Page 1

CONTROL VALVE

SOURCEBOOK

PULP & PAPER

Page 2

Page 3

Copyright © 2011 Fisher Controls International LLC

All Rights Reserved.

Fisher, ENVIRO-SEAL, Whisper Trim, Cavitrol, WhisperFlo, Vee‐Ball, Control‐Disk, NotchFlo, easy‐e and FIELDVUE are marks

owned by Fisher Controls International LLC, a business of Emerson Process Management. The Emerson logo is a trademark and

service mark of Emerson Electric Co. All other marks are the property of their respective owners.

This publication may not be reproduced, stored in a retrieval system, or transmitted in whole or in part, in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise, without the written permission of Fisher Controls International LLC.

Printed in U.S.A., First Edition

Page 4

Page 5

Table of Contents

Introduction v

Chapter 1 Control Valve Selection 1-1

Chapter 2 Actuator Selection 2-1

Chapter 3 Liquid Valve Sizing 3-1

Chapter 4 Cavitation & Flashing 4-1

Chapter 5 Gas Valve Sizing 5-1

Chapter 6 Control Valve Noise 6-1

Chapter 7 Steam Conditioning 7-1

Chapter 8 Process Overview 8-1

Chapter 9 Pulping 9-1

Chapter 10A Batch Digesters 10A-1

Chapter 10B Continuous Digesters 10B-1

Chapter 11 Black Liquor Evaporators/Concentrators 11-1

Chapter 12 Kraft Recovery Boiler 12-1

Chapter 13 Recausticizing & Lime Recovery 13-1

Chapter 14 Bleaching & Brightening 14-1

Chapter 15 Stock Preparation 15-1

Chapter 16 Wet End Chemistry 16-1

Chapter 17 Paper Machine 17-1

Chapter 18 Power & Recovery Boiler 18-1

iii

Page 6

iv

Page 7

Pulp and Paper Control Valves

Introduction

This sourcebook’s intent is to introduce a pulp

and paper mill’s processes, as well as the use of

control valves in many of the processes found in

the mill. It is intended to help you:

D Understand pulp and paper processes

D Learn where control valves are typically

located within each process

D Identify valves commonly used for specific

applications

D Identify troublesome/problem valves within

the process

The information provided will follow a standard

format of:

D Description of the process

D Functional drawing of the process

D FisherR valves to be considered in each

process and their associated function

Control Valves

Valves described within a chapter are labeled

and numbered corresponding to the identification

used in the proces s flow chart for that chapter.

Their valve function is described, and a

specification section gives added information on

process conditions, names of Fisher valves that

may be considered, process impact of the valve,

and any special considerations for the process

and valve(s) of choice.

Process Drawings

The process drawings within each chapter show

major equipment items, their typical placement

within the processing system, and process flow

direction. Utilities and pumps are not shown

unless otherwise stated.

Many original equipment manufacturers (OEMs)

provide equipment to the pulp and paper

industry, each with their own processes and

proprietary information. Process drawings are

based on general equipment configurations

unless otherwise stated.

D Impacts and/or considerations for

troublesome/problem valves

Valve Selection

The information presented in this sourcebook is

intended to assist in understanding the control

valve requirements of general pulp and paper

mill’s processes.

Since every mill is different in technology and

layout, the control valve requirements and

recommendations presented by this sourcebook

should be considered as general guidelines.

Under no circumstances should this information

alone be used to select a control valve without

ensuring the proper valve construction is identified

for the application and process conditions.

All valve considerations should be reviewed by the

local business representative as part of any valve

selection or specification activity.

Problem Valves

Often there are references to valve-caused

problems or difficulties. The list of problems

include valve erosion from process media,

stickiness caused by excessive friction (stiction),

excessive play in valve to actuator linkages

(typically found in rotary valves) that causes

deadband, excessive valve stem packing

leakage, and valve materials that are

incompatible with the flowing medium. Any one,

or a combination of these difficulties, may affect

process quality and throughput with a resulting

negative impact on mill profitability.

Many of these problems can be avoided or

minimized through proper valve selection.

Consideration should be given to valve style and

size, actuator capabilities, analog versus digital

instrumentation, materials of construction, etc.

Although not being all-inclusive, the information

found in this sourcebook should facilitate the

valve selection process.

v

Page 8

vi

Page 9

Chapter 1

Control Valve Selection

In the past, a customer simply requested a control

valve and the manufacturer offered the product

best-suited for the job. The choices among the

manufacturers were always dependent upon

obvious matters such as cost, delivery, vendor

relationships, and user preference. However,

accurate control valve selection can be

considerably more complex, especially for

engineers with limited experience or those who

have not kept up with changes in the control valve

industry.

An assortment of sliding-stem and rotary valve

styles are available for many applications. Some

are touted as “universal” valves for almost any

size and service, while others are claimed to be

optimum solutions for narrowly defined needs.

Even the most knowledgeable user may wonder

whether they are really getting the most for their

money in the control valves they have specified.

Like most decisions, selection of a control valve

involves a great number of variables; the everyday

selection process tends to overlook a number of

these important variables. The following

discussion includes categorization of available

valve types and a set of criteria to be considered in

the selection process.

What Is A Control Valve?

Process plants consist of hundreds, or even

thousands, of control loops all networked together

to produce a product to be offered for sale. Each

of these control loops is designed to control a

critical process variable such as pressure, flow,

level, temperature, etc., within a required operating

range to ensure the quality of the end-product.

These loops receive, and internally create,

disturbances that detrimentally affect the process

variable. Interaction from other loops in the

network provides disturbances that influence the

process variable. To reduce the effect of these

load disturbances, sensors and transmitters collect

information regarding the process variable and its

relationship to a desired set point. A controller then

processes this information and decides what must

occur in order to get the process variable back to

where it should be after a load disturbance occurs.

When all measuring, comparing, and calculating

are complete, the strategy selected by the

controller is implemented via some type of final

control element. The most common final control

element in the process control industries is the

control valve.

A control valve manipulates a flowing fluid such as

gas, steam, water, or chemical compounds to

compensate for the load disturbance and keep the

regulated process variable as close as possible to

the desired set point.

Many people who speak of “control valves” are

actually referring to “control valve assemblies.”

The control valve assembly typically consists of

the valve body, the internal trim parts, an actuator

to provide the motive power to operate the valve,

and a variety of additional valve accessories,

which may include positioners, transducers, supply

pressure regulators, manual operators, snubbers,

or limit switches.

It is best to think of a control loop as an

instrumentation chain. Like any other chain, the

entire chain is only as good as its weakest link. It

is important to ensure that the control valve is not

the weakest link.

www.Fisher.com

Page 10

Valve Types and Characteristics

The control valve regulates the rate of fluid flow as

the position of the valve plug or disk is changed by

force from the actuator. To do this, the valve must:

D Contain the fluid without external leakage.

D Have adequate capacity for the intended

service.

D Be capable of withstanding the erosive,

corrosive, and temperature influences of the

process.

D Incorporate appropriate end connections to

mate with adjacent pipelines and actuator

attachment means to permit transmission of

actuator thrust to the valve plug stem or rotary

shaft.

Many styles of control valve bodies have been

developed. Some can be used effectively in a

number of applications while others meet specific

service demands or conditions and are used less

frequently. The subsequent text describes popular

control valve body styles utilized today.

Globe Valves

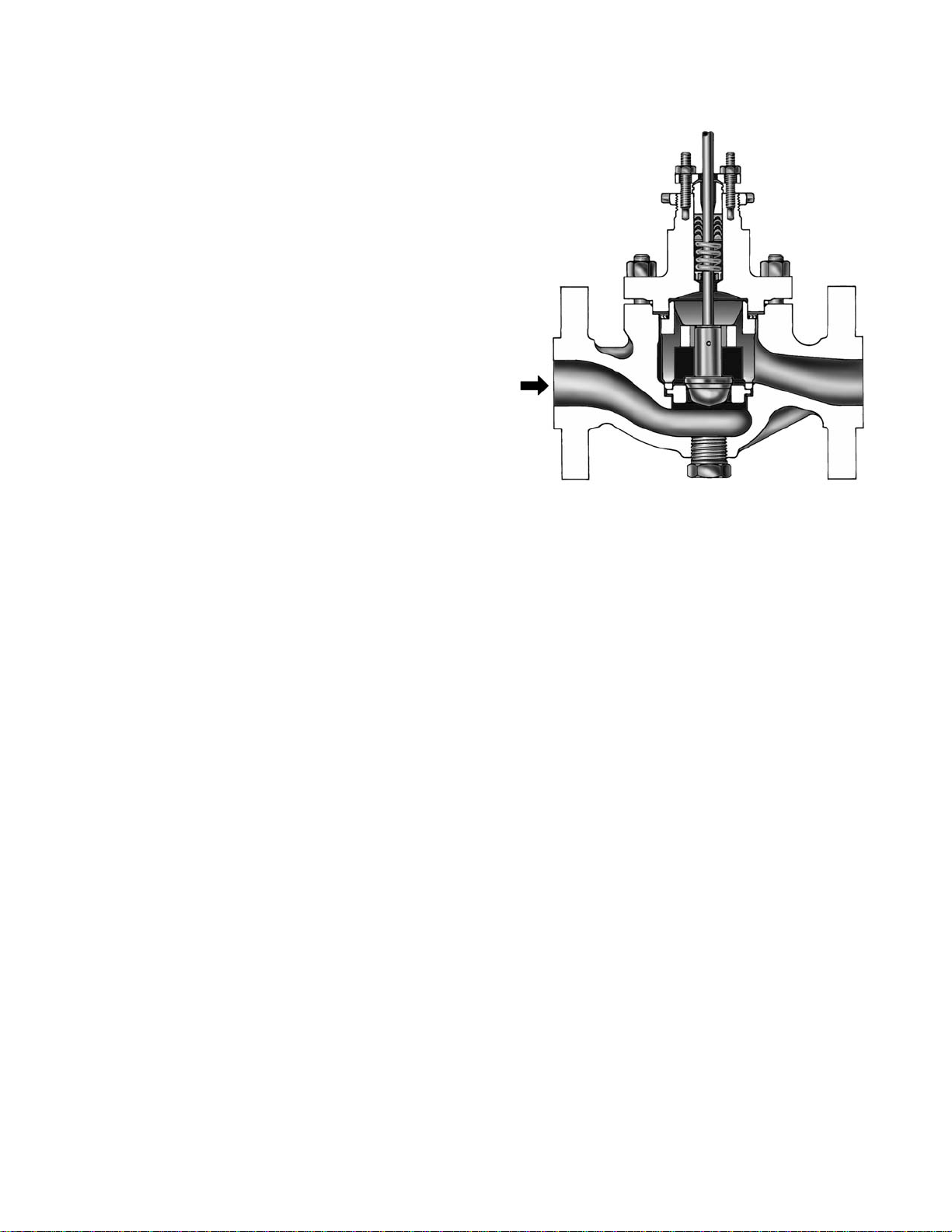

Single-Port Valve Bodies

Single-port is the most common valve body style

and is simple in construction. Single-port valves

are available in various forms, such as globe,

angle, bar stock, forged, and split constructions.

Generally, single-port valves are specified for

applications with stringent shutoff requirements.

They use metal-to-metal seating surfaces or

soft-seating with PTFE or other composition

materials forming the seal.

