Page 1

Instruction Manual

D104297X012

Fisher™ V270 Full-Bore Ball Control Valve

V270 Valve

September 2018

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 2...............................

Educational Services 3.........................

Installation 3..................................

Maintenance 6.................................

Packing Maintenance 6.........................

Stopping Leakage 6........................

Replacing Packing 7........................

Seal Ring Maintenance

Disassembly 9.............................

Assembly 11..............................

Actuator Mounting 13...........................

Determining Closed Position 14.................

Parts Ordering 14...............................

Parts List 16...................................

Figure 1. Fisher V270 Control Valve

X1492

Introduction

Scope of Manual

This instruction manual provides installation, operation, maintenance, and parts information for the Fisher V270

Full-Bore Ball control valve (see figure 1). Refer to separate manuals for information concerning the actuator,

positioner, and accessories.

Do not install, operate, or maintain a V270 valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

Description

The Fisher V270 is a three piece, trunnion mounted, full-bore control valve designed with features for optimized

pressure, flow and process control. The V270 comes standard with dual seal construction allowing unidirectional or

bidirectional flow and double block-and-bleed operation. The full-bore ball design presents little or no restriction to

flow at full travel. The V270 construction meets ANSI / NACE MR0175 / ISO 15156 as standard.

before proceeding.

www.Fisher.com

Page 2

V270 Valve

September 2018

Specifications

Instruction Manual

D104297X012

Valve Body Size

J NPS 6, J 8, J 10, J 12, J 14, J 16, J 20,

J 24.

and

End Connections

Raised Face per B16.5-2013

Shaft Connection Style

Body/Shell Pressure Rating

(1)

Keyed

J CL150, J CL300, and J CL600

pressure‐temperature ratings per ASME B16.34-2013

Face-to-Face Dimensions

Long Pattern per B16.10-2009

Valve Body, Tailpiece and Packing Box Material

SA350 LF2

Shutoff Classification

ANSI/FCI 70‐2 Class VI

Ball Material

SA350 LF2/ENP

Flow Direction

Unidirectional or Bidirectional flow

Seal/Insert Material

S31600/POM

Packing

Live-Loaded PTFE

Valve Temperature Capability

-40 to 82_C (-40 to 180_F)

1. The pressure‐temperature limits in this instruction manual and any applicable standard or code limitation for valve should not be exceeded.

2. POM stands for polyoxymethylene

(2)

