Emerson Net Safety SC311 Reference Manual

Net Safety™ SC311

Infrared Combustible Sensor

Reference Manual

00809-0100-4311, Rev AA

May 2019

Important instructions

Net Safety™ designs, manufactures, and tests products to function within specific conditions. Because these products are

sophisticated technical instruments, the owner and operation personnel must strictly adhere to both the information printed on

the product nameplate and all instructions provided in this manual prior to installation, operation, and maintenance.

WARNING

Explosions and hazardous substances

Installing, operating, or maintaining a Net Safety product improperly could lead to serious injury or death from explosion or

exposure to dangerous substances.

Comply with all information on the product, in this manual, and in any local and national codes that apply to this product.

Use Net Safety parts and work procedures specified in this manual.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This

could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical

access by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

Notice

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure

their accuracy, they are not to be construed as warranties or guarantees, expressed or implied, regarding the products or services

described herein or their use or applicability. All sales are governed by Net Safety™'s terms and conditions, which are available

upon request.

Net Safety does not assume responsibility for the selection, use, or maintenance of this product. Responsibility for proper

selection, use, and maintenance of any Net Safety product remains solely with the purchaser and end user.

To the best of Net Safety's knowledge, the information herein is complete and accurate. Net Safety makes no warranties,

expressed or implied, including implied warranties of merchantability and fitness for a particular purpose, with respect to this

manual, and in no event, shall Net Safety be liable for any incidental, punitive, special, or consequential damages, including, but

not limited to, loss of production, loss of profits, loss of revenue, or use and costs incurred including without limitation for capital,

fuel and power, and claims of third parties.

All rights reserved. No part of this work may be reproduced or copied in any form or by any means (graphic, electronic, or

mechanical) without first receiving written permission from Emerson.

Warranty

Three years

2

Reference Manual

00809-0100-4311 May 2019

Introduction

1 Introduction

1.1 Models covered

The Net Safety™ SC311 infrared combustible gas sensor is designed specifically for use

with the Net Safety Millennium II transmitter (models M21, M22, or M2B). This sensor is

both versatile and reliable for fast, accurate, and continuous monitoring of gases in

extreme environments.

The sensor consists of an explosion-proof enclosure (housing) rated for hazardous

locations and a replaceable sensor module. This sensor must only be used with a Net

Safety Millennium II series transmitter. If the sensor is connected to any other model of

transmitter, it will not function and may damage the sensor or transmitter.

1.2 Service support

For technical support, contact your local Emerson representative or the Technical Support

department at +1 866 347 3427 (toll free) or Safety.CSC@Emerson.com.

1.3 Return of material

To expedite the repair and return of this product, proper communication between the

customer and the factory is important.

Prerequisites

Before returning a product for repair, call +1 866 347 3427 (toll free) or email

Safety.CSC@emerson.com for a Return Material Authorization (RMA) number.

On the return of the equipment, include the following information:

1. RMA number provided to you by Net Safety™.

2. Company name and contact information.

3. Purchase order, from your company, authorizing repairs or request for quote.

Procedure

1. Ship all equipment, prepaid to:

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379

2. Mark all packages with Return for Repair and include RMA number and type of return

(e.g., return for evaluation).

Pack items to protect them from damage and use anti-static bags or aluminumbacked cardboard as protection from electrostatic damage.

Net Safety SC311 3

Introduction Reference Manual

May 2019 00809-0100-4311

Important

All equipment must be shipped prepaid. Emerson will not accept collect shipments.

1.4 Product recycling/disposal

Consider recycling equipment and packaging. Dispose of the product and packaging in

accordance with local and national legislations and regulations.

4 Emerson.com/FlameGasDetection

Reference Manual

00809-0100-4311 May 2019

Install

2 Install

2.1 Unpack and inspect

Carefully remove all the components from the packaging and check them against the

enclosed packing list. Inspect all components for any obvious damage such as broken or

loose parts. If you find any components missing or damaged, notify your local Net Safety

representative or the factory immediately.

2.2 Locate sensor

Prior to installation, plan where to place the sensor. Although there are no absolute rules

determining the quantity of detectors or location of a sensor, consider the following

points.

