Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert® Challenger™ ITR

Technical Data Manual - Row-Based, Floor-Mounted Nominal 23 or 33kW Systems, Air-Cooled,

Water/Glycol-Cooled, GLYCOOL, Chilled Water, Split Systems, 50 & 60 Hz

Page 2

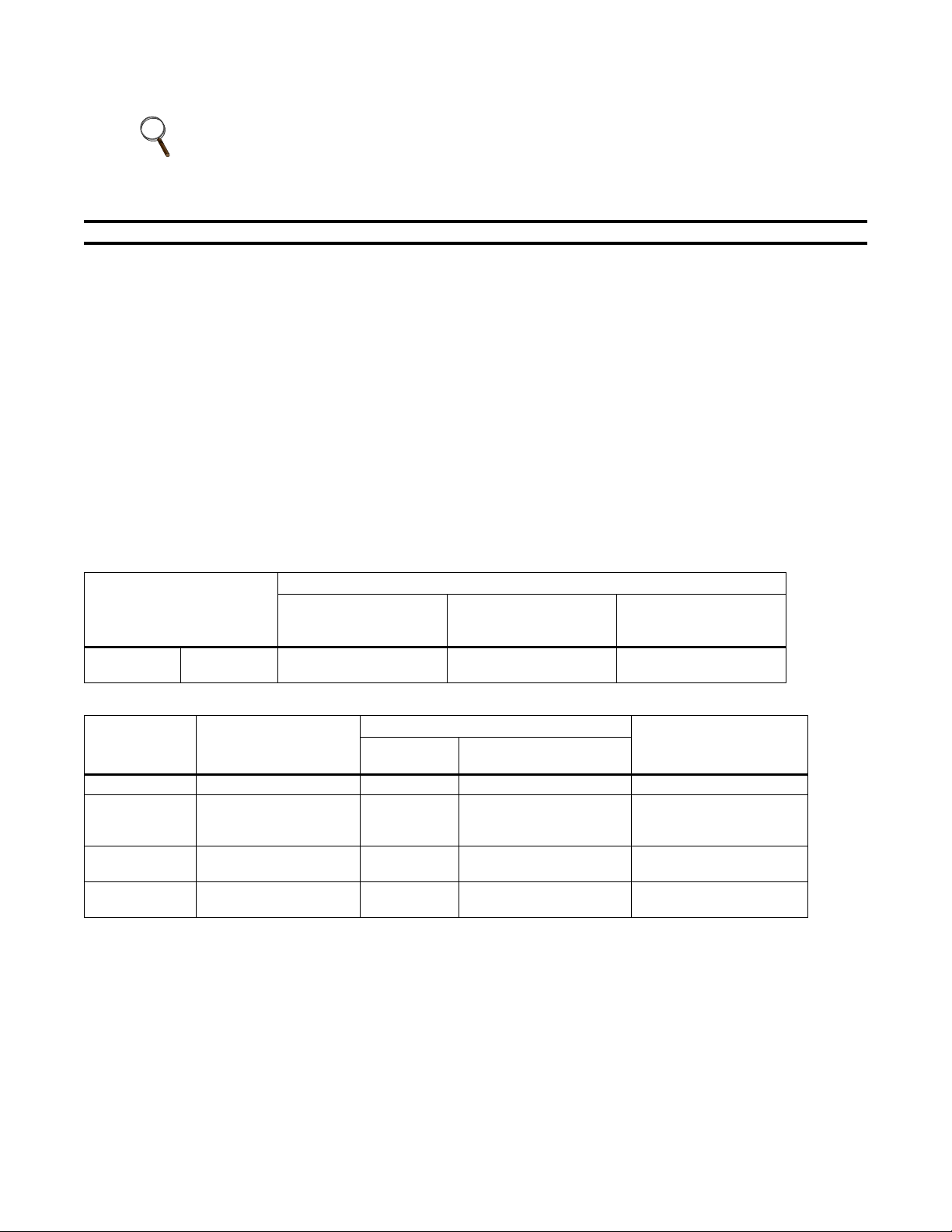

PRODUCT NOMENCLATURE

NOTE

Tables i, ii and iii show nomenclature for the complete range of all available product options.

Not all combinations are possible. For assistance, contact your local dealer, Liebert

representative or call 1-800-543-2778.

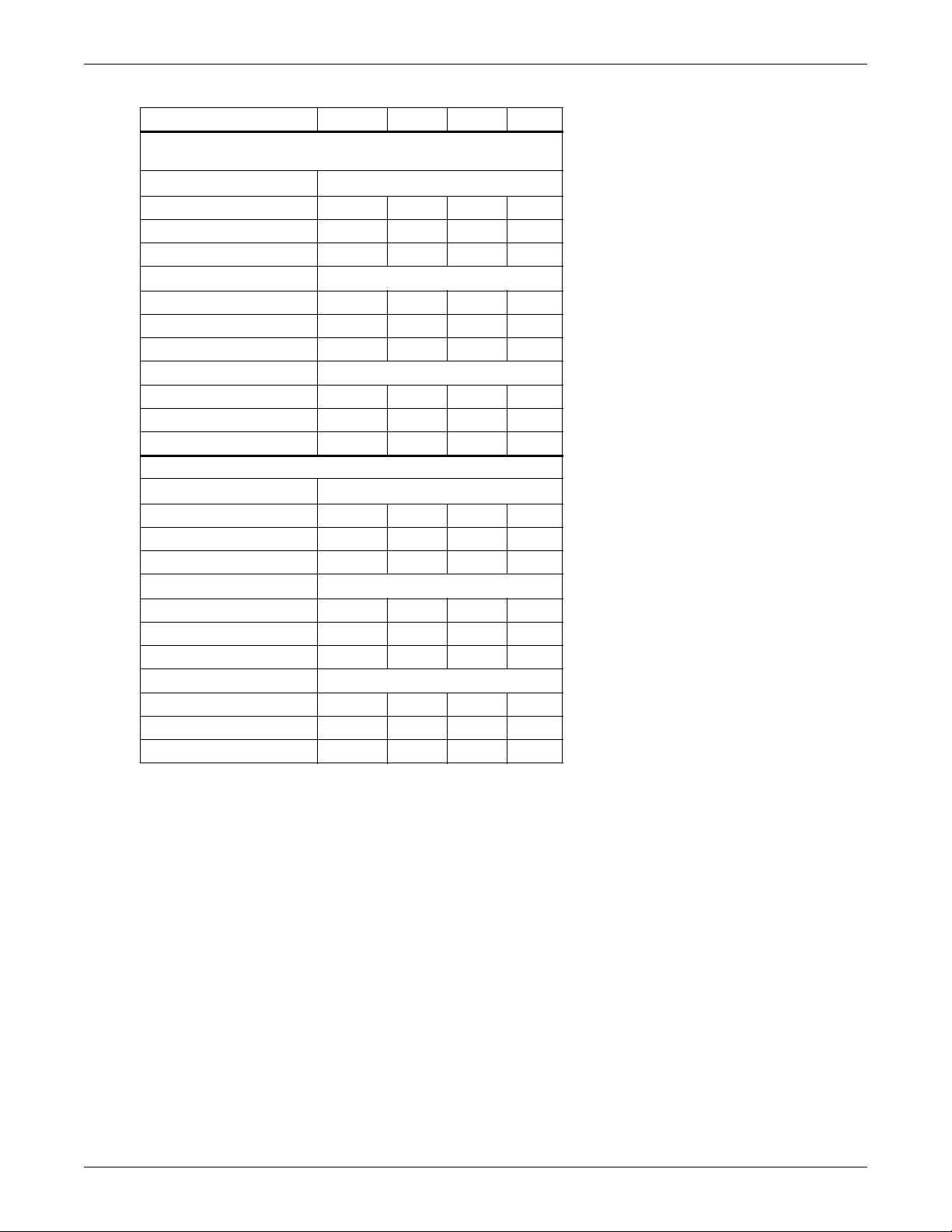

Table i Product model information

B F 042 A — A A E I

Challenger

ITR

H = 230/50/3

M = 380/415/50/3

R = ITR,

Horizontal Flow

M = ITR,

Horizontal Flow

with Econ-O-Coil

Nominal

capacity in

thousand

BTUH

E- = Evaporator C = 208/60/3 H = Hot Water

A-=Air-Cooled A = 460/60/3 A = Advanced

C-= Chilled

Water

G-= GLYCOOL D = 230/60/3 G = Hot Gas

WG = WaterCooled/Glycolcooled

B = 575/60/3 G = Advanced

2 = 380/60/3 S = SCR

J = 200/50/3

Microprocessor

Microprocessor

w/Graphics

0 = No Reheat 0 = No

E = Electric

Reheat

Reheat

Reheat

Reheat

Humidifier

I = Infrared

Humidifier

S = Steam

Generating

Humidifier

Table ii Split system configurations

Condensing Units

Air-Cooled

60 Hz

(50 Hz)

Evaporator

BR060E

(BR059E)

Air-Cooled Prop Fan

Condensing Unit

PFH067A_ _H3

PFH066A_ _H3

Centrifugal

Condensing Unit

MC_65A

(MC_64A)

Water/Glycol

Condensing Unit

MC_69W

(MC_68W)

Table iii Self-contained system configurations

Remote Equipment

Air-Cooled

Frequency Indoor Unit

Condenser Drycooler/Pump

60 Hz (50 Hz) BR067A (BR065A) CS@104 Air-Cooled

DSF112

60 Hz (50 Hz) BR071WG (BR070WG)

3/4 HP Pump 60 Hz

1-1/2 HP Pump 50 Hz

60 Hz (50 Hz) BM061G (BM058G)

DSO112

1-1/2 HP Pump

60 Hz (50 Hz) BR102C (BR101C)

@

F = Fan Speed Control

L = Lee Temp

System Type

Glycol-Cooled or SelfContained - Water-Cooled

GLYCOOL

Self-Contained - Chilled

Water

™

Page 3

TABLE OF CONTENTS

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

1.0 DEDICATED, PRECISE ENVIRONMENTAL CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Air Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Air Filtration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.5 Year Round Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.6 Agency Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 PRECISION ENVIRONMENTAL CONTROL FOR INDUSTRIAL, TELECOMMUNICATIONS,

MEDICAL AND DATA PROCESSING EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Liebert Challenger ITR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Multiple Configurations to Fit a Variety of Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Efficiency in Economic Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 GLYCOOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0 LOCAL MONITORING SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1 Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Control Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Internal System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.7 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.8 Graphical Displays—Advanced Graphic Control Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.0 STANDARD FEATURES—ALL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Cabinet and Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Electrical Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Fan Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Infrared Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 Electric Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.6 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.6.1 Condensate Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.6.2 Remote Temperature/ Humidity Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.6.3 Disconnect Switch—Locking Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.0 CHILLED WATER SYSTEM—STANDARD AND OPTIONAL FEATURES . . . . . . . . . . . . . . . . . . .9

5.1 Chilled Water System—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.1 Cooling Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.2 Modulating Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.3 Line Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.4 Three-Way Control Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

i

Page 4

5.2 Chilled Water System—Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2.1 Chilled Water Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2.2 High Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.0 REFRIGERATION SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.1 Self-Contained Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Split Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3 Refrigeration System Components—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3.1 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3.2 Evaporator Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3.3 Safety Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3.4 Expansion Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.0 AIR-COOLED SYSTEM—STANDARD AND OPTIONAL FEATURES . . . . . . . . . . . . . . . . . . . . . 11

7.1 Air-Cooled, Self-Contained Systems—Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1.1 Pump Down Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1.2 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1.3 Fan Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 Air-Cooled, Self-Contained Systems—Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2.1 Liebert Lee-Temp Winter Control Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2.2 Quiet-Line Condensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3 Air-Cooled Split Systems—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3.1 Centrifugal Fan, Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3.2 Propeller Fan Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3.3 Propeller Fan Condensing Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.4 Air-Cooled Split Systems—Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.0 WATER/GLYCOL-COOLED SYSTEMS—STANDARD AND OPTIONAL FEATURES. . . . . . . . . . . 13

8.1 Water/Glycol Self-Contained Systems—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.2 Water/Glycol-Cooled, Self-Contained System—Optional Features . . . . . . . . . . . . . . . . . . . . 13

8.3 Water/Glycol Split System—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.4 Water/Glycol-Cooled, Split System—Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.4.1 Glycol-Cooled System—Heat Rejection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.4.2 Self-Contained and Split Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.0 GLYCOOL SYSTEMS—STANDARD AND OPTIONAL FEATURES . . . . . . . . . . . . . . . . . . . . .15

9.1 GLYCOOL—Self-Contained Models Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 GLYCOOL System—Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2.1 Comparative Temperature Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2.2 Econ-O-Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2.3 GLYCOOL Three-Way Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2.4 Glycol-Regulating Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2.5 Drycooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3 Glycol and GLYCOOL-Cooled—Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.0 OPTIONAL EQUIPMENT—ALL SYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10.1 Steam Generating Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.2 Adjustable Floor Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ii

Page 5

10.3 SCR Reheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.4 High-Efficiency Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.5 High External Static Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.6 High-Efficiency Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.7 Plenums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.8 Low-Profile Plenum with Cold-Aisle Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.9 Smoke Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.10 Firestat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.11 Hot Water Reheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.0 COMPREHENSIVE MONITORING SYSTEMS—OPTIONAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

11.1 Enterprise Monitoring Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.2 Network Monitoring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.3 Stand-Alone Monitoring and Leak Detection Solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12.0 COMPREHENSIVE MONITORING SOLUTIONS—OPTIONAL . . . . . . . . . . . . . . . . . . . . . . . . . .22

12.1 Liebert SiteScan® Web. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.2 Liebert SiteLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.3 Liebert Nform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.4 Liebert IntelliSlot Web/485 Card With Adapter and Liebert IntelliSlot 485 Card

With Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.5 Environmental Discrete Outputs Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.6 Remote Contact Monitor (RCM4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.7 Auto-Changeover Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.8 Universal Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12.8.1 Leak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12.8.2 Temperature and Humidity Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

