Emerson Fisher CV500, Fisher V500, Fisher V250, Fisher V260, Fisher Control-Disk Instruction Manual

...Page 1

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

Fisherr ENVIRO-SEALt Packing System

for Rotary Valves

November 2011

Contents

Introduction 1.................................

Scope of Manual 1.............................

Valve/Actuator Shaft Coupler 2..................

Description 2.................................

Installation 3..................................

Removing the Actuator 3.......................

Installing an ENVIRO-SEAL Packing System 4.......

Other Considerations 11........................

Parts Ordering 13...............................

Parts Kits 13...................................

Retrofit Kits 13................................

Repair Kits 16.................................

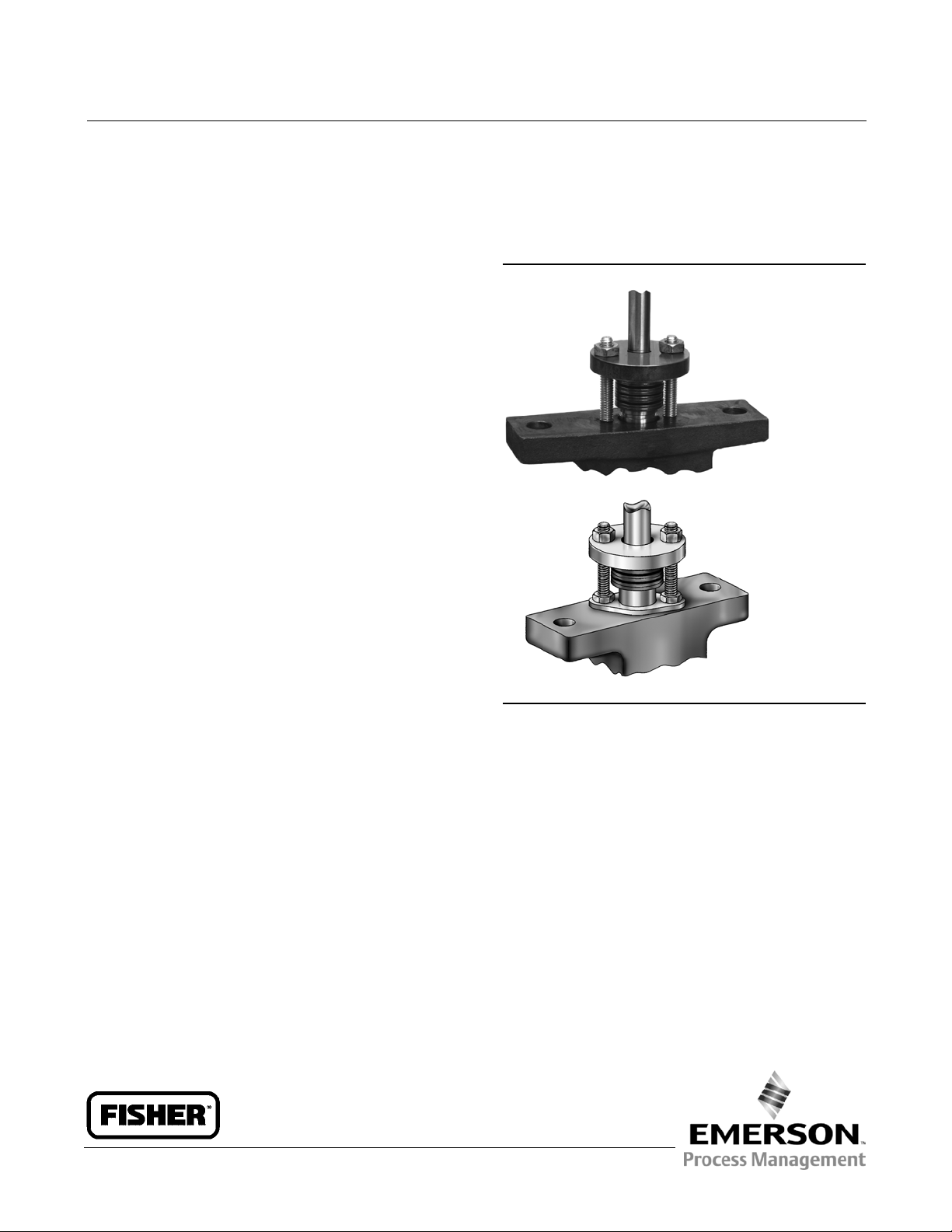

Figure 1. Typical ENVIRO-SEAL Packing System

W5882-1

W9058-1

ROTARY

BUTTERFLY

Introduction

Scope of Manual

This instruction manual includes installation and parts information for Fisher ENVIRO-SEAL live-loaded packing

systems(seefigure1).ThesesystemsareavailableforFisher rotary valves with 12.7 through 88.9 mm (1/2 through

3-1/2 inch) shaft diameters. The system can be used with many rotary valves, as shown in tables 1 and 3. Refer to

appropriate valve and actuator instruction manuals for necessary information relating to the disassembly and

assembly of the valve and actuator. ENVIRO-SEAL packing systems utilize a Belleville (coned-disk) spring system.

Do not install, operate, or maintain the ENVIRO-SEAL packing system, valve, actuator or accessories without being

fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal

injury or property damage, it is important to carefully read, understand, and follow all the contents of this manual,

including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson

Process Management sales office before proceeding.

www.Fisher.com

Page 2

ENVIRO-SEAL System - Rotary Valves

November 2011

Table 1. Specifications

Instruction Manual

D101643X012

Applicable Valve Designs

Fisher 8510B (single arrangements only), 8560 and

8532 eccentric disc control valves; A11, A31A, A31D

and A41 control valves; V150, V200 and V300

Vee-Ballt control valves (Series B & Non-Series B

(1)

);

V250 and V260 and BV500, CV500 and V500

eccentric plug rotary valves. Also see table 3.

1. Refer to Fisher Vee-Ball V150,V200 & V300 instruction manual, for distinctions between Series B & Non-Series B.

2. The pressure/temperature limits in this manual,in the valve literature, and any applicable code or standard limitation shouldnotbe exceeded.

