Emerson LR125 Instruction Manual

Instruction Manual

November 2014

Type LR125

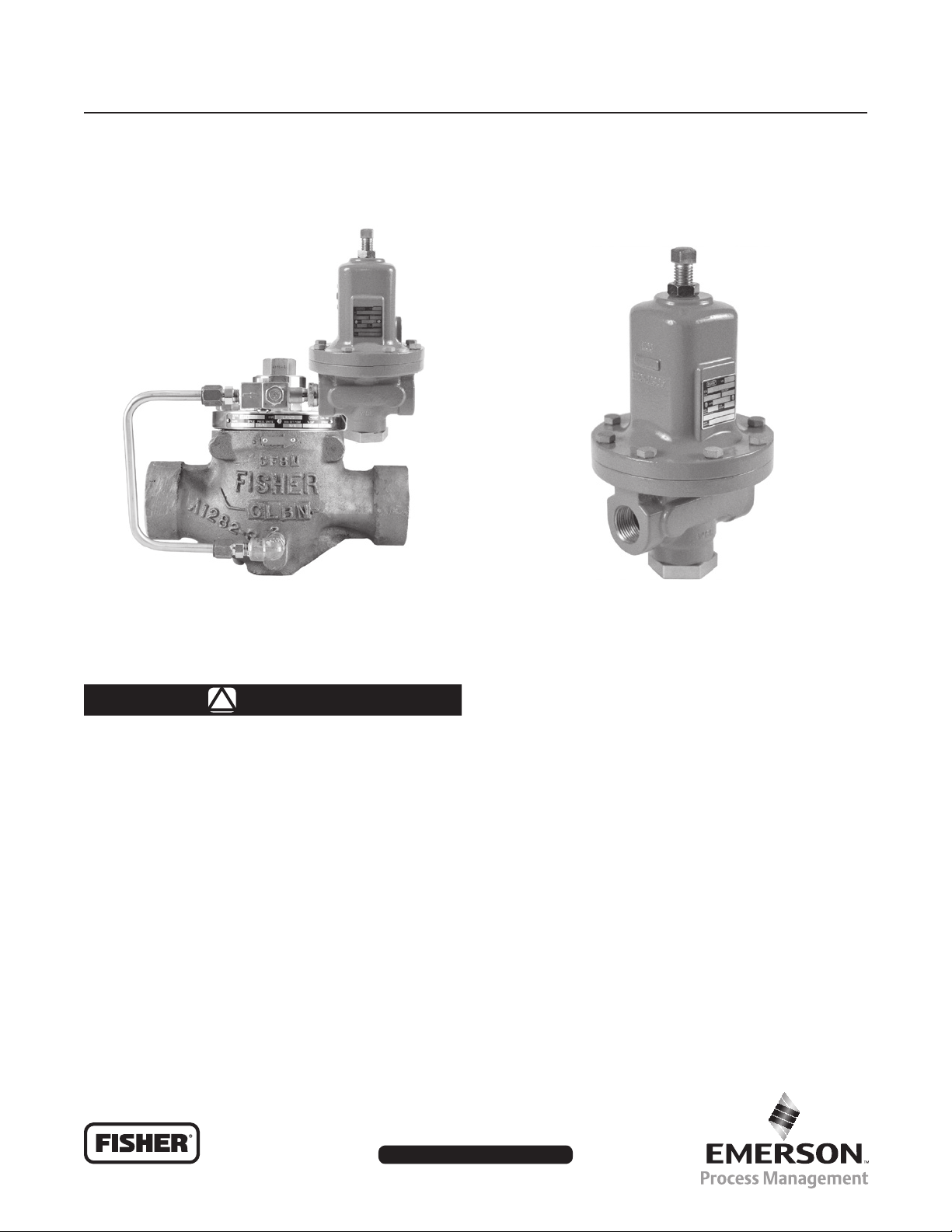

Type LR125 Pressure Reducing Liquid Regulator

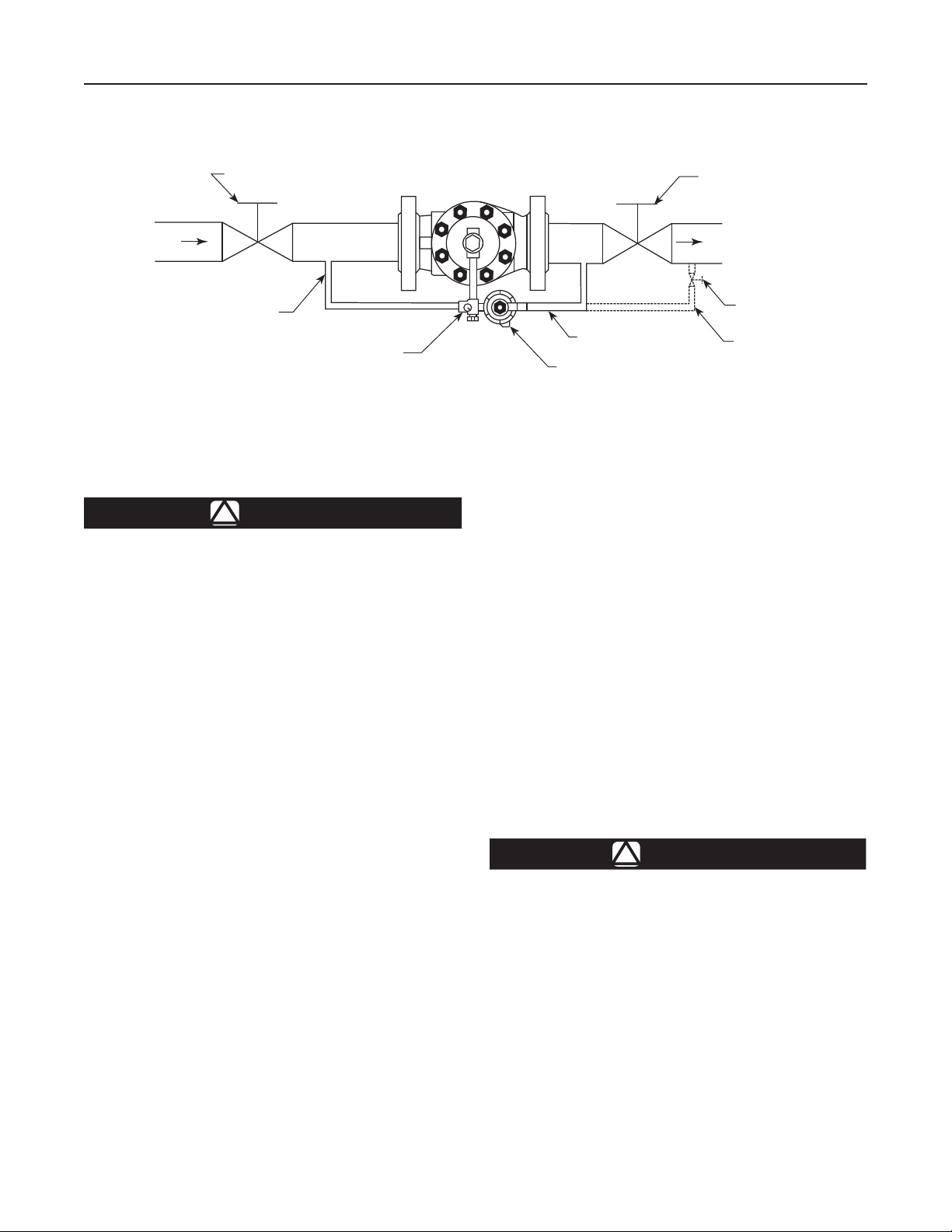

TYPE LR125 REGULATOR

Figure 1. Type LR125 Pressure Reducing Liquid Regulator and Type MR95H Pilot

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in bursting of the

equipment and/or chemical contamination

causing property damage and personal

injury or death.

Fisher® regulators must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies, Inc.

(Emerson™) instructions.

If the regulator discharges process

uid or a leak develops in the system,

service to the unit may be required.

TYPE MR95H PILOT

Failure to correct trouble could result in a

hazardous condition.

Call a quali ed service person to service

the unit. Installation, operation and

maintenance procedures performed

by unquali ed personnel may result

in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury.

Only a quali ed person must install or

service the regulator.

The Type LR125 is designed for liquid

service. Do not operate the regulator

in applications where temperatures are

below the process uid’s freezing point

or above its boiling point which are

dependent on the process uid and the

application pressures.

www.fisherregulators.com

D103576X012

Type LR125

Specications

Specications for the Type LR125 regulator are shown below. Other information for the main valve appears on the

nameplate. The control spring range for the pilot is marked on the nameplate of Type MR95H pilot.

Main Valve Body Sizes, End Connection Styles

and Structural Design Ratings

(1)

See Table 1

Maximum Inlet Pressures

Type LR125 Main Valve: See Table 1

(1)

Type MR95H Pilot: See Table 2

Type 112 Restrictor: 1500 psig / 103 bar

Outlet (Control) Pressure Ranges

See Table 3

Type LR125 Main Valve (continued)

Cage: Stainless steel

Spring: Stainless steel

Top Plug: Stainless steel

Bottom Plug: Stainless steel