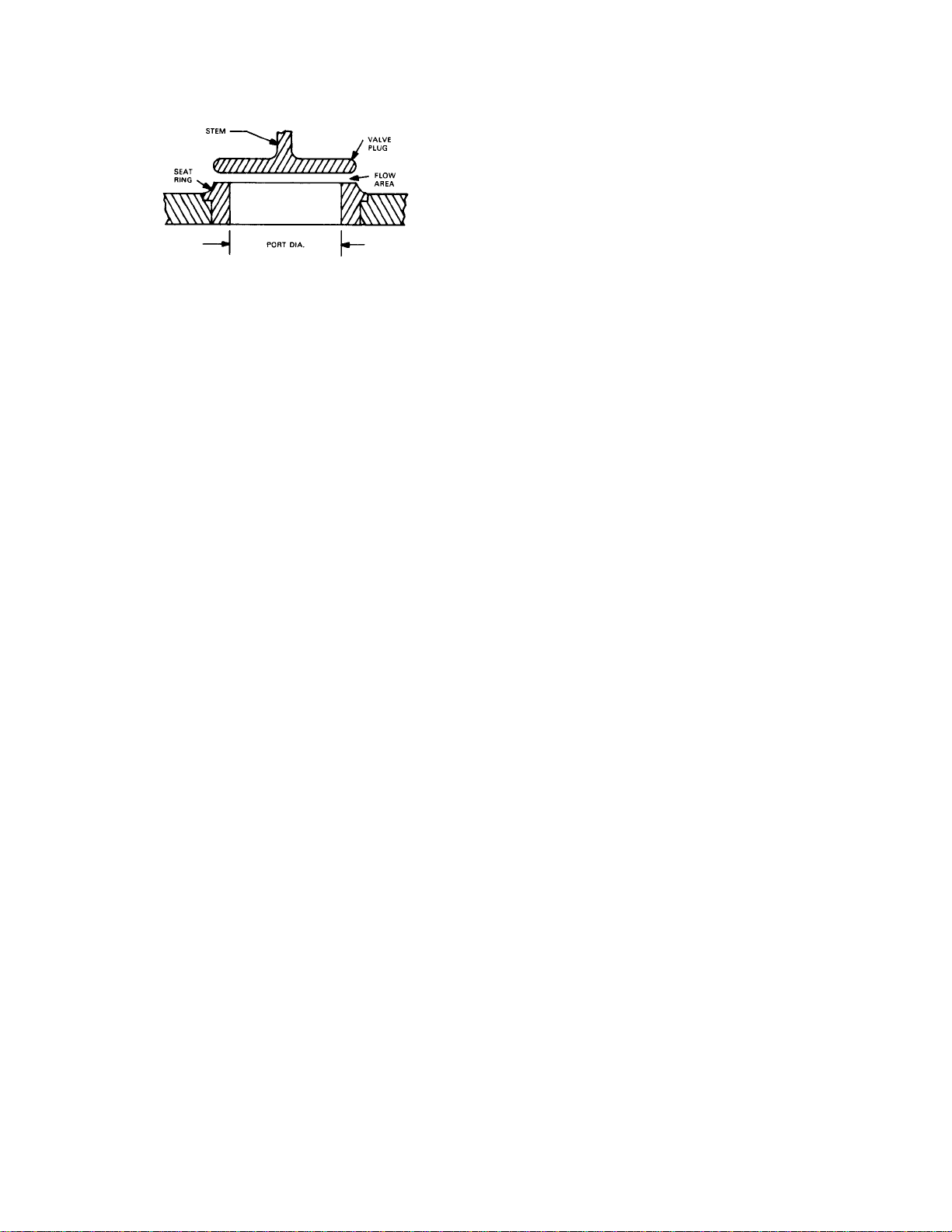

W7027-1

Figure 1-1. Single-Ported Globe-Style Valve

Body

characteristics. Retainer-style trim also offers ease

of maintenance with flow characteristics altered by

changing the plug. Cage or retainer-style

single-seated valve bodies can also be easily

modified by a change of trim parts to provide

reduced-capacity flow, noise attenuation, or

cavitation eliminating or reducing trim (see

chapter 4).

Figure 1-1 shows one of the more popular styles of

single-ported or single-seated globe valve bodies.

They are widely used in process control

applications, particularly in sizes NPS 1 through

NPS 4. Normal flow direction is most often flow-up

through the seat ring.

Angle valves are nearly always single ported, as

shown in figure 1-2. This valve has cage-style trim

construction. Others might have screwed-in seat

rings, expanded outlet connections, restricted trim,

and outlet liners for reduction of erosion damage.

Single-port valves can handle most service

requirements. Because high pressure fluid is

normally loading the entire area of the port, the

unbalance force created must be considered when

selecting actuators for single-port control valve

bodies. Although most popular in the smaller

sizes, single-port valves can often be used in NPS

4 to 8 with high thrust actuators.

Many modern single-seated valve bodies use cage

or retainer-style construction to retain the seat ring

cage, provide valve plug guiding, and provide a

means for establishing particular valve flow

1−2

Bar stock valve bodies are often specified for

corrosive applications in the chemical industry

(figure 1-3), but may also be requested in other

low flow corrosive applications. They can be

machined from any metallic bar-stock material and

from some plastics. When exotic metal alloys are

required for corrosion resistance, a bar-stock valve

body is normally less expensive than a valve body

produced from a casting.

High pressure single-ported globe valves are often

found in power plants due to high pressure steam

(figure 1-4). Variations available include

Page 11

W0971

Figure 1-2. Flanged Angle-Style

Control Valve Body

W0540

Figure 1-4. High Pressure Globe-Style

Control Valve Body

W9756

Figure 1-3. Bar Stock Valve Body

cage-guided trim, bolted body-to-bonnet

connection, and others. Flanged versions are

available with ratings to Class 2500.

Balanced-Plug Cage-Style Valve

Bodies

This popular valve body style, single-ported in the

sense that only one seat ring is used, provides the

advantages of a balanced valve plug often

W0992-4

Figure 1-5. Valve Body with Cage-Style Trim,

Balanced Valve Plug, and Soft Seat

associated only with double-ported valve bodies

(figure 1-5). Cage-style trim provides valve plug

guiding, seat ring retention, and flow

characterization. In addition, a sliding piston

ring-type seal between the upper portion of the

valve plug and the wall of the cage cylinder

virtually eliminates leakage of the upstream high

pressure fluid into the lower pressure downstream

system.

1−3

Page 12

W0997

Figure 1-6. High Capacity Valve Body with

Cage-Style Noise Abatement Trim

liquid service. The flow direction depends upon the

intended service and trim selection, with

unbalanced constructions normally flow-up and

balanced constructions normally flow-down.

Port-Guided Single-Port Valve Bodies

D Usually limited to 150 psi (10 bar) maximum

pressure drop.

D Susceptible to velocity-induced vibration.

D Typically provided with screwed in seat rings

which might be difficult to remove after use.

Three-Way Valve Bodies

D Provide general converging (flow-mixing) or

diverging (flow-splitting) service.

D Best designs use cage-style trim for positive

valve plug guiding and ease of maintenance.

Downstream pressure acts upon both the top and

bottom sides of the valve plug, thereby nullifying

most of the static unbalance force. Reduced

unbalance permits operation of the valve with

smaller actuators than those necessary for

conventional single-ported valve bodies.

Interchangeability of trim permits the choice of

several flow characteristics or of noise attenuation

or anticavitation components. For most available

trim designs, the standard direction of flow is in

through the cage openings and down through the

seat ring. These are available in various material

combinations, sizes through NPS 20, and pressure

ratings to Class 2500.

High Capacity, Cage-Guided Valve

Bodies

This adaptation of the cage-guided bodies

mentioned above was designed for noise

applications, such as high pressure power plants,

where sonic steam velocities are often

encountered at the outlet of conventional valve

bodies (figure 1-6).

The design incorporates oversized end

connections with a streamlined flow path and the

ease of trim maintenance inherent with cage-style

constructions. Use of noise abatement trim

reduces overall noise levels by as much as 35

decibels. The design is also available in cageless

versions with a bolted seat ring, end connection

sizes through NPS 20, Class 600, and versions for

D Variations include trim materials selected for

high temperature service. Standard end

connections (flanged, screwed, butt weld, etc.) can

be specified to mate with most any piping scheme.

D Actuator selection demands careful

consideration, particularly for constructions with

unbalanced valve plug.

A balanced valve plug style three-way valve body

is shown with the cylindrical valve plug in the down

position (figure 1-7). This position opens the

bottom common port to the right-hand port and

shuts off the left-hand port. The construction can

be used for throttling mid-travel position control of

either converging or diverging fluids.

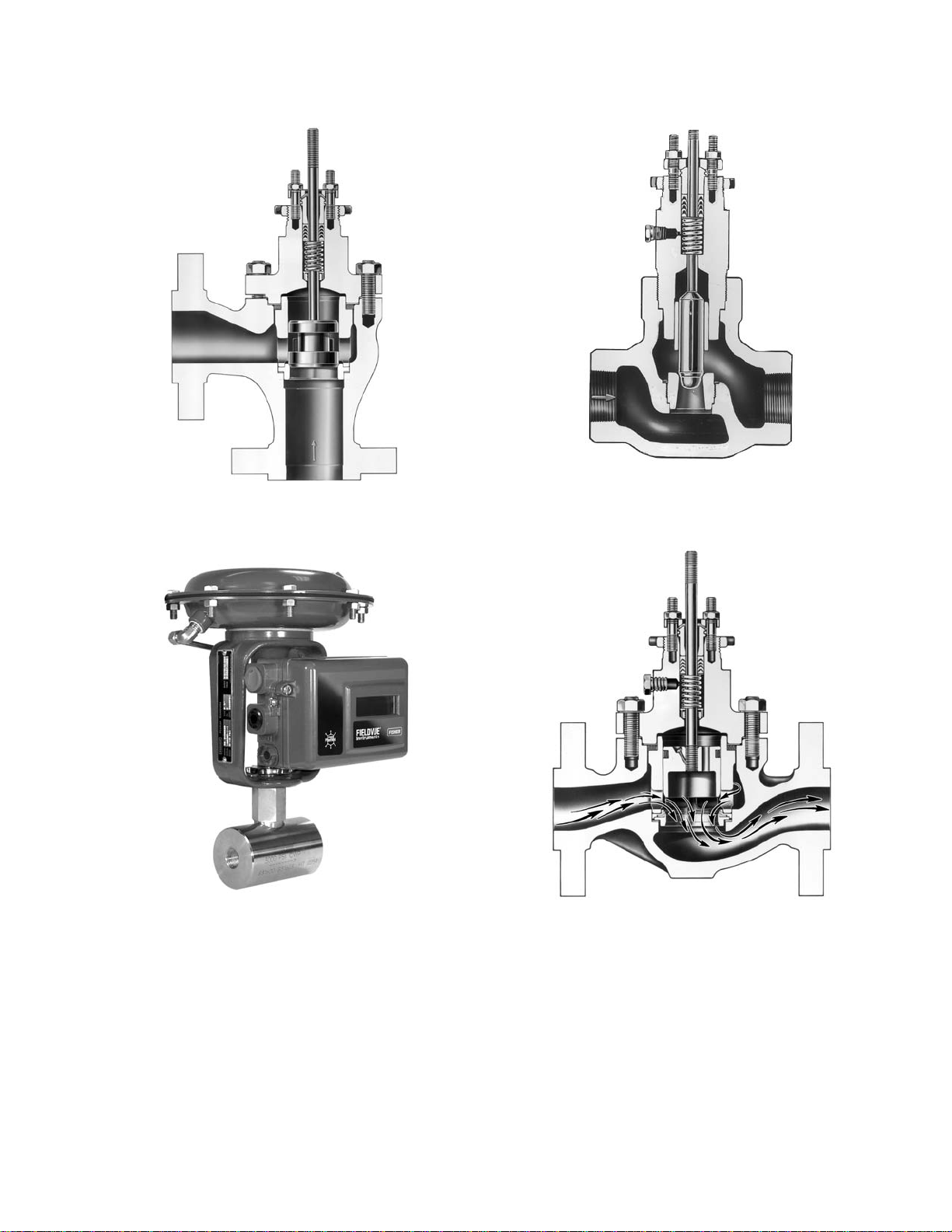

Rotary Valves

Traditional Butterfly Valve

Standard butterfly valves are available in sizes

through NPS 72 for miscellaneous control valve

applications. Smaller sizes can use versions of

traditional diaphragm or piston pneumatic

actuators, including the modern rotary actuator

styles. Larger sizes might require high output

electric or long-stroke pneumatic cylinder

actuators.

Butterfly valves exhibit an approximately equal

percentage flow characteristic. They can be used

1−4

Page 13

W8380

W9045-1

Figure 1-7. Three Way Valve with

Balanced Valve Plug

W4641

Figure 1-8. High-Performance Butterfly

Control Valve

for throttling service or for on-off control. Soft-seat

constructions can be obtained by utilizing a liner or

by including an adjustable soft ring in the body or

on the face of the disk.

Figure 1-9. Eccentric-Disk Rotary-Shaft

Control Valve

D Offer an economic advantage, particularly in

larger sizes and in terms of flow capacity per dollar

investment.

D Mate with standard raised-face pipeline

flanges.

D Depending on size, might require high output

or oversized actuators due to valve size valves or

large operating torques from large pressure drops.

D Standard liner can provide precise shutoff

and quality corrosion protection with nitrile or

PTFE liner.

Eccentric-Disk Control Valve

Eccentric disk rotary control valves are intended

for general service applications not requiring

precision throttling control. They are frequently

applied in applications requiring large sizes and

high temperatures due to their lower cost relative

to other styles of control valves. The control range

for this style of valve is approximately one third as

large as a ball or globe-style valves.

Consequently, additional care is required in sizing

and applying this style of valve to eliminate control

problems associated with process load changes.

They are well-suited for constant process load

applications.

D Provide effective throttling control.

D Require minimum space for installation

(figure 1-8).

D Provide high capacity with low pressure loss

through the valves.

D Linear flow characteristic through 90 degrees

of disk rotation (figure 1-9).

D Eccentric mounting of disk pulls it away from

the seal after it begins to open, minimizing seal

wear.

1−5

Page 14

W9425 W9418

WAFER STYLE SINGLE FLANGE STYLE

Figure 1-10. Fisher Control-Disk Valve with 2052 Actuator and FIELDVUE DVC6200 Digital Valve Controller

D Bodies are available in sizes through NPS 24

compatible with standard ASME flanges.

D Utilize standard pneumatic diaphragm or

piston rotary actuators.

