Page 1

Instruction Manual

D102178X012

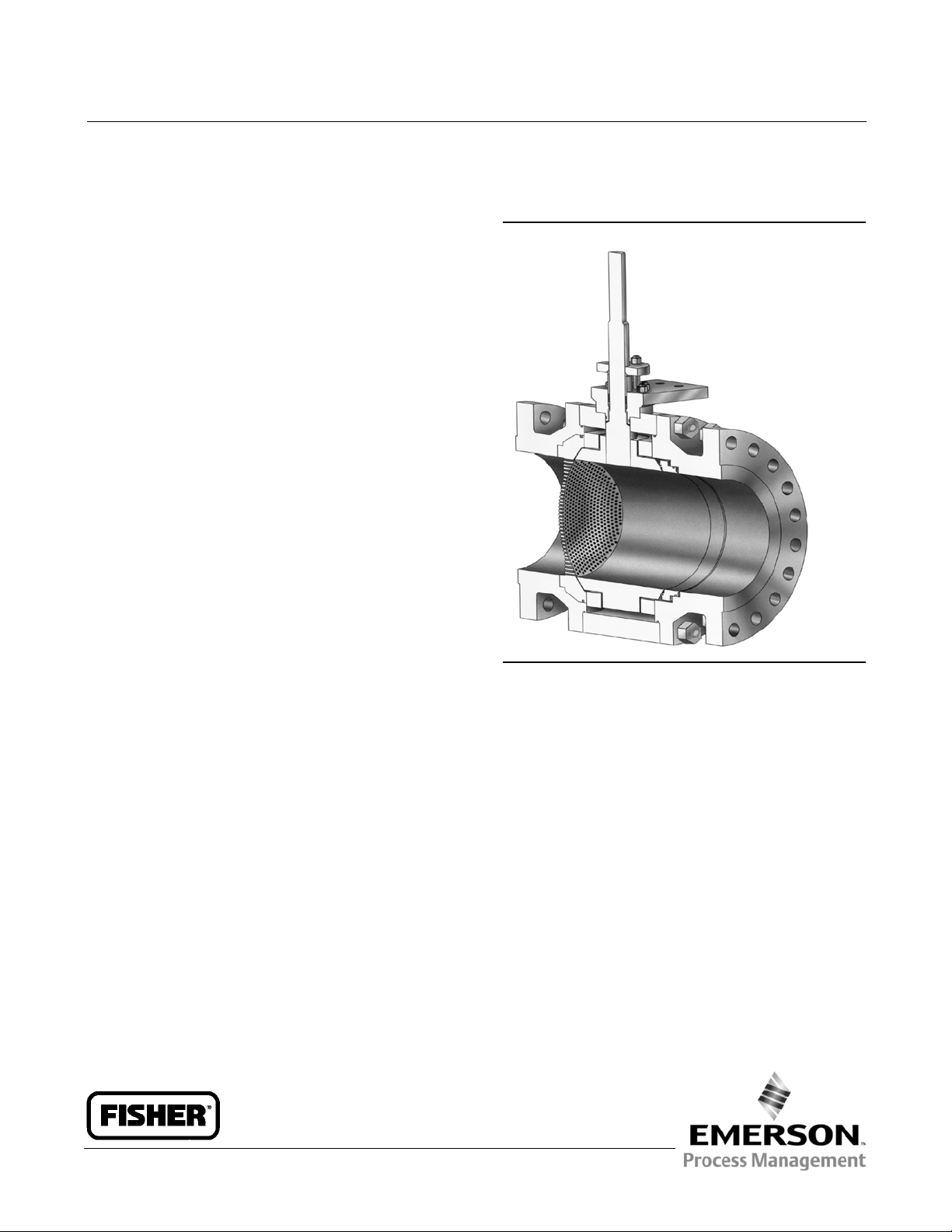

Fisherr V260 Rotary Pipeline Ball Valve

V260 Valve

September 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 2...............................

Installation 2..................................

Maintenance 4.................................

Packing Maintenance 5........................

Stopping Leakage 5........................

Replacing Packing 5........................

Seal Ring Maintenance

Disassembly 7............................

Assembly 9...............................

Actuator Mounting 11...........................

Determining Mounting Position 12...............

Determining Closed Position 12.................

Parts Ordering 12...............................

Parts List 14...................................

Figure 1. Fisher V260 Sectional View

W6365-2

Introduction

Scope of Manual

This instruction manual provides installation, operation, maintenance, and parts information for the Fisher V260

control valve. Refer to separate manuals for information concerning the actuator, positioner, and accessories (see

figure 1).

Do not install, operate, or maintain a V260 valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

V260 throttling ball valves are available in single-seal, double block-and-bleed, dual-seal, and bidirectional flow

constructions with or without attenuators. Valves with dome-style attenuators combine the efficiency of a rotary valve

with the noise reducing capability of a special trim (figure 4). Valves without attenuators present little or no restriction

to flow at full travel.

www.Fisher.com

Page 2

V260 Valve

September 2012

Table 1. Specifications

Instruction Manual

D102178X012

Valve Body Size and End Connection Styles

(1)

NPS 8, 10, 12, 16, 20, and 24 flanged valves with

CL150, CL300, and CL600 raised-face or ring-type

joint flanges compatible with ASME B16.5. See table 2

for face-to-face dimensions. Consult factory for other

pressure ratings.

Maximum Inlet Pressures and Temperatures

(1)

Consistent with CL150, CL300, and CL600

pressure-temperature ratings per ASME B16.34

Maximum Allowable Shutoff Pressure Drop

(1)

For Single-Seal and Dual-Seal Construction:

(Except where further limited by the

pressure-temperature rating of valve body material)

For LF2 valve body material:

CL150: 19.6 bar (285 psi) at 38_C (100_F)

CL300: 51 bar (740 psi) at 38_C(100_F)

CL600: 103 bar (1480 psi) at 38_C(100_F)

Seal Material and Temperature Capability

(1)

J POM (polyoxymethylene) (Standard) -29 to 82_C

(-20 to 180_F)

J PTFE/PEEK

(2)(3)

(Optional) -29 to 93_C(-20to

200_F)

Flow and Shutoff Direction

Unidirectional flow for Fisher V260 is forward flow.

