Page 1

Product Bulletin

A41 Valve

D500212X012

21.1:A41

January 2013

Fisherr A41 High-Performance Butterfly Valve

The Fisher A41 valve features an eccentrically

mounted disc with a soft or stainless steel seal ring.

Soft seals provide excellent sealing capabilities in both

flow directions. The metal seal ring provides excellent

shutoff against pressure applied in the recommended

flow direction for both liquid and gas applications. The

NOVEX and Phoenix III metal seals are available for

demanding applications requiring excellent shutoff

capabilities. The double D shaft combines with a

variety of power and manual actuators to form a

reliable, high-performance valve suitable for many

power applications requiring tight shutoff.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

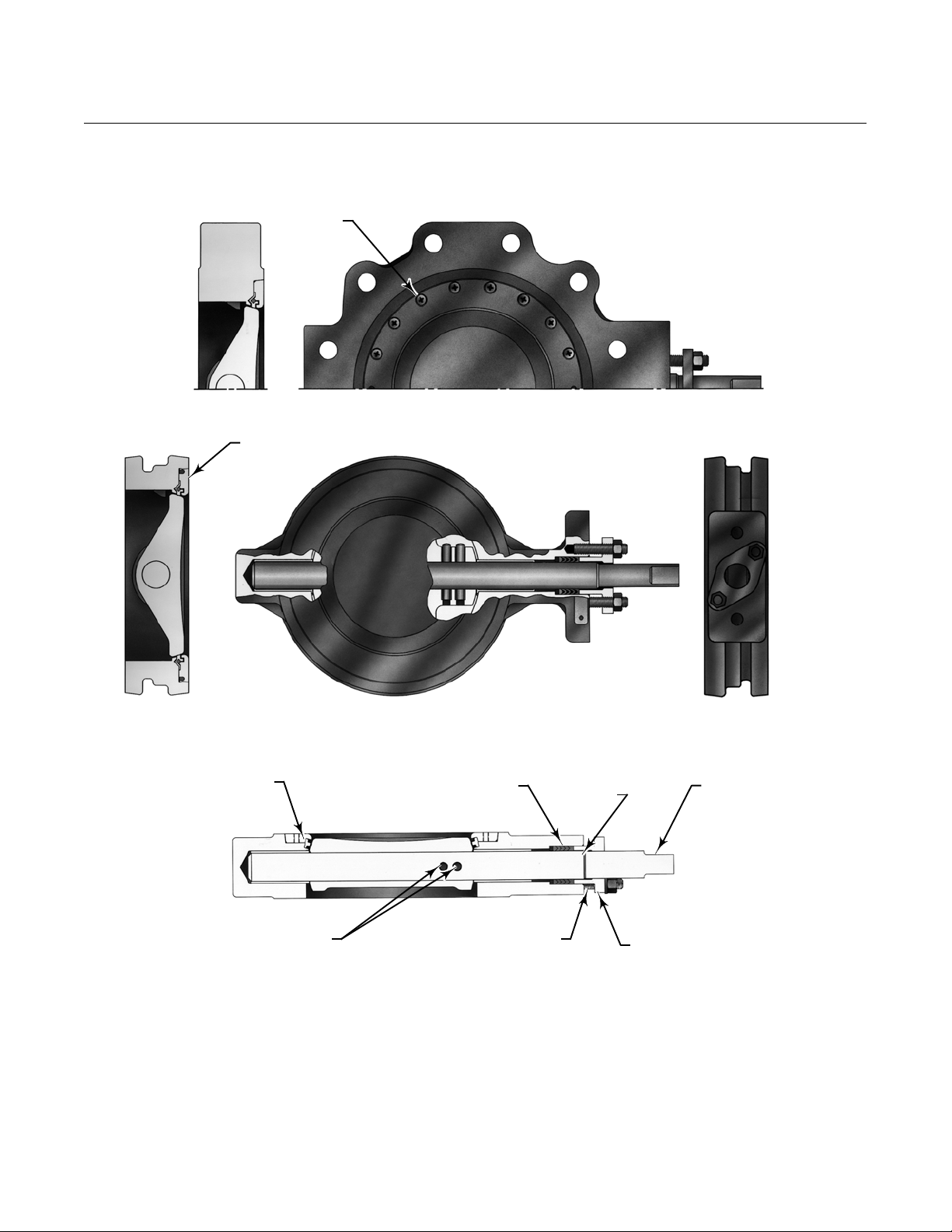

Exceptional Shutoff–Bidirectionalsoftsealring(see

figure 2) with pressure-assisting action results in

exceptional shutoff rates as shown in the

specifications.

