Page 1

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

INTRODUCTION

The Keystone F89 pneumatic actuator range

isavailable in 4 mounting options:

• F89D - ISO 5211 shaft and flange Metricthreading

• F89E - Keystone shaft / ISO flange Metricthreading

• F89U - Keystone shaft and flange Metricthreading

• F89U - Keystone shaft and flange Imperialthreading

GENERAL PNEUMATIC SYSTEM

RECOMMENDATIONS

All Keystone pneumatic actuators are factory

lubricated with Castrol LMM grease, and

unless the operating environment is extremely

harsh, do not require re-lubrication.

For applications where the environmental

temperature reaches temperatures up to

-52°C (-62°F) a low temp version is used

(Cassida LTS 1).

To maintain maximum efficiency with this

actuator we advise that the following basic

system recommendations are followed:

1. For maximum cycle life the air quality of

compressed air should be 2.4.1 as per

ISO8573-1 standard.

2. Where pipelines are subjected to extremes

of temperature, the system should be fitted

with suitable air drying equipment.

3. When working at low temperatures, it is

important that the compressed air has been

dried to a dew point of less than the ambient

temperature. If this is not the case, water

will be condensed from the compressed

air and freeze causing damage to the seals

inside the actuator, which could result in

actuator failure.

4. Air control lines should be fitted in

accordance with a “Recommended Piping

Practice” and should not have loops,

whichmay trap condensate.

5. All air connection pipe ends should be

thoroughly cleaned and deburred after

cutting, to ensure that the pipeline is clear

of debris.

6. If pipelines are hydraulically tested, then

the lines should be “blown down” with

pressurized air to clear all traces of water,

prior to connecting lines to the actuator.

7. Where pipe fitting sealants are used, they

should be applied to the male threads only,

to avoid excess compound being forced into

the actuator control lines.

8. Where air filter equipment is used, the air

filters should be situated in positions that

allow easy access to maintain and/or drain.

9. Where pneumatic valve positioners or

pneumatic controllers are fitted to the valve

actuator assemblies, oil mist lubricated air

should not be used unless the manufacturer

states specifically that the controllers are

compatible with lubricated air.

NOTE

Keystone F89 actuators are rated for compressed air

pressure in the range of 2.75 barg (40 psig) to 8.3barg

(120 psig) and will withstand a maximum static

pressure of 10 barg (145 psig).

WARNING

For safety reasons, DO NOT "air assist" single

acting pneumatic actuators.

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-03059-EN 20/12

Page 2

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CONSTRUCTION

Keystone F89 actuators are designed to be

mounted to quarter turn valves either directly

or using the correct mounting brackets/adapter

and sizing products.

All models are of the opposed piston type.

Eachpiston incorporates an integral rack

which engages with a one piece pinion drive

shaft. Thedrive shaft is Zinc+Nickel plated

for maximum protection. The actuator body

is of extruded aluminium, and fitted with

“engineered polymer” bearings at the drive

shaft locations. Bearing and piston seals are

dynamic “O-ring” type. The actuator drive is by

means of a double keyed female shaft output

(F89E/U) or female double square (star; F89D)

conforming to EN ISO 5211.

A comprehensive range of adaptors is available

for fitting the actuator shaft to the valve shaft.

The top of the actuator shaft has a female

DD16x11 connection for direct mounting of

theAVID accessories, or can be fitted with

an insert to be compliant with the Namur

standard.

Adjustable travel stops are provided for each

end of travel to ensure that the actuator will

open and close the valve precisely.

STORAGE

All actuators leave the factory tested and

in excellent working condition and finish.

Inorder to maintain these characteristics

until the actuator is installed in the plant, it is

necessary to observe the following rules and

take appropriate measures during the storage

period.

STANDARD INSTALLATION

The F89 actuator can be used for butterfly

valves, ball valves and all quarter turn devices,

in double acting or spring return configuration.

Single acting actuators are supplied

as FAIL-CLOSE (CW) as standard.

Reverseacting (FAIL-OPEN; CCW) must be

specified

at the time of order. Alternatively

it is possible to change an actuator from

FAIL-CLOSE

to FAIL-OPEN by a trained

and certified mechanical engineer using

the assembly/disassembly instructions as

described in this document.

These installation instructions assume that

the actuator is installed with the cylinder axis

parallel to the axis of the valve bore (in line).

Please ensure that you have an actuator

with the correct drive, and that the valve and

actuator are in the following positions:

1a. Double acting units and spring return

units in FAIL-CLOSE position: valve closed,

actuator fully clockwise.

1b. Double acting units and spring return units

in FAIL-OPEN position: valve open, actuator

fully counterclockwise.

