Page 1

Product Flier

PF51.3:Vee-Ball

D102429X012

May 2009

High-Capacity Rotary Valves

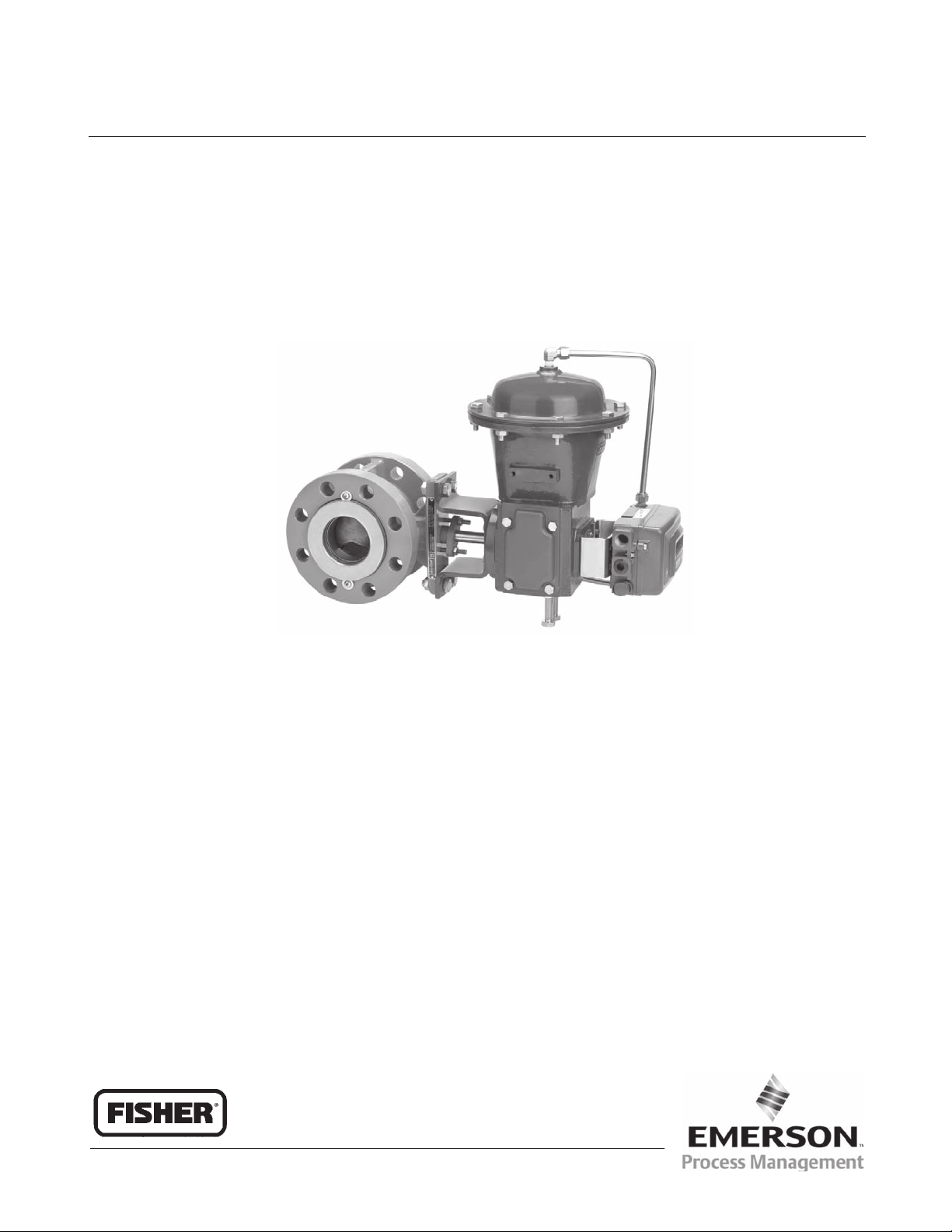

Fisher High-Capacity Rotary

Valves for General or Fibrous

Slurry Service

W9415

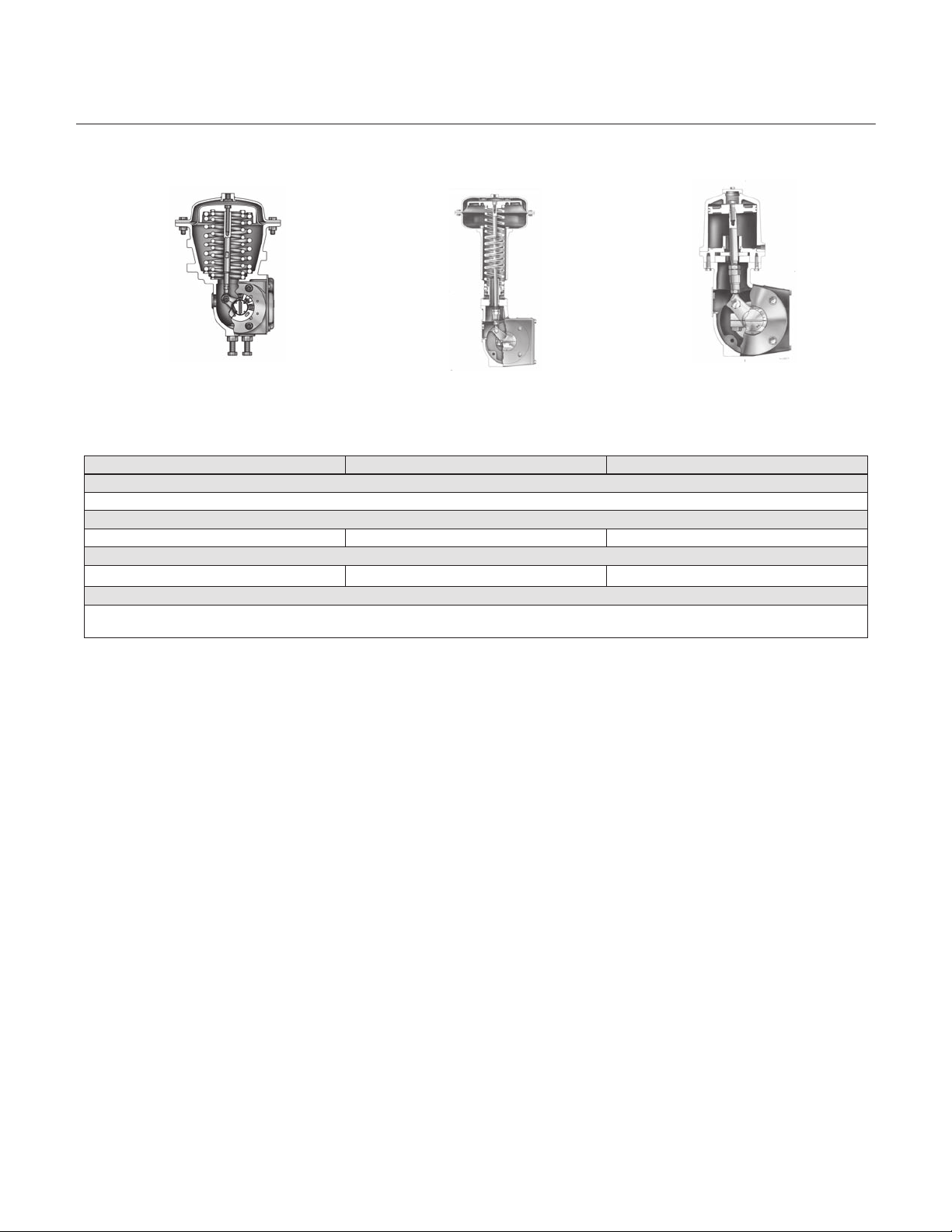

Figure 1. Fisher High-Capacity Rotary Valve

Rotary valve efficiency with globe valve ruggedness for general gas, steam, or liquid

service and for fibrous slurry applications

DN 25 to DN 300 and NPS 1 to 24 x 20

Choice of seal types and materials—composition, flat metal, heavy-duty metal, or

flow ring

Temperatures to 427C

Pressures to PN40 and CL600

ENVIRO-SEAL

emissions requirements

FIELDVUE

proven line of Fisher positioners, controllers, transmitters, and switches also is

available.

