Page 1

A81 Valve

D103301X012

Fisherr POSI-SEAL™ A81 Rotary Valve

The Fisher POSI-SEALA81rotaryvalvewithFieldQt

rack-and-pinion actuator offers automated on-off,

quarter-turn performance. It is available in

spring-return and double-acting piston designs.

The valve body meets PN 10 through PN 40, CL150,

and CL300 ratings. Face-to-face dimensions meet EN

558, API 609, and MSS-SP68 standards. Line centering

clips provide for versatility to mount and align the

same wafer style valve body in different piping

configurations (ASME and EN ratings).

The A81 rotary valve features an eccentricallymounted disk with either soft or metal seal, providing

capability for enhanced shutoff. The interchangeable

sealing technology allows for the same valve body to

accept both soft and metal seals.

Product Bulletin

21.1:A81

July 2012

The actuator sizing and selection process is improved

by simply reading a table for information.

A81 Features

Quarter-turn performance– The valve has a square

shaft-to-actuator connection and offers automated

on-off, quarter-turn performance.

Global Standards– The valve meets API, ASME, and

EN standards, making it suitable for use in all world

areas. An optional mounting bracket provides ISO

5211 actuator mounting capability.

PEEK/PTFE bearing as standard– The PTFE-lined

PEEK bearing is a low friction, low wear bearing. It

allows the valve to operate under high pressure

drops for a high cycle life while maintaining low

torque. The drop-in bearing design enables fast,

easy maintenance.

W9479

Improved shaft-disk pinning– The improved

expansion pin system ensures there is a positive,

durable connection between disk and shaft. This

reduces backlash and wear in the drive system,

optimizing long-term performance. It also makes

disassembly for maintenance quick and simple with

no need for special tools.

New Spring-Loaded Shaft– The spring in the

outboard shaft provides support to the drive train

and disk, enabling the shaft to be installed in both

horizontal and vertical orientations with no

detriment to performance or cycle life. This

complements the ability to mount the actuator on

the left- or right-hand side, enabling access for any

installation.

www.Fisher.com

Page 2

Product Bulletin

21.1:A81

July 2012

A81 Valve

D103301X012

Excellent Emissions Capabilities– The optional

ENVIRO-SEALt packing systems, are designed with

very smooth shaft surfaces and live-loading to

provide improved sealing, guiding, and loading

force transmission. The seal of the ENVIRO-SEAL

system can control emissions to below 100 ppm

(parts per million).

Sour Service Capability– Depending on material

selection, some trim and bolting materials are

available for applications involving sour liquids and

gases. These constructions comply with NACE

MR0175-2002, MR0103, and MR0175 / ISO 15156.

Contact your Emerson Process Management sales

office for more information.

Easy Installation– Line-centering clips engage the

line flange bolts to simplify installation and provide

for centering of wafer-style valves in the pipeline.

End connections are compatible with EN and ASME

standards.

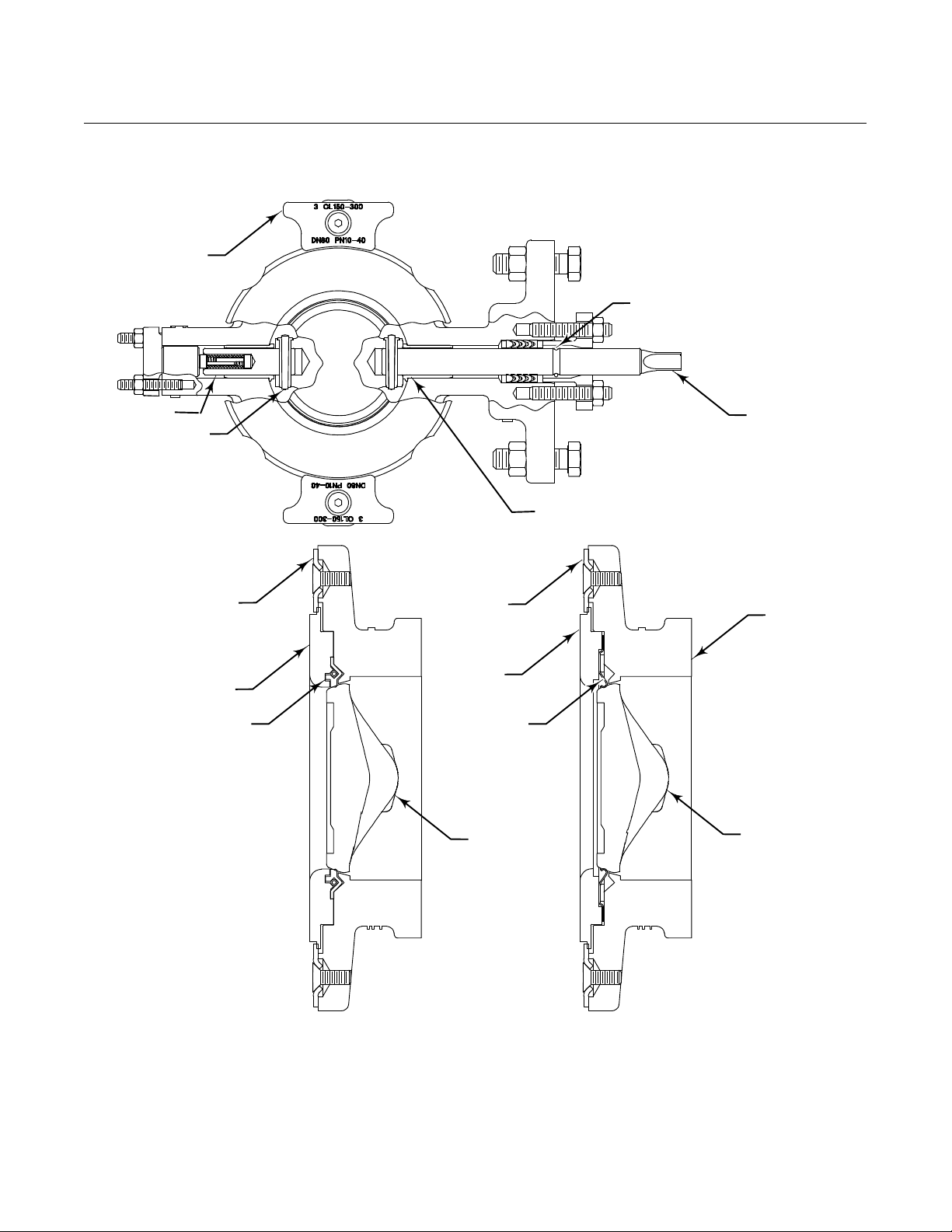

Excellent Shutoff– Both the metal and soft seal

rings have pressure-assisting sealing action that

ensures tight shutoff regardless of pressure drop.

