Page 1

Instruction Manual

MCK-1157

Types N480 and N481

October 1981

Types N480 and N481 Hose End Valves

WARNING

!

Install, use, and maintain per Fisher

instructions and all applicable federal,

state, laws and codes, and NFPA No. 58 or

Standards K61.1. Periodic inspection and

maintenance is essential.

Introduction

Types N480 and N481 hose end valves are intended

as quick-acting primary shutoff valves for the end of

the transfer hose on bobtail delivery trucks. Standard

valves can be used on propane, butane, and NH

3

service at ambient temperature. For other LP-gases

and compressed gases or other temperature conditions

consult the factory.

Type N480

—Includes a supplementary back check

assembly (Type M570) and is suitable for LP-gas

service only.

Type N481 —Without back check assembly, for use on

NH3 service only.

Installation

Apply suitable pipe compound to the 1-inch male pipe

threads of a hose coupling (Fisher Type M4100-16 or

equivalent). Screw the hose end valve on the hose

coupling using the wrenching flats on the valve’s inlet

connection. Use sufficient torque to make a tight seal

between the valve inlet and the hose coupling

.

The valve’s operating lever rests near the hose

connection when in the closed position. There must be

sufficient clearance between the operating lever and the

hose coupling to insure complete closure of the valve and

easy grasp of the operating lever.

Most hose couplings will work with the N480 or N481,

but if there is insufficient clearance, change the hose

coupling. If possible, store the hose end valve on the

delivery truck in a place protected from the elements.

Operation

When Type N480 or N481 is not connected to a

1 3/4-inch male Acme thread (such as a standard filler

connection), moving the operating lever to the open

position does not open the hose end valve, refer to view 3

1

LEVER CLOSED,

CONNECTED TO

FILLER VALVE

T40384

Figure 1. N480 Operational Schematic

in Figure 1. The valve must be attached to a male Acme

fitting, views 1 and 2 in Figure 1, before it will open.

Before attaching either the N480 or N481 to a filler valve,

make sure there is no dirt or other foreign material in

the top of the filler valve or in the hose end valve outlet.

Foreign material could be forced into the filler valve

causing damage and creating a hazardous malfunction.

Also make sure the hose end valve’s operating lever

the closed position, view 1 in Figure 1, before the valve

is attached to the filler valve. Otherwise the hose end

valve could open as it is threaded on to the filler valve.

As with many quick-acting valves, the

operating lever on the N480 or N481 can

snap closed with some force. Be careful

not to pinch a hand or fingers between the

operating lever and the body when closing

the valve.

!

As with any hose end valve, loosen

the connection on the filler valve slightly

to allow pressure to bleed off before

completely unscrewing the connection. If

pressure continues to bleed and does not

reduce, never unscrew the hose end valve

because either the filler valve or the hose

end valve has not shut off. Disconnecting

the hose end valve could permit the rapid

escape of gas.

2

LEVER OPEN,

CONNECTED TO

FILLER VALVE

CAUTION

WARNING

3

LEVER OPEN,

VALVE NOT

CONNECTED

is in

R

D450044T012

www.FISHERregulators.com/lp

Page 2

Types N480 and N481

Type N480 has a brass accessory back check

(Type M570) that can be tightened back onto filler valves

that fail to close. Then the N480 main valve can be

loosened from the back check. If the pressure bleeds

off between the N480 and the M570, the M570 can be

left on the filler valve until repairs can be made, and the

N480 main valve can be disconnected. Leave the M570

on a filler valve only until the tank can be emptied and

repair or replacement of the filler valve can be made.

If pressure does not bleed off between the N480 and

M570, there is still a problem. Do not disconnect until

the problem is corrected and the valves seal tightly. Try

quickly opening and closing the N480 or tapping the

sides of the valves to seat the check valves.

Should it be necessary to detach the M570 and leave

it on a ftiler valve, fit a new M570 to the N480 as soon

as possible. Do not use any model of back check

assembly other than the M570 because other models

could allow accidental opening of the N480 when

being carried.

Maintenance

Check the hose end valve periodically for signs of wear

or mechanical damage. The operating

should be kept free of obstructions. The surface of the

flow tube which seals against the filler valve’s gasket

should be kept free of large nicks. Check the coupler

for wear. If repair becomes necessary, contact a Fisher

distributor or the factory for information and assistance.