packing systems to help ensure compliance with environmental

digital valve controllers offer digital control and remote diagnostics. The

www.Fisher.com

Page 2

High-Capacity Rotary Valves

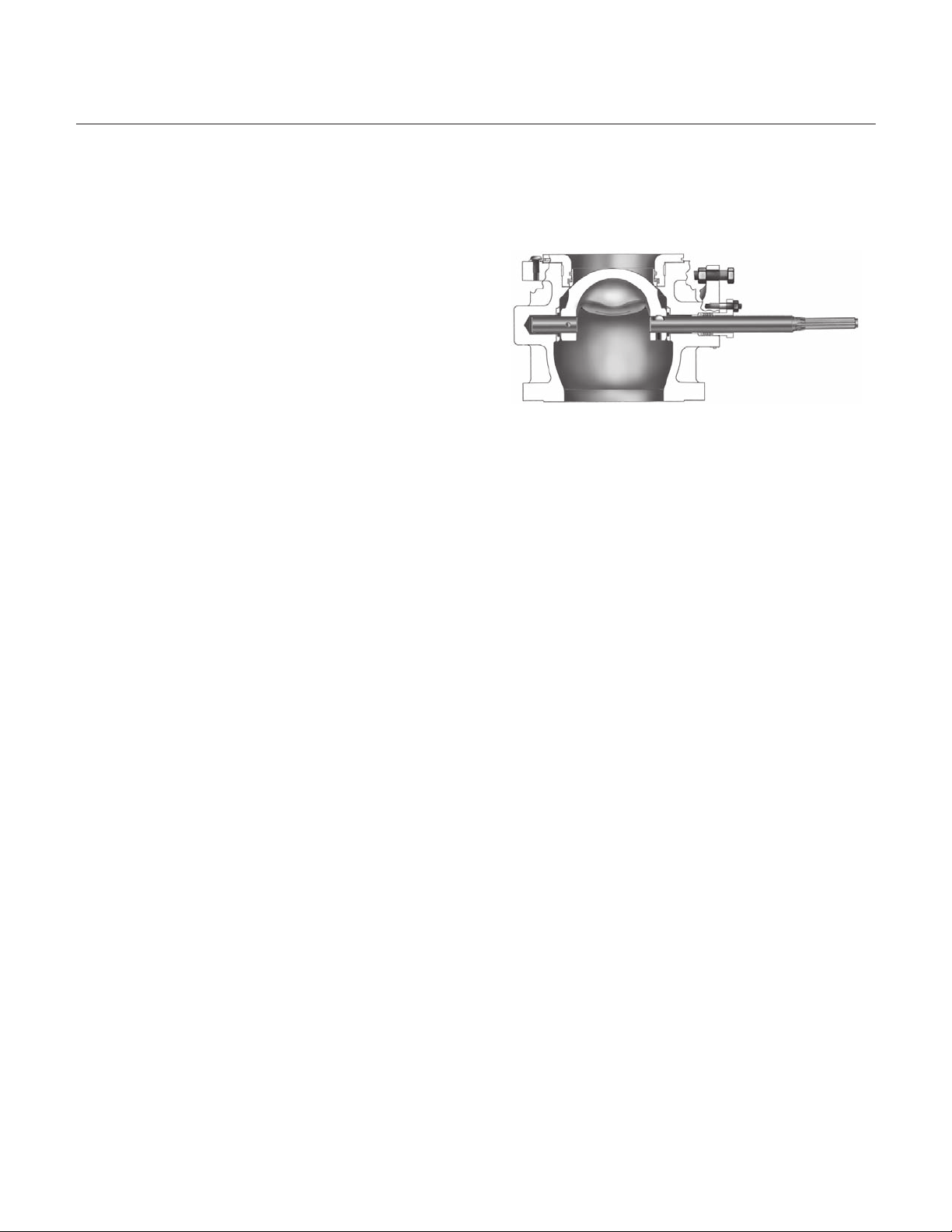

The Fisher Vee-Ball Valve Family

Vee-Ball rotary valves combine the features and

performance you need. These features are made

available through expertise in applications, valve

design, and manufacturing.

The valves are suitable for throttling or on-off

service. They are often used with a full 0 to 90

degree ball rotation.

Fisher V150, V200, and V300 Vee-Ball valves use

the time-proven V-notch ball that provides

high-capacity control of liquid, gas, steam, and

fibrous slurries. The shearing action of the ball

allows smooth, non-clogging operation, and the

unrestricted, straight-through flow ensures high

capacity.

Product Flier

PF51.3:Vee-Ball

May 2009

W74351/IL

Figure 2. Fisher V150 or V300 Valves

Easy Seal Inspection . . . Seals can be inspected

without removing the actuator or disassembling the

valve.

Easy Installation . . . Fisher V150 and V300 integral

flanges eliminate exposed flange studs, and the

V200 features line-centering lugs to simplify

alignment.

High Rangeability . . . Flow coefficient ratio is 300

to 1.

Reduced Maintenance Costs . . . The V150, V200,

and V300 valves have interchangeable trim parts to

reduce spare parts inventory and cost and simplify

maintenance procedures and training. Metal and soft

seals are interchangeable within a valve body.

Protection Against Process Fluid Emissions . . .

Optional ENVIRO-SEAL packing systems provide an

excellent shaft seal to prevent the loss of valuable or

hazardous process fluids. These live-loaded

systems provide long packing life and reliability.

Materials for Sour Service . . . Emerson Process

Management offers materials and manufacturing

procedures for compliance with NACE (National

Association of Corrosion Engineers) standard NACE

MR01752002, MR0103, and MR0175 / ISO 15156.

Noise Attenuator Ball. . . Depending on service

conditions, up to -10dBA acoustical attenuation and

a K

of 1.0 for liquid flow are possible with the noise

C

attenuator ball (available with DN 100 through DN

300 and NPS 4 through 20 valves).

Basis Weight Control Valve . . . Fisher V150,

V200, and V300 valves are available to meet the

precision control requirements of basis weight

control in the paper-making industry.

Other Rotary Products

Fisher V500 Valve . . . The V500 valve uses rugged

valve components and a choice of erosion-resistant

trim materials for highly erosive and severe

operating conditions at pressures to PN 100 (CL600)

and temperatures to 538C.

Fisher CV500 Valve . . . The CV500 combines the

rangeability of the cammed-segmented V-notched

ball, with the inherent ruggedness found in the V500

heavy duty bearings, seals and body. This

combination provides a balance of high capacity,

erosion resistance, and pressure control for liquid

and gas.

2

Page 3

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

The Fisher Vee-Ball Valve Family (Continued)

Other Rotary Products (Continued)

Fisher V250 . . . The V250 valve is a heavy-duty

valve often used in gas transmission lines, gas

distribution, or liquid pipelines. It is available in sizes

to NPS 24 and CL600 or CL900

pressure-temperature ratings.

Fisher V260 . . . The V260 valve has special

energy-dissipating trim to reduce noise effects that

cause pipeline vibrations. It is available in NPS 8,

10, 12, 16, 20, and 24 sizes.

Fisher Control-Disk Valve . . . This rotary valve

with an equal percentage flow characteristic

provides an improved throttling range. This improved

capability allows you to control closer to the target

set point, regardless of process disturbances. This

capability results in a reduction in process variability.

Fisher 8532, 8580, and 8510/8510B . . . This family

of high performance butterfly valves is designed for

optimal control performance, as well as tight shutoff

isolation service. These valves are available in size

range NPS 2 to 24 and a variety of pressure classes

and body styles.

Fisher A11 . . . The POSISEAL A11

high-performance butterfly valves are designed for

optimal control performance as well as tight shutoff

for isolation, automated on/off service. These valves

feature square, keyed, or splined shafts. These

valves are designed for use in highpressure,

hightemperature, or cryogenic applications, and

available in sizes NPS 3 through 72, and pressure

classes up to CL2500.

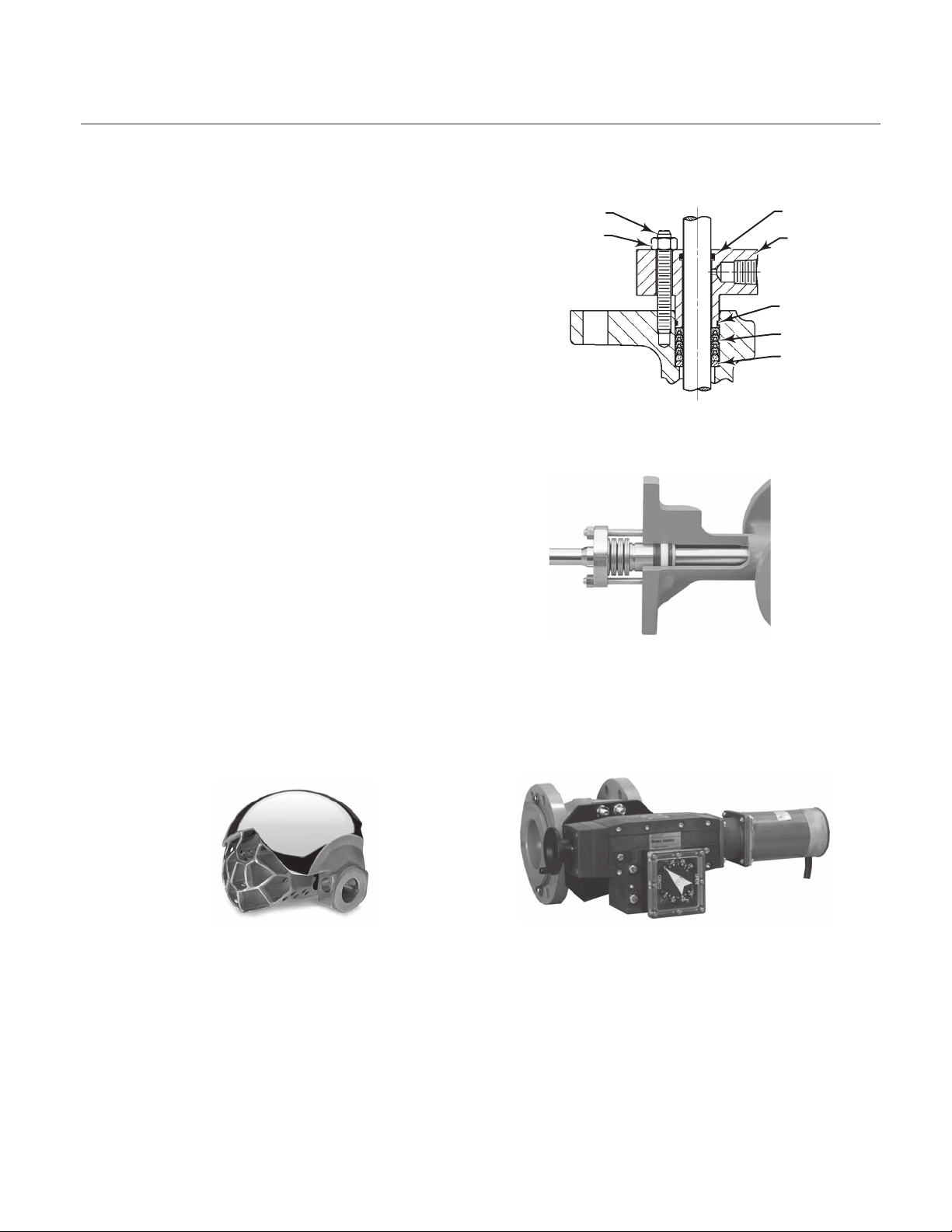

PACKING STUD

PACKING NUT

14B9917-B

E0735 / IL

LEAK-OFF PACKING ASSEMBLY

FOR NPS 1 THROUGH 12 VALVES

W7557-1/IL

ENVIRO-SEAL PACKING SYSTEM

(SINGLE PTFE V-RING)

Figure 3. Optional Rotary Valve Packing Assemblies

O-RING

PACKING

FOLLOWER

O-RING

PACKING

SET

PACKING BOX

RING

W7555/IL

Vee-Ball VALVE BALL WITH ATTENUATOR

Figure 4. Attenuator and Basis Weight Valve

W5393

BASIS WEIGHT VALVE AND ACTUATOR

3

Page 4

High-Capacity Rotary Valves

Selecting Vee-Ball Products

Only a few of the more commonly selected product materials,

sizes, options, and accessories are covered in this flier.

