Emerson ACE97 Instruction Manual

Instruction Manual

Form 5665

November 2011

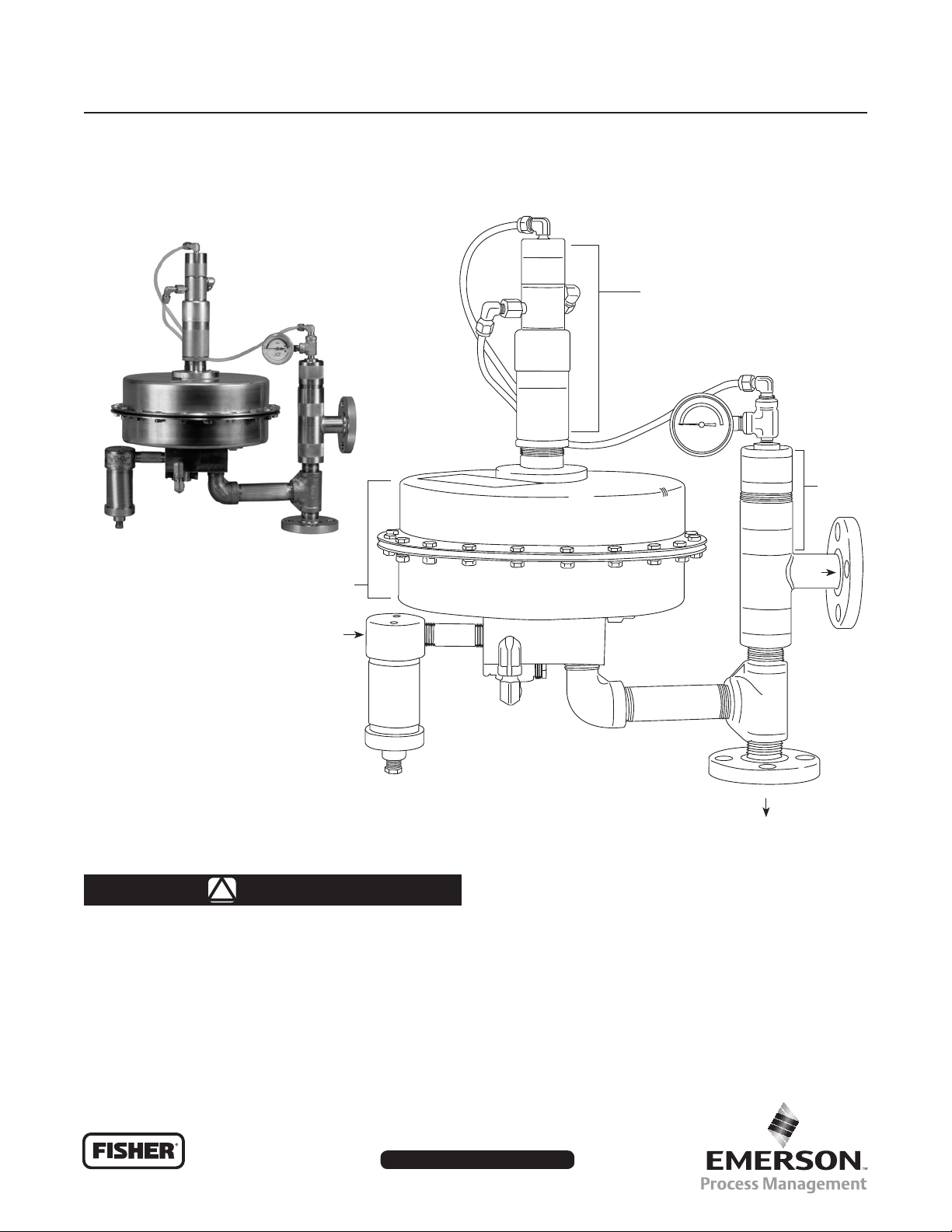

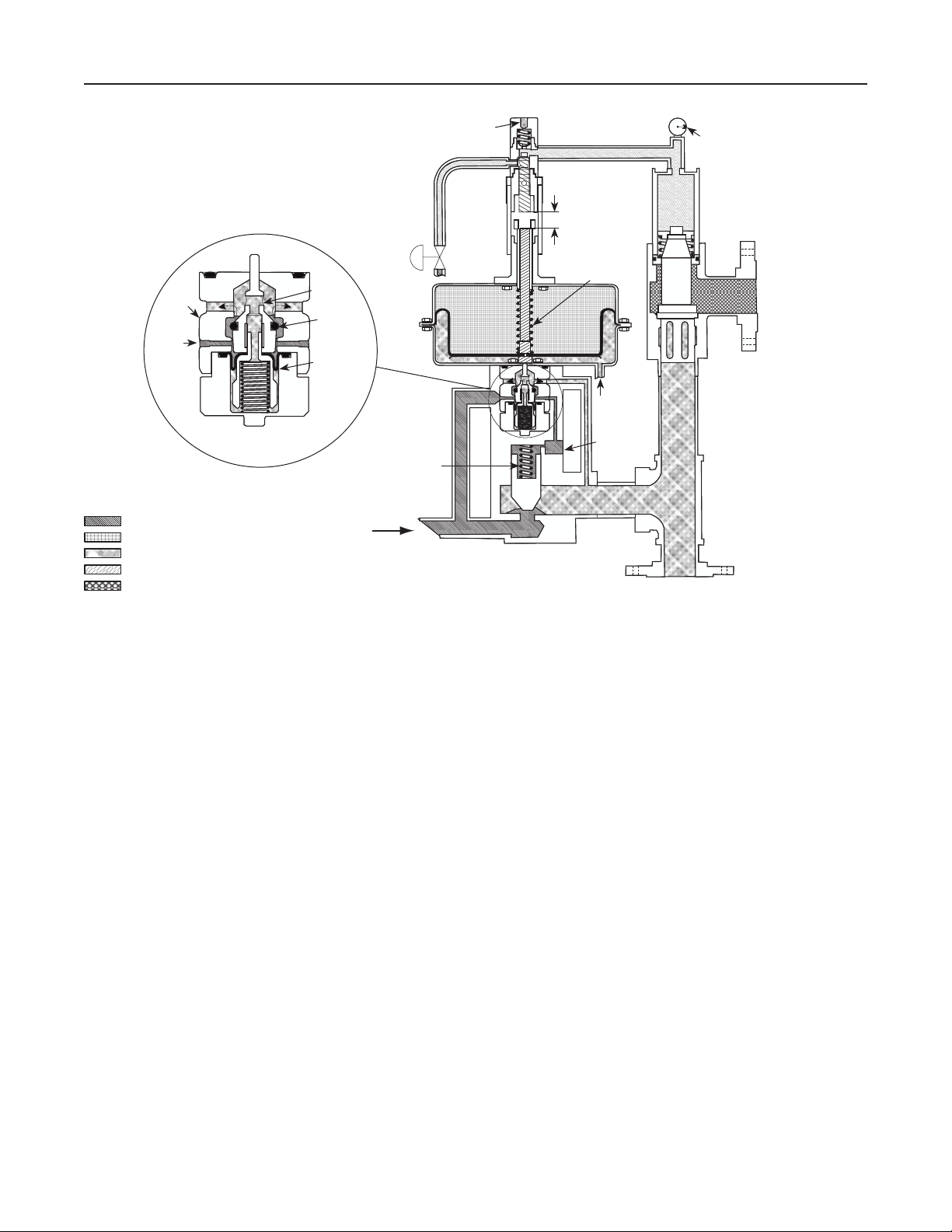

Type ACE97 Pad-Depad Valve

Type ACE97

DEPAD PILOT VALVE

DEPAD

MAIN

VALV E

W8161

ACTUATOR

GAS INLET

Figure 1. Type ACE97 Pad-Depad Valve (NPS 1/2 / DN 15 Pad Valve / 1 NPT Depad Valve Shown)

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

VENT

PAD VALVE

TO TANK

Fisher® pad-depad valves must be

installed, operated, and maintained

in accordance with federal, state, and

local codes, rules and regulations,

and Emerson Process Management

Regulator Technologies, Inc. (Regulator

Technologies) instructions.

www.sherregulators.com

D102773X012

Type ACE97

Specications

Ratings and specications for the Type ACE97 Pad-Depad valve are listed in the Specications section below.