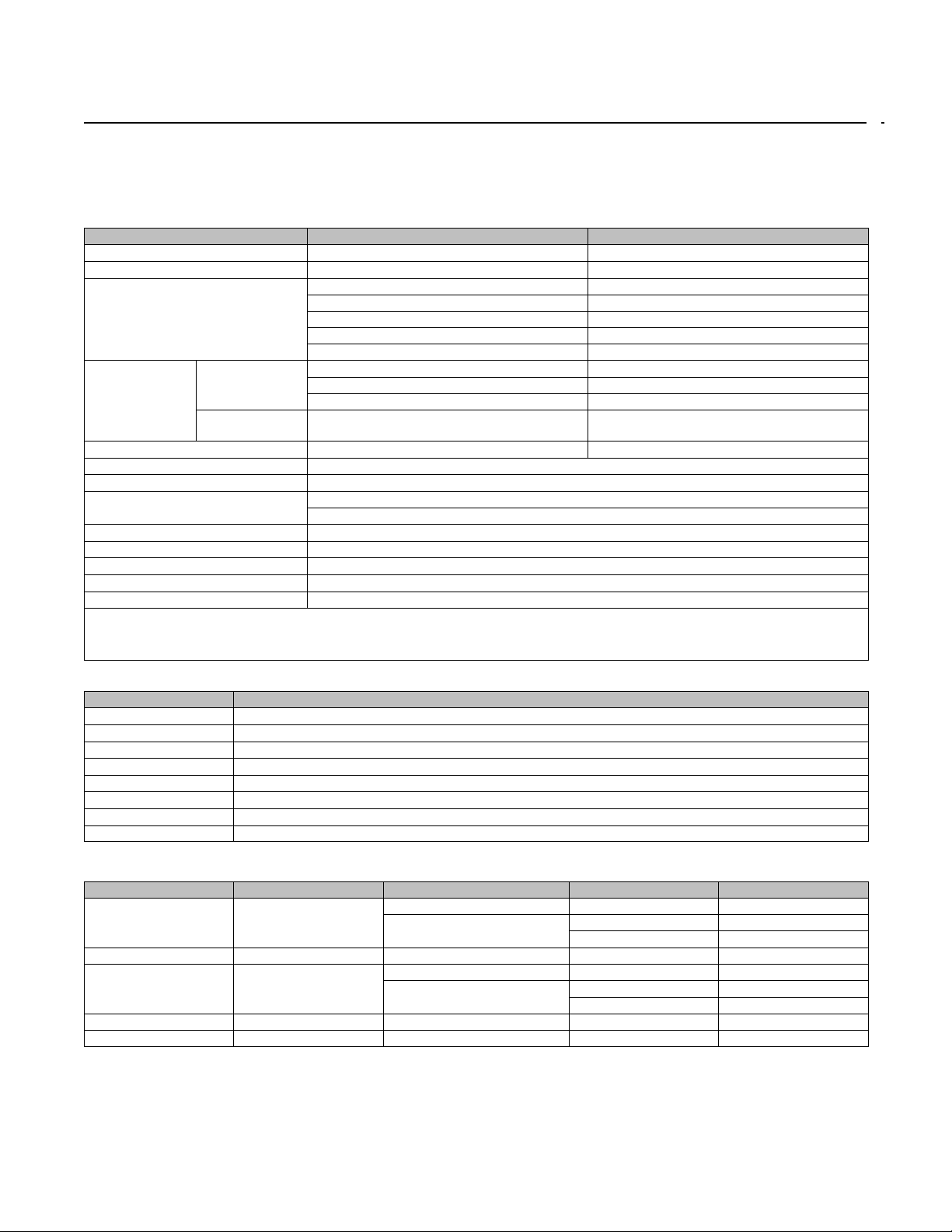

Long Seal Life– The opening and closing path of the

eccentric disk minimizes disk contact with the seal

ring, thereby reducing seal wear, undue friction,

and seating torque requirements. See

figure 2.

Reliable Flange Gasketing Surface– The seal

retainer screws and retention clips are outside the

gasket surface of the seal retainer. Spiral-wound or

flat-sheet gaskets can be installed between the

uninterrupted seal retainer face and the pipeline

flange.

Integral Shaft-to-Valve Body Bonding– Standard

valve construction includes conductive packing to

provide electrical bonding for hazardous area

applications.

Powder paint as standard– The Emerson Process

Managementt powder paint finish offers an

excellent corrosion-resistant finish to all steel parts.

High Temperature Capability– The valve will

operate at elevated temperatures, with the

appropriate trim components.

Shaft Retention– Redundant shaft retention

provides added protection. The packing follower,

anti-blowout ring, and shaft groove interact to hold

the shaft securely in the valve body (see figure 1).

Travel Indication– Additional travel indication can

be achieved by using the indication line on the

shaft, along with the disk position markings on the

packing follower (see figure 4).

Table of Contents

A81 Features 1.................................

A81 Valve Specifications and

Materials of Construction 3....................

2

FieldQ Actuator Features 16......................