Contact your Emerson Process Management sales office (refer

to the back cover) for assistance in selecting and sizing these

products. More detailed specifications are available on request.

Selecting Valve Components

Valve Type Selection 5...............................

Body Materials, End Connections, and Ratings 7.........

Valve Component Materials and Temperatures 7.........

Selecting an Actuator

Fisher 2052 Diaphragm Actuator 8.....................

Fisher 1051 and 1052 Diaphragm Actuators 9...........

Fisher 1061 Piston Actuator 10........................

Selecting Valve Instrumentation and Accessories

Fisher FIELDVUE Digital Valve Controllers 11...........

Fisher 3610J Valve Positioners 13......................

Other Accessories 14.................................

Reference Information

Maximum Inlet Pressure for CW2M Valve Bodies 15......

Shutoff Pressure Drop Limits for Trim Parts 15...........

Flow Coefficients 16..................................

Actuator-Valve Selection (Shutoff Pressure Drops) 17....

Approximate Weights 21..............................

Dimensions 22.......................................

Emerson Process Management Sales Offices 24........

Product Flier

PF51.3:Vee-Ball

May 2009

4

Page 5

Product Flier

PF51.3:Vee-Ball

May 2009

Fisher Vee-Ball Valves

High-Capacity Rotary Valves

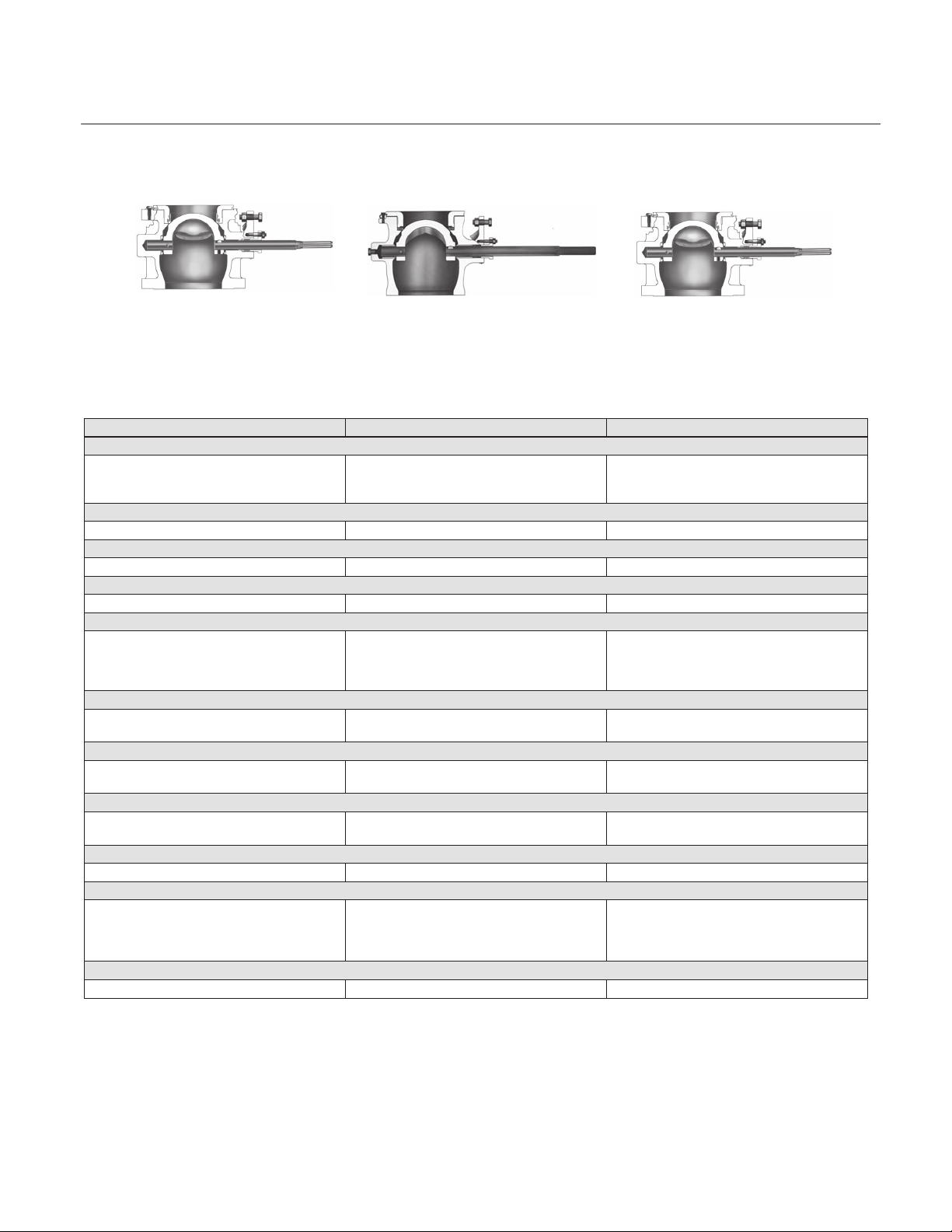

W7435/IL

V150 VALVE

W5787/IL

V200 VALVE

W7435/IL

V300 VALVE

Figure 5. Fisher Vee-Ball Valves

Table 1. Vee-Ball Valves

V150 V200 V300

Applications

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

V150: DN 25 - 500 or NPS 1 - 24 x 20 NPS 1, 1-1/2, 2, 3, 4, 6, 8, 10 DN 25 - 500 or NPS 1 - 20

V150: PN 10/16 or CL150 CL150, CL300, or CL600 depending on size. PN 25/40 or CL300

Raised-face (RF) flanged Flangeless Raised-face (RF) flanged

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M, CF8M

stainless steel, M35-1, or CW2M

SA351 CF3M, or CG8M, CG8M stainless steel,

CW2M

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

Modified equal percentage

Maximum Cv from 3.64 to 10,300

300 to 1 300 to 1 300 to 1

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Fisher 2052, 1051, 1052, 1061, and FieldQ Fisher 2052, 1051, 1052, 1061, and FieldQ

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

Sizes

Ratings

End Connections

Valve Body Materials

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M, CF8M

stainless steel, M35-1, or CW2M

Ball Material

SA351 CF3M or CG8M stainless steel, CW2M SA351 CF3M, or CG8M stainless steel, CW2M

Seal Types

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

Flow Characteristics and Maximum Flow Coefficients

Modified equal percentage

Maximum Cv from 8.4 to 3000

Rangeability

Shutoff Class

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Available Actuators (refer to page 8)

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M,

CG8M stainless steel M35-1, or CW2M

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

Modified equal percentage

Maximum Cv from 8.4 to 10,300

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Fisher 2052, 1051, 1052, 1061, and FieldQ

5

Page 6

High-Capacity Rotary Valves

Fisher Actuators

Product Flier

PF51.3:Vee-Ball

May 2009

W9589-1/IL

2052 ACTUATOR

W3813/IL

1051 AND 1052 ACTUATORS

W3827/IL

1061 ACTUATOR

Figure 6. Fisher Rotary Valve Actuators

Table 2. Fisher Rotary Valve Actuators

2052 1051 AND 1052 1061

Features

Heavy-duty actuator with enclosed linkage and splined actuator-valve connection for minimized lost motion

Style

Spring-return pneumatic diaphragm actuator Spring-return pneumatic diaphragm actuator Double-acting pneumatic piston actuator

Typical Operating Torque Range (Varies with Operating Pressure and Construction)

50.8 to 565 Nm 85 to 1370 Nm 282 to 19,800 Nm

Accessories

Pneumatic or electro-pneumatic valve positioners, FIELDVUE digital valve controllers, limit switches, position transmitters, handwheels, travel stops,

lock-out device to disable actuator during maintenance, supply pressure filter-regulator.