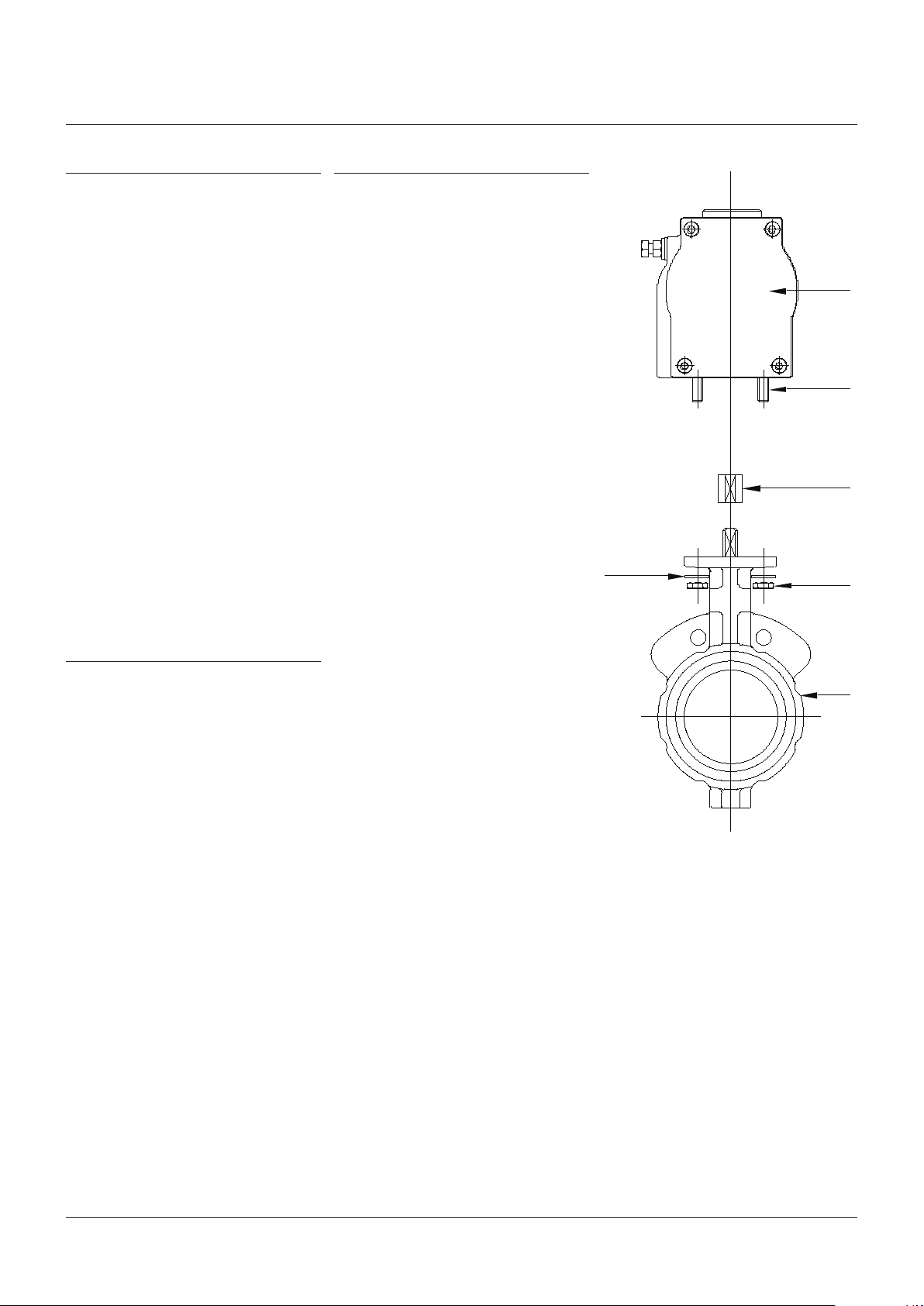

Butterfly valve application

Mounting to resilient seated butterfly valves

(withEN ISO 5211 or Keystone mounting)

2a. Screw the actuator mounting studs tightly

into the actuator base.

3a. Install the correct shaft adapter if required.

4a. Mount the actuator onto the valve top

flange and secure using a lockwasher and

nut on each mounting stud.

Lockwasher

Actuator mounting - BFV

KEYSTONE

Pneumatic

actuator

Stud

Adaptor

ifrequired

Nut

Valve

1. Make sure that the transport plugs remain

fitted in the air connections. These plastic

plugs close the air inlets, but do not have a

waterproof function, as they are a means

of protection against the entry of foreign

matter during transport.

For long term and specifically outdoor

storage these plastic plugs need to be

replaced with plugs providing a complete

weatherproof protection.

2. If the actuators are supplied separately

from the valves, they must be placed onto a

wooden pallet in order to prevent damaging

the valve coupling. For long term outdoor

storage it is advised to coat the coupling

parts with protective oil or grease.

3. In case of long term storage, it is advised

to keep the actuators in a dry place or to

provide some means of weather protection.

