Page 1

Product Bulletin

2052 Actuator

D103295X012

November 2014

Fisherr 2052 Diaphragm Rotary Actuator

Fisher 2052 spring-and-diaphragm rotary actuators are

used on rotary-shaft valve bodies for throttling or

on-off applications. The 2052 may be used for

throttling service with a positioner, or it may be used

for on-off service without a positioner. The 2052 has an

ISO 5211 mating interface that allows installation to

non-Fisher valves. Refer to separate bulletins for valve

and positioner information.

Features

61.1:2052

n Compact design, smaller actuators-- Ensures

reduced valve/actuator envelope dimensions

leading to greater mounting versatility for both

skids and process plants, where space is at a

premium.

n Compatible with DVC2000, DVC6200, and

DVC6000 digital valve controllers; and 3610J and

3620J positioners-- The new actuator allows

linkage-less feedback, via a contact-less magnetic

array, from the lever to the end-mounted DVC2000.

Integral window mounting of the DVC6200,

DVC6000, 3610J, and 3620J is also available.

n Clamped lever to reduce lost motion-- The clamping

of the lever onto a splined valve shaft, coupled with

the single pivot linkage, reduces lost motion

between the actuator and the valve. The typical

cumulative deadband for a Fisher rotary control

valve assembly results in 0.5% or less variability.

n No bench set required-- The new nested spring

design requires no bench set. This also simplifies the

actuator selection process, see table 3.

n ISO 5211 mounting with optional insert-- The

actuator can now be mounted directly onto

non-spline shafts, such as Square and Double D. This

allows the actuator, with its enhanced control, to

mount on a wider range of valves conforming to ISO

5211.

