Page 1

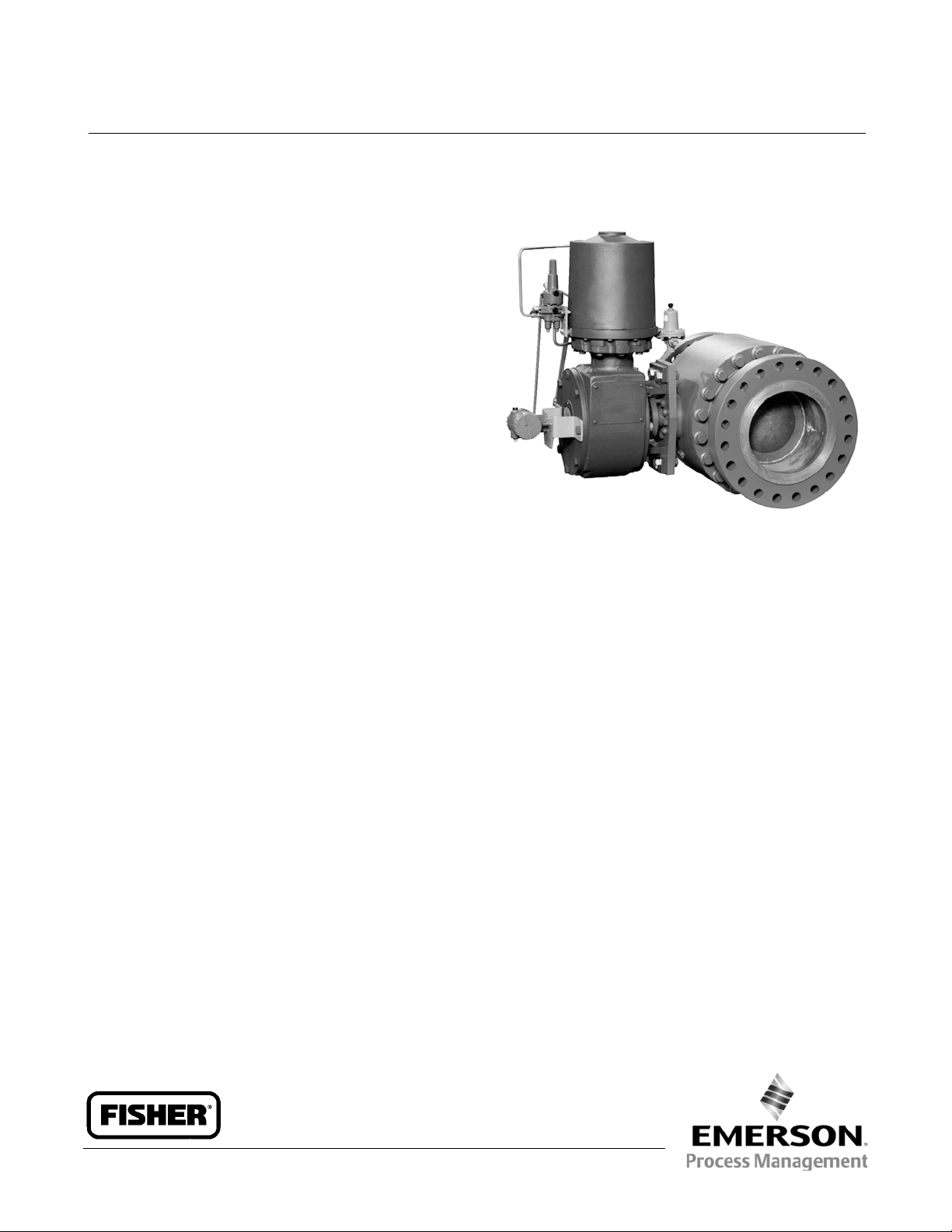

V260 Valve

D102352X012

Fisherr V260 Ball Control Valve

TheFisherV260isafull-borecontrolvalvedesigned

fromthegroundupwithfeaturesforoptimized

pressure, flow and process control. An integral drilled

attenuator controls noise and vibration from high

pressure drop liquids and gases. The splined shaft

connection to the actuator reduces lost motion.

