Page 1

Instruction Manual

D101299X012

Fisherr RSS Lined Globe Valve

RSS Valve

September 2014

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Educational Services 2.........................

Specifications 3...............................

Installation 3..................................

Maintenance 5.................................

Packing Maintenance 8.........................

Replacing Packing and Bushing Inserts 8..........

Trim Maintenance 11..........................

Disassembly 11............................

Assembly 12..............................

Parts Ordering 13...............................

Parts List 13...................................

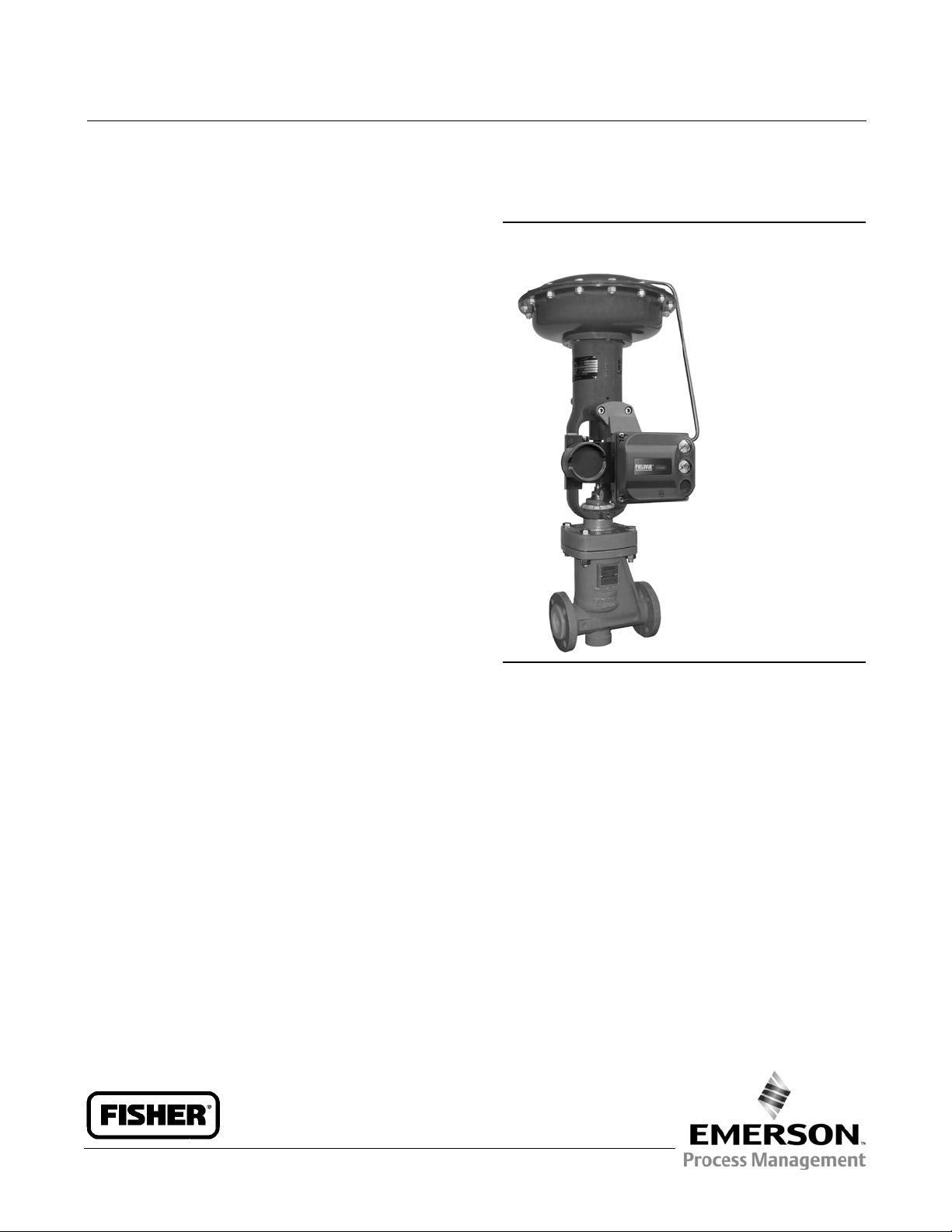

Figure 1. Fisher RSS Valve with 667 Actuator

and FIELDVUE™ DVC6200 Digital Valve Controller

W9164-2

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for NPS 1 through NPS 4 Fisher RSS

lined globe valves. Refer to separate manuals for instructions covering the actuator, positioner, and accessories.