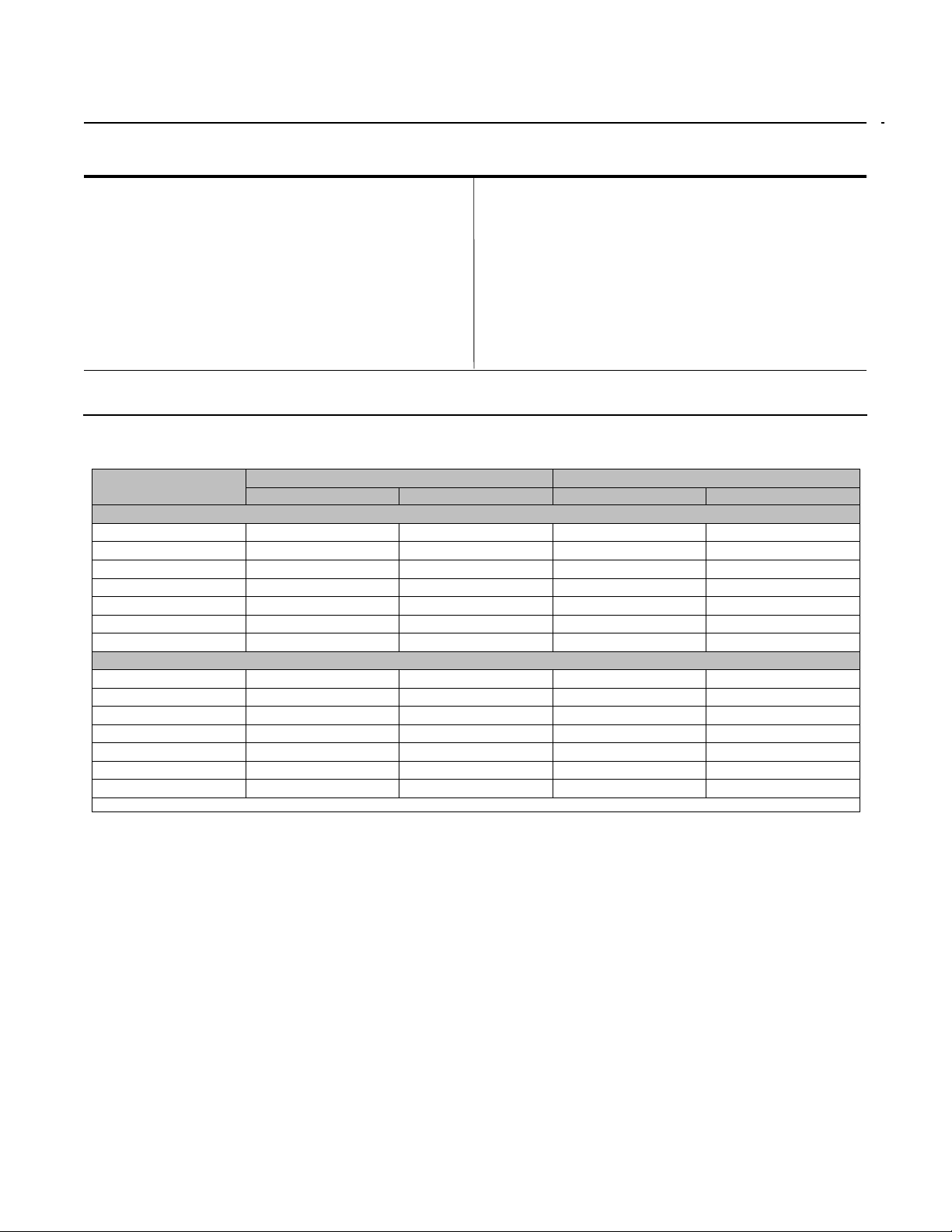

Shaft Retention–Redundant shaft retention

provides added protection. The packing follower

and shaft step interact to hold the shaft securely in

the valve body (see figure 1).

Easy Installation–The valve body self-centers on the

line flange bolts as a fast, accurate means of

centering the valve in the pipeline.