The V260A with Aerodome attenuator, V260B with

Hydrodome attenuator, and V260C Ball Control Valves

(figures 1 and 3) combine the efficiency of a rotary

valve with the energy-dissipating capability of a special

trim to provide improved performance for demanding

applications. The valve is available with single, dual, or

dual block-and-bleed seal options (see the

Specifications table).

Product Bulletin

51.3:V260

July 2014

ThetrimdesignoftheV260Aisusedingasserviceto

reduce noise effects that cause pipeline vibration. The

V260B provides improved performance for demanding

applications such as pump bypass and pipeline

take-off. The trim is designed for liquid service to help

eliminate or reduce cavitation and associated pipeline

noise and vibration. The V260C full-bore ball valve is

designed for automated control in bypass, batch,

monitor, and emergency shutoff service applications,

and it presents little or no restriction to flow.

The V260 full-bore ball valve is available with

composition seals, and process type stem packing for

improved service life.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

Excellent Flow Control-- The splined ball to shaft

connection, splined shaft to actuator connection,

double power-end bushing assemblies, and

trunnion guiding, all provide improved dynamic

control.

W6539

Fisher V260 Valve

Aerodynamic Performance-- Up to -20 dBA

acoustical attenuation can be achieved for the

V260A within a single stage construction.

Dual-stage construction can provide up to -25 dBA

attenuation.

Improved Service Life-- The attenuator is not part of

the seal assembly. The seal wipes to ball surface, not

the attenuator, promoting increased service life.

Trim Versatility-- Key valve components, such as

valve body, ball, shaft and bearings, are

interchangeable between the V260A, V260B and

V260C. This feature allows you to reduce your spare

parts inventory and maintenance time.

(continued on page 2)

www.Fisher.com

Page 2

Product Bulletin

51.3:V260

July 2014

Specifications

V260 Valve

D102352X012

Valve Body Sizes and End Connection Styles

NPS J 8, J 10, J 12, J 16, J 20, and J 24 flanged

valves with CL150, CL300, or CL600 raised-face

flanges compatible with ASME B16.5.

Consult your Emerson Process Management sales

office for other end style connections.

Shutoff Classification

Single-Seal Composition Constructions: 0.001% of

maximum valve capacity (less than 10% of ANSI/FCI

70-2 Class IV and IEC 60534-4)

Dual-Seal Composition Constructions: 0.001% of

maximum valve capacity (less than 10% of ANSI/FCI

70-2 Class IV and IEC 60534-4)

Maximum Inlet Pressures and Temperatures

Consistent with CL150, CL300, or CL600

pressure-temperature ratings per ASME B16.34

(1)

Seal Material and Temperature Capability

(1)

Standard: J POM (polyoxymethylene) -29 to 82_C

(-20 to 180_F)

Maximum Allowable Shutoff Pressure Drop

For Single-Seal and Dual-Seal Construction

(Except where further limited by the pressuretemperature rating of the valve body):

J CL150: 20 bar (285 psi) at 38_C(100_F)

J CL300: 51 bar (740 psi) at 38_C(100_F)

J CL600: 103 bar (1480 psi) at 38_C(100_F)

(1)

.

Optional: J PTFE/PEEK

(-20 to 200_F)

Maximum Ball Rotation

90 degrees

Actuator Mounting

(2)(3)

-29 to 93_C

Right-hand or left-hand mounted as viewed from the

Flow Characteristic

J Modified linear with single high density attenuator,

J Modified equal percentage with single

characterized attenuator (see figure 2), or

J Modified equal percentage without attenuator

valve inlet for forward flow

Packing Arrangements

PTFE Packing: Standard construction

(see figure 4)

ENVIRO-SEALt Packing: This optional packing

Flow and Shutoff Direction

Unidirectional flow for V260 is forward flow. Seal is

upstream.