Flow Characteristic

Modified equal percentage

Maximum Ball Rotation

90 degrees

Approximate Weight

See table 2

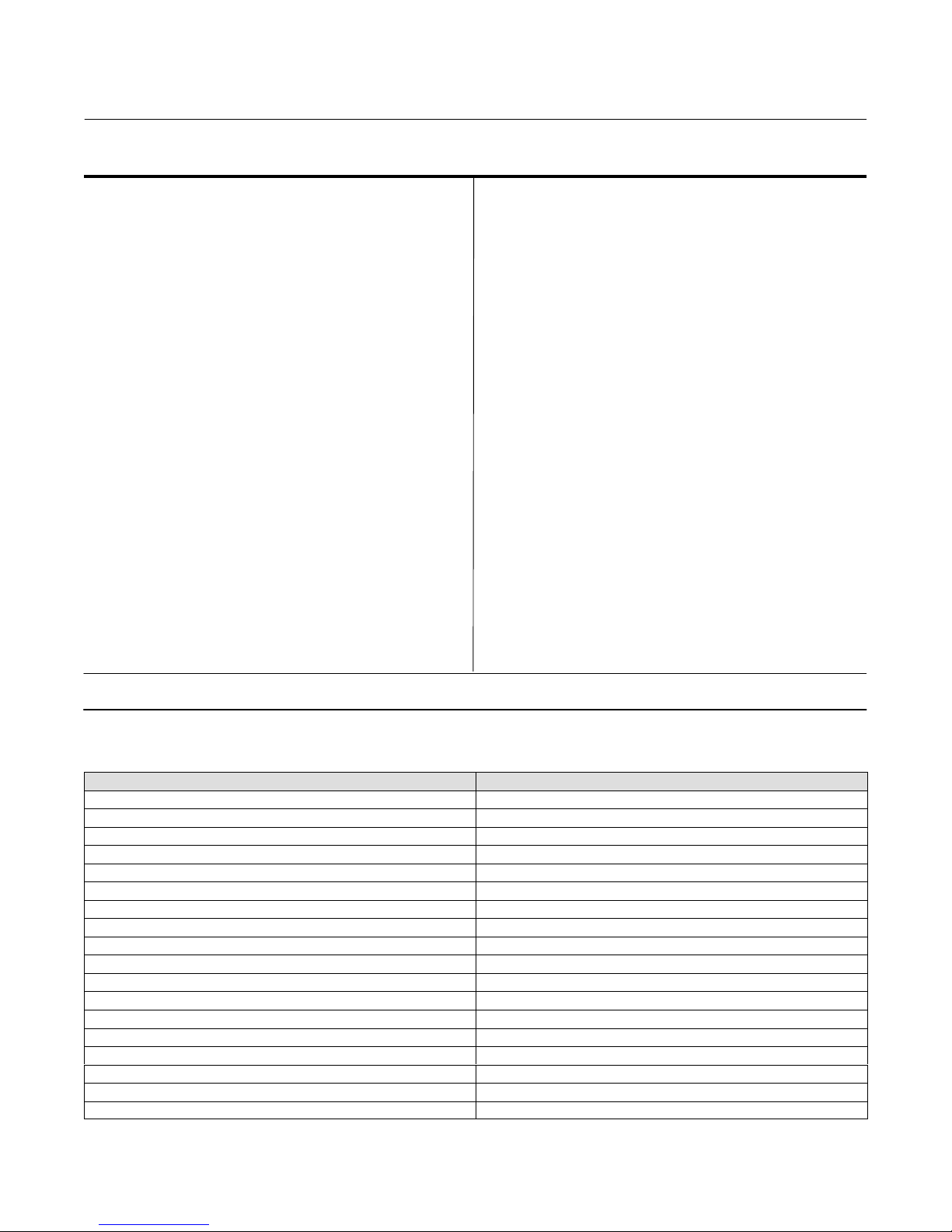

Table 1. Standard Materials of Construction

Part Material

Valve Body LF2 Carbon Steel

Ball LF2 Carbon Steel / ENP

Seal POM with S31600 SST Seal Carrier

Drive Shaft S17400 H1150D

Spring N07750

Tailpiece LF2 Carbon Steel

Tailpiece Mounting and Packing Box Bolting L7M Steel

Bearing Plate LF2 Carbon Steel

Trunnion Bushings

Thrust Washer Glass filled PTFE

Shaft Bushing N04400 / Comp

Packing Box Housing Carbon Steel

Packing Live-Loaded PTFE

Packing Bolting B7M Steel

Packing Follower, Packing Box Ring S31600 SST

Straight Pins S17400 H1150D

O-Rings, Backup Rings Nitrile

Actuator Mounting Bolting Steel Grade 5

2

Carbon Steel, Bronze, PTFE

Page 3

Instruction Manual

D104297X012

V270 Valve

September 2018

Educational Services

For information on available courses for Fisher V270 valves, as well as a variety of other products, contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

Installation

WARNING

D To avoid personal injury, always wear protective gloves, clothing, and eyewear when performing any installation

operations.

D To avoid personal injury or property damage resulting from the bursting of pressure retaining parts, be certain the

service conditions do not exceed the limits given in this manual.

D To avoid personal injury or property damage that can result from the sudden release of process pressure if valve or

mating pipe flange pressure ratings are exceeded, provide a relief valve for over‐pressure protection as required by

government or accepted industry codes and good engineering practices.

D Personal injury could result from packing leakage. See the Packing Maintenance section for adjustment information.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

D Use proper lifting and rigging practices while moving the valve or valve/actuator assembly.

3

Page 4

V270 Valve

September 2018

Table 2. Face‐to‐Face Dimensions and Approximate Weights

FACE‐TO‐FACE

VALVE SIZE, NPS CLASS

150 394 15.50 170 370

6

8

10

12

14

16

20

24

300 403 15.88 190 415

600 559 22.00 280 620

150 457 18.00 305 670

300 502 19.75 350 775

600 660 26.00 465 1020

150 533 21.00 430 950

300 568 22.38 495 1095

600 787 31.00 745 1640

150 610 24.00 645 1425

300 648 25.50 770 1695

600 838 33.00 1050 2320

150 686 27.00 1045 2305

300 762 30.00 1065 2350

600 889 35.00 1365 3015

150 762 30.00 1275 2810

300 838 33.00 1455 3210

600 991 39.00 1925 4250

150 914 36.00 2245 4945

300 991 39.00 2580 5685

600 1194 47.00 3450 7610

150 1067 42.00 3380 7450

300 1143 45.00 4280 9435

600 1397 55.00 5775 12740

DIMENSIONS

mm Inches kg Pounds

Instruction Manual

D104297X012

APPROXIMATE WEIGHT

4

Page 5

Instruction Manual

D104297X012

V270 Valve

September 2018

Key number locations are shown in figures 4, 5 and 6, unless otherwise noted. Throughout this manual, the

component key number will be identified for clarity.

1. Install a three‐valve bypass around the control valve assembly if continuous operation will be necessary during

inspection and maintenance of the valve.

2. The valve is normally shipped as part of a control valve assembly, with a factory adjusted actuator mounted on the

valve. If the valve or actuator has been purchased separately, or if the actuator has been removed, refer to the

Actuator Mounting section and the appropriate actuator instruction manual for installation and adjustment

procedures.

3. The standard valve construction allows uni-directional or bi-directional flow. If possible, install the valve in a

horizontal pipeline with the drive shaft vertical, however, the orientation of the valve does not affect the

performance.