Do not use valves that leak or fail to operate correctly;

repairs should be made promptly.

lever and linkages

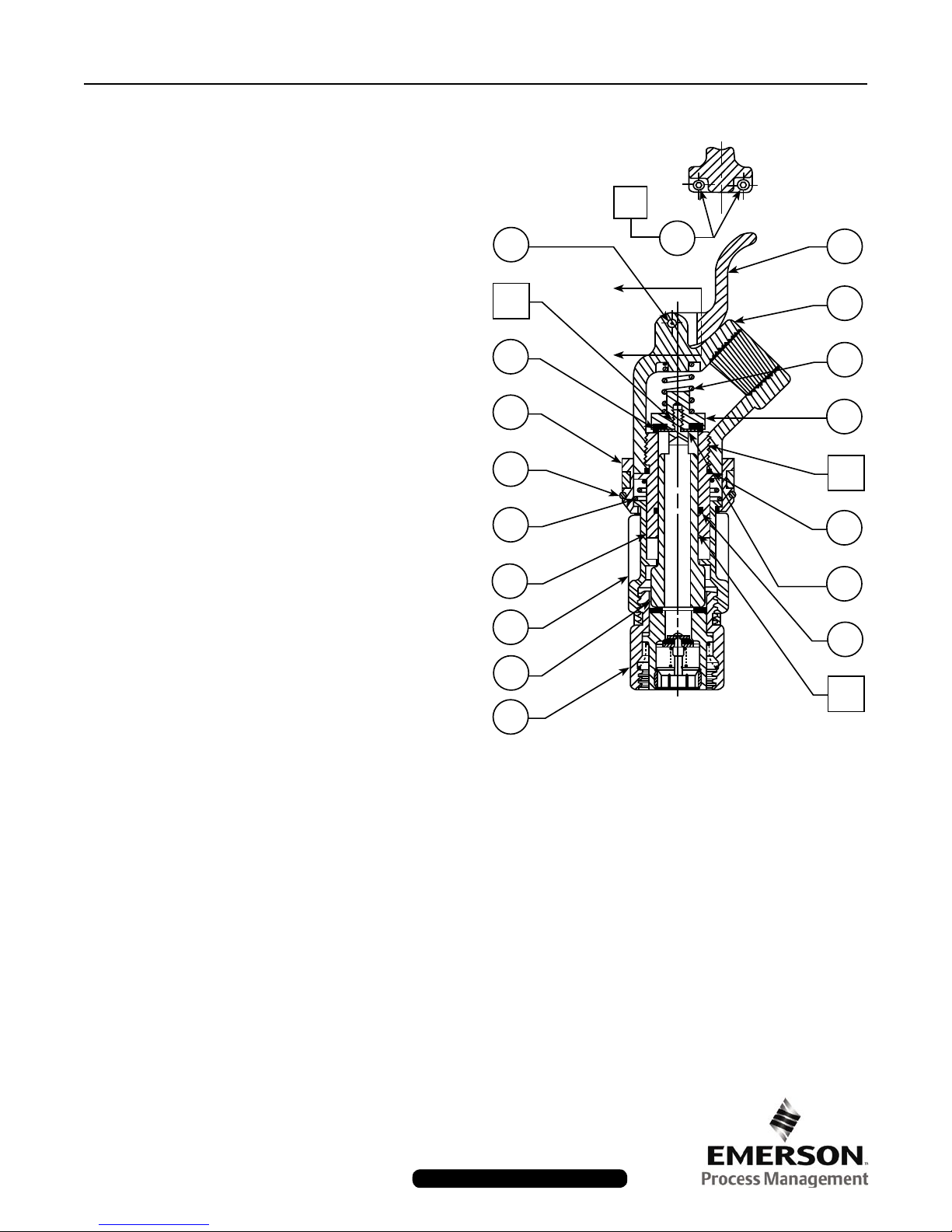

Parts List

Key Part Name

1 Body

2 Yoke (2 required)

3 Coupler

4 Handle

5 Dowel Pin

6 Guide

7 O-Ring

8 X-Ring

9 Flow Tube

10 Disc Holder

11 Disc

12 Washer

13 Flat Spring

SECTION: A ~ A

20

5

19

A

18

4

1

A

11

2

16

13

6

3

14

10

20

7

12

8

9

21

22

Figure 2. Type N480

Key Part Name

14 Spring

15 Linkage (2 required)

16 Snap Ring

17 Rivet (2 required)

18 Set Screw (2 required)

19 Apply Loctite No. 262

20 Apply Loctite No. 242

21 Apply Magnalube-G

22 Type M470

Fisher and Fisher Regulators are marks owned by Fisher Controls International, LLC. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the

property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time

without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Fisher product remains solely with

the purchaser.

Emerson Process Management

Fisher Controls International, LLC.

P.O. Box 8004

McKinney, Texas 75070, USA

Telephone: 1 (800) 588-5853

Telephone: 1 (469) 293-4201

©Fis her Cont rols Interna tio nal, LLC., 1981; All R igh ts Reserv ed

ed

www.FISHERregulators.com/lp

Loading...

Loading...