Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert® XDR

User Manual

™

Page 2

IMPORTANT SAFETY GUIDELINES

!

!

!

!

!

SAVE THESE INSTRUCTIONS

WARNING

Risk of top-heavy module falling over. Can cause equipment damage, personal injury or

death.

Improper handling can cause equipment damage, injury, or death. Read all of the following

instructions before attempting to move, lift, remove packaging from the module, or preparing

module for installation.

WARNING

Risk of explosive discharge of high-pressure refrigerant. Can cause personal injury or death.

This module contains fluids and/or gases under high pressure. Relieve system pressure before

cutting into or disconnecting piping or piping components.

WARNING

Risk of piping and component rupture. May cause equipment damage, personal injury or

death.

Closing service valves may isolate liquid refrigerant, causing high pressure and rupture of

piping. Do not close valves without following recommended procedures for repair,

maintenance and replacement of components. Install pressure relief valves in field piping

that may become isolated by service valves.

CAUTION

Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and

glasses should attempt to move, lift, remove packaging from, or prepare module for

installation.

CAUTION

Risk of improper operation and overpressurization. Can cause in personal injury or property

damage.

Only personnel properly trained and qualified in HVAC installation or service should install

or service this equipment.

Read all installation, operating and safety instructions before proceeding.

NOTICE

Risk of overhead interference. Can cause module or structural damage.

The module may be too tall to fit through a doorway while on the skid. Measure the module

and doorway heights and verify clearances by referring to the installation plans and other

site-specific drawings and documents before moving the module.

Fluorinated Greenhouse Gas Requirements—European Union

Stationary air conditioning, refrigeration, heat pump equipments and stationary fire protection systems in

the European Community market and operating with fluorinated greenhouse gases (f-gas), such as R407C,

R134a, R410A, must comply with the F-Gas Regulation: (EC) No. 842/2006 (F-gas). The regulation prohibits,

among other actions, venting fluorinated greenhouse gases to the atmosphere.

The F-Gas Regulation also requires operators to use all measures that are technically feasible and do not

entail disproportionate cost to prevent leakage of these gases, to test for leakage regularly and to recover f-gas

during equipment service and maintenance and before disposing of equipment.

Refer to the full regulation for additional details.

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

1.0 COMPONENT LOCATIONS AND MODEL NUMBER NOMENCLATURE. . . . . . . . . . . . . . . . . . . . .1

2.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Pre-Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4.1 Room Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0 GENERAL PRODUCT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.1 Product/System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Checking and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2.1 Recyclable Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.2 Module Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.3 Unpacking the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.4 Removing the Liebert XDR from the Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 MECHANICAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.1 Liebert XDR Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Determining Placement in the Conditioned Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Airflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.1 Installing the Rack-Mounting Kit onto the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Mounting the Liebert XDR on the Rack-Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Door Safety Catch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.0 PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.1 European Union Fluorinated Greenhouse Gas Requirements . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 System Connection Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Connection Methods and Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5 Venting the Holding Charge for Hard-Piped or Removable Liebert XD Flex Pipe

Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5.1 Brazing Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5.2 Recommended Piping Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.6 Hard-Piped Connection Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.6.1 Leak-Checking and Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.6.2 Header System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

i

Page 4

6.7 Field Installation of Liebert XD Flex Pipe Kit on Liebert XDR . . . . . . . . . . . . . . . . . . . . . . 18

6.7.1 Connecting Methods—One-Shot Couplings for Pre-Charged Refrigerant Option . . . . . . . . . 19

6.7.2 Connect a Liebert XDR with One-Shot Couplings to Liebert XD Flex Pipe . . . . . . . . . . . . . . 20

6.7.3 Connection Methods—Removable Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.7.4 Connect Liebert XD Flex Pipe with Removable Coupling to a Liebert XD Cooling

Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.7.5 Connect a Liebert XDR with Liebert XD Flex Pipe to a Liebert XD System . . . . . . . . . . . . . 23

6.7.6 Disconnect a Liebert XD Flex Pipe from a Liebert XD System . . . . . . . . . . . . . . . . . . . . . . . . 27

6.7.7 Disconnecting the Liebert XD Flex Pipe from the Liebert XDR . . . . . . . . . . . . . . . . . . . . . . . 28

6.7.8 Removing the Liebert XDR from a Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.0 INSTALLATION CHECKLIST AND SYSTEM FILL FOR STARTUP . . . . . . . . . . . . . . . . . . . . . . .29

7.1 Checklist for Proper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Charging with Refrigerant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.0 STARTING THE LIEBERT XD SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

9.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

9.1 Fluorinated Greenhouse Gas Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

ii

Page 5

FIGURES

Figure 1 Liebert XDR component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 Liebert XDR model number nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 3 Generic piping layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 4 Recommended module handling equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

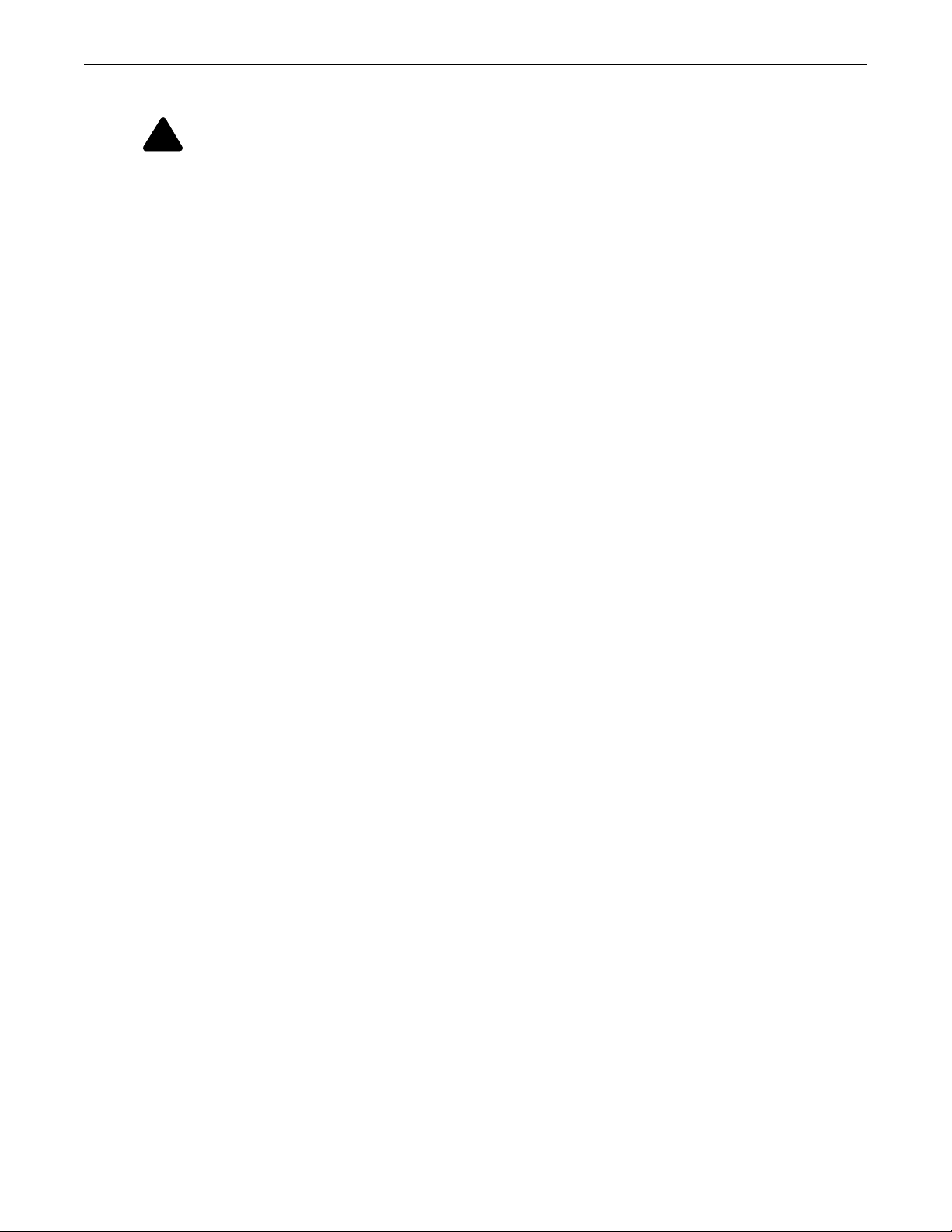

Figure 5 Removing packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

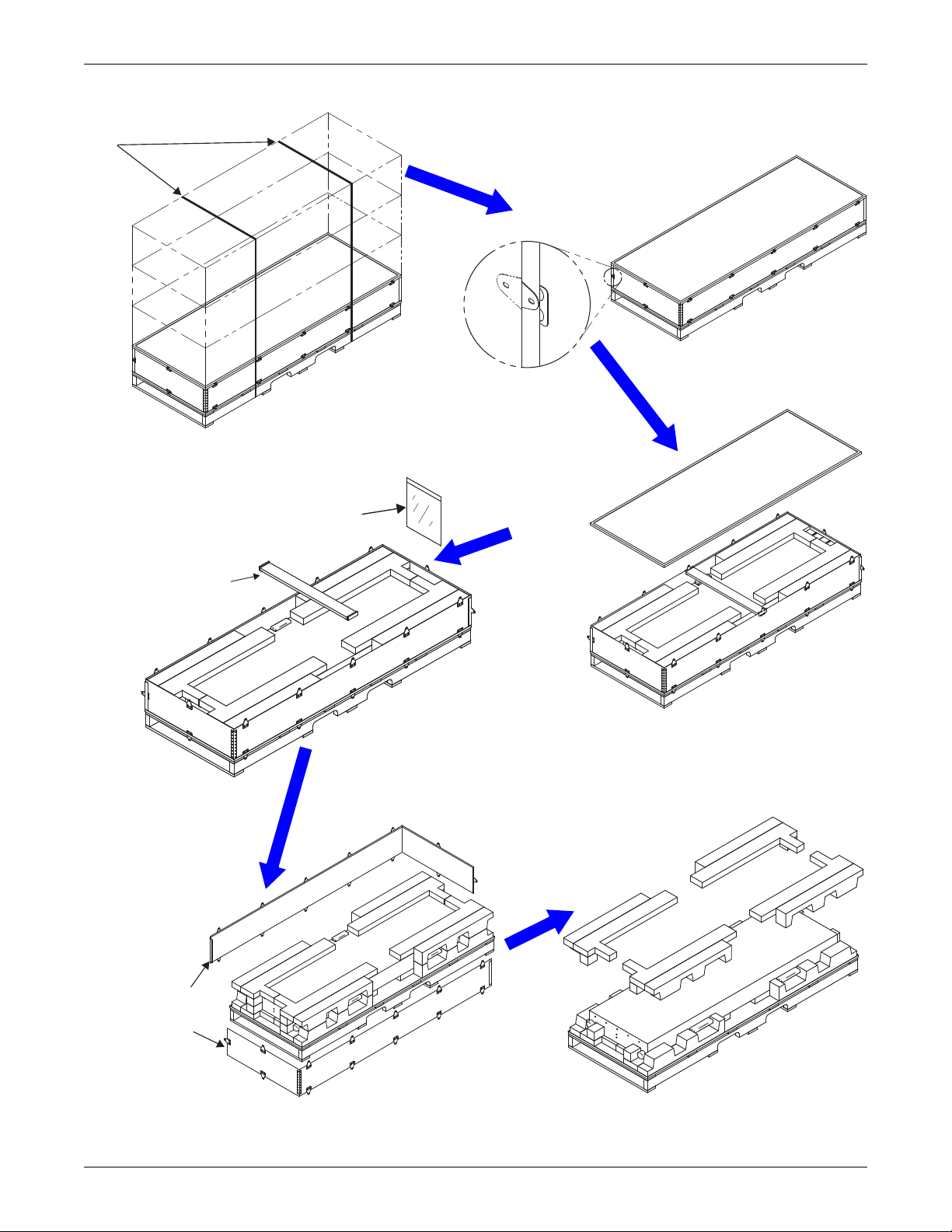

Figure 6 Remove Liebert XDR from pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