FIGURE 1

2

Page 3

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

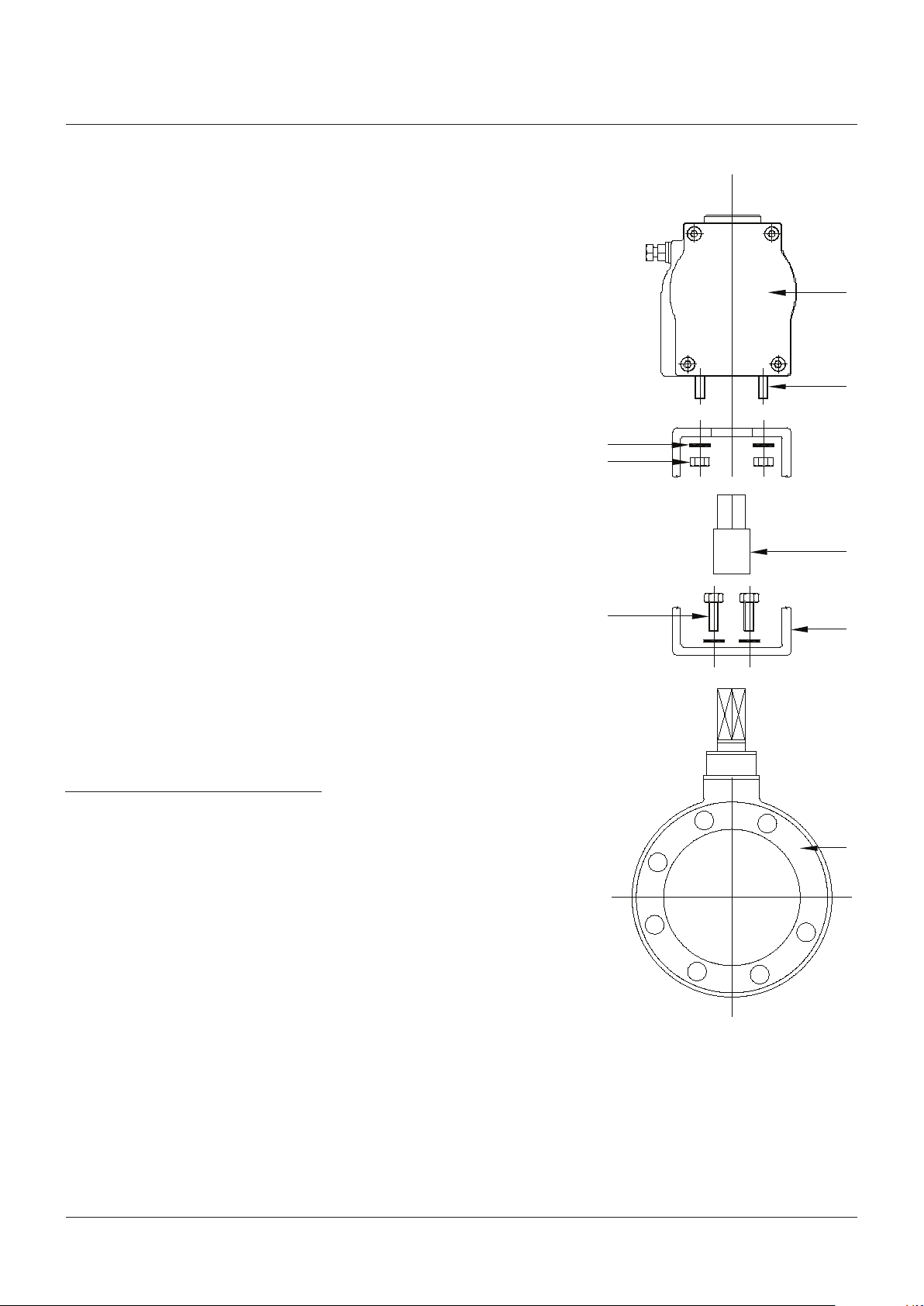

Ball valve application

Mounting to ball and high performance butterfly

valves using a bracket

2b. Screw the actuator mounting studs

tightly into the actuator base and secure

themounting bracket to the underside of

the actuator using four nuts and washers

as shown in Figure 1.

3b. Install the appropriate coupling onto the

valve stem. The coupling should be lightly

tapped or pressed onto the valve stem.

Theuse of a lubricant is recommended.

4b. Mount the actuator and bracket onto the

valve top flange using the appropriate bolts.

All quarter turn valve types

5. Before installing the valve/actuator

assembly in a piping system, the disc travel

should be verified and adjusted if necessary

using the travel stop screws (see detailed

instructions for travel setting).

6. When installing the valve/actuator

assembly into the pipeline, ensure that

thespecific instructions relating to

thevalve installation are followed.

NOTE

Some valves may require to be fitted into the pipeline

prior to mounting the actuator. Rubber lined butterfly

valves are an example of this.

Lockwasher

Nut

Bolt

Actuator mounting - BV

Pneumatic

actuator

Stud

Coupling

ifrequired

Bracket

ifrequired

7. For valves which need to be installed in

thepipeline prior to fitting the actuator,

ensure that the valve is operated into

its failsafe position before mounting

theactuator onto the valve.

