Page 1

Slurry Vee-Ball Valve

D103154X012

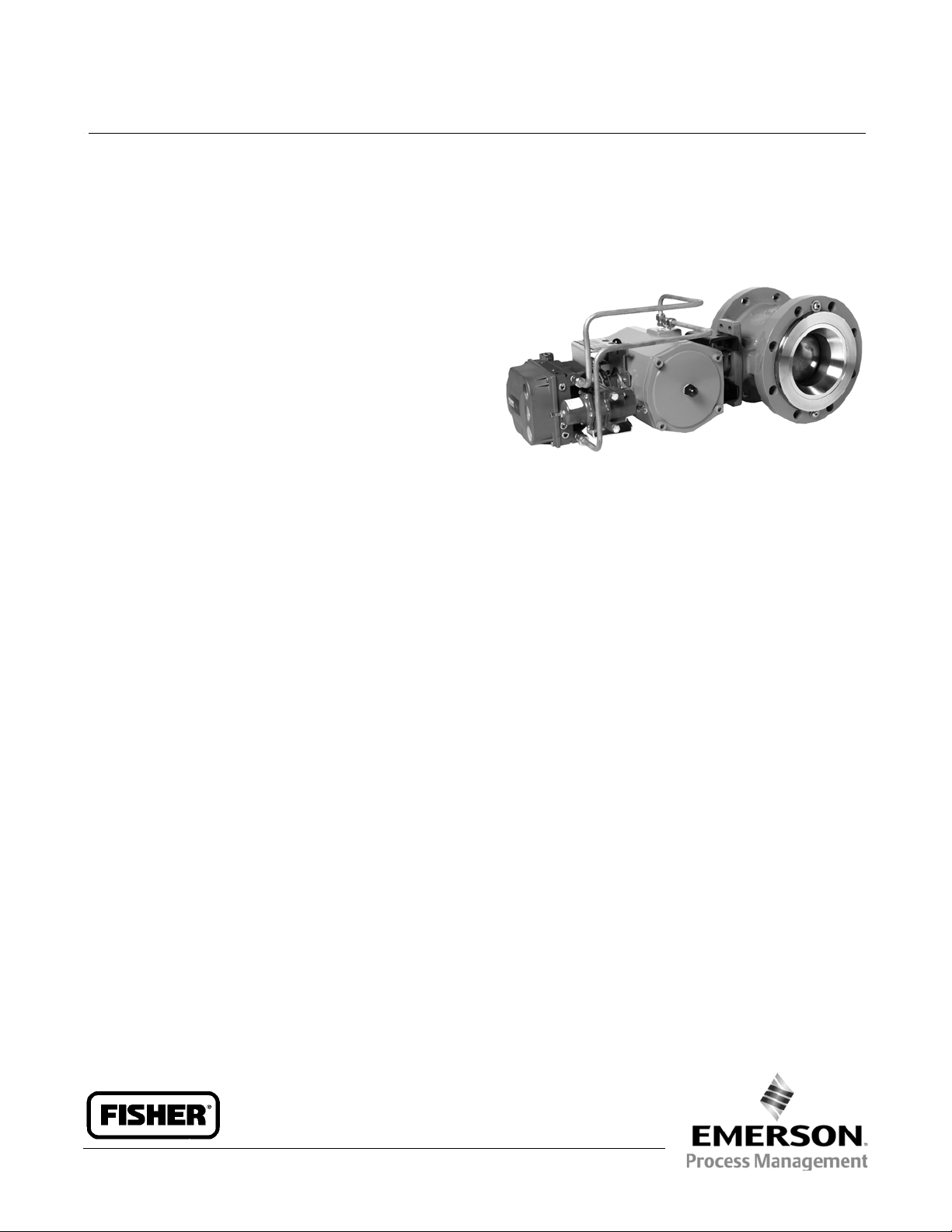

Fisherr V150S

Slurry Vee-Ball™ Control Valve

The Fisher V150S Slurry Vee-Ball valve mates with

CL150 raised face flanges. Rugged construction, highly

wear-resistant trim materials, and an unrestricted

straight through flow path make the design ideal for

controlling the most abrasive of slurries.