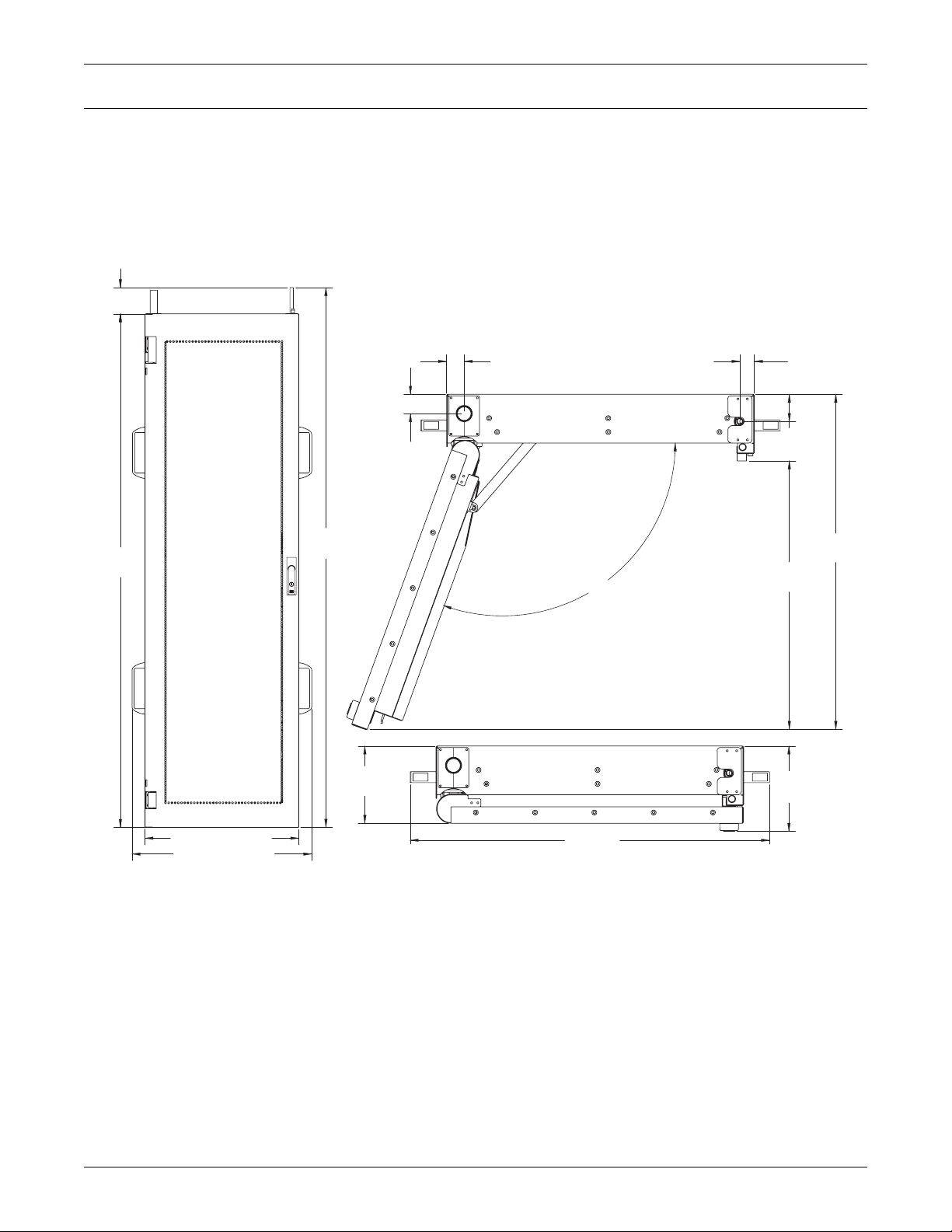

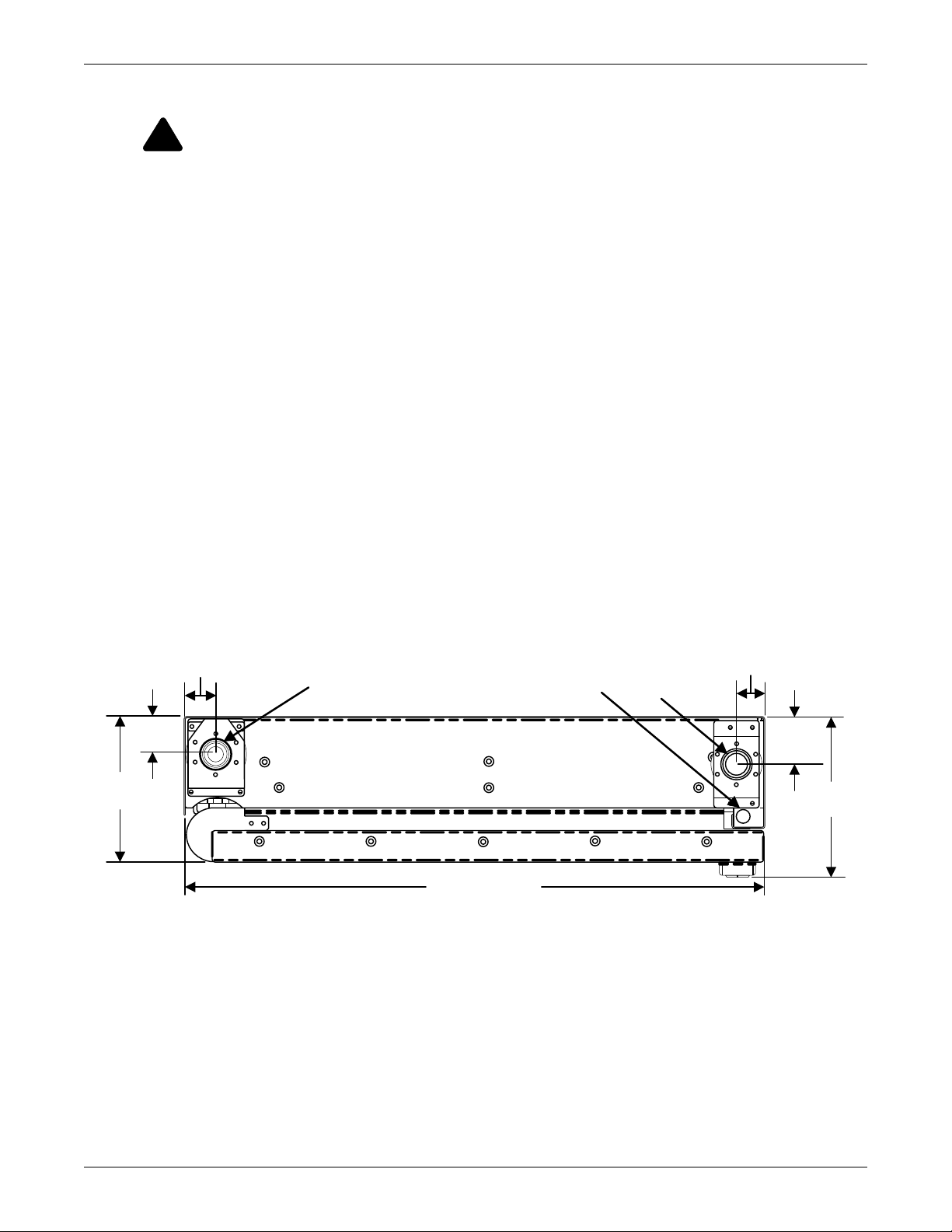

Figure 7 Overall dimensions with hard-piped connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

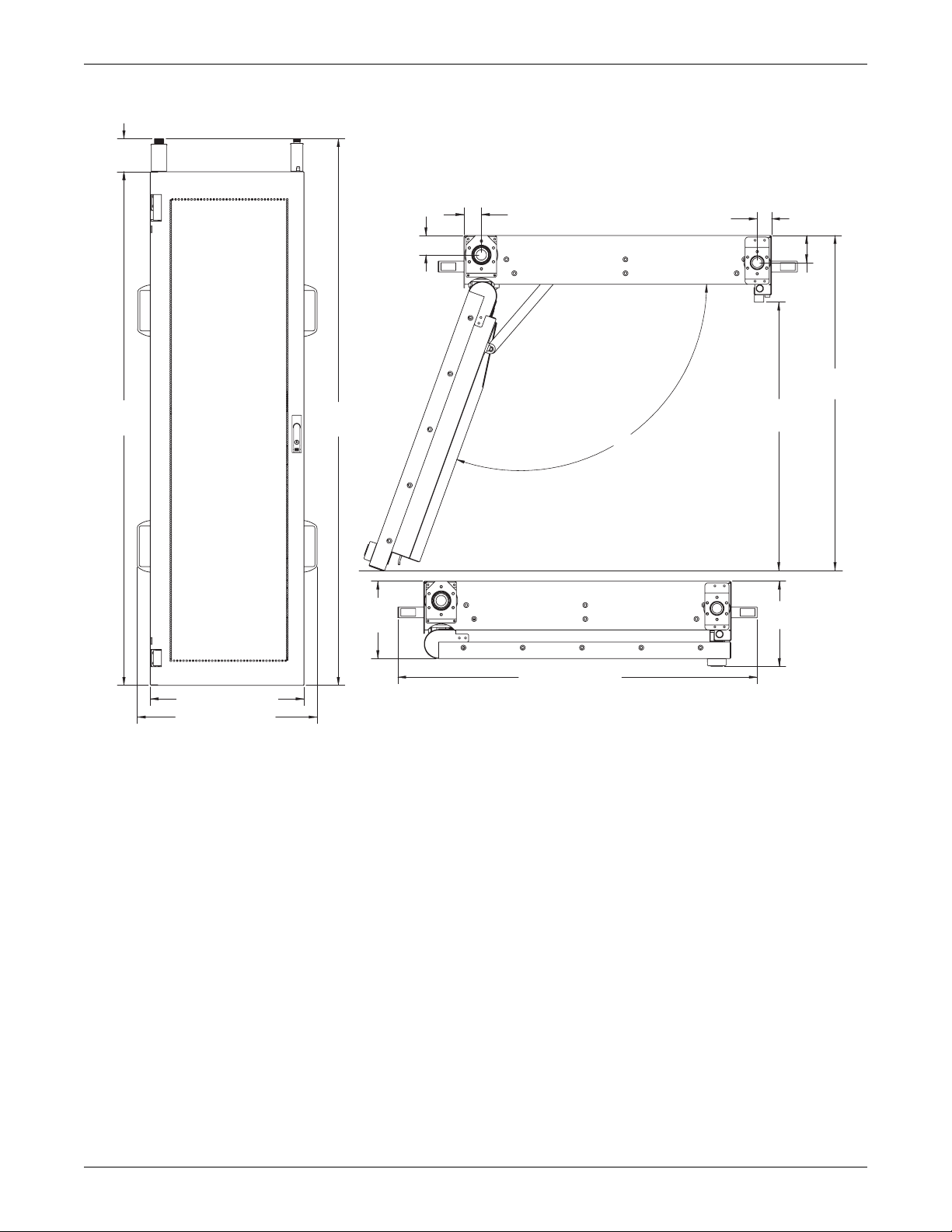

Figure 8 Overall dimensions with one-shot coupling (pre-charged) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

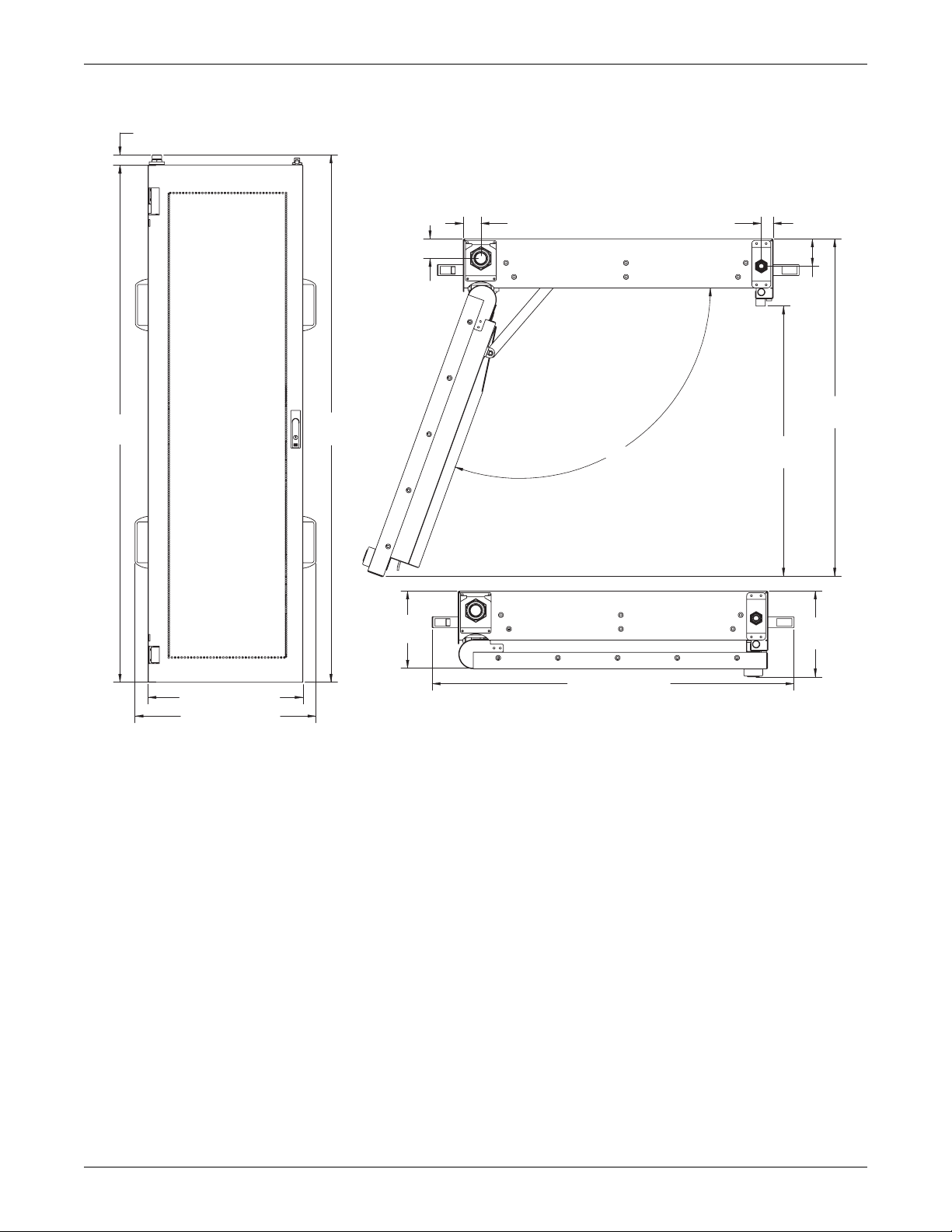

Figure 9 Overall dimensions with removable coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 10 Generic airflow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 11 Liebert XDR mounting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 12 Typical Liebert XDR piping—interlaced connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13 Typical Liebert XDR piping—non-interlaced connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 14 Piping location and connection sizes—modules with hard-piped connections . . . . . . . . . . . . . . . 16

Figure 15 Hard pipe connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

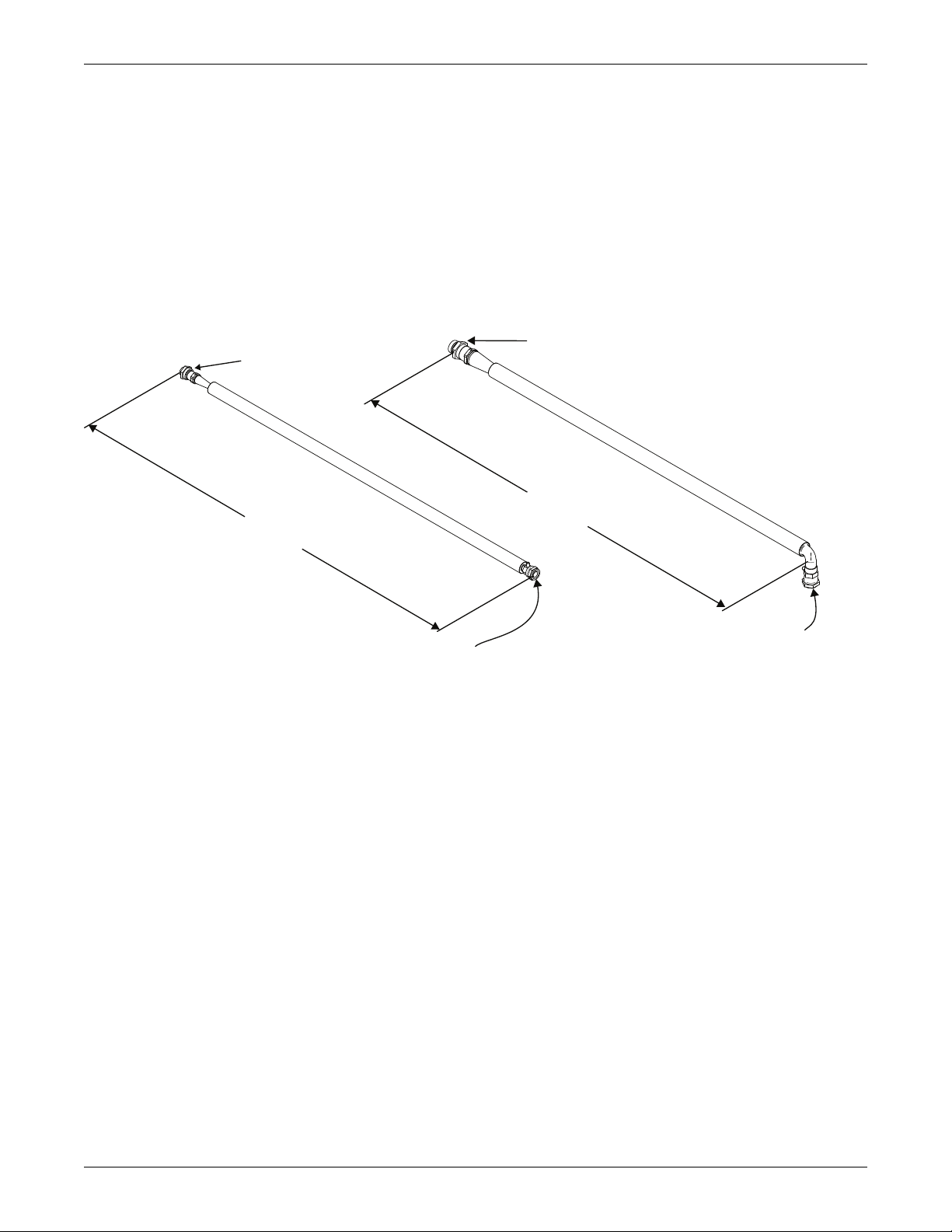

Figure 16 Liebert XD Flex Pipe dimensions—straight and 90-degree connections. . . . . . . . . . . . . . . . . . . . 18

Figure 17 Piping location and connection sizes—modules with pre-charged modules . . . . . . . . . . . . . . . . . 19

