers and Systems

SINT – Control command "Integrator"

Starting this command the FU will activate the internal integrators. The previous calculated

and stored integral averages will be set to zero. The integrator will calculate new integral

averages as long as the control command "SINT" will be received again. The result of the

integrator can be read with the command "AIKG".

Control command

SINT K0

Function associated to the whole system unit

Code

SINT K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SINT 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 21

Page 48

SLCH – Control command "Linearization check"

Starting this command the analyzers in a system or the single analyzer will switch on the

gas tubing to a gas distribution and a linearization procedure will run. The device will

record the correction values to the receiver specific raw curve. The deviations to the

correction values of the last determined linearization will be stored. Look at the command

"SLIN" for informations about the logic of the device control and of the gas distribution

control.

Control command

SLCH Kn Mn

Range n

Function associated to channel n

Code

Response

SLCH 0

Error status

Code

2 - 22

AK

90003752(3) [AK-Commands] 11/03

Page 49

II) V24/RS232/485 Interface - Single Analyzers and Systems

SLIN – Control command "Linearization"

Starting this command the analyzers in a system or the single analyzer will switch on the

gas tubing to a gas distribution. A linearization procedure for the selected range will run.

The device will record the determined correction values to the receiver specific raw curve.

The values will be stored in the device to calculate the gas concentration. This procedure

will be controlled by several commands of the TBCC or the system. The device or the gas

distribution will only accept those commands, it they have already received the "SLIN"

command. The "SLIN" command prepares the device or the gas distribution to receive and

execute further commands being necessary for the linearization procedure. The spangas

concentration has to be set up before by the "EKAK" command.

Control command

SLIN Kn Mn

Range n

Function associated to channel n

Code

Response

SLIN 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 23

Page 50

SLST – Control command "Set linearization step"

Starting this command the gas distribution will switch on the named distribution step. The

device will work like described for the commands "SLIN" or "SLCH" depending on the

current procedure. The device will only accept the "SLST" command, if the commands

"SLIN" or "SLCH" were received before followed by the command "ELST".

Control command

SLST K1 n

Distribution step

Function associated to channel 1

Code

Response

SLST 0

Error status

Code

2 - 24

AK

90003752(3) [AK-Commands] 11/03

Page 51

II) V24/RS232/485 Interface - Single Analyzers and Systems

SMAN – Control command "Operation mode MANUAL"

With this command the FU will change to the operation mode "Manual". Then it will only be

possible to start functions from an operating unit integrated in the FU. The same operation

mode will be enabled, if the service switch of the FU will be in the position "Remote

Disable". In that mode it will only be possible to answer to read commands of the TBCC.

Control command

SMAN K0

Function associated to the whole system unit

Code

SMAN K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SMAN 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 25

Page 52

SMGA – Control command "Samplegas"

Starting this command the analyzers in a system or the single analyzer will switch on the

sample gas valve and the pumps necessary for the samplegas transport. If continuous line

recorders will be available, the paper transport will also be switched on.

Control command

SMGA K0

Function associated to the whole system unit

Code

SMGA K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SMGA 0

Error status

Code

2 - 26

AK

90003752(3) [AK-Commands] 11/03

Page 53

II) V24/RS232/485 Interface - Single Analyzers and Systems

SNAB – Control command "Zerogas calibration"

Starting this command the analyzers in a system or the single analyzer will start a zerogas

calibration. The calibration gas flow will start automatically and the calibration procedure

will run. After this procedure will be over the system, the analyzer in a system or the single

analyzer will change to the stand-by mode. The running calibration procedure can be

canceled with the "STBY" command.

Control command

SNAB K0

Function associated to the whole system unit

Code

SNAB K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SNAB 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 27

Page 54

SNGA – Control command "Zerogas"

Starting this command the analyzers in a system or the single analyzer will switch on the

zerogas valve and the pumps necessary for the zerogas transport. This function will only

check the zero point. It will not correct the calibration. If continuous line recorders will be

available, the paper transport will also be switched on.

Control command

SNGA K0

Function associated to the whole system unit

Code

SNGA K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SNGA 0

Error status

Code

2 - 28

AK

90003752(3) [AK-Commands] 11/03

Page 55

II) V24/RS232/485 Interface - Single Analyzers and Systems

SPAB – Control command "Spangas calibration"

Starting this command the analyzers in a system or the single analyzer will start a spangas

calibration. The calibration gas flow will start automatically and the calibration procedure

will run. After this procedure will be over the system, the analyzer in a system or the single

analyzer will change to the stand-by mode. The running calibration procedure can be

canceled with the "STBY" command.

Control command

SPAB K0

Function associated to the whole system unit

Code

SPAB K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SPAB 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 29

Page 56

SPAU – Control command "Pause"

With this command the FU will be set to a defined status of interruption. This command will

only be accepted, if the FU is already in the stand-by mode. The "SPAU" command will

switch off the operation modes (e.g. FID flame, pump of an NO device) or the

corresponding setpoints (e.g. temperature of the hot pipe). With the control command

„Reset“ or „Stand-by“ the FU will change to the stand-by mode to get ready for operation.

