Emerson Fisher Fieldvue DVC6030f, Fisher Fieldvue DVC6010f, Fisher Fieldvue DVC6020f, Fisher Fieldvue DVC6000f Series Instruction Manual

Page 1

Errata Sheet

April 2007

FIELDVUE

FIELDVUE

DVC6000f Series

Errata Sheet

R

DVC6000f Series Digital Valve Controllers Quick Start Guide, Form 5778

(Quick Start Guides dated December 2005 and April 2005)

R

DVC6000f Series Digital Valve Controllers Instruction Manual, Form 5774

(Instruction Manuals dated March 2006, March 2005, and December 2004)

for

and

NOTE: This errata sheet replaces all existing

errata sheets for the DVC6000f Quick Start Guide

and Instruction Manual.

The first two pages of this errata sheet cover all

versions of the DVC6000f quick start guide and

instruction manual listed above. Refer to the

appropriate quick start guide or manual for all other

information and instructions pertaining to the

DVC6000f digital valve controller.

The NEPSI certification information found on

page 3, 4, and 5 of this errata sheet is only

applicable to the current DVC6000f quick start

guide (December 2005) and instruction manual

(March 2006).

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, and maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end-user.

DVC6000f Quick Start Guide Form − 5778

For Quick Start Guides dated December 2005

and April 2005

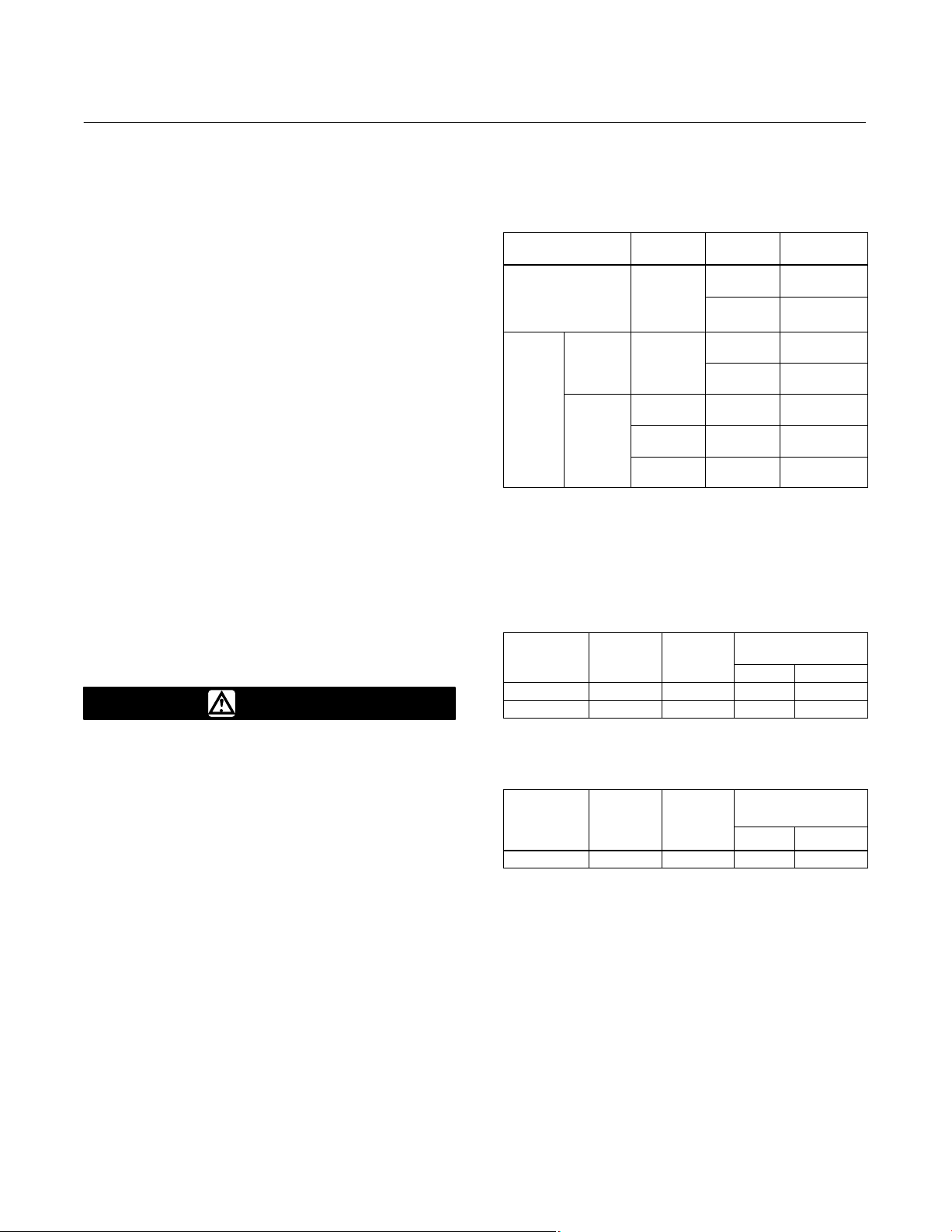

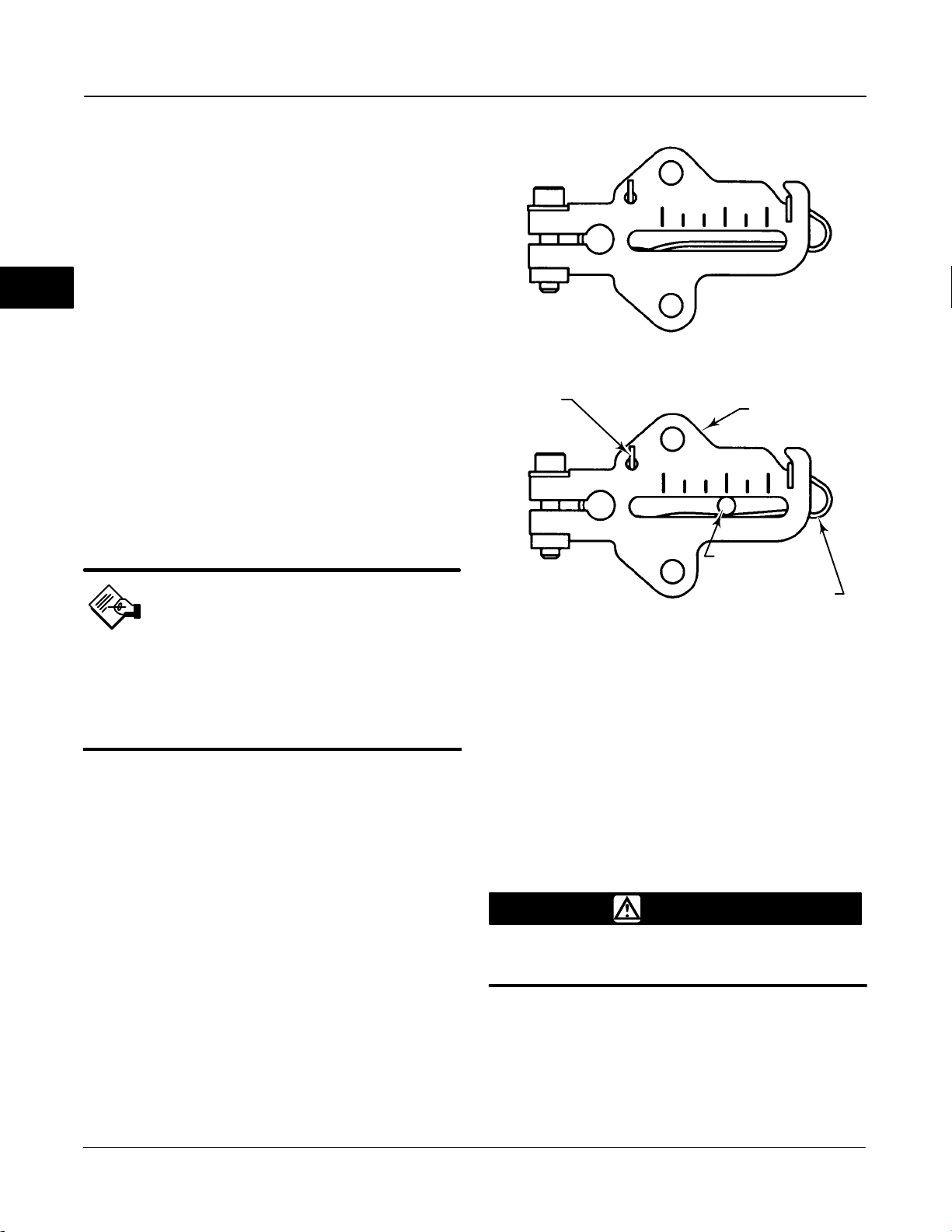

Replace figure 5-5. ATEX Nameplate; Intrinsically

Safe, Dust with the updated figure below. The

intrinsically safe maximum voltage entity parameter

(U

) has been corrected to read 24 VDC.

i

www.Fisher.com

TYPE DVC6010F, DVC6020F, DVC6030F, DVC6010FS, DVC6020FS, DVC6030FS

Figure 5−5. ATEX Nameplate; Intrinsic Safety, Dust

Page 2

DVC6000f Series

DVC6000f Instruction Manual − Form 5774

Errata Sheet

April 2007

For Instruction Manuals dated March 2006 and

March 2005

Replace the Intrinsic Safety, Dust-Tight nameplate

for Type DVC6010F, DVC6020F, DVC6030F,

DVC6010FS, DVC6020FS, DVC6030FS in

figure D-7 with the updated nameplate below. The

intrinsically safe maximum voltage entity parameter

(U

) has been corrected to read 24 VDC.

i

TYPE DVC6010F, DVC6020F, DVC6030F, DVC6010FS, DVC6020FS, DVC6030FS

For Instruction Manuals dated March 2006 and

March 2005

For Instruction Manuals dated December 2004

Replace the Intrinsic Safety, Dust-Tight nameplate

for Type DVC6010F, DVC6020F, DVC6030F,

DVC6010FS, DVC6020FS, DVC6030FS in

figure D-3 with the updated nameplate below. The

intrinsically safe maximum voltage entity parameter

(U

) has been corrected to read 24 VDC.

i

For Instruction Manuals dated December 2004

Replace the Intrinsic Safety, Dust-Tight nameplate

for Type DVC6005F in figure D-7 with the updated

nameplate below. The intrinsically safe maximum

voltage entity parameter (U

) has been corrected to

i

read 24 VDC.

Replace the Intrinsic Safety, Dust-Tight nameplate

for Type DVC6005F in figure D-3 with the updated

nameplate below. The intrinsically safe maximum

voltage entity parameter (Ui) has been corrected to

read 24 VDC.

TYPE DVC6005F

2

Page 3

Errata Sheet

April 2007

DVC6000f Series

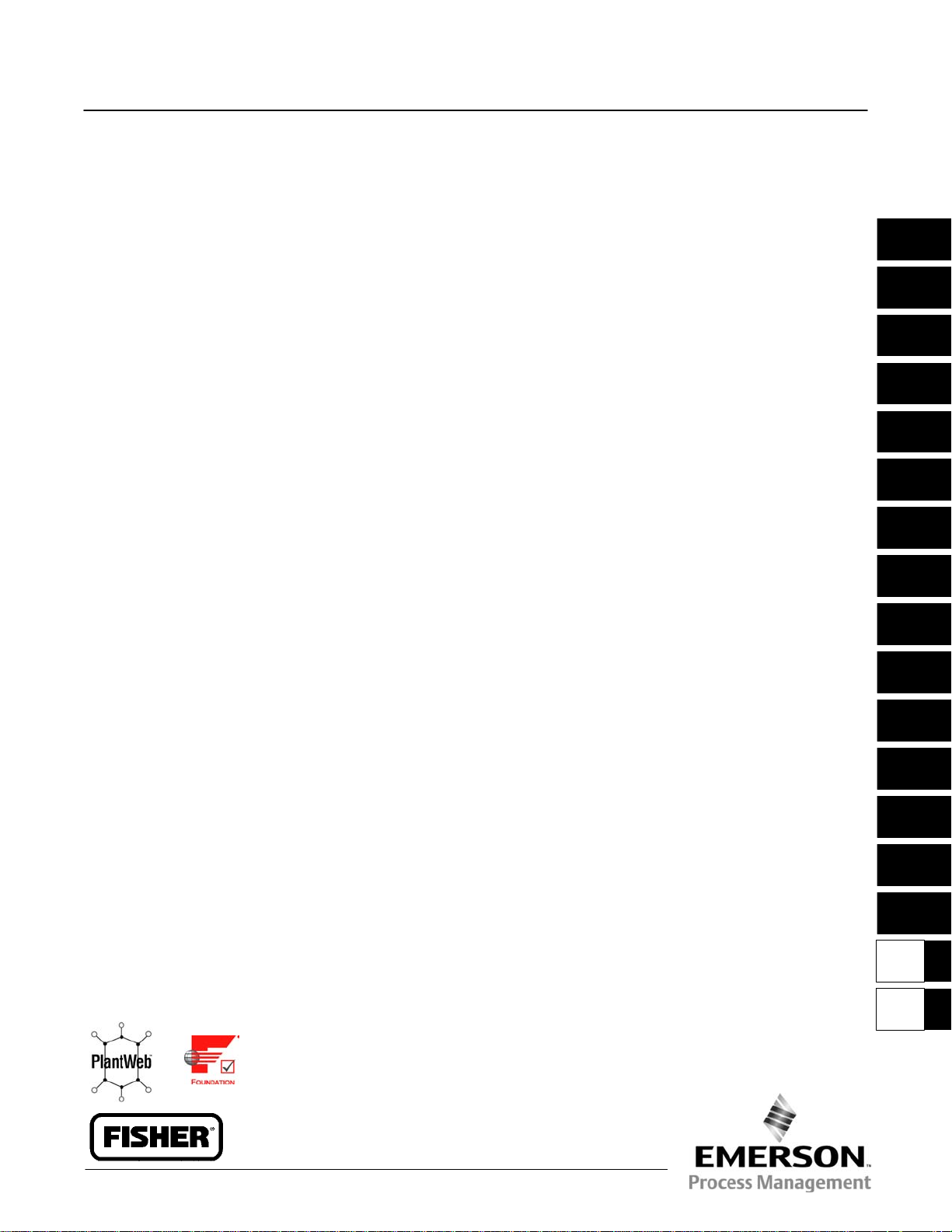

NEPSI Approvals

Page 3, 4, and 5 of this errata sheet contain

instructions for safe use in in hazardous locations

and nameplates (see figure 1) for NEPSI approvals.