Seal is upstream.

J Single Seal Constructions: Should be used for

unidirectional flow and unidirectional shutoff only.

J Dual Seal Constructions: V260A and V260C may be

used for unidirectional or bidirectional flow. V260B

should be used for unidirectional flow only for most

effective anti-cavitation protection. Bidirectional

shutoff requires the dual seal construction.

Shutoff Classification

Single-Seal Composition Constructions: 0.001% of

maximum valve capacity (less than 10% of ANSI/FCI

70-2 Class IV and IEC 60534-4)

Dual-Seal Composition Constructio ns: 0.001% of

maximum valve capacity (less than 10% of ANSI/FCI

70-2 Class IV and IEC 60534-4)

Maximum Ball Rotation

90 degrees

Actuator Mounting

Right-hand or left-hand mounted as viewed from the

valve inlet for forward flow

Flow Characteristic

Modified equal percentage

1. The pressure-temperature limits in this instruction manual and any applicablestandard or code limitationfor valve should not be exceeded.

2. PTFE stands for Polytetrafluorethylene,and PEEK stands for Polyetheretherketone.

3. Temperature limits of PTFE/PEEK is limited due to standard nitrile O-ring. Contact your Emerson Process Management sales office for higher temperature options, up to 232_C(450_F).

Approximate Weight

See table 2

Installation

WARNING

D To avoid personal injury, always wear protective gloves, clothing, and eyewear when performing any installation

operations.

D To avoid personalinjury or property damage resulting from the bursting of pressure retaining parts, be certain the

service conditions do not exceed the limits given in this manual.

D To avoid personal injury or property damage that can result from the sudden release of process pressure if valve or

mating pipe flange pressure ratings are exceeded, provide a relief valve for over-pressure protection as required by

government or accepted industry codes and good engineering practices.

D Service conditions are limited for valve and trim material combinations. Do not apply any other service condition to the

valve without first contacting your Emerson Process Management sales office.

D Personal injury could result from packing leakage. The valve packing was tightened before shipment however, the

packing might require some readjustment to meet specific service conditions.

2

Page 3

Instruction Manual

D102178X012

V260 Valve

September 2012

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

D To avoid personal injury or property damage, a minimum of two swivel hoists must be used when lifting NPS 24 CL600

assemblies.

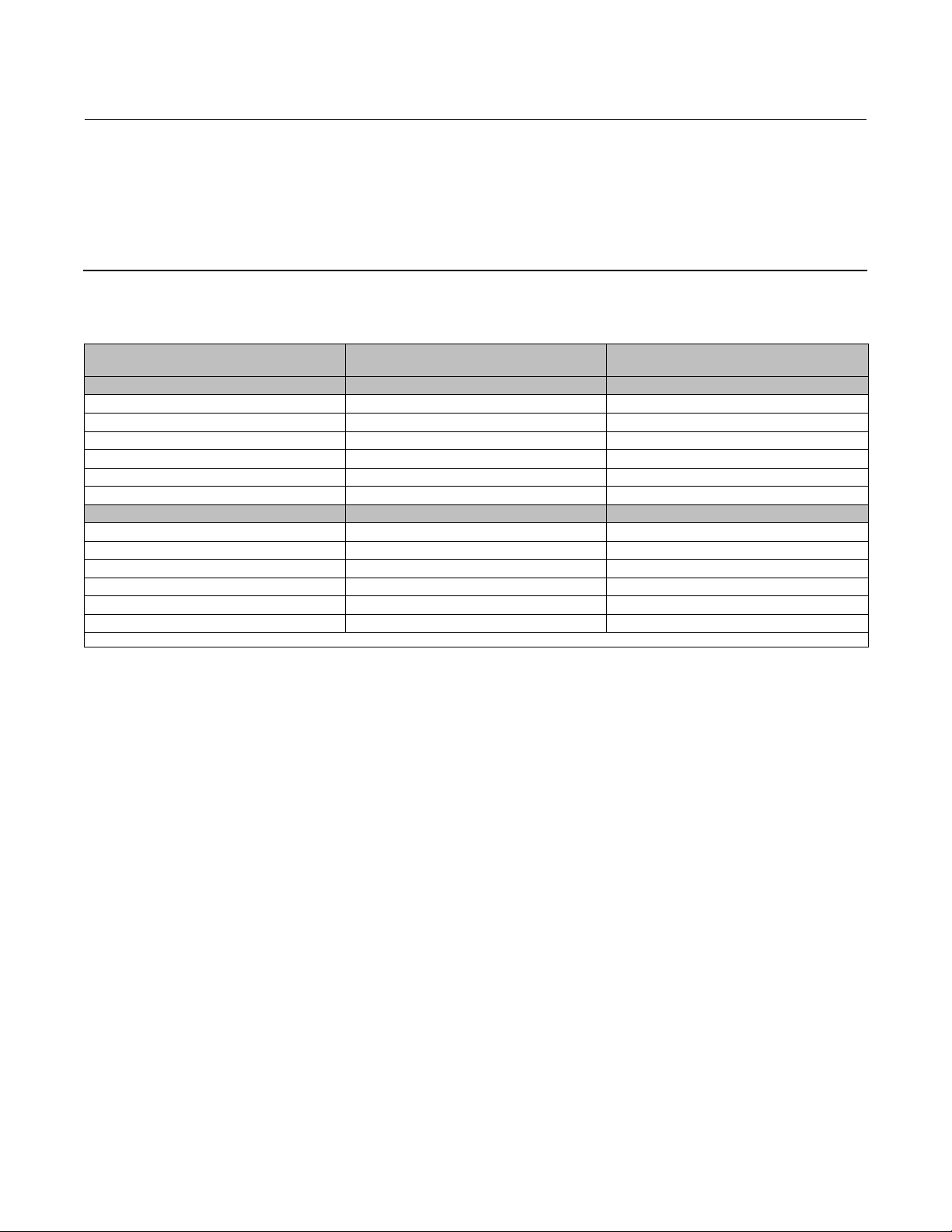

Table 2. Face-to-Face Dimensions and Approximate Weights

VALVE SIZE, NPS

1. For CL150 and CL300valves, face-to-face dimensionsare the same as CL600 valves.

(1)

(CL600

)

8 661 424

10 788 653

12 840 882

16 990.6 2472

20 1144 4313

24 1397 7257

8 26.04 975

10 31.04 1550

12 33.07 2025

16 39.0 5450

20 47.0 9500

24 55.0 16000

FACE-TO-FACE

DIMENSIONS

mm kg

Inches Pounds

APPROXIMATE WEIGHT

Key number locations are shown in figure 6, unless otherwise noted.

