Page 1

Instruction Manual

Form 5187

March 2009

Type H800 Relief Valve

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion, re and/or

chemical contamination causing property

damage and personal injury or death.

Fisher® relief valves must be installed, operated

and maintained in accordance with federal,

state, and local codes, rules and regulations,

and manufacturer’s instructions.

If a leak develops or if the outlet continually

vents gas, service to the unit may be required.

Failure to correct trouble could result in a

hazardous condition. Only a qualied person

must install or service the unit

Type H800

W3618

Figure 1. Type H800 Relief Valve

Installation, operation, and maintenance

procedures performed by unqualied personnel

may result in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury. Use

qualied personnel when installing, operating,

and maintaining the Type H800 relief valve.

Introduction

Scope of the Manual

This manual provides installation, maintenance, and parts

ordering information for the Type H800 relief valve. Information

for other equipment used with this relief valve is contained in

separate manuals.

Product Description

(1)

The Type H800 relief valve

Direct-Operated relief valve. It is used primarily between a

pneumatic instrument and its supply pressure regulator to limit

the instrument supply pressure to 50 psig (3,4 bar) should

the supply pressure regulator fail open. The Type H800 relief

valve can also be mounted on other equipment, such as an air

compressor, where limited relief capacity is desired.

(See Figure 1) is a compact,

Specications

Specications for the Type H800 relief valve are given on

page 2. Additional specications for 67 Series regulators used

with Type H800 relief valves are shown in Table 1.

Installation

Upon receipt, inspect the relief valve to be sure it is free of

foreign material.

WARNING

!

Installing a Type H800 relief valve where its

capabilities can be exceeded or where proper

operation might be impaired may cause

personal injury, property damage, or leakage

due to bursting of pressure-containing parts or

explosion of accumulated gas. To avoid such

conditions, install a Type H800 relief valve where:

• Service conditions are within the unit

capabilities are specied in specications

section and Table 1, and

• The relief valve is protected from

exposure to physical damage and/or

corrosive substances.

1. Relief valve dened in ANSI Standard B95.1-1972. Not all codes or regulations permit these valves to be used as nal overpressure protection devices.

www.emersonprocess.com/regulators

D100405X012

Page 2

Type H800

Specications

Body Size and End Connection Style

NPS 1/4, NPT (internal)

Maximum Allowable Inlet (Relief) Pressure

(1)

250 psig (17,2 bar)

Relief Pressure Ranges

Non-adjustable, Start-to-discharge between

39 and 44 psig (2,7 and 3,0 bar)

Reseat Pressure

(1)

35 psig (2,4 bar) or higher

Wide-Open Flow Coefcients for Relief Valve Sizing

Maximum Temperature Capabilities

-20° to 150°F (-29° to 66°C)

IEC Sizing Coefcients

XT: 0.775

FD: 0.50

FL: 0.89

Vent Connection

1/2 NPT (internal)

Approximate Weight

5 ounces (140 grams)

(1)