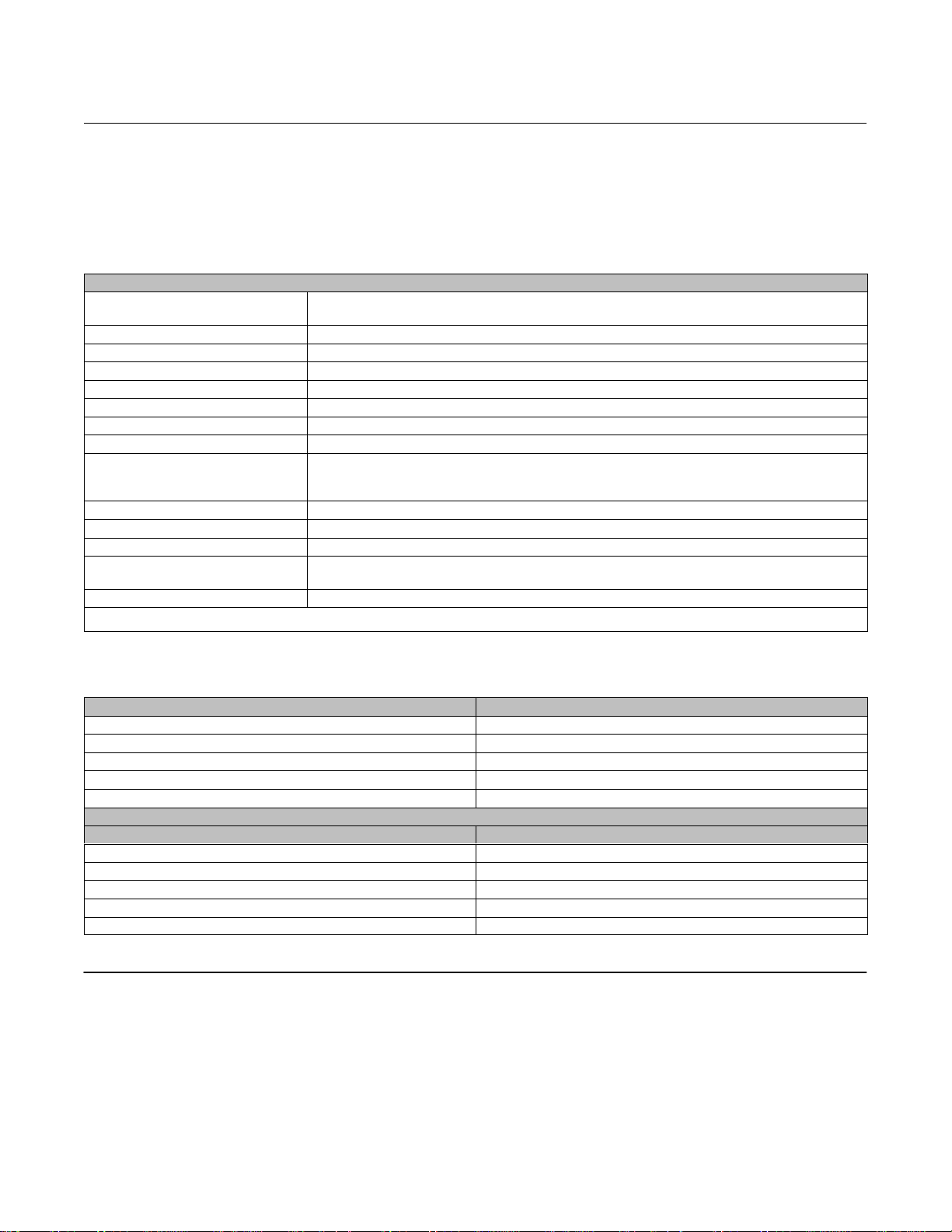

W9418-2

Fisher Control-Diskt Valve with 2052 Actuator and

FIELDVUE™ DVC6200 Digital Valve Controller

n Adjustable travel stops standard-- Provides the

ability to adjust or change the travel range by 30

degrees in either direction without removing the

actuator or the addition of extra parts.

n Fail-safe mechanism contains no aluminum-- All

parts in the fail-safe mechanism (made of steel, cast

iron, and ductile iron) ensure the actuator will

maintain safety integrity in the event of a fire.

n Powder paint as standard-- The Emerson Process

Managementt powder paint finish offers an

excellent corrosion-resistant finish to all external

steel and cast iron parts.

n NAMUR VDE/VDI 3845 bolt pattern for accessory

mounting-- Meeting the global standard ensures

compatibility for most accessories, enabling quick

and easy mounting.

n Field reversible, right- or left-hand mounting-- The

actuator/valve assembly action can be converted

from push-down-to-open to push-down-to-close, or

vice-versa, without additional parts.

n Declutchable and top-mounted handwheels--

Available for all sizes.

www.Fisher.com

Page 2

Product Bulletin

61.1:2052

November 2014

2052 Actuator Specifications and Materials of

Construction

See tables 1 and 2.

Table 1. Fisher 2052 Actuator Specifications

Specifications

Actuator Mounting Connections

Actuator Sizes See table 3

Operating Pressure

Maximum Diaphragm Casing Pressure Size 1, 2, and 3 Actuators: 5 barg (73 psig)

Pressure Connection See table 4

Torque Output See table 5

Actuator Temperature Capabilities

Operation Field reversible between PDTC and PDTO; right- and left-hand mounting, any angle of orientation

Approximate Weight

Controller/Positioners Available DVC2000, DVC6020, DVC6030, DVC6200, 3610J, 3620J, 4190, C1

Adjustable Travel Stops Standard adjustable up and down stops capable of 30 degrees of adjustment per stop.

Accessories Available 846, 646, 2625, and 67C Series, switches, i2P-100, VBL, DXP, GOt

Handwheel

Operational Lockout

1. The pressure/temperature limits in this bulletin should not be exceeded.

2. Lockout and declutchable handwheel cannot be used together on size 2 and size 3 actuators.

(1)

(1)

(2)

Splined shaft connection, ISO 5211 actuator-to-bracket connection

Top-mounted handwheel: Optional on Size 1, 2, and 3 actuators

Declutchable handwheel

Available for customer-supplied padlock to lock the actuator in the spring-fail position

Size 1: F07, Size 2: F10, Size 3: F14

See table 5

-45 to 80_C (-50 to 176_F)

Size 1: 22.2 kg (49 lb)

Size 2: 54.4 kg (120 lb)

Size 3: 113 kg (250 lb)

(2)

: Optional on Size 1, 2, and 3 actuators

2052 Actuator

D103295X012

Table 2. Materials of Construction

Component Material

Top Casing Steel

Housing Cast Iron

Diaphragm Nitrile and nylon standard

Lever Ductile iron

Diaphragm Plate Cast iron

OPTIONAL TOP-MOUNTED HANDWHEEL ASSEMBLY

Component Material

Handwheel Cast iron

Handwheel Stem Aluminum-Bronze

Top Casing Assembly Steel

O-ring Nitrile

Pusher Plate Steel

Contents

Features 1.....................................

2052 Actuator Specifications and Materials

of Construction 2............................

Options 3.....................................