Description

The RSS lined globe-style valve (figure 1) has pure-modified PTFE trim parts, push-down-to- close action, and positive

shutoff. This valve is intended for applications involving severely corrosive and toxic flowing media, and is well-suited

for pure media applications, as well. The RSS valve body provides an economical alternative to alloy valve bodies in a

wide variety of applications.

Do not install, operate, or maintain an RSS valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

Page 2

RSS Valve

September 2014

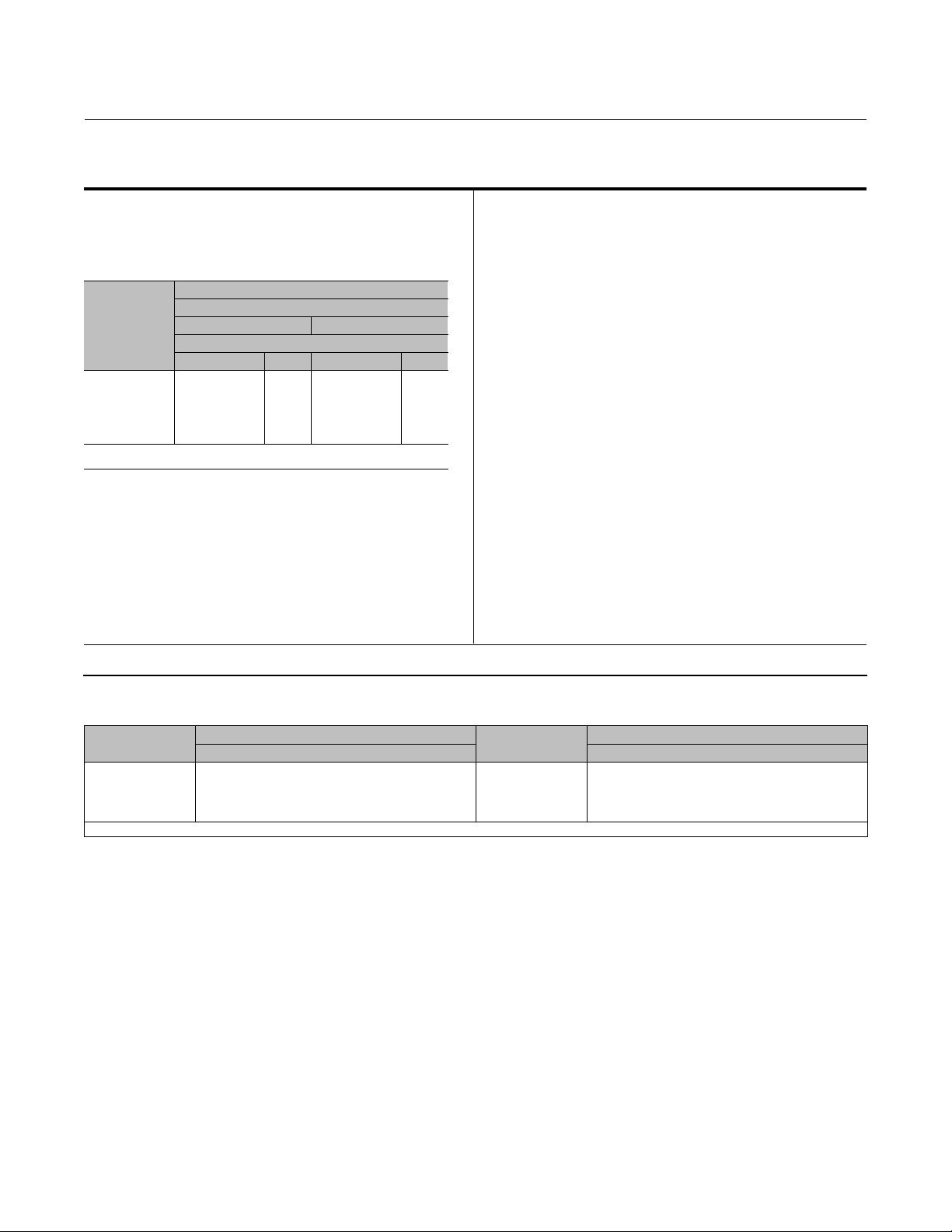

Table 1. Specifications

Instruction Manual

D101299X012

Valve Sizes

NPS J 1, J 1-1/2, J 2, J 3, and J 4

Application Limits

Liquid Service: For cavitating applications, contact

your Emerson Process Management sales office

Face-To-Face and Flange Compatibility

Gas Service: Velocity ± 0.33 MACH

DUCTILE IRON

VALVE SIZE,

NPS

ASME

1

1-1/2

2

3

4

1.ForANSI/ISAface-to-facedimensions,seefigure9.

