Page 1

Instruction Manual

Form 5715

June 2007

HF300 Series

FIELDVUER HF300 Series HARTR Filters

Introduction

Scope of Manual

This instruction manual includes installation and

maintenance information for the FIELDVUE

Series HART

Filters. Refer to separate manuals for

additional information on other FIELDVUE products

used with the HART filters, such as DVC6000 Series

digital valve controllers, and Type 2530H1 HART

interchange multiplexers.

Control system refers to a distributed control system

(DCS), programmable logic controller (PLC), or a

stand-alone controller that provides a control signal

to the FIELDVUE instrument.

Do not install, operate, or maintain HF300 Series

HART filters without first being fully trained and

qualified in valve, actuator and accessory

installation, operation and maintenance and

carefully reading and understanding the contents of

the manual. If you have any questions about these

instructions, contact your Emerson Process

Management sales office before proceeding.

HF300

Description

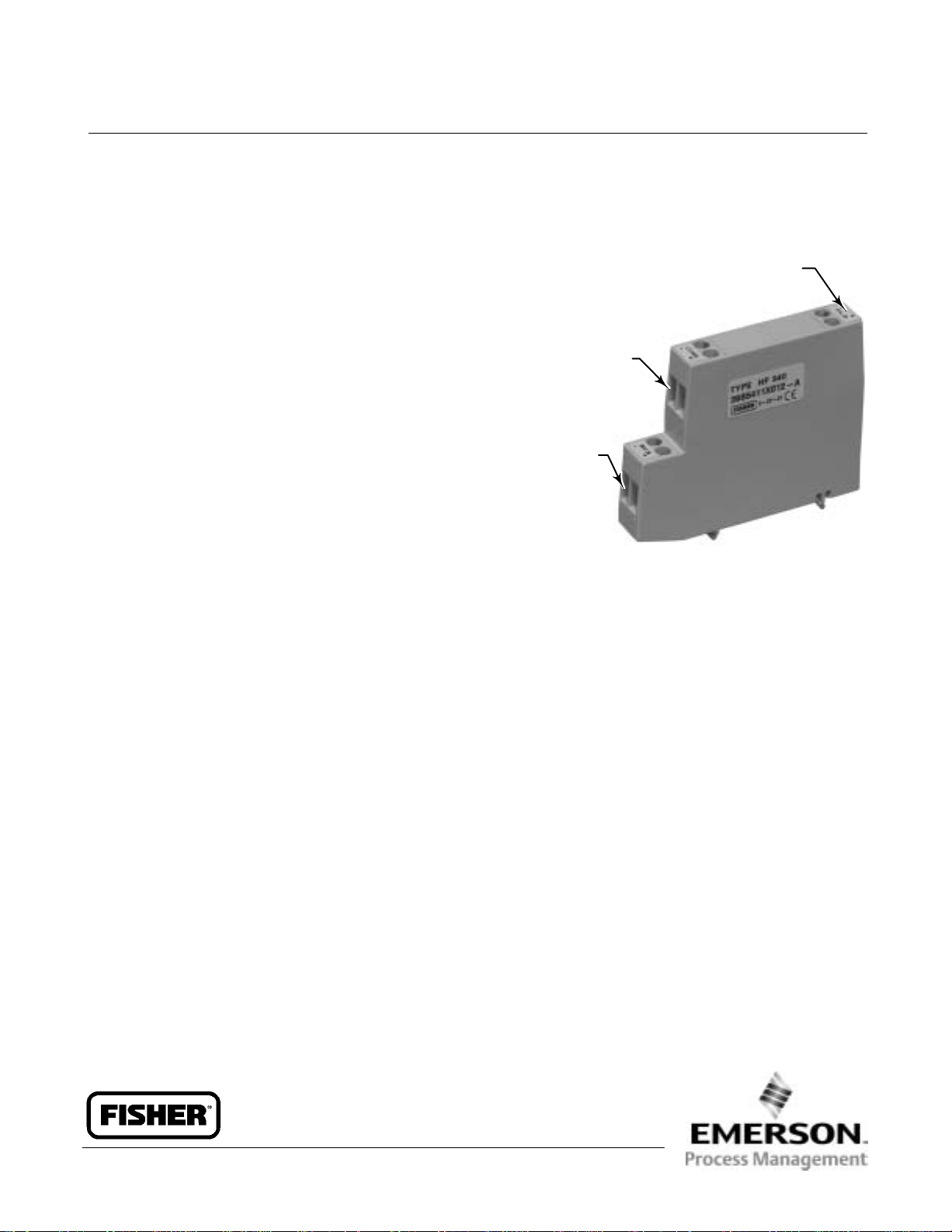

HF300 Series HART filters, shown in figure 1, are

used with HART-based FIELDVUE instrumentation,

such as DVC6000 Series digital valve controllers.

These filters are used when this instrumentation is

connected to a 4 to 20 mA DC control system output

that was not designed for the HART (Highway

Addressable Remote Transducer) communication

protocol.

The HF300 Series HART filters consist of the Type

HF340 HART filter that provides filtering and

isolation between the control system and FIELDVUE

instrument and the Type HF341 communication tap.

The Type HF341 does not provide any filtering. It is

simply a straight through device that provides a

convenient connection for HART communication.

FIELD INSTRUMENT CONNECTIONS (FLD)

HART COMMUNICATION

CONNECTIONS (COMM)

CONTROL SYSTEM

CONNECTIONS (SYS)

W8283 / IL

Figure 1. FIELDVUE

HF300 Series HART Filters

The Type HF340 HART filter is a passive device that

is inserted in-line with both wires of a HART 4 to 20

mA DC output loop. The purpose of the filter is to