CAUTION

Be certain the valve and adjacent pipelines are free of any foreign material that could damage the valve sealing surfaces.

4. Provide appropriate flange gaskets, and place the valve in the pipeline. Tighten flange bolting in a star pattern to

ensure the flange gaskets are compressed evenly.

Note

Standard Fisher V270 live-loaded PTFE packing is composed of partially conductive packing rings (carbon‐filled PTFE male and

female adaptors) to electrically bond the drive shaft to the valve body. For hazardous area service, an alternate shaft‐to‐body

bonding strap is also available by using the following step (see figure 2).

5. For hazardous area applications where redundant shaft-to-body grounding is preferred, attach the optional

bonding strap assembly (key 45) to the valve drive shaft (key 4) with the clamp (key 44) and connect the other end

of the bonding strap assembly to the valve body with the mounting cap screw as shown in figure 2.

Figure 2. Optional Shaft‐to‐Body Bonding Strap Assembly

VALVE BODY

ACTUATOR

A

A3143-2

VIEW A-A

A

5

Page 6

V270 Valve

September 2018

Instruction Manual

D104297X012

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and replacement depends upon the severity of service conditions.

WARNING

Avoid personal injury or equipment damage from sudden release of process pressure or uncontrolled movement of parts.

Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Do not loosen any pressure retaining bolting while the valve is still pressurized. This includes the body to tailpiece nuts

(key 21), packing box housing screws (key 10), packing nuts (key 36) or pipe plugs (keys 23 and 28).

D Avoid injury by keeping hands, tools, and other objects away from the ball while stroking the valve.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Check the

actuator cannot suddenly open or close the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure, relieve any process

pressure from both sides of the valve body, and drain the process media from both sides of the valve.

D Dual‐seal constructions can retain pressure and process fluid even after process pressure has been removed from both

sides of the valve. The ball should be partially opened to relieve this pressure before disassembling or removing the

valve from the line. Take additional care if the process fluid is hot, flammable, caustic, or hazardous.

D A tip over hazard exists for the valve/actuator assembly. Ensure the valve/actuator assembly is properly secured and

always supported to prevent falling or rolling which may cause injury or property damage.

D Use lock-out/tag-out best practices and procedures to be sure that the above measures stay in effect while you work on

the equipment.

D The valve packing box housing may contain process fluids that are pressurized, even when the valve has been removed

from the pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Packing Maintenance

Refer to figure 3 for details of the standard live-loaded PTFE packing. All maintenance operations in this section may be

performed on an unpressurized valve that is still installed inline.

Note

For additional information on the live-loaded packing system refer to the ENVIRO-SEAL Packing System Instruction Manual

(D101643X012

Stopping Leakage

Optimum performance of the PTFE live-loaded packing system is obtained when the Belleville springs are compressed

to the required “target load.” The target load is the point where the springs are compressed to 85% of their maximum

deflection.

6

).

Page 7

Instruction Manual

D104297X012

V270 Valve

September 2018

Under normal conditions, the packing nuts should not require re‐tightening. However, when servicing, if the springs

do not remain at the target load of 85% compression, retighten the packing box nuts per the following:

1. Tighten the packing flange nuts alternately and evenly, keeping the packing flange parallel with the valve flange

(see figure 3), until the Belleville springs are compressed 100% (or completely flat).

a. For PTFE packing, loosen each packing flange nut one half turn (180_ of rotation)

.

2. The target load of 85% compression has now been reached. If leakage continues, replace the packing components

and inspect the packing box housing bore and valve drive shaft for damage as described in the following

procedures.

Replacing Packing

Replacing the packing requires bleeding off the system and removing the actuator from the valve. Valve/actuator

adjustments cannot be made correctly without observing the fully open or closed position of the ball (key 3). It is not

necessary to remove the valve from the pipeline to make adjustments, if care is taken to note the position and

alignment of the shaft and coupler.

Refer to figure 3 which identifies the V270 packing components by key number.

Figure 3. Packing Arrangement Details

DRIVE SHAFT

(KEY 4)

ANTI-EXTRUSION

RING (KEY 32)

PACKING STUD

AND NUT

(KEYS 35 AND 36)

PACKING FLANGE

(KEY 37)

SPRING PACK AND

FOLLOWER ASSEMBLY

(KEY 38)

E1659

LIVE-LOADED

PACKING ARRANGEMENT

Packing Disassembly

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, shut off all pressure lines (or other power

source) to the power actuator, release pressure from the actuator, and disconnect the pressure lines from the

actuator. Use lockout/tagout procedures to be sure that the above measures stay in effect while disassembling the

equipment.

PTFE V-RING

PACKING SET

(KEY33)

PACKING BOX

RING (KEY 34)

B2472-1

7

Page 8

V270 Valve

September 2018

Instruction Manual

D104297X012

WARNING

D See the WARNING at the beginning of the Maintenance section for more information before removing the valve from

the pipeline.