2.ForENface-to-facedimensions,seefigure9.

Raised-Face Flange

CL150 CL300

(1)

X

X

X

X

X

Face-To-Face

(2)

EN

X

X

X

X

X

ASME

X

X

X

---

---

(1)

Maximum Inlet Pressures and Temperatures

(1)

EN

(2)

---

---

---

---

---

Temperature Capabilities

Positive Pressure Service: -29 to 180_C

(-20 to 360_F)

Vacuum Service: -29 to 180_C (-20 to 360_F)

Standard Flow Characteristic/Valve Plug Style

Equal percentage

Flow Direction

Up through the seat ring (see figure 7)

See table 2

Downstream/Outlet Pressure Ratings

(1)

See figures 3 and 4

Shutoff Classification

Class VI per ANSI/FCI 70-2 and IEC 60534-4

1. The pressure or temperature limits in this manual,and any applicable standard limitations should not be exceeded.

Packing Arrangement

Braided PTFE rings

Dimensions and Weights

Seefigure9

Table 2. Maximum Allowable Inlet Pressures and Temperatures

TEMPERATURE, _C

-29 to 38

93

149

180

1. Includes valves with CL300 flanges.

PRESSURE, BAR

Ductile Iron Ductile Iron

19.7

17.9

15.9

14.8

(1)

TEMPERATURE, _F

-20 to 100

200

300

360

PRESSURE, PSIG

285

260

230

215

Educational Services

For information on available courses for Fisher RSS valves, as w ell as a variety of other products, contact:

Emerson Process Management

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

http://www.emersonprocess.com/education

2

Page 3

Instruction Manual

D101299X012

RSS Valve

September 2014

Specifications

SpecificationsfortheRSSvalveareshownintable1.Ifthevalveisshippedwiththeactuator,someofthevalve

specifications are on the valve nameplate, which is attached to the actuator. If the valve is shipped without the

actuator, the valve nameplate is wired to the valve.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure can result if the valve is installed where service

conditions could exceed the limits given on the nameplate or in table 1 or 2, or figure 3 or 4. To avoid such injury or

damage, use pressure-limiting or pressure-relieving devices to prevent service conditions from exceeding these limits.

Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

When ordered, the valve configuration and construction materials are selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Since some valve body/trim material combinations are limited in their

pressure drop and temperature ranges, do not apply any other conditions to the valve without first contacting your

Emerson Process Management sales office.

CAUTION

Before installing the valve, inspect it to be certain that the valve cavity is free of foreign material. Use extra care in handling

to avoid damage to the exposed lining on the flanges. Clean out all pipelines to remove scale, welding slag, and any other

foreign materials that could cause erosion of the valve body lining.