D Standard flow direction is dependent upon

seal design; reverse flow results in reduced

capacity.

Control-Disk Valve

The Control-Diskt valve (figure 1-10) offers

excellent throttling performance, while maintaining

the size (face-to-face) of a traditional butterfly

valve. The Control-Disk valve is first in class in

controllability, rangeability, and tight shutoff, and it

is designed to meet worldwide standards.

D Utilizes a contoured edge and unique

patented disk to provide an improved control range

of 15 - 70% of valve travel. Traditional butterfly

lever design to increase torque range within each

actuator size.

valves are typically limited to 25% - 50% control

range.

V-notch Ball Control Valve

D Includes a tested valve sealing design,

available in both metal and soft seats, to provide

an unmatched cycle life while still maintaining

excellent shutoff

D Spring loaded shaft positions disk against the

inboard bearing nearest the actuator allowing for

the disk to close in the same position in the seal,

and allows for either horizontal or vertical

mounting.

D Complimenting actuator comes in three,

compact sizes, has nested springs and a patented

This construction is similar to a conventional ball

valve, but with patented, contoured V-notch in the

ball (figure 1-11). The V-notch produces an

equal-percentage flow characteristic. These

control valves provide precise rangeability, control,

and tight shutoff.

pressure drop.

erosive or viscous fluids, paper stock, or other

slurries containing entrained solids or fibers.

W8172-2

Figure 1-11. Rotary-Shaft Control Valve

with V-Notch Ball

D Straight-through flow design produces little

D Bodies are suited to provide control of

1−6

Page 15

on-off operation. The flanged or flangeless valves

feature streamlined flow passages and rugged

metal-trim components for dependable service in

slurry applications.

W4170-4

Figure 1-12. Sectional of Eccentric-Plug

Control Valve Body

D They utilize standard diaphragm or piston

rotary actuators.

D Ball remains in contact with seal during

rotation, which produces a shearing effect as the

ball closes and minimizes clogging.

D Bodies are available with either heavy-duty or

PTFE-filled composition ball seal ring to provide

excellent rangeability in excess of 300:1.

D Bodies are available in flangeless or

flanged-body end connections. Both flanged and

flangeless valves mate with Class 150, 300, or 600

flanges or DIN flanges.

D Valves are capable of energy absorbing

special attenuating trim to provide improved

performance for demanding applications.

Eccentric-Plug Control Valve

Control Valve End Connections

The three common methods of installing control

valves in pipelines are by means of:

D Screwed pipe threads

D Bolted gasketed flanges

D Welded end connections

Screwed Pipe Threads

Screwed end connections, popular in small control

valves, are typically more economical than flanged

ends. The threads usually specified are tapered

female National Pipe Thread (NPT) on the valve

body. They form a metal-to-metal seal by wedging

over the mating male threads on the pipeline ends.

This connection style, usually limited to valves not

larger than NPS 2, is not recommended for

elevated temperature service. Valve maintenance

might be complicated by screwed end connections

if it is necessary to take the body out of the

pipeline. This is because the valve cannot be

removed without breaking a flanged joint or union

connection to permit unscrewing the valve body

from the pipeline.

D Valve assembly combats erosion. The

rugged body and trim design handle temperatures

to 800°F (427°C) and shutoff pressure drops to

1500 psi (103 bar).

D Path of eccentric plug minimizes contact with

the seat ring when opening, thus reducing seat

wear and friction, prolonging seat life, and

improving throttling performance (figure 1-12).

D Self-centering seat ring and rugged plug

allow forward or reverse-flow with tight shutoff in

either direction. Plug, seat ring, and retainer are

available in hardened materials, including

ceramics, for selection of erosion resistance.

D Designs offering a segmented V-notch ball in

place of the plug for higher capacity requirements

are available.

This style of rotary control valve is well-suited for

control of erosive, coking, and other

hard-to-handle fluids, providing either throttling or

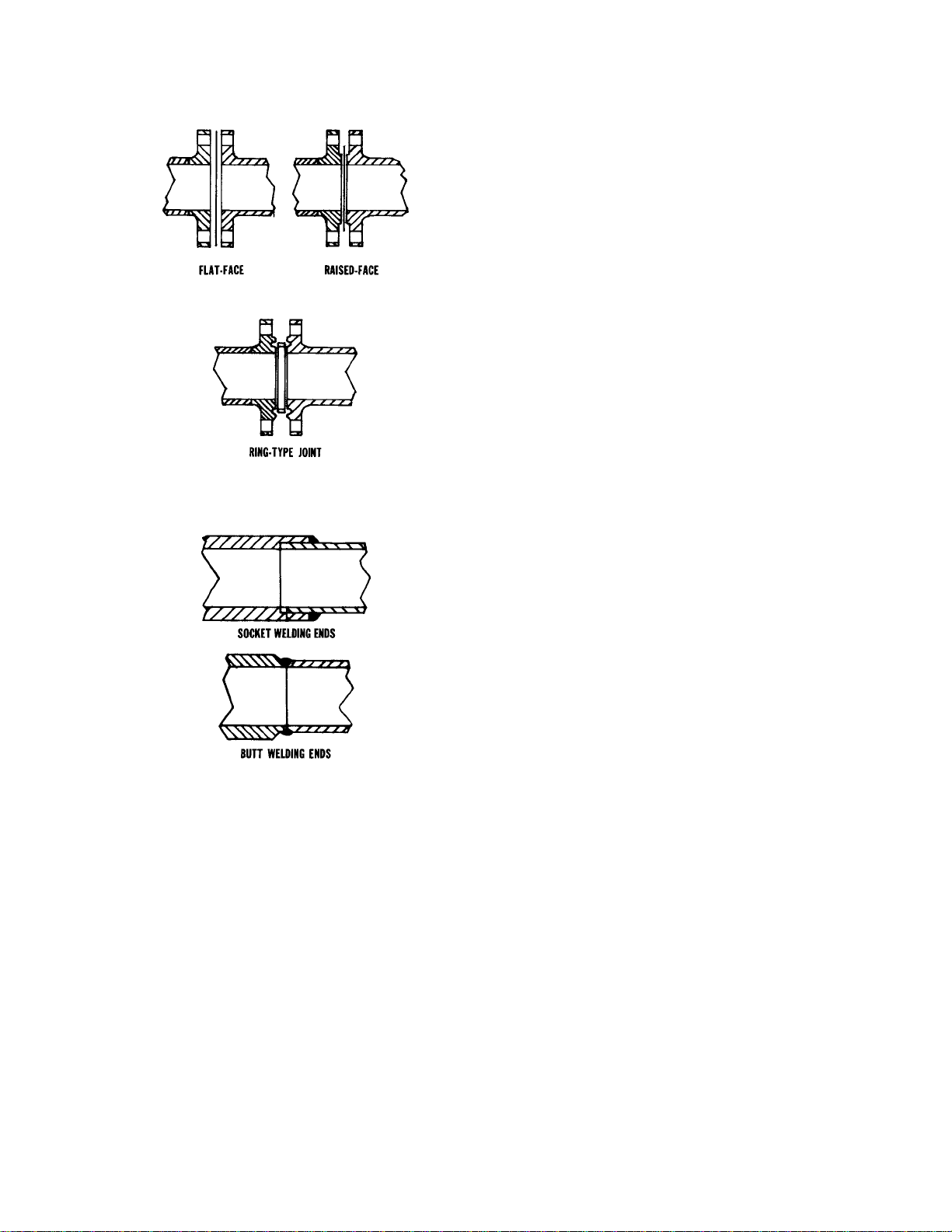

Bolted Gasketed Flanges

Flanged end valves are easily removed from the

piping and are suitable for use through the range

of working pressures for which most control valves

are manufactured (figure 1-13). Flanged end

connections can be used in a temperature range

from absolute zero to approximately 1500°F

(815°C). They are used on all valve sizes. The

most common flanged end connections include

flat-face, raised-face, and ring-type joint.

The flat face variety allows the matching flanges to

be in full-face contact with the gasket clamped

between them. This construction is commonly

used in low pressure, cast iron, and brass valves,

and minimizes flange stresses caused by initial

bolting-up force.

The raised-face flange features a circular

raised-face with the inside diameter the same as

the valve opening, and the outside diameter less

than the bolt circle diameter. The raised-face is

1−7

Page 16

or Monelt, but is available in almost any metal.

This makes an excellent joint at high pressures

and is used up to 15,000 psig (1034 bar),

however, it is generally not used at high

temperatures. It is furnished only on steel and

alloy valve bodies when specified.

Welding End Connections

Welding ends on control valves (figure 1-14) are

leak-tight at all pressures and temperatures, and

are economical in first cost. Welding end valves

are more difficult to take from the line and are

limited to weldable materials. Welding ends come

in two styles:

D Socket welding

A7098

Figure 1-13. Popular Varieties of

Bolted Flange Connections

A7099

Figure 1-14. Common Welded End Connections

finished with concentric circular grooves for

precise sealing and resistance to gasket blowout.

This kind of flange is used with a variety of gasket

materials and flange materials for pressures

through the 6000 psig (414 bar) pressure range

and for temperatures through 1500°F (815°C).

This style of flanging is normally standard on Class

250 cast iron bodies and all steel and alloy steel

bodies.

The ring-type joint flange is similar in looks to the

raised-face flange except that a U-shaped groove

is cut in the raised-face concentric with the valve

opening. The gasket consists of a metal ring with

either an elliptical or octagonal cross-section.

When the flange bolts are tightened, the gasket is

wedged into the groove of the mating flange and a

tight seal is made. The gasket is generally soft iron

D Buttwelding

The socket welding ends are prepared by boring in

a socket at each end of the valve with an inside

diameter slightly larger than the pipe outside

diameter. The pipe slips into the socket where it

butts against a shoulder and then joins to the valve

with a fillet weld. Socket welding ends in a given

size are dimensionally the same regardless of pipe

schedule. They are usually furnished in sizes

through NPS 2.

The buttwelding ends are prepared by beveling

each end of the valve to match a similar bevel on

the pipe. The two ends are then butted to the

pipeline and joined with a full penetration weld.

This type of joint is used on all valve styles and the

end preparation must be different for each

schedule of pipe. These are generally furnished for

control valves in NPS 2-1/2 and larger. Care must

be exercised when welding valve bodies in the

pipeline to prevent excessive heat transmitted to

valve trim parts. Trims with low-temperature

composition materials must be removed before

welding.

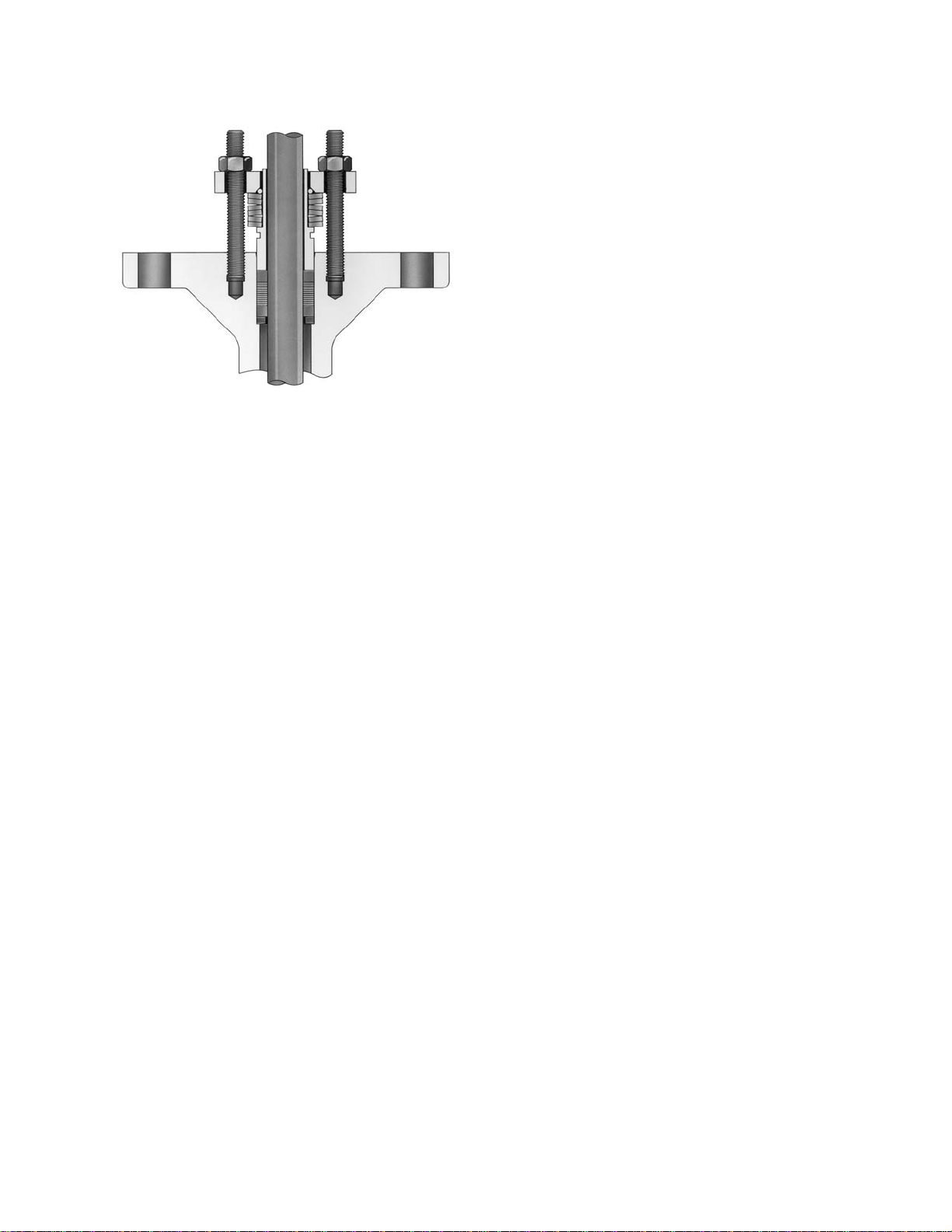

Valve Body Bonnets

The bonnet of a control valve is the part of the

body assembly through which the valve plug stem

or rotary shaft moves. On globe or angle bodies, it

is the pressure retaining component for one end of

the valve body. The bonnet normally provides a

means of mounting the actuator to the body and

houses the packing box. Generally, rotary valves

do not have bonnets. (On some rotary-shaft

valves, the packing is housed within an extension

of the valve body itself, or the packing box is a

separate component bolted between the valve

body and bonnet.)