effectively isolate the control system analog output

from modulated HART communication signals. The

filter receives a 4 to 20 mA DC current signal from

the control system, which it shunts with a capacitor

and then passes through an inductor. The low AC

impedance of the capacitor prevents sudden

changes in the control system current output from

interfering with the HART communication. The high

AC impedance of the inductor permits HART

communication on the instrument side of the filter. It

also prevents the voltage modulation in the HART

loop from being seen by, or having an affect on, the

control system output. The filter introduces a

maximum input-to-output voltage drop of 2 volts DC

at 20 mA as long as the output load voltage is less

than 14 volts DC.

www.Fisher.com

D102796X012

Page 2

HF300 Series

Instruction Manual

Form 5715

June 2007

Table 1. Specifications

Product Types

Type HF340: Standard 35 mm DIN rail mounting

with filtering components.

Type HF341: Standard 35 mm DIN rail mounting

without filtering components (straight through with

capacitor blocking on COMM terminals).

Connections

Three 2-pin Cage-clamp style connectors

accept up to 12 AWG wire

Power Requirements (Type HF340 only)

Input Current: 4−20 mA DC (nominal)

Input Voltage: At 20 milliamps DC, 2 volts above

input voltage required by the field instrument (2

volt drop across filter at 20 milliamps DC)

Filter Output

Filter output is clamped at 15 volts DC. Filter load

voltage requirement must not exceed 14 volts DC

Ambient Operating Temperature

−40 to 85C (−40 to 185F)

Ambient Relative Humidity

5 to 95%

Electromagnetic Interference (EMI)

These units have the CE mark in accordance with

the European Electromagnetic Compatibility

(EMC) Directive. They meet the emissions

requirements of IEC 61326-1 (Edition 1.1) for

Class A equipment for use in industrial locations

and Class B equipment for use in domestic

locations. They also meet the immunity

requirements listed in table 2 below. This table is

in accordance with Annex A of IEC 61326-1 for

equipment intended for use in industrial locations.