Factory specications are stamped on the nameplate fastened to the actuator of the valve.

Pad (Tank Blanketing) Specications

Pad Body Sizes and End Connection Styles

1/2, 1, and 2 NPT

NPS 1/2, 1, and 2 / DN 15, 25, and 50

CL150 RF

Maximum Operating Inlet Pressure

(1)

200 psig / 13,8 bar

Maximum Main Valve Inlet Pressure

(1)

200 psig / 13,8 bar

Inlet Operating Ranges

(1)

NPS 1/2 / DN 15 pad valve:

25 to 200 psig / 1,7 to 13,8 bar

NPS 1 and 2 / DN 25 and 50 pad valves:

25 to 50 psig / 1,7 to 3,4 bar

51 to 120 psig / 3,5 to 8,2 bar

121 to 200 psig / 8,3 to 13,8 bar

Control Pressure Ranges

(1)

See Table 1

Maximum and Minimum Differential Pressures

25 psig / 1,7 bar minimum

200 psig / 13,8 bar maximum

Maximum Backpressure

(1)

20 psig (1,4 bar)

Flow Coefcients for Relief Valve Sizing

(110% of rated Cv)

NPS 1/2 / DN 15:

Cv 0.2 use Cv 0.22

Cv 0.4 use Cv 0.44

NPS 1 / DN 25:

Cv 1 use Cv 1.1

Cv 2 use Cv 2.2

Cv 4 use Cv 4.4

Cv 7.5 use Cv 8.25

Cv 10 use Cv 11

NPS 2 / DN 50:

Cv 20 use Cv 22

Cv 45 use Cv 50

Cv 60 use Cv 66

Depad (Vapor Recovery) Specications

Depad Body Sizes

1 and 2 NPT

NPS 3 and 4 / DN 80 and 100

Depad Pressure Ranges

See Table 1

Valve Coefcients (110% of rated Cv)

1 NPT:

Cv 3 use Cv 3.3

Cv 6 use Cv 7

Cv 12 use Cv 13

Cv 17 use Cv 19

2 NPT:

Cv 20 use Cv 22

Cv 35 use Cv 39

Cv 70 use Cv 77

NPS 3 / DN 80:

Cv 90 use Cv 99

Cv 115 use Cv 127

Cv 140 use Cv 154

NPS 4 / DN 100:

(1)

Cv 150 use Cv 165

Cv 200 use Cv 220

Cv 280 use Cv 308

General Type ACE97 Specications

Pressure Registration

External

Temperature Capabilities

Nitrile (NBR):

-20° to 180°F / -29° to 82°C

Fluorocarbon (FKM):

0° to 212°F / -18° to 100°C

Ethylenepropylene (EPDM - FDA):

-20° to 212°F / -29° to 100°C

Peruoroelastomer (FFKM):

-20° to 212°F / -29° to 100°C

Approximate Weights

NPS 1/2 x 1 x 1 / DN 15 x 25 x 25:

70 pounds / 32 kg

NPS 1 x 2 x 2 / DN 25 x 50 x 50:

105 pounds / 48 kg

NPS 2 x 3 x 3 / DN 50 x 80 x 80:

175 pounds / 79 kg

(1)