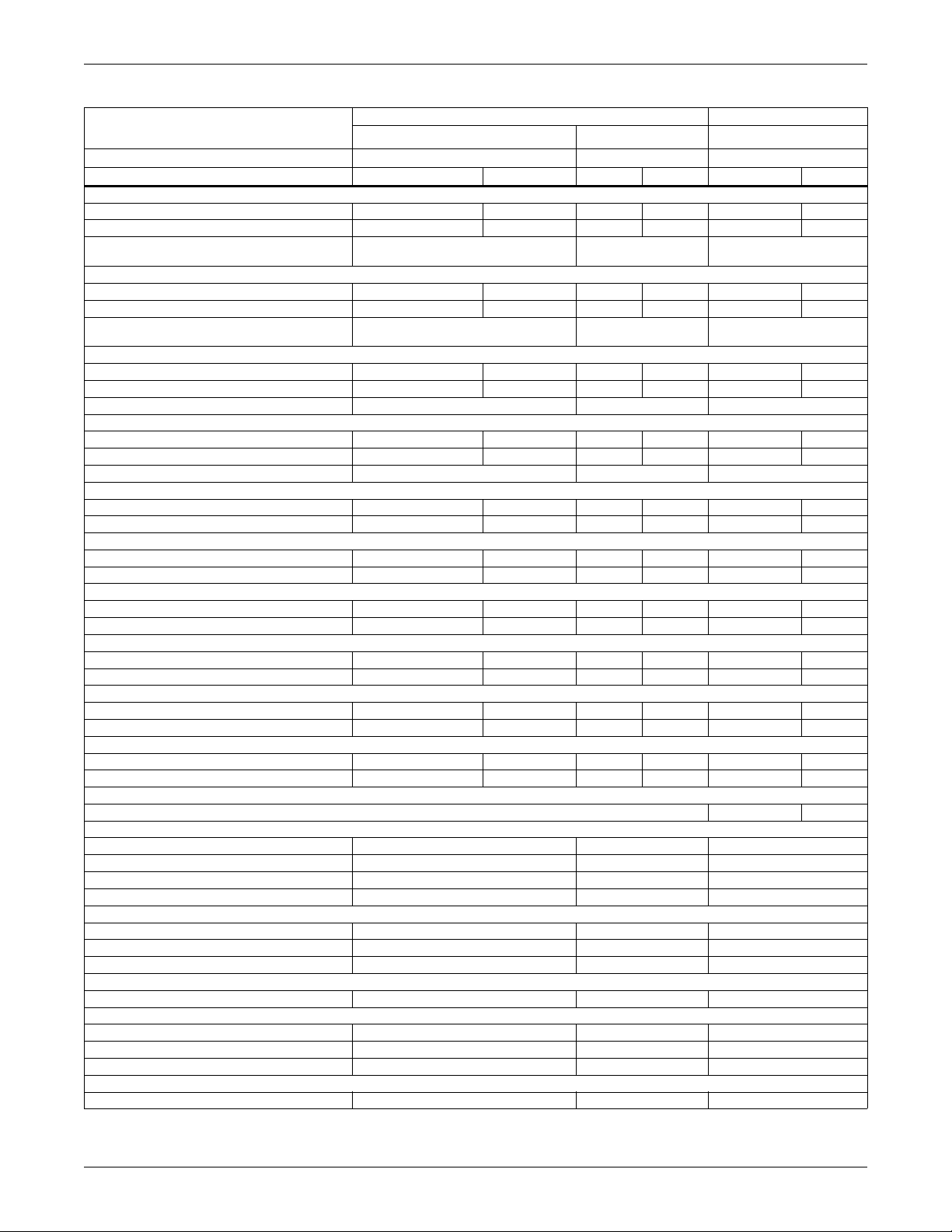

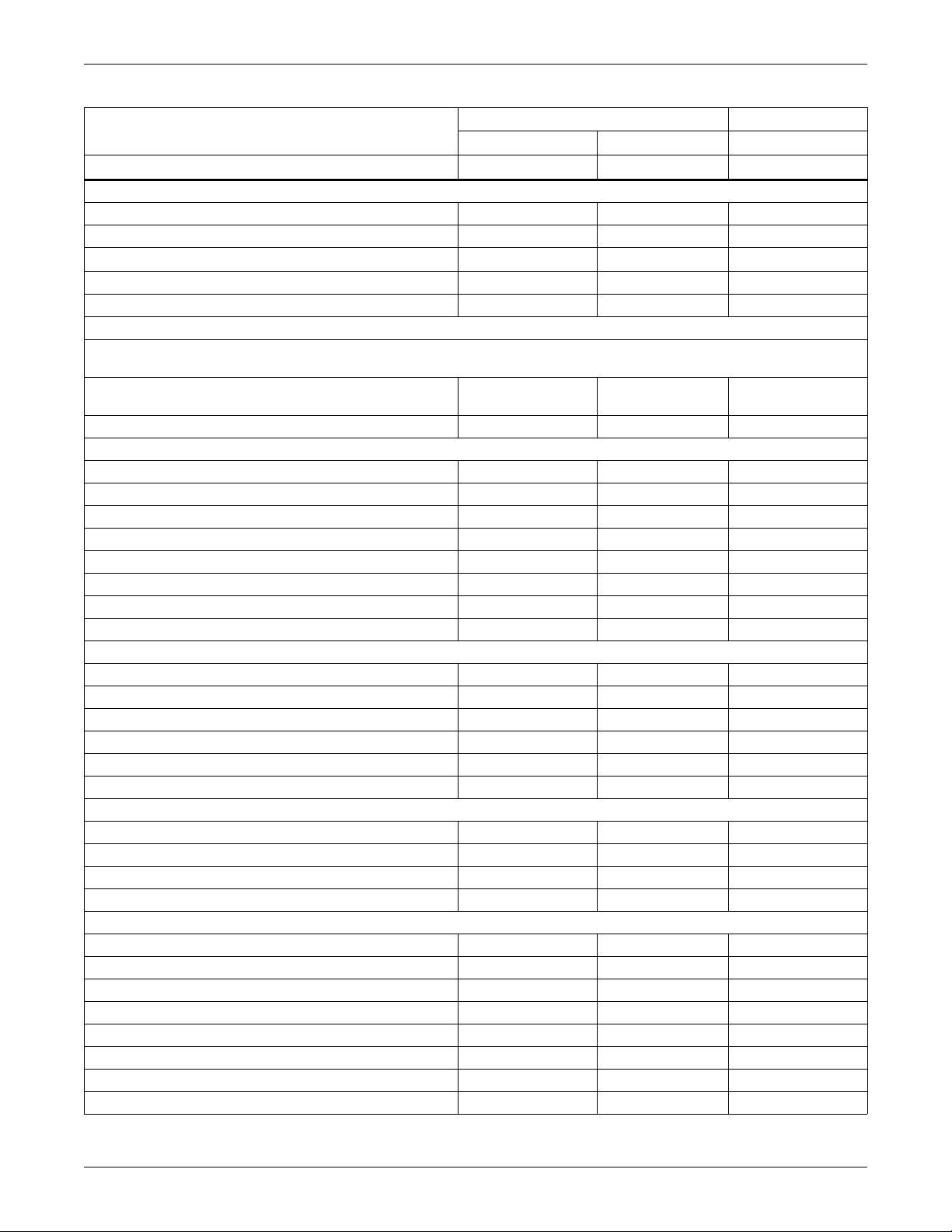

13.0 SYSTEM DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

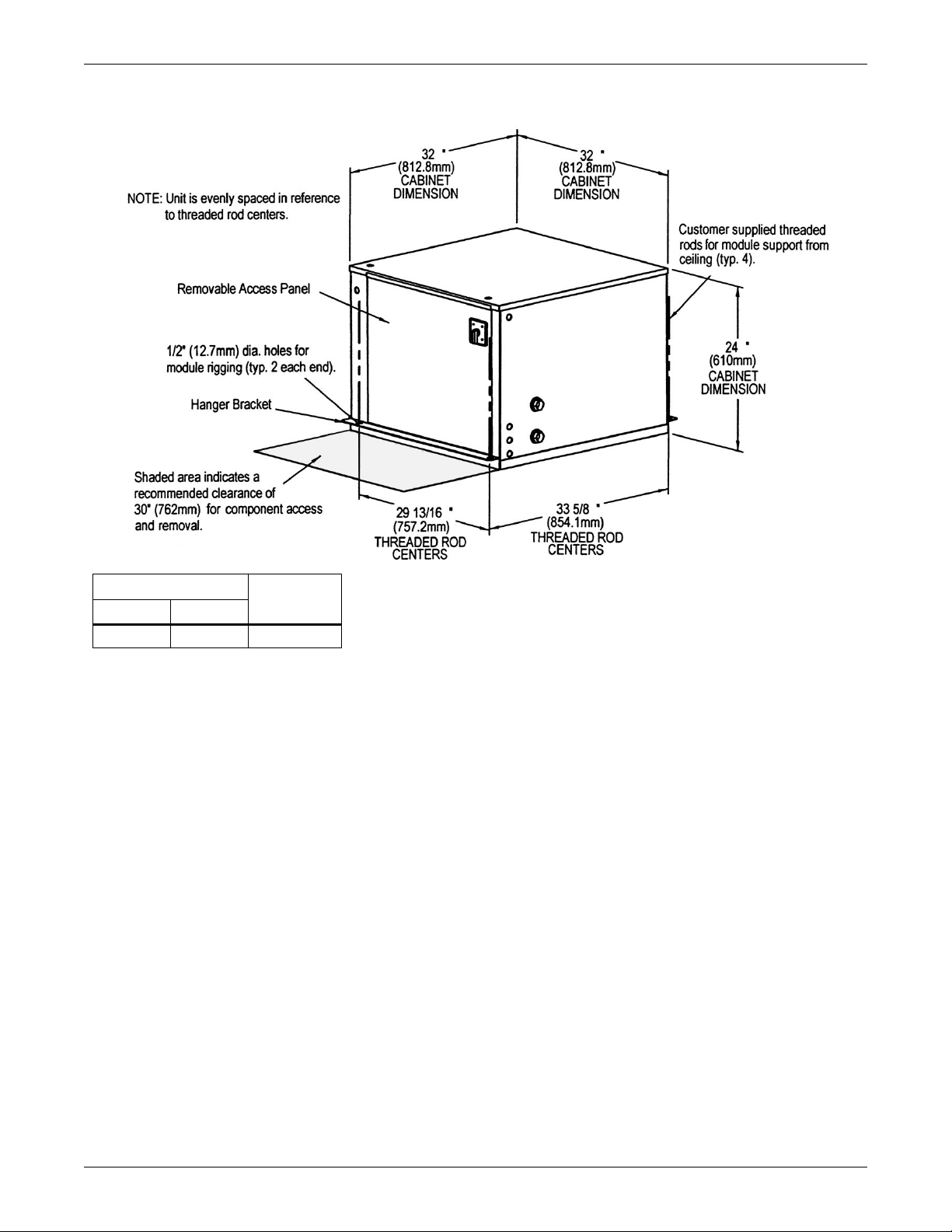

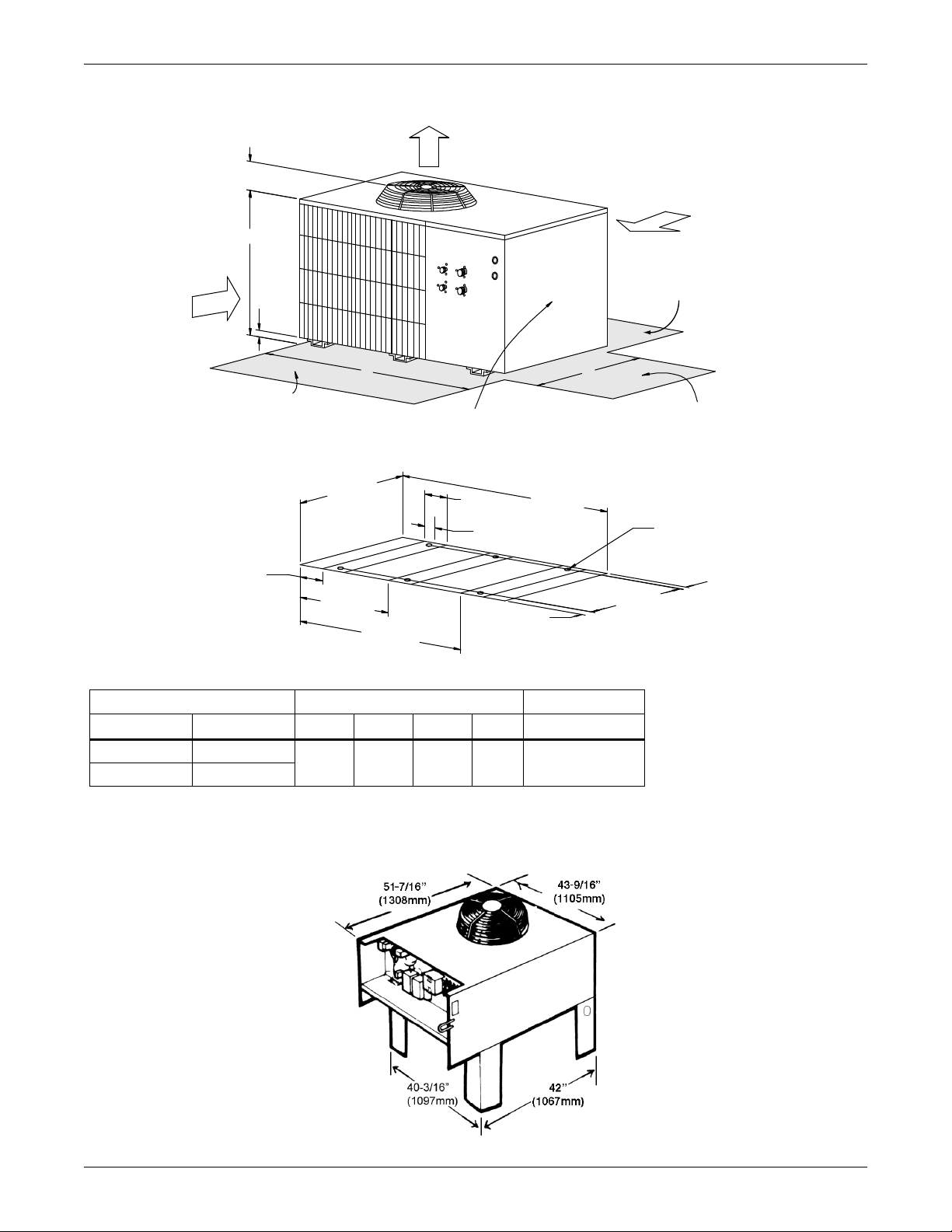

14.0 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

15.0 ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

G

UIDE SPECIFICATIONS—NOMINAL 23 OR 33KW ENVIRONMENTAL CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

iii

Page 6

FIGURES

Figure 1 Unit configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 2 Unit configurations, continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3 Microprocessor control systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4 Optional Views With Advanced Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5 Air-cooled condenser with Liebert Lee-Temp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6 Outdoor propeller fan condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