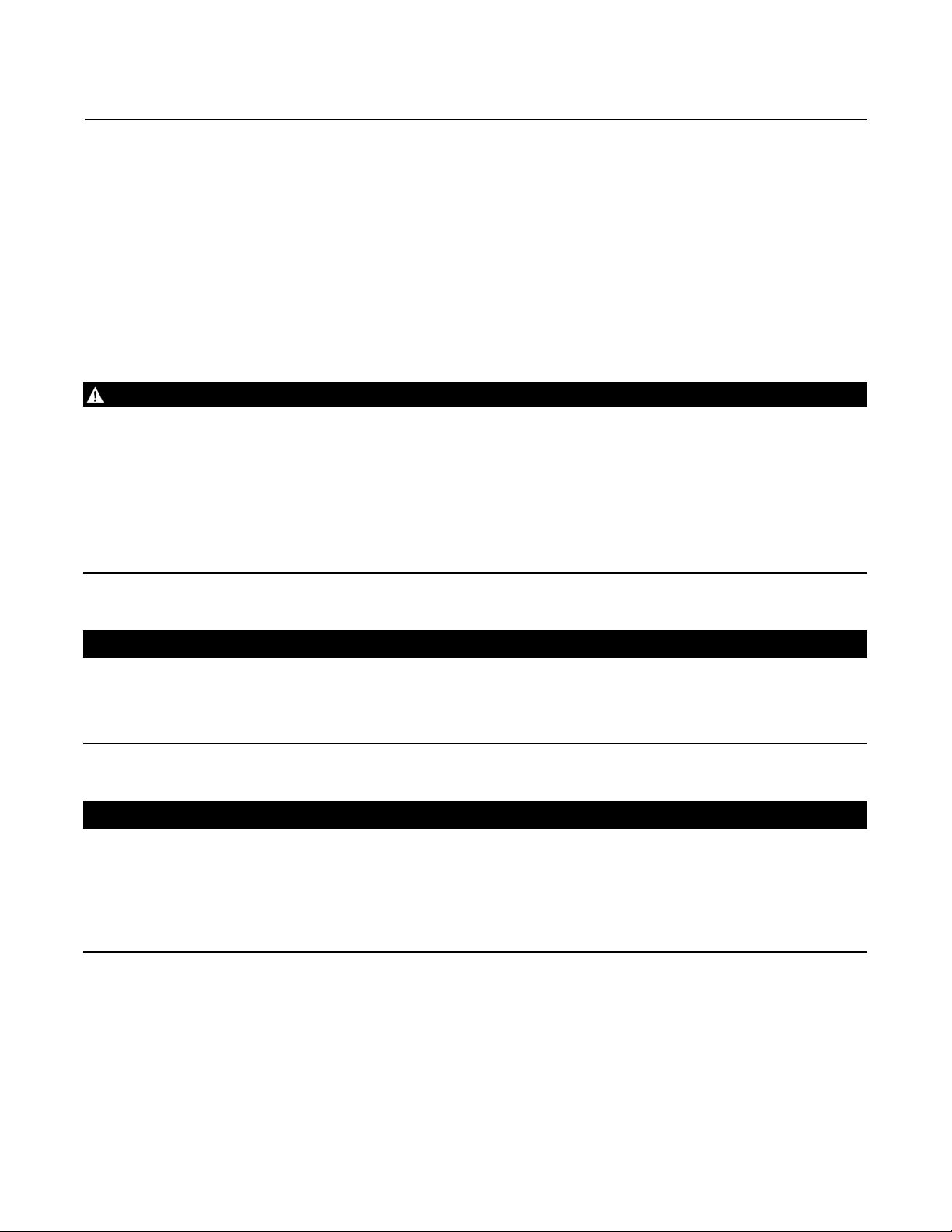

Use accepted piping practices when installing the valve in the pipeline. To minimize valve damage caused by expansion of

PTFE lined pipe, use a line flange gasket (figure 2). This gasket evenly distributes the piping loads across the valve flange

face and minimizes the potential for cutting or indenting the lined face on the valve flange.

3

Page 4

RSS Valve

September 2014

Instruction Manual

D101299X012

1. The control valve assembly should be installed in a horizontal pipeline with the valve stem in a vertical position.

Before installing in any other orientation, consult your Emerson Process Management sales office.

Flowthroughthevalvemustbeinthedirectionindicatedbythearrowcastonthevalve(figure7).

2. With a leak-off bonnet construction, remove the pipe plug (key 20, not shown) and install the leak-off piping into

thetappinginthebonnet(key2,figure10).

3. If continuous operation is required during inspection or maintenance, install a three-way bypass around the control

valve assembly.

4. For a valve used with a fail-closed actuator, remove the shim (key 24, not shown) from between the bonnet and the

travel stop. Discard the shim.

5. If the actuator and valve are shipped separately, refer to the appropriate actuator instruction manual for t he

actuator mounting procedure.

Note

Bench sets for Fisher 657 and 667 actuators must be adjusted after installation on the RSS valve. The heavy duty bellows on the

RSSvalvehasasignificantspringratethatmustbe included in the bench set for proper operation.

Figure 2. Typical Line Flange Gasket (Key 17)

A

PTFE

COMPOSITION

SECTION A-A

10B3224-C

A5039

STAINLESS STEEL

A

4

Page 5

Instruction Manual

D101299X012

RSS Valve

September 2014

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and maintenance

frequency depends on the severity of service conditions. This section includes instructions for packing and trim

replacement. All these maintenance operations may be performed with the valve in the line.

WARNING

Avoid personalinjury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieveany actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

Note

Whenever a line flange gasket (figure 2) seal is disturbed by removing the valve from the line, install a new gasket on reassembly.

This is necessary to ensure a good gasket seal.

5

Page 6

RSS Valve

September 2014

Figure 3. Downstream/Outlet Pressure Ratings (Positive Pressure Service)

1501005020

302

E0981

-29

232

217

203

188

174

159

145

130

116

101

87

gauge pressure (psi)

72.5

58

43.5

29

14.5

0

68

-20

HEAVY-DUTY BELLOWS WITH METAL SUPPORT RINGS

STANDARD PTFE BELLOWS

122 212

180_C

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

360_F

Instruction Manual

D101299X012

gauge pressure (bar)

NOTE: THE LINER DOES N OT LIMIT THE DOWNSTREAM PRESSURE RATING IN POSITIVE PRESSURE SERVICES.