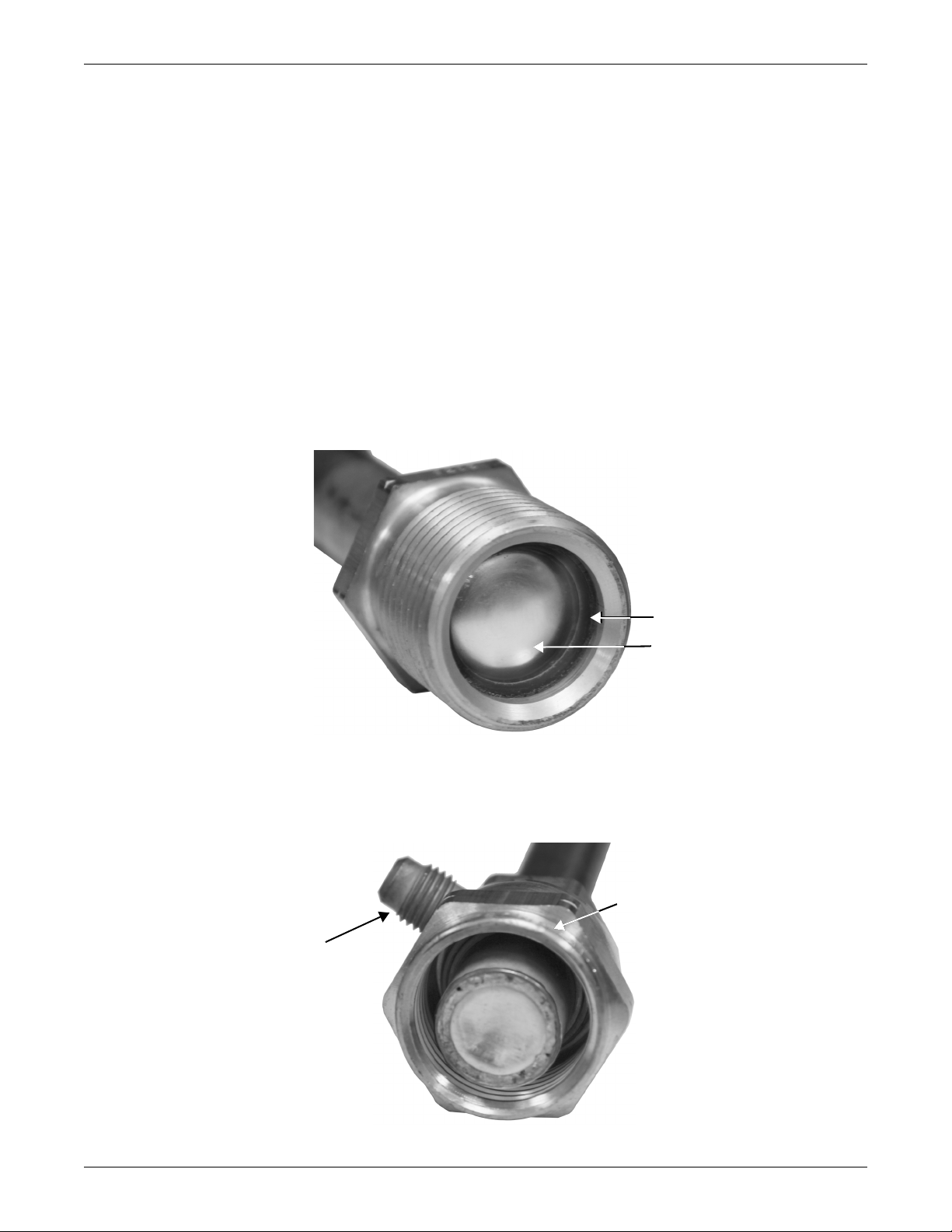

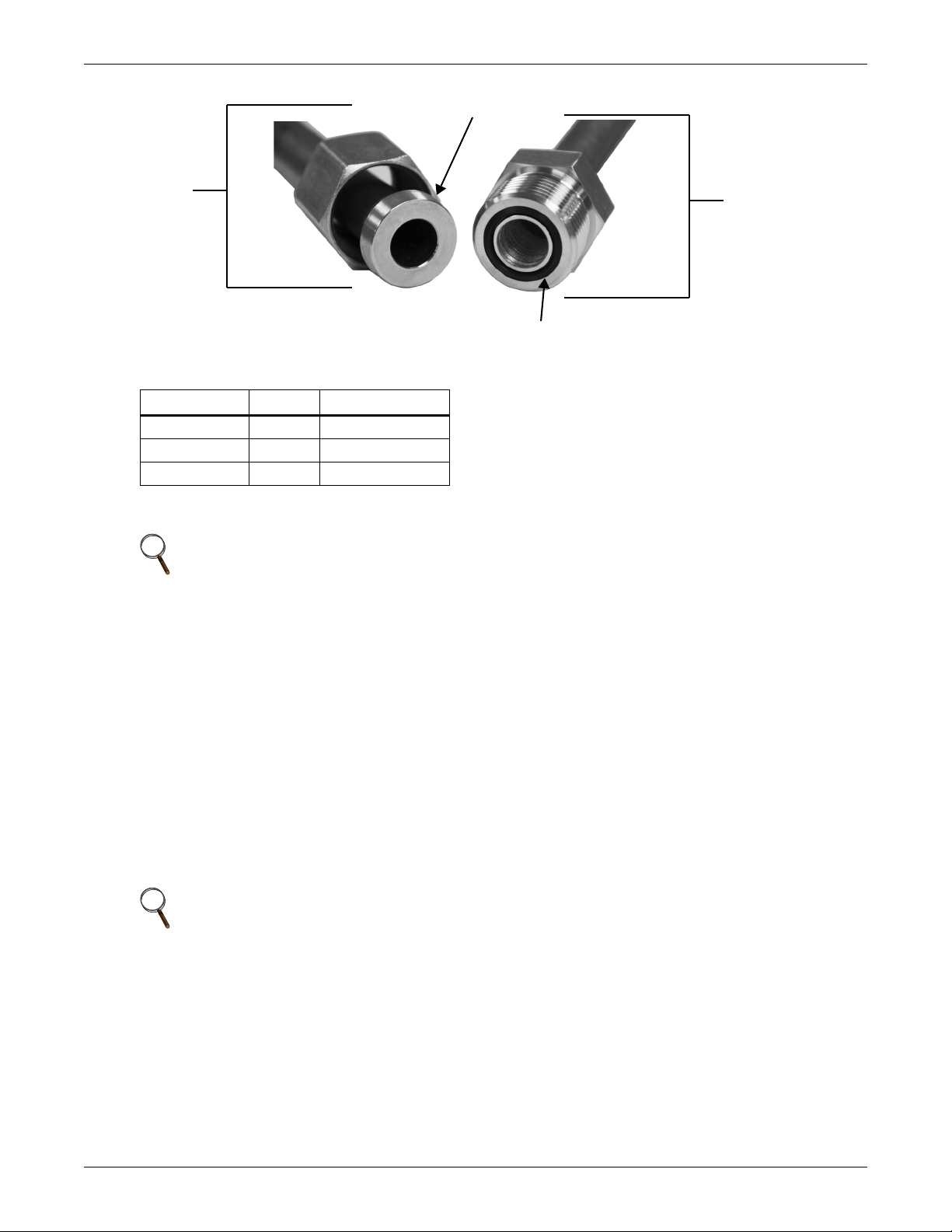

Figure 18 Male coupling on Liebert XD cooling module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 19 Female one-shot coupling Liebert Flex Pipe: Schrader valve location . . . . . . . . . . . . . . . . . . . . . 20

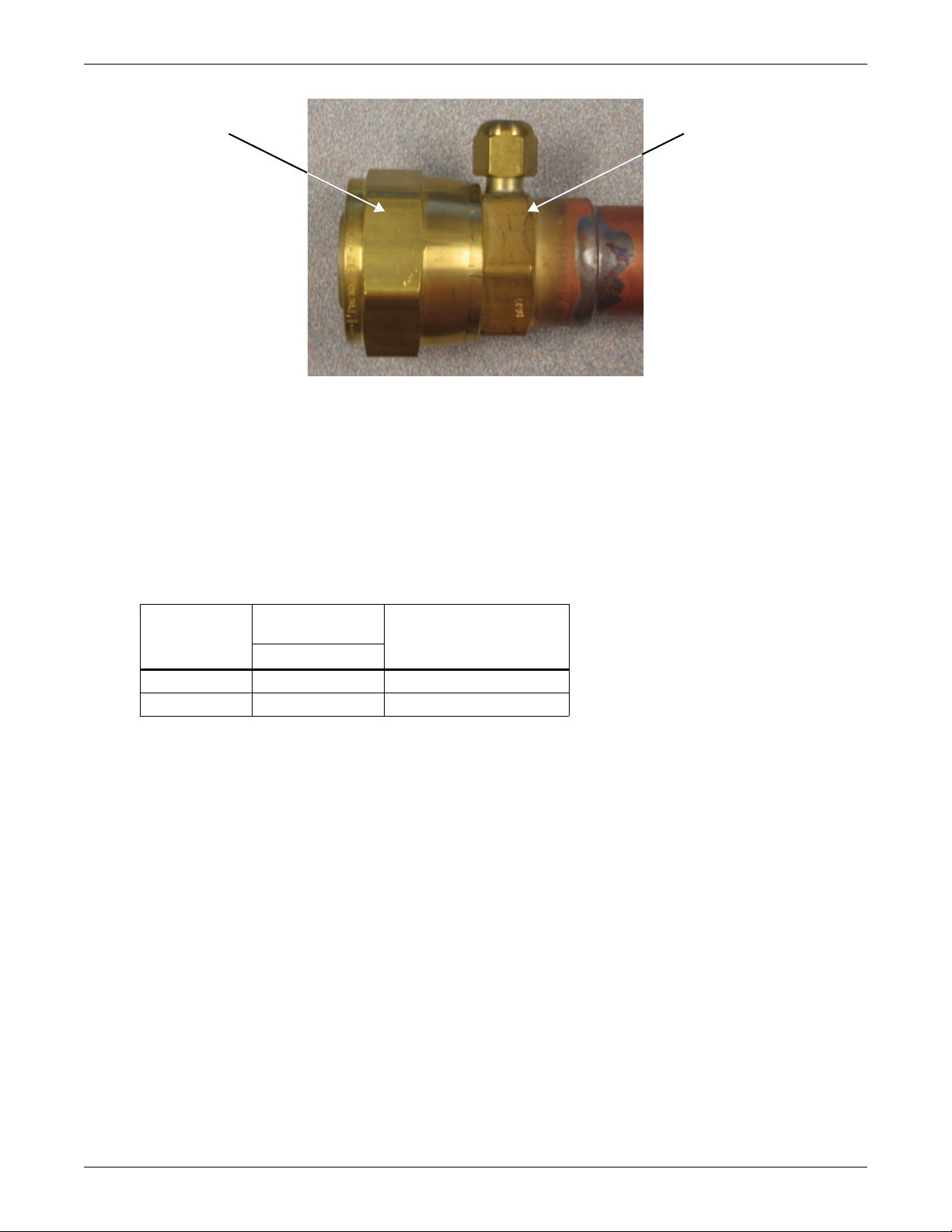

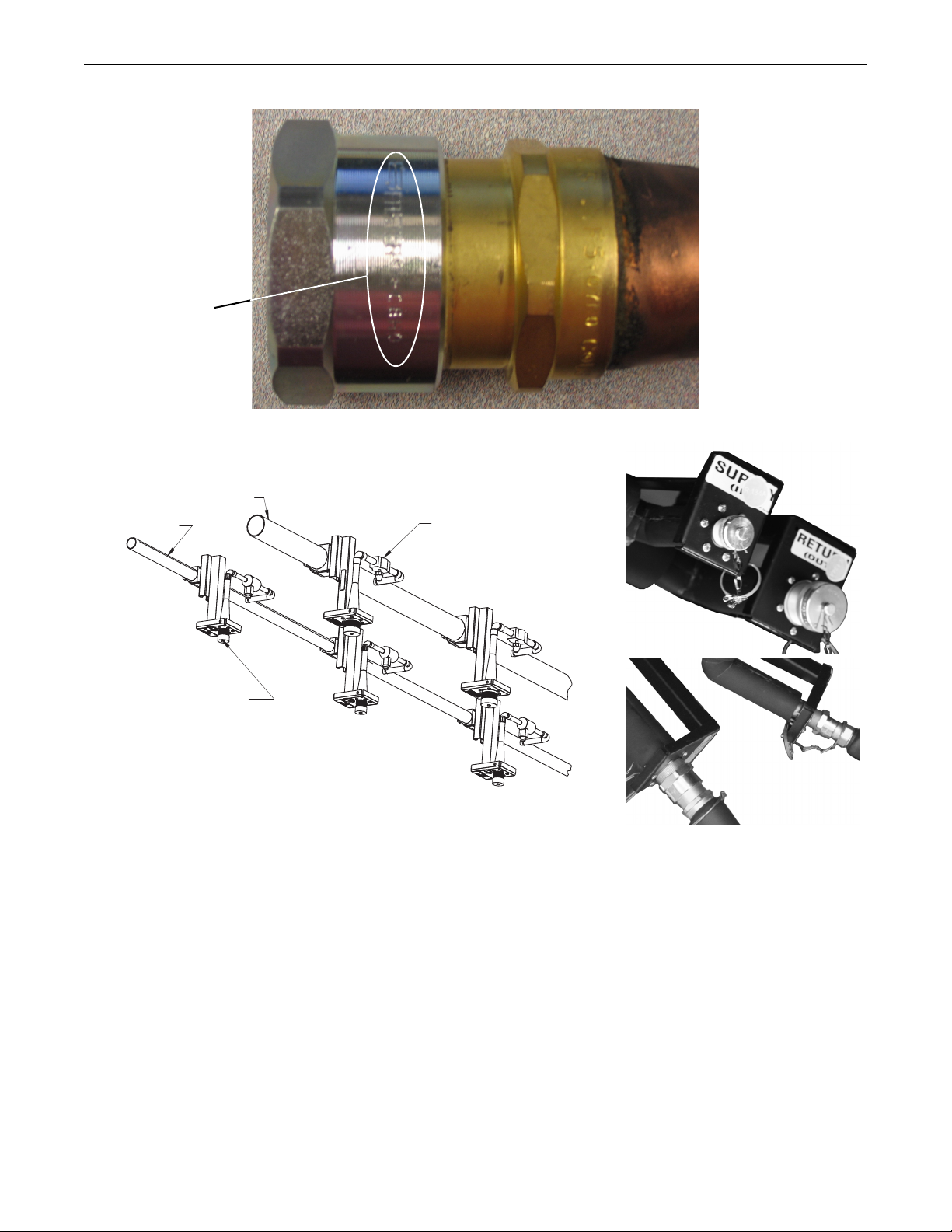

Figure 20 Hex body, union nut on one-shot coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21 Piping location and connection sizes—modules with removable couplings. . . . . . . . . . . . . . . . . . 22

Figure 22 Removable couplings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 23 Coupling size indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 24 Liebert XD prefabricated piping assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 25 Oil rings on header and Liebert XD Flex Pipe connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 26 Wrench arrangement for tightening couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 27 Detail view of Liebert XD Flex Pipe and prefabricated piping port. . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 28 Liebert XD prefabricated piping assembly and Liebert XD Flex Pipe. . . . . . . . . . . . . . . . . . . . . . 26

Figure 29 Piping mains without Liebert XD Flex Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TABLES

Table 1 Branch piping sizes for pumped refrigerant loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 2 Torque and wrench size for connecting Liebert XDR with one-shot couplings to

Liebert XD Flex Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3 Torque and wrench sizes for connecting Liebert Flex Pipe to the Liebert XDR with

removable couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 4 O-ring part number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 5 Torque for connecting Liebert XD Flex Pipe to prefabricated piping . . . . . . . . . . . . . . . . . . . . . . 25