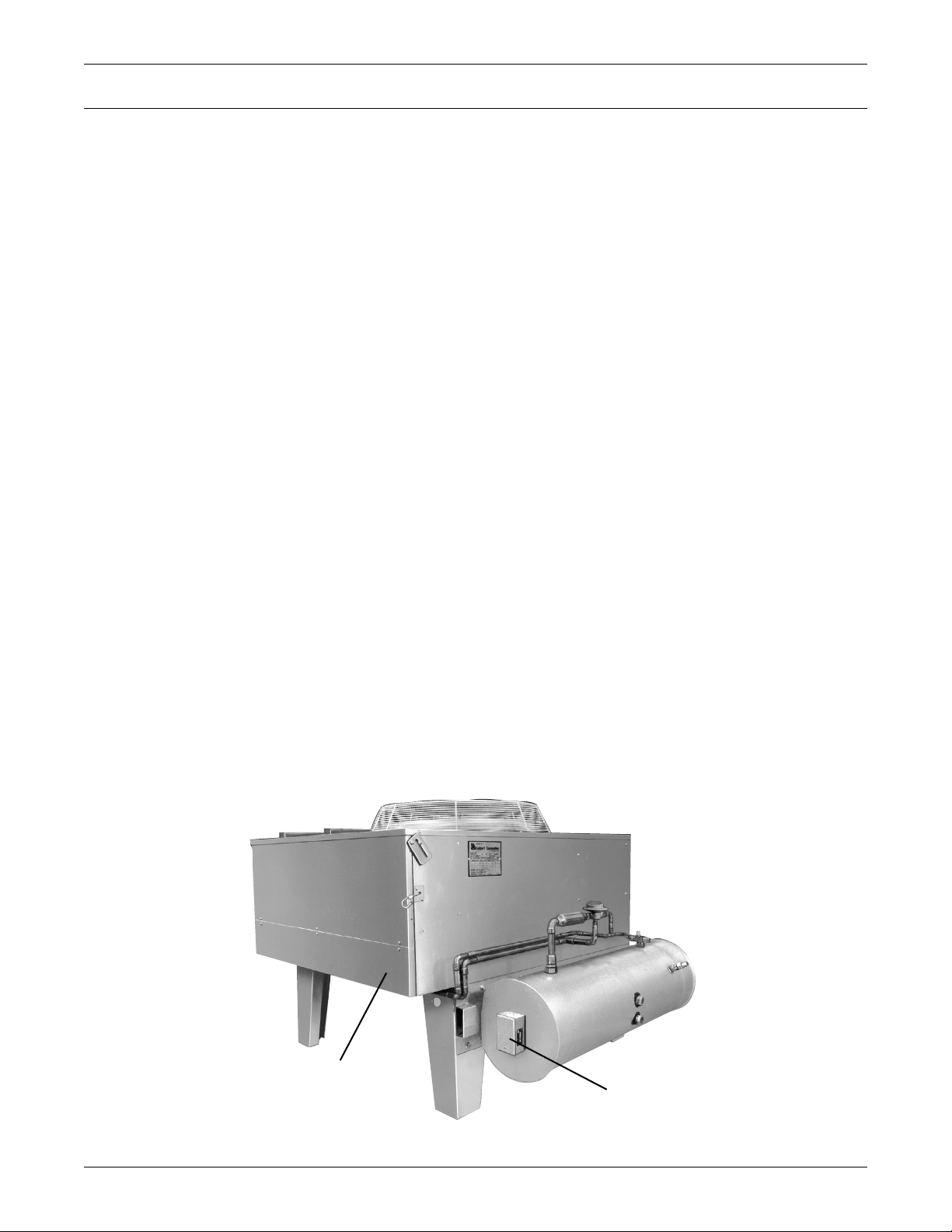

Figure 7 Liebert Challenger ITR unit core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8 Steam generating humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9 Adjustable floor stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10 Monitoring configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

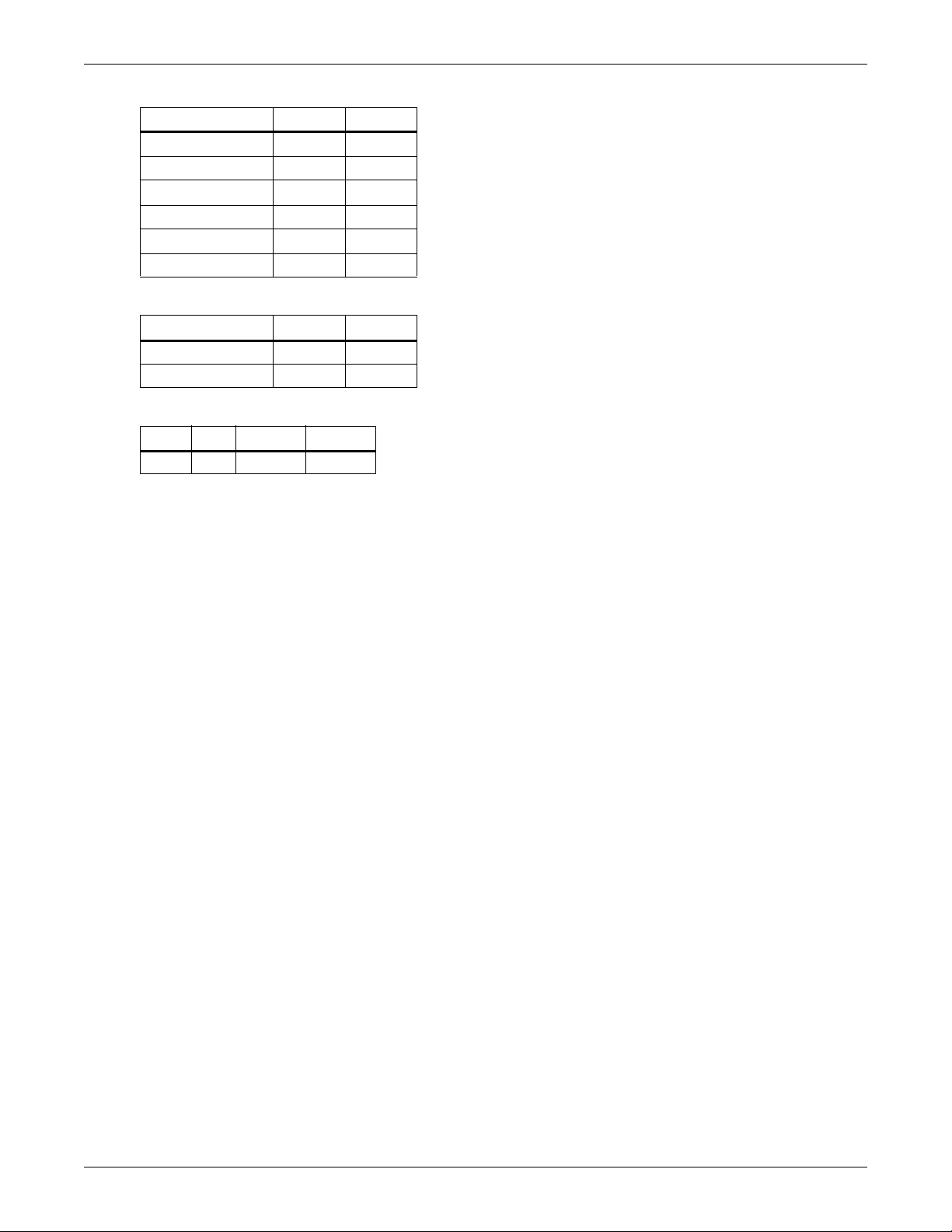

Figure 11 Cabinet and floor planning dimensional data—Horizontal flow models . . . . . . . . . . . . . . . . . . . . 38

Figure 12 Cabinet and floor planning dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 13 Cabinet and floor planning dimensional data—Split system—5-ton centrifugal fan

condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 14 Cabinet and floor planning dimensional data—Split system—5-ton water/glycol-cooled

condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 15 Cabinet and floor planning dimensional data—Split System—Propeller fan condensing

unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 16 Cabinet and floor planning dimensional data—Propeller fan condensing

modules—Vertical air discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 17 Cabinet and floor planning dimensional data—Self-contained system—Air-cooled