D Use proper lifting and rigging practices while moving the valve or valve/actuator assembly.

2. Remove line bolting, remove the control valve from the pipeline, and place the actuator/valve assembly on a flat

surface.

3. To assist with future reassembly, note and mark the orientation of the actuator with respect to the valve body and

the coupler orientation with respect to the valve drive shaft.

4. Refer to the appropriate actuator instruction manual for info on removal.

5. Remove the actuator mounting screws, bolts, or nuts while properly supporting the actuator then separate the

actuator and mounting bracket from the valve.

6. If necessary, remove the bonding strap assembly, shown in figure 2, from the valve before removing the packing

parts.

7. Remove the packing follower nuts, packing flange, and spring pack and packing follower (keys 36, 37, and 38).

8. Remove the packing parts:

a. If the packing box housing (key 6) is mounted on the valve: Use a formed wire hook with a sharp end to pierce

the packing rings, and pull the rings out of the packing box housing. Do not scratch the drive shaft or packing

gland bore. Scratching these surfaces could cause leakage. Clean, inspect, and obtain replacement parts as

necessary for reassembly. Examine the drive shaft and packing gland bore for any signs of damage that may

prevent proper sealing.

b. If the packing box housing is separated from the valve (refer to Seal Ring Maintenance section of this manual for

disassembly instructions): Remove the drive shaft (key 4) from the packing box housing. With the drive shaft

removed, remove all internal packing parts. Clean, inspect, and obtain replacement parts as necessary for

reassembly. Examine the drive shaft and packing gland bore for any signs of damage that may prevent proper

sealing.

Packing Assembly

For additional information on the live-loaded packing system refer to the ENVIRO-SEAL Packing System Instruction

Manual (D101643X012

1. If the packing housing box (key 6) is removed from the valve, use the valve assembly steps to reinstall the drive

shaft (key 4) and packing box housing assembly on the valve. (Refer to Seal Ring Maintenance section of this manual

for additional assembly instructions).

2. Place the new packing components over the drive shaft and slide each into the packing box housing until properly

seated at the bottom of the packing gland. Use the parts sequence shown in figure 3 and verify the Belleville

springs are in the correct configuration

3. Secure the spring pack and packing follower assembly and packing flange with the packing nuts (keys 38, 37, and

36).

4. Tighten the packing flange nuts alternately and evenly, keeping the packing flange parallel with the valve flange

(see figure 3), until the Belleville springs are compressed 100% (or completely flat).

).

.

a. For PTFE packing, loosen each packing flange nut one half turn (180_ of rotation).

5. If necessary, install the bonding strap assembly shown in figure 2.

6. Use the steps provided in the Actuator Mounting section to install the actuator on the valve. For actuator travel

adjustments, refer to the appropriate actuator instruction manual.

8

Page 9

Instruction Manual

D104297X012

V270 Valve

September 2018

7. When the control valve is in operation, carefully examine the packing follower region for any signs of leakage.

Seal Ring Maintenance

WARNING

D See the WARNING at the beginning of the Maintenance section for more information before removing the valve from

the pipeline.

D Use proper lifting and rigging practices while moving the valve or valve/actuator assembly.

Valve Disassembly

Refer to figures 4, 5, and 6 to identify the V270 valve components by key number.

Disassemble the valve only to the extent necessary to accomplish the needed inspection and repairs. For some repairs

complete disassembly of the valve is not necessary. Follow the disassembly procedures to the point necessary to

accomplish the repair, then skip to the appropriate assembly steps to complete the reassembly of the valve. Always

clean and protect sealing surfaces from damage.

Mark parts as necessary to allow them to be returned to the same position and orientation as removed. The tailpiece,

for instance, shall be returned to the same end of the valve from which it was removed. The seal assembly shall also be

returned to the same tailpiece and in the same orientation from which it was removed.

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, shut off all pressure lines to the power

actuator, release pressure from the actuator, and disconnect the pressure lines from the actuator. Use

lockout/tagout procedures to be sure that the above measures stay in effect while working on the equipment.

2. Remove line bolting, remove the control valve from the pipeline, and clean all valve surfaces. Place the

actuator/valve assembly on a flat working surface.

3. Mark parts as necessary to allow them to be returned to the same position during re‐assembly.

4. Refer to the appropriate actuator instruction manual for info on removal. Loosen the actuator mounting screws,

bolts, or nuts while properly supporting the actuator then separate the actuator and mounting bracket from the

valve. When valve maintenance is complete, refer to the Mounting Actuator procedure in this manual to reinstall

the actuator on the valve.

5. Provide a clean soft working surface to protect the tailpiece‐flange serrated surface. Lift the valve and place it on

either tailpiece flange face. Be sure the valve is in a stable, upright position before releasing the hoist connection.

Note

If the packing is in good condition, it is possible to remove and replace the seal assembly without removing the packing box

assembly. However, the packing box assembly must be removed to remove the ball (key 3) from the valve body.