6

Page 7

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Valve Component Materials and Temperatures

Table 3. Valve Component Materials and Temperatures

BODY, SHAFT, AND BALL (TEMPERATURE IS DETERMINED BY OTHER PARTS LISTED BELOW)

Valve Body

Valve Shaft

V-Notch Ball

SEAL MATERIAL BEARING MATERIAL

Composition (TCM plus)

Flat metal—(spring-tempered stainless steel)

(available on DN 80 through 300

[NPS 3 through 12] only)

HD (heavy-duty) metal

( CF10SMnN or

CD7MCuN [alloy 255 duplex stainless

steel], or R30006

Flow ring (steel or stainless to match

body material)

PART MATERIAL

Wave spring and radial seal (HD metal only)

Micro-notch V-notch ball for DN 25 (NPS 1)

Gasket Graphite

Optional line bolting

CF3M (316L stainless steel), chromium-plated CF3M, CG8M (317 stainless steel), or

PEEK (poly-ether-ether-ketone)/PTFE,

R30006 (alloy 6B) or silver-plated

R30006, silver-plated R30006, or

S31600L (316L stainless steel) nitride

R30006, silver-plated R30006, or

R30006, silver-plated R30006, or

OTHER PARTS

Chromium-plated CG8M or solid alloy 6

B7, B7M, or strain-hardened B8M

CF3M (316L stainless steel), DIN 1.0619 steel, WCC steel, or

S20910 or S17400 (17-4PH stainless steel)

SEAL, BEARING, AND PACKING

R30006

PEEK/PTFE 232 260

PEEK/PTFE 232 260

S31600L nitride

PEEK/PTFE 232 260

S31600L nitride

N07750 and PTFE with

N10276

Solid VTC ceramic 93 93

CG8M (317 stainless steel)

chromium-plated CG8M

MAXIMUM

TEMPERATURE, C

PTFE

V-Ring

Packing

232 232

232 427

232 288

232 427

MAXIMUM

TEMPERATURE, C

PTFE

V-Ring

Packing

Temperature is

determined by parts listed

above

Temperature is

determined by parts listed

above

Graphite

Packing

Graphite

Packing

NOTES

Minimum temperature

for DIN valve bodies is

10C

Minimum temperature

for ASME constructions

is 29C for steel

valves and 46C for

stainless steel valves

Contact your

Emerson Process

Management sales

office for

ENVIRO-SEAL packing

temperatures and

pressures

Contact your

Emerson Process

Management sales

office for pressure

drops and temperatures

with TCM-Ultra

composition seal.

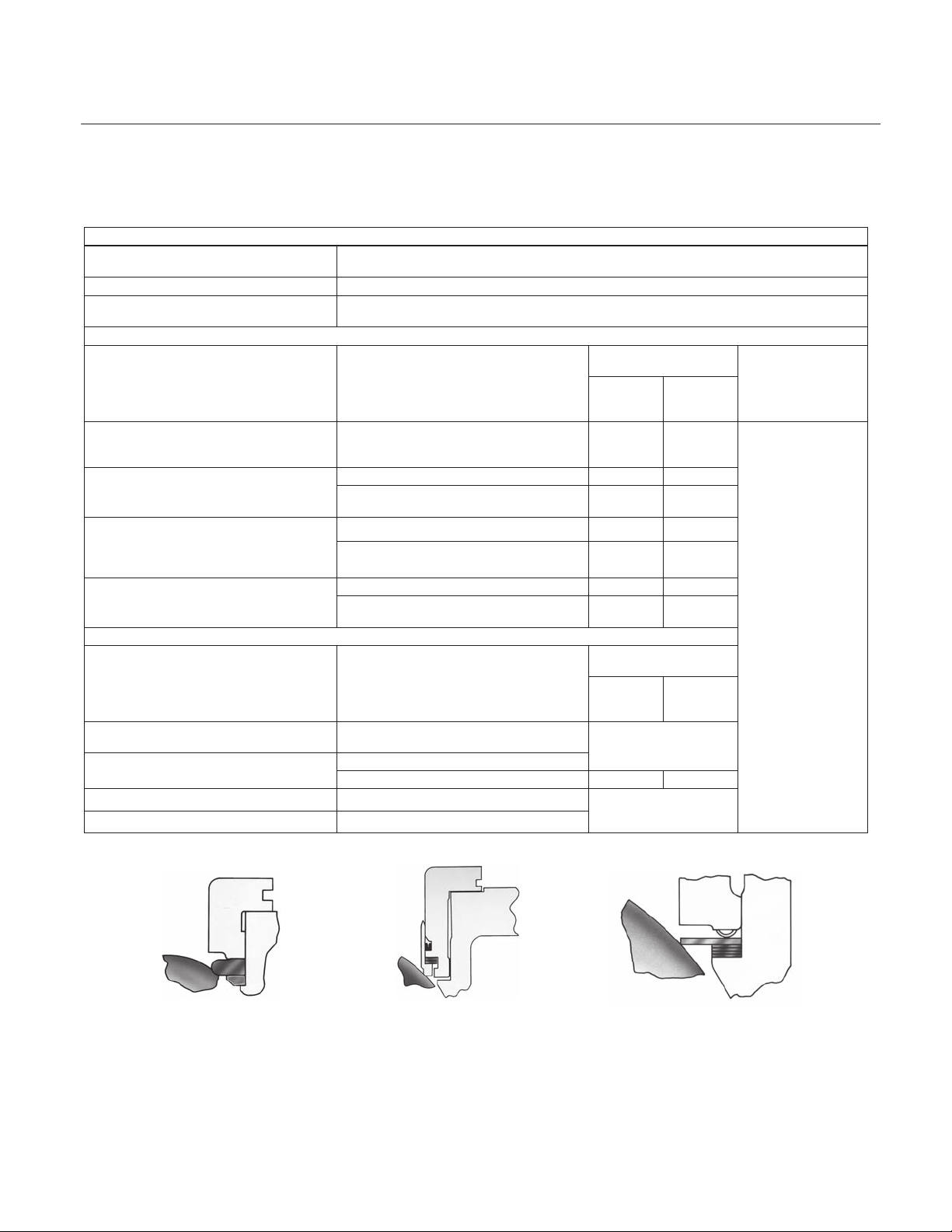

W6197-1*

COMPOSITION SEAL

W5704-1/IL

HD (HEAVY-DUTY) METAL SEAL

Figure 7. Fisher Vee-Ball Seals

W4713-3/IL

FLAT METAL SEAL

7

Page 8

High-Capacity Rotary Valves

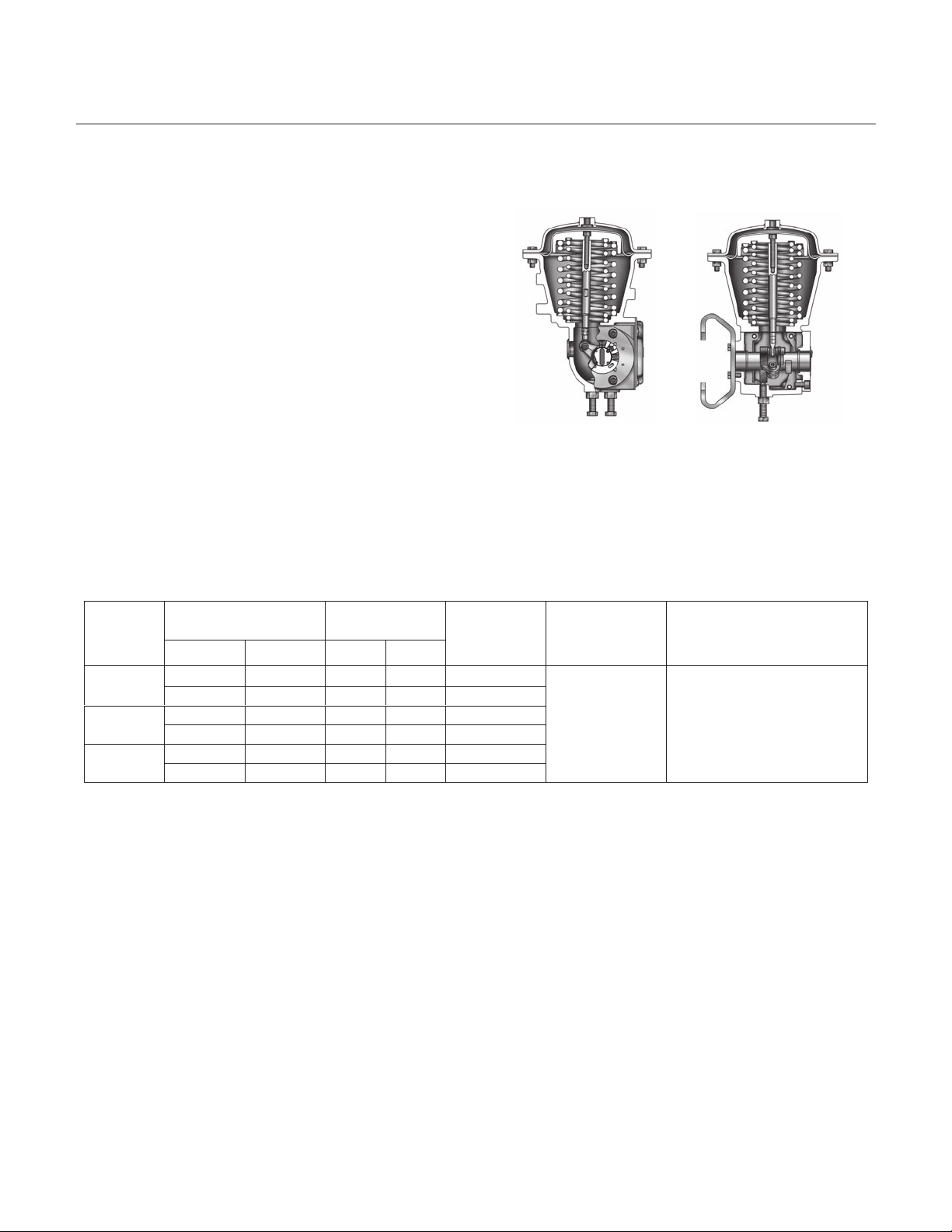

Fisher 2052 Diaphragm Actuators

The 2052 pneumatic diaphragm rotary actuators are

compact, spring-return actuators that provide reliable

operation for the valves in this flier.

The 2052 actuator mountings conform to ISO 5211;

the actuator can be mounted directly to non-spline

shafts, such as square or double-D, allowing the

actuator to be paired with a wider range of valves to

be used for both automated on/off and throttling

applications.

This actuator features single-joint linkage with

splined-and-clamped levers for minimum lost motion

and high control accuracy.

W9589/IL

Product Flier

PF51.3:Vee-Ball

May 2009

W9588-1/IL

It also features a nested spring design, which

requires no bench set, simplifying the actuator

selection process.

Options . . .