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

2

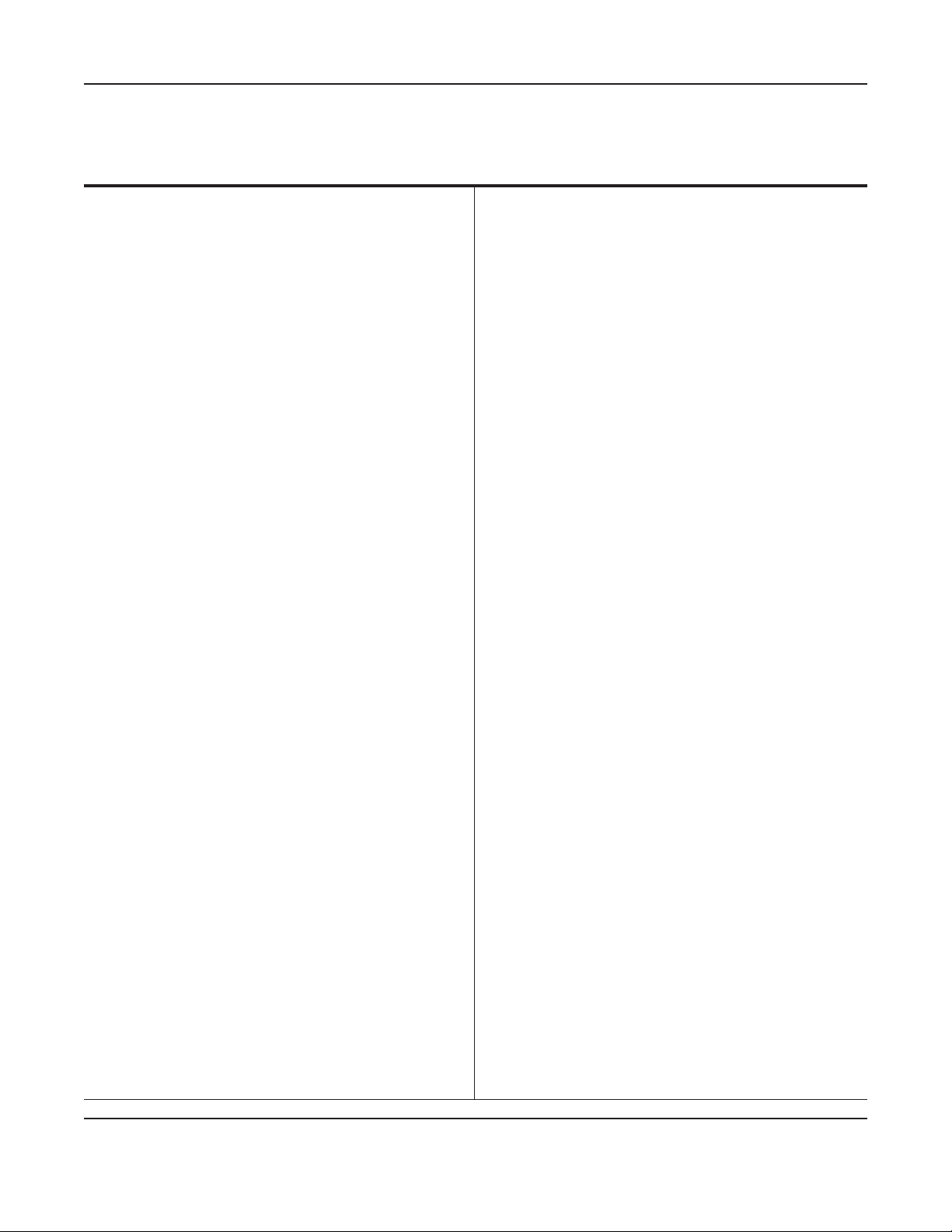

E0005

CAGE

INLET

OPEN PILOT

INLET PRESSURE

ATMOSPHERIC PRESSURE

TANK PRESSURE

PILOT LOADING PRESSURE

VENT HEADER PRESSURE

INLET BLEED PRESSURE

LOADING PRESSURE

EXHAUSTED BACK TO TANK

REGULATOR

POPPET

O-RING

SEAT

INLET

BLEED

ROLLING

DIAPHRAGM

INERT GAS IN

MAIN

VALVE

SPRING

ACTUATOR

PAD VALVE

Figure 2. Type ACE97 Pad On / Depad Off

DEPAD PILOT

ADJUSTABLE

DEADBAND

CONTROLLED

PRESSURE

RANGE SPRING

SENSING

CONNECTION

DIAGNOSTIC

PORT

Type ACE97

ON/OFF

DIAGNOSTIC

GAUGE

DEPAD

MAIN

VALVE

VENT

TANK

CONNECTION

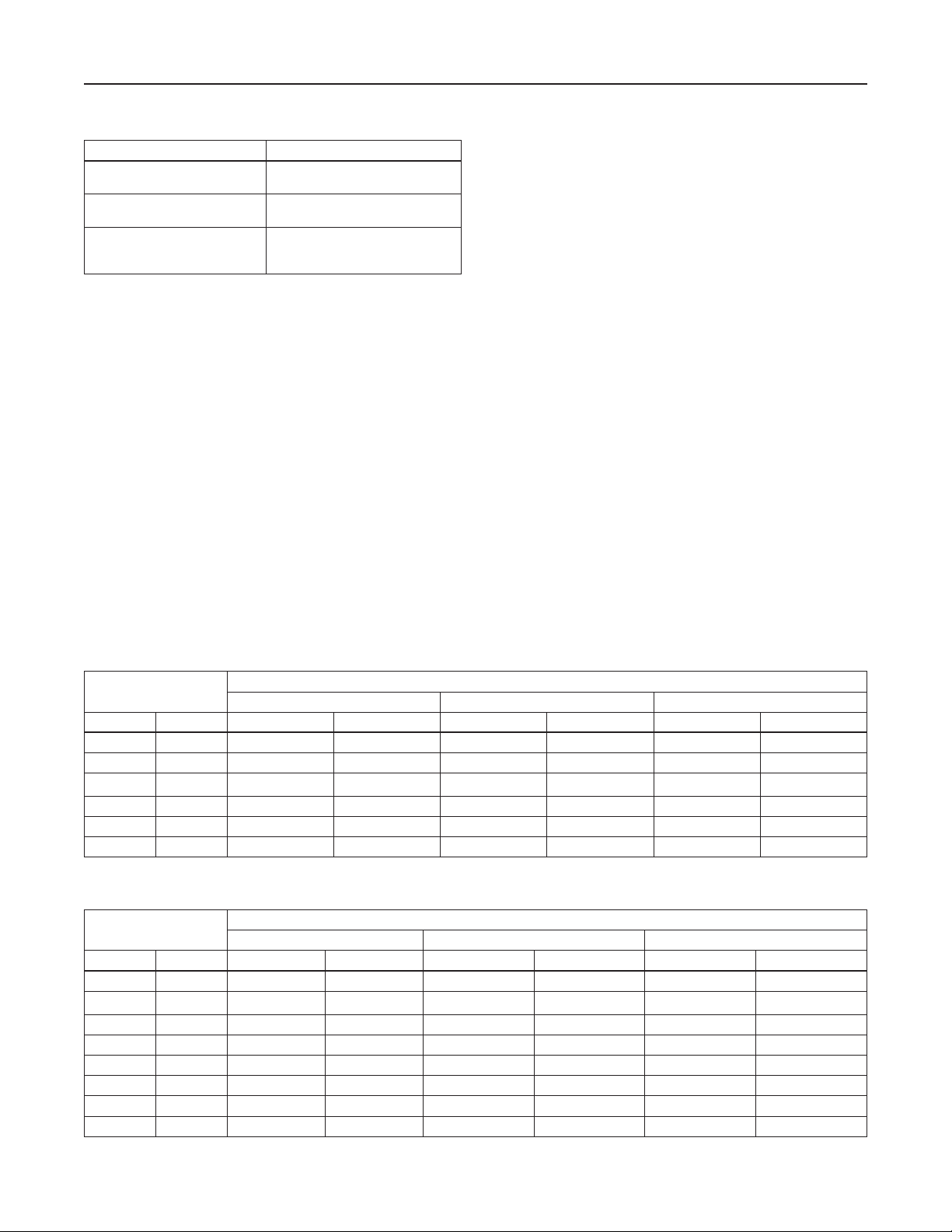

Table 1. Actuator Spring Pressure Ranges

CONTROL PRESSURE RANGES SPRING FREE LENGTH SPRING WIRE DIAMETER

Pad Setpoint Depad Setpoint (Above Pad)

inches w.c. mbar inches w.c. mbar

0.5 to 3- 1 to 7 4 to 10 10 to 25 3.08 78,2 0.105 2,67

0.5 to 7 1 to 17 4 to 6 10 to 15 4.0 102 0.092 2,34

3 to 13 7 to 32 4 to 16 10 to 40 3.73 94,7 0.156 3,96

4 to 10 10 to 25

0.5 to 1.4 psig 34 to 97 mbar 0.25 to 1 psig 17 to 69 3.8 96,5 0.250 6,35

1.0 to 2.2 psig 69 to 152 mbar 0.25 to 2 psig 17 to 138 3.8 96,5 0.313 7,95

1. Two nested springs are used (See Figure 12).

(1)

16 to 78 40 to 194

(1)

If a leak develops or if the unit or outlet

continually vents gas, service to the

unit may be required. Failure to correct

INCHES mm INCHES mm

3.73

2.90

94,7

73,7

0.156

0.250

personnel when installing, operating,

and maintaining the Type ACE97

pad-depad valve.

trouble could result in a hazardous

condition. Only a qualied person must

install or service the unit.

Installation, operation, and maintenance

Introduction

Scope of the Manual

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation.

Either condition may result in equipment

damage or personal injury. Use qualied

This instruction manual provides installation, startup,

maintenance, and parts ordering information for the

Type ACE97 Pad-Depad valve (Figure 1). The

product photo may vary depending on the size of

the valve ordered.