Table 6 Liebert XDR specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 7 Rack mounting kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 8 Liebert XD Flex Pipe one-shot assemblies, supply and return . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9 Liebert XD Flex Pipe removable assemblies, supply and return . . . . . . . . . . . . . . . . . . . . . . . . . . 32

iii

Page 6

iv

Page 7

Component Locations and Model Number Nomenclature

XD 20 B

20 = Model SizeLiebert

X-treme

heat

density

system

Example: XDR20B1R — *

R

Rear Cooling Module

—

- = Domestic Packaging

E = Export Packaging

1

1 = Standard

B = Basic Module

*

Revision

level

R

- = Hard-Piping

P = Pre-Charged One-Shot

Coupling

R = Removable Coupling

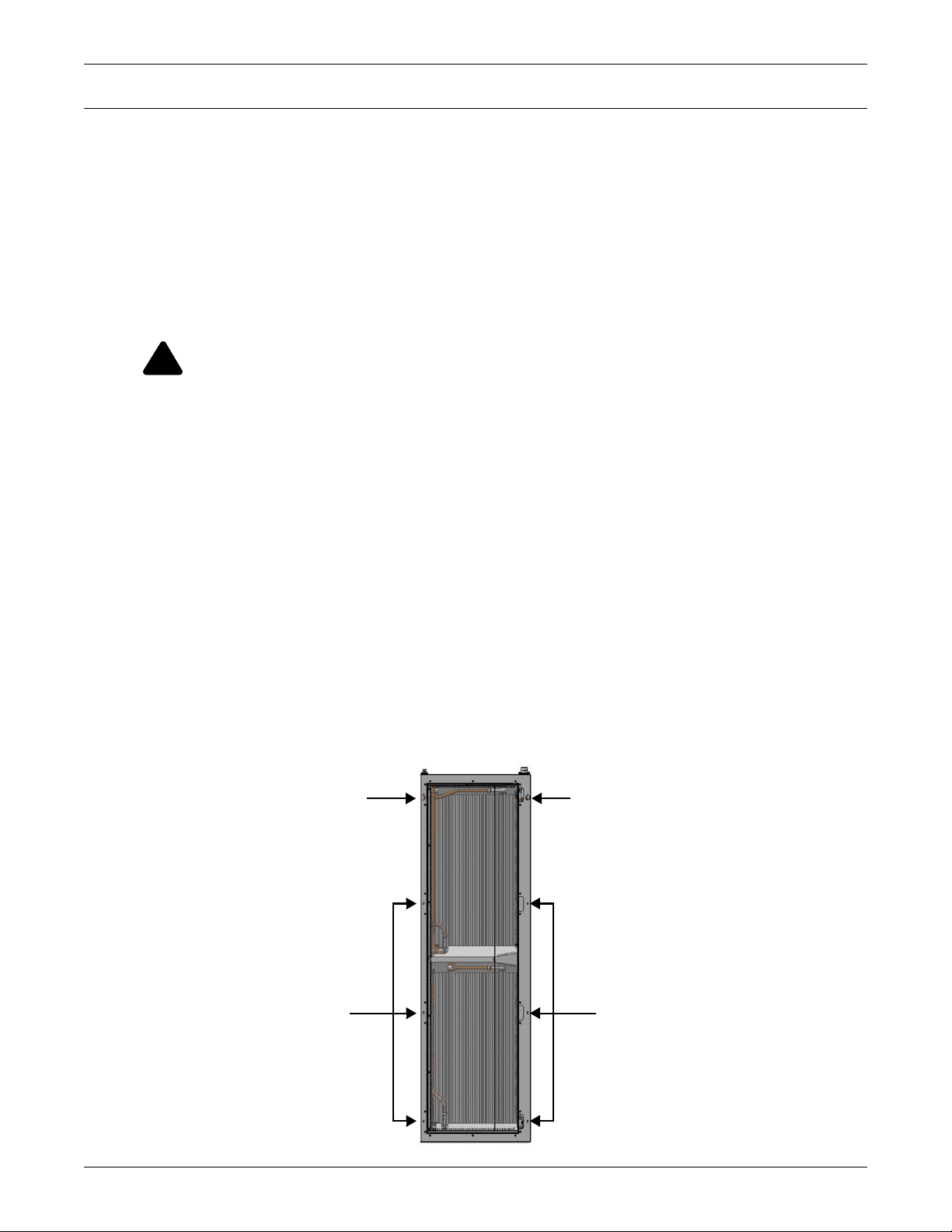

1.0 COMPONENT LOCATIONS AND MODEL NUMBER NOMENCLATURE

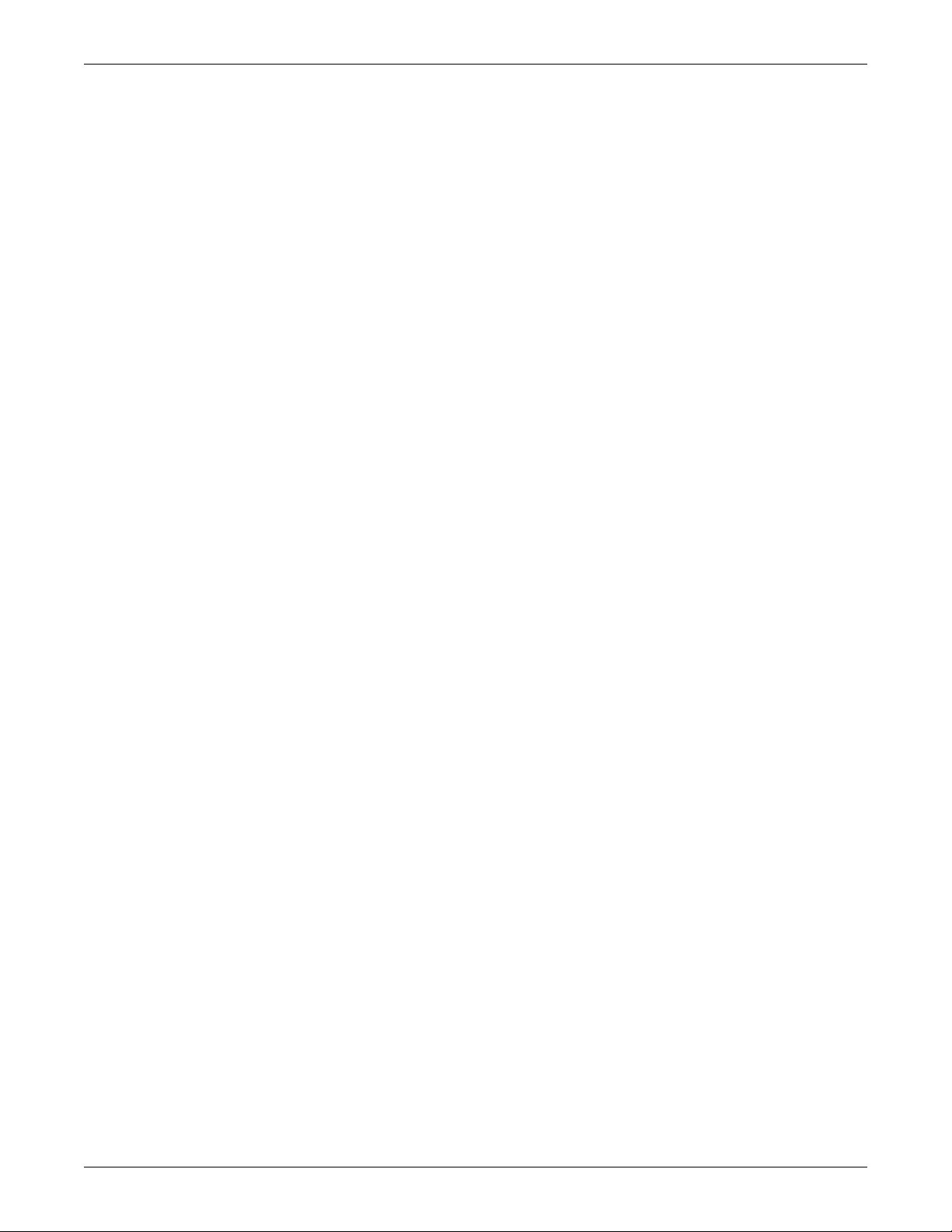

Figure 1 Liebert XDR component locations

2

4

3

1

7

5

Figure 2 Liebert XDR model number nomenclature

6

1. Supply Line

2. Door Safety Catch

3. Return Line

4. Evaporator Coils

5. Locking Door Latch

6. Removable Installation Handles

7. Frame

1

Page 8

2.0 INTRODUCTION

2.1 References

This document must be used together with site specific documentation and documentation for other

parts of the system.

2.2 Pre-Installation Checks

• Check the received materials to be sure all required assemblies and parts have been received. If

you discover any external damage, report it to the shipping company and your local Emerson representative.

2.3 Packing List

• User manual (this document)

• Liebert XDR module

2.4 Installation Considerations

The Liebert XDR is designed for attachment to the rear of computer cabinets in the data center. See

4.0 - Mechanical Considerations for details.

2.4.1 Room Preparation

Introduction

The room should be well-insulated and must have a sealed vapor barrier. The vapor barrier in the

ceiling and walls can be a polyethylene film. Paint on concrete walls and floors should contain either

rubber or plastic.

NOTE

The vapor barrier is the single most important requirement for maintaining environmental

control in the conditioned space.

Outside or fresh air should be kept to a minimum when temperature and humidity must be tightly

controlled. Outside air adds to the cooling, heating, dehumidifying and humidifying loads of the site.

Doors should be properly sealed to minimize leaks and should not contain ventilation grilles.

2

Page 9

3.0 GENERAL PRODUCT INFORMATION

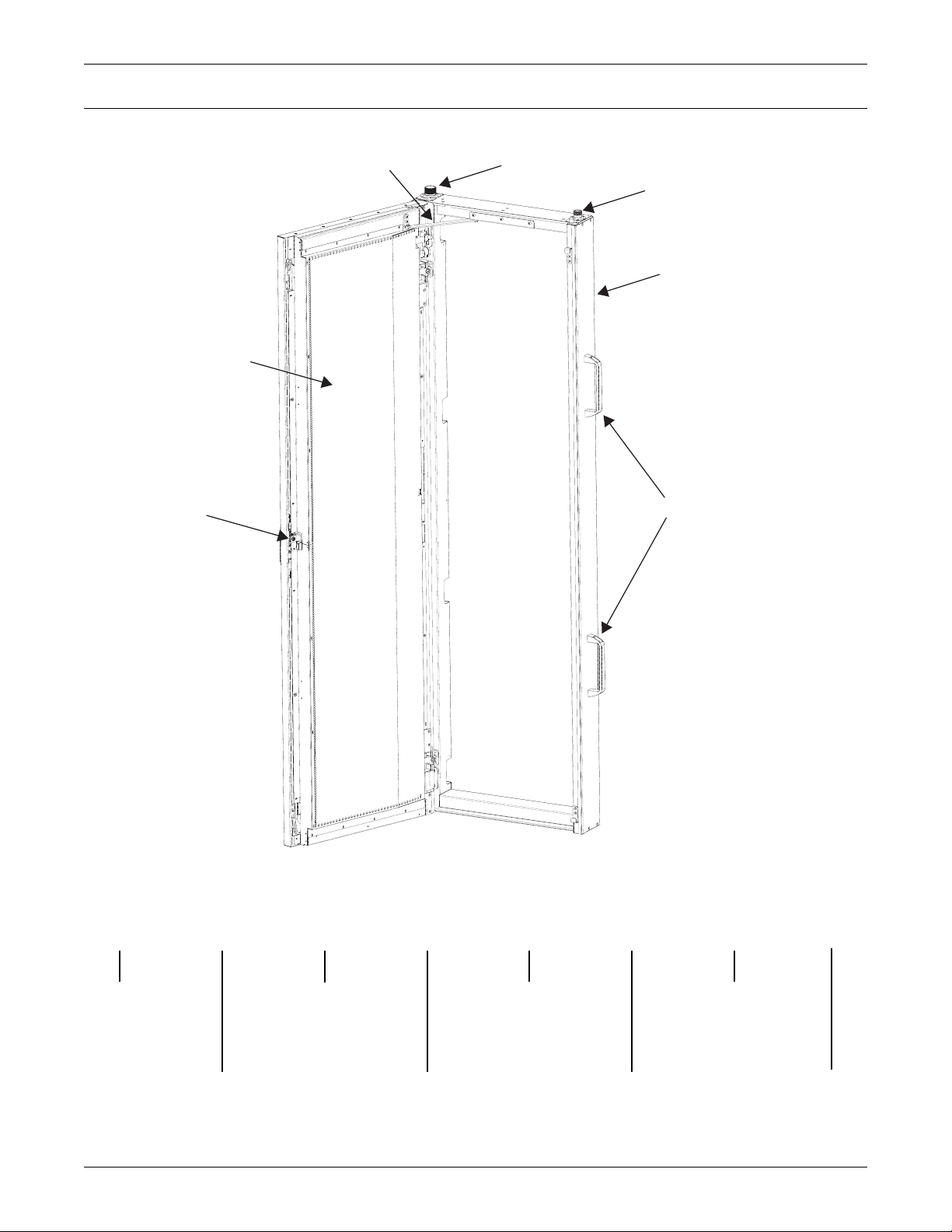

Liebert XDC

or

Liebert XDP

Supply Lines

Return Lines

* Liebert XDCF ; Liebert XDH

Liebert XDO ; Liebert XDR

Liebert XDV

Liebert

XD Cooling Module

Liebert

XD Cooling Module

Pumped

Refrigerant

R134a

*

*

3.1 Product/System Description

The Liebert XDR is a cooling system for high-density heat loads that mounts on the rear of a

24" x 42U rack (for other sizes consult the factory) and maintains access to the back of the server

rack. Room air is drawn in through the front of the rack and picks up heat from the servers. The coil

captures that heat, cooling the air, which is expelled through the rear of the rack.

General Product Information

The Liebert XDR relies on the rack equipment’s fans to move air across the micro-channel coil. Captured heat is carried away through pumped R-134a refrigerant supplied by either a Liebert XDP

Liebert XDC

The complete cooling system may include other Liebert XD cooling modules, such as the Liebert

™

XDO

™

.

, Liebert XDV™, Liebert XDH™, Liebert XDA™ or Liebert XDCF™ (see Figure 3) and Liebert

XD Flex Piping.

The Liebert XDR is not expected to produce any condensation because of its location, usually in the

data center. A condensate pan is provided as a precaution. It does not have a drain fitting or other

means of being emptied.

Four handles to ease carrying the Liebert XDR are attached at the factory. These should be removed

after the module is attached to the rear of the enclosure. Leaving the handles attached would require

space between the racks. The handles should be retained for use if the Liebert XDR is removed from

the enclosure.

Figure 3 Generic piping layout

™

or

3.2 Checking and Unpacking

Upon arrival of the module and before unpacking it, verify that the labeled equipment matches the

bill of lading.

Inspect all items for either visible or concealed damage. Damage should be immediately reported to

the carrier and a damage claim filed with a copy sent to Emerson or to your sales representative. If

you later find any concealed damage, report it to both the shipping company and your local Emerson

representative.

Check to be sure all required assemblies and parts have been received.

The Liebert XDR is shipped in protective packaging and secured to a pallet (see Figure 5). Do not

remove these protective items from the Liebert XDR before it is at the installation location. When

unpacking and handling the Liebert XDR, exercise extra care to prevent damage.

3

Page 10

3.2.1 Recyclable Packaging

!

!

R

Forklift

Pallet Jack

All material used to package this module is recyclable. Please save for future use

or dispose of the material appropriately.

CAUTION

Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and

glasses should attempt to move, lift, remove packaging from, or prepare module for

installation.

NOTICE

Risk of improper storage. Can cause module damage.

Keep the module indoors and protected from dampness, freezing temperatures and contact

damage.

NOTICE

Risk of damage from forklift. Can cause exterior and/or underside damage.

Keep tines of the forklift level and at a height suitable to fit below the skid.

Figure 4 Recommended module handling equipment

General Product Information

3.2.2 Module Handling

WARNING

Risk of 130-pound (59 kg) module falling. Can cause equipment damage, personal injury or

death.

Do not leave a Liebert XDR standing unattended on its side or its end without adequate

support to prevent it from falling over. The Liebert XDR must be supported at all times or laid

flat on protective material until it is installed.

Two properly trained and qualified people are required to move the module.

When unpacking and handling the module, exercise extra care to prevent damage.

Use a forklift or pallet jack to move the Liebert XDR. If multiple Liebert XDR modules are delivered,

they will be shipped on a pallet with up to four modules. A pallet jack will be required to move these

modules to the installation location.

• If using a forklift or pallet jack, ensure that the fork tine length is suitable to safely move the

packaged module.

• Keep the module in the protective packaging until it has been moved to the installation site.

• When handling and unpacking the module, exercise great care to prevent damage.

• Do not lift the module any higher than 6" (152mm) while moving it. If it must be lifted higher

than 6" (152mm), exercise great care and keep all personnel who are not helping move the module

at least 20 feet (5m) away from the module.

• Do not use module piping to lift or move the Liebert XDR.

4

Page 11

3.2.3 Unpacking the Module

!

WARNING

Risk of 130-pound (59 kg) module falling. Can cause equipment damage, personal injury or

death.

Do not leave a Liebert XDR standing unattended on its side or its end without adequate

support to prevent it from falling over. The Liebert XDR must be supported at all times or laid

flat on protective material until it is installed.

Two properly trained and qualified people are required to move the module.

Do not unpack the Liebert XDR before moving it to the installation location. Once at the installation

point:

1. Cut the banding and place all packaged modules on the floor for unpacking.

2. Unbend all metal tabs as shown in Figure 5.

Use any of these tools to unbend the tabs: flat-blade screwdriver, claw hammer, pliers or crowbar.