Refer to the DVC6000f Series FIELDVUE

Valve Controller Instruction Manual − Form 5774,

dated March 2006 or the DVC6000f Series

FIELDVUE

R

Digital Valve Controller Quick Start

Guide − Form 5778, dated December 2005, for all

other information and instructions pertaining to the

DVC6000f digital valve controller.

Special Instructions for Safe Use and

Installations in Hazardous Locations

Certain nameplates may carry more than one

approval, and each approval may have unique

installation requirements and/or conditions of safe

use.

After reading and understanding these special

special conditions of use, proceed with standard

installation procedures as found in the quick start

guide or instruction manual.

WARNING

R

Digital

1. The correlation of approved DVC6000f Series

digital valve controllers in specific product type, Ex

marking and operating ambient temperature this

time is as follows:

Mounting Style

Integral Mounting

Main Unit DVC6005f

Separate

Mounting

Feedback

Unit

Product

Type

DVC6010f

DVC6020f

DVC6030f

DVC6015 Ex ia II CT6

DVC6025 Ex ia II CT5

DVC6035 Ex ia II CT4

Ex Marking

Ex ia II CT6

Ex ia II CT5

Ex ia II CT6

Ex ia II CT5

Ambient

Temperature

−40_C to

+75_C

−40_C to

+80_C

−40_C to

+75_C

−40_C to

+80_C

−60_C to

+80_C

−60_C to

+95_C

−60_C to

+125_C

2. The enclosure of the controller provides a

grounding terminal, and the user should install a

reliable grounding wire connected to it when

mounting and using the controller.

3. The values for intrinsically safe parameters and

maximum internal equivalent parameters of the

controller are as follow:

Max Input

Voltage

Ui (V)

24 226 1.4 5 0

17.5 380 5.32 5 0

Max Input

Current

Ii (mA)

Max Input

Power

Pi (W)

Max Internal

Equivalent Parameter

Ci (nF) Li (mH)

Failure to follow these conditions of

safe use could result in personal injury

or property damage from fire or

explosion, or area re-classification.

NEPSI Intrinsic Safety

Notes for Safe Use of the Certified Product

DVC6000f series digital valve controllers

(designated as controller hereafter) have been

proved to be in conformity with the requirements

specified in the national standards GB3836.1-2000

and GB3836.4-2000 through inspections conducted

by National Supervision and Inspection Centre for

Explosion Protection and Safety of Instrumentation

(NEPSI). The Ex marking for the products is Ex ia II

CT6/T5/T4, and their Ex certificate number is

GYJ06280. When using the product, the user should

pay attention to the items stated below:

4. As a main unit of a separate design product, the

values for intrinsically safe output parameters of

DVC6005f are as follows:

Max Output

Voltage

Uo (V)

8.6 2.3 5 8.2 100

Max

Output

Current

Io (mA)

Max

Output

Power

Po (mW)

Max Equivalent

Parameter allowed

Co (mF) Lo (mH)

5. While the controller forms an intrinsically safe

explosion protection system together with an

associated equipment, the following requirements

must be met: Uo vUi, Io vIi, Po vPi, Co wCi + Cc,

Lo wLi + Lc.

Note

Where Cc and Lc represent

distributing capacitance and

inductance of the connecting cable

respectively.

6. The connection cable between the product and

associated equipment should be a cable with

3

Page 4

DVC6000f Series

Errata Sheet

April 2007

insulation screen and sheath. The screen should be

connected to the ground.

7. An appropriate heat-resistant cable should be

selected for use with the controller in an application

where the ambient temperature exceeds 70_C.

8. When using and maintaining the product in the

field, cleaning the plastic surface of the product with

dry cloth is strictly prohibited to avoid the risk of

producing electrical spark.

9. The user must not be allowed to replace at will

the electric components of the product on his own to

avoid damage to the intrinsically safe performance of

explosion protection of the product.

10. The user must follow the relevant rules specified

by the product instruction manual, the “13th Section

of Electric Equipment Used in Explosive Gaseous

Environment: Maintenance of Electric Equipment

Used in Explosive Gaseous Environment” of

GB3836.13-1997 standard, the “15th Section of

Electric Equipment Used in Explosive Gaseous

Environment: Electric Installation in Hazardous

Locations (except for coal mine)” of

GB3836.15-2000 standard and the “Electric

installation construction and acceptance test code

for electric equipment mounting engineering in an

explosive and fire-hazardous environment” of

GB50257:1996 standard while performing

installation, operation, and maintenance for the

product.

NEPSI Flameproof

DVC6000f Series digital valve controllers

(designated as controller hereafter) have been

proved to be in conformity with the requirements

specified in the national standards GB3836.1-2000

and GB3836.2-2000 through inspections conducted

by National Supervision and Inspection Centre for

Explosion Protection and Safety of Instrumentation

(NEPSI). The Ex markings for the products are Ex d

II B+H2T6/T5 (DVC6010f, DVC6020f, and

DVC6030f only), Ex d II BT6/T5 (DVC6005f only),

and Ex d II CT6/T5/T4 (DVC6015, DVC6025, and

DVC6035 only) respectively and their Ex certificate

number is GYJ06279. When using the product , the

user should pay attention to the items stated below:

1. The correlation of this approved DVC6000f

Series digital valve controllers in specific product

type, Ex marking, and operating ambient

temperature is as follows:

Product Type Ex Marking

DVC6010f, DVC6020f,

DVC6030f (integral design)

DVC6005f (main unit of

separate design)

DVC6015, DVC6025,

DVC6035 (feedback units

of separate design

Ex d II B+H2T6

Ex d II B+H2T5

Ex d II BT6

Ex d II BT5

Ex d II CT6

Ex d II CT5

Ex d II CT4

Ambient

Temperature

−40_C to

+75_C

−40_C to

+80_C

−40_C to

+75_C

−40_C to

+80_C

−60_C to

+80_C

−60_C to

+95_C

−60_C to

+125_C

2. The enclosure of the controller provides a

grounding terminal, and the user should install a

reliable grounding wire connected to it when

mounting and using the controller.

3. The controller’s cable entrance (1/2 NPT) must

be fitted with a cable entry device which is

Ex−approved through inspection of explosion

protection, in conformity with relevant standards of

GB3836.1-2000 and GB3836.2-2000 and has a

corresponding rating of explosion protection.

4. An appropriate heat−resistant cable should be

selected for use with the controller in an application

where the ambient temperature exceeds 70_C.

5. The principle of “Opening equipment’s cover is

strictly prohibited while its is active” must be abided

by when using and maintaining the controller in the

field.

6. The user must follow the relevant rules specified

by the product instruction manual, the “13th Section

of Electric Equipment Used in Explosive Gaseous

Environment: Maintenance of Electric Equipment

Used in Explosive Gaseous Environment” of

GB3836.13-1997 standard, the “15th Section of

Electric Equipment Used in Explosive Gaseous

Environment: Electric Installation in Hazardous

Locations (except for coal mine)” of

GB3836.15-2000 standard and the “Electric

installation construction and acceptance test code

for electric equipment mounting engineering in an

explosive and fire-hazardous environment” of

GB50257:1996 standard while performing

installation, operation, and maintenance for the

product.

4

Page 5

Errata Sheet

April 2007

DVC6000f Series

TYPE DVC6010f, DVC6020f, DVC6030f

TYPE DVC6005f

TYPE DVC6015, DVC6025, DVC6035

Figure 1. NEPSI Intrinsic Safety and Flameproof Nameplates

5

Page 6

DVC6000f Series

Errata Sheet

April 2007

FIELDVUE and Fisher are marks owned by Fisher Controls International LLC, a member of the Emerson Process Management business division of

Emerson Electric Co. Emerson and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use and

maintenance of any product. Responsibility for the selection, use and maintenance of any product remains with the purchaser and end-user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

6

EFisher Controls International LLC 2006, 2007; All Rights Reserved Printed in USA

Page 7

DVC6000f Series

FIELDVUE DVC6000f Series

Digital Valve Controllers

Instruction Manual

Form 5774

March 6, 2006

This manual applies to:

Standard Control (SC)

Fieldbus Control (FC)

Fieldbus Logic (FL)

Introduction

Installation

375 Field Communicator Basics

Basic Setup and Tuning

Detailed Setup / Blocks

Calibration

Viewing Device Information

Principle of Operation

PlantWeb

Maintenance

Alerts

1

2

3

4

5

6

7

8

9

10

Parts

OUNDATION Fieldbus Communication

F

Device Description (DD) Installation

Operating with DeltaV

Loop Schematics/Nameplates

Glossary

Index

Index

11

A

B

C

D

Glossary

16

Index

D103189X012

www.Fisher.com

Page 8

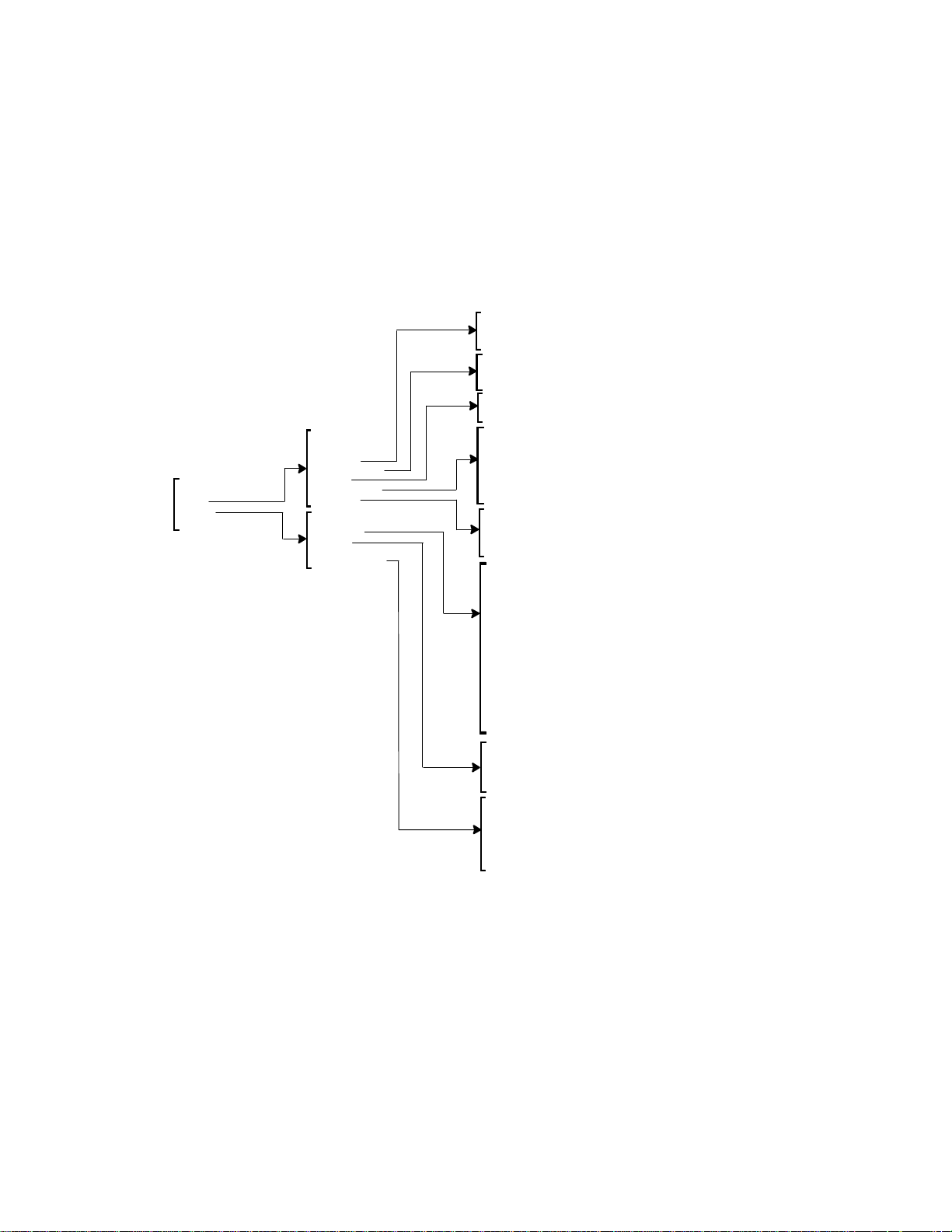

Model 375 Field Communicator Menu Tree for

FIELDVUE

Initial Setup

Basic Setup

Setup Wizard

Auto Tvl Calib

Stabilize/Optimize

Detailed Setup

Trans Block Mode

Protection

Initial Setup

Response Control

Alerts

Instrument

Act and Valve

2

Other

Display

Trans Block Mode

:Setpoint

:Travel

Drive Signal

:Supply Press

:Pressure A

:Pressure B

:Pressure Diff

Temperature

:Tvl/Press State

Input Char

Online

Basic Setup

Detailed Setup

Display

Calibrate

Instrument Status

Stroke Valve

Calibrate

Auto Tvl Calib

Manual Tvl Calib

Relay Adjust

Travel Sensor Adjust

Supply Press Sensor Cal

Output A Sensor Cal

Output B Sensor Cal

Instrument Status

Instrument Alerts

PlantWeb Alerts

This menu is only available in DD Revisions 3 and 4.

1

2

This menu item will read Simulate PlantWeb Alarms in DD Revisions 2

and 3, and Other in DD Revision 4. See the Simulate PlantWeb Alarms

menu for DD Revision 2 and 3.

