Page 1

Instruction Manual

D100639X012

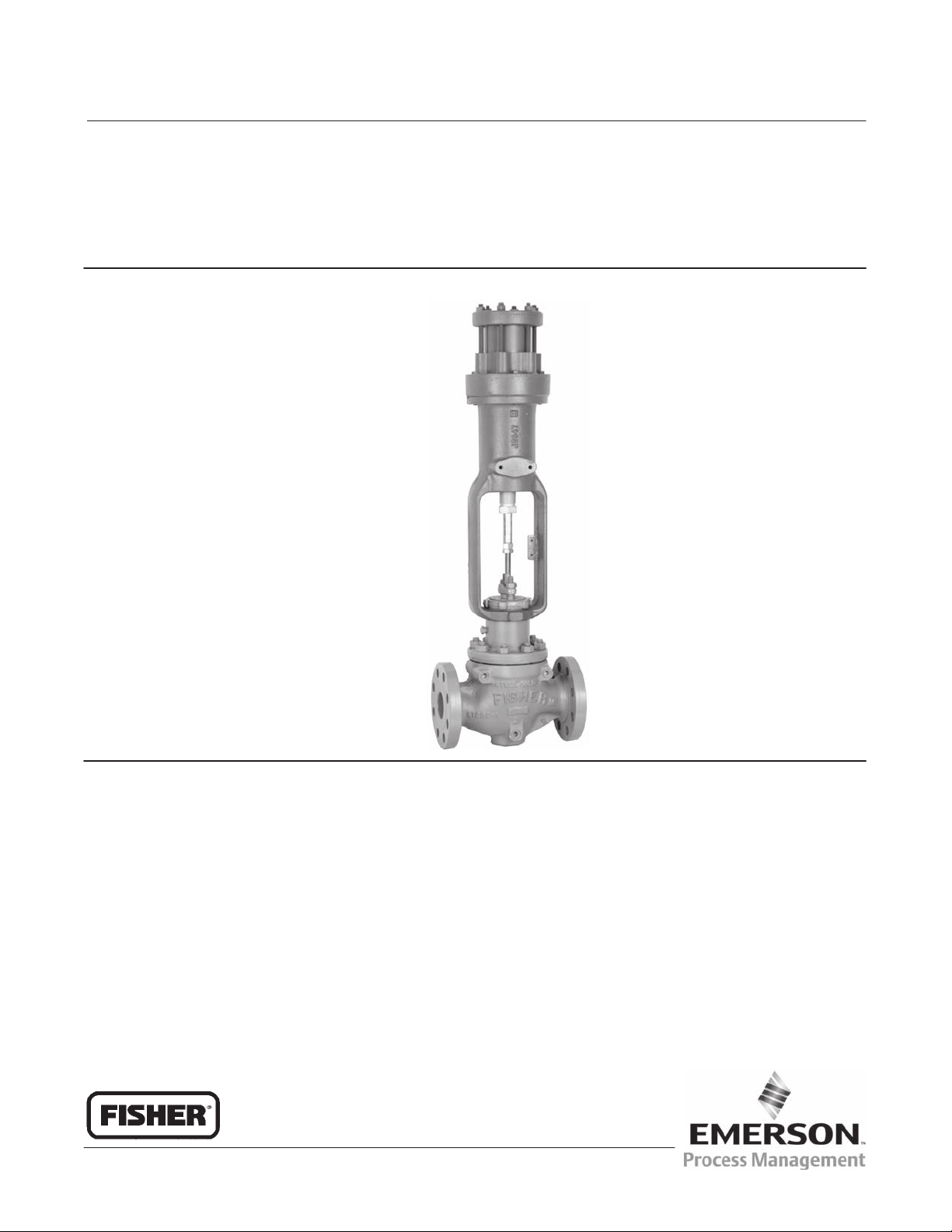

Fisherr 1B and 1BR Constant‐Pressure Pump

Governor Actuators

Figure 1. Fisher 1B Actuator on Direct‐Acting easy‐e™ Valve

1B Actuator

April 2011

W2232‐1

Introduction

Scope of Manual

This instruction manual provides information on installation, adjustment, maintenance, and parts ordering for the

Fisher 1B pump governor actuator. Refer to separate instruction manuals for information about the valve and other

accessories used with these actuators.

Do not install, operate, or maintain a 1B pump governor actuator without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and

www.Fisher.com

Page 2

1B Actuator

April 2011

Instruction Manual

D100639X012

warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office

before proceeding.