Cg: 55

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

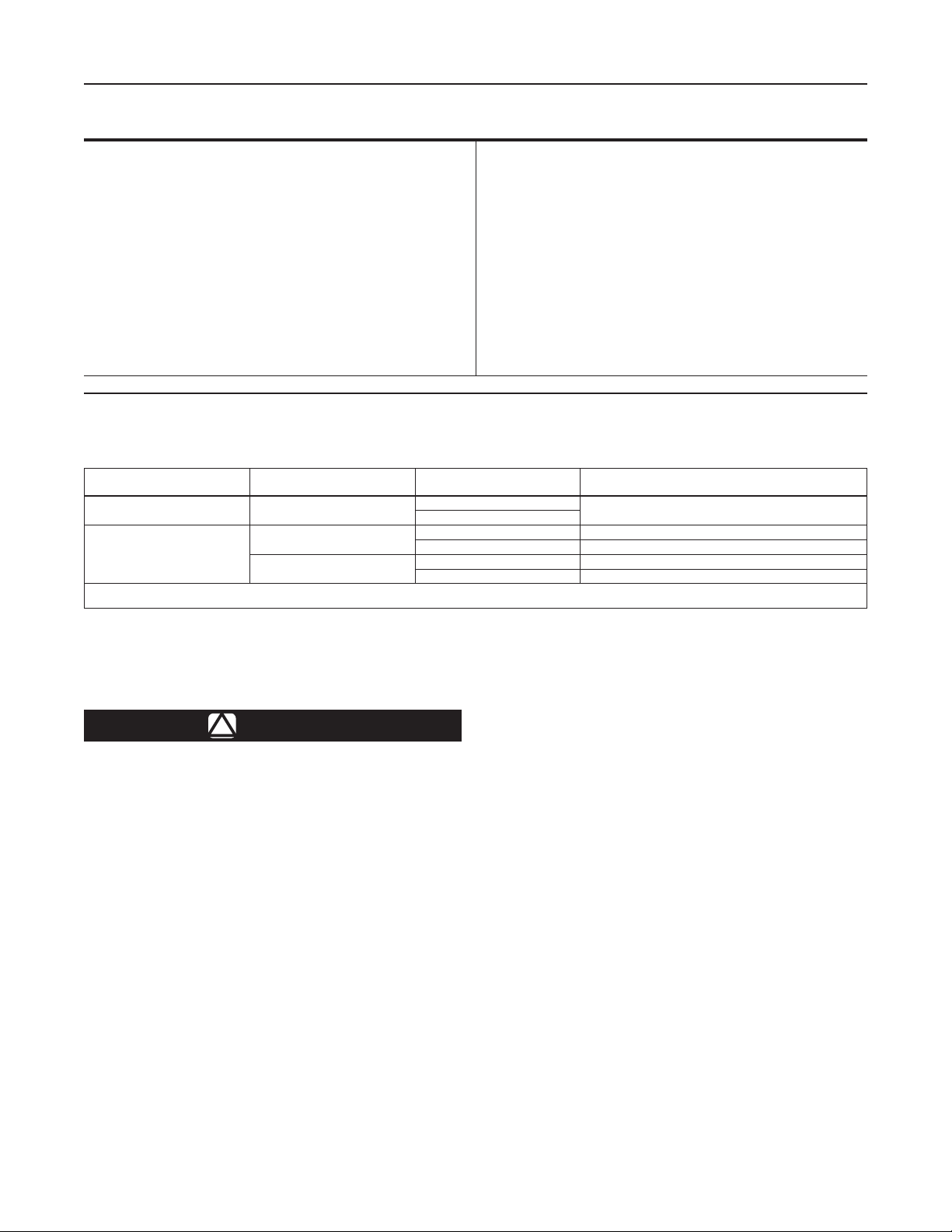

Table 1. Maximum Allowable Inlet Pressure to 67 Series Regulators (with Type H800 Relief Valve)

to Prevent Instrument Supply Pressure from Exceeding 50 psig (3,4 bar)

TYPE H800 INSTALLATIONS

FROM FIGURE 2

A

B

1. Limit vent piping to 30 equivalent feet (9,14 equivalent meters) of 1/2-inch (13 mm) piping. Lower vent piping may reduce the maximum allowable inlet pressure to supply

pressure regulator.

SUPPLY PRESSURE

REGULATOR TYPES

67, 67R, 67R, 67FR,

67CF, or 67CFR

67, 67R, 67CF, or 67CFR

67FR or 67F

REMOTE

VENT PIPING

(1)

Yes

No

Yes 100 (6,9)

No 250 (17,2)

Yes 100 (6,9)

No 200 (13,8)

MAXIMUM ALLOWABLE INLET PRESSURE TO

SUPPLY PRESSURE REGULATOR, PSIG (bar)

250 (17,2)

The relief valve may be shipped already mounted on other

equipment; if so, install that equipment by referring to its

Instruction Manual.

WARNING

!

This relief valve vents gas from the connection

marked “vent”. In hazardous or ammable

gas service, the vented gas may accumulate,

causing personal injury or equipment damage

due to re or explosion. Provide piping or

tubing to vent the gas to a safe, well-ventilated

location, and protect all vent openings from

condensation, freezing, or any substance that

could clog the vents.

The 1/2 NPT vent connection must face down in any installation.

Also, the screen (key 7) and disk restriction (key 6) must either

remain in the relief valve body (key 1) or be replaced by remote

vent piping or tubing that is as short and as straight as practical.

The piping or tubing should be 1/2-inch (13 mm) in diameter to

avoid the effects of backpressure build-up on relief performance.

Provide a screened vent for the open end of the remote vent

piping or tubing.

Figure 2 illustrates two typical methods of connecting a Type H800

relief valve to a 67 Series regulator. A yoke-mounted supply

pressure regulator and pneumatic instrument are shown in

Figure 2; however, the two methods of connecting a Type H800

relief valve to a 67 Series regulator also apply to pneumatic

instruments mounted on other equipment in other orientations.

Table 1 lists the conditions for the two typical methods of

installing a Type H800 relief valve. Whenever possible, use

installation A since a Type H800 relief valve with or without

remote vent piping will limit instrument supply pressure to 50 psig

(3,4 bar) when a 67 Series regulator fails open with 250 psig

(17,2 bar) inlet pressure.