CAUTION

™

Avoid placing the sensor where it may be exposed to splashing or direct water sprays. A

splashguard may be required to protect the sensor.

• Carefully locate the sensor in an area where gases may potentially accumulate,

considering that light gases tend to rise and heavy gases tend to accumulate in low

areas.

• Use redundant systems to enhance protection and reliability.

• Consider the air movement patterns within the facility.

• Consider the construction of the facility, such as trenches where heavy gases or peaks

where light gases may accumulate.

• Seek advice from experts knowledgeable about the primary gas to be detected.

• Refer to the regulatory publications that discuss guidelines for your industry.

2.3 Direct mount or sensor separation

2.3.1 Direct mount

You can attach the sensor directly to a Net Safety™ Millennium II transmitter and place it in

an appropriate location for detecting the target gas or separate the sensor and remotely

mount it away from the transmitter.

Make sure the sensor is accessible for calibration and maintenance purposes and that the

transmitter is accessible and visible.

Net Safety SC311 5

Install

May 2019 00809-0100-4311

Reference Manual

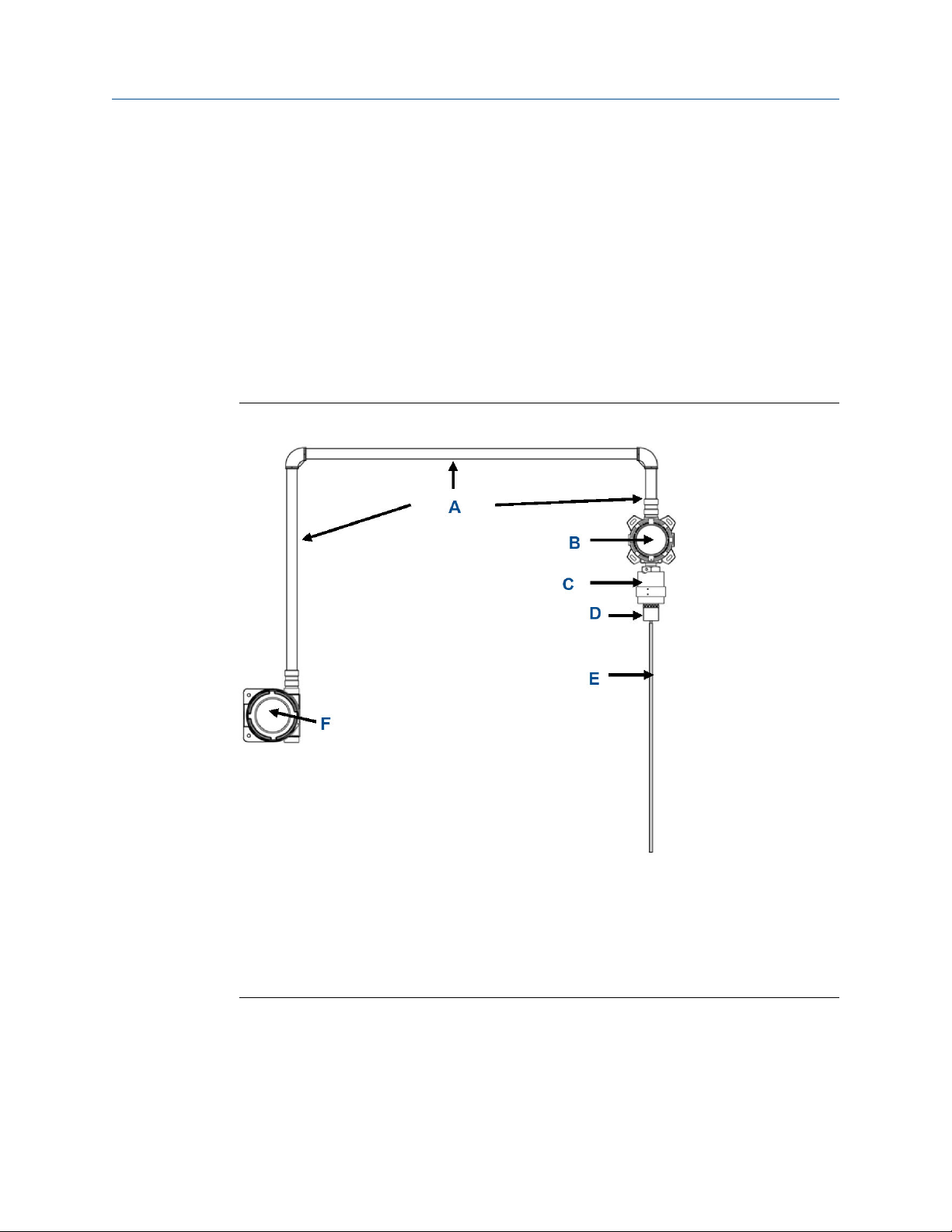

2.3.2 Remote mount

If mounting the sensor remotely, make sure it is connected to a certified junction box.

Locate the transmitter near eye-level for easy access and the mount the sensor where gas

is likely to accumulate.

To ease the calibration process, attach a calibration cup (CCS-1) to the bottom of the

sensor housing and run calibration tubing from the calibration cup to a convenient place

for applying calibration gas, eliminating the need to access the sensor directly. To

compensate for distance, you may decrease the calibration tubing length so that the end

of the tubing to the gas canister is still accessible or increase the calibration gas flow rate

between the calibration gas cylinder and sensor. Refer to Figure 2-1 for an example of

sensor separation.

Figure 2-1: Example of Sensor Separation

A. Conduit

B. Separation junction box

C. Net Safety™ Millennium II SC311 sensor

D. CCS-1 calibration cup

E. Calibration tubing

F. Net Safety Millennium II transmitter

For tubing lengths less than 10 ft. (3 m), use an 0.5 LPM regulator; for lengths greater than

10 ft. (3 m), use a 1.0 LPM regulator. On initial install, confirm readings directly at the

transmitter by applying a known gas concentration to the sensor and comparing the

output results. Readings should be accurate to the calibration gas concentration used,

taking into account the sensor accuracy specifications in .