Figure 4. Downstream/Outlet Pressure Ratings (Vacuum Service)

1501005020

E0980

14.5

7.25

4.35

2.9

1.45

0.72

0.43

0.29

0.14

vacuum (psia)

0.07

0.04

0.03

0.015

68 122 212 302

180_C

1

0.5

0.3

0.2

0.1

0.05

0.03

0.02

0.01

0.005

0.003

0.002

0.001

360_F

vacuum (bar)

THE PFA LINER CANNOT

BE USED IN THIS AREA

PFA LINING

6

Page 7

Instruction Manual

D101299X012

Figure 5. Bonnet, Travel Stop, and Seat Ring Installation Detail

VALVE

STEM

(KEY 5)

LOCKNUT

(KEY 10)

YOKE

LOCKNUT

(KEY 14)

TRAVEL

STOP

(KEY15)

0.6 mm

(O.020 INCH) GAP

BONNET

(KEY 2)

RSS Valve

September 2014

BONNET

LOCATING

DIAMETER

29B2880-B

E1021

EQUAL AT ALL BOLTING

LOCATIONS

BELLOWS

(KEY 6)

VALVE

PLUG

(KEY 3)

40B4191-E

SEAT RING

CONTACT SURFACE

SEAT RING

SEALING LEDGE

7

Page 8

RSS Valve

September 2014

Instruction Manual

D101299X012

Packing Maintenance

Key numbers are shown in figure 10.

The packing consists of braided packing rings (key 13). The packing box is only a safety measure in case of a leak

through the bellows (key 6). Therefore, the packing follower (key 11) is tightened to 1.13 NSm(10lbfSin) of torque

and then loosened one half turn. To detect a leak through the bellows (key 6), the bonnet (key 2) can be provided with

a connection for leak-off piping.

Replacing Packing and Bushing Inserts

Key numbers are shown in figure 10.

1. Isolatethecontrolvalvefromthelinepressure.Releasepressure from both sides of the valve and drain the process

media from both sides of the valve.

2. Exhaust all actuator pressure, and disconnect the operating lines from the actuator and any leak-off piping from the

bonnet (key 2). Disconnect the actuator stem connector, and then remove the actuator from the valve by

unscrewingtheyokelocknut(key14).

3. Remove any travel indicator parts, the locknut (key 10), and the travel stop (key 16) from the valve stem (key 5)

threads.

CAUTION

Follow the procedures as described in the next steps to prevent damage to the bonnet sealing surface and to prevent

packing box leakage.

4. Remove the packing follower (key 11). Unscrew the cap screws (key 7) and hex nuts (key 8) that secure the bonnet

(key 2) to the valve (key 1). Then, carefully lift the bonnet off and set it on a protective surface to prevent damage to

the bonnet sealing surface. If the valvestem,bellows,andvalveplug(keys5,6,and3)comeoutwiththebonnet,

remove these parts from the bonnet.

5. Remove bushing inserts, packing rings, and packing box ring (keys 13, 12, 28, and 29).

6. Clean the packing box, packing box ring, and packing follower.

7. Inspect the valve stem and packing box surfaces for any sharp edges that might cut the packing. Scratches or burrs

could damage new packing or cause packing box leakage. If the surface condition cannot be improved by light

sanding, replace the damaged parts.

8. Install bushing inserts (keys 28 and 29).

9. Install the bonnet (key 2) over the valve stem (key 5). Slide the bonnet down until it properly engages the bonnet

locating diameter (figure 5) of the valve.

Note

In order to ensure accurate positioning of the valve plug (key 3) and seat ring (key 4), clearance between the valve and bonnet at

all bolting locations (figure 5) must be equal and approximately 2.0 mm (0.080 inches) for NPS 1 through 4 valves. Be sure to

measure the clearance in the next step.

10. Tighten the cap screws and hex nuts (keys 7 and 8) in a crisscross pattern to a maximum torque value of 50 NSm

(37 lbfSft). To ensure accurate positioning of the valve plug (key 3) into the seat ring (key 4), check the gap between

8

Page 9

Instruction Manual

D101299X012

RSS Valve

September 2014

the valve and bonnet with a feeler gauge (figure 5). At all bolting locations, the gap must be equal and

approximately 2.0 mm (0.080 inches) for NPS 1 through 4 valves. In order to keep the gap equal, the individual

bolts may have to be tightened to different torque levels.