Internal Inlet Strainer: Stainless steel

Diaphragm: Nitrile (NBR) or Fluorocarbon (FKM)

O-rings: Nitrile (NBR) or Fluorocarbon (FKM)

Flanged Locknut: Stainless steel

Backup Rings: Polytetrauoroethylene (PTFE)

Upper Spring Seat: Stainless steel

Main Valve Plug Travel

1 in. / DN 25: 0.37 in. / 9.4 mm

2 in. / DN 50: 0.68 in. / 17 mm

3 in. / DN 80: 0.98 in. / 25 mm

4 in. / DN 100: 1.19 in. / 30 mm

Main Valve Minimum Differential Pressures

(1)

See Table 5

Main Valve Internal Inlet Strainer Sizes

1 in. / DN 25:

12 Mesh (0.0661 in. / 1.68 mm)

(2)

2, 3 and 4 in. / DN 50, 80 and 100:

10 Mesh (0.0787 in. / 2 mm)

Temperature Capabilities

(2)

(1)

See Table 4

Pressure Registration

External: 1/2 NPT

Spring Case Vent

Type Y602-12

Construction Materials

Type LR125 Main Valve

Body: WCC Steel, CF8M or CF3M Stainless steel

Bonnet: LF2 Steel or 316/316L Stainless steel

Indicator Protector and Cover: Plastic

Indicator Stem: Stainless steel

Indicator Fitting: Stainless steel

Travel Indicator Plug: Stainless steel

Type MR95H Pilot

Body: WCC Steel or CF8M Stainless steel

Spring Case: WCC Steel or CF8M Stainless steel

Orice: Stainless steel

Diaphragm: Neoprene (CR) or Fluorocarbon (FKM)

Disk: Nitrile (NBR) or Fluorocarbon (FKM)

Mounting Parts

Pilot Mounting Pipe Nipple: Plated steel or

Stainless steel

Pipe Fittings: Plated steel or Stainless steel

Tubing: Stainless steel

Type 112 Restrictor

Body: 15-5 Stainless steel

Groove Valve: Stainless steel

Retainer: Stainless steel

Pipe Plug: Stainless steel

O-rings: Nitrile (NBR) or Fluorocarbon (FKM)

Options

• Pre-piped Pilot Supply

• Travel Indicator

Bonnet Bushing: Stainless steel

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Nominal sieve opening

Introduction

Scope of the Manual

This instruction manual provides installation, startup,

adjustment, maintenance and parts ordering information

for Type LR125 pressure reducing regulator, 1/2 NPT

Type MR95H pilot and Type 112 restrictor.