6 Emerson.com/FlameGasDetection

Reference Manual Install

00809-0100-4311 May 2019

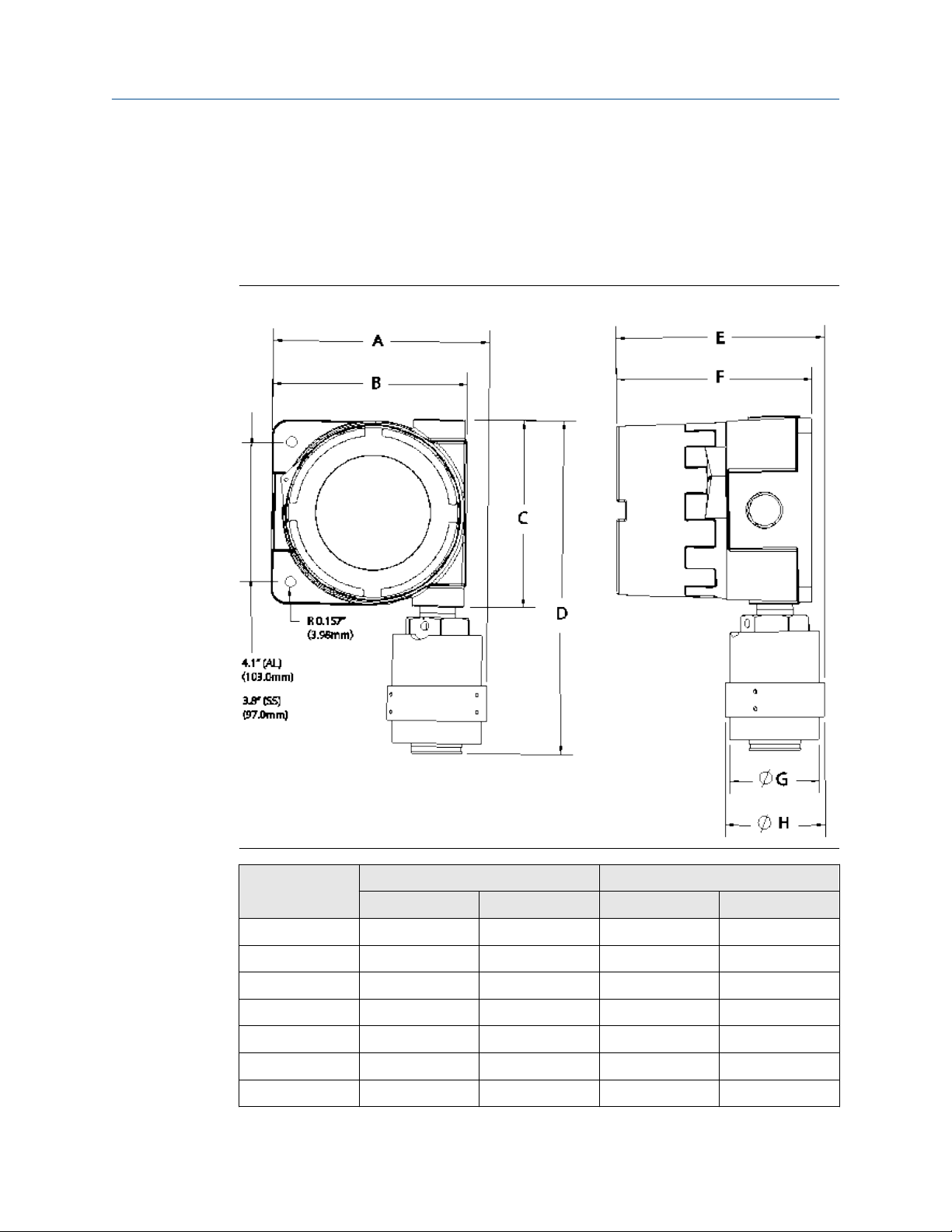

2.4 Dimensions

The following tables outline the dimensions of the sensor when connected to either the

Net Safety™ Millennium II transmitter or the Net Safety Millennium II basic transmitter/

junction box. Both the transmitter and sensor enclosures are offered in aluminum and

stainless steel.

Figure 2-2: Net Safety Millennium II (M21 or M22) Enclosure and Sensor Dimensions