The real functionality of the "SPAU" command will depend on the used FU. It is part of

each device or system specification.

Control command

SPAU K0

Function associated to the whole system unit

Code

SPAU Kn

Function associated to channel n

Code

Response

SPAU 0

Error status

Code

2 - 30

AK

90003752(3) [AK-Commands] 11/03

Page 57

II) V24/RS232/485 Interface - Single Analyzers and Systems

SQEF – Control command "Cross interference"

Starting this command the CO analyzer will measure wet C02. It will be produced by

streaming three percent C02 through water bottles at 20 degrees Celsius. The CO

analyzer will measure this gas mixture. The signal will be stored in the analyzer. It can be

read by the TBCC with the "AQEF" command. The measured concentration has to be

maximum 3 ppm for ranges smaller than 300 ppm. For bigger ranges it has to be

maximum 1 % of the end of range value. These limits will be controlled by the TBCC.

Control command

SQEF Kn

Function associated to channel n

Code

Response

SQEF 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 31

Page 58

SREM – Control command "Remote"

With this command the FU will change to the computing operation mode. Then, the

function start will only be possible by the TBCC. This operation mode may only be set, if

the service switch of the FU is in the position "Remote Enable".

Control command

SREM K0

Function associated to the whole system unit

Code

SREM K1 Kn

Function associated to channel n

Function associated to channel 1

Code

Response

SREM 0

Error status

Code

2 - 32

AK

90003752(3) [AK-Commands] 11/03

Page 59

II) V24/RS232/485 Interface - Single Analyzers and Systems

SRES – Control command "Reset"

With this command the FU will get a software reset. This command has the same effect to

the FU like the switching off and on of the power supply. All running procedures will be

canceled. An initializing will be started, e.g. check and control of temperature setpoints.

After that the operation modes "Manual" and "Stand-by" will be enabled.

Control command

SRES K0

Function associated to the whole system unit

Code

SRES Kn

Function associated to channel n

Code

Response

SRES 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 33

Page 60

SRON – Control command "Delay modus ON"

SROF – Control command "Delay modus OFF"

Starting this command the analyzers in a system or the single analyzer will determine

measurement and integral values (averages), that will be delayed according to the delay

time of the write command "EVEZ". The read commands "AKON", "AIKO" and "AIKG" will

get an old value according to the synchronization time of the command "EVEZ". The

analog output will get the same delay. With the command "Delay modus OFF" the

integrators will start immediately and the measurement and integral values will be

determined and sent out without delay.

Control command

SRON K0

SROF K0

Function associated to the whole system unit

Code

SRON Kn

SROF Kn

Function associated to channel n

Code

Response

SRON 0

SROF 0

Error status

Code

2 - 34

AK

90003752(3) [AK-Commands] 11/03

Page 61

II) V24/RS232/485 Interface - Single Analyzers and Systems

SSPL – Control command "Purging"

Starting this command the analyzers in a system or the single analyzer will switch on the

purge gas valve and the pumps necessary for the purge gas transport.

This function can be finished either by a new command or by a defined time interval. After

the purging will be over the system, the analyzer in a system or the single analyzer will

change to the stand-by mode.

Control command

SSPL K0

Function associated to the whole system unit

Code

SSPL Kn

Function associated to channel n

Code

Response

SSPL 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 35

Page 62

ST9O – Control command "Set t90 time step"

With this command the analyzer will use the t90 time according to the current step. The

abbreviation "S" means fast time, "M" means medium time and "L" means slow time. After

the switching on of the device or after a "Reset" the fastest time will be set.

Control command

ST9O K1 S

Function associated to channel 1, fast time

Code

Response

ST9O 0

Error status

Code

2 - 36

AK

90003752(3) [AK-Commands] 11/03

Page 63

II) V24/RS232/485 Interface - Single Analyzers and Systems

STBY – Control command "Stand-by"

With the command "Stand-by" the FU will be set to a defined status of interruption.

Running functions like measuring or purging will be canceled. Then, the stand-by mode will

be enabled. The ranges will keep selected. The FU will get ready for measurement and

operating, no matter which mode was the previous.

Control command

STBY Kn

Function associated to the whole system unit

Code

Response

STBY 0

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 37

Page 64

2 - 38

AK

90003752(3) [AK-Commands] 11/03

Page 65

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

4. Description of all Read Commands

AAEG – Read command "Deviation to spangas"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device):

∗ The measured and stored signal of the last spangas measurement.

∗ The deviation from the setpoint value of the linearized curve in ppm and percent,

referred to the end of range value.

Spangas measurement: Signal after the end of the functions "Automatic calibration" or

"Spangas", stability controlled or time controlled depending on the setup in "EFDA".

Read command

AAEG K0

AAEG Kn

Read of the whole system unit

Code

Response

AAEG 0 M1 XXX YYY ZZ ... Mn XXX YYY ZZ

Deviation [%]

Deviation [ppm]

Signal [ppm]

Range n

Deviation [%]

Deviation [ppm]

Signal [ppm]

Range 1

Error status

Code

The values will get the same format for the read of single channels.