1−8

Page 17

W0989

Figure 1-15. Typical Bonnet, Flange,

and Stud Bolts

guides the valve plug to ensure proper valve plug

stem alignment with the packing.

As mentioned previously, the conventional bonnet

on a globe-type control valve houses the packing.

The packing is most often retained by a packing

follower held in place by a flange on the yoke boss

area of the bonnet (figure 1-15). An alternate

packing retention means is where the packing

follower is held in place by a screwed gland (figure

1-3). This alternate is compact, thus, it is often

used on small control valves, however, the user

cannot always be sure of thread engagement.

Therefore, caution should be used if adjusting the

packing compression when the control valve is in

service.

Most bolted-flange bonnets have an area on the

side of the packing box which can be drilled and

tapped. This opening is closed with a standard

pipe plug unless one of the following conditions

exists:

D It is necessary to purge the valve body and

bonnet of process fluid, in which case the opening

can be used as a purge connection.

On a typical globe-style control valve body, the

bonnet is made of the same material as the valve

body or is an equivalent forged material because it

is a pressure-containing member subject to the

same temperature and corrosion effects as the

body. Several styles of valve body-to-bonnet

connections are illustrated. The most common is

the bolted flange type shown in figure 1-15. A

bonnet with an integral flange is also illustrated in

figure 1-15. Figure 1-3 illustrates a bonnet with a

separable, slip-on flange held in place with a split

ring. The bonnet used on the high pressure globe

valve body illustrated in figure 1-4, is screwed into

the valve body. Figure 1-8 illustrates a rotary-shaft

control valve in which the packing is housed within

the valve body and a bonnet is not used. The

actuator linkage housing is not a pressurecontaining part and is intended to enclose the

linkage for safety and environmental protection.

On control valve bodies with cage- or retainer-style

trim, the bonnet furnishes loading force to prevent

leakage between the bonnet flange and the valve

body, and also between the seat ring and the

valve body. The tightening of the body-bonnet

bolting compresses a flat sheet gasket to seal the

body-bonnet joint, compresses a spiral-wound

gasket on top of the cage, and compresses an

additional flat sheet gasket below the seat ring to

provide the seat ring-body seal. The bonnet also

provides alignment for the cage, which, in turn,

D The bonnet opening is being used to detect

leakage from the first set of packing or from a

failed bellows seal.

Extension Bonnets

Extension bonnets are used for either high or low

temperature service to protect valve stem packing

from extreme process temperatures. Standard

PTFE valve stem packing is useful for most

applications up to 450°F (232°C). However, it is

susceptible to damage at low process

temperatures if frost forms on the valve stem. The

frost crystals can cut grooves in the PTFE, thus,

forming leakage paths for process fluid along the

stem. Extension bonnets remove the packing box

of the bonnet far enough from the extreme

temperature of the process that the packing

temperature remains within the recommended

range.

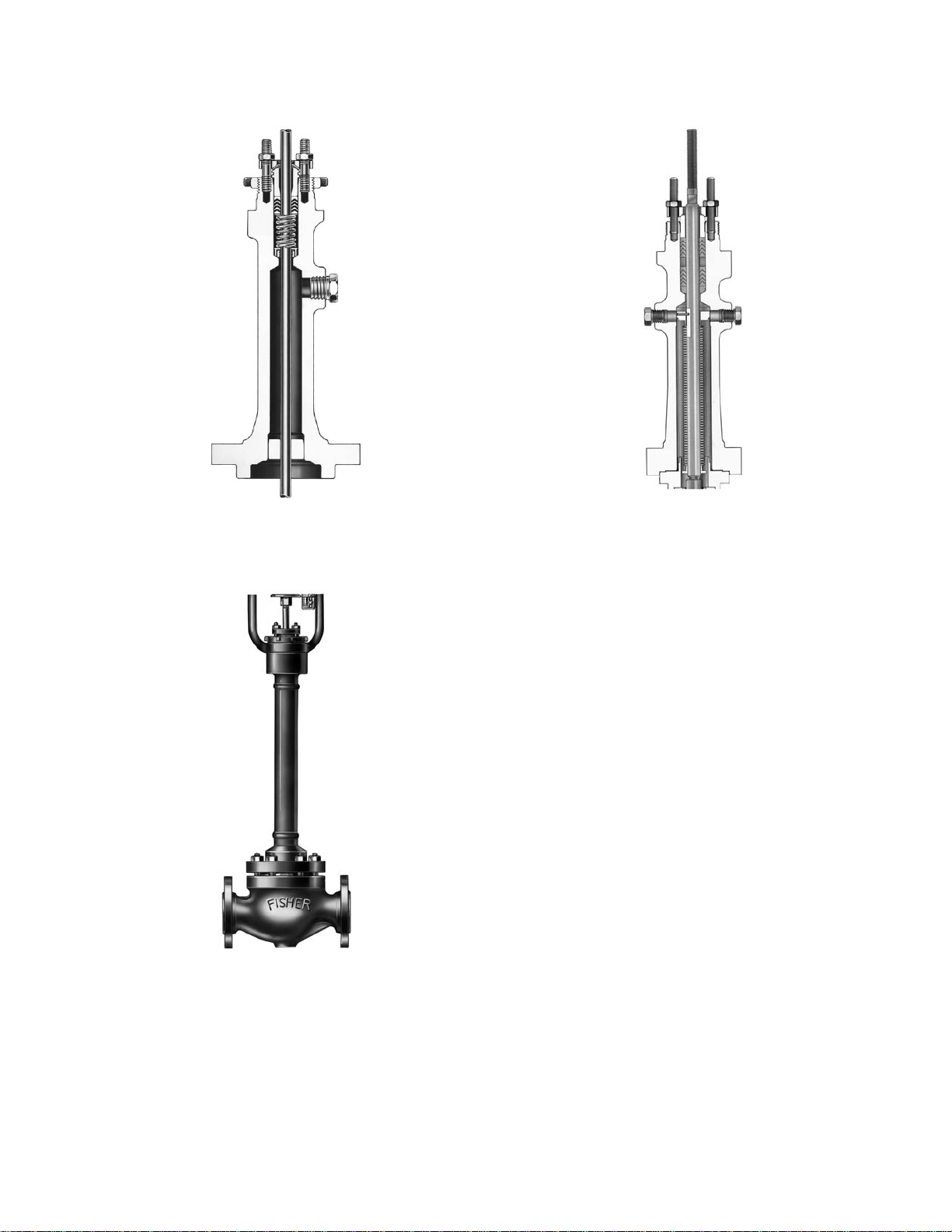

Extension bonnets are either cast (figure 1-16) or

fabricated (figure 1-17). Cast extensions offer

better high temperature service because of greater

heat emissivity, which provides better cooling

effect. Conversely, smooth surfaces that can be

fabricated from stainless steel tubing are preferred

for cold service because heat influx is usually the

major concern. In either case, extension wall

thickness should be minimized to cut down heat

transfer. Stainless steel is usually preferable to

1−9

Page 18

W0667-2

Figure 1-16. Extension Bonnet

W1416

Figure 1-17. Valve Body with

Fabricated Extension Bonnet

W6434

Figure 1-18. ENVIRO-SEALt Bellows

Seal Bonnet

Bellows Seal Bonnets

Bellows seal bonnets (figure 1-18) are used when

no leakage (less than 1x10−6 cc/sec of helium)

along the stem can be tolerated. They are often

used when the process fluid is toxic, volatile,

radioactive, or highly expensive. This special

bonnet construction protects both the stem and the

valve packing from contact with the process fluid.

Standard or environmental packing box

constructions above the bellows seal unit will

prevent catastrophic failure in case of rupture or

failure of the bellows.

As with other control valve pressure/ temperature

limitations, these pressure ratings decrease with

increasing temperature. Selection of a bellows

seal design should be carefully considered, and

particular attention should be paid to proper

inspection and maintenance after installation. The

bellows material should be carefully considered to

ensure the maximum cycle life.

Two types of bellows seal designs are used for

control valves:

D Mechanically formed as shown in figure 1-19

carbon steel because of its lower coefficient of

thermal conductivity. On cold service applications,

insulation can be added around the extension to

protect further against heat influx.

1−10

D Welded leaf bellows as shown in figure 1-20

The welded-leaf design offers a shorter total

package height. Due to its method of manufacture

and inherent design, service life may be limited.