6. Remove the packing box housing socket head cap screws (key 10).

a. If necessary, two packing box housing cap screws can be used as jack bolts to assist with separating the packing

box housing assembly from the valve.

b. Remove the two plastic plugs (key 39) from the packing box housing and install two packing box housing cap

screws until contact with the body occurs. Alternatively, and evenly turn each fastener clockwise until the

packing box housing assembly is adequately separated from the valve body. Remove the packing box housing

assembly from the valve body. The packing box housing assembly includes all packing parts, drive shaft (key 4),

9

Page 10

V270 Valve

September 2018

Instruction Manual

D104297X012

o‐ring seal (key 14), drive shaft bushing (key 8), and thrust washer (key 9). The two straight pins (key 7) may stay

attached to the packing box.

c. If necessary, use a punch and drive each straight pin towards the valve side of the packing box to remove.

7. If it is desired to separate the packing box assembly parts, loosen or remove the packing components and slide the

shaft down and out the valve side of the packing box. Inspect the drive shaft bushing (key 8) and the thrust washer

(key 9). If necessary, replace worn components.

8. Remove the heavy hex nuts (key 21) from the studs, if applicable, remove base brackets (key 25), and lift the upper

tailpiece from the body. If studs (key 19 and 20) are removed from the valve body, mark installed locations of long

studs (key 20) in valve body.

CAUTION

While lifting the tailpiece (key 2) from the valve body, check to see if the seal (key 5) is lifting with the tailpiece. If so, use

caution in case the seal falls out and protect the ball's spherical surface. An additional strap can be employed to ensure the

seal stays in place.

9. Turn the tailpiece assembly over so the seal is facing up, and place it on a clean soft surface to protect the flange

serrated surface. Note the tailpiece o-ring (key 13).

10. Lift the seal out of the tailpiece. Note the seal o-ring and back up ring (keys 15 and 16) and the multitude of springs

(key 18). Ensure all springs and the bearing plate dowel pins (key 22) are accounted for. Clean and protect all sealing

surfaces.

WARNING

When lifting the ball, ensure the bearing plates (key 11) are secure on the ball trunnions to prevent parts from falling which

may cause personal injury or property damage.

Note

Refer to figure 6 and note the NPS6 CL150 construction is different than the balance of the V270 product line in that it lacks

bearing plates and the ball design does not have male trunnions. Specific to the NPS6 CL150, ball removal also requires removal of

the follower trunnion (key 42) and fasteners (key 43).

11. Turn the ball (key 3) to the closed position. Use an approved lifting sling through the ball bore to lift the ball out of

the valve body. Lift the ball and set it on a clean soft surface.

12. Remove the two bearing plates (key 11) and thrust washers (key 17) from the ball. Inspect the lined bushing (key

12) in each bearing plate and the thrust washers. If necessary, replace worn components.

13. Evenly loosen the heavy hex nuts (key 21) from the studs, if applicable, remove base brackets (key 25), and lift the

body (key 1) from the lower tailpiece (key 2).

14. Lift the seal out of the lower tailpiece. Note the seal o-ring and back up ring (keys 15 and 16) and the multitude of

springs (key 18). Ensure all springs and the lower bearing plate dowel pins (key 22) are accounted for. Clean and

protect all sealing surfaces.

10

Page 11

Instruction Manual

D104297X012

V270 Valve

September 2018

Valve Assembly

Be sure to replace valve parts in the same position and orientation from which they were removed. Use the following

steps to reassemble the valve.

Note

Clean and protect all sealing surfaces from damage while installing parts. Lubricate components when necessary as an aid for

installation, and to help protect sealing surfaces.

Refer to figures 4, 5, and 6 that identify the V270 valve components by key number.

During assembly, visually inspect component surfaces that interface with an o-ring or seal for any damage that may

prevent proper sealing.

1. Place both tailpieces (key 2), flange end down on a clean soft surface with the seal assembly cavity facing up. Use

caution to protect the flange end serrated surfaces.

2. Lubricate the tailpiece counterbores where the seal will insert and inject lubricant into each of the spring holes.

Install the seal springs (key 18).

3. On both seals (key 5), install the o-ring (key 15) and backup ring (key 16) in the correct orientation (see figures 5

and 6).

4. Lubricate the seal o-rings and insert the seal assembly into the tailpiece counterbores. Maintain axial alignment of

the two components as the seal assembly is pushed into place.

5. Lubricate and install the o‐rings (key 13) in both tailpieces.

a. For NPS 6 through NPS 12 constructions, one o-ring per tailpiece is required.

b. For NPS 14 through NPS 24 constructions, two o-rings per tailpiece are required.

6. Place the body (key 1) on an appropriate work surface.

7. If studs (keys 19 and 20) were removed from valve body during disassembly, apply anti-seize lubricant (Key 47) to

threaded stud holes. Apply anti-seize lubricant to the long studs (key 20), which are used to attach the base

brackets (key 25). Install the long studs first in the stud hole locations marked during disassembly. (Note: Base

brackets are not available for the NPS6 CL150 and NPS6 CL300 valve constructions.) Apply anti-seize compound to

the balance of studs (key 19) and install in the body.