2

Product Description

The Type LR125 pilot-operated, pressure reducing

regulator is used for liquid applications and include a

Type 112 restrictor and a 1/2 NPT Type MR95H pilot.

Pilot Type Description

Type MR95H — Pressure reducing pilot for 15 to

150 psig / 1.0 to 10.3 bar outlet pressures. Designed

to handle inlet pressures up to 300 psig / 20.7 bar.

Type LR125

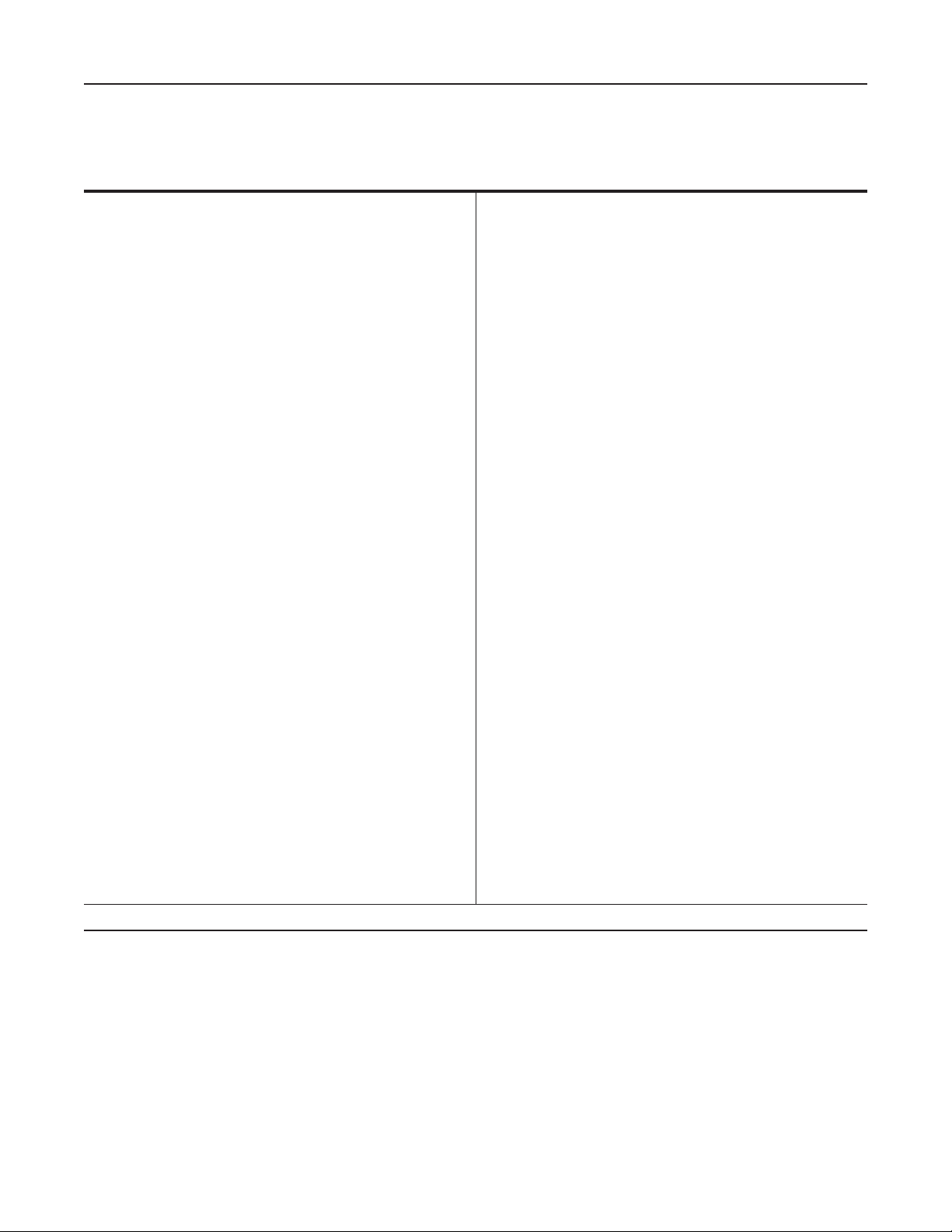

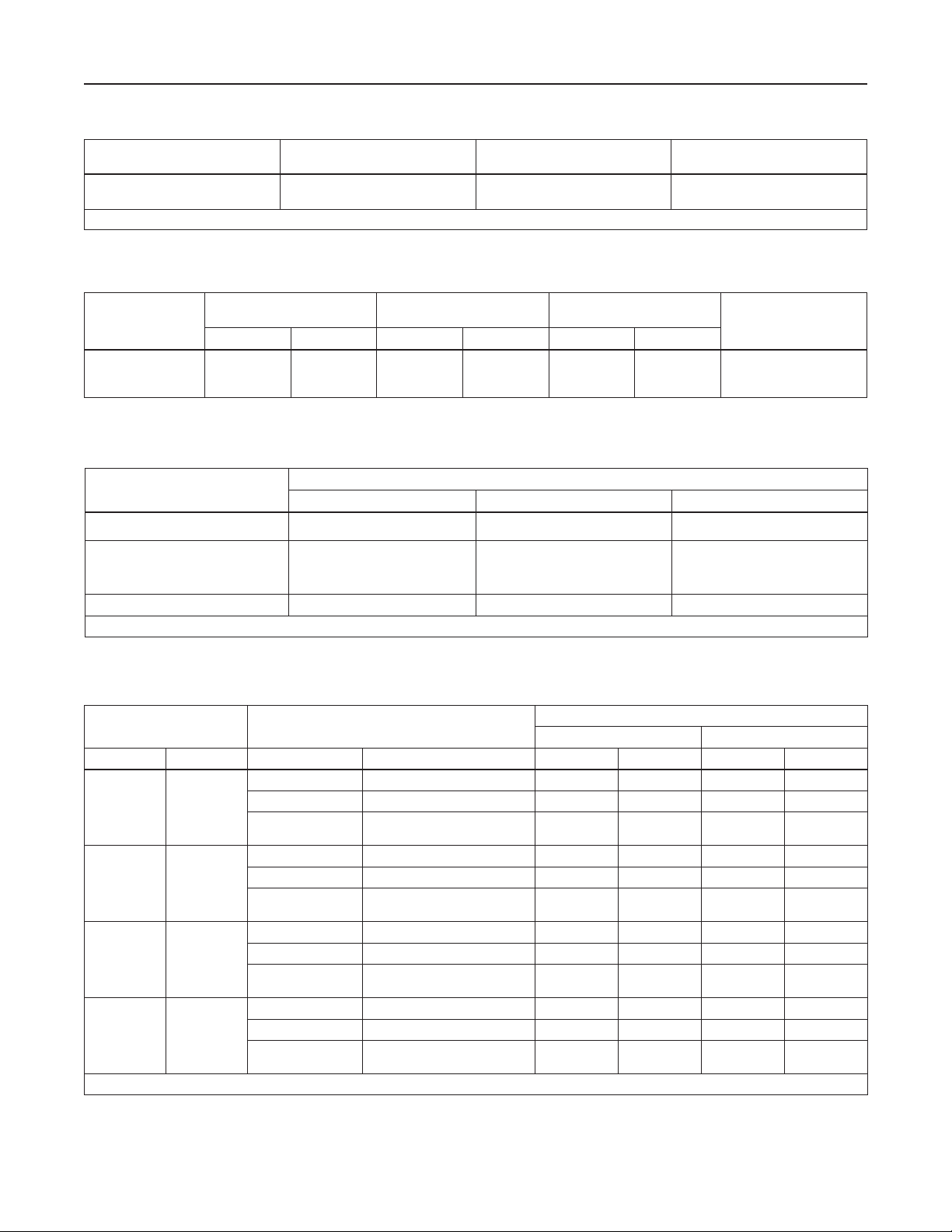

Table 1. Type LR125 Main Valve Body Sizes, End Connection Styles, Structural Design Ratings

and Maximum Operating Inlet Pressures

MAIN VALVE BODY SIZES

In. DN psig bar psig bar

1, 2, 3 and 4 25, 50, 80 and 100

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Ratings and end connections for other than ASME standard can usually be provided. Contact your local Sales Ofce for assistance.

3. Maximum cold working pressure (CWP) per ASME B16.34 or product bulletin limit, whichever is lowest. Temperature may decrease these maximum pressures.

4. Not available for 4 in. / DN 100 body size.

Principle of Operation

MAIN VALVE BODY

MATERIAL

WCC Steel

CF8M Stainless

Steel

END CONNECTION STYLES

NPT or SWE

(1 and 2 in. only)

CL150 RF 290 20.0 290 20.0

CL300 RF 750 51.7

PN 16/25/40 RF

(1 and 2 in. only)

CL150 RF 275 19.0 275 19.0

CL300 RF 720 49.6

PN 16/25/40 RF

(4)

NPT

(4)

Type LR125 Installation

(1)

STRUCTURAL DESIGN

(2)

1500 103 300 20.7

580 40.0

1440 99.2 300 20.7

580 40.0

RATING

(3)

MAXIMUM OPERATING

INLET PRESSURE

300 20.7CL600 RF 1500 103

300 20.7CL600 RF 1440 99.2

(3)