Top-mounted handwheel, Fisher

1078 declutchable handwheel actuator, and

actuator locking mechanism

Table 4 .Fisher 2052 Actuator Specifications

2052

ACTUATOR

SIZE

1

2

3

NOMINAL OPERATING

PRESSURE RATINGS

Bar Psig Bar Psig

2-3 30-43 5.0 73 28

4-5 60-72 5.0 73 50.8

2-3 30-43 5.0 73 104

4-5 60-72 5.0 73 209

2-3 30-43 5.0 73 270

4-5 60-72 5.0 73 565

MAXIMUM CASING

PRESSURE

Figure 8. Fisher 2052 Actuator

Accessories . . . Pneumatic and

electro-pneumatic positioners,

valve controllers, and

Limit and proximity

FIELDVUE digital

switches.

MAXIMUM

VALV E

BREAKOUT

TORQUE, N

m

AMBIENT

TEMPERATURE, qC

40 to 80

MATERIALS

Upper Casing: Steel

Housing: Cast Iron

Diaphragm: Nitrile and nylon is

standard; silicone and polyester

low-temperature is optional

Lever: Ductile iron

Diaphragm Plate: Cast iron

8

Page 9

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Fisher 1051 and 1052 Diaphragm Actuators

The 1051 and 1052 pneumatic diaphragm rotary

actuators are spring-return actuators that provide

reliable operation for the valves in this flier.

The 1051 actuator is suitable for on-off operation or

for throttling operation when equipped with a valve

controller or positioner. The 1052 actuator is suitable

for on-off or throttling with or without a controller or

positioner.

These actuators feature single-joint linkage with

splined-and-clamped levers for minimum lost motion

and high control accuracy. The actuator-valve

linkage is completely enclosed for safety, yet the

packing adjustment is accessible without removing

any parts.

Specifications . . . Refer to the table below and the

actuator selection tables.

W3813-1/IL

Figure 9. Fisher 1051 Actuator

Options . . .

declutchable handwheel actuator,

and down-travel stops,

mechanism that keeps the actuator in a locked

position during maintenance, and

for remote venting of the actuator housing.

Table 5. Fisher 1051 Actuator Specifications

1051 1052 Bar Psig 1051 1052 1051 1052

33 33

40 40 5.2 322 371

60 60

- - - 70

Top-mounted handwheel, 1078

Adjustable up-

Actuator locking

Pipe-away vent

0 to 1.2,0 to 2.3,

0 to 2.8, and

0 to 3.8

0 to 1.2,

0 to 2.3,

and 0 to 2.8

0 to 2.3,

0 to 2.8,

and 0 to 3.8

0 to 18, 0 to 33,

0 to 40, and

0 to 55

0 to 11, 0 to 33,

and 0 to 40

0 to 33, 0 to 40,

and 0 to 55

- - - 4.5 - - - 1370

Accessories . . . Pneumatic and

electro-pneumatic valve positioners,

digital valve controllers, and

switches.

4.5 85 132

3.4 626 730

Limit and proximity

AMBIENT

TEMPERATURES,

C

Nitrile: 40 to 82

Silicone: 50 to 149

FIELDVUE

MATERIALS

Diaphragm: Nitrile

(standard) or silicone

O-rings (for optional

handwheel): Nitrile or

EPDM

Housing: Cast iron

(standard) or steel

Other Major Metal

Parts: Aluminum, steel,

or cast iron

W4742-1/IL

Figure 10. Fisher 1052 Actuator, Size 33

9

Page 10

High-Capacity Rotary Valves

Fisher 1061 Piston Actuators

The 1061 pneumatic rotary actuators are

double-acting piston actuators that provide reliable

operation for the valves in this flier.

The 1061 can be used with a two-position control

signal for on-off operation or with a valve controller

or positioner for throttling operation.

Product Flier

PF51.3:Vee-Ball

May 2009

These actuators feature single-joint linkage with

splined-and-clamped levers for minimum lost motion

and high control accuracy.

The actuator-valve linkage is completely enclosed

for safety, yet the packing adjustment is accessible

without removing any parts.

Specifications . . . Refer to the table below and the

actuator selection tables.

Table 6. Fisher 1061 Actuator Specifications

ACTUATOR

SIZE

30

40 10.3 847

60 6.9 1130

68 5.9 1540

80 10.3 5080

100 10.3 6290

CYLINDER OPERATING PRESSURE, BAR

Minimum

Recommended

Without positioner: 1.4

With positioner: 0.35 bar

above actuator requirement

Maximum Allowable

6.9 232

Options . . . 1078 declutchable handwheel

actuator with cylinder bypass valve,

up- and down-travel stops,

mechanism that keeps the actuator in a locked

position during maintenance, and

for remote venting of the actuator housing.

Accessories . . .

electro-pneumatic valve positioners and

proximity switches.

MAXIMUM VALVE

BREAKOUT

TORQUE, Nm

W3827-1/IL

Figure 11. Fisher 1061 Actuator

Actuator locking

Pneumatic and

AMBIENT

TEMPERATURES,

C

Cylinder and flange: Aluminum

Piston: Aluminum or nylon-coated

34 to 82

(to 50 with optional

materials)

Mounting yoke bushing: PTFE

Other parts: Iron, aluminum, and

Adjustable

Pipe-away vent

Limit and

MATERIALS

aluminum

O-rings: Nitrile

and steel

Sliding seal: Brass

stainless steel

10

Page 11

Product Flier

PF51.3:Vee-Ball

May 2009

FIELDVUE Digital Valve Controllers

W8755

High-Capacity Rotary Valves

DVC2000

Figure 12. Fisher Digital Valve Controllers

FIELDVUE digital valve controllers are

communicating, microprocessor-based controllers

that convert a current signal to a pressure signal to

operate the actuator. Through digital

communications, the controller gives easy access to

actuator-valve information that is critical to operation.

Refer to following tables for FIELDVUE controller

specifications.

AMS ValveLink Software . . . AMS ValveLink

Software allows easy access to the information

available from FIELDVUE digital valve controllers.

The software provides diagnostic information such

as dynamic error band and step response on

easy-to-interpret screens. Tests can be run while the

valve is operating, without disrupting the process.

Access to diagnostics is through the 375 Field

Communicator or a personal computer using AMS

ValveLink Software.

Options (contact your Emerson Process

Management sales office for details on product

specific options) . . .

HART, FOUNDATION

fieldbus, remote mounting, stainless steel

housing,

applications,

Performance Diagnostics, extreme

temperatures, and

Safety Instrumented System (SIS)

Natural gas applications,

low bleed relay.

W9418

DVC6000 on Control-Disk VALVE

Approvals Available

Not all approvals are available on all FIELDVUE

products. Contact your Emerson Process

Management sales office for specific approvals.

Explosion proof, Division 2, Dust-Ignition

proof, Intrinsic Safety, Non-incentive

Explosion proof, Non-incendive,

Dust-Ignition proof, Intrinsic Safety

APPROVED

ATEX

Flameproof, Type n, Intrinsic Safety

IECEx Flameproof, Type n, Intrinsic Safety

Flameproof, Intrinsic Safety

Flameproof, Intrinsic Safety

Fisher DVC2000 Electrical Housing: Designed to

meet IP66 (FM--approval pending for other

agencies) NEMA 4X (approval pending). Contact

your Emerson Process Management sales office for

information on pending approvals.

Fisher DVC6000 and DVC6000f Electrical

Housing: Meets NEMA 4X, CSA Type 4X, IEC

60529 IP66

Natural Gas Approved: The DVC6000 and

DVC6000f are single-seal approved for use with

natural gas. Contact your Emerson Process

Management sales office for specific agency

approval information.

11

Page 12

High-Capacity Rotary Valves

FIELDVUE Digital Valve Controllers (Continued)

Table 7. Digital Valve Controller Electrical Specifications (HARTr instruments Only)

ELECTRICAL INPUT

POINT-TO-POINT CONNECTION

Analog Input

Signal

4 to 20 mA DC

nominal

Minimum

Control

Current

4.0 mA 3.5 mA 30 VDC

Minimum Current

without

Microprocessor

Restart

Maximum

Voltage

Overcurrent

Protection

Input circuit limits

current to prevent

internal damage

Table 8. Digital Valve Controller Electrical Specifications (FOUNDATIONt fieldbus Communication only)

POWER REQUIREMENTS

COMMUNICATION PROTOCOL

FOUNDATION fieldbus registered device

Physical Layer Type(s):

121—Low-power signaling, bus-powered, Entity Model I.S.

511—Low-power signaling, bus-powered, FISCO I.S.

Voltage Level

9 to 32 volts 18 mA

Maximum

Current

(DVC6000 ONLY)

approximately 8 mA

Reverse

Polarity

Protection

Device is not

polarity sensitive

MULTI-DROP

CONNECTION

INSTRUMENT

POWER

11 to 30 VDC at

Product Flier

PF51.3:Vee-Ball

May 2009

REVERSE

POLARITY

PROTECTION

No damage occurs

from reversal of loop

current

Termination

Bus must be properly

terminated per

ISA SP50 guidelines

12

Page 13

Product Flier

PF51.3:Vee-Ball

May 2009

Valve Positioners

Fisher 3610J, 3610JP, and 3620JP Valve Positioners

The 3610J single-acting pneumatic, 3610JP

double-acting pneumatic, and 3620JP double-acting

elector-pneumatic valve positioners are accurate,

efficient positioners for use with 1051, 1052, 1061

actuators.