3,96

6,35

3

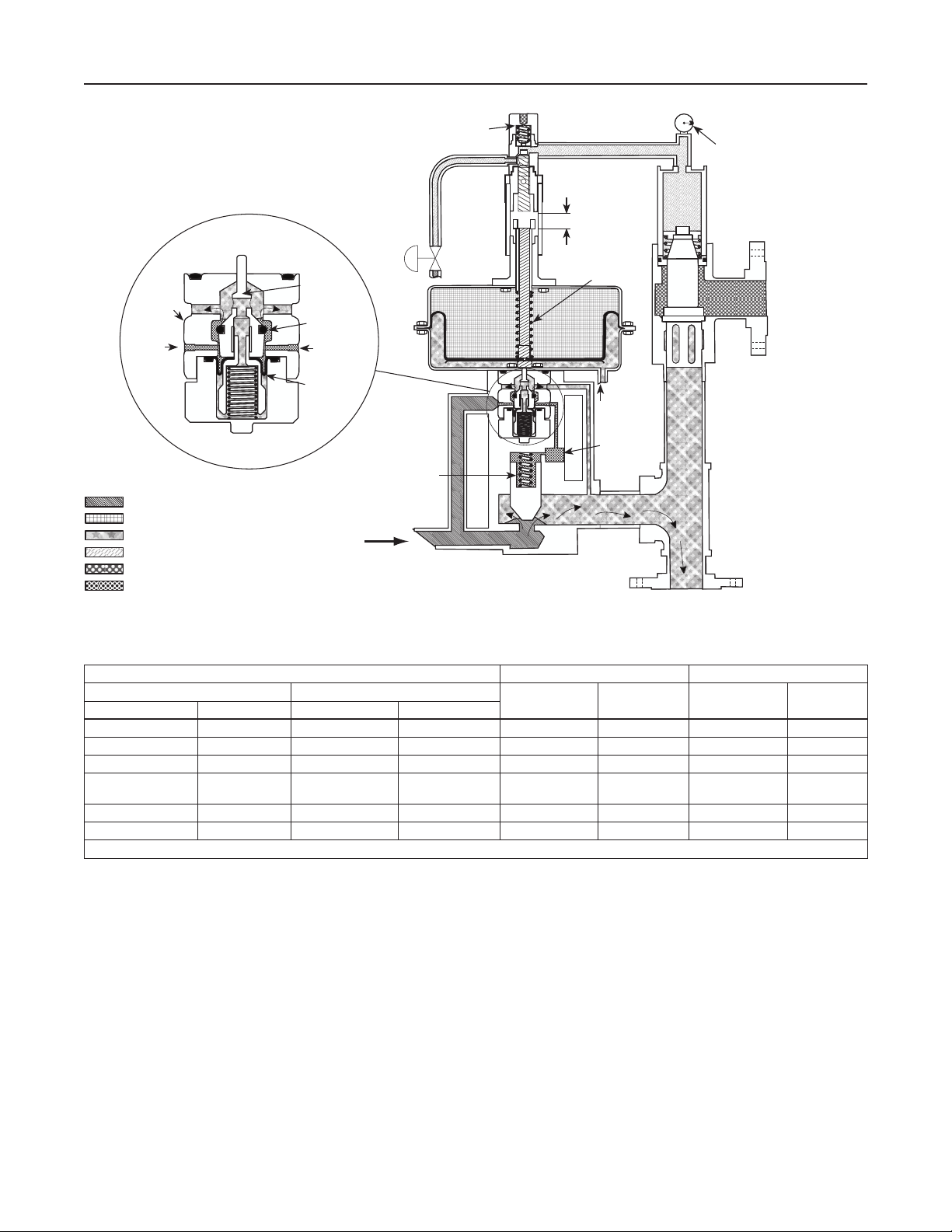

Type ACE97

LOADING PRESSURE

EXHAUSTED BACK TO TANK

DEPAD PILOT

ON/OFF

DIAGNOSTIC

GAUGE

CAGE

INLET

E0004

INLET PRESSURE

ATMOSPHERIC PRESSURE

TANK PRESSURE

PILOT LOADING PRESSURE

VENT HEADER PRESSURE

CLOSED PILOT

Product Description

REGULATOR

POPPET

O-RING

SEAT

ROLLING

DIAPHRAGM

CONTROLLED

PRESSURE

RANGE SPRING

ACTUATOR

SENSING

CONNECTION

DIAGNOSTIC

MAIN

VALVE

SPRING

INERT GAS IN

PAD VALVE

PORT

Figure 3. Type ACE97 Pad Off / Depad On

Principle of Operation

DEPAD

MAIN

VALVE

Vent

TANK

CONNECTION

VENT

The Type ACE97 Pad-Depad valve is a self-contained,

pilot-operated valve that maintains a blanket of inert gas

on top of a stored product to protect it from atmospheric

contamination. It reduces combustibility, decreases

vaporization, controls vapor space pressure during

pump-in and pump-out operations, and prevents the

tank from entering a vacuum condition and collapsing

upon itself. The Type ACE97 valve provides excellent

and accurate pressure control of the vapor space in the

tank. Blanketing pressure is kept to a minimum in order

to conserve the use of blanketing gas.

Pad (tank blanketing) is used to describe the process

of replacing the vapor space of a storage tank with

an inert gas.

Depad (vapor recovery) is used to describe the

process of relieving or venting the vapor space as

a result of pressure rise.

Tank and vapor recovery connections are available

to meet most customer requirements. A Single Array

Manifold (S.A.M) provides a single tank and sensing

connection and is required for tanks having a single

nozzle. Accessories include gauges, purge meters,

pressure switches, and check valves.

Type ACE97 pilot-operated valves (except for the

NPS 1/2 / DN 15 pad valve) control the vapor space

pressure over a stored liquid. The unit is stainless

steel and is controlled by a very large actuator

diaphragm. The oversized actuator diaphragm

offers high sensitivity to changes in tank pressure.

When a storage tank cools and tank vapors condense,

Type ACE97 pad (tank blanketing) valves replace the

condensing vapors with an inert gas to prevent internal

tank pressure from decreasing. Positive tank pressure

prevents outside air from contaminating the product

and reduces the possibility of atmospheric pressure

collapsing the tank.

Additionally, Type ACE97 valves provide depad (vapor

recovery) capabilities through the depad main valve

and depad pilot valve. When the temperature outside

the tank rises causing the vapor inside the tank to

expand, Type ACE97 depad valve vents the excess

tank pressure to a safe place.