condenser or drycooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

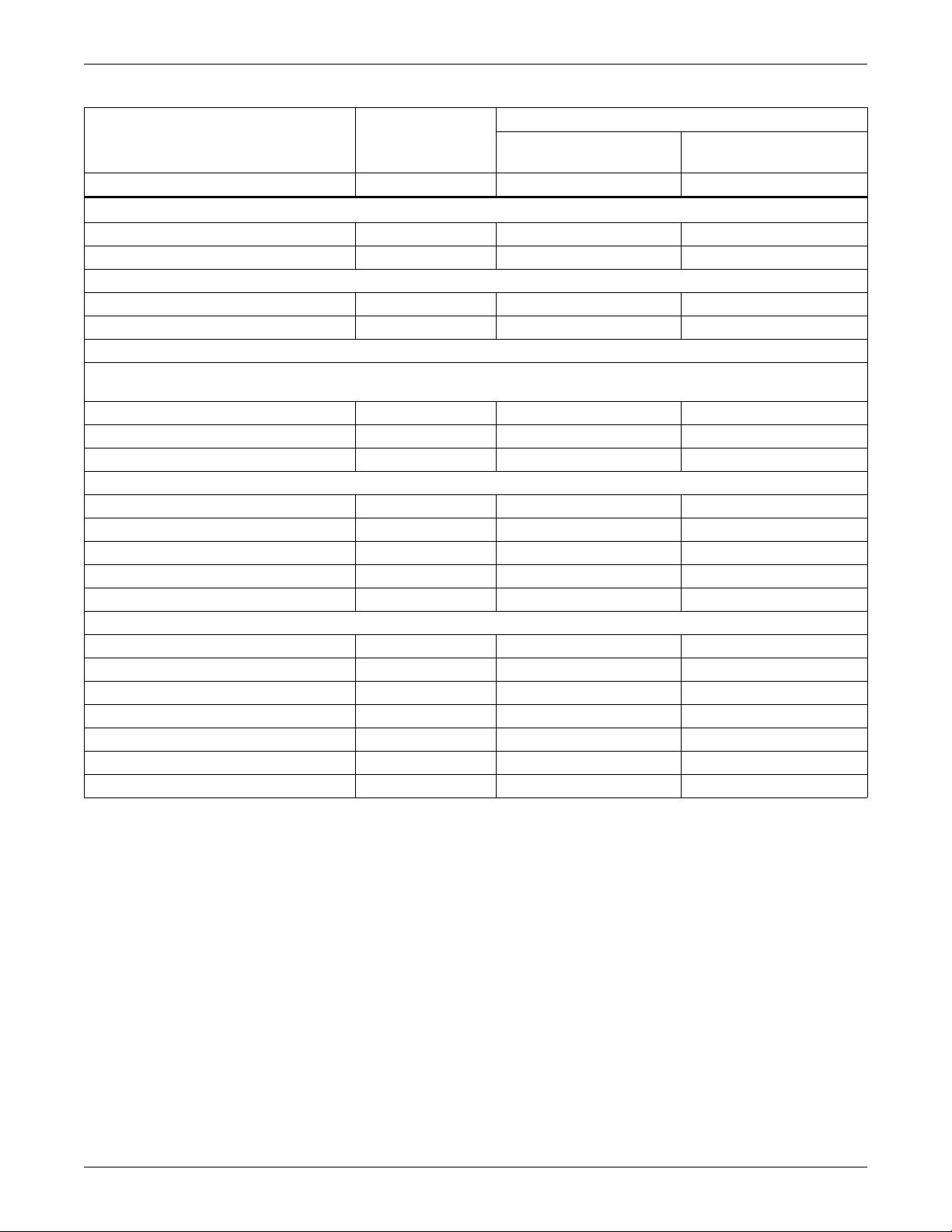

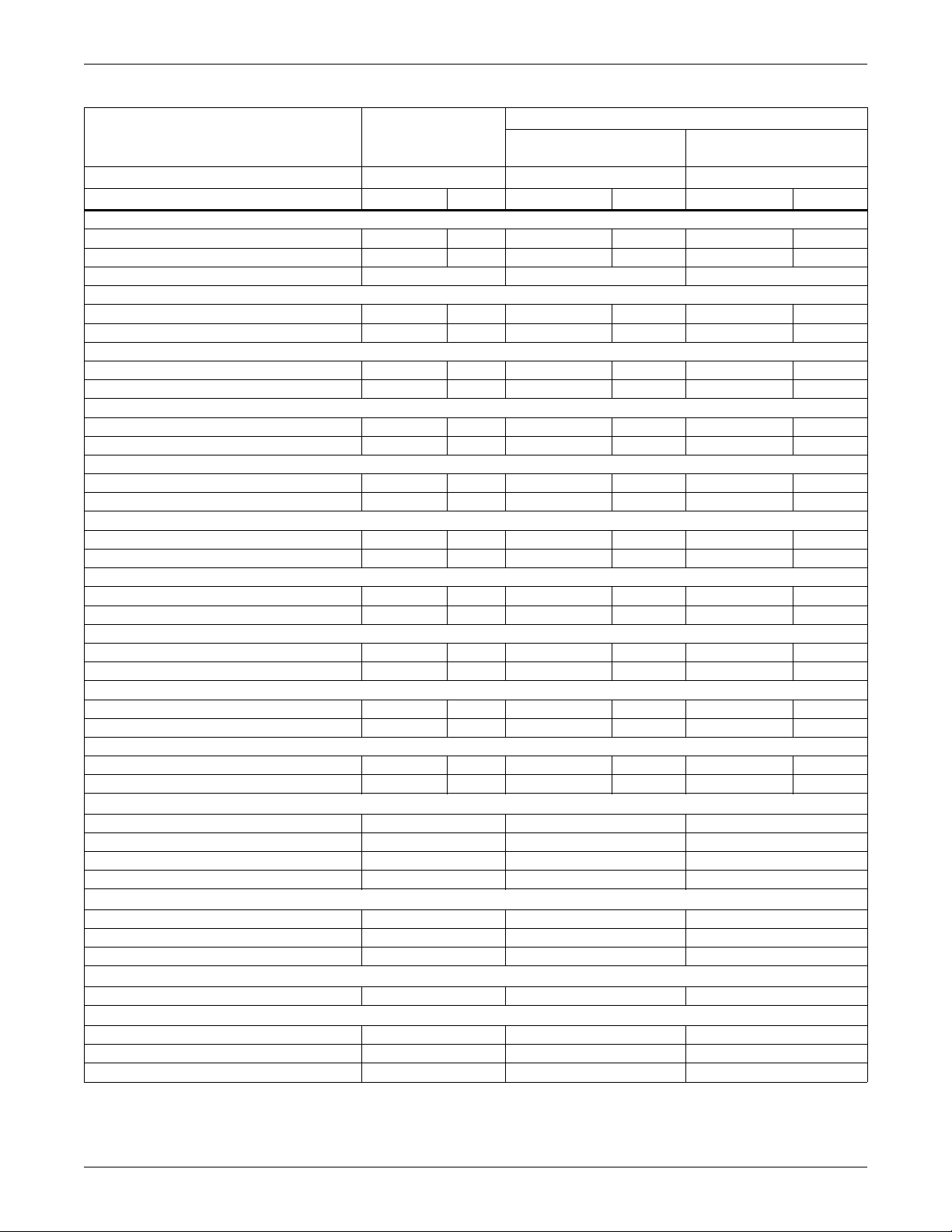

TABLES

Table 1 Condensate pump capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

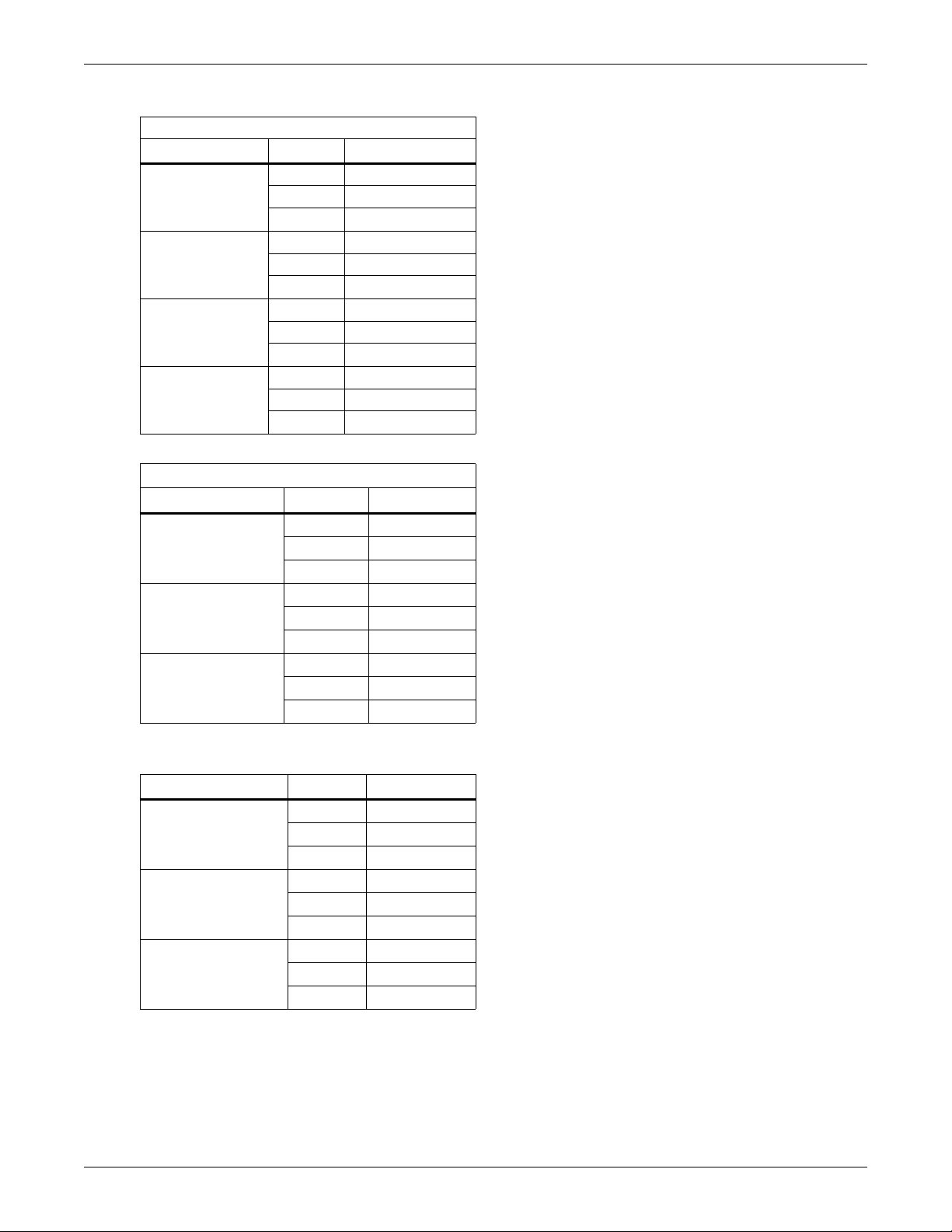

Table 2 Liebert Challenger ITR air-cooled data—60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 3 Liebert Challenger ITR air-cooled data—60 Hz (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 4 Liebert Challenger ITR air-cooled data—50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 5 Liebert Challenger ITR air-cooled data—50Hz (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 6 Liebert Challenger ITR water cooled data, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 7 Liebert Challenger ITR water cooled data, 60 Hz (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 8 Liebert Challenger ITR water cooled data, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 9 Liebert Challenger ITR water cooled data, 50 Hz (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 10 Liebert Challenger ITR glycol cooled data, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 11 Liebert Challenger ITR glycol cooled data, 60 Hz (continued). . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 12 Liebert Challenger ITR glycol cooled data, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 13 Liebert Challenger ITR glycol cooled data, 50 Hz (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14 Liebert Challenger ITR chilled water data, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 15 Liebert Challenger ITR chilled water data, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

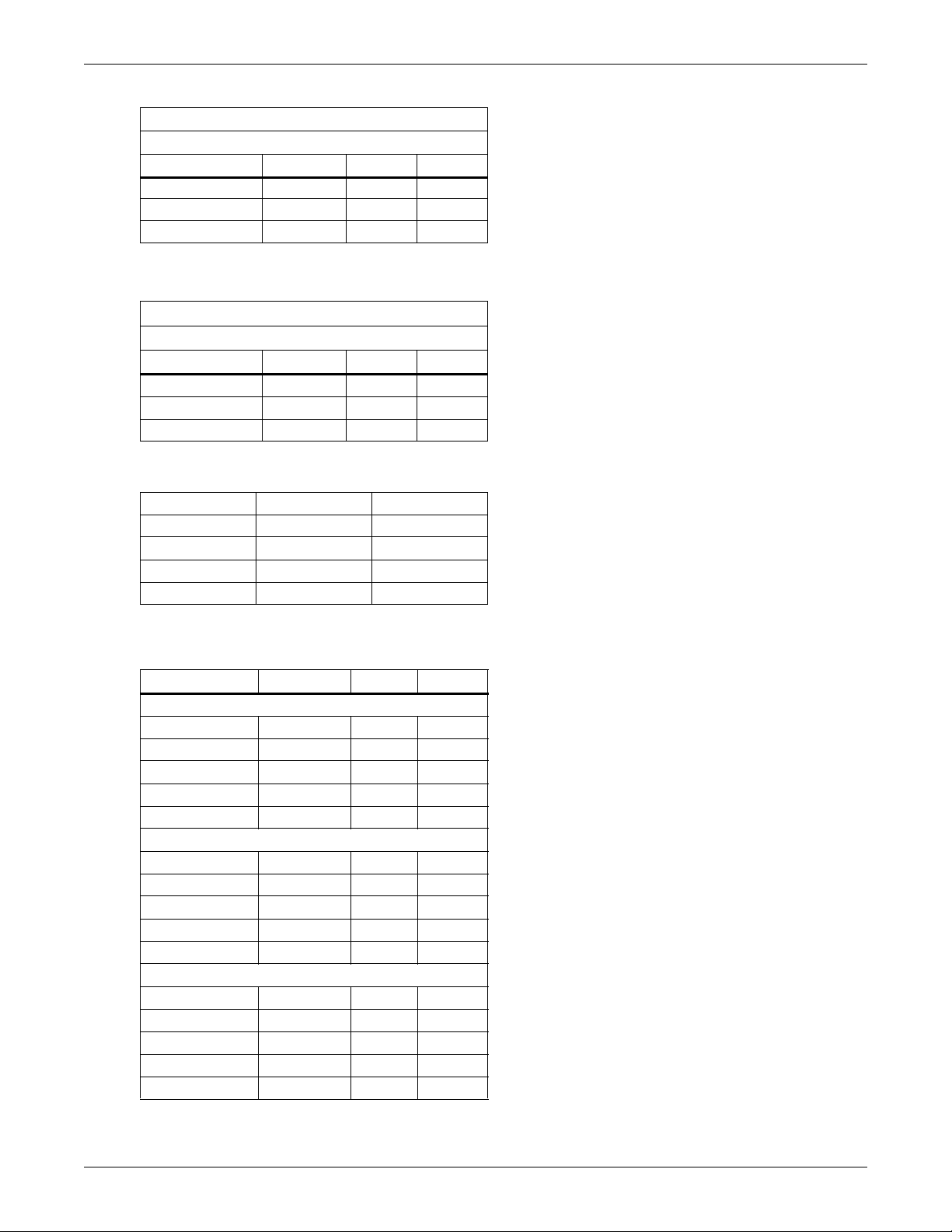

Table 16 Liebert Challenger ITR electrical data

Table 17 Self-contained with SCR reheat * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 18 Scroll compressor and main fan (for comparison purposes only) * . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 19 Outdoor condensing units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 20 Outdoor condensing units—Quiet-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 21 Indoor condensing units, air-cooled *. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 22 Indoor condensing units, water-cooled * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 23 Fan speed control condensers * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 24 Liebert Lee-Temp condensers * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 25 Liebert Lee-Temp receiver heater pads for use w/CSL condensers . . . . . . . . . . . . . . . . . . . . . . . . 47

1

—60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

iv

Page 7

Table 26 Drycooler and pump package - 95°F (35°C) ambient * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 27 Liebert Challenger ITR electrical data—50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 28 Scroll compressor and main fan (for comparison only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 29 Self-contained with SCR reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 30 Outdoor condensing units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 31 Indoor condensing units air-cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 32 Indoor condensing units water-cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 33 Fan speed control condensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 34 Liebert Lee-Temp condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 35 Liebert Lee-Temp receiver heater pads; for use w/CSL condensers . . . . . . . . . . . . . . . . . . . . . . . 50

Table 36 Drycooler only - 35°C (95°F) ambient, three-phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 37 Drycooler only - 35°C (95°F) ambient, single phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 38 Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

v

Page 8

vi

Page 9

1.0 DEDICATED, PRECISE ENVIRONMENTAL CONTROL

For sensitive electronics, environmental control is more than simple cooling. “Comfort” air conditioning systems are designed for the comfort of people and simply cannot provide the kind of environment

required by high performance computer or communication equipment.

1.1 Temperature Control

The high density heat load in a computer room or other similar application is beyond the capacity of

ordinary air conditioning systems.

Sensitive electronics are best maintained in a stable environment of 72°F ±2°F (22.2°C ±1°C). Because

computers and communications equipment generate large quantities of heat in small areas, six to 10

times the heat density of normal office space, the air conditioning system must have more than just

enough cooling capacity. It must have the precision to react quickly to a drastic change in heat load

and prevent wide temperature fluctuations—something a large building system cannot do.

1.2 Humidity Control

The electronic equipment must be protected from both internal condensation and static electricity discharges.

Maintaining the correct humidity level in the room is just as important as maintaining proper temperature. When humidity is too high, condensation may form inside electronic equipment and damage

it. If humidity is too low, static electricity could disrupt operation or even shut down the electronic

system. An ordinary building system cannot normally control the environment within these boundaries.

Dedicated, Precise Environmental Control

1.3 Air Volume

Computers and other sensitive electronics require greater air volumes than ordinary air conditioning

can provide. Typical comfort systems are designed to provide between 300 and 400 CFM (cubic feet

per minute), (500–700 CMH) per ton of cooling. Computer systems require between 500 and 600 CFM

(850–1020 CMH) per ton. The high density heat load in a relatively small space requires more

changes of air than a less dense “comfort” application.

While a normal office space requires only two air changes per hour, a room filled with electronic

equipment requires up to 30 changes per hour. Without proper air volume, hot spots and temperature

fluctuations could develop within the room. Also, greater air volumes provide the higher sensible heat

ratios required by electronic computer equipment.

1.4 Air Filtration

A clean environment of properly filtered air is essential. Build-up of dust and fibers attracted by operating electronics can cause faults and impair the operation of electromechanical devices, such as

switches and disk drives.

In short, today’s electronics need the same precision environmental control that mainframe computers need. The difference is that instead of one large computer room there are several small, often

crowded rooms, widely dispersed throughout a building, plant or campus. Conditions and requirements can vary widely.