3

This menu item only available in DD Revision 4

Cycle Count

Travel Accum

Tvl Count

Tvl Press Status

Device Record

Other

Simulate PlantWeb Alarms

Block Error Reporting

Simulate PlantWeb Alarms

PWA Simulate

Simulate Active Alarms

Tvl Press Status

:Travel

:Travel Status

:Supply Press

:Supply Press Status

:Pressure A

:Pressure A Status

:Pressure B

:Pressure B Status

:Pressure Diff

:Pressure Diff Status

Device Record

:Temp Max

:Temp Max Time

:Temp Min

:Temp Min Time

:Supp Press Max

:Supp Press Max Time

:Supp Press Min

:Supp Press Min Time

Response Control

Alerts

Instrument

Act and Valve

Simulate Active Alarms

Failed Active

Maint Active

Advise Active

Menu Tree for Model 375 Field Communicator

R

DVC6000f Digital Valve Controllers

Transducer Block

Travel Tuning

:Tvl/Press Select

:Zero Pwr Cond

Tvl Cutoff Low

:Actuator Style

:Relay Type

:Feedback Conn

:Tvl Sen Motion

:Tvl Cal Trigger

Travel Tuning

Pressure Tuning

Tvl Press Control

Input Char

Define Custom Char

PW Alarm Enable

PW Alarm Reporting

Elect and Config

Sensor and Enviro

Tvl and Prox

Performance

:Max Supp Press

Pressure Units

Temperature Units

Tvl Units

Length Units

Area Units

Spring Rate Units

Tag Description

:Relay Type

Calib Person

Calib Location

Calib Date

MAI Channel Map

Valve

Trim

Actuator

Reference

3

:Tvl Tuning Set

Tvl Prop Gain

Tvl Velocity Gain

:Tvl MLFB Gain

:Tvl Integ Enable

Tvl Integral Gain

:Tvl Integ DeadZ

:Tvl Integ Lim Hi

:Tvl Integ Lim Lo

Tvl Press Control

:Tvl/Press Select

Tvl Cutoff Hi

Tvl Cutoff Lo

1

:Press Cutoff Hi

:Press Cutoff Lo

:Press Range Hi

:Press Range Lo

MAI Channel Map

MAI Channel 1

MAI Channel 2

MAI Channel 3

MAI Channel 4

MAI Channel 5

MAI Channel 6

MAI Channel 7

MAI Channel 8

Valve

Valve Manufacturer Id

Valve Model Number

Valve Serial Number

Valve Style

:Valve Size

:Valve Class

:Rated Travel

:Actual Travel

:Shaft Stem Dia

:Packing Type

:Inlet Pressure

:Outlet Pressure

Trim

:Seat Type

:Leak Class

:Port Diameter

:Port Type

:Flow Direction

:Push Down To

:Flow Tends To

:Unbalanced Area

Actuator

Actuator Manufacturer Id

Actuator Model Number

Actuator Serial Number

:Actuator Size

Actuator Fail Action

:Feedback Conn

:Tvl Sen Motion

:Effective Area

:Air

:Lower Bench Set

:Upper Bench Set

:Nominal Supply Pressure

:Spring Rate

:Lever Style

:Moment Arm

Reference

:Trim Style 1

:Trim Style 2

:Stroking Time Open

:Stroking Time Close

DVC6000f DD Revision 2, 3, and 4

Pressure Tuning

:Press Tuning Set

:Press Prop Gain

:Press MLFB Gain

:Press Integ Gain

:Press Integ DeadZ

:Press Integ Hi Lim

:Press Integ Lo Lim

PW Alarm Enable

Failed Enable

Maint Enable

Advise Enable

PW Alarm Reporting

Failed Suppress

Maint Suppress

Advise Supress

Elect and Config

:Elect Active

:Elect Enable

:Shutdown Trigger

:Shutdown Recovery

Drive Current Config

Drive Signal

:Output Blk Timeout

Alert Key

Sensor and Enviro

:Sensor Active

:Sensor Enable

:Shutdown Trigger

:Shutdown Recovery

:Enviro Active

:Enviro Enable

Supply Press Sensor Config

Temp Sensor Config

Tvl and Prox

:Tvl Active

:Travel Enable

Tvl Config

:Prox Active

:Prox Enable

Prox Config

:Tvl History Active

:Tvl History Enable

Tvl History Config

Performance

:Performance Active

:Performance Enable

1

:PD Run

:PD Inside Status

1

Drive Current Config

Drive Current

:Drive Current Alrt Pt

:Drive Current Alrt Time

Supply Press Sensor Config

:Supply Press

:Supply Press Hi Alrt Pt

:Supply Press Lo Alrt Pt

Temp Sensor Config

Temperature

:Temp Hi Alrt Pt

:Temp Lo Alrt Pt

Tvl Config

:Travel

Tvl Deviation

:Tvl Dev Alrt Pt

:Tvl Dev Time

:Tvl Dev DB

:Tvl Lo Lo Alrt Pt

:Tvl Lo Lo DB

:Tvl Lo Alrt Pt

:Tvl Lo DB

:Tvl Hi Alrt Pt

:Tvl Hi DB

:Tvl Hi Hi Alrt Pt

:Tvl Hi Hi DB

Prox Config

:Tvl Open Alrt Pt

:Tvl Open DB

:Tvl Closed Alrt Pt

:Tvl Closed DB

Tvl History Config

Cycle Count

:Cycle Count Alrt Pt

:Cycle Count DB

Travel Accum

:Tvl Accum Alrt Pt

:Tvl Accum DB

i

i

Page 9

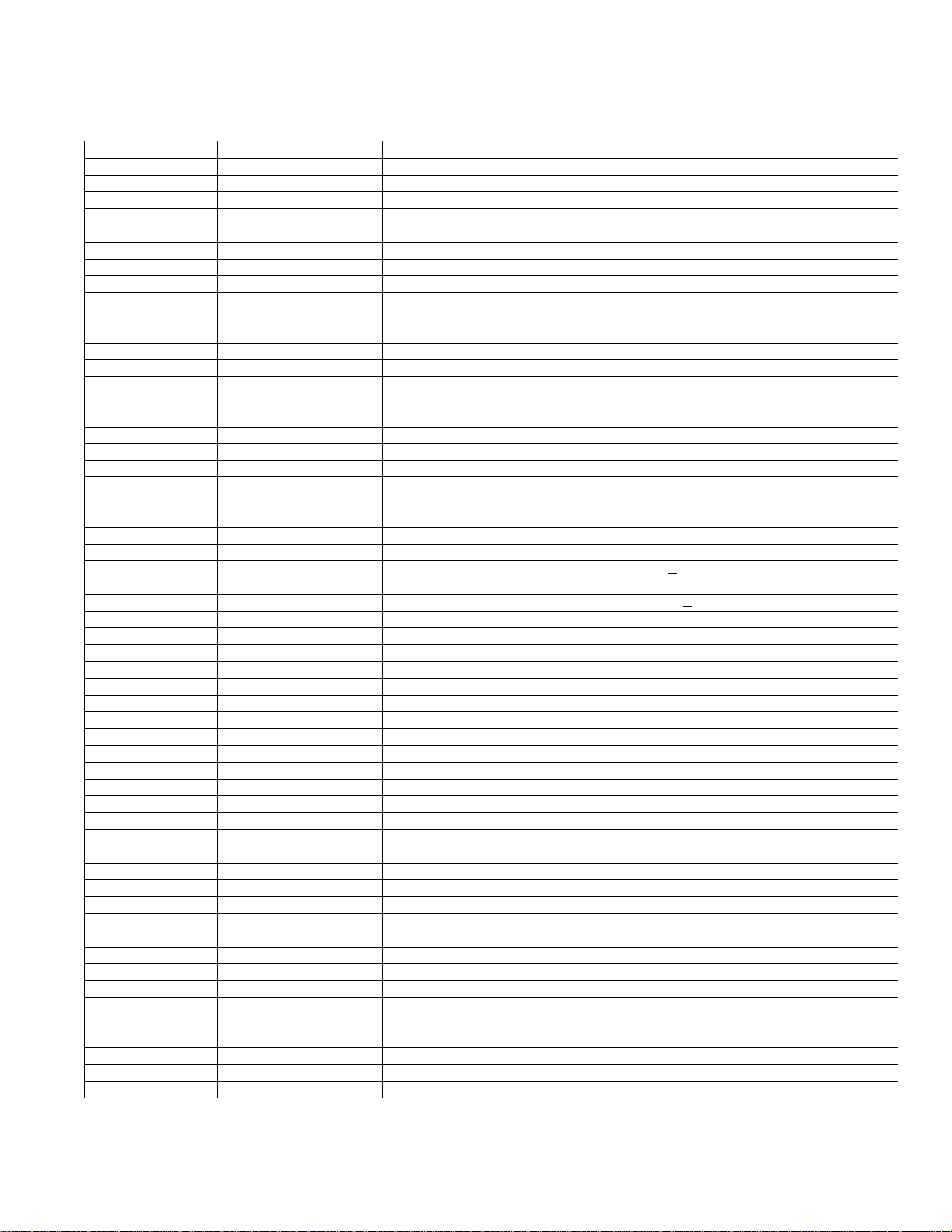

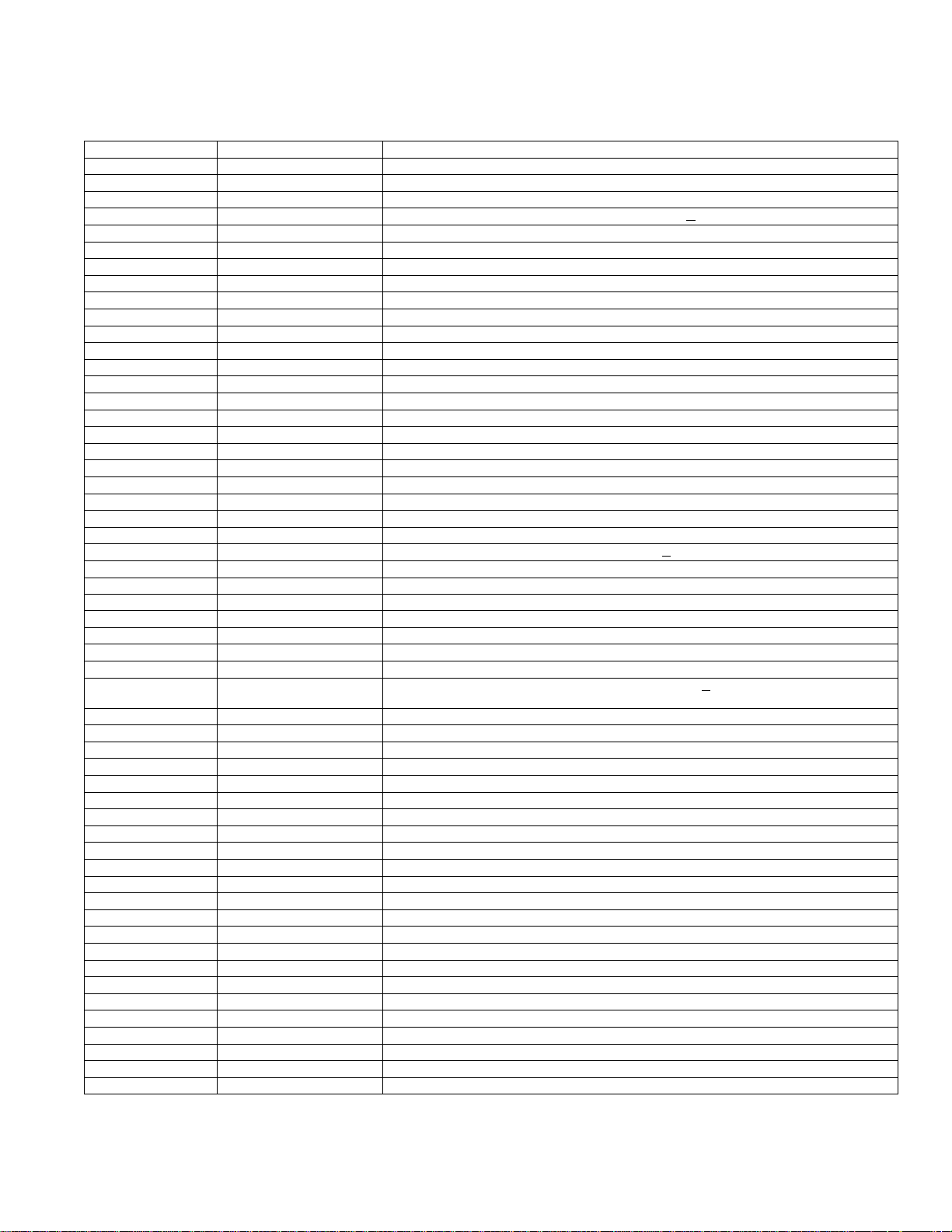

375 Field Communicator Transducer Block Menu Structure

PARAMETER LABEL PARAMETER NAME MENU STRUCTURE

Actual Travel ACTUAL_TRAVEL TB > Detailed Setup > Act and Valve > Valve > Actual Travel

Actuator Fail Action ACT_FAIL_ACTION TB > Detailed Setup > Act and Valve > Actuator > Actuator Fail Action

Actuator Manufacturer Id ACT_MAN_ID TB > Detailed Setup > Act and Valve > Actuator >Actuator Manufacturer Id

Actuator Model Number ACT_MODEL_NUM TB > Detailed Setup > Act and Valve > Actuator > Actuator Model Number

Actuator Serial Number ACT_SN TB > Detailed Setup > Act and Valve > Actuator > Actuator Serial Number

Actuator Size ACTUATOR_SIZE TB > Detailed Setup > Act and Valve > Actuator > Actuator Size

Actuator Style ACTUATOR_STYLE TB > Detailed Setup > Initial Setup > Actuator Style

Advise Active ADVISE_ACTIVE TB > Instrument Status > PlantWeb Alerts > Advise Active

Advise Enable ADVISE_ENABLE TB > Detailed Setup > Alerts > PW Alarm Enable > Advise Enable