Approvals Available

Electrical Classification (Applies to the 3620JP)

Intrinsic Safety, Explosion proof, Type

n Dust-Ignition proof, DIV 2,

Intrinsic Safety, Explosion proof, Type

APPROVED

ATEX

IECEx

INMETRO

n, Non-incendive, Dust-Ignition proof,

Intrinsic Safety, Type n, Flameproof

(Gas Atmospheres Only),

Intrinsic Safety, Type n, Flameproof,

(Gas Atmospheres Only),

Intrinsic Safety, Flameproof

High-Capacity Rotary Valves

W8693-1/IL

Hazardous Area Classifications

The 3610J and 3620J valve positioners comply

with the requirements of ATEX Group II Category

2 Gas and Dust

Table 9. Fisher 3610J and 3620J Positioner Specifications

Type Input Signal Supply Pressure

0.3 bar above the

3610J and

3610JP

3620J and

3620JP

0.2 to 1.0 or

0.4 to 2.0 bar

4 to 20 mA constant current with 30

VDC maximum compliance voltage;

equivalent circuit is 120 ohms

shunted by three 5.6 V zener diodes

3 to 15 or

6 to 30 psig

Table 10. Fisher 3610J and 3620J Capacities and Housing

Type Supply Pressure, Bar

3610J and 3620J

3610JP and 3620JP

1.4 13

2.4 17

5.2 37

6.9 46

actuator requirement

0.3 bar above the

actuator requirement

Supply Air Demand,

up to 10.3 bar

maximum

up to 10.3 bar

maximum

3

Nm

/h

Figure 13. Fisher 3610J Pneumatic Valve Positioner and

i2p-100 Electro-Pneumatic Transducer with 1052 Actuator

and V300 Valve

Operative

Temperature

40 to 80C

40 to 80C

Air Consumption, Nm3/h

3610J: 0.40 to 1.4 bar supply

3620J: 0.49 at 1.4 bar supply

3610JP: 0.64 at 6.9 bar supply

3620JP: 0.93 at 6.9 bar supply

Weight Connections

2.5 kg

3.6 kg

Pressure and Vent

Connections: 1/4 NPT

3620J and JP Conduit: 1/2

NPT

Housing (3620J and

3620JP)

IP 54 per IEC 529

classification

(weatherproof), NEMA 3;

vent should be on the

side or bottom for

weatherproof applications

13

Page 14

High-Capacity Rotary Valves

Other Accessories

Product Flier

PF51.3:Vee-Ball

May 2009

Fisher 67CFR Filter-Regulator . . . The 67CFR

provides constantly controlled supply pressure to

actuator accessories system. This regulator features

an internal filter and limited-capacity internal relief,

Table 11. Fisher 67CFR Filter-Regulator Specifications

OUTLET PRESSURE

SETTINGS

Bar Psig

0 to 1.4

0 to 2.4

0 to 4.1

0 to 8.6

0 to 125

0 to 20

0 to 35

0 to 60

MAXIMUM

INLET

PRESSURE

(BODY

RATING), BAR

17.2

MAXIMUM

DIAPHRAGM

PRESSURE,

BAR

3.4 over outlet

setting

Fisher 546, 646, 846, or i2P-100 ElectroPneumatic Transducers . . . These transducers

convert a standard 4 to 20 mA DC signal to a

proportional pneumatic signal. The 846 and i2P-100

transducers incorporate an explosive fluid process

seal to meet safety regulations for use with natural

gas as the pneumatic supply.

allowing partial reduction of downstream pressure.

Also featured is a Smart Bleed option that allows the

actuated valve to fail to a desired safe position when

inlet pressure is lost.

TEMPERATURE

CAPABILITIES,

C

Nitrile diaphragm

and plug: -29 to 82

Fluorocarbon

diaphragm, plug

and PVDF, SST, or

Glass Filter: -18 to

149

INMETRO

CONNECTIONS

Inlet and Outlet:

1/4 NPT internal

Vent: Drilled hole or

1/4 NPT internal

Intrinsic Safety, Flameproof

MAXIMUM

FLOW

COEFFICIENT,

C

V

0.36 0.5

WEIGHT,

GOST Intrinsic Safety, Flameproof, and Type n

Fisher 2625 Volume Booster . . . The volume

booster can be used in conjunction with a positioner

to increase actuator stroking speed.

kg

Approvals Available

Not all approvals are available on all accessories.

Contact your Emerson Process Management sales

office for specific approvals.

Explosion proof, Division 2, Dust-Ignition

proof, Intrinsic Safety, Type n

Explosion proof, Intrinsic Safety,

Non-incendive, Dust-Ignition proof, Type n

APPROVED

ATEX

Intrinsic Safety, Flameproof, and Type n

IECEx Intrinsic Safety, Flameproof, and Type n

Fisher C1 Pneumatic Controller . . . The controller

can sense pressure, differential pressure or vacuum

and send pneumatic control signal to an adjacent

valve or other control element.

Others . . .

regulators,

solenoid valves, signal volume boosters and

High-pressure supply pressure

proximity switches, microswitches,

pneumatic pressure transmitters.

Contact your Emerson Process Management sales

office for more information.

14

Page 15

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Maximum Inlet Pressure for CW2M Valve Bodies

Table 12. Maximum Inlet Pressure for CW2M Valve Bodies

TEMPERATURE, C

46 to 38

93

149

204

232

MAXIMUM INLET PRESSURE,

150 300 600

20.0

17.9

15.9

13.8

12.8

BAR

51.7

51.7

50.3

48.6

47.2

103

103

100

97.2

94.5

NOTE

CW2M is not listed in ASME

B16.34. The designations 150, 300,

and 600 indicate relative

pressure-retaining capabilities and

are not ASME

pressure-temperature rating

classes.

Shutoff Pressure Drop Limits for Trim Parts

WARNING

the EN or ASME pressure-temperature rating of

the valve or mating flanges, as exceeding the

pressure-temperature rating may cause personal

injury or equipment damage.

Pressure drops in the following table consider

only the trim parts (ball, shafts, bearings, and

seals).

In the following tables, the lower temperature limit is

10C for EN valves, 29C for ASME steel valves,

and 46C for ASME stainless steel valves.

The pressure drops shown might be higher than

the EN or ASME pressuretemperature rating of

the valve body or mating flanges. Do not exceed

Table 13. Pressure Drop in Bar (For HD Metal Seal, Pressure Drops are for Forward Flow Only. For Reverse HD Seal Flow, Limit

Pressure Drop to 6.9 Bar)

BEARING

MATERIAL

PEEK/PTFE

R30006

R30006

Silver Plated

S44004

S31600L

Nitride

BALL SEAL

TCM Plus

HD Metal -46 to 288 51.0 51.0 51.0 51.0 51.0 51.0 51.0 40.9 38.1 40.3 26.5 40.3

Flat Metal -29 to 260 - - - - - - - - - 20.7 20.7 20.7 20.7 10.3 10.3 - - - - - - - - -

Flow Ring - - - 99.3 99.3 99.3 99.3 72.4 75.2 73.8 40.5 37.7 40.5 35.0 44.7

HD Metal -46 to 288 51.0 50.0 25.7 17.5 11.0 10.9 11.2 6.14 5.72 6.14 7.52 6.83

Flat Metal -29 to 260 - - - - - - - - - 17.0 10.1 10.7 10.6 5.86 5.52 - - - - - - - - -

Flow Ring - - - 74.5 49.6 26.8 18.8 10.9 11.2 11.1 6.07 5.65 6.07 7.31 6.69

HD Metal -46 to 288 51.0 51.0 51.0 35.0 22.1 21.8 22.5 12.3 11.4 12.3 13.2 13.7

Flat Metal -29 to 260 - - - - - - - - - 20.7 20.1 20.7 20.7 10.3 10.3 - - - - - - - - -

Flow Ring - - - 99.3 99.3 53.5 37.6 21.8 22.5 22.2 12.1 11.3 12.1 14.6 13.4

HD Metal -46 to 288 51.0 51.0 51.0 - - - - - - - - - - - - - - - - - - 20.5 13.2 14.0

Flat Metal -29 to 260 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Flow Ring - - - 99.3 99.3 88.9 - - - - - - - - - - - - - - - - - - 20.2 20.1 22.3

HD Metal -46 to 288 - - - - - - - - - 51.0 36.7 36.3 37.4 20.5 19.1 - - - - - - - - -

Flat Metal -29 to 260 - - - - - - - - - 20.7 20.7 20.7 20.7 10.3 10.3 - - - - - - - - -

Flow Ring - - - - - - - - - - - - 62.7 36.3 37.4 37.0 20.2 18.8 - - - - - - - - -

TEMPERATURE,

C

-46 to 38 51.0 51.0 51.0 51.0 51.0 51.0 51.0 40.2 37.6 31.0 23.8 31.0

93 37.9 37.9 37.9 37.9 37.9 37.9 37.9 37.9 37.6 31.0 23.8 31.0

149 24.1 24.1 24.1 24.1 24.1 24.1 24.1 24.1 24.1 24.1 23.8 24.1

204 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3

232 3.45 3.45 3.45 3.45 3.45 3.45 3.45 3.45 3.45 3.45 3.45 3.45

1 1-1/2 2 3 4 6 8 10 12 14 16 20

DN25DN40DN50DN80DN

Also refer to the actuator sizing pages to select an

actuator size.