1.5 Year Round Operation

Comfort conditioning systems cannot be relied upon 24 hours per day 365 days per year. They are typically designed to operate 10 hours per day, from spring to autumn. Many “comfort” systems have no

provision for winter operation. A precision environmental control system is designed for operation at

temperatures down to -30°F (-34.4°C).

1.6 Agency Listed

Standard 60 Hz units are CSA (NRTL-C) certified. NRTL-C meets both U.S. and

Canadian government safety requirements, providing fast, problem-free inspection and building code approvals. The units are also MEA listed for New York

City applications.

1

Page 10

Precision Environmental Control for Industrial, Telecommunications, Medical and Data Processing Equipment

2.0 PRECISION ENVIRONMENTAL CONTROL FOR INDUSTRIAL, TELECOMMUNICATIONS, MEDICAL AND DATA PROCESSING EQUIPMENT

Data processing power is moving from the specialized environment of the computer room to the office

and the factory floor.

At the same time, the applications are growing exponentially. From yesterday’s spreadsheets and

word processors, micro- to mid-range computers control LANs and WANs, manage complex telecommunications systems, optimize manufacturing processes and facilitate sophisticated testing and laboratory functions.

Computers and sensitive electronics tend to be grouped, often in specialized rooms. This makes operation and service easier, but it also creates the need for precision environmental control—the coordinated management of temperature, humidity and air filtration.

2.1 Liebert Challenger ITR

Liebert Challenger ITR provides the precision and flexibility required by a broad range of applications.

• Microprocessor-based controls (with a choice of monitoring systems based on your needs) allow

you to select temperature and humidity ranges.

• A-frame coil (oriented to airflow) provides a large cooling surface area, and more precise control of

temperature and humidity.

2.2 Multiple Configurations to Fit a Variety of Spaces

Though electronic equipment rooms share some common protection requirements, their application

requirements can vary greatly. The room may or may not have a raised floor or an existing heat rejection loop. Budget and space requirements may limit the options a contractor has.

2.3 Efficiency in Economic Terms

The Liebert Challenger ITR occupies 9.8 square feet (.91 square meters) of floor space. It can be

located either between equipment racks or at the end of a row of racks. With room floor space valued

at a premium per square foot, the small footprint of the Liebert Challenger ITR makes economic good

sense.

2.4 GLYCOOL

GLYCOOL is a patented Liebert process that can significantly reduce energy costs during periods of

low outdoor temperatures.

The GLYCOOL system is a normal glycol system with the addition of a second cooling coil, known as

an Econ-O-Coil, in the air handling unit and a three-way valve. During colder months, the glycol solution returning from the outdoor drycooler is routed to the Econ-O-Coil and becomes the primary

source of cooling for the room. At ambient temperatures below 35°F (1.6°C), the cooling capacity is

sufficient to handle the total cooling needs of the room. Because the compressor is responsible for the

majority of the power consumption of the air conditioning unit, a GLYCOOL system can substantially

reduce energy costs.

2

Page 11

Precision Environmental Control for Industrial, Telecommunications, Medical and Data Processing Equipment

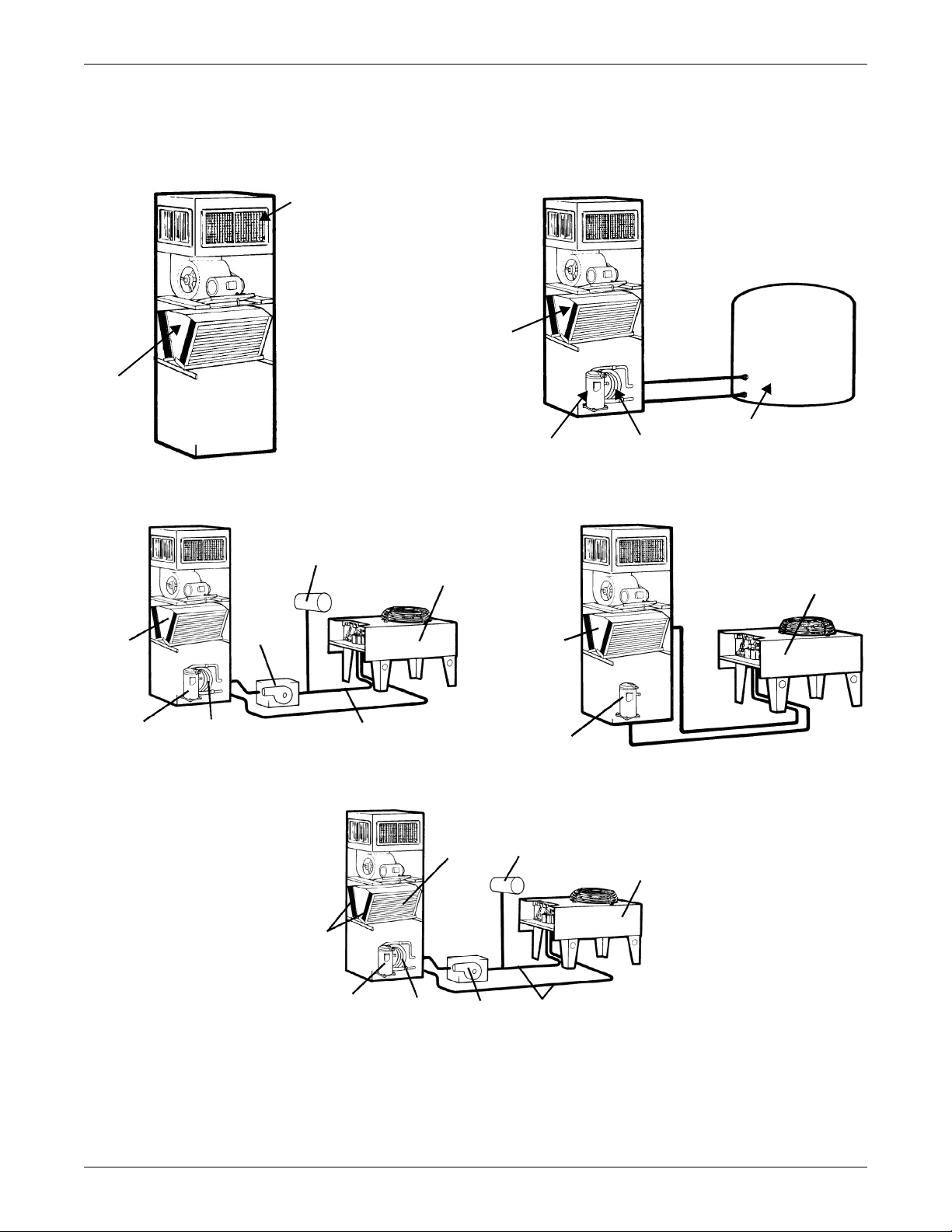

Chilled Water, Self-Contained System Water-Cooled, Self-Contained System

Plenum

Available in two-way,

three-way and four-way

Free Discharge Grilles,

Solid Plenum for ducting

or low-profile, cold-aisle

discharge plenum

V-Frame

Coil

Condenser

Water Pipes

V-Frame

Coil

Scroll

Compressor

Condenser

Remote Condenser

Water Source (not

supplied by Liebert)

IMAGES ARE

ILLUSTRATIVE ONLY

Air-Cooled, Self-Contained System

With Matching Condensers

Air-Cooled

Condenser

V-Frame Co il

Scroll Compressor

Glycol-Cooled, Self-Contained System

With Matching Drycooler and Pump

Scroll

Compressor

Condenser

V-Frame

Coil

Glycol Piping

Drycooler

Glycol

Pump

Expansion Tank

GLYCOOL-Cooled System

Scroll Compressor

Integrated

GLYCOOL Coil

Condenser

Glycol

Pump

Drycooler

Expansion Tank

V-Frame

Coil

Glycol Piping

Figure 1 Unit configurations

3

Page 12

Precision Environmental Control for Industrial, Telecommunications, Medical and Data Processing Equipment

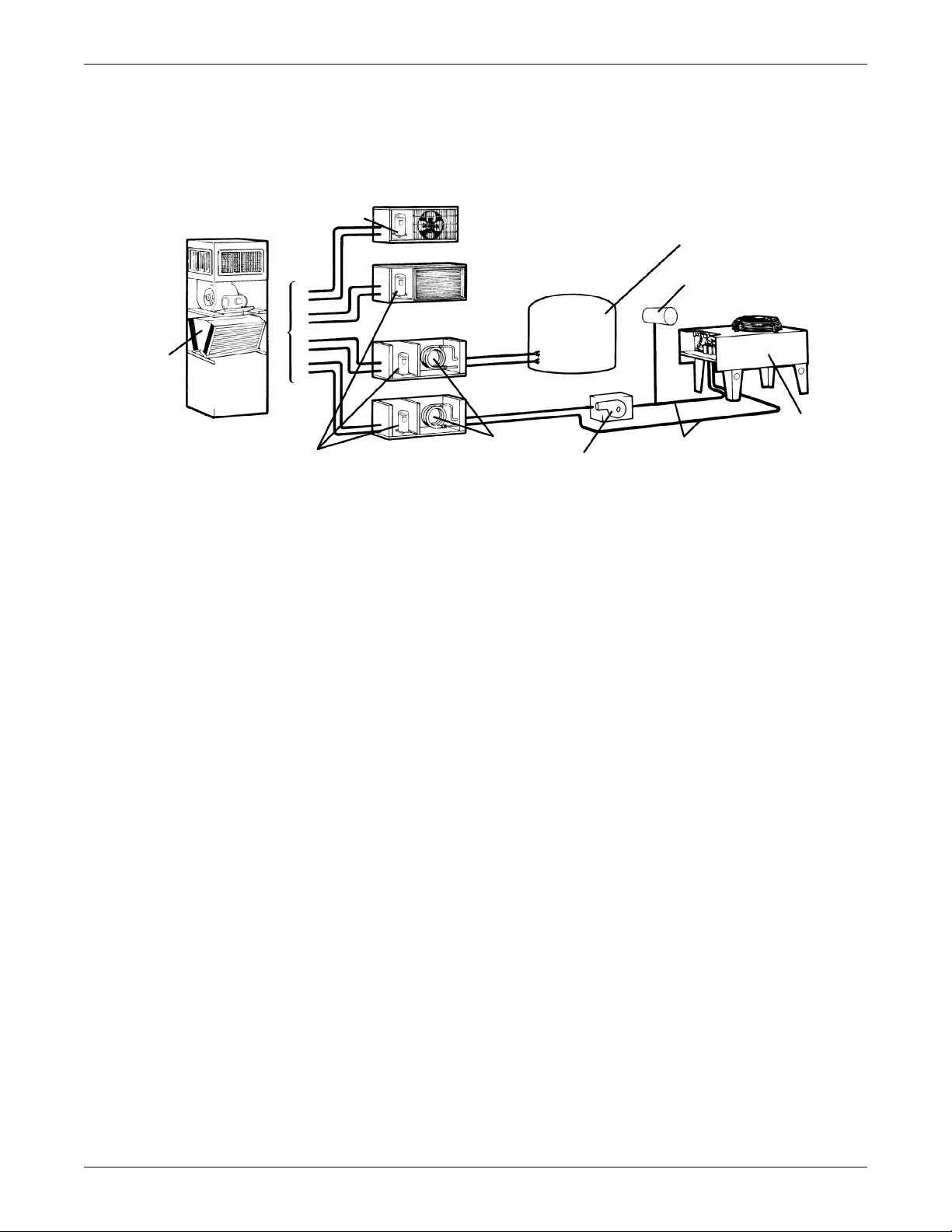

Split Systems Available

Scroll Compressor

Glycol Pump

Glycol Piping

Drycooler

Expansion Tank

V-Frame

Coil

Scroll Compressor

Remote Condenser

Water Source

(not supplied by Liebert)

Outdoor Prop-Fan

Air-Cooled Condensing Unit

Indoor Centrifugal Fan

Air-Cooled Condensing Unit

Indoor Water-Cooled

Condensing Unit

Coaxial

Condenser

Indoor Glycol-Cooled

Condensing Unit

IMAGE IS

ILLUSTRATIVE ONLY

Figure 2 Unit configurations, continued

4

Page 13

3.0 LOCAL MONITORING SYSTEMS

Two levels of microprocessor control systems are available providing precise control and monitoring of

the critical space.

The Advanced Microprocessor is standard, and the Advanced Microprocessor with Graphics

is optional. The main control functions are similar for both controls.

3.1 Control

The user must enter a three-digit password before making changes.

• Temperature Setpoint 65-85°F (18-29°C)*

• Temperature Sensitivity +1-10°F (0.6-5.6°C)

• Humidity Setpoint 20-80% RH*

• Humidity Sensitivity 1-30% RH

• High Temperature Alarm 35-90°F (2-32°C)

• Low Temperature Alarm 35-90°F (2-32°C)

• High Humidity Alarm 15-85% RH

• Low Humidity Alarm 15-85% RH

* The microprocessor may be set within these ranges; however, the unit may not be able to control to

extreme combinations of temperature and humidity.

Local Monitoring Systems

3.2 Control Type

Factory set-up for Intelligent Control which uses “fuzzy logic” and “expert systems” methods. Proportional and Tunable PID are user selectable options.

3.3 Internal System Control

• Compressor short cycle control: Prevents compressor short-cycling and needless compressor

wear.

• System auto restart: The auto restart feature will automatically restart the system after a

power failure. Time delay is programmable.

• Sequential Load Activation: On initial start-up or restart after power failure, each operational

load is sequenced to minimize total inrush current.

• Hot Water / Econ-O-Coil Flush Cycles: Hot water reheat coils and Econ-O-Coils are periodically flushed to prevent a build-up of contaminants.

• Temperature/Humidity Sensor Calibration: The sensors may be calibrated from the front

monitor panel to insure that all units in the room are similarly calibrated, assuring greater precision.

3.4 Monitoring

• Normal display: Includes present room temperature and humidity, active functions (cooling,

heating, dehumidifying), and any alarms.

• Operating status: Displays each control operation in percent.

• Read analog inputs function: Displays the present values of up to four analog inputs.