Page 19

B2565

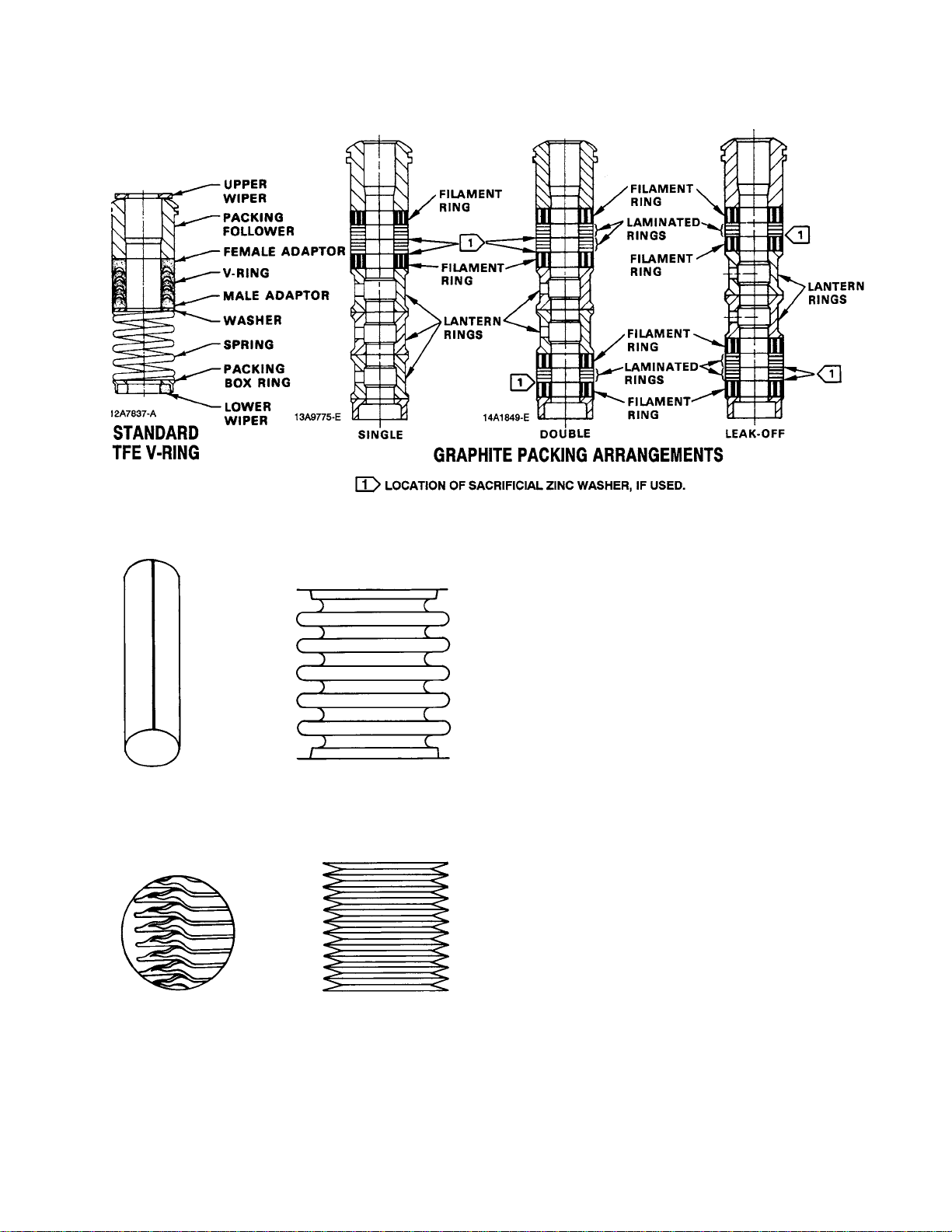

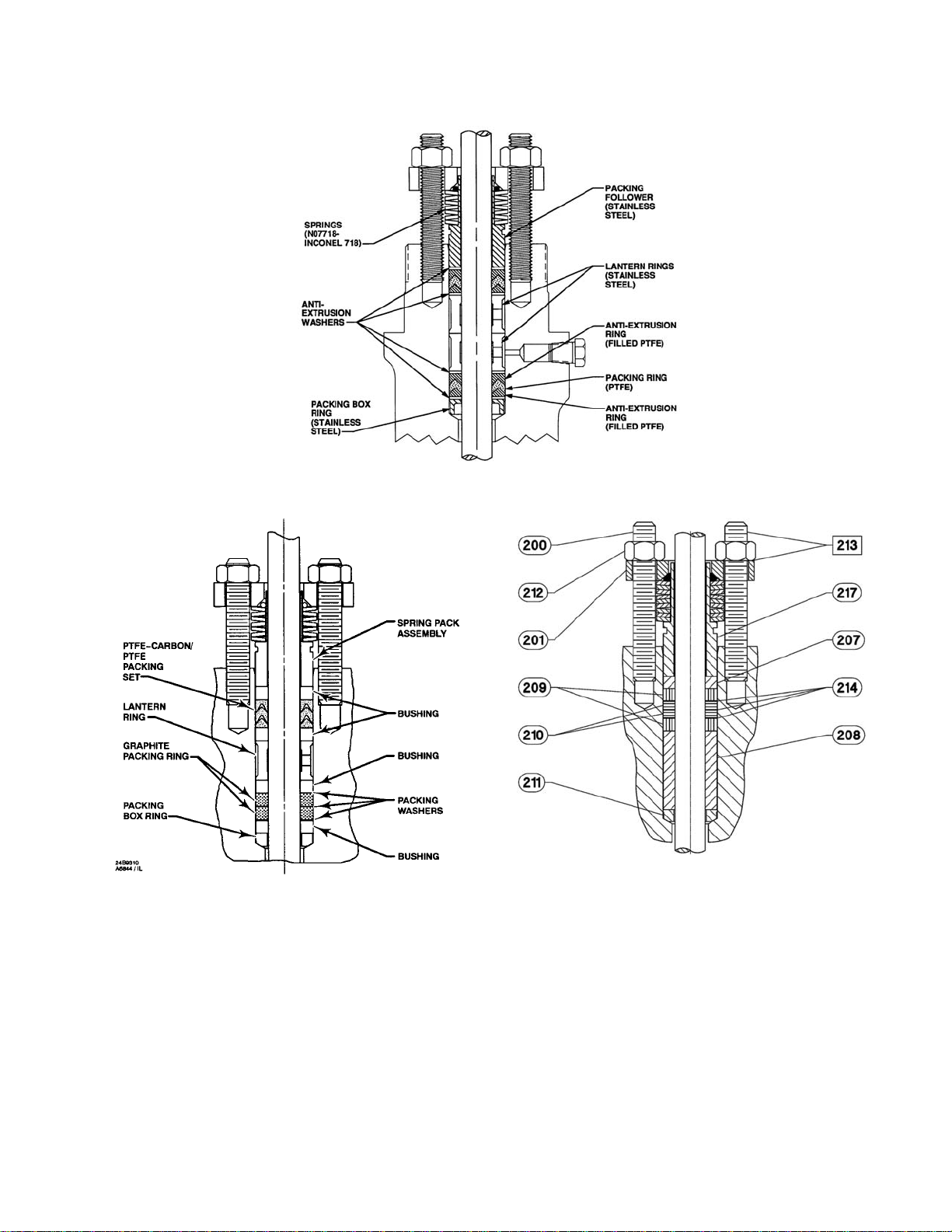

Figure 1-21. Comprehensive Packing Material Arrangements

for Globe-Style Valve Bodies

Control Valve Packing

Most control valves use packing boxes with the

packing retained and adjusted by a flange and

stud bolts (figure 1-27). Several packing materials

can be used depending upon the service

conditions expected and whether the application

requires compliance to environmental regulations.

Brief descriptions and service condition guidelines

for several popular materials and typical packing

material arrangements are shown in figure 1-21.

A5954

Figure 1-19. Mechanically Formed Bellows

A5955

Figure 1-20. Welded Leaf Bellows

The mechanically formed bellows is taller in

comparison and is produced with a more

repeatable manufacturing process.

PTFE V-Ring

D Plastic material with inherent ability to

minimize friction.

D Molded in V-shaped rings that are spring

loaded and self-adjusting in the packing box.

Packing lubrication not required.

D Resistant to most known chemicals except

molten alkali metals.

D Requires extremely smooth (2 to 4

micro-inches RMS) stem finish to seal properly.

Will leak if stem or packing surface is damaged.

D Recommended temperature limits: −40°F to

+450°F (−40°C to +232°C)

D Not suitable for nuclear service because

PTFE is easily destroyed by radiation.

1−11

Page 20

B2566

Figure 1-22. Measurement Frequency for Valves

Controlling Volatile Organic Chemicals (VOC)

Laminated and Filament Graphite

D Suitable for high temperature nuclear service

or where low chloride content is desirable (Grade

GTN).

D Provides leak-free operation, high thermal

conductivity, and long service life, but produces

high stem friction and resultant hysteresis.

D Impervious to most hard-to-handle fluids and

high radiation.

D Suitable temperature range: Cryogenic

temperatures to 1200°F (649°C).

D Lubrication not required, but an extension

bonnet or steel yoke should be used when packing

box temperature exceeds 800°F (427°C).

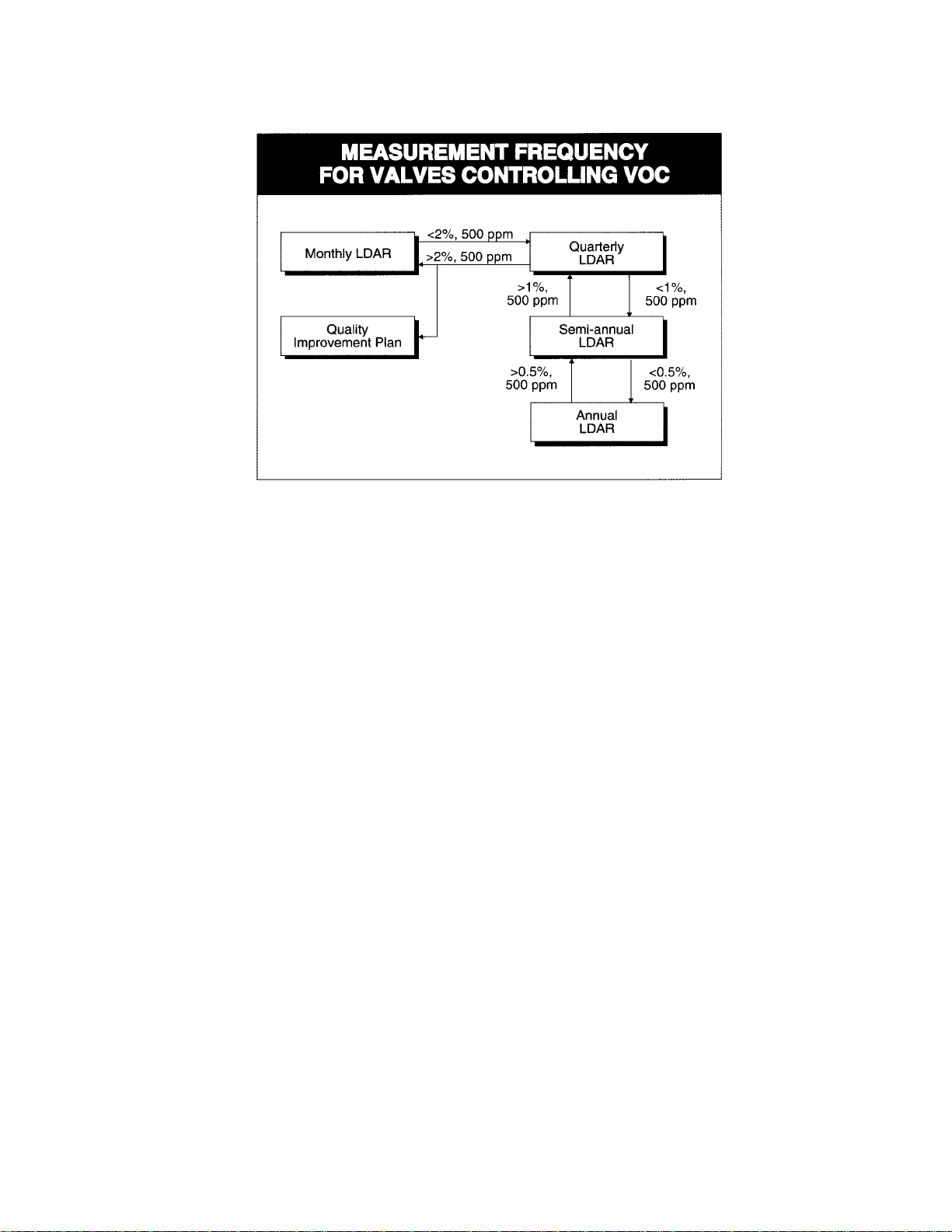

USA Regulatory Requirements for

Fugitive Emissions

Fugitive emissions are non-point source volatile

organic emissions that result from process

equipment leaks. Equipment leaks in the United

States have been estimated at over 400 million

pounds per year. Strict government regulations,

developed by the US, dictate Leak Detection and

Repair (LDAR) programs. Valves and pumps have

been identified as key sources of fugitive

emissions. In the case of valves, this is the

leakage to atmosphere due to packing seal or

gasket failures.

The LDAR programs require industry to monitor all

valves (control and noncontrol) at an interval that

is determined by the percentage of valves found to

be leaking above a threshold level of 500 ppmv

(some cities use a 100 ppmv criteria). This

leakage level is so slight you cannot see or hear it.

The use of sophisticated portable monitoring

equipment is required for detection. Detection

occurs by sniffing the valve packing area for

leakage using an Environmental Protection

Agency (EPA) protocol. This is a costly and

burdensome process for industry.

The regulations do allow for the extension of the

monitoring period for up to one year if the facility

can demonstrate an extremely low ongoing

percentage of leaking valves (less than 0.5% of

the total valve population). The opportunity to

extend the measurement frequency is shown in

figure 1-22.

Packing systems designed for extremely low

leakage requirements also extend packing seal life

and performance to support an annual monitoring

objective. The ENVIRO-SEALt packing system is

one example. Its enhanced seals incorporate four

key design principles including:

D Containment of the pliable seal material

through an anti-extrusion component.

1−12

Page 21

D Proper alignment of the valve stem or shaft

within the bonnet bore.

D Applying a constant packing stress through

Belleville springs.

D Minimizing the number of seal rings to reduce

consolidation, friction, and thermal expansion.

The traditional valve selection process meant

choosing a valve design based upon its pressure

and temperature capabilities as well as its flow

characteristics and material compatibility. Valve

stem packing used in the valve was determined

primarily by the operating temperature in the

packing box area. The available material choices

included PTFE for temperatures below 93°C

(200°F) and graphite for higher temperature

applications.

Today, choosing a valve packing system has

become much more complex due to the number of

considerations one must take into account. For

example, emissions control requirements, such as

those imposed by the Clean Air Act within the

United States and by other regulatory bodies,

place tighter restrictions on sealing performance.

Constant demands for improved process output

mean that the valve packing system must not

hinder valve performance. Also, today’s trend

toward extended maintenance schedules dictates

that valve packing systems provide the required

sealing over longer periods.

In addition, end user specifications that have

become de facto standards, as well as standards

organizations specifications, are used by

customers to place stringent fugitive emissions

leakage requirements and testing guidelines on

process control equipment vendors. Emerson

Process Management and its observance of

limiting fugitive emissions is evident by its reliable

valve sealing (packing and gasket) technologies,

global emissions testing procedures, and

emissions compliance approvals.

A6161-1

Figure 1-23. Single PTFE V-Ring Packing

Single PTFE V-Ring Packing (Fig.

1-23)

The single PTFE V-ring arrangement uses a coil

spring between the packing and packing follower.

It meets the 100 ppmv criteria, assuming that the

pressure does not exceed 20.7 bar (300 psi) and

the temperature is between −18°C and 93°C (0°F

and 200°F). It offers excellent sealing performance

with the lowest operating friction.