VALVE SIZE

100DN150DN200DN250DN300

- - - - - - - - -

15

Page 16

Product Flier

High-Capacity Rotary Valves

PF51.3:Vee-Ball

May 2009

Flow Coefficients

Table 14. Fisher V150, V200, and V300 (Forward Flow)

VALVE SIZE

DN NPS C

(1)

25

(1)

40

(1)

50

80

100

150

200

250

300

- - -

- - -

- - -

25

40

50

80

100

150

200

250

300

- - -

- - -

- - -

25 1 .0143 .360 1.43 5.23 .0124 .311 1.24 4.52 .95 .93 .90 .88 .551 .660 .620 .578

25 1 .0180 .415 1.78 3.64 .0156 .389 1.54 3.15 .90 .94 .90 .92 .581 .693 .612 6.12

1. The coefficient listed for 10 degrees was measured at 12 degrees rotation.

1

1-1/2

2

10

12

14

16

20

1

1-1/2

2

10

12

14

16

20

(1)

(1)

3

4

6

8

(1)

(1)

3

4

6

8

10 30 60 90 10 30 60 90 10 30 60 90 10 30 60 90

v

Composition Seals, Flat Metal Seals (DN 50 - DN 300 and NPS 3 - 12), and Flow Ring Construction

.0098

(1)

.0503

(1)

.0180

2.53

.014

.028

.746

3.56

5.34

6.99

43.5

44.2

60.0

70.0

110

.020

.169

.108

.996

1.41

7.28

7.48

56.0

30.0

105

Micro-Notch V-Notch Ball (Metal Ball with Composition or HD (Heavy-Duty) Metal Seal

12.4

6.15

27.8

9.60

46.1

27.7

120

47.2

195

82.1

340

122

518

252

1000

390

1530

541

1670

692

2380

993

3070

2.53

11.3

4.20

23.2

6.75

40.4

24.1

112

34.2

158

56.9

290

94.7

481

199

897

291

1300

502

1550

600

2040

942

2910

Micro-Notch V-Notch Ball (Ceramic Ball with HD (Heavy-Duty) Metal Seal

VALVE ROTATION, DEGREES (LINE SIZE EQUALS VALVE SIZE)

34.6

76.0

123

321

596

1100

1820

3000

3980

5610

8270

10,300

33.1

70.8

122

338

539

1070

1750

2950

4010

5200

7840

9770

K

v

C

C

C

.0085

v

.0435

.0156

v

v

2.19

5.32

8.30

24.0

40.8

71.0

106

218

337

468

599

859

2.19

3.63

5.84

20.8

29.6

49.2

81.9

172

252

434

519

815

10.7

24.0

39.9

104

169

294

448

865

1320

1450

2060

2660

9.77

20.1

34.9

96.9

137

251

416

776

1120

1340

1770

2520

.012

.024

.645

3.08

4.62

6.05

37.6

38.2

51.9

60.6

95.2

HD (Heavy-Duty) Metal Seats

.017

.146

.093

.862

1.22

6.30

6.47

48.4

26.0

90.8

29.9

65.7

106

278

516

952

1570

2600

3440

4850

7150

8910

28.6

61.2

106

292

466

925

1510

2550

3470

4500

6780

8450

.93

.87

.94

.91

.88

.93

.89

.85

.81

.89

.89

.89

.95

.91

.89

.96

.89

.94

.96

.97

.97

.89

.89

.89

.90

.86

.90

.88

.90

.91

.90

.88

.83

.79

.79

.79

.94

.94

.91

.91

.94

.95

.89

.90

.92

.79

.79

.79

F

L

.84

.82

.83

.80

.80

.80

.82

.80

.78

.80

.80

.80

F

L

.88

.87

.87

.82

.82

.84

.80

.79

.82

.80

.80

.80

F

L

F

L

.69

.73

.75

.74

.62

.58

.54

.56

.63

.37

.37

.73

.68

.70

.72

.73

.64

.58

.51

.54

.60

.37

.37

.37

.392

.492

.386

.664

.697

.574

.526

.219

.366

.999

.273

.999

.829

.591

.749

.710

.941

.578

.348

.107

.800

.999

.965

999

.571

.548

.585

.628

.792

.770

.735

.735

.632

.605

.566

.605

.687

.683

.589

.597

.718

.788

.693

.664

.710

.605

.593

.605

X

T

.507

.516

.559

.501

.518

.518

.537

.473

.490

.593

.452

.593

X

T

.553

.561

.558

.563

.605

.544

.508

.494

.508

.593

.533

.593

X

T

X

T

.275

.328

.366

.302

.221

.200

.176

.189

.245

.198

.133

.198

.243

.265

.314

.278

.233

.185

.158

.174

.228

.198

.135

1.98

Conversion of Sizing Coefficients

Following are conversions for use with other

common sizing equations.

K

= (0.865)C

v

C1= 39.76(pXT)

= CvC

C

g

Km = F

L

Cs = 1/20(Cg). Cs is only applicable for inlet

pressures up to 70 bar(a)

16

v

1

2

Line-to-Valve Size Ratios Greater than

1-to-1

Contact your Emerson Process Management sales

office for information on determining the F

piping geometry factor.

, the

P

Page 17

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Actuator-Valve Selection — Shutoff Pressure Drops

Note

The intent of the actuator-valve

selection tables is to present an

actuator size that will control a

relatively high valve pressure drop

with a standard actuator operating

pressure. It is not implied that the

selection shown is best for your

application.

For pressure drops lower than those

shown, a lower actuator pressure or

smaller actuator might be satisfactory.

For pressure drops higher than those

shown, a higher operating pressure or

larger actuator will be required.

Contact your Emerson Process

Management sales office for other

sizes and operating pressures.

With rotary valves, the highest pressure drop occurs

when the valve is shut off. When the valve is open,

pressure drop is normally much lower. However,

pressure drop capabilities of a rotary valve also are

lower when the valve is open. The allowable flowing

pressure drop across a valve depends on the valve

construction, on the type of flowing fluid (liquid or

Table 15. Temperature Capabilities Summary

Minimum for all

types

PROCESS

TEMPERATURE

Maximum

AMBIENT TEMPERATURE

Steel valve material

Stainless steel valve material

Valve Packing Bearing - - -

CV500 and V500

1051 and 1052 actuators

2052 actuator

1061 actuator

DVC6020 controller and 3610J

positioners

gas), and on the vapor pressure and critical pressure

ratio of liquids.

Only allowable shutoff pressure drops are shown

here. To determine the allowable flowing pressure

drop, provide your Emerson Process Management

sales office with the application information shown

on page 23.

Do not exceed any other limits presented in this flier.

Following is a brief reminder of some of those limits:

Maximum Shutoff Pressure Drop . . . Do not

exceed any of the pressure drops in these tables or

in the Maximum Allowable Shutoff Pressure Drops

section.

Maximum Inlet Pressure and Temperature . . . Do

not exceed the maximum rating of the valve: PN 10

through 100 or CL150 through CL600. Refer to the

Body Materials, End Connections, and Ratings

section.

Materials Temperature

Limits . . . Refer to the Valve Materials and

Temperatures section, the actuator specifications

tables, and the accessories specifications tables.

Some of the critical limits are repeated here.

EN: 10C

ASME: 29C

EN: 10C

ASME: 26C

PTFE

Graphite

O-rings for sealed bearing

40 to 82C with nitrile elastomers and 50 to 149C with silicone

34 to 82C (to 50C with optional materials)

Metal

PTFE

Metal

PTFE

CV500

V500

Nitrile

Fluorocarbon

45 to 80C

40 to 80C

232C

260C

232C

316C (260C

with CF8M

retainer)

427C

29 to 93C

18 to 204C

17

Page 18

High-Capacity Rotary Valves

Actuator-Valve Selection — Shutoff Pressure Drops (Continued)

Table 16. Fisher 2052 Actuator

BEARING AND SEAL

MATERIAL

PEEK Bearings with

TCM Plus Seal

PEEK Bearings with

HD (HeavyDuty)

Metal Seal

PEEK Bearings with

Flat Metal Seal

PEEK Bearings with

Flow Ring Construction

VALVE SIZE

DN NPS Bar Psig

25

40

50

80

100

150

200

250

300

25

40

50

80

100

150

200

250

300

80

100

150

200

250

300

25

40

50

80

100

150

200

250

300

1

1-1/2

2

3

4

6

8

10

12

1

1-1/2

2

3

4

6

8

10

12

3

4

6

8

10

12

1

1-1/2

2

3

4

6

8

10

12

Actuator Size

1

1

1

2

2

3

3

3

3

1

1

1

2

2

3

3

3

3

2

2

3

3

3

3

1

1

1

2

2

3

3

3

3

PUSHDOWNTOOPEN OR -CLOSE

AirtoDiaphragm

2

4

4

2

4

2

4

4

4

2

4

4

2

4

2

4

4

4

2

4

2

4

4

4

2

4

4

2

4

2

4

4

4

30

60

60

30

60

30

60

60

60

30

60

60

30

60

30

60

60

60

30

60

30

60

60

60

30

60

60

30

60

30

60

60

60

Product Flier

PF51.3:Vee-Ball

May 2009

Pressure Drop,

Bar

51.7

51.7

51.7

51.7

51.7

51.7

51.7

40.2

37.6

51.7

51.7

51.7

51.7

51.7

51.7

51.7

40.9

33.1

20.7

20.7

20.7

20.7

10.3

8.9

103.4

103.4

103.4

103.4

72.4

75.2

73.8

40.5

37.7

18

Page 19

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Actuator-Valve Selection — Shutoff Pressure Drops (Continued)

Table 17. Fisher 1052 Actuator

BEARING

AND SEAL

MATERIAL

PEEK

Bearings with

Composition

Seal

PEEK

Bearings with

HD

(Heavy-Duty)

Metal Seal

(Lubricated

Service)

PEEK

Bearings with

HD

(Heavy-Duty)

Metal Seal

(Non-Lubricated

Service)

PEEK

Bearings with

Flat Metal

Seal

PEEK

Bearings with

Flow Ring

Construction

VALVE SIZE

DN NPS Bar Psig Bar Psig

25

40

50

80

100

150

200

250

300

50

80

100

150

200

250

300

50

80

100

150

200

250

300

25

40

50

80

100

150

200

250

300

25, 40

50

80

100

150

200

250

300

1

1-1/2

2

3

4

6

8

10

12

2

3

4

6

8

10

12

2

3

4

6

8

10

12

1

1-1/2

2

3

4

6

8

10

12

1, 1-1/2

2

3

4

6

8

10

12

AIR TO OPEN (PUSH-DOWN-TO-OPEN) AIR TO CLOSE (PUSH-DOWN-TO-CLOSE)