Note

Due to the cold flowing tendency of the valve liner, this procedure should be repeated upon installation and after the first thermal

cycle of the valve.

11. Install the packing rings, packing box ring, and packing follower (keys 13, 12, and 11) over the valve stem. Tighten

the packing follower to 1.13 NSm(10lbfSin)oftorquetoensurethepackingrings are seated. After the packing

rings are seated, loosen the packing follower one half turn.

12. Manually press the valve stem (key 5) into the valve until the valve plug contacts the seat ring.

CAUTION

Improper adjustment in step 13 might cause damage to trim parts. Perform this step carefully.

13. Thread the travel stop (key 16) onto the valve stem until there is a 0.5 mm (0.020 inch) gap between the bottom

surface of the travel stop legs and the top of the bonnet (figure 5).

14. Thread the locknut (key 10) onto the stem and tighten it against the travel stop.

15. Mount the actuator and secure it with the yoke locknut (key 14). Connect the actuator stem and valve stem

according to the procedure in the appropriate actuator instruction manual.

Figure 6. Typical Locking Rope Installation

W9165-1

WITH LOCKING ROPE PARTIALLY REMOVED WITH LOCKING ROPE INSTALLED

W9166-1

9

Page 10

RSS Valve

September 2014

Figure 7. Fisher RSS Valve Body Shown with Tool Used to Remove or Install Seat Ring

SEAT

RING

SEAT

RING

W4473

TOOL

Instruction Manual

D101299X012

Table 3. Seat Ring Tool Dimensions

VALVE

SIZE,

NPS

1

1-1/2

2

3

4

VALVE

SIZE,

NPS

1

1-1/2

2

3

4

A B C

36.9

37.2

54.0

54.2

65.1

65.3

91.3

91.5

105.9

106.2

A B C

1.45

1.46

2.13

2.14

2.56

2.57

3.59

3.60

4.17

4.18

DIMENSIONS (MILLIMETERS)

D E F G

47.2

47.5

63.9

64.1

76.2

76.5

103.7

104.2

118.2

118.5

54.8

55.6

71.8

72.6

83.7

84.5

111.9

112.7

126.2

127.0

6.4 4.8

7.1 5.6

7.1 5.6

7.1 5.6

7.1 5.6

DIMENSIONS (INCHES)

D E F G

1.86

1.87

2.52

2.53

3.00

3.01

4.09

4.10

4.66

4.67

2.16

2.19

2.83

2.86

3.30

3.33

4.41

4.44

4.97

5.00

1/4 3/16

9/32 7/32

9/32 7/32

9/32 7/32

9/32 7/32

7.9

7.6

7.9

7.6

7.9

7.6

7.9

7.6

7.9

7.6

0.31

0.30

0.31

0.30

0.31

0.30

0.31

0.30

0.31

0.30

190

222

222

300

300

7-1/2

8-3/4

8-3/4

11-7/

8

11-7/

8

Figure 8. Seat Ring Tool

7.9

(5/16)

30_

15.8

(5/8)

DE

A3520-1

139.7

(5-1/2)

A4

B4

C4

9.5

(3/8)

3.9

(5/32)

F

G

mm

(INCH)

10

Page 11

Instruction Manual

D101299X012

RSS Valve

September 2014

Table 4. Recommended Seat Ring Torque

Valve Size,

NPS

1

1-1/2

2

3

4

Newton

Meters

8

23

30

50

50

Pound-Force

Inches

71

---

---

---

---

Pound-Force

Feet

--17

22

37

37

Trim Maintenance

Key numbers are shown in figure 10.

Disassembly

1. Remove the actuator and the bonnet as described in steps 1 through 4 of the Replacing Packing and Bushing Inserts

section.

2. Inspect parts for wear or damage that would prevent proper operation of the valve.

3. To replace the bellows (key 6), unscrew the valve stem (key 5) in a counterclockwise rotation. Install the valve stem

into the new bellows with a clockwise rotation by hand. Do not overtighten.

4. To remove the valve plug (key 3), use pliers to remove the locking rope (key 9) that locks the valve plug to the

bellows(key6)asshowninfigure6.Thenunscrewtheplugfromthebellows.

Note

To avoid cold flow of the valve liner and deforming of the valve body seat ring threads and seat ring contact surfaces, promptly

install a replacement seat ring according to step 1 of the Assembly procedures.

5. Toremovetheseatring(key4),usetheseatringtool(figure7or8)thatcanbeorderedfromthePartsListsection

or made according to the dimensions in figure 8 and table 3. To avoid cold flow of the valve liner and deforming of

the valve body seat ring threads and seat ring contact surfaces, promptly install a replacement seat ring according

to step 1 of the Assembly procedures.