3. Remove the top cover from the package.

4. Remove the center top brace.

5. Remove and set aside the hardware and key package.

6. Remove side panels from package.

7. Remove top protective foam from the package.

General Product Information

5

Page 12

Figure 5 Removing packaging

Cut

Bands

Center Top Brace

Hardware

and Keys

Remove

Side

Panels

Step 1

Step 2

Step 3

Steps 4, and 5

Step 6

Step 7

General Product Information

Unbend Tabs

Remove the

Top Cover

Remove Foam

Protecting Top

of Module

6

Page 13

Figure 6 Remove Liebert XDR from pallet

!

Two people are required

to remove the module from the pallet

and remove the bag

General Product Information

WARNING

Risk of 130-pound (59 kg) module falling. Can cause equipment damage, personal injury or

death.

Do not leave a Liebert XDR standing unattended on its side or its end without adequate

support to prevent it from falling over. The Liebert XDR must be supported at all times or laid

flat on protective material until it is installed.

Two properly trained and qualified people are required to move the module.

3.2.4 Removing the Liebert XDR from the Pallet

1. Unfold the module bag to expose the Liebert XDR.

2. Compare the serial tag information on the Liebert XDR to the bill of lading information. If the

information does not match the product specified, contact your local sales representative.

3. At least two properly trained and qualified personnel may lift the Liebert XDR off the pallet using

the four handles and stand it upright, supporting the module to keep it from falling.

4. If the Liebert XDR will not be installed immediately, lay a piece of protective material the length

of the module on a flat surface and lay the Liebert XDR on it.

7

Page 14

4.0 MECHANICAL CONSIDERATIONS

1-1/2"

(38mm)

4"

(102mm)

78-3/8"

(1991mm)

82-3/8"

(2092mm)

5-7/8"

(149mm)

1-5/16"

(33mm)

20-1/2"

(520mm)

110deg

23-1/2" (597mm)

1-1/8"

(29mm)

27-3/8" (695mm)

6-12"

(165mm)

2-1/8"

(54mm)

25-5/8"

(651mm)

27-3/8"

(695mm)

Piping is not load-bearing and

should never be used to lift or

move the Liebert XDR.

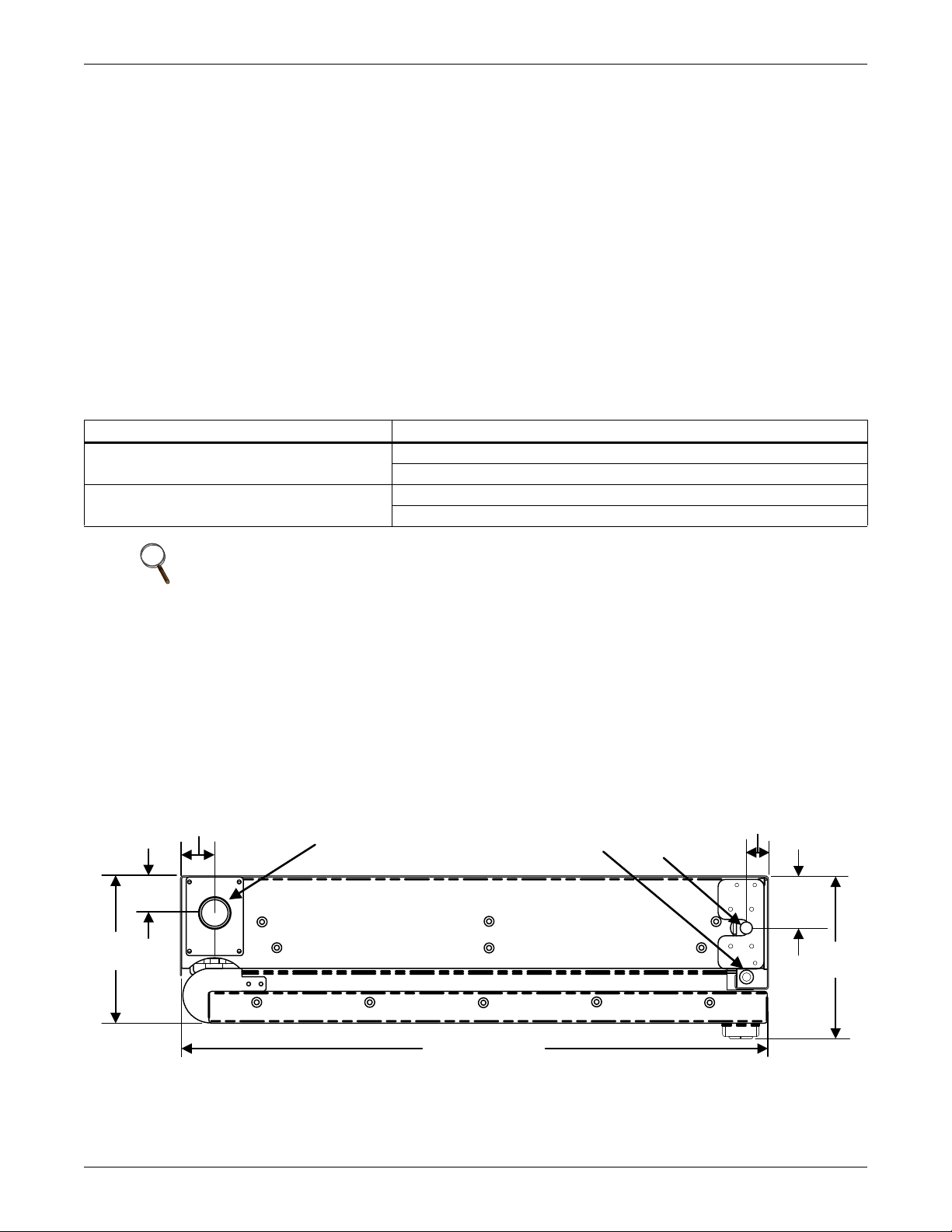

4.1 Liebert XDR Dimensions

The Liebert XDR is engineered to fit on the rear of a rack enclosure measuring approximately

24" x 42U. Consult the factory for other sizes. Figures 7, 8 and 9 illustrate the module’s dimensions

and the location of pipes. Figure 11 shows the attachment positions of each module.

Figure 7 Overall dimensions with hard-piped connections

Mechanical Considerations

8

Page 15

Figure 8 Overall dimensions with one-shot coupling (pre-charged)

Piping is not load-bearing and

should never be used to lift or

move the Liebert XDR.

5-1/8"

(130mm)

Mechanical Considerations

78-3/8"

(1991mm)

23-1/2" (597mm)

27-3/8" (695mm)

1-1/2"

(38mm)

83-1/2"

(2121mm)

5-7/8"

(149mm)

1-5/16"

(34mm)

27-3/8" (695mm)

1-1/8"

(29mm)

2-1/8"

(54mm)

25-5/8"

(651mm)

20-1/2"

(520mm)

110deg

6-1/2"

(165mm)

9

Page 16

Figure 9 Overall dimensions with removable coupling

1-1/2"

(38mm)

1-5/16"

(33mm)

1-1/2"

(38mm)

78-3/8"

(1991mm)

80"

(2032mm)

5-7/8"

(149mm)

20-1/2"

(520mm)

110deg

23-1/2" (597mm)

7/8"

(22mm)

27-3/8" (695mm)

6-1/2"

(165mm)

2-1/8"

(54mm)

25-5/8"

(651mm)

27-3/8" (695mm)

Piping is not load-bearing and

should never be used to lift or

move the Liebert XDR.

Mechanical Considerations

4.2 Determining Placement in the Conditioned Space

Refer to site-specific drawings for exact placement. Efficient cooling of the rack equipment depends on

proper placement of equipment, proper use of blanking plates in any voids in the rack, and good cable

management.

The Liebert XDR is engineered to fit the rear of computer enclosure cabinets. Figures 7, 8 and 9

illustrate the module's dimensions and the location of pipes.

Ensure that there is 25.6" (649mm) clearance in the rear to allow the door to open fully.

10

Page 17

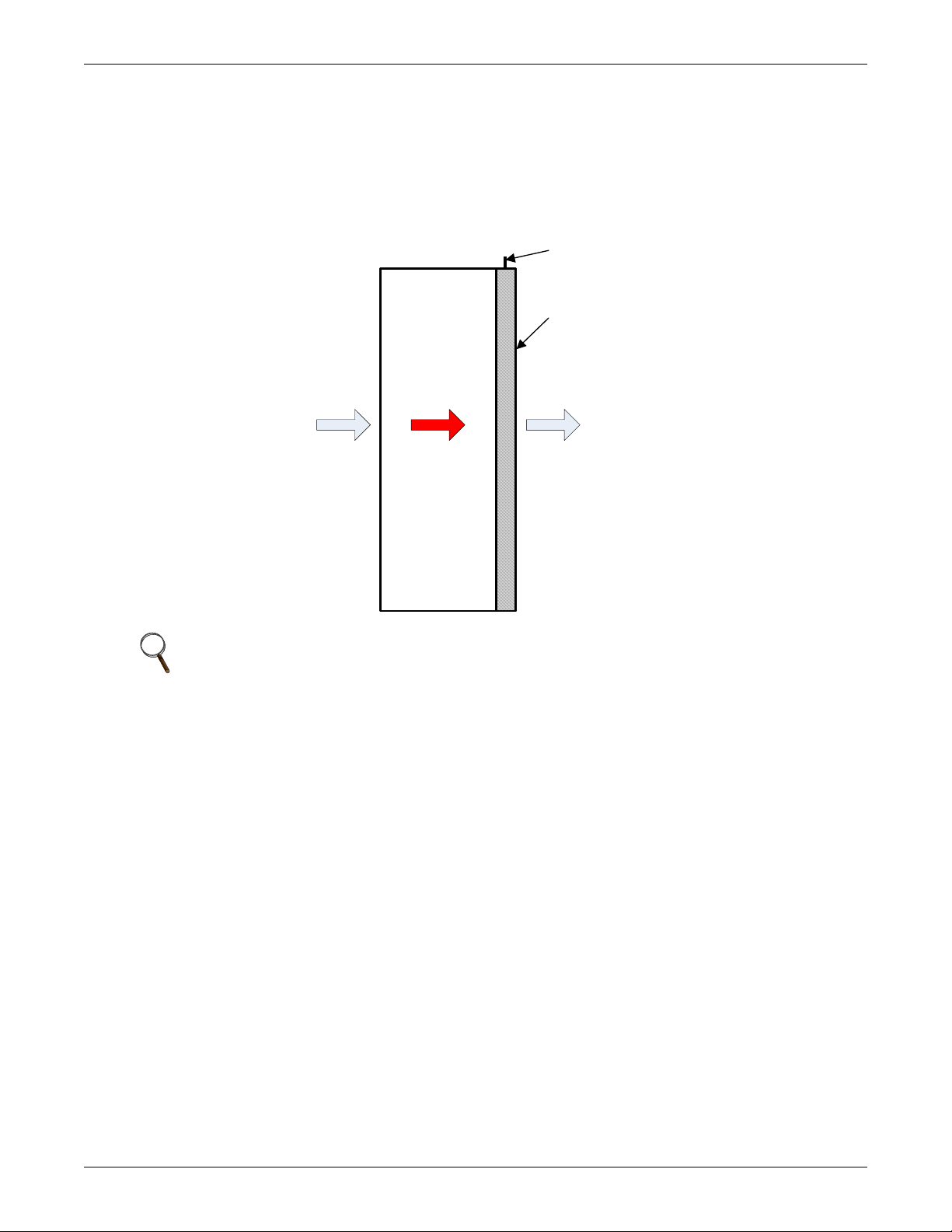

4.3 Airflow

Liebert XDR

Front

of

Rack

Rear

of

Rack

Refrigerant

Connections

Critical

Equipment

Enclosure /Rack

Show n from Side

The server fans draw air into the equipment enclosure. After heated the air, the server fans force the

air across the Liebert XDR’s two coils. The Liebert XDR has a low air-side pressure drop (similar to a

rack with perforated doors). The server fans within the rack create sufficient airflow to move the air.

Figure 10 Generic airflow diagram

Mechanical Considerations

Efficient cooling of rack equipment depends on proper use of blanking plates in any voids in the rack

and good cable management. Keep the Liebert XDR’s coils clear of any obstructions that may block

the airflow.

Each of the Liebert XDR’s coils removes approximately half the load. For even cooling in partially

filled racks, servers should be evenly spaced and blanking plates should be installed on unused rack

spaces to prevent recirculation of heated air.

NOTE

Air bypass and recirculation can severely reduce the cooling effectiveness of the Liebert XDR.

Blanking plates must be installed in any voids in the rack to prevent air bypass and air

recirculation. Contact the factory for further information. Refer to the user manual supplied

with the rack the Liebert XDR is mounted on.

11

Page 18

5.0 INSTALLATION

!

Bolt Holes

(3 on Each Side)

Piping is not load-bearing

and should never be used to

lift or move the Liebert XDR.

Keyhole Slot

(One on Each Side)

Bolt Holes

(3 on Each Side)

Keyhole Slot

(One on Each Side)

5.1 Installing the Rack-Mounting Kit onto the Rack

The Liebert XDR module mounts on the rear of the rack using a mounting kit. The mounting kit

secures the Liebert XDR's frame to the rack. Two rails are attached to the rear of the rack with

M6 x 12 bolts. The number of bolts can vary depending on the rack.

Before beginning to attach the rack-mounting brackets to the rack, remove the rear door from the

rack. Refer to the rack’s installation manual for details.

1. Insert and screw in the M6 x 12mm bolts that shipped with the Rack Connecting Bracket.

2. Tighten the bolts with a 10mm wrench.

5.2 Mounting the Liebert XDR on the Rack-Mounting Kit

WARNING

Risk of 130-pound (59 kg) module falling or causing cabinet to tip over. Can cause equipment

damage, personal injury or death.

• Read all instructions before beginning.

• Use caution when installing the Liebert XDR on an equipment cabinet, particularly a cabinet with little equipment installed. Lack of weight in the cabinet could cause it to tip while

the Liebert XDR is being installed.

• Two properly trained and qualified people are required to handle the Liebert XDR.

• Do not move a cabinet with a Liebert XDR installed on it.

Installation

The rack-mounting brackets must be mounted on the rack before the Liebert XDR can be installed.

1. Thread one of the provided M6x12 bolts into the top threaded hole of each rail attached to the

rack.

2. Use fingers or a 10mm wrench to tighten the bolts, leaving a 1/8" (3-4mm) gap between the bolt

heads and the rail. This gap is necessary to allow the door to fit over the bolts and hang safely on

the rack.

3. With another person, lift the Liebert XDR by the handles on the sides, match the two keyhole

slots near the top of the Liebert XDR frame to the bolts and hang the Liebert XDR on the rack.

4. Thread the remaining bolts through the holes in the frame and into the mounting rails.

5. Tighten all of the bolts snugly with a 10mm wrench.

Figure 11 Liebert XDR mounting locations

12

Page 19

5.3 Door Safety Catch

The door safety catch prevents the door from opening beyond 110°. When the door is fully open, the

safety catch will hold door in place. To release the door, push up on the door catch and close the door.

Installation

13

Page 20

6.0 PIPING

Return

Supply

Liebert XD P /

Liebert XDC A

Liebert

XDR A

Liebert

XDR B

TOP VIEW

Return

Supply

Liebert XD P /

Liebert XDC B

NOTE: Line size does NOT

indicate pipe size difference .

Liebert

XDR B

Liebert

XDR B

Liebert

XDR B

Liebert

XDR A

Liebert

XDR A

Liebert

XDR A

DRAWING IS

NOT TO SCALE

Refer to site-specific drawings for general locations of the piping connections. The drawings should

specify where the piping connects to the Liebert XDR.

6.1 European Union Fluorinated Greenhouse Gas Requirements

Stationary air conditioning, refrigeration, heat pump equipment and stationary fire protection systems in the European Community market and operating with fluorinated greenhouse gases (f-gas),

such as R407C, R-134a, R410A, must comply with the F-Gas Regulation: (EC) No. 842/2006 (F-gas).

The regulation prohibits, among other actions, venting fluorinated greenhouse gases to the atmosphere.

The F-Gas Regulation requires operators to use all measures that are technically feasible and do not

entail disproportionate cost to prevent leakage of these gases, to test for leakage regularly and to

recover f-gas before disposing of equipment, as well as during service and maintenance.

Refer to the full regulation for additional details.