Actuator

Size

20

20

33

33

40

60

60

70

70

20

33

40

60

70

70

70

20

40

40

60

70

70

70

20

33

33

40

60

60

60

60

70

20

20

33

40

60

60

70

70

Pressure to Actuator

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

Pressure

Drop, Bar

51.0

51.0

51.0

51.0

51.0

51.0

51.0

51.0

46.9

51.0

51.0

51.0

51.0

51.0

51.0

35.2

51.0

51.0

51.0

51.0

51.0

51.0

26.6

20.7

20.7

20.7

20.7

20.7

20.7

20.7

10.3

9.3

51.0

51.0

51.0

51.0

51.0

51.0

51.0

51.0

Actuator

Size

20

33

33

40

40

60

60

60

70

33

40

40

60

60

70

70

33

40

60

60

70

70

70

33

33

33

40

60

60

60

60

70

20

33

33

40

60

60

60

70

Pressure to Actuator

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 2.3

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 1.2

0 to 2.3

0 to 2.3

0 to 2.3

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

0 to 33

0 to 18

0 to 18

0 to 18

0 to 18

0 to 18

0 to 33

0 to 33

0 to 33

Pressure

Drop, Bar

51.0

51.0

51.0

51.0

51.1

43.3

51.0

51.0

51.0

51.0

51.0

51.0

51.0

51.0

15.3

26.5

51.0

51.0

51.0

51.0

51.0

43.6

18.1

20.7

20.7

20.7

20.7

20.7

20.7

20.7

10.3

7.5

50.1

50.1

50.1

50.1

50.1

50.1

50.1

50.1

19

Page 20

High-Capacity Rotary Valves

Actuator-Valve Selection — Shutoff Pressure Drops (Continued)

Table 18. Fisher 1061 Actuator

PRESSURE

VALV E

SIZE

DN NPS Composition Seal

25

40

50 - 100

150

200

250

300

25, 40

50 - 150

200

250

300

1-1/2

2 - 4

1-1/2

2 - 6

10

12

10

12

1061

SIZE

1

30

30

30

6

30

8

30

40

60

1,

30

30

8

40

40

60

TO

ACTUATOR

Bar Psig Bar Psig Bar Psig

4.1

4.1

4.1

5.5

5.5

4.1

4.1

4.1

4.1

4.1

4.1

4.1

60

60

60

80

80

60

60

Flat Metal Seal Flow Ring Construction - - -

60

60

60

60

60

PRESSURE

DROP, BAR

51.0

51.0

51.0

51.0

47.9

51.0

51.0

20.7

20.7

20.7

10.3

9.9

1061

SIZE

PRESSURE TO

ACTUATOR

HD (Heavy-Duty) Metal Seal

(Lubricated Service)

30

30

30

30

40

40

68

30

30

40

40

40

4.1

4.1

4.1

4.1

4.1

5.5

4.1

4.1

4.1

4.1

4.1

4.1

60

60

60

60

60

80

60

60

60

60

60

60

PRESSURE

DROP, BAR

51.0

51.0

51.0

51.0

51.0

40.5

51.0

51.0

51.0

51.0

51.0

43.4

1061

SIZE

Product Flier

PF51.3:Vee-Ball

PRESSURE

TO

ACTUATOR

HD (Heavy-Duty) Metal Seal

(Non-Lubricated Service)

30

30

30

30

40

60

68

4.1

4.1

4.1

4.1

4.1

4.1

4.1

60

60

60

60

60

60

60

- - -

- - -

May 2009

PRESSURE

DROP, BAR

51.0

51.0

51.0

51.0

48.3

51.0

51.0

20

Page 21

Product Flier

PF51.3:Vee-Ball

May 2009

High-Capacity Rotary Valves

Approximate Weight

Weights are in kilograms and are for valve and

actuator combined (CL150 flanged for V150 valves,

CL300 flangeless for V200, and CL300 flanged for

Table 19. Fisher V150, V200, V300 with Actuator

VALVE SIZE 2052 ACTUATOR 1051 ACTUATOR 1052 ACTUATOR 1061 ACTUATOR

DN NPS Size V150 V200 V300 Size V150 V200 V300 Size V150 V200 V300 SIze V150 V200 V300

25 1 1 28 27 30

40 1-1/2 1 30 29 34

50 2 1 31 32 39

80 3 2 58 60 73

100 4 2 71 67 82

150 6 3 130 124 148

200 8 3 160 150 191 60 161 151 192

250 10 3 195 202 288 60 196 203 289

300 12 3 245 - - - 381 60 246 - - - 382 70 280 - - - 416

- - - 14 - - - - - - - - - - - - 60 336 - - - 463 60 339 - - - 466 68 303 - - -

- - - 16 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - 20 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

3340264925

3340285126

3340295230

33

40

60

102

406069

11565111801264060711186711482129

406085

13179125

33

56

48

49

53

35

58

104

V300 valves). Not all possible valve and actuator

size combinations are shown.

2851203020

3255203022

3760203023

43

334034

71

117

103

60 134 128 152 30 64 58 82

149

6070164

6070199

27

29

30

58

195

230

192622

29

202726

33

243131

38

366049

73

154

195

185

2263040941018491

206

292

237

3234060

100

100

30 28 27 30

30 30 28 34

30 31 32 39

30 35 37 50

30 48 44 59

136

143

146

153

40

186

196

213

455

468

646

659

- - -

- - -

- - -

- - -

- - -

- - -

- - -

60

68

80

80

125

132

229

239

322

332

349

430

632

645

- - -

- - -

21

Page 22

High-Capacity Rotary Valves

Dimensions

C

E

Product Flier

PF51.3:Vee-Ball

May 2009

Figure 14. Dimensions

Table 20. Dimensions C and E (mm)

Actuator

Type

1051

1052

1061

2052

1061

Actuator

Size

33

40

60

20

33

40

60

70

30

40

60

1

2

3

68

80

100

C E

289

333

473

251

289

333

473

536

171

206

267

245

350

490

324

324

381

338

505

749

256

338

607

876

849

378

425

406

258

423

592

483

714

714

For V150 and V200 valves through DN 300 (NPS

12), the standard face-to-face dimension is IEC

534-3-2 (ISA S75.04). The optional face-to-face

dimension for these sizes is ISA B16.10 Short. The

face-to-face dimension for DN 350 and DN 400

(NPS 14 and 16) is ISA B16.10 Short. The

face-to-face dimension for DN 500 (NPS 20) is 508

mm. Face-to-face dimensions for EN versions of

these valves are the same as for the ASME versions

and might not conform to any standard other than

those mentioned here.

A

X

Table 21. Dimensions A, X for Fisher V150, V200, V300

VALVE SIZE A

DN NPS

25

1

40

1-1/2

50

2

80

3

100

4

150

6

200

8

250

3001012

- - -

14

- - -

16

- - -

20

Standard Optional

V150 V200 V150

297

338

381

406

508

102

114

124

165

194

229

243

297

- - -

- - -

- - -

- - -

127

165

178

203

229

267

292

330

356

- - -

- - -

- - -

V200

CL150

Only

330

- - -

- - -

- - -

- - -

V300 (IEC

534-3-2 &

ISA

S75.04)

102

114

124

165

194

229

243

297

338

381

406

- - -

X

232

258

264

290

301

324

380

408

451

629

601

692

22

Page 23

Product Flier

PF51.3:Vee-Ball

May 2009

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, or maintenance of any

product. Responsibility for the

selection, use and maintenance of any

product remains with the purchaser

and end-user.

High-Capacity Rotary Valves

23

Page 24

High-Capacity Rotary Valves

Emerson Process Management Sales Offices

For the name and location of your nearest Emerson Process Management sales office, refer to

www.emersonprocess.com/Fisher/support/contactus/index.html or contact our headquarters:

Europe

Emerson Process Management

Prince Regent House

Chatham Maritime Kent ME4 4QZ

United Kingdom

T +44 (0)16 34 89 58 00

F +44 (0)16 34 89 58 42

Latin America

Emerson Process Management

Av. Hollingsworth 325

Iporanga Sorocaba, SP

CEP 18.087-105

Brazil

T +(55)(15)3238-3788

F +(55)(15)3238-3300

Product Flier

PF51.3:Vee-Ball

May 2009

Middle East and Africa

Emerson Process Management

P.O. Box 17 003

Jebel Ali Free Zone

Dubai

United Arab Emirates

T +(971) 4 883 5235

F +(971) 4 883 5312

Russia

Emerson Process Management

Malaya Trubetskaya

Street 8 - 11th Floor

119881 Moscow

T (7) 095 232 69 68

F (7) 095 245 86 85

Asia Pacific

Emerson Process Management

Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

Singapore

T +(65) 6777 8211

F +(65) 6777 8010

Japan

Nippon Fisher Co. Ltd.

Shinagawa NF Building

4th Floor, 1-2-5 HigashiShinagawa

Shinagawa-Ku, Tokyo, 140-0002

Japan

T (81)-3-5769-6900

F (81)-3-5769-6901

North America

Emerson Process Management

301 S. 1st Avenue

Marshalltown IA 50158

USA

T (641) 754-3011

F (641) 754-2830

Fisher, ENVIRO-SEAL, FIELDVUE, Vee-Ball, Control-Disk, POSI-SEAL, and ValveLink are marks owned by one of the companies in the Emerson

Process Management business division of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks

and service marks of Emerson Electric Co. HART is a mark of HART Communication Foundation. F

Foundation. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or

specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes

responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains

solely with the purchaser and end-user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

Fisher Controls International LLC 1997, 2009; All Rights Reserved

24

OUNDATION fiedlbus is a mark of the Fiedlbus

Loading...

Loading...