Advise Suppress ADVISE_MASK TB > Detailed Setup > Alerts > PW Alarm Reporting > Advise Suppress

Air AIR TB > Detailed Setup > Act and Valve > Actuator > Air

Alert Key ALERT_KEY TB > Detailed Setup > Alerts > Elect and Config > Alert Key

Area Units AREA_UNITS TB > Detailed Setup > Instrument > Area Units

Calib Date XD_CAL_DATE TB > Detailed Setup > Instrument > Calib Date

Calib Location XD_CAL_LOC TB > Detailed Setup > Instrument > Calib Location

Calib Person XD_CAL_WHO TB > Detailed Setup > Instrument > Calib Person

Cycle Count CYCLE_COUNT TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Cycle Count

Cycle Count Alrt Pt CYCLE_COUNT_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Cycle Count Alrt Pt

Cycle Count DB CYCLE_COUNT_DB TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Cycle Count DB

Drive Current DRIVE_CURRENT TB > Detailed Setup > Alerts > Elect and Config > Drive Current

Drive Current Alrt Pt DRIVE_CURRENT_ALRT_PT TB > Detailed Setup > Alerts > Elect and Config > Drive Current Alrt Pt

Drive Current Alrt Time DRIVE_CURRENT_TIME TB > Detailed Setup > Alerts > Elect and Config > Drive Current Alrt Time

Drive Signal DRIVE_SIGNAL TB > Detailed Setup > Alerts > Elect and Config > Drive Signal

Effective Area EFFECTIVE_AREA TB > Detailed Setup > Act and Valve > Actuator > Effective Area

Elect Active ELECT_ACTIVE TB > Detailed Setup > Alerts > Elect and Config > Elect Active or TB > Instrument Status > Instrument Alerts

Elect Enable ELECT_ENABLE TB > Detailed Setup > Alerts > Elect and Config > Elect Enable

Enviro Active ENVIRO_ACTIVE TB > Detailed Setup > Alerts > Sensor and Enviro > Enviro Active or TB > Instrument Status > Instrument Alerts

Enviro Enable ENVIRO_ENABLE TB > Detailed Setup > Alerts > Sensor and Enviro > Enviro Enable

Failed Active FAILED_ACTIVE TB > Instrument Status > PlantWeb Alerts > Failed Active

Failed Enable FAILED_ENABLE TB > Detailed Setup > Alerts > PW Alarm Enable > Failed Enable

Failed Suppress FAILED_MASK TB > Detailed Setup > Alerts > PW Alarm Reporting > Failed Suppress

Feedback Conn FEEDBACK_CONN TB > Detailed Setup > Act and Valve > Actuator > Feedback Conn

Flow Direction FLOW_DIRECTION TB > Detailed Setup > Act and Valve > Trim > Flow Direction

Flow Tends To FLOW_TENDS_TO TB > Detailed Setup > Act and Valve > Trim > Flow Tends To

Inlet Pressure INLET_PRESSURE TB > Detailed Setup > Act and Valve > Valve > Inlet Pressure

Input Char INPUT_CHAR TB > Detailed Setup > Response Control > Input Char

Leak Class LEAK_CLASS TB > Detailed Setup > Act and Valve > Trim > Leak Class

Length Units LENGTH_UNITS TB > Detailed Setup > Instrument > Length Units

Lever Style LEVER_STYLE TB > Detailed Setup > Act and Valve > Actuator > Lever Style

Lower Bench Set LOWER_BENCH_SET TB > Detailed Setup > Act and Valve > Actuator > Lower Bench Set

MAI Channel 1 MAI_CHANNEL_1 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 1

MAI Channel 2 MAI_CHANNEL_2 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 2

MAI Channel 3 MAI_CHANNEL_3 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 3

MAI Channel 4 MAI_CHANNEL_4 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 4

MAI Channel 5 MAI_CHANNEL_5 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 5

MAI Channel 6 MAI_CHANNEL_6 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 6

MAI Channel 7 MAI_CHANNEL_7 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 7

MAI Channel 8 MAI_CHANNEL_8 TB > Detailed Setup > Instrument > MAI Channel Map > MAI Channel 8

Maint Active MAINT_ACTIVE TB > Instrument Status > PlantWeb Alerts > Maint Active

Maint Enable MAINT_ENABLE TB > Detailed Setup > Alerts > PW Alarm Enable > Maint Enable

Maint Suppress MAINT_MASK TB > Detailed Setup > Alerts > PW Alarm Reporting > Maint Suppress

Max Supp Press MAX_SUPP_PRESS TB > Detailed Setup > Instrument > Max Supp Press

Moment Arm MOMENT_ARM TB > Detailed Setup > Act and Valve > Actuator > Moment Arm

Nominal Supply Pressure NOMINAL_SUPPLY_PRESSURE TB > Detailed Setup > Act and Valve > Actuator > Nominal Supply Pressure

Outlet Pressure OUTLET_PRESSURE TB > Detailed Setup > Act and Valve > Valve > Outlet Pressure

Output Blk Timeout OUTPUT_BLK_TIMEOUT TB > Detailed Setup > Alerts > Elect and Config > Output Blk Timeout

−Continued−

ii

ii

Page 10

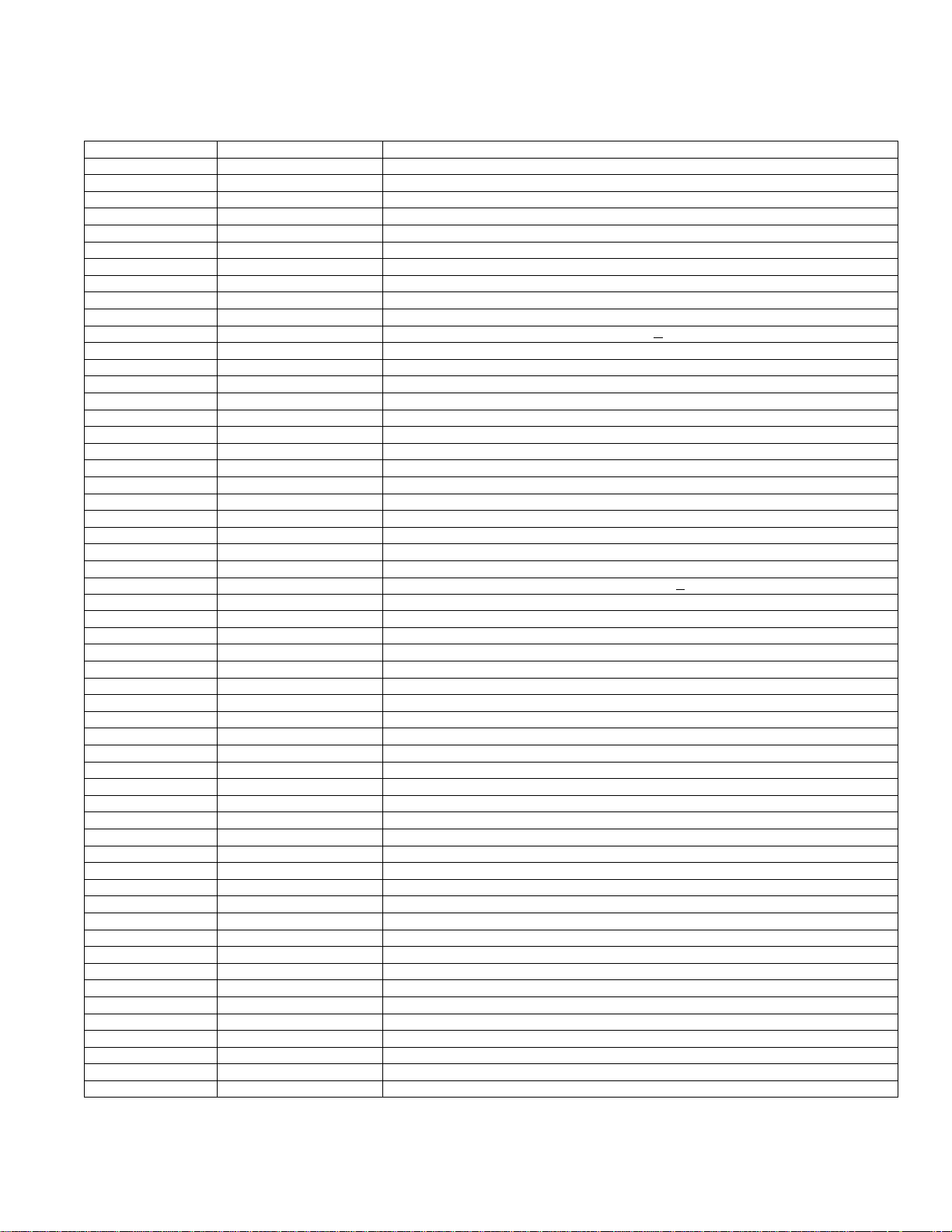

375 Field Communicator Transducer Block Menu Structure (Continued)

PARAMETER LABEL MENU STRUCTUREPARAMETER NAME

Packing Type PACKING_TYPE TB > Detailed Setup > Act and Valve > Valve > Packing Type

PD Inside Status PD_STATUS TB > Detailed Setup > Alerts > Performance > PD Status

PD Run PD_RUN TB > Detailed Setup > Alerts > Performance > PD Run

Performance Active PERF_ACTIVE TB > Detailed Setup > Alerts > Performance > Performance Active or TB > Instrument Status > Instrument Alerts

Performance Enable PERF_ENABLE TB > Detailed Setup > Alerts > Performance Enable

Port Diameter PORT_DIAMETER TB > Detailed Setup > Act and Valve > Trim > Port Diameter

Port Type PORT_TYPE TB > Detailed Setup > Act and Valve > Trim > Port Type

Press Cutoff Hi PRESS_CUTOFF_HI TB > Detailed Setup > Response Control > Tvl/Press Control > Press Cutoff Hi

Press Cutoff Lo PRESS_CUTOFF_LO TB > Detailed Setup > Response Control > Tvl/Press Control > Press Cutoff Lo

Press Integ DeadZ PRESS_INTEG_DEADZ TB > Detailed Setup > Response Control > Pressure Tuning > Press Integ DeadZ

Press Integ Gain PRESS_INTEG_GAIN TB > Detailed Setup > Response Control > Pressure Tuning > Press Integ Gain

Press MLFB Gain PRESS_MLFB_GAIN TB > Detailed Setup > Response Control > Pressure Tuning > Press MLFB Gain

Press Prop Gain PRESS_PROP_GAIN TB > Detailed Setup > Response Control > Pressure Tuning > Press Prop Gain

Press Range Hi PRESS_RANGE_HI TB > Detailed Setup > Response Control > Tvl/Press Control > Press Range Hi

Press Range Lo PRESS_RANGE_LO TB > Detailed Setup > Response Control > Tvl/Press Control > Press Range Lo

Press Tuning Set PRESS_TUNING_SET TB > Detailed Setup > Response Control > Pressure Tuning > Press Tuning Set

Pressure A PRESSURE_A.VALUE TB > Display > Tvl Press Status > Pressure A

Pressure A Status PRESSURE_A.STATUS TB > Display > Tvl Press Status > Pressure A Status

Pressure B PRESSURE_B.VALUE TB > Display > Tvl Press Status > Pressure B

Pressure B Status PRESSURE_B.STATUS TB > Display > Tvl Press Status > Pressure B Status

Pressure Diff PRESSURE_DIFF.VALUE TB > Display > Pressure Diff

Pressure Diff Status PRESSURE_DIFF.STATUS TB > Display > Tvl Press Status > Pressure Diff Status

Pressure Units PRESSURE_UNITS TB > Detailed Setup > Instrument > Pressure Units

Prox Active PROX_ACTIVE TB > Detailed Setup > Alerts > Tvl and Prox > Prox Active or TB > Instrument Status > Instrument Alerts

Prox Enable PROX_ENABLE TB > Detailed Setup > Alerts > Tvl and Prox > Prox Enable

Push Down To PUSH_DOWN_TO TB > Detailed Setup > Act and Valve > Trim > Push Down To

PWA Simulate PWA_SIMULATE TB > Detailed Setup > Simulate PlantWeb Alarms > PWA Simulate

Rated Travel RATED_TRAVEL TB > Detailed Setup > Act and Valve > Valve > Rated Travel

Relay Type RELAY_TYPE TB > Detailed Setup > Initial Setup > Relay Type

Seat Type SEAT_TYPE TB > Detailed Setup > Act and Valve > Trim > Seat Type

Setpoint FINAL_VALUE.VALUE TB > Display > Setpoint

Sensor Active SENSOR_ACTIVE

Sensor Enable SENSOR_ENABLE TB > Detailed Setup > Alerts > Sensor and Enviro > Sensor Enable

Shaft Stem Dia SHAFT_STEM_DIA TB > Detailed Setup > Act and Valve > Valve > Shaft Stem Dia

Shutdown Recovery SHUTDOWN_RECOVERY TB > Detailed Setup > Alerts > Elect and Config > Shutdown Recovery

Shutdown Trigger SHUTDOWN_TRIGGER TB > Detailed Setup > Alerts > Elect and Config > Shutdown Trigger

Spring Rate SPRING_RATE TB > Detailed Setup > Act and Valve > Actuator > Spring Rate

Spring Rate Units SPRING_RATE_UNITS TB > Detailed Setup > Instrument > Spring Rate Units

Stroking Time Close STROKING_TIME_CLOSE TB > Detailed Setup > Act and Valve > Reference > Stroking Time Close

Stroking Time Open STROKING_TIME_OPEN TB > Detailed Setup > Act and Valve > Reference > Stroking Time Open

Supply Press SUPPLY_PRESS.VALUE TB > Detailed Setup > Alerts > Sensor and Enviro > Supply Press Sensor Config > Supply Press

Supply Press Hi Alrt Pt SUP_PRES_HI_ALRT_PT TB > Detailed Setup > Alerts > Sensor and Enviro > Supply Press Sensor Config > Supply Press Hi Alrt Pt