Description

The 1B pump governor actuator (figure 1) is used to maintain a constant discharge pressure on steam driven turbine

or reciprocating pumps and for pressure reducing or pressure relief applications. Typical pump governor applications

include fire pumps, boiler feedwater pumps, and industrial or refining pumps where the discharge medium is oil,

steam, air, or other noncorrosive fluid.

The 1BR pump governor actuator is combined with a push‐down‐to‐open valve for service as a relief governor. A relief

governor is used to divert excess pump discharge to the suction side of the pump.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed the limits given on the appropriate nameplates. To avoid such injury or damage,

provide a relief valve for over‐pressure protection as required by government or accepted industry codes and good

engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve

materials with process media rests solely with the purchaser and end‐user. Since some valve body/trim material

combinations are limited in their pressure drop and temperature ranges, do not apply any other conditions to the valve

without first contacting your Emerson Process Management sales office.

The 1B pump governor can be installed either above or below the line but if possible it should be installed above it.

CAUTION

Thoroughly clean and blow out all pipe scale and other foreign matter. It is recommended that a Fisher strainer be installed

in the line ahead of the main valve to protect the governor while in service.

If continuous operation is desired during inspection or maintenance, install a conventional three‐valve bypass around

the governor.

2

Page 3

Instruction Manual

D100639X012

1B Actuator

April 2011

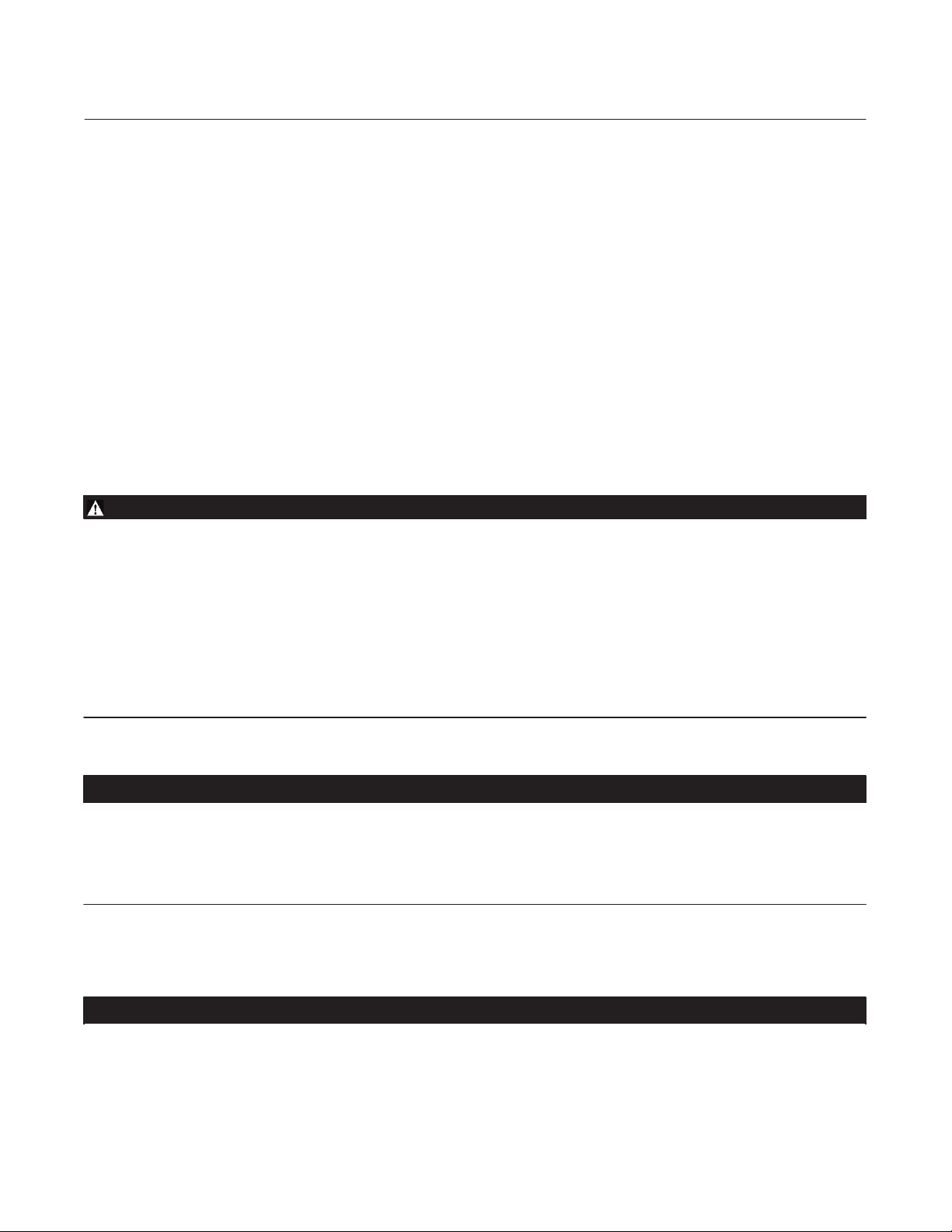

Refer to figure 2.

1. Using good piping procedure install the governor with flow in the direction of the arrow cast on the valve body.

2. Run a 1/4 inch control line from the top of the governor to the side or top of the pump discharge line, about 10 feet

from the pump. Install a pressure gauge and a large port needle valve in this line. Throttling this needle valve places

a restriction in the control line to smooth out operation.

Figure 2. Fisher 1B Installation

FISHER FRE-FLO STRAINER

FISHER 1B

PUMP GOVERNOR

NEEDLE VALVE

PUMP DISCHARGE

SUCTION

AC4650

Note

Before putting the governor into operation, be sure to remove the plastic shipping plug in the vent hole of the adaptor piece.

3. Open the gate valve on the downstream side and close the valve in the bypass line.