J Single Seal Constructions: Should be used for

system provides improved sealing, guiding, and

transmission of loading force to control liquid and gas

emissions. Contact your Emerson Process

Management sales office for availability of

ENVIRO-SEAL packing (see figure 4)

unidirectional flow and unidirectional shutoff only.

J Double Seal Constructions: V260A and V260C may

be used for unidirectional and bidirectional flow.

Dimensions

Seefigure5

V260B should be used for unidirectional flow only for

effective anti-cavitation protection. Bidirectional

shutoff requires the dual seal construction.

Options

J Double block-and-bleed applications (Dual-seal

Flow Coefficients

See Fisher Catalog 12

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation for t his valve should not be exceeded.

2. PTFE stands for Polytetrafluoroethylene, and PEEK stands for PolyEtherEtherKetone.

3. Temperature limit of PTFE/PEEK is limited due to standard Nitrile O-Ring. Contact your Emerson Process Management sales office for higher temperature options, up to 232_C (450_F).

construction is required), J Two Stage V260A

Attenuator, J Two or Three Stage V260B Attenuator,

J CL900 flanges, J Ring type joint flanges

Features (continued)

Sour Service and Sour Crude Oil Capability--

Optional materials are available that comply with

NACE Standard MR0175-2002.

2

Tight Shutoff-- Self-adjusting seal(s) that are

pressure assisted provide tight shutoff for long

reliable service. The design incorporates a heavy

duty S31600 stainless steel carrier that retains the

composition seal for full-rated pressure drop

service.

Page 3

V260 Valve

D102352X012

Product Bulletin

51.3:V260

July 2014

Heavy Duty Trunnion-- The ball trunnions are

designed for demanding applications requiring long

value of 1.0 is achievable depending on service

conditions.

service life, with a reduction in maintenance time

and costs.

Flexible Applications-- The attenuator is active

Broad Hydrodynamic Applications-- Single, dual,

and three-stage attenuators for the V260B may be

provided for a varying range of applications. A K

c

throughout the ball rotation for very demanding

services or a characterized attenuator is used to

matchtheserviceconditions(seefigure2).