Applicable Shaft Diameters

See table 3

Pressures and Temperatures

See table 2

(2)

Table 2. Maximum Application Temperature and Pressure for 100 PPM Service

ENVIRO-SEAL PACKING MATERIAL

Single PTFE 232 450 Not Restricted

Double PTFE

Graphite 316 600 Not Restricted

1. For pressure ratings through CL600 of valveslisted in this instruction manual.

2. These application conditions apply for double PTFE only in the valve types where double PTFE is available.

(2)

MAXIMUM APPLICATION TEMPERATURE

_C _F

177 350

MAXIMUM APPLICATION

PRESSURE

(1)

20.7 bar

(300 Psi)

(1)

Valve/Actuator Shaft Coupler

To install an ENVIRO-SEAL packing system on an A11, A31A, A31D, or 8532 valve with a non-standard, non-Fisher

produced actuator may require a special valve/actuator shaft coupler.

Table 10 contains a list of valve/actuator combinations and part numbers for the new coupler. If you are considering

installation of an ENVIRO-SEAL packing system in another existing valve/actuator package, check table 10 to see if a

new coupler is required.

In some cases, coupler replacement is not required when retrofitting valve/actuator combinations. Table 11 contains a

list of valve/actuator combinations that can use existing couplers.

Description

Fisher packing systems are offered with exceptional sealing capabilities that you can easily install in existing valves or

that you can purchase with new valves. These systems help you conserve valuable process fluid. The external

live-loading provides a constant load over the life of the packing material, which reduces the need for packing box

adjustment and maintenance.

The system design, coupled with very smooth shaft finishes and spring-loading of the packing, provides longer service

with lower maintenance than many other designs.

2

Page 3

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

November 2011

Installation

Use these instructions to install ENVIRO-SEAL packing in valves that have standard packing, or when inspecting or

replacing ENVIRO-SEAL packing.

If you are changing the packing system material from standard graphite to ENVIRO-SEAL graphite or ENVIRO-SEAL

PTFE packing, the packing friction for ENVIRO-SEAL packing will be lower than it was for the standard packing.

Therefore, no change should be needed in actuator sizing.

If you are changing the packing system material from standard PTFE to ENVIRO-SEAL graphite or ENVIRO-SEAL PTFE

packing, the packing friction will increase. Contact your Emerson Process Management sales office to determine if

your existing actuator will be large enough.

WARNING

Always wear protective gloves, clothing and eyewear when performing any maintenance operations to avoid personal

injury.

To avoid personal injury or property damage resulting from the sudden release of pressure, do not install the valve

assembly where service conditions could exceed the limits given in this manual, the appropriate valve instruction manual,

or the limits on the appropriate name plates. Use pressure relieving devices as required by government or accepted

industry codes and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Removing the Actuator section

in this instruction manual.

Removing the Actuator

WARNING

Avoid personal injury from sudden release of process pressure or uncontrolled movement of parts. Before performing any

maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. B e sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Uselock-outprocedurestobesurethattheabovemeasures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

3

Page 4

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

You must remove the actuator from the valve when you install ENVIRO-SEAL packing systems. To allow proper

readjustment of the valve disc position, it is recommended that you remove the valve from the pipeline. Refer to

appropriate valve and actuator instruction manuals.

WARNING

If a spring-return actuator is used, be sure the actuator spring is resting on its travel stop. If something is obstructing shaft

rotation, it is possible that disconnecting the shaft connector will allow the spring to force the actuator to the end of its

rotation, resulting in possible personal injury or property damage. Refer to the appropriate valve and actuator instruction

manuals to remove the actuator.

Installing an ENVIRO-SEAL Packing System

Note

When installing an ENVIRO-SEAL packing system into an insulated valve, do not cover the packing springs with insulation.

Note

The valve shaft surface condition is critical in obtaining a good seal. If the valve shaft surface is scratched, nicked, or worn, replace

the valve shaft before installing the ENVIRO-SEAL Packing System.

Refer to the appropriate valve instruction manual to replace the valve shaft.

Key number locations are shown in figures 2 and 4 for Vee-Ball, eccentric plug, 8560, and A41 valves, and in figures 3

and 5 for A11, A31A, A31D and 8532 valves.

1. If you are installing an ENVIRO-SEAL packing system in an existing valve, remove existing packing nuts, packing

flange, jam nuts, anti-blowout flange, packing follower, and any other external packing components from the valve

body.

CAUTION

Because the valve shaft surface condition is critical in obtaining a good seal, caution must be used when removing existing

internal packing parts. Do not scratch, nick or dent the valve shaft.

2. For A11, A31A, A31D and 8532 valves, remove the anti-blowout wire that surrounds the valve shaft.

3. For all valves, remove packing and all other internal components from the packing box.

4. Inspect the existing valve shaft. If necessary, replace the valve shaft. Refer to the appropriate valve instruction

manual to replace the valve shaft.