4. Slowly open the upstream gate valve.

5. Allow the governor sufficient time to assume normal operation before checking the controlled pressure. If the

governor is not controlling at the set point needed, make the necessary changes as directed in the section entitled

Adjustments.

Adjustments

The pump governor has been factory set for the operating conditions stated in the order. To change the pump

discharge, use the adjusting screw (key 3). To increase the discharge pressure, turn the adjusting screw into the yoke.

3

Page 4

1B Actuator

April 2011

Instruction Manual

D100639X012

Pressure pulsation in the discharge line can be minimized by slightly closing the needle valve in the control line. Never

completely close the needle valve while the pump governor is in operation.

Maintenance

Actuator parts are subject to normal wear and must be inspected and replaced when necessary. The frequency of

inspection and replacement depends on the severity of service conditions.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

When performing maintenance procedures, isolate the control valve from the process line pressure, release pressure

from both sides of the valve body, and drain the process media from both sides of the valve. Use lock‐out procedures

to be sure that the above measures stay in effect while you are working on the actuator.

To Replace the Piston Cup:

1. Isolate the pump governor.

2. Remove the control line connection.

3. Unscrew the hex nuts (key 8).

4. Remove the cylinder cap (key 12).

5. Unscrew the cap screw (key 10) and remove the follower (key 6).

6. Remove the old piston cup (key 13) and install the new one.

7. Reassemble the pump governor in the following order: piston cup (key 13), follower (key 6), cap screw (key 10),

cylinder cap (key 12), and hex nuts (key 8).

4

Page 5

Instruction Manual

D100639X012

1B Actuator

April 2011

Parts Ordering

Each actuator has a serial number stamped on the nameplate. Always mention this number when corresponding with

your Emerson Process Management sales office regarding technical information or replacement parts. Also, reference

the complete 11‐character part number of each needed part as found in the following Parts List.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should not,

under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Note

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use, or

maintenance of any product. Responsibility for the selection, use, and maintenance of any product remains with the purchaser and

end user.