A shaft with a choice of drive connections will allow a

variety of power operated actuators and valve

positioners or controllers to be used.

W8512

The design is particularly effective in minimizing

erosive damage to the adjoining pipework, thereby

providing greater operational safety and service life

when compared with other valve types.

Features

Fully protective trim–The valve body, shaft, and

bearings are fully protected by hard wear-resistant

trim materials.

Pipeline and flange protection–The throttled flow

stream is guided through a specially shaped flow

ring to minimize turbulence and impingement on

thepipewall.Thevalvecanbematchedtothebore

size of the inlet and outlet piping in order to prevent

turbulence being generated by the step resulting in

scouring erosion of the flange faces, unexpected

leakage, and expensive rework. In addition, both

the inlet and outlet valve flange faces are protected

by a portion of the hard trim.

Fisher V150S Slurry Vee-Ball Control Valve

Long Service Life–The Vee-Ball design, when used in

reverse flow mode, keeps the high velocity down

stream of the vena contracta within the flow ring

bore at the outlet of the valve. Compared with other

styles of valves, the exit flow is essentially parallel

with the flow ring wall and a minimum of flow

impingement occurs. Combined with a choice of

hard wear-resistant materials, a significantly long

life is obtained.

Easily replaceable trim parts allow the valve to be

overhauled at predetermined intervals and the

valve body used again during repeated operational

cycles.

Ease of installation–Full flanging on the valve body

allows the valve body to be easily aligned c entrally

with the pipe flanges, an essential requirement in

avoiding erosion across the flange faces.

Excellent Flow Control–Precise contouring of the

V-notch ball provides a modified equal percentage

flow characteristic. When combined with a valve

actuator/controller system having minimal lost

motion, improved process control can be obtained.

Product Bulletin

51.3:V150S

February 2013

(continued on page 2)

www.Fisher.com

Page 2

Product Bulletin

51.3:V150S

February 2013

Slurry Vee-Ball Valve

D103154X012

Features (continued)

Quick and Easy Maintenance–All trim parts are

retained without the use of press fits or screw

threads exposed to the process fluid. See figure 1.

Structural Integrity–The valve body, complete with

flanges, is made from a one-piece casting. No

welding is employed. No O-ring seals are used. Use

of a flanged valve body does not require the use of

extra long studs.

The shaft seal is made from well-proven PTFE

chevron ring packing with the means for external

adjustment.

Options

A PSZ (partially stabilized zirconia) ceramic flow ring

insert is available with HCI (high chrome iron) or PSZ

ceramic ball for particularly aggressive slurry

services with extended lifetime requirements. The

ceramic insert offers substantial increase in flow

ring lifetimes.

Trim materials are available to meet the

requirements of corrosive/erosive slurries.

See table 2.

The“FlowOvertheTop”V-NotchBalloffersan

alternative to the standard V-Notch Ball in scaling

applications.

The drive shaft is available with either a double D or

splined actuator connection to accommodate a

choice of actuation between a spring-opposed

diaphragm or a rack and pinion.

2

Page 3

Slurry Vee-Ball Valve

D103154X012

Specifications

Product Bulletin

51.3:V150S

February 2013

Valve Sizes

J NPS 3, J 4, J 6, J 8, J 10, and J 12

End Connection

V150S: CL150 Raised-face flange

Face to Face Dimension

Seefigure2

Maximum Inlet Pressure

Consistent with pressure-temperature ratings per

ASME B16.34 but do not exceed the material

temperature capabilities shown below or the pressure

drop limitations

Maximum Shut Off Pressure

See tables 3 and 4

Shutoff Classification

Class I per ANSI/FCI 70-2 and IEC 60534-4

(Class II and better not available). A defined initial

maximum leak rate can be provided subject to review

of service conditions.