Tables

Actuator and Shaft Size Availability 4.............

Torque versus Actuator Size 5...................

Pressure Connections 5........................

Dimensions 5.................................

Mounting Style 10.............................

2

Page 3

2052 Actuator

D103295X012

Product Bulletin

61.1:2052

November 2014

Options

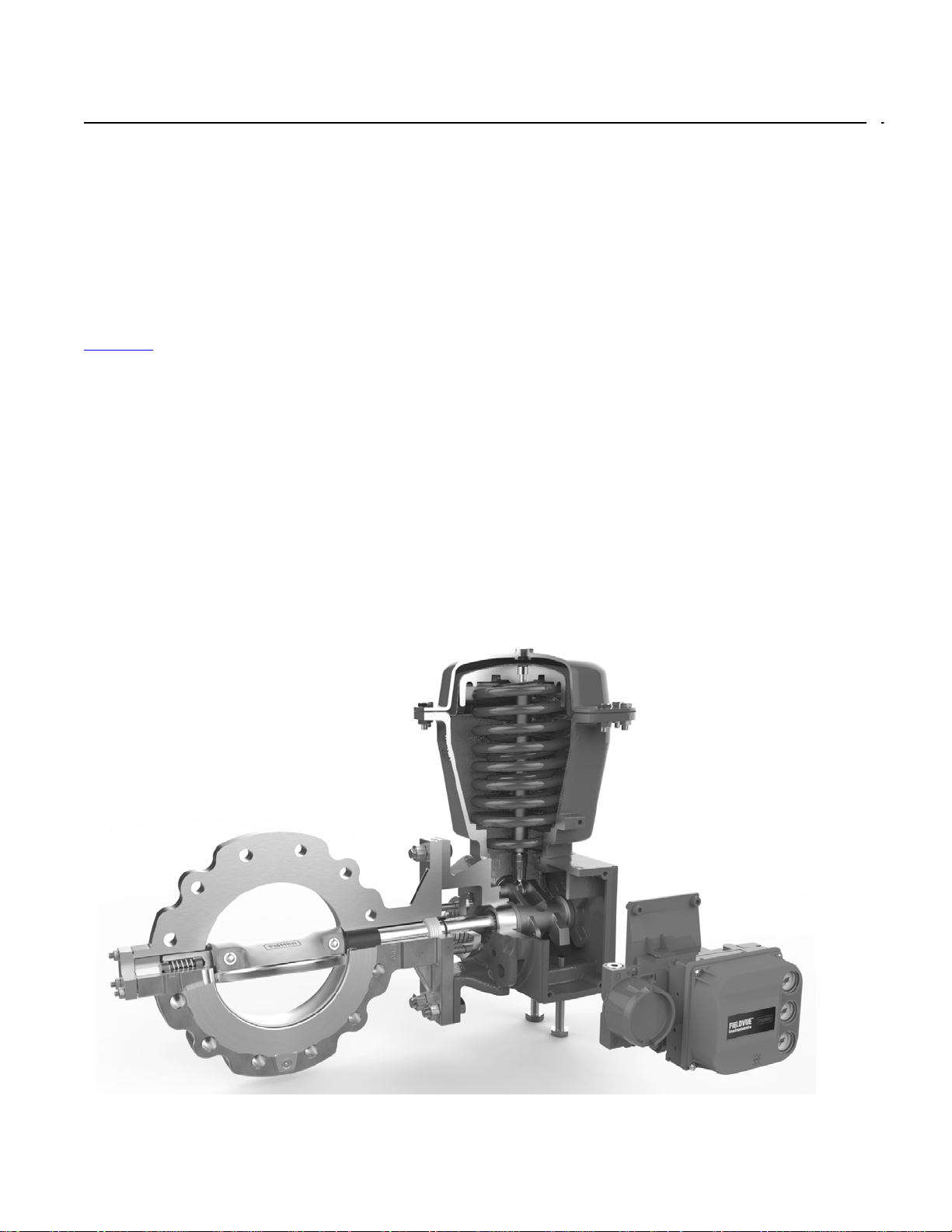

Top-Mounted Handwheel: For infrequent use as a

manual actuator (see figure 2). For repeated or daily

manual operation, the unit should be equipped with a

declutchable handwheel actuator.

Declutchable Handwheel Actuator: An end-mounted

manual actuator can be used to provide on-site control

and to provide override capabilities. See bulletin

61.8:1078

declutchable handwheel is not compatible with the

lockout option on the size 2 and size 3 actuators.