1. Install a three-valve bypass around the control valve assembly if continuous operation will be necessary during

inspection and maintenance of the valve.

2. The valve is normally shipped as part of a control valve assembly, with an actuator mounted on the valve. The

valve/actuator assembly is adjusted at the factory before the unit is shipped.

If the valve or actuator has been purchased separately or if the actuator has been removed, mount the actuator

according to the Actuator Mounting section and the appropriate actuator instruction manual. Make any necessary

adjustments on the bench before installing the valve in the pipeline. With the valve in the pipeline, you cannot see the

exact position of the ball to determine the fully open or closed positions.

3. Standard flow direction is shown in figure 6. If possible, install the valve in a horizontal pipeline with the drive shaft

horizontal. The actuator can be right- or left-hand mounted in any of the positions shown in the actuator instruction

manual. If necessary, refer to the appropriate actuator instruction manual for installation and adjustment

procedures.

4. Be certain the valve and adjacent pipelines are free of any foreign material that could damage the valve sealing

surfaces. Impurities or entrained solids in the process fluid could plug the passages in the trim. If the process fluid is

not clean, install a filter upstream to keep the pipeline free of impurities or entrained solids.

5. Provideappropriateflangegaskets,andplacethevalveinthepipeline.Tightenflangeboltinginacriss-cross

sequence to ensure the flange gaskets are loaded evenly.

3

Page 4

V260 Valve

September 2012

Note

Standard Fisher V260 valve packings (key 105) are composed of:

D Conductive packing ring (graphite ribbon packing), or

D Partially conductive packing rings (For example: a carbon-filled PTFE female adaptor with PTFE V-ring packing or a

graphite-composition packing ring with PTFE/composition packing ring)

In order to electrically bond the drive shaft to the valve body for hazardous area service, an alternate shaft-to-body bonding strap

canbeprovidedbyusingthefollowingstep.