4

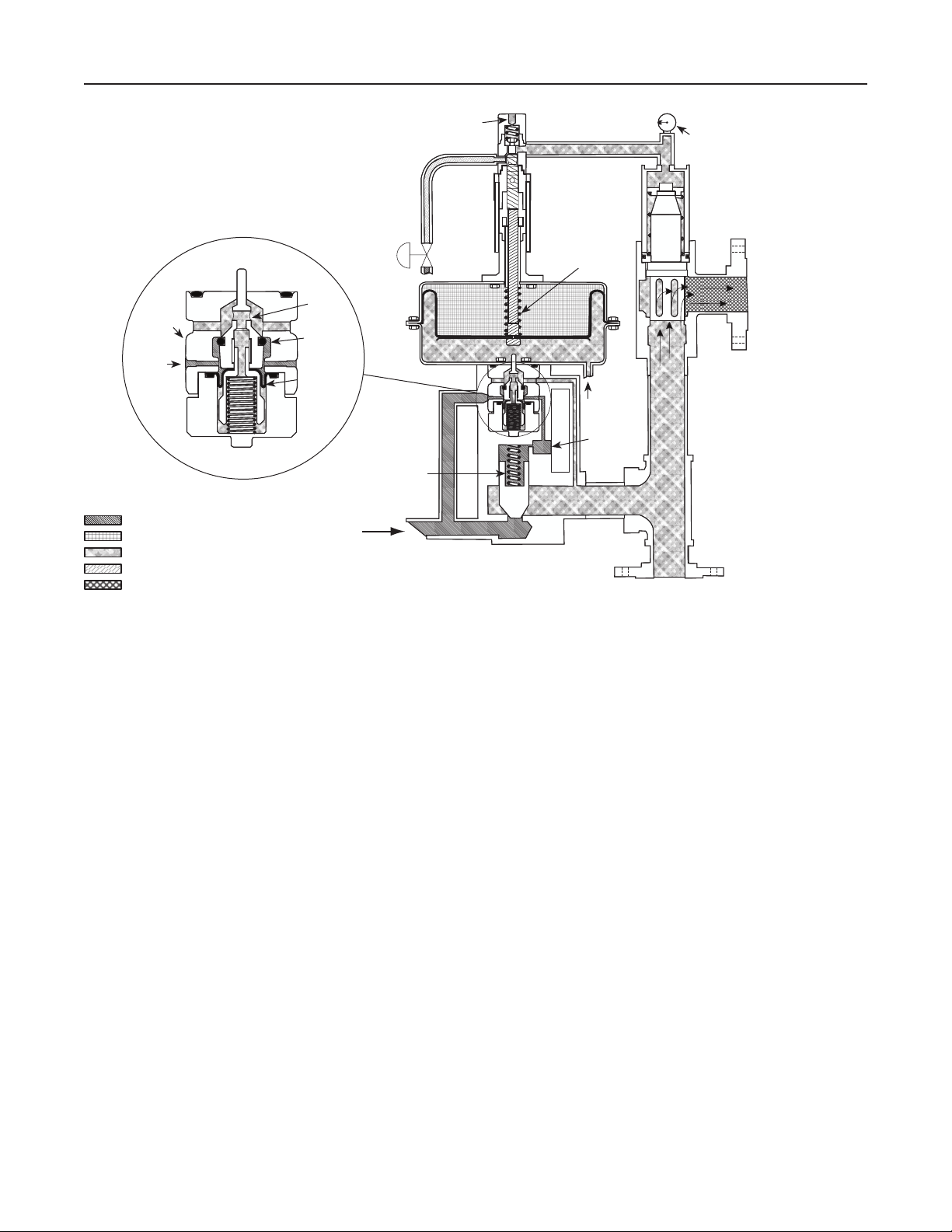

Type ACE97

E0006

CAGE

INLET

CLOSED PILOT

INLET PRESSURE

ATMOSPHERIC PRESSURE

TANK PRESSURE

PILOT LOADING PRESSURE

VENT HEADER PRESSURE

LOADING PRESSURE

EXHAUSTED BACK TO TANK

REGULATOR

POPPET

O-RING

SEAT

ROLLING

DIAPHRAGM

MAIN

VALVE

SPRING

INERT GAS IN

ACTUATOR

PAD VALVE

Figure 4. Type ACE97 Pad Off / Depad Off

DEPAD PILOT

ADJUSTABLE

DEADBAND

CONTROLLED

PRESSURE

RANGE SPRING

SENSING

CONNECTION

DIAGNOSTIC

PORT

ON/OFF

DIAGNOSTIC

GAUGE

DEPAD

MAIN

VALVE

TANK

CONNECTION

VENT

NPS 1 and 2 / DN 25 and 50 Pad Valves

(Figure 2)

When tank pressure decreases below the pad setpoint

(due to pump-out operations or thermal cooling), the

actuator diaphragm moves downward pushing open

the pad pilot. This creates ow from the pad loading

chamber to downstream. When pad loading pressure

decreases, the force created by inlet pressure on

the pad main valve plug overcomes the main spring

force and opens the main valve plug allowing ow

through the pad valve to the tank. Once tank pressure

reaches pad setpoint, the pad pilot closes, pad loading

pressure equalizes with inlet pressure and the pad

valve closes.

NPS 1/2 / DN 15 Pad Valve (Not Shown)

The NPS 1/2 / DN 15 pad valve has a main valve only.

When tank pressure decreases below the pad setpoint

the actuator diaphragm moves downward pushing the

valve plug open and allowing ow through the pad

valve to the tank.

Depad (Figure 3)

When tank pressure increases above the depad

setpoint (due to pump-in operations or thermal

heating), the actuator diaphragm moves upward and

pushes open the depad pilot. This releases depad

loading pressure (nitrogen or other supply gas). When

depad pilot loading pressure decreases, the depad

main valve opens by a spring and allows ow from the

tank to the vent or recovery system.

The blanketing (padding) gas is used as the pilot uid.

The link between the actuator and the depad main

valve is provided by the depad pilot valve, which is

located on top of the actuator. The depad pilot valve

is connected to the actuator by an adjustable coupling,

which can be rotated to adjust the depad setpoint. A

locknut is provided on the depad pilot valve to secure

the setpoint adjustment.

5

Type ACE97

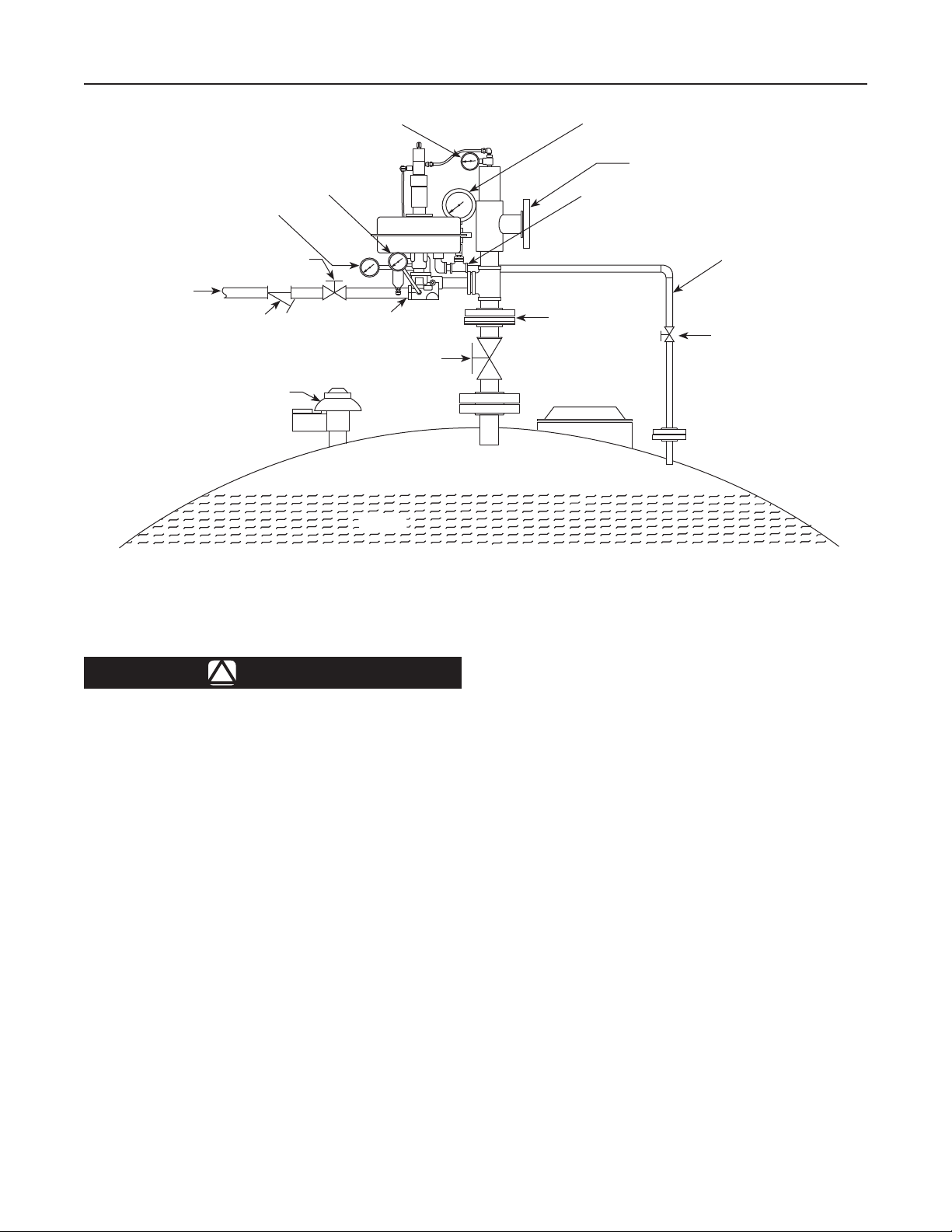

BLANKETING GAS

SUPPLY LINE

E0629

INLET PRESSURE GAUGE

INLET VALVE

LINE STRAINER

NORMAL

TANK VENT

PAD DIAGNOSTIC

GAUGE

BLANKETING GAS

CONNECTION

DEPAD DIAGNOSTIC

GAUGE

TANK VALVE

LIQUID

VAPOR SPACE

TANK VAPOR SPACE

PRESSURE GAUGE

SENSING

CONNECTION

VALVE TANK

CONNECTION

EMERGENCY

TANK VENT

VENT CONNECTION

SENSING LINE

SHUTOFF VALVE

Figure 5. Type ACE97 Pad-Depad Valve Installation

Installation and Startup

WARNING

!