Dimensions Stainless steel Aluminum

in. mm in. mm

A 5.9 150 6.3 160

B 5.1 130 5.6 142

C 4.6 117 5.4 137

D 8.9 226 9.7 246

E 6.0 152 6.0 152

F 5.8 147 5.7 145

G 2.6 66 2.6 66

Net Safety SC311 7

Install Reference Manual

May 2019 00809-0100-4311

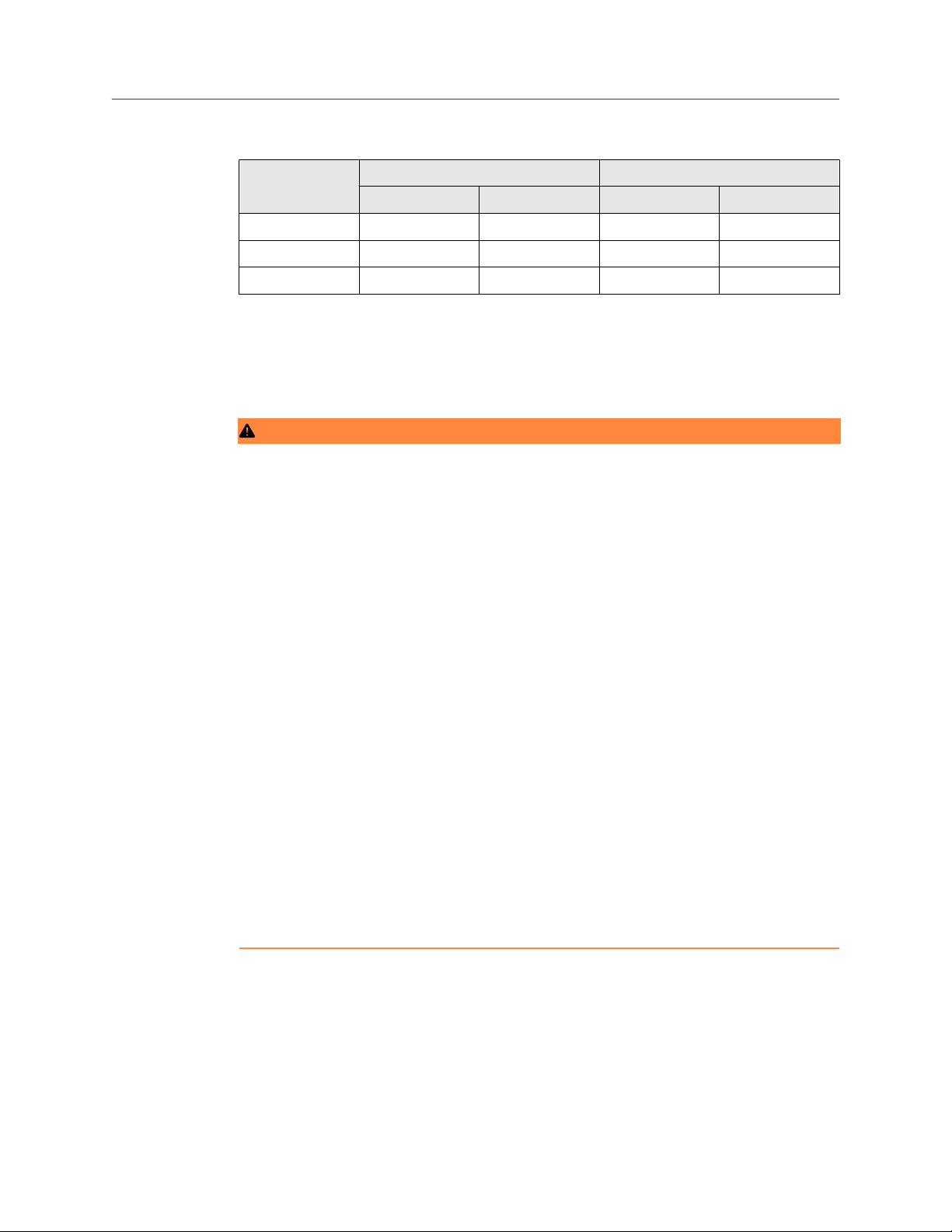

Dimensions Stainless steel Aluminum

in. mm in. mm

H 2.9 74 2.9 74

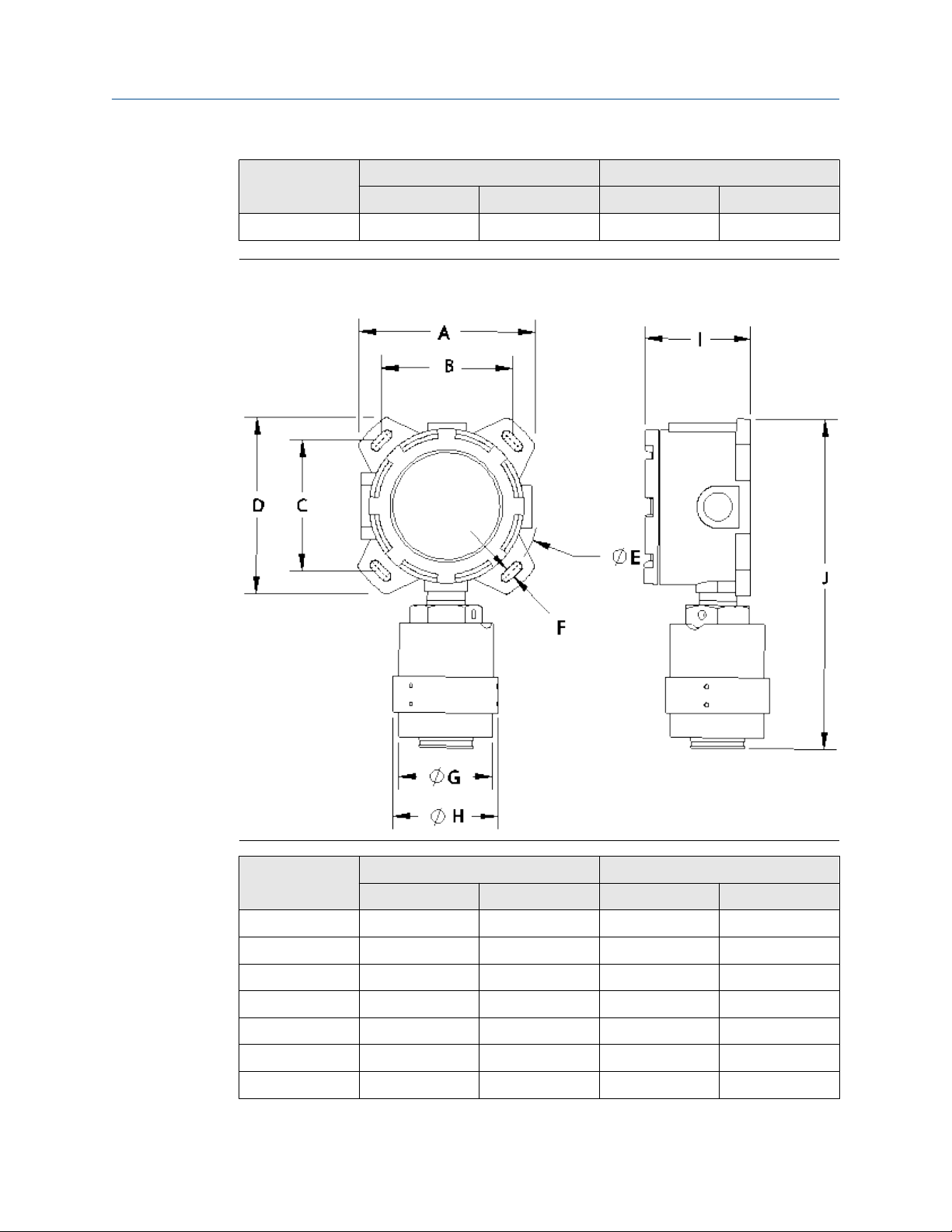

Figure 2-3: Net Safety Millennium II Basic (M2B) or Junction Box (JB) Enclosure and

Sensor Dimensions

Dimensions Stainless steel Aluminum

in. mm in. mm

A 4.7 119 4.8 122

B 3.6 91 3.6 91

C 3.6 91 3.6 91

D 4.7 199 4.8 122

E 5.1 130 5.1 130

F 0.3 7.6 0.3 7.6

G 2.6 66 2.6 66

8 Emerson.com/FlameGasDetection

Reference Manual

00809-0100-4311 May 2019

Dimensions Stainless steel Aluminum

in. mm in. mm

H 2.9 74 2.9 74

I 2.8 71 3.0 76

J 8.9 226 9.0 229

Install

2.5 Wire

2.5.1 Field installation

WARNING

Follow guidelines

Failure to follow safety instructions could result in serious injury or death.

Ensure only qualified personnel perform the installation.

Electrical shock

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Explosions

Do not open the transmitter, sensor, or junction box enclosure when in a classified area

or when an explosive atmosphere may be present unless the power to the transmitter

and sensor has been removed.

Wiring codes and regulations may vary.

Wiring must comply with all applicable regulations relating to the installation of

electrical equipment in a hazardous area and is the installer's responsibility.

If in doubt, consult a qualified official before wiring the system.

When separating the sensor from the transmitter, Emerson highly recommends

using shielded cable to protect against interference caused by extraneous electrical

or electromagnetic noise.

In applications where the wiring is installed in a conduit, do not use the conduit for

wiring to other equipment.