NON-STANDARD INSTALLATION - DOUBLE

ACTING AND SPRING RETURN ACTUATORS

In circumstances where the actuator is required

to be installed in the transverse position i.e.

at right angles to the valve bore (across line),

theactuator must be rotated through 90°.

Thisis achieved in the following manner.

All quarter turn valve types

1. Remove the actuator from the valve or the

bracket by removing the 4 fixing bolts/nuts,

and withdraw it vertically from the valve.

2. Reposition the shaft insert 90 degrees for

Double-D connections. Bored-keyed and

star drives do not require this action.

3. Rotate the actuator 90 degrees.

4. Refit the actuator to the top of the valve or

to the bracket. Pay attention to the output

drive of the actuator to be in line with

thevalve shaft and/or shaft insert.

FIGURE 2

Ball

valve

3

Page 4

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

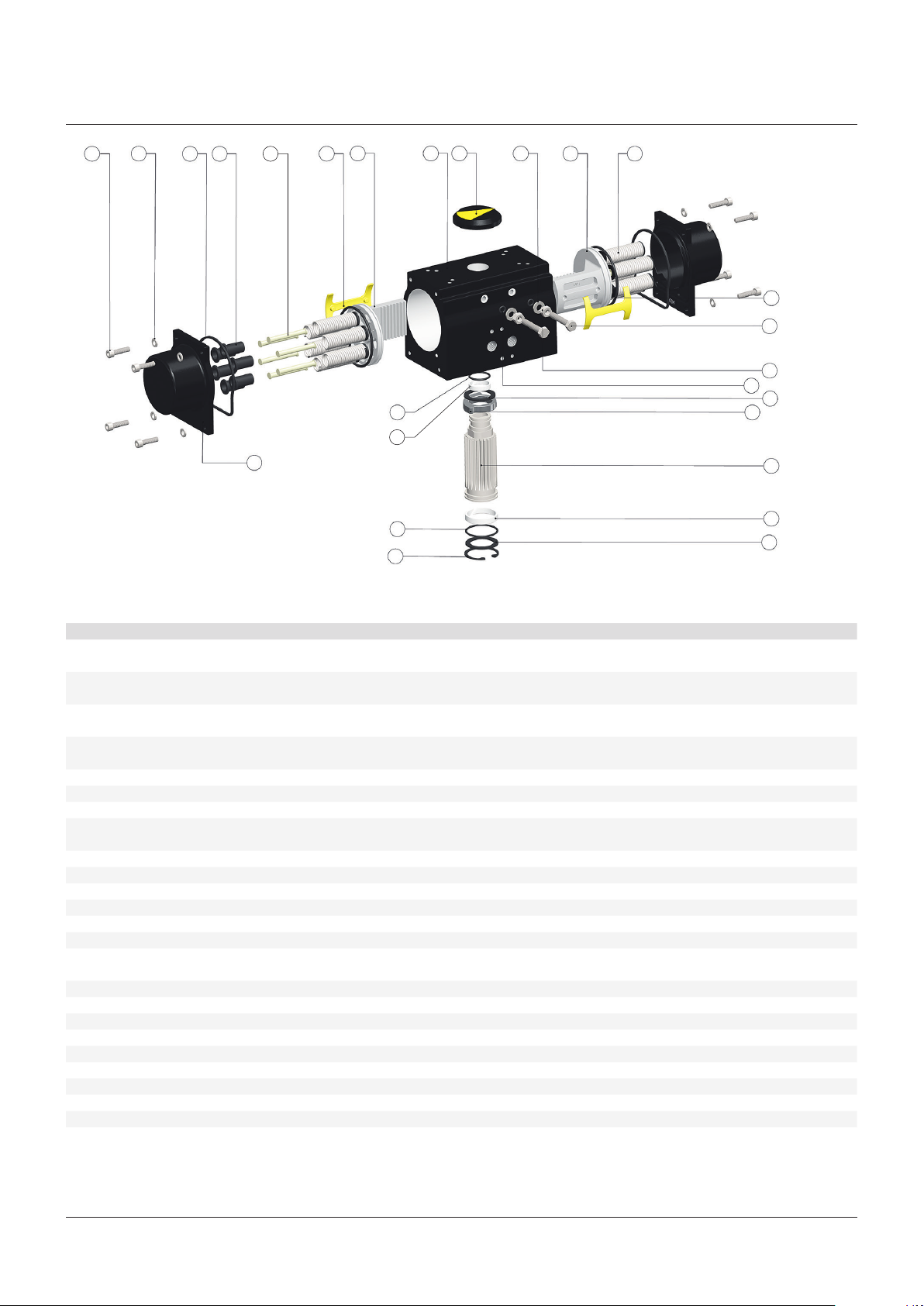

22 15 20

FIGURE 3

8 7

4

9 3

1 25 14 3 6

16

10

17

24

18

21

23

19

12

5

2

11

13

TABLE 1 MATERIALS OF CONSTRUCTION

No. Item Material US material std BS material std DIN material std Finish

1 Body Extruded aluminium

ASTM B221 type 6063T6

2 Pinion Hot rolled carbon steel bar ASTM

A108 grade 1045

3 Piston Die cast aluminium alloy ASTM B85

type A380 /BS 1490 grade LM24

4 End cap Die cast aluminium alloy ASTM B85

type A380/BS 1490 grade LM24

5 Cam Cast grade SAE 1045/C45 / EN8 Blackodised

6 Spring Spring steel as per ASTM A401 ASTM A401 BS 5216 HS3 DIN 17223 Pti Epoxy coated 30-40 microns

7 Spring retainer Carbon steel Zinc plated

8 Spring cup Die cast aluminium alloy ASTM B85

type A380 /BS 1490 grade LM24

9 Piston guide Zytel 101F NC010 Natural

(1)

10 Top bearing PAR

11 Bottom bearing PAR

12 Top thrust washer POM

13 Bottom thrust washer POM

14 Travel stop washer SS

15 End cap washer

+ 25% glass filled Natural

(1)

+ 25% glass filled Natural

(2)

(2)

(3)

ISO 3506 A2-70 grade Natural

(3)

SS

ISO 3506 A2-70 grade Natural

(spring washer)

16 Top O-ring (pinion) NBR shore 70 A Natural

17 Bottom O-ring (pinion) NBR shore 70 A Natural

18 O-ring (piston) NBR shore 70 A Natural

19 O-ring (travel stop) NBR shore 70 A Natural

20 Gasket (end cap) NBR shore 70 A Natural

(3)

21 Bolt - travel stop SS

22 Bolt - end cap SS

23 Nut - travel stop SS

ISO 3506 A2-70 grade Natural

(3)

ISO 3506 A2-70 grade Natural

(3)

ISO 3506 A2-70 grade Natural

24 Circlip (bottom) Mild steel Natural

25 Position indicator ABS plastic Natural

ASTM B221 BS 1474 6063 DIN 3.33206.51 Anodized 15-25 microns +

ESPC 80-120 microns

A108 BS 970 080M40 C40 Electroless nickel plated

10-15 microns

ASTM B85 BS 1490 DIN 1725-2300 or 226 Anodized