Instruction Manual

D102178X012

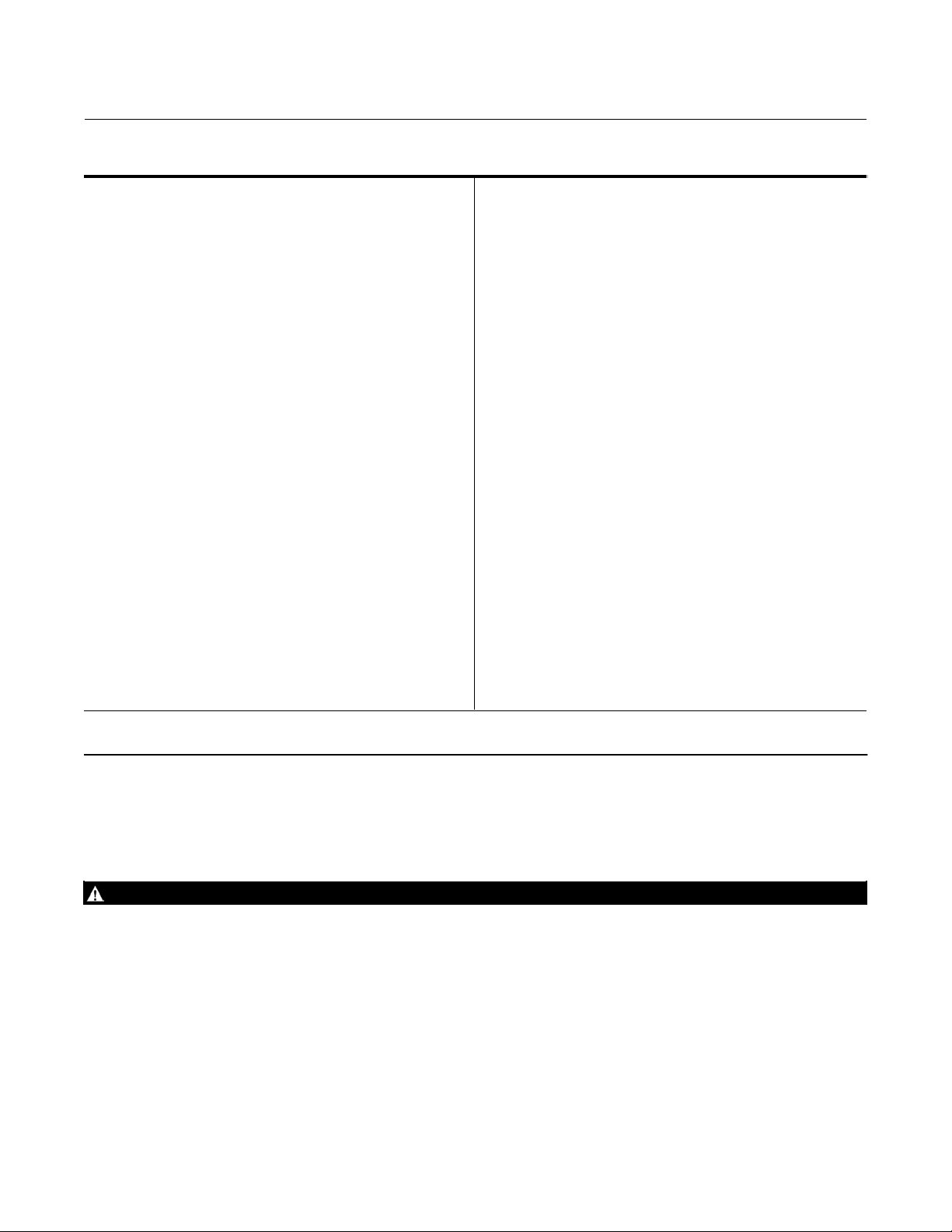

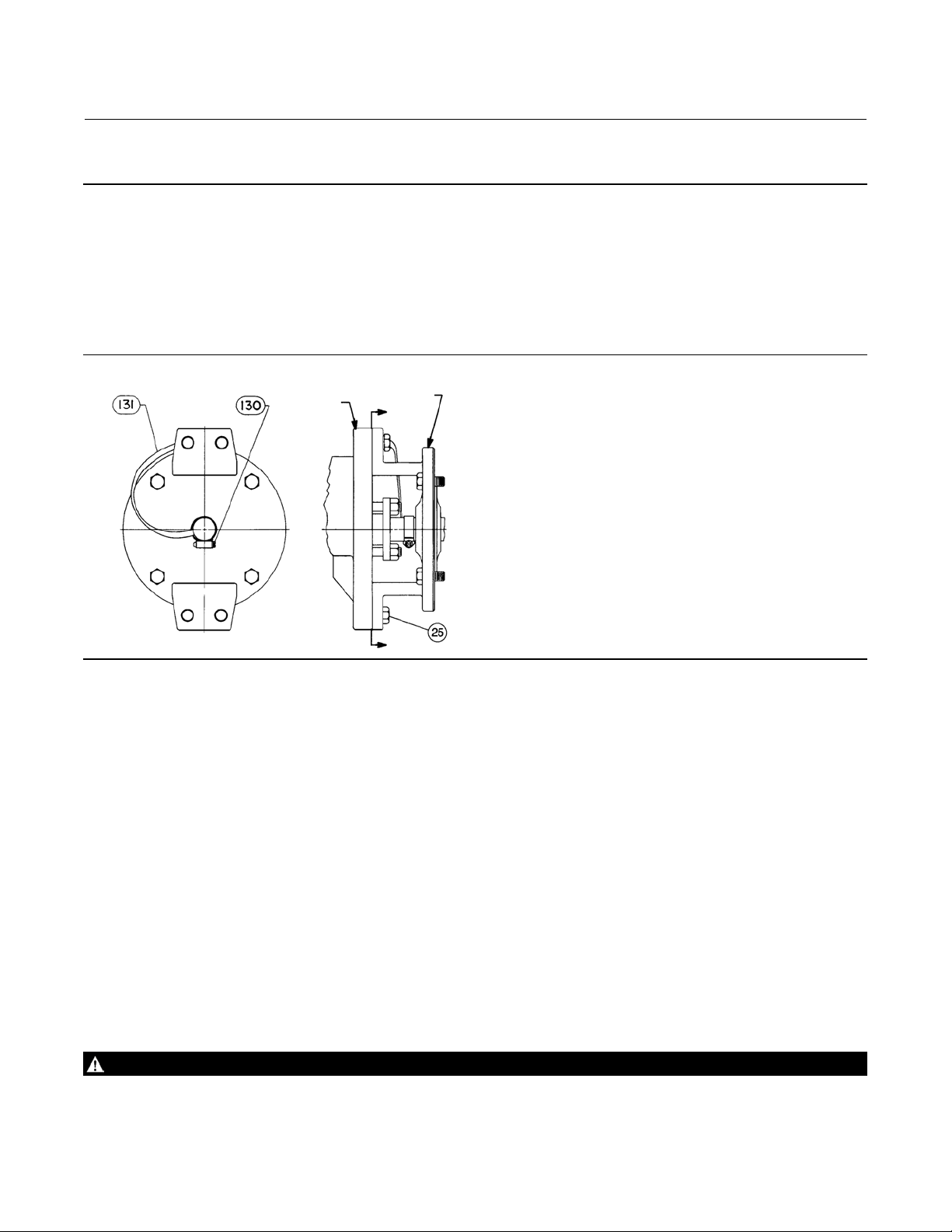

Figure 2. Optional Shaft-to-Body Bonding Strap Assembly

VALVE BODY

ACTUATOR

A

37A6528-A

A3143-2

VIEW A-A

A

6. For hazardous applications, attach the optional bonding strap assembly (key 131) to the valve drive shaft (key 6)

with the clamp (key 130) and connect the other end of the bonding strap assembly to the valve body with the

mounting cap screw as shown in figure 2.

7. Connect pressure lines to the actuator as indicated in the actuator instruction manual. When an auxiliary manual

actuator is used with a power actuator, install a bypass valve on the power actuator (if one is not supplied) for use

during manual operation.

8. If the valve has ENVIRO-SEAL™ live-loaded packing installed, an initial re-adjustment may not be required,

depending on your application. See the Fisher instruction manual titled ENVIRO-SEAL Packing System for Rotary

Valves, D101643X012, for packing instructions and adjustments (see figure 3).

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and replacement depends upon the severity of service conditions.

Key numbers are shown in figure 6, unless otherwise noted.

WARNING

Avoid personal injury or equipment damage from sudden release of process pressure or uncontrolled movement of parts.

Before performing any maintenance operations:

4

Page 5

Instruction Manual

D102178X012

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Dual-seal valve constructions can retain pressure and process fluid even after process pressure has been removed from

both sides of the valve. Relieve this pressure before disassembling or removing the valve from the line. Take additional

care if the process fluid is hot, flammable, caustic, or hazardous.

D Carefully secure the valve in an upright position. The roundness of the flanges and valve body allow it to easily roll from

side-to-side. The combined weight of the valve/actuator assembly could cause injury or property damage when falling

to the side.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Avoid injury by keeping hands, tools, and other objects away from the ball while stroking the valve.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D To avoid personal injury or property damage, a minimum of two swivel hoists must be used when lifting NPS 24 CL600

assemblies.

V260 Valve

September 2012

Packing Maintenance

Note

For the ENVIRO-SEAL Packing System, refer to the separate ENVIRO-SEAL Packing System for Rotary Valves instruction manual,

D101643X012, for maintenance instructions.

Stopping Leakage

For standard PTFE V-ring packing, leakage around the packing follower may be stopped by tightening the packing

follower nuts.

If the packing is relatively new and tight on the drive shaft, and if tightening the packing follower nuts does not stop

the leakage, the drive shaft may be worn or nicked so that a seal cannot be made. If the leakage comes from the

outside diameter of the packing, the leakage may be caused by nicks or scratches on the packing box wall. Inspect the

drive shaft and packing box wall for nicks or scratches while performing the following procedure.