2.5.2

Net Safety SC311 9

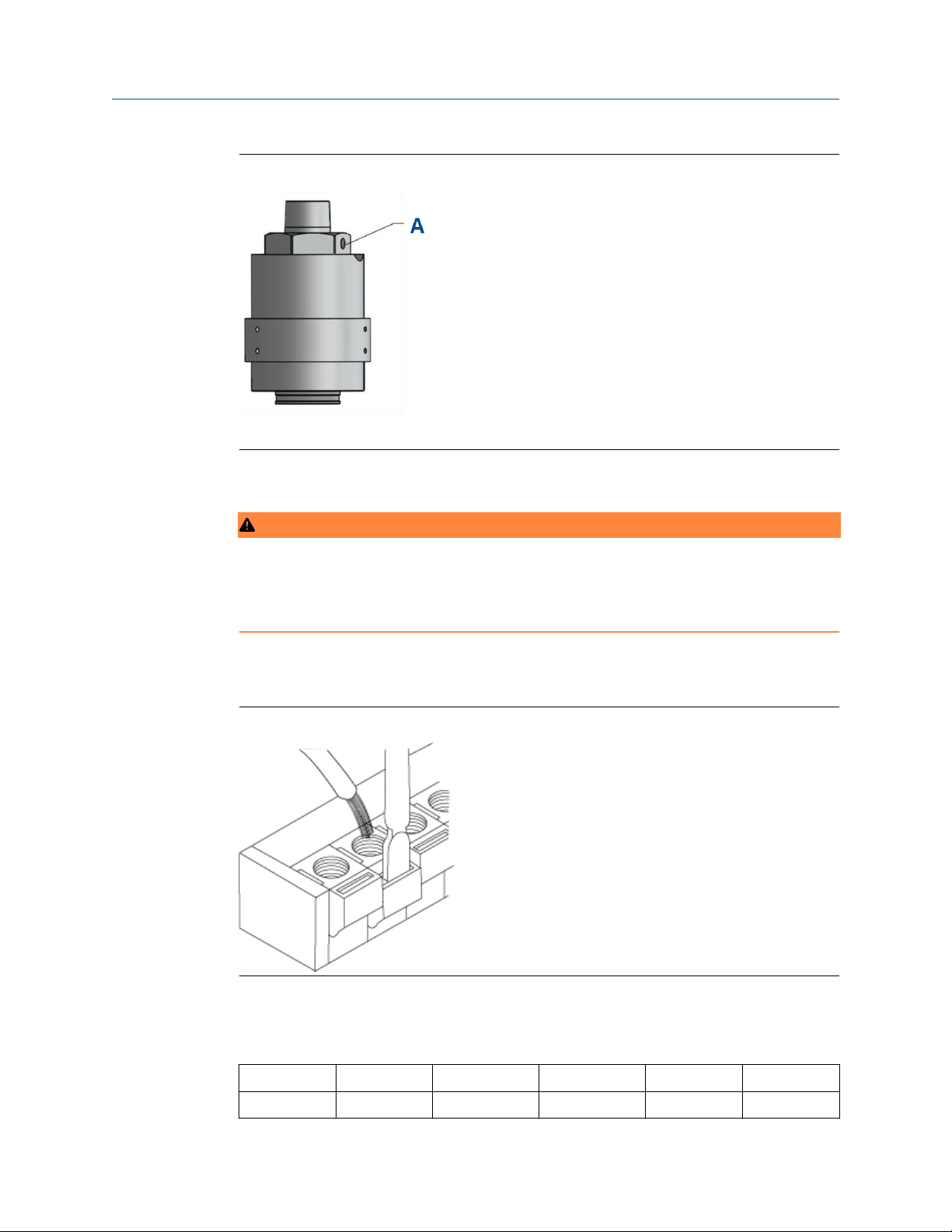

External ground

In order to ensure proper operation of the sensor, an external ground is required. The

external ground must be connected to the grounding point on the enclosure according to

IECEx requirements. Refer to Figure 2-4 for grounding connection location.

Install Reference Manual

May 2019 00809-0100-4311

Figure 2-4: External Grounding Point

A. External earth ground point

2.5.3

Wire sensor

WARNING

Do not open the transmitter, sensor, or junction box enclosure when in a classified area

or when an explosive atmosphere may be present unless the power to the sensor has

been removed.

When connecting cable wires, use a small flathead screwdriver to gently press down and

hold the spring connector open. Insert the appropriate wire into the open connector hole,

releasing the screwdriver to secure the wire. Refer to Figure 2-5.