4

Page 5

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

November 2011

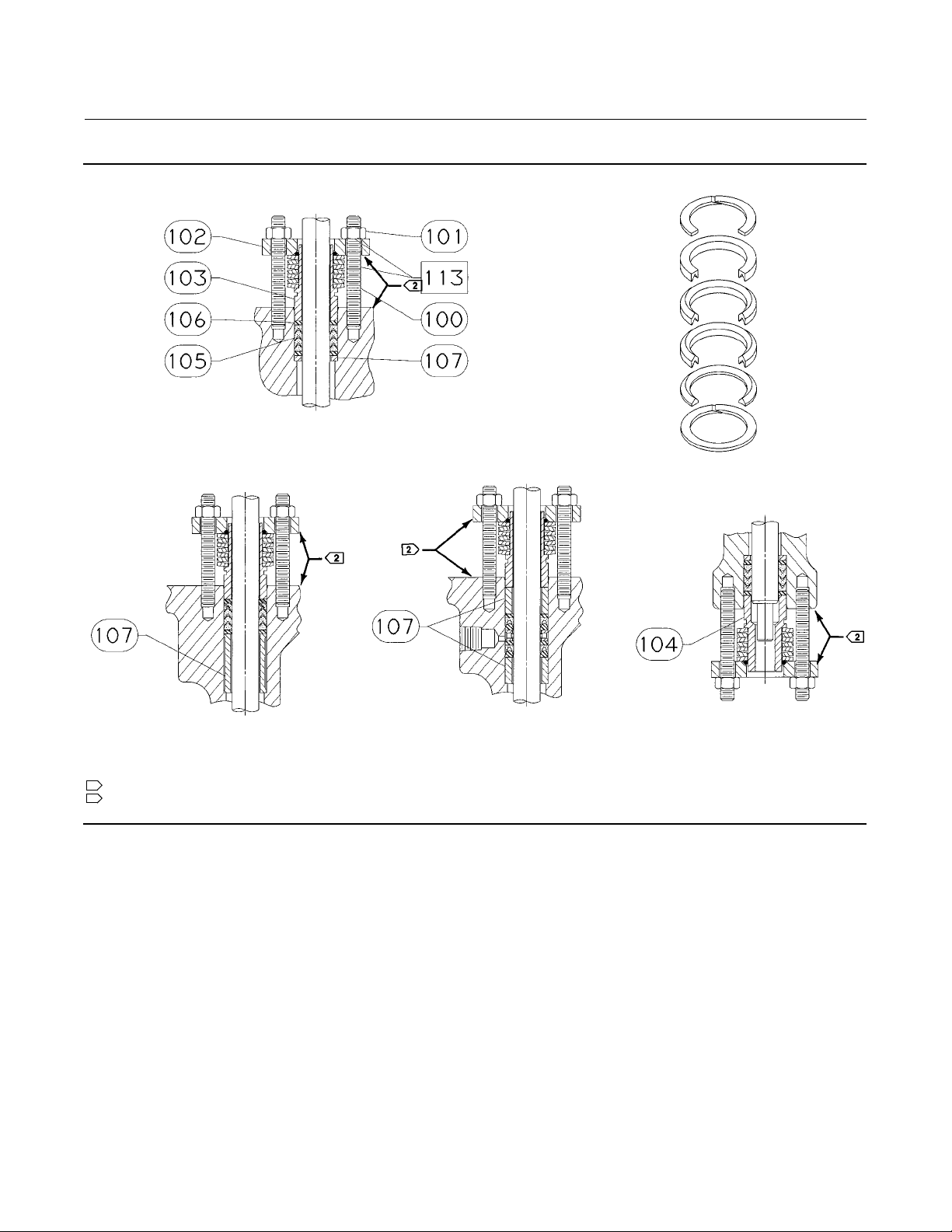

Figure 2. Typical ENVIRO-SEAL Rotary Packing Arrangements with PTFE Packing for Fisher Vee-Ball, Eccentric Plug,

A41, and 8560 Valves

42B8445-C

SINGLE PTFE PACKING

STANDARD DEPTH BOX

14B0095-A

STACKING ORDER

PTFE PACKING RINGS

42B8445-C

SINGLE PTFE PACKING

OPTIONAL DEEP PACKING BOX

V500

NOTES:

APPLY LUBRICANT

1

THESE TWO SURFACES MUST REMAIN PARALLELAS YOU ALTERNATELY AND EVENLY TIGHTEN THE PACKING NUTS (KEY101)

2

42B8445-C

DOUBLE PTFE PACKING WITH LEAKOFF

OPTIONAL DEEP PACKING BOX

V500, CV500

42B8445-C

SINGLE PTFE PACKING, OUTBOARD

STANDARD DEPTH BOX

8510B

5

Page 6

ENVIRO-SEAL System - Rotary Valves

November 2011

Note

ENVIRO-SEAL PTFE packing systems can be used in either vacuum or positive pressure service. It is not necessary to reverse

ENVIRO-SEAL PTFE packing components in vacuum service.

Make sure that the Belleville springs are stacked properly and packing box parts are assembled in t he correct order (see figure 6).

Packing parts cannot function properly if the Belleville springs or other packing parts are not stacked correctly.

Instruction Manual

D101643X012

5. With the shaft in place in the valve, install the packing parts into the valve packing box.

Note

Be sure to install the packing rings in the sequence shown in figures 2 through 5.

a. Place one of the packing box rings (key 107) into the packing box. Be sure the packing box ring is properly seated.

ThisdoesnotapplytoNPS3,4and6CL600A11valves.

b. For PTFE packing, place an anti-extrusion washer (key 106) into the packing box and push it in until it rests next

to the packing box ring (key 106 is not used with graphite packing).

Note

The graphite packing set has a carbon anti-extrusion ring on the top and bottom of the packing. These anti-extrusion rings are

designed to have a slight interference fit on the shaft. The rings have a single fracture to allow the ring to be installed on the shaft.

Additional fractures may develop while the valve is in service, however, these additional fractures will not affect the performance

of the ENVIRO-SEAL packing.

c. Place the packing set (key 105) into the packing box. Refer to figure 3 or 5 for the proper orientation of the

packing set.

d. For PTFE packing, place another anti-extrusion washer (key 106) into the packing box after the packing set (key

106 is not used with graphite packing).

e. Place the second packing box ring (key 107) into the packing box.

f. Locate the new spring pack assembly (key 103). Remove the O-ring and packing springs from the packing

follower. Use the packing follower to press the packing components into the packing box. Remove the packing

follower.

6. For A11, A31A, A31D and 8532 valves, install the anti-blowout wire (key 16) in the groove around the valve shaft.

7. Slide the packing follower from the new spring pack assembly over the valve shaft and the anti-blowout wire until it

rests against the packing box ring.

8. For all valves, install the longer packing studs (key 100).

9. For A11, A31A, A31D and 8532 valves, install the new anti-blowout flange (key 10) over the valve shaft, packing

studs, and packing follower. Secure the anti-blowout flange with the new jam nuts (key 17).

10. For all valves, install the spring pack assembly (key 103 or 104) which includes the Belleville springs, packing

follower, and O-ring arranged as shown in figures 2 through 6. (The O-ring is a non-functional part and is used to

retain the packing springs during assembly.)

6

Page 7

Instruction Manual

ENVIRO-SEAL System - Rotary Valves

D101643X012

Figure 3. ENVIRO-SEAL PTFE Packing System for Fisher 8532, A11, A31A and A31D Valves

32B9116-B

NOTES:

NOT USED ON VALVES LARGER THAN NPS12

1

NOT USED ON A11

2

NOT USED ON A11 CL600, NPS3,4, AND 6

3

November 2011

14B0095-A

3

STACKING ORDER OF

PTFE PACKING RINGS

11. Install the packing flange (key 102) on the shaft, and install the packing nuts (key 101). Hand tighten them.

Note

In general, the following tightening procedure applies to a ll ENVIRO-SEAL packing systems–both sliding-stem and rotary.

CAUTION

Excessive force could cause valve body bushing displacement in Non-Series B Vee-Ball valves, allowing Vee-Ball

misalignment, excessive seat leakage, or stalling of the actuator.

Note

Lubrication is required for the packing studs and nuts. Although it is important to properly lubricate the stud threads and internal

nut threads, it is also important to properly lubricate the contacting face of the nut. See figures 2 through 5 and 7 for lubrication

locations.