Replacing Packing

Replacingthepackingrequiresbleedingoffthesystemand removing the actuator from the valve. Valve/actuator

adjustments cannot be made correctly without observing the fully open or closed position of the ball (key 11). It is not

necessarytoremovethevalvefromthepipeline,ifcareistakentonotethepositionandalignmentoftheleverand

shaft and to not disturb the turnbuckle position.

5

Page 6

V260 Valve

September 2012

Figure 3. Packing Arrangement Details

DRIVE SHAFT

(KEY 20)

PACKING FLANGE

(KEY 102)

PACKING

FOLLOWER

(KEY 114)

TYPICAL PTFE

V-RING PACKING

SET (KEY 105)

PACKING BOX

RING (KEY 107)

94BA02200-D

B2472-1

STANDARD

PACKING ARRANGEMENT

Instruction Manual

D102178X012

PACKING STUD

AND NUT

(KEYS 100 AND 101)

TYPICAL

ENVIRO-SEAL

PTFE V-RING

PACKING SET

ENVIRO-SEAL

PACKING ARRANGEMENT

Disassembly

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, shut off all pressure lines (or other power

source) to the power actuator, release pressure from the actuator, and disconnect the pressure lines from the

actuator. Use lock-out procedures to be sure that the above measures stay in effect while you work on the

equipment.

See the WARNING at the beginning of the Maintenance section for more information before removing the valve from

the pipeline.

2. Remove line bolting, remove the control valve from the pipeline, and place the actuator/valve assembly on a flat

surface.

3. Remove the actuator cover. Note and mark the orientation of the actuator with respect to the valve body and the

lever orientation with respect to the valve drive shaft, to assist with reassembly.

4. Loosen the lever locking device cap screw. Loosening the lever turnbuckle adjustment is not necessary during

disassembly. When remounting the actuator, the turnbuckle will be used for actuator adjustments.

5. Removing the actuator from the valve:

a. Remove the actuator mounting screws, bolts, or nuts.

CAUTION

When removing the actuator from the valve, do not use a hammer or similar tool to drive the lever or actuator off the valve

shaft. Driving the lever or actuator off the valve shaft could damage the ball, seal(s), and valve.

If necessary, use a wheel puller to remove the lever or actuator from the valve shaft. Tap the wheel puller screw lightly to

loosen the lever or actuator. Do not hit the screw with excessive force. Using excessive force could damage the ball, seal(s),

and valve.

6

Page 7

Instruction Manual

D102178X012

b. Slide the lever along the valve shaft while removing the actuator from the valve.

6. If necessary, remove the bonding strap assembly, shown in figure 2, from the valve before attempting to remove

the packing box parts.

7. Remove the packing follower nuts, packing flange, and packing follower (keys 101, 102, and 114, figure 3).

8. Remove the packing parts:

a. If the packing housing (key 16) is mounted on the valve: Use a formed wire hook with a sharp end to pierce the

packing rings, and pull the rings out of the packing box. Do not scratch the drive shaft or packing box wall.

Scratching these surfaces could cause leakage. Clean, inspect, and obtain replacement parts as necessary for

reassembly.

b. If the packing housing is removed from the valve: Remove the drive shaft (key 20) from the packing housing.

With the drive shaft removed, remove all internal parts. Clean, inspect, and obtain replacement parts as

necessary for reassembly.

The packing sets (key 105) listed in the parts list do not include any metal parts. Either clean and reuse metal packing

parts or obtain replacements by ordering them individually.

V260 Valve

September 2012

Assembly

If the valve is equipped with the ENVIRO-SEAL packing system, refer to the ENVIRO-SEAL Packing System Rotary Valves

instruction manual for assembly.

1. If the packing housing assembly (key16) is removed from the valve, use the valve assembly steps to reinstall the

drive shaft (key 20) and packing housing assembly on the valve.

2. For standard packing arrangements, install the new packing parts using the parts sequence shown in figure 3.

3. Secure the packing follower and packing flange with the packing nuts (keys 114, 102, and 101). Tighten the nuts far

enough to stop leakage during operating conditions.

4. If necessary, install the bonding strap assembly shown in figure 2.

5. Use the steps provided in the Actuator Mounting section to install the actuator on the valve. For actuator travel

adjustments, refer to the appropriate actuator instruction manual.

6. When the control valve is installed in the pipeline and in operation, check around the packing follower for leakage

and retighten the packing nuts as necessary.

Seal Ring Maintenance

Disassembly

WARNING

For valves with dual-seals, fluid and/or a hazardous material may be trapped under pressure in the valve body cavity. To

avoid personal injury, relieve the pressure, and drain any remaining fluid or hazardous material from the valve body cavity.

If necessary, disassemble the valve in a safe area for cleaning.

See the WARNING at the beginning of the Maintenance section for more information before removing the valve from the

pipeline.

Disassemble the valve only to the extent necessary to accomplish the needed inspection andrepairs.Forsomerepairs

(for example, the trim parts only) complete disassembly of the valve is not necessary. Follow the disassembly

7

Page 8

V260 Valve

September 2012

Instruction Manual

D102178X012

procedures to the point necessary to accomplish the repair, then skip to the appropriate assembly steps to complete

the reassembly of the valve. Always clean and protect sealing surfaces from damage.

Mark parts as necessary to allow them to be returned to the same position as removed. Forexample:Besuretoreturn

the tailpiece to the same end of the valve from which it was removed. Also, the seal assembly within the tailpiece

should be returned to the same tailpiece from which it was removed. The bearing plates should be marked and

reinstalled on the ball in the same position as they were, when removed.

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, shut off all pressure lines to the power

actuator, release pressure from the actuator, and disconnect the pressure lines from the actuator. Use lock-out

procedures to be sure that the above measures stay in effect while you work on the equipment.

2. Remove line bolting, remove the control valve from the pipeline, and clean all valve surfaces. Place the

actuator/valve assembly on a flat working surface.

3. Mark parts as necessary to allow them to be returned to the same position during re-assembly.

4. Perform the procedure in the Packing Maintenance section to remove the actuator from the valve. When valve

maintenance is complete, refer to the Mounting Actuator procedure at the end of the Maintenance section to

re-install the actuator on the valve.