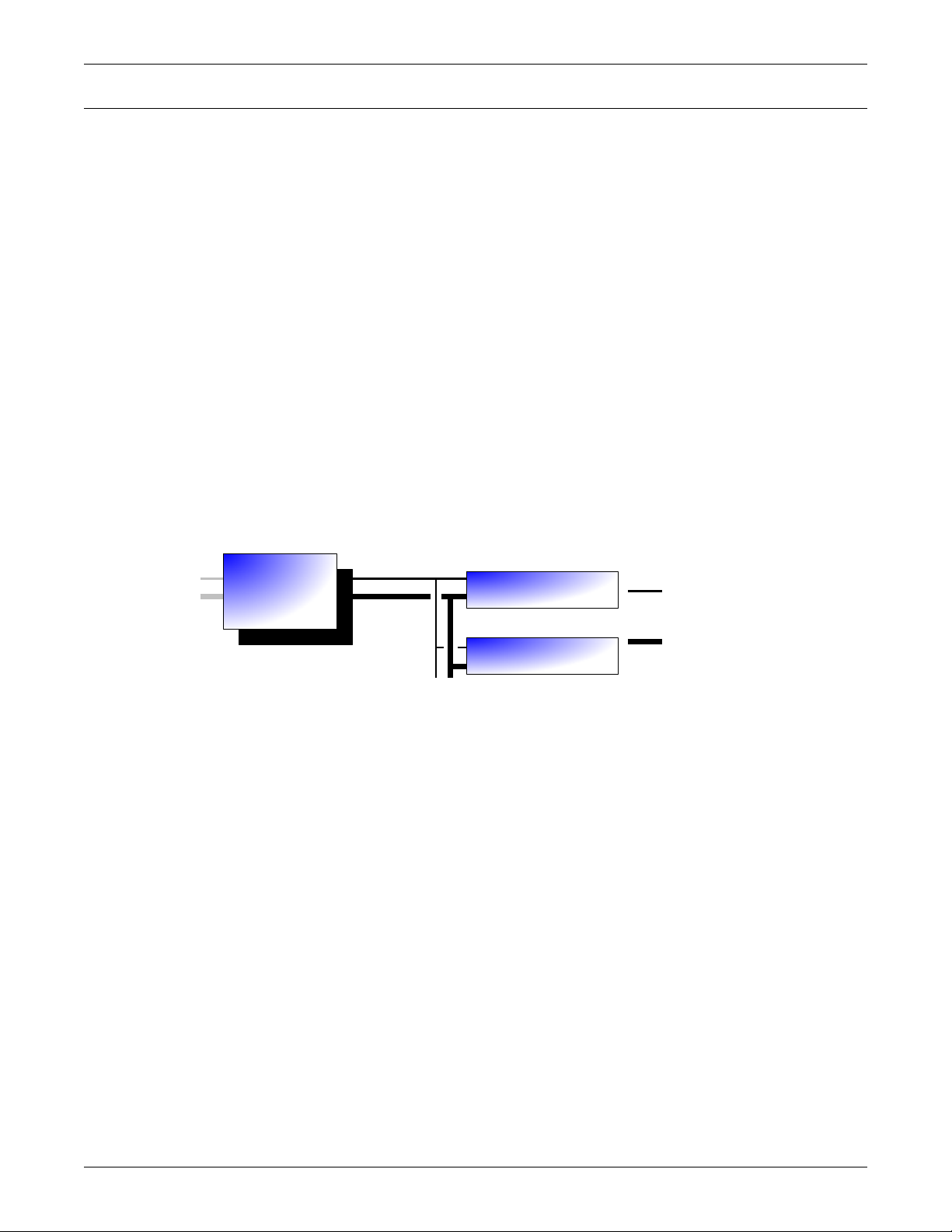

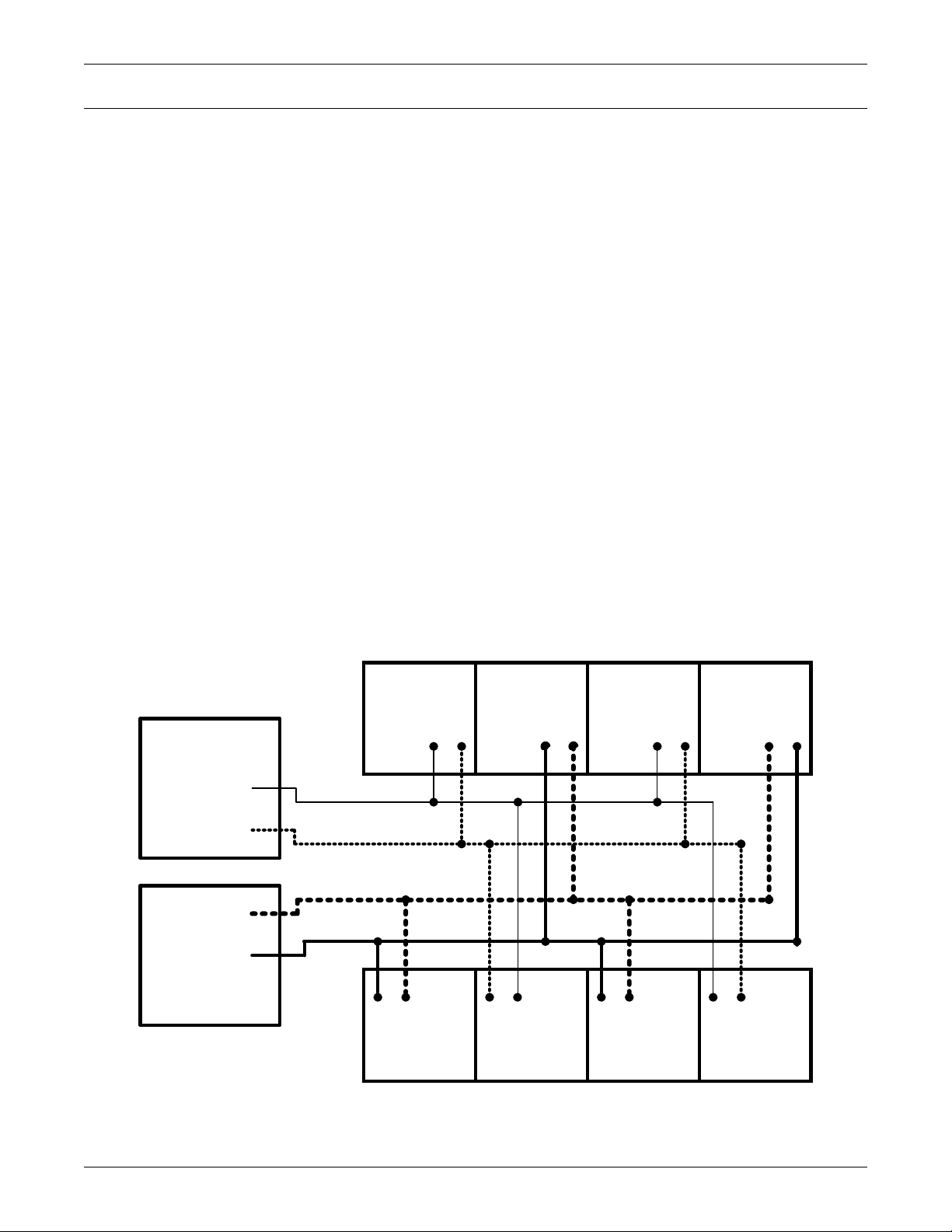

6.2 System Connection Configuration

If possible, connect the Liebert XDR modules to Liebert XDPs or Liebert XDCs in an interlaced

configuration (see Figure 12). In an interlaced configuration, half the cooling modules in an aisle are

connected to one Liebert XDP or Liebert XDC and the other half in that aisle are connected to another

Liebert XDP or Liebert XDC. Interlacing the connection piping will keep half the Liebert XDR

modules operating and maintain cooling in the conditioned space should one of the Liebert XDP or

Liebert XDC units fail.

However, if this is not possible, connect the Liebert XDR modules in a non-interlaced configuration

(see Figure 13).

Piping

Figure 12 Typical Liebert XDR piping—interlaced connections

14

Page 21

Figure 13 Typical Liebert XDR piping—non-interlaced connection

TOP VIEW

Return

Supply

Liebert XDP /

Liebert XDC A

Liebert XDR A

Liebert XDR A

Liebert XDR A Liebert XDR A

DRAWING IS

NOT TO SCALE

6.3 Connection Methods and Points

Refer to site specific drawings for general locations of the piping connections. For Liebert XDR connection locations, refer also to Figures 14, 17 and 21.

The assembly and connection means used for piping in the Liebert XD system are the same as those

used in conventional refrigeration systems. Observe all standard practices during installation and

startup to prevent damage and contamination. All piping must be ASTM Type ACR copper.

The Liebert XDR has supply and return piping access on the top of each module. Supply piping connection is 1/2" OD copper pipe, and return piping connection is 7/8" OD copper. The hard-piped Liebert XDR has a low-pressure nitrogen holding charge.

Both supply and return couplings may be supplied with optional one-shot couplings. These couplings

contain pressurized R-134a refrigerant inside the Liebert XDR.

For Liebert XDRs with removable couplings, the supply piping connection is 1/2" OD and the return

piping connection is 7/8" OD. Both the Liebert XDR and the Liebert XD Flex Pipe with removable couplings have a low-pressure nitrogen holding charge.

Piping

6.4 Insulation

6.5 Venting the Holding Charge for Hard-Piped or Removable Liebert XD Flex Pipe

To minimize the possibility of condensation, insulate all piping between the Liebert XDR and the Liebert XDP or Liebert XDC.

Couplings

The Liebert XDR in either hard-piped configuration or with removable couplings is shipped with a

low-pressure holding charge (about 30 psi) of nitrogen to prevent oxidation and moisture. This must be

vented from the refrigeration circuit before removing the copper cap.

NOTE

This procedure is for modules with hard-piped or removable couplings ONLY. Do not vent a

pre-charged Liebert XDR or pre-charged Liebert XD Flex Piping.

To vent the holding charge:

1. Find the Schrader valve that retains the nitrogen holding charge in the Liebert XDR. The valve is

inside the rear door, on the supply line (see Figure 14 for hard-piped connections and Figure 22

for removable couplings).

2. Vent the holding charge in the circuit by depressing the pin in the Schrader valve on the supply

line.

3. Replace and secure the cap on the Schrader valve that was opened.

15

Page 22

6.5.1 Brazing Preparations

5-7 /8"

(149mm)

1-1/ 2"

(38mm)

2-1/8"

(54mm)

1-1/8"

(29mm)

6-1/2"

(165mm)

TOP VIEW

(Rear of C abinet )

Re frigerant

Supply Line

Schrader Valve

23-1/2" (597mm)

Refrigerant

Return Line

1-5/16"

(33mm)

The assembly and connection means used for piping in the Liebert XD system are similar to those

used for conventional refrigeration systems. All piping should be installed with high-temperature

brazed joints. Soft soldering is not recommended.

After the holding charge has been vented and before brazing, wrap a wet rag around the copper connections before removing the caps to prevent internal component damage. A torch can be used to

remove the caps over the ends of the supply and return lines.

During brazing, the lines must be filled with flowing dry nitrogen to prevent excessive oxidation and scale

formation inside the piping. Prevailing good refrigeration practices must be employed for piping supports,

leak testing, dehydration and charging. Failure to use good system practices may result in damage to the

system. Refer to the ASHRAE refrigeration handbook for general good-practice refrigeration.

6.5.2 Recommended Piping Size

Connect the main pipes between the Liebert XDR branch piping and the Liebert XDP or Liebert XDC

according to Table 1. Elbows and restrictions must be minimized to ensure good fluid flow.

See Table 1 below for recommended pipe sizes and Figure 3 for piping segment locations.

Table 1 Branch piping sizes for pumped refrigerant loop

Pipe Function Size / Equivalent Pipe Length

From Liebert XDR supply to supply line of

Liebert XDP/Liebert XDC

From Liebert XDR return to return line of

Liebert XDP/Liebert XDC

1/2" OD (0.430" ID) for lengths up to 10 feet (3m)

7/8" OD (0.545" ID) for lengths over 10 feet but less than 25 feet (3-7.6m)

7/8" OD (0.545" ID) for lengths up to 10 feet (3m)

1-1/8" OD (1.025" ID) for lengths over 10 but less than 25 feet (3-7.6m)

Piping

NOTE

To minimize the amount of pumped refrigerant required, do NOT oversize the piping.

See Figure 14 for piping recommendations for hard-piping between the Liebert XDR and the header

system.

6.6 Hard-Piped Connection Sizes

The supply piping for the refrigeration circuit is 1/2" OD copper pipe. The return piping for the circuit

is 7/8" OD copper.

The Liebert XDR modules that are intended for hard-piping connections will have copper caps soldered in place and a holding charge of nitrogen.

Figure 14 Piping location and connection sizes—modules with hard-piped connections

16

Page 23

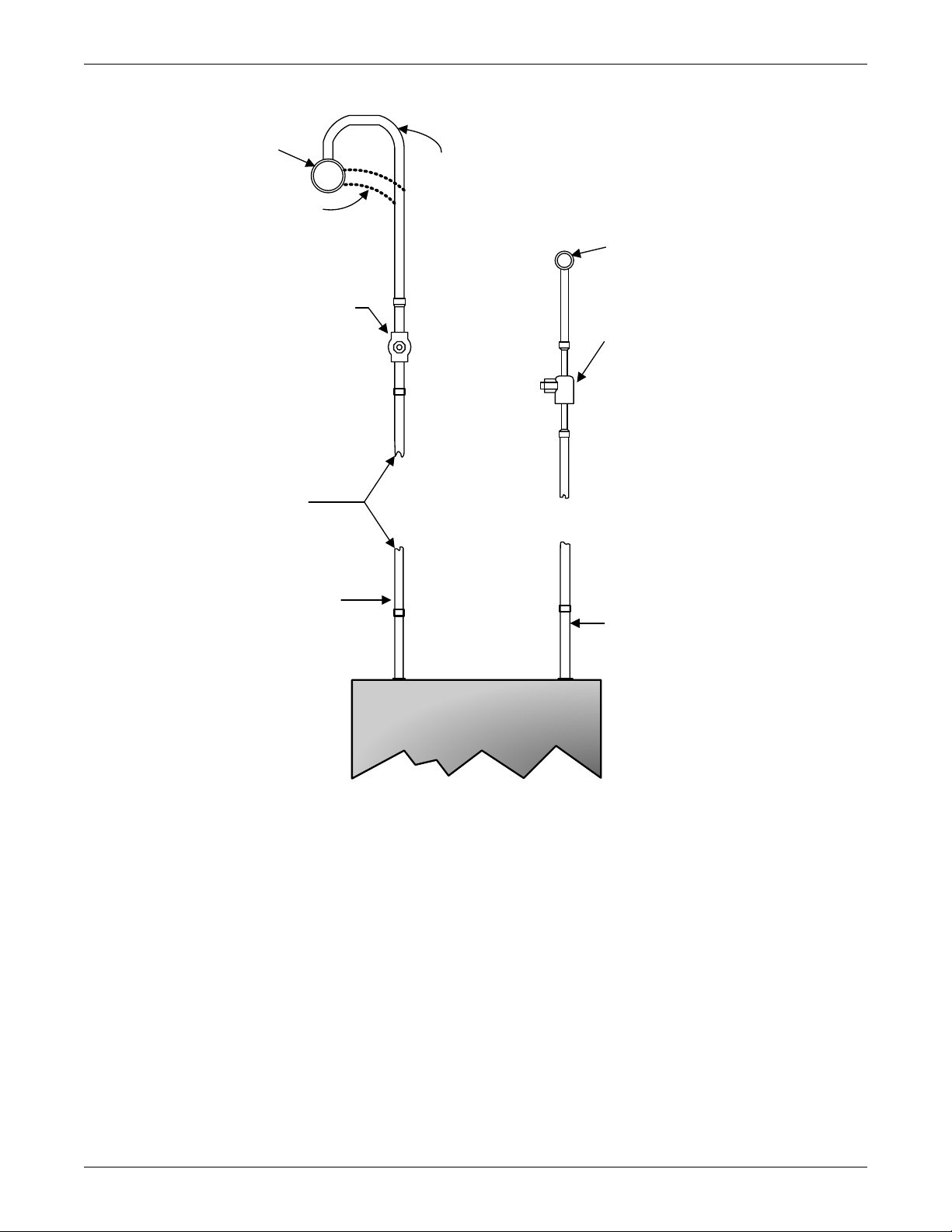

Figure 15 Hard pipe connection diagram

Top of

Liebert XDR

and

Equipment

Rack

Return Main

(seen from end )

2-1/8" O.D.

or 2-5/8" O.D .