ENVIRO-SEAL PTFE Packing

(Fig. 1-24)

The ENVIRO-SEAL PTFE packing system is an

advanced packing method that utilizes a compact,

live-load spring design suited to environmental

applications up to 51.7 bar and 232°C (750 psi

and 450°F). While it most typically is thought of as

an emission-reducing packing system,

ENVIRO-SEAL PTFE packing is, also, well-suited

for non-environmental applications involving high

temperatures and pressures, yielding the benefit of

longer, ongoing service life.

ENVIRO-SEAL Duplex Packing

(Fig. 1-25)

Given the wide variety of valve applications and

service conditions within industry, these variables

(sealing ability, operating friction levels, operating

life) are difficult to quantify and compare. A proper

understanding requires a clarification of trade

names.

This special packing system provides the

capabilities of both PTFE and graphite

components to yield a low friction, low emission,

fire-tested solution (API Standard 589) for

applications with process temperatures up to

232°C (450°F).

1−13

Page 22

A6163

Figure 1-24. ENVIRO-SEAL PTFE Packing System

Figure 1-25. ENVIRO-SEAL Duplex (PTFE and

Graphite) Packing System

39B4612-A

Figure 1-26. ENVIRO-SEAL Graphite

ULF Packing System

carbon fiber reinforced TFE, is suited to 260°C

(500°F) service.

KALREZt Valve Stem Packing (KVSP)

systems

The KVSP pressure and temperature limits

referenced are for Fisher valve applications only.

KVSP with PTFE is suited to environmental use up

to 24.1 bar and 204°C (350 psi and 400°F) and, to

some non-environmental services up to 103 bar

(1500 psi). KVSP with ZYMAXXt, which is a

1−14

ENVIRO-SEAL Graphite Ultra Low

Friction (ULF) Packing (Fig. 1-26)

This packing system is designed primarily for

environmental applications at temperatures in

excess of 232°C (450°F). The patented ULF

packing system incorporates thin PTFE layers

inside the packing rings and thin PTFE washers on

each side of the packing rings. This strategic

Page 23

W6125-1

Figure 1-27. ENVIRO-SEAL Graphite

Packing System for Rotary Valves

placement of PTFE minimizes control problems,

reduces friction, promotes sealing, and extends

the cycle life of the packing set.

Braided graphite filament and double PTFE are

not acceptable environmental sealing solutions.

The following applies to rotary valves. In the case

of rotary valves, single PTFE and graphite ribbon

packing arrangements do not perform well as

fugitive emission sealing solutions.

The control of valve fugitive emissions and a

reduction in industry’s cost of regulatory

compliance can be achieved through these stem

sealing technologies.

While ENVIRO-SEAL packing systems have been

designed specifically for fugitive emission

applications, these technologies should also be

considered for any application where seal

performance and seal life have been an ongoing

concern or maintenance cost issue.

Characterization of Cage-Guided

Valve Bodies

HIGH-SEAL Graphite ULF Packing

Identical to the ENVIRO-SEAL graphite ULF

packing system below the packing follower, the

HIGH-SEAL system utilizes heavy-duty, large

diameter Belleville springs. These springs provide

additional follower travel and can be calibrated

with a load scale for a visual indication of packing

load and wear.

ENVIRO-SEAL Graphite Packing for

Rotary Valves (Fig. 1-27)

ENVIRO-SEAL graphite packing is designed for

environmental applications from −6°C to 316°C

(20°F to 600°F) or for those applications where fire

safety is a concern. It can be used with pressures

to 103 bar (1500 psi) and still satisfy the 500 ppmv

EPA leakage criteria.

Graphite Ribbon Packing for Rotary

Valves

Graphite ribbon packing is designed for

non-environmental applications that span a wide

temperature range from −198°C to 538°C (−325°F

to 1000°F).

The following table provides a comparison of

various sliding-stem packing selections and a

relative ranking of seal performance, service life,

and packing friction for environmental applications.

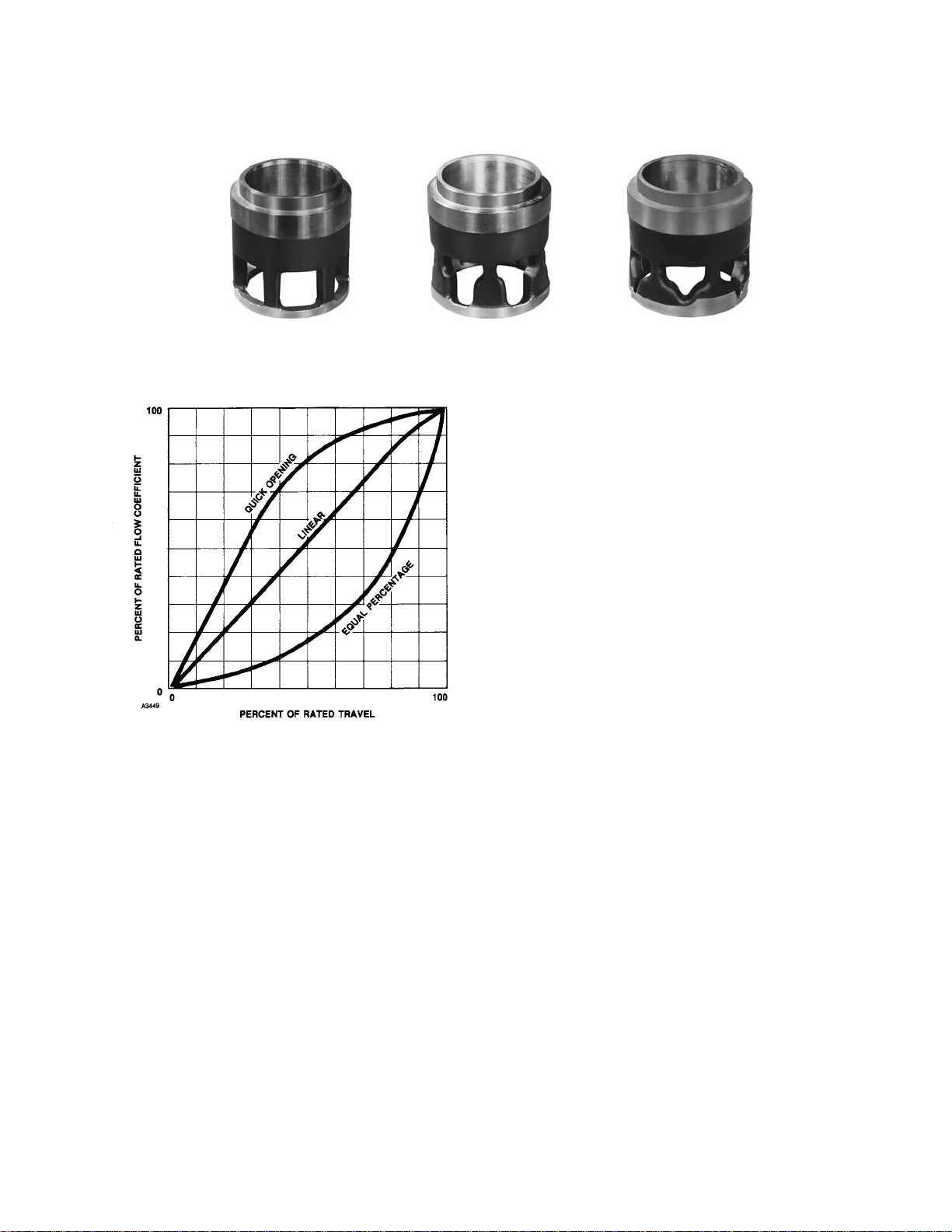

In valve bodies with cage-guided trim, the shape of

the flow openings or windows in the wall of the

cylindrical cage determines flow characterization.

As the valve plug is moved away from the seat

ring, the cage windows are opened to permit flow

through the valve. Standard cages have been

designed to produce linear, equal-percentage, and

quick-opening inherent flow characteristics. Note

the differences in the shapes of the cage windows

shown in figure 1-28. The flow rate/travel

relationship provided by valves utilizing these

cages is equivalent to the linear, quick-opening,

and equal-percentage curves shown for contoured

valve plugs (figure 1-29).

Cage-guided trim in a control valve provides a

distinct advantage over conventional valve body

assemblies in that maintenance and replacement

of internal parts is simplified. The inherent flow

characteristic of the valve can easily be changed

by installing a different cage. Interchange of cages

to provide a different inherent flow characteristic

does not require changing the valve plug or seat

ring. The standard cages shown can be used with

either balanced or unbalanced trim constructions.

Soft seating, when required, is available as a

retained insert in the seat ring and is independent

of cage or valve plug selection.

Cage interchangeability can be extended to

specialized cage designs that provide noise

attenuation or combat cavitation. These cages

furnish a modified linear inherent flow

characteristic, but require flow to be in a specific

1−15

Page 24

W0958 W0959 W0957

QUICK OPENING LINEAR EQUAL PERCENTAGE

Figure 1-28. Characterized Cages for Globe-Style Valve Bodies

Figure 1-29. Inherent Flow

Characteristics Curves

direction through the cage openings. Therefore, it

could be necessary to reverse the valve body in

the pipeline to obtain proper flow direction.

Characterized Valve Plugs

The valve plug, the movable part of a globe-style

control valve assembly, provides a variable

restriction to fluid flow. Valve plug styles are each

designed to:

D Provide a specific flow characteristic.

D Permit a specified manner of guiding or

alignment with the seat ring.

D Have a particular shutoff or

damage-resistance capability.

Valve plugs are designed for either two-position or

throttling control. In two-position applications, the

valve plug is positioned by the actuator at either of

two points within the travel range of the assembly.

In throttling control, the valve plug can be

positioned at any point within the travel range as

dictated by the process requirements.

The contour of the valve plug surface next to the

seat ring is instrumental in determining the

inherent flow characteristic of a conventional

globe-style control valve. As the actuator moves

the valve plug through its travel range, the

unobstructed flow area changes in size and shape

depending upon the contour of the valve plug.

When a constant pressure differential is

maintained across the valve, the changing

relationship between percentage of maximum flow

capacity and percentage of total travel range can

be portrayed (figure 1-29), and is designated as

the inherent flow characteristic of the valve.

Commonly specified inherent flow characteristics

include:

Linear Flow

D A valve with an ideal linear inherent flow

characteristic produces a flow rate directly

proportional to the amount of valve plug travel

throughout the travel range. For instance, at 50%

of rated travel, flow rate is 50% of maximum flow;

at 80% of rated travel, flow rate is 80% of

maximum; etc. Change of flow rate is constant

with respect to valve plug travel. Valves with a

linear characteristic are often specified for liquid

level control and for flow control applications

requiring constant gain.

Equal-Percentage Flow

D Ideally, for equal increments of valve plug

travel, the change in flow rate regarding travel may

be expressed as a constant percent of the flow

1−16

Page 25

Valve Plug Guiding

Accurate guiding of the valve plug is necessary for

proper alignment with the seat ring and efficient

control of the process fluid. The common methods

used are listed below.

A7100

Figure 1-30. Typical Construction to Provide

Quick-Opening Flow Characteristic

rate at the time of the change. The change in flow

rate observed regarding travel will be relatively

small when the valve plug is near its seat, and

relatively high when the valve plug is nearly wide

open. Therefore, a valve with an inherent

equal-percentage flow characteristic provides

precise throttling control through the lower portion

of the travel range and rapidly increasing capacity

as the valve plug nears the wide-open position.

Valves with equal-percentage flow characteristics

are used on pressure control applications, on

applications where a large percentage of the

pressure drop is normally absorbed by the system

itself with only a relatively small percentage

available at the control valve, and on applications

where highly varying pressure drop conditions can

be expected. In most physical systems, the inlet

pressure decreases as the rate of flow increases,

and an equal percentage characteristic is

appropriate. For this reason, equal percentage

flow is the most common valve characteristic.

D Cage Guiding: The outside diameter of the

valve plug is close to the inside wall surface of the

cylindrical cage throughout the travel range. Since

the bonnet, cage, and seat ring are self-aligning

upon assembly, the correct valve plug and seat

ring alignment is assured when the valve closes

(figure 1-15).

D Top Guiding: The valve plug is aligned by a

single guide bushing in the bonnet, valve body

(figure 1-4), or by packing arrangement.

D Stem Guiding: The valve plug is aligned with

the seat ring by a guide bushing in the bonnet that

acts upon the valve plug stem (figure 1-3, left

view).

D Top-and-Bottom Guiding: The valve plug is

aligned by guide bushings in the bonnet and

bottom flange.

D Port Guiding: The valve plug is aligned by the

valve body port. This construction is typical for

control valves utilizing small-diameter valve plugs

with fluted skirt projections to control low flow rates

(figure 1-3, right view).