ASTM B85 BS 1490 DIN 1725-2300 or 226 ESPC 80-120 microns

ASTM B85 BS 1490 DIN1725-2300 or 226 Anodized

Natural

Natural

1. POM Acetal Resin 2. Polyoxymethylene 3. Stainless steel

4

Page 5

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

DISASSEMBLY PROCEDURE - DOUBLE

ACTING ACTUATORS

WARNING

Remove air pressure and observe normal safety

precautions, including the use of eye protection.

1. Pull of the indicator cap (25) from the top

of the actuator. If this cap is too tight, light

pressure may be applied to the underside

via a short length of round bar inserted from

the bottom end of the actuator shaft.

Note: levering with a screwdriver is

considered to be a potentially dangerous

practice and should be avoided.

2. Remove both travel stop bolts (21),

afterslackening the lock nuts.

3. Verify that the end caps are for double

acting actuator (flat), and loosen end cap

fixing screws evenly (22).

4. Remove end caps (4).

5. Using a suitable wrench in the top of

thepinion shaft (2), turn the shaft counter

clockwise to drive the pistons apart.

Removethe pistons (3) complete with

backing pads/O-rings, etc.

6. Remove circlip (24) from the bottom bore of

the actuator including thrust washer (13).

7. Protect the actuator bore during pinion

disassembly, and tap shaft downward.

Thetravel stop cam (5) is firmly attached to

the pinion and needs to be released before

removing the pinion from the actuator body.

8. Remove the pinion, but take care to protect

the actuator bore.

9. Remove top and bottom O-rings (16 and 17)

from the pinion shaft.

10. Remove top and bottom bearings (10 and 11)

from the pinion shaft.

WARNING

If after loosening the screws by 5 mm there is

still compression on the spring pack re-tighten

theend cap screws and return the unit to the

factory for service.

4. Remove end caps (4) and spring packs.

Inorder to avoid the springs falling out place

the actuator with the end cap on top.

WARNING

Do not disassemble the pre-compressed spring

packs, as the springs are under high force.

5. Using a suitable wrench in the top of the

pinion shaft (2), turn the shaft counter

clockwise to drive the pistons apart.

Removethe pistons (3) complete with

backing pads/O-rings, etc.

6. Remove circlip (24) from the bottom bore of

the actuator including thrust washer (13).

7. Protect the actuator bore during pinion

disassembly, and tap shaft downward.

Thetravel stop cam (5) is firmly attached to

the pinion and needs to be released before

removing the pinion from the actuator body.

8. Remove the pinion, but take care to protect

the actuator bore.

9. Remove top and bottom O-rings (16 and 17)

from the pinion shaft.