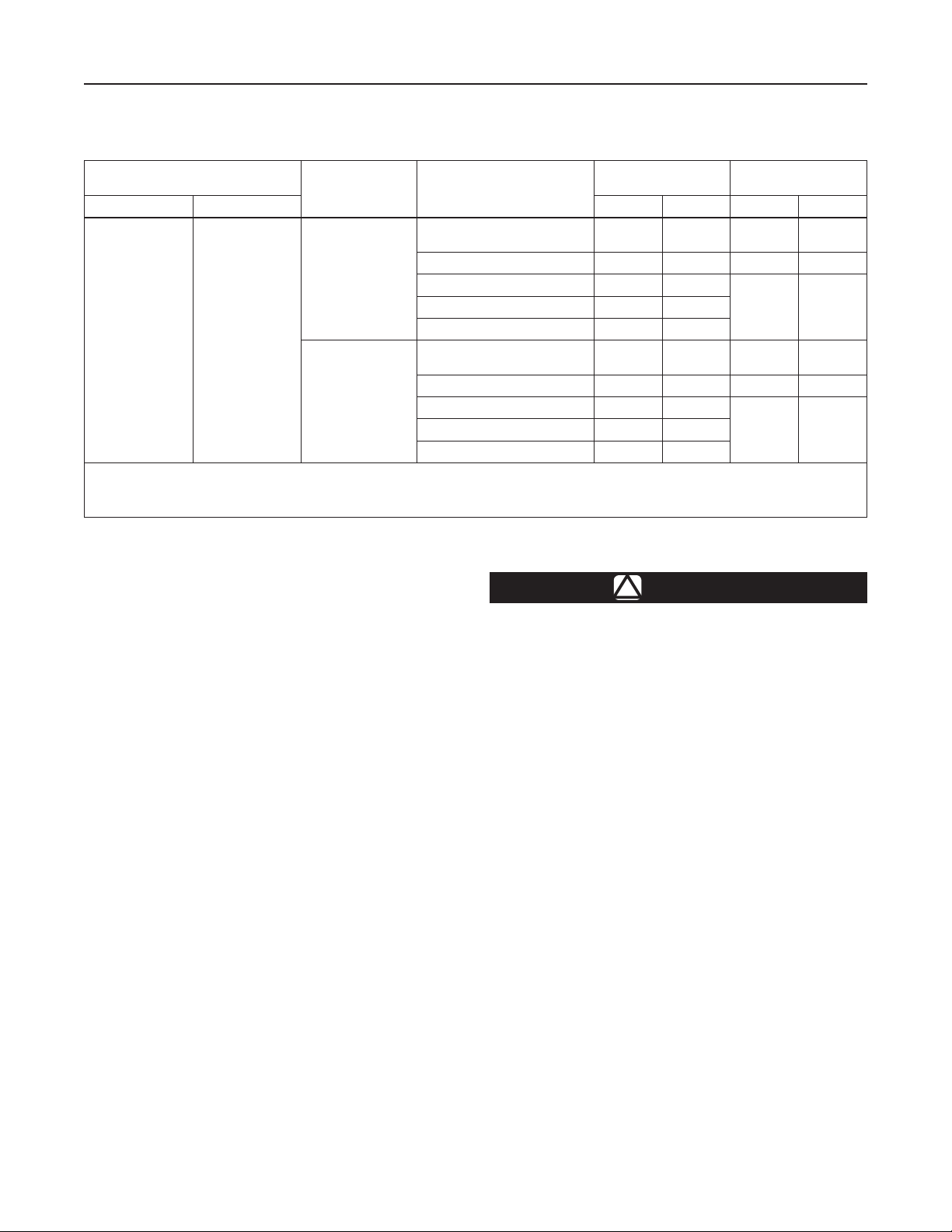

As long as the outlet (control) pressure is above

the outlet pressure setting, the pilot valve plug or

disk remains closed (Figure 2). Force from the main

spring, in addition to inlet pressure bleeding through

the restrictor, provide downward loading pressure to

keep the main valve diaphragm and plug assembly

tightly shutoff.

When the outlet pressure decreases below the pilot

outlet pressure setting, the pilot plug or disk assembly

opens. Loading pressure bleeds downstream through

the pilot faster than it can be replaced through the

supply line. This reduces loading pressure on top of

the main valve diaphragm and plug assembly and

lets the unbalanced force between inlet and loading

pressure overcome the main spring force to open the

Type LR125 diaphragm and plug assembly.

As the outlet pressure rises toward the outlet pressure

setting, it compresses the pilot diaphragm against

the pilot control spring and lets the pilot valve plug

or disk close. Loading pressure begins building on

the Type LR125 diaphragm and plug assembly. The

loading pressure, along with force from the main

spring, pushes the diaphragm and plug assembly onto

the tapered-edge seat, producing tight shutoff.

WARNING

!

Personal injury, equipment damage or

leakage due to escaping process uid

or bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed

the limits given in Specications

section or where conditions exceed

any ratings of the adjacent piping or

piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by the appropriate

code, regulation or standard) to prevent

service conditions from exceeding limits.

Additionally, physical damage to the

regulator could break the pilot off the

main valve, causing personal injury

and property damage due to escaping

process uid. To avoid such injury

and damage, install the regulator in a

safe location.