7

Page 8

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

Figure 4. Typical ENVIRO-SEAL Rotary Packing Arrangements with Graphite Packing for Fisher Vee-Ball, Eccentric

Plug, A41, and 8560 Valves

2

42B8445-C/DOC

GRAPHITE PACKING

STANDARD DEPTH BOX

3

3

14B0086-A/DOC

STACKING ORDER

GRAPHITE PACKING RINGS

42B8445-C/DOC

GRAPHITE PACKING, OUT-

BOARD

STANDARD DEPTH BOX

8510B

NOTES:

APPLY LUBRICANT

1

THESE TWO SURFACES MUST REMAIN PARALLEL AS YOU ALTERNATELY AND

2

EVENLY TIGHTEN THE PACKING NUTS (KEY 101)

3

VALVE WITH SHAFTS LARGER THAN 38.1 mm (1-1/2 INCH) USE THREE GRAPHITE RINGS

1

2

2

42B8445-C/DOC

3

GRAPHITE PACKING

OPTIONAL DEEP PACKING BOX

V500

Note the following definitions. You will need them for the next few steps. The target load isthepointwherethe

Belleville springs are designed for optimum performance, when they are compressed to 85% of their maximum

deflection, or nearly flat. Maximum deflection is when the springs are 100% compressed, or completely flat.

12. You will obtain maximum benefit from your ENVIRO-SEAL packing system when you tighten the packing flange

nuts and compress the Belleville springs to their “target load”.

To obtain the target load of 85% compression of maximum deflection, perform the following:

D Tighten the packing flange nuts alternately and evenly, keeping the packing flange parallel with the valve flange

(see figure 7), until the Belleville springs are compressed 100% (or completely flat).

8

Page 9

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

Figure 5. ENVIRO-SEAL Graphite Packing System for Fisher 8532, A11, A31A and A31D Valves

14B0086-A

STACKING ORDER OF

GRAPHITE PACKING RINGS

NOTES:

VALVES WITH SHAFTS LARGER THAN38.1mm (1-1/2 INCH) USE 3 GRAPHITE RINGS

1

NOT USED ON VALVES LARGER THAN NPS12

2

NOT USED ON A11 VALVES

3

NOT USED ON A11 CL600 NPS 3, 4, AND 6

4

32B9116-B

November 2011

4

CAUTION

Do not use pneumatic air tools. Do not apply torque in excess of 34 NSm(25ftSlbs) increments to any one flange nut at a

time. Excessive over-torquing of the flange nuts may cause the studs to break.

D For PTFE packing, loosen each packing flange nut 1/2 turn (180_ of rotation).

D For graphite packing, loosen each packing flange nut 1/4 turn (90_ of rotation).

The “target load” of 85% compression has now been reached.

13. Install the actuator. Refer to the appropriate valve and actuator instruction manuals when connecting the valve to

the actuator.

Under normal conditions, the packing nuts should not require re-tightening.

However, when servicing, if the springs do not remain at the target load of 85% compression, retighten the packing

boxnutsaccordingtostep11above.

9

Page 10

ENVIRO-SEAL System - Rotary Valves

November 2011

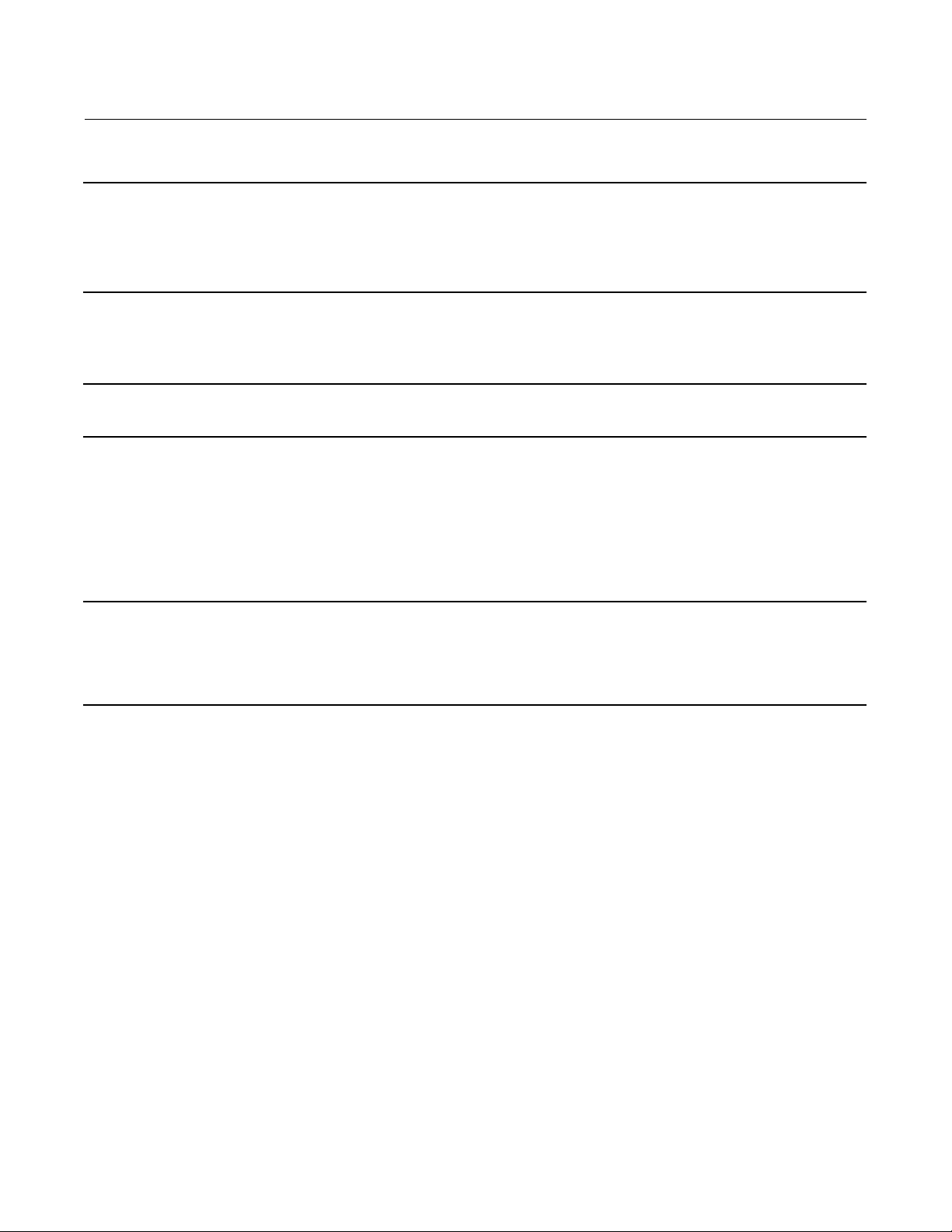

Figure 6. Belleville Spring Stacking Order

Instruction Manual

D101643X012

O-RING

BELLEVILLE

SPRINGS (10)