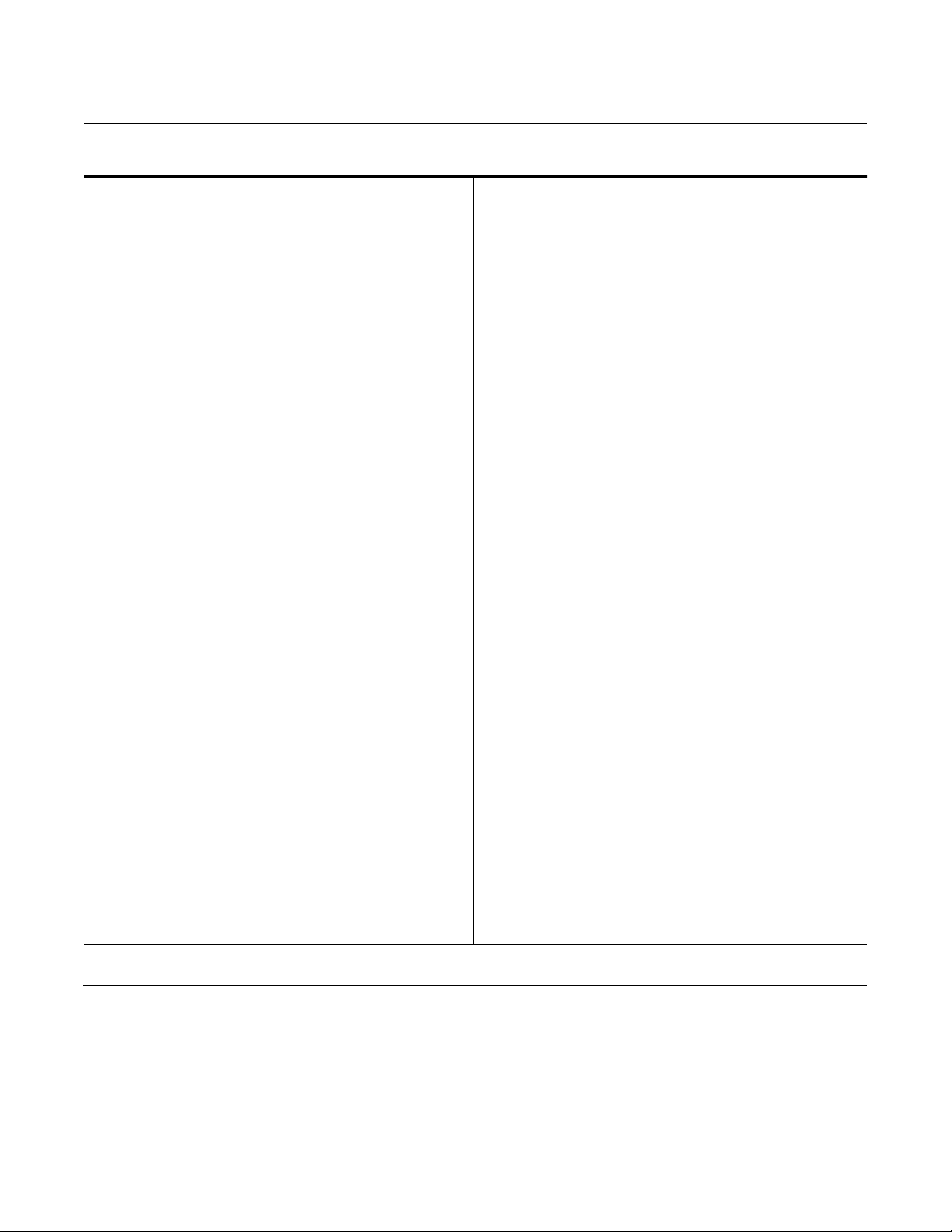

Table 1. Aerodome and Hydrodome Trim Benefits Comparison

Benefits Typical Competitive Device

Up to -20 dBA aerodynamic noise attenuation No Yes N/A

Excellent attenuation effect at critical opening position No Yes Yes

High Density (Full) or characterized attenuation No Yes Yes

2or3stageoptions No Yes Yes

Effective bidirectional attenuation option No Yes Yes

Integrated ball, shaft, and attenuator design for best

throttling dynamics

Dual seal option No Yes Yes

Ball seal exchange without actuator removal No Yes Yes

Kcimproved versus unattenuated device Yes N/A Yes

Double block -and-bleed option No Yes Yes

Overall ease of maintenance No Yes Yes

Trunnion-mounted ball for excellent wear resistance Yes Yes Yes

Low profile for ease of piping Yes Yes Yes

No Yes Yes

V260A with Aerodome

Attenuator

V260B with Hydrodome

Attenuator

Table 2. Standard Materials of Construction

Part Material

Valve Body LF2 Carbon Steel

Ball WCC Carbon Steel

Seal POM with S31600 SST Seal Blank or PTFE/PEEK with S31600 SST Seal Blank

Dome Attenuator S17400 SST

Shaft S17400 SST H1075 or S17400 SST H1150 DBL

Wave Spring S17700 SST or N07750

Tailpiece LCC Carbon Steel

Tailpiece Mounting Bolting B7 Steel or B7M Steel

Bearing Plate Carbon Steel

Bearings S30400 SST with Aramid liner

Thrust Washer Carbon filled PTFE

Packing Box Housing LCC Carbon Steel

Packing PTFE/Carbon filled PTFE

Packing Bolting B7 Steel, B7M Steel, or B8M Class 2 SST

Packing Follower, Packing Box Ring Annealed S31600 SST

Groove Pins B8M SST

O-Rings Nitrile

Actuator Mounting Bolting Steel Grade 5

3

Page 4

Product Bulletin

51.3:V260

July 2014

Figure 1. Sectional View of Valve (Single Seal)