Page 3

Product Bulletin

A81 Valve

D103301X012

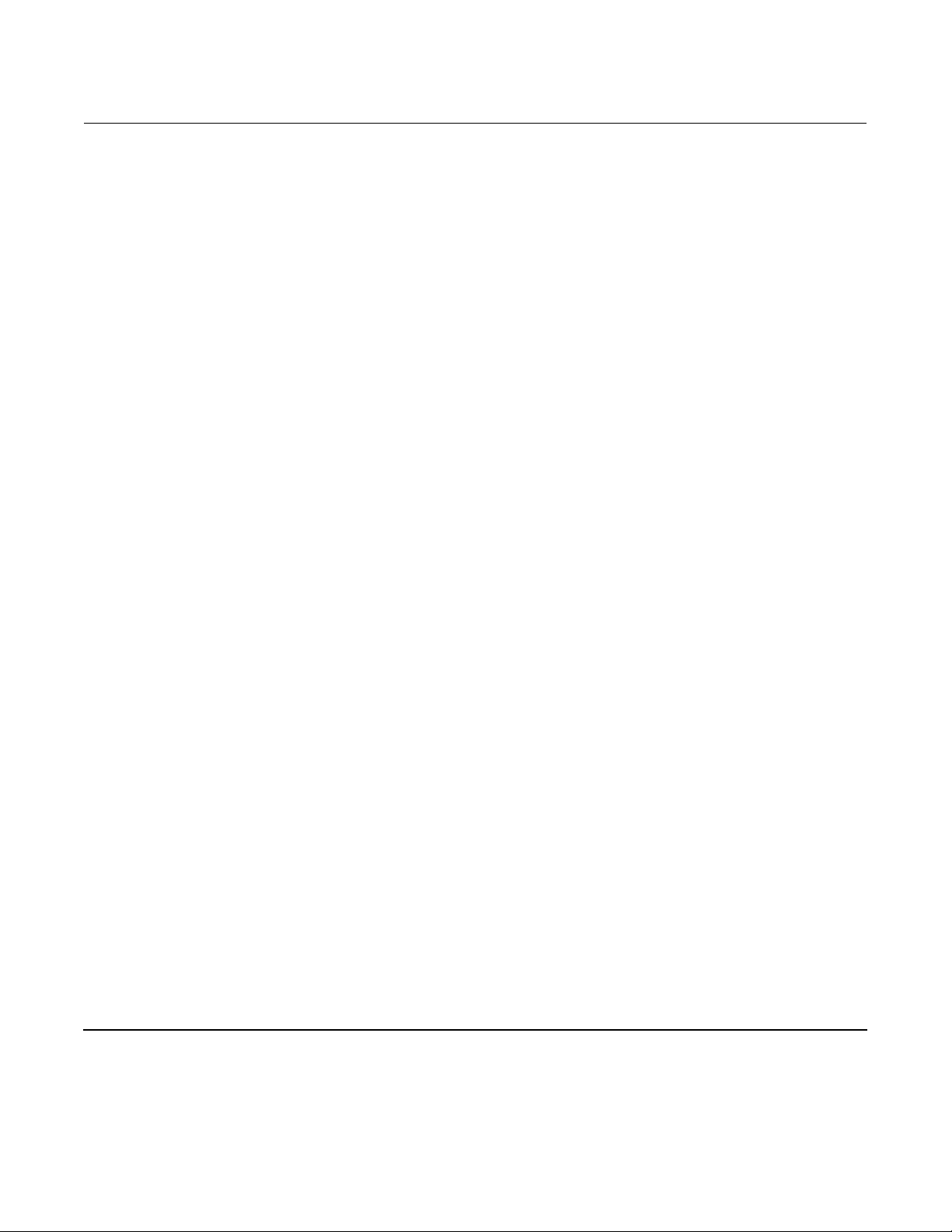

A81 Valve Specifications and Materials of Construction

Table 1. Fisher A81 Valve Specifications

Specifications EN ASME

Valve Body Size DN 50, 80, 100, 150, 200, 250,and 300 NPS2,3,4,6,8,10,and12

Pressure Rating PN 10to 40 per EN 12516-1 CL150 / 300 per ASME B16.34

EN 1.0619 steel WCC steel

EN 1.4409 stainlesssteel CF3M (316L) stainless steel

Valve Body Materials

EN 1.4409 stainlesssteel CF3M stainless steel

Chrome-plated EN 1.4409 Stainless Steel Chrome-plated CF3M Stainless Steel

S31600 (316SST) seal ring - 0.1scfhperunitofNPS(NPS6valve=0.6scfh)perMSSSP-61

Seal

(4)

Seal

(3)

Disk Materials

Face-to-Face Dimensions Meets MSS SP68, API 609, and EN 558 standards

Flow Characteristic Approximately linear

Shaft Diameters and Approximate Weights See table 8

1. This material is not listed in EN 12516-1orASMEB16.34.Seefigure6forpressure/temperatureratings.

2. This material is not listed in EN 12516-1.Seefigure6forpressure/temperatureratings.

3. UHMWPE stands for ultrahigh molecular weight polyethylene.

4. RPTFE is a reinforcedPTFE seal.

5.LCCconstructionisstandardinwaferstyleonly.ConsultyourEmersonProcess Management sales office for single flange valve body style information.

PTFE or RPTFE

Metal or UHMWPE

End Connections Mates with raised-face flanges per EN 1092-1 Mates with raised-face flanges per ASME B16.5

Valve Body Style Wafer (flangeless) and single flange with tapped or through holes

Shutoff

Flow Coefficients See Fisher Catalog 12

Flow Direction Standard (forward flow) is with the seal retainer facingupstream; reverse flow is permissible for soft seals only

Disk Rotation Counterclockwiseto open (when viewed from actuator side of valve body) through 90 degrees of disk rotation

LCC LCC

(1)

CW2M

(2)

M35-2

CW2M CW2M

M35-2 M35-2

PTFE, RPTFE, or UHMWPE seal ring - No visible leakage per MSS SP-61

CW2M

M35-2

(1)

(5)

21.1:A81

July 2012

Table 2. Materials (Other Valve Components)

Component Material

Shafts and Pins S17400 (17-4 PH) stainless steel,S20910 (XM-19) stainless steel, N10276, N05500

Anti-blowout Ring N07718

Seal PTFE, RPTFE, or UHMWPEwith S31600 (316 stainless steel) or R30003 spring. Metalseal is 316 stainless steel with graphite gaskets