3.5 Diagnostics

• Input diagnostics: Reviews inputs to the control system.

• Control board diagnostics: Initiates a self-test of the control system.

• Output diagnostics: Tests major components by turning them on and off from the control panel.

Includes: main fan, compressor, liquid line solenoid valve, hot gas bypass valve, chilled water or

chilled GLYCOOL valve, R-5 relay, reheat, hot water reheat valve, humidifier, humidifier makeup valve, and common alarm.

5

Page 14

3.6 Logging

Advanced Microprocessor w/Graphics Control

System—Optional. Backlit 240 x 128 dot matrix

graphics display.

Advanced Microprocessor Control System.

Backlit 4 x 20 Liquid Crystal Display.

The runtime screen provides data in either tabular

or easy-to-read graphic formats.

Histograms–historical depictions–of temperature or

humidity can be displayed on the screen for analysis.

This is especially helpful in tracking the environmental

factors of an alarm.

• Alarm history log: The Advanced Microprocessor displays the 10 most recent alarms. The

Advanced Microprocessor with Graphics displays the most recent 60 alarms. Both provide a time

and date stamp for each event

• Run time log: Displays run time and hours for major components (also allows reset of run hours)

including compressors, GLYCOOL, fan, humidifier, and reheat.

3.7 Alarms

• Humidifier Problem • Low Suction Pressure

• High Head Pressure • Short Cycle

• Change Filter • Loss Of Power

• Loss of Air Flow Custom Alarm (Maximum of Four)

• High Temperature • Water Under Floor

• Low Temperature • Smoke Detected

• High Humidity • Standby GC Pump On

• Low Humidity • Loss Of Water Flow

• Compressor Overload—Optional • Standby Unit On

• Main Fan Overload—Optional • User-Customized Text

Figure 3 Microprocessor control systems

Local Monitoring Systems

3.8 Graphical Displays—Advanced Graphic Control Only

• Individual plots of temperature, humidity and the four analog inputs.

• Bar graph plots of individual component run history by hour.

• Floor plan of optional water detection system layout including on alarm.

Status indication of operating modes with current temperature and humidity.

Figure 4 Optional Views With Advanced Graphics

6

Page 15

4.0 STANDARD FEATURES—ALL SYSTEMS

4.1 Cabinet and Frame

The frame, 14 gauge, MIG welded tubular and formed steel, provides maximum support while 1"

(25.4mm) deep steel panels with 1-1/2 lb. (.68 kg) insulation protect and quiet the system. The front

door can be opened for service without shutting off the system. All components are accessible for service/maintenance through the front and rear of the unit.

The Liebert Challenger ITR’s resistance to corrosion is enhanced by the black, powder-coat finish to

all frame components. Exterior panels are similarly protected with durable powder-coating.

4.2 Electrical Panel

The high voltage compartment contains the contactors, transformers and overloads and all other

high-voltage components.

Each high voltage component is protected by a separate overcurrent protective device. The entire high

voltage panel is enclosed by a safety lock dead front panel. When the front door is opened by operating

personnel, the high voltage components remain enclosed for operator safety.

4.3 Fan Section

The Liebert Challenger ITR features a quiet, low speed fan assembly with double inlet blower, lifetime lubrication and self-aligning ball bearings. The motor and variable pitch drive are mounted on

an adjustable base. The entire blower/ motor assembly is mounted on vibration isolators for smoother

operation.

Standard Features—All Systems

The draw-through design of the fan section provides even air distribution across the coil, controlled

air for bypass humidification, elimination of air bypass around the filters and low internal cabinet

pressure drop.

4.4 Infrared Humidifier

High-intensity quartz lamps over the stainless steel humidifier pan permit clean, particle-free vapor

to be added to the air within 5 to 6 seconds of the electronic call from the microprocessor control.

The quartz lamps provide radiant energy that evaporates water in a pure state, without solids.

The Infrared Humidifier is equipped with an automatic water supply system that significantly

reduces cleaning maintenance. This system has an adjustable water over-feed to prevent mineral precipitation. A drain valve is provided to easily empty the humidifier pan prior to inspection or servicing. A control valve regulates flow at water pressures between 5 and 150 psig (34.5 and 1034 kPa) and

includes a Y-strainer.

4.5 Electric Reheat

The two-stage 304 stainless steel reheat elements are a rigid, fin-tubular design that have extended

operation life. The reheat has ample capacity to maintain room dry-bulb conditions during a system

call for dehumidification. The two stages give an accurate, controlled response to the requirements of

the computer room. The low watt density, electrically enclosed elements are surrounded by the tube

and fins, reducing sheath temperatures and eliminating ionization.

4.6 Filters

The standard pleated 2" (51mm) filter with an efficiency of 20% (based on ASHRAE 52.1) can be

changed quickly and easily through the front of the unit.

7

Page 16

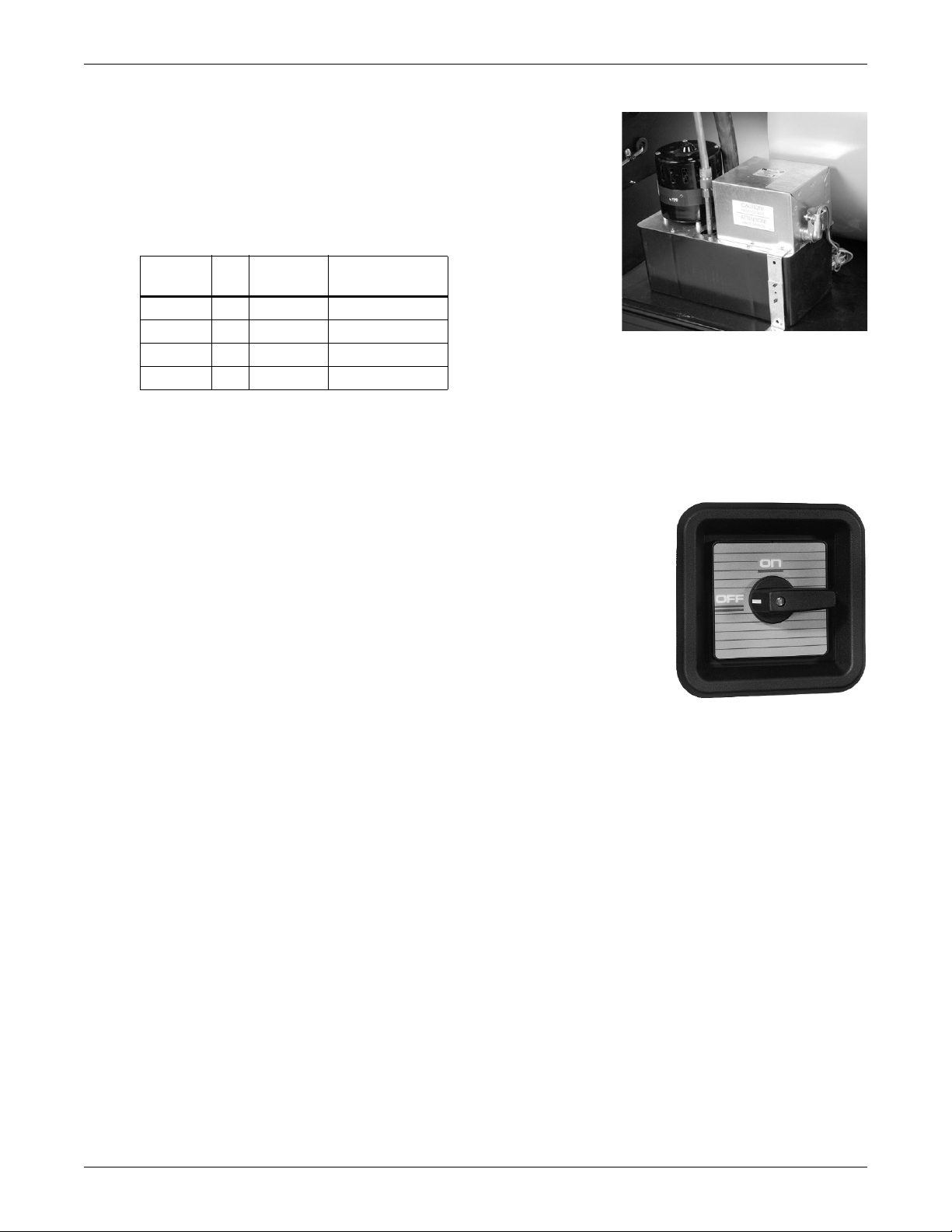

4.6.1 Condensate Pump

Disconnect Switch

(Locking)

The condensate pump, mounted in the bottom of most units, is

used for unit drain water only. The condensate pump is complete

with sump, motor and pump assembly and automatic control.

The standard model has single float. A dual-float condensate

pump, which includes connections to unit, common alarm, unit

shutdown and one customer N/O contact is also available.

Table 1 Condensate pump capacity

Capacity

Voltage Hz

200/230 50 50 (189) 10 (30)

208/230 60 50 (189) 17 (51)

380/415 50 200 (757) 26 (78)

460 60 200 (757) 43 (128)

GPH (l/s)

Head Pressure

ft. (kPa)

4.6.2 Remote Temperature/ Humidity Sensors

The remote temperature/ humidity sensors permit monitoring room conditions from an external

source. They are encased in an attractive case and are provided with a plug compatible shielded cable

in virtually any length.

Standard Features—All Systems

4.6.3 Disconnect Switch—Locking Type

The locking disconnect switch, mounted in the electrical panel, is connected to the safety lock dead front panel of the system and is interlocked mechanically. In this way the panel can’t be opened until the

switch is in the off position. And it complies with local codes as well as

those of the NEC.

8

Page 17

Chilled Water System—Standard and Optional Features

5.0 CHILLED WATER SYSTEM—STANDARD AND OPTIONAL FEATURES

5.1 Chilled Water System—Standard Features

5.1.1 Cooling Coil

The chilled water cooling coil is designed for closed-loop applications using properly maintained

water. It is constructed of copper tubes and aluminum fins. To ensure quality, the V-frame coil is

manufactured to the highest standards in the industry.

5.1.2 Modulating Motor

The flow of chilled water through the cooling coil is controlled by an electronic modulating motor. The

microprocessor control will activate the motor when a need for cooling or dehumidification exists. The

motor will position the valve to precisely match the needs of the conditioned space.

5.1.3 Line Insulation

All chilled water piping within the Liebert Challenger ITR is fully insulated to assure full system

capacity and prevent condensation.

5.1.4 Three-Way Control Valve

The fully insulated control valve gives the conditioned space the precise cooling needed by electronic

equipment. Its unique design requires no overtravel linkages and never requires adjustment.

5.2 Chilled Water System—Optional Features

5.2.1 Chilled Water Flow Switch

The flow switch will activate the alarm system and/or shut down the system should the chilled water

supply be interrupted. The switch is factory wired and mounted in the chilled water valve compartment.

5.2.2 High Pressure

For special applications, a high-pressure, modulating three-way or two-way valve can be provided.

The valve is designed for 400 psig (2758 kPa) water pressure.

9

Page 18

6.0 REFRIGERATION SYSTEMS

Two versions are available:

• Self-Contained Systems

• Split Systems

6.1 Self-Contained Systems

These systems feature a scroll compressor and controls, expansion valve, hot gas bypass and evaporator coil in the room unit.

Air-Cooled models also include a crankcase heater on the compressor and require field connection to

remote air-cooled condenser.

Water, Glycol and GLYCOOL models also include a coaxial condenser with field connections

required to the water or glycol coolant loop.

Water/Glycol models have two-way WRV with bypass.

GLYCOOL models have three-way WRV.

6.2 Split Systems

These systems feature the evaporator coil and expansion valve in the room unit, with the scroll compressor, and the condensing equipment located in one of several different types of pre-charged condensing units.

Refrigeration Systems

6.3 Refrigeration System Components—Standard Features

6.3.1 Compressor

The heart of the refrigeration system is the compressor.

All self-contained evaporator units and split system condensing units contain a high efficiency, quiet

operating scroll compressor. The compressors have internal vibration isolating mountings, pressure

safety controls and built-in overload protection.

6.3.2 Evaporator Coil

The evaporator coil is designed for the high sensible heat ratio required by electronic equipment

applications. The copper tube, aluminum fin coils are configured in a V-frame for smooth air flow

through the unit.

6.3.3 Safety Control

Every Liebert Challenger compressor has a high-pressure switch with an exclusive manual reset after

high pressure cut-out. This prevents cycling the compressor at high pressure, resulting in greater efficiency and longer compressor life.

6.3.4 Expansion Valve

The externally equalized thermostatic expansion valve smoothly controls the flow of refrigerant

through the coil and provides precise control of superheat.

10

Page 19

Air-Cooled System—Standard and Optional Features

Air-Cooled Condenser

Liebert Lee-Temp

Package (optional)

7.0 AIR-COOLED SYSTEM—STANDARD AND OPTIONAL FEATURES

7.1 Air-Cooled, Self-Contained Systems—Standard Features

7.1.1 Pump Down Control

The compressor pump-down control is accomplished by a liquid-line solenoid valve used in conjunction with a low pressure switch.

7.1.2 Condenser

The Liebert manufactured low profile, direct drive propeller fan type air-cooled condenser provides

quiet, efficient operation.

It is constructed of aluminum with a copper tube and aluminum fin coil for corrosion resistance. An

integral, factory wired and tested control panel reduces installation time.

7.1.3 Fan Speed Control

The winter control system features a variable speed motor and a specially designed solid-state fan

speed control transducer.

The transducer senses refrigerant pressure and varies the speed of the fan motor to maintain constant condensing temperature and system capacity. This system permits operation at ambient temperatures as low as -20°F (-29°C).

7.2 Air-Cooled, Self-Contained Systems—Optional Features

7.2.1 Liebert Lee-Temp Winter Control Condenser

The Liebert Lee-Temp winter control system’s heated receivers permit startup and positive head

pressure control at ambient temperatures as low as -30°F (-34.4°C). The Liebert Lee-Temp package

includes insulated receiver, a pressure relief valve, three-way head pressure control valves, and rotalock valves (see Figure 5 below).