8. Lubricate the tailpiece o-ring gland of the body and lower the tailpiece into place, guiding the male o-ring gland of

the tailpiece within the female gland of the body. Take special care to prevent pinching of the o-ring. The tailpiece

must be oriented such that, the bearing plate dowel pin holes are in alignment and parallel with the body shaft bore

axis. Refer to figure 4 and note the tailpiece (key 2) orientation in relation to the body (key 1), bearing plates (key

11), and dowel pins (key 22).

9. Apply anti-seize lubricant compound to the face and threads of the heavy hex nuts (key 21). If applicable, place the

base bracket (key 25) over the long studs. Install the heavy hex nuts on the studs by hand with the material

identifier facing outwards. Use an appropriate torque device to apply the final torque specification (see table 3).

10. Lift and orient the assembly so the raised face of the tailpiece end connection flange is sitting on a clean, soft

surface. Take special care to prevent damage to the raised face serrated surface. Install the bearing plate dowel pins

(key 22) in the tailpiece. (Note: The dowel pins are not applicable to the NPS6 CL150, as this construction does not

incorporate bearing plates.)

11. If necessary, install new bushings (key 12) in the bearing plates (key 11) by driving out the old and pressing in the

new.

11

Page 12

V270 Valve

September 2018

Instruction Manual

D104297X012

WARNING

When lifting the ball, ensure the bearing plates (key 11) are secure on the ball trunnions to prevent parts from falling which

may cause personal injury or property damage.

12. Use an approved lifting sling through the ball bore to lift the ball (key 3).

a. Lubricate and install the thrust washers (key 17) and bearing plates on both ball trunnions.

b. Install the ball and bearing plate assembly into the body.

c. Guarantee the dowel pins (key 22) in the lower tailpiece have engaged the holes in the bearing plates and that

the ball shaft interface geometry is aligned with the body shaft bore.

d. Note: Specific to the NPS 6 CL150 construction, lubricate and place the follower end thrust washer (key 17) in the

follower end bore of the ball then lubricate and press in the follower end bushing (key 12) prior to installing the

ball assembly into the body. See figure 6.

13. Insert the upper bearing plate dowel pins (key 22) into the intended holes and refer to steps 7 through 10 for the

installation procedure of the upper studs, tailpiece, base bracket, and heavy hex nuts.

14. Insert the drive shaft (key 4) into the body shaft bore and engage the ball interface geometry. Slide the shaft thrust

washer (key 9) into place.

15. Install the drive shaft bushing (key 8) in the packing box from the end that engages the body. Lubricate and install

the o-ring (key 14) in the packing box housing.

16. After lubricating the body shaft bore and thrust washer (key 9), position the packing box housing assembly over the

drive shaft and slide into place ensuring the o-ring (key 14) properly engages the body shaft bore. For all V270

constructions, other than the NPS6 CL150, skip to step 18.

17. Specific to the V270 NPS 6 CL150 construction, inject lubricant into the spring hole of the follower trunnion (key

42) and install the grounding spring (key 40) by pressing firmly into place (see figure 6).

a. Lubricate and install the o-ring (key 41) in the gland of the follower trunnion.

b. Lubricate the body follower bore and install the follower trunnion assembly.

c. Apply anti-seize lubricant to the socket head cap screws (key 43) and tighten in a star pattern to 60 ft

•lbf.

18. Apply anti-seize lubricant to the packing box housing socket head cap screws (key 10). Thread in all fasteners, but

do not tighten.

19. The packing box holes for the straight pins (key 7) were originally staked at the factory. Use a file to remove the

deformed material at the top of each pin hole to allow the pin to slide by with minimal interference. Lubricate the

straight pins (key 7) and drive each through the packing box housing and into the valve body. When properly

installed and bottomed out, the pin top surface will be slightly below the packing box top surface. Stake all pins in

place making sure the packing box housing material has been deformed within the bore to prevent the pins from

disengaging.

20. Tighten the socket head cap screws (key 10) in a star pattern to the appropriate torque specification (see table 3).

Reinstall the two plastic packing box plugs (key 39) into their respective jack bolt counterbores to prevent

environmental ingress.

21. Install the packing components as detailed in the Packing Maintenance section of this manual.

22. Install the valve shaft key (key 29), flat washer (key 30) and hex head bolt (key 31). The purpose of the washer and

hex bolt is to prevent the key from migrating axially out of the keyway in-service.