Limit Switches:

for one or two single-pole, double-throw contacts, or

J GO proximity switches for one or two single-pole,

double-throw contacts are available. See separate

bulletins for limit switch information.

Position Indicating Switch: TopWorxt DXP M21GNEB

switch for one through six single pole, double throw

switch contacts are available. See separate bulletin for

position indicating switch information.

Figure 1. Fisher 2052 Assembly

for handwheel actuator specifications. The

J Micro-Switch or NAMCO switches

Positioner: For precise positioning of the valve control

element, the actuator should be equipped with a

positioner. For additional information, contact your

Emerson Process Management sales office with

complete service conditions.

Optional Lockout Option: An actuator locking

mechanism is available, which can be used to keep the

actuator in a locked position (the same as the

spring-fail position) during maintenance. The padlock

is customer supplied. The lockout option on the size 2

and size 3 actuators is not compatible with the

declutchable handwheel.

Cold Service Construction: For services with ambient

temperatures down to -60_C (-76_F). This

construction is suitable for cold climate regions per

GOST 15150. Contact your Emerson Process

Management sales office for details. Note that the

current SIL certification for the 2052 actuator is only

relevant for the standard temperature ratings shown in

table 1. Not available with the top-mounted

handwheel option.

3

Page 4

Product Bulletin

61.1:2052

November 2014

Figure 2. Top-Mounted Handwheel

2052 Actuator

D103295X012

W9484

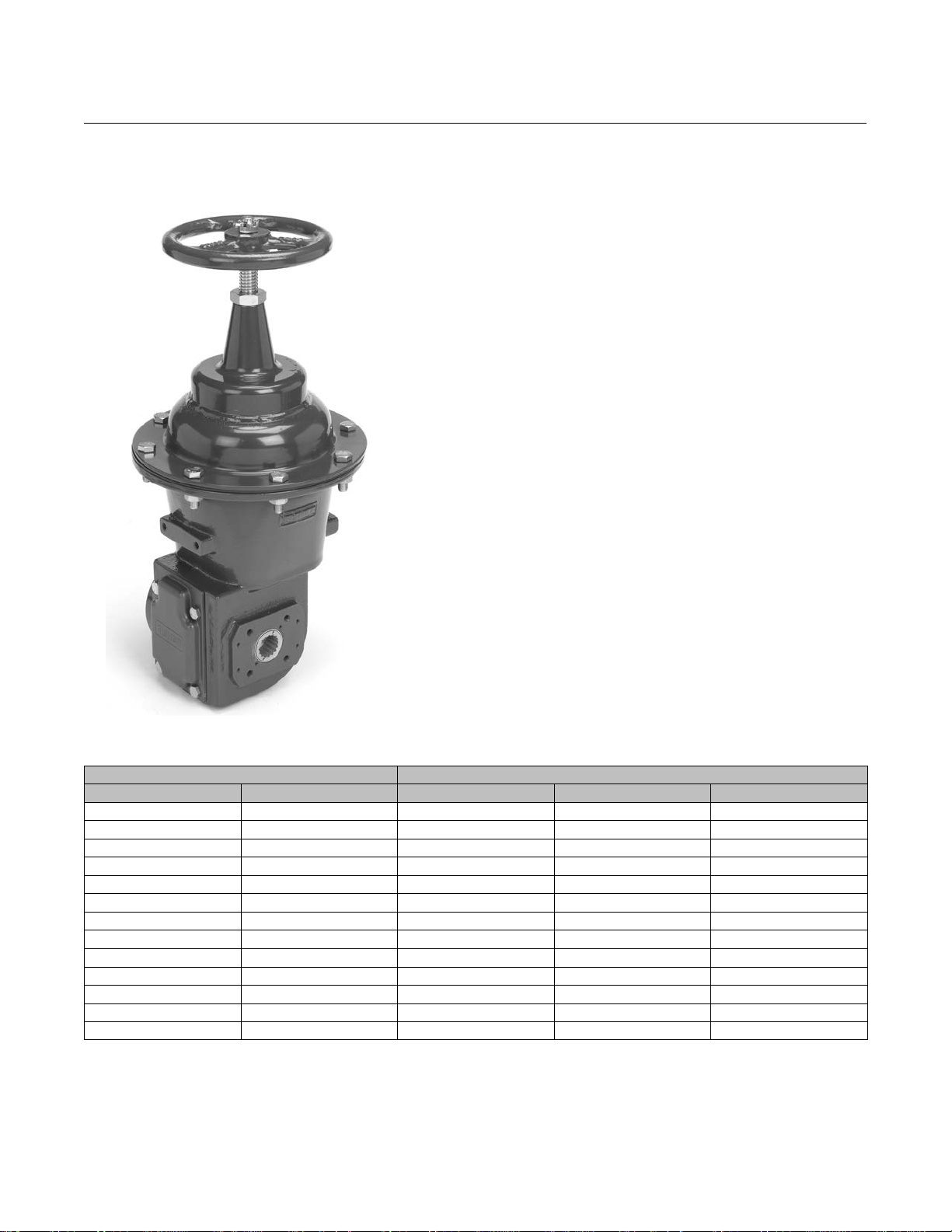

Table 3. Actuator and Shaft Size Availability