Bearings PEEK/PTFE, R30006 (Alloy 6), S31600 Nitride

Packing PTFE/carbon-filled PTFE (standard),graphite die-molded ribbon, ENVIRO-SEAL PTFE packing, ENVIRO-SEAL graphitepacking

Follower Spring N07718 with carbon-filled PEEK or S31600 spring seats

Bolting B8M Class2, B7M, N05500, N07718

Nuts 8M, 2HM,N04400, N10276

Table 3. Trim Combinations with Standard Construction Materials

Valve Body Material Shaft Material Disk Material Bearings Seal Material

1.4409 & CF3M PEEK/PTFE PTFE or RPTFE

1.0619 & WCC S17400 H1075

LCC S17400 H1075 1.4409 & CF3M PEEK/PTFE PTFE

1.4409 & CF3M S20910

CW2M N10276 CW2M PEEK/PTFE PTFE or RPTFE

M35-2 N05500 M35-2 PEEK/PTFE PTFE or RPTFE

1.4409 & CF3M Chrome-Plated

1.4409 & CF3M PEEK/PTFE PTFE or RPTFE

1.4409 & CF3M Chrome-Plated

PEEK/PTFE UHMWPE or Metal

Alloy 6or S31600 Nitride Metal

PEEK/PTFE UHMWPE or Metal

Alloy 6or S31600 Nitride Metal

3

Page 4

Product Bulletin

21.1:A81

July 2012

Figure 1. Typical Fisher A81 Valve Construction Detail

RETAINERCLIP (LINE

CENTERING CLIP)

A81 Valve

D103301X012

ANTI-BLOWOUT

RING

FOLLOWER

SHAFT

EXPANSION PIN

AND TAPER PIN

RETAINER

CLIP

SEAL

RETAINER

SEAL RING

RETAINER

CLIP

SEAL

RETAINER

SEAL RING

DISK

DRIVE SHAFT

BEARING

VALVE BODY

DISK

GE36289-A

4

SOFT SEAL

METAL SEAL

Page 5

A81 Valve

D103301X012

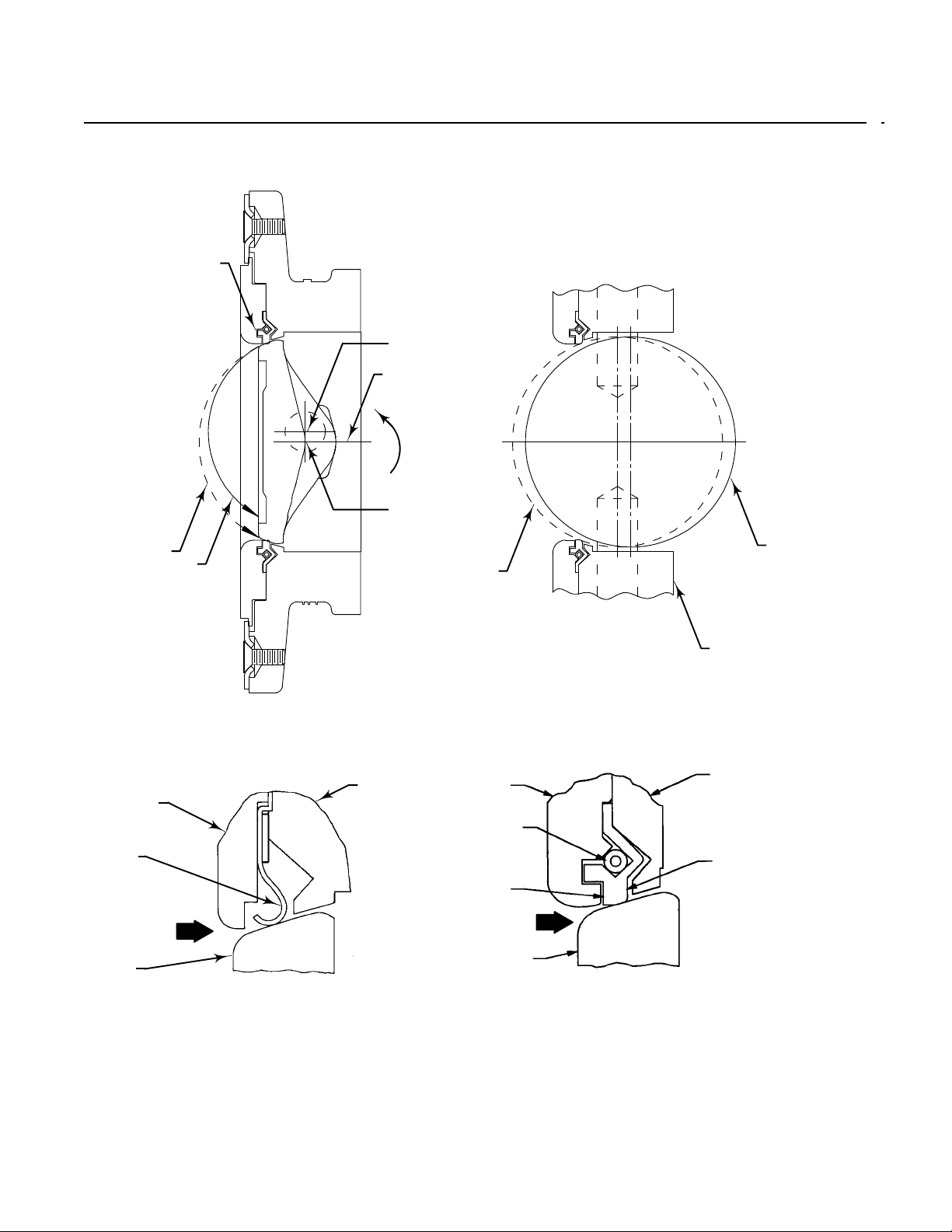

Figure 2. Comparison of Disk Action

SEAL RING (SOFT SEAL

CONSTRUCTION

SHOWN)