Construction Materials

Standard Construction: See table 1

Temperature Capability

For Trim 1: 427_C(801_F) maximum

For Trims 2 and 3: 230_C(446_F) maximum

For materials: See table 1

Flow Characteristic

Approximately equal percentage

Dimensions

See figures 2 and 3

Flow Direction

Reverse flow recommended (into concave face of

ball, out through the flow ring)

Flow Coefficients

See Fisher Catalog 12

Maximum Ball Rotation

90 degrees

Valve Installation

Shaft axis to be horizontal

Actuator Mounting

Right-hand or left-hand, as viewed from upstream

end of valve

Valve/Actuator Action

With diaphragm or piston rotary actuator and splined

shaft, the valve is field-reversible between PDTC or

PDTO:

rod closes valve) and

(extending actuator rod opens valve)

Actuator Size Selection

Contact your Emerson Process Management sales

office for information

Approximate Weight

NPS 3: 15 kg (33 lb)

NPS 4: 28 kg (62 lb)

NPS 6: 45 kg (99 lb)

NPS 8: 82 kg (180 lb)

NPS 10: 120kg(265lb)

NPS 12: 178kg(390lb)

J push-down-to-close (extending actuator

J push-down-to-open

3

Page 4

Product Bulletin

51.3:V150S

February 2013

Table 1. Standard Construction Materials

MATERIAL TEMPERATURE CAPABILITY

Part Material

Minimum Maximum Minimum Maximum

Valve Body Carbon Steel ASTM A216 WCC -29 427 -20 800

Body Liner High Chrome Iron ASTM A532 Class IIIType A -29 427 -20 800

V-Notch Ball

Flow Ring

Flow Ring Retainer Carbon Steel ASTM A105 -29 427 -20 800

Bearing Shroud High Chrome Iron ASTM A532 Class IIIType A -29 427 -20 800

Bearing S44004 58Rc -29 427 -20 800

Drive Shaft S17400 Cond.H1025 -29 427 -20 800

Follower Shaft S17400 Cond.H1025 -29 427 -20 800

Shaft Pins S42000 -29 427 -20 800

Gaskets Graphite SST Laminate -198 538 -325 1000

Packing Set

Packing Box Ring and Follower S31600 -198 538 -325 1000

Studs B8M Class 2 -45 538 -50 1000

Nuts S31600 -45 538 -50 1000

Retainer Screws and Clips S31600 -45 538 -50 1000

Spring S30400 -29 427 -20 800

Plug S31600 -45 538 -50 1000

High Chrome Iron ASTM A532 Class IIIType A -29 427 -20 800

PSZ Ceramic (optional) -29 427 -20 800

High Chrome Iron ASTM A532 Class IIIType A -29 427 -20 800

HCI with Ceramic Insert (optional) -29 230 -20 450

PTFE V-ring -46 230 -50 450

Graphite -198 538 -325 1000

_C _F

Slurry Vee-Ball Valve

D103154X012

Table 2. Trim Levels

Trim Level Ball Flow Ring Valve Body Liner Bearing Shrouds

1 (standard) HCI (High Chrome Iron) HCI HCI HCI

2 HCI HCI with ceramic insert HCI HCI

3 Ceramic Ball HCI with ceramic insert HCI HCI

4

Page 5

Slurry Vee-Ball Valve

D103154X012

Product Bulletin

51.3:V150S

February 2013

Table 3. Maximum Allowable Shutoff Pr essure Drops

(Valve Body Ratings) based on Carbon Steel Material.

Consult the tables for both trim and body limits.

TEMPERATURE

RANGE

_C Bar

-46 to-29 ---

-29 to 38 20.0

93 17.9

149 15.9

204 13.8

232 12.8

260 11.7

316 10.7

343 9.65

371 8.62

399 6.55

427 5.52

_F Psi

-50 to-20 ---

-20 to100 290

200 260

300 230

400 200

450 185

500 170

550 155

600 140

650 125

700 110

750 95

800 80

PRESSURE RATING

WCC CL150

Table 4. Maximum Allowable Shutoff Pressure Drops

based on Standard Trim.