Figure 2-5: Terminal Connection

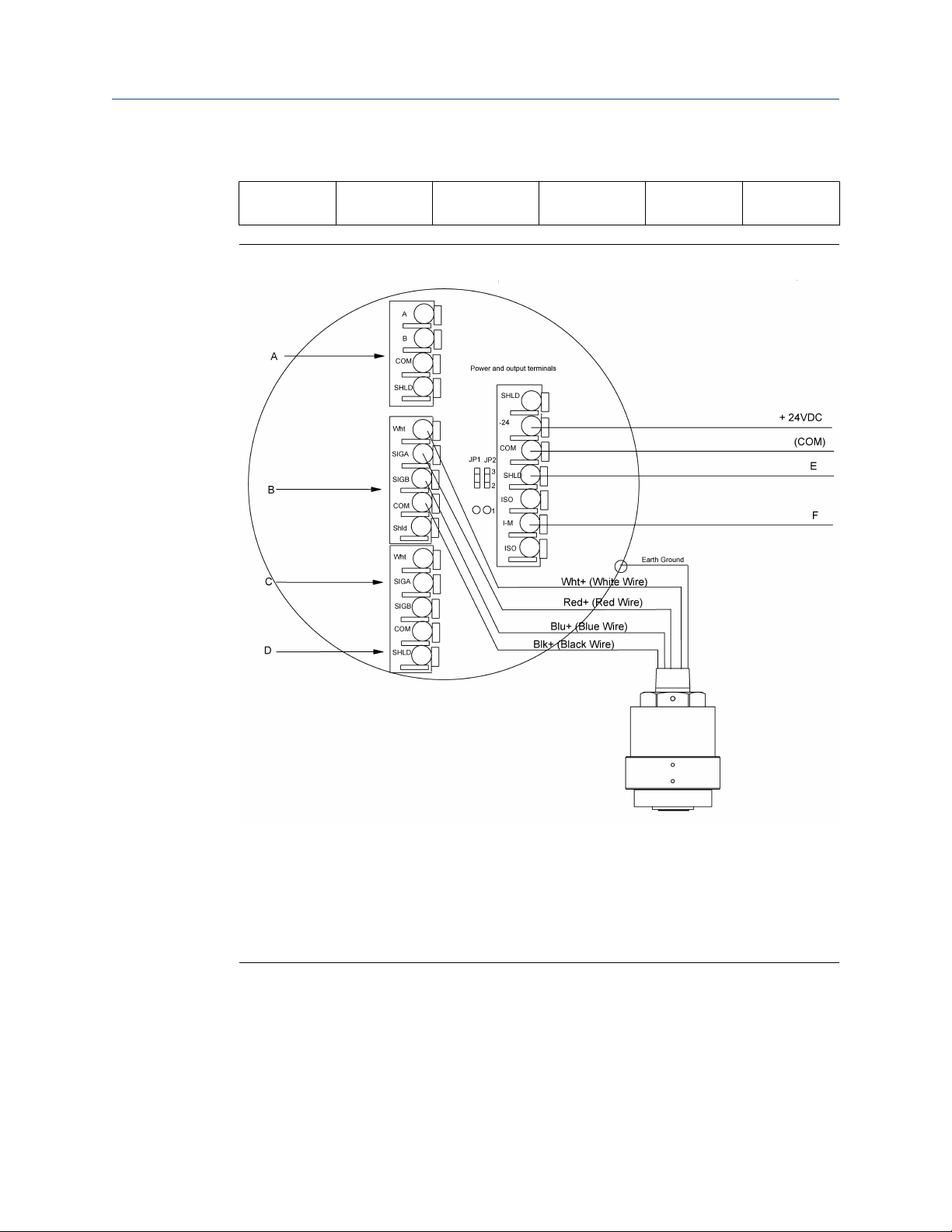

Connect sensor wires to the sensor terminals in the applicable transmitter. Refer to the

Table 2-1 for the wire colors and their purposes..

Table 2-1: Sensor wires and Millennium II series Terminal definitions

Sensor wire White Red Blue Black Green

Marked +Vdc Sig A Sig B COM

10 Emerson.com/FlameGasDetection

Reference Manual

00809-0100-4311 May 2019

Table 2-1: Sensor wires and Millennium II series Terminal definitions (continued)

Install

Function

Figure 2-6: Net Safety Millennium II M21 Sensor Wiring

10.5 - 32 Vdc

connection

Communication signal A

Communication signal B

Common/

supply ground

Earth ground

A. Modbus® terminals

B. Channel 1 sensor terminals

C. Channel 2 sensor terminals

D. Net Safety™ Millennium II transmitter terminal board

E. Channel #1 4-20 mA signal

F. Channel #2 4-20 mA signal

2.5.4

Net Safety SC311 11

Installation checklist

Review the following checklist prior to turning on power to the sensor after completing

installation.

• Ensure transmitter and sensor are properly and firmly mounted.

• Ensure that stopping plug is tightened on any unused conduit entries.

Loading...

Loading...