For installation A, install the relief valve in the instrument

supply tubing between the supply pressure regulator and the

pneumatic instrument. Apply pipe compound to the male

threads of the pipe nipple and the tting for the instrument

supply pressure tubing.

For installation B, connect the relief valve with a pipe nipple to

the outlet pressure gauge connection of the 67 Series regulator.

Install a pipe plug or pressure gauge as shown in Figure 2. Apply

pipe compound to the male threads of the pipe nipple and pipe

plug or pressure gauge.

Maintenance

Relief valve parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency of inspection

and parts replacement depends on the severity of service

conditions and the requirements of local, state, and federal rules

and regulations.

2

Page 3

Type H800

PNEUMATIC

INSTRUMENT

TYPE H800

RELIEF VALVE

TUBING FOR

INSTRUMENT

SUPPLY PRESSURE

PNEUMATIC

INSTRUMENT

INLET PRESSURE

TUBING

W3615

INSTALLATION A

ACTUATOR YOKE

TYPE 67AFR

REGULATOR

ACTUATOR YOKE

ACTUATOR YOKE

TYPE 67AFR

REGULATOR

TYPE H800

RELIEF VALVE

VENT

CONNECTION

INLET PRESSURE

TUBING

VENT CONNECTION

PIPE PLUG (MAY ALSO BE

OPTIONAL GAUGE)

W3616

INSTALLATION B

Figure 2. Typical Installation Orientations

The relief valve body may remain installed during maintenance or

inspection unless it is to be replaced. Instructions are given below

for disassembly and assembly of parts.

WARNING

!

To avoid personal injury or equipment

damage from sudden release of pressure or

explosion of accumulated gas, do not attempt

any maintenance or disassembly without

rst isolating the relief valve and associated

equipment from system pressure and relieving

all internal pressure from the relief valve and

associated equipment.

Disassembly

The following procedure describes the complete disassembly of

the Type H800 relief valve. When parts replacement or inspection

is required, complete only those steps necessary to accomplish

the job. Key numbers refer to Figure 3.

1. Vent any pressure in the relief valve.

2. Unscrew the machine screws (key 9), and remove

the spring case (key 2).

TUBING FOR

INSTRUMENT

SUPPLY PRESSURE

3. Remove the spring (key 3), spring cup (key 4),

diaphragm disk (key 11), and diaphragm (key 5).

4. If necessary, remove the retaining ring (key 8), the

screen (key 7), and disk restriction (key 6).

Assembly

This procedure describes complete assembly. If the relief valve

has been only partially disassembled, start these instructions at

the appropriate step. Key numbers refer to Figure 3.

1. Insert the diaphragm (key 5) so that the raised,

circular ridge faces toward the spring cup (key 4) as shown

in Figure 3.

2. Slide the spring (key 3) into the spring cup (key 4).

3. Place the diaphragm disk (key 11), spring cup, and spring

on the diaphragm. Orient the diaphragm disk so that its

raised, circular lip faces toward the spring cup as shown

in Figure 3.

4. Position the spring case (key 2) on the body (key 1). Insert

and tighten the machine screws (key 9).

5. Insert the disk restriction (key 6), screen (key 7), and

retaining ring (key 8).

3

Page 4

Type H800

2

3

4

5

6

11

9

1

7

8

Parts Ordering

When ordering replacement parts for a Type H800 relief

valve, refer to the following parts list, and specify the complete

11-character part number of each needed part.

Parts List

Key Description Part Number

1 Relief Valve Body, Aluminum 26A9050X012

2 Spring Case, Aluminum 26A9051X012

3 Spring, Steel 16A9052X012

4* Spring Cap, Valox® 730 plastic 26A9053X012

5* Diaphragm, Nitrile (NBR) 16A9054X012

6 Disk Restriction, 302 Stainless steel 16A9055X012

7 Screen, 304 Stainless steel 16A9056X012

8 Internal Retaining Ring, Plated steel 16A9057X012

9 Machine Screw, Plated steel (2 required) 1B7839X0012

10 Pipe Nipple (not shown), for use in

installation B, Galvanized steel 1C678926232

11 Diaphragm Disk, Plated steel 17A7753X012

26A9059-B

A2908

1/4 NPT

1/4 NPT

1/2 NPT VENT

*Recommended spare part.

Valox® 730 is a mark owned by General Electric Co.

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

Figure 3. Type H800 Relief Valve Assembly

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1982, 2009; All Rights Reserved

Loading...

Loading...