CONVENTIONAL

DISK PATH

OF ROTATION

ECCENTRIC

DISK PATH

OF ROTATION

ECCENTRIC

DISK CENTER

OF ROTATION

CENTERLINE OF

VALVE BODY

OPEN

CONVENTIONAL

DISK CENTER

OF ROTATION

CONVENTIONAL

DISK

Product Bulletin

21.1:A81

July 2012

ECCENTRIC

DISK

GE36289-A

DISK FULLY CLOSED DISK FULLY OPEN

Figure 3. Available Seal Configuration

SEAL

RETAINER

PRESSURE-ASSISTED

SEAL

HIGH

PRESSURE

SHUTOFF

DISK

FACE

B1558-3

METAL SEAL

VALVE BODY

SEAL

RETAINER

SPRING

PRESSUREASSISTED

SEAL

HIGH

PRESSURE

SHUTOFF

DISK FACE

VALVE BODY

VALVE

BODY

SEAL

RING

SOFT SEALS

5

Page 6

Product Bulletin

21.1:A81

July 2012

Figure 4. Travel Indication

A81 Valve

D103301X012

GE36289

Table 4. Material Temperature Capabilities

MATERIAL TEMPERATURE LIMITS

PN FLANGES

Valve Body Shaft Bearing Lining and Jacket Seal Packing _C _F

1.0619 Steel S17400 or S20910 PEEK / PTFE

R30006 (Alloy 6) or S31600 Nitride Metal Graphite —10 to 400

LCC S17400 or S20910 PEEK / PTFE PTFE PTFE —46 to 232 —50 to 450

1.4409

Stainless

Steel

CW2M N10276 PEEK / PTFE PTFE or RPTFE PTFE —10 to 232 14 to 450

M35-2 N05500 PEEK / PTFE PTFE or RPTFE PTFE —10 to 232 14 to 450

Valve Body Shaft Bearing Lining andJacket Seal Packing _C _F

WCC steel S17400 or S20910 PEEK / PTFE

LCC S17400 or S20910 PEEK / PTFE PTFE PTFE —46 to 232 —50 to 450

CF3M

Stainless

Steel

CW2M N10276 PEEK / PTFE PTFE or RPTFE PTFE —46 to 232 —50 to 450

M35-2 N05500 PEEK / PTFE PTFE or RPTFE PTFE —46 to 232 —50 to 450

1. For applications exceeding 316_C(600_F), consult your Emerson Process Management sales office for appropriate disk materialselection.

S20910 PEEK / PTFE

R30006 (Alloy 6) or S31600 Nitride Metal Graphite —46 to 500

R30006 (Alloy 6) or S31600 Nitride Metal Graphite —29 to 427

S20910 PEEK / PTFE

R30006 (Alloy 6) or S31600 Nitride Metal Graphite —46 to 454

PTFE or RPTFE PTFE or Graphite —10 to232 14 to 450

UHMWPE PTFE or Graphite —10 to 93 14 to 200

Metal

PTFE or RPTFE PTFE or Graphite —46 to232 —50 to 450

UHMWPE PTFE or Graphite —18 to 93 0 to 200

Metal

ASME FLANGES

PTFE or RPTFE PTFE or Graphite —29 to232 -20 to 450

UHMWPE PTFE or Graphite —18 to 93 0 to 200

Metal

PTFE or RPTFE PTFE or Graphite —46 to232 —50 to 450

UHMWPE PTFE or Graphite —18 to 93 0 to 200

Metal

PTFE —10 to232 14 to 450

Graphite —10 to 260 14 to 500

PTFE —46 to232 —50 to 450

Graphite —46 to 260 —50 to 500

PTFE —29 to232 -20 to 450

Graphite —29 to 260 -20 to 500

PTFE —46 to232 —50 to 450

Graphite —46 to 260 —50 to 500

(1)

(1)

(1)

(1)

—50 to932

—50 to850

14 to 752

-20 to800

(1)

(1)

(1)

(1)

6

Page 7

A81 Valve

D103301X012

Figure 5. Material Pressure/Temperature Curves

Product Bulletin

21.1:A81

July 2012

7

Page 8

Product Bulletin

21.1:A81

July 2012

Figure 6. Material Pressure/Temperature Curves

A81 Valve

D103301X012

1

2

1. CW2Mis not listed in EN 12516-1 or ASME B16.34. The PN and CL designations are used only toindicate relativepressure-retaining capabilities.

2. M35-2 is not listed in EN 12516-1. The PN designations are used only toindicate relative pressure-retaining capabilities.

8

Page 9

A81 Valve

D103301X012

Figure 7. Material Pressure/Temperature Curves

E1140

Product Bulletin

21.1:A81

July 2012

9

Page 10

Product Bulletin

21.1:A81

July 2012

Table 5. Maximum Allowable Shutoff Pressure Drops based on Trim (Seal, Shaft, and Bearings), Bar

Note: Donot exceed the EN or ASME pressure/temperature rating of the valve or mating flanges.

DN

TRIM TEMPERATURE, _C

-46 to 65

93

PTFE or RPTFE Seal

PEEK/PTFE Bearings

UHMWPE Seal

PEEK/PTFE Bearings

Metal Seal

Alloy 6 Bearings

Metal Seal

S31600/Nitride

Metal Seal

PEEK/PTFE Bearings

1. Pressure drops shown for metal seals arefor forward flow only.

(1)

(1)

Bearings

(1)