PACKING

FOLLOWER

GRAPHITE

A41, ECCENTRIC DISC, ECCENTRIC PLUG, AND VEEBALL VALVES: SIZE 12.7 & 15.9 (1/2 AND 5/8) SHAFT

A11 and A31A: SIZE 14.3 (9/16) SHAFT

O-RING

BELLEVILLE

SPRINGS (9)

O-RING

BELLEVILLE

SPRINGS (6)

PACKING

FOLLOWER

GRAPHITE

A41, ECCENTRIC DISC, ECCENTRIC PLUG, AND VEEBALL VALVES: SIZE 19.1(3/4), 38.1 (1-1/2),44.5 (1-3/4), 53.8

(2-1/8), 63.5 (2-1/2), 76.2 (3) AND 88.9 (3-1/2) SHAFT

A11: SIZE 19.2 - 88.9 (3/4 - 3-1/2) SHAFT

A31A: SIZE 17.5 - 31.8 (11/16 - 1-1/4) SHAFT

O-RING

BELLEVILLE

SPRINGS (7)

O-RING

BELLEVILLE

SPRINGS (5)

PACKING

FOLLOWER

PTFE

A41, ECCENTRIC DISC, ECCENTRIC PLUG,

AND VEE-BALL VALVES:

SIZE 12.7 AND 15.9 (1/2 AND 5/8) SHAFT

A11 and A31A: SIZE 14.3 (9/16) SHAFT

B2410-2

PACKING

FOLLOWER

PTFE

A41, ECCENTRIC DISC, ECCENTRIC PLUG, AND

VEE-BALL VALVES:

SIZE 19.1 (3/4), 22.2 (7/8), AND 25.4 (1) SHAFT

A11: SIZE 14.3 AND 19.1 (9/16 AND 3/4) SHAFT

A31A: SIZE 17.5 AND 23.8 (11/16 AND 15/16) SHAFT

PACKING

FOLLOWER

PTFE

A41, ECCENTRIC DISC, ECCENTRIC PLUG, AND

VEE-BALL VALVES: SIZE 19.1 (3/4), 38.1 (1-1/2), 44.5

(1-3/4), 53.8 (2-1/8), 63.5 (2-1/2), 76.2 (3) AND 88.9 (3-1/2)

SHAFT

A11: SIZE 28.5 - 88.9 (1-1/8 - 3-1/2) SHAFT

A31A: SIZE 28.5 - 63.5 (11/16 - 2-1/2) SHAFT

mm (INCH)

10

Page 11

Instruction Manual

D101643X012

Figure 7. ENVIRO-SEAL PTFE Packing System Detail

32B9116-B

NOTES:

1

APPLY LUBRICANT

THESE TWO SURFACES MUST REMAINPARALLEL AS YOU ALTERNATELYAND EVENLY TIGHTEN THE PACKING NUTS.

2

Other Considerations

ENVIRO-SEAL System - Rotary Valves

November 2011

Note

The following check is only valid for rotary ENVIRO-SEAL packing systems and sliding-stem ENVIRO-SEAL or HIGH-SEAL packing

systems.

When retrofitting an existing packing system or repacking a valve with ENVIRO-SEAL packing that has been in service,

check the condition of the packing bore after you have removed the packing. An easy method for cleaning debris and

minor imperfections from the bore is to use a brake cylinder hone attached to an electric drill. This method will do a

good job of cleaning the packing bore without changing the dimension of the bore.

When you have completed this exercise, a good guideline to use in checking the condition of the packing bore is the

20/20 rule. If less than 20% of the surface area of the bore is pitted and if no pits are deeper than 0.020 inch, then your

packing will work fine. This does not need to be an exact measurement; visual inspection is adequate. If the packing

bore does not meet this criteria, however, you should replace the valve or have your Emerson Process Management

service center repair it.

11

Page 12

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

Table 3. Applicable Valve Sizes

NPS

2

3

4

6

8

10

12

14

16

18

20

24

14

16

18

20

24

2

3

4

6

8

10

12

2

3

4

6

8

10

12

1

1-1/2

2

3

4

6

8

10

12

14

16

20

1

1-1/2

2

3

4

6

8

10

1

1-1/2

2

3

4

6

8

10

12

14

16

(1)

PRESSURE

CLASS

See Bulletin

51.6:8560

150

300

150

300

150

150/300/

600

300

and Shaft Diameters

VALVE

8510B

8532

8560

V150

V200

V300

VALVE SIZE,

VALVE SHAFT DIAMETER

mm Inches

12.7

15.9

19.1

25.4

31.8

31.8

38.1

34.9

38.1

44.5

50.8

63.5

50.8

57.2

63.5

76.2

88.9

12.7

12.7

15.9

19.1

25.4

31.8

38.1

12.7

15.9

19.1

25.4

31.8

38.1

44.5

12.7

15.9

15.9

19.1

19.1

25.4

31.8

31.8

38.1

44.5

54

63.5

12.7

15.9

15.9

19.1

19.1

25.4

31.8

31.8

12.7

15.9

15.9

19.1

19.1

25.4

31.8

31.8

38.1

44.5

54

1/2

5/8

3/4

1

1-1/4

1-1/4

1-1/2

1-3/8

1-1/2

1-3/4

2

2-1/2

2

2-1/4

2-1/2

3

3-1/2

1/2

1/2

5/8

3/4

1

1-1/4

1-1/2

1/2

5/8

3/4

1

1-1/4

1-1/2

1-3/4

1/2

5/8

5/8

3/4

3/4

1

1-1/4

1-1/4

1-1/2

1-3/4

2-1/8

2-1/2

1/2

5/8

5/8

3/4

3/4

1

1-1/4

1-1/4

1/2

5/8

5/8

3/4

3/4

1

1-1/4

1-1/4

1-1/2

1-3/4

2-1/8

Table 3. Applicable Valve Sizes

and Shaft Diameters (cont.)