3

Type LR125

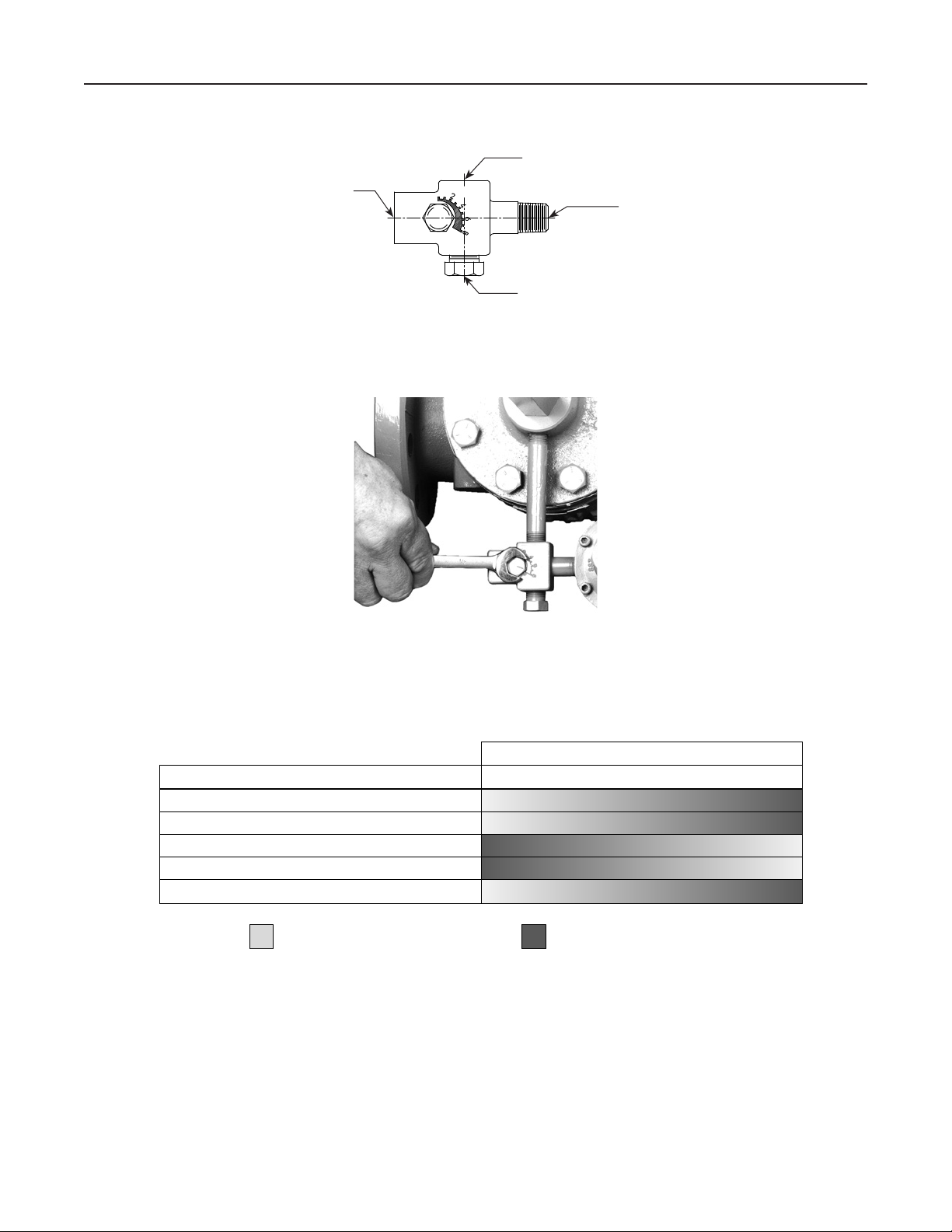

TYPE 112 RESTRICTOR

CONTROL SPRING

TYPE MR95H PILOT

DIAPHRAGM

SUPPLY

LINE

VALVE PLUG

MAIN SPRING

DIAPHRAGM AND

PLUG ASSEMBLY

INTERNAL STRAINER

M1215

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

4

Figure 2. Type LR125 Operational Schematic

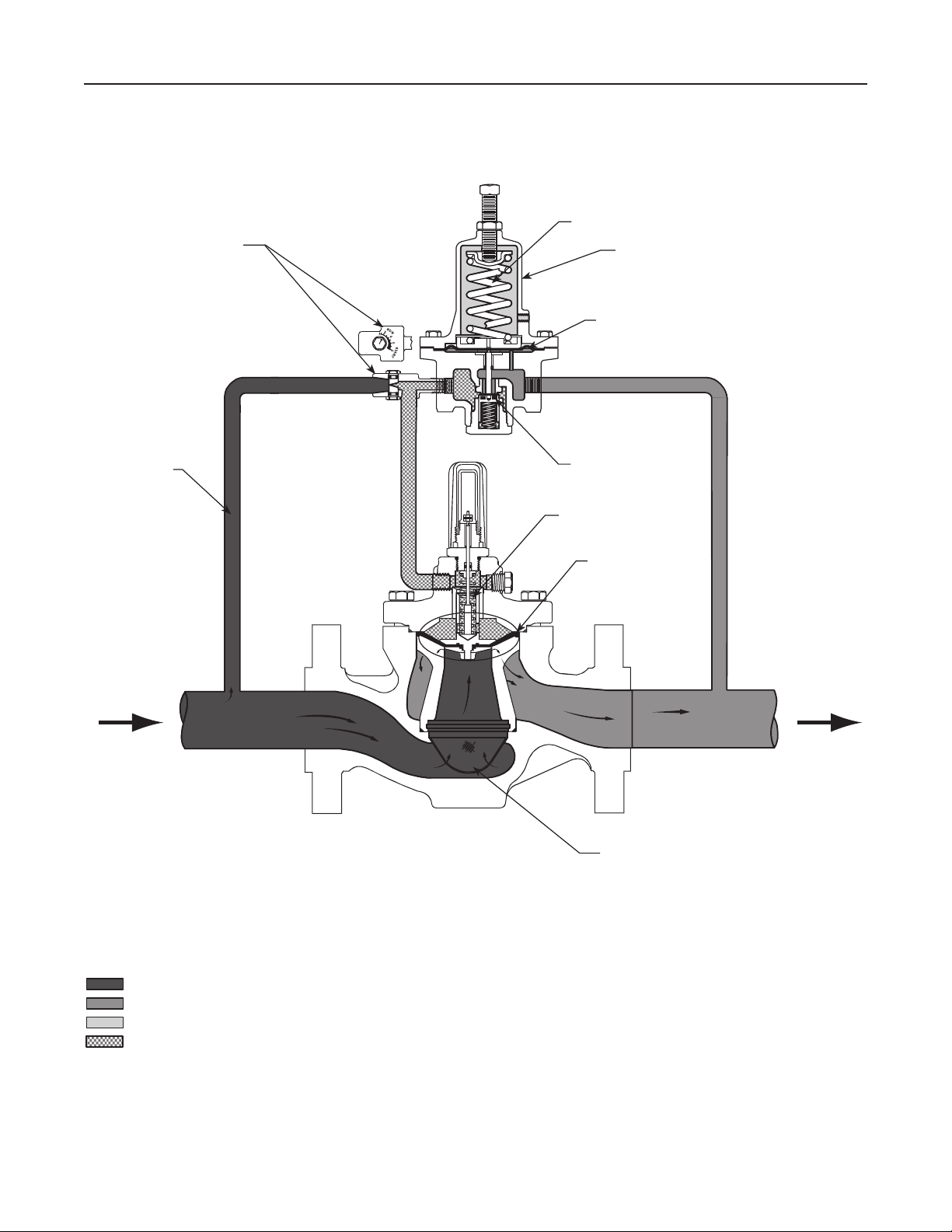

Type LR125

BLOCK VALVE

INLET

SUPPLY PRESSURE LINE

B2605_A

TYPE MR95H PILOT INSTALLATION WITH PILOT EXHAUST INTO CONTROL LINE

WARNING

!