Supply Press Lo Alrt Pt SUP_PRES_LO_ALRT_PT TB > Detailed Setup > Alerts > Sensor and Enviro > Supply Press Sensor Config > Supply Press Lo Alrt Pt

Supp Press Max SUPP_PRESS_MAX TB > Display > Device Record > Supp Press Max

Supp Press Max Time SUPP_PRESS_MAX_TIME TB > Display > Device Record > Supp Press Max Time

Supp Press Min SUPP_PRESS_MIN TB > Display > Device Record > Supp Press Min

Supp Press Min Time SUPP_PRESS_MIN_TIME TB > Display > Device Record > Supp Press Min Time

Supply Press Status SUPPLY_PRESSURE.STATUS TB > Display > Tvl Press Status > Supply Press Status

Tag Description TAG_DESC TB > Detailed Setup > Instrument > Tag Description

Temperature TEMPERATURE TB > Detailed Setup > Alerts > Sensor and Enviro > Temp Sensor Config > Temperature

Temp Hi Alrt Pt TEMP_HI_ALRT_PT TB > Detailed Setup > Alerts > Sensor and Enviro > Temp Sensor Config > Temp Hi Alrt Pt

Temp Lo Alrt Pt TEMP_LO_ALRT_PT TB > Detailed Setup > Alerts > Sensor and Enviro > Temp Sensor Config > Temp Lo Alrt Pt

Temp Max TEMP_MAX TB > Display > Device Record > Temp Max

Temp Max Time TEMP_MAX_TIME TB > Display > Device Record > Temp Max Time

Temp Min TEMP_MIN TB > Display > Device Record > Temp Min

TB > Detailed Setup > Alerts > Sensor and Enviro > Sensor Active or

TB > Instrument Status > Instrument Alerts

−Continued−

iii

iii

Page 11

375 Field Communicator Transducer Block Menu Structure (Continued)

PARAMETER LABEL MENU STRUCTUREPARAMETER NAME

Temp Min Time TEMP_MIN_TIME TB > Display > Device Record > Temp Min Time

Temperature Units TEMPERATURE_UNITS TB > Detailed Setup > Instrument > Temperature Units

Travel TRAVEL.VALUE TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Travel

Travel Accum TRAVEL_ACCUM TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Travel Accum

Travel Enable TRAVEL_ENABLE TB > Detailed Setup > Alerts > Tvl and Prox > Travel Enable

Travel Status TRAVEL.STATUS TB > Display > Tvl Press Status > Travel Status

Trim Style 2 TRIM_STYLE_2 TB > Detailed Setup > Act and Valve > Reference > Trim Style 2

Trim Style 1 TRIM_STYLE_1 TB > Detailed Setup > Act and Valve > Reference > Trim Style 1

Tvl Accum Alrt Pt TVL_ACCUM_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Tvl Accum Alrt Pt

Tvl Accum DB TVL_ACCUM_DB TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Config > Tvl Accum DB

Tvl Active TRAVEL_ACTIVE TB > Detailed Setup > Alerts > Tvl and Prox > Tvl Active or TB > Instrument Status > Instrument Alerts

Tvl Cal Trigger TVL_CAL_TRIGGER TB > Detailed Setup > Initial Setup > Tvl Cal Trigger

Tvl Closed Alrt Pt TVL_CLOSED_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Prox Config > Tvl Closed Alrt Pt

Tvl Closed DB TVL_CLOSED_DB TB > Detailed Setup > Alerts > Tvl and Prox > Prox Config > Tvl Closed DB

Tvl Count TVL_COUNT TB > Display >Tvl Count

Tvl Cutoff Hi FINAL_VALUE_CUTOFF_HI TB > Detailed Setup > Response Control > Tvl/Press Control > Tvl Cutoff Hi

Tvl Cutoff Lo FINAL_VALUE_CUTOFF_LO TB > Detailed Setup > Response Control > Tvl/Press Control > Tvl Cutoff Lo

Tvl Dev Alrt Pt TVL_DEV_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Dev Alrt Pt

Tvl Deviation TRAVEL_DEVIATION TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Deviation

Tvl Dev Time TVL_DEV_TIME TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Dev Time

Tvl Dev DB TVL_DEV_DB TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Dev DB

Tvl Hi Alrt Pt TVL_HI_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Hi Alrt Pt

Tvl Hi DB TVL_HI_DB TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Hi DB

Tvl Hi Hi Alrt Pt TVL_HI_HI_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Hi Hi Alrt Pt

Tvl Hi Hi DB TVL_HI_HI_DB TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Hi Hi DB

Tvl History Active TVL_HISTORY_ACTIVE TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Active or TB > Instrument Status > Instrument Alerts

Tvl History Enable TVL_HISTORY_ENABLE TB > Detailed Setup > Alerts > Tvl and Prox > Tvl History Enable

Tvl Integ DeadZ TVL_INTEG_DEADZ TB > Detailed Setup > Response Control > Travel Tuning > Tvl Integ DeadZ

Tvl Integ Enable TVL_INTEG_ENABLE TB > Detailed Setup > Response Control > Travel Tuning > Tvl Integ Enable

Tvl Integ Lim Hi TVL_INTEG_LIM_HI TB > Detailed Setup > Response Control > Travel Tuning > Tvl Integ Lim Hi

Tvl Integ Lim Lo TVL_INTEG_LIM_LO TB > Detailed Setup > Response Control > Travel Tuning > Tvl Integ Lim Lo

Tvl Integral Gain SERVO_RESET TB > Detailed Setup > Response Control > Travel Tuning > Tvl Integral Gain

Tvl Lo Alrt Pt TVL_LO_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Lo Alrt Pt

Tvl Lo DB TVL_LO_DB TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Lo DB

Tvl Lo Lo Alrt Pt TVL_LO_LO_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Lo Lo Alrt Pt

Tvl Lo Lo DB TVL_LO_LO_DB TB > Detailed Setup > Alerts > Tvl and Prox > Travel Config > Tvl Lo Lo DB

Tvl MLFB Gain TVL_MLFB_GAIN TB > Detailed Setup > Response Control > Travel Tuning > Tvl MLFB Gain

Tvl Open Alrt Pt TVL_OPEN_ALRT_PT TB > Detailed Setup > Alerts > Tvl and Prox > Prox Config > Tvl Open Alrt Pt

Tvl Open DB TVL_OPEN_DB TB > Detailed Setup > Alerts > Tvl and Prox > Prox Config > Tvl Open DB

Tvl/Press Select TVL_PRESS_SELECT TB > Detailed Setup > Response Control > Tvl/Press Control > Tvl/Press Select

Tvl/Press State TVL_PRESS_STATE TB > Display > Tvl/Press State

Tvl Prop Gain SERVO_GAIN TB > Detailed Setup > Response Control > Travel Tuning > Tvl Prop Gain

Tvl Sen Motion TRAVEL_SENSOR_MOTION TB > Detailed Setup > Act and Valve > Actuator > Tvl Sen Motion

Tvl Sen Motion TRAVEL_SENSOR_MOTION TB > Detailed Setup > Initial Setup > Tvl Sen Motion

Tvl Tuning Set TVL_TUNING_SET TB > Detailed Setup > Response Control > Travel Tuning > Tvl Tuning Set

Tvl Units TVL_UNITS TB > Detailed Setup > Instrument > Tvl Units

Tvl Velocity Gain SERVO_RATE TB > Detailed Setup > Response Control > Travel Tuning > Tvl Velocity Gain

Unbalanced Area UNBALANCED_AREA TB > Detailed Setup > Act and Valve > Trim > Unbalanced Area

Upper Bench Set UPPER_BENCH_SET TB > Detailed Setup > Act and Valve > Actuator > Upper Bench Set

Valve Class VALVE_CLASS TB > Detailed Setup > Act and Valve > Valve > Class

Valve Manufacturer Id VALVE_MAN_ID TB > Detailed Setup > Act and Valve > Valve > Valve Manufacturer Id

Valve Model Number VALVE_MODEL_NUM TB > Detailed Setup > Act and Valve > Valve > Valve Model Number

Valve Serial Number VALVE_SN TB > Detailed Setup > Act and Valve > Valve > Valve Serial Number

Valve Size VALVE_SIZE TB > Detailed Setup > Act and Valve > Valve > Valve Size

Valve Style VALVE_TYPE TB > Detailed Setup > Act and Valve > Valve > Valve Style

Zero Pwr Cond ZERO_PWR_COND TB > Detailed Setup > Initial Setup > Zero Pwr Cond

iv

iv

Page 12

Online

Setup

Display

Restart

Model 375 Field Communicator Menu Tree for

R

FIELDVUE

DVC6000f Digital Valve Controllers

Resource Block

WriteLock

Write Lock

Write Priority

Comm Time Out

RCas Timeout

ROut Timeout

Options

Feature Selection

Setup

Res Block Mode

WriteLock

Comm Time Out

Options

Alarm Handling

Instrument

Display

Instrument

Options

DD Information

Resource Status

Alarm Handling

Alert Key

Confirm Time

Max Alerts Allow

Acknowledge Option

Alarm Summary: Disabled

Block Alarm: Unacknowledged

Instrument

Strategy

Tag Description

Field Serial Number

Instrument

Strategy

Tag Description

Device ID

Electronics Serial Number

Factory Serial Number

Field Serial Number

Manufacturer ID

Device Type

Device Revision

DD Revision

ITK Version

Features

:Software Rev All

:Stby Software Rev All

Hardware Revision

Options

Diag Options

Function Block Options

Misc Options

Resource Status

Block Error

Block Alarm: Unacknowledged

Device State

Fault State

Write Lock

Write Alarm: Alarm State

Menu Tree for Model 375 Field Communicator

DVC6000f DD Revision 2, 3, and 4

v

v

Page 13

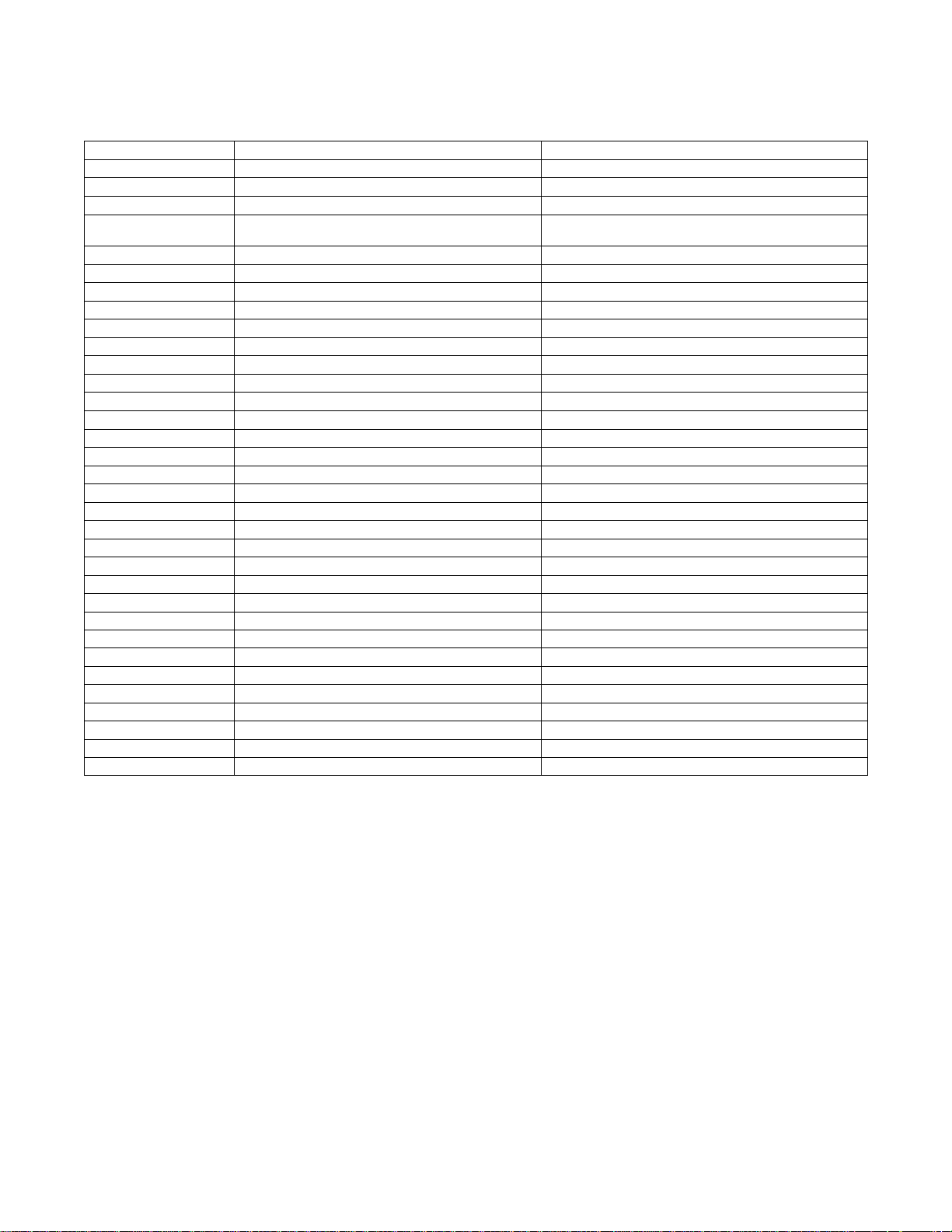

375 Field Communicator Resource Block Menu Structure

PARAMETER LABEL PARAMETER NAME MENU STRUCTURE

Acknowledge Option ACK_OPTION RB > Setup > Alarm Handling > Acknowledge Option

Alarm Summary: Disabled ALARM_SUM.DISABLED RB > Setup > Alarm Handling > Alarm Summary Disabled

Alert Key ALERT_KEY RB > Setup > Alarm Handling > Alert Key

Block Alarm:

Unacknowledged

BLOCK_ALM.UNACKNOWLEDGED

Block Error BLOCK_ERR RB > Display > Resource Status > Block Error

Confirm Time CONFIRM_TIME RB > Setup > Alarm Handling > Confirm Time

Device ID DEVICE_ID RB > Display > Instrument > Device ID

Device Revision DEV_REV RB > Display > Instrument > Device Revision

Device State RS_STATE RB > Display > Resource Status > Device State

Device Type DEV_TYPE RB > Display > Instrument > Device Type

DD Revision DD_REV RB > Display > Instrument > DD Revision

Diag Options DIAG_OPTIONS RB > Display > Options > Diag Options

Electronics Serial Number ELECTRONICS_SN RB > Display > Instrument > Electronics Serial Number

Factory Serial Number FACTORY_SN RB > Display > Instrument > Factory Serial Number

Fault State FAULT_STATE RB > Display > Resource Status > Fault State

Features FEATURES RB > Display > Instrument > Features

Feature Selection FEATURE_SEL RB > Setup > Options > Feature Selection

Field Serial Number FIELD_SN RB > Setup > Instrument > Field Serial Number

Function Block Options FB_OPTIONS RB > Display > Options > Function Block Options

Hardware Revision HARDWARE_REV RB > Display > Instrument > Hardware Revision

ITK Version ITK_VER RB > Display > Instrument > ITK Version

Manufacturer ID MANUFAC_ID RB > Display > Instrument > Manufacturer ID

Max Alerts Allow LIM_NOTIFY RB > Setup > Alarm Handling > Max Alerts Allow

Misc Options MISC_OPTIONS RB > Display > Options > Misc Options

RCas Timeout SHED_RCAS RB > Setup> Comm Time Out > RCas Timeout

ROut Timeout SHED_ROUT RB > Setup > Comm Time Out > ROut Timeout

Software Rev All SOFTWARE_REVISION.SOFTWARE_REV_ALL RB > Display > Instrument > Software Rev All

Stby Software Rev All STBY_SOFTWARE_REV.STBY_SOFTWARE_REV_ALL RB > Display > Instrument > Stby Software Rev All

Strategy STRATEGY RB > Setup > Instrument > Strategy

Tag Description TAG_DESC RB > Setup > Instrument > Tag Description

Write Alarm: Alarm State WRITE_ALM.ALARM_STATE RB > Display > Resource Status > Write Alarm: Alarm State

Write Lock WRITE_LOCK RB > Setup > WriteLock> Write Lock

Write Priority WRITE_PRI RB > Setup > WriteLock> Write Priority

RB > Setup > Alarm Handling > Block Alarm:

Unacknowledged

vi

vi

Page 14

THE FIELDVUE

PLANTWEBt DIGITAL PLANT ARCHITECTURE. THE DIGITAL VALVE CONTROLLER POWERS PLANTWEB

BY CAPTURING AND DELIVERING VALVE DIAGNOSTIC DATA. COUPLED WITH AMS VALVELINK

SOFTWARE, THE DVC6000f PROVIDES USERS WITH AN ACCURATE PICTURE OF VALVE

PERFORMANCE, INCLUDING ACTUAL STEM POSITION, INSTRUMENT INPUT SIGNAL AND PNEUMATIC

PRESSURE TO THE ACTUATOR. USING THIS INFORMATION, THE DIGITAL VALVE CONTROLLER

DIAGNOSES NOT ONLY ITSELF, BUT ALSO THE VALVE AND ACTUATOR TO WHICH IT IS MOUNTED.

R

DVC6000f SERIES DIGITAL VALVE CONTROLLER IS A CORE COMPONENT OF THE

R

FIELDVUEr DVC6000f Series Digital Valve Controller

vii

vii

Page 15

1-1

Introduction

Section 1 Introduction

Scope of Manual 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using this Manual 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Information 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fieldbus Installation and Wiring Guidelines 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Educational Services 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

March 2006

1-1

Page 16

DVC6000f Series

Scope of Manual

This instruction manual includes specifications,

installation, operating, and maintenance information

for the DVC6000f Series digital valve controllers. The

manual describes the functionality of the following

FIELDVUE

1

Revision

(Firmware)

1.3, 1.4 4601 1

1. Device descriptions can be downloaded from the internet at www.fieldvue.com.

This manual describes device setup using the Model

375 Field Communicator. For information on using

AMS ValveLink

the appropriate user guide or help.

No person may install, operate, or maintain a

DVC6000f Series digital valve controller without first

being fully trained and qualified in valve, actuator, and

accessory installation, operation and maintenance,

and carefully reading and understanding the

contents of this manual. If you have any questions

concerning these instructions, contact your Emerson

Process Managment

proceeding.

fieldbus instruments:

Device

Type

Device

Revision

DD Compatibility

2.0 or later;

4.0 or later recommended

Software with the instrument, refer to

sales office before

Note

Neither EmersonR, Emerson Process

Management, Fisher

affiliated entities assumes

responsibility for the selection, use or

maintenance of any product.

Responsibility for the selection, use,

or maintenance of any product

remains with the purchaser and

end-user.

R

, nor any of their

(1)

W9132-1

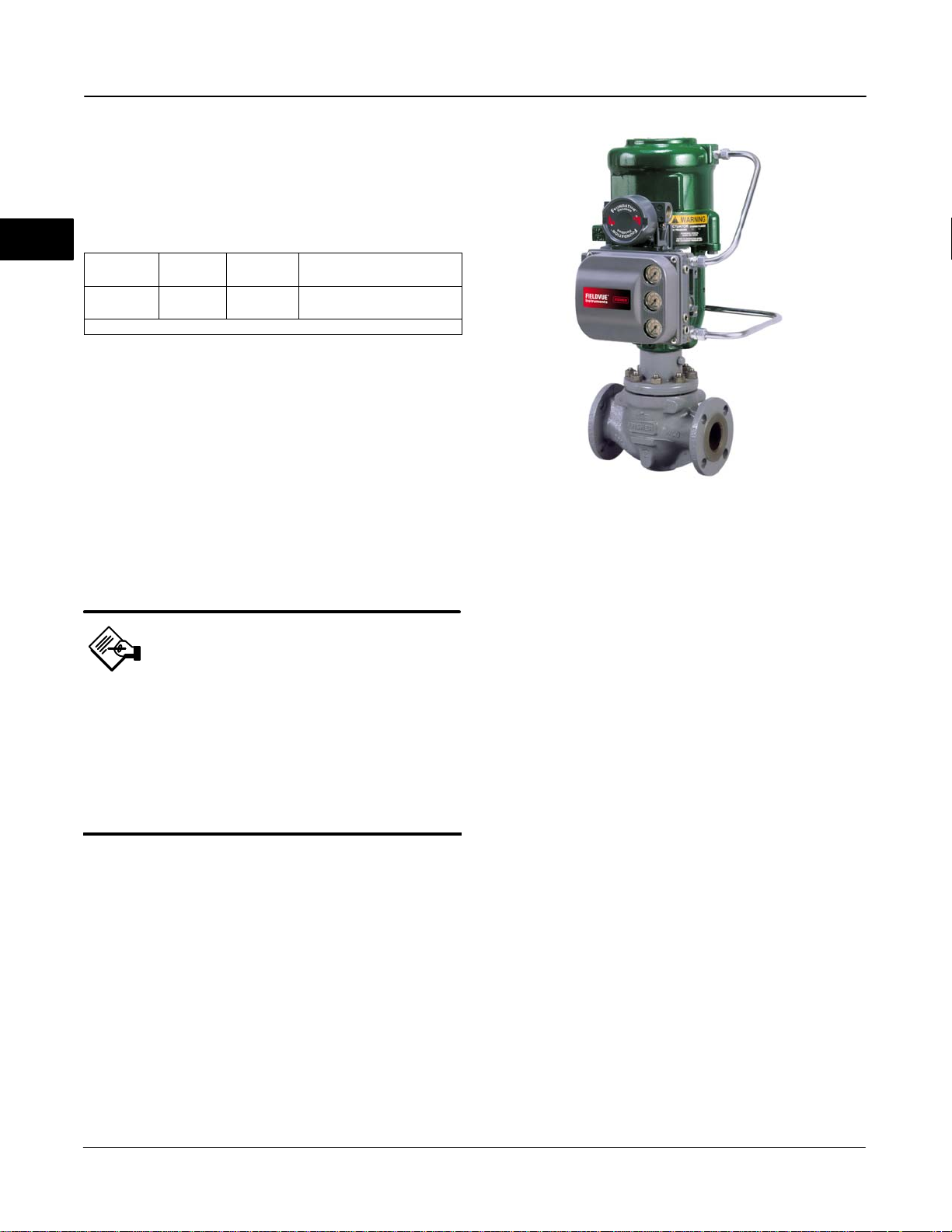

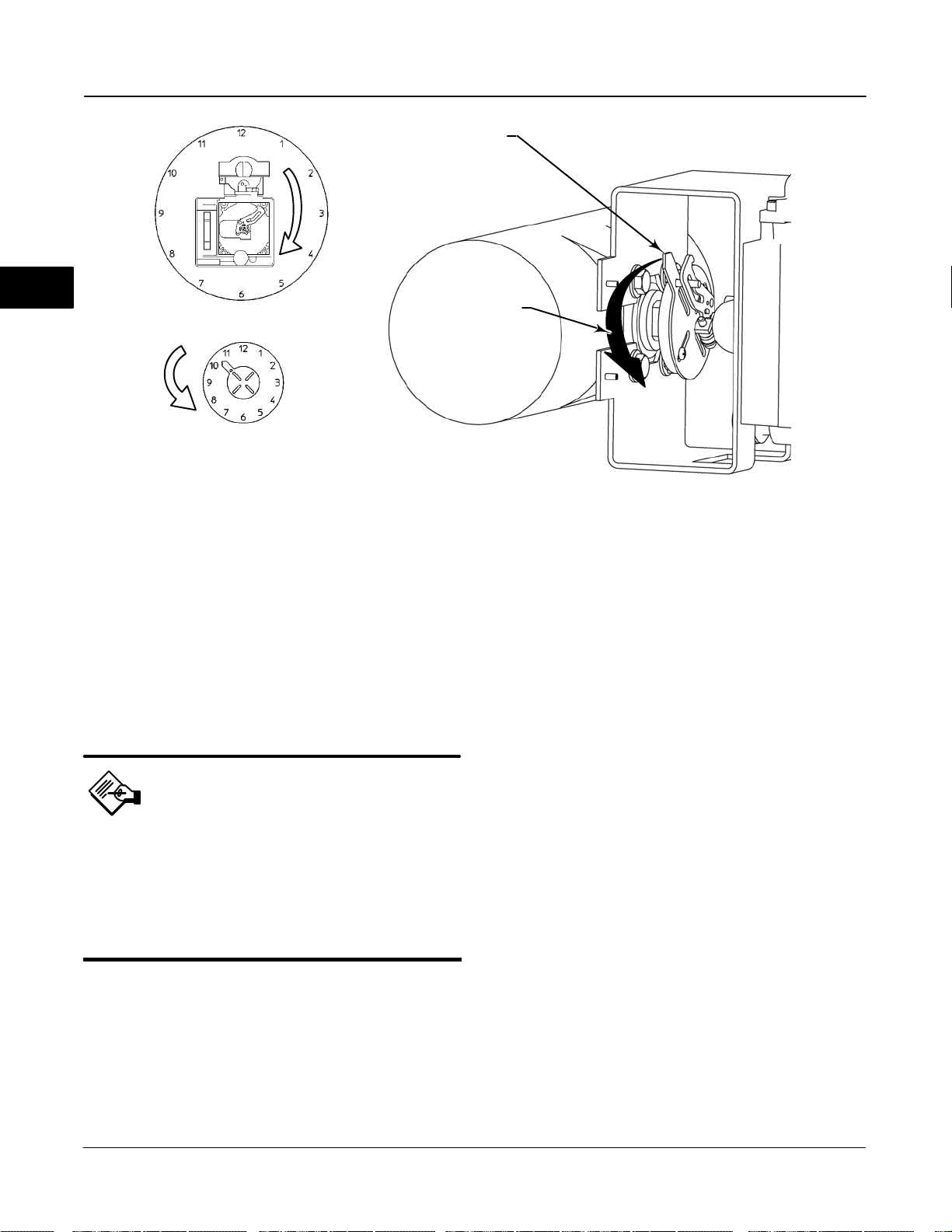

Figure 1-1. Type DVC6010f Digital Valve Controller

Mounted on Type 585C Piston Actuator

console, another FOUNDATION fieldbus system

console, or with AMS ValveLink Software.