VALVE

BV500

CV500

V500

A31A & A31D

A41

A11

1. Shaft Diameter through thepackingbox.

VALVE SIZE,

NPS

1

1-1/2

2

3

4

6

3

4

6

8

10

12

1

1-1/2

2

3

4

6

8

10

3

4

6

8

10

12

14

16

18

20

24

3

4

6

8

10

12

14

16

18

20

24

2

3

4

6

8

10

12

2

3

4

6

8

10

12

3

4

6

8

10

12

14

16

18

PRESSURE

CLASS

150/300

150/300/

600

150/300/

600

150

300

150

300

600

VALVE SHAFT DIAMETER

mm Inches

15.9

15.9

15.9

15.9

25.5

25.5

25.4

31.8

38.1

38.1

44.5

53.8

12.7

15.9

15.9

25.4

31.8

31.8

38.1

44.5

14.3

17.5

23.8

23.8

28.5

31.8

34.9

38.1

44.5

50.8

63.5

14.3

17.5

23.8

31.8

41.3

47.6

50.8

57.2

63.5

76.2

88.9

12.7

12.7

15.9

19.1

25.4

31.8

38.1

12.7

15.7

19.0

25.4

31.8

38.1

44.4

14.3

19.1

28.5

38.1

44.5

57.2

63.5

76.2

88.9

5/8

5/8

5/8

5/8

1

1

1

1-1/4

1-1/2

1-1/2

1-3/4

2-1/8

1/2

5/8

5/8

1

1-1/4

1-1/2

1-1/2

1-3/4

9/16

11/16

15/16

15/16

1-1/8

1-1/4

1-3/8

1-1/2

1-3/4

2

2-1/2

9/16

11/16

15/16

1-1/4

1-5/8

1-7/8

2

2-1/4

2-1/2

3

3-1/2

1/2

1/2

5/8

3/4

1

1-1/4

1-1/2

1/2

5/8

3/4

1

1-1/4

1-1/2

1-3/4

9/16

3/4

1-1/8

1-1/2

1-3/4

2-1/4

2-1/2

3

3-1/2

12

Page 13

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

November 2011

Parts Ordering

Each valve assembly is assigned a serial number that can be found on the valve body. Refer to the serial number when

contacting your Emerson Process Management sales representative for technical assistance.

When ordering replacement parts, refer to the serial number and to the 11-character kit number for each kit required

from the following list. Kits for valves with shaft sizes greater than 38.4 mm (1-1/2 inch) will not be available, however,

ENVIRO-SEAL parts may be ordered separately. Consult your Emerson Process Management sales office for details.

Parts Kits

Retrofit Kits

Retrofit kits include all parts required for installation of the ENVIRO-SEAL packing system into existing rotary and high

performance butterfly valves. Retrofit kits are available for single PTFE or graphite packing. See tables 5 through 7 for

retrofit kit part numbers.

The 8510B has two packing boxes, one at the actuator end and one at the outboard end. Select a kit from each column

of the following table.

Packing boxes in V500 and CV500 valve bodies may be deep drilled, (at one time standard on all CV500 and always

available as an option). If the valve body being retrofitted has a deep packing box, use the longer packing box ring (key

107) from the original packing. Discard the 3 mm (1/8-inch) packing box ring from the retrofit kit. If a replacement

packing box ring (long, key 107) is required, refer to the valve instruction manual for parts, or consult your Emerson

Process Management sales office. Refer to figure 2, the view titled: Double PTFE Packing with Leakoff–Optional Deep

Packing Box.

Note

1. Use the existing long packing box ring (key 107) that was furnished with the original valve when installing the retrofit kit in:

•V200 NPS 8 and 10 valves, or

•V150 and V300 NPS 8, 10, and 12 valves

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

13

Page 14

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

Table 4. Retrofit Kit Included Parts

Key Description Quantity

(5)

10

(5)

17

100

101

102

103

104

105

106

107

111

112

1.For use on Actuator end. Thespring pack assembly is made up of the packing spring stack held in place by an O-ring on the packingfollower.

2. For use on Outboard end. The spring packassemblyis made up of the packing spring stack held in place by an O-ring on the packing follower.

3. Not included in graphite packing kit.

4. Only 1 req'd for NPS 18 CL300,NPS 20 CL150 and NPS 24 CL150. Two packing box rings required for 8560, 44.5 mm (1-3/4inch)shaft. Not required on V150, V200 or V300 with 31.8 or 38.1

mm (1-1/4 or 1-1/2 inch) shafts.

5. These are included in retrofit kitsfor8532, A11, A31A and A31D valves.

6. NPS 3 through 12 CL150 andNPS3through 8 CL300 for A31A, 8532 and A31D; NPS 3 through 6 CL600,A11.

7. NPS 14 through 24 CL150/300 forA31A,8532 and A31D; NPS 8 through 18 CL600, A11.

Anti-blowout follower

Jam nut

Packing stud

Packing nut

Packing flange

Spring pack assembly

Spring pack assembly

Packing Set

Anti-extrusion washer

Packing box ring

Tag

Cable

(5)

(5)

(1)

(2)

1

1

(6)

(7)

2

or 4

(6)

(7)

2

or 4

1

1

1

1

(3)

2

(4)

2

1

1

Table 5. Retrofit Kits for Fisher Vee-Ball, Eccentric Plug, 8560 and 8510B Valves with Spline Shafts

PTFE RETROFIT KITS

SHAFT DIAMETER, mm (INCH)

Actuator End

PACKING BOX END

Outboard End for

8510B Only

12.7 (1/2) RRTYXRT0012 RRTYXRT0082 RRTYXRT0312 RRTYXRT0382

15.9 (5/8) RRTYXRT0022 RRTYXRT0092 RRTYXRT0322 RRTYXRT0392

19.1 (3/4) RRTYXRT0032 RRTYXRT0102 RRTYXRT0332 RRTYXRT0402

25.4 (1) RRTYXRT0052 RRTYXRT0112 RRTYXRT0352 RRTYXRT0412

31.8 (1-1/4) RRTYXRT0062 RRTYXRT0122 RRTYXRT0362 RRTYXRT0422

38.1 (1-1/2)

8560 NPS 10 (CL 300)

8560 NPS 12 (CL 150)

44.5 (1-3/4)