W9269

Fisher A41 Valve

Improved Environmental Capabilities–The optional

ENVIRO-SEALt packing system is designed with

improved sealing, guiding, and loading force

transmission. The ENVIRO-SEAL packing system can

control emissions to below the EPA (Environmental

Protection Agency) limit of 100 ppm (parts per

million) for valves.

Low Cost Maintenance–Individual disc/shaft

components can be replaced after disassembly due

to sleeve and taper pin connections (see figure 1).

Sour Service Capability–Materials are available for

applications handling sour fluids and gases. These

materials comply with the requirements of NACE

MR0175-2002.

www.Fisher.com

Page 2

Product Bulletin

21.1:A41

January 2013

Specifications

A41 Valve

D500212X012

Valve Sizes and End Connection Styles

NPS

J 2, J 3, J 4, J 6, J 8, J 10, and J 12 valve

sizes available in

J wafer or J single-flanged style

(NPS 2 only in wafer style)

Maximum Inlet Pressures

(1)

Carbon Steel and Stainless Steel Valve Bodies:

Consistent with CL150 and 300 pressure-temperature

ratings per ASME B16.34 unless limited by material

temperature capabilities. NPS 2 is also consistent with

CL600

Maximum Pressure Drops

(1)

Consistent with CL150 and 300 pressure/

temperature ratings per ASME B16.34 except for

PTFE, UHMWPE, and Phoenix III seals that are derated

at some higher pressure/temperatures values. (See

figure 3)

Shutoff Classifications

J PTFE, Reinforced PTFE, and UHMWPE Seal:

(4)

No

visible leakage for this bidirectional seal per MSS

SP-61. See figure 4

J NPS 2 Metal Seal: Bidirectional shutoff. 0.001% of

maximum valve capacity (1/10) of Class IV per

ANSI/FCI 70-2 and IEC 60534-4. Pressure Drop is 740

psigforwardand100psigreverse

J NOVEX Seal: For NPS 3 through 12. Unidirectional

shutoff is MSS SP-61 in the preferred flow direction.

Seefigure4

J Phoenix III Seal: For NPS 3 through 12. No visible

leakage for this bidirectional seal per MSS SP-61. See

figure 4. For optional Phoenix III Fire-Tested seal

(3)

consult your Emerson Process Management sales

office

NOVEX Seal: -46 to 538_C(-50to1000_F)

Phoenix III: -46 to 232_C (-50 to 450_F)

See table 3 for component temperature ranges

Construction Materials

Refer to table 3 for standard and optional material

selections

Flow Characteristic

Approximately linear

Flow Direction

Refer to figure 4

Flow Coefficients

See table 2, and Fisher Catalog 12

Noise Levels

See Catalog 12 for sound pressure level prediction

Disc Rotation

Clockwise to close (when viewing from the drive shaft

end) through 90 degrees of disc rotation

Available Actuators

J Pneumatic piston, J manual handwheel or

J handlever (handlevers are available for CL150 up to

anNPS8valve,andforCL300uptoanNPS6valve)

Actuator/Valve Action

,

With a pneumatic actuator, the valve action is

reversible. Refer to the information provided in the

Installation section and figure 4

Material Temperature Capabilities

(1)

PTFE and Reinforced PTFE Seals: -46 to 232_C(-50to

450_F)

UHMWPE Seal:

(4)

-18 to 93_C (0 to 200_F)

NPS 2 Metal Seal: -46 to 538_C(-50 to 1000_F)

2

Valve Classification

Face-to-face dimensions of NPS 3 through 12 in

CL150 or 300, and meets API 609 or MSS SP-68

standards for face-to-face dimensions of wafer style

and single-flange valves (see figure 6)

(continued)

Page 3

A41 Valve

D500212X012

Specifications (continued)

Product Bulletin

21.1:A41

January 2013

Mating Flange Capabilities

All sizes compatible with appropriate CL150 or 300,

and NPS 2 also compatible with CL600, flanges

(schedule 80 or lighter, see figure 6, dimension M)

Approximate Weights

See table 1

ENVIRO-SEAL Packing

This optional PTFE or graphite packing system

provides improved sealing, guiding, and transmission

of loading force to control liquid and gas emissions

Shaft Diameters

(see figure 5). See Bulletin 59.3:041 ENVIRO-SEAL

Packing Systems for Rotary Valves for more

Seefigure6

1. The pressure/temperaturelimits in this bulletin and any applicable standard or code limitation for valve should not be exceeded.