5. Provide a clean soft working surface to protect the tailpiece-flange sealing surface.

a. If the valve does not have an attenuator dome, lift the valve and place it on its side with either tailpiece flange

resting on the flat surface. Be sure the valve is in a stable, upright position before releasing the hoist connection.

b. If the valve has a single attenuator dome, it is best to position the valve body so the tailpiece with the dome is in

the down position. Be sure the valve is stable, in an upward position before releasing the hoist connection.

Note

If the packing is in good condition, it is possible to remove and replace the seal assembly, or dome assembly without removing the

packing box assembly. However, the packing assembly must be removed to remove the ball (key 11) from the valve body.

6. Remove the packing housing nuts (key 23). Remove the packing housing assembly from the valve. The assembly

includes all the packing box parts, drive shaft, O-ring seals, bearing, and other parts.

7. Remove the nuts from the studs (keys 19 and 3) to remove the tailpiece/valve connection. (Refer to figure 6).

Note

While lifting the tailpiece (key 2 or 6) from the valve body, check to see if the seal assembly is lifting with the tailpiece. (Note:

Some valve constructions do not have a seal assembly installed in the tailpiece.) If it is, slide something between the ball and

tailpiece to protect the ball in case the seal assembly falls out of the tailpiece.

8. Ifthevalvehasdualattenuatordomes,tapthedometoloosenitfromthetoptailpiecebeforethetoptailpieceis

lifted from the valve body.

9. Turnthetailpieceoversothesealassemblyisfacingup,andplaceitonacleansoftsurfacewiththeflangeface

down.

10. From the tailpiece assembly or from the valve, remove the seal assembly, wave spring, and O-ring seal (keys 8 and

7). Clean and protect all sealing surfaces.

8

Page 9

Instruction Manual

D102178X012

V260 Valve

September 2012

WARNING

In the next step, be sure to secure the bearing plates on the ball to prevent them from falling. When lifting the ball, the

bearing plates may slide-off the ball trunnions which may cause personal injury or property damage.

11. Turn the ball (key 11) to the closed position. Use a nylon sling through the ball bore to lift the ball out of the valve

body. Lift the ball and set it on a clean soft surface.

12. Remove the two bearing plates and thrust washers (key 4 and 30) from the ball (key 11). Inspect the bearing in the

bearing plates and thrust washers (keys 29 and 30). If necessary, remove and replace the bearings (key 29).

13. Evenly loosen the hex nuts from the studs on the lower tailpiece (key 2 or 6). Remove the valve body from the

tailpiece.

14. Remove from the tailpiece assembly, the dome assembly and/or the seal assembly, wave spring, and O-ring seal.

Clean and protect all sealing surfaces.

Assembly

Be sure to replace valve parts in the same position that they were removed. Use the following suggested sequence to

reassemble the valve.

Note

Clean and protect all sealing surfaces from damage while installing parts. Lubricate parts when necessary as an aid for installing

parts,andtohelpprotectsealingsurfaces.

Key number locations are shown in figure 6.

1. Placethetailpiece(key2or6),pipeflangeenddownona clean soft surface with the seal assembly or attenuator

dome cavity facing up.

2. Lubricate and install the O-rings (key 12) on both tailpieces.

For characterized domes, install the grooved end of the dome groove pin (key 33) into the tailpiece, as far as it will go.

Use only a light tapping force, taking care not to bend the pin. This groove pin will prevent the attenuator dome from

rotating with respect to the tailpiece.

3. Install the inlet end attenuator dome (key 28 or 10) into the tailpiece (key 6). Use the lifting lugs in the two

threaded holes for ease of handling.

For characterized attenuators, align the pin hole in the dome with the groove pin (key 33) placed in the tailpiece in

step 3. High Density attenuators don't require this orientation.

For dual seal V260A or V260B constructions, lubricate and install the O-ring (key 15) on the dome spacer (key 13). If a

dual dome is being assembled, install the dome spacer into the tailpiece, using the two threaded holes as lifting lugs.

4. Apply thread locking adhesive to and install the two cap screws (key 36) that hold the washers (key 37) which help

retain the dome or dome spacer (if applicable) in the tailpiece.

For constructions with dual dome and/or dual seals, lubricate and install the O-ring (key 7) in the groove on the inlet

seal (key 9). Install the wave spring (key 8) over the end of the seal. Install the seal assembly O-ring (key 7) between the

dome spacer and the dome (key 10).

Note

D Verify that the ball opens into the dome windows last. (See figure 5)

9

Page 10

V260 Valve

September 2012

D If not, remove the dome and tailpiece and turn it 180 degrees to allow the windows to open last.

Instruction Manual

D102178X012

5. Install the grooved end of the groove pins (key 5) into the bearing plates (key 4) as far as they will go. Use only a

light tapping force, taking care not t o bend the pins.

6. Apply dry film lubrication between the trunnion surfaces on the ball and the trunnion bearings.

7. Install new bearings (key 29) in the bearing plates (key 4).

WARNING

In the next step, be sure to secure the bearing plates on the ball to prevent them from falling. When lifting the ball, the

bearing plates may slide off the ball trunnions which may cause personal injury or property damage.

8. Lift the ball with a nylon sling through the bore and turn the ball until the port and trunnions are horizontal.

9. Slide one ball thrust washer (key 30) onto each side of the ball trunnions, and install a bearing plate (key 4) on each

side of the ball trunnions.

10. Carefully lower the ball and bearing plates onto the lower (inlet) tailpiece taking care not to damage the ball

surface.

While lowering the ball, guide the groove pins in the bearing plates into their proper location in the tailpiece. To

determine the proper location for Right Hand Mounting, turn the splined trunnion so that it is on your right hand side

whentheattenuatordomeisinfrontofyouandthebottomofthevalveisnearestyou.

11. Install the grooved end of the groove pin (key 18) into the valve body, as far as it will go. Use only a light tapping

force, taking care not to bend the pin. Install the body studs (key 3) in the valve body and install two swivel hoists for

lifting the valve body.

12. Lift the valve body, using the swivel hoists, so it is centered over the ball and bearing plates. Be sure the shaft hole

is aligned with the splined trunnion on the ball. When lowering the valve body, take care not to damage the ball.