Dimensions

75 mm (3 inches) long by 12.5 mm (0.5 inches)

wide by 60 mm (2.4 inches) deep

Approximate Weight

0.1 kg (4 oz)

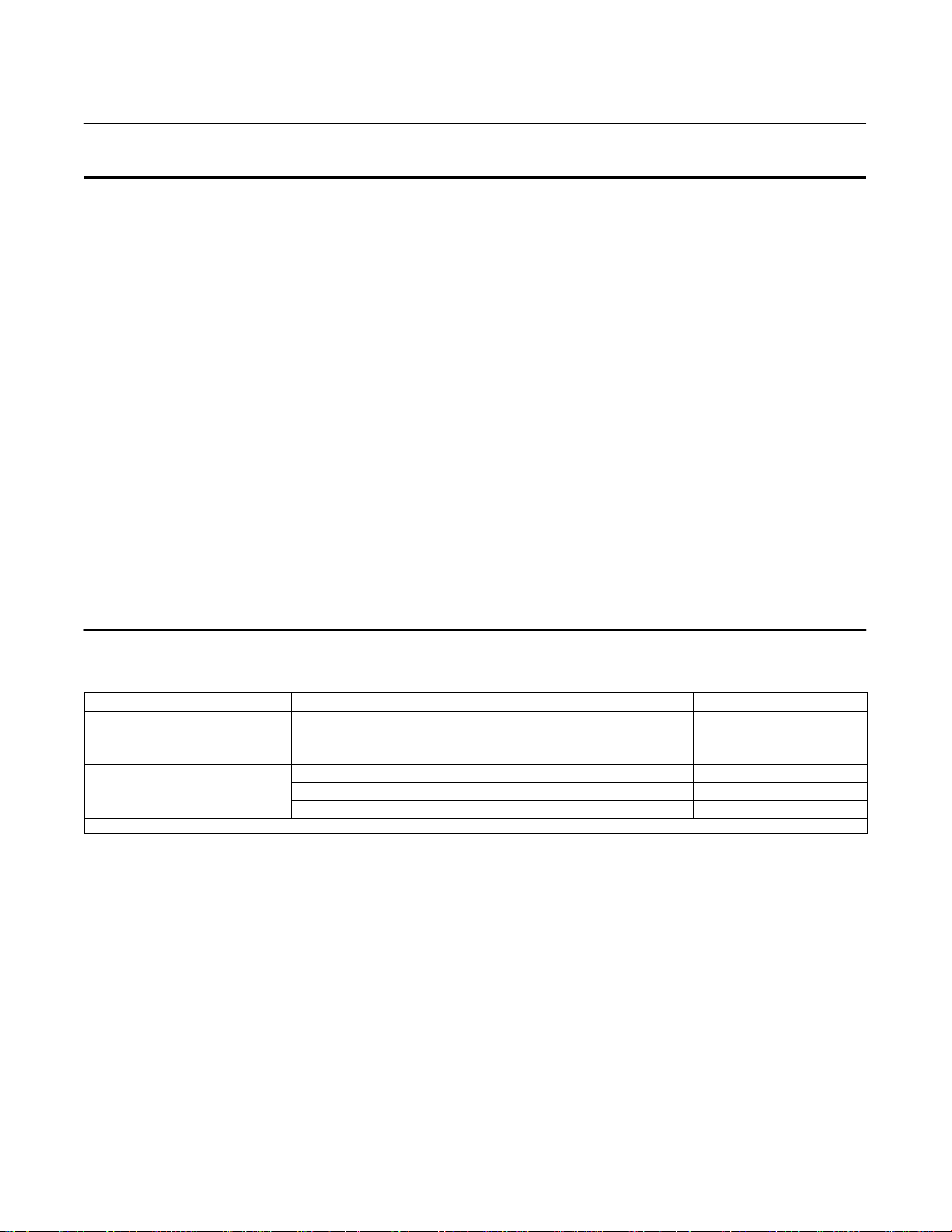

Table 2. EMC Immunity Performance Criteria

Port Phenomenon Basic Standard Performance Criteria

Electrostatic discharge (ESD) IEC 61000-4-2 A

Enclosure

I/O signal/control

1. Not applicable; only applicable to magnetically sensitive equipment.

EM field IEC 61000-4-3 A

Rated power frequency magnetic field IEC 61000-4-8 N/A

Burst IEC 61000-4-4 A

Surge IEC 61000-4-5 A

Conducted RF IEC 61000-4-6 A

The filter is normally installed near the field wiring

terminals of the control system I/O. HART

communication is only possible between the filter

and the field instrument and at the filter COMM

terminals, but not on the control system side of the

filter. The filter is not designed or intended for use in

the process environment. Neither the filter nor its

outputs are approved for hazardous areas. However,

a recommended intrinsic safety barrier can be

connected between the FIELDVUE instrument and

the filter in intrinsically safe installations. In most

cases, if an IS barrier is used, the filter will not be

needed.