121

149

191

204

232

-17 to 37

66

93

-46 to 37

93

149

204

260

316

371

427

454

-46 to 37

93

149

204

260

316

371

427

454

-46 to 37

93

149

204

232

260

50 80 100 150 200 250 300

Bar

51.7

48.5

38.6

28.7

13.8

10.3

3.4

51.7

38.6

25.9

18.5

17.0

16.0

15.1

14.3

13.8

13.2

12.5

12.1

19.5

19.3

17.0

15.9

14.5

13.8

13.2

12.5

12.1

51.7

51.7

50.3

48.6

47.2

24.7

51.7

48.5

38.6

28.7

13.8

10.3

3.4

51.7

38.6

25.9

16.5

15.1

14.2

13.4

12.8

12.3

11.9

11.6

11.5

22.4

22.4

22.4

22.4

22.4

22.1

21.5

20.7

20.3

51.7

51.7

50.3

48.6

47.2

21.9

51.7

48.5

38.6

28.7

13.8

10.3

3.4

51.7

38.6

25.9

13.9

12.8

12.0

11.4

10.8

10.3

10.0

9.8

9.7

26.1

26.0

23.7

22.7

21.4

20.8

20.2

19.5

19.2

51.7

51.7

50.3

48.6

46.3

18.5

51.7

48.5

38.6

28.7

13.8

10.3

3.4

51.7

38.6

25.9

12.8

11.7

11.0

10.4

9.9

9.5

9.2

9.0

8.9

20.8

20.6

18.7

17.8

16.8

16.2

15.7

15.2

14.9

51.7

51.7

50.3

48.2

42.6

17.0

51.7

48.5

38.6

28.7

13.8

10.3

3.4

51.7

38.6

25.9

11.0

10.1

9.4

9.0

8.5

8.2

7.9

7.7

7.7

27.6

27.6

27.6

26.3

24.6

23.2

22.4

21.8

21.6

31.0

31.0

31.0

31.0

31.0

14.6

A81 Valve

D103301X012

35.2

35.0

33.8

28.7

13.8

10.3

3.4

35.2

35.1

25.9

6.8

6.3

5.9

5.6

5.3

5.1

5.0

4.8

4.8

12.8

12.8

12.8

12.8

12.5

12.1

11.8

11.4

11.2

17.2

17.2

17.2

17.2

17.2

9.1

41.4

38.8

35.7

28.7

13.8

10.3

3.4

41.4

38.6

25.9

7.0

6.5

6.1

5.7

5.4

5.2

5.0

5.0

4.9

8.0

7.9

7.1

6.8

6.3

6.1

5.9

5.6

5.4

17.2

17.2

17.2

17.2

17.2

9.4

10

Page 11

A81 Valve

D103301X012

Table 6. Maximum Allowable Shutoff Pressure Drops based on Trim (Seal, Shaft, and Bearings), Psi

Note: Donot exceed the EN or ASME pressure/temperature rating of the valve or mating flanges.

NPS

TRIM TEMPERATURE, _F

-50 to150

200

PTFE or RPTFE Seal

PEEK/PTFE Bearings

UHMWPE Seal

PEEK/PTFE Bearings

Metal Seal

Alloy 6 Bearings

Metal Seal

S31600/Nitride

Metal Seal

PEEK/PTFE Bearings

1. Pressure drops shown for metal seals arefor forward flow only.

(1)

(1)

Bearings

(1)

250

300

375

400

450

0 to100

150

200

-50 to100

200

300

400

500

600

700

800

850

-50 to100

200

300

400

500

600

700

800

850

-50 to100

200

300

400

450

500

2 3 4 6 8 10 12

Psi

750

704

560

416

200

150

50

750

560

375

268

246

232

219

208

200

192

181

176

283

280

246

230

211

200

192

181

176

750

750

730

705

685

358

750

704

560

416

200

150

50

750

560

375

239

219

206

195

186

178

172

168

167

325

325

325

325

325

321

312

300

295

750

750

730

705

685

318

750

704

560

416

200

150

50

750

560

375

202

185

174

165

157

150

145

142

141

379

377

344

329

311

301

293

283

278

750

750

730

705

672

269

750

704

560

416

200

150

50

750

560

375

185

170

160

151

144

138

134

130

129

301

299

271

258

243

235

228

220

216

750

750

730

699

618

247

750

704

560

416

200

150

50

750

560

375

159

146

137

130

124

119

115

112

111

400

400

400

382

357

337

325

316

313

450

450

450

450

450

212

Product Bulletin

21.1:A81

July 2012

511

508

490

416

200

150

50

511

509

375

99

91

86

81

77

74

72

70

69

185

185

185

185

182

176

171

165

162

250

250

250

250

250

132

600

563

518

416

200

150

50

600

560

375

102

94

88

83

79

76

73

72

71

116

115

103

98

91

88

85

81

79

250

250

250

250

250

136

Table 7. ISO 5211 F Sizes Available with Optional Mounting Bracket

VALVE SIZE

DN NPS

50 2 F07, F10

80 3 F07, F10

100 4 F07, F10,F12, F14, F16

150 6 F07, F10,F12, F14, F16

200 8 F10, F12,F14, F16

250 10 F10, F12,F14, F16

300 12 F10, F12,F14, F16

ISO 5211F SIZES

11

Page 12

Product Bulletin

21.1:A81

July 2012

Table 8. Dimensions and Weights

VALVE SI ZE /

A C D E

PRESSURE RATING

PN10-40/

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

DN150/

NPS 6

DN200/

NPS 8

DN250/

NPS 10

DN300/

NPS 12

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

DN150/

NPS 6

DN200/

NPS 8

DN250/

NPS 10

DN300/

NPS 12

CL150-

300

PN10-40/

CL150-

300

PN10-40/

CL150-

300

PN10-40/

CL150-

300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

PN10-40/

CL150-

300

PN10-40/

CL150-

300

PN10-40/

CL150-

300

PN10-40/

CL150-

300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

1. This nominal valve shaft diameter is the shaft diameter through the packing box. Use this diameter when selectingFisher actuators.

2. Valve assembly only.

3. 48 mm for CL150and CL300 single flange only.