RESTRICTOR

Figure 3. Typical Type LR125 Installation Schematic

Liquid pressure control systems should

be designed using engineering practices

to eliminate quick control starting or

stopping of the ow stream, which can

produce water hammer.

The robust design of the Type LR125 allows this

regulator to be installed indoors or outdoors. This

regulator is designed to withstand the elements.

The powder paint coating protects against minor

impacts, abrasions and corrosion. When installed

outdoors, the Type LR125 does not require protective

housing. However, the Type MR95H pilot should be

oriented so that the pilot spring case vent is pointed

down. Otherwise, make sure the vent is protected

so that rain, moisture, insects or any debris will not

accumulate inside or block the vent assembly.

When installed indoors, no remote venting is required

except on the pilot spring case. Refer to Step 5 of the

following procedure for the correct venting practices.

1. Only personnel quali ed through training and

experience should install, operate and maintain a

regulator. Before installation, make sure that there

is no damage to or debris in the regulator. Also,

make sure that all tubing and piping are clean

and unobstructed.

BLOCK VALVE

OUTLET

HAND VALVE

CONTROL LINE

TYPE MR95H PILOT

ALTERNATE CONTROL LINE

Note

The Type LR125 internal inlet strainer

is intended to prevent occasional

large particles from entering the main

valve. If the owing media contains

continuous particles, upstream ltration

is recommended before the main

valve and in the pilot supply piping.

See the Speci cations section for the

corresponding mesh size of the internal

inlet strainer.

2. A Type LR125 regulator may be installed in any

orientation, as long as ow through the regulator

matches the direction of the arrow on the main

valve body and the pilot vent is pointed down.

However, for easier maintenance, install the

regulator with the bonnet up.

CAUTION

Provide adequate support to the bonnet

when disassembling Type LR125

pressure reducing regulator installed in

a vertical installation or other application

where the bonnet is not oriented upward.

Without adequate support, the bonnet

may fall and cause physical injury when

the cap screws are loosened.

3. The standard pilot mounting position is as shown in

Figure 1. Other mounting positions are available.

5

Type LR125

Table 2. Type MR95H Pilot Maximum Operating Pressures

BODY SIZE

1/2 NPT

1. The pressure/temperature limits in this manual, and any applicable standard or code limitation should not be exceeded.

BODY AND SPRING

CASE MATERIAL

Steel

Stainless Steel

MAXIMUM INLET PRESSURE MAXIMUM OUTLET PRESSURE

300 psig / 20.7 bar 300 psig / 20.7 bar

(1)

Table 3. Outlet (Control) Pressure Ranges

PILOT

Type MR95H

OUTLET PRESSURE RANGE

SPRING WIRE

DIAMETER

psig bar In. mm In. mm

15 to 30

25 to 75

70 to 150

1.0 to 2.1

1.7 to 5.2

4.8 to 10.3

0.207

0.234

0.283

5.26

5.94

7.19

SPRING

FREE LENGTH

2.50

2.60

2.44

63.5

65.9

62.0

SPRING PART NUMBER

AND COLOR

1E395627022, Yellow

1D7455T0012, Green

1E395727192, Red

Table 4. Diaphragm Material Selection Information

CRITERIA

17E68 Nitrile (NBR) (Standard) 17E97 Nitrile (NBR) 17E88 Fluorocarbon (FKM)

Liquid Temperature -20 to 150°F / -29 to 66°C 0 to 150°F / -18 to 66°C 0 to 250°F / -18 to 121°C

Best for low pressure differential

General Applications

service or cold temperature

applications

Heavy Particle Erosion Fair Excellent Good

1. Fluorocarbon (FKM) is limited to 200°F / 93°C in hot water.

DIAPHRAGM MATERIAL

Best for abrasive or erosive service

applications

Best for high temperature applications

(1)

Table 5. Main Valve Minimum Differential Pressures

MAIN VALVE BODY SIZE DIAPHRAGM

In. DN Diaphragm Code Diaphragm Material psid bar d psid bar d

17E68 (Standard) Nitrile (NBR), Low Minimum Differential 30 2.1 30 2.1

1 25

2 50

3 80

4 100

1. See Table 1 for Type LR125 main valve structural design ratings and Table 2 for Type MR95H pilot rating.

17E97 Nitrile (NBR), High Erosion Resistance 35 2.5 35 2.5

17E88

17E68 (Standard) Nitrile (NBR), Low Minimum Differential 18 1.2 19 1.3

17E97 Nitrile (NBR), High Erosion Resistance 24 1.7 24 1.7

17E88

17E68 (Standard) Nitrile (NBR), Low Minimum Differential 21 1.5 28 1.9

17E97 Nitrile (NBR), High Erosion Resistance 23 1.6 23 1.6

17E88

17E68 (Standard) Nitrile (NBR), Low Minimum Differential 16 1.1 30 2.1

17E97 Nitrile (NBR), High Erosion Resistance 16 1.1 34 2.3

17E88

Fluorocarbon (FKM),

High Temperature Capability

Fluorocarbon (FKM),

High Temperature Capability

Fluorocarbon (FKM),

High Temperature Capability

Fluorocarbon (FKM),

High Temperature Capability

30 2.1 30 2.1

18 1.2 19 1.3

21 1.5 28 1.9

16 1.1 30 2.1

(1)

MINIMUM DIFFERENTIAL, PERCENT OF CAPACITY

For 90% Capacity For 100% Capacity

6

Type LR125

4. Apply a good grade of pipe compound to the

external pipeline threads for a threaded body,

or use suitable line gaskets for a anged body.