10. Remove top and bottom bearings (10 and 11)

from the pinion shaft.

DISASSEMBLY PROCEDURE - SINGLE ACTING

ACTUATORS

WARNING

Remove air pressure and observe normal safety

precautions, including the use of eye protection.

Always ensure that spring return actuators

are in fail safe position before attempting any

maintenance. Pay particular attention to this

requirement when manual operators are fitted.

1. Pull of the indicator cap (25) from the top

of the actuator. If this cap is too tight, light

pressure may be applied to the underside

via a short length of round bar inserted

from the bottom end of the actuatorshaft.

Note:levering with a screwdriver is

considered to be a potentially dangerous

practice and should be avoided.

2. Remove both travel stop bolts (21),

afterslackening the lock nuts.

3. Loosen end cap fixing screws evenly (22)

until the spring load is relaxed (3-5 mm).

5

Page 6

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

ASSEMBLY PROCEDURE - DOUBLE ACTING

ACTUATORS

1. Clean all disassembled items and replace

all items as O-rings, bearings, and backing

pads as provided in the soft good kit.

2. Liberally grease the body bore with

thegrease specified.

3. Coat all O-rings and seals with the grease

specified.

4. Output shaft assembly:

a. Fit the top bearing assembly (10) on

thetop of the pinion shaft (2) with the top

O-ring (16) uppermost.

b. Fit the bottom bearing assembly (11) on

to the bottom of the pinion shaft with

thebottom O-ring (17) at the bottom.

c. Fit the top thrust washer (12).

5. Carefully insert pinion shaft assembly from

underside of the actuator.

6. While inserting, fit the travel stop cam

(5) on top of the pinion shaft from within

theactuator bore and monitor the position

of the key in the shaft and the travel stop

cam as shown in figure 4. Finish with a firm

push to ensure full location.

7. Fit bottom thrust washer (13) and internal

circlip (25) to bottom recess of body to

locate the shaft assembly.

8. Fit the O-ring seals (18) on the pistons (3),

and grease the rack.

9.

Orientate the output shaft at 45° as in figure 4.

10. Insert pistons completely with backing

pads (9) with piston legs on left hand side of

thebore when viewed from the O-ring end

of the piston (figure 4), until racks engages

with the pinion and then push gently inward.

Theactuator is now in the fully closed

position, and the shaft indication should be

at -5 degrees (pointing slightly to the right).

11. Turn the pinion shaft counterclockwise until

it is orientated in line with the major axis of

the actuator body. The shaft is now in the

closed position.

12. Insert the right (close) travel stop bolt (21)

together with the O-ring (19), washer (14)

and lock nut (23) until the bolt hits the travel

stop cam. Tighten the lock nut.

13. Turn the shaft counterclockwise through

90° to bring it in line with the center line of

the actuator bore. The actuator is now in

theopen position.

14. Insert the left (open) travel stop bolt (21)

together with the O-ring (19), washer (14)

and lock nut (23) until the bolt hits the

travel stop cam. Tighten the lock nut.

Thepositionof the travel stop bolts need

to be verified after valve assembly and

adjusted if required.

15. Fit end cap gaskets (20) to the end caps (4)

using a light smear of grease.

16. Fit double acting end caps (flat model) to

body evenly and tighten the end cap screws

with the recommended torque (table 2).

17. Fit position indicator to top of the actuator.

18. Operate the actuator to open and close

positions using compressed air and note

the actual positions. Adjust the travel stops

if required following the routine described

in this document. If the required travel is

not achieved, refer to the trouble shooting

guide.

Standard direction of rotation

Piston guide

Stopper bolt

FIGURE 4 (top view)

Cam

Pinion Body

Direction of movement

Piston

O-ring

Gear mark

indication

6

Page 7

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

ASSEMBLY PROCEDURE - SPRING RETURN

ACTUATORS

(FAIL-CLOSE - clockwise to close)

1. Follow the steps 1 to 14 of the double acting

assembly procedure.

2. For spring return actuators the following

additional actions are required:

a. Turn the pinion (2) clockwise to the close

position.

b. Position the actuator vertically with

thepiston top in a horizontal plane

(makesure that the lower part is placed

on a clean surface).

c.

Locate the correct number of spring

packs (6) in the cavities on the piston head.

Fordurability make sure to divide the

number of springs evenly on both sides,

with a maximum difference of 1 spring,

and use the configuration as indicated in

figure 6 based on thenumber of springs.

d. Fit the first end cap as described in

thefollowing description and repeat

thesequence for the other side.

3. Fit end cap gaskets (20) to the end caps (4)

usingalight smear of grease.

4. Place end cap on top of the spring packs

and make sure that the springs are located

in the spring pockets (cavities). Fit end cap

to body evenly using end cap screws (

22)

and washer (15). Tighten the end capscrews

with the recommended torque (table 2).

Makesure that the springs remain in

position during assembly of the end cap.

5. Fit position indicator (25) to top of

theactuator.

6.