Quick-Opening Flow

D A valve with a quick opening flow

characteristic provides a maximum change in flow

rate at low travels. The curve is essentially linear

through the first 40 percent of valve plug travel,

then flattens out noticeably to indicate little

increase in flow rate as travel approaches the

wide-open position. Control valves with

quick-opening flow characteristics are often used

for on/off applications where significant flow rate

must be established quickly as the valve begins to

open. As a result, they are often utilized in relief

valve applications. Quick-opening valves can also

be selected for many of the same applications for

which linear flow characteristics are

recommended. This is because the quick-opening

characteristic is linear up to about 70 percent of

maximum flow rate. Linearity decreases

significantly after flow area generated by valve

plug travel equals the flow area of the port. For a

typical quick-opening valve (figure 1-30), this

occurs when valve plug travel equals one-fourth of

port diameter.

Restricted-Capacity Control Valve

Trim

Most control valve manufacturers can provide

valves with reduced- or restricted- capacity trim

parts. The reduced flow rate might be desirable for

any of the following reasons:

D Restricted capacity trim may make it possible

to select a valve body large enough for increased

future flow requirements, but with trim capacity

properly sized for present needs.

D Valves can be selected for adequate

structural strength, yet retain reasonable

travel/capacity relationship.

D Large bodies with restricted capacity trim can

be used to reduce inlet and outlet fluid velocities.

D Purchase of expensive pipeline reducers can

be avoided.

D Over-sizing errors can be corrected by use of

restricted capacity trim parts.

1−17

Page 26

Conventional globe-style valve bodies can be fitted

with seat rings with smaller port size than normal

and valve plugs sized to fit those smaller ports.

Valves with cage-guided trim often achieve the

reduced capacity effect by utilizing valve plug,

cage, and seat ring parts from a smaller valve size

of similar construction and adapter pieces above

the cage and below the seat ring to mate those

smaller parts with the valve body (figure 1-28).

Because reduced capacity service is not unusual,

leading manufacturers provide readily available

trim part combinations to perform the required

function. Many restricted capacity trim

combinations are designed to furnish

approximately 40% of full-size trim capacity.

General Selection Criteria

Most of the considerations that guide the selection

of valve type and brand are rather basic. However,

there are some matters that may be overlooked by

users whose familiarity is mainly limited to just one

or a few valve types. Table 1-1 below provides a

checklist of important criteria; each is discussed at

length following the table.

Table 1-1. Suggested General Criteria for Selecting Type

and Brand of Control Valve

Body pressure rating

High and low temperature limits

Material compatibility and durability

Inherent flow characteristic and rangeability

Maximum pressure drop (shutoff and flowing)

Noise and cavitation

End connections

Shutoff leakage

Capacity versus cost

Nature of flowing media

Dynamic performance

Pressure Ratings

Body pressure ratings ordinarily are considered

according to ANSI pressure classes — the most

common ones for steel and stainless steel being

Classes 150, 300 and 600. (Source documents

are ASME/ANSI Standards B16.34, “Steel

Valves,” and ANSI B16.1, “Cast Iron Pipe

Flanges and Flanged Fittings.”) For a given body

material, each NSI Class corresponds to a

prescribed profile of maximum pressures that

decrease with temperature according to the

strength of the material. Each material also has a

minimum and maximum service temperature

based upon loss of ductility or loss of strength. For

most applications, the required pressure rating is

dictated by the application. However, because all

products are not available for all ANSI Classes, it

is an important consideration for selection.

Temperature Considerations

Required temperature capabilities are also a

foregone conclusion, but one that is likely to

narrow valve selection possibilities. The

considerations include the strength or ductility of

the body material, as well as relative thermal

expansion of various parts.

Temperature limits also may be imposed due to

disintegration of soft parts at high temperatures or

loss of resiliency at low temperatures. The soft

materials under consideration include various

elastomers, plastics, and PTFE. They may be

found in parts such as seat rings, seal or piston

rings, packing, rotary shaft bearings and butterfly

valve liners. Typical upper temperature limits for

elastomers are in the 200 - 350°F range, and the

general limit for PTFE is 450°F.

Temperature affects valve selection by excluding

certain valves that do not have high or low

temperature options. It also may have some affect

on the valve’s performance. For instance, going

from PTFE to metal seals for high temperatures

generally increases the shutoff leakage flow.

Similarly, high temperature metal bearing sleeves

in rotary valves impose more friction upon the

shaft than do PTFE bearings, so that the shaft

cannot withstand as high a pressure-drop load at

shutoff. Selection of the valve packing is also

based largely upon service temperature.

Material Selection

The third criterion in table 1-1, “material

compatibility and durability”, is a more complex

consideration. Variables may include corrosion by

the process fluid, erosion by abrasive material,

flashing, cavitation or pressure and temperature

requirements. The piping material usually indicates

the body material. However, because the velocity

is higher in valves, other factors must be

considered. When these variables are included,

often valve and piping materials will differ. The trim

materials, in turn, are usually a function of the

body material, temperature range and qualities of

the fluid. When a body material other than carbon,

alloy, or stainless steel is required, use of an

alternate valve type, such as lined or bar stock,

should be considered.

1−18

Page 27

Flow Characteristic

The next selection criterion, “inherent flow

characteristic”, refers to the pattern in which the

flow at constant pressure drop changes according

to valve position. Typical characteristics are

quick-opening, linear, and equal-percentage. The

choice of characteristic may have a strong

influence upon the stability or controllability of the

process (see table 1-3), as it represents the

change of valve gain relative to travel.

Most control valves are carefully “characterized”

by means of contours on a plug, cage, or ball

element. Some valves are available in a variety of

characteristics to suit the application, while others

offer little or no choice. To quantitatively determine

the best flow characteristic for a given application,

a dynamic analysis of the control loop can be

performed. In most cases, however, this is

unnecessary; reference to established rules of

thumb will suffice.

The accompanying drawing illustrates typical flow

characteristic curves (figure 1-29). The quick

opening flow characteristic provides for maximum

change in flow rate at low valve travels with a fairly

linear relationship. Additional increases in valve

travel give sharply reduced changes in flow rate,

and when the valve plug nears the wide open

position, the change in flow rate approaches zero.

In a control valve, the quick opening valve plug is

used primarily for on-off service; but it is also

suitable for many applications where a linear valve

plug would normally be specified.

Rangeability

operating stability. To a certain extent, a valve with

one inherent flow characteristic can also be made

to perform as though it had a different

characteristic by utilizing a nonlinear (i.e.,

characterized) positioner-actuator combination.

The limitation of this approach lies in the

positioner’s frequency response and phase lag

compared to the characteristic frequency of the

process. Although it is common practice to utilize a

positioner on every valve application, each

application should be reviewed carefully. There

are certain examples of high gain processes

where a positioner can hinder valve performance.

Pressure Drop

The maximum pressure drop a valve can tolerate

at shutoff, or when partially or fully open, is an

important selection criteria. Sliding-stem valves

are generally superior in both regards because of

the rugged nature of their moving parts. Many

rotary valves are limited to pressure drops well

below the body pressure rating, especially under

flowing conditions, due to dynamic stresses that

high velocity flow imposes on the disk or ball

segment.

Noise and Cavitation

Noise and cavitation are two considerations that

often are grouped together because both result

from high pressure drops and large flow rates.

They are treated by special modifications to

standard valves. Chapter four discusses the

cavitation phenomenon and its impact and

treatment, while chapter six discusses noise

generation and abatement.

Another aspect of a valve’s flow characteristic is its

rangeability, which is the ratio of its maximum and

minimum controllable flow rates. Exceptionally

wide rangeability may be required for certain

applications to handle wide load swings or a

combination of start-up, normal and maximum

working conditions. Generally speaking, rotary

valves—especially partial ball valves—have

greater rangeability than sliding-stem varieties.

Use of Positioners

A positioner is an instrument that helps improve

control by accurately positioning a control valve

actuator in response to a control signal. They are

useful in many applications and are required with

certain actuator styles in order to match actuator

and instrument pressure signals, or to provide

End Connections

The three common methods of installing control

valves in pipelines are by means of screwed pipe

threads, bolted flanges, and welded end

connections. At some point in the selection

process, the valve’s end connections must be

considered with the question simply being whether

the desired connection style is available in the

valve being considered.

In some situations, this matter can limit the

selection rather narrowly. For instance, if a piping

specification calls for welded connections only, the

choice usually is limited to sliding-stem valves.

Screwed end connections, popular in small control

valves, offer more economy than flanged ends.

1−19

Page 28

The threads usually specified are tapered female

NPT on the valve body. They form a

metal-to-metal seal by wedging over the mating

male threads on the pipeline ends. This

connection style is usually limited to valves not

larger than NPS 2, and is not recommended for

elevated temperature service.

Valve maintenance might be complicated by

screwed end connections if it is necessary to take

the body out of the pipeline. Screwed connections

require breaking a flanged joint or union

connection to permit unscrewing the valve body

from the pipeline.

Flanged end valves are easily removed from the

piping and are suitable for use through the range

of working pressures that most control valves are

manufactured (figure 1-13).

Flanged end connections can be utilized in a

temperature range from absolute zero (−273°F) to

approximately 1500°F (815°C). They are utilized

on all valve sizes. The most common flanged end

connections include flat face, raised face, and ring

type joint.

the trim. Special precautions in seat material

selection, seat preparation and seat load are

necessary to ensure success.

Flow Capacity

Finally, the criterion of capacity or size can be an

overriding constraint on selection. For extremely

large lines, sliding-stem valves are more

expensive than rotary types. On the other hand,

for extremely small flows, a suitable rotary valve

may not be available. If future plans call for

significantly larger flow, then a sliding-stem valve

with replaceable restricted trim may be the

answer. The trim can be changed to full size trim

to accommodate higher flow rates at less cost than

replacing the entire valve body assembly.

Rotary style products generally have much higher

maximum capacity than sliding-stem valves for a

given body size. This fact makes rotary products

attractive in applications where the pressure drop

available is rather small. However, it is of little or

no advantage in high pressure drop applications

such as pressure regulation or letdown.

Welded ends on control valves are leak-tight at all

pressures and temperatures and are economical

in initial cost (figure 1-14). Welded end valves are

more difficult to remove from the line and are

limited to weldable materials. Welded ends come

in two styles, socket weld and buttweld.

Shutoff Capability

Some consideration must be given to a valve’s

shutoff capability, which is usually rated in terms of

classes specified in ANSI/FCI70-2 (table 1-4). In

service, shutoff leakage depends upon many

factors, including but not limited to, pressure drop,

temperature, and the condition of the sealing

surfaces. Because shutoff ratings are based upon

standard test conditions that can be different from

service conditions, service leakage cannot be

predicted accurately. However, the shutoff class

provides a good basis for comparison among

valves of similar configuration. It is not uncommon

for valve users to overestimate the shutoff class

required.

Because tight shutoff valves generally cost more

both in initial cost, as well as in later maintenance

expense, serious consideration is warranted. Tight

shutoff is particularly critical in high pressure

valves, considering that leakage in these

applications can lead to the ultimate destruction of

Conclusion

For most general applications, it makes sense

both economically, as well as technically, to use

sliding-stem valves for lower flow ranges, ball

valves for intermediate capacities, and high

performance butterfly valves for the very largest

required flows. However, there are numerous

other factors in selecting control valves, and

general selection principles are not always the

best choice.

Selecting a control valve is more of and art than a

science. Process conditions, physical fluid

phenomena, customer preference, customer

experience, supplier experience, among numerous

other criteria must be considered in order to obtain

the best possible solution. Many applications are

beyond that of general service, and as chapter 4

will present, there are of number of selection

criteria that must be considered when dealing with

these sometimes severe flows.

Special considerations may require out-of-theordinary valve solutions; there are valve designs

and special trims available to handle high noise

applications, flashing, cavitation, high pressure,

high temperature and combinations of these

conditions.