Use approved piping procedures when installing

the regulator.

CAUTION

A regulator may leak toxic chemical to

the environment. In toxic or hazardous

liquid service, leaked chemical may

accumulate and cause personal injury,

death or property damage due to

escaping uid.

To prevent such injury or damage,

provide piping or tubing to vent the

hazardous liquid to a remote, safe

location away from air intakes or any

hazard-prone location. The exhaust

piping must be designed and installed to

guard against excessive ow restriction.

Protect the vent line or stack opening

against condensation or clogging.

5. If system operation during maintenance is required,

install isolating and vent valves as needed.

6. A clogged pilot spring case vent may cause

the regulator to function improperly. To prevent

plugging (and to keep the spring case from

collecting moisture, corrosive chemicals or other

foreign material) point the vent down, orient it to

the lowest possible point on the spring case or

otherwise protect it. Protect the vent assembly

from icing, moisture or debris that may cause

blockage, as required. Inspect the vent regularly

to make sure it has not been plugged. To remotely

vent a spring case, remove the vent and install

obstruction-free tubing or piping into the 1/4 NPT

vent tapping. Provide protection on a remote vent

by installing a screened vent cap onto the remote

end of the vent pipe.

7. As shown in Figure 3, run a supply pressure line

from the upstream pipeline to the restrictor inlet

(use 3/8 NPT outer diameter tubing or larger).

Install a lter or strainer upstream of the restrictor,

if needed, to keep the supply source from clogging

the restrictor or pilot. Inspect and clean this lter

regularly to make sure it has not been plugged

which can prevent proper regulator operation.

8. Install a downstream pressure control line with

a minimum size of 1/2 in. / 13 mm (as shown

in Figure 3) to the pilot control line or outlet

connection. Connect the other end of the control

line at a minimum of 8 to 10 pipe diameters

downstream of the regulator in a straight run of

pipe. Do not place a control line connection in a

turbulent area, such as in or directly downstream

of a swage or elbow. Signicant restrictions in

the control line can prevent proper pressure

registration. When using a hand valve, it should be

a full ow valve, such as a full port ball valve.

9. Good piping practices usually require swaging up

to larger downstream piping to obtain reasonable

downstream uid velocity.

Startup and Adjustment

Note

Tables 1 and 2 show the maximum inlet

pressures for specic constructions.

Use pressure gauges to monitor inlet

pressure, outlet pressure and any

intermediate pressure during startup.

Startup

1. Make sure all block and vent valves are closed.

2. Back out the pilot adjusting screw.

3. Set the restrictor to the “4” position.

4. SLOWLY OPEN the valves in the following order:

a. Pilot supply and control line valve(s), if used

b. Inlet block valve

c. Outlet block valve

5. Set the pilot to the desired outlet (control) pressure

according to the pilot adjustment procedure.

Pilot Adjustment

The factory setting of the regulator can be varied

within the pressure range stamped on the nameplate.

To change the outlet pressure, loosen the jam nut

(key 17, Figure 15) and turn the adjusting screw

(key 15) clockwise to increase outlet pressure or

counterclockwise to decrease it. Monitor the outlet

pressure with a test gauge during the adjustment.

Tighten the locknut to maintain the desired setting.

All regulator springs can be backed off to provide zero

outlet. Recommended outlet pressure ranges available

and color codes of the respective springs are shown

in Table 3.

7

Type LR125

Regulator Performance 2 4 6 8

Accuracy

Hysteresis

Stability

Speed of Response (Demand Decrease)

Speed of Response (Demand Increase)

Increased Performance Decreased Performance

Regulator Performance

2 4 6 8

Accuracy

Hysteresis

Stability

Speed of Response (Demand Decrease)

Speed of Response (Demand Increase)

Increased Performance Decreased Performance

Regulator Performance

2 4 6 8

Accuracy

Hysteresis

Stability

Speed of Response (Demand Decrease)

Speed of Response (Demand Increase)

Increased Performance Decreased Performance

112 Restrictor Adjustment Guide

112 Restrictor Adjustment Guide

112 Restrictor Adjustment Guide

PILOT SUPPLY CONNECTION: 1/4 NPT PIPE

CONNECTS TO UPSTREAM PILOT SUPPLY TAP

LOADING CONNECTION: 1/4 NPT PIPE CONNECTS TO

TYPE LR125 DIAPHRAGM LOADING PORT

OUTLET CONNECTION: 1/4 NPT PIPE

CONNECTS TO PILOT INLET CONNECTION

11B5004-A

OPTIONAL LOADING CONNECTION:

1/4 NPT NORMALLY PLUGGED

Figure 4. Type 112 Restrictor

W4559_1

RESTRICTOR ADJUSTMENT

REGULATOR PERFORMANCE 2 4 6 8

Accuracy

Hysteresis

Stability

Speed of Response (Demand Decrease)

Speed of Response (Demand Increase)

TYPE 112 RESTRICTOR SETTING

Increased Performance

RESTRICTOR ADJUSTMENT GUIDE

Figure 5. Restrictor Adjustment

8

Decreased Performance

Loading...

Loading...