8560 NPS 12 (CL 300)

V500 NPS 10

RRTYXRT0072

RRTYXRT0672

RRTYXRT0672

RRTYXRT0682

RRTYXRT0692

RRTYXRT0702

RRTYXRT0132

---

---

RRTYXRT0762

---

---

RRTYXRT0372

RRTYXRT0812

RRTYXRT0812

RRTYXRT0822

RRTYXRT0832

RRTYXRT0842

54 (2-1/8) RRTYXRT0722 --- RRTYXRT0862 ---

63.5 (2-1/2) RRTYXRT0732 RRTYXRT0782 RRTYXRT0872 RRTYXRT0922

GRAPHITE RETROFITKITS

PACKING BOX END

Actuator End

Outboard End for

8510B Only

RRTYXRT0432

---

---

RRTYXRT0902

---

---

Table 6. Retrofit Kits for Fisher Vee-Ball, Eccentric Plug, 8510B and A41 valves with Double D and Keyed End

Connection

PTFE RETROFIT KITS PACKING BOX END GRAPHITE RETROFIT KITS PACKING BOX END

SHAFT DIAMETER, mm (INCH)

12.7 (1/2) RRTYXRT0972 RRTYXRT0082 RRTYXRT1072 RRTYXRT0382

15.9 (5/8) RRTYXRT0982 RRTYXRT0092 RRTYXRT1082 RRTYXRT0392

19.1 (3/4) RRTYXRT0992 RRTYXRT0102 RRTYXRT1092 RRTYXRT0402

25.4 (1) RRTYXRT1012 RRTYXRT0112 RRTYXRT1102 RRTYXRT0412

31.8 (1-1/4) RRTYXRT1022 RRTYXRT0122 RRTYXRT1112 RRTYXRT0422

38.1 (1-1/2) RRTYXRT1032 RRTYXRT0132 RRTYXRT1122 RRTYXRT0432

44.5 (1-3/4) RRTYXRT1042 RRTYXRT0762 RRTYXRT1132 RRTYXRT0902

54 (2-1/8) RRTYXRT1052 --- RRTYXRT1142 ---

63.5 (2-1/2) RRTYXRT1062 RRTYXRT0782 RRTYXRT1152 RRTYXRT0922

14

Actuator End

Outboard End for

8510B Only

Double D

Keyed

Actuator End

Outboard End for

8510B Only

Page 15

Instruction Manual

ENVIRO-SEAL System - Rotary Valves

D101643X012

Table 7. Retrofit Kit Part Numbers for Fisher 8532, A31A, A31D and A 11 Butterfly Valves

8532, A31A, A31D

Shaft

Valve Size, NPS Pressure Class

3 150, 300 14.3 (9/16) RRTYXRT0202 RRTYXRT0502

4 150, 300 17.5 (11/16) RRTYXRT0212 RRTYXRT0512

6 150, 300 23.8 (15/16) RRTYXRT0222 RRTYXRT0522

8

10

12

14

16

18

20 150 50.8 (2) RRTYXRT0652

24 150 63.5 (2-1/2) RRTYXRT0662

Valve Size, NPS Pressure Class Shaft Diameter

3

4 19.1 (3/4) 14B3988X012 14B3989X012

6 28.6 (1-1/8) 12B4105X012 12B4107X012

8 38.1 (1-1/2) 13B9289X012 14B3985X012

10 44.5 (1-3/4) 13B9285X012 13B9286X012

12 57.2 (2-1/4) 14B1323X012 14B3978X012

14 63.5 (2-1/2) 12B4111X012 12B4116X012

16 76.2 (3) 14B5651X022 14B5660X022

18 88.9 (3-1/2) 14B5729X042 14B5736X042

1. Shaft diameter: Diameter throughthepacking box.

2. For larger shaft sizes,consultyour Emerson Process Management sales office.

150 23.8 (15/16) RRTYXRT0232 RRTYXRT0532

300 31.8 (1-1/4) RRTYXRT0242 RRTYXRT0542

150 28.5 (1-1/8) RRTYXRT0252 RRTYXRT0552

300 41.3 (1-5/8) RRTYXRT0572 --150 31.8 (1-1/4) RRTYXRT0262 RRTYXRT0562

300 47.6 (1-7/8) RRTYXRT0582

150 34.9 (1-3/8) RRTYXRT0592

300 50.8 (2) RRTYXRT0602

150 38.1 (1-1/2) RRTYXRT0612

300 57.2 (2-1/4) RRTYXRT0622

150 44.5 (1-3/4) RRTYXRT0632

300 63.5 (2-1/2) RRTYXRT0642

A11

600

Diameter

(1)(2)

mm (Inch)

14.3 (9/16) 12B4122X012 12B4125X012

,

November 2011

Retrofit Kits

PTFE Graphite

PTFE Retrofit

Kits

Retrofit Kits

---

Graphite

15

Page 16

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

Repair Kits

PTFE repair kits include one packing set and two anti-extrusion washers. Graphite packing sets include two packing

rings and two anti-extrusion rings. See table 8.

The 8510B has two packing boxes, one at the actuator end and one at the outboard end. A quantity of two of the

appropriate kit is required to repair both ends.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Table 8. Repair Kits for Fisher Vee-Ball, Eccentric Plug, 8560, 8510B and A41 Valves

Shaft Diameter mm (Inch) PTFE Kits Graphite Packing Set

12.7 (1/2)

15.9 (5/8)

19.1 (3/4)

25.4 (1)

31.8 (1-1/4)

38.1 (1-1/2)

44.5 (1-3/4)

54.0 (2-1/8)

63.5 (2-1/2)

RRTYX000012

RRTYX000022

RRTYX000032

RRTYX000052

RRTYX000062

RRTYX000072

RRTYX000232

RRTYX000252

RRTYX000262

13B8816X012

13B8816X032

13B8816X052

13B8816X092

13B8816X112

13B8816X142

13B8816X152

13B8816X182

13B8816X162

16

Page 17

Instruction Manual

ENVIRO-SEAL System - Rotary Valves

D101643X012

Table 9. Repair Kit Part Numbers for Fisher 8532, A31A, A31D and A11 Butterfly Valves