90003752(1) [AK-Commands] 10/98

AK

2 - 39

Page 66

AALI – Read command "Deviations of the last linearization check with spangas"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device) and subchannel (range):

∗ The determined and stored deviations in ppm of the last linearization check with

spangas.

Read command

AALI Kn Mx

Read of channel n and range x

Code

Response

AALI 0 AAA BBB ...... XXX

xth difference

2nd difference

1st difference

Error status

Code

2 - 40

AK

90003752(1) [AK-Commands] 10/98

Page 67

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

AANG – Read command "Deviation to zerogas"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device):

∗ The determined and stored signal of the last zerogas measurement with its range.

∗ The deviation from the setpoint value of the linearized curve in ppm and percent,

referred to the end of range value.

Zerogas measurement: Signal after the end of the functions "Automatic calibration" or

"Zerogas", stability controlled or time controlled depending on the setup in "EFDA".

Read command

AANG K0

AANG Kn

Read of the whole system unit

Code

Response

AANG 0 M1 XXX YYY ZZ ... Mn XXX YYY ZZ

Deviation [%]

Deviation [ppm]

Signal [ppm]

Range n

Deviation [%]

Deviation [ppm]

Signal [ppm]

Range 1

Error status

Code

The values will get the same format for the read of single channels.

90003752(1) [AK-Commands] 10/98

AK

2 - 41

Page 68

ABST – Read command "Counter of operating hours"

To this read command the FU will send to the TBCC the following data:

∗ The operating hours until now for the roots fan, the turbo compressor, the sampling

pumps etc. The operating hours will only be sent as integers.

Read command

ABST K0

Read of the whole system unit

Code

Response

ABST 0 T1 T2 ... Tn

Value of each hour of operation

Error status

Code

2 - 42

AK

90003752(1) [AK-Commands] 10/98

Page 69

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

ADRU – Read command "Pressure"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device) and if need be for the subchannel

(pressure measurement):

∗ The signal in Pascal.

Note: At the moment no subchannels will be used.

Read command

ADRU K0

ADRU Kn (m)

Read of channel n (and subchannel m)

Code

Response

ADRU 0 XXX

Pressure value

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 43

Page 70

ADUF – Read command "Flow"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device) and subchannel (flow

measurement):

∗ The signal in liter per time unit.

Read command

ADUF K0

ADUF Kn (m)

Read of channel n (and subchannel m)

Code

Response

ADUF 0 XXX

Flow value

Error status

Code

2 - 44

AK

90003752(1) [AK-Commands] 10/98

Page 71

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

AEMB – Read command "Selected range"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device):

∗ The selected and used range at this moment.

Read command

AEMB K0

AEMB Kn

Read of channel n

Code

Response

AEMB 0 Mn

Range with setup

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 45

Page 72

AFDA – Read command "Function length"

To this read command the FU will send to the TBCC the following data for the called

channel (device):

∗ The function or procedure times of the function determined in "CODE".

Functions like "SATK", "SLIN", "SLCH", "SALI", "SQEF", "SNGA" or "SEGA" will run time

controlled according to the times T1 to T4 or stability controlled.

Time control: If only T1 is set or if T2 = 0, time control will run with step time T1

(total function time).

Stability control: Times T1 to T4 have to be set.

Read command

AFDA K0 CODE

AFDA Kn CODE

Code for the function

Read of channel n

Code

Response

AFDA 0 T1 (T2 T3 T4)

"Time out"; after this time is over, the procedure will be

canceled and you will get an error message; this time will

start after the wait.

Integration time to get the mean value of one signal.

Stability time: All signals have to be in a certain tolerance

during this time.

Time to wait for: after the switching on resp. changing of

gases or the stepping time of time control.

Error status

Code

2 - 46

AK

90003752(1) [AK-Commands] 10/98

Page 73

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

AGID – Read command "Device identification"

To this read command the gas analyzer will send to the TBCC a text string consisting of

several data. These data will be separated by a slash ( / ).

Read command

AGID K0

Read of the whole system unit

Code

Response

AGID 0 a/b/c

Device identification a = Name and serial number

b = Program version

c = Date

Error status

Code

90003752(1) [AK-Commands] 10/98

AK

2 - 47

Page 74

AGRW – Read command "Limits"

To this read command the analyzers in a system or the single analyzer will send to the

TBCC the following data for the called channel (device):

∗ The corresponding limits, e.g. maximum deviations of calibration.

Read command

AGRW K0 m

AGRW Kn m

Read of channel n and subchannel m

m = 0: Zerogas calibration

m = 1: Spangas calibration

Code

Response

AGRW 0 XXX

Limit

Error status

Code

2 - 48

AK

90003752(1) [AK-Commands] 10/98

Page 75

II) V24/RS232/485 Int e r f a c e - Single Analy zers and Sy stems

AIKG – Read command "Concentration integral value; all"

To this read command the FU will send to the TBCC the following data:

∗ The corrected average signal valid at that moment (e.g. analyzed value), that has been

calculated since the last "SINT" command. The physical parameter is described in the

section about FU. The value will be limited to six relevant digits, because it is useless to

send gas concentrations in an accuracy less than pars pro mille. Look at the example of