Guide the groove pins in the valve body into their proper location in the tailpiece.

13. Install the hex nuts(key 19) on the studs (key 3) and hand-tighten them.

14. Lubricate and install the O-ring (key 14) on the packing housing (key 16). Install the shaft bearing (key 32) in the

packing box housing.

15. Install the packing housing studs (key 22) in the valve body.

16. Apply anti-seize lubricant to the large spline on the shaft. Line-up the missing spIine tooth with the appropriate

space in the ball, and install the drive shaft (key 20) into the ball.

17. Install the shaft thrust washer (key 24) onto the shaft.

18. Install the packing housing (key 16) and nuts (key 23), and tighten them evenly. Orient the length of the packing

box housing perpendicular to the bore of the valve body.

WARNING

Refer to table 3 for bolt torque requirements. Exceeding any torque requirements could damage the valve and impair safe

operation.

10

Page 11

Instruction Manual

D102178X012

Table 3. Torque Values

VALVE SIZE, NPS

8

10

12

16

20

24

September 2012

PRESSURE

RATING

CL150 393 290

CL300 549 405

CL600 746 550

CL150 549 405

CL300 746 550

CL600 990 730

CL150 549 405

CL300 990 730

CL600 990 730

CL150 746 550

CL300 1750 1290

CL600 1750 1290

CL150 990 730

CL300 2237 1650

CL600 3470 2560

CL150 1749 1290 990 730

CL300 3470 2560 990 730

CL600 6088 4490 1749 1290

VALVE BODY HEX NUT (KEY 19) MOUNTING FLANGE HEX NUT (KEY 23)

NSm lbf-ft NSm lbf-ft

271 200

746 550

990 730

V260 Valve

19. Assemble the seal and install the second tailpiece using the following steps.

For dual seal and dual dome constructions, it is easier to lay the valve assembly on its side while installing the second

tailpiece.

20. Install the dome, dome spacer, and alignment groove pins (if a characterized attenuator is used) in the tailpiece.

21. LubricateandinstallthesealassemblyO-ring(key7)inthegrooveofthesealasshowninfigure6.

22. Install the wave spring (key 8) over the end of the seal (key 17 or 9). Note that the spring is not required with the

attenuator dome (key 28, figure 6).

23. For single seal constructions, place the seal ring assembly into the tailpiece, taking care not to damage the O-ring

(key 7) while sliding it into the tailpiece. Also, be careful to protect all sealing surfaces.

For dual seal constructions, place the s eal assembly (key 17) into the dome, dome spacer and tailpiece.

24. Lift the second tailpiece assembly and align it with the valve body studs and pins. Slide the tailpiece onto the studs

andbearingplatepins.Thegroovepinsinthevalvebodyshouldbeguidedintothepinholesinthetailpiece.Pullit

up tightly, taking care not to damage the tailpiece O-ring as it is pulled into the valve body.

25. Install the hex nuts (key 19) on the studs (key 3) and hand-tighten them. Torque all the hex nuts evenly.

WARNING

Refer to table 3 for bolt torque requirements. Exceeding any torque requirements could damage the valve and impair safe

operation.

26. Refer to the Packing Maintenance section to install the packing parts.

Actuator Mounting

Use the appropriate actuator instruction manual when mounting the actuator or changing actuator styles and

positions.

11

Page 12

V260 Valve

September 2012

Instruction Manual

D102178X012

Determining Mounting Position

The actuator can be either right- or left-hand mounted.

Note

D Right-hand mounting means that the actuator is mounted on the right side of the valve when viewed from the valve inlet.

D Left-hand mounting means that the actuator is mounted on the left side of the valve when viewed from the valve inlet.

Right- or left-hand mounting can change the actuator action from push-down-to-close to push-down-to-open, or

vice-versa.

Determining Closed Position

1. Youmustremovethevalvefromthepipelinetocheckthepositionoftheball.

2. Adjust the actuator linkage or travel stops as described in the actuator instruction manual. Adjust the actuator so

that the valve ball will be fully open or closed when the actuator is at the end of its stroke, depending on the

actuator action selected.

Parts Ordering

A serial number is assigned to each valve and stamped on the nameplate. Always refer to the valve serial number when

corresponding with your Emerson Process Management sales office regarding spare parts or technical information.

When ordering replacement parts, also specify the part name and desired material.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

12

Page 13

Instruction Manual

D102178X012

Figure 4. Ball AttenuatorConstructionDetails

V260 Valve

September 2012

E0816

HI-DENSITY

ATTENUATOR

Figure 5. Exploded View of Dome, Ball, Tailpiece and Bearing Plates

CHARACTERIZED

ATTENUATOR

E0817

13

Page 14

V260 Valve

September 2012

Instruction Manual

D102178X012

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

Key Description Part Number

1ValveBody

If you need a valve body as a replacement part, order the

valve size, pressure rating, serial number, and desired

material. Contact your Emerson Process Management

sales office.

2 Inlet Tailpiece

3BodyStud

4BearingPlate(2req'd)

5DowelPin(8req'd)

6 Outlet Tailpiece

7* Seal AssemblyO-Ring (1 req'd for single, 2 req'd for dual seal)

NPS 8 17B1353X012

NPS 10 17B1354X012

NPS 12 17B1355X012

NPS 16 17B4974X012

NPS 20 17B7414X012

NPS 24 GE00497X012

8 Wave Spring (1 req'd for single, 2 req'd for dual-seal)

9* Outlet Seal Assembly See following table

10* Attenuator Dome for Dual Seal See following table

11 Ball

12* Tailpiece O-Ring (2 req'd)

NPS 8 18B8211X012

NPS 10 18B8212X012

NPS 12 18B8213X012

NPS 16 18B8214X012

NPS 20 18B8215X012

NPS 24 GE00724X012

13 Dome Spacer

14* Packing Box O-Ring

NPS 8 17B1364X012

NPS 10 1D7104X0012

NPS 12 1D7104X0012

NPS 16 K18791X0012

NPS 20 17B7416X012

NPS 24

CL150 and CL300 17B7416X012

CL600 GE36050X012

15 Dome Spacer O-Ring

16 Packing Box Housing

17* Inlet Seal Assembly See following table

18* Dowel Pin (4 req'd)