1−20

Page 29

After going through all the criteria for a given

application, the selection process may point to

several types of valves. From there on, selection

becomes a matter of price versus capability,

institutional preferences. As no single control valve

package is cost-effective over the full range of

applications, it is important to keep an open mind

to alternative choices.

coupled with the inevitable personal and

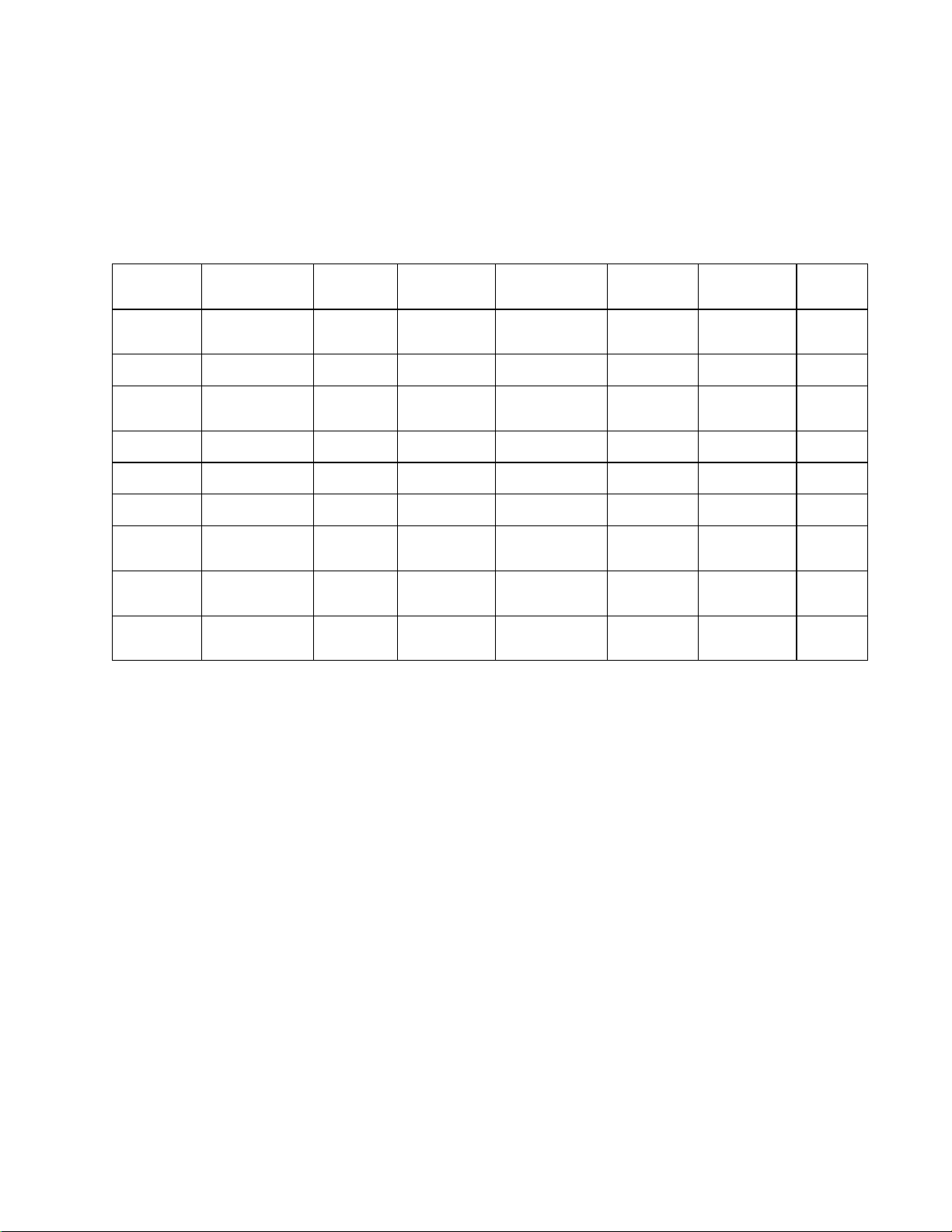

Table 1-2. Major Categories and Subcategories of Control Valves with Typical General Characteristics

Valve Style

Regular

Sliding-stem

Bar Stock

Economy

Sliding-stem

Thru-Bore

Ball

Partial Ball

Eccentric Plug Erosion Resistance 1 to 8

Swing-Thru

Butterfly

Lined Butterfly

High

Performance

Butterfly

Main

Characteristics

Heavy Duty

Versatile

Machined from Bar

Stock

Light Duty

Inexpensive

On-Of f Service 1 to 24

Characterized for

Throttling

No Seal 2 to 96

Elastomer or

TFE Liner

Offset Disk

General Service

Typical Size

Range,

inches

1 to 24

½ to 3

½ to 2

1 to 24

2 to 96

2 to 72

Typical

Standard Body

Materials

Carbon Steel

Cast Iron

Stainless

Variety of Alloys

Bronze

Cast Iron

Carbon Steel

Carbon Steel

Stainless

Carbon Steel

Stainless

Carbon Steel

Stainless

Carbon Steel

Cast Iron

Stainless

Carbon Steel

Cast Iron

Stainless

Carbon Steel

Stainless

Typical Standard

End Connection

ANSI Flanged

Welded

Screwed

Flangeless

Screwed

Screwed To ANSI 125 Moderate Good

Flangeless To ANSI 900 High Excellent

Flangeless

Flanged

Flanged To ANSI 600 Moderate Excellent

Flangeless

Lugged

Welded

Flangeless

Lugged

Flangeless

Lugged

Typical

Pressure

Ratings

To ANSI 2500 Moderate Excellent

To ANSI 600 Low Excellent

To ANSI 600 High Excellent

To ANSI 2500 High Poor

To ANSI 300 High Good

To ANSI 600 High Excellent

Relative Flow

Capacity

Relative

Shutoff

Capability

1−21

Page 30

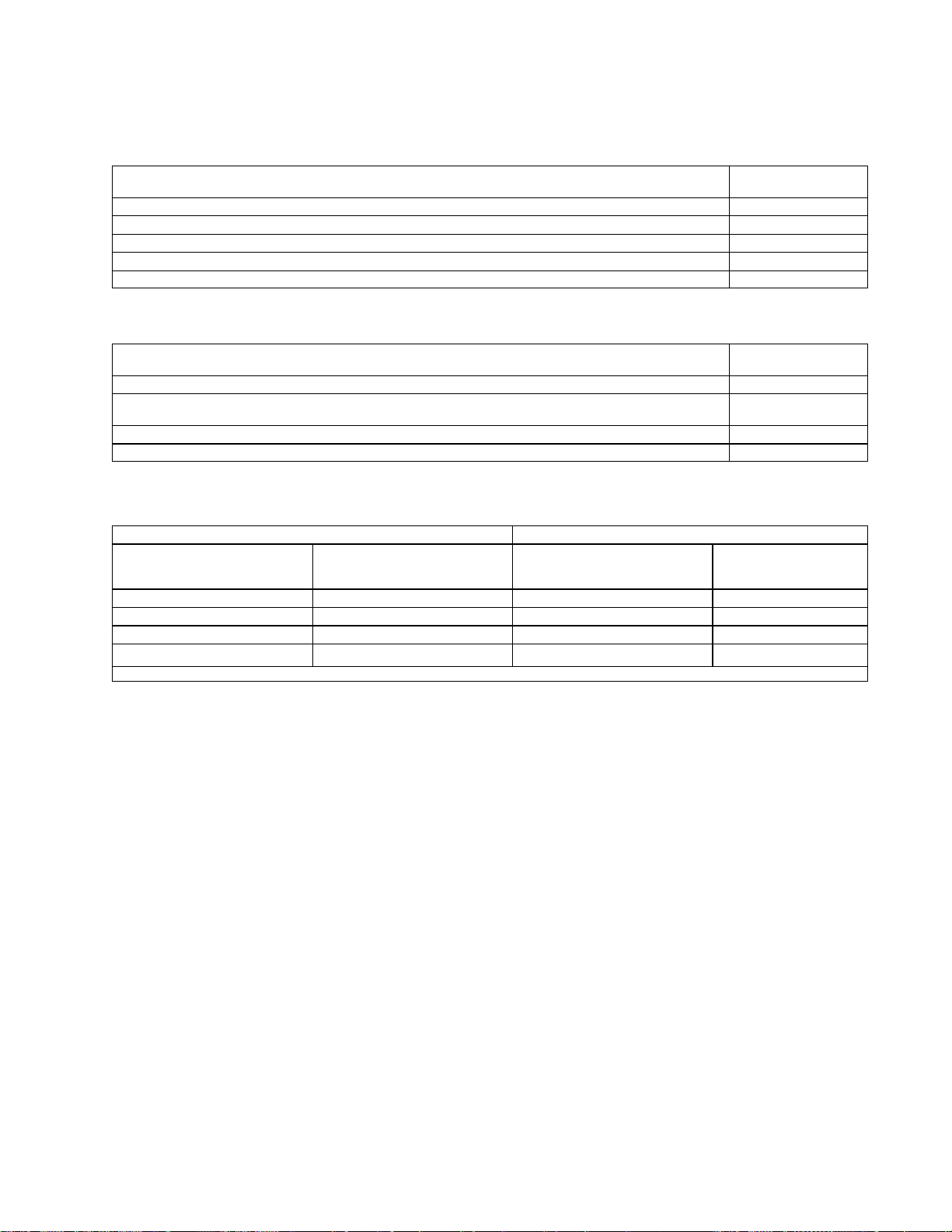

Table 1-3. Control Valve Characteristic Recommendations

Liquid Level Systems

Control Valve Pressure Drop

Constant ΔP Linear

Decreasing ΔP with increasing load, ΔP at maximum load > 20% of minimum load ΔP Linear

Decreasing ΔP with increasing load, ΔP at maximum load < 20% of minimum load ΔP Equal-percentage

Increasing ΔP with increasing load, ΔP at maximum load < 200% of minimum load ΔP Linear

Increasing ΔP with increasing load, ΔP at maximum load > 200% of minimum load ΔP Quick Opening

Best Inherent

Characteristic

Pressure Control Systems

Application

Liquid Process Equal-Percentage

Gas Process, Large Volume (Process has a receiver, Distribution System or Transmission Line Exceeding 100 ft. of

Nominal Pipe Volume), Decreasing ΔP with Increasing Load, ΔP at Maximum Load > 20% of Minimum Load ΔP Linear

Gas Process, Large Volume, Decreasing ΔP with Increasing Load, ΔP at Maximum Load < 20% of Minimum Load ΔP Equal-Percentage

Gas Process, Small Volume, Less than 10 ft. of Pipe between Control Valve and Load Valve Equal-Percentage

Best Inherent

Characteristic

Flow Control Processes

Application Best Inherent Characteristic

Flow Measurement Signal to

Controller

Proportional to Flow In Series Linear Equal-Percentage

Proportional to Flow Squared In Series Linear Equal-Percentage

*When control valve closes, flow rate increases in measuring element.

Location of Control Valve in Relation

to Measuring Element

In Bypass* Linear Equal-Percentage

In Bypass* Equal-Percentage Equal-Percentage

Wide Range of Flow Set Point

Small Range of Flow but

Large ΔP Change at Valve

with Increasing Load

1−22

Page 31

Table 1-4. Control Valve Leakage Standards

ANSI

B16.104-1976

Class II 0.5% valve capacity at full travel Air

Class III 0.1% valve capacity at full travel Air

Class IV 0.01% valve capacity at full travel Air

Class V

Class VI

Copyright 1976 Fluid Controls Institute, Inc. Reprinted with permission.

Maximum Leakage Test Medium Pressure and Temperature

5 x 10-4 mL/min/psid/inch port dia. (5

-12 m3

x 10

/sec/Δbar/mm port dia)

Nominal Port

Diameter

In

1

1-1/2

2

2-1/2

3

4

6

8

mm

25

38

51

64

76

102

152

203

Bubbles per

Minute

1

2

3

4

6

11

27

45

Water

mL per Minute

0.15

0.30

0.45

0.60

0.90

1.70

4.00

6.75

Service ΔP or 50 psid (3.4 bar differential),

whichever is lower, at 50_ or 125_F (10_ to 52_C)

Service ΔP or 50 psid (3.4 bar differential),

whichever is lower, at 50_ or 125_F (10_ to 52_C)

Service ΔP or 50 psid (3.4 bar differential),

whichever is lower, at 50_ or 125_F (10_ to 52_C)

Service ΔP at 50_ or 125_F (10_ to 52_C)

Test

Medium

Pressure and Temperature

Service ΔP or 50 psid (3.4 bar

Air

differential), whichever is lower, at 50_

or 125_F (10_ to 52_C)

1−23

Page 32

1−24

Page 33

Chapter 2

Actuator Selection

The actuator is the distinguishing element that

differentiates control valves from other types of

valves. The first actuated valves were designed in

the late 19th century. Today, they would be better

described as regulators since they operated

directly from the process fluid. These “automatic

valves” were the mainstay of industry through the

early 1930s.

It was at this time that the first pneumatic

controllers were used. Development of valve

controllers and the adaptation of standardized

control signals stimulated design of the first, true,

control valve actuators.

The control valve industry has evolved to fill a

variety of needs and desires. Actuators are

available with an array of designs, power sources

and capabilities. Proper selection involves process

knowledge, valve knowledge, and actuator

knowledge.

A control valve can perform its function only as

well as the actuator can handle the static and

dynamic loads placed on it by the valve.

Therefore, proper selection and sizing are very

important. Since the actuator can represent a

significant portion of the total control valve price,

careful selection of actuator and accessory options

can lead to significant dollar savings.

The range of actuator types and sizes on the

market today is so great that it seems the selection

process might be highly complex. With a few rules

in mind and knowledge of fundamental needs, the

selection process can be simple.

The following parameters are key as they quickly

narrow the actuator choices:

D Power source availability

D Fail-safe requirements

D Torque or thrust requirements

D Control functions

Power Source Availability

The power source available at the location of a

valve can often point directly to what type of

actuator to choose. Typically, valve actuators are

powered either by compressed air or by electricity.

However, in some cases water pressure, hydraulic

fluid, or even pipeline pressure can be used.

Since most plants have both electricity and

compressed air readily available, the selection

depends upon the ease and cost of furnishing

either power source to the actuator location.