V260 Valve

D102352X012

W6365-2

Figure 2. Aerodome and Hydrodome Attenuator Details

FLOW

A6749-2

4

47B1309-A

HIGH DENSITY

ATTENUATOR

47B1312-A

CHARACTERIZED

ATTENUATOR

Page 5

V260 Valve

D102352X012

Figure 3. Typical Fisher V260 Valve Assembly

PTFE

PACKING

PTFE-LINED

BEARING

BALL

SEAL

FLOW

Product Bulletin

51.3:V260

July 2014

SPLINED

SHAFT

BALL

W6521-1*

BALL

SEAL

FLOW

PTFE

PACKING

PTFE-LINED

BEARING

PTFE-LINED

BEARING

V260C WITH DUAL SEAL

SPLINED

SHAFT

W7511-1

V260A OR V260B WITH DUAL SEAL

AERODOME

ATTENUATOR

BALL

PTFE-LINED

BEARING

W7509-2/IL

V260A OR V260B WITH SINGLE SEAL

5

Page 6

Product Bulletin

51.3:V260

July 2014

Figure 4. Packing Arrangement Details

DRIVE SHAFT

PACKING FLANGE

PACKING

FOLLOWER

TYPICAL PTFE

V-RING PACKING SET

PACKING BOX RING

V260 Valve

D102352X012

PACKING STUD

AND NUT

TYPICAL

ENVIRO-SEAL

PTFE V-RING

PACKING SET

94BA02200-D

B2472-1

STANDARD PACKING ARRANGEMENT ENVIRO-SEAL PACKING ARRANGEMENT

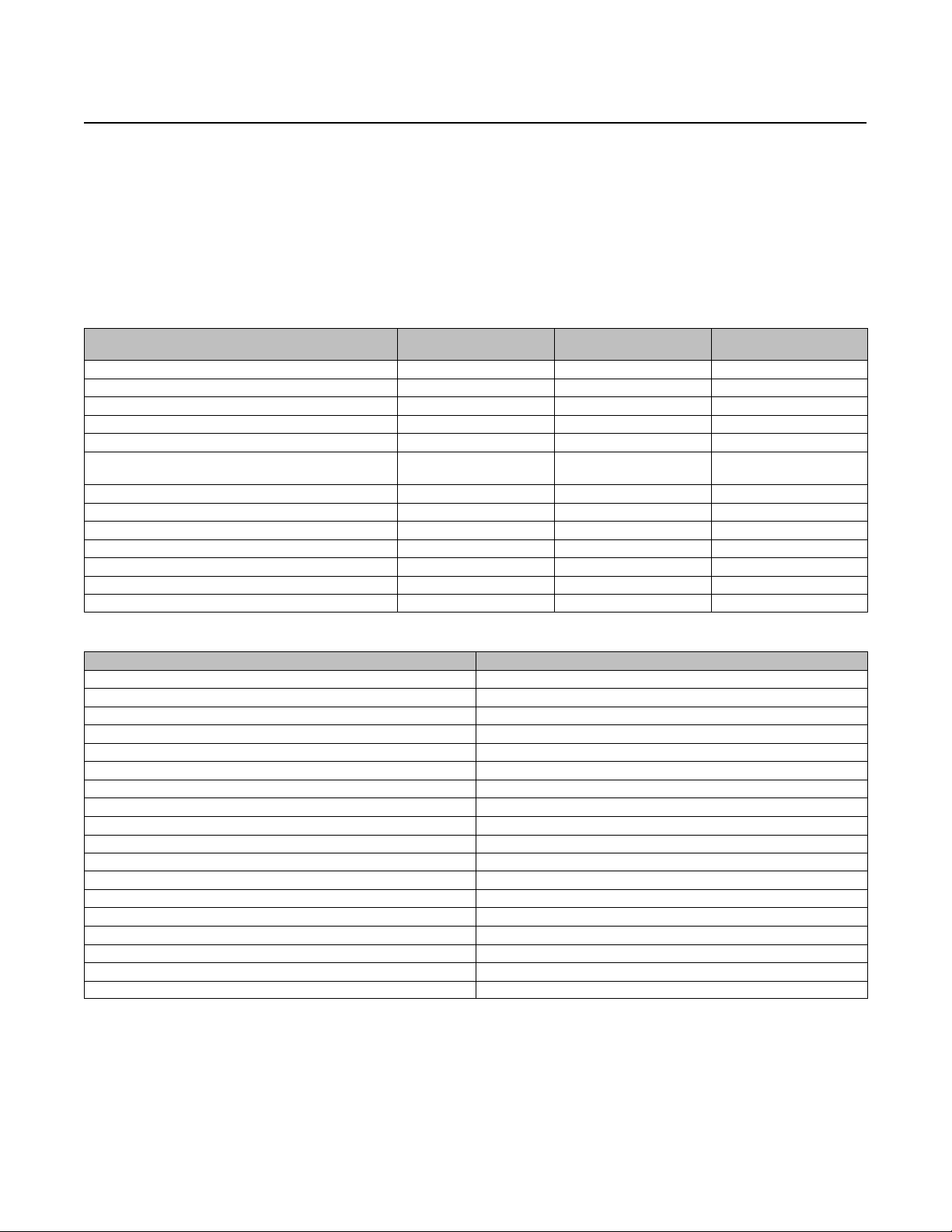

Table 3. Dimensions

VALVE SIZE,

NPS

A D K R

Shaft Dia. Spline Dia.

mm kg

8 661

10 788 324 553

356

273 457 44.4 44.4 273 51

12 840 369 639 919

16 991

20 1194

508

471 76.2 63.5

508

471 88.9 63.5

508 848

602 1040

24 CL150 1397 314 671 1158 88.9

24 CL300 1397 508 708 1158 88.9 88.9 533 127 5761

24 CL600 1397 364 708 1241 102

Inches Pounds

8 26.04

10 31.04 12.75 21.77

14.00

10.75 18.00 1-3/4 1-3/4 10.75 2.00 3/4-10 975