SHAFT SIZE ACTUATOR SIZE

mm Inches 1 2 3

12.7 1/2 X

14.3 x 15.9 9/16 x 5/8 X X

15.9 5/8 X X

19.1 3/4 X X X

22.2 7/8 X X

25.4 1 X X

28.6 x 31.8 1-1/8 x 1-1/4 X X

31.8 1-1/4 X X

31.8 x 38.1 1-1/4 x 1-1/2 X

38.1 1-1/2 X

39.7 x 44.5 1-9/16 x 1-3/4 X

44.5 1-3/4 X

50.8 2 X

4

Page 5

Product Bulletin

2052 Actuator

D103295X012

Table 4. Pressure Connections

ACTUATOR

SIZE

1 standard optional not available optional

2 standard optional not available optional

3 not available standard optional not available

1/4 NPT 1/2 NPT 3/4 NPT G 1/4

PRESSURE CONNECTION

Table 5. Torque versus Actuator Size

ACTUATOR

SIZE AND

ACTION

1 (PDTO)

1 (PDTC)

2 (PDTO)

2 (PDTC)

3 (PDTO) 327 2890 327 2890 631 5580 631 5580

3 (PDTC) 280 2480 557 4930 584 5170 930 8230

1. Do not interpolate between operating pressures. Consult your Emerson Process Management sales office for assistance.

2 barg (29 psig)

NSm lbfSin NSm lbfSin NSm lbfSin NSm lbfSin

25.5

25.5

105

105

(1)

226

226

930

930

3 barg (44 psig)

25.5

36.2

105

175

OPERATING PRESSURE

(1)

Torque

226

320

930

1550

4 barg (58 psig)

51.2

51.2

210

210

(1)

453

453

1860

1860

November 2014

4.7 barg (68 psig)

51.2

72.4

210

320

61.1:2052

(1)

453

641

1860

2840

Table 6. Dimensions

ACTUATOR

SIZE

1 245 9.65 267 10.51 29 1.14 103 4.06 107 4.21 71 2.80

2 350 13.78 424 16.69 49 1.93 187 7.36 170 6.69 84.5 3.33

3 496 19.53 592 23.31 64 2.52 254 10.0 185 7.28 92 3.62

C E F H P Y

mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches

Table 7. Actuator / Valve Body Mounting Dimensions

VALVE SHAFT DIAMETER

mm Inches mm Inches mm Inches mm Inches

Style F Mounting: Control-Disk, Vee-Ball™, 8532, 8510B, 8560, and 8580 Eccentric Disk Valves