Personal injury, equipment damage, or

leakage due to escaping accumulated

gas or bursting of pressure-containing

parts may result if this gas blanketing

system is overpressured or installed

where service conditions could exceed

the limits given in the Specications

section or on the valve nameplate, or

where conditions exceed any ratings of

the adjacent piping, piping connections,

or compatibility of valve materials with

process uids.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by Title 49, Part 192,

of the U.S. Code of Federal Regulations,

by the National Fuel Gas Code Title 54 of

the National Fire Codes of the National

Fire Protection Agency, or by other

applicable codes) to prevent service

conditions from exceeding those limits.

Additionally, physical damage to the

tank blanketing system could result in

personal injury and property damage

due to escaping gas or tank contents.

To avoid such injury and damage,

install the tank blanketing valve in

a safe location.

The Type ACE97 Pad-Depad valve is assembled and

preset to the customer specied pressure and setpoint.

The pressure ranges of the valve are stamped on the

nameplate attached to the upper actuator case.

1. Use qualied personnel when installing, operating,

and maintaining valves. Before installing, inspect

the main valve, pilot, and tubing for any shipment

damage or foreign material that may have

collected. Ensure that the body interior is clean

and the pipelines are free of foreign material.

Apply pipe compound only to the external pipe

threads with a threaded body, or use suitable

line gaskets and good bolting practices with

a anged body.

2. Inspect the nameplate on the upper actuator

case. It displays the model number, serial number,

blanketing gas supply pressure range, maximum

inlet pressure, Cv value, and set pressures. These

6

Type ACE97

must agree with the system that you are Padding

(blanketing) or Depadding (recovering). The serial

number will be needed in any communication with

your local Sales Ofce.

3. Clean the gas padding (blanketing) supply lines of

all dirt and foreign material before connecting

them to the Type ACE97 Pad-Depad valve.

4. The valve should be mounted above the tank

with the actuator case in a horizontal position.

Four connections are required (see Figure 5):

a. Blanketing gas supply to the valve

b. Vapor recovery/process connection (vent)

c. System tank connection

d. Sensing line to the tank

Piping Considerations

Piping must be capable of supporting the weight of

the system. Use pipe supports when necessary.

Refer to Figure 5.

Inlet Piping

The padding (blanketing) gas supply line should be

equipped with a Number 100 mesh strainer to remove

dirt and pipe scale. Inlet piping must be sized to

adequately deliver padding (blanketing) gas at the

specied inlet pressure under full ow conditions.

CAUTION

Undersized piping may inadequately

deliver Padding (blanketing) gas at

the specied inlet pressure under full

ow conditions. This may result in

unacceptable performance under high

demand conditions.

Outlet Piping

Valve outlet is piped into the tank vapor space.

Outlet piping should be self-draining to the tank and

of equal or greater size than the Type ACE97 valve

tank connection. The valve should be situated

above and as close as possible to the tank vapor

space for best performance.

CAUTION

Unnecessarily long or restricted outlet

piping may result in poor setpoint control.

Sensing Line

The sensing line should be 1/2-inch / 13 mm tubing

or pipe, must slope toward the tank, and should not

contain low points (or traps) that could catch liquid.

The sensing line must enter the tank above the liquid

level at a point that senses the vapor space pressure

and is free from turbulence associated with tank

nozzles or vents.

Note

Best control is obtained when both

connections to the tank are separate.

If the tank has only one available

nozzle, contact Regulator Technologies

for alternate methods of installation.

A Single Array Manifold (S.A.M.) is

available for such situations.

Vent Connection

The vent connection must be self-draining, facing

away from the valve, and of equal or greater size than

the valve tank connection.

Tank Venting

The tank may require normal and emergency vents.

The Type ACE97 Pad-Depad valve does not perform

these functions, it only controls the vapor space

pressure under process conditions.

Diagnostic Gauges

An on/off diagnostic gauge is mounted on the depad

main valve at the inlet to the cylinder. The face on

the gauge is marked to indicate whether the main pad

valve is opened, closed, or throttled.

Shutoff Valves

Note

Safety considerations may dictate

shutoff valves between the tank and

Type ACE97 valve.

Inlet (isolation) valves are desirable for servicing the

Type ACE97 valve. If this valve was not ordered with

an inlet pressure gauge, it is advisable to install a

gauge between the inlet isolation (full-port) valve and

the padding (blanketing) valve.