7.2.2 Quiet-Line Condensers

Quiet-Line Condensers can help your facility meet the strictest noise codes, and do so at less cost than

traditional condensers with acoustical shielding.

Figure 5 Air-cooled condenser with Liebert Lee-Temp

11

Page 20

Air-Cooled System—Standard and Optional Features

7.3 Air-Cooled Split Systems—Standard Features

7.3.1 Centrifugal Fan, Condensing Unit

The centrifugal condensing unit’s copper-tube, aluminum-fin coil is equipped with low-temperature

controls to ensure year-round operation to -20°F (-29°C). The condensing unit is factory-wired,

charged and tested and is ready for final connections.

The centrifugal fan condensing unit includes scroll compressor, condenser coil, centrifugal blower

assembly, high-pressure switch and Liebert Lee-Temp head pressure control.

Condensing unit has hot gas bypass standard feature which bypasses hot gas around the compressor

directly to the suction side of the compressor to provide capacity control and reduce compressor

cycling. System includes liquid injection valve to maintain proper suction superheat.

Unit must be mounted indoors. Duct flanges are provided.

7.3.2 Propeller Fan Condensing Unit

The air-cooled condensing unit can be mounted on the roof or a ground level site. The condensing unit

housing is manufactured of galvanized steel with a powder coat finish. The copper-tube, aluminumfin coil is equipped with low temperature controls to assure year-round operation to -30°F (-34.4°C).

The condensing unit is completely factory-wired, charged and tested and is ready for final connections. (See illustration below)

The standard prop fan condensing unit includes scroll compressor, prop fan, high head pressure

switch, hot gas bypass and Liebert Lee-Temp head pressure control (for operation down to -30°F (39°C) ambient.)

Figure 6 Outdoor propeller fan condensing unit

7.3.3 Propeller Fan Condensing Unit Options

This unit is available in these optional configurations:

• 105°F (40°C) ambient for high ambient conditions.

• 95°F (35°C) ambient Quiet-Line for low noise level conditions below 58 dBa.

7.4 Air-Cooled Split Systems—Optional Features

Factory-installed, non-fused disconnect switch allows turning off the Challenger ITR for maintenance. Disconnect switch is available on indoor condensing units only.

12

Page 21

Water/Glycol-Cooled Systems—Standard and Optional Features

8.0 WATER/GLYCOL-COOLED SYSTEMS—STANDARD AND OPTIONAL FEATURES

8.1 Water/Glycol Self-Contained Systems—Standard Features

Liquid-Cooled Condensers

A co-axial condenser provides ample capacity to handle the heat rejection needs of the system while

using a minimum of liquid and low total pressure drop.

Regulating Valves

Head pressure operated regulating valves accurately control the condensing temperature and maintain system capacity for various entering liquid flow rates and temperatures. Two-way valves with

bypass are standard.

8.2 Water/Glycol-Cooled, Self-Contained System—Optional Features

Three-way Regulating Valves

Three-way valves provide accurate control of condensing temperature and thus maintain constant

system capacity while also keeping the condenser water flow rate constant.

High Pressure

The high pressure option for the condenser circuit consists of a regulating valve and a condenser

rated at 350 psig (2413 kPa) water-pressure. This option is required in applications with large static

head pressures.

Compressor Crankcase Heater

A compressor crankcase heater is available to prevent the migration of refrigerant to the compressor

during off cycles.

Hot Gas Reheat

The hot gas reheat assembly consists of a three-way directional solenoid operated valve and a hot gas

reclaim coil.

70/30 Cu-Ni Econ-O-Coil

This coil replaces the standard copper tube coil to provide improved resistance to corrosion. This

option must be specified whenever a GLYCOOL or Dual Cooling Source system is applied to a cooling

tower loop or other open water system.

8.3 Water/Glycol Split System—Standard Features

Water/Glycol-Cooled Condensing Units

Factory charged and sealed, the water-cooled condensing unit is ready to be installed quickly and easily. The counter-flow coaxial condenser with two-way or three-way regulating valve designed for 150

psi (1034.3 kPa) is matched to the heat rejection requirements of the compressor for a variety of flow

rates and fluid temperatures.

Condensing unit has a hot gas bypass standard feature that bypasses hot gas around the compressor

directly to the suction side of the compressor to provide capacity control and reduce compressor

cycling. System includes liquid injection valve to maintain proper suction superheat.

13

Page 22

Water/Glycol-Cooled Systems—Standard and Optional Features

8.4 Water/Glycol-Cooled, Split System—Optional Features

High Pressure

The high pressure option for the condenser circuit consists of a two-way or three-way water regulating valve and condenser rated at 350 psig (2413 kPa) water pressure. This option is required in applications with large static heads.

Factory Installed Non-Fused Disconnect Switch

Allows unit to be turned off for maintenance. Disconnect switch is available on indoor condensing

units only.

70/30 Cu-Ni Econ-O-Coil

This coil replaces the standard copper tube coil to provide improved resistance to corrosion. This

option must be specified whenever a GLYCOOL or Dual Cooling Source system is applied to a cooling

tower loop or other open water system.

8.4.1 Glycol-Cooled System—Heat Rejection Devices

8.4.2 Self-Contained and Split Systems

Fan Speed Control Drycooler

The Liebert manufactured Fan Speed Control drycooler is constructed of aluminum and features copper tubes and aluminum fin design. It is low profile, propeller fan type and provides quiet, trouble

free heat rejection. The drycooler features a variable speed fan motor and a specially engineered solid

state fan speed transducer. The transducer senses the temperature of the leaving glycol and modulates the speed of the fan to maintain proper glycol temperatures. An integral, factory-wired and

tested control panel reduces installation time.

Glycol Pump

The glycol system includes a matching centrifugal glycol pump. It is mounted in a vented, weatherproof enclosure. Optional Equipment—See page 16.

14

Page 23

GLYCOOL Systems—Standard and Optional Features

9.0 GLYCOOL SYSTEMS—STANDARD AND OPTIONAL FEATURES

9.1 GLYCOOL—Self-Contained Models Only

The Liebert GLYCOOL free-cooling system is integrated with a glycol-cooled Liebert Challenger ITR.

At outdoor temperatures below 35°F (1.6°C), the Econ-O-Coil is capable of providing total system

capacity. At outdoor temperatures between 35° and 65°F (1.6° and 18.3°C), the unique modulating

valve permits partial cooling of the space by the Econ-O-Coil with the DX system picking up the rest

of the load. Above 65°F (18.3°C) the unit functions as a glycol unit and all the cooling is accomplished

by the DX system. When cooling is required, the three-way modulating valve and water regulating

valve direct glycol (from the heat rejection loop) to the Econ-O-Coil located upstream of the evaporator

coil, to the condenser, or to both.

The GLYCOOL system contains all the standard features of a glycol-cooled system plus the following.

9.2 GLYCOOL System—Standard Features

9.2.1 Comparative Temperature Monitor

A solid-state temperature monitor compares the room air temperature and entering glycol temperature. When air temperature is higher than glycol temperature, the monitor communicates to the

microprocessor control that “free-cooling” is available.

9.2.2 Econ-O-Coil

The Econ-O-Coil is strategically located in the return air stream of the environmental control system.

This coil is designed for closed-loop applications using properly treated glycol solutions. Applications

using a cooling tower loop or other open water system must specify a 70/30 Cu-Ni Econ-O-Coil for

improved corrosion resistance.

The air is first filtered before entering the coil and then is either precooled or totally cooled before

entering the refrigeration coil. The glycol flow to the coil is controlled by a pre-piped modulating

three-way valve. When supplied with a 45°F (7.2°C) glycol solution, the coil is sufficiently sized to

offer the identical cooling capacity as is obtained during the refrigeration cycle of the compressor.

9.2.3 GLYCOOL Three-Way Control Valve

The GLYCOOL Three-Way Control Valve opens full anytime the temperature of the glycol solution is

below room temperature, to take full advantage of all possible free cooling. As the outdoor ambient

drops, the three-way control valve modulates the flow to the Econ-O-Coil. It maintains constant temperature in the room and includes operating linkage and electronic motor. Unlike other valves of this

nature, there is no over travel linkage or end switches to be adjusted.

9.2.4 Glycol-Regulating Valve

A head pressure operated glycol regulating valve accurately controls the condensing temperature and

system capacity for various entering glycol temperatures. The valve has three-way action.

15

Page 24

9.2.5 Drycooler

Evaporator

Coil

Three-way GLYCOOL

Control Valve

Econ-O-Coil

The Liebert manufactured drycooler is constructed of aluminum with a copper tube aluminum fin

coil. The low profile design features multiple direct drive propeller type fans, balanced to the heat

rejection load. An integral, factory wired and tested control panel reduces installation time.

Figure 7 Liebert Challenger ITR unit core

GLYCOOL Systems—Standard and Optional Features

9.3 Glycol and GLYCOOL-Cooled—Optional Equipment

High Pressure

For high pressure applications, the GLYCOOL system can be equipped with components rated at 300

psig (2069 kPa).

9.3.1 Dual Pump Package

The dual pump package features two full size glycol pumps, each capable of providing sufficient flow

for system operation. A flow switch will sense the loss of flow, should the lead pump fail, and automatically command the standby pump to start. The complete system includes dual pump housing, pumps,

lead-lag switch and flow switch (for field installation). The dual pump package provides redundancy,

protecting against costly downtime in the computer room.

Quiet-Line Drycoolers

Quiet-Line Drycoolers can help your facility meet the strictest noise codes, and do so at less cost than

traditional drycoolers with acoustical shielding.

16

Page 25

10.0 OPTIONAL EQUIPMENT—ALL SYSTEMS

10.1 Steam Generating Humidifier

Clean, pure steam is generated in a disposable canister that is complete with supply and drain valves,

electronic controls and steam distributor. The humidifier is provided with an automatic flush cycle to

lengthen service life. An indicator on the Liebert Challenger ITR monitor panel is activated when the

canister should be changed.

Optional Equipment—All Systems

Figure 8

Steam generating humidifier

10.2 Adjustable Floor Stand

Available in heights from 9" to 24" (228.6 to 609.6mm) in 3" (76.2mm) increments, adjustable +1-1/2"

(38.1mm). Allows for installation and connection of the Liebert Challenger ITR prior to installation of

the raised floor.

Figure 9 Adjustable floor stand

NOTE

Some options or combinations of options may result in reduced air flow. Consult factory for

recommendations.

17

Page 26

10.3 SCR Reheat

Plenum With Two-Way Grille

Low-Profile, Cold Aisle Discharge Plenum

This reheat uses stainless steel elements and also includes the necessary sensors and controls to provide variable heat output to help maintain tighter control of room conditions, especially in lightly

loaded applications. (Contact factory for available voltages.) Direct expansion units only.

10.4 High-Efficiency Filter

Four optional filters are available in lieu of standard package. A 4" (102mm) 20%, 30%, 40%-45% or

60%-65% filter may be specified. (Efficiency based on ASHRAE 52.1). 2" (51mm) 20% pre-filters may

also be specified.

10.5 High External Static Blowers

These blower/motor packages are available where external static pressures are up to 2.0 inches (500

Pa) on 60 Hz units, and up to 1.5 inches (370 Pa) on 50 Hz units. These blowers are rigidly mounted

for ducting directly to the blower housing.

(Consult the factory for specific applications.)

10.6 High-Efficiency Motors

These motors replace the standard efficiency motors to provide increased energy savings during operation (consult factory for specific efficiencies).

Optional Equipment—All Systems

10.7 Plenums

Standard height of 18" (457mm) with top duct connection or two-way, three-way or 4-way grille discharge styles available.

10.8 Low-Profile Plenum with Cold-Aisle Discharge

This plenum is designed to distribute supply air to electronic equipment beside and across from the

cooling unit. In addition to air exiting the front of the plenum, internal baffles direct air through the

left-side and right-side discharge vents. Factory-supplied hardware allows air to be blocked from exiting one side of the plenum, allowing the cooling unit to be installed at the end of a row of equipment.

18

Page 27

10.9 Smoke Detector

Firestat

The smoke detector senses the return air, shuts down the unit upon detection, and sends visual and

audible alarm. Dry contacts are available for a remote customer alarm. This smoke detector is not

intended to function as or replace any room smoke detection system that may be required by local or

national codes.

Supervised smoke detectors are also available as an option. Consult factory.

10.10 Firestat

The firestat senses return air temperature of the system. Upon sensing high temperatures, the environmental control system is shut down. Required by codes in

certain areas.

10.11 Hot Water Reheat

Controlled by a two-way solenoid valve from the microprocessor control panel, these economical reheats have

the capacity to maintain dry bulb conditions when the

system is calling for dehumidification. The system is

completely pre-piped and includes a control valve and

Y-strainer. The reheat coil is constructed of copper

tubes and aluminum fins.

Optional Equipment—All Systems

19

Page 28

Comprehensive Monitoring Systems—Optional

11.0 COMPREHENSIVE MONITORING SYSTEMS—OPTIONAL

You will find a full range of monitoring and control systems, communications modules designed to

interface Liebert equipment with a variety of building management systems, plus stand-alone monitoring, control and leak detection devices.

11.1 Enterprise Monitoring Systems

SiteScan Web is a comprehensive critical systems monitoring solution dedicated to ensuring reliability through graphics, event management and data extrapolation. The standard Web interface allows

users easy access from anywhere at anytime.

• Single- and multi-site applications.

• Event management and unit control.

• Trend and historical data captures and reporting.

• Full ASHRAE BACnet compatibility.

• Java based.

• Windows 2000 and XP compatible.

Liebert SiteLink

• Connectivity to building management systems using Modbus and BACnet.

Liebert Site I/O

®

™

• Integrates sensors and contacts.

Liebert Site TPI

• Integrates non-Liebert equipment.

™

11.2 Network Monitoring Systems

The Liebert IntelliSlot® line of products leverages one-to-one unit connections and your existing network for a comprehensive monitoring solution for distributed equipment.

Liebert IntelliSlot Web/485 Card With Adapter

• Monitoring option available for Liebert precision air conditioning units.