12

Page 13

Instruction Manual

D104297X012

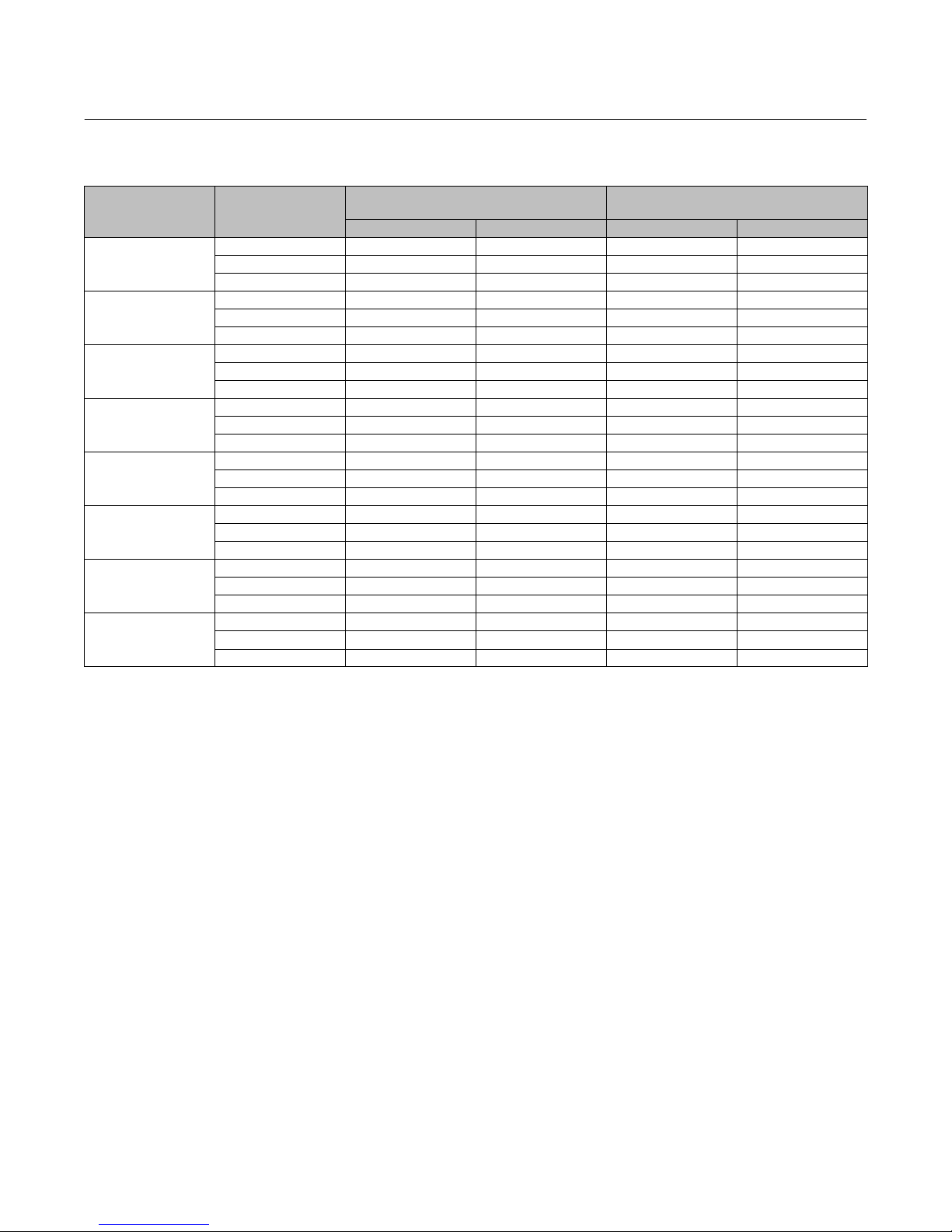

Table 3. Torque Values

VALVE SIZE, NPS CLASS

150 255 188 81 60

6

8

10

12

14

16

20

24

1. Fasteners must be lubricated to achieve proper preload

300 255 188 81 60

600 525 387 81 60

150 376 277 81 60

300 525 387 81 60

600 711 524 81 60

150 376 277 81 60

300 376 277 81 60

600 941 694 81 60

150 376 277 81 60

300 711 524 81 60

600 1267 934 81 60

150 525 387 81 60

300 525 387 81 60

600 1660 1224 81 60

150 525 387 81 60

300 711 524 81 60

600 2126 1568 81 60

150 711 524 81 60

300 1267 934 81 60

600 3305 2437 153 113

150 941 694 153 113

300 2777 2048 153 113

600 5782 4264 247 182

VALVE BODY HEAVY HEX NUT TORQUE

N•m ft•lbf N•m ft•lbf

(1)

PACKING BOX HOUSING SOCKET

HEAD CAP SCREW TORQUE

V270 Valve

September 2018

(1)

Actuator Mounting

Use the appropriate actuator instruction manual for mounting the actuator or changing the actuator position. Attach

the actuator mounting bracket to the valve packing box and tighten the mounting bracket fasteners as detailed in

table 4.