7

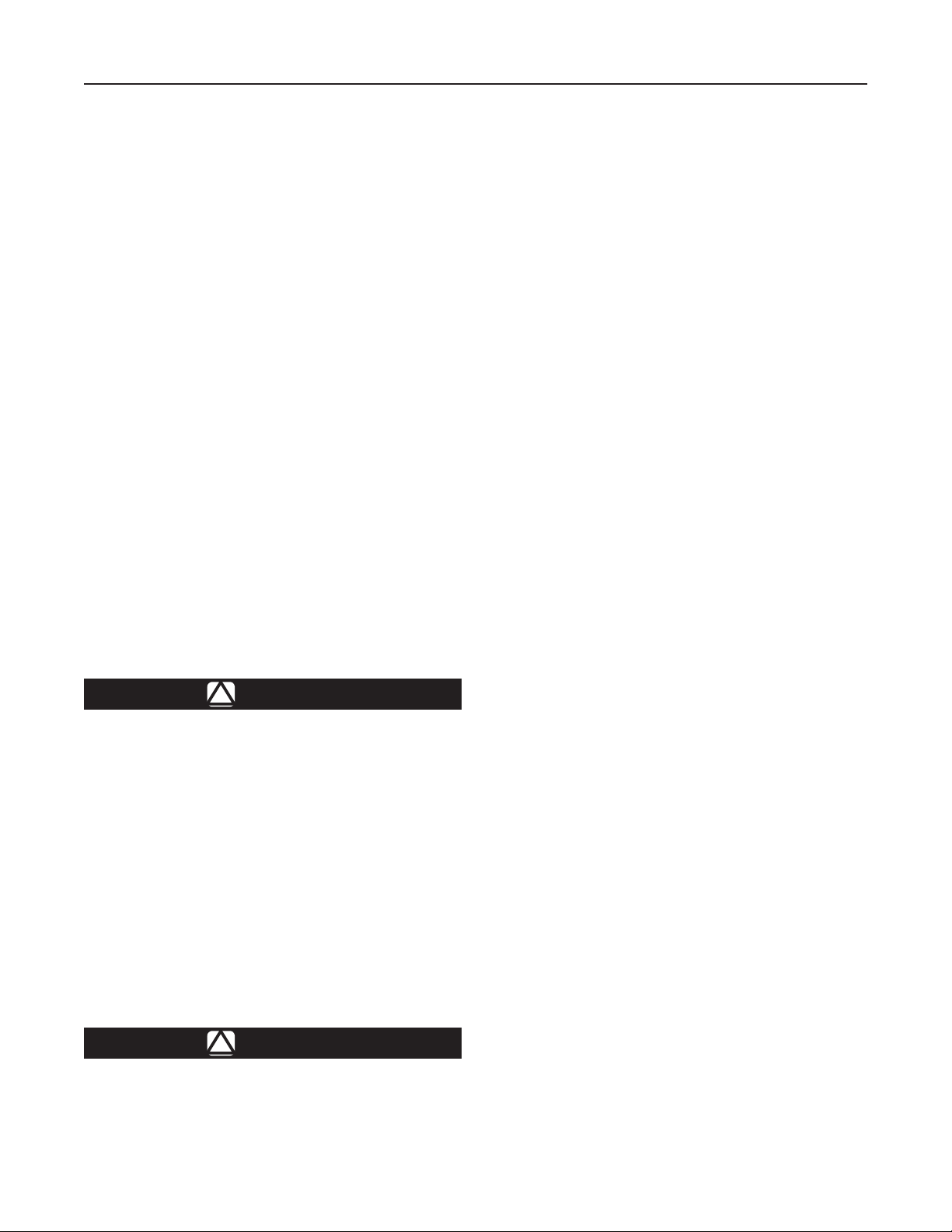

Type ACE97

TUBING

ADJUSTING SCREW

COUPLING

ACTUATOR

E0678

Figure 6. Unthreading the Adjusting Coupling

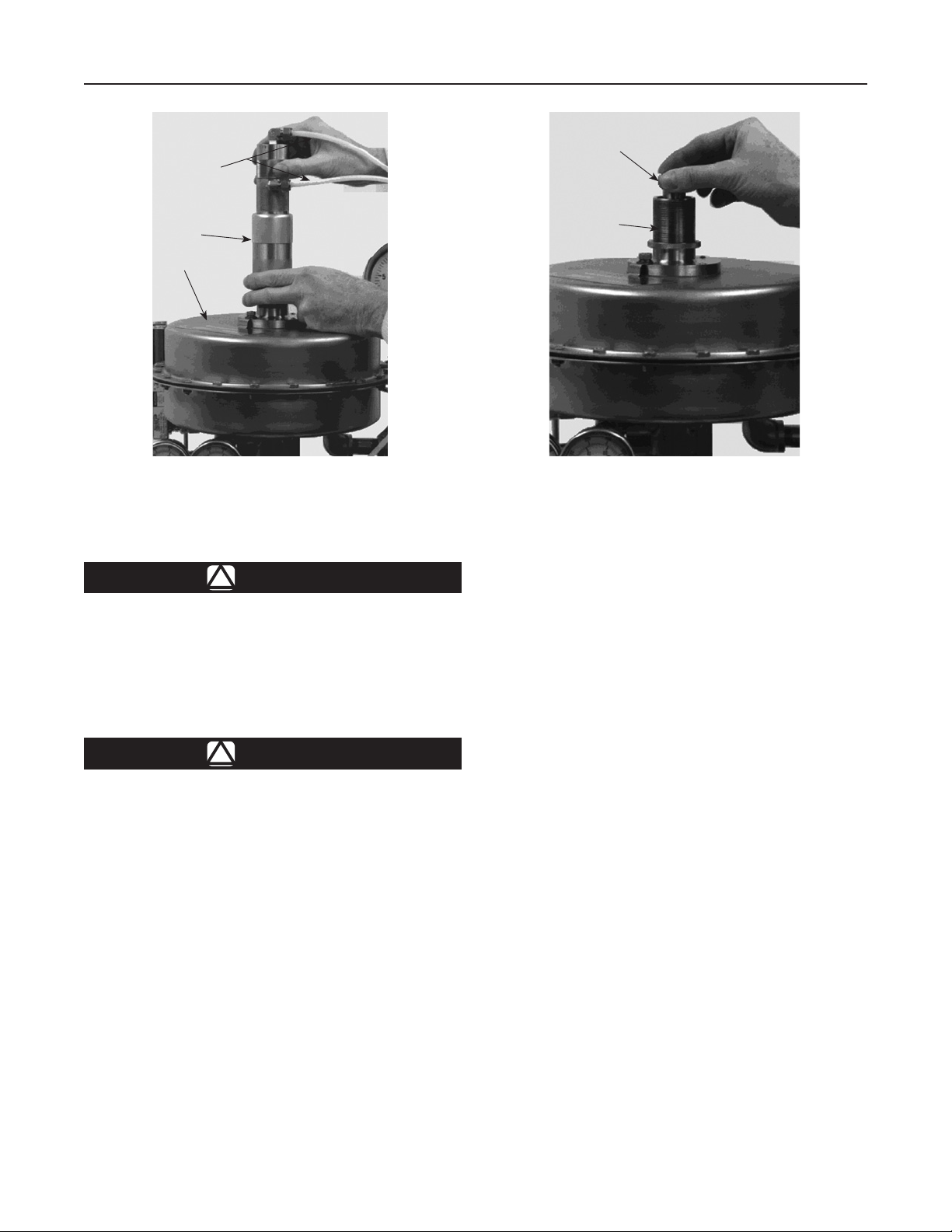

Startup, Adjustment, and Shutdown

CAUTION

If required, tank vents (normal

and emergency) must be in place

and operating.

LOCKNUT

E0679

Figure 7. Changing the Pad Setpoint

Adjustment

The setpoint of this unit is factory set. If an adjustment

is to be made, it should be made in small increments

while the unit is controlling tank pressure. It is difcult

to make eld adjustments due to the slow changes in

tank pressure.

To change the pad (blanketing) setpoint:

Startup

CAUTION

Always open the tank shutoff valve prior

to the inlet shutoff valve. Failure to do

so could result in inlet pressure being

applied to the actuator casing, potentially

damaging it. Refer to Figure 5.

1. Open the tank and sensing line shutoff valves

(between the Type ACE97 valve and tank).

2. A tank vapor space pressure gauge should be

installed and visible.

3. Slowly open the inlet shutoff valve (to the pad

valve) and leave it fully open.

4. Monitor the tank vapor space pressure.

1. Disconnect the tubing from the depad pilot valve

(See Figure 6).

2. Loosen the locknut (See Figure 7), but maintain its

position in relation to the adjusting coupling.

Doing so leaves the depad setpoint unchanged.

3. Separate the depad pilot valve from the actuator

by unthreading and removing.

4. Unthread and remove the adjusting coupling.

5. Increase the pad setpoint by turning the adjusting

screw clockwise. (Turning the screw counterclockwise

decreases the setpoint). See Figure 7.

6. Replace the depad adjusting collar against the

locknut to re-establish the depad setpoint.

To change the depad setpoint:

1. Loosen the locknut below the adjusting coupling.

2. Rotate the collar to change the setpoint. (The

bottom of the coupling—nearest the locknut—is

left-hand threaded).