Rec ommended Arc

Acceptable

Arc

Copper Tubing

Total length of each line

from Liebert XDR to

Main not to exceed 72 "

(1829 mm)

7/8” Refrigerant -Grade

Full-Port Ball Valve

Field-Supplied and

Field-Installed

Return from

Cooling Module

Supply Main

(seen from end )

1-1/8" O.D.

or 1-3/8" O.D.

1/2” Refrigerant - Grade

Full-Port Ball Valve

Field-Supplied and

Field- Installed

Supply

to Cooling

Module

Rear of

Equipment Rack

Refer to Table 1 for details.

Piping

6.6.1 Leak-Checking and Evacuation

Refer to the Liebert XDC or Liebert XDP user manual for procedures for evacuation, leak check,

charging and startup.

6.6.2 Header System

The Liebert XDR module system with optional flexible piping requires use of the Liebert XD prefabricated piping assembly. The prefabricated piping is compatible with the Liebert XD Flex Pipe required

to attach to the Liebert XDR modules. For the details on piping connection locations, see Figure 14.

For additional information, refer to the Liebert X-treme Density System Design Manual, SL-16655,

available at the Liebert Web site: www.liebert.com

17

Page 24

6.7 Field Installation of Liebert XD Flex Pipe Kit on Liebert XDR

Connection

to Prefabricated

Piping assembly

Straight Connection

90-Degree

Connection

Connection to Liebert XD Cooling Module

Length

4, 6, 8 or 10 feet

(1.2, 1.8, 2.4 or 3 meters)

Connection

to Prefabricated

Piping assembly

90° Connection to Liebert XD

Cooling Module

DPN000780

Length

4, 6, 8 or 10 feet

(1.2, 1.8, 2.4 or 3 meters)

If you are not performing a service installation or a field-retrofit, skip this section and proceed with

the instructions in 6.7.2 - Connect a Liebert XDR with One-Shot Couplings to Liebert XD Flex

Pipe.

Liebert XD Flex Pipe kits are available in lengths of 4, 6, 8 and 10 feet (1.2, 1.8, 2.4 and 3 meters).

Connection style to the module end may be straight or 90 degrees with one-shot or removable couplings. Connection to the prefab piping assembly is a threaded coupling. For data on acquiring the

correct kit for your installation, see Table 8.

The Liebert XD Flex Pipe should be connected to the Liebert XD module then to the header system to

ease installation and prevent twisting the flex pipe.

Figure 16 Liebert XD Flex Pipe dimensions—straight and 90-degree connections

Piping

18

Page 25

6.7.1 Connecting Methods—One-Shot Couplings for Pre-Charged Refrigerant Option

!

5-7 /8"

(149mm)

1-1/ 2"

(38mm)

2-1/ 8"

(54mm)

1-1/8"

(29mm)

6-1/2"

(165mm)

TOP VIEW

(Rear of Cabinet )

Refrigerant

Supply Line

Schrader Valve

(Do Not Vent)

23-1/2" (597mm)

Refrigerant

Return Li ne

1-5/16"

(33mm)

CAUTION

Risk of sudden refrigerant discharge. Can cause loss of charge and minor injury.

If the optional pre-charged option is chosen, the Liebert XDR is shipped with a full charge of

R-134a refrigerant under pressure. Do not remove the pipe caps or plugs before the module is

ready for connection to Liebert XD Piping.

Supply and return fittings on the pre-charged Liebert XDR modules are one-shot couplings.

Do not disconnect one-shot couplings after they have been connected. Disconnection will

release pressurized R-134a refrigerant from the Liebert XDR.

Liebert XDRs with the pre-charged option are equipped with one-shot couplings on the supply and

return fittings. These contain a charge of R-134a refrigerant under pressure within the module. This

charge must not be vented.

Do not remove the pipe caps or plugs before the module is ready for connection to Liebert XD Piping.

Do not disconnect one-shot Liebert XD Flex Pipes after they have been connected.

The assembly and connection means used for piping in the Liebert XD system are the same as those

used in conventional refrigeration systems. Observe all standard practices during installation and

startup to prevent damage and contamination.

Both supply and return fittings may be supplied with optional, one-shot couplings. These fittings contain pressurized R-134a refrigerant inside the Liebert XDR.

Piping

If the module includes the optional, factory-installed, one-shot style couplings, proceed with 6.7.2 Connect a Liebert XDR with One-Shot Couplings to Liebert XD Flex Pipe and see Figure 17.

If the module does not include Liebert Flex Pipes, refer to 6.5 - Venting the Holding Charge for

Hard-Piped or Removable Liebert XD Flex Pipe Couplings.

Figure 17 Piping location and connection sizes—modules with pre-charged modules

19

Page 26

6.7.2 Connect a Liebert XDR with One-Shot Couplings to Liebert XD Flex Pipe

Oil Rubber Seal

and Face of Diaphragm

Coupling Size

Marking on Lip

of Coupling

Schrader

Valve

NOTICE

Risk of improper reuse of Liebert XD Flex Pipes with one-shot couplings. Can cause

refrigerant leaks.

Liebert XD Flex Pipes with one-shot couplings must not be removed from the Liebert XDR

unless they are being replaced with Liebert XD Flex Pipes with one-shot couplings. Do not

reuse Liebert XD Flex Pipes with one-shot couplings. Reuse may result in refrigerant leaks.

Tools Required

• Two adjustable wrenches with a maximum adjustment size of 2 inches

• One torque wrench, half-inch drive (see Table 2 for sizes)

• Refrigerant oil

1. Check the Liebert XD Flex Pipe for proper length.

2. Remove the protector cap and plug from the connections and carefully wipe the couplings and

threaded surfaces clean.

3. Use a small applicator brush saturated with refrigerant oil to lubricate the entire surface of the

diaphragm and the O-ring. Refer to Figure 18.

Figure 18 Male coupling on Liebert XD cooling module

Piping

If refrigerant oil is not used, an alternate lubricant for this application is a refrigerant-compatible

silicone grease product, such as Dow Corning DC200/60,000 cst.

4. Thread the coupling halves together by hand to ensure that the threads mate properly. Ensure

that the Schrader valve is oriented so that it is accessible for service.

Figure 19 Female one-shot coupling Liebert Flex Pipe: Schrader valve location

20

Page 27

Figure 20 Hex body, union nut on one-shot coupling

Hex BodyUnion Nut

NOTICE

Risk of improper tightening. Can cause equipment damage.

It is imperative that the brass body on the Liebert XD Flex Pipe coupling does not rotate while

the union nut is being tightened. If the brass body rotates, it may damage the Liebert XD Flex

Pipe.

Piping

5. Hold the brass body of the Liebert XD Flex Pipe with a wrench so that it does not rotate and use

the torque wrench to tighten the union nut to the proper value shown in Table 2.

Table 2 Torque and wrench size for connecting Liebert XDR with one-shot couplings to

Liebert XD Flex Pipe

Coupling

Size

#10 (Supply) 1-5/16 (34) 35-45 (13.5-6.2)

#12 (Return) 1-3/8 (35) 50-60 (67.8-88.1)

Wrench Sizes,

in. (mm)

Union Nut

Torque, Union Nut

Only, ft-lb (Nm)

If a torque wrench is not available, continue with the steps below.

6. Tighten the union nut on the Liebert XD Flex Pipe to the coupling on the module with the propersized wrench until a definite resistance is felt, metal-to-metal contact.

7. Use a marker or pen to draw a line lengthwise across the module coupling to the Liebert XD Flex

Pipe. The line should parallel the Liebert XD Flex Pipe.

8. Tighten the nuts an additional one (1) wrench flat (60°), judging the amount by the mark drawn

in Step 7.

21

Page 28

6.7.3 Connection Methods—Removable Couplings

TOP VIEW

(Rear of C abinet )

23-1/2" (597mm)

1-5 /16 "

(33mm)

Re frigerant

Return Line

Schrader Valve

Refrigerant

Supply Line

1-1/2"

(38mm)

7/8"

(22mm)

6-1/2"

(165mm)

2-1 /8"

(54mm)

5-7 /8"

(14 9m m)

The assembly and connection means used for piping in the Liebert XD system are the same as those

used in conventional refrigeration systems. Observe all standard practices during installation and

startup to prevent damage and contamination.

Both supply and return fittings may be supplied with optional, removable couplings.

Figure 21 Piping location and connection sizes—modules with removable couplings

Piping

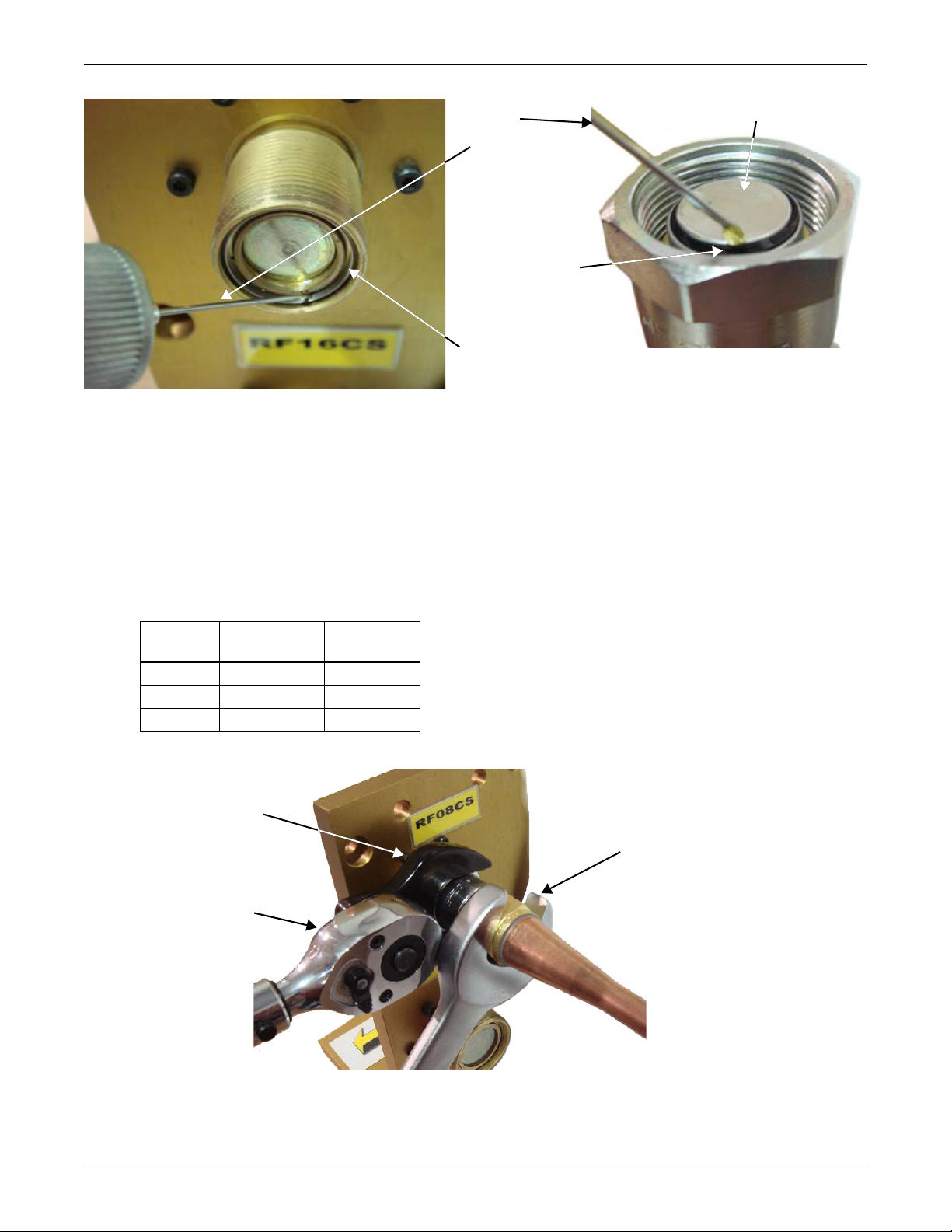

6.7.4 Connect Liebert XD Flex Pipe with Removable Coupling to a Liebert XD Cooling Module

Tools Required

• One adjustable wrench with a maximum adjustment size of 2 inches

• One torque wrench, half-inch drive (see Table 3 for sizes)

1. Check the Liebert XD Flex Pipe for proper length.

2. Remove the protector plugs from the Liebert XD Flex Pipe.

3. Remove the protector cap from the couplings on the module.

4. Wipe the fittings and threaded surfaces clean of particles and other foreign substances.

5. Verify the O-ring is in place on the module coupling.

Should additional O-rings be required, refer to Table 4.

6. Place the Liebert Flex Pipe assembly so that the flat face of the flange on the Liebert XD Flex Pipe

coupling comes into contact with the O-ring on the module coupling.

7. Thread the coupling halves together by hand to ensure that the threads mate properly.

If a torque wrench is not available, continue with the steps below.

Table 3 Torque and wrench sizes for connecting Liebert Flex Pipe to the Liebert XDR with

removable couplings

Wrench Size, in.

(mm)

Union Nut

Torque, Union Nut

Only, ft-lb (Nm)

Coupling

Size, in.

1/2 (Supply) 15/16 (24) 40 (55)

1 (Return) 1-5/8 (41) 110 (150)

8. Hold the Liebert XD Flex Pipe so that is does not rotate and use the torque wrench to tighten the

union nut to the proper value shown in Table 3.

9. Tighten the union nut on the Liebert XD Flex Pipe to the coupling on the module with the

adjustable wrench until a definite resistance is felt.

10. Use a marker or pen to draw a line lengthwise across the module coupling to the Liebert XD Flex

Pipe. The line should parallel the Liebert XD Flex Pipe.

11. Tighten the nuts an additional quarter-turn, judging the amount by the mark drawn in Step 10.

22

Page 29

Figure 22 Removable couplings

Removable Female Coupling on

the end of Liebert XD Flex Pipe

On the Liebert

Flex Pipe

On the Liebert

XD Module

Flange

O-Ring

Table 4 O-ring part number

Liebert Part # Size, in. Fitting

192917P1 1/2 FD57-1224-08-10

192917P2 5/8 FD57-1224-10-11

192917P3 7/8 FD57-1224-14-12

Piping

6.7.5 Connect a Liebert XDR with Liebert XD Flex Pipe to a Liebert XD System

NOTE

Check the entire system for leaks before connecting the Liebert XDR with Liebert XD Flex Pipe

to the prefabricated piping mains.

Read all instructions before beginning installation.

NOTICE

Risk of refrigerant loss. Can cause environmental pollution and equipment malfunction.

Before connecting the Liebert XDR with Liebert XD Flex Pipe to the prefabricated piping

mains, check the whole system for leaks.

Check the Liebert XDR to ensure that the module has no refrigerant leaks.

Read all instructions before beginning installation.

Tools Required

• One adjustable wrench with a maximum adjustment size of 2 inches

• One torque wrench, half-inch drive

• Crowsfoot (supplied with Liebert XDP and Liebert XDC)

• Liebert XDP or Liebert XDC user manual

NOTE

This operation requires two or more people.

1. Determine the port location of the supply and return piping overhead.

2. Make sure the service valve for each port is closed

3. Remove caps from only the required ports. Do not remove caps from the unused ports.

4. Remove the pipe plugs that are supplied on the Liebert XD Flex Pipe.

5. Inspect both halves of the coupling and remove any foreign contamination from the sealing

surfaces and threads before connecting the fittings.

6. Determine the coupling size by locating the number scribed on the Liebert XD Flex Pipe coupling.

See Figure 23.

23

Page 30

Figure 23 Coupling size indicator

Coupling size

indicator

Threaded Cap

(Typical)

Supply Main

Service Valve, typical

(all ports)

Return Main

Headers, Capped

Headers, Connected

Figure 24 Liebert XD prefabricated piping assembly

Piping

7. Use mineral oil or polyol ester oil to lubricate the face of the poppet valve and the seal around the

poppet valve on the female connector (on the Liebert XD Flex Pipe) (see Figure 25).