4. Wafer

5. Single Flange

43 9 15 74 150 --- 109 --- 125 102 12.7 117 --- 14 4.7 6.7

47/

48

(3)

53 14 19 103 222 226 122 147 172 162 19.1 152 32 14 12.5 17.6

57 19 25 108 270 300 147 182 205 218 25.4 152 32 14 15.7 26.5

61 22 30 107 327 342 225 225 258 271 31.8 235 46 18 30.2 40.2

73 22 30 107 358 364 225 225 258 285 31.8 235 46 18 33.9 46.0

69 22 30 109 390 395 218 250 270 324 31.8 235 46 18 38.9 50.5

83 22 30 109 400 450 265 265 270 345 31.8 235 46 18 51.8 79.2

78 27 35 114 381 467 309 309 304 381 38.1 235 46 18 68.7 98.3

92 27 35 114 410 512 309 309 304 410 38.1 235 46 18 76.6 105

1.69 0.35 0.59 2.91 5.91 --- 4.29 --- 4.92 4.02 0.50 4.62 --- 0.55 10 15

1.85/

1.89

(3)

2.09 0.55 0.75 4.06 8.74 8.90 4.80 5.79 6.77 6.38 0.75 6.00 1.25 0.55 28 39

2.24 0.75 0.94 4.25 10.63 11.81 5.79 7.17 8.07 8.58 1.00 6.00 1.25 0.55 35 58

2.40 0.87 1.18 4.21 12.87 13.46 8.86 8.86 10.16 10.67 1.25 9.25 1.81 0.71 67 89

2.87 0.87 1.18 4.21 14.09 14.33 8.86 8.86 10.16 11.22 1.25 9.25 1.81 0.71 75 102

2.72 0.87 1.18 4.29 15.35 15.55 8.58 9.84 10.63 12.76 1.25 9.25 1.81 0.71 86 111

3.27 0.87 1.18 4.29 15.75 17.72 10.43 10.43 10.63 13.58 1.25 9.25 1.81 0.71 114 175

3.07 1.06 1.38 4.49 15.00 18.39 12.17 12.17 11.97 15.00 1.50 9.25 1.81 0.71 151 217

3.62 1.06 1.38 4.49 16.14 20.16 12.17 12.17 11.97 16.14 1.50 9.25 1.81 0.71 169 231

11 15 76 196 196 133 133 130 134 15.9 117 --- 14 7.5 11.2

0.43 0.59 2.99 7.72 7.72 5.24 5.24 5.12 5.28 0.63 4.62 --- 0.55 17 25

F G

(4) (5) (4) (5) (4) (5)

K R S

mm kg

Inches lbs

(1)

T U W

A81 Valve

D103301X012

APPROX-

IMATE

(2)

WEIGHT

12

Page 13

Product Bulletin

A81 Valve

D103301X012

Table9.LineBoltingDimensions

Y

VALVE SIZE

CL150 CL300 PN10 PN16 PN25 PN40

DN80 / NPS 3 4X 5/8-11 8X 3/4-10 8X M20X2.5

DN100 / NPS 4 8X 5/8-11 8X 3/4-10 8X M16X2 8X M20X2.5

DN150 / NPS 6 8X 3/4-10 12X 3/4-10 8XM20X2.5 8X M24X3

DN200 / NPS 8 8X 3/4-10 12X 7/8-9 8X M20X2.5 12X M20X2.5 12X M24X3 12X M27X3

DN250 / NPS 10 12X 7/8-9 16X 1-8 12X M20X2.5 12X M24X3 12X M27X3 12X M30X3.5

DN300 / NPS 12 12X 7/8-9 16X 1-1/8-8 12X M20X2.5 12X M24X3 16X M27X3 16X M30X3.5

1. Not availablein single flange with threaded holes.

Pressure Rating

21.1:A81

July 2012

(1)

(1)

(1)

Figure 8. Dimensions for Fisher A81, Single Flange Valve

Y

F

R

GE42533_3

G

K

Figure 9. Dimensions for Fisher A81, Wafer Style Valve

A

D

C

S

E

A

T

W

A

T

W

U

A

F

GE42533_3

R

D

C

S

KG

E

TT

W

U

W

13

Page 14

Product Bulletin

21.1:A81

July 2012

A81 Valve

D103301X012

Table 10. Dimensions and Weights, Optional Mounting Bracket

(1)

VALVE SIZE /

PRESSURE RATING

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

DN150/

NPS 6

DN200/

NPS 8

DN250/

NPS 10

DN300/

NPS 12

1. This nominal valve shaft diameter is the shaft diameter through the packing box. Use this diameter when selectingFisher actuators.

PN10-40/

CL150-300

PN10-40/

CL150-300

PN10-40/

CL150-300

PN10-40/

CL150-300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

PN10-16/

CL150

PN25-40/

CL300

S

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

12.7 0.50 9 0.35 74 2.91 64 2.52 10 0.39

15.9 0.63 11 0.43 76 2.99 64 2.52 12 0.47

19.1 0.75 14 0.55 103 4.06 87 3.43 16 0.63

25.4 1.00 19 0.75 108 4.25 87 3.43 21 0.82

31.8 1.25 22 0.87 107 4.21 85 3.35 22 0.87

31.8 1.25 22 0.87 107 4.21 85 3.35 22 0.87

31.8 1.25 22 0.87 109 4.29 85 3.35 24 0.94

31.8 1.25 22 0.87 109 4.29 85 3.35 24 0.94

38.1 1.50 27 1.06 114 4.49 85 3.35 29 1.14

38.1 1.50 27 1.06 114 4.49 85 3.35 29 1.14

C E L M T U W

49.50 1.95 49.50 1.95 10 0.39 F07

72.12 2.84 72.12 2.84 12 0.47 F10

49.50 1.95 49.50 1.95 10 0.39 F07

72.12 2.84 72.12 2.84 12 0.47 F10

49.50 1.95 49.50 1.95 10 0.39 F07

72.12 2.84 72.12 2.84 12 0.47 F10

88.39 3.48 88..39 3.48 14 0.55 F12

49.50 1.95 49.50 1.95 10 0.39 F07

72.12 2.84 72.12 2.84 12 0.47 F10

88.39 3.48 88.39 3.48 14 0.55 F12

99.00 3.90 99.00 3.90 18 0.71 F14

116.67 4.59 116.67 4.59 22 0.87 F16

72.12 2.84 72.12 2.84 12 0.47 F10

88.39 3.48 88.39 3.48 14 0.55 F12

99.00 3.90 99.00 3.90 18 0.71 F14

116.67 4.59 116.67 4.59 22 0.87 F16

72.12 2.84 72.12 2.84 12 0.47 F10

88.39 3.48 88.39 3.48 14 0.55 F12

99.00 3.90 99.00 3.90 18 0.71 F14

116.67 4.59 116.67 4.59 22 0.87 F16

72.12 2.84 72.12 2.84 12 0.47 F10

88.39 3.48 88.39 3.48 14 0.55 F12

99.00 3.90 99.00 3.90 18 0.71 F14

116.67 4.59 116.67 4.59 22 0.87 F16

ISO

5211

Figure 10. Dimensions for Fisher A81, Wafer Style Valve with Optional Mounting Bracket