2. Optional ClassV shutoff isavailable by contactingyour Emerson Process Management sales office.

3. For component selection and applicable fire-tested standards and codes,consult your Emerson Process Managementsales office (see table2).

4. UHMWPE stands for ultra high molecular weightpolyethylene.

information

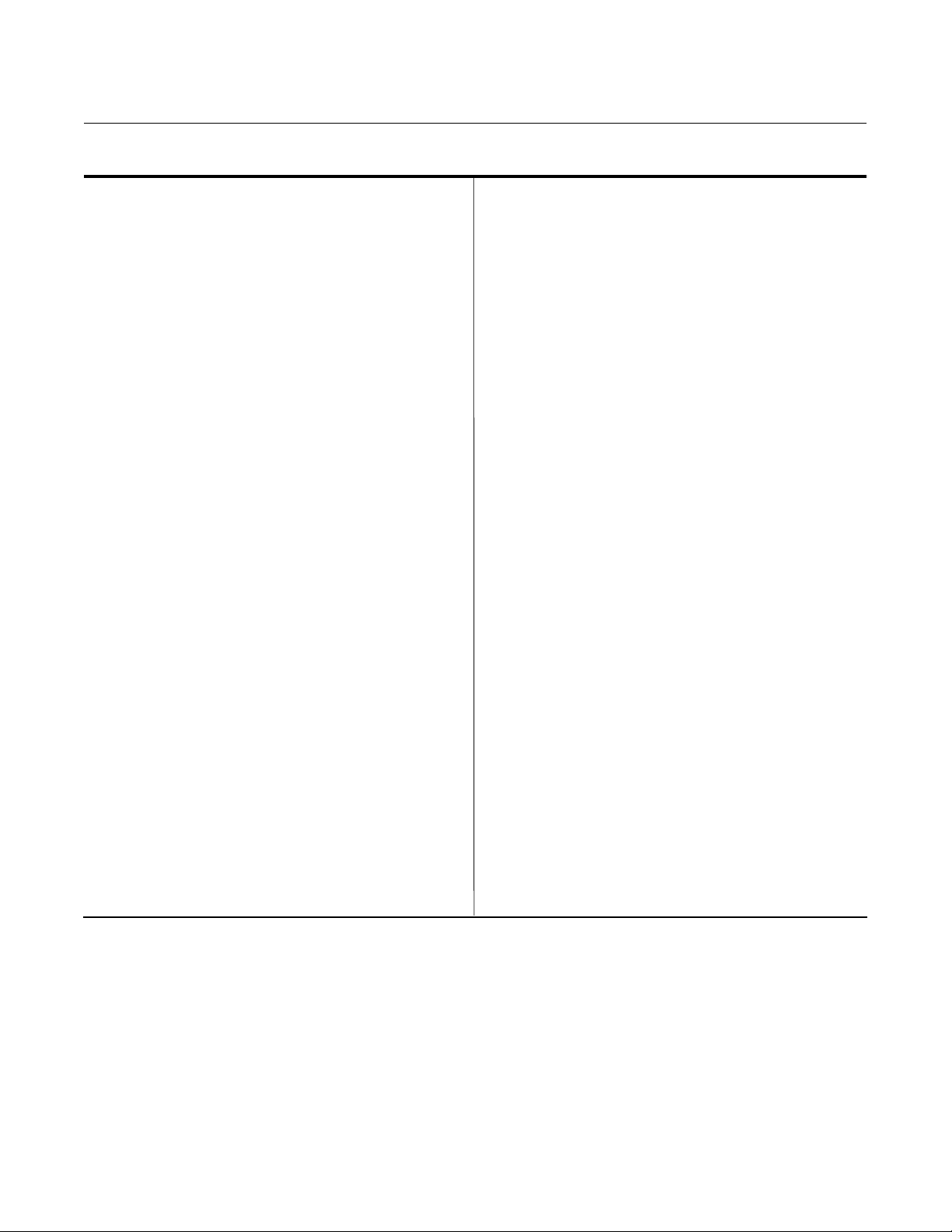

Table 1. Valve Weights

VALVE SIZE, NPS

2 4 4 --- ---

3 5 6 6 11

4 9 10 11 18

6 13 15 16 27

8 21 24 27 42

10 34 44 40 78

12 49 64 62 131

(1)