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

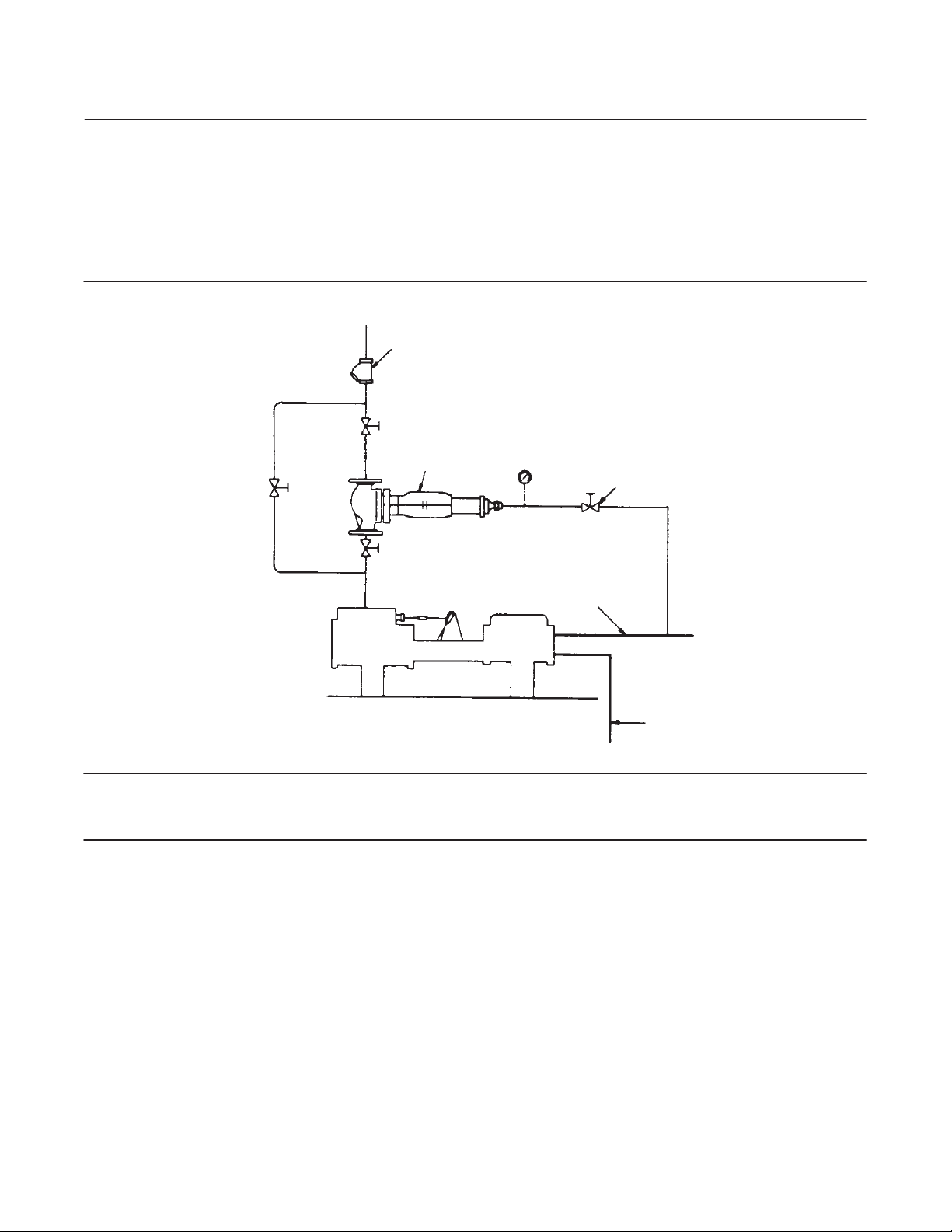

Key Description Part Number

1 Yoke, iron

2 Piston Rod Assembly, Steel Zn Pl

2A Piston Rod

2B Pin

2C Piston

3 Adjusting Screw, Brass Chrome Pl

Key Description Part Number

4 Spring, Steel

6 Follower, Steel Zn Pl

7 Cylinder, Brass

8 Finished Hex Nut, Steel Zn Pl (6 req'd)

9 Stud Bolt, Steel, Zn Pl (6 req'd)

10 Cap Screw, Steel Zn Pl

11* Gasket, Composition 1F640104022

12 Cylinder Cap, Iron

13* Piston Cup, Nitrile 1N575806992

14 Adaptor Assembly

15 Hex Head Cap Screw, Steel Zn Pl (6 req'd)

16 Travel Stop, Steel Zn Pl (reverse‐acting only)

17 Spring Seat, (2 req'd)

18 Finished Hex Nut, Steel Zn Pl

19 Finished Hex Jam Nut, Steel Zn Pl

20 Name Plate, SST

21 Drive Screw, SST (4 req'd)

*Recommended spare parts

5

Page 6

1B Actuator

April 2011

Figure 3. Fisher 1B Assembly

Instruction Manual

D100639X012

BN5768

6

Page 7

Instruction Manual

D100639X012

1B Actuator

April 2011

7

Page 8

1B Actuator

April 2011

Instruction Manual

D100639X012

Fisher and easy-e are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales

are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of

such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the

selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser

and end user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

EFisher Controls International LLC 1997, 2011; All Rights Reserved

Loading...

Loading...