11

Page 12

RSS Valve

September 2014

Figure 9. Dimensions and Weights

ANSI/ISA CL150 FACE-TO-FACE DIMENSIONS

MATING WITH CL150 FLANGES

Valve

Size

NPS mm kg

1

1-1/2

2

3

4

NPS Inches Pounds

1

1-1/2

2

3

4

Valve

Size

NPS mm kg

1

1-1/2

2

NPS Inches Pounds

1

1-1/2

2

A B D

184.0

222.0

254.0

298.0

350.0

7.25

8.75

10.00

11.75

13.78

ANSI/ISA CL300 FACE-TO-FACE DIMENSIONS

A B D

197.0

235.0

267.0

7.75

9.25

10.50

Dimensions

83.0

97.0

107.0

121.0

176.0

3.27

3.82

4.21

4.76

6.94

MATING WITH CL300 FLANGES

90.0

101.0

115.0

3.54

3.97

4.53

185.0

225.0

230.0

340.0

350.0

7.28

8.86

9.06

13.39

13.78

Dimensions

185.0

225.0

230.0

7.28

8.86

9.06

Approximate

E

108.0

127.0

152.4

190.5

220.0

4.25

5.00

6.00

7.50

8.66

Approximate

E

123.8

156.0

165.0

4.87

6.14

6.50

Weight

10

17

20

39

42

23

36

43

86

92

Weight

11

18

20

25

40

45

E4

10B4744-G

A5216-1

Instruction Manual

D101299X012

MATCH LINE

FOR ACTUATOR

D

B

A

Assembly

CAUTION

To avoid damage to the seat ring sealing surface and/or threads in the valve body liner, make or order the seat ring tool

shown in figures 7 and 8. Installing the seat ring using other tools might cause permanent damage to the seat ring sealing

surface and/or threads allowing excessive leakage of the valve.

1. Install the seat ring (key 4) with the seat ring tool (figure 7 or 8) that can be ordered from the Parts List or made

according to the dimensions in table 3 and figure 8. Tighten the seat ring until contac t is felt between the sealing

ledge of the seat ring and its mating surface in the valve (figure 5). At this point, tighten the seat ring one quarter

turn or to the torque values listed in table 4.

2. To install the valve plug (key 3), screw the valve plug onto the bellows and insert the locking rope with pliers (figure

6).

3. Install the assembled valve plug, bellows, and valve stem (keys 3, 6, and 5). For metal bellows, install the gasket

(key 27).

4. Install the bonnet according to steps 9 and 10 of the Replacing Packing and Bushing Inserts procedure.

12

Page 13

Instruction Manual

D101299X012

RSS Valve

September 2014

5. Tighten the packing follower (key 11) to 1.13 NSm(10lbfSin)oftorquetoensurethepackingringsareseated.After

the packing rings are seated loosen the packing follower one half turn.

6. Perform steps 12 through 15 of the Replacing Packing and Bushing Inserts section.

Parts Ordering

Each valve body-bonnet assembly is assigned a serial number, which can be found on the valve nameplate. Refer to

this serial number when contacting your Emerson Process Management sales office for technical assistance. If the

valve is shipped with the actuator, the valve nameplate is attached to the actuator. If the valve is shipped without the

actuator, the valve nameplate is wired to the valve. When ordering replacement parts, refer to this serial number and

to the part number from the following Parts List.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Parts List

Note

Part numbers are shown for recommended spares only. Forpart

numbers not shown, contact your Emerson Process Management sales

office.

Except where indicated, sizes shown are valve body sizes.

Key Description Part Number

1 Valve Body or valve body/ring assembly

If you need a valve body or valve body/ring assembly as a

replacement part, order by valve size, serial number, and

desired material.

2 Bonnet/Bushing Assembly

If you need a bonnet/bushing assemblyas a replacement

part, order by valve size and stem diameter, serial number,

and desired material.