2

3 10 13 14 25

4 19 23 24 39

6 29 33 35 59

8 47 53 59 93

10 75 96 88 172

12 107 141 137 288

1. Weight of the CL600 NPS 2 valve is the same as the CL150 and CL300 values.

CL150 CL300 CL150 CL300

9.5 9.5 --- ---

WAFER STYLE SINGLE-FLANGE

Kilograms

Pounds

3

Page 4

Product Bulletin

21.1:A41

January 2013

Figure 1. Typical Valve Construction

RETAINER RING

SCREWS

A41 Valve

D500212X012

W6236

RETAINER RING

(PRESSED-IN)

NOVEX SEAL RING

SINGLE-FLANGED STYLE

WAFER STYLE

PTFE V-RING PACKING

SHAFT

STEP

DOUBLE D SHAFT

4

W6237-1

TAPER PINS

AND HOLLOW PINS

PACKING FOLLOWER

PACKING

FLANGE

Page 5

A41 Valve

D500212X012

Product Bulletin

21.1:A41

January 2013

Figure 2. Available Seal Configurations

RETAINING

RING

PRESSUREASSISTED

SEAL

HIGH PRESSURE

SHUTOFF

DISC

FACE

B1558-3

GRAPHITE

GASKET

RETAINING

RING

A6301-1

NPS 2 METAL SEAL

HIGH

PRESSURE

SHUTOFF

UNIDIRECTIONAL SEAL

NOVEX METAL SEAL

VALVE BODY

VALVE

BODY

PRESSUREASSISTED

SEAL

SEAL RING

HUB SIDE

OF DISC

RETAINING

RING

SPRING

PRESSUREASSISTED

SEAL

HIGH

PRESSURE

SHUTOFF

DISC FACE

BIDIRECTIONAL S EAL

PTFE, REINFORCED PTFE, AND UHMWPE SEALS

RETAINING

RING

GRAPHITE

GASKET

BACKUP

O-RING

RESILIENT

INSERT

BIDIRECTIONAL SEAL

PHOENIX III METAL SEAL

VALVE

BODY

SEAL

RING

VALVE

BODY

SEAL RING

HUB SIDE

OF DISC

HIGH

PRESSURE

SHUTOFF

Figure 3. Maximum Pressure-Temperature Ratings

OPERATING TEMPERATURE,_C

PHOENIX III SEAL

WITH PTFE INSERT

PTFE AND

REINFORCED PTFE

UHMWPE

SEAL

A6306-2

Note:

Temperaturelimitationsdo not account for the additional limitations imposed by the backup ringused with this seal. To determine the effective temperature limitation of the appropriate

1

seal/backup ring combination,,refer to table 3.

OPERATING TEMPERATURE,_F

SEAL

5

Page 6

Product Bulletin

21.1:A41

January 2013

A41 Valve

D500212X012

Table 2. Flow Coefficients

VALVE SIZE,

NPS

2

3

4

6

8

10

12

1. Refer to Fisher Catalog 12 for a complete listing of flow coefficients.

(1)

CvFORWARD FLOW WITH DISC W IDE OPEN (90 DEGREES ROTATION)

CL150 CL300

80.2

286

499

1250

2180

3600

5400

80.2

237

488

1110

2070

3480

5130

Table 3. Construction Material Temperature Limits

COMPONENTS AND MATERIALS OF CONSTRUCTION

Valve Body Material

Carbon Steel

S31600

S31700

Disc Material

316

CG8M

Shaft Material

S20910

17-4PH

Bearing Material

PEEK / PTFE lined

Metal

Packing Material

PTFE V-rings

Graphite rings

Seal Ring

PTFE (Standard) -46 to232 -50 to450

Reinforced PTFE Soft Seal Ring -46 to232 -50 to450

UHMWPE Soft Seal Ring -18 to93 0 to200

NOVEX MetalSealRing -46 to538 -50 to1000

NPS2MetalSealring -46 to538 -50 to1000

Phoenix III MetalSealRing

Fluorocarbon backup ring -40 to232 -40 to450

Phoenix III Fire-Te sted

Fluorocarbon backup ring

(Specify metal bearings and graphite packing)

1. For component selection and applicable fire-tested standardsand codes, consult yourEmerson Process Management sales office.