Table 4. Required Actuator Mounting Bracket-to-Valve Bolt Torque

VALVE SIZE, NPS

6

8

10

12

14

16

20

24

1. Fasteners must be lubricated to achieve proper preload

FASTENER

SIZE INCH

¾-10 339 250

⅞-9 508 375

1-1/4-8 1491 1100

N•m ft•lbf

GRADE 5/NCF3

(1)

13

Page 14

V270 Valve

September 2018

Instruction Manual

D104297X012

Determining Closed Position

1. To confirm proper actuator adjustment visually check the position of the ball.

2. Adjust the actuator linkage or travel stops as described in the actuator instruction manual so that at the end of

stroke, the valve ball bore diameter in the full open (100%) position is in alignment and centered within the

upstream and downstream valve seal inside diameters. The actuator linkage or travel stops should be adjusted so

that the full closed (0%) valve position is precisely 90 degrees from the visually verified 100% open position.

3. For reference, two parallel lines are machined on the actuator mounting end of the valve drive shaft (key 4). The

lines represent the orientation of the valve ball bore. The ball is in the closed position when the two lines are

perpendicular to the pipeline bore.

Parts Ordering

A serial number is assigned to each valve and stamped on the nameplate. Always refer to the valve serial number when

corresponding with your Emerson sales office

replacement parts, also specify the part name and desired material.

WARNING

regarding spare parts or technical information. When ordering

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Parts Kits

V270 Seal Spring kits

VALVE

SIZE,

NPS

6 150-600 18 4 RV270SPX002

8-24 150-600 18 4 RV270SPX012

CLASS

KEY

NUMBER

QUANTITY

IN KIT

KIT PART

NUMBER

14

Page 15

Instruction Manual

D104297X012

Figure 4. V270 Exploded View

V270 Valve

September 2018

NOTE:

1. KEY NUMBERS 24, 26, 27, 39, 44, 45 AND 46 ARE NOT SHOWN

APPLY LUBRICANT

GE89572

15

Page 16

V270 Valve

September 2018

Instruction Manual

D104297X012

Parts List

Note

Contact your Emerson sales office

Key Description

1 Valve Body

If you need a valve body as a replacement part, order the

valve size, pressure rating, serial number, and desired

material.

2 Tailpiece

3 Ball

4 Drive Shaft Assembly

5* Seal (2 req'd)

6 Packing Box Housing

7 Pin, Straight

8* Drive Shaft Bushing (1 req'd)

9* Thrust Washer (1 req'd)

10 Hex Socket Screw Cap

11 Bearing Plate

12* Lined Bushing (2 req'd)

13* O-Ring (2 req'd NPS 6-NPS 12; 4 req'd NPS 14-NPS 24)

14* O‐Ring (1 req'd)

15* O‐Ring (2 req'd)

16* Back up Ring (2 req'd)

for Part Ordering information.

Key Description

17* Thrust Washer (2 req'd)

18 Spring

19 Continuous Thread Stud - short

20 Continuous Thread Stud - long

21 Heavy Hex Nut

22 Dowel Pin

23 Hex Head Pipe Plug

24 NACE Label (not shown)

25 Base Bracket

26 Nameplate (not shown)

27 Drive Screw, for nameplate (not shown)

28 Hex Head Pipe Plug

29 Square Key

30 Flat Washer

31 Hex Head Screw Cap

32* Anti-Extrusion Ring (2 req'd)

33* Packing Set (1 req'd)

34 Packing Box Ring

35 Bolt Stud

36 Heavy Hex Nut

37 Packing Flange

38 Spring Pack Assembly

39* Packing Box Plug (not shown) (2 req'd)

40 Spring

41* O-Ring (1 req'd)

42 Follower Trunnion

43 Hex Socket Screw Cap

44 Clamp (not shown)

45 Ground Strap (not shown)

46 Round Head Screw Machine (not shown)

47 Lub Anti-seize/Lub-3

16

*Recommended spare parts

Page 17

Instruction Manual

D104297X012

Figure 5. Fisher NPS 6 CL300 through NPS 24 CL600 V270 Valve Assembly

VIEW A

V270 Valve

September 2018

VIEW B

SCALE 1:1

VIEW B

VIEW A

SCALE 1:1

GE89573

NOTE: KEY NUMBERS 10, 23, 24, 26, 27, 28, 29, 35, 36, 39, 44 AND 45 ARE NOT SHOWN

APPLY LUBRICANT

17

Page 18

V270 Valve

September 2018

Figure 6. Fisher NPS 6 CL150 V270 Valve Assembly

Instruction Manual

D104297X012

VIEW A

VIEW C

SCALE 2:1

VIEW B

VIEW C

VIEW A

SCALE 4:1

VIEW B

SCALE 4:1

GE90204

NOTE: KEY NUMBERS 10, 23, 24, 26, 27, 28, 29, 35, 36, 39, 44 AND 45 ARE NOT SHOWN

APPLY LUBRICANT

18

Page 19

Instruction Manual

D104297X012

V270 Valve

September 2018

19

Page 20

V270 Valve

September 2018

Instruction Manual

D104297X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson

Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

20

E 2017, 2018 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...