12.7 - 15.9 1/2 - 5/8 A 117 4.62 - - - - - - 14.2 0.56

19.1 - 25.4 3/4 - 1 B 152 6.00 32 1.25 14.2 0.56

31.8 - 38.1 1-1/4 - 1-1/2 B 235 9.25 46 1.81 17.5 0.69

44.5 - 50.8 1-3/4 - 2 B 273 10.75 51 2.00 20.6 0.81

12.7 1/2 A 117 4.62 - - - - - - 11.0 0.44

15.9 - 25.4 5/8 - 1 B 146 5.75 32 1.25 11.0 0.44

31.8 - 38.1 1-1/4 - 1-1/2 B 210 8.25 51 2.00 17.5 0.69

FIGURE 6 REFERENCE

Style G Mounting: 9500 Series Valves

T U W

5

Page 6

Product Bulletin

61.1:2052

November 2014

Table 8. Actuator / Valve Body Mounting Dimensions

VALVE SHAFT DIAMETER

mm Inches mm Inches mm Inches mm Inches

12.7 1/2 135 5.3

15.9 5/8 135 5.3 148.5 5.8

19.1 3/4 158 6.2 171.5 6.8 179 7.0

25.4 1 171.5 6.8 179 7.0

31.8 1-1/4 169.5 6.7 177 7.0

38.1 1-1/2 177 7.0

44.5 1-3/4 316 12.4

50.8 2 316 12.4

Size 1 Size 2 Size 3

V

Table 9. Actuator / Valve Body Mounting Dimensions

ACTUATOR SIZE

1 207 8.1 171 6.7 1/4 NPT

2 289 11.4 305 12.0 1/4 NPT

3 398 15.67 356 14.0 1/2 NPT

mm Inches mm Inches NPT Connection Used

Hc Jc R

2052 Actuator

D103295X012

Table 10. NAMUR Instrument Mounting Dimensions

ACTUATOR SIZE

1 80 30 30.4 35

2 130 30 48.34 55

3 130 30 65 75

J K L N

mm mm mm mm

Table 11. ISO 5211 Mounting Information

ACTUATOR SIZE F SIZE

1 F07 70 M8 16.5

2 F10 102 M10 29.0

3 F14 140 M16 49.0

A B AA BB

mm mm mm mm

Table 12. ISO 5211 Square Insert Sizes Available

SQUARE SIZE ACTUATOR SIZE

mm 1 2 3

9 X

11 X X

14 X X X

19 X X

22 X X

27 X

36 X

See table 12

6

Page 7

2052 Actuator

D103295X012

Figure 3. Dimensions (also see tables 6, 7, and 8)

C DIAMETER

Product Bulletin

61.1:2052

November 2014

E

GG00138-A

H

F

P

Y

(Y)

V

7

Page 8

Product Bulletin

61.1:2052

November 2014

Figure 4. Handwheel Dimensions (also see tables 6 and 9)

Jc DIA

Hc

R

2052 Actuator

D103295X012

E

GE38370_1

Figure 5. Mounting Yokes Dimensions (also see table 7)

T

W DIA

GE38375_1

U

T

W DIA

REFERENCE A REFERENCE B

8

Page 9

2052 Actuator

D103295X012

Figure 6. NAMUR Instrument Mounting Dimensions (also see tables 10 and 11)

45_

Product Bulletin

61.1:2052

November 2014

2X M3

K

1

N

L

GG06029_B

N is the outside diameter of the lever hub.

1

J

Figure 7. ISO 5211 Square Lever Insert Dimensions (also see table 11)

4X M5

A

4X B

BB

AA

VIEW C-C

9

Page 10

Product Bulletin

61.1:2052

November 2014

Figure 8. Fisher 2052 Actuator Mounting Styles (also see table 13)

2052 Actuator

D103295X012

LEFT HAND MOUNTING

STYLE D SHOWN

STYLE D

4

2

3

POSITION 1

STANDARD

4

STYLE C

3

RIGHT HAND MOUNTING

VALVE

INLET

2

FLOW

VALVE

INLET

FLOW

STYLE A

4

STYLE B SHOWN

STYLE B

POSITION 1

STANDARD

2

3

4

2

3

GE37285-B

Table 13. Fisher 2052 Actuator Mounting Styles

MOUNTING

(SEE FIGURE

8)

RIGHT-HAND

LEFT-HAND

LEFT-HAND

(Optional)

1. PDTC = Push Down To Close. PDTO = Push Down To Open.

(1)

ACTION

PDTC CCW A A A CW NA B

PDTO CCW B B B CW NA A

PDTC CCW D D NA CW C C

PDTO CCW C C NA CW D D

PDTC CW C NA NA NA NA NA

PDTO CW D NA NA NA NA NA

Ball/Plug

Rotation to

Close

V150, V200,

V300 Series

CV500 and

V500

VALVE

V250

Ball/Plug

Rotation to

Close

V250

8510, 8510B,

8532, 8560,

8580, 9500,

Control-Disk

10

Page 11

2052 Actuator

D103295X012

Product Bulletin

61.1:2052

November 2014

11

Page 12

Product Bulletin

61.1:2052

November 2014

2052 Actuator

D103295X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, Control-Disk, FIELDVUE, GO, TopWorx, and Vee-Ball are marks owned by one of the companies in the Emerson Process Management business unit of

Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other

marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2008, 2014 Fisher Controls International LLC. All rights reserved.

12

Loading...

Loading...