(1)

MetalSealRing

TEMPERATURE LIMITS

_C _F

-29 to427

-198 to538

-198 to538

-198 to538

-198 to538

-198 to538

-62 to427

-73 to260

-198 to538

-46 to232

-198 to438

(1) (1)

-20 to800

-325 to1000

-325 to1000

-325 to1000

-325 to1000

-325 to1000

-80 to800

-100 to500

-325 to1000

-50 to450

-325 to1000

6

Page 7

A41 Valve

D500212X012

Figure 4. Flow Direction

Product Bulletin

21.1:A41

January 2013

RETAINER RING SIDE

MFG LABEL

FLOW ARROW

ARROW SHOWS PREFERRED FLOW DIRECTION FOR SOFT

SEALS AND NPS 2 METAL SEAL

FORWARD FLOW REVERSE FLOW

RETAINER RING SIDE

MFG LABEL

FLOW ARROW

ARROW SHOWS FLOW DIRECTION FOR NOVEX METAL SEAL,

ANDPREFERRED FLOW DIRECTION FORPHOENIX METAL SEAL

REVERSE

FLOW

FORWARD

FLOW

75B1181-A

A6881-2

Note:

1. By Emerson Process Management definition: Forward flow is into the face side of the disc. Reverse flow is into the hubside of the disc.

FACE SIDE OF DISC

7

Page 8

Product Bulletin

21.1:A41

January 2013

A41 Valve

D500212X012

Installation

It is recommended that the valve drive shaft be

mounted in a horizontal position. Operating

conditions may require specific valve/actuator fail

action, styles, positions and flow direction. Valves with

NOVEX seal rings require mounting in the reverse flow

direction. Refer to figure 4. Large valve/actuator

assemblies may require additional support because of

the combined weight.

Fail Action: For actuators with spring returns, spring

fail action is available for: fail-to-open or fail-to-close

valveaction.Thevalveaction is field reversible.

For assistance in selecting the valve/actuator

mounting suited to your application, consult your

Emerson Process Management sales office.

Dimensions for wafer-style and single-flanged valves

are shown in figure 6.

8

Page 9

A41 Valve

D500212X012

Figure 5. Packing Arrangements

Product Bulletin

21.1:A41

January 2013

PACKING

FOLLOWER

PTFE V-RING PACKING

PACKING FLANGE

SPRING PACK

ASSEMBLY

ANTI-EXTRUSION

RING

PACKING SET

PACKING SET

PACKING RING

PACKING BOX

RING

STANDARD PACKING

ENVIRO-SEAL PTFE PACKING SYSTEM

1

GRAPHITE RIBBON PACKING

PACKING FLANGE

NUT

LUBRICANT

PACKING FLANGE

STUD

PACKING BOX

RING

PACKING FLANGE

SPRING PACK

ASSEMBLY

PACKING SET

C0785*A

Note:

Includes zinc washers for graphite ribbon packing only.

1

PACKING FLANGE

NUT

LUBRICANT

PACKING FLANGE

STUD

PACKING BOX

RING

ENVIRO-SEAL GRAPHITE PACKING SYSTEM

9

Page 10

Product Bulletin

21.1:A41

January 2013

Figure 6. Typical Valve Dimensions (also see tables 4 and 5)

A41 Valve

D500212X012

R

R

G

WAFER STYLE VALVE

G

K

K

E

E

Y-4 CLEARANCE

HOLES

S

FLAT

LENGTH

S

Y

G

R

K

E

S

SINGLE-FLANGE VALVE

A

FLAT SIZE

T

14B0818-D

14B0829-D

14B0830-D

B2437-2

18A3110-E

18A9075-C

A7082

NPS 12 CL300

W

WAFER-STYLE VALVE

U

TYPICAL VALVE MOUNTING

FLAT LENGTH

R

S

GKE

NPS 2 A41

WAFER STYLE VALVE

WTHD

F

T

A

10

Page 11

Product Bulletin

A41 Valve

D500212X012

Table4.CL150ValveDimensions

Valve

Size,

NPS

A E

2 45 83 102 --- 102 --- 103 --- 9.50 25.4 79 --3 48 83 70 79 121 73 133 189 12.7 9.50 25.4 83 19

4 54 83 86 102 124 97 171 219 15.9 11.07 25.4 83 19

6 57 83 121 129 152 146 219 273 19.1 14.25 25.4 95 25

8 64 83 155 157 181 191 272 333 25.4 17.45 25.4 95 25

10 71 89 186 198 229 238 330 406 31.8 20.60 25.4 133 38

12 81 89 222 230 254 284 387 476 38.1 25.37 38.1 133 38

2 1.78 3.25 4.00 --- 4.00 1.88 4.06 --- 1/2 0.374 1 3.12 --- 1/2-13 ---

3 1.88 3.25 2.75 3.12 4.00 2.88 5.25 7.44 1/2 0.374 1 3.25 0.75 3/8-16 5/8-11 4-holes