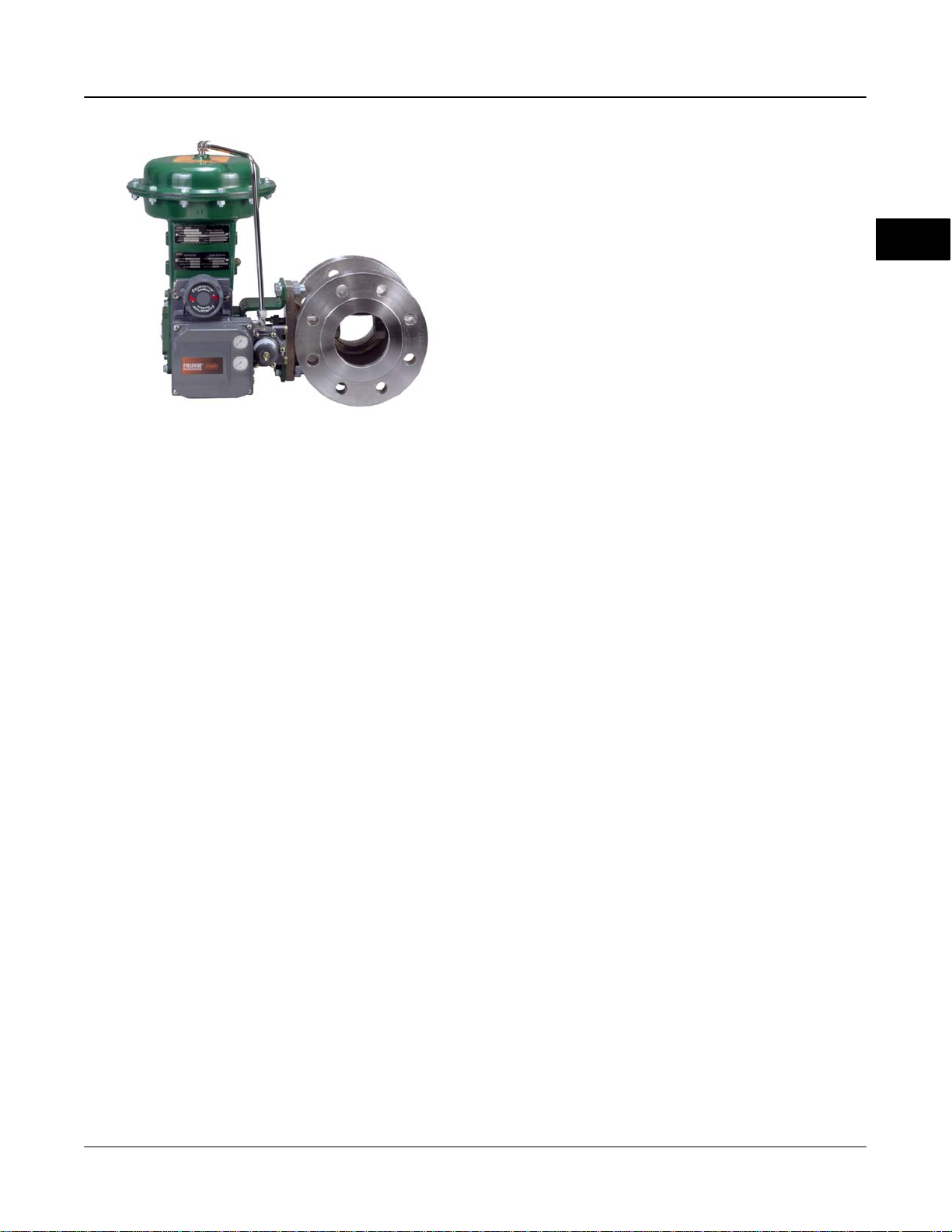

DVC6000f Series digital valve controllers can be

mounted on single or double-acting sliding-stem

actuators, as shown in figure 1-1, or on rotary

actuators, as shown in figure 1-2. DVC6000f Series

digital valve controllers mount on most Fisher and

other manufacturers’ rotary and sliding-stem

actuators.

DVC6000f Series digital valve controllers are available

with several selections of control and diagnostic

capability. Control selections include:

Standard Control (SC)— Digital valve

controllers with Standard Control have the AO, PID,

ISEL, OS, AI, MAI, DO, and four DI function blocks in

addition to the resource and transducer blocks.

Instrument Description

DVC6000f Series digital valve controllers for

FOUNDATION fieldbus are interoperable,

communicating, microprocessor-based,

digital-to-pneumatic instruments. In addition to the

primary function of converting a digital input signal to a

pneumatic output, the DVC6000f Series digital valve

controller, using

communications protocol, gives easy access to

information critical to process operation as well as

process control. This can be done using a DeltaV

FOUNDATION fieldbus

1-2

Fieldbus Control (FC)—Digital valve controllers

with Fieldbus Control have the AO function block in

addition to the resource and transducer blocks.

Fieldbus Logic (FL)—Digital valve controllers

with Fieldbus Logic have the DO, and four DI function

blocks, in addition to the resource and transducer

block.

The diagnostic capabilities include:

Performance Diagnostics (PD)

Advanced Diagnostics (AD)

Fieldbus Diagnostics (FD)

March 2006

Page 17

W8115-FF

Figure 1-2. Rotary Control Valve with Type DVC6020f Digital

Valve Controller

Introduction

Analog Output (AO) Function Block—The

analog output function block accepts the output from

another function block (such as a PID block) and

transfers it as an actuator control signal to the

transducer block. If the DO block is selected, the AO

block is not functional.

1

Proportional-Integral-Derivative (PID)

Function Block—The PID function block performs

proportional-plus-integral-plus-derivative control.

Input Selector (ISEL) Function block—The

input selector function block selects from up to four

inputs and may provide the selected signal as input to

the PID block. The input selection can be configured

to select the first good input signal; a maximum,

minimum or average value; or a hot spare.

Performance and Advanced Diagnostics are available

with AMS ValveLink Software. They provide visibility

to instrument alerts. Fieldbus Diagnostics can be

viewed with any host system.

Instrument Blocks

The digital valve controller is a block-based device.

For detailed information on the blocks within the digital

valve controller, see the Detailed Setup / Blocks

section of this manual.

All DVC6000f Series digital valve controllers include

the resource and transducer block:

Resource Block—The resource block contains

the hardware specific characteristics associated with a

device; it has no input or output parameters. The

resource block monitors and controls the general

operation of other blocks within the device. For

example, when the mode of the resource block is Out

of Service, it impacts all function blocks.

Transducer Block—The transducer block

connects the analog output function block to the I/P

converter, relay, and travel sensor hardware within the

digital valve controller.

Output Splitter (OS) Function Block—The

output splitter function block accepts the output from

another function block (such as a PID block) and

creates two outputs that are scaled or split, according

to the user configuration. This block is typically used

for split ranging of two control valves.

Analog Input (AI) Function Block—The analog

input function block monitors the signal from a

DVC6000f sensor or internal measurement and

provides it to another block.

Multiple Analog Input (AI) Function

Block—The Multiple Analog Input (MAI) function block

has the ability to process up to eight DVC6000f

measurements and make them available to other

function blocks.

Discrete Output (DO) Function Block—The

discrete output function block processes a discrete set

point and sends it to a specified output channel, which

can be transferred to the transducer block for actuator

control. In the digital valve controller, the discrete

output block provides both normal open/closed control

and the ability to position the valve in 5% increments

for course throttling applications. If the AO block is

selected, the DO block is not functional.

Function Blocks

In addition to the resource and transducer block, the

digital valve controller may contain the following

function blocks. For additional information on function

blocks, refer to Appendix B,

Communication.

March 2006

FOUNDATION fieldbus

Discrete Input (DI) Function Block—The

discrete input function block processes a single

discrete input from a DVC6000f and makes it available

to other function blocks. In the digital valve controller,

the discrete input function block can provide limit

switch functionality and valve position proximity

detection.

1-3

Page 18

DVC6000f Series

Using This Manual

Procedures that require the use of the Model 375 Field

Communicator have the Field Communicator symbol

in the heading.

Also included is the path required to accomplish

1

various tasks; the sequence of steps through the Field

Communicator menus. For example, the path to

Resource Block Mode is RB > Setup > Res Block

Mode.

An overview of the Model 375 Field Communicator

resource block and transducer block menu structures

are shown at the beginning of this manual. Menu

structures for the function blocks are included with

each function block section in Detailed Setup / Blocks.

Throughout this document, parameters are typically

referred to by their common name or label, followed by

the parameter name and index number; for example,

Write Priority (WRITE_PRI [39]). However, not all

interface systems support the use of the parameter

label and instead use only the Parameter Name,

followed by the index number, when referring to the

block parameters.

Related Documents

Other documents containing information related to the

DVC6000f Series digital valve controllers include:

FIELDVUE

Controller (Bulletin 62.1:DVC6000f)

FIELDVUE

Controllers Quick Start Guide - Form 5778

AMS ValveLink Help or Documentation

DeltaV Online Help or documentation

www.fieldvue.com

DVC6000f Series Digital Valve

DVC6000f Series Digital Valve

Specifications

Specifications for the DVC6000f Series digital valve

controllers are shown in table 1-1.

Related Information

Fieldbus Installation and Wiring Guidelines

This manual describes how to connect the fieldbus to

the digital valve controller. For a technical description,

planning, and installation information for a

FOUNDATION fieldbus, refer to the FOUNDATION

Fieldbus Technical Overview available from the

Fieldbus

DeltaV System available from your Emerson Process

Management sales office.

FOUNDATION and Fieldbus Installations in a

Educational Services

For information on available courses for DVC6000f

Series digital valve controllers, as well as a variety of

other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158−2823

Phone: 800−338−8158 or

Phone: 641−754−3771

FAX: 641−754−3431

e-mail: education@emersonprocess.com

1-4

March 2006

Page 19

Table 1-1. Specifications

Introduction

Available Configurations

Type DVC6010f: Sliding stem applications

Type DVC6020f: Rotary and long-stroke

sliding-stem applications [over 102 mm (4-inch)

travel]

Type DVC6030f: Quarter-turn rotary applications

Remote-Mounted Instrument

(1)

DVC6005f: Base unit for 2-inch pipestand or wall

mounting

DVC6015: Feedback unit for sliding-stem

applications

DVC6025: Feedback unit for rotary or long-stroke

sliding-stem applications

DVC6035: Feedback unit for quarter-turn rotary

applications

DVC6000f Series digital valve controllers can be

mounted on Fisher and other manufacturers rotary

and sliding-stem actuators.

Function Block Suites

Standard Control (throttling control)

Includes AO, PID, ISEL, OS, AI, MAI, DO, and four

DI function blocks

Fieldbus Control (throttling control)

Contains the AO function block

Fieldbus Logic [discrete on/off]

Includes DO, and four DI function blocks

Digital Communication Protocol

F

OUNDATION fieldbus registered device

Physical Layer Type(s):

121—Low−power signaling, bus−powered, Entity

Model I.S.

511—Low−power signaling, bus−powered, FISCO

I.S.

Output Signal

(2)

Pneumatic signal as required by the actuator, up to

full supply pressure.

Minimum Span: 0.4 bar (6 psig)

Maximum Span: 9.5 bar (140 psig)

Action: Double, Single direct, and Single reverse

Supply Pressure

(2,6)

Recommended: 0.3 bar (5 psi) higher than

maximum actuator requirements, up to maximum

supply pressure

Maximum: 10 bar (145 psig) or maximum pressure

rating of the actuator, whichever is lower

Steady-State Air Consumption

Standard Relay: At 1.4 bar (20 psig) supply

pressure: Less than 0.38 normal m

At 5.5 bar (80 psig) supply pressure: Less than 1.3

normal m

3

/hr (49 scfh)

Low Bleed Relay: At 1.4 bar (20 psig) supply

pressure: Average value 0.056 normal m

(2,3,4)

3

/hr (14 scfh)

3

/hr

(2.1 scfh)

At 5.5 bar (80 psig) supply pressure: Average value

0.184 normal m

3

/hr (6.9 scfh)

1

Block Execution Times

AO Block: 25 ms AI Block: 25 ms

PID Block: 30 ms MAI BLock: 40 ms

ISEL Block: 25 ms DO Block: 25 ms

OS Block: 25 ms DI Block: 20 ms

Electrical Input

Voltage Level: 9 to 32 volts

Maximum Current: 18 mA

Reverse Polarity Protection: Unit is not polarity

sensitive

Termination: Bus must be properly terminated per

ISA SP50 guidelines

March 2006

Maximum Output Capacity

Independent Linearity

Electromagnetic Interference (EMI)

−continued−

(3,4)

At 1.4 bar (20 psig) supply pressure:

10.0 normal m3/hr (375 scfh)

At 5.5 bar (80 psig) supply pressure:

29.5 normal m

3

/hr (1100 scfh)

(2,5)

±0.5% of output span

Tested per IEC 61326-1 (Edition 1.1). Meets

emission levels for Class A equipment (industrial

locations) and Class B equipment (domestic

locations). Meets immunity requirements for

industrial locations (Table A.1 in the IEC

specification document). Immunity performance is

shown in table 1-2.

1-5

Page 20

DVC6000f Series

Table 1-1. Specifications (continued)

Operating Ambient Temperature Limits

−40 to 80C (−40 to 176F) for most approved

valve-mounted instruments.

−40 to 125C (−40 to 257F) for remote-mounted

1

feedback unit.

−52 to 80C (−62 to 176F) for valve-mounted

instruments utilizing the Extreme Temperature

option (fluorosilicone elastomers)

Electrical Classification

Explosion proof, Division 2,

Dust-Ignition proof, Intrinsic Safety,

and FISCO

Explosion proof, Non-incendive,

APPROVED

ATEX

IECEx

Dust-Ignition proof, Intrinsic Safety,

and FISCO

Flameproof, Type n, Intrinsic Safety,

and FISCO

Flameproof, Type n, Intrinsic Safety,

and FISCO

Refer to Special Instructions for Safe Use and

Installation in Hazardous Locations in section 2,

tables 1-3, 1-4, 1-5, and 1-6, and figures D-1, D-2,

D-3, D-4, D-5, D-6, D-7, D-8, D-9 and D-10 for

specific approval information.

Electrical Housing: NEMA 4X, CSA Type 4X, IEC

60529 IP66

Connections

Supply Pressure: 1/4-inch NPT female and

integral pad for mounting 67CFR regulator

Output Pressure: 1/4-inch NPT female

Tubing: 3/8-inch metal, recommended

Vent: 3/8-inch NPT female

Electrical: 1/2-inch NPT female, M20 adapter

optional

Stem Travel

DVC6010f, DVC6015:

0 to 102 mm (4-inches) maximum

0 to 9.5 mm (0.375 inches) minimum

DVC6020f, DVC6025:

0 to 606 mm (23.875 inches) maximum

(6)

Shaft Rotation (DVC6020f, DVC6025, DVC6030f

and DVC6035)

0 to 50 degrees minimum

0 to 90 degrees maximum

Mounting

Designed for direct actuator mounting or remote

pipestand or wall mounting. Mounting the

instrument vertically, with the vent at the bottom of

the assembly, or horizontally, with the vent pointing

down, is recommended to allow drainage of

moisture that may be introduced via the instrument

air supply.