• Web interface for viewing and control.

• Modbus interface for building management systems.

• SNMP interface for network management systems.

Liebert Nform

• Centralized monitoring of all Liebert SNMP enabled devices.

• Event and alarm management.

• Adaptable and configurable graphical user interface.

• Integration of third-party SNMP enabled devices through custom Liebert services.

• Windows NT, 2000 and XP compatible.

™

11.3 Stand-Alone Monitoring and Leak Detection Solutions

Autonomous microprocessor controlled modules are available to provide supervision, control and

remote notification of Liebert equipment. These stand-alone devices include:

Contact Closure Alarm Panels

• Continuously monitor critical support equipment and instantly notify on alarm condition.

Autochangeover Control Panels

• Sequence the operation of multiple environmental units.

20

Page 29

Leak Detection Modules

Enterprise Monitoring

Network Monitoring

Stand-Alone Monitoring

and Leak Detection

• Provide quick detection and location of hazardous fluid leaks.

Discrete Output Interface Card

• Straightforward way to tie environmental units to a building management system or alarm panel.

Figure 10 Monitoring configurations

Comprehensive Monitoring Systems—Optional

21

Page 30

Comprehensive Monitoring Solutions—Optional

Auto-Changeover -

RAC2-8

12.0 COMPREHENSIVE MONITORING SOLUTIONS—OPTIONAL

12.1 Liebert SiteScan® Web

Liebert SiteScan Web is a monitoring solution for critical environments that utilize a facility-view

approach. The system enables communications from Liebert environmental and power units—as well

as many other pieces of analog or digital equipment to a front end software package that provides

monitoring, control and alarm management.

Liebert SiteScan monitoring gives you decision making power to effectively manage the equipment

that is critical to your business. Designed with flexibility for large, complex systems as well as

smaller, single-site facilities, the Liebert SiteScan line of products can provide real-time status and

alarms.

12.2 Liebert SiteLink

The microprocessor-based module provides two-way communication between an existing building

management system and up to 12 Liebert units via Modbus or BACnet.

12.3 Liebert Nform

Liebert Nform centralizes the management of your distributed Liebert network equipment. Liebert

Nform software solution combines full-scale monitoring with the use of the existing network infrastructure—so the cost of dedicated, out-of-band communications cabling is eliminated. It is both scalable and adaptable so it can grow as your systems expand and needs change. Liebert Nform will

monitor any Liebert SNMP device that supports a network interface, such as the Liebert IntelliSlot

485 Card With Adapter and the Liebert IntelliSlot Web/485 Card With Adapter. Authenticated alarm

management and event notification ensures that alarms are detected and acted upon, which allows

problems to be quickly resolved.

12.4 Liebert IntelliSlot Web/485 Card With Adapter and Liebert IntelliSlot 485 Card With Adapter

The Liebert IntelliSlot Web/485 Card With Adapter and the Liebert IntelliSlot 485 Card With

Adapter provide Ethernet connectivity for Liebert equipment. Operating status and alarms are communicated via the network to external systems utilizing industry standard open protocols.

12.5 Environmental Discrete Outputs Card

The Environmental Discrete Outputs Card (ENV-DO) provides 16 discrete outputs, corresponding to

status and major alarm conditions. These Form-C contact closures provide a straightforward means

to connect Liebert environmental units to Building Management Systems (BMS), I/O or alarm panels.

12.6 Remote Contact Monitor (RCM4)

LEDs display customized alarm indication for any dry contact input including alarms for Liebert

environmental, power and UPS systems. The RCM4 monitors and displays four dry contact points.

12.7 Auto-Changeover Control

Up to eight environmental units can be automatically and centrally controlled for

emergency switching and to balance unit runtime. The AC3 controls two or three

units. The RAC2-8 controls two through eight units and has the ability to provide

alarm notification to pagers.

22

Page 31

12.8 Universal Monitor

Universal Monitor

Large and Small Enclosures

Area Leak

Detection

Zone Leak

Detection

The Universal Monitor keeps personnel on-site and at remote locations

apprised of the status of equipment through local alarming and remote

paging services. The panel will interface with anything that closes an

electrical contact and any device with a 4-20mA signal. To improve process efficiency and troubleshooting, the panel tracks data in an alarm

log, an event log and a trend log. The Universal Monitor has a local

LCD interface and a remote dial-up interface.

12.8.1 Leak Detection

Zone detectors with cable or single point detectors provide fast and

accurate indication of water in you critical space. These systems communicate with your unit or with a separate monitoring system. Area

water detection cable with distance measurement and monitoring

protects your entire room. This system quickly and accurately calculates and displays the location of water on the cable, allowing you to

promptly fin and correct a leak.

12.8.2 Temperature and Humidity Recorder

A seven-day temperature and humidity recorder permits close examination of

computer room environment condition and can be used as a permanent record of

the environmental control system’s operation efficiency. The system includes

pens, 100 recording charts; two bottles of recording ink (1 red ink and 1 blue

ink).

Comprehensive Monitoring Solutions—Optional

23

Page 32

System Data

13.0 SYSTEM DATA

Table 2 Liebert Challenger ITR air-cooled data—60 Hz

Split Systems

System Type

BR = Horizontal Flow

Self-Contained

w/Outdoor Prop-Fan

Condensing Unit

Indoor Unit BR 067A BR 060E BR 060E

Net Capacity Data BTU/H kW BTU/H kW BTU/H kW

100°F DB, 70°F WB (37.8°C DB, 21.1°C WB) 20% RH

Total 78,100 22.9 76,200 22.3 73,200 21.4

Sensible 78,100 22.9 76,200 22.3 73,200 21.4

Non Standard Flow Rates 2400 CFM 2300 CFM 2100 CFM

95°F DB, 68.3°F WB (35°C DB, 20.2°C WB) 24% RH

Total 77,500 22.7 75,800 22.2 73,000 21.4

Sensible 77,500 22.7 75,800 22.2 73,000 21.4

Non Standard Flow Rates 2700 CFM 2500 CFM

90°F DB, 66.5°F WB (32°C DB, 19.2°C WB) 28% RH

Total 73,600 21.6 72,400 21.2 70,600 20.7

85°F DB, 64.4°F WB (29.4°C DB, 18

80°F DB, 62.7°F WB (26.7°C DB, 17.1°C WB) 38% RH

80°F DB, 66.5°F WB (26.7°C DB, 19.2°C WB) 50% RH

75°F DB, 62.5°F WB (23.9°C DB, 16.9°C WB) 50% RH

75°F DB, 61.1°F WB (23.9°C DB, 16.2°C WB) 45% RH

72°F DB, 60.1°F WB (22.2°C DB, 15.6°C WB) 50% RH

72°F DB, 58.7°F WB (22.2°C DB, 14.8°C WB) 45% RH

Fan Data (Blower A12x9AT)**

Evaporator Coil (V-FRAME, at standard conditions)

Electric Reheat 2 Stage (Stainless Steel, Fin Tubular) - Standard

Capacity, inc. motor heat, BTU/H (

Hot Water Reheat 180°F (82.2°C) EWT, 75°F (23.9°C) EAT - Optional (includes std air volume and opt fan motor hp)

Capacity, inc. motor heat, BTU/H (kW) 88,700 (26.0) 88,700 (26.0) 88,700 (26.0)

* The net capacity data has fan motor heat factored in for all ratings and the entering air condition of 72°F (22.2°C) and 50% RH is the

standard rating for ASHRAE 127-2001. All capacities are nominal values; actual performance will be ±5%.

** Data rated with 2" 20% ASHRAE filter. Some options or combinations of options may result in reduced airflow. Consult factory for

recommendations.

°

C WB) 32% RH

Standard Air, CFM (CMH) 2800 (4760) 2800 (4760) 2800 (4760)

Standard Fan Motor, hp (kW) 1-1/2 (1.1) 1-1/2 (1.1) 1-1/2 (1.1)

Opt Fan Motor, hp (kW) 2 (1.5) 2 (1.5) 2 (1.5)

Ext Static, in. WG (Pa) .3 (75) .3 (75) .3 (75)

Face Area, ft.

Face Velocity - FPM (m/s) 405 (2.1) 405 (2.1) 405 (2.1)

Flow Rate - GPM (l/s) 5.0 (.32) 5.0 (.32) 5.0 (.32)

Pressure drop - ft. (kPa) 16.9 (50.4) 16.9 (50.4) 16.9 (50.4)

Sensible 73,600 21.6 72,400 21.2 70,600 20.7

Total 69,700 20.4 68,400 20.0 66,800 19.6

Sensible 69,700 20.4 68,400 20.0 66,800 19.6

Total 66,000 19.3 64,400 18.9 63,100 18.5

Sensible 66,000 19.3 64,400 18.9 63,100 18.5

Total 66,900 19.6 65,300 19.1 63,800 18.7

Sensible 54,600 16.0 54,000 15.8 53,400 15.6

Total 62,700 18.4 60,800 17.8 59,600 17.5

Sensible 53,000 15.5 52,300 15.3 51,800 15.2

Total 61,200 17.9 60,700 17.8 59,600 17.5

Sensible 57,000 16.7 60,700 17.8 59,600 17.5

Total 60,200 17.6 58,200 17.1 57,200 16.8

Sensible 52,000 15.2 51,200 15.0 50,700 14.9

Total 58,900 17.3 58,400 17.1 57,500 16.8

Sensible 55,800 16.3 58,400 17.1 57,500 16.8

2

(m2) 6.67 (.62) 6.67 (.62) 6.67 (.62)

Rows 4 4 4

element kW) 56,200 (15) 56,200 (15) 56,200 (15)

w/Indoor Centrifugal

Condensing Unit

24

Page 33

System Data

Table 3 Liebert Challenger ITR air-cooled data—60 Hz (continued)

Split Systems

System Type

Indoor Unit

Self-Contained

BR 067A BR 060E BR 060E

w/Outdoor Prop-Fan

Condensing Unit

w/Indoor Centrifugal

Condensing Unit

Infrared Humidifier - Standard

Capacity - lb/hr (kg/hr) 11 (5) 11 (5) 11 (5)

kW 4.8 4.8 4.8

Steam Generating Humidifier - Optional

Capacity - lb/hr (kg/hr) 11 (5) 11 (5) 11 (5)

kW 3.9 3.9 3.9

Filter Section - Efficiencies per ASHRAE 52.1 - Disposable Type

20% efficiencies available in 2" (51mm) - Standard, or optional 4" (102mm) depths; other optional 4" (102mm) efficiencies

are: 30%, 40-45%, 60-65%

Nominal Size - inches 28.5 x 29.5 28.5 x 29.5 28.5 x 29.5

Nominal Size - mm 724 x 749 724 x 749 724 x 749

2

Effective Surface Area - ft

Connection Sizes Liebert Challenger ITR Unit

Hot Gas Line 7/8 OD Cu N/A N/A

Humidifier Supply Line 1/4 OD Cu 1/4 OD Cu 1/4 OD Cu

Condensate Drain Line 1/2 FPT 1/2 FPT 1/2 FPT

Condenser Air 95°F (35°C) Ambient

Motor, hp (kW) 3/4 (.56) 3/4 (.56) 2 (1.5)

Ext. Static, in. WG (Pa) N/A N/A 0.5 (125)

Liquid Line Connection 5/8 OD Cu 1/2 OD Cu 1/2 OD Cu

Hot Gas Connection 1-1/8 OD Cu N/A N/A

Suction Line Connection N/A 1-1/8 OD Cu 1-1/8 OD Cu

(m2) 24.1 (2.2) 24.1 (2.2) 24.1 (2.2)

Liquid Line 1/2 OD Cu 1/2 OD Cu 1/2 OD Cu

Suction Line N/A 1-1/8 CD Cu 1-1/8 CD Cu

Model CSF104 PFH067A_ _H MC_65A

CFM (CMH) 6200 (10533) 6700 (11383) 3500 (5947)

25

Page 34

System Data

Table 4 Liebert Challenger ITR air-cooled data—50 Hz

System Type

BR = Horizontal Flow

Self-Contained

w/Outdoor Prop-Fan

Condensing Unit

Indoor Unit BR 065A BR 059E BR 059E

Net Capacity Data

37.8°C DB, 21.1°C WB (100°F DB, 70°F WB) 20% RH

Total 22.4 76,300 25.8 87,900 21.0 71,800

Sensible 22.4 76,300 25.8 87,900 21.0 71,800

Non Standard Flow Rates 2300 CFM 2100 CFM

35°C DB, 20.2°C WB (95°F DB, 68.3°F WB) 24% RH

Total 22.0 75,100 24.3 83,100 21.3 72,600

Sensible 22.0 75,100 24.3 83,100 21.3 72,600

32.2°C DB, 19.2°C WB (90°F DB, 66.5°F WB) 28% RH

Total 20.9 71,200 23.0 78,400 20.2 68,800

Sensible 20.9 71,200 23.0 78,400 20.2 68,800

29.4°C DB, 18°C WB (85°F DB, 64.4°F WB) 32% RH

Total 19.7 67,200 21.6 73,800 19.1 65,100

Sensible 19.7 67,200 21.6 73,800 19.1 65,100

26.7°C DB, 17.1°C WB (80°F DB, 62.7°F WB) 38% RH

Total 18.6 63,600 20.3 69,300 18.0 61,400

Sensible 18.6 63,600 20.3 69,300 18.0 61,400

26.7°C DB, 19.2°C WB (80°F DB, 66.5°F WB) 50% RH

Total 19.0 64,900 21.3 72,600 18.3 62,400

Sensible 15.2 51,800 16.0 54,700 14.9 50,900

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total 17.8 60,600 19.5 66,600 17.0 58,100

Sensible 14.7 50,300 15.5 52,800 14.4 49,300

23.9°C DB, 16.2°C WB (75°F DB, 61.1°F WB) 45% RH

Total 17.3 59,100 19.0 64,700 16.6 56,700

Sensible 15.8 54,000 16.5 56,300 15.5 53,000

22.2°C DB, 15.6°C WB (72°F DB, 60.1°F WB) 50% RH

Total 17.0 58,100 18.6 63,600 16.3 55,700