8532, A31A, A31D

Valve Size,

NPS

3 150, 300 14.3 (9/16) RRTYX000112 13B8816X022

4 150, 300 17.5 (11/16) RRTYX000122 13B8816X042

6 150, 300 23.8 (15/16) RRTYX000132 13B8816X082

8

10

12

14

16

18

20 150 50.8 (2) RRTYX000182

24 150 63.5 (2-1/2) RRTYX000222

Valve Size, NPS Pressure Class Shaft Diameter PTFE Packing Kits

3

4 19.1 (3/4) 12B7414X012 12B7418X012 13B8816X052 16A6084X012

6 28.6 (1-1/8) 12B9078X012 12B9084X012 13B8816X102 12B9077X012

8 38.1 (1-1/2) 12B7462X012 12B7466X012 13B8816X142 16A6087X012

10 44.5 (1-3/4) 13B9155X012 13B9159X012 14B3541X032 13B9160X012

12 57.2 (2-1/4) 14B3647X012 14B3642X012 14B3541X052 13B2187X012

14 63.5 (2-1/2) 12B7782X012 12B7783X012 14B3541X042 13B8709X012

16 76.2 (3) 14B5652X012 14B5656X012 14B3541X062 18A4189X012

18 88.9 (3-1/2) 14B5730X012 14B5734X012 14B3541X072 14B5735X012

1. Shaft diameter: Diameter throughthepacking box.

2. For larger shaft sizes,consultyour Emerson Process Management sales office.

3. The A11 requires 2 Anti-Extrusion Rings.

Pressure Class

150 23.8 (15/16) RRTYX000132 13B8816X082

300 31.8 (1-1/4) RRTYX000142 13B8816X122

150 28.5 (1-1/8) RRTYX000092 13B8816X102

300 41.3 (1-5/8) RRTYX000152 --150 31.8 (1-1/4) RRTYX000142 13B8816X122

300 47.6 (1-7/8) RRTYX000162

150 34.9 (1-3/8) RRTYX000172

300 50.8 (2) RRTYX000182

150 38.1 (1-1/2) RRTYX000192

300 57.2 (2-1/4) RRTYX000202

150 44.5 (1-3/4) RRTYX000212

300 63.5 (2-1/2) RRTYX000222

600

Shaft

Diameter

(1)(2)

mm (Inch)

,

14.3 (9/16) 12B9122X012 12B9121X012 13B8816X022 12B9118X012

PTFE Graphite Packing Set

A11

Extrusion Ring

Anti-

Repair Kits

Graphite Packing

(3)

---

Kits

November 2011

Packing Box Ring

17

Page 18

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

A coupler is required for the following valve/actuator combinations when retrofitting an existing A31A or A31D with an

ENVIRO-SEAL packing system.

Table 10. Coupler Part Number for Fisher A31A or A31D Valves with Selected Actuators

SHAFT DIAMETER,

mm (INCH)

14.3 (9/16)

17.5 (11/16)

23.8 (15/16)

28.5 (1-1/8)

31.8 (1-1/4)

Valve Size Actuator Type

NPS 3 CL150/300

NPS 3 CL150/300

NPS 3 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 6 CL150/300, NPS 8 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 10 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

Fisher 1032 XL70 thru XL280

Fisher 1032 XL425 thru XL680

D and S Series (Elomatic) SR15

Fisher 1032 XL185 thru XL280

Fisher 1032 XL425 thru XL680

Bettis HD 521, 721, 722

DandSSeries(Elomatic)S20

Fisher 1031 Size 26

Fisher 1031 Size 33

Fisher 1032 XL680-XL1370

5M Gear

Bettis CB 315

Bettis CB 415

Bettis CB 420

Bettis CB 520

Bettis CB 525

Bettis CB 725

Bettis HD 251.5

Bettis HD 521, 721, 722

Fire Sentry

Limitorque T-100

Fisher 1031 Size 26

Fisher 1031 Size 33

Fisher 1032 XL680-XL1370

Bettis CB 525

Bettis CB 725

Bettis HD 521, 721, 722

Fire Sentry

Limitorque T-100

Fisher 1031 Size 26

Fisher 1031 Size 33

Fisher 1032 XL680 - XL1370

Bettis CB 525

Bettis CB 725

Bettis HD 521, 721, 722

150 Bettis HD 731, 732

D and S Series (Elomatic) SR110

Limitorque SMB-000-5-HOBC

Limitorque T-250

Rotork 250

Coupler

Part No.

13B1596X012

13B1907X012

13B1595X012

13B1600X012

13B1908X012

13B1597X012

13B1599X012

13B1610X012

13B1611X012

13B1613X012

13B1601X012

13B1602X012

13B1905X012

13B1605X012

13B1906X012

13B1604X012

13B1606X012

13B1609X012

13B1603X012

13B1608X012

13B1607X012

13B1620X012

13B1621X012

13B1624X012

13B1614X012

13B1617X012

13B1615X012

13B1619X012

13B1618X012

13B1081X012

13B1082X012

13B1086X012

13B1073X012

13B1077X012

13B1074X012

13B1075X012

13B1076X012

13B1084X012

13B1246X012

13B1079X012

18

Page 19

Instruction Manual

D101643X012

ENVIRO-SEAL System - Rotary Valves

November 2011

The existing couplers, listed below, can accommodate a retrofit with an ENVIRO-SEAL packing system. Coupler

replacement is not required when retrofitting the valve/actuator combinations listed below. For information about

couplers for the A11 CL600 valves, contact your Emerson Process Management sales office.

Table 11. Coupler Part Number for Fisher A31A or A31D Valves with Selected Actuators

SHAFT DIAMETER,

mm (INCH)

14.3 (9/16)

17.5 (11/16)

28.5 (1-1/8)

31.8 (1-1/4)

Valve Size Actuator Type

NPS 3 CL150/300

NPS 3 CL150/300

NPS 3 CL150/300

NPS 3 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 4 CL150/300

NPS 10 CL150

NPS 10 CL150

NPS 8 CL300, NPS 12 CL150

NPS 8 CL300, NPS 12 CL150

Bettis CB 315

Bettis CB 415

Bettis CB 420

Bettis CB 520

Bettis CB 315

Bettis CB 415

Bettis CB 420

Bettis CB 520

Bettis CB 420

Bettis CB 520

Bettis CB 420

Bettis CB 520

Coupler

Part No.

V160124X012

V160125X012

V151828X012

V154549X012

V160108X012

V160107X012

V151731X012

V154600X012

V160209X012

V160212X012

V160208X012

V160213X012

19

Page 20

ENVIRO-SEAL System - Rotary Valves

November 2011

Instruction Manual

D101643X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end u ser.

Fisher, ENVIRO-SEAL, and Vee-Ball are marks owned by one of the companies in the Emerson Process Management business division of Emerson ElectricCo.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

20

EFisher Controls InternationalLLC 1991, 2011; All Rights Reserved

Loading...

Loading...