S

L

E

GE42533_3

M

TC

W

U

14

Page 15

Product Bulletin

A81 Valve

D103301X012

Table 11. Fisher A81 Valve Breakout Torque Requirements

TRIM CONFIGURATION: SOFT SEAL WITH PEEK/PTFE BEARINGS

200

psid

200

psid

TORQUE, NSm

Shutoff nP

TORQUE, LbfSin

Shutoff nP

TORQUE, NSm

Shutoff nP

TORQUE, LbfSin

Shutoff nP

max

max

300

psid

max

max

300

psid

400

psid

400

psid

500

psid

500

psid

600

psid

600

psid

VALVE

SIZE

DN mm 3bar 7bar 10 bar 15 bar 20 bar 25 bar 35 bar 45 bar 50 bar

50 12.7 12.8 14.7 16.2 18.7 21.1 23.6 28.5 33.4 35.9

80 15.9 19.7 23.4 26.1 30.7 35.3 39.9 49.1 58.2 62.8

100 19.1 31.1 37.6 42.4 50.5 58.7 66.8 83.0 99.2 107

150 25.4 60.8 75.9 87.2 106 125 144 181 219 238

200 31.8 103 135 158 198 237 276 355 434 473

250 31.8 159 212 252 318 385 451 584 --- ---

300 38.1 228 310 371 473 576 678 883 --- ---

VALVE

SIZE

NPS Inch

2 1/2 115 130 145 160 190 220 250 280 325

3 5/8 178 206 234 262 318 374 430 486 570

4 3/4 282 331 381 430 529 628 727 826 975

6 1 553 668 783 898 1130 1360 1590 1820 2160

8 1-1/4 945 1190 1430 1670 2150 2630 3110 3590 4310

10 1-1/4 1460 1870 2270 2680 3490 4300 5110 --- ---

12 1-1/2 2100 2720 3350 3970 5220 6470 7720 8970 ---

VALVE

SIZE

DN mm 3bar 7bar 10 bar 15 bar 20 bar 25 bar 35 bar 45 bar 50 bar

50 12.7 37.3 42.4 46.2 52.5 --- --- --- --- ---

80 15.9 67.7 78.9 87.3 101 115 --- --- --- ---

100 19.1 112 134 151 178 208 233 --- --- ---

150 25.4 241 292 331 395 458 --- --- --- ---

200 31.8 310 422 506 646 786 927 --- --- ---

250 31.8 598 761 884 --- --- --- --- --- ---

300 38.1 926 1270 --- --- --- --- --- --- ---

VALVE

SIZE

NPS Inch

2 1/2 336 374 413 451 --- --- --- --- ---

3 5/8 611 696 782 867 1040 --- --- --- ---

4 3/4 1020 1180 1350 1520 1850 --- --- --- ---

6 1 2190 2580 2970 3360 4140 --- --- --- ---

8 1-1/4 2860 3710 4570 5420 7130 --- --- --- ---

10 1-1/4 5450 6700 7950 --- --- --- --- --- ---

12 1-1/2 8540 11200 --- --- --- --- --- --- ---

SHAFT DIA

SHAFT DIA

SHAFT DIA

SHAFT DIA

50

psid

50

psid

100

psid

TRIM CONFIGURATION: METAL SEAL WITH METAL BEARINGS

100

psid

150

psid

150

psid

21.1:A81

July 2012

750

psid

750

psid

15

Page 16

Product Bulletin

21.1:A81

July 2012

A81 Valve

D103301X012

FieldQ Actuator Features

Simple, modular construction– Makes operation

and maintenance easier. The basic actuator module

includes the pistons, rack and pinion gear, springs

(for spring-return actuators), housing, and position

indicator. Pneumatic operation is accomplished

with an ASCO 8551 solenoid valve. The solenoid is

activated by a 120 VAC 60 Hz or 110 VAC 50 Hz

signal. It is pad mounted and does not require a

bracket. The basic actuator features built-in visual

position indication, travel stops for both directions,

and a balanced pinion design.

Three Point Suspension System–Three carbon-filled

PTFE guide bands provide a low friction bearing

surface for piston alignment and rack support.

Elimination of metal-to-metal contact between

pistons and cylinder wall reduces friction for

outstanding cycle life, smooth piston travel, and

maximum power.

Balanced Piston Design–As part of the design, three

equally spaced bearing surfaces are cast into each

piston. The rack and pinion construction results in

even distribution of bearing loads, optimum gear

engagement, and reduced piston tilt. Equal spring

force applied to each piston enhances actuator life.

Multiple Constructions–Conversion from double

acting to spring return, or vice versa, is simple and

safe, thus reducing spare part requirements.

Valve/actuator action is also field reversible.

Dual Stop Adjustment– This adjustment is standard

on all E Series actuators. The P Series actuators are

supplied with a limit plate adjustment feature.

Dual Piston Design–Air pressure applies a balanced

force across the common pinion gear.

Symmetrically balanced center mount construction

eliminates undue stress on the valve stem,

bearings, and disk.

For further information, refer to:

http://www.emersonprocess.com/valveautomation/

fieldq/index.html

Neither Emerson, Emerson Process Management,nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use,and maintenance of any product remains solely with the purchaser and end user.

Fisher, POSI-SEAL, FieldQ, and ENVIRO-SEAL are marks owned by one ofthe companies inthe Emerson Process Management business unit of Emerson

Electric Co. Emerson Process Management, Emerson, and t he Emerson logoare trademarks andservice marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available uponrequest. We reserve the right tomodify orimprove thedesigns or specifications ofsuch

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2008, 2012 Fisher ControlsInternational LLC.All rights reserved.

16

Loading...

Loading...