3* Valve Plug See following table

4* Seat Ring See following table

5* Valve Stem

Stainless steel

NPS 1 21B7543X012

NPS 1-1/2 & 2 21B7544X012

NPS 3 & 4 20B2511X012

6* Bellows Seefollowing table

7 Cap Screw

7Stud

8HexNut

9* Locking Rope, PTFE

NPS 1,1-1/2, & 2 20B2519X022

NPS 3& 4 20B2519X032

Key Description Part Number

10 Locknut

11 PackingFollower

12* Packing Box Ring

Stainless steel

NPS 1, 1-1/2, 2, 3,& 4 20B2495X012

13* Packing Ring, PTFE

NPS 1, 1-1/2, & 2 (2 req'd) 20B2504X012

NPS 3 & 4 (3 req'd) 20B2504X012

14 Yoke Locknut

16 TravelStop

17* Line Flange Gasket (for use only if specified, see figure 2),

PTFE/composition/stainlesssteel (2 req'd)

For CL150

NPS 1 10B3223X022

NPS 1-1/2 10B3224X022

NPS 2 10B3225X022

NPS 3 10B3226X022

NPS 4 10B3227X022

For CL300

NPS 1 11B5886X022

NPS 1-1/2 11B5887X022

NPS 2 11B5888X022

18 LineFlange Cap Screws (for NPS 2 useonly)

20 Pipe Plug (for use w/tapped bonnet only--not shown)

21 Seat Ring Tool (for use only if specified--see figure 7 or 8)

22 Nameplate Seal & Wire (not shown)

24* Shim (for use only w/fail-to-close actuator during

shipping [notshown]), aluminum 10B4192X012

25 Identification Plate, (not shown)

26 DriveScrew

28* Bushing Insert, Carbon-filled PTFE

NPS 1, 1-1/2, & 2 21B9345X042

NPS 3 & 4 (2 req'd) 21B9345X032

29* Bushing Insert, Carbon-filled PTFE

NPS 1, 1-1/2, & 2 21B9345X022

*Recommended spare parts

13

Page 14

RSS Valve

September 2014

Figure 10. Fisher RSS Valve Assembly

Instruction Manual

D101299X012

SEE VIEW A

40B4191-E

NOTE: KEYS 17, 19, 20,21, 22

23, 24, 25, AND 26 ARE NOT SHOWN

COMPLETE VALVE BODY ASSEMBLY

BELLOWS

BELLOWS

SUPPORT

RING

LOCKING

ROPE

SEE VIEW B

40B4191-E

VIEW A

DETAIL OF BONNET

FORNPS3AND4VALVES

14

A3598-3

VIEW B

VALVE

PLUG

DETAIL OF HEAVY DUTY

PTFE BELLOWS CONSTRUCTION

DETAIL OF NPS 3 AND 4 U-PLUG

Page 15

Instruction Manual

D101299X012

RSS Valve

September 2014

Key3*ValvePlugfor8through96mm(0.3125through4-inch)PortDiameters(IncludesLockingRope,Key9)

VALVE SIZE,

NPS

mm Inches

PORT DIAMETER

8

1

15

20

25

1-1/2

2

3

4

1. Inch equivalents of these metric port diameters have been roundedto common fractional diameters. Actualdiameter of the 15 millimeter port is 0.591 inches, of the 40 millimeter porti s

1.575 inches, and of the 96 millimeter port is3.780 inches.

2. NPS 1 valve with 15 mm (0.591 inch)travel.

25

40

30

50

50

80

65

96

(1)

PART NUMBER

0.3125

0.5

0.75

1

1

1.5

1.1875

2

2

3.1875

2.5

4

23B9209X022

23B9208X022

23B9207X022

23B9206X022

21B9632X062

21B9631X062

21B9634X062

21B9633X062

22B0701X062

22B0434X062

22B0702X062

21B5680X062

(2)

(2)

(2)

(2)

Key 4* Seat Ring

VALVE

SIZE,

NPS

mm Inches

8

1

15

20

25

1-1/2

2

3

4

1. Inch equivalents of these metric port diameters have been roundedto common fractional diameters. Actualdiameter of the 15 millimeter port is 0.591 inches, of the 40 millimeter porti s

1.575 inches, and of the 96 millimeter port is3.780 inches.

25

40

30

50

50

80

65

96

PORT

DIAMETER

(1)

0.3125

0.5

0.75

1

1

1.5

1.1875

2

2

3.1875

2.5

4

PART NUMBER

20B4169X032

20B4170X042

20B4172X042

20B2509X032

20B4174X032

20B2508X032

20B4164X032

20B2507X032

20B4159X032

20B2506X032

20B4157X032

20B2505X032

Key 6* Bellows

VALVE SIZE, NPS PORT DIAMETER PART NUMBER

1 All 29B2879X022

1-1/2 and2 All 29B2880X022

3and4 All 29B2881X022

15

Page 16

RSS Valve

September 2014

Instruction Manual

D101299X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibilityfor proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned byone of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the rightto modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

16

E 1986, 2014 Fisher Controls International LLC.All rights reserved.

Loading...

Loading...