8. Apply mineral oil or polyol ester oil to the stainless steel delta ring on the male connector (header

port connector) (see Figure 25).

24

Page 31

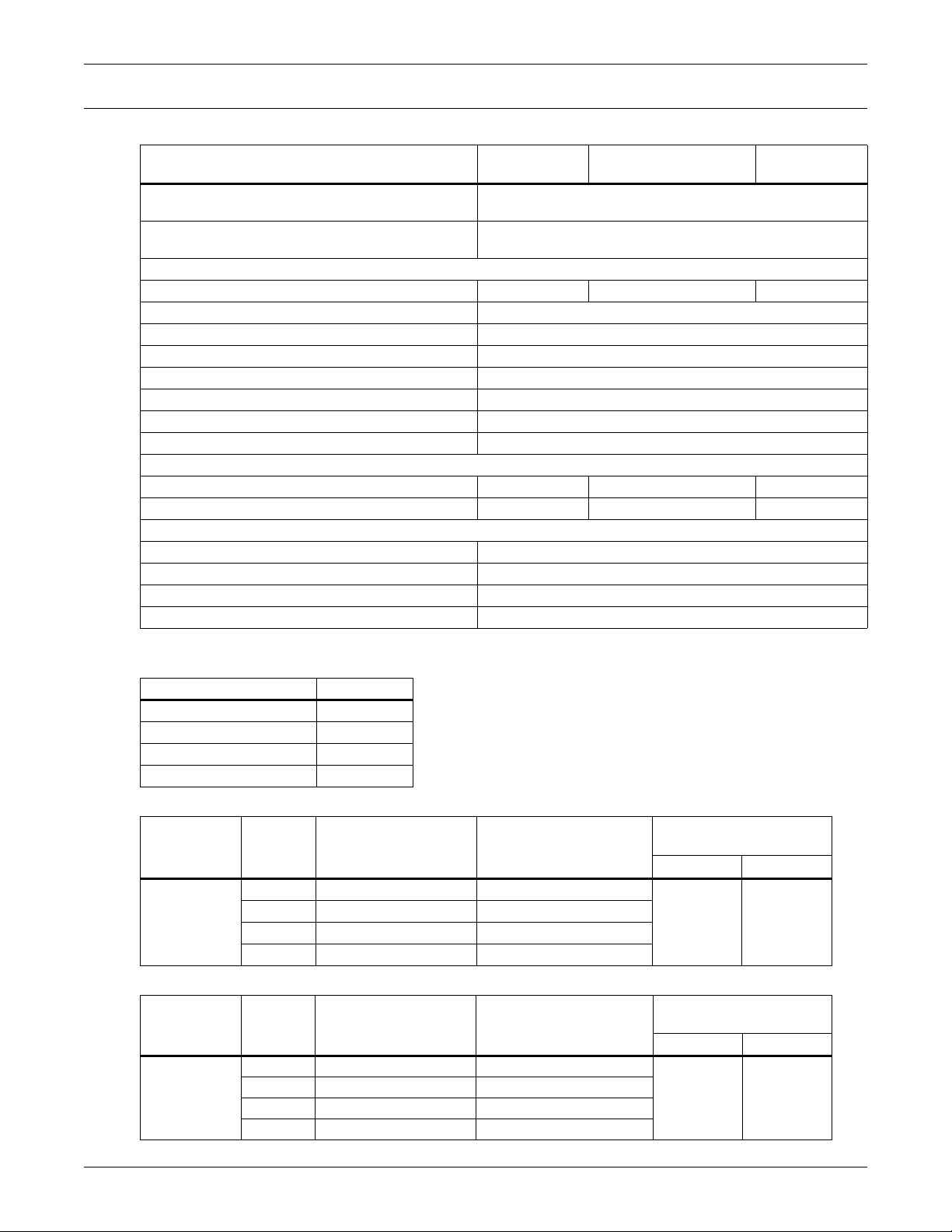

Figure 25 Oil rings on header and Liebert XD Flex Pipe connectors

Stainless Steel Delta Ring

on Header Port Connector

Rubber Ring

Around Poppet

Val ve Fa ce

Oil

Applicator

Spout

Poppet Valve Face

Crowsfoot

Torque Wrench

Wrench holding brass body of

female coupling stationary

to prevent it from turning

9. Thread the union nut of the Liebert XD Flex Pipe coupling onto the port coupling to ensure the

threads mate properly.

10. Using the wrench arrangement shown in Figure 26, torque the couplings to the values in

Table 5.

Piping

NOTICE

Risk of twisted or kinked piping. Can cause flow restriction or leaks.

It is imperative that the brass body of the Liebert XD Flex Pipe coupling does not rotate while

the couplings are being tightened. Failing to do so may damage the female coupling.

Table 5 Torque for connecting Liebert XD Flex Pipe to prefabricated piping

Coupling

Size

RF08 1-3/16 (30) 25.8 (30-35)

RF12 1-5/8 (41) 48.0 (60-65)

RF16 1-31/32 (50) 62.7 (80-85)

Figure 26 Wrench arrangement for tightening couplings

Crowsfoot

Size, in (mm)

Torque,

ft-lb (Nm)

25

Page 32

Figure 27 Detail view of Liebert XD Flex Pipe and prefabricated piping port

Tighten with

torque wrench.

DO NOT

OVERTIGHTEN!

Service Valve

Note: Make sure the valve

is closed before attaching

Liebert XD Flex Pipe to the system.

Hold threaded coupler

here with a wrench to keep

the brass body on

the female connector

from rotating while tightening

collar with a torque wrench.

Flex Pipe

11. Repeat Steps 3 through 10 for the remaining Liebert XD Flex Pipe.

12. For a Liebert XDR module with removable couplings, open the return and then supply service

valves. If the Liebert XDR is pre-charged DO NOT open either of the service valves.

13. Refer to the Liebert XDC or Liebert XDP user manual for procedures for evacuation,

leak check, charging and startup.

Piping

Figure 28 Liebert XD prefabricated piping assembly and Liebert XD Flex Pipe

If adding a one-shot, pre-charged Liebert XD module with one-shot pre-charged Liebert

XD Flex Pipes to an operational Liebert XD system, after connecting to the header system:

1. Open the return service valve.

2. Open the supply service valve.

Return Service Valve

Make sure valve is

open after system

leak check

Supply Service Valve.

Make sure valve is

open after system

Return

Main

Return Liebert

XD Flex Pipe from

Liebert XDR

leak check

Supply Main

Supply Liebert XD Flex Pipe

from Liebert XDR

26

Page 33

6.7.6 Disconnect a Liebert XD Flex Pipe from a Liebert XD System

!

Dust caps attach here

CAUTION

Risk of sudden discharge of pressurized refrigerant. Can cause equipment damage or injury.

Do not disconnect threaded refrigerant couplings at the module cabinet end without relieving

system pressure. Reclaim any refrigerant during removal of module from system.

Tools Required

• Two adjustable wrenches with a maximum adjustment size of 2 inches

1. Close the service valve in the supply line.

2. Ensure there is airflow across the coil.

3. Wait two minutes for the refrigerant to flow out of the module.

4. Close the service valve in the return line.

5. Loosen the Liebert XD Flex Pipe coupling from the header port coupling. This requires a wrench.

Refer to Figure 27.

The Liebert XD Flex Pipe coupling must be held stationary while the union nut on the coupling is

being loosened.

6. Disconnect the coupling.

7. Place the protective dust cap on the port.

8. Place the protective plug back on the Liebert XD Flex Pipe.

9. Repeat Steps 5 through 7 for the remaining Liebert XD Flex Pipe.

Figure 29 Piping mains without Liebert XD Flex Pipe

Piping

27

Page 34

6.7.7 Disconnecting the Liebert XD Flex Pipe from the Liebert XDR

!

NOTICE

Risk of improper reuse of Liebert XD Flex Pipes with one-shot connections. Can cause

refrigerant leaks.

Liebert XD Flex Pipes with one-shot connections must not be removed from the Liebert XDR

unless they are being replaced with Liebert XD Flex Pipes with one-shot couplings. Do not

reuse Liebert XD Flex Pipes with one-shot connections. Reuse may result in refrigerant leaks.

Tools Required

• Two adjustable wrenches with a maximum adjustment size of 2 inches

1. Reclaim the refrigerant in the Liebert XD Flex Pipe and in the module by attaching a refrigerant

reclaim device to the Schrader valve. For help finding the Schrader valve, see Figures 14, 17

and 21.

2. Hold the Liebert XD Flex Pipe so it does not rotate.

For the Liebert XD Flex Pipe with one-shot couplings, additionally, hold the brass body of the cou-

pling so it does not rotate while loosening the couplings. Failing to do so may cause damage.

3. Loosen the Liebert XD Flex Pipe coupling from the module with a wrench.

4. Replace the dust plug on the Liebert XD Flex Pipe.

5. Replace the dust cap on the Liebert XD module.

6. Lay the Liebert XD Flex Pipe with removable couplings aside where it will not be damaged.

Discard or recycle the one-shot Liebert XD Flex Pipes.

Piping

NOTICE

Risk of permanent damage to the Liebert XD Flex Pipes. Do not fold or bend pipe tightly.

6.7.8 Removing the Liebert XDR from a Cabinet

WARNING

Risk of 130-pound (59 kg) module falling. Can cause equipment damage, personal injury or

death.

Removing a Liebert XDR from above a cabinet will require two properly trained and qualified

people. Read all instructions before beginning.

1. Reinstall the four removable installation handles.

2. Loosen the bolts holding the Liebert XDR on the cabinet.

3. With the help of another person, lift the Liebert XDR from the cabinet or hanging bracket onto a

stable surface.

28

Page 35

Installation Checklist and System Fill for Startup

7.0 INSTALLATION CHECKLIST AND SYSTEM FILL FOR STARTUP

7.1 Checklist for Proper Installation

___ 1. Liebert XDR modules are securely attached to the cabinet and aligned properly with the rack.

___ 2. Check to ensure there are no obstructions that prevent the Liebert XDR from opening.

___ 3. Piping from Liebert XDP or Liebert XDC, with isolation valves, is properly connected to each

Liebert XDR module.

___ 4. Liebert XD Flex Pipe couplings to prefabricated header assembly are secure and according to

specifications.

___ 5. System checked for leakage.

___ 6. Check the R-134a refrigerant charge (see the user manual for either the Liebert XDP,

SL-16671 or the Liebert XDC, SL-16644; each is available on the Liebert Web site,

www.liebert.com).

___ 7. Run system and verify that the Liebert XDP or Liebert XDC and the Liebert XDR modules

operate properly.

___ 8. Piping is insulated.

7.2 Charging with Refrigerant

The Liebert XD system must be completely installed before it is charged with refrigerant. After

installation is complete, refer to the Liebert XDP or Liebert XDC user manual for instructions on

charging Liebert XD modules with refrigerant and the starting of the system. The complete Liebert

XD system includes all Liebert XD cooling modules, a Liebert XDC or Liebert XDP and any other connected equipment.

29

Page 36

8.0 STARTING THE LIEBERT XD SYSTEM

Refer to the user manual for the refrigerant supply unit, either a Liebert XDP or Liebert XDC, for

details on starting the system. The Liebert XDP user manual is SL-16644 and the Liebert XDC user

manual is SL-16671. The user manuals were supplied with the units and are available on the Liebert

Web site, www.liebert.com

Starting the Liebert XD System

30

Page 37

9.0 MAINTENANCE

Minimal maintenance is required to keep the Liebert XDR operating at optimal levels. The module

should be cleaned and checked for damage. Suggested maintenance includes:

• Cooling fins—Clean any dust and debris from the cooling fins, taking care not to bend them.

9.1 Fluorinated Greenhouse Gas Requirements

Stationary air conditioning, refrigeration, heat pump equipment and stationary fire protection systems in the European Community market and operating with fluorinated greenhouse gases (f-gas),

such as R407C, R134a, R410A, must comply with the F-Gas Regulation: (EC) No. 842/2006 (F-gas).

The regulation prohibits, among other actions, venting fluorinated greenhouse gases to the atmosphere.

The F-Gas Regulation requires operators to use all measures that are technically feasible and do not

entail disproportionate cost to prevent leakage of these gases, to test for leakage regularly and to

recover f-gas during equipment service and maintenance and before disposing of equipment.

Refer to the full regulation for additional details.

Maintenance

31

Page 38

10.0 SPECIFICATIONS

Table 6 Liebert XDR specifications

Models

Cooling Capacity, Nominal,

rated at 104ºF (40°C) EAT & 2400ft

Conditions

Dimensions, inches (mm)

Height, Including Pipe Connections 82-3/8 (2093) 83-1/2 (2121) 80 (2032)

Max Shipping Depth (4 modules) 62 (1575)

Weight, lb (kg)

Pipe Connections

Exterior Finish Black Matte, Heat-Fused Powder Coat

Safety CSA, CE Approved

* Refer to Figure 2 for the complete part number.

Table 7 Rack mounting kit

Rack Part #

Knurr Miracel 198163G1

Dell PowerEdge 4210 199050G1

HP 10642 199051G1

APC AR3100 199054G1

XDR20B1- *

3

/m (68m3/m)

55°F (13°C) entering fluid temperature

50°F (10°C) or lower dew point

Width With Handles Attached 27-3/8 (695)

Handles Removed 23-1/2 (597)

Depth 6-1/2 (165)

Shipping Length 90 (2286)

Shipping Width 30-1/2 (775)

Shipping Depth 15-1/2 (394)

Module Only 130 (59) 133 (60) 130 (59)

Shipping 225 (103) 228 (104) 225 (103)

Refrigerant Supply 1/2" OD Type ACR

Refrigerant Return 7/8" OD Type ACR

XDR20B1P *

(Pre-Charged R-134a)

20.5 kW (5.8 tons)

Specifications

XDR20B1R *

Table 8 Liebert XD Flex Pipe one-shot assemblies, supply and return

Minimum Bend Radius

Description

Liebert XD

Flex Pipe Kit

Length

ft (m)

10 (3.0) 186566G2 186565G2

8 (2.5) 186566G3 186565G3

6 (1.8) 186566G1 186565G1

4 (1.2) 186566G4 186565G4

Liebert P/N

Straight Connection

Assembly

Liebert P/N

90-Degree

Connection Assembly

Table 9 Liebert XD Flex Pipe removable assemblies, supply and return

Minimum Bend Radius

Description

Liebert XD

Flex Pipe Kit

Length

ft (m)

10 (3.0) 187865G2 187864G2

8 (2.5) 187865G3 187864G3

6 (1.8) 187865G1 187864G1

4 (1.2) 187865G4 187864G4

Liebert P/N

Straight Connection

Assembly

32

Liebert P/N

90-Degree Connection

Assembly

in (mm)

Supply Return

7 (178) 9 (229)

in (mm)

Supply Return

7 (178) 9 (229)

Page 39

Page 40

Ensuring The High Availability

Of Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2009 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert is a registered trademark of Liebert Corporation.

All names referred to are trademarks

or registered trademarks of their respective owners.

SL-16935_REV02_06-10

Technical Support / Service

Web Site

www.liebert.com

Monitoring

liebert.monitoring@emerson.com

800-222-5877

Outside North America: +00800 1155 4499

Single-Phase UPS & Server Cabinets

liebert.upstech@emerson.com

800-222-5877

Outside North America: +00800 1155 4499

Three-Phase UPS & Power Systems

800-543-2378

Outside North America: 614-841-6598

Environmental Systems

800-543-2778

Outside the United States: 614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

29/F, The Orient Square Building

F. Ortigas Jr. Road, Ortigas Center

Pasig City 1605

Philippines

+63 2 687 6615

Fax: +63 2 730 9572

Emerson Network Power.

The global leader in enabling Business-Critical Continuity

AC Power

Connectivity

DC Power

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks of Emerson Electric Co. or one of its affiliated companies.

©2009 Emerson Electric Co.

Embedded Computing

Embedded Power

Infrastructure Management & Monitoring

™

Outside Plant

Power Switching & Controls

Precision Cooling

EmersonNetworkPower.com

Racks & Integrated Cabinets

Services

Surge Protection

Loading...

Loading...