12 33.07 14.53 25.15 2025

16 39.00

20 47.00

20.00

18.56 3 2-1/2

20.00

18.56 3-1/2 2-1/2

19.99 33.38

23.70 40.96

24 CL150 55.00 12.38 26.40 45.60 3-1/2

24 CL300 55.00 20.00 27.87 45.60 3-1/2 3-1/2 21.00 5.00 1-1/4-8 12700

24 CL600 55.00 14.32 27.87 48.86 4

1. For 1069 size 100 actuator.

2. For 1061 size 100 actuator.

3. See table 6 for NPS 24 U1 and U2 information.

S

T U

W

(THREADED)

63.5 63.5 337 76

76.2 76.2

88.9 88.9

(1)

(2)

(1)

(2)

88.9

(keyed shaft)

102

(keyed shaft)

533 127

See thread

info below

533 127 5352

(3)

457 (U1)

610

254 (U2)

(3)

2-1/2 2-1/2 13.25 3.00 7/8-9

3 3

3-1/2 3-1/2

(1)

(2)

(1)

(2)

3-1/2

(keyed shaft)

4

(keyed shaft)

21.00 5.00 1-1/4-8

21.00 5.00 1-1/4-8 11800

(3)

24.00

18 (U1)

10 (U2)

(3)

1-1/4-8 15600

APPROXIMATE

WEIGHT

442

703

2472

4309

7076

1550

5450

9500

6

Page 7

V260 Valve

D102352X012

Figure 5. Dimensions (also see table 3)

MATCHES CL600

(1)

FLANGES

S

Product Bulletin

51.3:V260

July 2014

K

A

U

R

14B0995-B

Note:

1. For CL300 valves, face-to-face dimensions are the same as CL600 valves.

2. Valve shown meets CL600 flanges. Flange and bolt dimensions vary for CL300 valves.

D

T

W

7

Page 8

Product Bulletin

51.3:V260

July 2014

Figure 6. NPS 24 Additional Dimensions (also see table 3)

U1

U2

T

V260 Valve

D102352X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1990, 2014 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...