3. Tighten the locknut.

8

Type ACE97

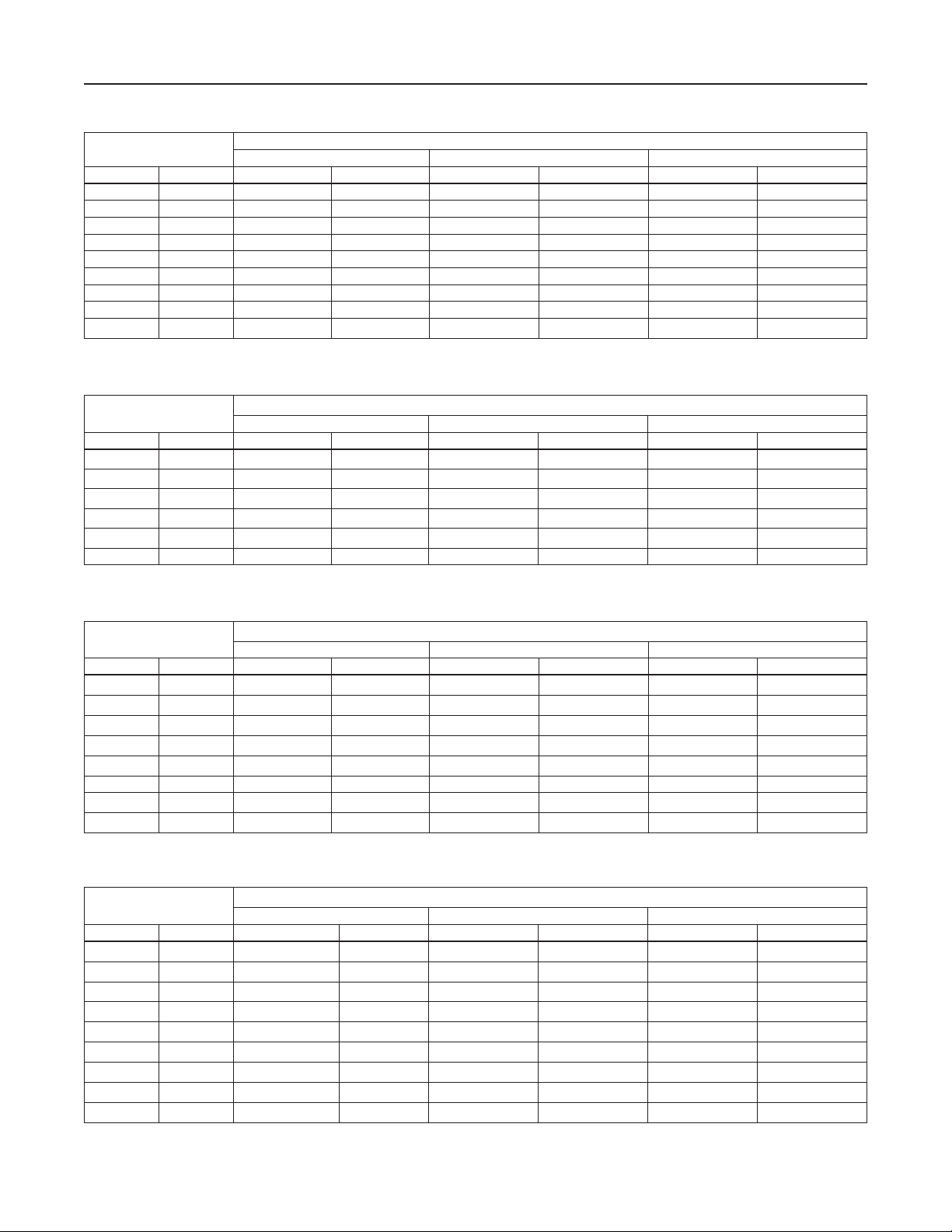

Table 2. Diagnostic Analysis Pressure Ranges

DIAGNOSTIC STATUS

Equal to inlet supply pressure

Slightly below inlet supply pressure

Well below inlet supply pressure

Pilot and main valves are closed.

Tank pressure is at or above set pressure.

Pilot valve supplies gas to tank. Tank

pressure is just below set pressure.

Pilot and main valves are both

supplying gas to the tank. Tank

pressure is below setpoint.

Shutdown

In any installation it is important to open and close

valves slowly and to close the inlet shutoff valve rst

when shutting down the system.

Maintenance

Valve parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency

of inspection and replacement of parts depend on the

severity of service conditions and the requirements

of local, state, and federal regulations. Due to the

care Regulator Technologies takes in meeting all

manufacturing requirements, use only replacement parts

manufactured or furnished by Regulator Technologies.

All O-rings, gaskets, and seals should be lubricated

with a good grade of general purpose lubricant and

installed gently rather than forced into position.

Approved lubricants, sealants, thread protectors,

and adhesives are as follows:

Lubricants: Dow Corning® #111, Dow

Corning® #3452 Chemical Resistant Lubricant

Thread Protector: Anti-Seize

Sealant: Loctite® PST #592,

Polytetrauoroethylene (PTFE) Tape

Adhesive: Loctite® #222

Be certain that nameplates are updated to accurately

indicate any eld changes in equipment, materials,

service conditions, or pressure settings.

Monthly Maintenance

1. Visually inspect the unit to ensure tight

connections, tight seals, and safe operation.

2. Observe the pad and depad (tank blanketing

and vapor recovery) pressures.

3. Inspect the inlet pressure for the proper range

(stamped on the valve nameplate).

Table 3. Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 25 to 50 psig / 1,7 to 3,4 bar

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

25 1,7 24 1,7 9 0,62 2 0,14

30 2,1 29 2,0 13 0,90 6 0,41

35 2,4 34 2,3 16 1,1 9 0,62

40 2,8 39 2,7 20 1,4 13 0,90

45 3,1 44 3,0 24 1,7 17 1,2

50 3,4 49 3,4 28 1,9 21 1,4

Table 4. Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 51 to 120 psig / 3,5 to 8,3 bar

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

51 3,5 50 3,4 29 2,0 5 0,35

60 4,1 59 4,1 36 2,5 12 0,83

70 4,8 69 4,8 43 3,0 19 1,3

80 5,5 79 5,4 51 3,5 27 1,9

90 6,2 89 6,1 59 4,1 34 2,3

100 6,9 99 6,8 66 4,5 42 2,9

110 7,6 109 7,5 74 5,1 50 3,4

120 8,3 119 8,2 81 5,6 57 3,9

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

DIAGNOSTIC PORT PRESSURE

DIAGNOSTIC PORT PRESSURE

9

Type ACE97

Table 5. Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 121 to 200 psig / 8,3 to 13,8 bar

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

121 8,3 120 8,3 74 5,1 30 2,1

130 9,0 129 8,9 81 5,6 37 2,5

140 9,6 139 9,6 88 6,1 45 3,1

150 10,3 149 10,3 96 6,6 53 3,6

160 11,0 159 10,9 104 7,2 60 4,1

170 11,7 169 11,7 111 7,6 68 4,7

180 12,4 179 12,3 119 8,2 75 5,2

190 13,1 189 13,0 127 8,8 83 5,7

200 13,8 199 13,7 134 9,2 91 6,3

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

Table 6. Diagnostics Table: Cv 7.5 through 10, Inlet Pressure Range Spring 25 to 50 psig / 1,7 to 3,4 bar

DIAGNOSTIC PORT PRESSURE

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

25 1,7 24 1,7 11 0,76 0 0,00

30 2,1 29 2,0 14 0,96 3 0,21

35 2,4 34 2,3 17 1,2 6 0,41

40 2,8 39 2,7 21 1,4 9 0,62

45 3,1 44 3,0 24 1,7 13 0,89

50 3,4 49 3,4 27 1,9 16 1,1

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

DIAGNOSTIC PORT PRESSURE

Table 7. Diagnostics Table: Cv 7.5 through 10, Inlet Pressure Range Spring 51 to 120 psig / 3,5 to 8,3 bar

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

51 3,5 50 3,4 24 1,7 3 0,21

60 4,1 59 4,1 30 2,1 9 0,62

70 4,8 69 4,8 36 2,5 15 1,0

80 5,5 79 5,4 42 2,9 22 1,5

90 6,2 89 6,1 49 3,4 28 1,9

100 6,9 99 6,8 55 3,8 34 2,3

110 7,6 109 7,5 61 4,2 41 2,8

120 8,3 119 8,2 68 4,7 47 3,2

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

DIAGNOSTIC PORT PRESSURE

Table 8. Diagnostics Table: Cv 7.5 through 10, Inlet Pressure Range Spring 121 to 200 psig / 8,3 to 13,8 bar

ACTUAL INLET SUPPLY

PRESSURE TO VALVE

psig bar psig bar psig bar psig bar

121 8,3 120 8,3 63 4,3 31 2,1

130 9,0 129 9,0 69 4,8 37 2,5

140 9,6 139 9,6 75 5,2 43 3,0

150 10,3 149 10,3 82 5,6 49 3,4

160 11,0 159 10,9 88 6,1 56 3,9

170 11,7 169 11,7 94 6,9 62 4,3

180 12,4 179 12,3 101 7,0 68 4,7

190 13,1 189 13,0 107 7,4 75 5,2

200 13,8 199 13,7 113 7,8 81 5,6

Pressure when Pilot Starts to Open Pressure when Main Valve Starts to Open Pressure when Main Valve is Fully Open

10

DIAGNOSTIC PORT PRESSURE

Loading...

Loading...