Operate the actuator to open and close

positions using compressed air and note

theactual positions. Adjust the travel stops

if required following the routine described in

this document. If the required travel is not

achieved, refer to the trouble shooting guide.

ASSEMBLY PROCEDURE - SPRING RETURN

ACTUATORS

(FAIL-OPEN - counterclockwise to open)

1. Follow the steps 1 to 8 of the double acting

assembly procedure.

2.

Orientate the output shaft at 45° as in figure 5.

3. Insert pistons completely with backing pads

(9) with piston legs on right hand side of

the bore when viewed from the O-ring end

of the piston (figure 5), until racks engages

with the pinion and then push gently

inward. Theactuator is now in the fully open

position, and the shaft indication should be

at 95 degrees.

4. Turn the pinion shaft clockwise until it is

orientated in line with the center line of

theactuator bore (90° position). The shaft is

now in the open position.

5. Insert the left (open) travel stop bolt (21)

together with the O-ring (19), washers (14)

and lock nut (23) until the bolt hits the travel

stop cam. Tighten the lock nut.

6. Turn the shaft clockwise to 0° to bring it in

line with the major axis of the actuator body.

The actuator is now in the close position.

7.

Insert the right (close) travel stop bolt (21)

together with the O-ring (19), washer (14) and

lock nut (23) until the bolt hits the travel stop

cam. Tighten the lock nut. The position of

the travel stop bolts need to be verified after

valve assembly and adjusted if required.

8. For spring return actuators the following

additional actions are required:

a. Turn the pinion counterclockwise to

theopen position.

b. Position the actuator vertically with

the piston top in a horizontal plane

(makesure that the lower part is placed

on a clean surface).

c. Locate the correct number of springs

in the cavities on the piston head.

Usetheconfiguration as indicated

in figure 6 based on the number of

springs. For durability make sure to

divide thenumber of springs evenly on

both sides, with a maximum difference

of1spring.

d. Fit the first end cap as described in

thefollowing description and repeat

thesequence for the other side.

9. Fit end gap gaskets (20) to the end caps (4)

using alight smear of grease.

10. Place end cap on top of the spring packs,

and fit end cap to body evenly using end cap

screws (22) and washer (15). Tighten the end

cap screws with the recommended torque

table. Make sure that the springs remain in

position during assembly of the end cap.

11. Fit position indicator (25) to top

oftheactuator.

12. Operate the actuator to open and close

positions using compressed air and note

the actual positions. Adjust the travel stops

if required following the routine described

in this document. If the required travel is

not achieved, refer to the trouble shooting

guide.

Non-standard direction of rotation

Piston

Direction of

FIGURE 5 (top view)

movement

Pinion

Cam

Body Piston guide O-ring

Stopper bolt

Gear mark

indication

7

Page 8

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SPRING ALLOCATION

In spring return applications the number of

springs used determine the torque provided for

fail safe applications. For optimal performance

the number of springs used is based on

thevalve type used using the F89 actuator

torque table (normaly closed applications):

- Ball valves: use spring torque level which

matches the spring torque at 90 degrees with

the supplied air starting torque at 0 degrees.

- Butterfly valves: use spring torque level which

matches the spring torque at 0 degrees with

the supplied air torque at 0 degrees.

The number of springs used can vary between

4 and 12 pieces. For durability make sure to

divide the number of springs evenly on both

sides, with a maximum difference of 1 spring,

and use the configuration as indicated in

figure6 based on the number of springs.

Left

Right

4 springs

5 springs

6 springs

7 springs

8 springs

FIGURE 6 - Spring allocation

9 springs

10 springs

11 springs

12 springs

8

Page 9

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SETTING OF INTERNAL TRAVEL STOPS

The Keystone F89 is fitted with integral travel

stops to enable setting of exact travel for the

valve being operated. These stops allow over and

under travel adjustment of ± 5° on each end.

WARNING

• Under no circumstances the travel stop bolts

should be completely withdrawn from the

actuator while compressed air is being applied.

• Travel stop bolts should not be used for manual

override actions.

• After setting the travel stops, accessories

mounted to the top of the actuator must be

re-adjusted accordingly.

To set the travel stops - double acting actuator

1. Operate the valve/actuator assembly to

theclosed position.

2. Remove air supply.

3. Slacken locknut on the close travel stop

(right).

4. Turn the travel stop clockwise to reduce

travel or counterclockwise to increase

travel.

5. Re-tighten locknut.

6. Reconnect air supply and check that

theclose position is correct. If not repeat

from instruction 2.

7. Apply air to the open position.

8. Remove air supply.

9. Adjust open travel stop bolt (left) as per

instruction 3 to 6 above.

To set the travel stops - spring return

actuator FAIL-CLOSE

1. Remove air supply and check actual

closeposition.

2. Apply air to operate the actuator to the

openposition.

3. Whilst the air supply is maintained, slacken

locknut on the close travel stop (right)

as the close position is now able to be

adjusted.