4 2.12 3.25 3.38 4.00 4.88 3.81 6.75 8.62 5/8 0.436 1 3.25 0.75 3/8-16 5/8-11 8-holes

6 2.25 3.25 4.75 5.06 6.00 5.75 8.62 10.75 3/4 0.561 1 3.75 1.00 1/2-13 3/4-10 8-holes

8 2.50 3.25 6.12 6.19 7.12 7.50 10.69 13.12 1 0.687 1 3.75 1.00 1/2-13 3/4-10 8-holes

10 2.81 3.50 7.31 7.81 9.00 9.38 13.00 16.00 1-1/4 0.811 1 5.25 1.50 5/8-11 7/8-912-holes

12 3.19 3.50 8.75 9.06 10.00 11.19 15.25 18.75 1-1/2 0.999 1.5 5.25 1.50 5/8-11 7/8-912-holes

1. This nominal valve shaft diameter is the shaft diameterthrough the packing box. Use this diameter when selecting Fisher actuators.

2. Disc chordal swing diameter at valve face. Please verify clearance with piping.

Wafer

Style

G

Flange

Single

(2)

K

M

Wafer

Style

R

Single

Flange

Inches

mm

Flat

Size

Flat

Length

T U W

See thread

information

below

(1)

S

21.1:A41

January 2013

Y

Single Flange

Only

---

See thread

information

below

Table5.CL300ValveDimensions

Valve

Size,

NPS

A E

2 45 83 102 --- 102 --- 103 --- 9.50 25.4 79 ---

3 48 83 89 95 119 73 132 206 15.7 11.07 25.4 83 19

4 54 83 114 121 146 97 162 238 19.0 14.25 25.4 95 25

6 59 83 146 152 178 145 221 308 25.4 17.45 25.4 95 25

8 73 89 175 183 210 188 276 375 31.8 20.60 25.4 133 38

10 83 89 232 229 243 233 330 438 38.1 25.37 38.1 133 38

12 92 89 308 308 279 278 389 508 44.4 28.55 38.1 146 38

2 1.78 3.25 4.00 --- 4.00 1.88 4.06 --- 1/2 0.374 1 3.12 --- 1/2-13 ---

3 1.88 3.25 3.50 3.75 4.69 2.88 5.19 8.12 5/8 0.436 1 3.25 0.75 3/8-16 3/4-10 8-holes

4 2.12 3.25 4.50 4.75 5.75 3.81 6.38 9.38 3/4 0.561 1 3.75 1.00 1/2-13 3/4-10 8-holes

6 2.31 3.25 5.75 6.00 7.00 5.69 8.69 12.12 1 0.687 1 3.75 1.00 1/2-13 3/4-10 12-holes

8 2.88 3.50 6.88 7.19 8.25 7.38 10.88 14.75 1-1/4 0.811 1 5.25 1.50 5/8-11 7/8-912-holes

10 3.25 3.50 9.12 9.00 9.56 9.19 13.00 17.25 1-1/2 0.999 1.5 5.25 1.50 5/8-11 1-816-holes

12 3.62 3.50 12.12 12.12 11.00 10.94 15.31 20.00 1-3/4 1.124 1.5 5.75 1.50 3/4-10 11/8-816-holes

1. This nominal valve shaft diameter is the shaft diameterthrough the packing box. Use this diameter when selecting Fisher actuators.

2. Disc chordal swing diameter at valve face. Please verify clearance with piping.

WaferS

tyle

G

Single

Flange

(2)

K

M

Wafer

Style

R

Flange

Single

Inches

mm

Flat

Size

Flat

Length

T U W

See thread

informationb

elow

(1)

S

Y

Single FlangeOnly

---

See thread

information below

11

Page 12

Product Bulletin

21.1:A41

January 2013

A41 Valve

D500212X012

Neither Emerson, Emerson Process Man agement, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solely withthe purchaserand end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business unitof EmersonElectric Co.Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. We reserve the right to modify or improve the designs or specificationsof such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1991, 2013 Fisher Controls International LLC. All rightsreserved.

12

Loading...

Loading...