NPS 8 17B1374X012

NPS 10 1C7729X0012

NPS 12 1C7729X0012

NPS 16 1C7729X0012

NPS 20 17B7413X012

NPS 24 17B7413X012

19 Body Hex Nut

20 Drive Shaft

21 Actuator Mounting Cap Screw (4 req'd)

22 Packing Housing Stud, Steel

Key Description Part Number

23 Packing Housing Nut, Steel

24* Shaft Thrust Washer

NPS 8 17B1343X012

NPS 10 & 12 17B1345X012

NPS 16 17B4965X012

NPS 20 17B5026X012

NPS 24

CL150 and CL300 17B5026X012

CL600 GE36303X022

25 Pipe Plug (notshown)

26 Flow Arrow

27 Drive Screw,for nameplate

28* Attenuator Dome for Single Seal See following table

29* Trunnion Bearing (2 req'd)

NPS 8 17B1359X012

NPS 10 17B1360X012

NPS 12 17B1361X012

NPS 16 17B4977X012

NPS 20 17B5027X012

NPS 24

CL150 and CL300 17B5027X012

CL600 GE36300X012

30* Ball Thrust Washer (2 req'd)

NPS 8 17B1342X012

NPS 10 17B1344X012

NPS 12 17B1346X012

NPS 16 17B4966X012

NPS 20 17B5028X012

NPS 24

CL150 and CL300 17B5028X012

CL600 GE36360X012

32* Shaft Bearing

NPS 8 17B1362X012

NPS 10 & 12 17B1363X012

NPS 16 17B4978X012

NPS 20 17B5029X012

NPS 24

CL150 and CL300 17B5029X012

CL600 GE36302X012

33 Pin, Attenuator Dome (not shown)

34 Nameplate (not shown)

36 Drive Screw (not shown)

37 Washer (not shown)

100 Packing Stud (2 req'd for NPS 8-12,4 req'd for NPS 16-24)

101 Packing Nut (2 req'd for NPS 8-12, 4 req'd for NPS 16-24)

102 Packing Flange

105* Packing Set

ENVIRO-SEAL

PTFE/Carbon-FilledPTFE

NPS 8 14B3049X012

NPS 10 & 12 14B3060X012

NPS 16 14B5652X012

NPS 20 14B5730X012

Standard

PTFE/Carbon Filled PTFE

NPS 8 12A9057X022

NPS 10 & 12 1R6699X0012

NPS 16 14B5652X012

NPS 20 14B5730X012

NPS 24 17B5129X012

106 Anti-Extrusion Ring, PTFE

107 Packing Box Ring

116 Clamp (grounding strap assembly)

117 Grounding Strap Assembly

14

*Recommended spare parts

Page 15

Instruction Manual

D102178X012

Figure 6. Fisher V260 Valve Assembly

V260 Valve

September 2012

STANDARD

FLOW

DIRECTION

NOTE: KEY NUMBERS 25, 33,AND 34 ARE NOT SHOWN.

54B9811-D

ATTENUATOR

DOME

WITH NO SEAL

15

Page 16

V260 Valve

September 2012

Instruction Manual

D102178X012

Keys 9* & 17* Seal Assembly

VALVE

SIZE, NPS

8 28B1218X032 28B1218X012 28B1218X062 28B1218X052 27B1350X032 27B1350X012 27B1350X062 27B1350X052

10 28B1219X032 28B1219X012 28B1219X062 28B1219X052 27B1351X032 27B1351X012 27B1351X062 27B1351X052

12 28B1220X032 28B1220X012 28B1220X062 28B1220X052 27B1352X032 27B1352X012 27B1352X062 27B1352X052

16 37B4961X032 37B4961X012 37B4961X062 37B4961X052 37B4961X032 37B4961X012 37B4961X062 37B4961X052

20 37B5019X032 37B5019X012 37B5019X062 37B5019X052 37B5019X032 37B5019X012 37B5019X062 37B5019X052

24 CL150

& CL300

24 CL600 GE02813X022 GE02813X012 GE02813X032 GE02813X042 GE02813X022 GE02813X012 GE02813X032 GE02813X042

1. The V260C uses Key 17 in both the inlet and outlet.

2. POM (polyoxymethylene).

PTFE/PEEK POM

GE00488X032 GE00488X022 --- --- GE00488X032 GE00488X022 --- ---

Key 9 (Outlet) - for dual seal constructions Key 17 (Inlet) - for single and dual seal constructions

(1)

SEAL PART NUMBER

(2)

NACE

PTFE/PEEK

NACE POM PTFE/PEEK POM

NACE

PTFE/PEEK

NACE POM

Keys 10* & 28* Attenuator Dome, S17400 SST

ATTENUATOR DOME PART NUMBER

VALVE VALVE SIZE, NPS

8 47B1312X012 47B1309X012 48B0916X012 48B0915X012

10 47B1313X012 47B1310X012 48B0918X012 48B0917X012

12 47B1314X012 47B1311X012 48B0920X012 48B0919X012

V260A

V260B

16 57B4946X012 57B4980X012 57B4982X012 57B4981X012

20 47B4990X012 47B4991X012 47B4992X012 47B4993X012

24 CL150 & CL300 GE39617X012 --- --- ---

24 CL600 GG03694X012 GG03697X012 GG03695X012 GG03696X012

8 47B3510X012 47B3509X012 48B0922X012 48B0921X012

10 47B3514X012 47B3531X012 48B0924X012 48B0923X012

12 47B3518X012 47B3517X012 48B0988X012 48B0987X012

16 57B4984X012 57B4983X012 57B4986X012 57B4985X012

20 47B5033X012 47B5032X012 47B5031X012 47B5030X012

24 CL150 & CL300 GE00545X012 GE07146X012 GE00699X012 GE07157X012

24 CL600 GG02722X012 GG03691X012 GG02718X012 GG03688X012

Key 28 For single seal constructions Key 10 For dual seal constructions

Characterized High Density Characterized HighDensity

*Recommended spare parts

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection,use, and maintenance of any product remains solely with thepurchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one ofthe companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our termsand conditions, whichare availableupon request.We reservethe right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

16

E 1995, 2012 Fisher Controls International LLC.All rights reserved.

Loading...

Loading...