4. Turn the travel stop clockwise to reduce

travel or counterclockwise to increase

travel.

5. Re-tighten locknut

6. Remove air supply to close the actuator.

Ifcorrect close position is not achieved

repeat from instruction 2.

7. Apply air to drive the actuator to the open

position and check actual open position.

8. Remove air supply so that actuator closes,

and the open travel stop bolt (left) can

beadjusted.

9. Adjust open travel stop bolt as per

instruction above.

10. Re-tighten lock nut.

11. Apply air and check open position.

Ifcorrectopen position is not achieved,

repeat from instruction 7.

Cam adjustment (standard direction of rotation)

Cam

Pinion

O-ring

Actuator body

Plain washer

Spring washer

Locking nut

Piston close adjustment bolt

Cam

Pinion

O-ring

FIGURE 7 - Travel stop adjustment double acting and spring return FAIL-CLOSE

Actuator body

Plain washer

Spring washer

Locking nut

Piston open adjustment bolt

9

Page 10

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

To set the travel stops - spring return

actuator FAIL-OPEN

1. Remove air supply and check actual

openposition.

2. Apply air to operate the actuator to the close

position.

3. Whilst the air supply is maintained, slacken

locknut on the open travel stop (left) as

theopen position is now able to be adjusted.

4. Turn the travel stop clockwise to reduce

travel or counterclockwise to increase

travel.

5. Re-tighten locknut.

6. Remove air supply to open the valve.

Ifcorrect open position is not achieved

repeat from instruction 2.

7. Apply air to operate the actuator to the close

position and check actual close position.

8. Remove air supply so that actuator opens,

and the close travel stop bolt (right) can

beadjusted.

9. Adjust close travel stop bolt as per

instruction above.

10. Re-tighten lock nut.

11. Apply air and check open position.

Ifcorrectclose position is not achieved,

repeat from instruction 7.

Cam adjustment (non-standard direction of rotation)

Cam

Pinion

O-ring

Piston open adjustment bolt

Actuator body

Plain washer

Spring washer

Locking nut

FIGURE 8 - Travel stop adjustment spring return FAIL-OPEN

Cam

Pinion

O-ring

Actuator body

Plain washer

Spring washer

Locking nut

Piston close adjustment bolt

10

Page 11

KEYSTONE FIGURE 89 PNEUMATIC ACTUATORS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

MAINTENANCE

Under normal operating conditions and

when basic pneumatic system maintenance

procedures are applied, the F89 actuator will

require minimum maintenance for hundred

thousands of cycles.

If O-rings wear out and air leakage occurs,

a soft goods kit can be ordered. Please use

the (dis)assembly routines as described in

this document. Carefully inspect all other

components for wear and replace if required.

TROUBLE SHOOTING

If the actuator fails to operate the valve

correctly, carry out the following checks:

1. Check that the air supply is at the required

pressure.

2. Ensure that the air supply is not restricted in

any way.

3. Check for air leakage on supply lines to

theactuator

4. Check for air leakage at the top and bottom

of the pinion shaft.

5. Check for air leakage across the piston

seals by applying pressure to port 4 (B) and

looking for leakage from port 2 (A) and/or

reverse.

6.

Check that the valve torque has not increased

due to problems with the valve itself.

NOTE 1

Refer to disassembly and assembly procedures

forgaining access to O-rings and actuator internals

ifrequired.

NOTE 2

Reduced stroke i.e. valve not traveling the required

stroke or “backlash” may be caused by an incorrect fit

between output bore and valve stem.

PNEUMATIC AIR CONNECTION

The Series 89 actuator has 2 pcs ¼” BSP or

NPT air connections which can be used for tube

connection. Alternatively it is possible to mount

a Namur solenoid valve directly.

Comments

1. As standard, applying air to port 2 (A)

will cause the actuator to rotate in a

counterclockwise (CCW) direction to open

the valve.

2. For double acting applications, applying air

to port 4 (B) will cause the actuator to rotate

in a clockwise direction to close the valve.

3. Single acting (also called spring return)

actuators should not be “air assisted” as

this will apply excessive load to the valve

stem and cause damage.

BOLT TORQUE VALUES

As the end caps are pressurized during normal

operation, it’s important to fix them correctly

and not damage the threading due to excessive

torque. Please use the torque values as

indicated in table 2.

TABLE 2 - END CAP BOLTS TIGHTENING TORQUE

Actuator size Bolt size Tightening torque (Nm) Tightening torque (lbin)

002 M5 3 27

003 M5 3 27

004 M5 3 27

006 M5 3 27

009 M6 9 80

014 M8 15 133

020 M8 15 133

032 M10 28 248

052 M12 40 354

085 M12 40 354

140 M16 110 974

240 M16 110 974

© 2015, 2020 Emerson Electric Co. All rights reserved 12/20. Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of

Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson Electric Co. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of

any Emerson Electric Co. product remains solely with the purchaser.

Emerson.com/FinalControl

11

Loading...

Loading...