(1)

Specifications

Typical specifications for the HF300 Series HART

filters are shown in table 1.

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, and maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end-user.

2

Page 3

Instruction Manual

Form 5715

June 2007

HART MULTIPLEXER NETWORK

TYPE 2530H1 HART INTERCHANGE

MULTIPLEXER OR OTHER HART

MULTIPLEXER

HF300 Series

SYS TERMINALS

+

−

+

−

CONTROL

SYSTEM OUTPUT

TERMINALS

Figure 2. Typical HF300 Series HART Filter Installation

+

−

+

−−

Installation

Refer to figure 2 for typical installations. HF300

Series filters mount on a type 35 DIN rail. To install

the filter, provide a temporary means of process

control, then take the loop out of service. Remove

the DIN interconnect blocks from the rail without

disconnecting existing wiring. Install the filter on the

rail. Disconnect the wires from the control system

output side of the interconnect blocks and connect

them to the SYS terminals on the filter, taking care to

maintain correct polarity. Disconnect the wires from

the field side of the interconnect blocks and connect

them to the FLD terminals on the filter, taking care to

maintain correct polarity.

COMM TERMINALS

+

−

+

375 FIELD

COMMUNICATOR

FLD TERMINALS

HF300 SERIES HART FILTER

FIELD

DEVICES

Shields

If using shielded wiring on both sides of the filter, the

shield should connect across the filter. If the filter

connects directly to the control system output and

shielded loop wiring is being used, connect the

shield to system ground on the instrument side of

the filter.

HART Wiring Connections

The COMM terminals on the filter provide a

convenient means to tap into the loop wiring for

HART communication. A HART Interchange

multiplexer or the 375 Field Communicator can be

connected to these terminals, or they may be left

with no connections.

3

Page 4

HF300 Series

Instruction Manual

Form 5715

June 2007

Corrective Maintenance

The most likely malfunction of a loop containing an

HF300 Series HART filter is reverse polarity

installation of one of the wire pairs. The Type HF340

filter will work with either polarity, but misconnection

could result in the wrong polarity reaching the field

instrument. If the loop is not operating properly,

check the polarity of the voltage at the inputs and

outputs of the filter and at the inputs of the

instrument.

If the instrument appears to operate properly in the

loop, but communication with a non-isolated

multiplexer or PC modem is not possible, it may help

to reverse the wires to the COMM terminals. The

Type HF340 filter inserts a high impedance in the +

side of the loop only. A reversal of the connections

to the SYS and FLD terminals of the filter will result

in the control loop operating properly, but inoperative

HART communication.

Inadequate control system compliance voltage will

not support filter operation. This is an installation

problem that may appear initially to be a filter

malfunction. For the filter to operate properly, the

control system must have a compliance voltage that

is at least 2 volts higher than the voltage required to

drive the loop to maximum current. Refer to the

appropriate instrument instruction manual for

information on determining the control system

compliance voltage.

Excessive load voltage will interfere with filter

operation. A transient clamping device limits the

output voltage to a nominal 15 volts. If the voltage at

the output (due to the total impedances connected)

is greater than 14 volts DC at maximum loop current,

some of the current may be shunted by the clamping

device.

The Type HF340 filter is protected against accidental

over-current from sources up to 30 volts DC. If an

over-current condition occurs, the filter may be

inoperative for several seconds thereafter.

Fisher and FIELDVUE are marks owned by Fisher Controls International LLC, a member of the Emerson Process Management business division of

Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co.

HART is a mark owned by the HART Communication Foundation. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use and

maintenance of any product. Responsibility for the selection, use and maintenance of any product remains with the purchaser and end-user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

4

Fisher Controls International LLC 2001, 2007; All Rights Reserved Printed in USA

Loading...

Loading...