Weight

Valve-Mounted Instruments

Aluminum: 3.5 Kg (7.7 lbs)

Stainless Steel: 7.7 Kg (17 lbs)

Remote-Mounted Instruments

DVC6005f Base Unit: 4.1 Kg (9 lbs)

DVC6015 Feedback Unit: 1.3 Kg (2.9 lbs)

DVC6025 Feedback Unit: 1.4 Kg (3.1 lbs)

DVC6035 Feedback Unit: 0.9 Kg (2.0 lbs)

Options

Supply and output pressure gauges or Tire

valves, Integral mounted filter regulator,

Stainless steel housing, module base and

terminal box (valve-mounted instruments only)

Declaration of SEP

Fisher Controls International LLC declares this

product to be in compliance with Article 3 paragraph

3 of the Pressure Equipment Directive (PED) 97 /

23 / EC. It was designed and manufactured in

accordance with Sound Engineering Practice (SEP)

and cannot bear the CE marking related to PED

compliance.

However, the product may bear the CE marking to

indicate compliance with other applicable EC

Directives.

1. 3-conductor shielded cable, 22 AWG minimum wire size, is recommended for connection between base unit and feedback unit. Pneumatic tubing between base unit output connection

and actuator has been tested to 15 meters (50 feet) maximum without performance degradation.

2. Defined in ISA Standard S51.1.

3. Normal m3/hour − Normal cubic meters per hour at 0C and 1.01325 bar, absolute. Scfh − Standard cubic feet per hour at 60F and 14.7 psia.

4. Values at 1.4 bar (20 psig) based on a single-acting direct relay; values at 5.5 bar (80 psig) based on double-acting relay.

5. Typical value. Not applicable for travels less than 19 mm (0.75 inch) or for shaft rotation less than 60 degrees. Also, not applicable to Type DVC6020f digital valve controllers in long-stroke

applications.

6. The pressure/temperature limits in this manual and any applicable code or standard should not be exceeded.

1-6

March 2006

Page 21

Introduction

Table 1-2. Immunity Performance

Port Phenomenon Basic Standard Performance Criteria

Electrostatic discharge (ESD) IEC 61000-4-2 A

Enclosure

I/O signal/control

1. A = No degradation during testing. B = Temporary degradation during testing, but is self-recovering.

Radiated EM field IEC 61000-4-3 A

Rated power frequency magnetic field IEC 61000-4-8 A

Burst IEC 61000-4-4 A

Surge IEC 61000-4-5 A

Conducted RF IEC 61000-4-6 A

Table 1-3. Hazardous Area Classifications for Canada (CSA)

CERTIFICATION

BODY

CSA

TYPE

DVC60x0F

DVC60x0FS

(x = 1,2,3)

DVC6005F

DVC60x5

(x = 1,2,3)

CERTIFICATION OBTAINED ENTITY RATING

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP A,B,C,

D,E,F,G per drawing GE04331

(including FISCO)

V

= 30 Vdc

max

= 226 mA

I

max

= 5 nF

C

i

L

= 0 mH

i

V

= 17.5 Vdc

max

= 380 mA

I

max

Ci = 5 nF

Li = 0 mH

FIELDBUS

FISCO

Pi = 5.32 W

(Explosion Proof)

Class/Division

Class I Division 1 GP B,C,D

Class I Division 2 GP A,B,C,D

Class II Division 1 GP E,F,G

Class III Division 1

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP A,B,C,

D,E,F,G per drawing GE07476

(including FISCO)

(Explosion Proof)

Class/Division

Class I Division 1 GP C,D

Class I Division 2 GP A,B,C,D

Class II Division 1 GP E,F,G

Class III Division 1

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP A,B,C,

D,E,F,G per drawing GE07476

(Explosion Proof)

Class/Division

Class I Division 1 GP B,C,D

Class I Division 2 GP A,B,C,D

Class II Division 1 GP E,F,G

Class III Division 1

V

= 30 Vdc

max

I

= 226 mA

max

= 5 nF

C

i

= 0 mH

L

i

V

= 17.5 Vdc

max

= 380 mA

I

max

= 5 nF

C

i

Li = 0 mH

V

= 10 Vdc

max

= 4 mA

I

max

= 0 nF

C

i

Li = 0 mH

− − −

− − −

FIELDBUS

FISCO

− − −

− − −

− − −

− − −

Voc = 8.6 Vdc

= 2.3 mA

I

sc

= 6.2 µF

C

a

L

= 100 mH

a

Voc = 8.6 Vdc

I

= 2.3 mA

sc

= 6.2 µF

C

a

La = 100 mH

TEMPERATURE

CODE

T5(T

v 80C)

amb

T5(T

v 80C)

amb

T6(T

v 80C)

amb

T6(T

v 60C)

amb

T6(T

v 60C)

amb

T6(T

v 60C)

amb

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

(1)

1

ENCLOSURE

RATING

4X

4X

4X

4X

4X

4X

4X

March 2006

1-7

Page 22

DVC6000f Series

CERTIFICATION

BODY

1

FM

TYPE

DVC60x0F

DVC60x0FS

(x = 1,2,3)

DVC6005F

DVC60x5

(x = 1,2,3)

Table 1-4. Hazardous Area Classifications for United States (FM)

CERTIFICATION OBTAINED ENTITY RATING

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP

A,B,C,D,E,F,G per drawing

GE04332 (including FISCO)

(Explosion Proof)

Class/Division

Class I, Division 1 GP B,C,D

Class I Division 2 GP A,B,C,D

Class II,III Division 1 GP E,F,G

Class II,III Division 2 GP F,G

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP

A,B,C,D,E,F,G per drawing

GE07475 (including FISCO)

(Explosion Proof)

Class/Division

Class I Division 1 GP C,D

Class I Division 2 GP A,B,C,D

Class II,III Division 1 GP E,F,G

Class II,III Division 2 GP F,G

(Intrinsic Safety)

Class/Division

Class I,II,III Division 1 GP A,B,C,

D,E,F,G per drawing GE07475

(Explosion Proof)

Class/Division

Class I Division 1 GP A,B,C,D

Class I Division 2 GP A,B,C,D

Class II,III Division 1 GP E,F,G

Class II,III Division 2 GP F,G

V

= 24 Vdc

max

I

= 226 mA

max

= 5 nF

C

i

L

= 0 mH

i

P

= 1.4 W

i

V

= 17.5 Vdc

max

I

= 380 mA

max

= 5 nF

C

i

L

= 0 mH

i

= 5.32 W

P

i

− − −

− − −

V

= 24 Vdc

max

= 226 mA

I

max

= 5 nF

C

i

Li = 0 mH

P

= 1.4 W

i

V

= 17.5 Vdc

max

= 380 mA

I

max

= 5 nF

C

i

L

= 0 mH

i

= 5.32 W

P

i

− − −

− − −

V

= 10 Vdc

max

= 4 mA

I

max

= 0 nF

C

i

Li = 0 mH

= 10 mW

P

i

− − −

− − −

FIELDBUS

FISCO

FIELDBUS

Voc = 8.6 Vdc

I

sc

C

La = 100 mH

P

o

FISCO

Voc = 8.6 Vdc

I

sc

C

L

a

P

o

= 2.3 mA

= 6.2 µF

a

= 5 mH

= 2.3 mA

= 6.2 µF

a

= 100 mH

= 5 mW

TEMPERATURE

CODE

T5(T

v 80C)

amb

T6(T

v 80C)

amb

T6(T

v 80C)

amb

T6(T

v 60C)

amb

T6(T

v 60C)

amb

T6(T

v 60C)

amb

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

ENCLOSURE

RATING

4X

4X

4X

4X

4X

4X

4X

4X

4X

1-8

March 2006

Page 23

CERTIFICATE TYPE

DVC60x0F

DVC60x0FS

(x = 1,2,3)

ATEX

DVC6005F

DVC60x5

(x = 1,2,3)

Table 1-5. Hazardous Area Classifications—ATEX

CERTIFICATION OBTAINED ENTITY RATING

II 1 G D

Gas

EEx ia IIC T5/T6 - Intrinsic Safety

Dust

T85C (Tamb v 80C)

II 2 G D

Gas

EEx d IIB+H2 T5/T6 - Flameproof

Dust

T90C (Tamb v 85C)

II 3 G D

Gas

EEx nCL IIC T5/T6 - Type n

Dust

T85C (Tamb v 80C)

II 1 G D

Gas

EEx ia IIC T5/T6 - Intrinsic Safety

Dust

T85C (Tamb v 80C)

II 2 G D

Gas

EEx d IIB T5/T6 - Flameproof

Dust

T90C (Tamb v 80C)

II 3 G D

Gas

EEx nL IIC T5/T6 - Type n

Dust

T85C (Tamb v 80C)

II 1 G D

Gas

EEx ia IIC T4/T5/T6 - Intrinsic Safety

Dust

T130C (Tamb v 125C)

II 2 G D

Gas

EEx d IIC T4/T5/T6 - Flameproof

Dust

T130C (Tamb v 125C)

II 3 G D

Gas

EEx nA IIC T4/T5/T6 - Type n

Dust

T130C (Tamb v 125C)

Ui = 24 Vdc

= 226 mA

I

i

Ci = 5 nF

= 0 mH

L

i

Pi = 1.4 W

U

= 17.5 Vdc

i

I

= 380 mA

i

= 5 nF

C

i

= 0 mH

L

i

P

= 5.32 W

i

Ui = 24 Vdc

Ii = 226 mA

= 5 nF

C

i

= 0 mH

L

i

Pi = 1.4 W

Ui = 17.5 Vdc

Ii = 380 mA

= 5 nF

C

i

Li = 0 mH

P

= 5.32 W

i

Ui = 10 Vdc

Ii = 4 mA

= 0 nF

C

i

L

= 0 mH

i

= 5 mW

P

i

FIELDBUS

FISCO

− − −

− − −

FIELDBUS

FISCO

− − −

− − −

− − −

− − −

Uo = 8.6 Vdc

Io = 2.3 mA

= 6.2 µF

C

a

= 100 mH

L

a

Po = 5 mW

Uo = 8.6 Vdc

Io = 2.3 mA

= 6.2 µF

C

a

La = 100 mH

P

= 5 mW

o

Introduction

TEMPERATURE

CODE

T5(T

v 80C)

amb

v75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

ENCLOSURE

RATING

IP66

IP66

IP66

IP66

IP66

IP66

IP66

IP66

IP66

1

March 2006

1-9

Page 24

DVC6000f Series

CERTIFICATE TYPE

1

DVC60x0F

DVC60x0FS

(x = 1,2,3)

IECEx

DVC6005F

DVC60x5

(x = 1,2,3)

Table 1-6. Hazardous Area Classifications—IECEx

CERTIFICATION OBTAINED ENTITY RATING

Gas

Ex ia IIC T5/T6 - Intrinsic Safety

Gas

Ex d IIB+H2 T5/T6 - Flameproof

Gas

Ex nC IIC T5/T6 - Type n

Gas

Ex ia IIC T5/T6 - Intrinsic Safety

Gas

Ex d IIB T5/T6 - Flameproof

Gas

Ex nC IIC T5/T6 - Type n

Gas

Ex ia IIC T4/T5/T6 - Intrinsic Safety

Gas

Ex d IIC T4/T5/T6 - Flameproof

Gas

Ex nA IIC T4/T5/T6 - Type n

V

= 24 Vdc

max

I

= 226 mA

max

= 5 nF

C

i

= 0 mH

L

i

P

= 1.4 W

i

V

= 17.5 Vdc

max

I

= 380 mA

max

= 5 nF

C

i

= 0 mH

L

i

P

= 5.32 W

i

V

= 24 Vdc

max

= 226 mA

I

max

= 5 nF

C

i

L

= 0 mH

i

= 1.4 W

P

i

V

= 17.5 Vdc

max

= 380 mA

I

max

= 5 nF

C

i

= 0 mH

L

i

Pi = 5.32 W

V

= 10 Vdc

max

I

= 4 mA

max

= 0 nF

C

i

Li = 0 mH

= 10 mW

P

i

FIELDBUS

FISCO

− − −

− − −

FIELDBUS

FISCO

− − −

− − −

− − −

− − −

Voc = 8.6 Vdc

= 2.3 mA

I

sc

= 6.2 µF

C

a

L

= 100 mH

a

= 5 mH

P

o

Voc = 8.6 Vdc

= 2.3 mA

I

sc

= 6.2 µF

C

a

= 100 mH

L

a

Po = 5 mH

TEMPERATURE

CODE

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T5(T

v 80C)

amb

v 75C)

T6 (T

amb

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

T4(Tamb v 125C)

T5(Tamb v 95C)

T6(Tamb v 80C)

ENCLOSURE

RATING

IP66

IP66

IP66

IP66

IP66

IP66

IP66

IP66

IP66

1-10

March 2006

Page 25

2-2

Installation

Section 2 Installation

Special Instructions for Safe Use and

Installation in Hazardous Locations

CSA 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATEX Intrinsic Safety, Dust 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATEX Flameproof, Dust 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATEX Type n, Dust 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IECEx Instrinsic Safety, Type n, Flameproof 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting

Type DVC6010f on Sliding-Stem Actuators (up to 4 inches travel) 2-4. . . . . . . . .

Type DVC6020f on Long-Stroke Sliding-Stem Actuators

(4 to 24 inches travel) and Rotary Actuators

Type DVC6030f on Quarter-Turn Actuators 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines for Mounting Type DVC6005f Base Unit 2-10. . . . . . . . . . . . . . . . . . . . . . .

Wall Mounting 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pipestand Mounting 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type DVC6015 on Sliding-Stem Actuators (up to 4 inches travel) 2-12. . . . . . . . . .

2

2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

March 2006

Type DVC6025 on Long-Stroke Sliding-Stem Actuators

(4 to 24 inches travel) and Rotary Actuators

Type DVC6035 on Quarter-Turn Actuators 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Control 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Mounting 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67CFR Filter Regulator

Integral-Mounted Regulator 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Yoke-Mounted Regulator 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Casing-Mounted Regulator 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Connections

Supply Connections 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Connections 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single-Acting Actuators 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Double-Acting Actuators 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vent Connections 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Page 26

DVC6000f Series