Note: Do not exceed the pressure/temperature

rating of the valve or mating flanges

TEMPERATURE

RANGE

_C Bar

-29 to427 47.0 27.5 28.3 27.5 15.2 13.8

_F Psi

-20 to800 680 400 410 400 220 200

1. Refer totable 3.

3 4 6 8 10 12

VALVE SIZE, NPS

Figure 1. V150S Cutaway View

W9177

5

Page 6

Product Bulletin

51.3:V150S

February 2013

Slurry Vee-Ball Valve

D103154X012

Table 5. Fisher V150S Dimensions

VALVE SIZE

DN mm

80 165 80.0 235 140 130 104 98.0 19.1 152 31.8 14.2

100 194 102 214 152 140 117 98.0 19.1 152 31.8 14.2

150 230 111 214 175 164 124 112 25.4 152 31.8 14.2

200 304 184 208 220 231 195 124 31.8 235 46.0 17.5

250 385 235 208 250 261 235 132 31.8 235 46.0 17.5

300 455 291 208 300 304 270 132 38.1 235 46.0 17.5

NPS Inch

3 6.49 3.15 9.26 5.51 5.12 4.11 3.86 0.75 6.00 1.25 0.56

4 7.62 4.02 8.44 5.98 5.53 4.61 3.86 0.75 6.00 1.25 0.56

6 9.06 4.38 8.44 6.89 6.45 4.90 4.40 1.00 6.00 1.25 0.56

8 11.96 7.25 8.19 8.66 9.11 7.68 4.90 1.25 9.25 1.81 0.69

10 15.16 9.26 8.18 9.84 10.26 9.25 5.19 1.25 9.25 1.81 0.69

12 17.91 11.47 8.18 11.81 11.97 10.63 5.19 1.50 9.25 1.81 0.69

1. Stud length associated with clearance dimension “M”is longer than standard length specified in ASME B16.5.

2. Clearance necessary to removeflange bolts.

A B D G K M

V150S DIMENSIONS

(2)

(1)

(2)

N

SDiameter T U W

Figure 2. V150S Dimensions (see table 5)

SDIAMETER

U

E0875

T

W

B

A

MN

G K D

SIZE

3 THROUGH 12

6

Page 7

Slurry Vee-Ball Valve

D103154X012

Product Bulletin

51.3:V150S

February 2013

Table 6. Fisher V150S Dimensions for Double D Shaft

Drive

VALVE

SIZE

DN mm

80 83 19.0 25.4 14.2 95 25

100 83 19.0 25.4 14.2 95 25

150 83 25.4 25.4 17.5 95 25

200 83 31.8 25.4 20.6 133 38

250 89 31.8 25.4 20.6 133 38

300 89 38.1 38.1 25.4 133 38

NPS Inch

10 3.5 1.25 1.0 0.81 5.25 1.5 5/8-11

12 3.5 1.5 1.5 1.0 5.25 1.5 5/8-11

1. This nominal valve shaft diameteris the shaft d iameter through the packing box.

Use this diameter when selecting Fisher actuators.

E S

3 3.25 0.75 1.0 0.56 3.75 1.0 1/2-13

4 3.25 0.75 1.0 0.56 3.75 1.0 1/2-13

6 3.25 1 1.0 0.69 3.75 1.0 1/2-13

8 3.25 1.25 1.0 0.81 5.25 1.5 5/8-11

FLAT

(1)

LENGTH

FLAT

SIZE

T U W

see

below

Figure 3. V150S Dimensions for Double D Shaft Drive

(see table 6)

E

FLAT

LENGTH

38B2695-A

FLAT SIZE

S

T

W

U

7

Page 8

Product Bulletin

51.3:V150S

February 2013

Figure 4. Fisher V150S NPS 6 Valve

FLOW RING

FOLLOWER SHAFT

PLUG

Slurry Vee-Ball Valve

D103154X012

V-NOTCH BALL

FLOW RING RETAINER

GASKET

DRIVE SHAFT

SHAFT PIN

W8509

VALVE BODY

PACKING FOLLOWER

PACKING SET

BEARING

BEARING SHROUD

VALVE BODY LINER

Neither Emerson, Emerson Process Man agement, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solelywith the purchaser and end user.

Fisher and Vee-Ball are marks owned by one of thecompanies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emersonlogo are trademarks and service marksof EmersonElectric Co. All other marks are the property oftheir respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. We reserve the right to modify or improve the designs or specificationsof such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2003, 2013 Fisher Controls International LLC. All rightsreserved.

8

Loading...

Loading...